Page 1

hobby

Owner´s manual

114 2

Page 2

2525

24

24

44

8

3

3

Page 3

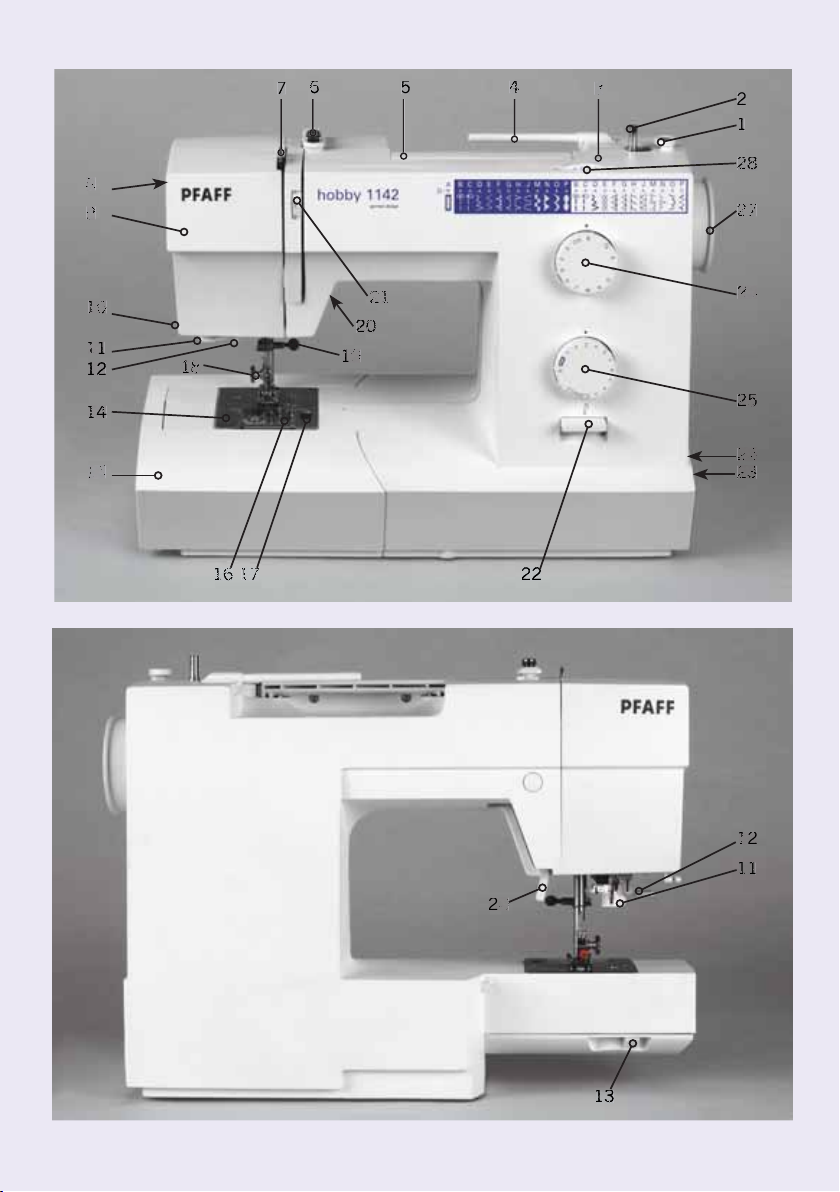

Parts of your hobby™ 1142 sewing machine

1 Bobbin winder stop

2 Bobbin winder spindle

3 Hole for extra spool pin

4 Spool pin

5 Carrying handle

6 Bobbin thread guide

7 Take-up lever

8 Foot pressure dial

9 Face plate

10 Thread cutter

11 Buttonhole lever

12 Needle threader

13 Slide for lowering the feed dog

14 Needle plate

15 Accessory tray

16 Throat plate

17 Throat plate release button

18 Thumbscrew

19 Needle screw

20 Presser foot lifter

21 Thread tension dial

22 Reverse stitch lever

23 Power switch

24 Connecting socket

25 Stitch length dial

26 Stitch selector dial

27 Handwheel

28 Stitch width dial

Page 4

Congratulations on purchasing

your new PFAFF® hobby!

Your hobby is so easy to use and offers a

whole range of features and accessories

for you to explore. Please spend some time

reading these operating instructions as it is

a great way to learn the machine and also to

make full use of the features.

Your Pfaff dealer will be at your service

with any help or advice you need.

We wish you many enjoyable

hours of sewing !

Some fabrics have excess dye which can cause

discoloration on other fabric but also on your sewing

impossible to remove.

Fleece and denim fabric in especially red and blue often contain a

lot of excess dye.

If you suspect that your fabric/ready-to-wear garment

contains a lot of excess dye, always pre-wash it before sewing/

embroidering to avoid the discoloring.

machine. This discoloring may be very difÀ cult or

Page 5

This houshold sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including

the following:

Read all instructions before using this household sewing machine.

DANGER - To reduce the risk of electric shock:

• A sewing machine should never be left unattended when plugged in. Always unplug this sewing

machine from the electric outlet immediately after using and before cleaning.

• Always unplug before relamping. Replace bulb with same type rated 15 Watt.

WARNING - To reduce the risk of burns, À re,

electric shock, or injury to persons:

• This sewing machine is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the sewing machine by a person

responsible for their safety.

• Children should be supervised to ensure that they do not play with the sewing machine.

• Use this sewing machine only for its intended use as described in this manual. Use only

attachments recommended by the manufacturer as contained in this manual.

• Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly,

if it has been dropped or damaged, or dropped into water. Return the sewing machine to the

nearest authorised dealer or service center for examination, repair, electrical or mechanical

adjustment.

• Never operate the sewing machine with any air openings blocked. Keep ventilation openings of

the Sewing machine and foot controller free from the accumulation of lint, dust, and loose cloth.

• Keep À ngers away from all moving parts. Special care is required around the Sewing machine

needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may deÁ ect the needle causing it to break.

• Wear safety glasses.

• Switch the sewing machine off (“0”) when making any adjustment in the needle area, such as

threading needle, changing needle, threading bobbin, or changing presser foot, etc.

• Always unplug the sewing machine from the electrical outlet when removing covers, lubricating,

or when making any other user servicing adjustments mentioned in the instruction manual.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being

administrated.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

SAVE THESE INSTRUCTIONS

Page 6

II

Introduction

TABLE OF CONTENTS

Introduction

Standard accessories IV

Optional accessories V

Accessory tray V

Stitch table VI

1. Operate your hobby 1142

Carrying handle, carrying case 1:2

Connecting the foot control 1:2

Foot preassure dial 1:3

Dropping the feed dog 1:3

Presser foot lifter 1:4

Changing the presser foot 1:4

Removing and attaching

the foot holder 1:5

Changing the needle 1:5

Bobbin winding 1:6

Inserting the bobbin 1:8

Threading the machine 1:9

Needle threader 1:10

Threading for twin needle 1:11

Bringing up the bobbin thread 1:12

Stitch selection 1:13

Stitch length dial 1:13

Adjusting stretch stitch balance 1:14

Stitch width dial 1:14

Variable needle position 1:15

Reverse sewing 1:15

Balancing needle thread tension 1:16

2. Utility stitches and practical

sewing

Basic sewing 2:2

Free arm sewing 2:4

Seam guides on the needle plate 2:5

Turning a square corner 2:5

Explanation of the sewing chart 2:6

Straight stitch 2:7

Stretch triple straight stitch 2:8

Zigzag stitch 2:8

Tricot stitch (Triple zigzag stitch) 2:9

Honeycomb stitch 2:9

Open overlock stitch (Knit stitch) 2:10

Closed overlock stitch 2:10

Blindhem 2:11

Blindhem stitch (elastic) 2:11

Automatic buttonhole 2:12

Buttonhole with gimp thread 2:14

Manual buttonhole 2:14

Button sewing 2:15

Sewing on zippers 2:16

Sewing on patches 2:18

Darning with the elastic stitch 2:18

Repairing tears 2:18

Page 7

3. Maintenance and

trouble-shooting

Cleaning 3:2

Changing the light bulb 3:3

Trouble-shooting 3:4

Index 3:6

Technical data 3:8

Introduction

III

Page 8

IV

Introduction

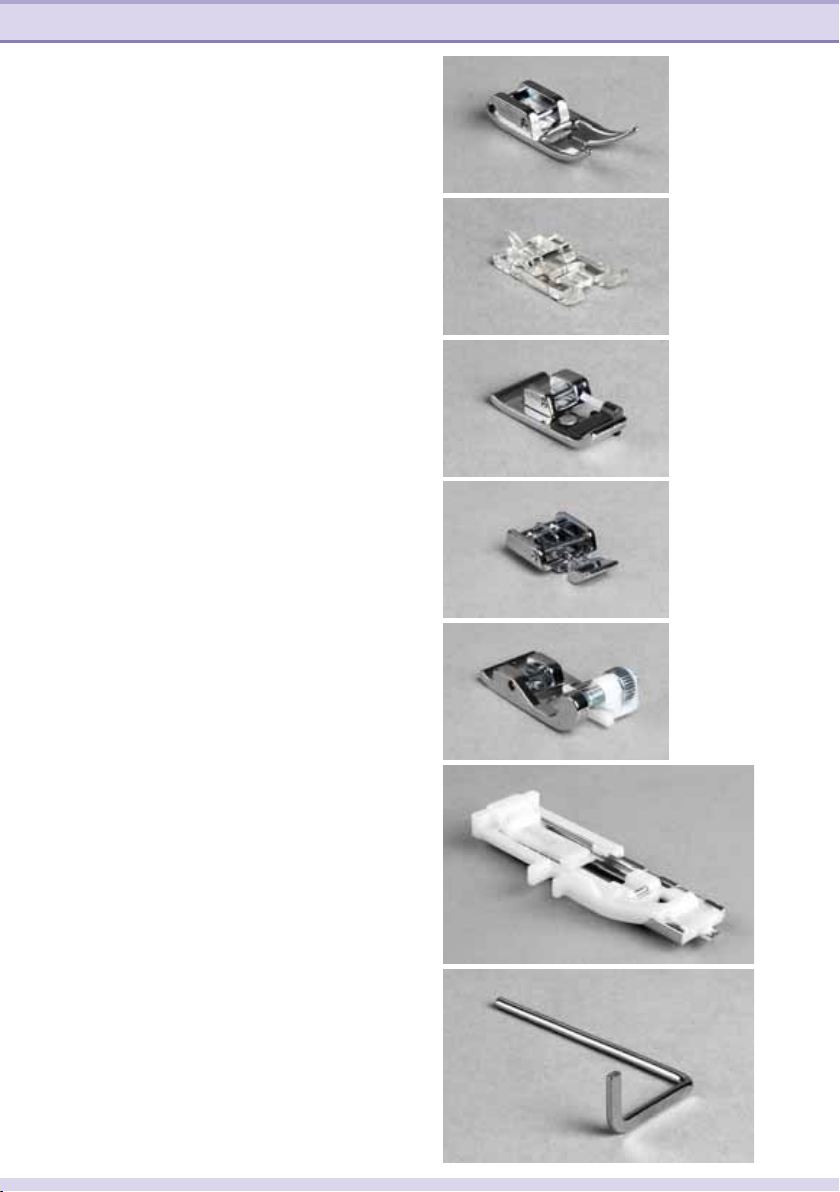

Standard accessories

1 Standard presser foot A

Part No. 820 546-096

2 Buttonhole foot B

Part No. 820 547-096

3 Overcasting foot C

Part No. 820 548-096

4 Zipper foot E

Part No. 820 549-096

5 Blindhem foot G

Part No. 820 550-096

1

2

3

4

5

6 Automatic buttonhole foot R

Part No. 820 551-096

7 Edge Guide/Quilting Guide

Part No. 820 552-096

6

7

Page 9

Introduction

V

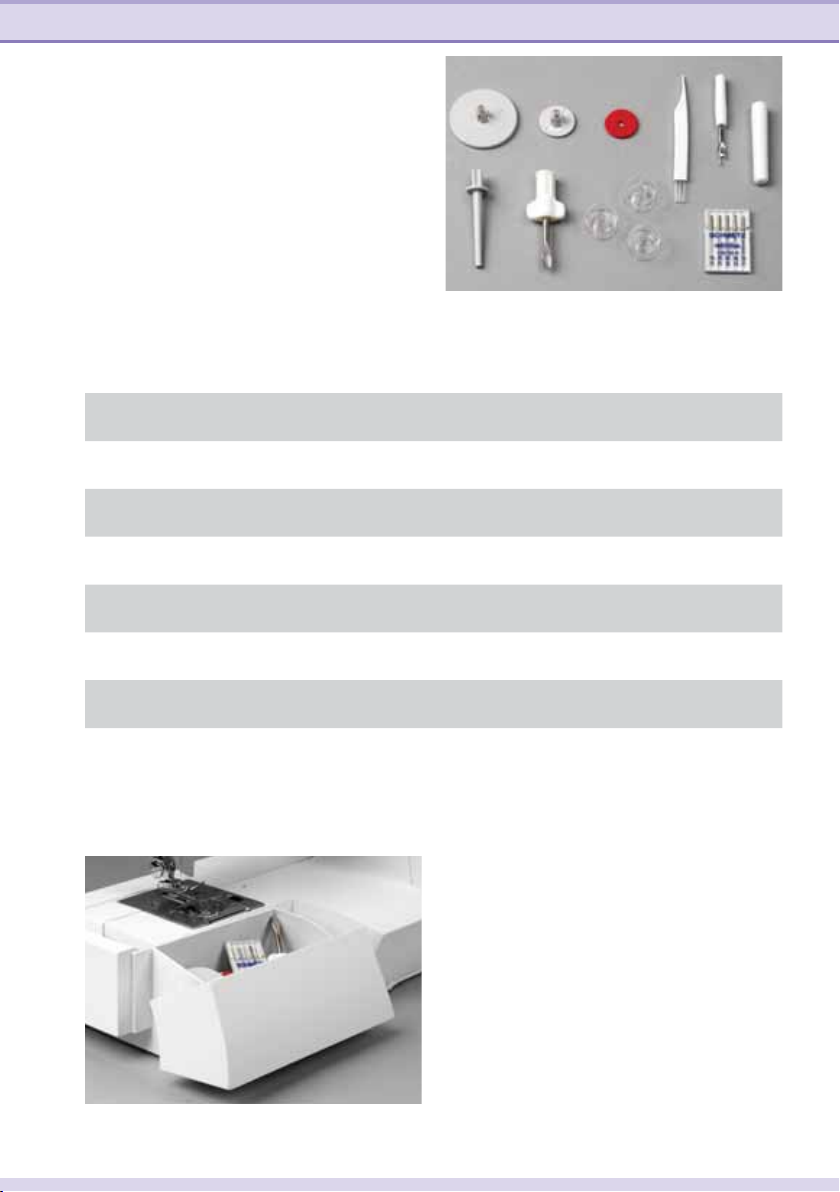

8-9 Spool cap

Part No. 4160424-01

10 Cushion felt

Part No. 4160234-01

11 Brush

Part No. 4160409-01

12 Seam ripper

Part No. 4160304-01

13 Extra spool pin

Part No. 4160292-01

14 Screwdriver

Part No. 4160422-01

15 Bobbins

Part No. 4160233-01

16 Needles

Part No. 4160471-01

910

13 14 15 16

11

128

Optional accessories - available from your dealer

Bias binder foot 820 554-096 Makes it easier to put bias tape on your projects, pre-

Dual feeder with

quilting guide

Gathering foot 820 556-096 When you want to have a nice gathering on a single

Pintuck foot deep

groove with yarn guide

Piping foot 820 558-096 The foot has grooves to make it easier to sew perfect

Ribbon sewing foot 820 559-096 Your ribbon is hold perfectly in place while you sew it

Roller foot 820 560-096 For a better feed on material like vinyl plastic and

820 555-096 This foot will help the fabric move more smoothly,

820 557-096 Make nice even rows of pintucks, with or without

fabricated or hand made

feeding from both top and bottom

layer of fabric

cording

piping

onto your project

leather

Accessory tray

Your sewing machine has a removable

accessory tray which is also used as an

extended work support. The enclosed

accessories are numbered.

Page 10

VI

Introduction

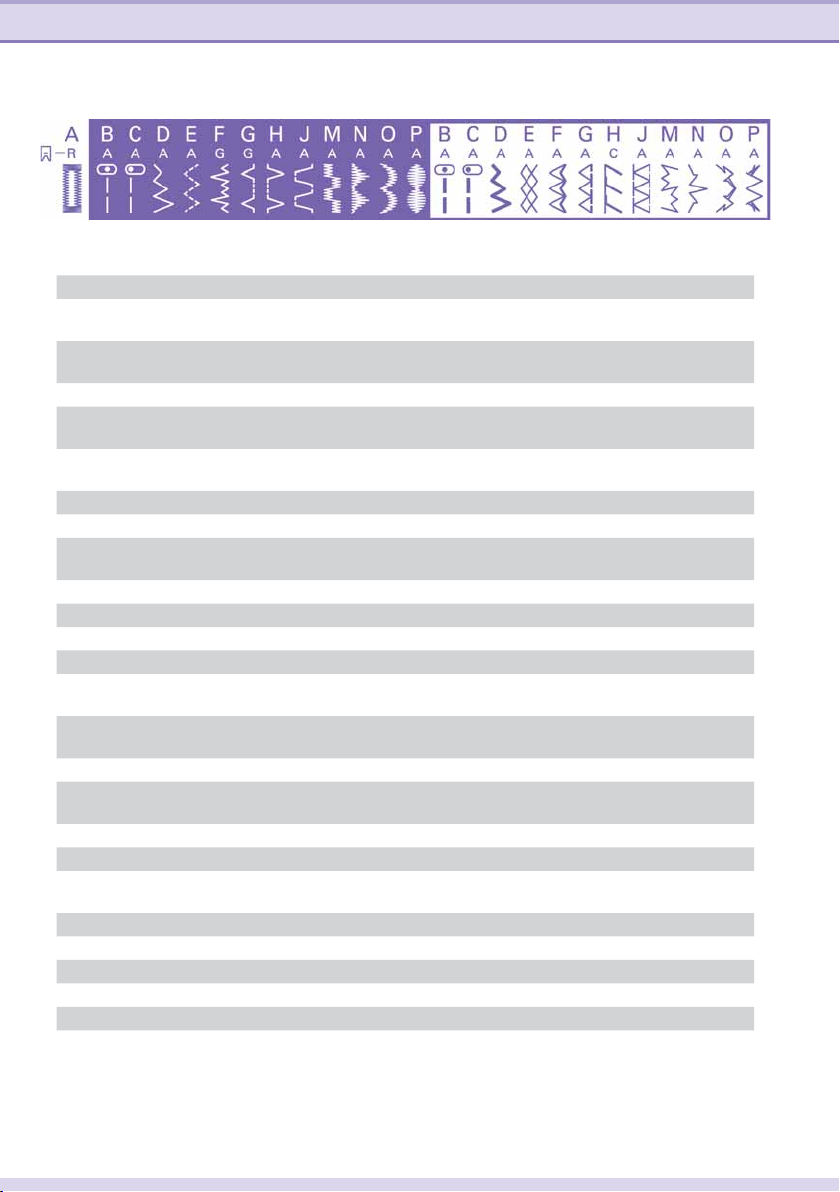

Stitch table hobby 1142

Stitch Description

Buttonhole Standard buttonhole for blouses or bed linens

A

Straight stitch, needle position

B

middle

Straight stitch, needle position left For all sewing and topstitching work requiring a

C

Zigzag stitch For serging and appliqué

D

Triple zigzag stitch For stitching on elastic band, darning tears and

E

Elastic blindhem stitch For invisible hem attachment and simultaneous

F

Blindhem stitch For invisible hem attachment

G

Shell-edging stitch For decorative hems on À ne materials, e.g. linen

H

Greek stitch A traditional decorative stitch e.g. for borders and

J

Checker satin stitch Satin decorative stitch

M

Triangle satin stitch Satin decorative stitch

N

Open scallop Satin decorative stitch

O

Oval satin stitch Satin decorative stitch

P

Stretch triple straight stitch, needle

B

position middle

Stretch triple straight stitch, needle

C

position left

Stretch triple zigzag stitch For attaching elastic tape on elastic materials

D

Honeycomb stitch For sewing on elastic threads, overlocking

E

Edge stitch wide For closing and serging one or more fabric layers

F

Edge stitch narrow For closing and serging one or more fabric layers

G

Open overlock stitch A closing and serging seam for stronger or non-

H

Closed overlock stitch A closing and serging seam for fraying materials

J

Decorative stitch A decorative stretch stitch

M

Decorative stitch A decorative stretch stitch

N

Decorative stitch A decorative stretch stitch

O

Decorative stitch A decorative stretch stitch

P

For all straight stitching and topstitching work up

to 4 mm

left needle position

patches

serging. Also for stretch fabrics

towels

For stretch seams, e.g. crotch seams on sports- and

workwear

For stretch seams requiring a left needle position

towelling and for decorative hem seams

fraying materials

Page 11

1. Operate your hobby 1142

Page 12

Operate your hobby 1142

1:2

Carrying handle

Lift up the carrying handle of the sewing

machine from behind.

Carrying case

The carrying case, which is part of the

basic equipment, protects your sewing

machine from dust and damage while

transporting.

Before putting on the carrying case, lift up

the carrying handle.

Connecting the foot control

Before connecting to the power supply,

make sure the voltage shown on the

machine conforms to your electrical power.

Connect the plug of the foot control to

the connecting socket (A) of the sewing

machine and to the wall socket. The

sewing speed is regulated by pressing the

foot control.

Make sure that you have the right type of

foot control:

For USA and Canada, 120V - YC-482J

(not shown)

For Europe, 230V - YC-190

For Australia, 240V - YC-190A

Main switch

When the main switch (B) is turned on,

the sewing light bulb lights up. The

sewing machine is now ready to use.

A

B

For the USA and Canada

This appliance has a polarized plug (one

blade wider than the other). To reduce the

risk of electric shock, this plug is intended

to À t in a polarized outlet only one way.

If the plug does not À t fully in the outlet,

reverse the plug. If it still does not À t,

contact a qualiÀ ed electrician to install the

proper outlet.

DO NOT modify the plug in any way.

Page 13

C

DE

Operate your hobby 1142

Foot pressure dial

Turn the foot pressure dial to adjust the

foot pressure.

The foot pressure dial should be set at

“III” for regular sewing.

Reduce the pressure to “II” for appliqué,

cutwork, drawn work and basting.

Set the setting mark (C) at “I” when

sewing chiffon, lace, organdy and other

À ne fabrics.

Dropping the feed dog

For certain sewing work, e.g. darning the

feed dog has to be dropped.

The slide for lowering the feed dog is

located underneath the free-arm bed on

the backside of the machine.

To drop the feed dog, push the slide in

the direction of the arrow, as shown in the

picture (D).

To raise the feed dog, push the silde in

the direction of the arrow, as shown in

the picture (E), and turn the handwheel

toward you.

The feed dog must be up for regular

sewing.

1:3

Page 14

Operate your hobby 1142

1:4

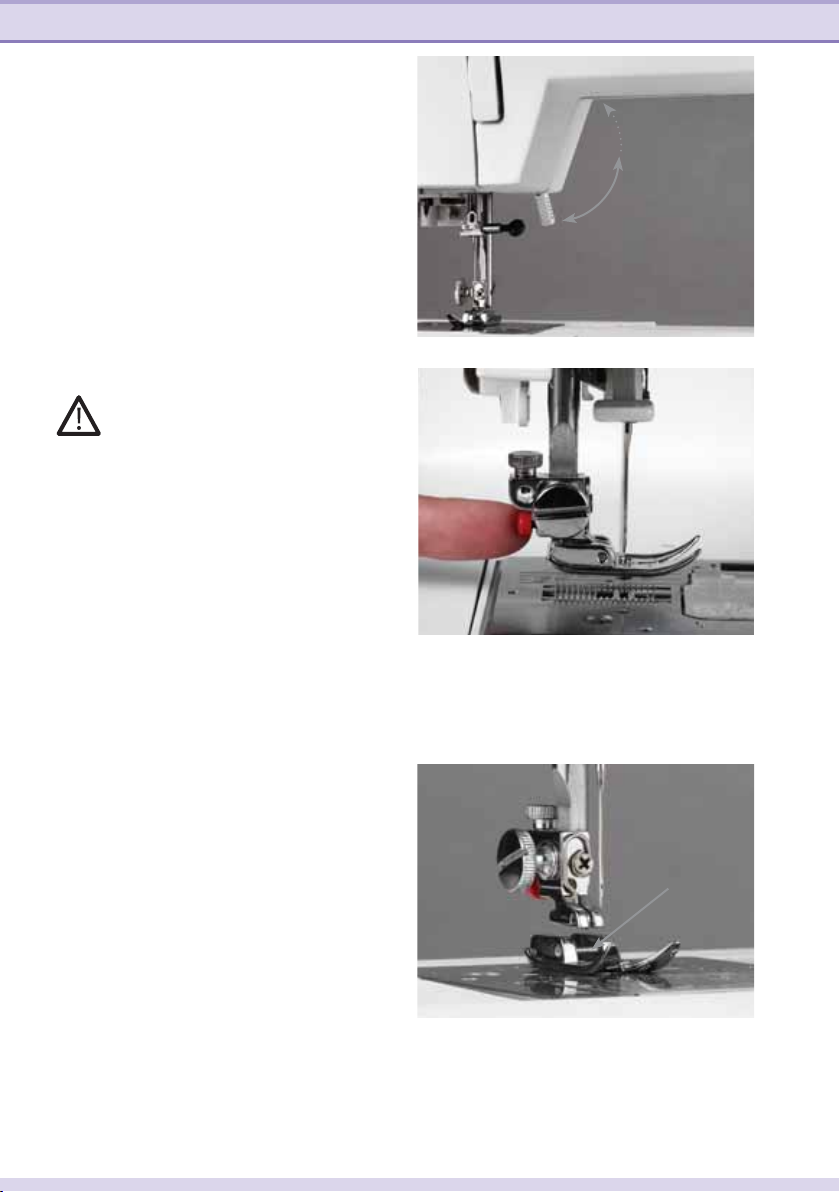

Presser foot lifter

The presser foot is raised or lowered with

the presser foot lifter.

You can raise the foot about 1/4" (6 mm)

higher than the normal up position for

easy removal of the presser foot, or to

help you place heavy fabric under the

foot.

A Lowered position

B Normal up position

C Extra lift position

Changing the presser foot

Turn off the main switch.

Removing the presser foot

Raise the needle to its highest position by

turning the handwheel.

Raise the presser foot, and press the red

button on the back of the foot holder.

C

B

A

Engaging the presser foot

Place the desired presser foot, so that

when the presser foot lifter is lowered, the

pins (D) of the foot engage in the presser

foot holder.

Note: Check that the presser foot is properly

engaged by raising the presser foot lifter.

D

Page 15

Operate your hobby 1142

Removing and attaching the foot

holder

1:5

E

Turn off the main switch.

To remove the foot holder

Remove the thumbscrew (E) by turning it

counterclockwise with a screwdriver and

remove the foot holder.

To attach the foot holder

Match the hole in the foot holder with

the threaded hole in the presser bar. Fit

the thumbscrew into the hole. Tighten

the screw by turning it clockwise with a

screwdriver.

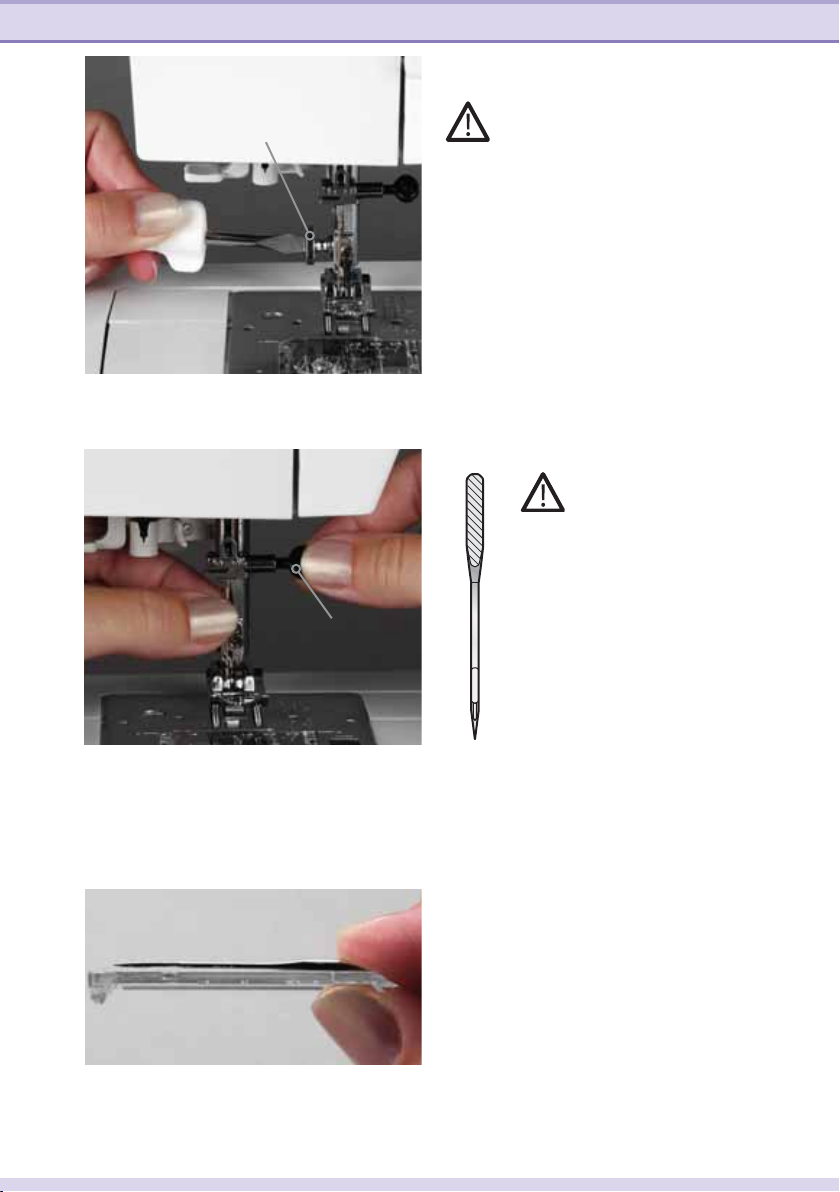

Changing the needle

Turn off the main switch.

To remove the needle

Lower the presser foot and

move the needle to its highest

point. Now loosen the needle

screw (F) and pull the needle

F

downwards.

To insert the needle

The Á at side of the needle

must face to the rear. Lower

the presser foot and insert the

needle, pushing it up as far as

it goes. Hold the needle and tighten the

needle screw À rmly.

To check for a good needle:

Put the Á at side of the needle onto

something Á at (needle plate, glass etc.).

The gap between the needle and the Á at

surface should be consistent.

Never use a bent or blunt needle.

Note: Check the needle frequently for barbed

or blunted points.

A damaged needle can cause permanent

snaps or runs in knits, À ne silks and silk-

like fabrics.

Page 16

Operate your hobby 1142

1:6

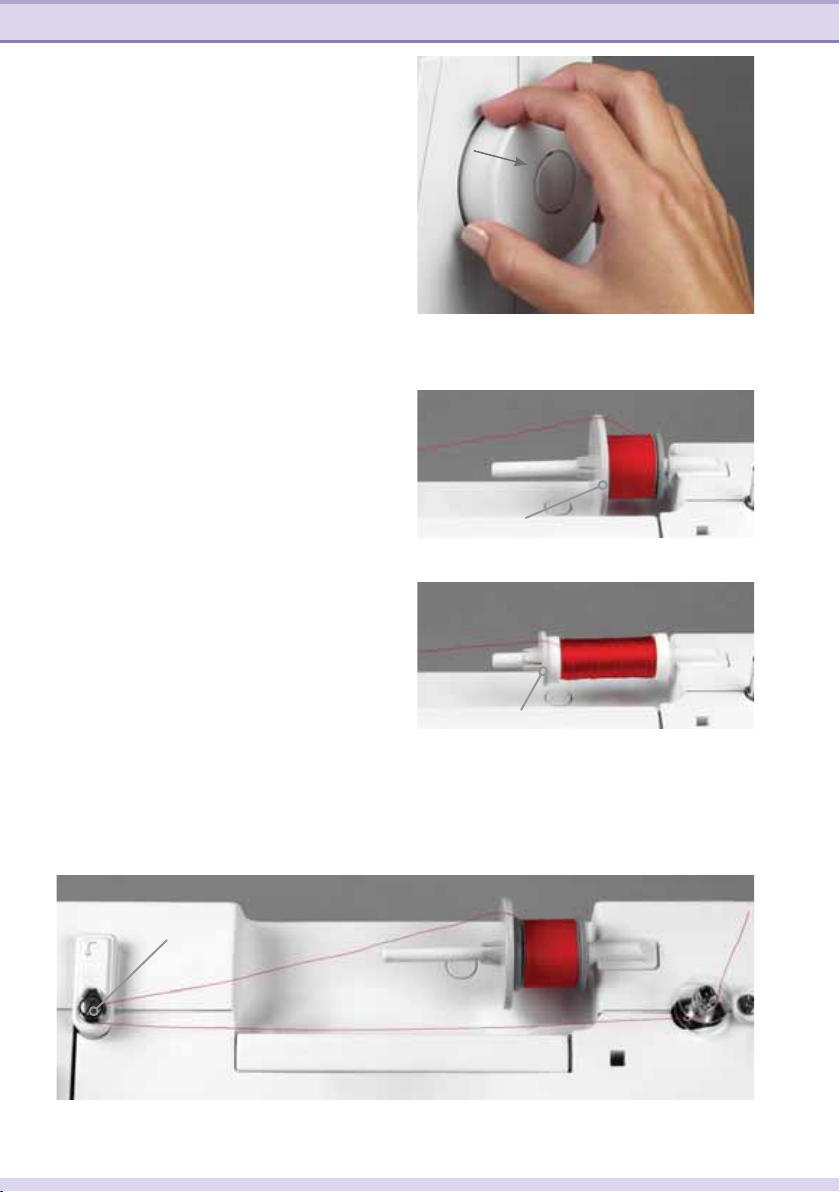

Bobbin winding

Preparing the machine for bobbin

winding

Pull out the handwheel to disengage the

clutch.

Setting the spool

Place a spool of thread on the spool pin

with the thread coming off the spool as

shown in the picture.

Press the large spool cap (A) À rmly

against the spool of thread.

For a small spool, use the small spool cap

(B).

A

Pull the thread around the bobbin thread

guide(C).

C

B

Page 17

Operate your hobby 1142

1:7

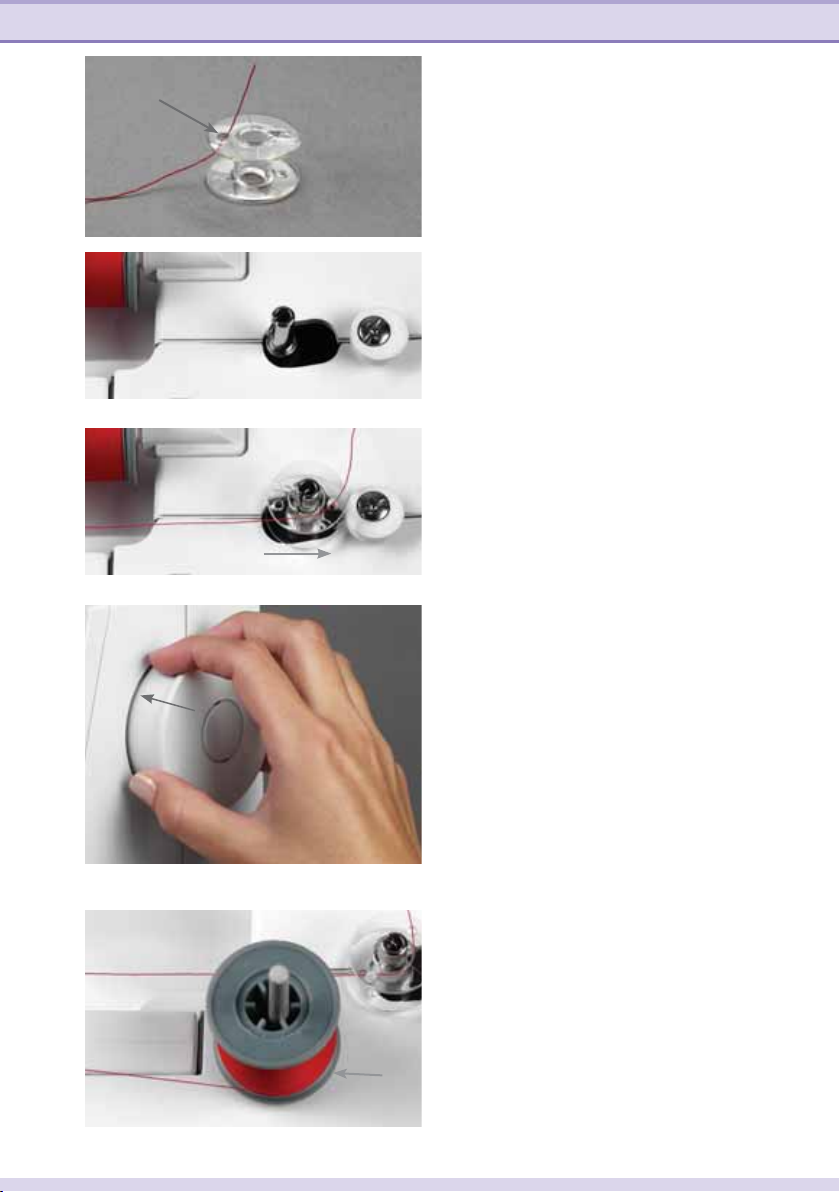

Thread through the hole in the bobbin (D)

D

from the inside to the outside as shown in

the picture.

Place the bobbin on the bobbin winder

spindle with the free end of the thread at

the top.

Push the bobbin to the right.

Note: The bobbin can only be wound when it

is moved fully to the right. Do not move the

bobbin winder spindle while the machine is

running.

Hold the end of the thread À rmly and

press the foot control. Stop the machine

when the bobbin has made several turns,

and cut the free thread end close to the

bobbin.

Press the foot control again. When

the bobbin is fully wound, it will stop

automatically.

Push the bobbin to the left, remove it and

cut the thread.

Push in the handwheel to engage the

clutch.

Extra spool pin

If the machine is already threaded, you

can easily wind thread from the second

spool pin without unthreading the

machine.

Insert the extra spool pin into the hole (E).

Place the felt and a spool on the pin.

E

Thread the machine for winding in the

same way as before.

Page 18

Operate your hobby 1142

1:8

Inserting the bobbin

Turn off the main switch.

Place the bobbin in the bobbin holder

with the thread running off as shown in

the picture.

Pull the thread into the front notch (A) on

the front side of the bobbin holder. Pull

the thread to the left, sliding it between

the tension spring blades.

Continue to pull the thread lightly until

the thread slips into the side notch (B).

Pull out about 10 cm (4”) of thread.

Attach the throat plate. Check the

threading by referring to the chart shown

on the throat plate (C).

A

B

Removing the bobbin

Push the throat plate release button (D) to

the right and remove the throat plate (E).

Lift out the bobbin.

C

D

E

Page 19

Operate your hobby 1142

1:9

G

F

H

Threading the machine

F

Turn off the main switch.

Raise the presser foot and turn the

handwheel towards you until the take-up

lever (F) is in it's highest position.

Pull the thread from the spool and pass it

under the thread guide (G). Then pull it

down along the right threading slot.

Pull the thread up around the bottom of

the thread guide plate (H).

Firmly pull the thread from right to left

over the take-up lever (F) and down into

I

the take-up lever eye.

Pull the thread down into the left

threading slot and slip the thread behind

the needle bar thread guide (I) from the

left.

Thread the needle from front to back

through the needle eye.

To thread the needle using the needle

threader, please refer to the next page.

Page 20

Operate your hobby 1142

1:10

Needle threader

Turn off the main switch.

To make threading the needle easier and

quicker, you have been provided with a

needle threader.

Lower the presser foot. Turn the

handwheel until the needle is at its

highest position.

Move the needle threader (A) completely

downwards and turn it towards the

needle so that the small hook B goes

through the needle eye from behind. Pull

the thread from the left around the guide

and under the hook.

Turn the needle threader towards the

rear, releasing the thread carefully, and

allow the threader to move upwards. A

loop of the thread is pulled up through

the needle eye.

You can now pull the thread through the

needle eye.

B

A

Page 21

Operate your hobby 1142

C

1:11

D

E

Threading the twin needle

Turn off the main switch

Insert the twin needle.

Insert the extra spool pin into its hole (C).

Place a piece of felt and a spool on the

extra spool pin.

The threading path is the same as single

needle threading.

Slide one of the threads through the

needle bar thread guide (D) on the left,

and the other one on the right (E).

Thread the needles from the front to back.

Note: You cannot use the needle threader for

a twin needle.

How to sew with a twin needle

Do not set the stitch width at more than 3

mm, otherwise the needle hit the needle

plate and the needle will break.

Set the stitch length at 2 mm or more for

straight stitches. Set the stitch length at 1.5

mm or more for other stitches.

Use the same foot as recommended for

single needle sewing of the selected stitch.

Cotton threads and cotton wrapped

threads are recommended. Synthetic

threads are not recommendable, as they

tend to twist.

Note: When changing the sewing direction,

raise the needle and turn the fabric.

Page 22

Operate your hobby 1142

1:12

Bringing up the bobbin thread

Turn off the main switch.

Raise the presser foot. Hold the needle

thread and turn the handwheel towards

you until the needle is at the top again

and the bobbin thread has formed a loop.

Bring the bobbin thread (B) up by pulling

the needle thread (A) as shown in the

picture.

A

B

Pull 10 cm (4”) of both threads back and

under the presser foot.

Page 23

D

0 1 2 3 4

Operate your hobby 1142

Stretch stitches

Stitch selection

Raise the needle to its highest position.

Turn the stitch selector dial (C) to set the

desired stitch at the setting mark (D).

C

Note: Do not turn the stitch selector dial

while the needle is in the fabric, otherwise the

needle may bend or break.

1:13

F

Stitch length dial

With the stitch length dial(E) you can

adjust the stitch length to the required

length, between 0 and 4 mm, by turning

the dial to the setting mark (F).

The higher the number, the longer the

stitch

E

The buttonhole marking shows

the adjustment range when

sewing the buttonhole. The further you

turn the dial to 0, the higher the density of

the stitch.

To sew stretch stitches (light

background), you must turn

the stitch length dial to the

stretch area. The closer to “–” , the higher

density of the stitch.

Page 24

Operate your hobby 1142

1:14

Adjusting stretch stitch balance

If the stretch stitches are uneven when

you sew on a particular fabric, correct

them by turning the stitch length dial.

Balancing stitches:

If the stitches are drawn out, correct them

by turning the dial in the “–” direction.

If the stitches are compressed, correct

them by turning the dial in the “+”

direction.

Stitch width dial

The stitch width can be adjusted with the

stitch width dial (A). Set the desired stitch

width number at the setting mark (B).

The higher the number, the wider the

stitch.

Straight stitch is sewn with stitch width 0.

Note: Do not turn the stitch width dial while

the needle is in the fabric, otherwise the needle

may bend or break.

A

B

5 4 3 2 1 0

Page 25

Operate your hobby 1142

Variable needle position

The needle drop position of the straight

stitches can be moved between the center

(5) and left (0) with the stitch width dial.

Note: Do not turn the stitch width dial while

the needle is in the fabric, otherwise the needle

may bend or break

Reverse sewing

Push the reverse stitch lever down to sew

in reverse.

The machine sews in reverse only as long

as the reverse sewing button is pressed.

1:15

Page 26

Operate your hobby 1142

1:16

Balancing needle thread tension

The thread tension should be adjusted

depending on the sewing materials, layers

of fabric and sewing method. To ensure

perfect sewing results, the needle thread

tensions must be perfectly tuned.

Balanced tension:

The ideal straight stitch has threads

locked between two layers of fabric, as

shown in the picture.

Check the tension with a wide zigzag

stitch. The threads must be interlaced

between the two fabric pieces.

• If the needle thread tension is too high

the threads are interlaced above the top

fabric. Loosen the needle thread tension

by moving the dial to a lower number.

• If the needle thread tension is too low,

the threads are interlaced below the lower

fabric. Tighten the needle thread tension

by moving the dial to a higher number

Setting the needle thread tension

Set the required needle thread tension

with the needle thread tension dial.

The normal setting for sewing is 4 to 5.

For darning and buttonhole set the

tension between 2 and 3.

Perfect tension

Too high tension

Too low tension

Page 27

2. Utility stitches

and practical sewing

Page 28

Utility stitches and practical sewing

2:2

Basic sewing

Starting to sew

Raise the presser foot and place the fabric

under the foot.

Lower the needle into the fabric.

Lower the presser foot and smooth the

threads toward the back. Depress the foot

control.

Gently guide the fabric along the seam

guide letting the fabric feed by itself.

Note: Pull the threads to the left when sewing

with the buttonhole foot.

To lock the beginning of the seam, À rst sew a

few stitches forward, then sew a few stitches

in reverse, then sew forward.

Changing the sewing direction

Stop the machine and turn the handwheel

toward you to bring the needle down into

the fabric.

Raise the presser foot.

Pivot the fabric around the needle to

change sewing direction as desired.

Lower the presser foot and continue

sewing in the new direction.

Page 29

Utility stitches and practical sewing

Finishing sewing

Press the reverse stitch lever and sew

several stitches in reverse at the end of the

seam.

Raise the presser foot and remove the

fabric, pulling the threads to the back.

Pull the threads up and into the thread

cutter.

The threads are cut the proper length for

starting the next seam.

2:3

Page 30

Utility stitches and practical sewing

2:4

Free arm sewing

For stitching sleeves, waistbands, pant

legs or any other tubular garments. In

order to sew with the free arm, you must

remove the accessory tray.

Hook your À ngers on the bottom left of

the accessory tray and pull it to the left.

When replacing the accessory tray to its

proper position, insert the pins (A) into

the holes (B) and push the accessory tray

to snap it in place.

A

B

Page 31

mm

inches

Utility stitches and practical sewing

Seam guides on the needle plate

The seam guides on the needle plate help

you to measure seam allowance.

The numbers indicate the distance

between the center needle position and

the seam guide.

Turning a square corner

When the fabric edge facing you lines up

with the cornering guide (C) as shown

in the picture, stop stitching and lower

the needle into the fabric by turning the

handwheel toward you.

Raise the presser foot and pivot the fabric

to line the edge with the 1.6 cm (5/8”)

seam guide.

Lower the presser foot and start stitching

in the new direction.

2:5

C

Page 32

Utility stitches and practical sewing

2:6

Explanation of the sewing chart

The following charts show the

recommended settings for each stitch or

technique.

These charts also provide you with

further instructions that are necessary

when sewing the selected stitches.

The choice of the sewing foot, the

setting of the needle thread tension and

recomended presser foot.

Always use the “center” needle position

if not otherwise speciÀ ed in the

instructions.

stitch

stitch

Recommended stitch

Stitch width in mm

Stitch length in mm

Thread tension

Recommended presser

foot

Page 33

stitch

B/C 0/5 1.5-4 2-6 A

Straight stitch

Straight stitch B/C is the basic straight

stitch. The stitch length can be increased

up to 4 mm.

It is easier to do some sewing jobs by

changing the needle position, e.g. topstitching a collar or sewing in a zipper.

The needle position is determined by the

stitch width dial. (5 is center, 0 is left).

If you wish to make a topstitch farther

from the fabric edge, simply guide the

fabric along the guide marks on the

needle plate or use the edge guide. The

edge guide is inserted into hole (A) and is

secured with À xing screw (B).

Note: Ensure that the needle is at its highest

position when adjusting the needle position.

Utility stitches and practical sewing

B

A

Note: To ensure a consistent feed when

beginning sewing at a thick seam, we

recommend supporting the presser foot on

a piece of fabric of the same thickness as the

workpiece.

Attach the quilting guide

Loosen the screw on the back of the foot

holder.

Insert the quilting guide into the opening

and set the quilting guide at the desired

seam spacing then tighten the screw.

Sew, tracing the previous row of stitching

with the quilting guide.

2:7

Page 34

Utility stitches and practical sewing

2:8

stitchstitch

B/C 0/5 stretch 2-5 A

Stretch triple straight stitch

This stitch is used for sewing all seams

where great strength is needed, e.g. inside

trouser seams, crotch and armhole seams.

The stitch is sewn with two stitches

forward and one stitch backward,

forming a seam that does not rip easily.

Also use it when constructing items such

as backpacks for extra strength.

Carefully guide the fabric while sewing as

the fabric moves back and forth.

A

B

D 1-5 0.5-3 2-5 B/C

Zigzag stitch

Simple zigzag stitching is widely used for

overcasting, sewing on buttons etc. Adjust

the stitch length to suit your sewing needs.

Note: Use a stabilizer for stretch fabrics such

as tricot and knits to prevent puckering.

Overcasting

In addition to overlock stitching, zigzag

stitch D, is also suitable for overcasting

various materials. In this case, the

material should only be positioned

halfway under the sewing foot.

When overcasting the edge, make sure the

needle goes into the material and over the

edge alternately.

When sewing with the overcasting foot

C, the thread lies over pin (A), guide the

edge of the fabric along guide (B). This

prevents curling of the fabric

edge. In this way you can sew

beautiful smooth seams.

Note: Do not set the stitch

width less than 5 when using the

overcasting foot C, otherwise the

needle may hit the foot causing the

needle to bend or break.

Page 35

Utility stitches and practical sewing

2:9

stitch

E 3-5 0.5-1.5 3-6 A

Tricot stitch (Triple zigzag stitch)

This stitch is used to À nish the seam

allowance on synthetics and other fabrics

that tend to pucker.

Place the fabric to leave a 1.6 cm (5/8")

seam allowance.

Trim the extra allowance after sewing.

It is also used for mending tears.

Elastic stitch

Because of its high elasticity, this

stitch can be used for sewing elastic on

swimwear, skirts or lingerie.

Mark elastic and fabric in quarters.

Pin elastic to fabric at quarter markings.

Place fabric and elastic under sewing foot.

Stretch elastic to À t the fabric. Begin

sewing.

stitch

E 5 stretch 3-7 A

Honeycomb stitch

The honeycomb stitch is an elastic and

decorative hem which is particularly

suitable for hems on T-shirts and

childrens clothes.

Fold the hem over double and overstitch

it.

Note: When stretching elastic, make sure to

stretch from the front and back of the sewing

foot.

Page 36

Utility stitches and practical sewing

2:10

stitchstitch

H 5 stretch 3-7 C

What is an overlock stitch?

For elastic materials and knits, the hobby

1142 offers an overlock stitch which sews

two fabric layers together and overcasts

simultaneously. It is more elastic than

normal seams, very durable and quickly

sewn.

When sewing overlock seams, use

overcasting foot C. It guides particularly

well and prevents the seam from

puckering.

Open overlock stitch

With this stitch, thicker materials and

fabrics which do not fray too much can be

sewn together perfectly.

This stitch seams and À nishes the fabric

edges simultaneously.

Place the edge of the fabric next to the

guide of foot and sew while guiding the

fabric edge along the guide.

Tip: Make sure that the needle is just off the

raw edge of the fabric and not into it, when

the needle swings to the right.

Note: Do not set the stitch width less than 5

when using the overcasting foot C, otherwise

the needle may hit the foot causing the needle

to bend or break.

J 5 stretch 3-7 C

Closed overlock stitch

The closed overlock stitch is perfect for

sewing jersey knits. You can also sew

sleeve cuffs and knit collars which are

well-sewn and long-lasting.

Tip: Ensure that the sleeve cuff is stretched

while it is being sewn.

Remember!

When overlocking, if you select a needle

position other than center, and

stitch width other than 5, make sure the

needle does not strike the bar (A) of the

overcasting foot C.

A

Page 37

Utility stitches and practical sewing

2:11

Stitch G

stitch

F/G 2-3 2-3 1-4 G

Blindhem

Blindhem foot G is best suited for

invisible hems; sewing by hand is no

longer necessary.

Note: On heavy weight fabrics that ravel, the

raw edge should be overcasted À rst.

Serge the edge of the hem

Fold the edge inwards by the hem width.

Now unfold the hem again so that the

hem edge protrudes by about 1 cm.

Place the fabric under the sewing foot

so that the needle just pierces the folded

edge. If the needle pierces too far left,

move the guide slightly to the left. If the

needle misses the fold, move the guide

slightly to the right.

Sew slowly while guiding the folded edge

along the guide.

When the needle enters the crease line, it

must only pick up one À ber of the fabric.

Note: If the needle goes too far left, the

stitches will be apparent on the right side of

the fabric.

Stitch F

Blindhem stitch (elastic)

Stitch F is a blindhem stitch for woven

or elastic materials. The hem is sewn and

overcast at the same time.

Page 38

Utility stitches and practical sewing

2:12

A

D

C

B

stitch

A 4-5 0.5-1 1-5 R

Automatic Buttonhole

Buttonholes are generally sewn onto a

piece of doubled fabric. However, for

some materials, e.g. silk, organza and

viscose, it is necessary to use stabilizer to

prevent the material from puckering.

To produce beautiful buttonholes,

embroidering or darning threads are

ideally suited to this purpose.

Mark the starting point of the buttonhole

either with a magic pen or dress pin, and

always sew a sample buttonhole À rst,

using the actual fabric

Note: The size of buttonhole is automatically

determined by placing the button in the

automatic buttonhole foot R.

The button holder of the foot takes a

button size up to 2.5 cm (1") in diameter.

Use stabilizer on stretch fabrics and check

the settings.

Turn the handwheel toward you to raise

the needle to its highest position. Attach

the automatic buttonhole foot.

E

F

To open the button holder (A), pull to the

back and place the button in it. Push back

the button holder against the button to

keep it in place.

Pull the buttonhole lever (B) down as far

as it will go.

Raise the foot and pass the needle thread

through the opening in the foot (C). Pull

both needle and bobbin threads to the left.

Insert the fabric under the foot and lower

the needle into the starting point using

the handwheel. Lower the presser foot.

Note: Make sure there is no gap between the

slider (D) and front stopper (E). If there is a

gap, the length of the right and left rows of the

buttonhole will differ(F).

Page 39

Utility stitches and practical sewing

2:13

G

The machine sews the front bartack and

left row À rst, then the back bartack and

right row.

Sew slowly and stop the machine when a

buttonhole is completed.

Raise the foot and remove the fabric. Cut

both needle and bobbin threads leaving

about 10 cm (4") thread ends.

Pull the needle thread to wrong side of

fabric by pulling the bobbin thread. Knot

the threads.

To open the buttonhole

Insert a pin inside the bartack. Carefully

cut the opening. Take care not to cut the

stitches.

To sew another buttonhole, turn the stitch

selector to “ ”, then back to “A” again.

Then press the foot control to sew an

identical buttonhole.

When buttonhole sewing is À nished, push

the buttonhole lever upward as far as it

will go.

Adjusting the buttonhole stitch density

Turn the stitch length dial within

the range of "

" to adjust the

buttonhole stitch density. To get a narrow

buttonhole, set the marking as close to "0"

as possible, still in the " "-range. To

get a wide buttonhole, set the marking

close to "1".

Note: For thick buttons, make a test

buttonhole. If the button does not À t through

the test buttonhole, lengthen the buttonhole

by pulling the button holder a little to the back

and make a small gap (G).

Page 40

Utility stitches and practical sewing

2:14

A

B

C

stitch

A 4-5 0.5-1 1-5 R

Buttonhole with gimp thread

To sew strong durable buttonholes, on

heavy fabrics, knits or sportswear, using a

gimp thread is recommended.

On knits the gimp thread is important to

prevent the buttonhole from stretching.

With the buttonhole foot raised, hook the

gimp thread on the spur (A) at the back of

the foot.

Bring the ends toward you under the foot,

clearing the front end.

Hook the gimp thread into the forks on

the front of the foot (B) to hold them tight.

Pull both needle and bobbin thread to

the left. Lower the needle into the fabric

at the starting point and lower the foot.

Press the foot control gently and sew the

buttonhole over the gimp thread.

The sewing sequence is the same as the

automatic buttonhole.

Pull the left end of the gimp cord to

tighten it and cut the excess tails. To

cut the buttonhole opening, refer to the

instructions on page 2:13.

stitch

A 4-5 0.5-1 1-5 B

Manual buttonhole

If the diameter of the button is more than

2.5 cm (1"), a buttonhole must be made

manually as follows:

Attach the buttonhole foot B.

Pull the buttonhole lever down as far as

it will go.

Pull both needle and bobbin thread to the

left. Lower the needle into the fabric at the

starting point, and lower the presser foot.

Sew the front bartack and left row to the

desired length then stop the machine.

Click the buttonhole lever toward you

(C).

Start sew again to make the machine sew

the back bartack and right row, and then

stop the machine at the starting point.

When buttonhole sewing is À nished, push

the buttonhole lever upward as far as it

will go.

Page 41

stitch

D adjust 0 3-7 B

Utility stitches and practical sewing

2:15

Button sewing

With zigzag stitch D you can sew on twoand four-hole buttons.

Note: Lower the feed dog when sewing on

buttons.

Adjust the stitch width to match it with

the span of the holes in the button. Turn

the handwheel to check if the needle

enters into each hole in the button.

Lower the foot to hold the button in place.

The holes in the button should align with

the slot of the foot.

A pin can be placed on the foot to form a

shank.

Make sure to check if the needle enters

into both holes in the button.

Sew about 10 stitches.

Note: When sewing a four-hole button, move

the button to the other pair of holes, and sew

the button again.

Raise the presser foot and remove the

fabric. Cut the needle and bobbin threads

leaving 20 cm (8") tails.

Bring the needle thread between the

button and fabric through the holes in the

button.

Pull the needle thread to pick bobbin

thread up to the right side of the fabric.

Wind the threads to form a shank and tie

them together.

Note: Raise the feed dog after sewing.

Page 42

Utility stitches and practical sewing

2:16

stitch

B 5 1.5-4 3-6 E

Sewing on zippers

There are various methods of sewing

on zippers. For skirts, we recommend

the fully concealed zipper, for men’s

and ladies’ trousers the semi concealed

zipper. Various zippers are available.

We recommend using a metal zipper for

strong fabrics such as denim. For all other

materials we recommend a plastic zipper.

It is important for all types of zippers to

sew very close to the edge of the teeth of

the zipper. This is why it is possible to

insert the zipper foot either on the right or

the left of the presser foot holder.

To sew the left side of the zipper, attach

zipper foot with the right side pin (A).

To sew the right side of zipper, attach the

zipper foot with the left side pin(B).

The trouser zipper

• Iron the seam allowances, making

sure that the underlap extends by about 4

mm.

• Baste the zipper under the underlap

so that the teeth are visible.

• Insert the zipper foot on the right side

(A) to sew on the left side of the zipper.

• Stitch along the edge of the zipper.

• Just before the end of the seam, open

the zipper and À nish sewing the seam.

• Close the zipper and baste the overlap

evenly to the other half of the zipper.

• Then sew through the basted seam.

Note: To achieve a perfect seam, we

recommend using the edge guide.

A

B

Page 43

Utility stitches and practical sewing

2:17

Fully concealed, sew-in zipper

• Insert the zipper foot on the right side

(A) to sew on the left side of the zipper.

• Baste in the zipper and lay it

underneath the presser foot so that the

teeth of the zipper run alongside the foot.

• Stitch in half of the zipper, leave the

needle in the fabric, raise the presser foot

and close the zipper.

• Now you can continue sewing the

seam up to the end of the zipper and sew

the cross seam.

• Sew the second half of the zipper

parallel at the same distance.

• Stop after the À rst half and leave the

needle in the fabric. Raise the presser foot

and open the zipper.

• Now you can À nish sewing the seam.

Page 44

Utility stitches and practical sewing

2:18

stitch

E 5 0.2-1.5 3-5 A

Sewing on patches

To cover large holes it is necessary to sew

a new piece of fabric onto the damaged

area.

• Baste the new piece of fabric onto

the damaged area of the face side of the

fabric.

• Sew over the fabric edges with the

elastic stitch.

• Now cut the damaged area back to the

seam from the reverse side of the fabric.

Darning with the elastic stitch

Darning with the elastic stitch is suitable

for repairing damaged areas.

• Sew over the damaged area in rows

until it is well covered. Make sure that the

rows overlap.

Repairing tears

On tears, frayed edges or small holes it is

useful to lay a piece of material under the

reverse side of the fabric. The underlayed

fabric reinforces the workpiece and

ensures perfect repair.

• Lay a piece of fabric underneath the

damaged fabric. It must be a little larger

than the damaged area.

• Now sew over the damaged area.

• Cut the under layed piece of material

back to the seam.

Page 45

3. Maintenance and

trouble-shooting

Page 46

Maintenance and trouble-shooting

3:2

Cleaning:

Turn off the main switch

It is very important to clean your sewing

machine, because it will reward you with

a longer service life. The more often you

use the machine, the more care it needs.

Do not dismantle the machine other than

as explained in this section.

Clean the outside of the machine with a

soft cloth and mild soap.

Removal

• Remove the presser foot and needle.

• Remove the screw (A) on the needle

plate with the screwdriver. Remove the

needle plate and take out the bobbin

holder.

• Lift up the bobbin holder (B) and

remove it.

• Clean the bobbin holder with the

brush. Wipe the bobbin holder with a soft,

dry cloth.

• Clean the feed dog and hook race with

the brush. Wipe the hook race with a soft,

dry cloth.

A

B

Replacing

• Insert the bobbin holder into the hook

race.

Note: Make sure the knob (C) of the bobbin

holder À ts next to the stopper (D) in the race.

• Attach the needle plate, inserting the

two guide pins into the holes (E) in the

needle plate. Tighten the screw (A) À rmly

with the screwdriver.

D

C

E

A

E

Page 47

Maintenance and trouble-shooting

Changing the light bulb

Turn off the main switch

• Disconnect the main plug and the foot

control plug from the machine.

• If you have used the machine, wait for

the lamp to cool before touching it.

Removal

• Remove the cap and screw. Remove

the face plate.

• Push and turn the bulb

counterclockwise, seen from below, to

remove it.

Insertion

• Push and turn the bulb clockwise to

replace it

• Replace the faceplate, the screw and

the cap.

Important!

The maximum allowed wattage of the lamp

with a plug-in socket is 15 watts!

3:3

Page 48

Maintenance and trouble-shooting

3:4

Trouble-shooting

The needle thread breaks.

The needle thread is not threaded properly. Page 1:9

The needle thread tension is too tight. Page 1:16

The needle is bent or blunt. Page 1:5

The needle is incorrectly inserted. Page 1:5

The needle thread and the bobbin thread are not set under the

presser foot when start sewing.

The threads were not pulled to the rear after sewing. Page 2:3

The bobbin thread breaks

The bobbin thread is not threaded properly in the bobbin holder. Page 1:8

Lint has collected in the bobbin holder. Page 3:2

The bobbin is damaged and does not turn smoothly. Change the

The needle breaks

The needle is incorrectly inserted. Page 1:5

The needle screw is loose. Page 1:5

The threads were not pulled to the rear after sewing. Page 2:3

The needle is incorrectly inserted, bent or blunt. Page 1:5

Page 2:2

bobbin

The machine skips stitches

The needle thread is not threaded properly. Page 1:9

A poor quality needle is used. Change the

needle; 1:5

The needle thread tension is too tight. Page 1:16

Seam puckering

The needle thread is not threaded properly. Page 1:9

The stitch length is too long for the fabric.

Page 1:13

Page 49

Maintenance and trouble-shooting

The cloth is not fed smoothly

The feed dog is packed with lint. Page 3:2

The stitches are too À ne. Page 1:13

The feed dog is not raised after ”drop feed” sewing. Page 1:3

Loops on the seams

The needle thread tension is too loose. Page 1:16

The machine does not sew or run

The machine is not plugged in. Page 1:2

Thread has been caught in the hook race. Page 3:2

The bobbin winder spindle is not returned to the left after

Page 1:6

bobbin winding. (Bobbin winding condition)

The stitch density is not suitable for the fabric being sewn Page 1:14

The machine is noisy

Thread has been caught in the hook race. Page 3:2

Lint has built up in the hook race or bobbin holder. Page 3:2

3:5

Buttonhole is not sewn neatly

The stitch density is not suitable for the fabric being sewn. Page 2:13

Stabilizer is not used when sewing on the stretch fabrics. Use stabilizer

Layer slippage

Foot pressure is not adjusted properly. Page 1:3

Important notes: Before changing presser feet and needle you must turn the main

switch off. Do not attempt to sew without fabric under the presser foot.

When leaving the machine, even for only a short time, switch off the main switch.

This is important if there are any children nearby.

Page 50

Maintenance and trouble-shooting

3:6

Index

A

Accessories

- optional V

- standard IV

Accessory tray V

Automatic buttonhole 2:12

B

Basic sewing 2:2

Blindhem 2:11

Blindhem stitch (elastic) 2:11

Bobbin winding 1:6

Bringing up the bobbin thread 1:12

Button sewing 2:15

Buttonhole

- automatic 2:12

- manual 2:14

- with gimp thread 2:14

C

Carrying handle, carrying case 1:2

Changing the needle 1:5

Changing the presser foot 1:4

Changing the light bulb 3:3

Cleaning 3:2

Closed overlock stitch 2:10

Connecting the foot control 1:2

F

Foot preassure dial 1:3

Free arm sewing 2:4

H

Honeycomb stitch 2:9

I

Inserting the bobbin 1:8

M

Manual buttonhole 2:14

N

Needle threader 1:10

O

Open overlock stitch 2:10

Optional accessories V

P

Presser foot lifter 1:4

Presser foot holder

- remove and attach 1:5

D

Darning with the elastic stitch 2:18

Dropping the feed dog 1:3

E

Extra spool pin 1:7

R

Repairing tears 2:18

Reverse sewing 1:15

Page 51

S

Seam guides on the needle plate 2:5

Sewing chart - explanation 2:6

Sewing on patches 2:18

Sewing on zippers 2:16

Special accessories V

Straight stitch 2:7

Stretch stitch balance - adjust 1:14

Stretch triple straight stitch 2:8

Standard accessories IV

Stitch length dial 1:13

Stitch selection 1:13

Stitch table VI

Stitch width dial 1:14

T

Thread tension 1:16

Threading for twin needle 1:11

Threading the machine 1:9

Tricot stitch (triple zigzag stitch) 2:9

Trouble-shooting 3:4

Turning a square corner 2:5

Maintenance and trouble-shooting

3:7

V

Variable needle position 1:15

Z

Zigzag stitch 2:8

Zippers 2:16

Page 52

Technical data

Dimensions (w x h x d) 385 x 280 x 170

Weight 8 kg

Nominal voltage (Europe) 230 V

Nominal voltage (USA/Canada) 120 V

Nominal voltage (Australia) 240 V

Power consumption 75 W

Sewing lamp 15 W

Sewing speed Max 800 stitches/minute

Stitching width 0...5 mm

Stitching length 0...4 mm

Presser foot lift 6 mm

Max. presser foot height 13 mm

Needle system 103 / 705 H

Package contents

Sewing machine

Carrying case

Foot control

Accessories

Owner's manual

Please note that on disposal, this product must be

safely recycled in accordance with relevant National

legislation relating to electrical/electronic products.

If in doubt please contact your retailer for guidance.

Page 53

Page 54

Page 55

We reserve the right to change the machine equipment

and the ass ort ment of accessories without prior notice,

or make modiÀ cations to the performance or design.

Such modiÀ cations, however, will always be to the

beneÀ t of the user and the product.

Intellectual Property

PFAFF and HOBBY are trademarks of

KSIN Luxembourg II, S.ar.l.

All trademarks are used under license by VSM Group AB.

Page 56

VSM Group AB • SE-561 84 Huskvarna • SWEDEN

www.pfaff.com

412 90 10 - 26H • English • Inhouse • © 2009 KSIN Luxembourg II, S.ar.l. • All rights reserved • Printed in Sweden on environmentally-friendly paper

Loading...

Loading...