Page 1

MVI69-MCM

CompactLogix or MicroLogix

Platform

Modbus Communication Module

March 22, 2011

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2011 ProSoft Technology, Inc., all rights reserved.

MVI69-MCM User Manual

March 22, 2011

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM,

and are available at no charge from our web site: www.prosoft-technology.com

Page 3

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

A WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIV. 2;

B WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

C WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

D THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

MVI (Multi Vendor Interface) Modules

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DÉCONNECTER L'ÉQUIPEMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Warnings

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or rewiring modules.

Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C Suitable for use in Class I, Division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction.

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Warning: This module is not hot-swappable! Always remove power from the rack before inserting or removing this

module, or damage may result to the module, the processor, or other connected devices.

Battery Life Advisory

The MVI46, MVI56, MVI56E, MVI69, and MVI71 modules use a rechargeable Lithium Vanadium Pentoxide battery to

backup the real-time clock and CMOS. The battery should last for the life of the module. The module must be

powered for approximately twenty hours before the battery becomes fully charged. After it is fully charged, the battery

provides backup power for the CMOS setup and the real-time clock for approximately 21 days. When the battery is

fully discharged, the module will revert to the default BIOS and clock settings.

Note: The battery is not user replaceable.

Page 4

Markings

Electrical Ratings

Backplane Current Load: 800 mA @ 5.1 Vdc

Power Supply Distance Rating: 2

Operating Temperature: 0°C to 60°C (32°F to 140°F)

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

Relative Humidity: 5% to 95% (without condensation)

All phase conductor sizes must be at least 1.3 mm(squared) and all earth ground conductors must be at least

4mm(squared).

Label Markings

Class I, Division 2 Groups A, B, C, D

II 3 G

Ex nA IIC X

0°C <= Ta <= +60°C

II - Equipment intended for above ground use (not for use in mines).

3 - Category 3 equipment, investigated for normal operation only.

G - Equipment protected against explosive gasses.

Agency Approvals and Certifications

Agency Applicable Standard(s)

ATEX EN 60079-0:2006, EN 60079-15:2005

DNV DET NORSKE VERITAS Test 2.4

CE EMC-EN61326-1:2006; EN61000-6-4:2007

CB Safety CA/10533/CSA, IEC 61010-1 Ed. 2, CB 243333-2056722

(2090408)

GOST-R EN 61010

ME06

Page 5

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Contents

Modbus Communication Module User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Installation Instructions ....................................................................................................... 3

MVI (Multi Vendor Interface) Modules ................................................................................................ 3

Warnings ............................................................................................................................................. 3

Battery Life Advisory ........................................................................................................................... 3

Markings .............................................................................................................................................. 4

Guide to the MVI69-MCM User Manual 9

1 Start Here 11

1.1

1.2

1.3

1.4

1.5

System Requirements ............................................................................................. 12

Package Contents ................................................................................................... 13

Installing ProSoft Configuration Builder Software ................................................... 14

Setting Jumpers ...................................................................................................... 15

Install the Module in the Rack ................................................................................. 16

2 Configuring the MVI69-MCM Module 19

2.1

2.2

2.3

2.4

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

2.1.6

2.1.7

2.1.8

2.1.9

2.1.10

2.2.1

2.2.2

2.4.1

2.4.2

2.4.3

2.4.4

MVI69-MCM Sample Add-On Instruction Import Procedure ................................... 20

Create a new RSLogix5000 project ........................................................................ 20

Create the Module ................................................................................................... 21

Import the Ladder Rung .......................................................................................... 23

Set the Read/Write Data Lengths ........................................................................... 27

Set the Block Transfer Parameter Size ................................................................... 29

Set the Connection Input Size Values ..................................................................... 30

Adding Multiple Modules (Optional) ........................................................................ 31

Connecting Your PC to the Processor .................................................................... 39

Download the Sample Program to the Processor ................................................... 39

Connect your PC to the Module .............................................................................. 45

Using ProSoft Configuration Builder ....................................................................... 46

Setting Up the Project ............................................................................................. 46

Renaming PCB Objects .......................................................................................... 48

Downloading the Project to the Module Using a Serial COM port .......................... 49

Module Configuration .............................................................................................. 50

[Module] ................................................................................................................... 50

[Backplane 69] ......................................................................................................... 50

[MCM Port x] ........................................................................................................... 53

[Modbus Port x Commands] .................................................................................... 59

3 Ladder Logic 69

3.1

3.2

3.2.1

3.2.2

Ladder Logic and Firmware Compatibility Note ...................................................... 70

Module Data Object (MCM1ModuleDef) ................................................................. 71

Status Object (MCM1Status)................................................................................... 72

User Data Objects ................................................................................................... 73

ProSoft Technology, Inc. Page 5 of 167

March 22, 2011

Page 6

Contents MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

3.2.3

3.3

3.4

3.2.4

Slave Polling Control and Status ............................................................................ 73

MODBUS Message Data ........................................................................................ 74

Adding the Module to an Existing CompactLogix Project ....................................... 75

Adding the Module to an Existing MicroLogix Project ............................................ 79

4 Diagnostics and Troubleshooting 81

4.1

4.2

4.3

4.1.1

4.1.2

4.2.1

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

4.2.7

4.2.8

4.2.9

LED Status Indicators ............................................................................................. 82

Clearing a Fault Condition ...................................................................................... 83

Troubleshooting ...................................................................................................... 84

Using ProSoft Configuration Builder (PCB) for Diagnostics ................................... 85

Using the Diagnostic Window in ProSoft Configuration Builder ............................. 85

Navigation ............................................................................................................... 87

Main Menu .............................................................................................................. 88

Database View Menu .............................................................................................. 90

Backplane Menu ..................................................................................................... 92

Protocol Serial MCM Menu ..................................................................................... 93

Master Command Error List Menu.......................................................................... 94

Serial Port Menu ..................................................................................................... 95

Data Analyzer ......................................................................................................... 96

Reading Status Data from the Module ................................................................... 99

5 Reference 101

5.1

5.1.1

5.1.2

5.1.3

5.1.4

5.2

5.2.1

5.2.2

5.2.3

5.2.4

5.3

Processor 110

5.3.1

5.3.2

5.4

5.4.1

5.4.2

5.4.3

5.4.4

5.4.5

5.4.6

5.4.7

5.5

5.5.1

5.5.2

5.5.3

5.5.4

5.5.5

5.5.6

Product Specifications .......................................................................................... 102

General Specifications .......................................................................................... 102

Hardware Specifications ....................................................................................... 103

General Specifications - Modbus Master/Slave .................................................... 104

Functional Specifications ...................................................................................... 105

Functional Overview ............................................................................................. 106

About the MODBUS Protocol ............................................................................... 106

Module Power Up ................................................................................................. 106

Main Logic Loop ................................................................................................... 107

Backplane Data Transfer ...................................................................................... 107

Data Flow between MVI69-MCM Module and CompactLogix or MicroLogix

Slave Driver .......................................................................................................... 110

Master Driver Mode .............................................................................................. 112

Normal Data Transfer ........................................................................................... 115

Block Request from the Processor to the Module ................................................ 115

Block Response from the Module to the Processor ............................................. 115

Read Block and Write Block Transfer Sequences ................................................ 116

If Block Transfer Size = 60 ................................................................................... 117

If Block Transfer Size = 120 ................................................................................. 118

If Block Transfer Size = 240 ................................................................................. 119

Status Data Block (Read Block ID = 0) ................................................................. 119

Special Control and Status Blocks........................................................................ 121

Slave Disable and Enable Control Blocks ............................................................ 121

Slave Status Blocks .............................................................................................. 124

Event Command ................................................................................................... 125

Command Control ................................................................................................. 127

Pass-Through Control Blocks ............................................................................... 129

Initialize Output Data ............................................................................................ 133

Page 6 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 7

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Contents

Modbus Communication Module User Manual

5.5.7

5.6

5.7

5.8

5.9

5.5.8

5.6.1

5.6.2

5.6.3

5.6.4

5.6.5

5.6.6

5.6.7

5.6.8

5.6.9

5.6.10

5.6.11

5.7.1

5.7.2

5.7.3

5.7.4

5.7.5

Warm Boot Block (9998) ....................................................................................... 133

Cold Boot Block (9999) ......................................................................................... 133

Modbus Protocol Specification .............................................................................. 134

Commands Supported by the Module ................................................................... 134

Read Coil Status (Function Code 01) ................................................................... 134

Read Input Status (Function Code 02) .................................................................. 135

Read Holding Registers (Function Code 03) ........................................................ 136

Read Input Registers (Function Code 04) ............................................................. 137

Force Single Coil (Function Code 05) ................................................................... 138

Preset Single Register (Function Code 06) ........................................................... 139

Diagnostics (Function Code 08) ............................................................................ 140

Force Multiple Coils (Function Code 15) ............................................................... 142

Preset Multiple Registers (Function Code 16) ...................................................... 143

MODBUS Exception Responses ........................................................................... 144

Cable Connections ................................................................................................ 146

RS-232 Configuration/Debug Port ........................................................................ 146

RS-232 Application Port(s) ................................................................................... 146

RS-422 .................................................................................................................. 149

RS-485 Application Port(s) .................................................................................... 149

DB9 to RJ45 Adaptor (Cable 14) .......................................................................... 150

MCM Database Definition ..................................................................................... 151

Status Data Definition ............................................................................................ 152

6 Support, Service & Warranty 155

Contacting Technical Support ......................................................................................................... 155

6.1

6.2

6.1.1

6.1.2

6.1.3

6.2.1

6.2.2

6.2.3

6.2.4

6.2.5

6.2.6

6.2.7

6.2.8

6.2.9

6.2.10

Return Material Authorization (RMA) Policies and Conditions.............................. 157

Returning Any Product .......................................................................................... 157

Returning Units Under Warranty ........................................................................... 158

Returning Units Out of Warranty ........................................................................... 158

LIMITED WARRANTY ........................................................................................... 159

What Is Covered By This Warranty ....................................................................... 159

What Is Not Covered By This Warranty ................................................................ 160

Disclaimer Regarding High Risk Activities ............................................................ 160

Intellectual Property Indemnity .............................................................................. 161

Disclaimer of all Other Warranties ........................................................................ 161

Limitation of Remedies ** ...................................................................................... 162

Time Limit for Bringing Suit ................................................................................... 162

No Other Warranties ............................................................................................. 162

Allocation of Risks ................................................................................................. 162

Controlling Law and Severability ........................................................................... 163

Index 165

ProSoft Technology, Inc. Page 7 of 167

March 22, 2011

Page 8

Contents MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

Page 8 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 9

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Guide to the MVI69-MCM User Manual

Modbus Communication Module User Manual

Guide to the MVI69-MCM User Manual

Function

Introduction

(Must Do)

Diagnostic and

Troubleshooting

Reference

Product Specifications

Functional Overview

Support, Service, and

Warranty

Index

Section to Read Details

Start Here (page 11) This section introduces the customer to the

→

Diagnostics and

→

Troubleshooting

(page 81)

Reference (page

→

101)

Product

Specifications (page

102)

Functional Overview

(page 106, page 91)

Support, Service

→

and Warranty (page

155)

Index

module. Included are: package contents,

system requirements, hardware installation, and

basic configuration.

This section describes Diagnostic and

Troubleshooting procedures.

These sections contain general references

associated with this product, Specifications, and

the Functional Overview.

This section contains Support, Service and

Warranty information.

Index of chapters.

ProSoft Technology, Inc. Page 9 of 167

March 22, 2011

Page 10

Guide to the MVI69-MCM User Manual MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

Page 10 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 11

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Start Here

Modbus Communication Module User Manual

1 Start Here

In This Chapter

System Requirements ........................................................................... 12

Package Contents ................................................................................. 13

Installing ProSoft Configuration Builder Software .................................. 14

Setting Jumpers .................................................................................... 15

Install the Module in the Rack ............................................................... 16

To get the most benefit from this User Manual, you should have the following

skills:

Rockwell Automation® RSLogix™ software: launch the program, configure

ladder logic, and transfer the ladder logic to the processor

Microsoft Windows: install and launch programs, execute menu commands,

navigate dialog boxes, and enter data

Hardware installation and wiring: install the module, and safely connect

MODBUS and CompactLogix or MicroLogix devices to a power source and to

the MVI69-MCM module’s application port(s)

ProSoft Technology, Inc. Page 11 of 167

March 22, 2011

Page 12

Start Here MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

1.1 System Requirements

The MVI69-MCM module requires the following minimum hardware and software

components:

Rockwell Automation CompactLogix or MicroLogix processor, with

compatible power supply and one free slot in the rack, for the MVI69-MCM

module. The module requires 800 mA of available power.

Important: The MVI69-MCM module has a power supply distance rating of 2 (L43 and L45

installations on first 2 slots of 1769 bus).

Important: For 1769-L23x processors, please make note of the following limitations.

1769-L23-QBFC1B = 800 mA at 5 Vdc (One MVI69-MCM will use all 800 mA of available

power. No other modules can be used with an MVI69 module connected to this processor.)

1769-L23E-QB1B = 1000 mA at 5 Vdc (One MVI69-MCM will use 800 mA of available power.

One other module can be used on this rack provided it consumes less than 200 mA at 5 Vdc.)

1769-L23E-QBFC1B = 450 mA at 5 Vdc (No MVI69 module can be used with this processor.)

Rockwell Automation RSLogix 5000 (CompactLogix) or RSLogix 500

(MicroLogix) programming software

Rockwell Automation RSLinx communication software

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or better)

recommended

Supported operating systems:

o

Microsoft Windows XP Professional with Service Pack 1 or 2

o

Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o

Microsoft Windows Server 2003

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

100 Mbytes of free hard disk space (or more based on application

requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 × 768 recommended)

CD-ROM drive

HyperTerminal or other terminal emulator program capable of file transfers

using Ymodem protocol.

Page 12 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 13

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Start Here

Modbus Communication Module User Manual

1.2 Package Contents

The following components are included with your MVI69-MCM module, and are

all required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

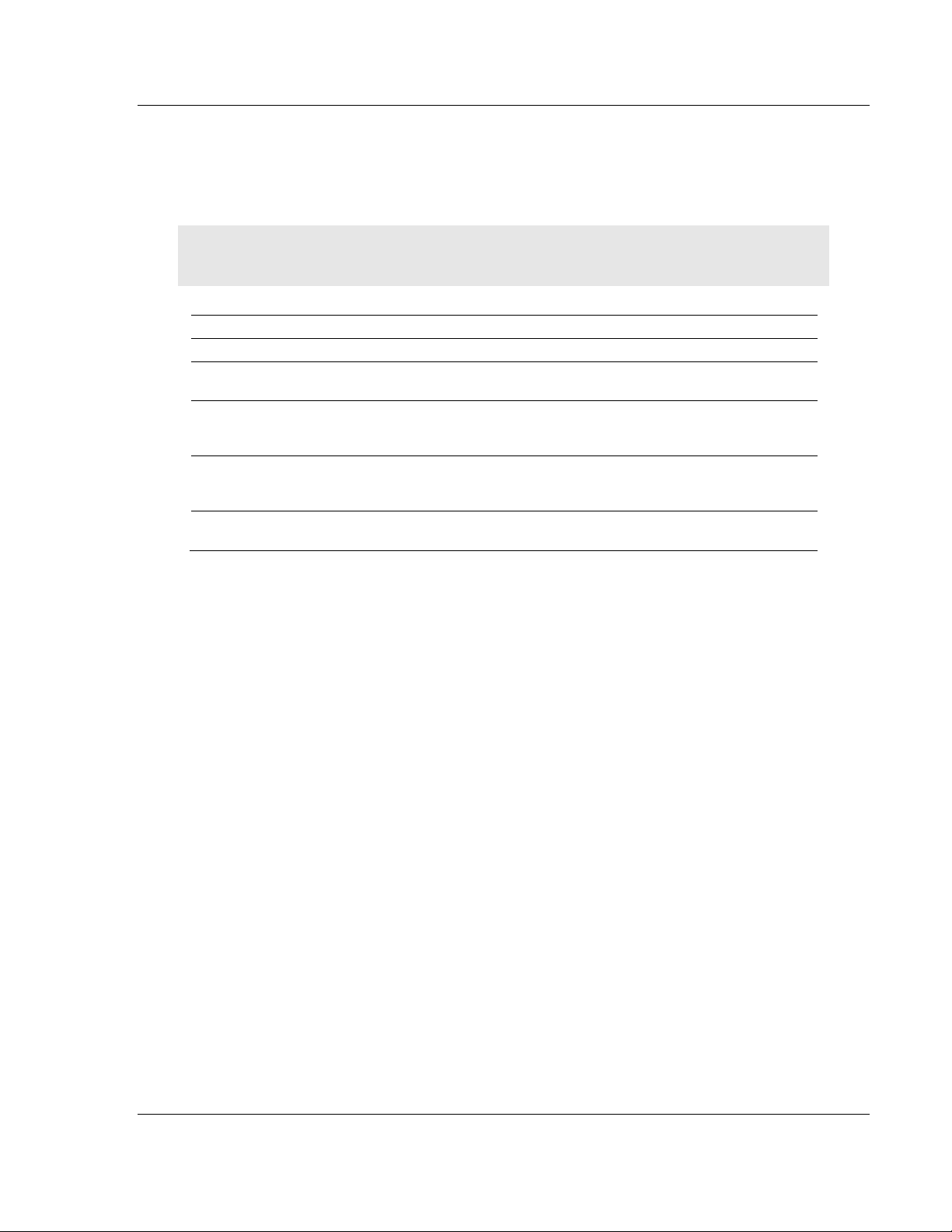

Qty. Part Name Part Number Part Description

1 MVI69-MCM Module MVI69-MCM Modbus Communication Module

1 Cable Cable #15, RS232

3 Cable Cable #14, RJ45 to

2 Adapter 1454-9F Two Adapters, DB9 Female to Screw

1 ProSoft Solutions CD Contains sample programs, utilities and

If any of these components are missing, please contact ProSoft Technology

Support for replacement parts.

For RS232 Connection to the CFG Port

Null Modem

For DB9 Connection to Module’s Port

DB9 Male Adapter

cable

Terminal. For RS422 or RS485

Connections to Port 1 and 2 of the Module

documentation for the MVI69-MCM module.

ProSoft Technology, Inc. Page 13 of 167

March 22, 2011

Page 14

Start Here MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

1.3 Installing ProSoft Configuration Builder Software

You must install the ProSoft Configuration Builder (PCB) software to configure

the module. You can always get the newest version of ProSoft Configuration

Builder from the ProSoft Technology website.

Installing ProSoft Configuration Builder from the ProSoft website

1 Open your web browser and navigate to http://www.prosoft-

technology.com/pcb

2 Click the D

Configuration Builder.

3 Choose S

4 Save the file to your Windows Desktop, so that you can find it easily when

you have finished downloading.

5 When the download is complete, locate and open the file, and then follow the

instructions on your screen to install the program.

If you do not have access to the Internet, you can install ProSoft Configuration

Builder from the ProSoft Solutions Product CD-ROM, included in the package

with your module.

Installing ProSoft Configuration Builder from the Product CD-ROM

1 Insert the ProSoft Solutions Product CD-ROM into the CD-ROM drive of your

PC. Wait for the startup screen to appear.

2 On the startup screen, click P

Windows Explorer file tree window.

3 Click to open the U

and files you will need to set up and configure your module.

4 Double-click the S

PCB_*.

software on your PC. The information represented by the "*" character in the

file name is the PCB version number and, therefore, subject to change as

new versions of PCB are released.

OWNLOAD HERE

AVE

or S

AVE FILE

TILITIES

ETUP CONFIGURATION TOOL

EXE

file and follow the instructions on your screen to install the

link to download the latest version of ProSoft

when prompted.

RODUCT DOCUMENTATION

folder. This folder contains all of the applications

folder, double-click the

. This action opens a

Note: Many of the configuration and maintenance procedures use files and other utilities on the

CD-ROM. You may wish to copy the files from the Utilities folder on the CD-ROM to a convenient

location on your hard drive.

Page 14 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 15

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Start Here

Modbus Communication Module User Manual

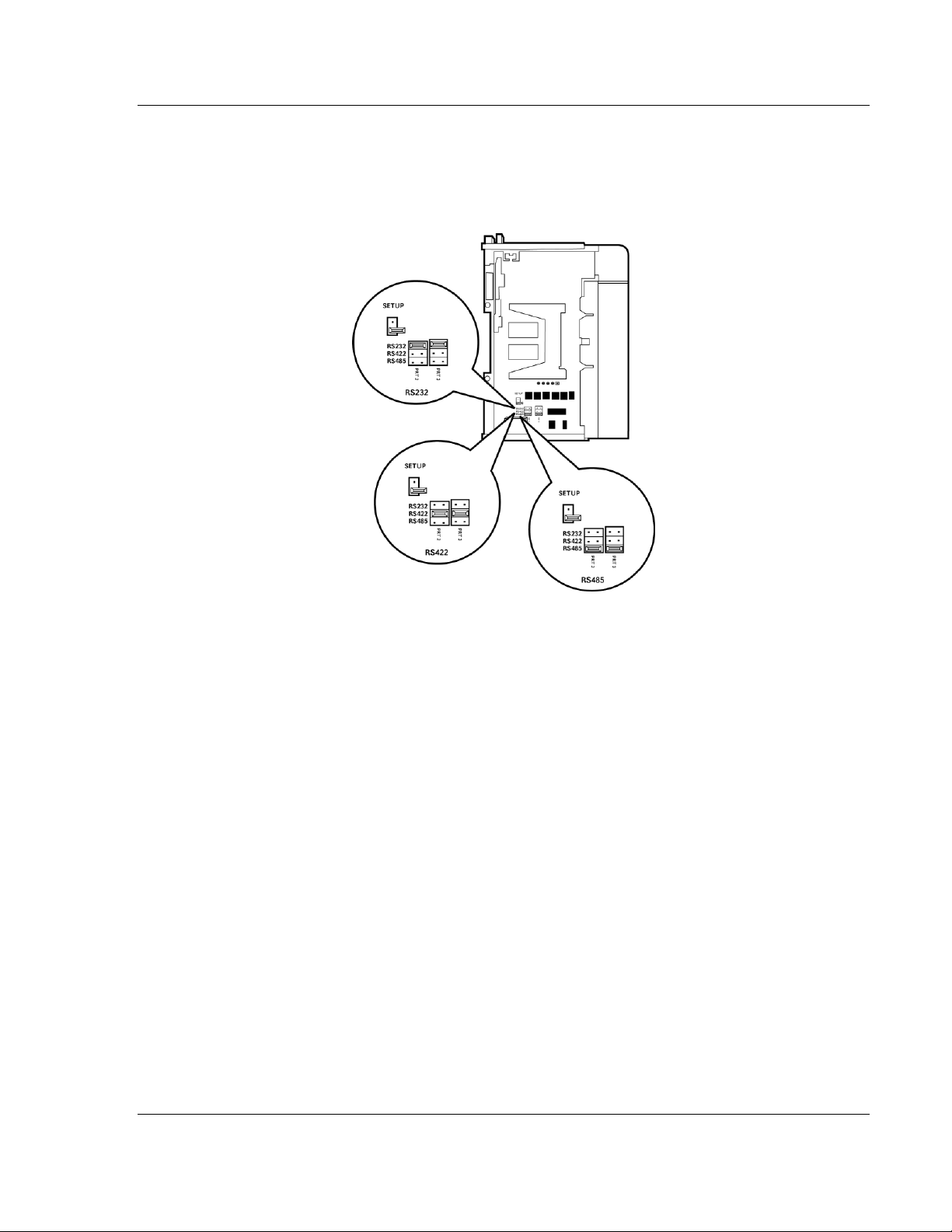

1.4 Setting Jumpers

When the module is manufactured, the port selection jumpers are set to RS-232.

To use RS-422 or RS-485, you must set the jumpers to the correct position. The

following diagram describes the jumper settings.

The Setup Jumper acts as "write protection" for the module’s flash memory. In

"write protected" mode, the Setup pins are not connected, and the module’s

firmware cannot be overwritten. Do not jumper the Setup pins together unless

you are directed to do so by ProSoft Technical Support.

ProSoft Technology, Inc. Page 15 of 167

March 22, 2011

Page 16

Start Here MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

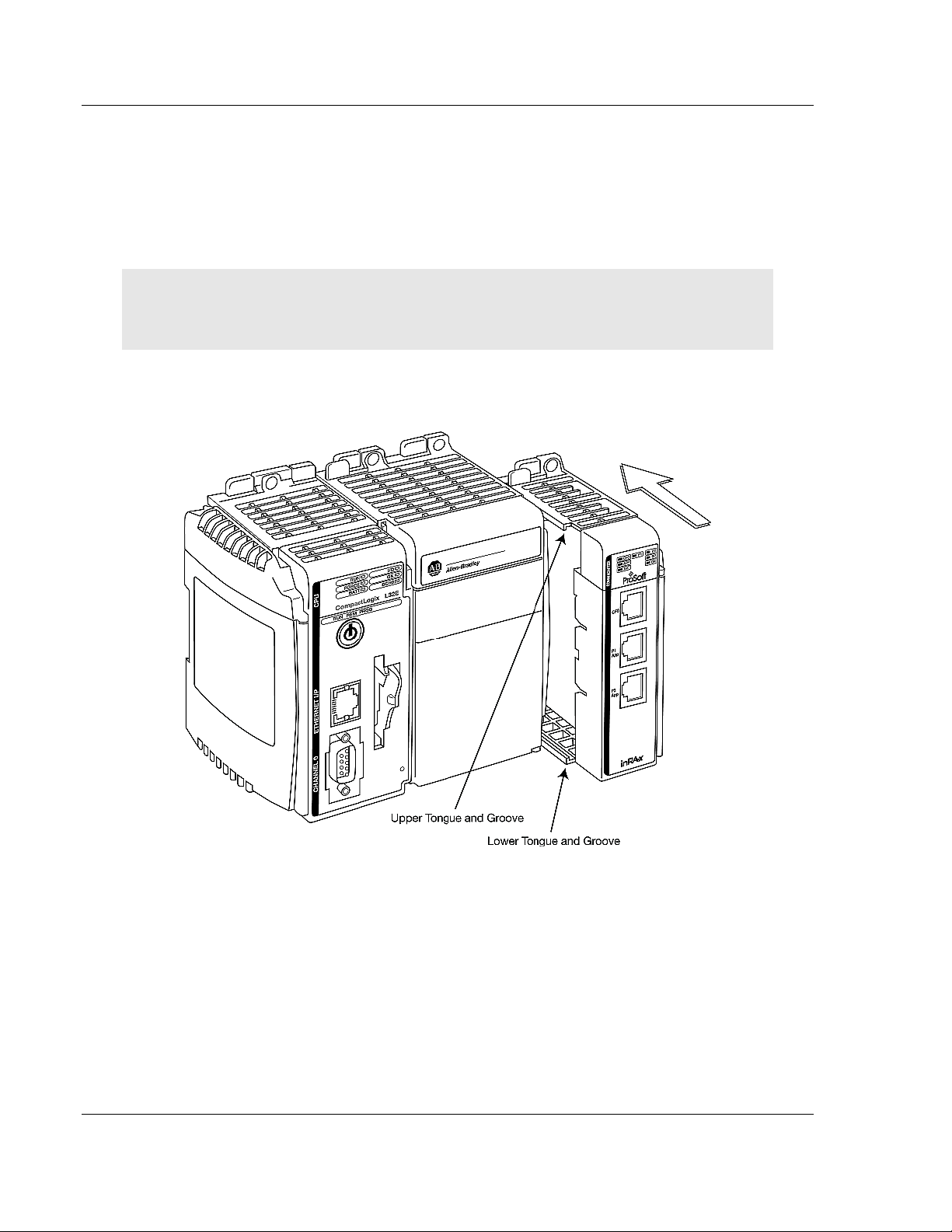

1.5 Install the Module in the Rack

This section describes how to install the module into a CompactLogix or

MicroLogix rack

Before you attempt to install the module, make sure that the bus lever of the

adjacent module is in the unlocked (fully right) position.

Warning: This module is not hot-swappable! Always remove power from the rack before

inserting or removing this module, or damage may result to the module, the processor, or other

connected devices.

1 Align the module using the upper and lower tongue-and-groove slots with the

adjacent module and slide forward in the direction of the arrow.

2 Move the module back along the tongue-and-groove slots until the bus

connectors on the MVI69 module and the adjacent module line up with each

other.

Page 16 of 167 ProSoft Technology, Inc.

March 22, 2011

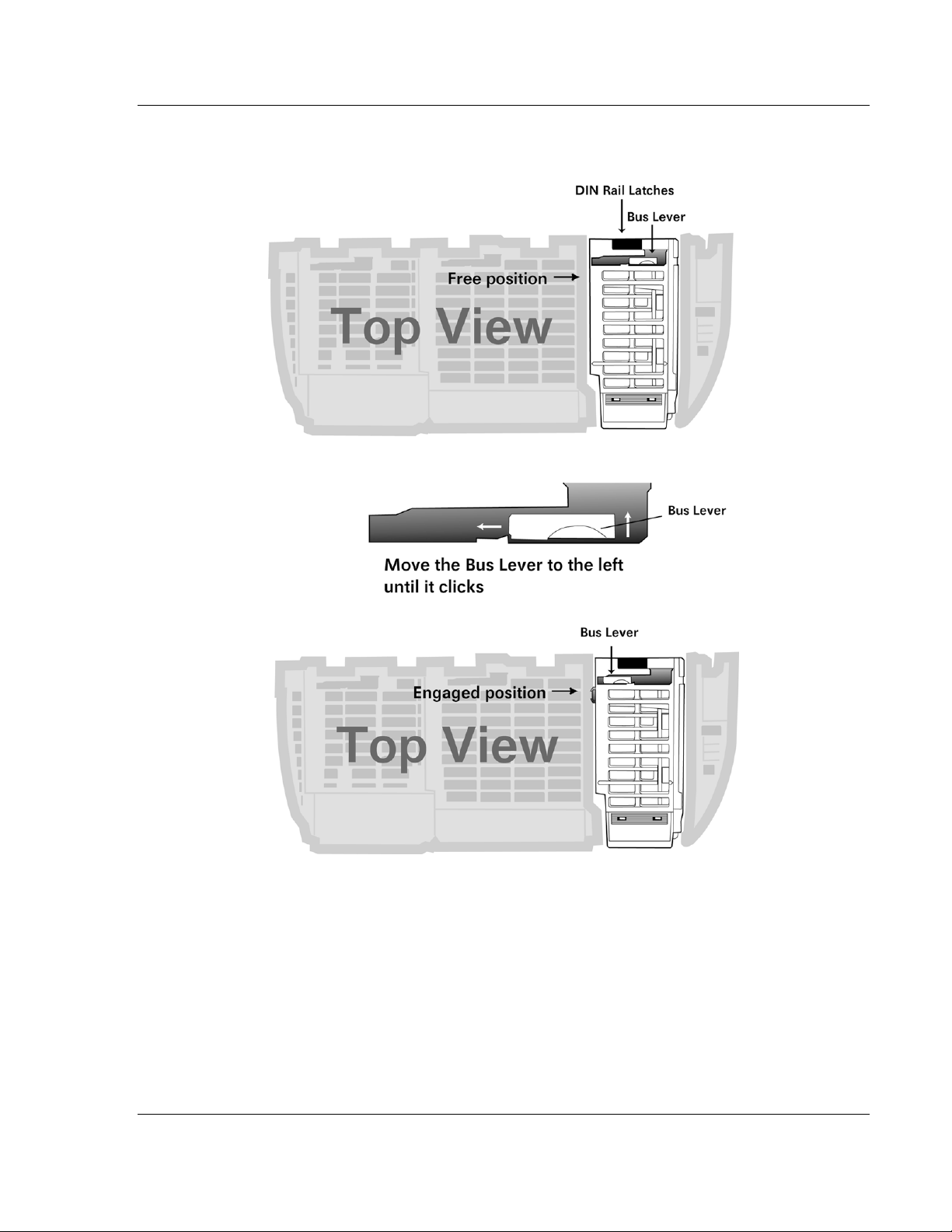

Page 17

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Start Here

Modbus Communication Module User Manual

3 Push the module’s bus lever back slightly to clear the positioning tab and

move it firmly to the left until it clicks. Ensure that it is locked firmly in place.

4 Close all DIN-rail latches.

ProSoft Technology, Inc. Page 17 of 167

March 22, 2011

Page 18

Start Here MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

5 Press the DIN-rail mounting area of the controller against the DIN-rail. The

latches will momentarily open and lock into place.

Page 18 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 19

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

2 Configuring the MVI69-MCM Module

In This Chapter

MVI69-MCM Sample Add-On Instruction Import Procedure .................. 20

Using ProSoft Configuration Builder ...................................................... 46

Downloading the Project to the Module Using a Serial COM port ......... 49

Module Configuration ............................................................................ 50

ProSoft Technology, Inc. Page 19 of 167

March 22, 2011

Page 20

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

2.1 MVI69-MCM Sample Add-On Instruction Import Procedure

Note: this section only applies if you are using RSLogix 5000 version 16 or higher. If you are

configuring the MVI69-MCM module with an earlier version of RSLogix 5000, please refer to

Installing and Configuring the Module with a CompactLogix Processor (page 75).

The following file is required before you start this procedure. Copy the file from

the ProSoft Solutions CD-ROM, or download it from

www.prosoft-technology.com.

File Name Description

MVI69MCM_AddOn_Rung_v1_4.L

5x

L5X file contains the Add-On instruction, the user defined data

types, data objects and ladder logic required to set up the

MVI69-MCM module

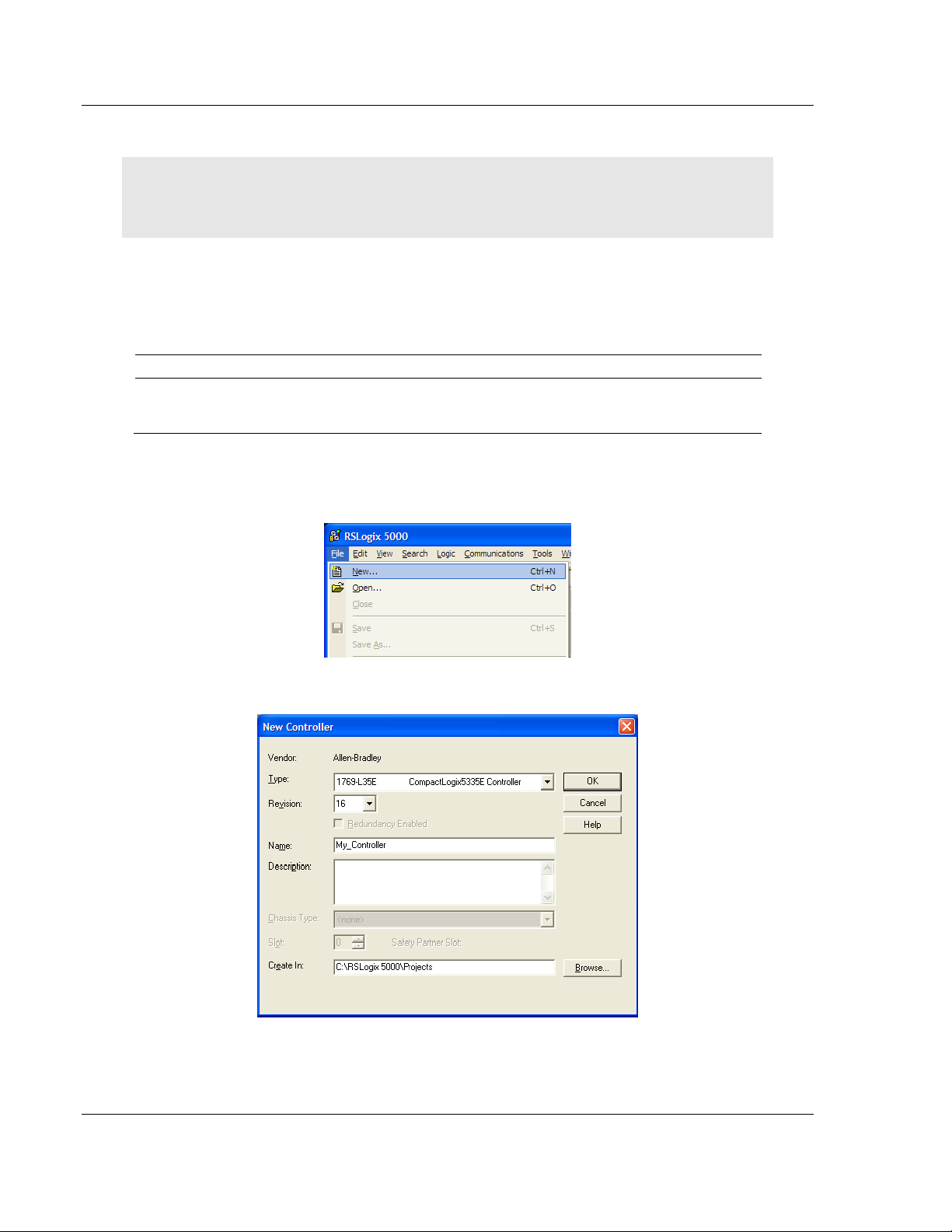

2.1.1 Create a new RSLogix5000 project

1 Open the F

ILE

menu, and then choose NEW…

2 Select R

EVISION

16

Page 20 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 21

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

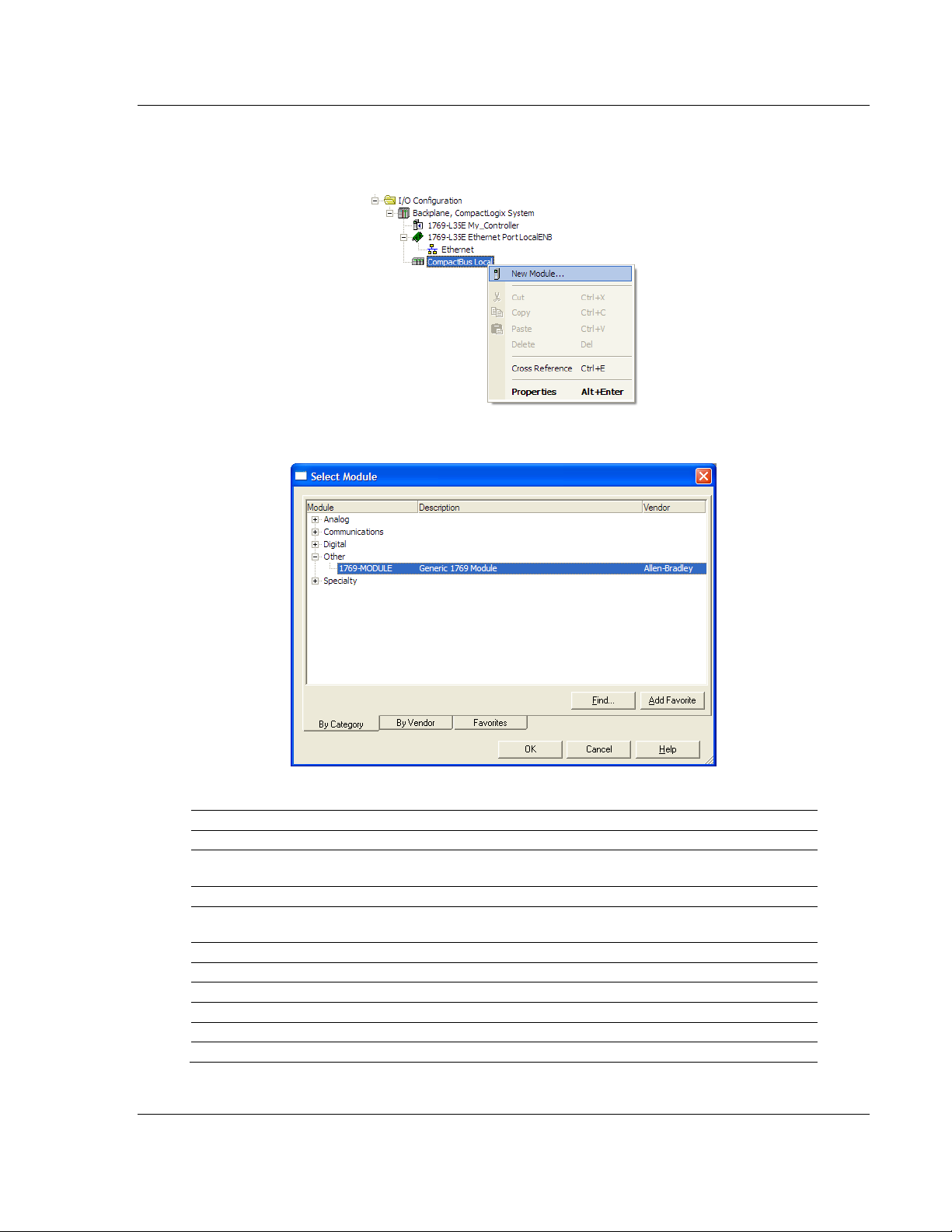

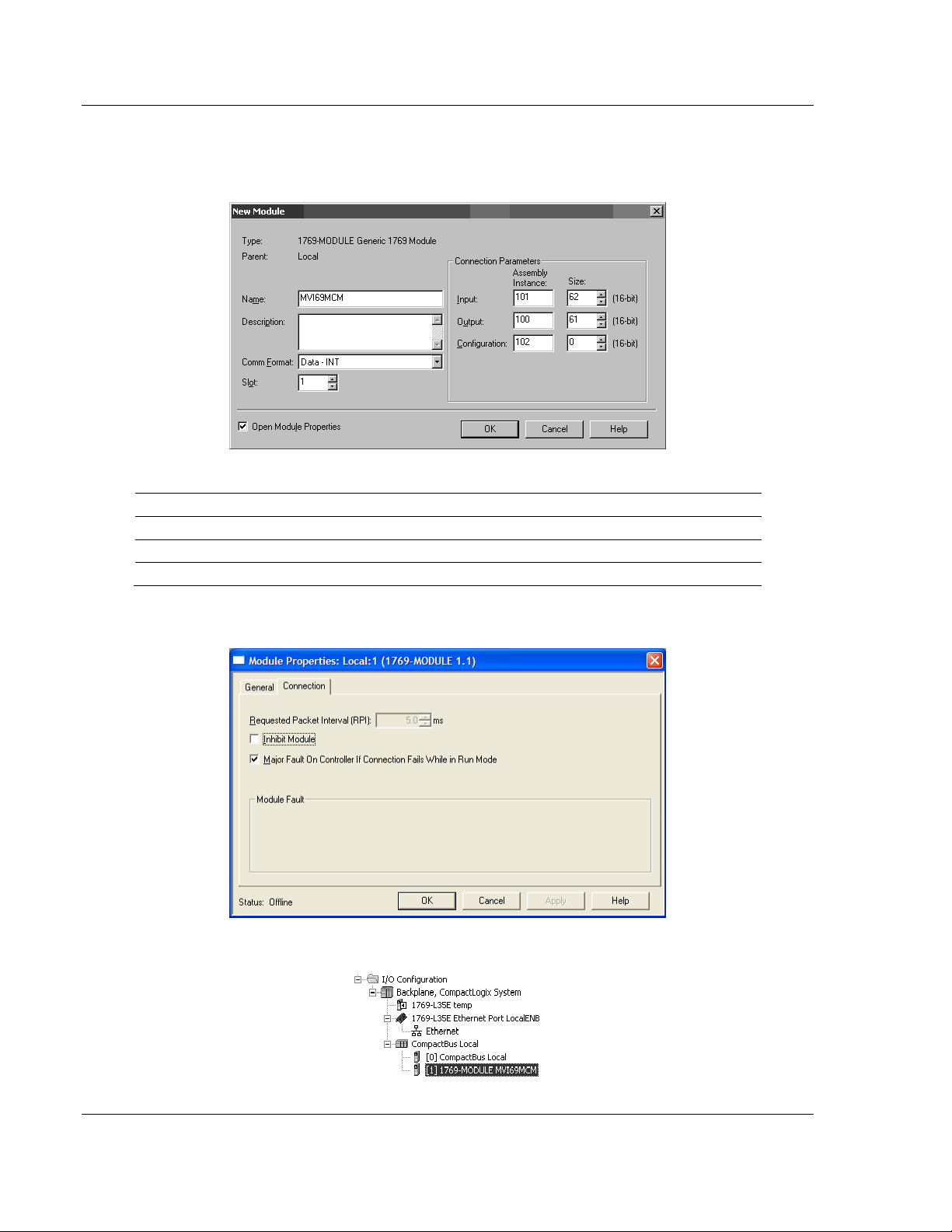

2.1.2 Create the Module

1 Right-click I/O C

ONFIGURATION

2 Select 1769-MODULE

and choose N

EW MODULE

…

3 Set the Module Properties values as follows:

Parameter Value

Name Enter a module identification string. Example: MVI69MCM

Description Enter a description for the module. Example: ProSoft

communication module for Serial Modbus communications.

Comm Format Select Data-INT

Slot Enter the slot number in the rack where the MV69-MCM

module will be installed.

Input Assembly Instance 101

Input Size 62 / 122 / 242

Output Assembly Instance 100

Output Size 61 / 121 / 241

Configuration Assembly Instance 102

Configuration Size 0

ProSoft Technology, Inc. Page 21 of 167

March 22, 2011

Page 22

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

The following illustration shows an example where the module was

configured for a block transfer size of 60 words (input block size = 62 words,

output block size = 61 words):

The following options are available:

Block Transfer Size Input Block Size Output Block Size

60 62 61

120 122 121

240 242 241

4 On the Connection tab, set the RPI value for your project. Click OK to

confirm.

Now the MVI69-MCM module will be visible at the I/O Configuration section.

Page 22 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 23

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

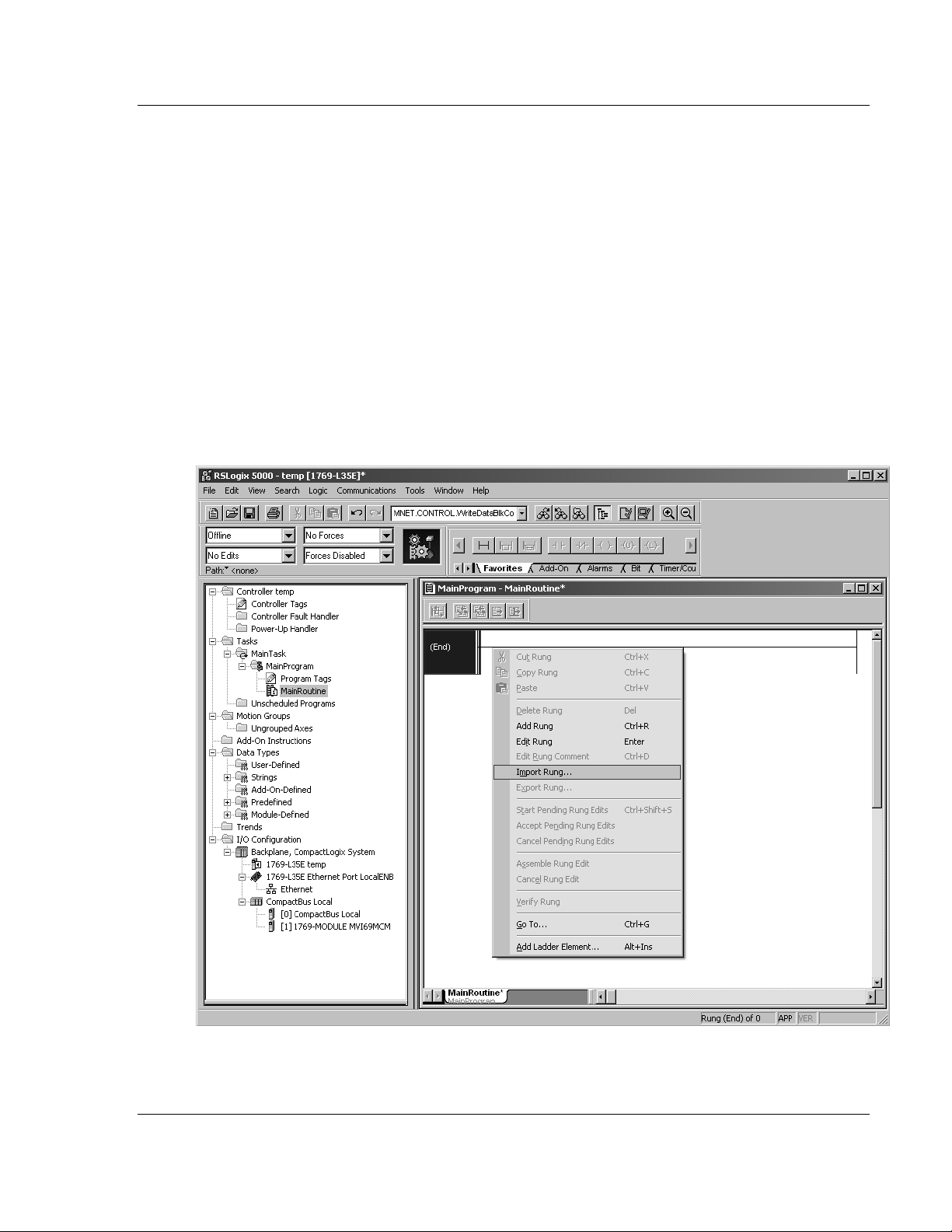

2.1.3 Import the Ladder Rung

1 Open your application in RSLogix 5000.

2 To create a new routine, expand the T

T

ASK

folder.

3 On the M

AIN PROGRAM

folder, click the right mouse button to open a shortcut

menu. On the shortcut menu, choose N

4 In the N

EW ROUTINE

dialog box, enter the name and description of your

routine, and then click OK. In this example we are demonstrating the

importing of the ladder rung using the default MainRoutine. In the case where

you create a routine by an other name for placing the Add-On instruction,

then in your original routine where your other ladder logic is located you need

to add a rung with a jump instruction to the new routine holding the Add-On

instruction.

5 Select an empty rung in the new routine, and then click the right mouse

button to open a shortcut menu. On the shortcut menu, choose "I

R

UNG

…".

ASKS

folder, and then expand the M

EW ROUTINE

.

AIN

MPORT

ProSoft Technology, Inc. Page 23 of 167

March 22, 2011

Page 24

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

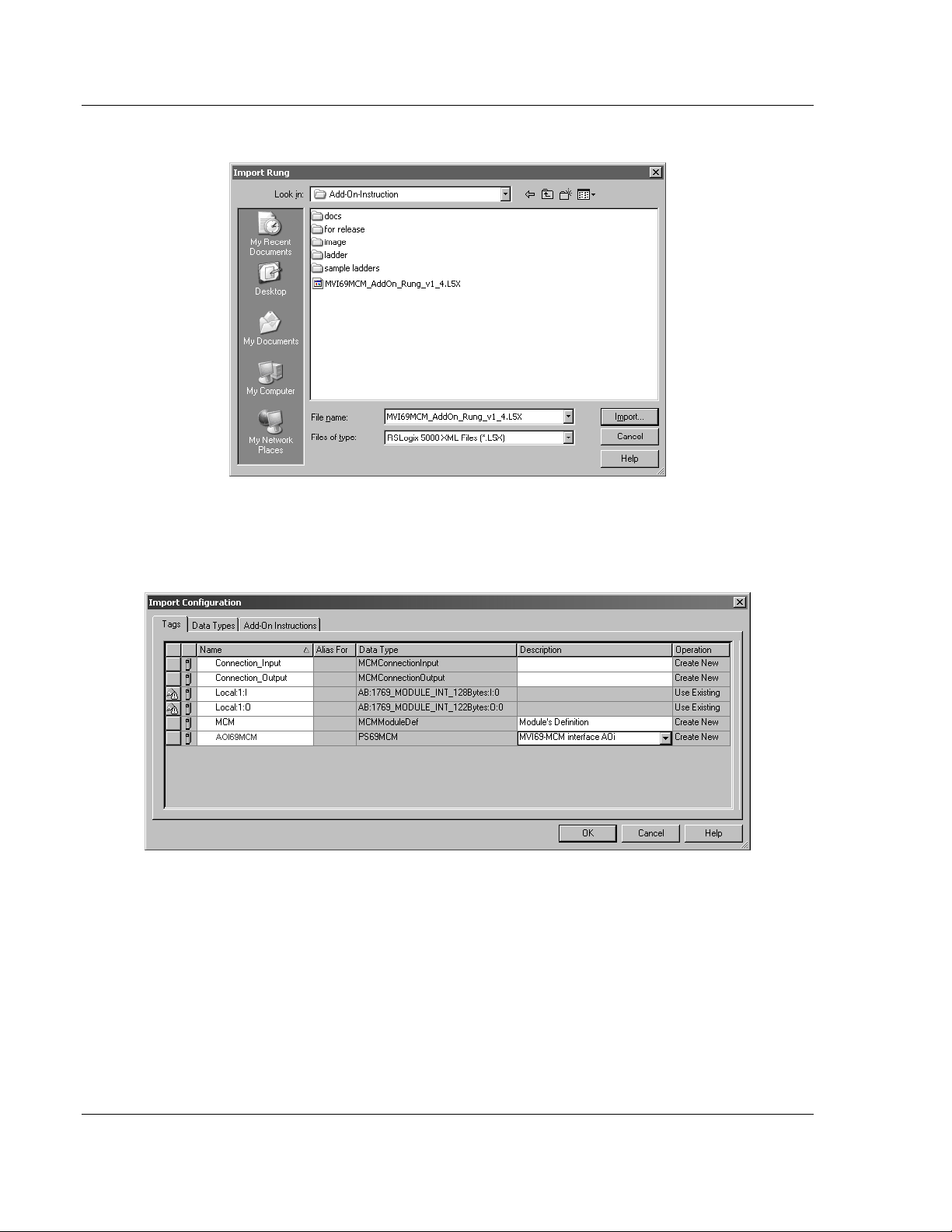

6 Select the MVI69MCM_ADDON_R

UNG_V

1_4.L5X file

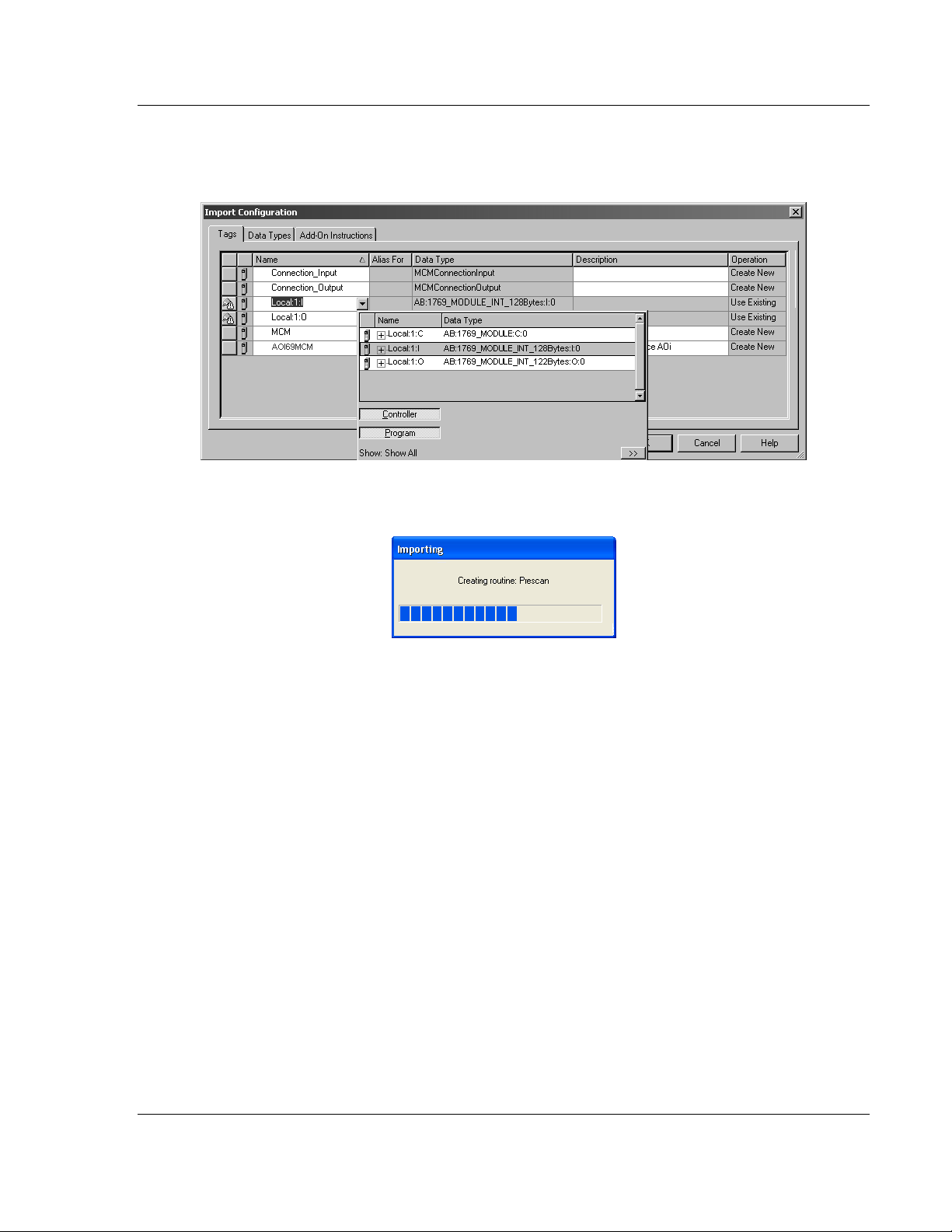

7 The following window will be displayed showing the controller tags to be

created during the import procedure: If desired, the description, "MVI69-MCM

Interface AOI" may be typed into the description field for

MVI69MCM_AddOn_Rung_v1_4.L5x file.

Page 24 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 25

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

8 If you are using the module in a different slot (or remote rack) select the

correct connection input and output variables associated to the module. If

your module is located in slot 1 of the local rack this step is not required.

9 Click OK to confirm the import. RSLogix will indicate that the import is under

progress:

ProSoft Technology, Inc. Page 25 of 167

March 22, 2011

Page 26

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

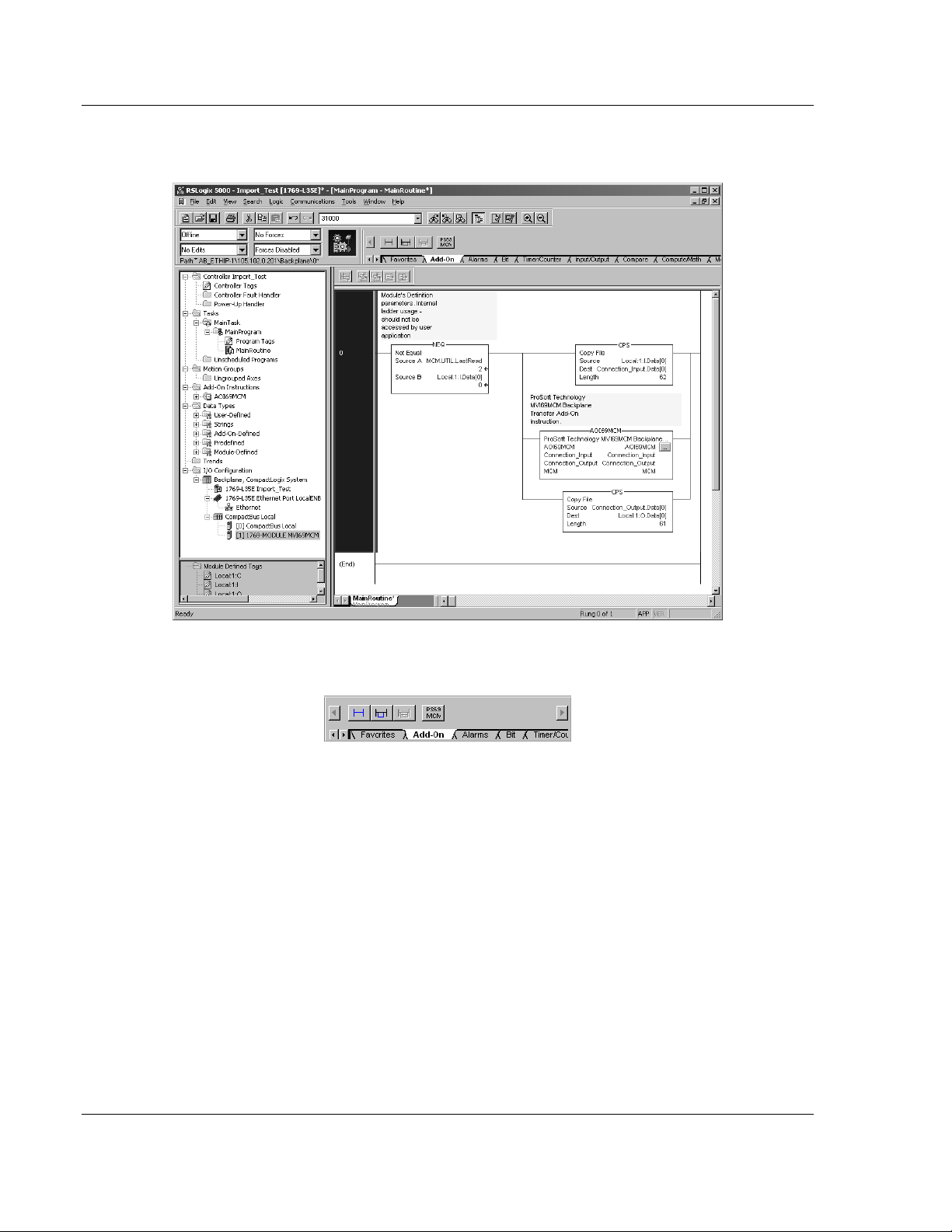

When the import is completed, the new rung with the Add-On instruction will

be visible as shown in the following illustration.

The procedure has also imported new user defined data types, data objects

and the Add-On instruction to be used at your project.

Page 26 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 27

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

10 The imported rung will contain the Add-On instruction with two CPS

instructions as follows below. The CPS instructions are set by default for a

length of 62/61 words as follows:

Edit the above CPS instructions Length field values according to the following

table.

"Block Transfer Size Parameter" –

60/120/240 options)

Connection Parameters: CPS instructions Length field values:

Input Size: Output Size:

62 61 62 61

122 121 122 121

242 241 242 241

Ladder Routine window:

2.1.4 Set the Read/Write Data Lengths

1 The imported rung contains the MCMDATA object Tag arrays R

W

RITEDATA

o READDATA

o

W

RITEDATA

set to the factory default values of 480. These tags will contain:

- data area copied from the module to the processor

- data area copied from the processor to the module

EADDATA

and

ProSoft Technology, Inc. Page 27 of 167

March 22, 2011

Page 28

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

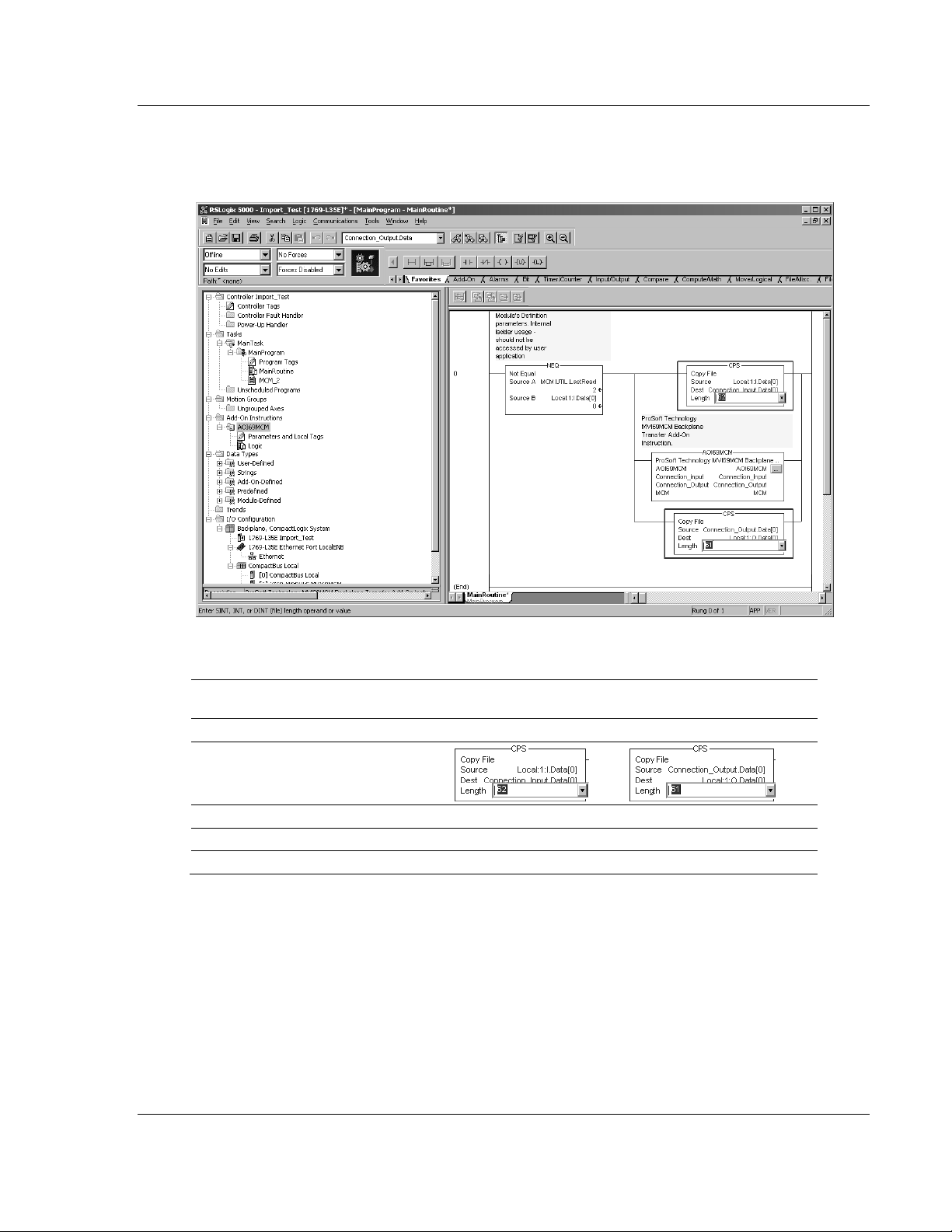

2 If you have changed the R

values in the [B

ACKPLANE

EAD REGISTER COUNT

and W

RITE REGISTER COUNT

69] section of the module’s configuration file, you

must adjust these array sizes to match those values.

Example: If in the configuration file section [Backplane 69] the parameter

setting is "Read Register Count : 1440" then set ReadData tag array size to

INT[1440].

Page 28 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 29

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

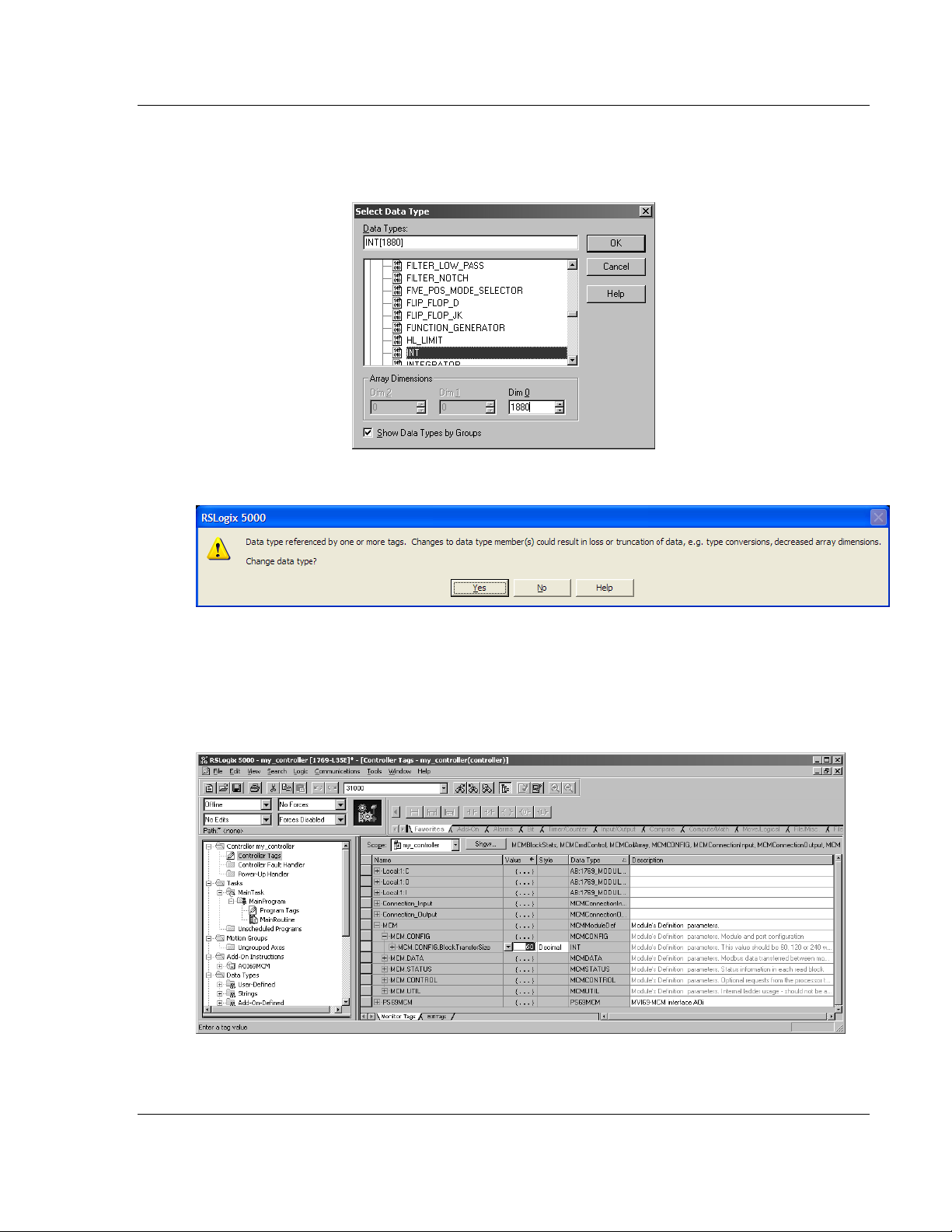

Example: If in the configuration file section [Backplane 69] the parameter

setting is "Write Register Count : 1880" then set WriteData tag array size to

INT[1880].

You will be prompted to confirm the changes. Click Yes to continue.

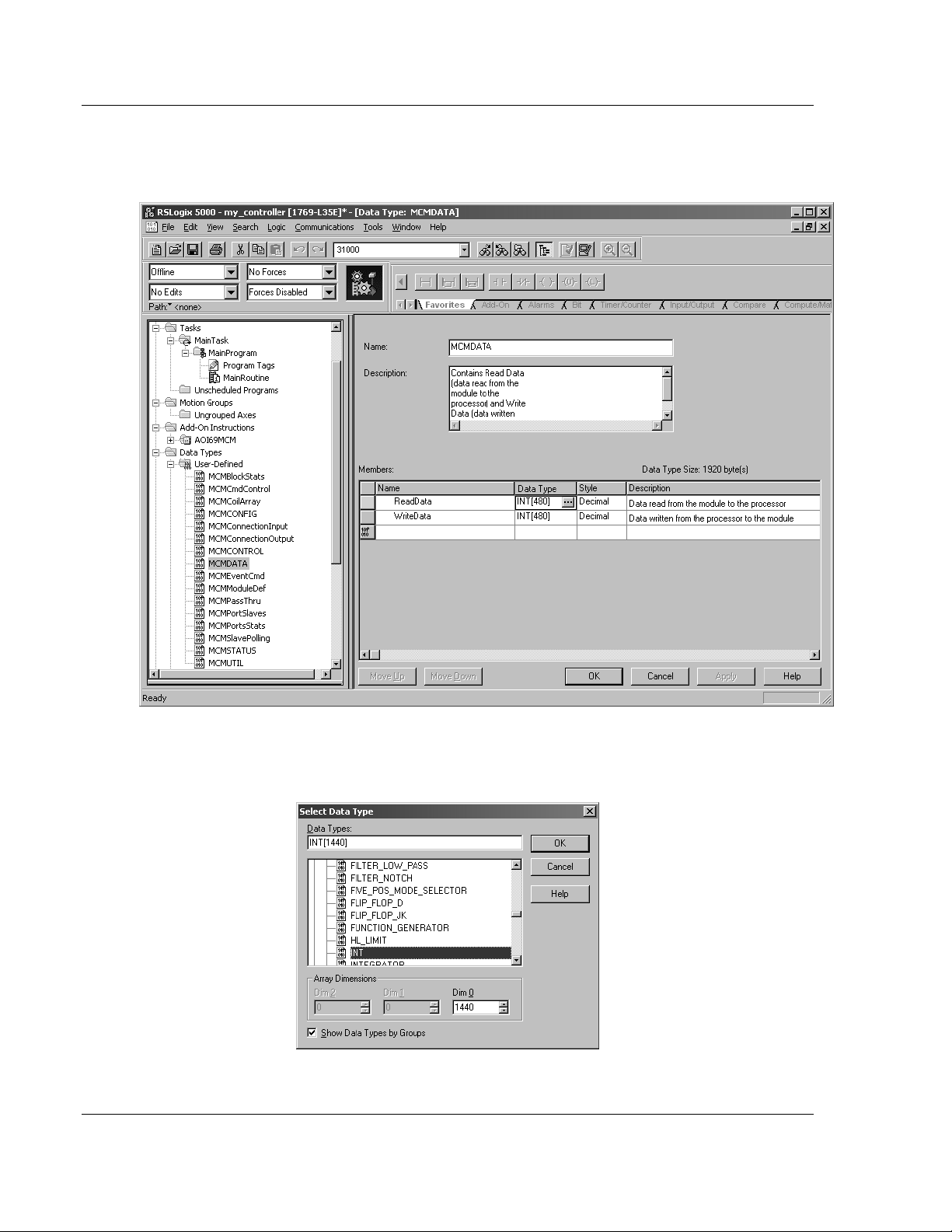

2.1.5 Set the Block Transfer Parameter Size

The MCM.B

Instruction. If you have configured a different block transfer size in the module’s

configuration file, you must change this value to match.

LOCKTRANSFERSIZE

controller tag is set to 60 in the Add-On

Edit the tag values according to the following table.

ProSoft Technology, Inc. Page 29 of 167

March 22, 2011

Page 30

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

Module Properties dialog box: Controller Organizer’s Controller Tags folder:

Connection Parameters: MCM.BlockTransferSize tag value:

Input Size: Output Size:

62 61 60

122 121 120

242 241 240

2.1.6 Set the Connection Input Size Values

If you change the block transfer size, you must also change the following data

types:

MCMC

Add-On instruction.

MCMC

the Add-On instruction.

Access the user data type definition MCMC

ONNECTIONINPUT

ONNECTIONOUTPUT

– Data type used for the Connection Input pin in the

– Data type used for the Connection Output pin in

ONNECTIONINPUT

as follows

Edit the tag values according to the following table.

Module Properties dialog box: Controller Organizer’s Controller Tags folder:

Connection Parameters: MCMConnectionInput.Data tag value:

Input Size:

62 62

122 122

242 242

Page 30 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 31

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

Access the user data type definition MCMC

ONNECTIONOUTPUT

as follows:

Edit the tag values according to the following table.

Module Properties dialog box: Controller Organizer’s Controller Tags folder:

Connection Parameters: MCMConnectionOutput.Data tag value:

Output Size:

61 61

121 121

241 241

2.1.7 Adding Multiple Modules (Optional)

Important: If your application requires more than one MVI69-MCM module into the same project,

follow the steps below and make certain that both modules are assigned identical Block Transfer

Sizes.

ProSoft Technology, Inc. Page 31 of 167

March 22, 2011

Page 32

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

1 In the I/O C

ONFIGURATION

folder, click the right mouse button to open a

shortcut menu, and then choose New Module.

2 Select 1769-MODULE

3 Fill the module properties as follows:

Parameter Value

Name Enter a module identification string. Example:

MVI69MCM_2

Description Enter a description for the module. Example: ProSoft

communication module for Serial Modbus communications.

Comm Format Select Data-INT

Slot Enter the slot number in the rack where the MV69-MCM

module will be installed.

Input Assembly Instance 101

Input Size 62 / 122 / 242

Output Assembly Instance 100

Output Size 61 / 121 / 241

Configuration Assembly Instance 102

Configuration Size 0

Page 32 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 33

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

4 Click OK to confirm. The new module is now visible:

5 Expand the T

6 On the M

menu. On the shortcut menu, choose N

ASKS

folder, and then expand the M

AINPROGRAM

AINTASK

folder.

folder, click the right mouse button to open a shortcut

EW ROUTINE

.

7 In the New Routine dialog box, enter the name and description of your

routine, and then click OK.

8 Select an empty rung in the new routine, and then click the right mouse

button to open a shortcut menu. On the shortcut menu, choose "I

R

UNG

…".

MPORT

Note: It is not necessary to create a completely new routine. It is possible to add the MVI69MCM_2 module in the previously created routine. If it is desired to create a new routine the user

needs to also create a rung with a jump instruction in the previous routine to the new routine.

ProSoft Technology, Inc. Page 33 of 167

March 22, 2011

Page 34

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

9 Select the file MVI69MCM_ADDON_R

UNG_V

1_4.L5X

10 The following window will be displayed showing the tags to be imported:

Page 34 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 35

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

11 Associate the I/O connection variables to the correct module. The default

values are L

OCAL

:1:I and L

OCAL

:1:O. These require re-assignment to the

new module's location.

ProSoft Technology, Inc. Page 35 of 167

March 22, 2011

Page 36

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

12 Change the default tags MCM and AOI69MCM to avoid conflict with existing

tags. This example procedure will append the string "_2" as follows:

13 You will be prompted to confirm your change. Click OK to continue.

Page 36 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 37

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

14 Click OK to confirm.

ProSoft Technology, Inc. Page 37 of 167

March 22, 2011

Page 38

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

15 Because the second module's logic was created in a new routine, enter a

rung in the Main routine with a JSR instruction to the new routine to enable

the PLC logic to communicate with both modules.

The setup procedure is now complete. Save the project and download the

application to your CompactLogix processor.

Page 38 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 39

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

2.1.8 Connecting Your PC to the Processor

1 Connect the right-angle connector end of the cable to your controller at the

communications port.

2 Connect the straight connector end of the cable to the serial port on your

computer.

2.1.9 Download the Sample Program to the Processor

Configuring the RSLinx Driver for the PC COM Port

If RSLogix is unable to establish communication with the processor, follow these

steps.

1 Open RSLinx.

ProSoft Technology, Inc. Page 39 of 167

March 22, 2011

Page 40

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

2 Open the C

OMMUNICATIONS

menu, and choose C

ONFIGURE DRIVERS

.

This action opens the Configure Drivers dialog box.

Note: If the list of configured drivers is blank, you must first choose and configure a driver from the

Available Driver Types list. The recommended driver type to choose for serial communication with

the processor is RS-232 DF1 Devices.

Page 40 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 41

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

1 Click to select the driver, and then click C

ONFIGURE

. This action opens the

Configure RS-232 DF1 Devices dialog box.

2 Click the A

UTO-CONFIGURE

button. RSLinx will attempt to configure your

serial port to work with the selected driver.

3 When you see the message Auto Configuration Successful, click the OK

button to dismiss the dialog box.

Note: If the auto-configuration procedure fails, verify that the cables are connected correctly

between the processor and the serial port on your computer, and then try again. If you are still

unable to auto-configure the port, refer to your RSLinx documentation for further troubleshooting

steps.

Downloading to the Processor

Note: The key switch on the front of the CompactLogix processor must be in the REM

OR

PROG

position.

1 If you are not already online to the processor, open the C

menu, and then choose D

OWNLOAD.

RSLogix will establish communication

OMMUNICATIONS

with the processor.

ProSoft Technology, Inc. Page 41 of 167

March 22, 2011

Page 42

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

2 When communication is established, RSLogix will open a confirmation dialog

box. Click the D

OWNLOAD

button to transfer the sample program to the

processor.

3 RSLogix will compile the program and transfer it to the processor. This

process may take a few minutes.

4 When the download is complete, RSLogix will open another confirmation

dialog box. Click OK to switch the processor from P

ROGRAM

mode to R

UN

mode.

Note: If you receive an error message during these steps, refer to your RSLogix documentation to

interpret and correct the error.

Page 42 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 43

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

Disabling the RSLinx Driver for the Com Port on the PC

The communication port driver in RSLinx can occasionally prevent other

applications from using the PC’s COM port. If you are not able to connect to the

module’s configuration/debug port using ProSoft Configuration Builder (PCB),

HyperTerminal or another terminal emulator, follow these steps to disable the

RSLinx Driver.

1 Open RSLinx and go to C

OMMUNICATIONS

>RSWHO

2 Make sure that you are not actively browsing using the driver that you wish to

stop. The following shows an actively browsed network:

3 Notice how the DF1 driver is opened, and the driver is looking for a processor

on node 1. If the network is being browsed, then you will not be able to stop

this driver. To stop the driver your RSWho screen should look like this:

Branches are displayed or hidden by clicking on the or the icons.

4 When you have verified that the driver is not being browsed, go to

C

OMMUNICATIONS>CONFIGURE DRIVERS

ProSoft Technology, Inc. Page 43 of 167

March 22, 2011

Page 44

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

You may see something like this:

If you see the status as running, you will not be able to use this com port for

anything other than communication to the processor. To stop the driver press

the S

TOP

button on the side of the window:

5 After you have stopped the driver you will see the following:

6 You may now use the com port to connect to the debug port of the module.

Note: You may need to shut down and restart your PC before it will allow you to stop the driver

(usually only on Windows NT machines). If you have followed all of the above steps, and it will not

stop the driver, then make sure you do not have RSLogix open. If RSLogix is not open, and you

still cannot stop the driver, then reboot your PC.

Page 44 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 45

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

2.1.10 Connect your PC to the Module

With the module securely mounted, connect your PC to the Configuration/Debug

port using an RJ45-DB-9 Serial Adapter Cable and a Null Modem Cable.

1 Attach both cables as shown.

2 Insert the RJ45 cable connector into the Configuration/Debug port of the

module.

3 Attach the other end to the serial port on your PC.

ProSoft Technology, Inc. Page 45 of 167

March 22, 2011

Page 46

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

2.2 Using ProSoft Configuration Builder

ProSoft Configuration Builder (PCB) provides a quick and easy way to manage

module configuration files customized to meet your application needs. PCB is not

only a powerful solution for new configuration files, but also allows you to import

information from previously installed (known working) configurations to new

projects.

2.2.1 Setting Up the Project

To begin, start ProSoft Configuration Builder. If you have used other Windows

configuration tools before, you will find the screen layout familiar. ProSoft

Configuration Builder’s window consists of a tree view on the left, an information

pane and a configuration pane on the right side of the window. When you first

start ProSoft Configuration Builder, the tree view consists of folders for Default

Project and Default Location, with a Default Module in the Default Location

folder. The following illustration shows the ProSoft Configuration Builder window

with a new project.

Your first task is to add the MVI69-MCM module to the project.

1 Use the mouse to select D

EFAULT MODULE

in the tree view, and then click the

right mouse button to open a shortcut menu.

Page 46 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 47

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

2 On the shortcut menu, select C

HOOSE MODULE TYPE

. This action opens the

Choose Module Type dialog box.

3 In the Product Line Filter area of the dialog box, select MVI69. In the Select

Module Type dropdown list, select MVI69-MCM, and then click OK to save

your settings and return to the ProSoft Configuration Builder window.

ProSoft Technology, Inc. Page 47 of 167

March 22, 2011

Page 48

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

2.2.2 Renaming PCB Objects

Notice that the contents of the information pane and the configuration pane

changed when you added the module to the project.

At this time, you may wish to rename the Default Project and Default Location

folders in the tree view.

1 Select the object, and then click the right mouse button to open a shortcut

menu. From the shortcut menu, choose R

ENAME

.

2 Type the name to assign to the object.

3 Click away from the object to save the new name.

Configuring Module Parameters

1 Click on the [+] sign next to the module icon to expand module information.

2 Click on the [+] sign next to any icon to view module information and

configuration options.

3 Double-click any icon to open an Edit dialog box.

4 To edit a parameter, select the parameter in the left pane and make your

changes in the right pane.

5 Click OK to save your changes.

Printing a Configuration File

1 Select the module icon, and then click the right mouse button to open a

shortcut menu.

2 On the shortcut menu, choose V

IEW CONFIGURATION

. This action opens the

View Configuration window.

3 In the View Configuration window, open the F

ILE

menu, and choose P

RINT.

This action opens the Print dialog box.

4 In the Print dialog box, choose the printer to use from the drop-down list,

select printing options, and then click OK.

Page 48 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 49

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

2.3 Downloading the Project to the Module Using a Serial COM port

For the module to use the settings you configured, you must download (copy) the

updated Project file from your PC to the module.

1 In the tree view in ProSoft Configuration Builder, click once to select the

module.

2 Open the Project menu, and then choose M

will scan your PC for a valid com port (this may take a few seconds). When

PCB has found a valid COM port, the Download dialog box will open.

ODULE/DOWNLOAD

. The program

3 Choose the COM port to use from the dropdown list, and then click the

D

OWNLOAD

button.

The module will perform a platform check to read and load its new settings.

When the platform check is complete, the status bar in the Download dialog

box will display the message Module Running.

ProSoft Technology, Inc. Page 49 of 167

March 22, 2011

Page 50

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

2.4 Module Configuration

2.4.1 [Module]

This section defines the configuration for the Module level data.

Module Name

0 to 80 characters

This parameter assigns a name to the module that can be viewed using the

configuration/debug port. Use this parameter to identify the module and the

configuration file.

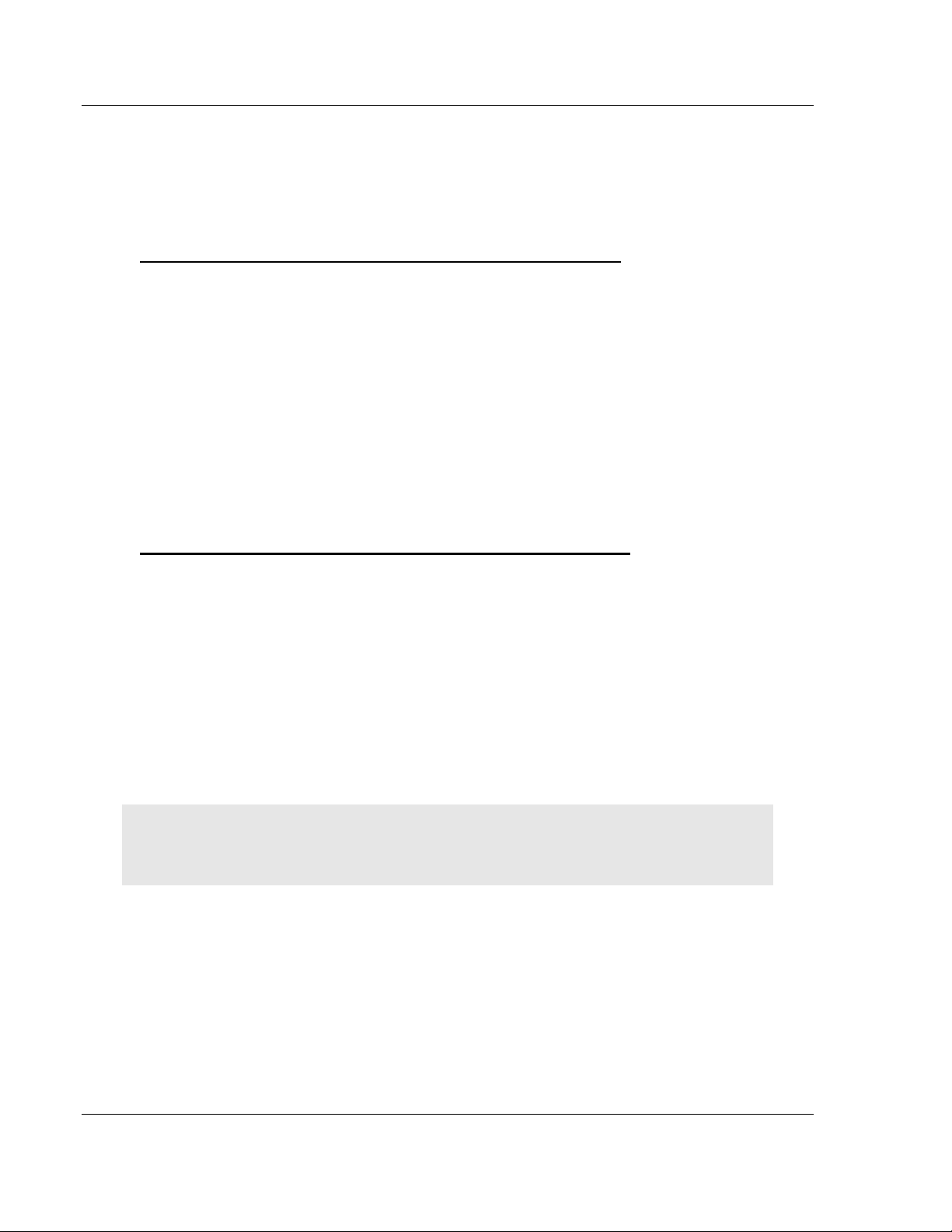

2.4.2 [Backplane 69]

This section provides the module with a unique name, identifies the method of

failure for the communications for the module if the processor is not in run, and

describes how to initialize the module upon startup.

The following example shows a sample [Backplane Configuration] section:

Modify each of the parameters based on the needs of your application.

Page 50 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 51

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

Read Register Start

0 to 4999

The Read Register Start parameter specifies the start of the Read Data area in

module memory. Data in this area will be transferred from the module to the

processor.

Note: Total user database memory space is limited to the first 5000 registers of module memory,

addresses 0 through 4999. Therefore, the practical limit for this parameter is 4999 minus the value

entered for Read Register Count, so that the Read Data Area does not try to extend above address

4999. Read Data and Write Data Areas must be configured to occupy separate address ranges in

module memory and should not be allowed to overlap.

Read Register Count

0 to 5000

The Read Register Count parameter specifies the size of the Read Data area of

module memory and the number of registers to transfer from this area to the

processor, up to a maximum of 5000 words.

Note: Total Read Register Count and Write Register Count cannot exceed 5000 total registers.

Read Data and Write Data Areas must be configured to occupy separate address ranges in

module memory and should not be allowed to overlap.

Write Register Start

0 to 4999

The Write Register Start parameter specifies the start of the Write Data area in

module memory. Data in this area will be transferred in from the processor.

Note: Total user database memory space is limited to the first 5000 registers of module memory,

addresses 0 through 4999. Therefore, the practical limit for this parameter is 4999 minus the value

entered for Write Register Count, so that the Write Data Area does not try to extend above address

4999. Read Data and Write Data Areas must be configured to occupy separate address ranges in

module memory and should not be allowed to overlap.

ProSoft Technology, Inc. Page 51 of 167

March 22, 2011

Page 52

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

Write Register Count

0 to 5000

The Write Register Count parameter specifies the size of the Write Data area of

module memory and the number of registers to transfer from the processor to

this memory area, up to a maximum value of 5000 words.

Note: Total Read Register Count and Write Register Count cannot exceed 5000 total registers.

Read Data and Write Data Areas must be configured to occupy separate address ranges in

module memory and should not be allowed to overlap.

Backplane Fail Count

0 to 65535

This parameter specifies the number of consecutive backplane transfer failures

that can occur before communications should be halted.

Error/Status Block Pointer

-1 to 4939

Starting register location in virtual Modbus database for the error/status table. If a

value of -1 is entered, the error/status data will not be placed in the database. All

other valid values determine the starting location of the data. This data area

includes the module version information and all server error/status data. Refer to

Status Data Definition for more information.

Initializing Output Data

YES or NO

This parameter determines if the output data for the module should be initialized

with values from the processor. If the value is set to NO (0), the output data will

be initialized to 0. If the value is set to YES (1), the data will be initialized with

data from the processor. Use of this option requires associated ladder logic to

pass the data from the processor to the module.

Block Transfer Size

60, 120 or 240

This read-only parameter specifies the number of words in each block transferred

between the module and processor.

Page 52 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 53

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

2.4.3 [MCM Port x]

The information in this section applies to both Port 1 and Port 2.

Enable

Yes or No

This parameter specifies whether to enable or disable the port. No = Port

Disabled, Yes = Port Enabled.

Type

0=Master, 1=Slave, 2=PT Formatted, 3=PT Formatted Swap

This parameter specifies which device type the port will emulate. Refer to Pass-

Through Control Blocks (page 129) for information on using port types 2 or 3.

ProSoft Technology, Inc. Page 53 of 167

March 22, 2011

Page 54

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

Float Flag

YES or NO

This flag specifies how the Slave driver will respond to Function Code 3, 6, and

16 commands (read and write Holding Registers) from a remote Master when it

is moving 32-bit floating-point data.

If the remote Master expects to receive or will send one complete 32-bit floatingpoint value for each count of one (1), then set this parameter to YES. When set to

YES, the Slave driver will return values from two consecutive 16-bit internal

memory registers (32 total bits) for each count in the read command, or receive

32-bits per count from the Master for write commands. Example: Count = 10,

Slave driver will send 20 16-bit registers for 10 total 32-bit floating-point values.

If, however, the remote Master sends a count of two (2) for each 32-bit floatingpoint value it expects to receive or send, or, if you do not plan to use floatingpoint data in your application, then set this parameter to NO, which is the default

setting.

You will also need to set the Float Start and Float Offset parameters to

appropriate values whenever the Float Flag parameter is set to YES.

Float Start

0 to 32767

This parameter defines the first register of floating-point data. All requests with

register values greater-than or equal to this value will be considered floating-point

data requests. This parameter is only used if the Float Flag is enabled. For

example, if a value of 7000 is entered, all requests for registers 7000 and above

will be considered as floating-point data.

Float Offset

0 to 4999

This parameter defines the start register for floating-point data in the internal

database. This parameter is used only if the Float Flag is enabled. For example,

if the Float Offset value is set to 3000 and the float start parameter is set to 7000,

data requests for register 7000 will use the internal Modbus register 3000.

Protocol

RTU or ASCII

This parameter specifies the Modbus protocol to be used on the port. Valid

protocols are: rtu = Modbus RTU and ascii = Modbus ASCII.

Page 54 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 55

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

Baud Rate

This is the baud rate to be used on the port. Enter the baud rate as a value. For

example, to select 19K baud, enter 19200.

Baud Rate Parameter Value Options

110 110

150 150

300 300

600 600

1200 12 or 1200

2400 24 or 2400

4800 48 or 4800

9600 96 or 9600

19,200 19, 192 or 19200

38,400 38, 384 or 38400

57,600 57 or 576

115,200 115 or 1152

Parity

None, Odd, Even

Parity is a simple error checking algorithm used in serial communication. This

parameter specifies the type of parity checking to use.

All devices communicating through this port must use the same parity setting.

Data Bits

7 or 8

This parameter sets the number of data bits for each word used by the protocol.

All devices communicating through this port must use the same number of data

bits.

Stop Bits

1 or 2

Stop bits signal the end of a character in the data stream. For most applications,

use one stop bit. For slower devices that require more time to re-synchronize,

use two stop bits.

All devices communicating through this port must use the same number of stop

bits.

RTS On

0 to 65535 milliseconds

This parameter sets the number of milliseconds to delay after Ready To Send

(RTS) is asserted before data will be transmitted.

ProSoft Technology, Inc. Page 55 of 167

March 22, 2011

Page 56

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

RTS Off

0 to 65535 milliseconds

This parameter sets the number of milliseconds to delay after the last byte of

data is sent before the RTS modem signal will be set low.

Minimum Response Delay

0 to 65535

This parameter is used only when the port is configured as a slave. It sets the

number of milliseconds to wait before responding to a command received on the

port from a remote Master. This delay is sometimes required to accommodate

slower Master devices.

Use CTS Line

YES or NO

This parameter specifies if the Clear To Send (CTS) modem control line is to be

used or not. If the parameter is set to NO, the CTS line will not be monitored. If

the parameter is set to YES, the CTS line will be monitored and must be high

before the module will send data. Normally, this parameter is required when halfduplex modems are used for communication (2-wire). This procedure is

commonly referred to as hardware handshaking.

Slave Address

1 to 255

This parameter defines the Slave Node Address for the internal database. All

requests received by the port with this address are processed by the module.

Verify that each device has a unique address on a network. Valid range for this

parameter is 1 to 255.

Bit Input Offset

0 to 4999

This parameter specifies the offset address into the internal Modbus database for

network requests for Modbus function 2 commands. For example, if the value is

set to 150, an address request of 0 will return the value at register 150 in the

database.

Word Input Offset

0 to 4999

This parameter specifies the offset address into the internal Modbus database for

network requests for Modbus function 4 commands. For example, if the value is

set to 150, an address request of 0 will return the value at register 150 in the

database.

Page 56 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 57

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

Output Offset

0 to 4999

This parameter specifies the offset address into the internal Modbus database for

network requests for Modbus function 1, 5 or 15 commands. For example, if the

value is set to 100, an address request of 0 will correspond to register 100 in the

database.

Hold Offset

0 to 4999

This parameter specifies the offset address in the internal Modbus database for

network requests for Modbus function 3, 6, or 16 commands. For example, if a

value of 50 is entered, a request for address 0 will correspond to the register 50

in the database.

Command Count

0 to 100

This parameter specifies the number of commands to be processed by the

Modbus Master port.

Minimum Command Delay

0 to 65535

This parameter specifies the number of milliseconds to wait between issuing

each command. This delay value is not applied to retries.

Command Error Pointer

-1 to 4899

This parameter sets the address in the internal Modbus database where the

command error will be placed. If the value is set to -1, the data will not be

transferred to the database. The valid range of values for this parameter is -1 to

4899. For example, if this parameter is configured for 1000, the command errors

will be copied to the database as follows:

1000: error code for command 0

1001: error code for command 1

and so on.

An error code of 0 means that the command was successfully sent (no error).

Refer to Status Data Definition for the command error code listings.

ProSoft Technology, Inc. Page 57 of 167

March 22, 2011

Page 58

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

Response Timeout

0

TO

65535 milliseconds

This parameter sets the command response timeout period in 1 millisecond

increments. This is the time that a port configured as a Master will wait for a

response from the addressed slave before re-transmitting the command (Retries)

or skipping to the next command in the Command List. The value to set depends

on the communication network used and the expected response time (plus a little

extra) of the slowest device on the network.

Retry Count

0 to 10

This parameter specifies the number of times a command will be retried if it fails.

Error Delay Counter

0 to 65535

This parameter specifies the number of polls to skip on the slave before trying to

re-establish communications. After the slave fails to respond, the Master will skip

commands to be sent to the slave the number of times entered in this parameter.

Page 58 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 59

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

2.4.4 [Modbus Port x Commands]

The [Modbus Port x Commands] section of the configuration file defines the

command list specifications for the Master port. The information in this section

applies to both Port 1 and Port 2.

Command List Overview

In order to interface the MVI69-MCM module with MODBUS slave devices, you

must construct a command list. The commands in the list specify the slave

device to be addressed, the function to be performed (read or write), the data

area in the device to interface with and the registers in the internal database to

be associated with the device data. The Master command list supports up to 100

commands.

The command list is processed from top (command #0) to bottom. A poll interval

parameter is associated with each command to specify a minimum delay time in

number of seconds between the issuance of a command. If the user specifies a

value of 10 for the parameter, the command will be executed no more frequently

than every 10 seconds.

Write commands have a special feature, as they can be set to execute only if the

data in the write command changes, which can improve network performance. If

the register data values in the command have not changed since the command

was last issued, the command will not be executed. To enable this feature, set

the enable code for the command to a value of 2.

Modbus Command Configuration

The ProSoft Technology MCM Modbus Master and Slave communication drivers

support several data read and write commands. When configuring a Master port,

the decision on which command to use is made depending on the type of data

being addressed, and the level of Modbus support in the slave equipment. When

configuring as a slave, it may be important to understand how the Modbus

commands function in order to determine how to structure the application data.

ProSoft Technology, Inc. Page 59 of 167

March 22, 2011

Page 60

Configuring the MVI69-MCM Module MVI69-MCM ♦ CompactLogix or MicroLogix Platform

User Manual Modbus Communication Module

Floating Point Support

The movement of floating point data between the MCM module and other

devices is easily accomplished as long as the device supports IEEE 754 Floating

Point format. This IEEE format is a 32-bit single precision floating point format.

The programming necessary to move the floating point data takes advantage of

the CPS command that exists in the Compact Logix and SLC processors. The

CPS command is unique for CPX/SLC data movement commands in that it is an

untyped function, meaning that no data conversion is done when moving data

between file types (that is, it is an image copy not a value copy).

The structure of the CPS command to move data from a Floating Point file into

an integer file (something you would do to move floating point values to the

module) is as follows:

This command will move one floating point value in two 16 bit integer images to

the integer file. For multiple floating point values increase the count field by a

factor of 2 per floating point value.

The structure of the COP command to move data from an Integer file to a

Floating Point file (something you would do to receive floating point values from

the module) is as follows:

This command will move two 16 bit integer registers containing one floating point

value image to the floating point file. For multiple values increase the count field.

Page 60 of 167 ProSoft Technology, Inc.

March 22, 2011

Page 61

MVI69-MCM ♦ CompactLogix or MicroLogix Platform Configuring the MVI69-MCM Module

Modbus Communication Module User Manual

ENRON Floating Point Support

Many manufacturers have implemented special support in their drivers to support

what is commonly called the Enron version of the MODBUS protocol. In this