Pioneer DVHP-950-MP Service manual

DVD RDS RECEIVER

ORDER NO.

CRT3931

DVH-P5900MP/XN/EW5

DVH-P5900MP

DVH-P590MP

This service manual should be used together with the following manual(s):

Model No. Order No. Mech.Module Remarks

CX-3212 CRT3896 MS5 DVD Mech. Module : Circuit Descriptions, Mech. Descriptions, Disassembly

Manufactured under license from Dolby Laboratories. "Dolby", "Pro Logic", and the double-D

symbol are trademarks of Dolby Laboratories.

/XN/RE

/XN/EW5

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2007

K-ZZA. APR. 2007 Printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

1. Safety Precautions for those who Service this Unit.

B

Follow the adjustment steps in the service manual when servicing this unit. When check ing or adjusting the emitting power of the laser diode exercise caution in order to get safe, reliable results.

Caution:

1. During repair or tests, minimum distance of 13 cm from the focus lens must be kept.

2. During repair or tests, do not view laser beam for 10 seconds or longer .

2. The triangular label is attached to the mechanism

unit frame.

C

On the top of the player.

D

E

F

2

1234

DVH-P5900MP/XN/EW5

5678

WARNING!

The AEL (accessible emission level )of the laser power output is less than CLASS 1

but the laser component is capable of emitting radiation exceeding the limit for

CLASS 1.

A specially instructed person should do servicing operation of the apparatus.

Laser diode characteristics

W

ave length:

DVD:660 nm to 670 nm

CD:780 nm to 800 nm

Maximum Output

DVD : 1.27 mW(Emitting period :9 sec.)

CD : 6.26 mW(Emitting period : unlimited)

Additional Laser Caution

A

B

Transistors Q1103 and Q1104 in PCB drive the laser diodes for DVD and CD

respectively. When Q1103 or Q1104 is shorted between their terminals,

the laser diodes for DVD or CD will radiate beam. If the top cover is removed

with no disc loaded while such short-circuit is continued, the naked eyes may

be exposed to the laser beam.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replaced only with the same or equivalent type recommended by the manufacture.

Discord used batteries according to the manufacture's instructions.

C

D

E

56

DVH-P5900MP/XN/EW5

F

7

8

3

1234

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

A

B

C

D

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

E

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

F

4

1234

DVH-P5900MP/XN/EW5

5678

CONTENTS

SAFETY INFORMATION .....................................................................................................................................2

1. SERVICE PRECAUTIONS................................................................................................................................6

1.1 SERVICE PRECAUTIONS.........................................................................................................................6

1.2 NOTES ON SOLDERING...........................................................................................................................6

2. SPECIFICATIONS.............................................................................................................................................7

2.1 SPECIFICATIONS ......................................................................................................................................7

2.2 DISC/CONTENT FORMAT.........................................................................................................................9

2.3 PANEL FACILITIES ..................................................................................................................................10

2.4 CONNECTION DIAGRAM........................................................................................................................15

3. BASIC ITEMS FOR SERVICE........................................................................................................................16

3.1 CHECK POINTS AFTER SERVICING.....................................................................................................16

3.2 PCB LOCATIONS.....................................................................................................................................17

3.3 JIGS LIST.................................................................................................................................................18

3.4 CLEANING ...............................................................................................................................................18

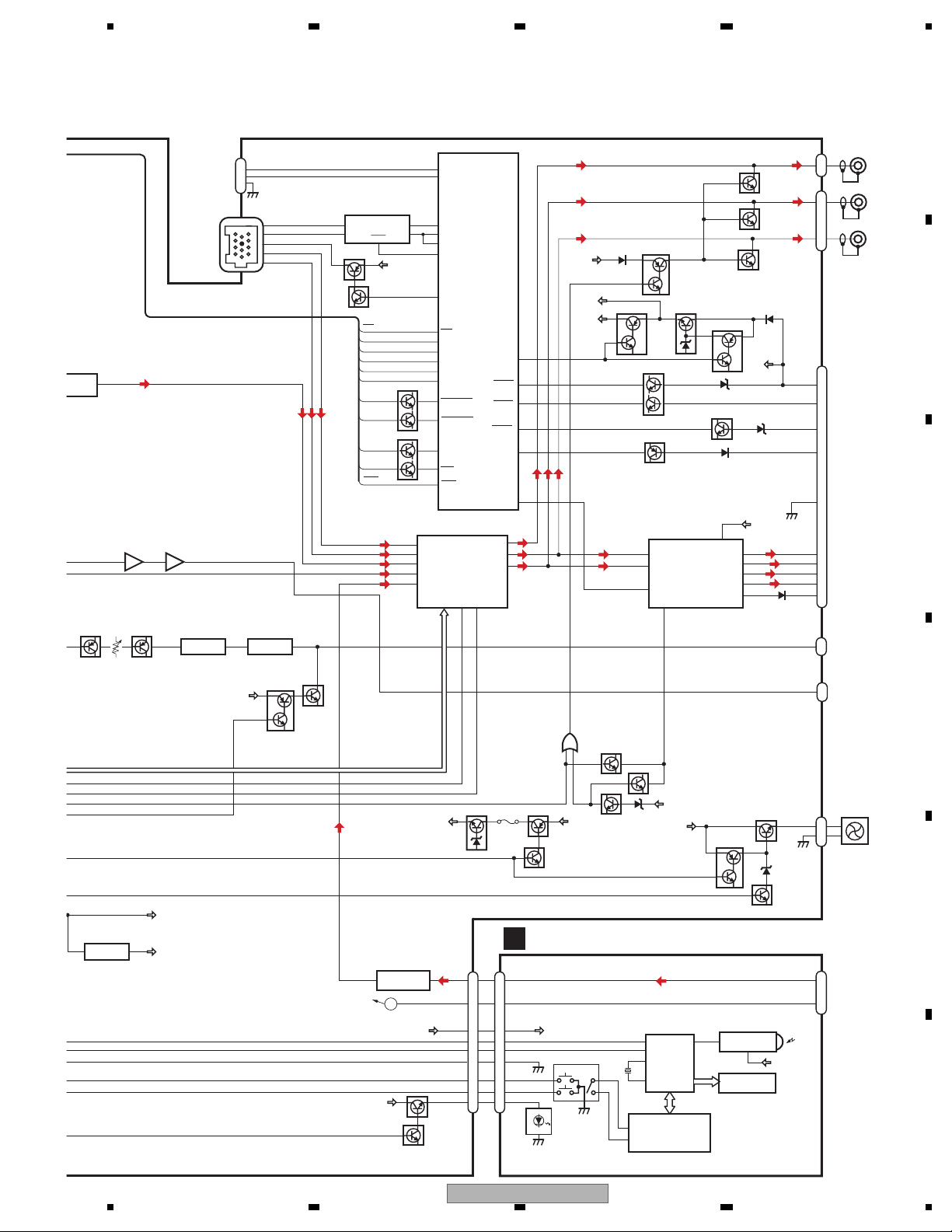

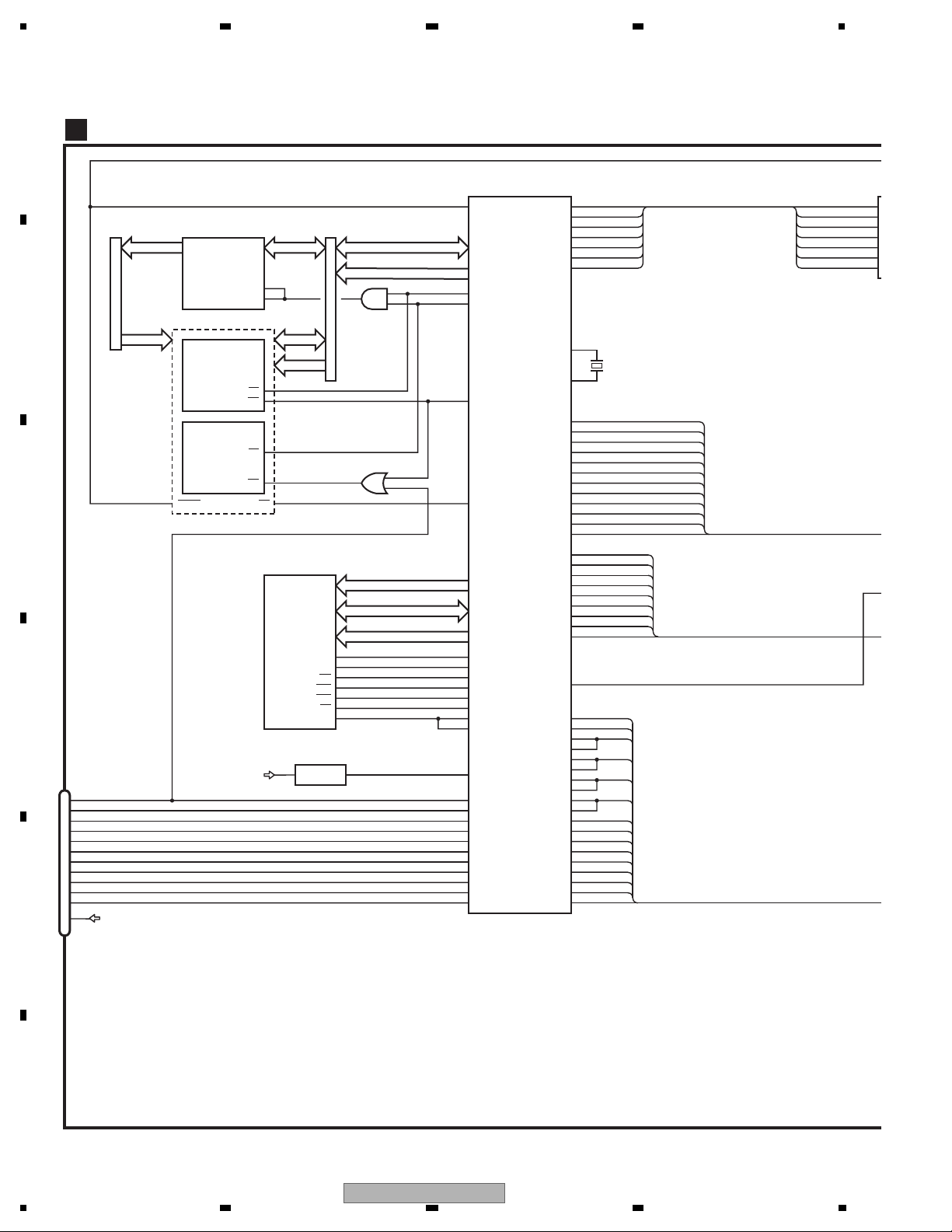

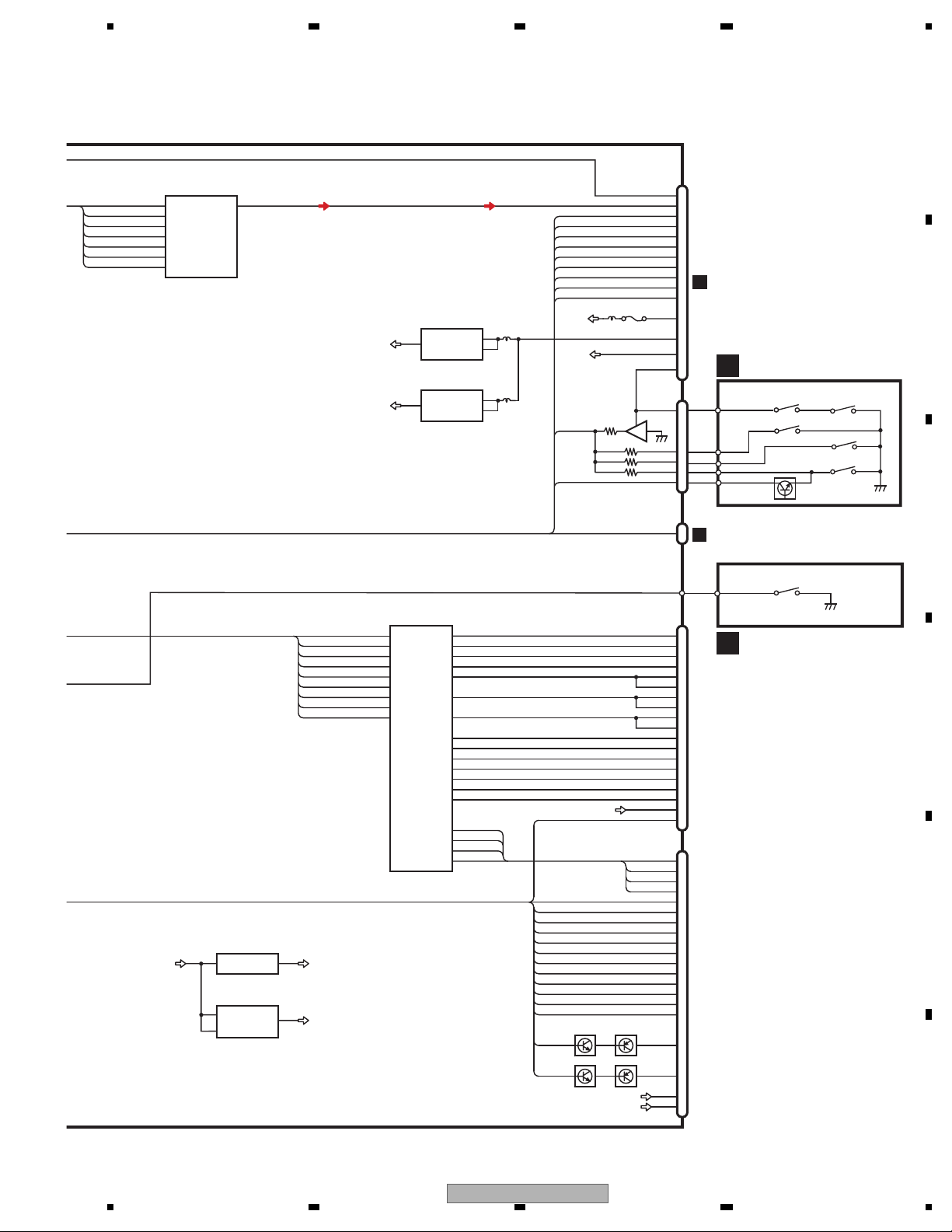

4. BLOCK DIAGRAM ..........................................................................................................................................20

4.1 BLOCK DIAGRAM....................................................................................................................................20

5. DIAGNOSIS ....................................................................................................................................................26

5.1 OPERATIONAL FLOWCHART.................................................................................................................26

5.2 DIAGNOSIS FLOWCHART......................................................................................................................27

5.3 ERROR CODE LIST.................................................................................................................................49

5.4 CONNECTOR FUNCTION DESCRIPTION .............................................................................................50

6. SERVICE MODE.............................................................................................................................................51

6.1 DVD TEST MODE ....................................................................................................................................51

7. DISASSEMBLY...............................................................................................................................................54

8. EACH SETTING AND ADJUSTMENT............................................................................................................58

8.1 DVD ADJUSTMENT.................................................................................................................................58

8.2 TUNER AMP UNIT ADJUSTMENT..........................................................................................................63

8.3 SYSTEM MICROCOMPUTER TEST PROGRAM....................................................................................65

9. EXPLODED VIEWS AND PARTS LIST ..........................................................................................................66

9.1 PACKING..................................................................................................................................................66

9.2 EXTERIOR(1)...........................................................................................................................................68

9.3 EXTERIOR(2)...........................................................................................................................................70

9.4 DVD MECHANISM MODULE...................................................................................................................72

10. SCHEMATIC DIAGRAM................................................................................................................................74

10.1 OVERALL CONNECTION DIAGRAM(GUIDE PAGE)............................................................................74

10.2 KEYBOARD UNIT ..................................................................................................................................80

10.3 DVD CORE UNIT(1/2)(GUIDE PAGE) ...................................................................................................82

10.4 DVD CORE UNIT(2/2)............................................................................................................................88

10.5 COMPOUND UNIT(A) AND COMPOUND UNIT(B)...............................................................................90

10.6 WAVEFORMS.........................................................................................................................................91

11. PCB CONNECTION DIAGRAM ....................................................................................................................94

11.1 TUNER AMP UNIT .................................................................................................................................94

11.2 KEYBOARD UNIT...................................................................................................................................98

11.3 DVD CORE UNIT..................................................................................................................................100

11.4 COMPOUND UNIT(A) AND COMPOUND UNIT(B) .............................................................................104

12. ELECTRICAL PARTS LIST.........................................................................................................................105

A

B

C

D

56

DVH-P5900MP/XN/EW5

E

F

7

8

5

1234

1. SERVICE PRECAUTIONS

1.1 SERVICE PRECAUTIONS

A

- Service Precaution

1. You should conform to the regulations govering the product (safety, radio and noise, and other regulations),

and should keep the safety during servicing by following the safety instructions described in this manual.

2. Be careful in handling ICs. Some ICs such as MOS type are so fragile that they can be damaged by

electrostatic induction.

3. Before disassembling the unit, be sure to turn off the power. Unplugging and plugging the connectors

during power-on mode may

ICs inside the unit.

4. To protect the pickup unit from electrostatic discharge during servicing, take an appropriate treatment

(shorting-solder) by referring to “the DISASSEMBLY”.

5. After replacing the pickup unit, be sure to skew adjustment.

B

6. During disassembly, be sure to turn the power off since an internal IC might be destroyed when aconnector

is plugged or unplugged.

7. : Hot area. Be careful not to burn yourself.

C

D

1.2 NOTES ON SOLDERING

NOTES ON SOLDERING

For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

E

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

F

6

1234

DVH-P5900MP/XN/EW5

5678

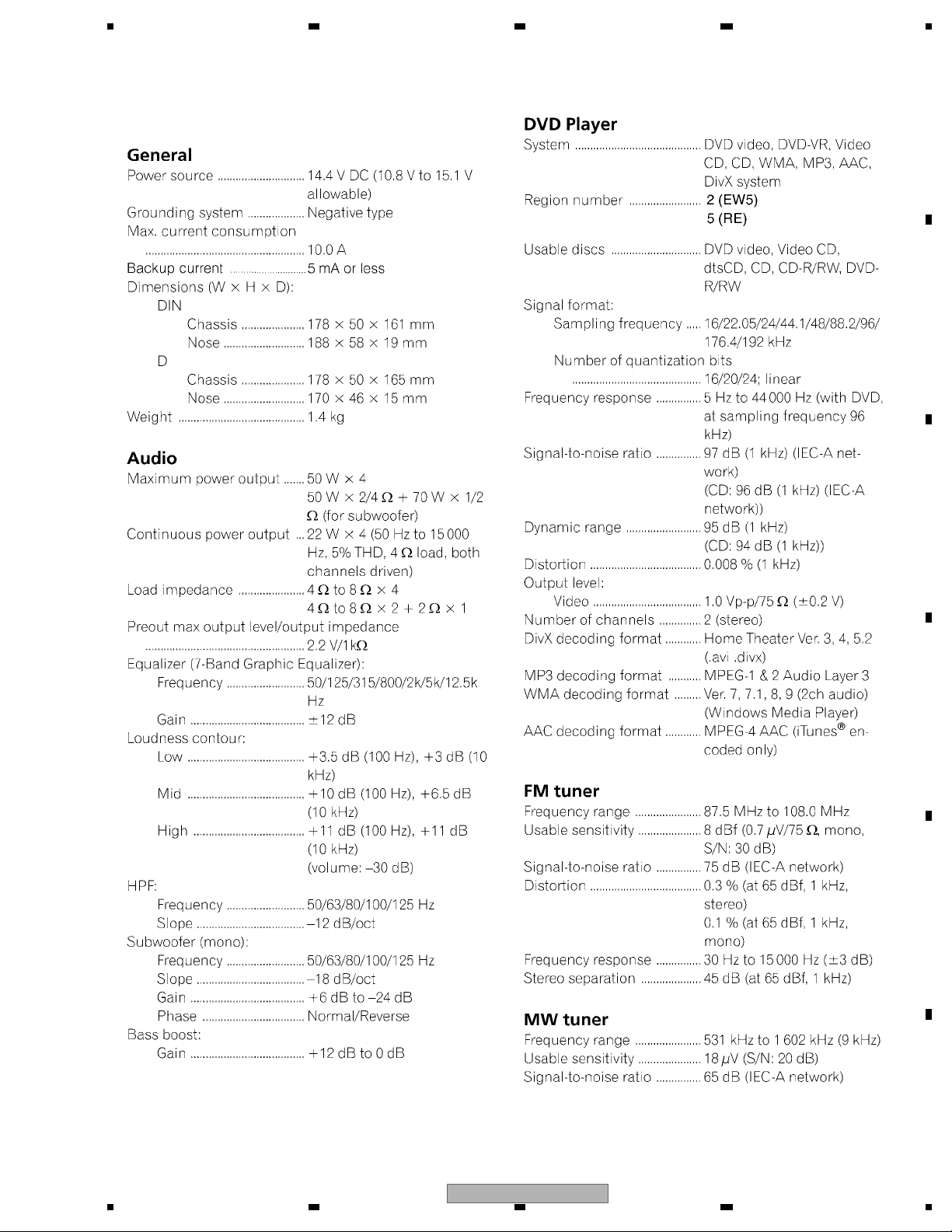

2. SPECIFICATIONS

2.1 SPECIFICATIONS

A

B

C

D

E

56

DVH-P5900MP/XN/EW5

F

7

8

7

1234

A

B

C

D

E

F

8

1234

DVH-P5900MP/XN/EW5

5678

2.2 DISC/CONTENT FORMAT

A

is a trademark of DVD Format/Logo Licensing Corporation.

B

C

D

56

DVH-P5900MP/XN/EW5

E

F

7

8

9

1234

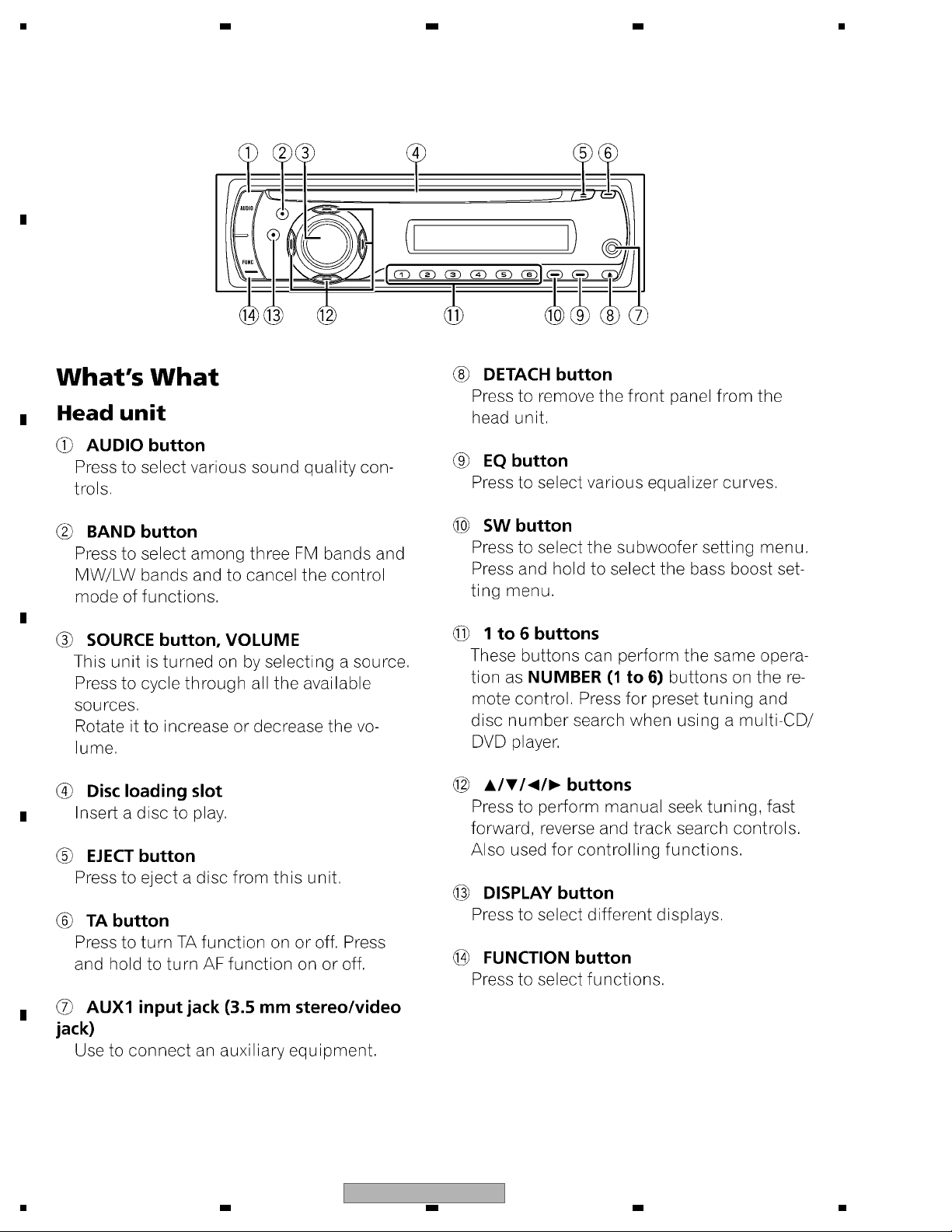

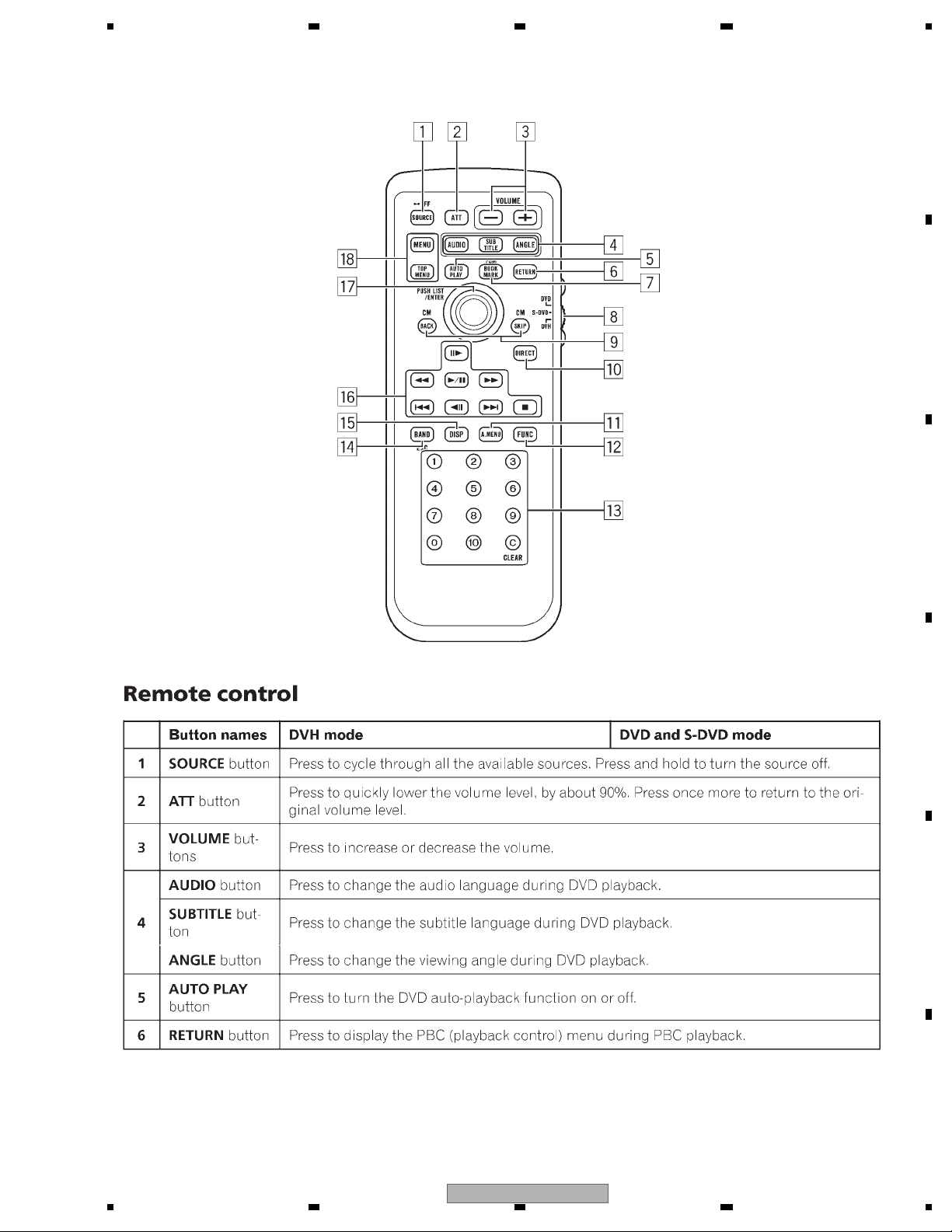

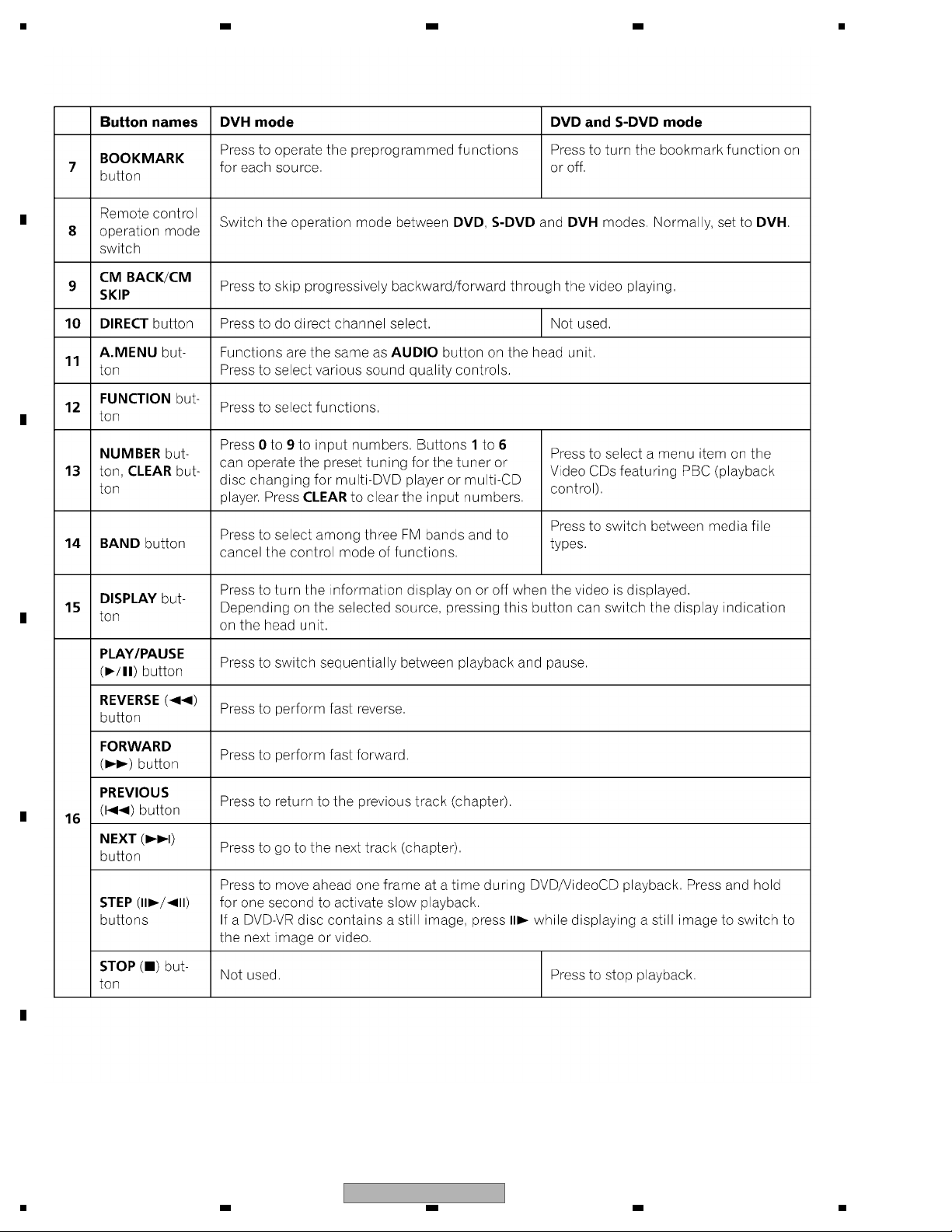

2.3 PANEL FACILITIES

A

B

C

D

E

F

10

1234

DVH-P5900MP/XN/EW5

5678

A

B

C

D

E

56

DVH-P5900MP/XN/EW5

F

7

8

11

1234

A

B

C

D

E

F

12

1234

DVH-P5900MP/XN/EW5

5678

A

B

C

D

E

56

DVH-P5900MP/XN/EW5

F

7

8

13

1234

A

B

BPZ20P080FTC

C

D

E

F

14

1234

DVH-P5900MP/XN/EW5

5678

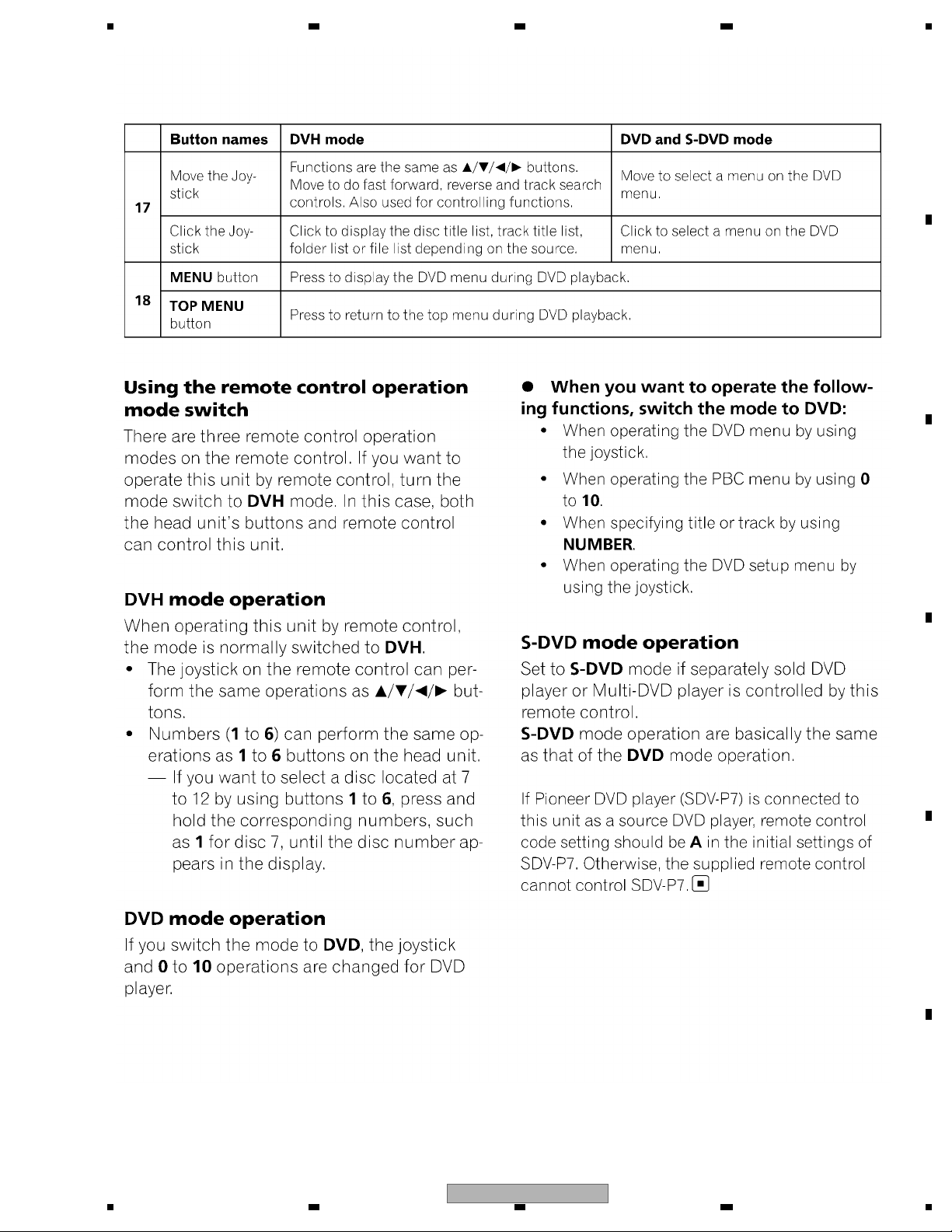

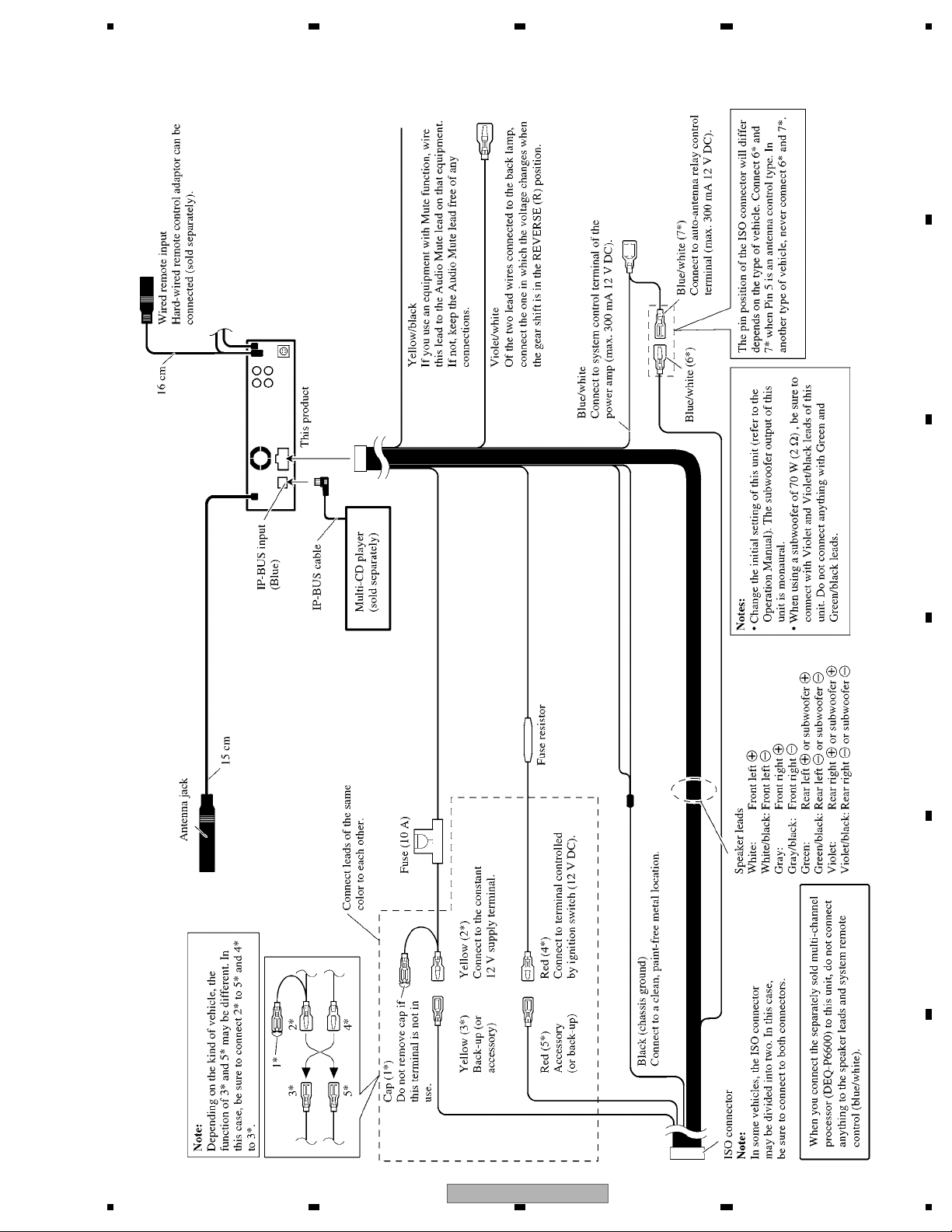

2.4 CONNECTION DIAGRAM

A

B

C

D

E

56

DVH-P5900MP/XN/EW5

F

7

8

15

1234

test disc (GGV1025)

(

)

(

)

j

g

g

g

g

g

g

g

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

To keep the product quality after servicing, please confirm followingcheck points.

1 Confirm whether the customer complain has

been solved.

If the customer complain occurs with the

ifi

m

i

ifr

h

2 Flap-mecha Check the operation of the flap mechanism. The flap mechanism operation must be

3 DVD Measure playback error rates at the

B

4 DVD Play back a DVD.

5 CD Play back a CD.

6 FM/AM tuner Check FM/AM tuner action.

7 Check whether no disc is inside the product. The media used for the operating check must

C

For check items concernin

D

innermost and outermost tracks by using the

test mode with the following disc.

DVD

Menu operation;Title/chapter search

Track search

(Seek, Preset)

Switch band to check both FM and AM.

image and voice, please refer to the followings:

Check items concerning image Check items concerning voice

Distorted ima

Low bri

Too bri

Color fadin

Partial discoloration

e(Image skip) High volume

rinhk.

The customer complain must not be

reappeared.

Display, video, audio and operations must be

rm

l.

n

smooth without makin

scratches.

Deterioration of mecha-drive can be checked.

The error rates must be less than 2.5e-4

Display, video, audio and operations must be

normal.

Display, audio and operations must be

normal.

Display, audio and operations must be

normal.

ected.

be e

receivin

noitrotsiDesion-kcolB

esioNesiontucssorC

nahCssenth

es in level

it for service.

emulovwoLesiontoD

g the noise and

.

retfaecnaraeppastinotridrosehctarcsoNkcehcecnaraeppA8

dnuosfoesuaPth

krameRdemrifnocebotmetIserudecorP.oN

When flap-mecha

exists

E

F

16

DVH-P5900MP/XN/EW5

1234

5678

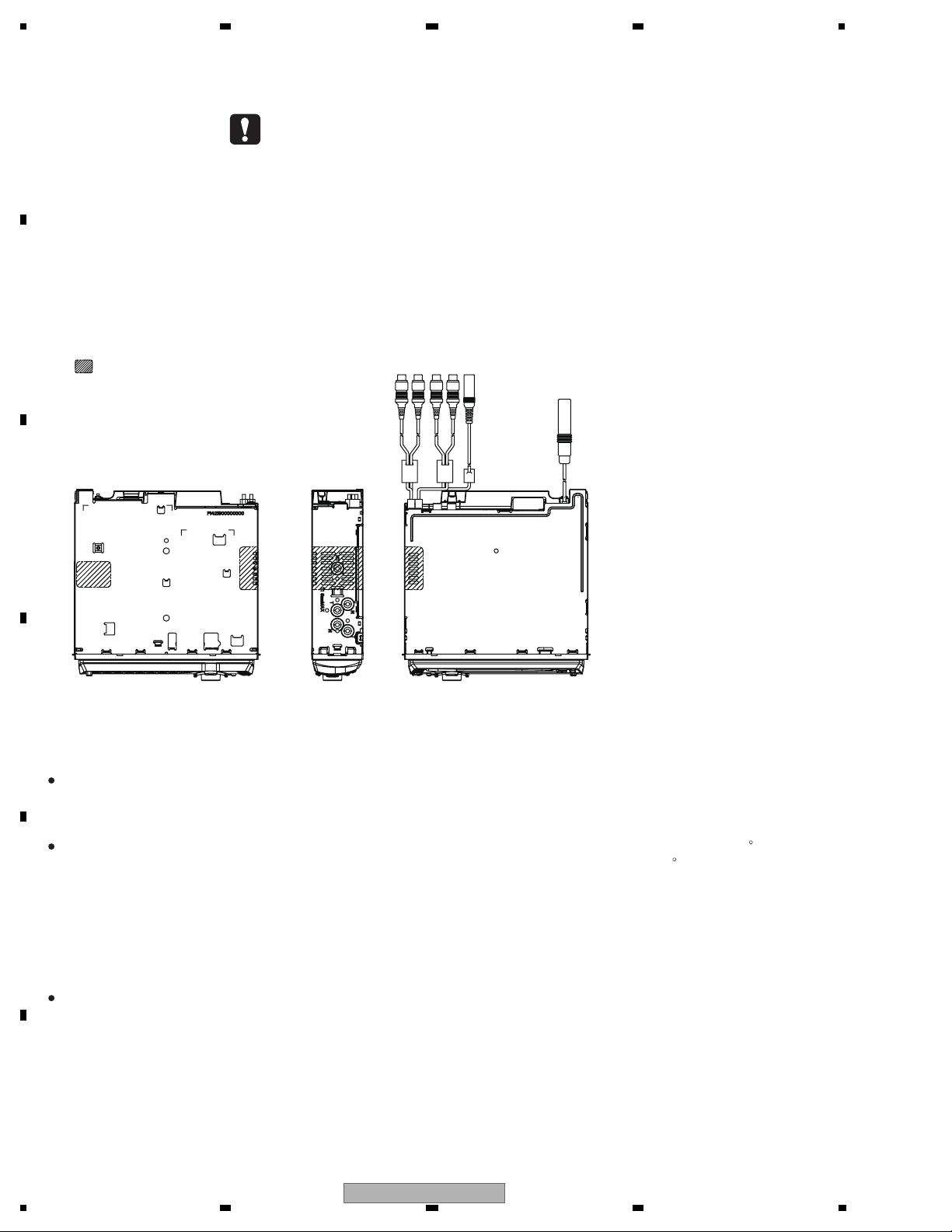

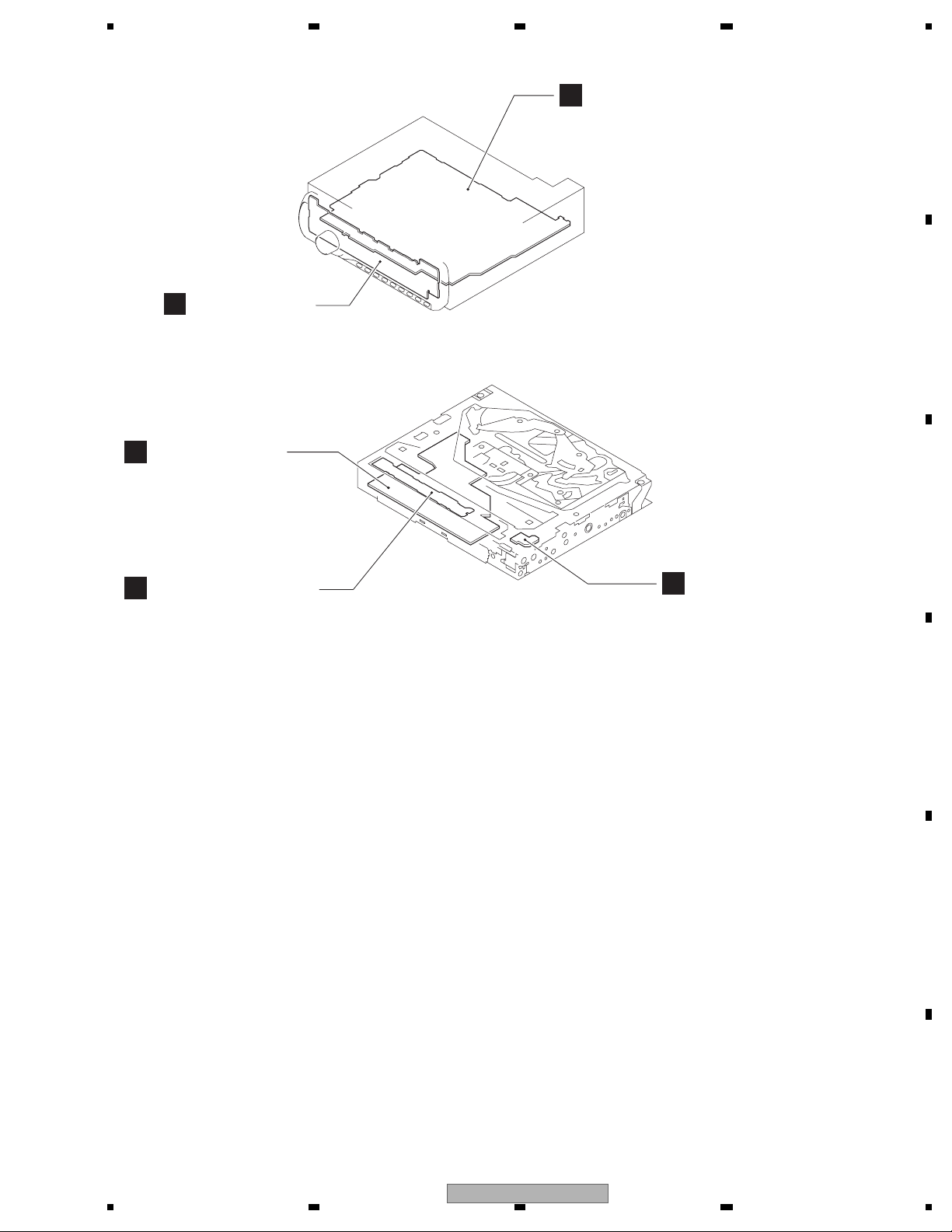

3.2 PCB LOCATIONS

Keyboard Unit

B

DVD Core Unit

C

Tuner Amp Unit

A

A

B

Compound Unit (A)

D

Unit Number : CWN2384(EW5)

Unit Number : CWN2373(RE)

Unit Name : Tuner Amp Unit

Unit Number : (EW5)

Unit Name : Keyboard Unit

Unit Number : (RE)

Unit Name : Keyboard Unit

Unit Number : YWX5005

Unit Name : DVD Core Unit

Unit Number : CWX3154

Unit Name : Compound Unit(A)

Unit Number : CWX3394

Unit Name : Compound Unit(B)

Compound Unit (B)

E

C

D

E

56

DVH-P5900MP/XN/EW5

F

7

8

17

1234

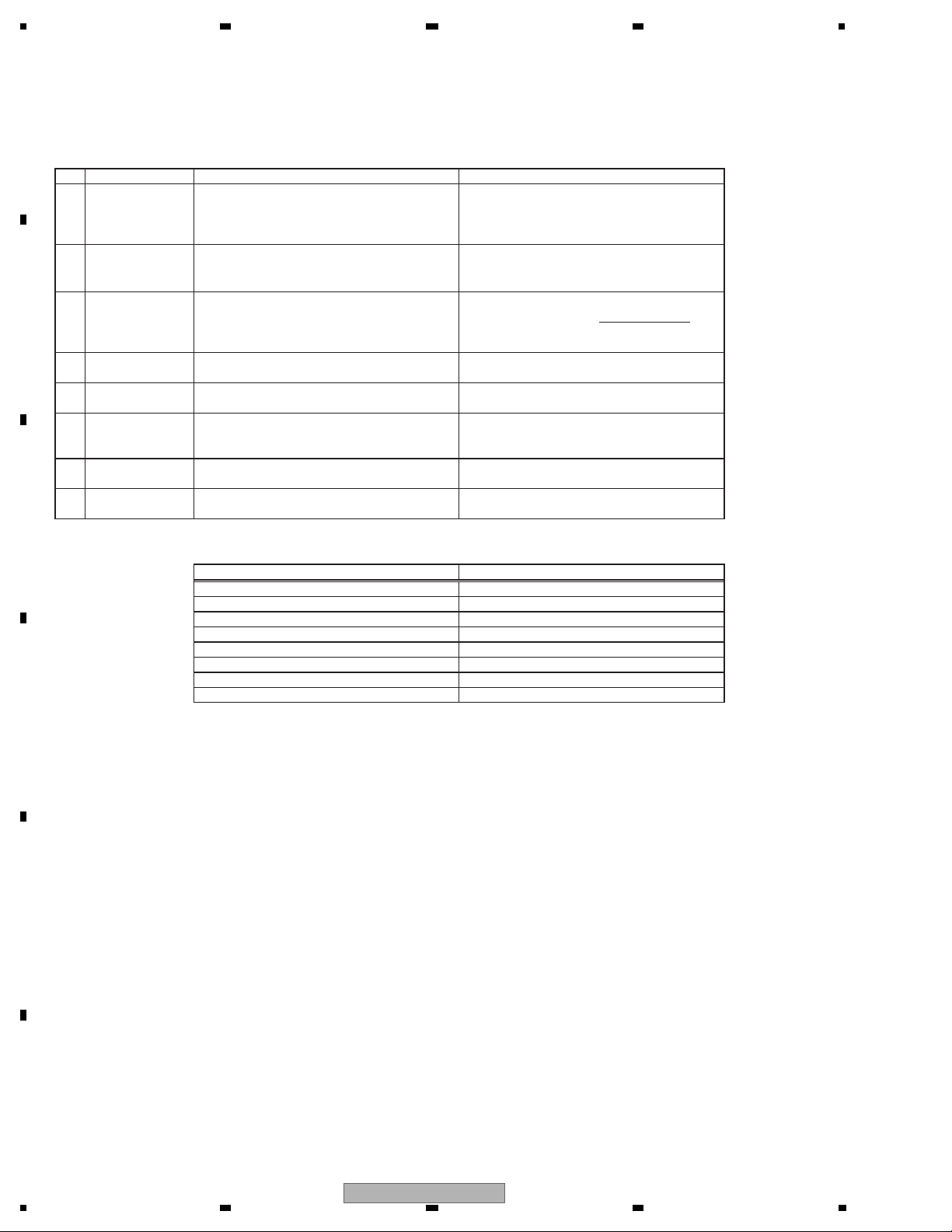

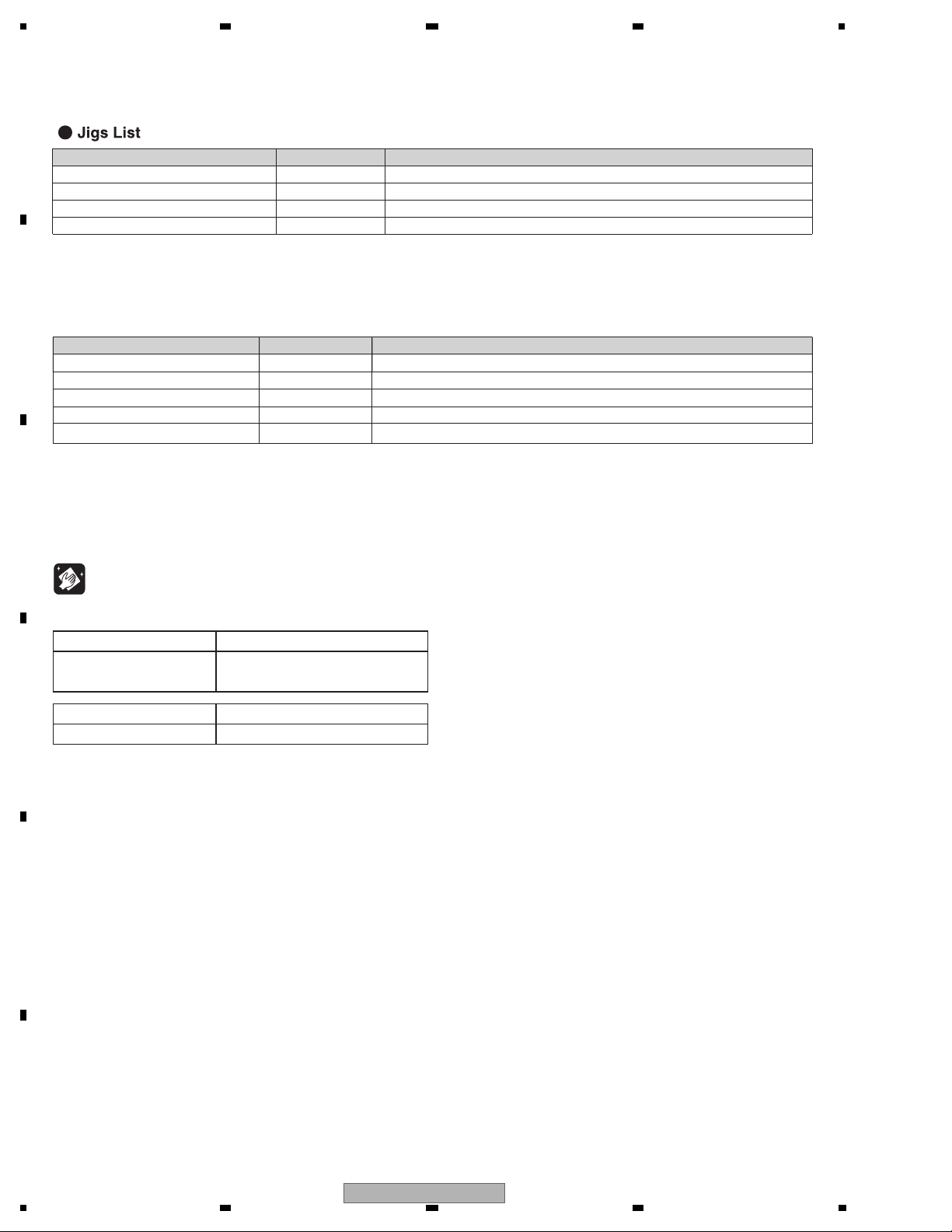

3.3 JIGS LIST

A

Name Jig No. Remarks

Disc GGV1018 Skew adjustment

TORX driver(T2) GGK1095 Skew adjustment

Bond GEM1033 Skew adjustment

DVD test disc GGV1025 Check points after servicing

B

- Grease List

Name

Grease

Grease

Grease

Grease

Locking agents

Jig No.

GEM1024

GEM1043

GEM1045

GEM1050

1401M

Remarks

DVD Mechanism Module

DVD Mechanism Module

DVD Mechanism Module

DVD Mechanism Module

DVD Mechanism Module (1401M:produced by THREE BOND)

C

3.4 CLEANING

Before shipping out the product, be sure to clean the following portions by using the prescribed cleaning tools:

Portions to be cleaned Cleaning tools

DVD pickup lenses Cleaning liquid : GEM1004

Cleaning paper : GED-008

Portions to be cleaned Cleaning tools

D

Fans Cleaning paper : GED-008

E

F

18

1234

DVH-P5900MP/XN/EW5

5678

A

B

C

D

E

56

DVH-P5900MP/XN/EW5

F

7

8

19

1234

3

D

F

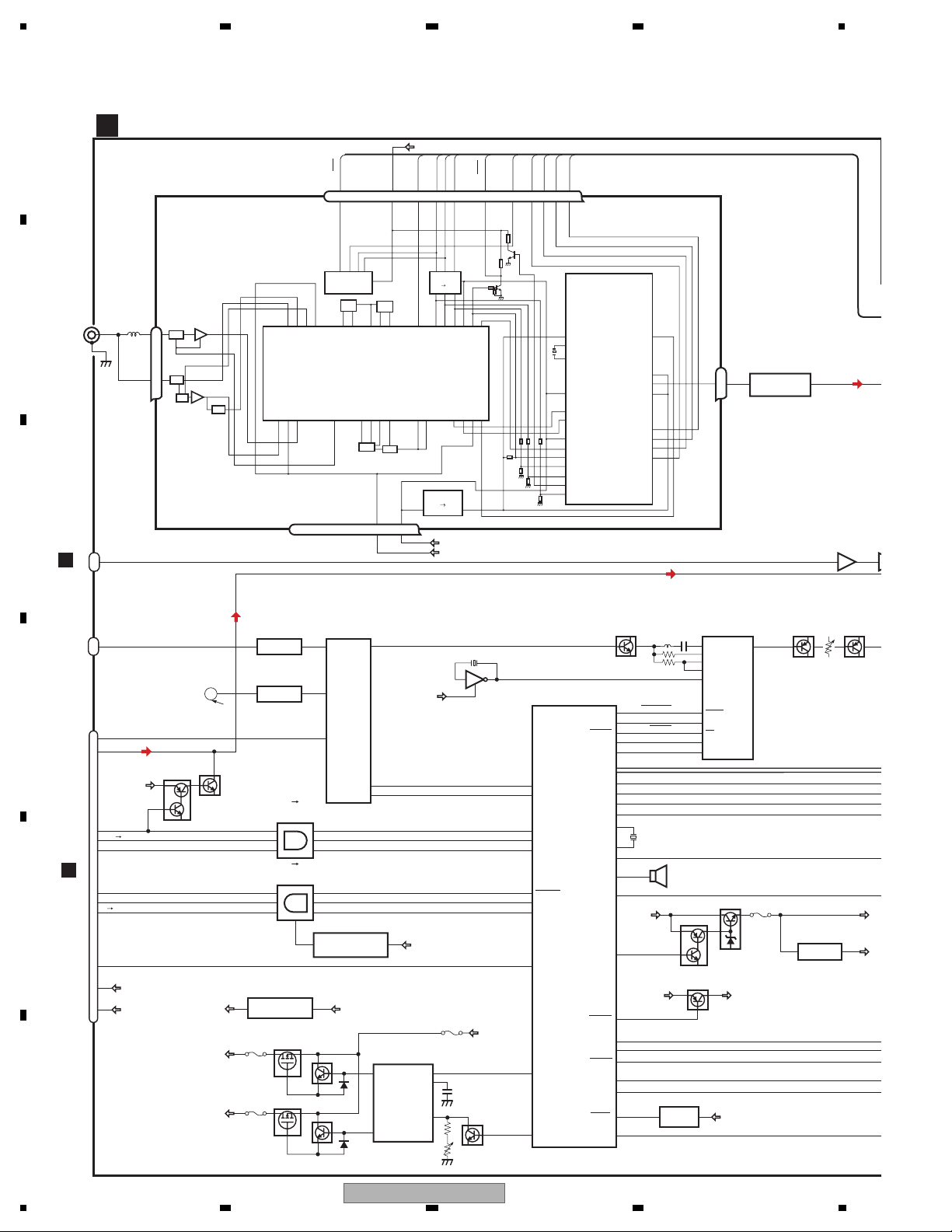

4. BLOCK DIAGRAM

4.1 BLOCK DIAGRAM

A

B

C

D

E

F

ANTENNA

C

CN1852

C

CN1901

TUNER AMP UNIT

A

CN402

1

2,3

1

3

AM ANT

FM ANT

CN301

1

CN281

(1/3)

VIDEO IN

4

CN101

COMPOSIT

9

LOUT

12

SYS+B

AMUTE

21

MS4 SRX

17

STANBY

16

XRES

20

IRQPWR

19

S MS4TX

18

WAKEUP

1

40

VD

|

38

VDD5

27

MSVDD5

|

24

FM/AM TUNER UNIT

FMRF

ATT

ATT

FMRF

RF adj

ANT adj

VIDEO IN ISO

IC152

NJM2505AF

VIN VOUT

MINIJACK VIDEO ISO

IC171

NJM2505AF

A

MS5L

Q101

Q102

TUN33

MSVDD5

VD

VIN VOUT

3V 5V

TC74VHCT08AFTS1

1

4

12

5V 3V

TC74VHC08FTS1

11

8

3

2,10,13,14

TUNER3V REG.

3

IC1021

NJM2885DL1-33

Q1105

FU1103

Q1104 Q1102

FU1102

VDD5V

CE2

76 13 5 1098 11 14 18192021

NC

CE2

IC 3 EEPROM

5.0V

OSC

IC 1

3.3V

MIXER, IF AMP

T51

RFGND

OSCGND

DGND

212 1522 16 4 17

AUDIO GNDNCVCC

VIDEO SELECTOR

IC191

BA7611AF

14

1

IN1 VOUT

14

6

IN3

4

IN2

CTLA

CTLB

SL

CE1

TUNPDO

TUNPCK

DI

SL

CK

CE1

ROM_VDD

IC 5

5V 3.3V

LPF

CF52

IC 4

3.3V 2.5V

V33

2.5V

TUN33

SYS+B

IC503

TC7SU04FU

X502

14.31818MHz

24

5

3.3V

VDD_3.3

8

2

3

IC101

3

6

11

IC102

12

9

1

3.3V REG.

3

IC103

S-812C33AMC-C2N

1

SYS+B

Q1103

2

D/D CONVERTER

IC1101

AN8011S

7

ON/OFF

OUT2

10

OUT1

VDD5V

CT

RT

FU1101

3

1

2

Q1101

VR1101

BUP

LDET

LDET

TUNPDI

DO

68

69

39

30

42

40

41

29

43

44

75

RDS_CK

RDS_DATA

RDS_CK

RDS_DATA

VSEL1

VSEL2

AMUTE

RXMS5

STANDBY

XRESET

IRQPW

TXMS5

WAKEUP

CONTROLLER

VDCONT

DDCONF

RDS_HSLK

RDS_LOCK

RDS_LOCK

SYSTEM

IC601(2/2)

PEG324A

RDS_HSLK

DET, FM MPX,

RDS DECODER

OSDMUTE

SYNCJDG

OSDCS

OSDD

OSDCLK

SACLK

SAIN

MUTE

VMUTE

XOUT

SYSPW

BEEP

COOLCONT

OSDPW

SWVDD

DPDT

KYDT

DSENS

ROT1

ROT0

RESET

ILMPW

IC 2

2.5V

Lch

65

23

IC401

NJM2794RB2

TC7WT125

256

IC301

OSD

IC504

Q551

OSDMUTE

59

SYNCJDG

77

OSDCS

4

OSDDT

99

OSDCLK

100

51

90

48

70

13

XIN

X601

11

15.000MHz

46

24

26

BUP

55

5

33

34

16

1

2

1

10

BD4835G

3

30

32

29

31

2

7

9

14

15

16

BZ601

BUZZER

VIDEO5V REG.

Q1032

SWDVDD REG.

Q1061

RESET

2

IC651

PDC150A

CVcr

CVout

SYNin

CVin

HFTin

XTALin

MUTE

SYNCJDG/Rout

CS

SIN

SCLK

Q1031

SWVDD5VDD5V

VDD5V

27

FU1031

VIDEO3V REG.

IC1041

S-812C33AMC-C2N

VIN VOUT

Q572VR571Q571

VI

32

V3

20

DVH-P5900MP/XN/EW5

1234

5678

A

REMOTE

IP BUS

WIRED

1

2

3

CN331

KEYAD

KEYD

CN131

92

KEYAD

32

KEYD

28

TX

27

RX

25

RX2

47

IPPW

SYSTEM

CONTROLLER

IC601(1/2)

PEG324A

IP-BUS DRIVER

IC131

5

1

8

IPBUSL+

7

IPBUSL-

11

5

BUS-

6

BUS+

Q131

HA12241FP

STBY

1

DIN1

2

ROUT

8

BUP

SWL

RL

FL

BUP

Q284

Q281

Q283

Q282

SWL

CN281

RL

FL

(2/3)

CN282

1

8

4

S/W L

REAR L

FRONT L

01

94RB2

5

IC301

TC7WT125FU

2563

VIDEO OUT ISO

Q572VR571Q571

IC592

NJM2505AF

VIN VOUT

14

BUP

6dB AMP

IC591

TK15405BMI

IN OUT

VMUTE

Q285

Q132

CE2

CE1

TUNPDO

TUNPDI

TUNPCK

SL

RDS_LOCK

RDS_HSLK

RDS_DATA

RDS_CK

LDET

IPBUSL+

IPBUSLTUNL

MS5L

24

38

ASENBO

63

CE2

64

CE1

84

TUNPDO

66

TUNPDI

65

TUNPCK

95

SL

Q401

79

RDS-LOCK

81

RDS-HSLK

Q402

80

RDS-DATA

72

RCK

73

LDET

ELECTRONIC VOLUME/

SOURCE SELECTOR

7

IN4L+

6

IN4L-

8

IC201

IN3L

9

PML017A

IN2L

10MINIL

IN1L

13

VDD5V

ACC5V REG.

ACC5V

Q1071

45

ACCPW

17

BSENS

18

ASENS

21

BGENS

36

TELIN

49

AMPPW

40

OutPreL

38

OutFL

39

OutRL

SAOut

SAClk

12

BACKUP SENSE

Q710

ACC SENSE

Q741

12

15

TELIN

4

FLIN

RLIN

STBY

MUTE

22

VDD5V REG.

Q1033

B.GEAR SENSE

Q731

POWER AMP

IC251

PAL007C

Q1034

VCC1/2,3/4

B.REMOTE

B

CN751

BUP

B.U

1

ACC

5

B.G.SENS

3

TELM

7

POWER

CONNECTOR

GND

2

BUP

6,20

5

FL+

3

FL-

17

RL+

19

RL-

25

BREM

CN281

(3/3)

VIDEO OUT

FL+

RL+

FL-

RL-

12

10

11

9

4

5

VIDEO OUT

C

CN302

4

OPT-OUT

Q286

VST,VCK,VDT

SYS+B

Q1001

SYS+B REG.

SYSPW

MUTE

Q251

Q253

Q252

Q1002FU1001

BUP

Q1003

BUP

FAN REG.

BUP

Q1083

Q1081

CN1081

FAN

2

1

D

VIDEO3V REG.

IC1041

S-812C33AMC-C2N

VIN VOUT

Q1082

VIDEO5

B

32

V33

MINIJACK

AUDIO ISO

5MINIL

IC231

NJM2794RB2

A

ILM+B REG.

BUP

SWVDD5

Q1091

Q1092

6

SY_2_KY

KY_2_SY

CN701

AUXL

AUXV

SWVDD

DSENS

ROT1

ROT0

11

12

3

5

6

14

4

7

ILM

9

KEYBOARD UNIT

CN1801

AUXL

11

AUXV

12

3

5

6

14

4

7

9

SYS_KY

KY_SYS

DSENS

ROT1

ROT0

ILM

SWVDD

1

2

ILLUMI

NATION

S1827

CN1802

4

KEY/LCD CONTROL

IC1801

PD6569A

50

RXD

49

TXD

55

X1801

X1

5MHz

5

54

4

3

X0

KEY MATRIX

S1801,S1802,S1804-S1807,

S1809-S1815,S1817-S1822,

S1824,S1825,S1828,S1829

REM

57

REMOTE CONTROL

SENSOR

IC1802

1

GP1UX51RK

3

LCD

LCD1801

SWVDD

1

OPT IN

DVH-P5900MP/XN/EW5

56

7

8

E

F

21

1234

O

5

A

DVD CORE UNIT

C

NRES

VIDEO+AUDIO

IC1501

MN2DS0016AAUB

101

LATCH

IC1352

TC74LCX16373FT

1LE

2LE

CE

WE

CE

WE

AD0-15

48

25

AD0-15

A16-19

XCSSR26

XWR111

XCSFM26

IC1403

TC7SZ32FU

11 XWR2

XRDNRES 28 50

OE

A0-15

B

A0-15

12

FLASH 16M

CWW1434

CWW1435

RESET

IC1401

IC1402

AD0-15

A16-19

1

4

2

IC1351

TC7SZ08FU

1

4

2

XCSSR

XCSFM

C

SDRAM

IC1481

EDS1232AATA-75

NRST

77

XCSSR

51

NEXCE

62

NEXWE

NEXOE

PHOTOSNS

MA0-11

MDQ0-31

DQM0-3

232

189

192

191

190

188

187

186

185

184

183

8

88

BA0

BA1

NWE

NCAS

NRAS

NCSM

MCK

MCKI

VSENCE

P0

EXTRG1

SCLOCK

SDATA

EXTRG0

TRCCLK

TRCDATA0

TRCDATA1

TRCDATA2

TRCDATA3

TRCST

22

BA0

23 10

BA1

WE

CAS

RAS

20

CS

68

D

CN1951

PR_A20 92

11

EXTRG1_SPD_SW

10

SCLOCK

9

SDATA

8

EXTRG0

7

TRCCLK

6

TRCD0

5

TRCD1

4

TRCD2

DEBUG

3

TRCD3

2

TRCST

1

12

E

VCC33

|

13

VD8

CLK

VOLTAGE DETECT

IC1003

S-80859CNNB-B9K

2 1 VSENS

OUTVDD

XWE17 3

XCAS18 4

XRAS19 5

XCSM 6

MCK 234

SRCK

ADOUT3

LRCK

SDODAC

SCKDAC

LTDAC

DACCK

OSCO

OSCI

Comp

STANDBY

SLVSTS

HOSTCMD

IRQPWR

AMUTE

DSCSNS

IECOUT

CONT2

CONT1

DRV3

DRV2

LOADIN

CLAMP

HOME

TEMP

VIN2RF

VIN2

VIN1RF

VIN1

VIN3RF

VIN3

VIN4RF

VIN4

VIN5

VIN6

CDMPD

DVDMPD

RFINN

F+H_G+H

E+G_E+F

LPCO2

LPCO1

174

175

173

91

90

74

172 DACCLK

169

170

152

Cr

153

Cb

154

Y

161

78

79

80

89

87

147

144

179

85

84

95

96

97

MD

93

99

FG

150

FD

149

TD

94

98

145

122

142

123

143

121

140

120

141

136

137

130

128

116

134

135

131

129

X1501

(CR)

(CB)

(COMPOSIT)

LDIN

B

A

C

D

FE1

FE2

RF

(Y)

COMPOSIT

STANBY

STSCOMN

CMDCOMN

CR

CB

Y

SRCK

ADOUT3

LRCK

SDODAC

SCKDAC

LTDAC

DACCLK

AUDI

1

2

3

13

14

15

16

VDD

F

22

1234

DVH-P5900MP/XN/EW5

5678

A

SRCK

ADOUT3

LRCK

SDODAC

SCKDAC

LTDAC

DACCLK

AUDIO 2CH ANALOG OUT

IC1801

PCM1753DBQ

1

BCK

2

DATA

3

LRCK

13

MD

14

MC

15

ML

16

SCK

VDD5 VCC33

7

VOUTL

3.3V REG.

IC1007

NJM2885DL1-33

OUTIN

1.2V REG.

IC1008

R1232D121B

2

VIN

VDD

LX

3

31

8

CONT2

CONT1

DRV3

DRV2

MD

FD

TD

VCC12

VCC5

S-L2980A50MC-C7J

AVCC5

MOTOR DRIVER

IC1201

BD7996EFV

20 18

CTL2 SLO2-

21

CTL1

25

SLIN2

26

SLIN1

29

SPIN

10

LDIN

13

FG

51

ACTIN1

50

ACTIN2

VCC5 REG.

IC1004

NJM2880U1-05

4

5

VIN

VOUT

CONT

AVCC5 REG.

IC1005

VIN

VOUT

ON/OFF

16

SLO1-

17

SLO2+

15

SLO1+

42

V

39

W

44

U

36

HB

30

HW-

31

HW+

32

HV-

33

HV+

34

HU-

35

HU+

2

ACO1-

1

ACO1+

3

ACO2+

4

ACO2-

FOM

FOP

TOM

TOP

CN1901

XRESETNRES

COMPOSIT

STANBY

SLVSTS

HSTCMD

IRQPWR

AMUTE

VD5

VD8

WAKE UP

CN1301

DiscDetect

1

2

8cm

8cm

12cm

PhotoPHOTOSNS

CN1852

IECOUT

CLAMP1

21

29

CR

38

CB

36

Y

34

32

25

24

23

CN101

A

22

20

14

|

17

3

2

|

1

40

3

2

4

5

1

COMPOUND UNIT(A)

D

S1203

DISC SENS

4

3

2

5

6

8cm

12cm

8cm

S1202

Q1299

S1204

S1201

S1205

B

C

1

CN301

A

CLAMP

S1206

TP1

LOUT

STSCOMN

CMDCOMN

5

1

1

3

VDD5

VD8

DISC DET

TC7SZ125FU

ANALOG LOUT

FU1901

IC1301

4DSCSNS

CN1201

B-

1

A-

COILV

COILW

COILU

HBM

HWM

HWP

HVM

HVP

HUM

HUP

VDD5

COIL_V

COIL_W

COIL_U

HALL_BIAS-

HALL_W-

HALL_W+

HALL_V-

HALL_V+

HALL_U-

HALL_U+

HALL_BIAS+

SWITCHHOME

2

B+

3

A+

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

20

COMPOUND UNIT(B)

E

D

CN1101

F-

FOM

1

F+

FOP

2

T-

TOM

3

T+

TOP

4

THTEMP

5

B

7

LPCO2

LPCO1

Q1104Q1102

Q1103Q1101

VREF

VCC5

78MDCDMPD

65MDDVDMPD

F+H/G+HF+H_G+H

E+G/E+FE+G_E+F

LD(CD)

LD(DVD)

FE1

FE2

VCC

RF

A

C

D

8

9

10

11

12

14

15

PU (DP8)

17

21

22

24

25

19

20

E

F

56

DVH-P5900MP/XN/EW5

7

8

23

1234

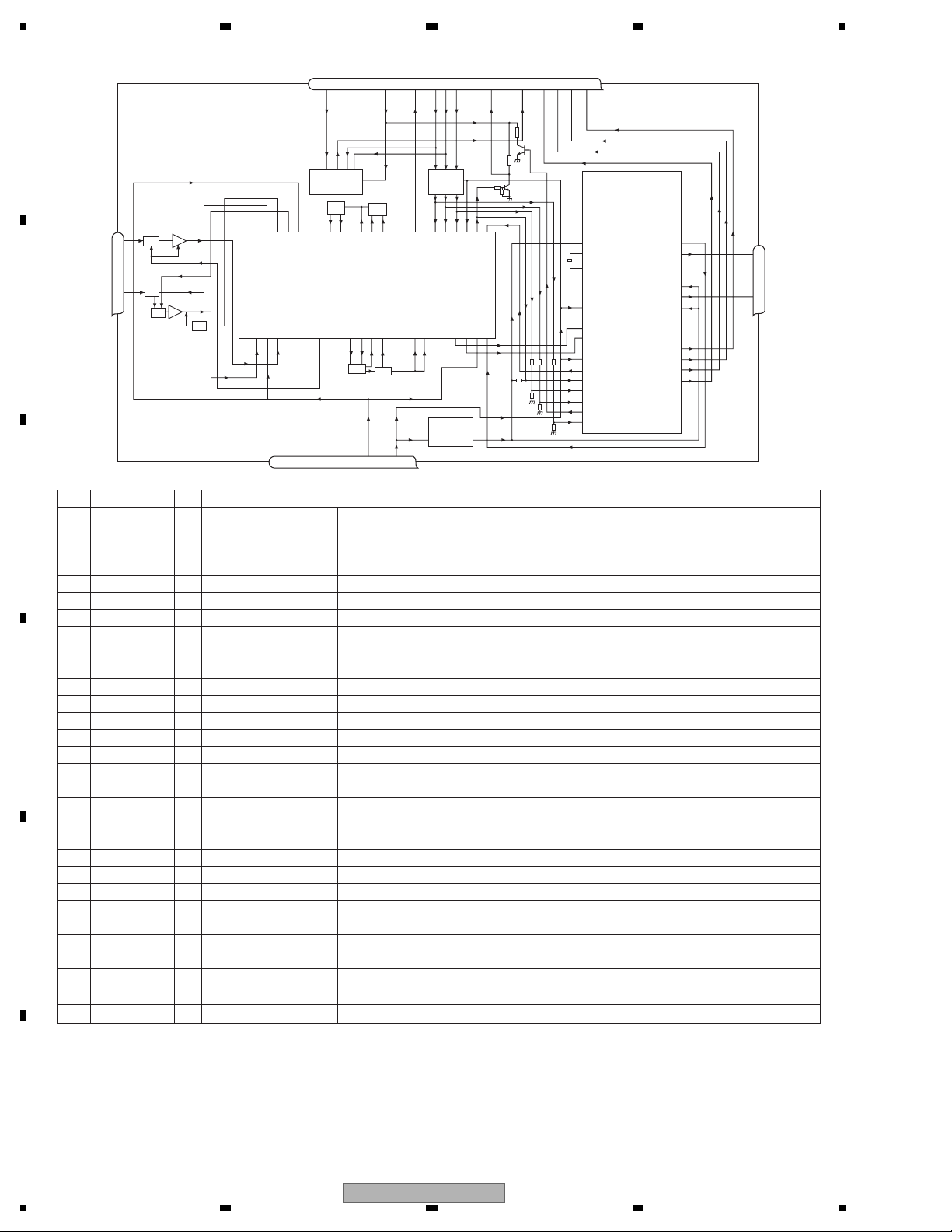

- FM/AM Tuner Unit

A

7 6 13 5 10 9 8 11 14 18 19 20 21

NC

CE2

ROM_VDD

DI

SL

CK

CE1

LDET

DO

RDS_CK

RDS_DATA

RDS_LOCK

RDS_HSLK

AM ANT

1

AT T

FM ANT

3

AT T

B

ANT adj

No. Symbol I/O Explain

C

1 AMANT I AM antenna input AM antenna input high impedance AMANT pin is connected with

2 RFGND RF ground Ground of antenna block

3 FMANT I FM antenna input Input of FM antenna 75 Ω Surge absorber

4 VCC power supply The power supply for analog block. D.C 8.4 V ± 0.3 V

5 SL O signal level Output of FM/AM signals level

6 CE2 I chip enable-2 Chip enable for EEPROM ”Low” active

7 NC non connection Not used

8 CE1 I chip enable-1 Chip enable for AF•RF ”High” active

9 CK I clock Clock

D

10 DI I data in Data input

11 LDET O lock detector “Low” active

12 OSCGND osc ground Ground of oscillator block

13 ROM_VDD power supply Power supply for EEPROM pin 13 is connected with a power supply of

14 DO O data out Data output

15 DGND digital ground Ground of digital block

16 NC non connection Not used

17 VDD_3.3 power supply The power supply for digital block. 3.3 V ± 0.2 V

18 RDS_CK O RDS clock Output of RDS clock(2.5 V)

19 RDS_DATA O RDS data Output of RDS data(2.5 V)

E

20 RDS_LOCK O RDS lock Output unit “High” active(2.5 V) (RDS_LOCK turns over by the

21 RDS_HSLK O RDS high speed Output unit “High” active(2.5 V)(RDS_HSLK turns over by the

22 AUDIOGND audio ground Ground of audio block

23 L ch O L channel output FM stereo “L-ch” signal output or AM audio output

24 R ch O R channel output FM stereo “R-ch” signal output or AM audio output

3.3V

IC 5

t

5V

3.3V

IC 4

t

3.3V 2.5V

FMRF

FMRF

RF adj

IC 3 EEPROM

5.0V

OSC

LPF

IC 1

3.3V

MIXER, IF AM P

T51

CF52

RFGND

OSCGND

DGND

212 1522 16 4 17

AUDIOGNDNCVCC

VDD_3.3

an all antenna by way of 4.7 µH. (LAU type inductor) A series circuit

including an inductor and a resistor is connected with RF ground for

the countermeasure against the hum of power transmission line.

micro computer.

external transistor . “Low” active)

lock external transistor. “Low” active)

2.5V

Rch

IC 2

2.5V

DET, FM MPX,

RDS DECODER

24

Lch

23

(DSP-201M-S00B)is necessary.

F

24

1234

DVH-P5900MP/XN/EW5

5678

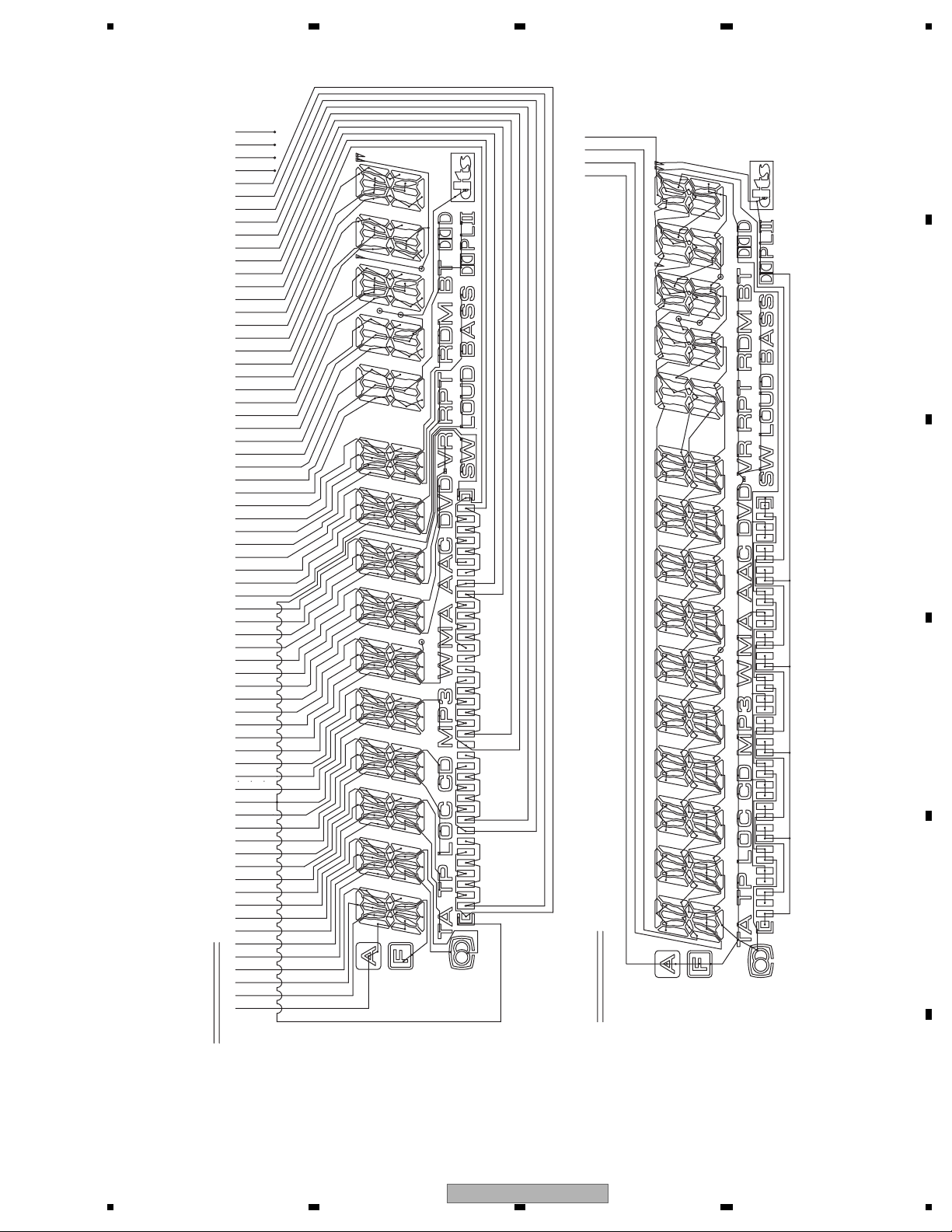

- LCD(CAW1947)

COM 0

COM 1

COM 2

COM 3

SEG 0

SEG 1

SEG 2

SEG 3

SEG 4

SEG 5

SEG 6

SEG 7

SEG 8

SEG 9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

SEG31

SEG32

SEG33

SEG34

SEG35

SEG36

SEG37

SEG38

SEG39

SEG40

SEG41

SEG42

SEG43

SEG44

SEG45

SEG46

SEG47

SEG48

SEG49

SEG50

SEG51

SEG52

SEG53

SEG54

SEG55

SEG56

SEG57

SEG58

SEG59

SEG60

SEG61

SEG62

SEG63

SEG64

SEGMENT

COM 0

A

COM 1

COM 2

COM 3

B

C

D

E

COMMON

56

DVH-P5900MP/XN/EW5

F

7

8

25

1234

5. DIAGNOSIS

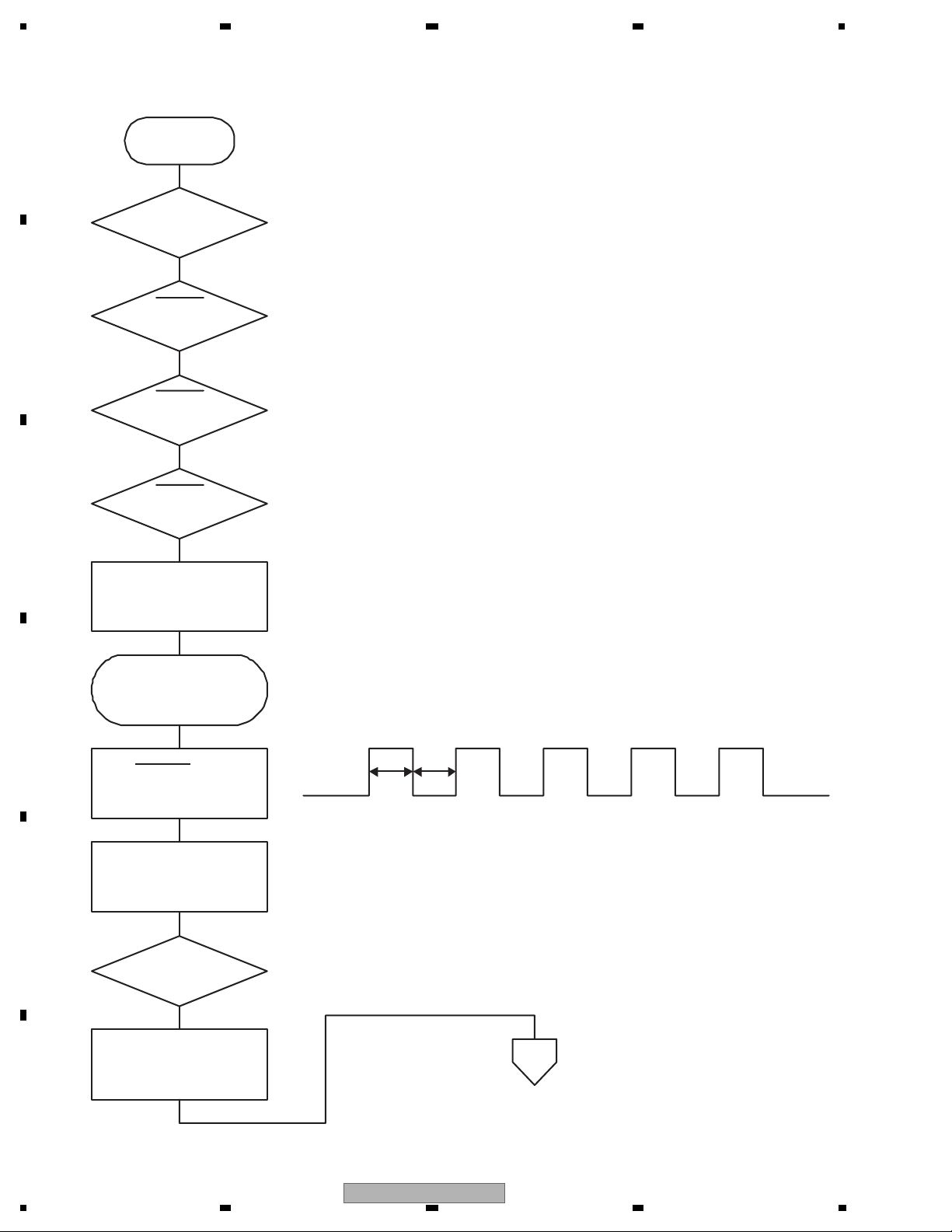

5.1 OPERATIONAL FLOWCHART

A

Power ON

Vcc = 5 V

14, 60 pin

B

BSENS

17 pin

BSENS = L (B.UP ON)

ASENS

18 pin

ASENS = L (ACC ON)

DSENS

C

16 pin

DSENS = L (ACC ON)

ASENBO ← H

38 pin

Starts communication with Grille microcomputer.

D

300 ms

SWVDD ← L

5 pin

300 ms

In case of the above signal, the communication

with Grille microcomputer may fail.

Source keys

operative

E

If the time interval is not 300 msec, the oscillator

may be defective.

Source ON

SYSPW ← H

46 pin

F

Completes power-on operation.

(After that, proceed to each source operation.)

26

1234

DVH-P5900MP/XN/EW5

5678

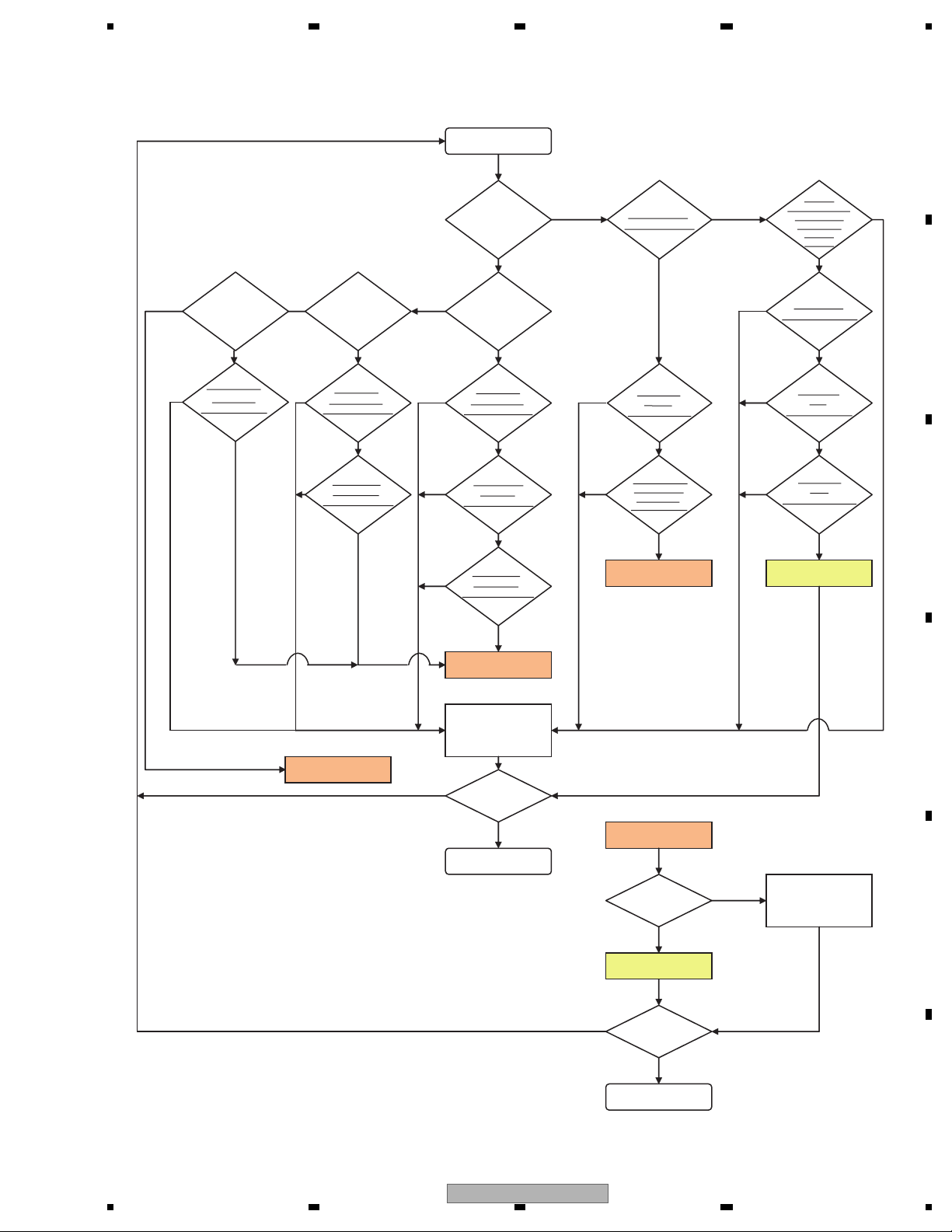

5.2 DIAGNOSIS FLOWCHART

BACK END

START

Can the

playback

start?

YES

NO

Standby OK?

Execute check 1.

YES

NO

Is VDD5

(VCC33, VCC12)

power supply

voltage OK?

Execute

check 2.

YES

A

NO

NO

Does the

operation

take time?

Is the life of flash

memory OK?

Conduct check item 12.

NO

YES

YES

NO

Is the image

in error?

Is AVCC5

NO

voltage OK?

Execute check 8.

Is the video

NO

circuit OK?

Execute check 11.

YES

YES

YES

NO

NO

NO

NO

Is the sound

in error?

YES

Is AVCC5

voltage OK?

Execute check 8.

YES

Is DACCLK

normal?

Execute check 9.

YES

Is the audio

circuit OK?

Execute check 10.

YES

Go to FE

section check.

Repair the

defective part.

NO

NO

Is SDRAM

IF OK?

Execute check 6.

YES

Is VD8, VCC5

power supply

voltage OK?

Execute check 7.

Go to FE

section check.

YES

NO

Reset OK?

Execute check 3.

NO

NO

Is VSENS

Execute check 4.

Is 27 MHz

Execute check 5.

Replace the unit.

B

YES

OK?

YES

OK?

C

YES

D

Go to FE

section check.

NO

Normal?

YES

END

DVH-P5900MP/XN/EW5

56

FE section check.

Is FE section

normal?

Replace the unit.

NO

Normal?

END

7

YES

YES

NO

Go to FE related

repair process.

8

E

F

27

1234

DGND1

STANBY

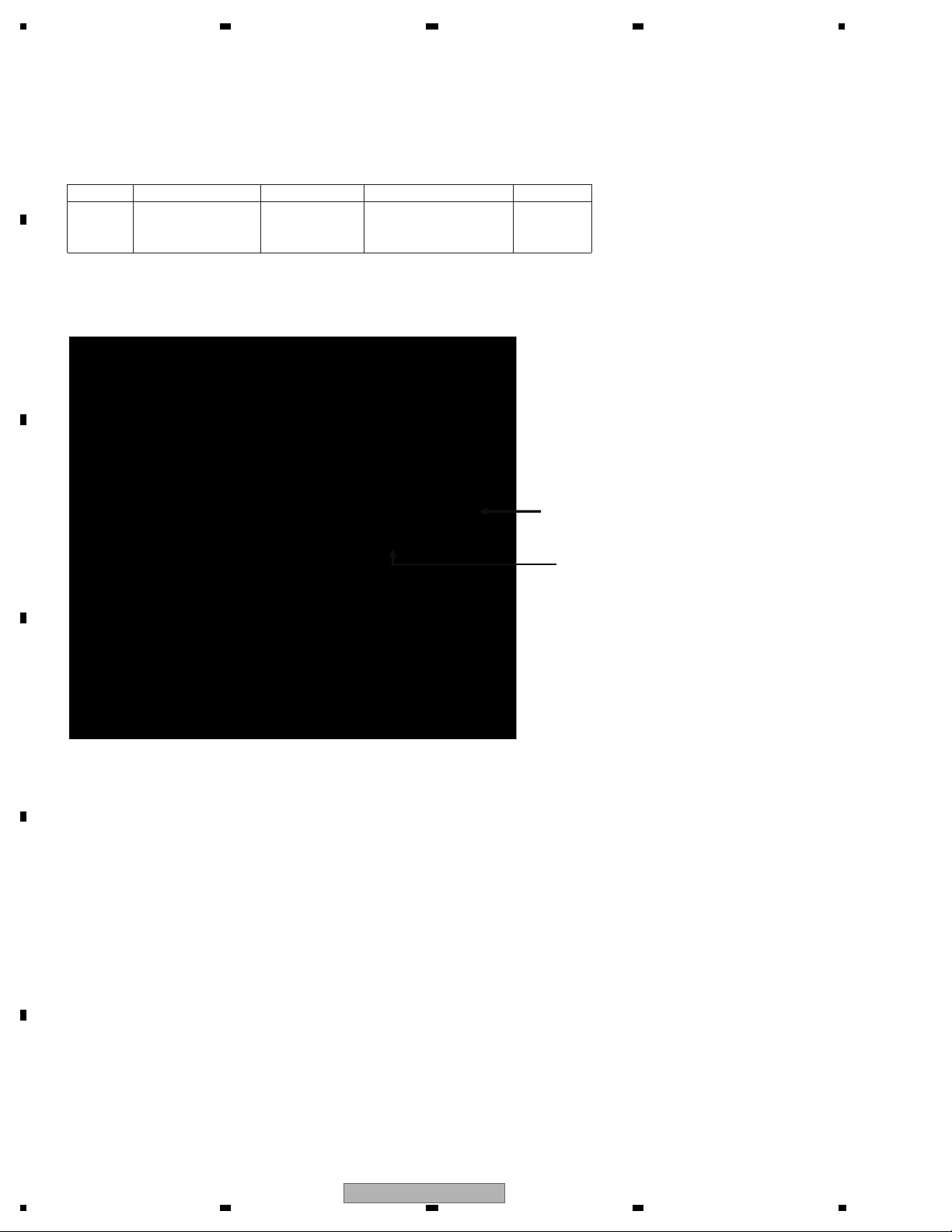

Check 1: Standby OK?

A

<Check> Check the voltage at the “STANBY” test point while the power is on.

Use the “DGND1” test point at the reference.

NO. Check point Module No.

1

STANBY-DGND1 ALL

Specification value

VCC33 V-

Unit

V

0.6 V or more

B

C

Side A

D

Fig 1.1: STANBY check point

E

F

28

DVH-P5900MP/XN/EW5

1234

5678

DGND1

VCC 12_1

VCC 33

VDD 5_3

Check 2: Is VDD5 (VCC33, VCC12) power supply voltage OK?

A

VDD5

F.E. driver control system

IC1401 FLASH power supply (Data)

IC1402 FLASH power supply (Program)

IC1481 SDRAM power supply

VDD5

IC1007

3.3 V output regulator

IC1008

VCC33 (= 3.3 V )

VCC12 (= 1.2 V )

IC1501 DVD-LSI power supply

IC1501 DVD-LSI power supply

DC/DC converter

1.2 V output

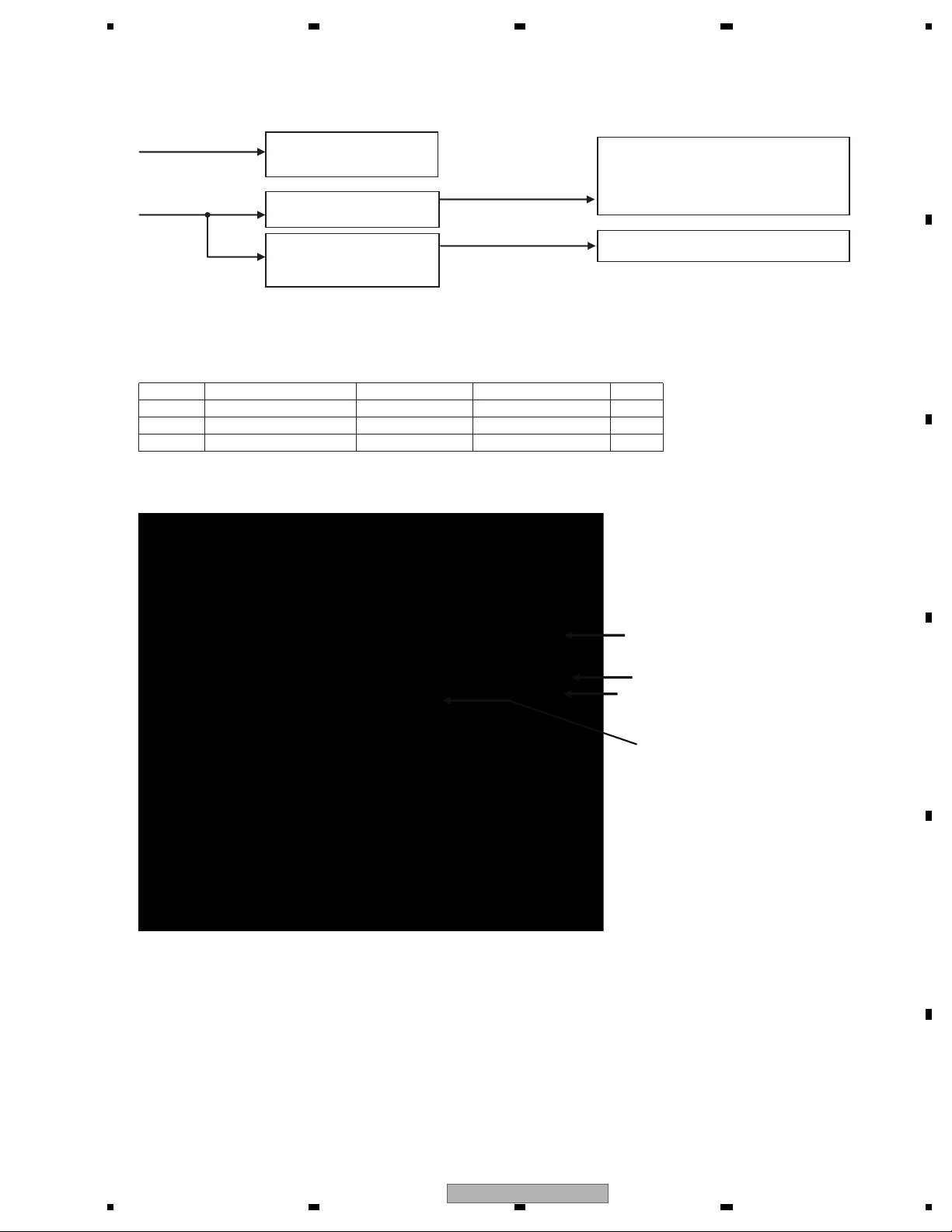

Fig 2.1: Power supply configuration

<Check> Check the voltage at the “VDD5_3, VCC33_3 and VCC12_1” test point while the power is on.

Use the “DGND1” test point at the reference.

NO. Check point Module No.

VDD5_3 - DGND1

1

VCC33_3 - DGND1

2

VCC12_1 - DGND1

3

ALL

ALL

ALL

Specification value

5.0 ± 0.4

3.3 ± 0.15

1.2 ± 0.12

Unit

V

V

V

Side A

B

C

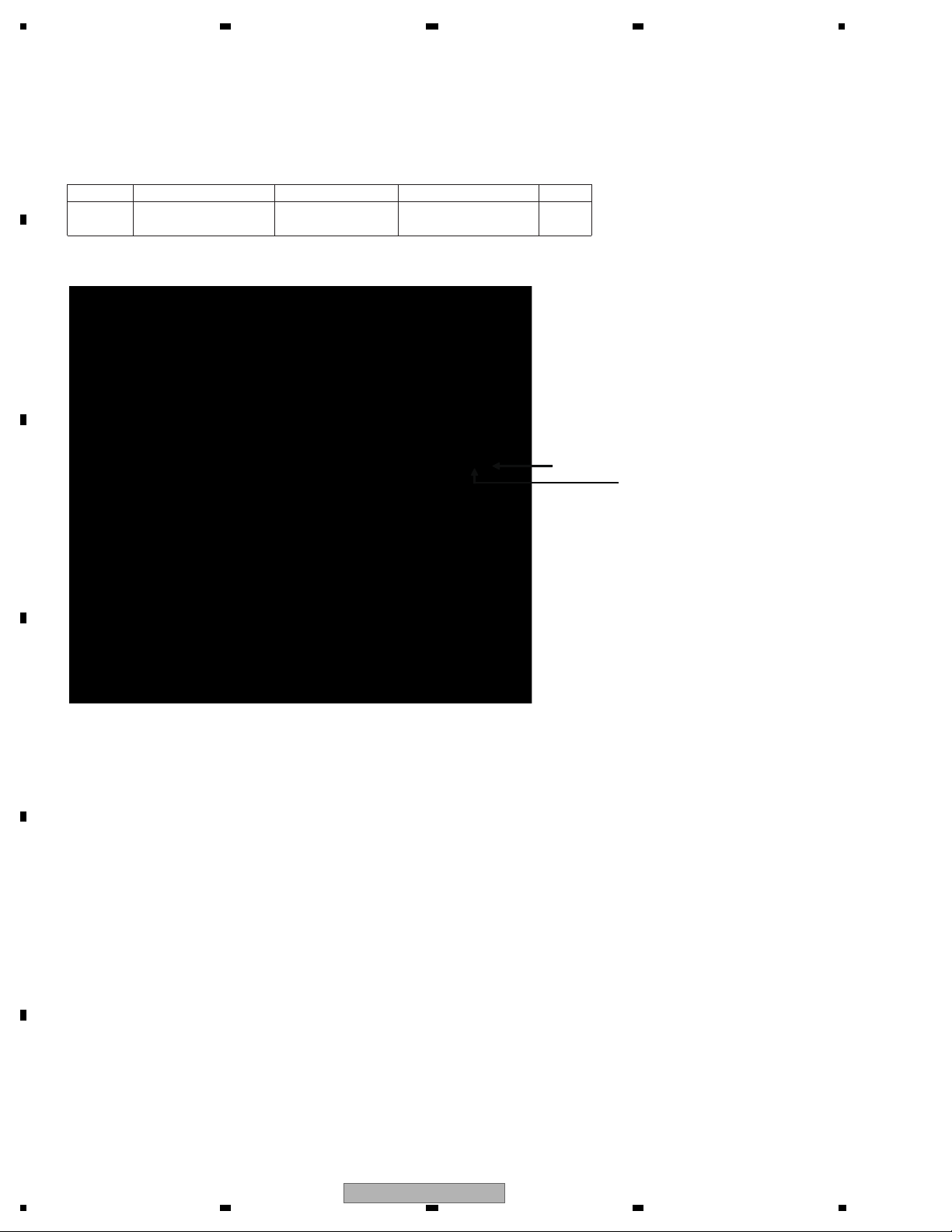

Fig 2.2: VDD5, VCC33, VCC12 voltage check points

D

E

F

56

DVH-P5900MP/XN/EW5

7

8

29

1234

DGND1

XRES

Check 3: Reset OK?

A

<Check> Check the voltage at the “XRES” test point while the power is on.

Use the “DGND1” test point at the reference.

NO. Check point Module No. Specification value Unit

1 XRES-DGND1 ALL

VCC33 ×

0.7 or more

Side A

B

V

C

D

E

Fig 3.1: RESET check point

F

30

DVH-P5900MP/XN/EW5

1234

Loading...

Loading...