REMKO AMT 60E User Manual

Operation

Technology

Spare Parts

Edition GB – M02

REMKO – powerful like a bear.

REMKO AMT 60-E - 90-E

Mobile Dehumidifier

3

AMT 60-E

AMT 90-E

Make sure to read these instructions carefully before starting/using the unit!

Our guarantee will become void when the unit supplied by us is used and

installed for inadequate purposes, or maintained incorrectly, etc.,

or if it is changed without our prior consent.

Subject to alterations!

Operating Instructions

Mobile Dehumidifier

REMKO AMT 60-E - AMT 90-E

G

Always keep these operating instructions near or on the unit!

G

Contents page

Air Dehumidification 4

Safety Instructions 6

Unit Description 6

Working Range 7

Installation 7

Condensate 7

Starting 8

Discard the Unit 9

Transport Instructions 9

Maintenance and Service 9

Contents page

In Case of Troubles 10

Technical Data 11

Exploded View AMT 60-E 12

Spare Part List AMT 60-E 13

Exploded View AMT 90-E 14

Spare Part List AMT 90-E 15

Wiring Diagram AMT 60-E 16

Wiring Diagram AMT 90-E 17

Maintenance and Service Log 18

4

Air Dehumidification

The processes that take place during air dehumidifica-

tion are based on physical laws. We will try to describe

these in a simplified form to give you a rough idea about

the principle of air dehumidification.

There are two different ways of drying the buildings:

1. By heating and exchanging the air:

The ambient air is heated to absorb humidity and to

be carried off to the outside. However, the total gen-

erated energy is lost with the carried off humid air.

2. By dehumidifying:

The humid air in the closed room is continuously de-

humidified according to the condensation principle.

Dehumidification has a decisive advantage regarding

energy consumption:

Energy is exclusively needed for the existing room vol-

ume. The mechanical heat released during the dehu-

midification process increases the room temperature

slightly.

When used correctly the air dehumidifier consumes

only approx. 25 % of the energy to be supplied accord-

ing to the “heating and ventilation” principle.

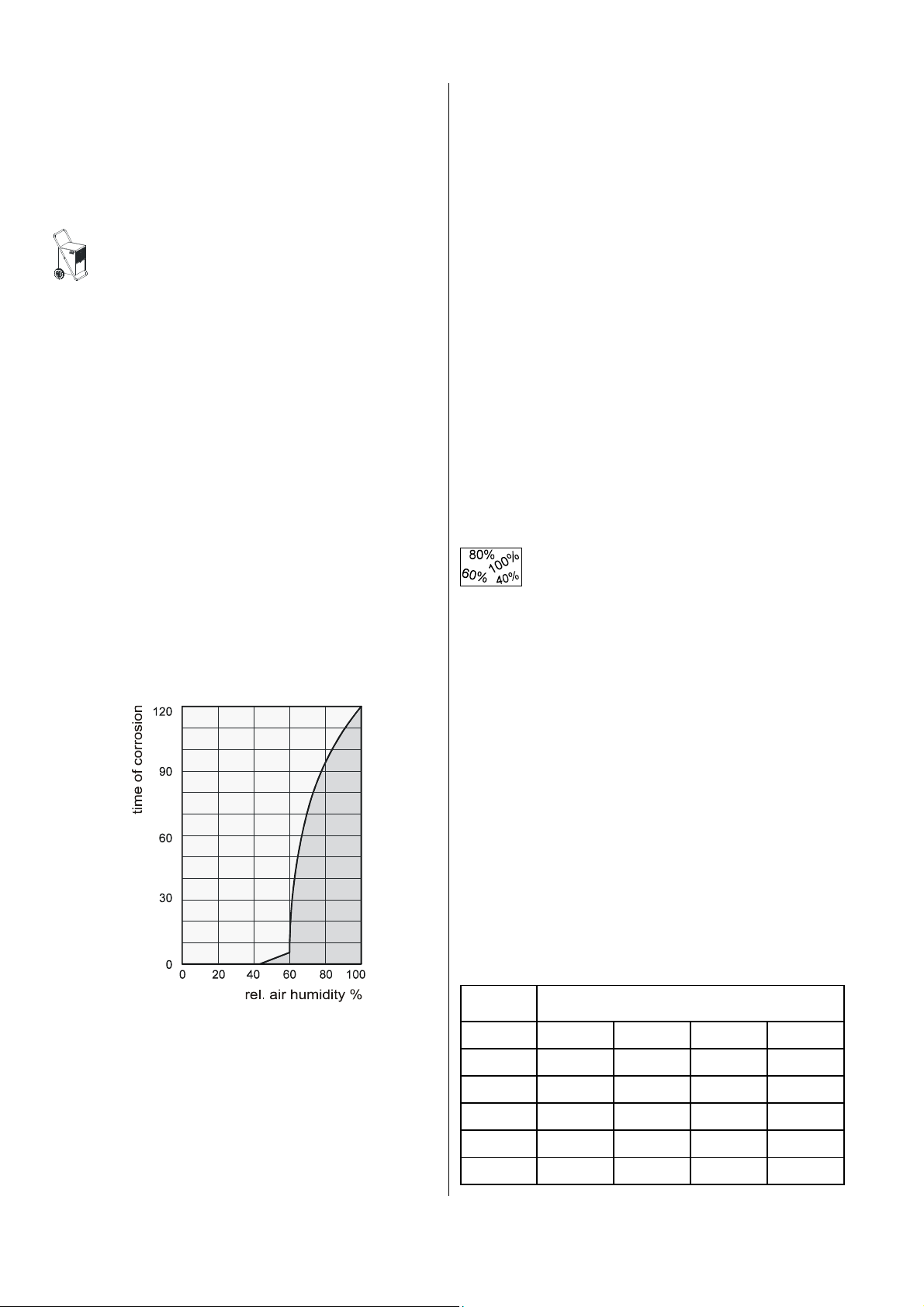

As you can see the corrosion speed is insignificant at a

relative air humidity of less than 50 % and at a humidity

rate of less than 40 % it can even be neglected. When

the relative humidity exceeds 60 % corrosion speed in-

creases considerably.

This limit regarding damages caused by humidity is also

applicable to many other materials, such as powdery

substances, packing materials, wood, and electronic

apparatuses.

Relative Air Humidity

Ambient air is a gas mixture and it always contains a

certain rate of water in the form of water vapour.

This percentage of water is indicated in g per kg of dry

air (absolute water content).

1 m³ of air weighs approx. 1.2 kg at 20° C.

Depending on the temperature each kg of air can only

absorb a defined quantity of water vapour. When this

quantity has been absorbed, the air is “saturated” and

has a relative humidity of 100 %.

By relative air humidity we understand the relation be-

tween the percentage of water vapour contained in the

air at the moment concerned and the maximum possi-

ble percentage of the water vapour, based on equal

temperatures.

The capacity of air to absorb water vapour increases

with raising temperatures. This means that the maxi-

mum possible (= absolute) water content is increased

with increasing temperatures.

The Use of REMKO Air Dehumidifiers

◊ No matter how well doors and windows are insu-

lated, wetness and humidity penetrate even through

thick concrete walls.

◊ The water quantities required for binding regarding

the production of concrete, mortar, plaster, etc. need

in some cases 1 or 2 months to diffuse.

◊ And even the humidity that penetrates into the brick-

work after floods and inundations is released very

slowly.

◊ E.g. this is also the case regarding humidity con-

tained in stocked materials.

The humidity that emanates from parts of buildings or

materials (water vapour) is absorbed by the ambient air.

Consequently the humidity content of the air increases

which results in corrosion and in the formation of mil-

dew, decay, flaked off paint coats and other undesired

damage caused by humidity.

E.g. the following diagram shows in an exemplary way

the corrosion speed of metal at different air humidity

rates.

Temp. °C

Water vapour content in g/m³ at an air humidity of

40% 60% 80% 100%

-5 1,3 1,9 2,6 3,3

+10 3,8 5,6 7,5 9,4

+15 5,1 7,7 10,2 12,8

+20 6,9 10,4 13,8 17,3

+25 9,2 13,8 18,4 23,0

+30 12,9 18,2 24,3 30,3

5

Water Vapour Condensation

The maximum possible percentage of water vapour

that can be absorbed becomes higher while the air is

heated, but the obtained percentage of water vapour

remains unchanged, and consequently the relative air

humidity is reduced.

However, when the air is cooled the maximum possi-

ble percentage of water vapour that can be absorbed

is continuously reduced, whereas the water vapour

quantity contained in the air remains unchanged, and

consequently the relative air humidity rises.

When the air is further cooled off the absorption ca-

pacity regarding the maximum possible water vapour

quantity is continuously reduced until it is equal to the

obtained percentage of water vapour. This is the dew

point temperature.

If the air is cooled down below the dew point, the ob-

tained percentage of water vapour will be higher than

the maximum possible water vapour quantity.

Water vapour is deposited.

It condenses, is converted into water and thus is ex-

tracted from the air

Steamed up window panes in winter or

steamed up bottles containing cold drinks

are typical examples of condensation.

The higher the relative air humidity is, the

higher is the dew point temperature, and

consequently it is easier for the tempera-

tures to fall below the dew point.

The generated conden-

sate is collected in the

apparatus and carried

away.

Condensation Heat

The energy transferred from the condenser to the air

consists of:

◊ The heat that was previously extracted in the evapo-

rator.

◊ The electric driving energy.

◊ The condensation heat released by liquefying water

vapour.

When the liquid condition is converted into a gaseous

condition energy must flow back. This energy is called

evaporation heat. It does not cause the temperature to

raise but is used for the conversion from the liquid to

the gaseous state. On the other hand energy is re-

leased when gas is liquefied, and this energy is called

condensation heat.

The energy rate of evaporation and condensation heat

is identical.

For water this is 2250 kJ / kg ( 4,18 kJ = 1kcal )

This shows that a relatively high energy rate is released

through water vapour condensation.

If the humidity to be condensed is not generated by

evaporation within the room, but fed from the outside,

e.g. by aeration, the condensation heat released

thereby contributes to room heating.

When materials or rooms are to be dried the heat en-

ergy flows in a circulation, i.e. it is consumed during

evaporation and released during condensation.

A larger amount of heat energy is generated when fed

air is dehumidified, and this heat energy is expressed in

the form of a rise in temperature.

Generally the time needed for drying does not depend

on the apparatus capacity, but it is determined by the

speed at which the material or the parts of the building

emit the humidity contained in them.

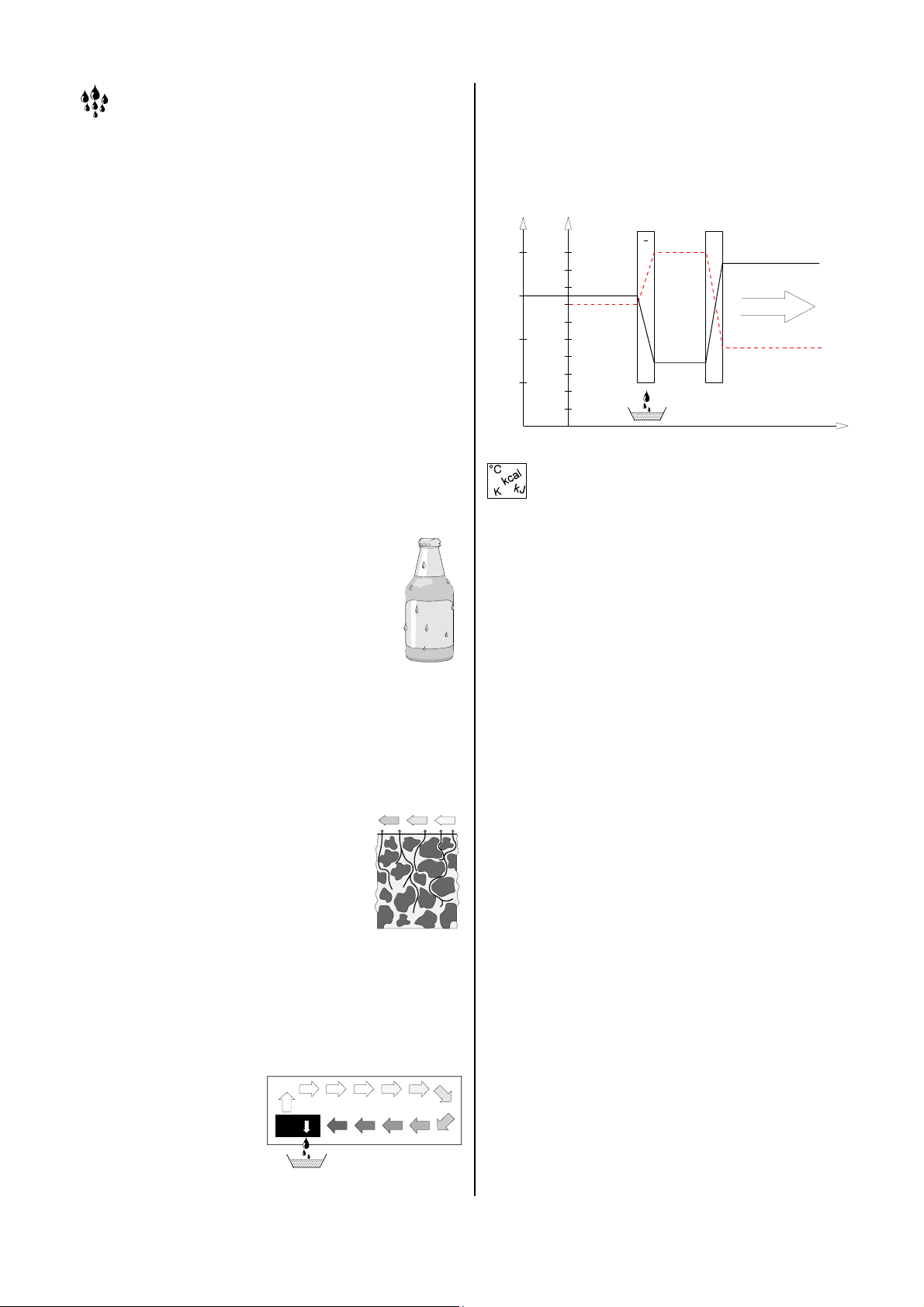

The air current is cooled off on its way through/via the

evaporator until its temperature falls below the dew

point. The water vapour condenses, it is collected in a

condensate trap and carried away.

Material Drying

Building materials/buildings can absorb considerable

quantities of water; e.g. bricks 90-190 l/m³, heavy con-

crete 140-190 l/m³, calcareous sandstone 180-270 l/m³.

Humid materials such as brickwork dries in the following

way:

◊ The contained humidity flows from the

inside of the material to its surface

◊ Evaporation takes place on the sur-

face = water vapour is absorbed by the

ambient air.

◊ The air enriched with water vapour is continuously cir-

culating through the REMKO air dehumidifier. It is de-

humidified and leaves the apparatus in a slightly

heated up state to absorb again water vapour.

◊ By this the humidity contained in the material is con-

tinuously reduced; the material becomes dry.

°C

30

25

20

15

% r.F.

100

90

80

70

60

50

40

30

20

10

+

+

-

condenser evaporator

air-temperature

air-direction

humidity

course

6

G

Any work regarding the refrigerating plant and its

electrical equipment is to be carried out exclu-

sively by especially authorized experts!

Safety Instructions

REMKO dehumidifiers will provide you with high utility

and long life thanks to our extensive material, function

and quality controls.

Dangers may arise nevertheless if the unit is used by

persons not familiar with its operation or if the unit is not

used for its intended purpose.

◊ Make sure to install and use the unit only in explo-

sion-proof rooms.

◊ Make sure not to install and use the unit in an atmos-

phere containing fuel, oil, sulphur and salt.

◊ Make sure to install the unit on a solid base and in a

vertical position.

◊ Make sure not to expose the unit to a direct water

jet.

◊ Make sure that the air can be freely sucked in and

blown off.

◊ Make sure that the suction side is always free from

dirt and loose objects.

◊ Never put objects into the unit.

◊ Do not cover the unit during operation.

◊ Make sure not to transport the unit during operation.

◊ Avoid strong vibrations on the unit as soon as there

is condensate in the condensate tank.

◊ Make sure to protect all electric cables outside the

unit from damage (e.g. by animals).

◊ Before installing connection cable extensions make

sure that they are suitable for the connected power,

cable length and the intended purpose.

◊ Make sure to empty the condensate tank before in-

stalling the unit in another place.

◊ Make sure to transport the unit only in a vertical posi-

tion.

◊ Damage on the compressor will be avoid by a wait-

ing period of at least 1 minutes before starting the

unit.

◊ Uses/operations other than that indicated in these

operating instructions are not allowed!

In the case of non-observation, any of our responsi-

bilities and guarantees will become void.

◊ The unit is to be used with the environmentally

friendly, ozone-neutral refrigerant R407C.

◊ The refrigerant/oil mixture in the unit is to be dis-

posed of correctly and in accordance with the legal

or local prescriptions.

Important Tip Regarding Recycling!

Unit Description

These unit have been designed for automatic, universal

and problem-free air dehumidification. Thanks to their

compact dimensions they can be easily transported and

installed.

The unit work according to the condensation principle

and are equipped with a hermetically sealed refrigerat-

ing plant, a silent nearly maintenance-free ventilator as

well as with a connection cable with plug.

For an operation-control exists a green control-lamp

“operation” on the control-panel. The correct time of op-

eration will record by a hour counter.

The fully automatic electronic control, the condensate

container with integrated overflow safety device, as well

as the connecting branch for direct condensation drain-

ing ensure trouble-free continuous operation.

The unit correspond to the fundamental safety and

health requirements of the relevant EC regulations, they

operate safely and are easy to handle.

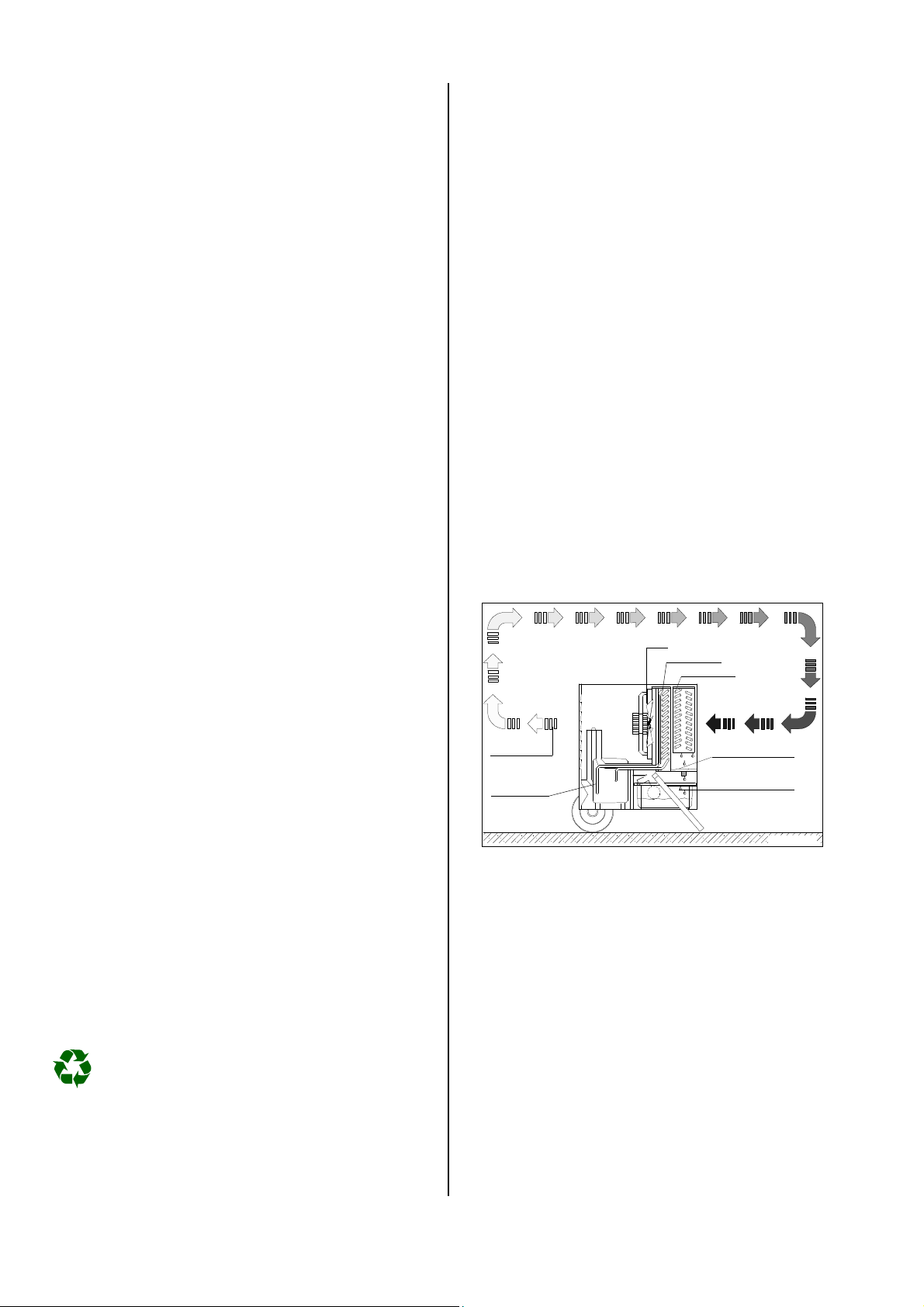

Function

When the unit is switched on the electronic control and

monitoring starts.

The green control lamp is lit up.

The compressor and fan are switched on time-delayed.

The fan sucks in the ambient air via the air filter, the

evaporator and the condenser placed behind the latter.

Heat is extracted from the ambient air at the cold

evaporator. It cools down below the dew point, and the

water vapour contained in the air is deposited as con-

densate or hair frost on the evaporator lamellas.

When necessary the evaporator is defrosted with hot

gas with temperature control.

The dehumidified cooled down air is reheated at the

condenser (heat exchanger), and then it is blown out

when it has reached a temperature of approx. 3 - 5 de-

grees above the ambient temperature.

The treated dry air is mixed with the ambient air.

Thanks to the continuous circulation of the ambient air

through the unit, the relative air humidity in the place of

installation is continuously reduced until it has reached

the desired value.

water container

condensate trap

ambient air

fan

compressor

dehumidified

ambient air

condenser

evaporator

fig. AMT 60

Schematic display of function

Loading...

Loading...