REMKO PWW

Warm water heaters

Operation · Technology · Spare Parts

Edition GB - T08

3

Contents

Safety information

Unit description

Unit installation

Mounting examples

Electrical connection

Heating medium connection

Commissioning

Switching off

Care and maintenance

Repair

Air outlet accessories

Air inlet accessories

Accessory installation

4

4

5

6

7

8

9

9

10

10

11

12

14

Control units

Exploded drawing

Spare parts list

Intended use

Customer service and warranty

Environmental protection and recycling

Ratings tables/Characteristics

Calculation examples

Planning/Calculation/Units

Unit dimensions

Technical data

16

20

20

21

21

21

22

30

32

34

35

Made by REMKO

These operating instructions must be read thoroughly

before commissioning/using the unit!

These instructions are part of the unit and must always

be kept near to the site of installation or the unit.

Subject to changes; errors and typographical errors excepted!

4

REMKO PWW

Safety information

The units were subjected to extensive material, functional and

quality inspections and tests prior

to delivery.

The units can however constitute

a hazard if used improperly by

untrained persons or not for the

intended purpose.

Always observe the following

safety information:

■ The locally applicable building

regulations must be observed.

■ The operator is responsible for

correct installation of the units,

correct electrical installation and

safe operation of the units.

■ The units must be installed

and operated in a manner that

excludes any risk to persons

through radiated heat.

■ The units must only be attached

to constructions or ceilings with

sufficient load bearing capacity.

■ Attachment must take place

using suitable anchors to be attached to the unit.

■ Only trained specialists may

install and connect the heating

medium, establish electrical connections and carry out maintenance.

■ The units must not be installed

and operated in locations

where there is a risk of fire and

explosion.

■ The units must only be operated

in a completely installed

condition.

■ Safety components, e.g. protec-

tion grilles must not be removed

or rendered inoperational.

■ The units must only be operated

within the specified capacity

limits and with the approved

operating media.

Observe rating plate!

■ The air intake grilles must

always be kept free of dirt and

loose objects and the air outlet

must not be closed.

■ Never insert foreign objects into

the unit.

■ The units must not be sprayed

with a direct jet of water.

■ Never allow water to enter the

unit.

■ All electrical cables of the units

must be protected against damage, e.g. animals, etc.

NOTE

Perfect functioning of the units

is only ensured when the flow

temperature at the unit inlet

and the pump capacity correspond to the selected unit

classification.

Unit description

These units are stationary, indirectly fed air heaters with copper/

aluminium fin heat exchanger for

connection to a pumped hot water

system up to max. 130°C.

The units are suitable for wall or

ceiling mounting.

The units can be provided with

diverse air inlet and air outlet

accessories.

The units are provided with horizontal, individually adjustable air

outlet fins as standard.

The units are provided with a lownoise, aerodynamically designed,

sickle-shaped high-power axial

fan, individually adjustable air outlet fins and electrical terminal box.

The units are fitted with a

400V/50Hz, two-speed externalrotor motor as standard.

The units comply with the basic

health and safety requirements of

the pertinent EU regulations and

are easy to operate.

■ The units must be installed

outside traffic zones, e.g. also

the operating areas of cranes. A

protection zone of 1 m distance

must be kept free.

5

Unit installation

The following information must be

observed for safe unit installation.

■ The units must be arranged so

that accessed areas and workplaces are not located in the

direct air stream.

■ The units must only be mount-

ed on ceilings or roof constructions with sufficient load bearing capacity.

■ The heat exchangers must be

connected so that no vibrations

can be transferred from the unit

to the pipe system or vice versa.

■ For wall mounting, a minimum

height of 2.5 m to the bottom

edge of the unit must be

maintained.

■ For wall mounting above 4 m,

suction of the recirculated air

should take place from the

ground to ensure uniform

heating.

■ For ceiling mounting below

4 m, the units should be fitted

with an air outlet hood HG 4.

■ For ceiling mounting above

4 m, the units should be fitted

with the ceiling air outlet nozzle

AD.

■ Before connecting the units

to an existing water heating

system, the boiler and pump

must be checked for sufficient

capacity.

■ For maintenance and repair

purposes, a repair switch should

be mounted near to the unit.

■ The gap between the fan

impeller and housing must be

checked for the same distance.

■ Units with fresh air inlet

must be fitted with anti-frost

protection.

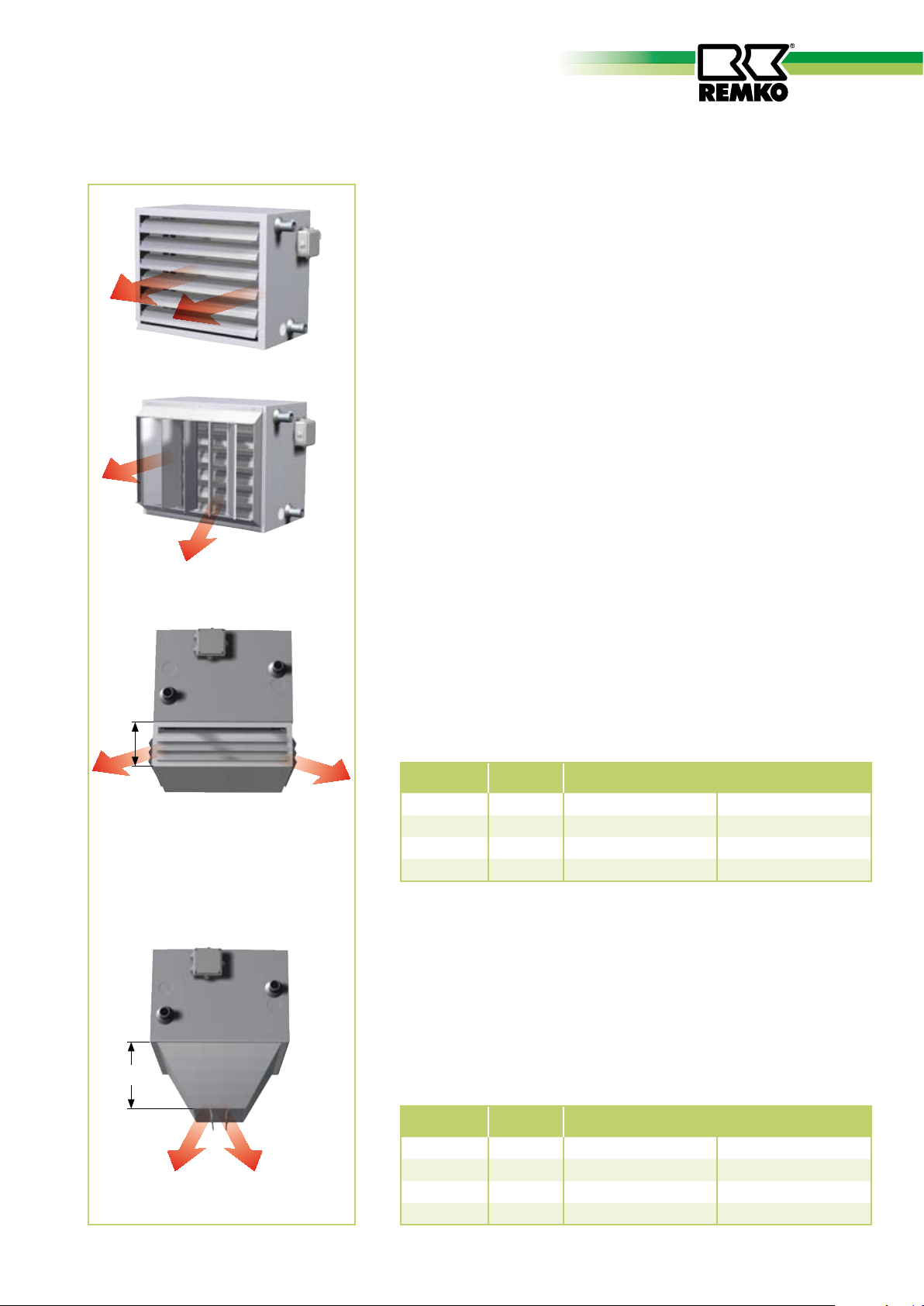

Brackets

Brackets (KO) for wall and ceiling mounting (2 per unit) must be inserted

into the recesses in the rear wall of the unit and attached to the unit using the enclosed screws.

Direct mounting parts such as

mixed-air or filter box must be

attached using a wall fastening

bracket (WFM).

When using local bracket construc-

ATTENTION

The brackets must be screwed

to the de-energised unit and

wall or ceiling.

tions, the minimum wall distance

“e” must be maintained!

Bracket KO

for wall and ceiling mounting

e

d

b

d

c

a

e

in mm

f

f

in mm

KO (L

PWW

40 x 40 x 3)

30

50

80

100

ø 12.5

f

a

in mm

b

in mm

c

in mm

d

in mm

552 432 506 155 270 40

632 507 586 192 270 40

792 622 746 250 270 40

872 732 826 305 340 40

Heat exchanger

copper/aluminium

The fin heat exchangers consist

of copper pipes with pressed on

pipe adapters.

■ The water inlet (flow) is

generally the bottom.

aluminium fins.

The fin assembly is enclosed by a

galvanised steel frame.

Collector, distributor and heating

medium connections are made of

■ The maximum operating tem-

perature is 130°C.

■ The maximum operating pres-

sure is 16 bar.

steel.

■ The heat exchangers are not

■ Heating medium connections

are established via threaded

suitable for operation with

steam or thermal oil.

6

REMKO PWW

Mounting examples

Circulation/fresh air operation

via the roof.

ALH

Circulation/fresh air operation

via the outside wall.

PWW

FK

SG

KA

MLK

4

KA

RK

ß

ß

KA

PWW

AG

1

2

WFM

ß

ß

FK

SG

KA

4

4

SG

2

MLK

WFM

UA

ß

ß

Wall opening appropriate to air

1

inlet grille size.

The mixed-air box must be fas-

2

tened using the wall bracket WFM

to a load bearing outside wall.

UA

3

3

ß

ß

The air intake channel and

3

air inlet piece must be fastened

to the outside wall locally.

The vertical part of this system

4

arrangement must be attached to the

wall using brackets so that the flexible

pipes are not subjected to weight.

7

U1

V1 W1 W2U2V2 11 12

TK TK

Electrical connection

Ceiling mounting

In circulation operation with

bracket KC

KO

PWW

Wall mounting

In circulation operation with filter

FK, mixed-air box MLK, bracket

WFM and injection shutter.

MLK

FK

PWW

IJ

WFM

Legend:

AG = Fresh air inlet grille

ALH = Fresh air inlet hood

FK = Filter box

KA = Warmth channel interim

piece

KO = Brackets

MLK = Mixed-air box

Electrical connections of the unit

must only be established by authorised specialists in compliance

with the applicable regulations of

the local electricity supply company as well as the VDE installation

requirements relating to the unit.

ATTENTION

Failure to observe the pertinent

requirements, operating instructions and electrical wiring diagrams relating to the unit can

give rise to malfunctions with

consequential damage.

This will invalidate the

warranty!

Unit connection

The units are fitted with twospeed, 400V three-phase axial fans

as standard.

With the appropriate control units

(accessory), speed selection takes

place via Y/D switching.

Motor protection is provided

via built-in thermal contacts

that drop out at a fan motor

winding temperature of 130°C in

conjunction with a suitable control

unit (accessory).

Connection of the three-phase

motors to the respective control

units takes place via the associated

electrical wiring diagrams.

ATTENTION

When the fan is stationary, the

heating medium supply must

be simultaneously interrupted.

Connection of several units

If necessary, several units (also different sizes) can be operated parallel via a control unit (accessory).

The total capacity of the connected units must not exceed the

maximum switching capacity of

the respective control unit.

For thermal motor protection, the

thermal contacts of all motors

must be connected in series. See

separate wiring diagrams.

Only one external control device

(thermostat, day/night control,

etc.) can be connected per control

unit.

Terminal box on unit

Fuse protection in the supply

to the control unit must be in

compliance with the applicable

regulations.

The connections in the terminal

box must be connected to the

respective control unit (accessory).

ATTENTION

Only trained specialists may

establish electrical connections.

RK = Rain collar

SG = Flexible pipe

WFM= Wall bracket

IJ = Injection shutter

8

REMKO PWW

Heating medium connection

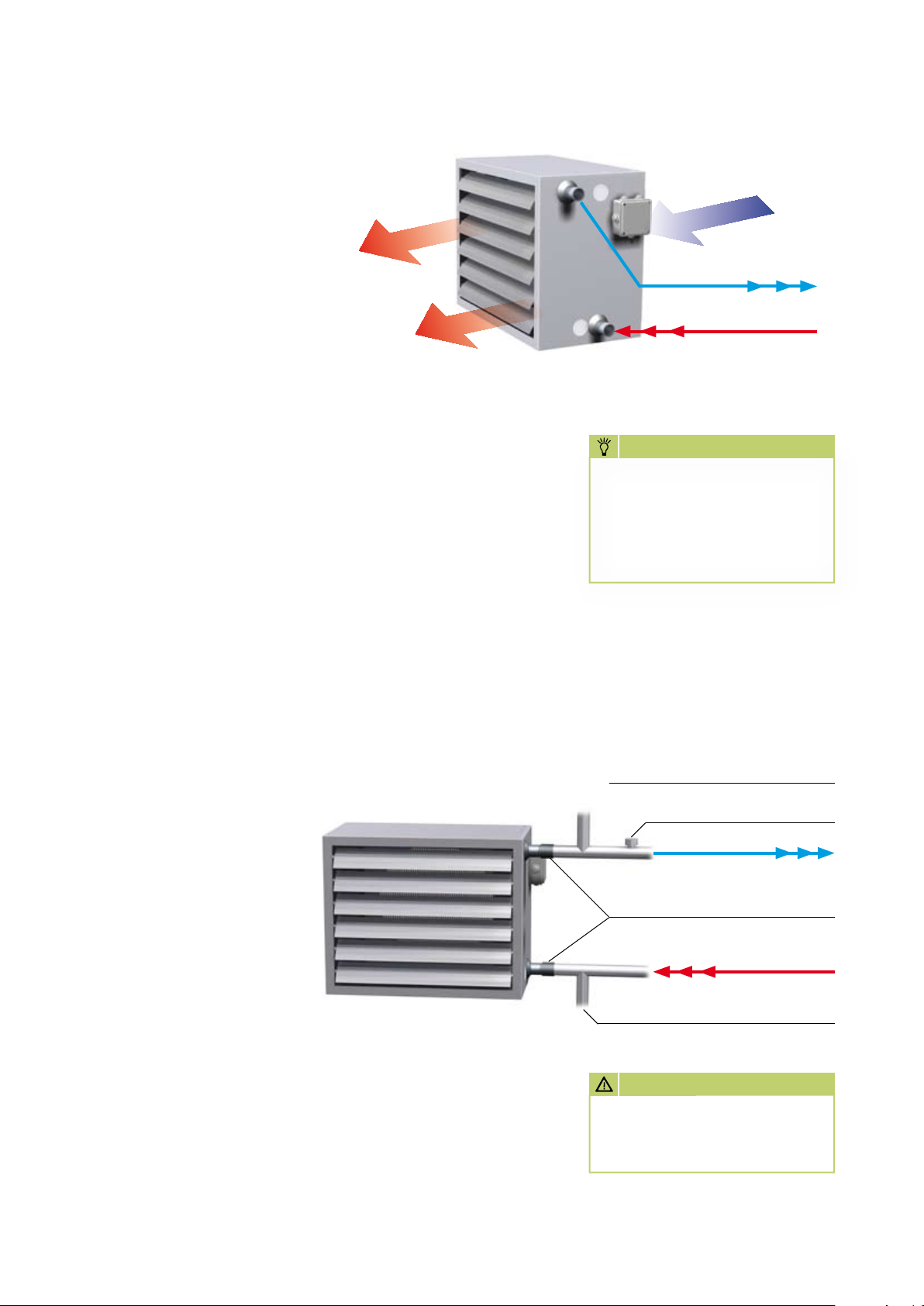

Connection to water

heating system

Prior to connection to the heating

system on-site, it must be ensured that the respective capacity

requirements of the unit can be

made available at all times.

■

Connection of the unit on the

water side must take place onsite via suitable pipe fittings and

shut-off valves in the flow and

return.

The use of compensators and

automatic deculators is recommended!

■

T he water inlet (flow) is gener-

ally at the “top“.

Air outlet

■

The fin heat exchangers must

be thoroughly vented after

installation.

Air cushions in the heat

exchanger will reduce the

heating capacity!

■

The fin heat exchangers operate

in counterflow.

Air inlet

Water outlet

Water inlet

■

See technical data for pipe con-

nection thread sizes.

NOTE

When tightening the screwed

connections of the heating

medium connection, a suitable

tool must be used to prevent

the connecting pipes rotating

in order to avoid damage.

■

The connection side can be

either on right or left.

Draining if there is a risk of

frost

It is not possible to statically drain

the fin heat exchanger completely.

The fin heat exchanger can only be

drained completely using compressed air.

Important information

on frost protection!

To prevent frost damage, anti-frost

protection must be provided at

temperatures below 0°C.

Where systems in rooms at risk

from frost are not used for extended periods, under no circumstances must water be present in

the heat exchanger.

If this is not possible, a suitable

antifreeze agent must be added to

the heating medium (water).

Venting

❄

ATTENTION

Frost damage to the fin heat

exchanger does not fall under

the warranty!

Anti-frost thermostat

Water outlet

Pipe fitting

Water inlet

Draining

9

Commissioning Switching off

Prior to initial use

ATTENTION

Commissioning can only

take place when it is ensured

that mounting and electrical

installation has been carried

out in compliance with the

pertinent requirements of the

EC Directives.

1. Correct mechanical installation

must be verified.

2. Correct connection to the

heating system on-site must be

verified.

3. It must be ensured that hot

surfaces are protected against

accidental contact.

4. It must be verified that the

electrical wiring of the units has

been carried out in compliance

with the applicable directives

and standards using the supplied wiring diagrams.

9. It must be ensured that the fan

rotates in the direction of the

arrow.

The direction of rotation can

be changed by interchanging

two phases.

10. It should be noted that when

using a speed control (accessory) the power of the control

unit must correspond to the

power of the motor.

During initial

commissioning

During initial commissioning, all

regulating, control and safety

devices must be checked for their

proper functioning and correct

adjustment.

1. The power consumption of the

fan must be measured.

The nominal current must not

exceed the values on the rating

plate at the respective operating speeds.

Set the switch of the respective

control unit to the “Off” or “0”

position.

For extended periods of nonuse:

■

Disconnect the electrical con-

nection in all poles.

■

Shut-off the heating medium

connection.

■

Where there is s risk of frost,

the entire system must be

drained if no suitable antifreeze

agent has been added.

NOTE

The heat exchanger can only

be drained completely using

compressed air.

5. The fan space as well as the

inlet and outlet area must be

checked for the presence of

foreign bodies.

6. It must be ensured that all air

outlets are open.

7. The fan must be checked for

smooth operation.

8. Switch on the power to the control unit (accessory) and switch

on the unit via the control

switch of the control.

2. Check the control/regulating

function of the fan.

3. Check the motor protection

function of the fan.

4. If fitted, check the function of

the frost protection and room

thermostats.

5. Check the complete system for

de-energised installation and

possible vibrations.

6. Check the heating medium supply pipes for correct connection

and tightness.

NOTE

After disconnecting the control

unit from the power supply, in

the event of a power failure or

shutdown on faults, the control switch must always first be

switched to back to the “0”

position.

10

REMKO PWW

Care and maintenance

The units are virtually maintenance-free in normal operation.

However, to ensure trouble-free

operation, they should be inspected regularly and cleaned if

necessary.

Important precautions to be

taken before carrying out any

maintenance:

■

The units must be disconnected

from the supply in all poles and

locked to prevent unauthorised

reconnection.

ATTENTION

It does not suffice to switch off

the unit only via the switch!

■

Wait for the fan to stop.

■

Shut-off the water circuit and

lock to prevent unauthorised

opening.

■

Allow the fin heat exchanger to

cool down.

NOTE

The fan impeller and aluminium fins must not be damaged

or bent.

Cleaning agents

■

The units must be cleaned only

dry or with a moist cloth and a

small amount of soap solution if

necessary.

■

Under no circumstances use

high-pressure cleaners or steam

jet equipment.

■

Do not use caustic or solvent-

containing cleaning agents.

Cleaning the units

■

Clean all air inlets and air outlet

fins.

■

Clean the fan impeller. If ne-

cessary, remove the motor or

protection grille.

■

Clean the heat exchanger fins

either by blowing out, suction

or with a soft brush.

■

Remove heavy fouling on the

fan and aluminium fins with a

soap solution.

Repair

Fan replacement

1. Disconnect the electrical connection of the motor.

2. Remove the protection grille

with fan from the housing.

3. Remove the protection grille

from the fan motor.

4. Carefully refit the new fan in

reverse order.

5. Check the fan impeller for

smooth operation and freedom

of movement with respect to

the fan housing.

6. Re-establish the electrical connection of the motor correctly.

Replacement of

fin heat exchanger

1. Disconnect the electrical con-

nection of the unit.

2. Shut-off the water-sided unit

connection.

3. Drain the fin heat exchanger

completely and disconnect the

heating medium connections.

4. Remove any fitted air inlet and

air outlet accessories and remove the unit from the bracket

(support).

5. Remove the rear wall (support

plate) together with the fan.

6. Loosen the fin heat exchanger

fastening screws and remove

the heat exchanger towards the

air inlet side.

7. Fit the new heat exchanger and

reassemble the unit in reverse

order including accessories.

8. Re-establish electrical connections.

Checks after repairs:

■

The fan impeller must rotate

freely in the fan housing

■

The distance between the fan

impeller and fan housing must

be the same

■

The fan motor must rotate in

the direction of the arrow and

connected in correct phase

■

All screw connections must be

checked for tightness

ATTENTION

After completing all work on

the units, an electrical safety

test must be carried out in

accordance with VDE 0701.

NOTE

■

Only suitable cleaning agents

must be used to remove heavy

fouling.

Repair and maintenance work

must only be carried out by

authorised specialists.

11

Air outlet accessories

Standard type

The units are provided with horizontal, individually

adjustable air outlet fins as standard.

■

The fins can easily be removed by unclipping.

Air outlet shutter B

Vertical, individually adjustable air outlet fins for

wall and ceiling use.

The air outlet shutter B is mounted directly in front of the horizontal air outlet fins.

Use of the shutter enables a high blowing range.

The unit depth increases by 115 mm in the case of all unit types.

■

Retrofitting is easily possible.

W

Air outlet hood HG 4

This air outlet hood serves uniform air distribution in four directions

at low mounting heights.

The air outlet hood is not suitable for mounting hoods above 4 m.

■

For retrofitting, the standard horizontal air outlet fins of the unit

c

W

must be removed.

PWW

30

50

80

100

c

in mm

166 6 m 1.- Setting 9 m 2.- Setting

166 8 m 1.- Setting 11 m 2.- Setting

166 10 m 1.- Setting 13 m 2.- Setting

236 12 m 1.- Setting 15 m 2.- Setting

Blowing range W in metres

Ceiling air outlet nozzle AD

The ceiling air outlet nozzle serves for concentrated control of the

hot air stream and must be used at mounting heights above 4 m in

high halls.

■

For retrofitting, the standard horizontal air outlet fins of the unit

c

must be removed.

PWW

30

50

W

W

80

100

We reserve the right to make changes to dimensions and design in the interest of technical advances.

c

in mm

200 5.0 m 1.- Setting 6.5 m 2.- Setting

230 5.5 m 1.- Setting 6.5 m 2.- Setting

270 5.5 m 1.- Setting 7.0 m 2.- Setting

290 7.0 m 1.- Setting 9.0 m 2.- Setting

Blowing range W in metres

12

REMKO PWW

Air inlet accessories

Fresh air inlet grille AG

Fresh air inlet grille for fresh air intake through the outside wall

PWW

30

b1

b

50

80

100

a

For wall opening: Dimension a and b + about 15 mm

a

in mm

518 598 398 478

598 678 483 563

758 838 588 668

838 918 698 778

a1

in mm

b

in mm

b1

in mm

a1

Wall bracket WFM

for fastening the unit with air inlet accessories (PWW+FK+MLK or

a

d

b

c

PWW+FK) to the outside wall.

PWW

30

50

80

100

a

in mm

1115 490 55 60

1165 590 55 60

1215 690 55 60

1295 690 55 60

b

in mm

c

in mm

d

in mm

Mixed-air box MLK

for circulation/fresh air/and mixed air operation. With two shutter

flaps working in opposite direction as standard, without servomotor (accessory). With the supplied variable cover, the air direction

b

a

c

can be freely selected.

PWW

30

50

80

100

in mm

560 440 300

640 515 350

800 630 400

880 740 450

a

b

in mm

c

in mm

Filter box FK

with pocket filter insert removable from the side

(filter class G3, depth 100 mm)

b

PWW

30

a

c

50

80

100

a

in mm

560 440 400

640 515 400

800 630 400

880 740 400

b

in mm

c

in mm

We reserve the right to make changes to dimensions and design in the interest of technical advances.

13

Air inlet accessories

Fresh air inlet hood ALH

for fresh air intake via roof.

e

d

b

a

15

c

PWW

30

50

d

80

100

a

in mm

b

in mm

c

in mm

d

in mm

in mm

520 240 260 20 215

600 310 290 20 215

760 360 290 20 215

840 410 400 20 325

e

Rain collar RK

with warmth channel interim piece in 1000 or 500 mm length

e

c

c1

PWW

30

50

d

b

a

d

d

80

100

Flexible pipe SG

a

in mmbin mmcin mmc1in mmdin mmein mm

520 240 1000 500 20 220

600 310 1000 500 20 220

760 360 1000 500 20 220

840 410 1000 500 20 220

Flexible conn. (vibration isolation) betw. unit and air channel system.

(Dimension(s) for mounting on warmth channel intermediate piece).

(e)

b

PWW

30

c

a

d

50

80

100

a

in mm

b

in mm

c

in mm

d

in mm

in mm

520 400 120 20 240

600 475 120 20 310

760 590 120 20 360

840 700 120 20 410

e

b

d

a

d

Warmth channel interim piece KA

Warmth channel interim piece in 1000 or 500 mm length

c1

d

PWW

c

30

50

80

100

a

in mm

520 240 1000 500 20

600 310 1000 500 20

760 360 1000 500 20

840 410 1000 500 20

b

in mm

c

in mm

Circulation suction adapter UA

a

d

c

We reserve the right to make changes to dimensions and design in the interest of technical advances.

b

With air inlet protection grille for mounting on a channel as

standard.

PWW

30

50

80

100

a

in mm

520 240 400 20

600 310 450 20

760 360 650 20

840 410 800 20

b

in mm

c

in mm

d

in mm

e

in mm

d

in mm

14

REMKO PWW

1

C

ϑ

2

Accessory installation

Mixed-air box MLK

The mixed-air box MLK is designed for both wall and ceiling

mounting.

The ratio of fresh air to recirculated

air can be continuously adjusted

manually or with a flap servomotor

(accessory).

With the supplied variable cover,

the direction of the air on the inlet

side can be freely selected.

For operation of the mixed-air box

with flap servomotor, the mixedair flaps must be checked regularly

for easy movement and fouling.

Filter box FK

The filter box with pocket filter is

designed for direct mounting on

the units.

The pocket filter can be removed

from the side.

The filter medium of the pocket

filter can be regenerated and has

the filter class G3.

Further filter classes are available

on request.

Filter maintenance

Depending on the operating conditions, the pocket filter must be

checked regularly and cleaned or

replaced if necessary.

Automatic monitoring

The degree of clogging of the

pocket filter can be monitored

via a differential pressure switch

(special accessory).

Anti-frost thermostat FS

The anti-frost thermostat is a

precise water temperature sensor,

which can be subsequently mounted on the surface of pipes.

The thermostat is fitted with a

precision sensitive switch.

The supplied strap with clamp

enables easy subsequent fitting

without draining the heating system.

Installation

Prior to fitting, the pipe insulation

in the contact area of the sensor

must be removed.

The parts required for fitting, e.g.

strap or clamp, etc., are supplied

with the unit.

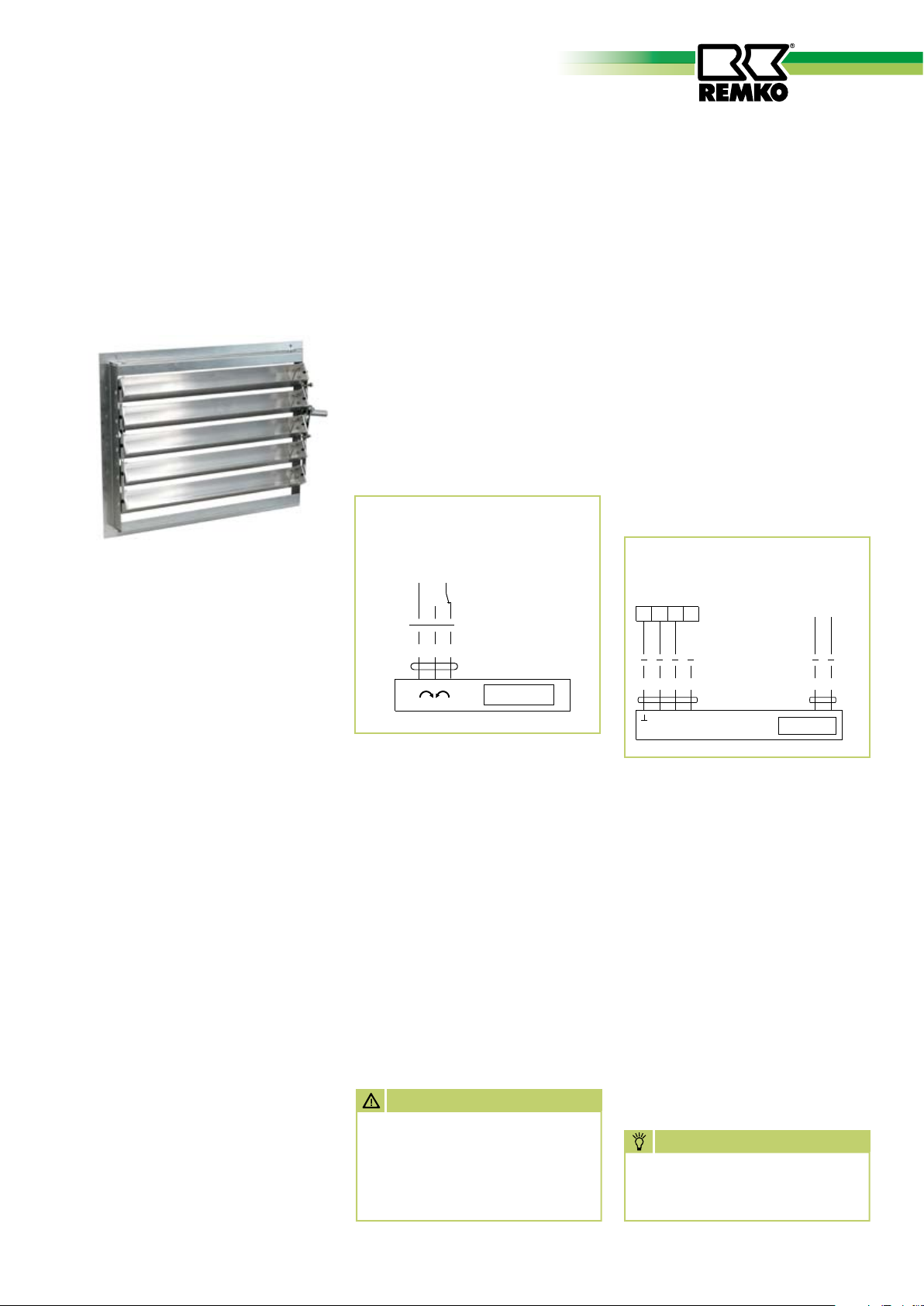

Wiring diagram

Mounting clips

Installation

Fastening of the mixed-air and

filter box takes place with the supplied mounting clips (4 pieces).

When the final pressure difference

is reached, the filters must be

replaced with filters with the same

quality class.

Spare pocket filter EF:

PWW 30 EDP No. 385405

PWW 50 EDP No. 385406

PWW 80 EDP No. 385407

PWW 100 EDP No. 385408

Contact 1

opens with a rise of temperature.

Contact 2

closes with a rise of temperature.

Technical data:

Setting range 25 to 95°C

Switching difference adjustable.

Maximum ambient temperature

70°C.

NOTE

In order to ensure perfect functioning of the freeze protection

control, the sensor must always be mounted at the water

outlet (return).

15

Typ KSH

N L1

230V/1~

1 2 3

Aderbezeichnung

Stellungsgeber 0-10V

Aderbezeichnung

1 2

3

5

N L1

y

N L1

230V/1~

1 2

3

U

vcc

4

Typ KSP

Injection shutter IJ

The injection shutter is a useful extension for the REMKO PWW unit

and is designed for direct mounting on the units.

The supply air is optimally blown in

via the injection shutter. The position of the air directing fins influences the air velocity and air outlet

temperature of the total air flow.

This technology provides for a higher blowing range and more rapid

heating of the rooms.

Intake of the already heated room

air prevents the occurrence of

varying air temperatures. The heat

is distributed evenly throughout

the room.

Installation

Unclip the existing fins and fix the

injection shutter with four screws.

The position of the fins can also be

electrically regulated via an optional control.

Servomotor KSH

(open/closed)

The servomotor is mounted directly on the flap shaft. It is provided

with a universal terminal block and

is fixed with the supplied locking

element.

The drive is overload-proof and

requires no limit switch.

For manual actuation, the gear can

be disengaged with a self-resetting

pushbutton.

Wiring diagram

Technical data:

Servomotor Type KSH

overload-proof

Rating 2.5 W, 230V, 50Hz

Degree of protection IP 54

Operating time about 150 seconds

Maximum ambient temperature

50°C.

Servomotor KSP

(variable speed)

The servomotor type KSP is supplied with 230V.

A transformer converts the system

voltage into a low voltage of 24V.

The motor is controlled depending

on the input voltage and position

of the feedback potentiometer.

The direction of rotation of the

motor can be reversed with the

rotary control switch.

The connection of an electrical

indicator for the flap position and

further servomotors is possible.

Wiring diagram

Technical data:

Servomotor type KSP

overload-proof

Rating 3.5 W, 230V, 50Hz

Degree of protection IP 54

Operating time about 150 seconds

Maximum ambient temperature

50°C.

ATTENTION

Installation and repairs to the

electrical installation must

only be carried out by authorised electrical specialists for

safety reasons.

NOTE

All electrical wiring terminals

must be checked for tightness

and retightened if necessary.

16

REMKO PWW

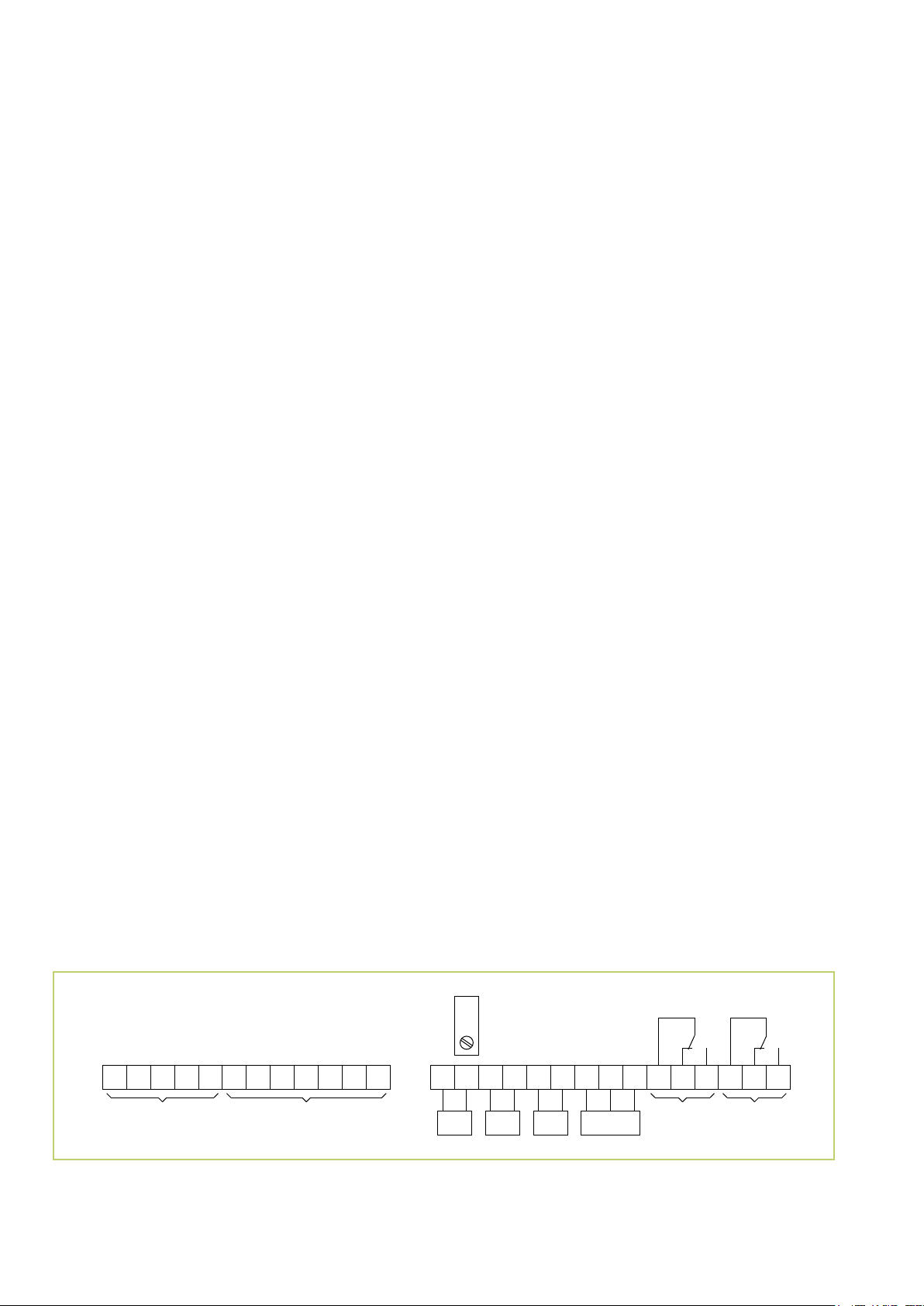

Switchgear SW 2 - 380 DI

Three-phase 400V,

two-speed fan

maximum switching capacity

4 kW, surface mounting, motor

protection by means of built-in

thermal contacts in fan motor.

Design

Sturdy plastic housing,

Degree of protection IP 54.

Totally-insulated according to VDE.

Front plate with symbols for switch

positions, supply and protective

conductor terminals, main contactor, control switch with the

functions “Off/Setting 1/Setting

2“, control fuse, indicator light

(extinguishes on fan faults and/or

interruption of power supply to

control unit), fault reset button,

terminals for motor output, terminals for thermal contacts and room

thermostat.

Reconnection after a fault

After each main break or fan fault,

the “Fan fault reset button“ must

be pressed once!

Multiple series connection

The control unit is suitable for

multiple series connection. Several

motors in the same circuit can be

connected to a control unit

The total rating of the connected

motors must not exceed the permissible switching capacity of the

control unit.

The thermal contacts of all motors

must be connected in series.

Note on safe operation

Earthing, multiple earthing or

protection switching and mains

protection must be carried

out on-site according to VDE

specifications and the regulations

of the responsible electricity supply

company. Only specialists may

establish electrical connections

based on the wiring diagrams in

compliance with the applicable

regulations, taking into account

local regulations.

Circuit and wiring diagram

S1 = Fan fault reset button

K2A = Auxiliary relay

We reserve the right to make changes to dimensions and design in the interest of technical advances.

F1 = Control fuse

S2 = Control switch

K1M = Contactor for fan motor

H1 = Indicator light

17

Control unit MSRD 2.5

0

D

U

1 2 3

4

7 8 9

10

11

12

13

14

15

16

17

18

5

6

S1

R1

K1

13

14

K1

F1

6,3 A

H1

X1

X2

K1

A1

A2

PE L1 L2 L3 N

PE U1 V1 W1 U2 V2 W2 TK TK

15

RT RT

16

4

4

4

11

1

3

5

13

2

4

6

14

Raumthermostat

Thermokontakte

im Motor

Einspeisung 400 V / 50 Hz

Erdung nach örtlichen Vorschriften

Motor 3~

Thermoschutz

für 2 Geräte

Thermoschutz

für 3 Geräte

Thermoschutz

für 4 Geräte

weitere Thermokontakte

in Reihe schalte n

13TK14

TK

13TK14

TK

13TK14

TK

6 7 8 9 10 11 12 14

13

1 2 3 4 5

1 3 5

2 4 6

Three-phase 400V,

two-speed fan

maximum switching capacity 2.5

kW, surface mounting, motor

protection by means of built-in

thermal contacts in fan motor.

Design

Sturdy plastic housing,

Degree of protection IP 41.

Totally-insulated according to VDE.

Front plate with symbols for switch

positions, supply and protective

conductor terminals, main contactor, control switch with the

functions “Off/Setting 1/Setting

2”, control fuse, indicator light

(extinguishes on fan faults and/or

interruption of power supply to

control unit), fault reset button,

terminals for motor output, terminals for thermal contacts and room

thermostat.

Reconnection after a fault

In the event of a fault, the unit

switches off and does not switch on

again automatically. After clearing

the fault, the unit can be switched

on again by setting the control

switch to “0” and waiting for

about30 seconds.

Multiple series connection

The control unit is suitable for

multiple series connection. Several

motors in the same circuit can be

connected to a control unit.

The total rating of the connected

motors must not exceed the permissible switching capacity of the

control unit.

The thermal contacts of all motors

must be connected in series.

Note on safe operation

Earthing, multiple earthing or

protection switching and mains

protection must be carried

out on-site according to VDE

specifications and the regulations

of the responsible electricity supply

company. Only specialists may

establish electrical connections

based on the wiring diagrams in

compliance with the applicable

regulations, taking into account

local regulations.

Circuit and wiring diagram

S1 = Control switch K1 = Contactor R1 = PTC element

F1 = Control fuse H1 = Indicator light

We reserve the right to make changes to dimensions and design in the interest of technical advances.

18

REMKO PWW

PE L1 L2 L3 N PE U1 V1 W1U2 V2 W2X1 1 2 3 4 5 6 7 8 9 10 11 12X2 13 14 15

TK FS TF

Mischluft-

klappe

Potenzialfreier

Kontakt TK

Potenzialfreier

Kontakt FS

Potentiometer

zum Abgleich des

Temperaturfühlers

Spannungsversorgung Ventilatoranschluß

Control unit MAK-2

Three-phase 400V,

two-speed fan

maximum switching capacity 8 kW

Surface mounting, motor protection by means of built-in thermal

contacts in the fan motor, terminals for thermal contacts, room

thermostats, anti-frost thermostat

and mixed-air box servomotor.

Design

Sturdy plastic housing,

Degree of protection IP 54.

Totally-insulated according to VDE.

Fully electronic two-step control

unit with digital display.

Two modes are available, “Manual“ and “Automatic“.

Operation takes place via a large

sized membrane keyboard.

In the automatic mode, the fan

speeds are controlled according to

the freely programmable temperature difference.

Day/night/temperature control including week programme provided

as standard. Four switching times

are available for day and night

respectively.

Available for motor protection are

thermal contact terminals.

Terminals for anti-frost thermostat

and continuously variable flap servomotor are provided as standard.

Function

The mixed-air flaps can be continuously controlled via flap servomotor. When the unit is switched

off, the flaps assume a “CLOSED“

position.

The anti-frost thermostat also

closes the flaps and switches off

the fan.

Reconnection after a fault

After a power failure (up to

three hours) the unit restarts

automatically.

After operation of the thermal

contacts, the unit can be reset

after cooling down via the “OFF“

button.

The antifreeze sensor automatically

starts the unit in the previously

selected programme mode after a

rise of temperature.

Multiple series connection

The control unit is suitable for

multiple series connection. Several

motors in the same circuit can be

connected to a control unit.

The total capacity of the connected motors must not exceed

the permissible switching capacity

of the control unit.

The thermal contacts of all motors

must be connected in series.

Note on safe operation

Earthing, multiple earthing or protection switching and mains protection must be carried out on-site

according to VDE specifications

and the regulations of the responsible electricity supply company.

Only specialists may establish

electrical connections based on the

wiring diagrams in compliance with

the applicable regulations, taking

into account local regulations.

Wiring diagram

We reserve the right to make changes to dimensions and design in the interest of technical advances.

19

Control unit, 5-stage

EG

TK

TK W2 U2 V2

W1V1U1

J

N

L1 L2

L3 U1

V1 W1

TK TKRT RT

N L1 L2 L3PE

J

FS FS

12

11 14

N L L

Raum-

thermostat

Frostschutz-

thermostat

250VAC

max.2A

230VAC

max.1A

Eingangsspannung

400V / 3~N / 50 Hz

3~ Motor mit

Thermokontakten

Kontaktbelastung

Lüfter

Aus/Ein

hohe Drehzahl

∆ - Schaltung

niedere Drehzahl

Y - Schaltung

TK

W2 U2 V2

TK

U1

V1 W1

PE

L1 L2 L3

TK W2 U2 V2

TK

U1

V1 W1

PE

L1 L2 L3

Voltage Current

Degree of

protection

Weight

Control unit V A IP kg

3 EG

5 EG

400 3.0 54 11.1

400 5.2 54 15.6

Wiring diagram five-stage control unit 3 EG/5 EG

Five-stage control units,

400V/50Hz, three-phase with

indicator light.

Motor protection takes place

by the connection of thermal

contacts.

In the event of a fault, (operation of the thermal contacts), the

internal contactor drops out and

disconnects the motor from the

power supply.

After the motor has cooled down

and the fault cleared, the mode selector switch must first be switched

to the “0“ position and then back

to the required operating position

(speed position).

The control units have a connection for external control devices,

e.g. room thermostat, anti-frost

thermostat, servomotor, recirculating pump, indicator light, solenoid

valve, mixer, etc. (observe contact

rating).

Fan motor 400V, two-step

D / Y switching and thermal contacts

Standard units

Wiring diagram

We reserve the right to make changes to dimensions and design in the interest of technical advances.

ATTENTION

Electrical heater connection

must be carried out by authorised specialists as defined

in DIN EN 60335-1 and VDE

0116.

NOTE

All electrical wiring terminals

must be checked for tightness

and retightened if necessary.

20

REMKO PWW

Exploded drawing

4

5

6

1

1a

1b

2

We reserve the right to make changes to dimensions and design in the interest of technical advances.

Spare parts list

No. Designation

PWW 30

EDP No.

3

7

PWW 50

EDP No.

PWW 80

EDP No.

PWW 100

EDP No.

1 Heat exchanger Bg. 2 1105211 1105215 1105219 1105223

1a Heat exchanger Bg. 3 1105212 1105216 1105220 1105224

1b Heat exchanger Bg. 4 1105213 1105217 1105221 1105225

2 Electrical terminal box 1105268 1105268 1105268 1105268

3 Housing 1105274 1105275 1105276 1105277

4 Fan protection grille 1105207 1105208 1105209 1105210

5 Fan 400V/two-speed 1105242 1105243 1105244 1105245

6 Support plate 1105264 1105265 1105266 1105267

7 Air outlet fin 1105284 1105285 1105286 1105287

When ordering spare parts, also quote the serial number of the unit (see rating plate) in addition to the EDP number!

21

Intended use

Customer service and

warranty

Environmental

Protection and

Recycling

Owing to their design and equipment, the devices are intended

solely for heating and ventilation

purposes in industrial or commercial use (not for domestic heating).

The unit is designed for use with

air inlet and air outlet accessories

approved by the manufacturer.

The units must only be operated

by suitably trained personnel.

The manufacturer disclaims all

liability for any damage

attributed to failure to observe

relevant instructions, statutory requirements applicable at the place

of use or unauthorised changes to

the unit.

NOTE

A precondition for any warranty claims is that the dealer or his

customer has completed and

returned the enclosed “Warranty

document“ to REMKO GmbH &

Co. KG at the time of sale and

commissioning.

The units were repeatedly tested for perfect functioning at the

factory.

However, if faults should occur

which cannot be cleared by the

operator via troubleshooting

measures, your specialised dealer or contract partner should be

contacted.

NOTE

Disposal of packaging

Think of the environment when

disposing of the packaging

material.

Our appliances are carefully packed for transport and delivered in

sturdy cardboard packaging and

on a wooden pallet if necessary.

The packaging materials are environmentally-friendly and can be

recycled.

The reuse of packaging material

makes a valuable contribution to

the reduction of waste and the

preservation of raw materials.

Dispose of packaging materials at

the facilities provided.

Disposal of old unit

Our production is subject to constant quality controls.

Use for any other purpose

than that described in these

operating instructions is not

permitted.

Failure to observe this rule

will invalidate all liability and

warranty.

Adjustment and maintenance

must only be carried out by

authorised specialists.

Only high-quality materials are

used, the majority of which are

recyclable.

Make your contribution towards

environmental protection by disposing of your old appliance in an

environmentally friendly manner.

Only dispose of old appliances at

recycling sites or where suitable

facilities exist.

22

REMKO PWW

PWW 30 ratings tables • Technical data

Type

Design

Speed

Electrical connection

Frequency

Power input

Nominal current

Air capacity

Sound pressure level

Blow. range ceiling*max.

Blow. range wall max.

Heating medium conn.

Weight

Heating medium

50/40 °C

60/50 °C

70/50 °C

80/60 °C

90/70 °C

rpm

Volt

Hz

kW

A

m³/h

dB(A)

m

m

Inch

kg

tL1 °C

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

PWW 30-2

two-speed

1340 1040

3 x 400 3 x 400

50 50

0.13 0.10

0.26 0.16

2250 1850

52 46

7.5 6.0

17 14

R ¾“ R ¾“

24 24

kW tL2 °C kW tL2 °C

13.1 2 10.6 2

12.0 5 10.7 7

10.9 9 9.7 10

0

0

0

0

0

9.6 12 8.6 14

8.3 16 7.5 18

7.0 20 6.4 21

5.9 23 5.3 24

4.5 26 4.0 27

16.5 5 14.0 5

15.1 9 12.9 9

13.8 12 11.8 12

12.7 16 10.7 16

11.5 20 9.6 20

10.1 23 8.6 24

8.7 27 7.5 27

7.4 30 6.4 30

17.3 6 14.7 6

15.9 9 13.4 9

14.4 13 12.1 13

13.1 16 10.7 16

11.8 21 9.8 20

10.4 24 8.6 24

8.5 26 7.2 26

7.1 29 5.8 29

20.3 10 17.5 10

18.8 13 16.1 13

17.3 16 14.7 16

15.9 19 13.4 19

14.4 24 12.1 24

13.1 27 10.7 27

11.8 31 9.8 30

10.4 34 8.6 34

23.2 13 20.4 15

21.7 17 18.9 18

20.3 20 17.5 20

18.8 23 16.1 23

17.3 28 14.7 28

15.9 31 13.4 31

14.4 34 12.1 34

13.1 37 10.7 37

tL1 Air inlet temperature tL2 Air outlet temperature* with ceiling air outlet nozzle AD

PWW 30-3

two-speed

1340 1040

3 x 400 3 x 400

50 50

0.13 0.10

0.26 0.16

2050 1640

53 48

7.0 5.5

16 13

R 1“ R 1“

26 26

kW tL2 °C kW tL2 °C

16.7 9 15.2 12

15.4 12 13.8 14

14.0 15 12.3 17

12.2 17 11.0 20

11.0 22 9.4 23

9.0 24 7.8 25

7.6 27 6.6 28

5.8 29 5.1 30

20.6 13 18.1 16

19.2 16 16.6 18

17.7 19 15.2 21

16.2 22 13.7 23

14.8 26 12.3 28

12.9 29 11.0 30

11.6 32 9.4 32

9.5 34 7.8 34

22.1 15 18.1 16

20.3 17 16.6 18

18.4 20 15.2 21

16.7 22 13.7 23

15.1 27 12.3 28

13.3 29 10.8 30

11.0 31 9.3 32

9.0 33 7.6 34

25.7 19 21.0 21

23.9 22 19.5 23

22.1 25 18.1 26

20.3 27 16.6 28

18.4 32 15.2 33

16.7 34 13.7 35

15.1 37 12.3 38

13.3 39 10.8 40

29.4 24 23.9 25

27.6 27 22.4 28

25.7 29 21.0 31

23.9 32 19.5 33

22.1 37 18.1 38

20.3 39 16.6 41

18.4 42 15.2 43

16.7 44 13.7 45

PWW 30-4

two-speed

1340 1040

3 x 400 3 x 400

50 50

0.13 0.10

0.26 0.16

1850 1500

55 49

6.5 5.0

15 12

R 1 ¼“ R 1 ¼“

27 27

kW tL2 °C kW tL2 °C

21.0 18 19.1 22

19.4 20 17.4 24

17.6 23 15.4 25

15.5 24 13.8 27

13.0 28 11.8 30

11.3 29 10.0 31

9.5 31 8.2 32

7.3 32 6.4 33

26.1 23 21.7 24

24.2 25 20.4 27

22.2 27 19.0 29

20.5 30 17.4 31

18.5 34 15.4 35

16.3 36 13.7 37

14.0 37 11.8 38

12.0 39 10.0 40

26.4 23 23.5 28

24.5 26 21.4 29

22.9 28 19.4 30

21.1 31 17.4 31

19.0 35 15.8 36

16.7 36 13.6 37

13.8 37 11.7 38

11.5 38 9.3 38

29.9 28 27.5 35

28.2 31 25.5 36

26.4 33 23.5 38

24.5 36 21.4 39

22.9 41 19.4 43

21.1 43 17.4 44

19.0 45 15.8 46

16.7 46 13.6 47

33.6 36 28.9 41

31.3 38 27.2 42

30.2 41 25.7 44

27.8 42 24.1 46

26.6 49 22.7 52

24.5 50 21.4 55

22.7 52 19.5 56

20.9 54 18.0 56

We reserve the right to make changes to dimensions and design in the interest of technical advances.

23

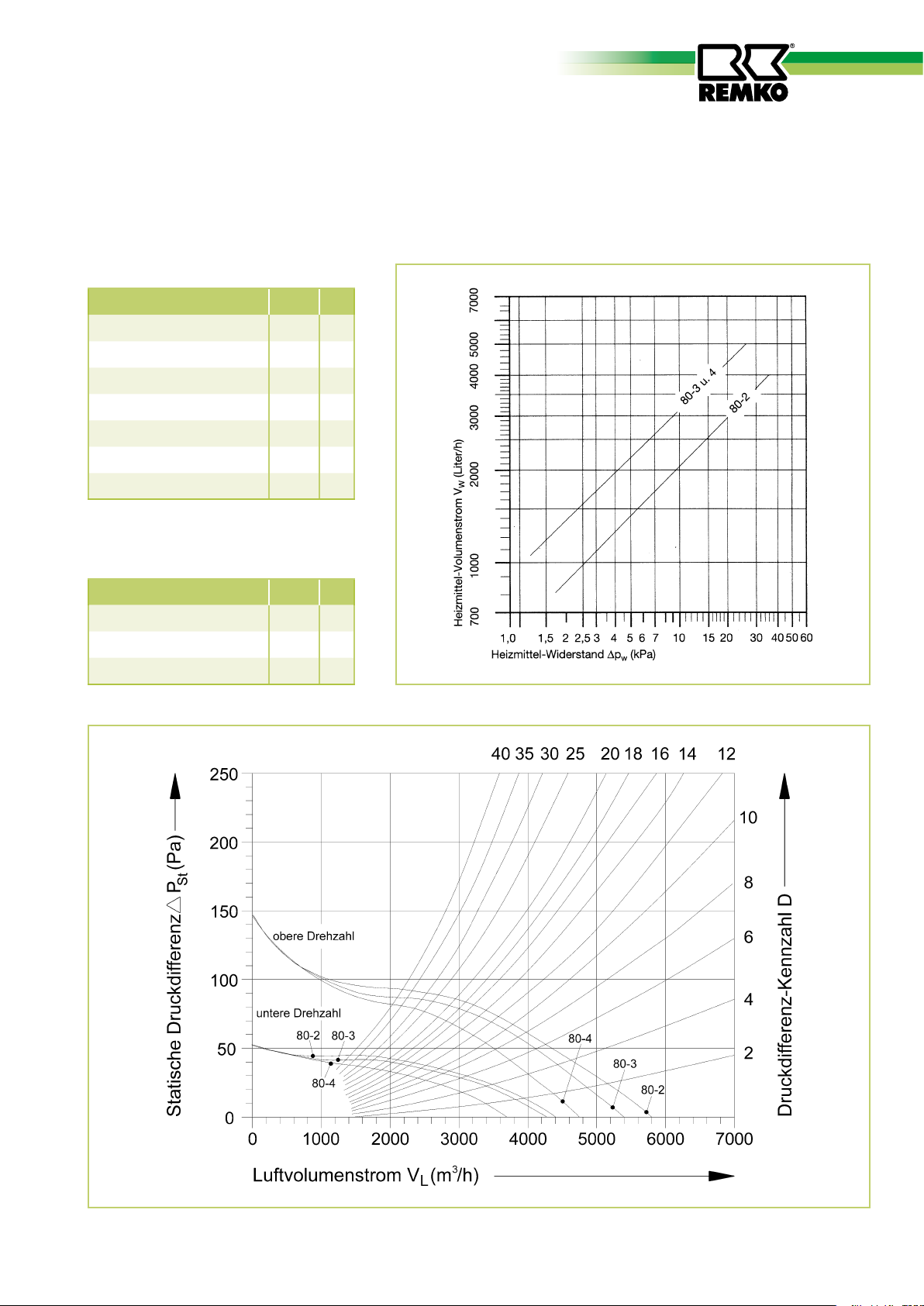

Characteristics • Heating medium resistances

Pressure difference values D of

accessories:

1. Accessories mounted on suction side

Component Type D

Mixed-air box MLK 5

Filter box (filter clean) FK 2

moderate filter clogging FK 7

Warmth channel interim piece

(per m)

Fresh air inlet grille AG 4

Circulation suction adapter UA 1

Fresh air inlet hood ALH 3

2. Accessories mounted on pressure side

Component Type D

Air outlet shutter B 4

KA 1

Air outlet hood HG 3

Ceiling air outlet nozzle AD 10

We reserve the right to make changes to dimensions and design in the interest of technical advances.

24

REMKO PWW

PWW 50 ratings tables • Technical data

Type

Design

Speed

Electrical connection

Frequency

Power input

Nominal current

Air capacity

Sound pressure level

Blow. range ceiling*max.

Blow. range wall max.

Heating medium conn.

Weight

Heating medium

50/40 °C

60/50 °C

70/50 °C

80/60 °C

90/70 °C

rpm

Volt

Hz

kW

A

m³/h

dB(A)

m

m

Inch

kg

tL1 °C

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

PWW 50-2

two-speed

1360 1020

3 x 400 3 x 400

50 50

0.26 0.18

0.52 0.29

3800 3180

55 50

8.0 7.0

22 18

R ¾“ R ¾“

31 31

kW tL2 °C kW tL2 °C

21.2 1 19.3 3

20.4 6 17.4 6

16.9 8 15.5 9

0

0

0

0

0

15.1 12 13.7 12

13.0 16 11.7 17

11.0 19 9.7 20

9.0 22 7.7 23

7.0 26 5.9 26

26.5 4 23.1 5

24.5 8 21.3 9

22.4 11 19.3 12

20.3 15 17.4 15

17.9 19 15.5 20

15.9 22 13.6 23

13.7 26 11.7 26

11.6 29 9.6 29

26.6 4 22.9 5

24.5 8 21.0 8

22.3 11 19.0 12

20.1 15 16.9 15

18.1 19 14.8 19

15.6 22 12.9 22

13.4 26 11.1 26

11.2 29 9.3 29

30.7 7 26.8 8

27.7 11 24.9 12

26.6 14 22.9 15

24.5 18 21.0 18

22.3 23 19.0 23

20.1 26 16.9 26

18.1 29 14.8 29

15.6 32 12.9 32

34.9 10 30.7 12

32.7 14 28.4 15

30.7 17 26.8 18

28.7 21 24.9 22

26.6 26 22.9 27

24.5 29 21.0 30

22.3 33 19.0 33

20.1 36 16.9 36

tL1 Air inlet temperature tL2 Air outlet temperature* with ceiling air outlet nozzle AD

PWW 50-3

two-speed

1360 1020

3 x 400 3 x 400

50 50

0.26 0.18

0.52 0.29

3400 2870

55 51

7.0 5.5

20 16.5

R 1“ R 1“

34 34

kW tL2 °C kW tL2 °C

27.3 8 24.7 10

24.9 11 22.2 12

22.3 14 19.8 15

19.7 17 17.4 18

17.1 21 14.8 21

14.4 23 12.5 24

11.8 26 10.1 26

9.2 29 7.7 28

34.8 13 29.4 13

32.1 16 27.1 16

28.8 18 24.7 19

26.2 21 22.2 21

23.5 26 19.8 26

20.7 28 17.4 28

18.1 31 14.8 30

15.3 33 12.5 33

34.9 13 29.4 13

32.2 16 26.8 16

29.4 19 24.3 18

26.5 21 21.8 21

23.8 26 19.4 25

20.9 28 16.6 27

17.3 30 14.5 30

13.8 32 11.9 32

40.1 17 34.2 18

37.6 20 31.8 21

34.9 23 29.4 23

32.2 26 26.8 26

29.4 31 24.3 30

26.5 33 21.8 33

23.8 36 19.4 35

20.9 38 16.6 37

45.1 21 38.8 22

42.3 24 35.9 24

40.1 27 34.2 28

37.6 30 31.8 31

34.9 36 29.4 36

32.2 38 26.8 38

29.4 41 24.3 40

26.5 43 21.8 43

PWW 50-4

two-speed

1360 1020

3 x 400 3 x 400

50 50

0.26 0.18

0.52 0.29

3150 2770

58 54

6.5 5.5

18 16

R 1 ¼“ R 1 ¼“

36 36

kW tL2 °C kW tL2 °C

36.1 18 32.8 19

32.8 20 29.3 21

29.5 22 26.1 22

25.9 24 23.0 24

22.6 27 19.6 27

19.0 29 16.6 29

15.6 31 13.5 30

12.0 32 10.1 31

45.9 24 38.8 24

42.3 26 35.8 26

38.1 28 32.7 27

34.6 30 29.3 29

31.1 34 26.0 33

27.3 36 22.9 35

23.8 37 19.5 36

20.1 39 16.5 38

46.1 25 38.8 24

42.6 27 35.3 25

38.8 28 32.2 27

34.9 30 28.8 29

31.4 34 25.7 33

27.6 36 21.9 34

22.8 36 19.0 36

18.2 37 15.8 37

52.9 31 45.1 30

49.7 33 42.1 32

46.1 35 38.8 34

42.6 37 35.3 35

38.8 41 32.2 40

34.9 43 28.8 41

31.4 44 25.7 43

27.6 46 21.9 44

54.0 31 48.5 33

50.8 34 44.9 35

48.1 36 42.8 37

45.1 39 39.8 39

41.9 44 36.8 45

38.6 46 33.5 46

35.3 48 30.4 48

31.8 50 27.8 51

We reserve the right to make changes to dimensions and design in the interest of technical advances.

25

Characteristics • Heating medium resistances

Pressure difference values D of

accessories:

1. Accessories mounted on suction side

Component Type D

Mixed-air box MLK 5

Filter box (filter clean) FK 2

moderate filter clogging FK 7

Warmth channel interim piece

(per m)

Fresh air inlet grille AG 5

Circulation suction adapter UA 2

Fresh air inlet hood ALH 4

2. Accessories mounted on pressure side

Component Type D

Air outlet shutter B 5

KA 1

Air outlet hood HG 4

Ceiling air outlet nozzle AD 10

We reserve the right to make changes to dimensions and design in the interest of technical advances.

26

REMKO PWW

PWW 80 ratings tables • Technical data

Type

Design

Speed rpm

Electrical connection

Frequency

Power input

Nominal current

Air capacity

Sound pressure level

Blow. range ceiling*max.

Blow. range wall max.

Heating medium conn.

Weight

Heating medium tL1 °C

50/40 °C

60/50 °C

70/50 °C

80/60 °C

90/70 °C

Volt

Hz

kW

A

m³/h

dB(A)

m

m

inch

kg

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

+ 5

+ 10

+ 15

+ 20

PWW 80-2

two-speed

880 670

3 x 400 3 x 400

50 50

0.42 0.28

0.76 0.46

5800 4400

55 49

8.5 6.5

25 19

R 1“ R 1“

44 44

kW tL2 °C kW tL2 °C

35.2 3 32.1 6

31.9 6 29.0 9

28.5 9 25.9 12

0

0

0

0

0

25.2 13 22.7 15

22.0 17 19.8 19

18.6 20 16.8 22

15.7 23 14.3 25

12.2 27 11.0 28

44.3 6 38.3 9

40.7 9 35.2 12

37.2 13 32.1 15

33.7 16 28.9 18

30.1 21 25.8 22

26.6 24 22.7 25

23.2 27 19.8 28

19.6 30 16.7 32

45.9 7 39.2 9

42.5 10 36.3 13

39.2 14 33.4 16

35.7 17 30.5 19

32.5 22 27.6 24

28.9 25 24.6 27

25.4 28 21.0 29

21.8 31 17.4 32

52.7 10 44.8 13

49.3 13 42.1 16

45.9 17 39.2 19

42.5 20 36.3 23

39.2 25 33.4 28

35.7 28 30.5 31

32.5 32 27.6 34

28.9 35 24.6 37

60.0 14 50.7 17

56.7 17 47.7 20

52.7 20 44.8 23

49.3 23 42.1 26

45.9 29 39.2 32

42.5 32 37.0 35

39.2 35 33.4 38

35.7 38 30.5 41

Air inlet temperature tL2 Air outlet temperature* with ceiling air outlet nozzle AD

t

L1

PWW 80-3

two-speed

880 670

3 x 400 3 x 400

50 50

0.42 0.28

0.76 0.46

5400 4300

55 49

8.0 6.0

23 18.5

R 1 ¼“ R 1 ¼“

47 47

kW tL2 °C kW tL2 °C

44.8 9 39.2 11

40.7 12 35.8 14

36.5 15 32.1 17

32.3 17 28.5 19

28.1 21 24.7 23

23.8 24 21.0 25

20.1 27 17.6 28

15.6 29 13.7 30

56.1 14 46.6 15

51.7 17 42.9 18

47.3 19 39.2 20

42.9 22 35.5 23

38.6 27 32.1 27

34.2 29 28.4 30

29.6 32 24.7 32

25.5 34 21.0 35

58.7 15 50.2 17

54.4 18 46.5 20

50.1 21 42.7 22

45.8 24 39.0 25

41.6 28 35.3 30

37.0 31 31.5 32

32.5 33 26.9 34

27.9 36 22.2 35

67.2 20 57.7 22

63.0 22 54.0 25

58.7 25 50.2 27

54.4 28 46.5 30

50.1 33 42.7 35

45.8 36 39.0 37

41.6 38 35.3 40

37.0 41 31.5 42

75.8 24 65.2 27

71.5 27 61.5 29

67.2 30 57.7 32

63.0 32 54.0 35

58.7 38 50.2 40

54.4 40 46.5 42

50.1 43 42.7 45

45.8 46 39.0 47

PWW 80-4

two-speed

880 6700

3 x 400 3 x 400

50 50

0.42 0.28

0.76 0.46

4730 3700

55 49

7.0 5.5

20.5 16

R 1 ¼“ R 1 ¼“

51 51

kW tL2 °C kW tL2 °C

58.0 21 49.1 24

52.6 22 44.4 37

47.1 24 39.7 47

41.7 26 35.1 37

36.3 29 30.6 40

30.8 30 26.0 39

26.0 32 22.2 40

20.1 33 17.1 40

72.7 27 58.4 28

67.0 29 53.7 30

61.2 31 49.0 31

55.5 32 44.3 33

49.8 36 39.6 37

44.0 38 34.9 38

38.3 39 30.5 40

32.6 41 25.9 41

74.2 28 63.1 32

68.7 30 58.4 33

63.2 32 53.7 35

57.7 34 49.0 36

52.3 38 44.2 41

46.6 39 39.5 42

40.9 41 33.9 42

35.3 42 28.4 43

85.2 35 72.5 39

79.7 36 67.8 40

74.2 38 63.1 42

68.7 40 58.4 43

63.2 45 53.7 48

57.7 46 49.0 50

52.3 48 44.2 51

46.6 49 39.5 52

91.0 38 77.6 43

85.8 40 73.2 44

80.6 42 68.7 46

75.6 44 64.3 48

70.4 48 59.5 51

65.3 50 55.3 53

60.1 52 50.8 54

55.0 54 46.4 56

We reserve the right to make changes to dimensions and design in the interest of technical advances.

27

Characteristics • Heating medium resistances

Pressure difference values D of

accessories:

1. Accessories mounted on suction side

Component Type D

Mixed-air box MLK 5

Filter box (filter clean) FK 3

moderate filter clogging FK 7

Warmth channel interim piece

(per m)

Fresh air inlet grille AG 4

Circulation suction adapter UA 2

Fresh air inlet hood ALH 4

2. Accessories mounted on pressure side

Component Type D

Air outlet shutter B 5

KA 1

Air outlet hood HG 4

Ceiling air outlet nozzle AD 9

We reserve the right to make changes to dimensions and design in the interest of technical advances.

28

REMKO PWW

PWW 100 ratings tables • Technical data

Type

Design

Speed

Electrical connection

Frequency

Power input

Nominal current

Air capacity

Sound pressure level

Blow. range ceiling*max.

Blow. range wall max.

Heating medium conn.

Weight

Heating medium

50/40 °C

60/50 °C

70/50 °C

80/60 °C

90/70 °C

rpm

Volt

Hz

kW

A

m³/h

dB(A)

m

m

Inch

kg

tL1 °C

- 15

- 10

- 5

0

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

0

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

0

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

0

+ 5

+ 10

+ 15

+ 20

- 15

- 10

- 5

0

+ 5

+ 10

+ 15

+ 20

PWW 100-2

two-speed

870 650

3 x 400 3 x 400

50 50

0.76 0.47

1.50 0.81

9050 7400

58 54

10.5 9.0

35 29.5

R 1 ¼“ R 1 ¼“

58 58

kW tL2 °C kW tL2 °C

53.2 2 50.1 5

48.6 6 45.7 8

43.8 9 40.9 11

38.9 12 36.2 14

34.0 17 31.6 18

28.9 20 27.0 21

23.9 23 22.3 24

18.9 27 17.7 27

66.6 5 59.3 7

61.4 9 54.7 10

56.2 12 50.0 14

51.4 16 45.5 17

46.2 20 40.8 22

41.1 24 36.2 25

35.9 27 31.6 28

30.5 30 27.0 31

67.3 6 59.6 7

62.1 9 54.9 10

56.9 12 50.1 14

51.6 16 45.4 17

46.4 20 40.7 21

41.2 24 35.9 25

36.1 27 31.2 28

30.9 30 26.4 31

77.6 9 69.2 11

72.7 12 64.5 14

67.3 16 59.6 17

62.1 19 54.9 20

56.9 24 50.1 25

51.6 27 45.4 28

46.4 30 40.7 31

41.2 34 35.9 35

88.2 12 78.7 14

82.8 15 73.9 17

77.6 19 69.2 21

72.6 22 64.5 24

67.3 27 59.6 29

62.1 31 54.9 32

56.9 34 50.1 35

51.6 37 45.4 38

tL1 Air inlet temperature tL2 Air outlet temperature* with ceiling air outlet nozzle AD

PWW 100-3

two-speed

870 650

3 x 400 3 x 400

50 50

0.76 0.47

1.50 0.81

8250 6620

58 54

10.0 8.0

32 26

R 1 ½“ R 1 ½“

60 60

kW tL2 °C kW tL2 °C

67.9 9 62.3 12

61.7 12 56.6 15

55.3 14 51.1 17

49.1 17 45.4 20

42.9 21 40.4 24

36.5 24 33.8 26

30.4 27 28.1 28

24.0 29 22.2 30

84.7 13 73.4 16

78.2 16 67.8 18

71.6 19 62.2 21

65.1 22 56.5 24

58.4 26 51.0 28

51.9 29 45.3 31

45.3 31 40.2 33

38.6 34 33.7 35

86.3 14 75.7 17

79.4 17 69.9 19

72.5 19 63.9 22

65.8 22 58.1 24

58.8 26 52.2 29

52.0 29 46.8 31

45.1 31 40.4 33

38.2 34 34.6 36

100.0 19 87.5 22

93.2 21 81.6 24

86.3 24 75.7 27

79.4 27 69.9 29

72.5 31 63.9 34

65.8 34 58.1 36

58.8 36 52.2 39

52.0 39 46.8 4

113.7 23 99.3 26

106.8 26 93.4 29

100.0 29 87.5 32

93.2 31 81.6 34

86.3 36 75.7 39

79.4 39 69.9 42

72.5 41 63.9 44

65.8 44 58.1 46

PWW 100-4

two-speed

870 650

3 x 400 3 x 400

50 50

0.76 0.47

1.50 0.81

7670 6180

59 55

9.0 7.0

30 25

R 1 ½“ R 1 ½“

68 68

kW tL2 °C kW tL2 °C

85.6 17 78.5 22

77.8 19 71.4 24

69.7 21 64.4 25

61.9 23 57.3 27

54.0 27 50.8 31

46.0 29 42.7 32

38.3 31 35.3 33

30.3 32 28.1 34

106.6 23 92.4 26

98.6 25 85.4 28

90.3 27 78.3 30

82.1 29 71.1 32

73.7 34 64.2 36

65.4 35 57.1 38

57.1 37 50.7 40

48.6 39 42.5 41

108.7 24 95.3 27

100.0 26 88.1 29

91.3 28 80.5 31

82.8 30 73.1 33

74.1 34 65.8 37

65.5 36 58.9 39

56.9 37 50.9 40

48.1 39 43.6 41

126.0 30 110.3 34

117.5 32 102.8 36

108.7 34 95.3 37

100.0 36 88.1 39

91.3 41 80.5 44

82.8 42 73.1 45

74.1 44 65.8 47

65.5 46 58.9 49

135.3 36 117.2 27

127.1 36 110.2 39

119.0 38 103.3 41

110.9 40 96.3 43

102.7 45 89.3 48

94.5 47 82.5 50

86.3 49 75.4 51

78.3 51 66.8 52

We reserve the right to make changes to dimensions and design in the interest of technical advances.

29

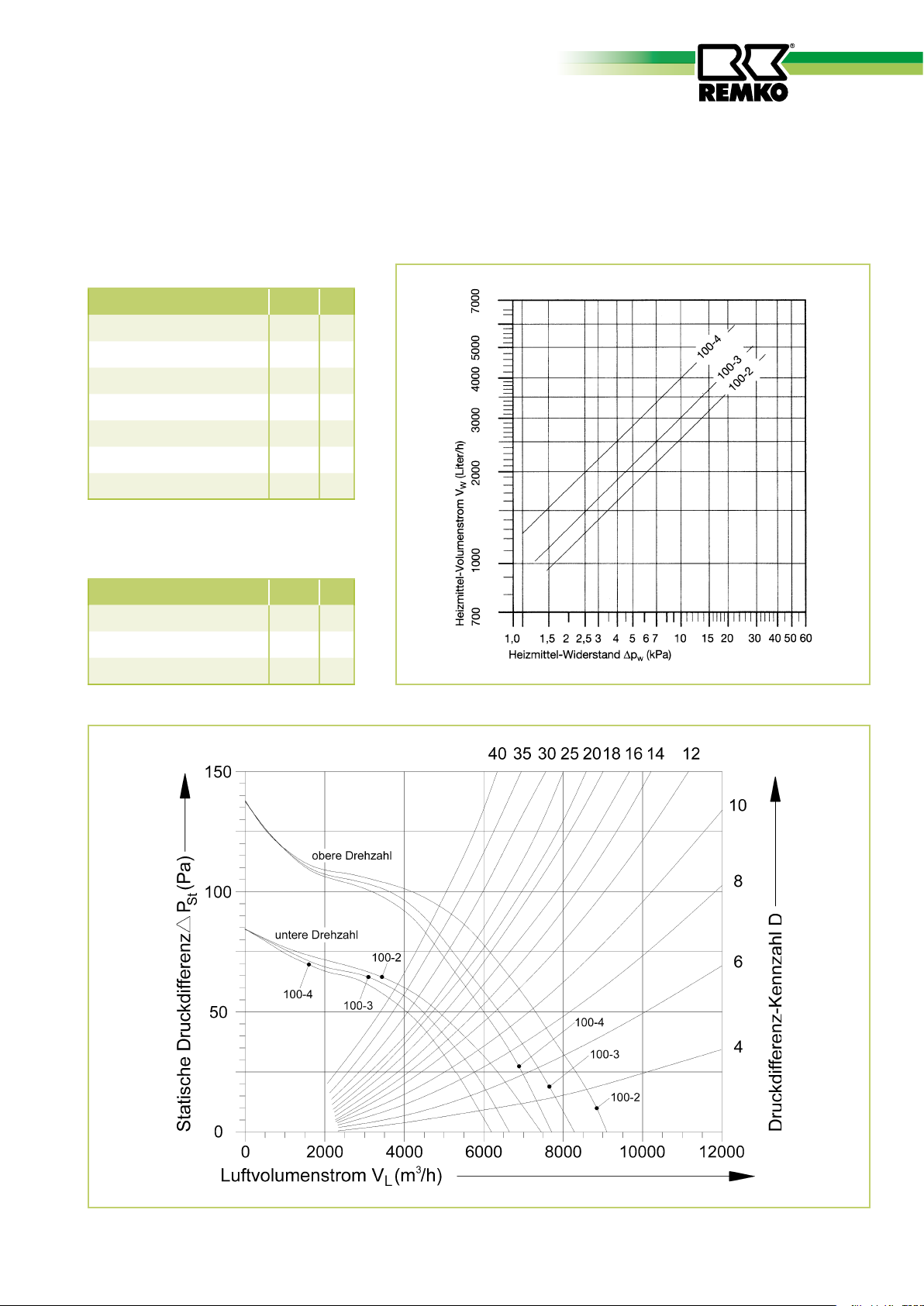

Characteristics • Heating medium resistances

Pressure difference values D of

accessories:

1. Accessories mounted on suction side

Component Type D

Mixed-air box MLK 6

Filter box (filter clean) FK 3

moderate filter clogging FK 8

Warmth channel interim piece

(per m)

Fresh air inlet grille AG 4

Circulation suction adapter UA 2

Fresh air inlet hood ALH 4

2. Accessories mounted on pressure side

Component Type D

Air outlet shutter B 6

KA 1

Air outlet hood HG 4

Ceiling air outlet nozzle AD 10

We reserve the right to make changes to dimensions and design in the interest of technical advances.

30

REMKO PWW

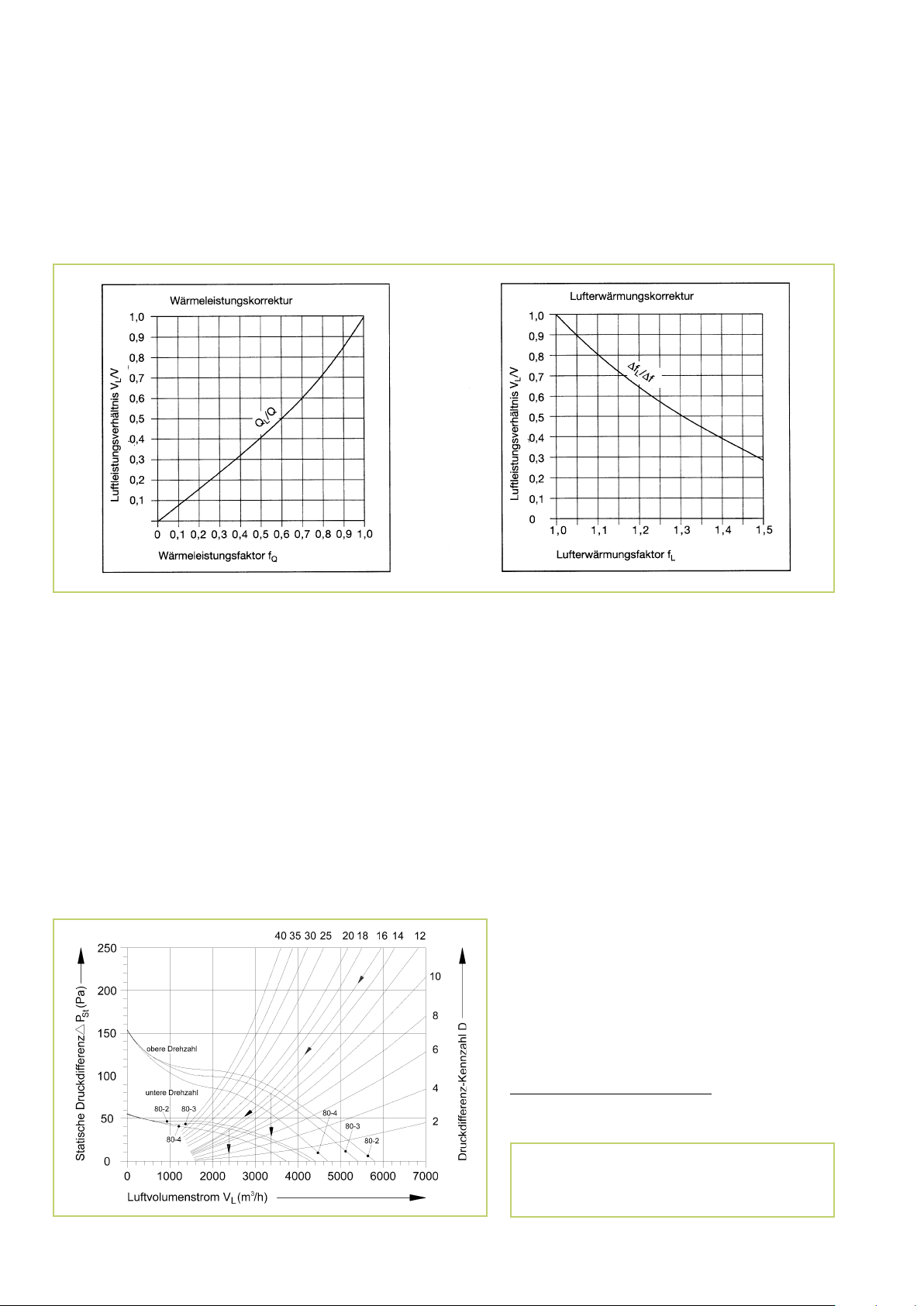

Calculation example and explanation

The heat outputs shown in the ratingtables are subject to variation as a result of:

Reduced air volumes with additionally mounted accessories such as

(mixed-air box, filter box, air outlet nozzle, etc.). Observe pressure difference values!

Determination of heat output and air volume when using accessories:

Actual: Unit type PWW 80-3

with filter box FK

with ceiling air outlet nozzle AD

Heating medium PWW 90/70

Air inlet temperature t

= 15°C

L1

Required: Air volume V

Heat output Q

Air outlet temperature t

Heating medium resistance ∆p

1. Determination of the air volume VL (m3/h)

The following data is provided

in the ratings tables (page 30).

Air capacity V = 5400/4300 m

Heat output Q = 50.1/42.7 kW

Air outlet temp. t

this results in an air heating of

∆t = 28/30 K

The individual pressure difference values D

(see page 31) are added:

Filter box FK 7

Air outlet nozzle AD 9

(m3/h)

L

L

L2

= 43/45°C

L2

(kw)

(°C)

W

(kPa)

3

/h

Total difference = 16

Solution from the diagram:

= 3400/2400 m3/h

V

L

We reserve the right to make changes to dimensions and design in the interest of technical advances.

31

Calculation example and explanation

2. Heat output Q

(kW)

L

In the ratio VL to air

volume V (ratings table value), the

heat output factor can be determined from the “heat output factor

correction” f

diagram.

Q

The heat output from the ratings

table multiplied by the factor f

Q

results in the effective heat output

Q

(kW).

L

3. Air outlet temperature tL2 (°C)

For the calculation example, this results in:

Higher speed:

Air volume ratio =

Heat output correction factor f

VL 3400

V 5400

= 0.75

Q

= 0.63

Effective heat output QL = 50.1 x 0.75 = 37.6 kW

Lower speed:

V

= 2400

Air volume ratio =

Heat output correction factor f

Effective heat output Q

L

V 4300

= 0,67

Q

= 42.7 x 0.67 = 28.6 kW

L

= 0.56

Solution:

Heat output QL = 37.6/28.6 kW

For the calculation example, this results in:

From the ratio V

to air volume V

L

(ratings table value), the air heating factor can be determined.

The air heating from the ratings

table (t

- tL1) multiplied by the

L2

air heating factor fL results in the

effective air heating.

4. Heating medium resistance

Higher speed:

Air volume ratio 0.63 (see above)

Air heating factor f

Effective air heating ∆

= 1.20

L

= 28°C x 1.20 = 33.6°C [34°C]

t

L

Air outlet temperature tL2 = 34 + 15 = 49°C

Lower speed:

Air volume ratio 0.56 (see above)

Air heating factor f

Effective air heating ∆

= 1.25

L

= 30°C x 1.25 = 37.5°C [37°C]

t

L

Air outlet temperature tL2 = 37 + 15 = 52°C

Solution:

Air outlet temperature t

= 49/52°C

L2

The heating medium volume VW is calculated from:

Q

= 860 x (litre/h)

V

W

∆

= 90 – 70 = 20 °C

t

W

= 37.6 (see solution under 2.))

Q

L

This results in: V

L

∆

t

W

= 860 x = 1620 l/h

W

37.6

20

For the calculation example, given from the diagram (see Page 31) is

the heating medium resistance for the unit type 80-3:

= 2.8 kPa

Dp

W

We reserve the right to make changes to dimensions and design in the interest of technical advances.

32

REMKO PWW

Planning • Calculation • Units

■

■

Planning and selection criteria

■

Total heat requirement of room

to be heated.

■

Number of units necessary to

cover the heat requirement and

to also ensure sufficient fine heat

and air distribution in the room.

In any event, it is advantageous

to use several smaller units in order to achieve a more favourable

temperature distribution, lower

air velocities and a lower noise

level.

Required mode of operation

(circulation, mixed-air or fresh

air operation).

■

Mounting site (wall or ceiling).

■

Permissible sound pressurelevel.

■

Air inlet temperature in accessed

areas

(guide value = 35-40°C).

■

Circulated total air flow in

relation to volume

(guide value 2-3-fold air

circulation).

Determination of the required heat output, fresh air volume and air outlet temperature

Mixed-air or fresh-air that utilise

the required fresh air volumes

for the number of air changes

necessary for the room size.

■

Horizontal and vertical penetration depth of air blast required

to provide sufficient heat in the

room.

Heat capacity:

Fresh air volume:

The heating capacity Q of the REMKO heater takes into account the following components:

1. Heat requirement QH of room to be heated. (Calculation according to DIN 4701 and 4108)

2. Heat requirement QAL to heat fresh air to room temperature.

QAL = VAL · cPL · fL· (tL2 - tL1) in [kW]

Q = Q

The required fresh air volume VAL depends on the system requirements and

building regulations.

The following values are guide values and recommendations from the technical literature

Type of room Air changes x per hour Noise level dB(A)

Workshop, general 3 .... 6 70 .... 80

Warehouses 2 .... 4 60 .... 70

Textile industry 4 .... 20 about 90

Pickling shop, dye shop 5 .... 15 60 .... 70

Office rooms, small businesses 4 .... 8 about 45

Garages 4 .... 5 60 .... 70

Canteen kitchens 10 .... 30 50 .... 60

Large sales rooms, supermarkets 8 .... 10 about 60

Tennis halls 1 .... 2 45 .... 55

+ QAL in [kW]

H

VAL = X · L · W · H in [m3/h]

Air outlet temperatures: Note:

Extreme air outlet temperatures can produce uneven heat distribution and temperatures in the room. In order to provide comfortable conditions in accessed areas, we

recommend the following max. air outlet temperatures:

The data shown in the ratings tables take into account the following values:

t

L1

f

L

We reserve the right to make changes to dimensions and design in the interest of technical advances.

Comfort range 30-40°C / Industrial range 35-45°C

-15 -10 0 +15 +20

[°C]

kg

1.37 1.34 1.29 1.23 1.20

[ ]

3

m

as well as the specific heat capacity CPL

of air with 1

sure of 1013 hPa

kWs

at constant air pres-

kg · K

33

Planning • Calculation • Units

Symbol Unit Explanation

Q kW Heating capacity of air heater

Q

H

Q

AL

Q

L

V m

V

L

V

AL

V

W

t

L1

t

L2

∆

t

∆

t

W

∆

t

C

PL

ϕ

L

kW Heating requirement for room to be heated

kW Heat requirement to heat fresh air to room temperature

kW

m3/h

Effective heating capacity of air heater with mounted

accessory components

Air volume flow of air heater without mounted

3

/h

accessory components

Effective air volume flow of air heater with mounted

accessory components

m3/h Fresh air volume flow

l/h Heating medium volume flow

°C Air inlet temperature at air heater

°C Air outlet temperature at air heater

°C Air inlet/outlet temperature difference at air heater

°C Heating medium inlet/outlet temperature difference at air heater

°C

kWs

———

kg · K

kg

m

Effective air inlet/outlet temperature difference at air heater

with mounted accessory components

Specific heat capacity of air at constant pressure

Dry air density

3

Q = QH + Q

AL

QAL = VAL · CPL · ∆

VL = V · f

V

VAL = X · B · L

860 · Q

VW =

∆t = t

∆

t

W

∆

t

L

1 ———

– t

L2

= tW1 – t

= ∆

t · f

kWs

kg · K

t

W

L1

W2

L

t

L m Length of room to be heated

W m Width of room to be heated

H m Height of room to be heated

X 1/h Number of air changes in room to be heated

f

Q

f

V

f

L

∆

P

W

∆

P

ST

- Heat output factor

- Air capacity ratio

- Air heating factor

kPa Heating medium resistance (pressure loss on water-side)

Pa Static pressure difference with mounted accessory components

D - Pressure difference value with mounted accessory components

We reserve the right to make changes to dimensions and design in the interest of technical advances.

fQ = QL / Q

fV = VL / V

34

REMKO PWW

Unit dimensions

A

R

E

V

F

G

G

V = Water inlet (flow)

R = Water outlet (return)

B

98

167

C

D

The water inlet (flow) is always at the

“BOTTOM”.

Even if the units are turned during

installation and connected from the

other side.

Dim.

in

mm

A 560 640 800 880

B 440 515 630 740

C 360 360 360 390

D 403 406 412 452

E 344 419 534 644

F 80 80 80 80

G 45 45 45 45

Dim.

in

Inch

V R ¾“ R 1“ R 1¼“ R ¾“ R 1“ R 1¼“ R 1“ R 1¼“ R 1¼“ R 1¼“ R 1½“ R 1½“

R R ¾“ R 1“ R 1¼“ R ¾“ R 1“ R 1¼“ R 1“ R 1¼“ R 1¼“ R 1¼“ R 1½“ R 1½“

PWW 30 PWW 50 PWW 80 PWW 100

30-2 30-3 30-4 50-2 50-3 50-4 80-2 80-3 80-4 100-2 100-3 100-4

Unit type

Unit type

We reserve the right to make changes to dimensions and design in the interest of technical advances.

35

Technical data

Series PWW 30-2 PWW 30-3 PWW 30-4 PWW 50-5 PWW 50-3 PWW 50-4

Elec. connection V 400/3~N 400/3~N 400/3~N 400/3~N 400/3~N 400/3~N

Frequency

Power input

HZ 50 50 50 50 50 50

kW 0.13/0.10 0.13/0.10 0.13/0.10 0.26/0.18 0.26/0.18 0.26/0.18

Nominal current A 0.26/0.16 0.26/0.16 0.26/0.16 0.52/0.29 0.52/0.29 0.52/0.29

Speed

Air capacity

Sound press. level

Heating medium conn.

Heating medium

Operat. press. max.

rpm 1340/1040 1340/1040 1340/1040 1360/1020 1360/1020 1360/1020

3

/h 2250/1850 2050/1640 1850/1500 3800/3180 3400/2870 3150/2770

m

1)

dB(A) 52/46 53/48 55/49 55/50 55/51 58/54

Inch R ¾“ R 1“ R 1¼“ R ¼“ R 1“ R 1¼“

Pumped warm water or pumped hot water up to maximum 130°C

bar 16 16 16 16 16 16

Weight kg 24 26 27 31 34 36