Philips FWM-355 Service manual

Service

Service

FW-M355

A02 - 163

Service

Product Service Group CE Audio

Service Information

Already published Service Informations: A02-162 3139 785 30076

CHANGES DURING PRODUCTION

* From production wk233 onwards a new 3CDC-LC-

MP3CD2002 module will be introduced due to cost reduction.

This new 3CDC-LC-MP3CD2002 module can be recognized by the much smaller square shape MP3CD2002

board instead of a shielded MPEG board.

A completely new chapter 10 is attached.

This chapter will replaced the existing MPEG-01B board

(chapter 8) and 3CDC-LC-VCD module (chapter 10).

This changeover must be synchronized with the following

changes on the Front and Combi board:

Front Board:

7400 3103 308 84531 TMP87CS71BF "M355TIV85431"

Combi Board:

3507 4822 051 30562 5k6 5% 0,1W

3508 4822 051 30562 5k6 5% 0,1W

2002 - 07 - 17

3139 785 30094

10-1

TABLE OF CONTENTS

Service Hints ...................................................................10-2

Wiring Diagram................................................................10-4

Blockdiagram...................................................................10-5

CD PART

Component Layout Main Board ...................................10-6

Circuit Diagram ............................................................10-7

MP3 PART

Component Layout Main Board ...................................10-8

Circuit Diagram ............................................................10-9

Exploded View...............................................................10-10

Partslist..........................................................................10-12

3CDC-LC-MP3CD2002

(3 Disc Carousel Changer+MP3 Board)

Layout stage .2

10-2

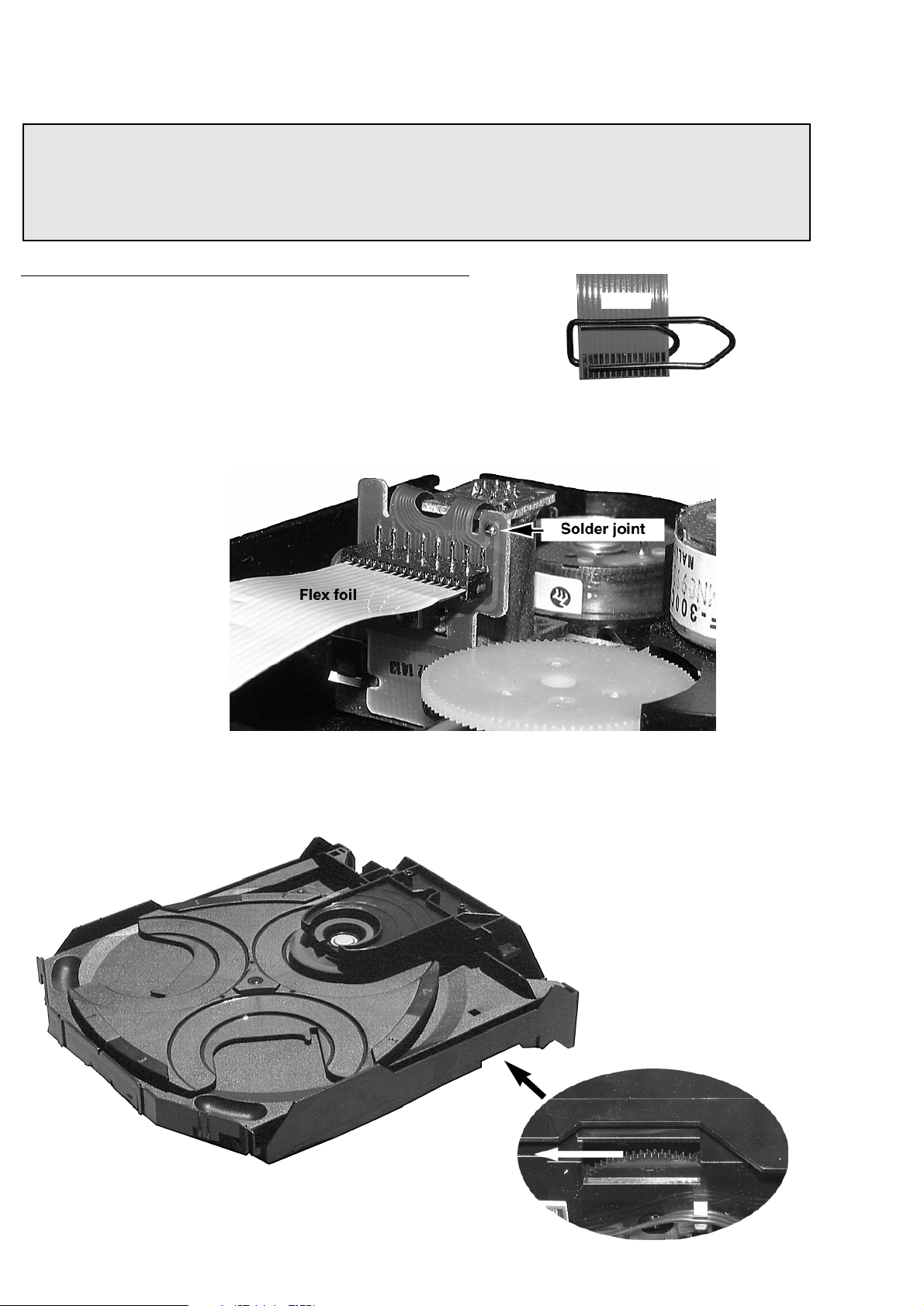

The following steps have to be done when replacing the CD mechanism:

1. Disconnect flexfoil cable from the old CD drive

2. Put a paperclip on the flexfoil to short-circuit the contacts (fig.1)

3. Remove the old CD drive

4. Remove paperclip from the flexfoil and connect it to the new drive

5. Position the new CD drive in its studs

6. Remove solder joint from the Laserunit

CHARGED CAPACITORS ON THE SERVO BOARD MAY DAMAGE THE CD DRIVE ELECTRONICS WHEN

CONNECTING A NEW CD MECHANISM. THAT´S WHY, BESIDES THE SAFETY MEASURES LIKE

• SWITCH OFF POWER SUPPLY

• ESD PROTECTION

ADDITIONAL ACTIONS MUST BE TAKEN BY THE REPAIR TECHNICIAN.

fig.1

Attention: The laser diode of this CD drive is protected against ESD by a solder joint which shortcircuits the

laserdiode to ground.

For proper functionality of the CD drive this solder joint must be removed after connection the drive to

the set.

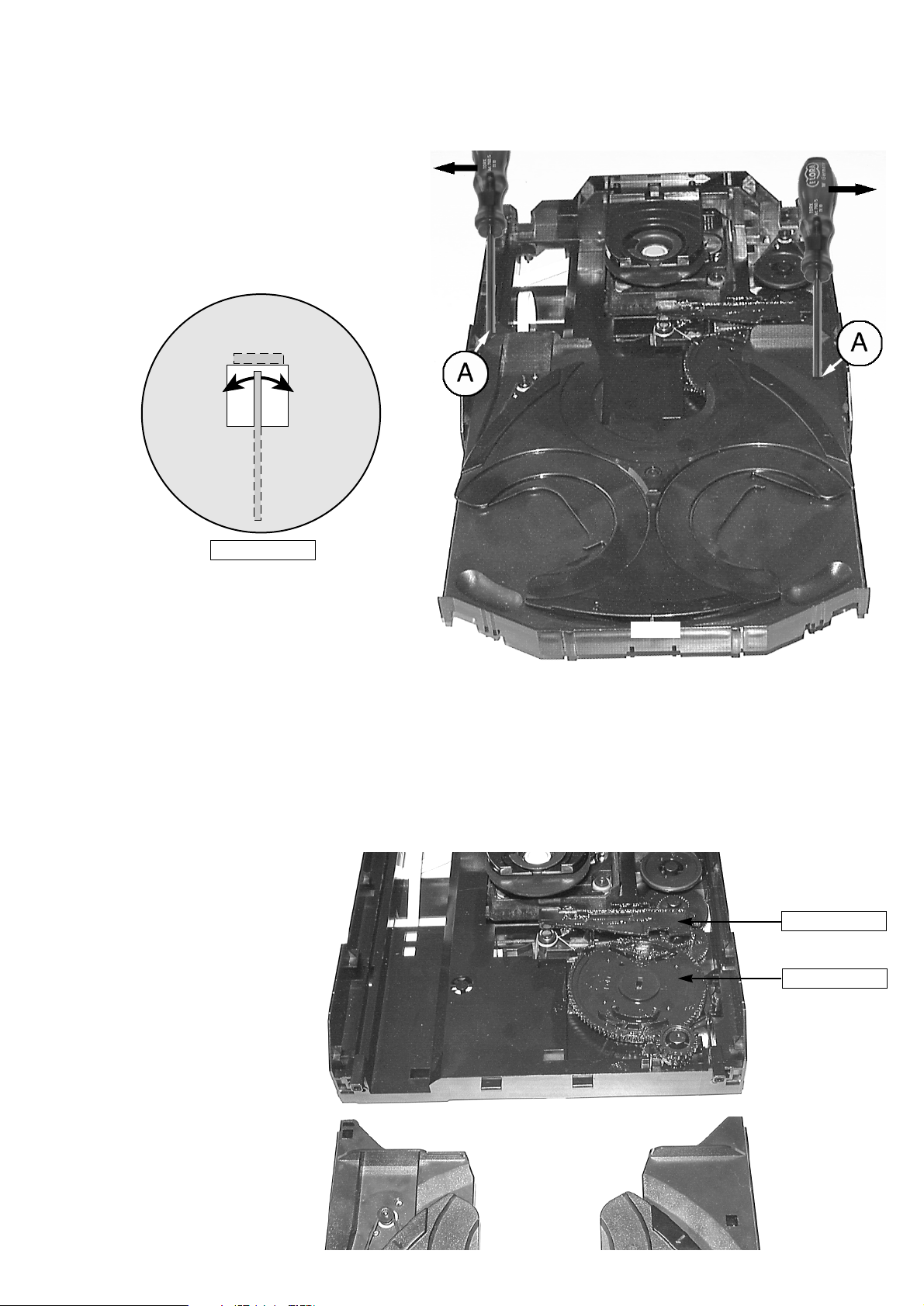

Emergency open

Service hints

In case of a Supply fault, the tray can be opened manually.

1. Remove the top cover of the set to get access to the Changer Module.

2. Turn gearwheel clockwise (as shown in picture below).

CAUTION

10-3

Pos 49 Guiding

Pos 48 Cam

Detail A

Dismantling of Tray

Service hints

1. Open the tray.

2. Release 2x catch as shown in fig. 2 and

Detail A

3. Pull tray out.

fig.2

Assembling of Tray

1. Turn Cam (pos. 48) clockwise to end

position.

2. If necessary - move Guiding (pos. 49) to the

right end position.

3. Insert the Tray.

10-4

Wiring

Disc Motor

Inner switch

Slide Motor

Service Position

Loading...

Loading...