REMKO AMT 40E User Manual

REMKO AMT

Dehumidifier

Operation · Technology ·Spare Parts

Edition GB – S07

Contents

Dehumidification |

4 |

Safety Instruction |

6 |

Proper use |

7 |

Customer Service and Warranty |

7 |

Environmental Protection and Recycling |

7 |

Equipment Description |

8 |

Installation |

9 |

Commissioning |

10 |

Shutdown |

12 |

Unit transport |

13 |

Maintenance and Service |

13 |

Trouble Shooting |

14 |

Electrical wiring diagram |

15 |

Exploded view AMT 40-E |

16 |

Spare parts list AMT 40-E |

17 |

Exploded view AMT 55-E + 80-E |

18 |

Spare Parts List AMT 55-E + 80-E |

19 |

Exploded view AMT 110-E |

20 |

Spare parts list AMT 110-E |

21 |

Maintenance log |

22 |

Technical Data |

23 |

|

Before commissioning/use of the equipment, these |

|

operating instructions must be read carefully! |

|

These instructions are a part of the device and must thus always be |

Made by REMKO |

kept in the direct vicinity of the mounting site or on the device itself. |

|

Subject to changes, errors and typographical errors excepted. |

3

REMKO AMT

Dehumidification

The interrelated processes that take place during dehumidification are based on physical laws. These are to be illustrated here in simplified form in order to explain the principle of dehumidification.

The use of

REMKO dehumidifiers

–No matter how well windows and doors are insulated, damp and moisture can penetrate even through thick concrete walls.

–The water volumes required for binding concrete, mortar, plaster, etc. are diffused out initially after 1-2 months under certain circumstances.

–Even moisture that has penetrated masonry following high water or flooding, is only released very slowly.

–This applies similarly, e.g. also to moisture contained in deposited materials.

The moisture (water vapour) escaping from buildings or materials is absorbed by the ambient air. This increases their moisture content and ultimately results in corrosion, mould, rot, peeling of paint coatings and other unwanted moisture damage.

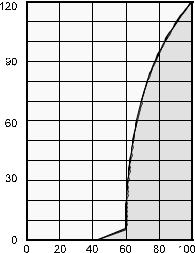

The diagram opposite shows an example of the rate of corrosion, e.g. for metal at different humidity levels.

This shows that the rate of corrosion below 50% relative humidity (R H) is insignificant and below 40% R H can be disregarded.

From 60% R H, the rate of corrosion increases considerably. This moisture damage limit applies also to numerous other materials, e.g. powders, packaging, wood or electronic units.

Buildings can be dried out in different ways:

1.By heating and air exchange:

The room air is heated to absorb moisture in order to then be discharged to the atmosphere. The total input energy is lost with the discharged, moist air.

2.By dehumidification:

The moist air in an enclosed room is continuously dehumidified by the condensation principle.

In terms of energy consumption, dehumidification has one decisive advantage:

Energy expenditure is restricted solely to the existing room volume. The mechanical heat released through the dehumidification process is returned to the room.

With correct use, the dehumidifier only uses about 25% of the energy that would be needed for the „heating and ventilation” principle.

The relative humidity

Our ambient air is a gas mixture and contains always a certain amount of water in the form of water vapour. This water volume is expressed in g per kg dry air (absolute water content).

1m3 air

weighs about 1,2 kg at 20 ° C

Depending on the temperature, each kg of air is only able to absorb a certain amount of water vapour. When this absorptive capacity is reached, reference is made to “saturated” air; this has a relative humidity of (R H) 100%.

Relative humidity is therefore understood to be the ratio between the amount of water vapour currently contained in the air and the maximum water vapour volume at the same temperature.

The ability of air to absorb water vapour increases with increasing temperature. This means that the maximum (= absolute) water content increases with increasing temperature.

4

Temp. |

Water vapour content in g/m3 at a humidity of |

|||

°C |

40% |

60% |

80% |

100% |

-5 |

1,3 |

1,9 |

2,6 |

3,3 |

+10 |

3,8 |

5,6 |

7,5 |

9,4 |

+15 |

5,1 |

7,7 |

10,2 |

12,8 |

+20 |

6,9 |

10,4 |

13,8 |

17,3 |

+25 |

9,2 |

13,8 |

18,4 |

23,0 |

+30 |

12,9 |

18,2 |

24,3 |

30,3 |

|

|

|

|

|

Drying materials

Building material and structures can absorb considerable amounts of water, e.g. bricks 90-190 l/m³, heavy concrete 140-190 l/m³, sand-lime bricks 180-270 l/m³. The drying of moist materials, e.g. masonry, takes place as follows:

■ The contained moisture moves from within the material to its surface

■Evaporation takes place on the surface = change to water vapour in the ambient air

■The air enriched with water vapour continuously circulates the REMKO dehumidifier. It is dehumidified and leaves the unit at a slightly higher temperature to absorb water vapour from anew.

■In this way, the moisture contained in the material is gradually reduced

The material dries!

The produced condensate is collected in the unit and discharged

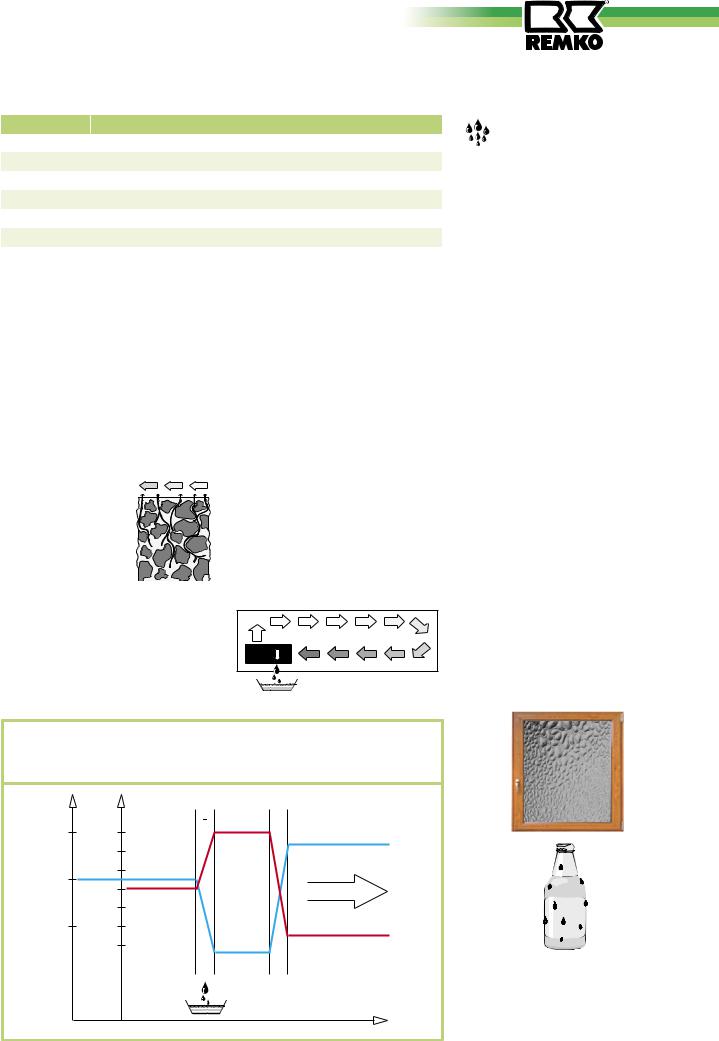

The air flow is cooled on its way through or via the evaporator to below the dew point. The water vapour condenses and is collected in a condensate trap and discharged.

|

|

Evaporator Condenser |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The condensation of water vapour

Since the maximum water vapour volume increases when the air is heated, the contained water vapour volume remains the same however, this results in a reduction of the relative humidity.

In contrast, when the air is cooled, the capacity to absorb the maximum water vapour volume reduces, the water vapour volume contained in the air remains the same and the relative humidity increases. If the temperature falls further, the capacity to absorb the maximum water vapour volume is reduced until it is equal to the contained water vapour volume.

This temperature is called the dewpoint temperature. When the air is cooled below the dew-point temperature, the contained water vapour volume is larger than the maximum water vapour volume. Water vapour is released.

This condenses to water. The air is relieved of moisture.

Examples of condensing are misted windows in winter or misting of a cold drinks bottle.

The higher the relative humidity, the higher the dew-point temperature, which is easier to fall below.

5

REMKO AMT

Heat of condensation

The energy transferred from the condenser to the air is composed of:

1.Heat energy extracted from the evaporator.

2.Electrical drive power.

3.The heat of condensation released through the condensation of water vapour.

For the change from a liquid to a gaseous state, energy is neces-

sary. This energy is termed heat of evaporation. It does not cause any rise of temperature, it is only necessary for the change from a liquid to a gaseous state. Vice versa,

energy is released during the liquefaction of gas, which is termed heat of condensation.

The amount of heat of evaporation and condensation is the same.

For water, this is:

2250 kJ/kg (4.18 kJ = 1kcal)

This shows that a relatively large amount of energy is released through the condensation of water vapour.

If the moisture to be condensed is not introduced through evaporation in the room itself, but from outside, e.g. via ventilation, the heat of condensation released in the process contributes towards room heating. In drying processes,

the heat energy is recirculated, which is consumed during evaporation and released during condensation. The supplied air during dehumidification creates a large amount of heat energy, which is expressed as a rise of temperature.

The time necessary for drying normally does not depend only on the unit capacity, but is rather determined by the rate at which the material or parts of the building release their moisture.

Safety Instructions

The units were subjected to extensive material, functional and quality inspections and tests prior to delivery.

The unit can however constitute a hazard if used improperly by untrained persons or not for the intended purpose.

The following information must be observed:

■The units must not be installed or operated in locations subject to explosion hazards

■The units must not be installed and operated in oil, sulphur, chlorine or salt containing atmospheres

■The units must be installed upright and stable

■The units must not be subjected to a direct jet of water

■The air inlet and outlet must always be kept free

■The intake guard grilles must always be free of dirt and loose objects

■The units must not be covered during operation

■Never insert objects in the unit

■The units must not be transported during operation

■The units must only be transported with drained condensate containers and dry evaporator

■All electric cables outside the units must be protected against damage (e.g. due to animals)

■The condensate containers must be drained prior to each change of location

CAUTION

CAUTION

Extension of the connecting cable may only be carried out by authorised electricians taking into account the unit power consumption, cable length and local use.

CAUTION

CAUTION

Only specially authorised firms may carry out work on the refrigeration system and electrical equipment.

6

Proper Use

The units are designed and equipped for drying and dehumidification purposes in industrial or commercial use.

The equipment may be operated only by accordingly trained personnel.

The manufacturer is not liable for damage that occurs due to nonobservance of manufacturer instructions or the legal requirements or due to unauthorised changes to the device.

NOTE

NOTE

Another operation other than that described in these operating instructions is not permitted. Nonobservance leads to the extinguishment of any liability and warranty claims.

Customer service and Warranty

The prerequisite for any warranty claims is that the customer or its recipient has returned the completed „Warranty Document“ included in delivery to REMKO GmbH & Co. KG at the time of the sale and commissioning of the equipment.

The equipment was

tested several times at the factory for perfect function.

If any malfunctions should occur, however, which cannot be eliminated by trouble shooting measures performed by the operator, please consult your dealer or contract partner.

NOTE

NOTE

Adjustment and maintenance tasks may be performed only by authorised expert personnel!

Environmental

Environmental

Protection and

Protection and

Recycling

Disposal of packaging

When disposing of the packaging material, please think of the environment.

Our equipment is carefully packed for transport and delivered in a stable cardboard transport package on a wooden pallet, if necessary. The packaging materials are en- vironmentally-friendly and can be recycled.

With the reuse of packaging material, you make a valuable contribution to the reduction of waste and the preservation of raw materials.

You should thus dispose of the packaging material at the corresponding disposal sites.

Disposal of the old device

The unit production is subject to continuous quality control.

Only high-quality materials are used, the majority of which are recyclable.

Important information

Important information  on recycling

on recycling

The units are operated with en- vironmentally-friendly and ozone neutral refrigerant R407c or R134a.

In accordance with legal and locally applicable requirements, the mixture of refrigerant and oil contained in the unit must be disposed of properly.

You also contribute to environmental protection by guaranteeing that your old equipment is disposed of in an environmentally friendly manner.

For this reason, bring the old equipment only to an authorised recycling company or to a corresponding disposal site.

7

REMKO AMT

Device Description

The units are designed for universal and problem-free dehumidification.

Owing to their compact size, they are easy to transport and install. The units operate according to the condensation principle and feature a hermetically sealed refrigeration system, low noise and maintenance circulating fan, operating hour counter and connecting cable with plug.

Fully automatic electronic control, condensate container with integrated overflow protection (not with AMT 110-E) as well as connections for direct condensate removal ensure trouble-free continuous use.

The units comply with the fundamental safety and health requirements of the permanent EU regulations.

The units are reliable and easy to operate.

Unit applications

The units are used wherever dehumidication is necessary and consequential damage (e.g.

through mould formation) is to be prevented.

The units are also suitable for drying and dehumidification of:

■New buildings, industrial buildings

■Cellar rooms, storage rooms

■Archives, laboratories

■Weekend homes, caravans

■Bathrooms, washrooms and changing rooms, etc.

Sequence of functions

The electronic control is activated when the unit is switched on. The green pilot light in the switch illuminates.

Owing to automatic pressure equalisation, the units start with a delay of about 10 seconds and then operate in continuous duty.

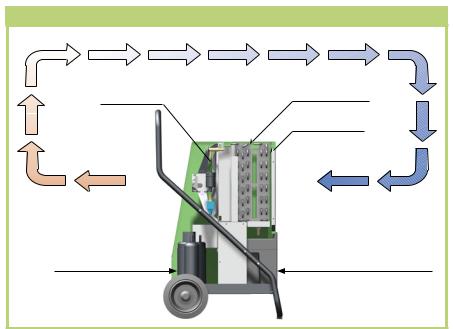

The circulating fan sucks the moist room air via the dust filter, evaporator and downstream condenser.

At the cold evaporator, heat is extracted from the room air and cooled to below the dew point.

The water vapour contained in the room air deposits as condensate or frost on the evaporator fins.

When the temperature sensor measures a specific minimum value here, a timer is activated with a delay of 30 minutes.

If during this time the evaporator temperature does not rise again, the cooling circuit is switched to hot gas defrost after the time has elapsed.

During the defrost phase, the circulating fan is off.

As soon as the frost (ice) has defrosted and the temperature at the sensor rises again, the unit switches back to normal dehumidification operation.

At a sufficiently high room temperature, the gill surface is not cold enough for the formation of frost so that defrosting is unnecessary.

This makes dehumidifiers particularly economical in operation.

At the condenser (heat exchanger), the cooled and dehumidified air is reheated and blown back into the room via the air outlet.

The conditioned, drier and heated air mixes with the room air again.

Due to the constant circulation of the room air through the unit, the relative humidity in the room is gradually reduced to the required humidity (% R.H).

Depending on the room temperature and humidity, only about 30-40% of electrical energy is required depending on the unit cooling capacity.

Diagram of the mode of operation of a REMKO dehumidifier |

|

Fan |

Condenser |

|

Evaporator |

Dehumidified |

Moist room air |

Room air |

|

Compressor |

Condensate con- |

|

tainer |

8

Loading...

Loading...