Page 1

MODEL

SERVICE MANUAL

DVD-300

CAUTION : Before servicing this chassis, read the "PRODUCT SAFETY SERVICE FOR VIDEO PRODUCTS" section

on page 2 of this manual.

CONTENTS

SERVICE PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . 2,3

BLOCK DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ELECTRICAL TROUBLE SHOOTING GUIDE. . . . . . . . . . 5,15

PRINTED CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16,20

REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . 21,24

Page 2

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

CAUTION: DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY AND

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT

MANUFACTURER'S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT

ONLY VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR

ANY RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY CHECKS

AND SERVICING GUIDELINES. TO DO OTHERWISE, INCREASES THE RISK OF

POTENTIAL HAZARDS AND INJURY TO THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION

FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRECTED, A CHECK

SHOULD BE MADE OF THE FOLLOWING.

SUBJECT: FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY AS

TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS. THIS IS

ESPECIALLY IMPORTANT ON THOSE MODULES WITCH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS

INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN RELIEFS, POWER

SUPPLY CORDS, AND OTHER HARDWARE HAVE BEEN REINSTALLED PER

ORIGINAL DESIGN. BE SURE THAT THE SAFETY PURPOSE OF THE

POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS. BE

CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE DF DAMAGE OR DETERIORATION TO

PARTS AND COMPONENTS, FOR FRAYED LEADS AND DAMAGED

INSULATION (INCLUDING A.C. CORD), AND REPLACE IF NECESSARY

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING TUBE OR A

RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUDING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES. FLAMEPROOF RESISTORS,

CAPACITORS, ETC. MUST BE REPLACED WITH EXACT FACTORY TYPES,

DO NOT USE REPLACEMENT COMPONENTS OTHER THAN THOSE

SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

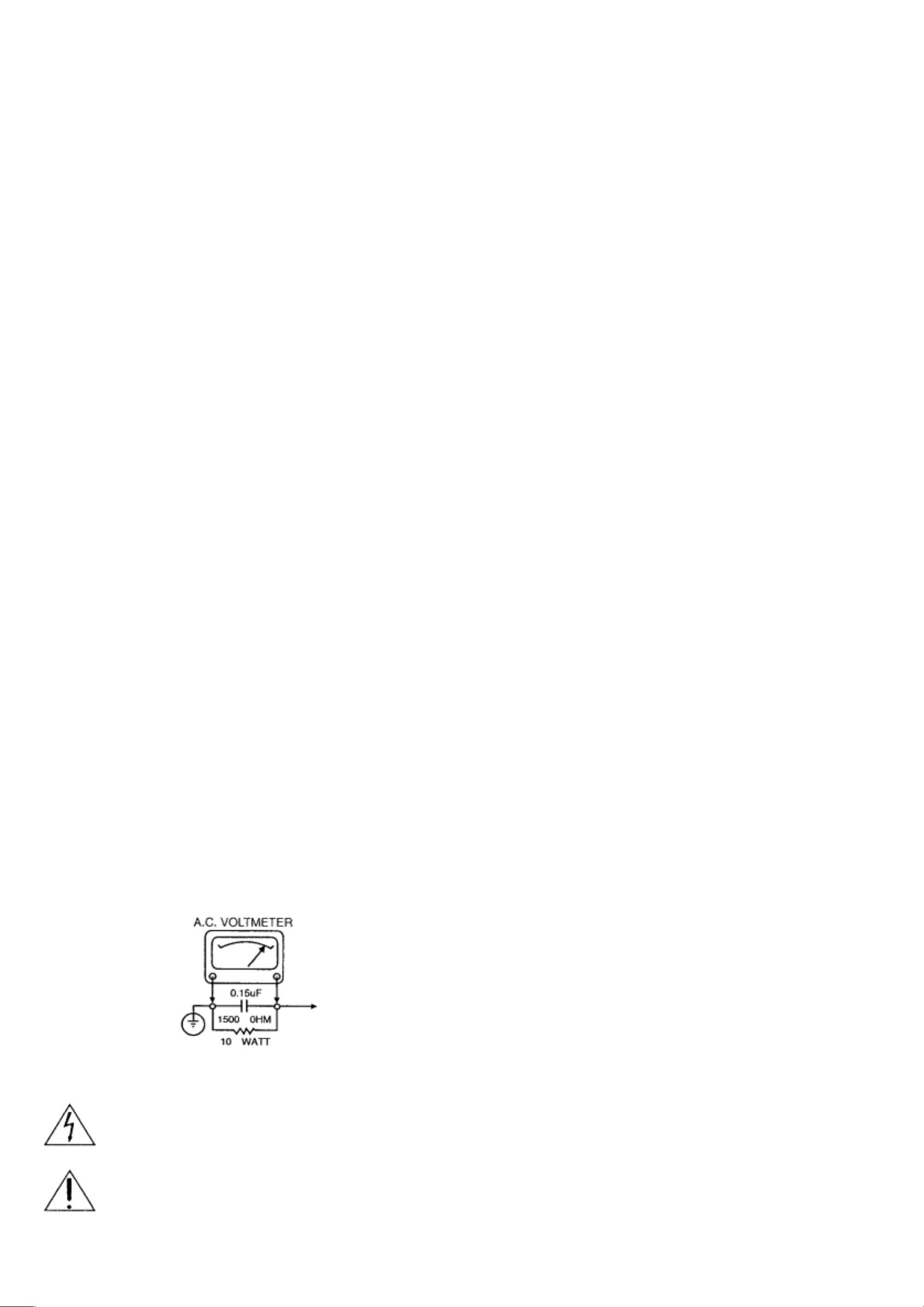

7. AFTER RE-ASSEMBLY OF THE SET, ALWAYS PERFORM AN A.C. LEAKAGE

TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET, (THE

CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HANDLE AND

SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE WITHOUT DANGER

OF ELECTRICAL SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER

DURING THIS TEST, MAKE SURE TO USE AN A.C. VOLTMETER. HAVING

5000 OHMS PER VOLT OR MORE SENSITIVITY, IN THE FOLLOWING

MANNER; CONNECT A 1500 OHMS 10 WATT RESISTOR, PARALLELED BY

A.15 MFD. 150V A.C. TYPE CAPACITOR BETWEEN A KNOWN GOOD EARTH

GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC

PARTS, ONE AT A TIME. MEASURE THE A.C. VOLTAGE ACROSS THE

COMBINATION OF 1500 OHM RESISTOR AND 15 MFD CAPACITOR.

REVERSE THE A.C. PLUG AND REPEAT A.C. ANY VOLTAGE

MEASUREMENTS FOR EACH EXPOSED METALLIC PART. VOLTAGE

MEASURED MUST NOT EXCEED 75 VOLTS R.M.S. THIS CORRESPONDS

TO 0.5 MILLIAMP A.C. ANY VALUE EXCEEDING THIS LIMIT CONSTITUTES A

POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL

COVER THE SUBJECT OF

X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER,

THIS TUBE DOES NOT EMIT X-RYS WHEN THE HIGH VOLTAGE IS AT THE

FACTORY SPECIFIED LEVEL. THE PROPER VALUE IS GIVEN IN THE

APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A

FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER

CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF

DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T ANODE CONNECTORS MUST BE USED.

DEGAUSSING SHIELDS ALSO SERVE AS AN X-RAY SHIELD IN COLOR SETS,

ALWAYS RE-INSTALL THEM.

3. IT IS ESSENTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRATION OF

THE METER SHOULD BE CHECKED PERIODICALLY AGAINST A

REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE AT YOUR

DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY, THERE IS

NO POSSIBILITY OF AN

CHASSIS IS SERVICED, THE BRIGHTNESS SHOULD BE RUN UP AND DOWN

WHILE MONITORING THE HIGH VOLTAGE WITH A METER TO BE CERTAIN

THAT THE HIGH VOLTAGE DOES NOT EXCEED THE SPECIFIED VALUE AND

THAT IT IS REGULATING CORRECTLY. WE SUGGEST THAT YOU AND YOUR

SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE

REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING

PROCEDURE AND THAT THE HIGH VOLTAGE READING BE RECORDED ON

EACH CUSTOMER'S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN A

PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE AVOID BEING

UNNECESSARILY CLOSE TO THE PICTURE TUBE AND THE HIGH VOLTAGE

SUPPLY DO NOT OPERATE THE PRODUCT LONGER THAN IT IS NECESSARY

TO LOCATE THE CAUSE OF EXCESSIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS(WHERE

USED).

X-RADIATION. THE ONLY POTENTIAL SOURCE OF

X-RADIATION PROBLEM. EVERY TIME A COLOR

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTEGRAL

IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE TAKEN TO

AVOID DAMAGE DURING INSTALLATION, AVOID SCRATCHING THE TUBE. IF

SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT: TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS. CUBBYHOLE OR

CLOSELY FITTING SHELF SPACE, OVER OR CLOSE TO HEAT DUCT, OR IN

THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS

WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT REAR VENTING.

THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE

SCARVES OR OTHER COVERINGS WHICH MIGHT OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL

MOUNTING KIT, MUST FOLLOW THE FACTORY APPROVED MOUNTING

INSTRUCTIONS. A PRODUCT MOUNTED TO A SHELF OR PLATFORM MUST

RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT THICKNESS IN SPACERS)

TO PROVIDE ADEQUATE AIR FLOW ACROSS THE BOTTOM. BOLTS OR

SCREWS USED FOR FASTENERS MUST NOT TOUCH ANY PARTS OR

WIRING. PERFORM LEAKAGE TEST ON CUSTOMIZED INSTALLATIONS.

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE, CONDUIT, ETC.

SUBJECT GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN

EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF UNINSULATED "DANGEROUS

VOLTAGE" THAT MAY BE OF SUFFICIENT MAGNITUDE TO

CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS

INTENDED TO ALERT THE SERVICE PERSONNEL TO THE

PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE

LITERATURE.

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART CAUTION THE CUSTOMER ON THE HAZARDS OF

TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS THRESHOLDS

OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND WHICH

HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES, INC. FOR USE

WITH THEIR SPECIFIC MODEL OF TELEVISION RECEIVER OR

GENERICALLY APPROVED FOR USE WITH TV'S OF THE SAME OR LARGER

SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS. EXPLAIN

THAT A FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET

CAN LEAD TO DISASTROUS CONSEQUENCES TO HOME AND FAMILY.

2

Page 3

SERVICING PRECAUTIONS

CAUTION : Before servicing the DVD covered by this

service data and its supplements and ADDENDUMS, read

and follow the SAFETY PRECAUTIONS NOTE : if

unforeseen circumstances create conflict between the

following servicing precautions and any of the safety

precautions in this publications, always follow the safety

precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the DVD AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an

electrolytic capacitor

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may

result in an explosion hazard.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface

such as aluminum toil, to prevent electrostatic charge

buildup or exposure of the assembly.

2. Do not spray chemicals on or near this DVD or any of its

assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data,

lubrication of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

witch instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this DVD and/or any of its

electrical assemblies unless all solid-state device heat

sinks are correctly installed.

3. Use only a GROUNDED-tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a "anti-static" can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil, or comparable

conductive material.)

6. Always connect test instrument ground lead to the

appropriate ground before connection the test

instrument positive lead. Always remove the test

instrument ground lead last.

Insulation Checking Procedure

Disconnect the attachment plug trom the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation

resistance between each blade of the attachment plug and

accessible conductive parts (Note 1) should be more than

1M ohm.

Note 1 : Accessible Conductive Parts including Metal

panels, input terminals, Earphone jacks, etc.

3

7. Immediately before removing the protective material

from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly

into which the device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion

such as the brushing together of your clothes fabric or the

lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ES device.)

Page 4

4

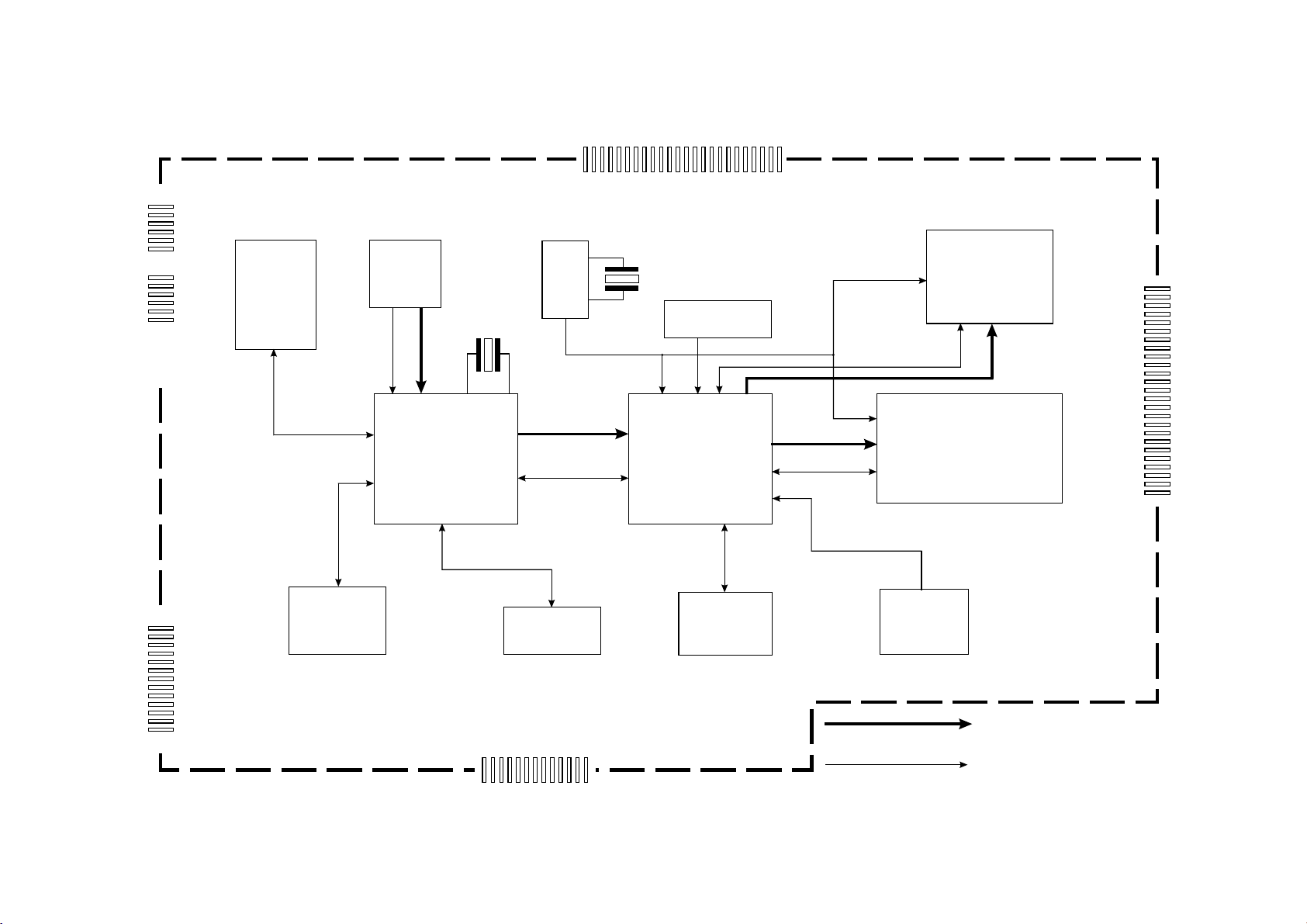

OVERALL BLOCK DIAGRAM

XS100

XS103

SPSP+

LIM

GND

SLED+

SLED-

XS102

GND

CLOSE

GND

OPEN

UNLOD

LOAD

TO PICK UP

MECHANISM

CHASSIS

SERVO

& TRAY

DRIVER

BA5954

& CD6208

CONTROL

BUS

RF AMP

D1890

SERVO &

DVD

PROCESSOR

D1870

TO PICK UP

MECHANISM

CHASSIS

HCU04

33.868MHz

ATAPI

INTERFACE

F-F+T+T-NCBAEGNDVCVCCFDCCD/DVD

NC

(CD-LD)

27MHz

16M SDRAM* 2

27MHz

MPEG-2

DECODER

VS2811

VR-CD

VR-DVDMDLD-CD

AVC C

LD-DVD

GND

AUDIO DATA

VIDEO

ENCODER

CS4955

AUDIO DAC

PCM1723

CHROMA

RED/AGND

LUMA

BLUE/AGND

CVBS2

VGND

G/CVBS1

VGND

12V

GND

SPDIF

5V

ZERO

AGD

CEN

AGD

R-S

AGND

WOOF

AGD

L-S

AGD

L

AGD

R

XS109

TO OUTPUT

BOARD

XS107

RMC

FDATA

FCS

FCLK

GND

3.5V

3.5V

24V

VCC

12V

POWER

NC

NC

TO KEY BOARD

CPU

D1850

12V

POWER5V12V8VVcc

64M DRAM

3.6V

GND

GND

GND

24V

3.5V

3.5V

XS106

EEPROM

24C01

TO POWER

SUPPLY BOARD

4M ROM

29F040

Bus of Data

Control signals

Page 5

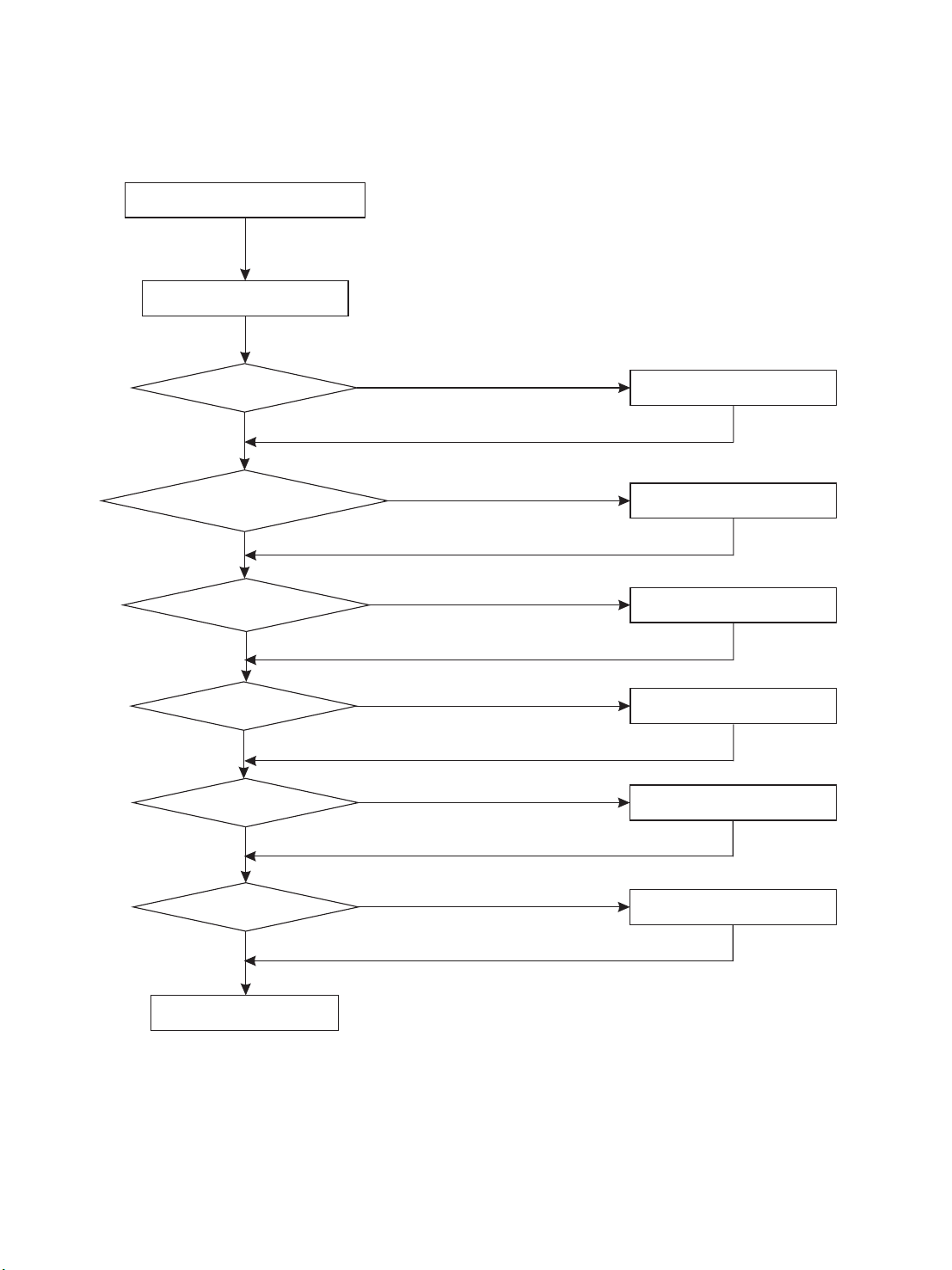

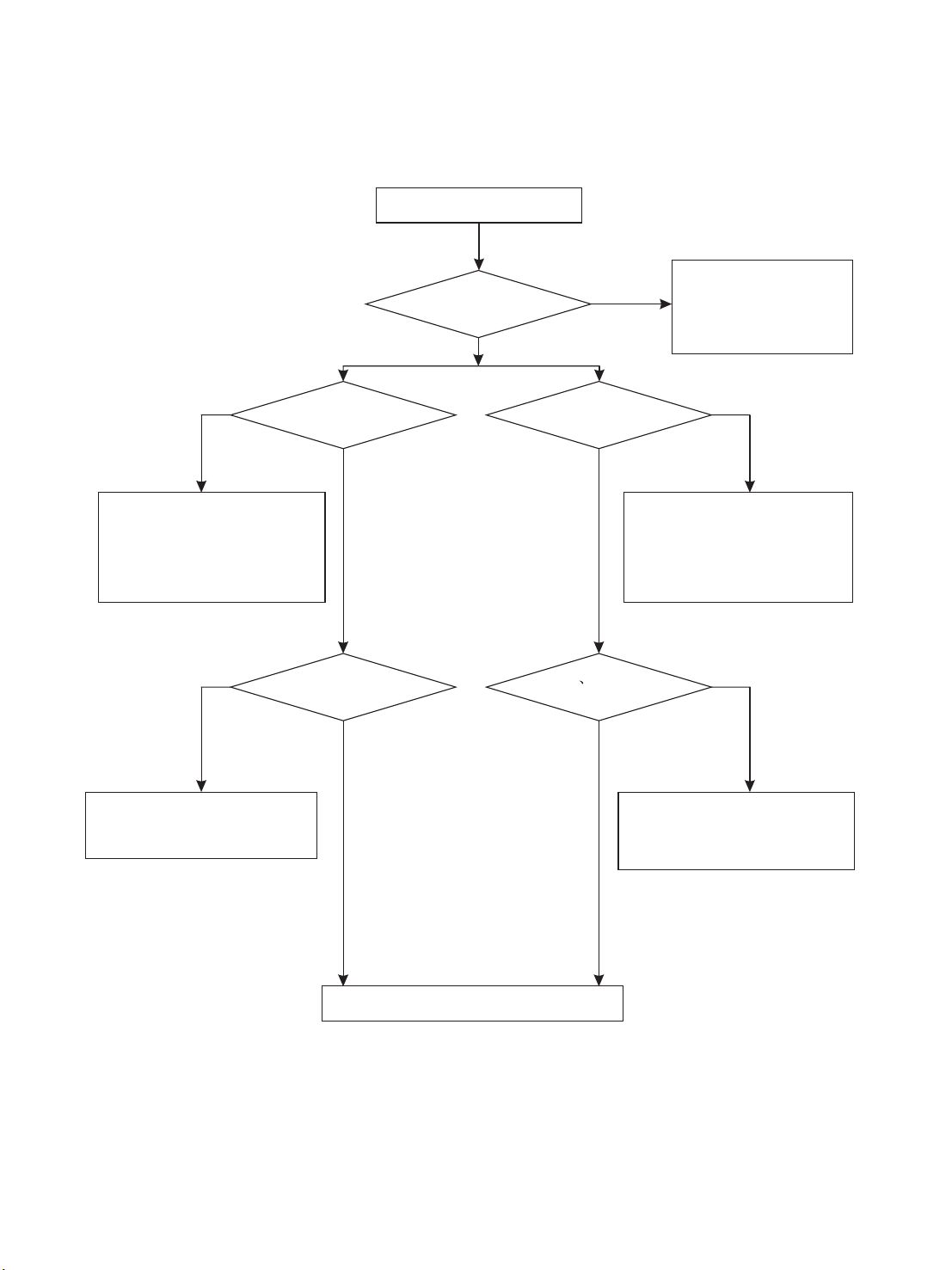

Electrical Trouble Shooting Guide

Connection of the unit is correct.

Setting of the unit is correct

Is power normal?

Yes

Is fluoresce display correct?

Yes

Is open/close normal?

Yes

Can disc be read?

Yes

Is video normal?

Yes

No

No

No

No

No

Refer to power guide.

Refer to display .guide

Refer to open/close .guide

Refer to read disc .guide

Refer to video .guide

Is audio normal?

Yes

Normal operation.

No

Refer to audio .guide

5

Page 6

A Power Circuit abnormal

Start

Yes

12V AC input

Yes

No

12V out of output

Board normal

L401 is open

XS402 is open

XP002 is open

No

C301 or R301 is open.

Is the 7 pin of D301

Voltage output?

Check logic circuit N304.

Check drive circuit N306.

No No

Check commuting circuit

L305,C323,L204,C322

Is there pulse

wave in V302?

Yes Yes

Is 5 pin of XP201

8V output?

Yes

Is there pulse

wave in V301?

Are 3 6 pin of

XP201 5V output?

Yes

Check if transformer is damaged.

L302 is open.

C318 is open.

C319 is open.

No

C301 or R301 is open.

Is the 10 pin of D301

Voltage output?

Check logic circuit N302.

Check drive circuit N305.

Normal

6

Page 7

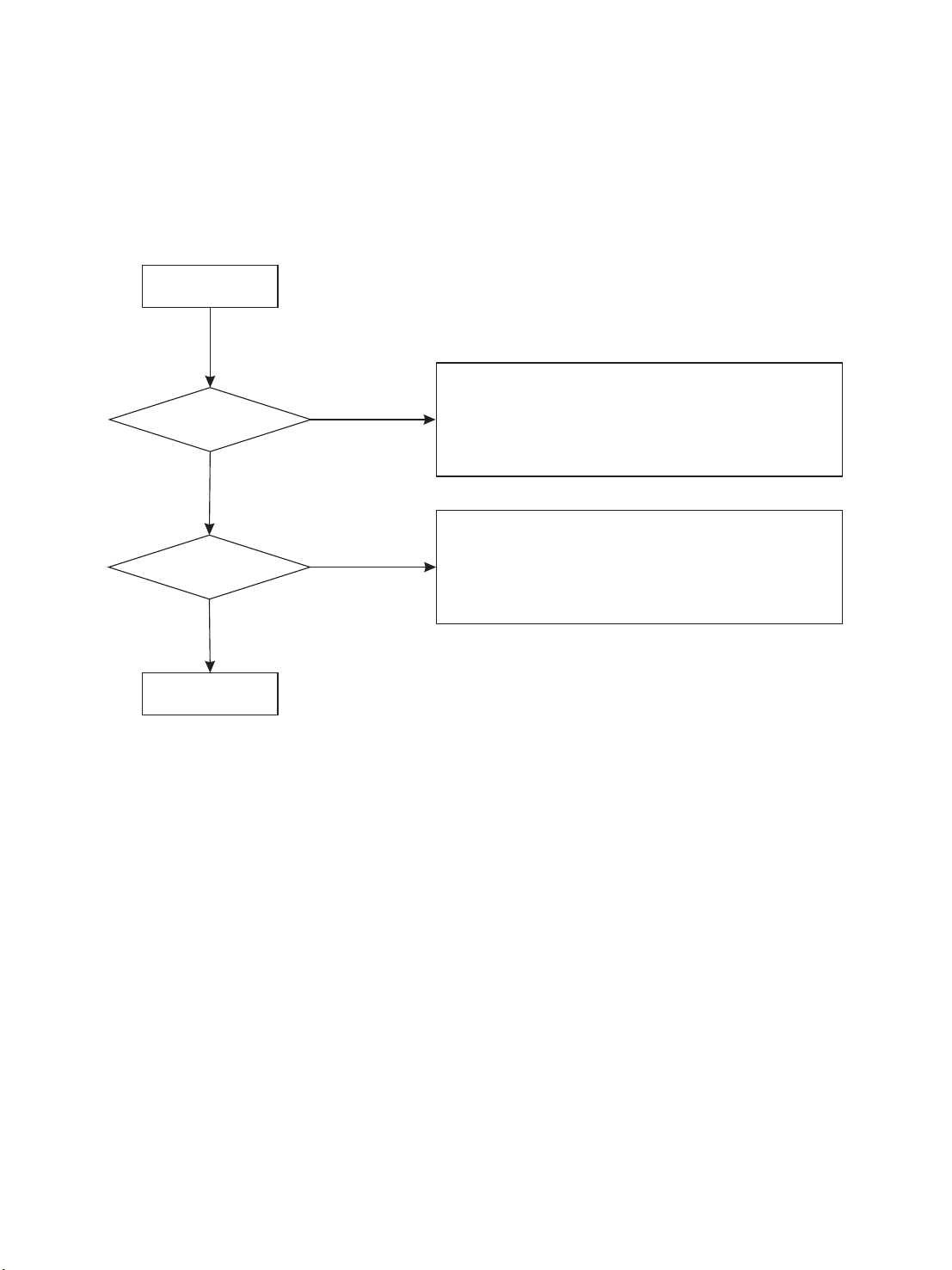

B Display abnormal

START

Does the screen

appear?

Yes

Is display normal?

Yes

Normal

No

No

Check if voltage of screen F1 and F2 is 3.3V.

Check if voltage of 34 pin of UPD16311 is -24V.

Check grounded negative voltage of screen F1 and F2.

Replace UPD16311.

Check if connection cord between screen and

main board is broken?

Check if UPD16311 pin is connected.

Check if pin of screen is connected.

7

Page 8

C Open/close abnormal

Is "OPEN" showed on the screen?

The door isn't open.

Is there voltage difference

in XP102UNLOAD pin and

No

Replace connection cord.

Yes

LOAD pin?

No

Yes

Does drive motor

have voltage?

Yes Yes

No

Does XS107 power

have voltage?

No

Check if RMC pin of

XS107 has a waveform.

Yes

No

Replace key-circuit board.

Replace motor.

END

8

Page 9

D Read disc abnormal

DISC IN

Focus on?

Yes

Is laser normal?

Yes

Does the disc turn?

Yes

Can TOC be read?

Yes

Normal

No

No

No

No

Refer to focus guide.

Refer to laser .guide

Refer to focus .guide

Refer to TOC .guide

9

Page 10

E Video abnormal

Is voltage of XS109 normal?

Yes

No picture, no sound.

No

No picture, have sound.

No

Have picture, no color or color

disappeared during playback .

No

Have picture, but picture

disappeared during playback .

No

Yes

Yes

Yes

Yes

Check connection between

video encoder and XS109.

Replace main board.

Check jack of output board

or replace main board.

Check main board and replace

G102(27MHz).

Check main board and replace

G102(27MHz).

10

Page 11

F Audio abnormal

Have picture, no sound

Check if voltage of R, L pin

of XP001 is normal

Yes

Is N001 and N002 signal

output?

Yes

Is transistor V304 and

V312 for mute usage

broken down?

No

Normal

No

No

Yes

Check connection between R, L pin of XP001

and PCM1723

Check 4558 and surrounding components

Replace transistor

11

Page 12

G Focus abnormal

No focus

Does normal voltage at FCS+

and FCS- of XS100?

Yes

Does normal voltage at

D104 pin 14, 7?

Yes

Does data output at

D101 pin 154?

Yes

Does parallel data output

at D105 pin 36 43?

No

No

No

No

1. Check connection cord.

2. Replace pickup.

1. Check connection between 14, 7 pin of

BA5945 and FCS+, FCS- of XS100.

2. Check if G101, G102 normal operation.

3. Check BA5945 and peripheral

components.

1. Check connection between D1870

and BA5945.

2. Check D1870 and peripheral

components.

1. Check connection between CPU

and D1870.

2. Check CPU and peripheral

components.

12

Yes

Normal

Page 13

H Laser abnormal

No laser

Is LD pin of XS100(18, 30)

4.5V?

No

Does voltage at D103

pin of 52, 81?

No

Does normal voltage

at D105 pin 44?

Yes

Yes

Yes

No

1. Check connection between pickup

and main board.

2. Replace pickup.

1. Check connection between D1890

of pin LD and XS100.

2. Check D1890 and peripheral

components.

1. Check connection between CPU

pin 44 and D1890 pin4.

2. Check CPU and peripheral

components.

Normal

13

Page 14

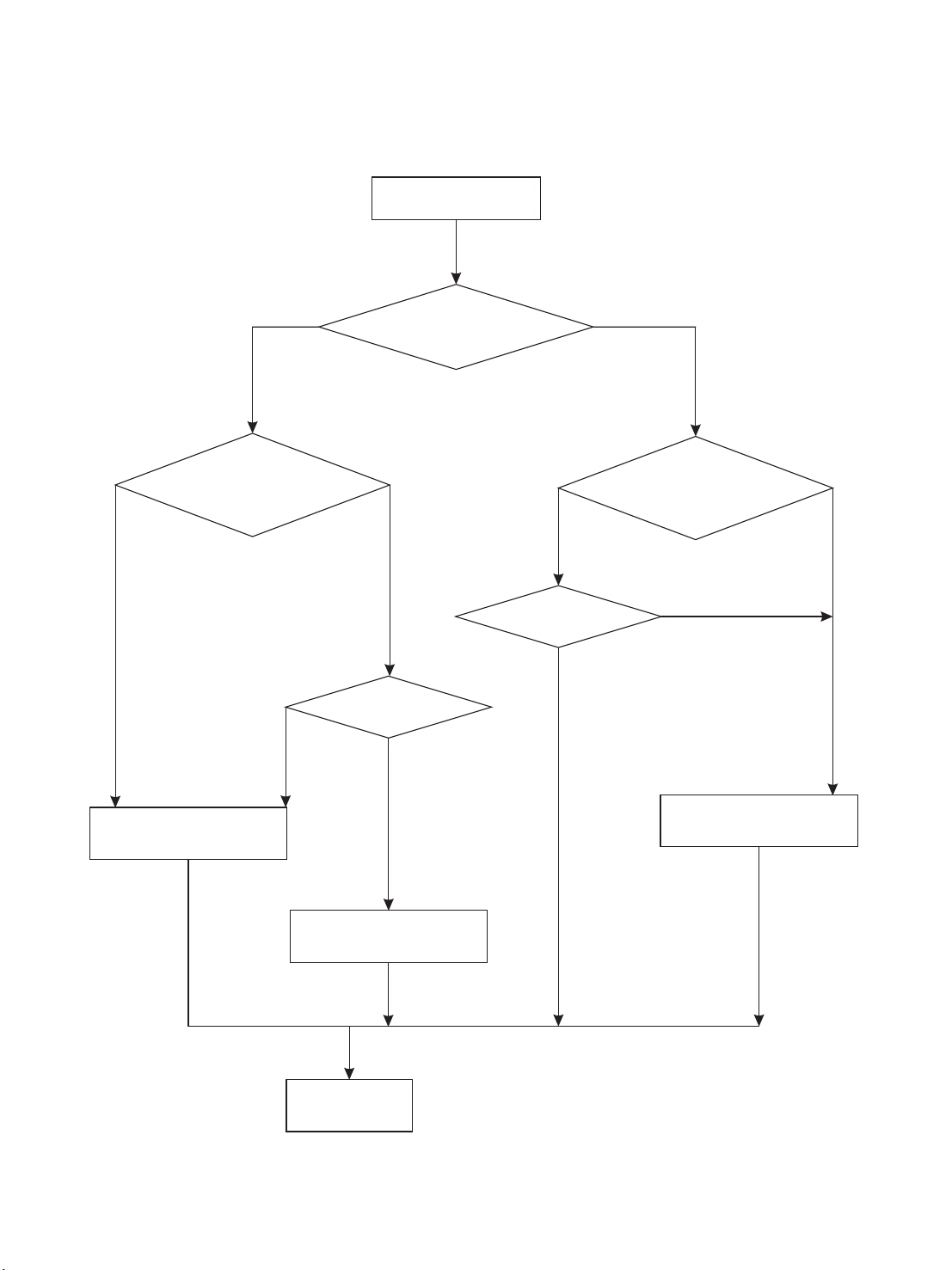

I Turn abnormal

Disc doesn't turn.

Check if voltage of SP+ and

SP- of XS103 are different.

No

Check if voltage of 11 and

12 pin of D104 are different.

No

Check if voltage of 17 pin

of D101 is normal.

No

Yes

Yes

Yes

Check connection of mechanism.

1. Check connections between BA5954

and XS103.

2. Check BA5954 and peripheral

components.

1. Check connections between D1870

pin 17 and BA5954 pin 4.

2. Check D1870 and peripheral

components.

14

Check if data signal of

18,19,30,31,36 43 pin

of D105 is normal.

Yes

Normal

No

1. Check connections between CPU cortrol

bus, data bus and D1870.

2. Check CPU and peripheral components.

Page 15

J TOC abnormal

TOC doesn't read.

Limited switch is closed.

Is laser on?

Is FOK normal?

Yes

Does normal RFsignal at

D103 pin 39?

Yes

Does normal RFIN at

D101(D1870) pin 176?

Yes

Have sound,

no picture.

Yes

No

No

No

1. Refer to laser guide.

2. Check slide motor and connections

to main board.

1. Check connection between 39 pin of

D1890 and 7 pin of XS100.

2. Check connection between XS100 and

pickup.

3. Replace pickup.

1. Check connection between D1870

and D1890.

2. Check D1890 and peripheral components.

1. Check ATAPI channel.

2. Check VS2811E and peripheral components.

3. Check CS4955 and peripheral components.

4. Check connection between VS2811E and

CS4955.

No

Have picture,

no sound.

No

Normal

Yes

1. Check ATAPI channel.

2. Check and peripheral components.

3.

4. Check connection between VS2811E and

CS4955.

VS2811E

Check CS4955 and peripheral components.

15

Page 16

OUTPUT BOARD

16

Page 17

17

KEY BOARD

Page 18

POWER BOARD

18

Page 19

168 KEY BOARD

168 OUTPUT BOARD

168 POWER BOARD

19

Page 20

DSM7012BDECODER

Page 21

REPLACEMENT PARTS LIST

PART No. PARTS NAME Q'TY

DVD300

S8027 KHL232C(UL) LOADING 1

01003 D168K KEY ASS'Y 1

0856 DC168 POWER ASS'Y 1

00948 DSM7012B DECODER ASS'Y 1

0857 D168OUT OUTPUT ASS'Y 1

S3230 RCA CORD AUDIO 1

S3231 RCA CORD VIDEO 1

S3118 WIRE 1

S3119 LASER SERVO WIRE 1

S2701a 7# BATTERY 2

S3251e CC-0.5×24×210-6 1

S3126 CC-1.0×12×150 1

S3190 CC-1.0×12×40 1

S0588 6.2mH INDUCTOR ASS'Y 1

04003 REMOTE CONTROL ASS'Y 1

S3219a DC168 POWER CORD ASS'Y 1

02005 PHONE JACK ASS'Y 1

S0676n RC168 REMOTE 1

S1024a OWNER MANUAL 1

Page 22

REF No. PART No. PART NAME REF No. PART No. PART NAME

CONTROL ASSY

RESISTOR

R409 P11019 RC-03K104JT

R410 P11019 RC-03K104JT

R501 G0735 RT13-0.167W-10K±5% R411 P11013 RC-03K103JT

R502 G0735 RT13-0.167W-10K±5% R412 P11013 RC-03K103JT

R503 G0735 RT13-0.167W-10K±5% R413 P11003 RC-03K100JT

R504 G0735 RT13-0.167W-10K±5% R430 P11003 RC-03K100JT

R505 G0735 RT13-0.167W-10K±5% R431 P11009 RC-03K102JT

R506 G0735 RT13-0.167W-10K±5% R432 P11009 RC-03K102JT

R507 G0735 RT13-0.167W-10K±5%

CAPACITOR

R508 G0728 RT13-0.167W-4.7K±5% C401 a3636 CD11CX-10uF-M-16V

R509 G0719 RT13-0.167W-1K±5% C402 a3636 CD11CX-10uF-M-16V

R510 G0714 RT13-0.167W-180±5% C403 P20064 GRM39CH510J50PT

R511 G0784 RT13-0.167W-56K±5% C404 P20064 GRM39CH510J50PT

R512 G0705 RT13-0.167W-10±5% C405 a3574 CD11CX-220uF-M-10V

R513 G0705 RT13-0.167W-10±5% C406 P20015 GRM39F104Z25PT

CAPACITOR

C407 a3574 CD11CX-220uF-M-10V

C403 a3540 CD110X-100u+50%-6.3V C408 a3574 CD11CX-220uF-M-10V

C404 a3304 CT4-0.1u+50%-63V C409 a3574 CD11CX-220uF-M-10V

C405 a3540 CD110X-100u+50%-6.3V C410 a3574 CD11CX-220uF-M-10V

C406 a3304 CT4-0.1u+50%-63V C411 P20015 GRM39F104Z25PT

OTHER

S501 G6434 EVQ21504M(4.5mm) TOUCH

C412 a3639 CD11CX-100uF-M-10V

OTHER

S502 G6434 EVQ21504M(4.5mm) TOUCH X401 a6662 HSJ1715-01110

S503 G6434 EVQ21504M(4.5mm) TOUCH X402 a6985 AV -8.4-01

S504 G6434 EVQ21504M(4.5mm) TOUCH X403 a6976 53259-02 POWER SOCKET

S507 G6434 EVQ21504M(4.5mm) TOUCH XS401 a6515 B-10B-PH SOCKET

VD501 a5004 IN4148 DIODE XS402 a6531 B-4B-XH SOCKET

VD502 a5004 IN4148 DIODE XP401 a6519 S-3B-PH SOCKET

VD503 a5004 IN4148 DIODE L401 a6878 FILTER

V501 a6918 VFD20-0605 DISPLAY L402 P6817 BSZ-2012-600T3

B501 a6733 HS0038B RECEIVE L403 P6817 BSZ-2012-600T3

D501 a4399 UPD16311 IC V401 P5073a 2SB601AR

LED a1500 ø3 RED LED V402 P5073a 2SB601AR

XP501 a6569 12FPZ-SM-TF SOCKET D401 P4513 NJM4580

XP2 a8820 DVD168 PHONE WIRE VD401 a1226 18-1 MANOSTAT

OUTPUT ASSY

RESISTOR

R001 P11033 RC-03K682JT

POWER ASSY

R401 P11012 RC-03K472JT R002 P11013 RC-03K103JT

R402 P11012 RC-03K472JT R003 P11019 RC-03K104JT

R403 P11009 RC-03K102JT R004 P11031 RC-03K392JT

R404 P11009 RC-03K102JT R005 P11013 RC-03K103JT

R405 P11036 RC-02K223JI R006 P11033 RC-03K682JT

R406 P11036 RC-02K223JI R007 P11019 RC-03K104JT

R407 P11026 RC-03K122JT R008 P11013 RC-03K103JT

R408 P11026 RC-03K122JT R009 P11031 RC-03K392JT

Page 23

REF No. PART No. PART NAME REF No. PART No. PART NAME

R010 P11013 RC-03K103JT R313 P11029 RC-03K222JT

R011 P11006 RC-03K101JT R314 P11039 RC-03K563JT

R012 P11018 RC-03K473JT R315 P11039 RC-03K563JT

R013 P11018 RC-03K473JT R316 P11140 RC-03K220JT

R014 P11018 RC-03K473JT R317 P11140 RC-03K220JT

R015 P11018 RC-03K473JT R318 P11205 RC-05K0000T

R016 P11009 RC-03K102JT R319 P11205 RC-05K0000T

R017 P11018 RC-03K473JT R320 P11026 RC-03K122JT

R018 P11019 RC-03K104JT R321 P11030 RC-03K272JT

R019 P11013 RC-03K103JT R322 P11027 RC-03K132JT

R020 P11009 RC-03K102JT R323 P11004 RC-03K330JT

R021 P11018 RC-03K473JT R327 P11205 RC-05K0000T

R022 P11013 RC-03K103JT R328 P11095 RC-05K100JT

R023 P11019 RC-03K104JT R329 P11098 RC-05K681JT

R024 P11006 RC-03K101JT R330 a0028 RT14-0.25W-220±5%

R025 P11018 RC-03K473JT R331 P11012 RC-03K472JT

R026 P11018 RC-03K473JT R332 P11009 RC-03K102JT

R027 P11006 RC-03K101JT R333 P11010 RC-03K202JT

R028 P11006 RC-03K101JT R335 P11013 RC-03K103JT

R029 P11009 RC-03K102JT R335 P11013 RC-03K103JT

R030 P11013 RC-03K103JT R339 P11051 RC-03K-152JT

R031 P11009 RC-03K102JT R340 P11080 470

R032 P11012 RC-03K472JT

CAPACITOR

R033 P11018 RC-03K473JT C001 a3561 CD110X-16V-10u±20%

R034 P11008 RC-03K471JT C002 a3561 CD110X-16V-10u±20%

R035 P11013 RC-03K103JT C003 P20030 GRM39B272K50PT

R036 P11009 RC-03K102JT C004 P20029 GRM39CH331J50PT

R037 P11009 RC-03K102JT C005 P20029 GRM39CH331J50PT

R038 P11013 RC-03K103JT C006 a3561 CD110X-16V-10u±20%

R039 P11008 RC-03K471JT C007 a3561 CD110X-16V-10u±20%

R040 P11067 RC-03K201JT C008 a3609 CD110X-16V-100u±20%

R041 P11067 RC-03K201JT C009 a3594 CD110X-10V-47u±20%

R042 P20054 GRM39CH271J50PT C010 P20030 GRM39B272K50PT

R301 P11035 RC-03K203JT C011 a3561 CD110X-16V-10u±20%

R302 P11038 RC-03K393JT C012 a3561 CD110X-16V-10u±20%

R303 P11038 RC-03K393JT C013 P20064 GRM39CH510J50PT

R304 P11040 RC-03K683JT C014 P20064 GRM39CH510J50PT

R305 P11038 RC-03K393JT C015 a3561 CD110X-16V-10u±20%

R306 P11038 RC-03K393JT C016 a3561 CD110X-16V-10u±20%

R307 P11038 RC-03K393JT C017 a3609 CD110X-16V-100u±20%

R308 P11013 RC-03K103JT C018 a3594 CD110X-10V-47u±20%

R309 P11013 RC-03K103JT C023 P20029 GRM39CH331J50PT

R310 P11006 RC-03K101JT C024 P20029 GRM39CH331J50PT

R311 P11006 RC-03K101JT C026 a3514 CD110X-220uF-M-16V

R312 P11029 RC-03K222JT C027 a3594 CD110X-10V-47u±20%

Page 24

REF No. PART No. PART NAME REF No. PART No. PART NAME

C028 a3664 CD110X-10V-470u±20% V005 P5073a 2SD601AR

C034 a3609 CD110X-16V-100u±20% V006 P5700 2SB709

C301 P20054 GRM39CH271J50PT V203 P5700 2SB709

C302 P20035 GRM39F105210PT V205 P5073a 2SD601AR

C303 P20015 GRM39F104225PT V206 P5073a 2SD601AR

C304 P20015 GRM39F104225PT V301 P5723 2SJ357

C305 P20015 GRM39F104225PT V302 P5723 2SJ357

C306 P20015 GRM39F104225PT V303 a5063 3DA3852

C307 P20015 GRM39F104225PT V304 P5700 2SB709

C308 P20035 GRM39F105210PT VD201 P1200 ISS355

C309 P20012 GRM39B103K50PT VD203 P1200 ISS355

C310 P20012 GRM39B103K50PT VD301 a5001 IN4001

C311 P20009 GRM39B102K50PT VD302 P1556 MA152

C312 P20009 GRM39B102K50PT VD303 P5721 RB160L-40

C313 P20042 GRM39B222K50PT VD304 P5721 RB160L-40

C314 P20042 GRM39B222K50PT VD305 P5722 RB060L-40

C317 P20035 GRM39F105210PT VD306 a1139 5A1

C318 a3542 CD110X-1000u-6.3V±20% VD307 a1106 2CW-5.1V

C319 a3542 CD110X-1000u-6.3V±20% VD308 a1136 2CW-4C2

C320 a3594 CD110X-10V-47u±20% VD309 P11000 RC-03K0000T

C321 a3594 CD110X-10V-47u±20% VD310 P1200 ISS355

C322 a3209 CD288-10V-1000u-10%+30% VD312 P1200 ISS355

C323 a3209 CD288-10V-1000u-10%+30%

IC

C325 a3607 CD110-50V-22u±20% N001 P4530 4558

C326 a3607 CD110-50V-22u±20% N002 P4530 4558

C327 a3607 CD110-50V-22u±20% D301 P4580 TL1451AC

C330 a3613 CD110X-25V-100u±20% N302 P4590 BU4S71-JR

C331 P20015 GRM39F104225PT N303 P4590 BU4S71-JR

C332 a3609 CD110X-16V-100u±20% N304 P5714 FMC3AT148

C333 a3609 CD110X-16V-100u±20% N305 P5702 XN4601

C334 a3648 CD110X-6.3V-100u±20% N306 P5702 XN4601

INDUCTOR

N307 a4714 CW7809

L001 P6817 BSZ2012-600T N308 a4571 CW7805

L002 P6817 BSZ2012-600T N309 P90090 PQ05DZ11

L003 P6817 BSZ2012-600T

OTHER

L004 P6817 BSZ2012-600T W2 a6946 EPC-19 TRANSFORMER

L005 P6817 BSZ2012-600T XP001 a8821 OUTPUT CONNECT WIRE 1

L006 P6817 BSZ2012-600T XP002 a8822 OUTPUT CONNECT WIRE 2

L204 a6945 5uH XP201 a6947 S-13B-PH SOCKET

L302 a6945 5uH XS001 a6787 FABSE1252 SOCKET

L301 a6879 100uH

WIRE ASSY

L305 a6879 100uH a6969 0.4mHINDUCTOR

TRANSISTOR

a8844 DVD168 WIRE 1

V003 P5700 2SB709 a8845 DVD168 WIRE 2

V004 P5700 2SB709

Loading...

Loading...