Operating instructions

REMKO RAV 35

High-performance fans

for the construction and renovation industry

0190-2018-07 Edition 1, en_GB

Read the instructions prior to performing any task!

Read these operating instructions carefully before commissioning / using this device!

These instructions are an integral part of the system and must

always be kept near or on the device.

Subject to modifications; No liability accepted for errors or misprints!

Translation of the original operating instructions

Table of contents

1 Safety and usage instructions............................................................................................................. 4

1.1 General safety notes....................................................................................................................... 4

1.2 Identification of notes...................................................................................................................... 4

1.3 Personnel qualifications.................................................................................................................. 4

1.4 Dangers of failure to observe the safety notes................................................................................ 4

1.5 Safety-conscious working............................................................................................................... 4

1.6 Safety instructions for the operator................................................................................................. 5

1.7 Safety notes for installation, maintenance and inspection work...................................................... 5

1.8 Unauthorised modification and changes......................................................................................... 6

1.9 Intended use................................................................................................................................... 6

1.10 Warranty........................................................................................................................................ 6

1.11 Transport and packaging............................................................................................................... 6

1.12 Environmental protection and recycling........................................................................................ 6

2 Technical data........................................................................................................................................ 7

2.1 Unit data.......................................................................................................................................... 7

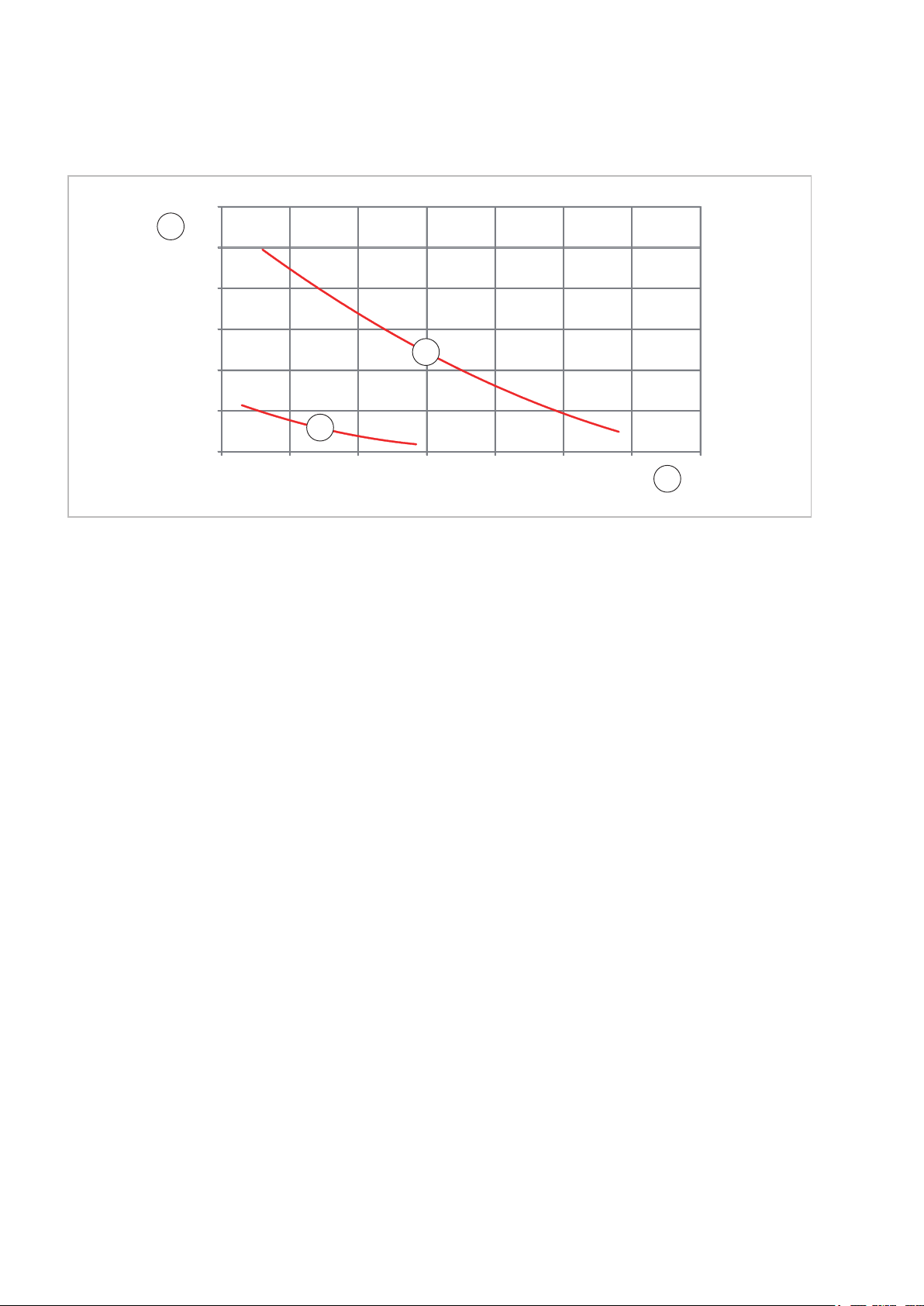

2.2 Characteristic curves....................................................................................................................... 8

3 Unit description..................................................................................................................................... 8

4

Electrical wiring..................................................................................................................................... 9

5 Commissioning..................................................................................................................................... 9

6 Motor overload protection switch..................................................................................................... 10

7 Shutdown............................................................................................................................................. 10

8 Care and maintenance........................................................................................................................ 11

9 General view of unit and spare parts................................................................................................ 12

9.1 Exploded view of the unit.............................................................................................................. 12

9.2 Spare parts list.............................................................................................................................. 12

10 Index..................................................................................................................................................... 13

3

REMKO RAV

1 Safety and

usage instructions

1.1 General safety notes

Carefully read the operating manual before commissioning the units for the first time. It contains

useful tips and notes such as hazard warnings to

prevent personal injury and material damage.

Failure to follow the directions in this manual not

only presents a danger to people, the environment

and the system itself, but will void any claims for

.

liability

Keep this operating manual and the refrigerant

data sheet near to the units.

1.2 Identification of notes

This section provides an overview of all important

safety aspects for proper protection of people and

safe and fault-free operation.The instructions and

safety notes contained within this manual must be

observed in order to prevent accidents, personal

injury and material damage.

Notes attached directly to the units must be

observed in their entirety and be kept in a fully

legible condition.

Safety notes in this manual are indicated by symbols. Safety notes are introduced with signal words

which help to highlight the magnitude of the danger

in question.

DANGER!

CAUTION!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause injury or material and environmental damage.

NOTICE!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause material and

environmental damage.

This symbol highlights useful tips and recommendations as well as information for efficient

and fault-free operation.

1.3 Personnel qualifications

Personnel responsible for commissioning, operation, maintenance, inspection and installation must

be able to demonstrate that they hold a qualification which proves their ability to undertake the

work.

Contact with live parts poses an immediate

danger of death due to electric shock. Damage

to the insulation or individual components may

pose a danger of death.

DANGER!

This combination of symbol and signal word

warns of a situation in which there is immediate

danger

cause serious injury.

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may be fatal or cause

serious injury

, which if not avoided may be fatal or

WARNING!

.

1.4

Dangers of failure to observe the safety notes

Failure to observe the safety notes may pose a risk

to people, the environment and the units. Failure to

observe the safety notes may void any claims for

damages.

In particular, failure to observe the safety notes

may pose the following risks:

n The failure of important unit functions.

n The failure of prescribed methods of mainte-

nance and repair

n Danger to people on account of electrical and

mechanical effects.

.

1.5 Safety-conscious working

The safety notes contained in this manual, the

existing national regulations concerning accident

prevention as well as any internal company

working, operating and safety regulations must be

observed.

4

1.6 Safety instructions for the oper-

ator

The operational safety of the units and components is only assured providing they are used as

intended and in a fully assembled state.

This unit can be used by children above the age of

8, as well as by people with impaired physical,

sensory or mental capabilities or a lack of experience and knowledge if they are supervised or have

received instruction in the safe operation of the

unit, and if they understand the associated potential hazards. Children must never play with the unit.

Cleaning and user maintenance must not be carried out by unsupervised children.

n Persons who use the unit must be aware of the

hazards involved with the use of such fans.

n The respective building code regulations or

other regulations must be observed as a basic

rule.

n The operator is responsible for the proper unit

installation, the correct electrical supply and

the safe operation of the units.

n Do not operate units or components with

obvious defects or signs of damage.

n Safety components (e.g. protection grids) must

not be removed or rendered inoperative.

n The units must always be installed and oper-

ated in a stable position

n The units may not be installed or operated in

potentially flammable or explosive environments.

n The units must not be installed or operated in

atmospheres containing oil, sulphur

salt.

n Protect the surroundings and the unit itself

from any objects that could be swirled up.

n The units and components must not be

exposed to any mechanical load, extreme

levels of humidity or extreme temperatures.

n Never allow water to enter the inside of the

units.

n All housing parts and unit openings, e.g. air

inlets and outlets, must be free from foreign

objects. An unobstructed air inlet and air outlet

must be guaranteed at all times.

n Never insert foreign objects into the units.

n The units may only be used as intended within

the specified output limits.

n The units must not be covered during opera-

tion.

n The units must not be transported while they

are running.

n All electrical cables on the outside of the units

must be protected against damage (e.g. by animals etc.).

, chlorine or

ear hearing protection if spending a longer

n W

period of time in the vicinity of the unit.

n The units must be inspected by a service tech-

nician to ensure that they are safe to use and

fully functional at least once yearly. Visual

inspections and cleaning may be performed by

the operator when the units are disconnected

from the mains.

DANGER!

or allen Arbeiten an den Geräten muss der

V

Netzstecker aus der Netzsteckdose gezogen

werden.

Reparaturen bzw. Änderungen an der Elektroinstallation sowie der Zuleitung dürfen aus sicherheitstechnischen Gründen ausschließlich durch

autorisiertes Fachpersonal ausgeführt werden.

NOTICE!

Extensions to the connection cable must only

be conducted by authorised specialist electricians, taking into consideration the unit power

consumption, cable length and local use.

1.7 Safety notes for installation, maintenance and inspection work

n Appropriate hazard prevention measures must

be taken to prevent risks to people when performing installation, repair

cleaning work on the units.

n The setup, connection and operation of the

units and its components must be undertaken

in accordance with the usage and operating

conditions stipulated in this manual and comply

with all applicable regional regulations.

n If the mains power supply line of this unit is

damaged, this must be replaced by the manufacturer or their customer services department

or a similarly qualified person in order to avoid

any hazard.

n The units and components must not be

exposed to any mechanical load, extreme

levels of humidity or extreme temperatures.

n Never allow water to enter the inside of the

units.

n Never insert foreign objects into the units.

n The units must be inspected by a service tech-

nician to ensure that they are safe to use and

fully functional at least once yearly. Visual

inspections and cleaning may be performed by

the operator when the units are disconnected

from the mains.

, maintenance or

5

REMKO RAV

1.8 Unauthorised modification and changes

Modifications or changes to units and components

are not permitted and may cause malfunctions.

Safety devices may not be modified or bypassed.

Original replacement parts and accessories

authorised by the manufactured ensure safety

use of other parts may invalidate liability for

resulting consequences.

. The

1.9 Intended use

The units are designed and equipped exclusively

for the purposes of aeration, ventilation, circulating

air or for extracting dust whilst complying with the

technical data and the safety instructions. The

design of the mobile units allows rapid change in

location and may only be operated in the design

delivered from the factory. The units may not be

installed or operated on muddy or flooded surfaces.

Any different or additional use is a non-intended

use. The manufacturer/supplier assumes no liability for damages arising from non-intended use.

The user bears the sole risk in such cases.

Intended use also includes working in accordance

with the operating and installation instructions and

complying with the maintenance requirements.

The threshold values specified in the technical

data must not be exceeded.

1.11 Transport and packaging

The devices are supplied in a sturdy shipping container

. Please check the equipment immediately

upon delivery and note any damage or missing

parts on the delivery and inform the shipper and

your contractual partner. For later complaints can

not be guaranteed.

WARNING!

Plastic films and bags etc. are dangerous

toys for children!

Why:

- Leave packaging material are not around.

- Packaging material may not be accessible to

children!

1.12 Environmental protection

and recycling

Disposal of packaging

All products are packed for transport in environmentally friendly materials. Make a valuable contribution to reducing waste and sustaining raw materials. Only dispose of packaging at approved

collection points.

1.10 Warranty

For warranty claims to be considered, it is essential

that the ordering party or its representative complete and return the "certificate of warranty" to

REMKO GmbH & Co. KG at the time when the

units are purchased and commissioned.

The warranty conditions are detailed in the "General business and delivery conditions". Furthermore, only the parties to a contract can conclude

special agreements beyond these conditions. In

this case, contact your contractual partner in the

first instance.

Disposal of equipment and components

Only recyclable materials are used in the manufacture of the devices and components. Help protect

the environment by ensuring that the devices or

components (for example batteries) are not disposed in household waste, but only in accordance

with local regulations and in an environmentally

safe manner

cling specialists or at collection points.

, e.g. using certified firms and recy-

6

2 Technical data

2.1 Unit data

Unit type RAV 35

Configuration Axial fan

2-speed air flow rate

Pressure, max. Pa 500

Electrical wiring V/~/Hz 230/1~/50

Max. power consumption W 750

Customer-provided electrical protection A 10

Max. current consumption A 3.2

Sound pressure level 5 m *) dB(A) 68

Max. temperature of conveyed medium °C 40

Hose connection Ø mm 300

Max. hose length m 38

Dimensions H/W/D mm 440/380/420

Weight kg 17

EDP no.: 1610635

*) Calculated for solid ball. Measurement per DIN EN ISO 9614-2

W

e reserve the right to modify the dimensions and design as part of the ongoing technical development

process.

m3/h

1350/2900

7

0

100

200

300

400

500

600

0 500 1000 1500 2000 2500 3000 3500

2

1

A

B

REMKO RAV

2.2 Characteristic curves

Fig. 1: Characteristic curves

1: Pressure build-up [Pa]

2:

Medium flow rate [m3/h]

A: Characteristic curve for the smaller stage

B: Characteristic curve for the higher stage

Measurement carried out per DIN EN ISO 5801 – Test set-up category B.

3 Unit description

The combination of powerful axial fan and well

thought out accessories for connecting air distribution hoses make the unit a particularly versatile solution for aeration and ventilation, air circulation and

also for transporting warming air or cooling air over

longer distances.

The unit is also ideally suited to provide ef

support for dehumidifiers when drying buildings.

The rapid air movement breaks up the high

humidity layer on the material and increases the

evaporation rate. This results in walls, ceilings and

floors drying faster! The higher the flow rate on the

damp surface of the material, the faster the drying

process. Thus, the drying time can be drastically

shortened through the combination of dehumidifiers and this powerful fan, depending on the

respective environment and temperature. The use

of additional fans accelerates the evaporation

whereby the drying process can be shortened by

up to 50%.

The unit has hose connection ports on both sides

allowing very versatile use.

The unit is equipped with a 2-speed high-performance axial fan, operating hours counter, motor

overload protection switch and mains cable with

230 V CEE connector.

fective

The unit conforms to the fundamental health and

safety requirements of the appropriate EU stipulations and is simple to operate.

8

A

B

Reset

MS

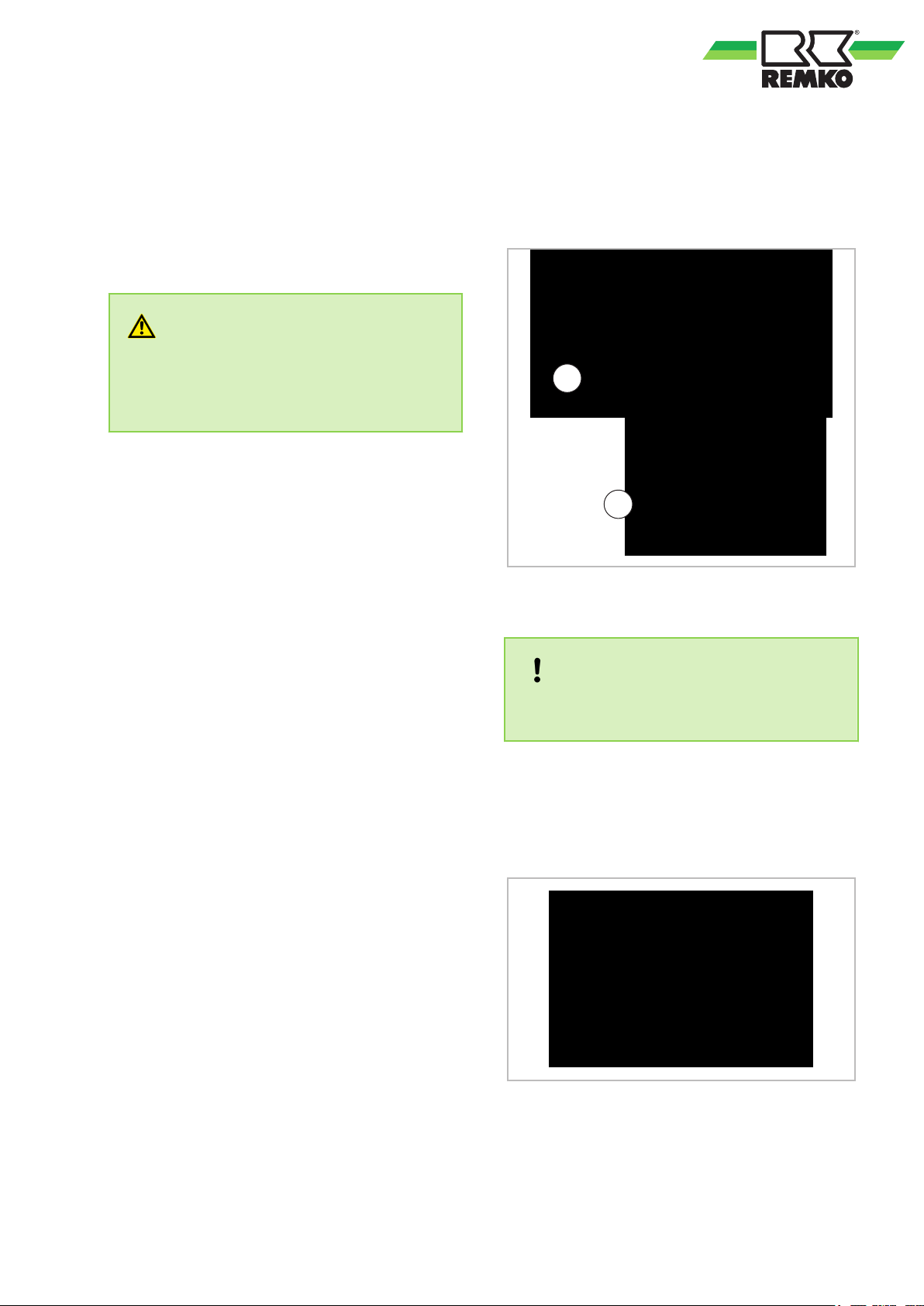

4 Electrical wiring

n The 230V electrical connection is made using a

built-in mains cable with earthed safety plug.

n Connect the power plug to a properly installed

and appropriately safeguarded mains socket.

n All cable extensions must only be used in fully

un-reeled or reeled of

WARNING!

The electrical connection for the units must be

made at a separate feed point with a residual

current device in accordance with VDE 0100,

Section 55.

f condition.

5 Commissioning

Before the initial commissioning

n Check that the unit and any accessories being

used are installed correctly

A: Example 1 - Optional dust bag # 1009540

B: Example 2 - Optional WL hose # 1009512

.

NOTICE!

Always fasten hoses and dust bag with suitable

lashing straps or clamps.

Commissioning

Connect unit

n Switch unit to desired power stage using the 2-

stage operating switch.

n If required, read of

hours on the operating hours counter.

f and record the operating

9

REMKO RAV

6 Motor overload protec-

tion switch

The unit is equipped with a motor overload protection switch (MS), which interrupts the power supply

in the event of the electrical motor being overloaded and electrically interlocks the unit. The MS

is unlocked (reset) manually

button on the MS.

NOTICE!

If the motor overload protection switch has

been triggered, the cause of the malfunction

must be identified and rectified before a reset is

performed.

. To do so, press in the

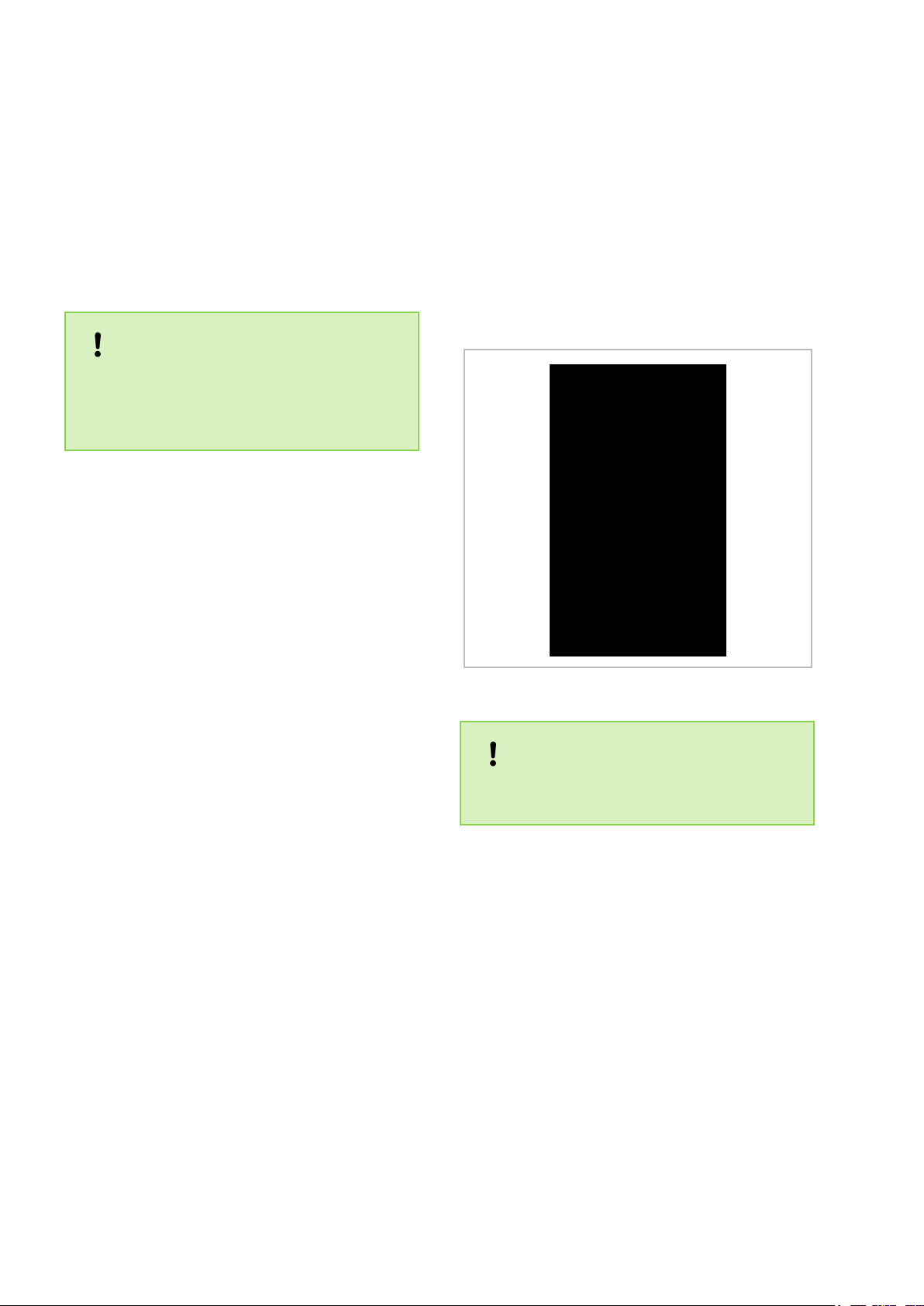

7 Shutdown

n Move the operating switch to the “0” position.

n Read of

required.

With longer breaks in operation:

n Disconnect the unit from the power supply

n Clean the unit if required and store in a location

protected from dust and direct sunlight.

The units can be stacked to save space if required.

f the operating hours counter if

.

Fig. 2: Stacking with max. 2 units

NOTICE!

The units must be protected against falling

down and unauthorised access after stacking.

10

8 Care and maintenance

General notes

Regular care and maintenance is fundamental

to a long service life and fault-free operation of

the unit.

In normal operation, the units are almost maintenance-free. However

uous fault-free operation, they should be checked

at regular intervals and cleaned or repaired when

necessary and in accordance with the respective

operating conditions.

, in order to guarantee contin-

DANGER!

Before undertaking any work on the units, the

mains plug must be removed from the mains

socket.

Cleaning the units

n The units should be disconnected from the

electrical power supply and secured to prevent

unauthorised reactivation.

n Clean the intake grill at regular intervals and

replace it if damaged.

n Clean all intake openings and discharge fins.

o clean the fan blades, it is necessary to

n T

remove the protection grid beforehand.

n Clean severe soiling on the fan and the fan

housing with soap solution.

n Clean the units dry or with a moistened cloth

and some soap solution if necessary.

n High pressure cleaners or steam cleaners shall

not be used under any circumstances.

n Never use abrasive or solvent-based cleaners.

n Ensure that the unit is not damaged if using

compressed air.

11

REMKO RAV

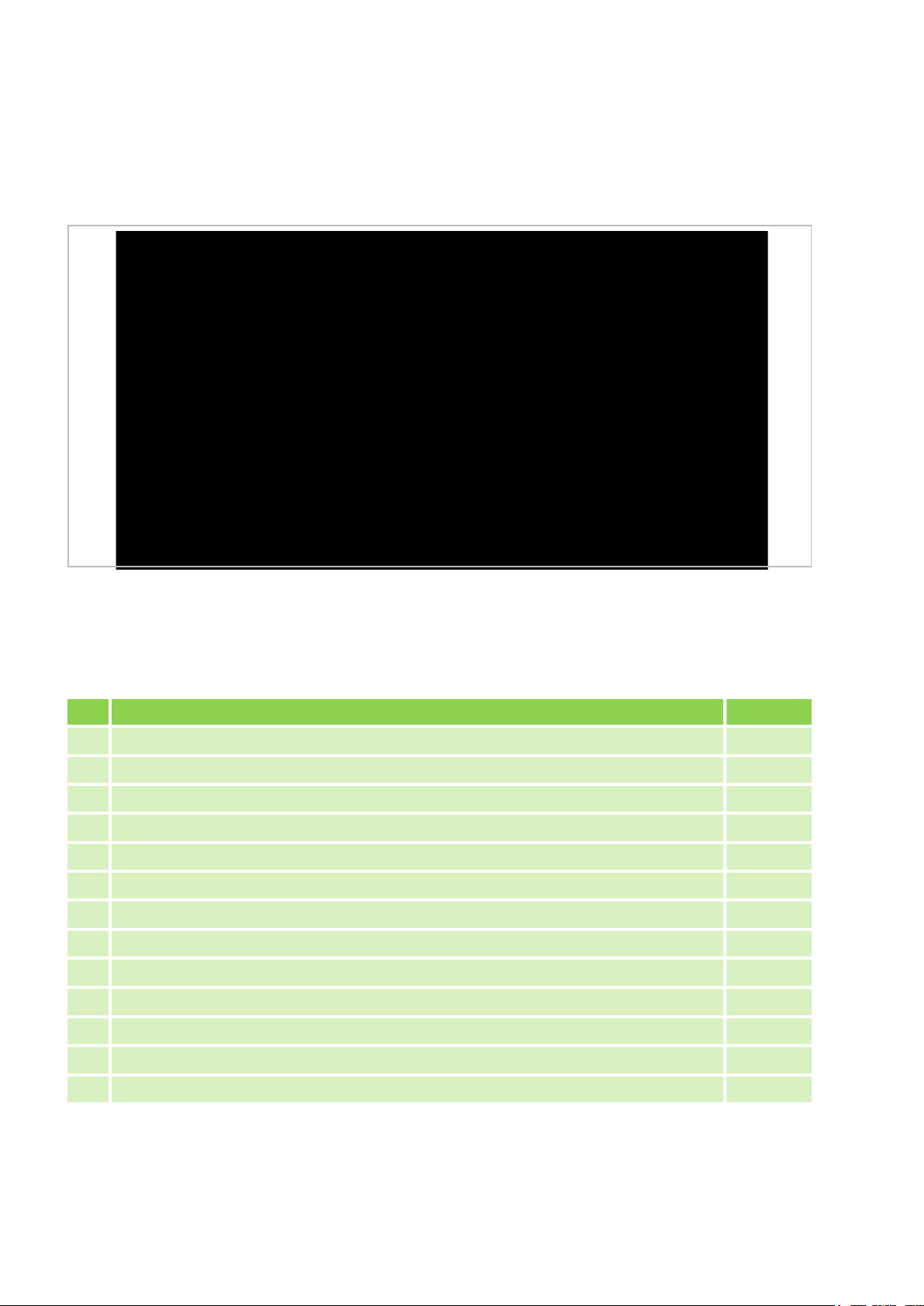

9 General view of unit and spare parts

9.1 Exploded view of the unit

We reserve the right to modify the dimensions and design as part of the ongoing technical development

process.

Spare parts list

9.2

No. Designation EDP no.

1 Mains cable with plug 1113049

2 Cable gland 1122990

3 Metal grill 1122991

4 Hose connection ports 1122992

5 Fan housing 1113039

6 Control panel 1122995

7 Operating hours counter 1113048

8 Reset button 1122997

9 12 µF capacitor 1122998

10 5 µF capacitor 1122999

11 Operating switch 1122996

12 Electric motor 1122993

13 Fan blade 1122994

To assure the correct delivery of spare parts, please always provide the unit type with its corresponding

serial number (see name plate).

12

10 Index

C

Care ................................. 1

Care and maintenance ................... 11

Commissioning .......................... 9

1

D

Disposal of equipment .....................6

E

Electrical wiring .......................... 9

Environmental protection ...................6

Exploded view drawing ................... 12

Exploded view of the unit ................. 12

M

Maintenance ........................... 11

Motor overload protection switch ............10

O

Ordering spare parts ..................... 12

S

Safety

Dangers of failure to observe the safety

notes ............................... 4

General ............................. 4

Identification of notes ................... 4

Instructions for the operator .............. 5

Note for inspection work .................5

Note for installation work ................ 5

Note for maintenance work .............. 5

Personnel qualifications ................. 4

Safety-conscious working ................4

Unauthorised modification ...............6

Unauthorised replacement part manufacture . 6

Shutdown ............................. 10

Spare parts list ......................... 12

W

Warranty ............................... 6

13

REMKO RAV

14

Consulting

Thanks to intensive training,

our consultants are always

completely up-to-date in terms

of technical knowledge. This has

given us the reputation of being

more than just an excellent,

reliable supplier:

REMKO, a partner

helping you find solutions to

your problems.

Distribution

REMKO offers not just a well

established sales network both

nationally and internationally, but

also has exceptionally highlyqualified sales specialists.

REMKO field staff are more than

just sales representatives: above

all, they must act as advisers to

our customers in air conditioning

and heating technology.

SFlbCustomer Service

Our equipment operates

precisely and reliably. However,

in the event of a fault, REMKO

customer service is quickly at

the scene. Our comprehensive

network of experienced dealers

always guarantees quick and

reliable service.

REMKO INTERNATIONAL

… and also right in your neighbourhood!

Make use of our experience and advice

We reserve the right to make technical changes, and provide no guarantee as to the accuracy of this data!

REMKO GmbH & Co. KG

Air conditioning and heating technology

Im Seelenkamp 12 D-32791 Lage

Postfach 1827 D-32777 Lage

Telephone +49 5232 6 06-0

Telefax +49 5232 606-2 60

E-mail info@remko.de

Website www.remko.de

Loading...

Loading...