Page 1

PLX51-DLplus-232

Data Logger Plus

Data Storage Module

October 3, 2019

USER MANUAL

Page 2

Page 2

Page 3

CONTENTS

1 Preface .................................................................................................................................... 7

1.1 Introduction to the PLX51-DLplus-232 ............................................................................. 7

1.2 Features ............................................................................................................................ 8

1.3 Additional Information ................................................................................................... 10

2 Installation ............................................................................................................................ 11

2.1 Module Layout ............................................................................................................... 11

2.2 Module Mounting .......................................................................................................... 13

2.3 Power ............................................................................................................................. 14

2.4 RS232 Port ...................................................................................................................... 14

2.5 Ethernet Port .................................................................................................................. 14

3 Setup ..................................................................................................................................... 15

3.1 Install Configuration Software ....................................................................................... 15

3.2 Network Parameters ...................................................................................................... 15

DHCP Server Settings ............................................................................................................ 15

Network Settings ................................................................................................................... 18

3.3 Creating a New Project ................................................................................................... 20

3.4 Configuring the PLX51-DLplus-232 ................................................................................. 22

General Tab ........................................................................................................................... 22

Serial Tab ............................................................................................................................... 24

3.5 Data Source Configuration ............................................................................................. 25

Group and Tag Triggers ......................................................................................................... 26

Logix Source .......................................................................................................................... 26

DF1 Source ............................................................................................................................ 29

Modbus Source ..................................................................................................................... 30

3.6 Module Download .......................................................................................................... 31

4 RSLogix 5000 Configuration .................................................................................................. 33

4.1 Add Module to I/O Configuration .................................................................................. 33

4.2 Importing UDT’s and Mapping Routines ........................................................................ 35

Page 3

Page 4

4.3 RSLogix 5000 assemblies ................................................................................................ 38

Input Assembly...................................................................................................................... 38

4.4 Inhibiting the Module ..................................................................................................... 39

5 Diagnostics ............................................................................................................................ 41

5.1 LEDs ................................................................................................................................ 41

5.2 Module Status Monitoring ............................................................................................. 42

General Tab ........................................................................................................................... 44

Statistics tab .......................................................................................................................... 45

Tag Status Tab ....................................................................................................................... 46

Recent Records Tab .............................................................................................................. 47

Record Management Tab ..................................................................................................... 48

CIP Statistics Tab ................................................................................................................... 49

Ethernet Clients Tab .............................................................................................................. 50

TCP / ARP Tab ........................................................................................................................ 51

6 Retrieving Logged Data from the PLX51-DLplus-232 ............................................................ 53

6.1 DF1 Packet Capture ........................................................................................................ 53

6.2 Modbus Packet Capture ................................................................................................. 56

6.3 Module Event Log........................................................................................................... 59

6.4 Web Server ..................................................................................................................... 61

6.5 Web Reporting ............................................................................................................... 62

Retrieve Trend Data .............................................................................................................. 64

Customize Graph Axis ........................................................................................................... 67

Upload Records to CSV File ................................................................................................... 71

7 JSON Client ............................................................................................................................ 73

7.1 General Status ................................................................................................................ 73

7.2 Cache Statistics ............................................................................................................... 74

7.3 Unload Log Index Update ............................................................................................... 74

7.4 Cache Records ................................................................................................................ 75

7.5 Reset Log Indexes ........................................................................................................... 76

7.6 Get Tag Names ............................................................................................................... 76

7.7 Trend Data ...................................................................................................................... 77

Page 4

Page 5

7.8 Trend Data UTC .............................................................................................................. 78

7.9 Invalid Request Response .............................................................................................. 80

7.10 Operation ....................................................................................................................... 80

Get Tag Database .................................................................................................................. 80

Get Trend Data ...................................................................................................................... 80

Get Cache Records ................................................................................................................ 81

7.11 Examples ........................................................................................................................ 82

General Status Message ....................................................................................................... 82

Cache Records Message........................................................................................................ 83

8 Technical Specifications ........................................................................................................ 85

8.1 Dimensions ..................................................................................................................... 85

8.2 Electrical ......................................................................................................................... 86

8.3 Ethernet .......................................................................................................................... 86

8.4 Data Cache ..................................................................................................................... 87

8.5 Serial Port ....................................................................................................................... 87

8.6 DF1.................................................................................................................................. 87

8.7 Modbus .......................................................................................................................... 88

8.8 Agency Approvals & Certifications ................................................................................. 88

9 Support, Service & Warranty ................................................................................................ 89

9.1 Contacting Technical Support ........................................................................................ 89

9.2 Warranty Information .................................................................................................... 91

10 Index ...................................................................................................................................... 93

Page 5

Page 6

Page 6

Page 7

1 PREFACE

1.1 Introduction to the PLX51-DLplus-232

This manual describes the installation, configuration, operation, and diagnostics of the PLX51DLplus-232. The PLX51-DLplus-232 can read and store data from Logix Controllers, DF1 Serial

Interfaces, or Modbus devices. The PLX51-DLplus-232 has the capacity to store over 16 million

records in its solid-state non-volatile memory. Each stored record includes a Date Time stamp

with a 50 ms resolution, Tag Name, Data Type, and Value.

The PLX51-DLplus-232 can be used to log data at a remote site with limited communication

with its base. The PLX51-DLplus-232 is also used to store records on mobile equipment such as

trucks, drilling rigs, or snow plows. Once the equipment returns back to its base, the historical

data can be uploaded and transferred to a more permanent storage device. The PLX51-DLplus232 can also be configured to collect data which is only downloaded and examined if a fault

occurs, otherwise the data is overwritten.

Compared to the PLX51-DL-232, the PLX51-DLplus-232 has the following additional features:

Trend up to five variables dynamically via the integrated webserver

Upload logged data directly from the integrated webserver

REST API support retrieves data automatically via JSON-encoded messages.

Page 7

Page 8

Non-Historian Option

Parameter

Link

Date Time

UTC Time includes: Year, Month, Day, Hour, Minute, Second, Milliseconds.

Time has a resolution of 50 milliseconds.

Tag Name

As defined in Controller or in the PLX50 Configuration Utility for other sources

Data Type

BOOL, SINT, INT, DINT, or REAL

Value

Logix Tag / DF1 File / Modbus Register value

1.2 Features

The PLX51-DLplus-232 provides temporary extensive on-board storage capability for storing

process tags. A total of 16,777,216 records can be stored in its non-volatile memory.

Each record consists of the following data:

Components of a Record

Page 8

Page 9

The Log Index is managed by the PLX51-DLplus-232 and incremented each time a new record is

stored. The Unload Index is managed externally by the unload service. It is only incremented after

a record has been logged successfully to a text file. The records can be unloaded in Logix with the

Example Code. Both the Log Index and Unload Indices loop around, eventually reaching the end

of the cache. The cache becomes 100% full when the Log Index loops around and equals the

Unload Index. In this situation, either older records are overwritten (Log Mode = Overwrite) or

newer records are not logged (Log Mode = Hold).

Memory Schematic

The PLX51-DLplus-232 is configured using the ProSoft PLX50 Configuration Utility. This program

can be downloaded from www.prosoft-technology.com, free of charge. The PLX50 Configuration

Utility offers various configuration methods, including a controller tag browser. The PLX50

Configuration Utility can also be used to monitor the status and download historical data to a

local file.

The PLX51-DLplus-232 can operate in both a Logix “owned” and standalone mode. With a Logix

connection, the input and output assemblies provide additional diagnostics information. This

information is available in the Logix controller environment.

The PLX51-DLplus-232 uses isolated RS232 for DF1 communication. The RS232 port also uses a

terminal block for convenient installation.

A built-in webserver provides detailed diagnostics of system configuration and operation.

Page 9

Page 10

1.3 Additional Information

Resource

Link

PLX50 Configuration

Utility Installation

www.prosoft-technology.com

User Manual

Datasheet

Example Code & UDTs

www.prosoft-technology.com

Ethernet wiring standard

www.cisco.com/c/en/us/td/docs/video/cds/cde/cde205_220_420/installation/

guide/cde205_220_420_hig/Connectors.html

CIP Routing

The CIP Networks Library, Volume 1, Appendix C:Data Management

For professional users in the European Union

If you wish to discard electrical and electronic equipment (EEE), please contact your dealer

or supplier for further information.

Warning – Cancer and Reproductive Harm – www.P65Warnings.ca.gov

The following documents contain additional information that can assist you with installation and

operation.

Additional Information

Page 10

Page 11

2 INSTALLATION

2.1 Module Layout

The PLX51-DLplus-232 has three ports at the bottom of the enclosure, as shown in the figure

below. The ports are used for Ethernet, RS232 serial, and power.

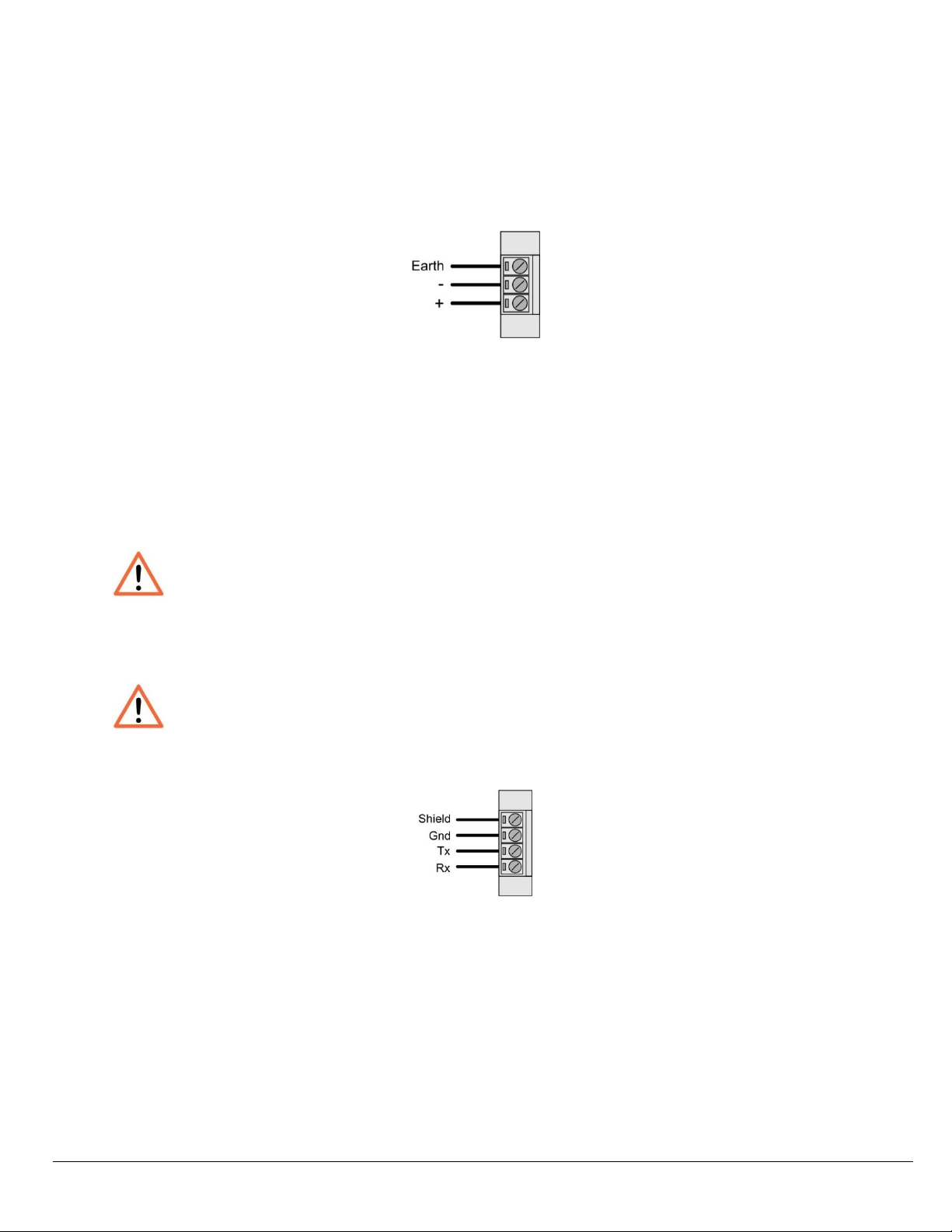

The DC power port uses a three-way connector (+ positive, - negative, and Earth).

The RS232 port uses a four-way connector (Tx Transmit, Rx Receive, Gnd Ground, and Shield

earth connection).

The Ethernet cable must be wired according to industry standards which can be found in the

additional information section of this document.

Figure 2.1 –Side and bottom view

The PLX51-DLplus-232 provides three diagnostic LEDs (Ok, Act, and Eth). These LEDs provide

information on system operation, the Ethernet interface, and the auxiliary communication

interface (RS232).

Page 11

Page 12

DIP Switch

Description

DIP 1

Used to force the PLX51-DLplus-232 into “Safe Mode”. When in “Safe Mode”, the

PLX51-DLplus-232 does not load the application firmware. It waits for new firmware

to be downloaded. This should only be used when a firmware update was interrupted

at a critical stage.

DIP 2

Used to force the PLX51-DLplus-232 into DHCP mode, useful when the user has

forgotten the IP address of the PLX51-DLplus-232.

Note: If multiple network cards are running on your PC, the DHCP will be unreliable.

Only one DHCP server should be used.

DIP 3

Reserved

DIP 4

Reserved

Figure 2.2 – Front and top view

The PLX51-DLplus-232 has four DIP switches at the top of the enclosure as shown above.

Table 2.1 - DIP Switch Settings

Page 12

Page 13

2.2 Module Mounting

The PLX51-DLplus-232 provides a DIN rail clip to mount onto a 35mm DIN rail.

Figure 2.3 - DIN rail specification

The DIN rail clip is mounted on the bottom of the PLX51-DLplus-232. Use a flat screw driver to

pull the clip downward. Once the PLX51-DLplus-232 is mounted onto the DIN rail, the clip must

be pushed upward to lock the PLX51-DLplus-232 in place.

Figure 2.4 - DIN rail mouting

Page 13

Page 14

2.3 Power

A three-way power connector is used to connect + positive, - negative, and Earth. The PLX51DLplus-232 requires an input voltage of 10 to 28 Vdc.

Figure 2.5 - Power connector

2.4 RS232 Port

The RS232 connector is used to connect the Transmit (Tx), Receive (Rx), and Ground conductors

for serial communication. The shield terminal can be used for shielded cable in high noise

environments.

NOTE: The shield of the RS232 port is internally connected to the power connector

earth. Thus, when using a shield it is important to connect the Earth terminal on

the power connector to a clean earth. Failing to do this can lower the signal quality

of the RS232 communication.

NOTE: When using a shielded cable, it is important that only one end of the shield

is connected to earth to avoid current loops. It is recommended to connect the

shield to the PLX51-DLplus-232, and not to the other Serial device.

Figure 2.6 - RS232 connector

2.5 Ethernet Port

The Ethernet connector should be wired according to industry standards. Refer to the additional

information section in this document for further details.

Page 14

Page 15

3 SETUP

3.1 Install Configuration Software

The PLX51-DLplus-232 is configured using the PLX50 Configuration Utility environment. This

software can be downloaded from www.prosoft-technology.com.

Figure 3.1 - PLX50 Configuration Utility Environment

3.2 Network Parameters

DHCP SERVER SETTINGS

By default, the PLX51-DLplus-232 has DHCP (Dynamic Host Configuration Protocol) enabled.

Thus, a DHCP server must be used to provide the PLX51-DLplus-232 with the required network

parameters (IP address, subnet mask, etc.). There are a number of DHCP utilities available.

However, it is recommended to use the DHCP server in the PLX50 Configuration Utility.

Note: If multiple network cards are running on your PC, the DHCP will be unreliable. Only one

DHCP server should be used.

Page 15

Page 16

1 Within the PLX50 Configuration Utility, click on TOOLS > DHCP SERVER.

Figure 3.2 - Selecting DHCP Server

2 Once opened, the DHCP server listens on all available network adapters for DHCP requests

and displays their corresponding MAC addresses.

Figure 3.3 - DHCP Server

NOTE: If the DHCP requests are not displayed in the DHCP Server, it may be due

to the local PC’s firewall. During installation, the necessary firewall rules are

automatically created for the Windows firewall. Another possibility is that another

DHCP Server is operational on the network and it has assigned the IP address.

Page 16

Page 17

3 To assign an IP address, click on the corresponding ASSIGN button. The Assign IP Address

dialog box opens.

Figure 3.4 - Assigning IP Address

The required IP address can then be either entered, or a recently used IP address can be

selected by clicking on an item in the Recent list.

If the Enable Static checkbox is checked, the IP address will be set to static after the IP

assignment, thereby disabling future DHCP requests.

4 Click OK when complete.

5 Once the Assign IP Address dialog box has been accepted, the DHCP server automatically

assigns the IP address to the PLX51-DLplus-232 and reads the Identity Object Product

name from the device. The device indicates a green background upon successful

assignment of the IP address.

Figure 3.5 - Successful IP address assignment

Page 17

Page 18

It is possible to force the PLX51-DLplus-232 into DHCP mode by powering up the device with DIP

switch 2 in the On position. A new IP address can be assigned by repeating the previous steps.

NOTE: It is important to return DIP switch 2 back to Off position, to avoid the

PLX51-DLplus-232 returning to a DHCP mode after the power is cycled again.

In addition to the setting the IP address, other network parameters can be set during the DHCP

process. These settings can be viewed and edited by clicking on TOOLS > APPLICATION SETTINGS.

NETWORK SETTINGS

Once the DHCP process has been completed, the network settings can be set using the Ethernet

Port Configuration via the Target Browser.

1 Click on TOOLS > TARGET BROWSER

Figure 3.6 - Selecting the Target Browser

2 The Target Browser automatically scans the Ethernet network for EtherNet/IP devices.

Figure 3.7 - Target Browser

Page 18

Page 19

3 Right-clicking on a device reveals the context menu, including the Port Configuration

option.

Figure 3.8 - Selecting Port Configuration

4 All relevant Ethernet port configuration parameters can be modified using the Port

Configuration dialog box.

Figure 3.9 - Port Configuration

Alternatively, these parameters can be modified using the Rockwell Automation RSLinx software.

Page 19

Page 20

3.3 Creating a New Project

Before you configure the PLX51-DLplus-232, a new PLX50 Configuration Utility project must be

created.

1 Click on FILE > NEW.

Figure 3.10 - Creating a new project

2 A new project is created and displayed in the Project Explorer tree view.

3 Add a new device by clicking on DEVICE > ADD.

Figure 3.11 - Adding a new device

Page 20

Page 21

4 In the Add New Device dialog box, select the PLX51-DLplus-232 and click the Ok button.

Figure 3.12 – Selecting the PLX51-DLplus-232

5 The device appears in the Project Explorer tree, and its configuration window is opened.

The device configuration window can also be opened by double-clicking the PLX51DLplus-232 icon in the Project Explorer tree, or right-clicking the PLX51-DLplus-232 icon

and selecting Configuration.

Figure 3.13 – PLX51-DLplus-232 configuration

Page 21

Page 22

3.4 Configuring the PLX51-DLplus-232

The PLX51-DLplus-232 is configured by the PLX50 Configuration Utility. The configuration consists

of a general configuration, serial configuration for DF1 or Modbus RTU, data source

configuration, and tag selections. The PLX51-DLplus-232 configuration is saved in non-volatile

memory that persists when the PLX51-DLplus-232 is powered down.

NOTE: When a firmware upgrade is performed, the PLX51-DLplus-232 will clear all

configuration and cached records.

GENERAL TAB

The general configuration is shown in the figure below. The general configuration window is

opened by either double-clicking on the PLX51-DLplus-232 icon in the tree, or right-clicking the

PLX51-DLplus-232 icon and selecting Configuration.

Figure 3.14 - General Configuration

Page 22

Page 23

The general configuration consists of the following parameters:

Parameter

Description

Instance Name

This parameter is a user defined name to identify between various PLX51-DLplus232’s.

Description

This parameter is used to provide a more detailed description of the PLX51-DLplus-

232.

Major Revision

The major revision of the PLX51-DLplus-232.

IP Address

The PLX51-DLplus-232’s IP address used by the PLX50 Configuration Utility to

communicate with the PLX51-DLplus-232.

Data Source

This parameter selects the source of the data.

Logix – Rockwell Automation ControlLogix or Compact Logix controller

DF1 – Serial DF1

ModbusRTU – Serial Modbus

ModbusTCP – Modbus over Ethernet

Logging Mode

This parameter determines if records are overwritten once the memory is filled.

Overwrite = Old records are overwritten, giving priority to newer data.

Hold = Old records are preserved while new records are not stored.

Table 3.1 - General configuration parameters

Page 23

Page 24

SERIAL TAB

Parameter

Description

Baud Rate

This configures the speed of the data that is sent across the RS232 serial network.

The PLX51-DLplus-232 provides the following speeds:

1200, 2400, 4800, 9600, 19200, 38400, 57600, and 115200

Parity

This configures the parity of the RS232 serial port. The PLX51-DLplus-232 allows

for Even, Odd, or None.

Protocol

This configures the PLX51-DLplus-232 to operate in full duplex or half duplex mode

on the DF1 network.

Error Detection

The PLX51-DLplus-232 can be configured to perform either BCC or CRC checksum

validation on incoming and outgoing packets. CRC checksums is a much stronger

validation method, but is more processor-intensive to perform.

Embedded Response

This configures the PLX51-DLplus-232 to add the acknowledge responses in the

data payload. It can be configured to be Auto Detect or On.

This function is only available in Full Duplex mode.

The Serial tab is shown in the figure below. The Serial configuration is opened by either doubleclicking on the PLX51-DLplus-232 icon in the tree, or right-clicking the PLX51-DLplus-232 icon and

selecting Configuration. Select the Serial tab.

Figure 3.15 - Serial configuration

The Serial configuration (Serial tab) consists of general Serial and DF1-specific parameters. For

Modbus RTU, only the Baud Rate and Parity need be configured.

Page 24

Page 25

Node Address

The node address is the local node address of the PLX51-DLplus-232.

Retry Limit

This determines how many times the PLX51-DLplus-232 must retry and message

exchange before failing it.

Timeout

This determines the interval between retries for a failed message exchange.

Reply Msg Wait

This is the minimum delay before the DF1 reply is transmitted to the DF1 device.

Duplicate Detection

This configures the PLX51-DLplus-232 to check for duplicate packets and flagging

them.

Table 3.2 - Serial Modbus RTU and DF1 configuration parameters

3.5 Data Source Configuration

The Data Source tabs determine the PLX51-DLplus-232 communication mode used to acquire

data. The Data Source options include:

Logix Source – ControlLogix and Compact Logix controllers

DF1 Source – For collecting data over DF1 Serial communications

Modbus Source – for Modbus RTU (Serial) and ModbusTCP (Ethernet) communications

Once the data source is selected, each tab allows the configuration of up to three source devices

and a total of 200 tags.

Tags can be logged as a result of their individual log criteria or via a group trigger. There are eight

trigger groups (A thru H), and a tag can be a member of any trigger group. Groups are in turn

triggered by one or more tags. The triggering of a group ensures all its member’s values are

logged at the same instance.

Page 25

Page 26

GROUP AND TAG TRIGGERS

Three parameters determine when a tag is triggered:

Delta Y (Δy) – A change in the value of the tag by this amount or more, AND

Min ΔT – The minimum time in seconds between each consecutive trigger, OR

Max ΔT – The maximum time between each consecutive trigger. Setting the Max ΔT to ‘0’

disables the “heartbeat” and allows you to log on trigger.

The first two parameters work together to ensure tags are not logged too frequently, and the

Max ΔT is set at a minimum logging frequency.

Figure 3.17 – Group and Tag Triggers

LOGIX SOURCE

The Logix Source tab is used to configure tags from Rockwell Automation Logix controllers over

EtherNet/IP. The PLX51-DLplus-232 can read tags from up to three separate controllers. A Target

Name must be provided. This acts as a reference to the Logix CIP path. The Target Name does

not have to match the actual controller name set in RSLogix. The Controller’s CIP Path can either

be typed in or selected from a list in the Target Browser.

Figure 3.20 – Logix Source Configuration Tab

Page 26

Page 27

1 Click the BROWSE button in the browse column to launch the Target Browser. The Target

Browser opens and automatically scans for all available EtherNet/IP devices.

Figure 3.21 – Target Browser Window

2 If the Ethernet/IP module is a bridge module, it can be expanded by right-clicking on the

PLX51-DLplus-232 icon and selecting the Scan option.

Figure 3.22 - Scanning node in the Target Browser

Page 27

Page 28

3 The Logix controller can be selected by clicking the Ok button, or by double-clicking on

the controller module.

4 Once the controller references have been configured, the individual Logix tags can be

added. Tags can either be entered manually or selected by using the Tag Browser

associated with each controller.

Figure 3.23 - Logix Tag configuration

NOTE: Tag names need to match in order for the PLX51-DLplus-232 to correctly

identify the tag. Full tag names are needed for tags to be located in program scopes.

5 To launch the Tag Browser, click the BROWSE TAGS button associated with the controller.

Tags that are were already selected and identified are highlighted in green. See Fig 3.24.

Figure 3.24 – Tag Browser Selection

Page 28

Page 29

6 Tags can be removed by selecting the rows in the left margin, and right-clicking to display

the DELETE option.

Figure 3.25 – Deleting Tags

DF1 SOURCE

A maximum of three DF1 Sources can be configured. The configuration of each source requires a

Device Name (used as a reference for tag data sources), the Device Type (either PLC5 or SLC), and

a Node Address.

Each DF1 Tag requires a unique Tagname and Data Address.

Figure 3.26 – DF1 Source configuration

Page 29

Page 30

MODBUS SOURCE

Both Modbus RTU and Modbus TCP/IP are configured using the Modbus Source tab. For Modbus

RTU, a maximum of three Modbus sources can be configured. The configuration of each source

requires a Device Name (used as a reference for tag data sources), the IP Address (Modbus TCP/IP

only), and a Node Address.

Fig 3.27 – Modbus Source Configuration

Page 30

Page 31

3.6 Module Download

Once the configuration is complete, it must be downloaded to the PLX51-DLplus-232.

Before downloading, the connection path of the PLX51-DLplus-232 should be set. This path

automatically defaults to the PLX51-DLplus-232 IP address, as set in the PLX51-DLplus-232

configuration. It can be modified if the PLX51-DLplus-232 is not on a local network.

1 The connection path can be set by right-clicking on the PLX51-DLplus-232 icon and

selecting the Connection Path option.

2 The new connection path can be entered manually or selected by means of the Target

Browser.

Figure 3.29 - Connection Path

3 To initiate the download, right-click on the PLX51-DLplus-232 icon and select Download.

Figure 3.30 - Selecting Download

Page 31

Page 32

4 Once complete, you will be notified that the download was successful.

Figure 3.31 - Successful download

5 During the download process, the PLX51-DLplus-232’s time will be compared to that of

the PC’s time. Should the difference be greater than 30 seconds, you will be prompted

to set the PLX51-DLplus-232 time to that of the PC time.

Figure 3.32 – Setting module time

6 The PLX51-DLplus-232 time is used only for the event log. Within the PLX50

Configuration Utility environment, the PLX51-DLplus-232 will be in the Online state,

indicated by the green circle around the PLX51-DLplus-232 icon.

Figure 3.33 - Module Online

7 The PLX51-DLplus-232 is now configured.

Page 32

Page 33

4 RSLOGIX 5000 CONFIGURATION

Connection Parameter

Assembly Instance

Size

Input

103

29 (32-bit)

Output

104

1 (32-bit)

Configuration

102

0 (8-bit)

4.1 Add Module to I/O Configuration

The PLX51-DLplus-232 can operate in both a Logix “owned” and standalone mode. When the

PLX51-DLplus-232 operates in a Logix “owned” mode, the PLX51-DLplus-232 needs to be added

to the RSLogix 5000 / Studio5000 IO tree, as a generic Ethernet module.

1 Right-click on the Ethernet Bridge in RSLogix 5000 and select New Module. Then select

ETHERNET-MODULE and click Ok.

2 Enter the IP address of the PLX51-DLplus-232. The Assembly Instance and Size must also

Figure 5.1 - Add a Generic Ethernet Module in RSLogix 5000

be added for the input, output, and configuration in the Connection Parameters section.

Below are the required connection parameters.

Table 5.1 - RSLogix class 1 connection parameters

Page 33

Page 34

Figure 5.2 - RSLogix General module properties in RSLogix 5000

3 Add the connection requested packet interval (RPI). This is the rate at which the input and

output assemblies are exchanged. The recommended value is 500 ms. Refer to the

technical specification section in this document for further details on the limits of the RPI.

NOTE: Although the PLX51-DLplus-232 is capable of running with an RPI of 10 ms,

it is recommended to set the RPI to 500 ms to avoid unnecessary overloading of

the PLX51-DLplus-232 processor.

Figure 5.3 - Connection module properties in RSLogix 5000

Page 34

Page 35

4 Once the PLX51-DLplus-232 has been added to the RSLogix 5000 IO tree, assign the User

Defined Types (UDTs) to the input and output assemblies. You can import the required

UDTs by right-clicking on the User-Defined sub-folder in the Data Types folder and

selecting Import Data Type. The assemblies are then assigned to the UDTs with a ladder

copy instruction (COP).

Figure 5.4 – RSLogix 5000 I/O module tree

4.2 Importing UDT’s and Mapping Routines

To simplify the mapping of the input image, an RSLogix 5000 Routine Partial Import (.L5X) file is

provided.

1 Right-click on the required Program and select the Import Routine option.

Figure 5.5 – RSLogix 5000 Importing PLX51-DLplus-232 routine and UDTs

Page 35

Page 36

2 Select the proper .L5X file.

Figure 5.6 - Selecting import file

The import creates the following:

The required UDTs (user defined data types)

Controller tags representing the Input Assembly.

A routine mapping the PLX51-DLplus-232 to the aforementioned tag.

Page 36

Page 37

3 You may need to change the routine to map to the correct PLX51-DLplus-232 instance

name. Make sure that the mapping routine is called by the Program’s Main Routine.

Figure 5.7 - Imported RSLogix 5000 objects

Refer to the Additional Information section of this document for an RSLogix 5000 project

example, as well as the required UDTs.

Page 37

Page 38

4.3 RSLogix 5000 assemblies

Parameter

Datatype

Description

Instance

STRING

Instance name of the PLX51-DLplus-232 that was configured under

the General Configuration tab in the PLX50 Configuration Utility.

Status.Running

BOOL

Set if the PLX51-DLplus-232 has a valid configuration and is reading

tags.

Status.ConfigValid

BOOL

Set if a valid configuration is executing in the PLX51-DLplus-232.

Status.ContinuousLogging

BOOL

Set if Logging Mode is set to Overwrite, clear for Hold.

Status.ConfigurationValid

BOOL

Set if a valid configuration is executing in the PLX51-DLplus-232.

Status.LoggingInhibited

BOOL

Not Used.

Status.LoggingStopped

BOOL

Not Used.

CachePercentage

REAL

The number of cached records not yet uploaded, as a percentage of

the total record capacity of 16,777,216.

CacheRecordCount

DINT

The number of cached records not yet uploaded.

When the PLX51-DLplus-232 operates in a Logix “owned” mode, the Logix controller establishes

a class 1 cyclic communication connection with the PLX51-DLplus-232. An input assembly is

exchanged at a fixed interval. The provided UDTs convert the input arrays into tag-based

assemblies. Refer to the Additional Information section in this document for more information

on the input UDTs. There are no Output or Configuration assemblies.

Figure 5.8 - Input assembly UDT structure

INPUT ASSEMBLY

The following parameters are used in the input assembly of the PLX51-DLplus-232.

Page 38

Page 39

TotalRecordCount

DINT

The total number of cached records uploaded or not.

ActiveTagCount

DINT

The number of individual tags configured to be read.

DataSource .EtherNetIP

BOOL

Set if the data source is set to Logix.

DataSource .DF1

BOOL

Set if the data source is set to DF1.

DataSource .ModbusRTU

BOOL

Set if the data source is set to Modbus RTU.

DataSource .ModbusTCP

BOOL

Set if the data source is set to Modbus TCP/IP.

DataSourceReadCount

DINT

The number of tag reads from the configured data source.

Table 5.2 - RSLogix 5000 input assembly parameters

4.4 Inhibiting the Module

The PLX51-DLplus-232 can be inhibited by setting the first bit of the DLplus232:O.Data[0] output

image to ‘1’, as shown below:

Page 39

Page 40

Page 40

Page 41

5 DIAGNOSTICS

LED

Description

Ok

The Ok LED provides information of the system-level operation of the PLX51-DLplus-

232.

If the LED is green, then the PLX51-DLplus-232 has booted and is running correctly.

If the LED is red, then the PLX51-DLplus-232 is not operating correctly. For example, if

the PLX51-DLplus-232 application firmware has been corrupted or there is a hardware

fault, Ok LED will be red.

Act

The Act LED is used for the RS232 serial port. For every successful received DF1 or

Modbus-RTU packet, the Act LED toggles green. The LED toggles red if a corrupted

packet is received (eg. failed checksum).

Eth

The Eth LED illuminates when an Ethernet link is detected (by plugging in a connected

Ethernet cable). The LED flashes when traffic is detected.

5.1 LEDs

The PLX51-DLplus-232 provides three LEDs for diagnostics purposes as shown below.

Figure 6.1 - Front view

Table 6.1 - Module LED operation

Page 41

Page 42

5.2 Module Status Monitoring

The PLX51-DLplus-232 provides a range of statistics that can assist with module operation,

maintenance, and troubleshooting. The statistics can be accessed by the PLX50 Configuration

Utility or using the PLX51-DLplus-232 web server.

1 To view the PLX51-DLplus-232’s status in the PLX50 Configuration Utility, the PLX51-

DLplus-232 must be online. If the PLX51-DLplus-232 is not Online (following a recent

configuration download), right-click on the PLX51-DLplus-232 icon and select the Go

Online option.

Figure 6.2 - Selecting to Go Online

2 The Online mode is indicated by the green circle behind the PLX51-DLplus-232 in the

Project Explorer tree.

Figure 6.3 - Selecting online Status

Page 42

Page 43

3 The Status window is opened by either double-clicking on the Status option in the Project

Explorer tree, or by right-clicking on the PLX51-DLplus-232 icon and selecting Status.

4 The Status window contains multiple tabs to display the current status of the PLX51-

DLplus-232.

Figure 6.4 - Status monitoring - General

Page 43

Page 44

GENERAL TAB

Parameter

Description

Data Source

Logix, DF1, Modbus RTU, Modbus TCP/IP

State

This is the current state of the module.

Running

The module is reading tags and logging to the log.

Stopped

The module is idle and not reading tags or logging data.

Logging Mode

Hold or Overwrite – determines if records are overwritten when the cache is full.

Logging State

This is the current state of the logging in the module.

Running

Data is being read from the source and logged if the criteria is met.

Running Rollover

Data is being read from the source and logged if the criteria is met. In this state the

event index has rolled over at least once.

Inhibited

The module has stopped reading and logging data, because the user has inhibited it

from Logix.

Stopped

The module has stopped logging data, because it has reached maximum events and

the module is set to not overwrite.

Owned

Indicates whether or not the PLX51-DLplus-232 is currently owned (Class 1) by a Logix

controller.

Up Time

Indicates the elapsed time since the PLX51-DLplus-232 was powered up.

Module Time

Indicates the PLX51-DLplus-232’s internal time. The PLX51-DLplus-232 time is stored

in UTC (Universal Coordinate Time) but displayed on this page according to the local

PC Time Zone settings

MAC Address

Displays the PLX51-DLplus-232’s unique Ethernet MAC address.

Temperature

Internal temperature of the PLX51-DLplus-232.

Processor Scan

Amount of time (microseconds) taken by the PLX51-DLplus-232’s processor in the last

scan.

DIP Switch Position

Status of the DIP switches when the PLX51-DLplus-232 booted.

Note that this status will not change if the DIP switches are altered when the PLX51-

DLplus-232 is running.

The General tab displays the following general parameters as well as setting the PLX51-DLplus232 time to the PC time:

Table 6.2 - Parameters displayed in the Status Monitoring – General Tab

Page 44

Page 45

STATISTICS TAB

Statistic

Description

Total Records

The total number of cached records, uploaded or not.

Cache Records

The number of cached records not yet uploaded.

Cache Percentage

The number of cached records not yet uploaded, as a percentage of the total record

capacity of 16,777,216.

Active Tags

The number of individual tags configured to be read.

Data Source Reads

The number of tag reads from the configured data source.

Log Index

The current record index being written to.

Unload Index

The upload record index. Managed by the Unload Service.

Statistic

Description

Current Connections

The number of current open class 3 connections.

Connection Failures

The number of failed attempts at establishing a class 3 connection with a Logix

controller.

Tag Not Exist Errors

The number of failed tag read/write transactions due to a non-existent destination tag.

Privilege Violations

The number of failed tag read/write transactions due to a privilege violation error.

This may be caused by the External Access property of the Logix tag being set to either

None or Read Only.

Tag Reads

The number of tag read transactions executed by the PLX51-DLplus-232.

The Statistics tab displays the statistics of the record cache and data source.

Figure 6.5 - Status monitoring - Transactions

Table 6.3 – Cache Statistics

Table 6.4 – Logix statistics

Page 45

Page 46

TAG STATUS TAB

Statistic

Description

TagID

Configured Tag ID for the specific Tag/Register/File.

Device

The configured source device where the tag is extracted.

Tagname

The Tagname configured for the specific tag.

Value

The last read value from the specific tag.

Delta Y

Configured deadband for the tag value.

Time

The time in seconds since the last data was logged.

Min Delta Time

Minimum time in seconds between consecutive data logging.

Max Delta Time

Maximum time in seconds between consecutive data logging.

The Tag Status tab provides current values for all tags, along with their trigger settings. The

following tag mapping statistics are only relevant when the PLX51-DLplus-232 is running in

either Reactive Tag or Scheduled Tag mode.

Figure 6.6 – Tag Status

Table 6.4 – Tag Status

Page 46

Page 47

RECENT RECORDS TAB

Statistic

Description

Index

Logged data index.

Date Time

The time stamp when the data was logged.

Tag ID

Configured Tag ID for the specific Tag/Register/File.

Device

The configured source device where the tag is extracted.

Tagname

The Tagname configured for the specific tag.

Value

The last logged value from the specific tag.

The Recent Records tab provides a list of the last records recorded with their time stamp and

value.

Figure 6.7 – Recent Records

Table 6.5 – Recent Records

Page 47

Page 48

RECORD MANAGEMENT TAB

Parameter

Description

Upload All Records to CSV

Upload all records currently in the module.

Upload Unread Records to CSV

Upload unread records currently in the module.

Reset Records

Resets the log indices

Erase Record Storage

Erases the cache of all records

The Record Management tab manages the PLX51-DLplus-232 records. Records can be

downloaded to a (.csv) file format. Options to reset the log indices and erasing the cache are

also available.

Figure 6.8 – Record Management

Table 6.6 – Record Management

Page 48

Page 49

CIP STATISTICS TAB

Statistic

Description

Class 1 Timeout Count

Number of times a Class 1 connection has timed out

Class 1 Forward Open Count

Number of Class 1 Connection establish attempts

Class 1 Forward Close Count

Number of Class 1 Connection close attempts

Class 1 Connection Count

Number of Class 1 Connections currently active

Class 3 Timeout Count

Number of times a Class 3 connection has timed out

Class 3 Forward Open Count

Number of Class 3 Connection establish attempts

Class 3 Forward Close Count

Number of Class 3 Connection close attempts

Class 3 Connection Count

Number of Class 3 Connections currently active

The CIP Statistics tab provides a set of Common Industrial Protocol (CIP) communication

statistics.

Figure 6.9 – CIP Statistics

Table 6.7 – CIP Statistics

Page 49

Page 50

ETHERNET CLIENTS TAB

Statistic

Description

ARP Clients

Number of active clients in the ARP table

TCP Clients

Number of active connections in the TCP client table

EtherNet/IP Clients

Number of active connections in the ENIP client table

Statistic

Description

IP Address

IP address of the client in the ENIP client table

Session Handle

Session handle in the ENIP client table

The Ethernet Clients tab provides a count of EtherNet Client and EtherNet/IP connections.

Figure 6.10 – Ethernet Connection Counts

Table 6.8 – Ethernet Client Counts

Table 6.9 – EtherNet/IP Table

Page 50

Page 51

TCP / ARP TAB

Statistic

Description

MAC Address

MAC address of the client in the ARP Table

IP Address

IP address of the client in the ARP Table

Statistic

Description

MAC Address

MAC address of the client in the TCP Table

Remote Port

Remote TCP port of the client in the TCP Table

Local Port

Local TCP port of the client in the TCP Table

The TCP / ARP tab lists the ARP and TCP/IP information associated with the known MAC addresses

in the network. Parameters include the IP Address, Remote Port number, and Local Port number.

Figure 6.11 – TCP and ARP Table Entries

Table 6.10 – ARP Table

Table 6.11 – TCP Table

Page 51

Page 52

Page 52

Page 53

6 RETRIEVING LOGGED DATA FROM

THE PLX51-DLplus-232

6.1 DF1 Packet Capture

The PLX51-DLplus-232 provides the capability to capture the DF1 traffic for analysis.

1 To begin the packet capture of the PLX51-DLplus-232, double-click on the DF1 Packet

Capture selection in the Project Explorer tree.

Figure 6.10 - Selecting DF1 Packet Capture

2 The DF1 Packet Capture window opens and automatically starts capturing all DF1 packets.

NOTE: The PLX51-DLplus-232 keeps a circular buffer of the last twenty DF1

packets. Thus, there may be up to 20 packets in the capture that were received /

sent before the capture was initiated.

Figure 6.11 - DF1 packet capture

Page 53

Page 54

3 To display the captured DF1 packets, the capture process must first be stopped by

Statistic

Description

Index

The packet index, incremented for each packet sent or received.

Time

The elapsed time since the PLX51-DLplus-232 was powered up.

Status

The status of the packet. Received packets are checked for valid DF1 constructs

and valid checksums.

Dirn

The direction of the packet, either transmitted (Tx) or received (Rx).

Src

DF1 node address of the message source.

Dest

DF1 node address of the message destination.

Description

Brief description of the packet, usually the command.

Address

The string representing a PLC data address, where applicable.

Detail

Additional details associated with command.

TNS

Transaction number. Used to match request and reply messages.

Data

The packet’s raw data displayed in space delimited hex.

pressing the STOP button.

Figure 6.12 - DF1 Packet Capture complete

The captured DF1 packets are listed as follows:

Table 6.1 - DF1 Packet Capture fields

Page 54

Page 55

4 The packet capture can be saved to a file for further analysis by selecting the SAVE button

on the toolbar.

5 Previously saved DF1 Packet Capture files can be viewed by selecting the DF1 Packet

Capture Viewer option in the Tools menu.

Figure 6.13 - Selecting the DF1 Packet Capture Viewer

Page 55

Page 56

6.2 Modbus Packet Capture

The PLX51-DLplus-232 provides the capability to capture the Modbus traffic for analysis.

1 To begin the capture of the PLX51-DLplus-232, double-click on the Modbus Packet

Capture selection in the Project Explorer tree.

Figure 6.14 - Selecting Modbus Packet Capture

2 The Modbus Packet Capture window opens and automatically starts capturing all Modbus

packets.

Figure 6.15 – Modbus packet capture

Page 56

Page 57

3 To display the captured Modbus packets, the capture process must first be stopped by

Statistic

Description

Index

The packet index, incremented for each packet sent or received.

Time

The elapsed time since the PLX51-DLplus-232 was powered up.

Status

The status of the packet. Received packets are checked for valid Modbus constructs

and valid checksums.

Dirn

The direction of the packet, either transmitted (Tx) or received (Rx).

Node

Modbus node address of the message destination.

Description

A brief description of the packet, showing the function and register range if applicable.

Data

The raw packet data.

pressing the STOP button.

Figure 6.16 – Modbus Packet Capture complete

The captured Modbus packets are tabulated as follows:

Table 6.5 – Modbus Packet Capture fields

4 The packet capture can be saved to a file for further analysis by selecting the SAVE button

on the toolbar.

Page 57

Page 58

5 Previously saved Modbus Packet Capture files can be viewed by selecting the Modbus

Packet Capture Viewer option in the Tools menu.

Figure 6.17 - Selecting the Modbus Packet Capture Viewer

Page 58

Page 59

6.3 Module Event Log

The PLX51-DLplus-232 logs various diagnostic records to an internal event log. These logs are

stored in non-volatile memory and can be displayed in the PLX50 Configuration Utility or the web

server.

1 To view them in the PLX50 Configuration Utility, select the Event Viewer option in the

Project Explorer tree.

Figure 6.18 - Selecting the PLX51-DLplus-232 Event Log

2 The Event Log window opens and automatically reads all the events from the PLX51-

DLplus-232.

3 The log entries are listed with the latest record at the top. Custom sorting is achieved by

double-clicking on the column headings.

Page 59

Page 60

Figure 6.19 – Module Event Log

4 The log can also be stored to a file for future analysis by selecting the SAVE button in the

tool menu. To view previously saved files, use the Event Log Viewer option under the Tools

menu.

Page 60

Page 61

6.4 Web Server

The PLX51-DLplus-232 provides a web server allowing you to view various diagnostics of the

PLX51-DLplus-232 without the PLX50 Configuration Utility or RSLogix 5000. This includes Ethernet

parameters, system event log, advanced diagnostics, and application diagnostics (DF1

diagnostics).

NOTE: The web server is read-only, no parameters or configuration can be altered

from the web interface.

Figure 6.20 - Web interface

Page 61

Page 62

6.5 Web Reporting

The PLX51-DLplus-232 allows the user to extract logs and draw trends from the module using a

standard web browser as shown below.

Figure 6.1 – Web reporting

The reporting page can be accessed via the standard web interface of the module by entering the

IP address of the module into the browser and clicking on the REPORT button as shown below:

Page 62

Page 63

Figure 6.2 – Web report – access via normal webserver

Alternatively, the user can directly access the Report page by entering the IP address of the

module into the browser followed by the report page url; report.html (eg.

http://192.168.1.xxx/report.html). This allows the user to have full screen access of the trend,

as shown below.

Figure 6.3 – Web report – access directly

The PLX51-DLplus-232 supports five trend objects (or pens) that can be used to trend logged data

over a requested period. Each trend can be set to any of the configured tags (in the PLX50

Configuration Utility). The user can also upload all the records for a requested period to a CSV

file via the web browser.

Page 63

Page 64

Each of the five trends can plot up to 10,000 records. Uploading data to CSV can store up to

1,000,000 records.

NOTE: If a new configuration has been downloaded to the module, the entire web

page will need to be refreshed.

RETRIEVE TREND DATA

When drawing a trend, the user must first select the tags that need to be trended.

1 Click on the drop-down box for each trend and selecting the tag that must be displayed.

NOTE: Selecting “-“ results in no trend being drawn for that specific pen.

Figure 6.4 – Selecting data to trend

2 Once the required tags have been selected, the user will need to select the time period

over which the data must be trended.

Page 64

Page 65

Figure 6.5 – Selecting time period

3 Press the Retrieve Trend Data button.

Figure 6.6 – Retrieve Trend Data

This will start collecting the required data from the PLX51-DLplus-232.

Figure 6.7 – Busy indication

Page 65

Page 66

4 Once the data has successfully been collected it will be trended on the graph as shown

below:

Figure 6.8 – Trends of the selected tags over the requested time period

NOTE: Depending on the amount of data that needs to be collected, it can take a

few minutes to retrieve all the required data (each trend can have up to 10,000

data points).

5 The user can see how many points were plotted for each trend by viewing the Log Counts

below the graph. In the example below, each of the five trends has 256 data points.

Figure 6.9 – Data point count for each trend

Page 66

Page 67

6 The user can also view the local time zone that will be applied to the UTC time retrieved

for each record.

Figure 6.10 – Web browser local time zone

CUSTOMIZE GRAPH AXIS

Each trend will have its own y-axis on the graph. The y-axis can be customized by scrolling down

on the report page and selecting the Manual option for the specific y-axis.

Figure 6.11 – Manual option for y-axis

Page 67

Page 68

Once selected, the max and min values of the current trend will be populated in the textboxes.

The user can enter the max and min range for the specific trend and press the UPDATE #X Y-AXIS

button. This will update the selected y-axis with the current loaded data.

Figure 6.12 – Update Y-Axis

NOTE: Once the user selects to retrieve new data from the PLX51-DLplus-232, the

current selection for the custom y-axis will be removed.

NOTE: By un-selecting the Manual option and pressing the UPDATE #X Y-AXIS

button, the trend y-axis will return to the original scaled values

Page 68

Page 69

Figure 6.13 – Updated Y-Axis

Similarly, the x-axis of the graph can be updated for a specific time range. The user can select the

Manual option on the X-Axis range (as shown below):

Page 69

Page 70

Figure 6.14 – Manual X-Axis selection

Once selected, the start and stop times of the current trend will be populated in the textboxes.

The user can now enter the new custom time and press the UPDATE X-AXIS button.

Figure 6.15 – Updated X-Axis

NOTE: Once the user selects to retrieve new data from the PLX51-DLplus-232, the

current selection for the custom x-axis will be removed.

NOTE: By un-selecting the Manual option and pressing the UPDATE X-AXIS button,

the trend y-axis will return to the original scaled values.

Page 70

Page 71

UPLOAD RECORDS TO CSV FILE

The user can also upload all records for a requested time period to a CSV file. The user can then

save and open this file in MS Excel. To create the CSV file, the user must select the required time

range, followed by pressing the SAVE ALL EVENTS button.

Figure 6.16 – Upload records to CSV file

NOTE: All tag records will be uploaded to the CSV file, and NOT the tags selected

in the trend selections.

NOTE: Up to 1,000,000 records can be uploaded to a CSV file at a time. This can

take several minutes to collect from the PLX51-DLplus-232.

Depending on the web browser, the created CSV file will be displayed in the web browser

window:

Figure 6.17 – Created CSV file

NOTE: The value in brackets () of the file name is the number of records stored in

the CSV file. In the above example, there are 1664 records stored.

The file can be opened in MS Excel and will have the following Columns:

Page 71

Page 72

Parameter

Description

Log Index

The number of the log index in this specific file.

UTC Date Time

The UTC (GMT + 0) time when the record was logged.

Local Date Time

The local time (GMT + local time zone) when the record was logged.

Millisecond

Millisecond when record was logged (50ms resolution).

Tag ID

The Tag ID of the specific tag.

Tagname

The tagname of the specific tag.

Data Type

The data type of the logged record.

Data Value

The data value of the logged record.

Figure 6.18 – CSV file opened in MS Excel

Table 6.2 – CSV file Parameters

Page 72

Page 73

7 JSON CLIENT

Accessing the PLX51-DLplus-232 REST API statistics can be accomplished by using a JSON Client.

These statistics and their definitions can also be found in the PLX51-DLplus-232 Web Reporting

section. In this example, the JSON Client utility is used. You can download a JSON Client sample

from www.prosoft-technology.com.

The PLX51-DLplus-232 webserver supports multiple status-based and record-based queries.

These queries are typically CIP messages encapsulated in a HTTP GET command.

This section provides a number of JSON-based queries to extract the information. The JSON

requests and responses are encapsulated in an HTTP GET or POST command.

7.1 General Status

REQUEST

{

"header": {

"messageType": "reqGenSts"

},

"requestData": {}

}

RESPONSE

{

"header": {

"messageType": "resGenSts"

},

"responseData": {

"Running": 1,

"ConfigValid": 1,

"ContinousLogging": 1,

"Rollover": 0,

"LoggingInhibited": 0,

"LoggingStopped": 0,

“ConfigCRC”:1234,

“LogIndex”:1,

“UnloadIndex”:0,

"DataSource": "EtherNet/IP"

}

}

Data Source Values: EtherNet/IP, DF1, Modbus RTU, Modbus TCP

Page 73

Page 74

7.2 Cache Statistics

REQUEST

{

“header”: {

“messageType”: “reqCacheStats”

},

“requestData”: {}

}

RESPONSE

{

“header”: {

“messageType”: “resCacheStats”

},

“responseData”: {

“totalRecordCount”: 0,

“cacheRecordCount”: 0,

“cachePercentage”: 0

}

}

7.3 Unload Log Index Update

REQUEST

{

“header”: {

“messageType”: “reqUnloadIdxUpdate”

},

“requestData”: {

“unloadLogIndex”: 0

}

}

RESPONSE

{

“header”: {

“messageType”: “resUnloadIdxUpdate”

},

“responseData”: {}

}

Page 74

Page 75

7.4 Cache Records

NOTE: Maximum of 5 records can be read at a time.

NOTE: When a PLX51-DLplus-232 is powered down, a certain amount of

fragmentation can occur within the Non-volatile memory (due to the NAND NV

memory page alignment). This can result in the data to be displayed as 0xFF (eg.

the year will be 65535 for the record – 0xFFFF) in certain log indexes. If this value

is received, ignore that specific log index.

REQUEST

{

“header”: {

“messageType”: “reqCacheRecords”

},

“requestData”: {

“logIndex”: 0,

“recordCount”: 0

}

}

RESPONSE

{

“header”: {

“messageType”: “resCacheRecords”

},

“responseData”: {

“reqLogIndex”: 0,

“currentLogIndex”: 0,

“currentLogUnloadIndex”: 0,

“storage”: “Non-volatile”,

“records”: [

{

“tsUTC”: 1553401472,

“50msTick”: 3,

“tagId”: 12,

“dataType”: “REAL”,

“checksum”: 5555,

“data”: 12.345

},

{

“tsUTC”: 1553401472,

“50msTick”: 5,

“tagId”: 14,

“dataType”: “DINT”,

“checksum”: 4444,

“data”: 98765

}

]

}

}

Storage Values: Non-volatile, RAM

Page 75

Page 76

7.5 Reset Log Indexes

REQUEST

{

“header”: {

“messageType”: “reqLogIndexReset”

},

“requestData”: {}

}

RESPONSE

{

“header”: {

“messageType”: “resLogIndexReset”

},

“responseData”: {}

}

7.6 Get Tag Names

NOTE: Maximum of 4 tag names can be read at a time.

REQUEST

{

“header”: {

“messageType”: “reqGetTagNames”

},

“requestData”: {

“tagNameIndex”: 7,

“tagNameCount”: 2

}

}

RESPONSE

{

“header”: {

“messageType”: “resGetTagNames”

},

“responseData”: {

“tagNameCount”: 2,

“tags”: [

{

“tagDataType”: “REAL”,

“tagId”: 14,

“tagName”: “Outlet Flow 01”

},

{

“tagDataType”: “DINT”,

“tagId”: 15,

“tagName”: “High Level Count”

}

]

}

}

Page 76

Page 77

7.7 Trend Data

NOTE: Maximum of 5 records can be read at a time.

NOTE: When a module is powered down a certain amount of fragmentation can occur

with the Non-volatile memory (due to the NAND NV memory page alignment). This

can result in the data to be displayed as 0xFF (eg. the year will be 65535 for the record

– 0xFFFF) in certain log indexes. If this value is received, ignore that specific log index.

REQUEST

{

“header”: {

“messageType”: “reqTrendData”

},

“requestData”: {

“command”: “Start”,

“duration”: “Last 5 min”,

“startTime”: “2019/03/02 14:22:00”,

“stopTime”: “2019/03/02 14:29:00”,

“extractedTags”: “Tags 1 to 5”,

“tag Idx 1”: 12,

“tag Idx 2”: 19,

“tag Idx 3”: 24,

“tag Idx 4”: 27,

“tag Idx 5”: 28

}

}

RESPONSE

{

“header”: {

“messageType”: “resTrendData“

},

“responseData”: {

“status”: “Last Packet”,

“recordCount”: 2,

“records”: [

{

“tsUTC”: 1553401472,

“50msTick”: 3,

“tagId”: 12,

“dataType”: “REAL”,

“checksum”: 5555,

“data”: 12.345

},

{

“tsUTC”: 1553401472,

“50msTick”: 5,

“tagId”: 14,

“dataType”: “DINT”,

“checksum”: 4444,

“data”: 98765

}

]

}

}

Page 77

Page 78

Command Values: Start, Poll

Duration Values: Last 5 min, Last 30 min, Last hour, Last 6 hours, Last 12 hours, Last day, Last 5 days,

Last week, Last month, Last year, Custom Dates

ExtractedTags Values: Tags 1 to 5, All tags

Status: Last packet, Busy, More Data

7.8 Trend Data UTC

NOTE: Maximum of 5 records can be read at a time.

NOTE: When a module is powered down a certain amount of fragmentation can

occur with the Non-volatile memory (due to the NAND NV memory page

alignment). This can result in the data to be displayed as 0xFF (eg. the year will be

65535 for the record – 0xFFFF) in certain log indexes. If this value is received,

ignore that specific log index.

REQUEST

{

“header”: {

“messageType”: “reqTrendDataUTC”

},

“requestData”: {

“command”: “Start”,

“duration”: “Last 5 min”,

“startUTC”: 1553401472,

“stopUTC”: 1553401672,

“extractedTags”: “All tags”,

“tag Idx 1”: 12,

“tag Idx 2”: 19,

“tag Idx 3”: 24,

“tag Idx 4”: 27,

“tag Idx 5”: 28

}

}

Page 78

Page 79

RESPONSE

{

“header”: {

“messageType”: “resTrendDataUTC”

},

“responseData”: {

“status”: “Last Packet”,

“recordCount”: 2,

“records”: [

{

“tsUTC”: 1553401472,

“50msTick”: 3,

“tagId”: 12,

“dataType”: “REAL”,

“checksum”: 5555,

“data”: 12.345

},

{

“tsUTC”: 1553401472,

“50msTick”: 5,

“tagId”: 14,

“dataType”: “DINT”,

“checksum”: 4444,

“data”: 98765

}

]

}

}

Command Values: Start, Poll

Duration Values: Last 5 min, Last 30 min, Last hour, Last 6 hours, Last 12 hours, Last day, Last 5 days,

Last week, Last month, Last year, Custom Dates

ExtractedTags Values: Tags 1 to 5, All tags

Status: Last packet, Busy

Page 79

Page 80

7.9 Invalid Request Response

NOTE: When a request message was received which was incorrect or had illegal request

parameters the following response will be received.

RESPONSE

{

“header”: {

“messageType”: “resInvalidRequest”

},

“responseData”: {}

}

7.10 Operation

There are multiple ways to extract data from the PLX51-DLplus-232. The following operations are

described in the form of pseudocode examples.

GET TAG DATABASE

Before reading the tags, it is recommended to first read the configuration CRC. If

the tag configuration changes during the tag upload, the upload process can be repeated.

crcStart = reqGenSts().ConfigCRC

tagIndex = 0

Loop

reqGetTagNames(tagIndex,7)

tagIndex = tagIndex +7

crcEnd = reqGenSts().ConfigCRC

if(crcEnd != crcStart) then repeat

GET TREND DATA

The Get Trend Data request extracts up to 5 specific tags, or all of them, between a start and stop

time. The interpolation and record index searched are managed by the PLX51-DLplus-232.

status = reqTrendData(“start”, duration, startDT, stopDT).Status

while(status != LastPacket)

status = reqTrendData(“poll”, duration, startDT, stopDT).Status

Page 80

Page 81

GET CACHE RECORDS

The Get Cache Records request can extract subsets of records by using the record index. This is a

low-level approach where the application is expected to manage the record indices.

The PLX51-DLplus-232 stores records in a 16 million record circular buffer, using a LogIndex and

UnloadIndex. Each time a record is logged, the LogIndex is incremented.

The UnloadIndex is typically controlled by the PLX50 Configuration Utility, and is used to

determine the records that have not yet been uploaded.

To unload records, the application should first read the GeneralStatus to determine the LogIndex,

UnloadIndex and RollOver flag. The records are then read out, 16 at a time.

If the application requires these records to be flagged as “Read”, the application should use the

UnloadLogIndexUpdate command at the end of the read cycle.

If the requirement is to unload all the events, then it is not necessary to consider the

UnloadIndex.

If the RollOver flag is set, then the Unload can start at the LogIndex+1. Otherwise, it starts at

index 0. The unloading stops when the index reaches the LogIndex. If the RollOver flag is set, the

index should rollover after 16777215.

Page 81

Page 82

7.11 Examples

Below are examples extracted from Wireshark on two message request types.

GENERAL STATUS MESSAGE

REQUEST

POST / HTTP/1.1

Host: 192.168.1.230

Connection: keep-alive

Content-Length: 55

Origin: http://192.168.1.230

User-Agent: Mozilla/5.0 (Windows NT 10.0; Win64; x64)

AppleWebKit/537.36 (KHTML, like Gecko) Chrome/73.0.3683.103

Safari/537.36

Content-Type: application/json

Accept: */*

Referer: http://192.168.1.230/

Accept-Encoding: gzip, deflate

Accept-Language: en-US,en;q=0.9

{"header":{"messageType":"reqGenSts"},"requestData":{}}

RESPONSE

HTTP/1.1 200 OK

Content-Type: application/json

Content-Length: 364

{"header":{"messageType":"resGenSts"},"responseData":{"Running":

1,"ConfigValid": 1,"ContinousLogging": 1,"Rollover":

0,"LoggingInhibited": 0,"LoggingStopped": 0,"ConfigCRC":

5947,"LogIndex": 4487,"UnloadIndex": 0,"DataSource":

"EtherNet/IP","currentDateTime": "2019/04/30 11:42:51","currentUTC":

1556624571,"serialNum": "35216C41","instance": "Data Logger Plus"}}

Page 82

Page 83

CACHE RECORDS MESSAGE

REQUEST

POST / HTTP/1.1

Host: 192.168.1.230

Connection: keep-alive

Content-Length: 91

Origin: http://192.168.1.230

User-Agent: Mozilla/5.0 (Windows NT 10.0; Win64; x64)

AppleWebKit/537.36 (KHTML, like Gecko) Chrome/73.0.3683.103

Safari/537.36

Content-Type: application/json

Accept: */*

Referer: http://192.168.1.230/

Accept-Encoding: gzip, deflate

Accept-Language: en-US,en;q=0.9

{"header":{"messageType":"reqCacheRecords"},"requestData":{"logIndex":

100,"recordCount":4}}

RESPONSE

HTTP/1.1 200 OK

Content-Type: application/json

Content-Length: 720

{"header":{"messageType":"resCacheRecords"},"responseData":{"reqLogInd

ex": 100,"currentLogIndex": 559,"currentLogUnloadIndex": 0,"storage":

"Non-volatile","records": [{"year": 2019,"mon": 4,"day": 30,"hour":

11,"min": 46,"sec": 12,"50msTick": 14,"tagId": 12,"dataType":

"DINT","checksum": 42,"data": 555},{"year": 2019,"mon": 4,"day":

30,"hour": 11,"min": 46,"sec": 12,"50msTick": 14,"tagId":

13,"dataType": "DINT","checksum": 92,"data": 777},{"year": 2019,"mon":

4,"day": 30,"hour": 11,"min": 46,"sec": 12,"50msTick": 14,"tagId":

8,"dataType": "DINT","checksum": 44,"data": 111},{"year": 2019,"mon":

4,"day": 30,"hour": 11,"min": 46,"sec": 12,"50msTick": 14,"tagId":

9,"dataType": "DINT","checksum": 133,"data": 222}]}}

Page 83

Page 84

Page 84

Page 85

8 TECHNICAL SPECIFICATIONS

8.1 Dimensions

Below are the PLX51-DLplus-232 enclosure and DIN rail dimensions. All dimensions are in

millimeters.

Figure 8.1 - Module enclosure dimensions

Figure 8.2 - Required DIN dimensions

Page 85

Page 86

8.2 Electrical

Specification

Rating

Power requirements

Input: 10 to 28V DC, (70 mA @ 24 VDC)

Power consumption

1.7 W

Connector

3-way terminal

Conductors

24 to 18 AWG

Enclosure rating

IP20, NEMA/UL Open Type

Temperature

-20 to 70 °C

Earth connection

Yes, terminal based

Emissions

IEC61000-6-4

ESD Immunity

EN 61000-4-2

Radiated RF Immunity

IEC 61000-4-3

EFT/B Immunity

EFT: IEC 61000-4-4

Surge Immunity

Surge: IEC 61000-4-5

Conducted RF Immunity

IEC 61000-4-6

Specification

Rating

Connector

RJ45

Conductors

CAT5 STP/UTP

ARP connections

Max 20

TCP connections

Max 20

CIP connections

Max 10

Communication rate

10/100 Mbps

Duplex mode

Full/Half

Auto-MDIX support

Yes

Table 8.1 - Electrical specification

8.3 Ethernet

Table 8.2 - Ethernet specification

Page 86

Page 87

8.4 Data Cache

Specification

Rating

Max Record Count

16,777,216

Maximum tag count

200

Log criteria supported

Delta change

Heart beat

Tag Triggers

Minimum Log Interval

50 ms

Data Types Supported

BOOL, SINT, INT, DINT, or REAL

Cached Records Non-Volatile

Yes

Log triggers supported

Yes

Data Sources

Logix Tags

DF1 Files

Modbus (RTU and TCP/IP) registers

Specification

Rating

Connector

4-way terminal

Conductor

24 to 18 AWG

Isolation voltage

2.5 kV

BAUD

1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200

Parity

None, Even, Odd

Specification

Rating

Duplex

Full/Half

Error detection

CRC, BCC

Embedded response

Auto, On

Table 8.3 – Data Cache specification

8.5 Serial Port

8.6 DF1

Table 8.4 – Serial Port specification

Table 8.5 - DF1 specification

Page 87

Page 88

8.7 Modbus

Specification

Rating

Supported Ports

Modbus RTU

Modbus TCP/IP

Functions Supported

Read Coils (Function Code 1)

Read Discrete Inputs (Function Code 2)

Read Holding Register (Function Code 3)

Read Input Register (Function Code 4)

Table 8.6 - Modbus specification

8.8 Agency Approvals & Certifications

Please visit our website: www.prosoft-technology.com

Page 88

Page 89

9 SUPPORT, SERVICE & WARRANTY

9.1 Contacting Technical Support

ProSoft Technology, Inc. is committed to providing the most efficient and effective support