Page 1

Operation and

Maintenance

Manual

SEBU8190-00

April 2006

4006 TRS Gas and 4008 TRS Gas

Industrial Engines

Page 2

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Perkins dealers or Perkins distributors have the most current information available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to premature failures, product damage, personal injury or

death.

Page 3

SEBU8190 3

Table of Contents

Table of Contents

Foreword ............................................. .................... 4

Safety Section

Safety Messages .................................................... 5

General Hazard Information ................................... 7

Burn Prevention ...................................................... 9

Fire Prevention and Explosion Prevention .............. 9

Crushing Prevention and Cutting Prevention ......... 11

Mounting and Dismounting .................................... 11

Ignition Systems .................................................... 11

Before Starting Engine ........................................... 11

Engine Starting ..................................................... 12

Engine Stopping ................................................... 12

Index Section

Index ..................................................................... 68

Electrical System .................................................. 12

Product Information Section

Model Views and Specifications ........................... 14

Product Identification Information ........................ 20

Operation Section

Lifting and Storage ................................................ 22

Gauges and Indicators .......................................... 23

Features and Controls .......................................... 24

Engine Starting ..................................................... 27

Engine Operation .................................................. 30

Engine Stopping ................................................... 31

Maintenance Section

Refill Capacities .................................................... 33

Maintenance Interval Schedule ............................ 36

Reference Information Section

Reference Materials .............................................. 64

Page 4

4 SEBU8190

Foreword

Foreword

Literature Information

This manual con

lubrication and maintenance information. This

manual should be stored in or near the engine area

in a literatur

study and keep it with the literature and engine

information.

English is the primary language for all Perkins

publications. The English used facilitates translation

and consiste

Some photographs or illustrations in this manual

show details

from your engine. Guards and covers may have

been removed for illustrative purposes. Continuing

improvemen

may have caused changes to your engine which are

not included in this manual. Whenever a question

arises reg

consult with your Perkins dealer or your Perkins

distributor for the latest available information.

Safety

This safety section lists basic safety precautions.

In addition, this section identifies hazardous,

warning si

precautions listed in the safety section before

operating or performing lubrication, maintenance and

repair on

this product.

tains safety, operation instructions,

e holder or literature storage area. Read,

ncy.

or attachments that may be different

t and advancement of product design

arding your engine, or this manual, please

tuations. Read and understand the basic

Recommended se

appropriate intervals as indicated in the Maintenance

Interval Schedule. The actual operating environment

of the engine a

Schedule. Therefore, under extremely severe,

dusty, wet or freezing cold operating conditions,

more frequen

specified in the Maintenance Interval Schedule may

be necessary.

The maintenance schedule items are organized for

a preventive maintenance management program. If

the prevent

periodic tune-up is not required. The implementation

of a preventive maintenance management program

should mini

avoidances resulting from reductions in unscheduled

downtime and failures.

ive maintenance program is followed, a

mize operating costs through cost

rvice should be performed at the

lso governs the Maintenance Interval

t lubrication and maintenance than is

Maintenance Intervals

Perform maintenance on items at multiples of

the original requirement. We recommend that the

maintenan

near the engine as a convenient reminder. We also

recommend that a maintenance record be maintained

as part of

Your authorized Perkins dealer or your Perkins

distribu

maintenance schedule to meet the needs of your

operating environment.

ce schedules be reproduced and displayed

the engine’s permanent record.

tor can assist you in adjusting your

Overhaul

Operatio

Operating techniques outlined in this manual are

basic. Th

techniques required to operate the engine more

efficiently and economically. Skill and techniques

develop

engine and its capabilities.

The oper

Photographs and illustrations guide the operator

through procedures of inspecting, starting, operating

and sto

discussion of electronic diagnostic information.

n

ey assist with developing the skills and

as the operator gains knowledge of the

ation section is a reference for operators.

pping the engine. This section also includes a

Maintenance

The mai

The illustrated, step-by-step instructions are grouped

by service hours and/or calendar time maintenance

interv

referenced to detailed instructions that follow.

ntenance section is a guide to engine care.

als. Items in the maintenance schedule are

Major engine overhaul details are not covered in

the Operation and Maintenance Manual except

for the i

interval. Major repairs should only be carried out by

Perkins authorized personnel. Your Perkins dealer

or your P

regarding overhaul programs. If you experience

a major engine failure, there are also numerous

after f

your Perkins dealer or your Perkins distributor for

information regarding these options.

nterval and the maintenance items in that

erkins distributor offers a variety of options

ailure overhaul options available. Consult with

California Proposition 65 Warning

Diesel engine exhaust and some of its c onstituents

are known to the State of California to cause cancer,

defects, and other reproductive harm. Battery

birth

posts, terminals and related accessories contain lead

and lead compounds. Wash hands after handling.

Page 5

SEBU8190 5

Safety Section

Safety Messages

Safety Section

i02409464

Safety Messages

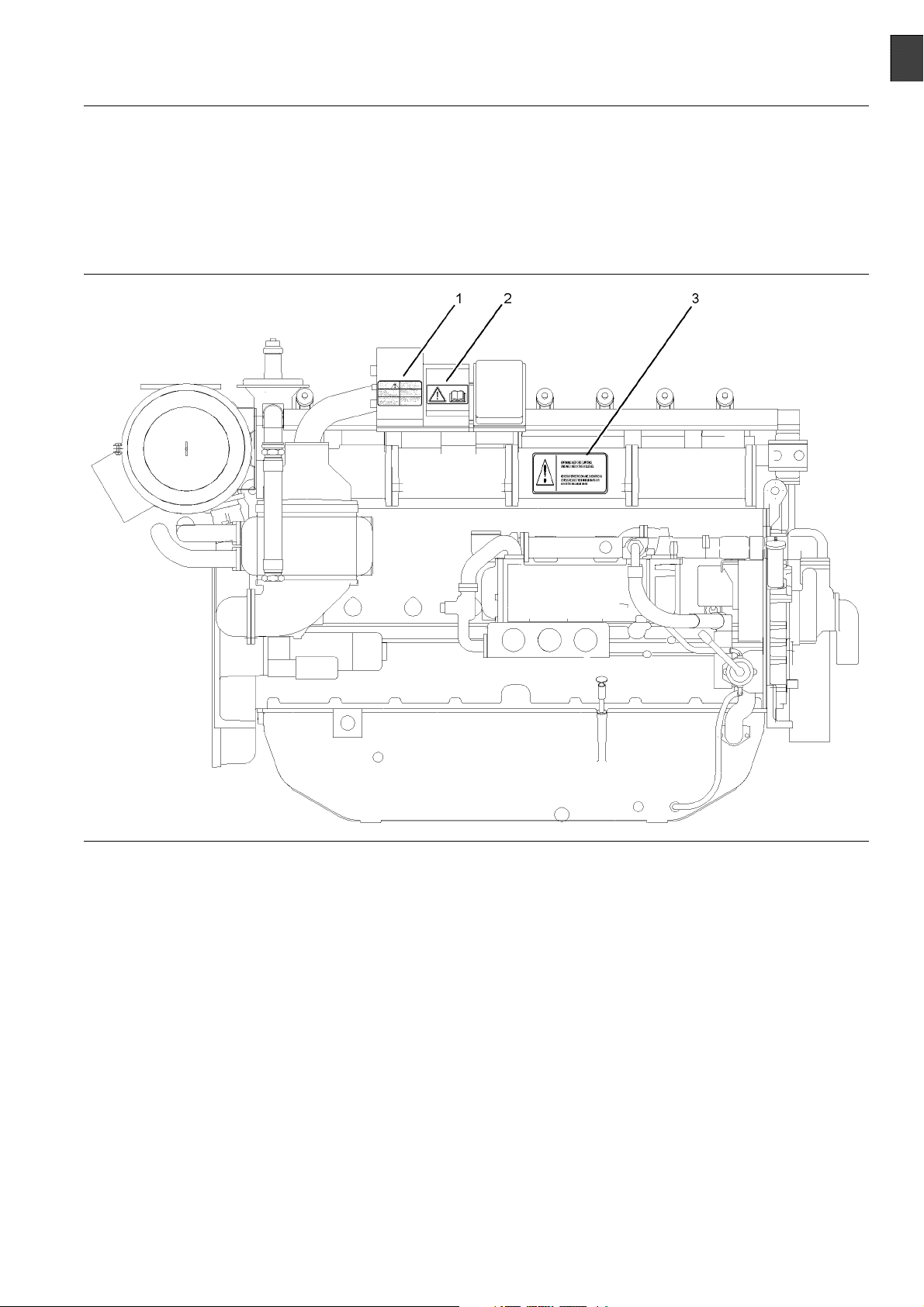

Illustration 1

Typical example

(1) E ngine Derate (2) Universal warning (3) Engine Oil Level

There may be several specific warning signs on your

engine. The exact location and a description of the

warning signs are reviewed in this section. Please

become familiar with all warning signs.

Ensure that all of the warning signs are legible. Clean

the warning signs or replace the warning signs if

the words cannot be read or if the illustrations are

not visible. Use a cloth, water, and soap to clean

the warning signs. Do not use solvents, gasoline, or

other harsh chemicals. Solvents, gasoline, or harsh

chemicals could loosen the adhesive that secures the

warning signs. The warning signs that are loosened

could drop off of the engine.

Replace any warning sign that is damaged or

missing. If a warning sign is attached to a part of the

engine that is replaced, install a new warning sign on

the replacement part. Your Perkins dealer or your

distributor can provide new warning signs.

The safety messages that may be attached on the

engine are illustrated .

g01269446

Page 6

6 SEBU8190

Safety Section

Safety Messages

(1) Engine Derate

Illustration 2

Typical example

The warning label for derating engine information (1)

is located on the governor control unit. The governor

control unit is located on the right hand side of the

engine.

(2) Universal Warning

Do not operate or work on this equipment unless

you have read and understand the instructions

and warnings in the Operation and Maintenance

Manuals. Failure to follow the instructions or

heed the warnings could result in serious injury

or death.

g01241021

The Universal Warning label (2) is located on the

fuse box for the ignition system. The fuse box for

the ignition system is located on the right hand side

of the engine.

Illustration 3

Typical example

g01234595

Page 7

SEBU8190 7

Safety Section

General Hazard Information

(3) Engine Oil Level

Illustration 4

Typical example

The warning label for checking the engine oil Level

(3) is located on the inlet manifold. The inlet manifold

islocatedontherighthandsideoftheengine.

i02414560

General Hazard Information

Illustration 5

Attach a “Do Not Operate” warning tag or a similar

warning tag to the start switch or to the controls

before the engine is serviced or before the engine

is repaired.

g00104545

g01241033

Engine exhaust contains products of combustion

which may be harmful to your health. Always start the

engine and operate the engine in a well ventilated

area. If the engine is in an enclosed area, vent the

engine exhaust to the outside.

Cautiously remove the following parts. To help

prevent spraying or splashing of pressurized fluids,

hold a rag over the part that is being removed.

Filler caps

•

Grease fittings

•

Pressure taps

•

Breathers

•

Drain plugs

•

Use caution when cover plates are removed.

Gradually loosen, but do not remove the last two

bolts or nuts that are located at opposite ends of

the cover plate or the device. Before removing the

last two bolts or nuts, pry the cover loose in order to

relieve any spring pressure or other pressure.

Do not allow unauthorized personnel on the engine,

or around the engine when the engine is being

serviced.

Page 8

8 SEBU8190

Safety Section

General Hazard Information

Pressure Air and Water

Illustration 6

Wear a hard hat, protective glasses, and other

•

protective equipment, as required.

When work is performed around an engine that is

•

operating, wear protective devices for ears in order

to help prevent damage to hearing.

Do not wear loose clothing or jewelry that can snag

•

on controls or on other parts of the engine.

Ensure that all protective guards and all covers are

•

securedinplaceontheengine.

g00702020

Pressurized ai

and/or hot water to be blown out. This could result in

personal injury.

When pressure air and/or pressure water is used for

cleaning, wear protective clothing, protective shoes,

and eye prote

oraprotectivefaceshield.

The maximum a

must be below 205 kPa (30 psi). The maximum

water pressure for cleaning purposes must be below

275 kPa (40 ps

Fluid Penetr

r and/or water can cause debris

ction. Eye protection includes goggles

ir pressure for cleaning purposes

i).

ation

Never put maintenance fluids into glass containers.

•

Glass containers can break.

Use all cleaning solutions with care.

•

Report all necessary repairs.

•

Unless other instructions are provided, perform

the maintenance under the following conditions:

The engine is stopped. Ensure that the engine

•

cannot be started.

Disconnect the batteries when maintenance

•

is performed or when the electrical system is

serviced. Disconnect the battery ground leads.

Tape the leads in order to help prevent sparks.

Do not attempt any repairs that are not understood.

•

Use the proper tools. Replace any equipment that

is damaged or repair the equipment.

If work is carried out on the fuel system obey the

•

local regulations for isolation of the gas supply.

California Proposition 6 5 Warning

Some constituents of engine exhaust are known to

the State of California to cause cancer, birth defects,

and other reproductive harm.

Illustration 7

Always use a board or cardboard when you check

for a leak. Leaking fluid that is under pressure can

penetrate body tissue. Fluid penetration can cause

serious injury and possible death. A pin hole leak can

cause severe injury. If fluid is injected into your skin,

you must get treatment immediately. Seek treatment

from a doctor that is familiar with this type of injury.

g00687600

Containing Fluid Spillage

Care must be taken in order to ensure that fluids

are contained during performance of inspection,

maintenance, testing, adjusting and repair of the

engine. Prepare to collect the fluid with suitable

containers before opening any compartment or

disassembling any component that contains fluids.

Tools that are suitable for collecting fluids and

•

equipment that is suitable for collecting fluids

Tools that are suitable for containing fluids and

•

equipment that is suitable for containing fluids

Obey all local regulations for the disposal of liquids.

Page 9

SEBU8190 9

Safety Section

Burn Prevention

Dispose of Waste Properly

Illustration 8

Improperly disposing of waste can threaten the

environment. Potentially harmful fluids should be

disposed o

Always use leakproof containers when you drain

fluids. Do

drain, or into any source of water.

f according to local regulations.

not pour waste onto the ground, down a

g00706404

i02414602

Burn Prevention

Oils

Hot oil and hot lubricating components can cause

personal injury . Do not allow hot oil or hot components

to contact the skin.

If the application has a makeup tank, remove the cap

for the makeup tank after the engine has stopped.

The filler cap must be cool to the touch.

Batteries

The liquid in a battery is an electrolyte. Electrolyte is

an acid that can cause personal injury. Do not allow

electrolytetocontacttheskinortheeyes.

Do not smoke while checking the battery electrolyte

levels. Batteries give off flammable fumes which can

explode.

Always wear protective glasses when you work with

batteries. Wash hands after touching batteries. The

use of gloves is recommended.

i02415237

Fire Prevention and Explosion

Preventio

n

Do not touch any part of an operating engine.

Allow the engine to cool before any maintenance

is performed on the engine. Relieve all pressure in

the appropriate system before any lines, fittings or

related items are disconnected.

Coolant

When the engine is at operating temperature, the

engine coolant is hot. The coolant is also under

pressure. The radiator, the heat exchanger, the

heater and lines contain hot coolant. Any contact with

hot coolant or with steam can cause severe burns.

Allow cooling system components to cool before the

cooling system is drained.

Check the coolant level after the engine has stopped

and the engine has been allowed to cool. Ensure

that the filler cap is cool before removing the filler

cap. The filler cap must be cool enough to touch with

a bare hand. Remove the filler cap slowly in order

to relieve pressure.

Cooling system conditioner contains alkali. Alkali can

cause personal injury. Do not allow alkali to contact

the skin, the eyes, or the mouth.

Illustration 9

All fuels, most lubricants, and some c oolant mixtures

are flammable.

Flammable fluids that are leaking or spilled onto hot

surfaces or onto electrical components can cause

a fire. Fire may cause personal injury and property

damage.

A flash fire may result if the covers for the engine

crankcase are removed within fifteen minutes after

an emergency shutdown.

g00704000

Page 10

10 SEBU8190

Safety Section

Fire Prevention and Explosion Prevention

Determine whet

environment that allows combustible gases to be

drawn into the air inlet system. These gases could

cause the engi

property damage, or engine damage could result.

If the applic

gases, consult your Perkins dealer for additional

information about suitable protection devices. All

local regula

Remove all flammable materials such as fuel, oil, and

debris from t

materials to accumulate on the engine.

Store fuels a

containers away from unauthorized persons. Store

oily rags and any flammable materials in protective

containers

storing flammable materials.

Do not expo

Exhaust shields (if equipped) protect hot exhaust

component

a hose, or a seal failure. Exhaust shields must be

installed correctly.

Do not weld on lines or tanks that contain flammable

fluids. Do not flame cut lines that contain flammable

fluid. Cle

nonflammable solvent prior to welding or flame

cutting.

Wiring must be kept in good condition. All electrical

wires must be properly routed and securely attached.

Check all

that are loose or frayed before you operate the

engine. Clean all electrical connections and tighten

all elec

Eliminate all wiring that is unattached or unnecessary.

Do not us

the recommended gauge. Do not bypass any fuses

and/or circuit breakers.

Arcing or sparking could cause a fire. Secure

connections, recommended wiring, and properly

maintai

or sparking.

Inspec

deterioration. The hoses must be properly routed.

The lines and hoses must have adequate support

and sec

recommended torque. Leaks can cause fires.

Oil fil

The filter housings must be tightened to the proper

torque.

trical connections.

ned battery cables will help to prevent arcing

t all lines and hoses for wear or for

ure clamps. Tighten all connections to the

ters and fuel filters must be properly installed.

her the engine will be operated in an

ne to overspeed. Personal injury,

ation involves the presence of combustible

tions must be observed.

he engine. Do not allow any flammable

nd lubricants in properly marked

. Do not smoke in areas that are used for

setheenginetoanyflame.

s from oil or fuel spray in case of a line,

an any such lines thoroughly with a

electrical wires daily. Repair any wires

e any wires or cables that are s maller than

Illustration 10

Gases from a battery can explode. Keep any open

flames or sparks away from the top of a battery. Do

not smoke in battery charging areas.

Never check the battery charge by placing a metal

object across the terminal posts. Use a voltmeter or

ahydrometer.

Improper jumper cable connections can cause

an explosion that can result in injury. Refer to

the Operation Section of this manual for specific

instructions.

Do not charge a frozen battery. This may cause an

explosion.

The batteries must be kept clean. The covers

(if equipped) must be kept on the cells. Use the

recommended cables, connections, and battery box

covers when the engine is operated.

g00704135

Fire Extinguisher

Make sure that a fire extinguisher is available. Be

familiar with the operation of the fire extinguisher.

Inspect the fire extinguisher and service the fire

extinguisher regularly. Obey the recommendations

on the instruction plate.

Lines, Tubes and Hoses

Donotbendhighpressurelines.Donotstrikehigh

pressure lines. Do not install any lines that are bent

or damaged.

Page 11

SEBU8190 11

Safety Section

Crushing Prevention and Cutting Prevention

Repair any line

can cause fires. Consult your Perkins dealer for

repair or for replacement parts.

Check lines, tubes and hoses carefully. Do not use

your bare hand to check for leaks. Use a board or

cardboard to

to the recommended torque.

Replace the p

are present:

End fittings

•

Outer coverings are chafed or cut.

•

Wires are exposed.

•

Outer coveri

•

Flexible part of the hoses are kinked.

•

Outer covers have embedded armoring.

•

End fittings

•

Make sure that all clamps, guards, and heat shields

are installe

will help to prevent vibration, rubbing against other

parts, and excessive heat.

s that are loose or damaged. Leaks

check for leaks. Tighten all connections

arts if any of the following conditions

are damaged or leaking.

ngs are ballooning.

are displaced.

d correctly. During engine operation, this

i02143194

i02453744

Mounting and Dismounting

The steps or han

engine. Refer to the OEM for information before any

maintenance or repair is performed.

Inspect the steps, the handholds, and the work area

before mounting the engine. Keep these items clean

and keep these

Mount the engine and dismount the engine only at

locations th

climb on the engine, and do not jump off the engine.

Face the engi

dismount the engine. Maintain a three-point contact

with the steps and handholds. Use two feet and one

hand or use o

controls as handholds.

Do not stand

your weight. Use an adequate ladder or use a work

platform. Secure the climbing equipment so that the

equipment w

Do not carry tools or supplies when you mount the

engine or w

line to raise and lower tools or supplies.

dholds may not be installed on the

items in good repair.

at have steps and/or handholds. Do not

ne in order to mount the engine or

ne foot and two hands. Do not use any

on components which cannot support

ill not move.

hen you dismount the engine. Use a hand

Crushing Prevention and

Cutting Prevention

Support th

the component is performed.

Unless oth

never attempt adjustments while the engine is

running.

Stay clear of all rotating parts and of all moving

parts. Leave the guards in place until maintenance

is perfor

reinstall the guards.

Keep obje

blades will throw objects or cut objects.

When obje

order to avoid injury to the eyes.

Chips or o

are struck. Before objects are struck, ensure that no

one will be injured by flying debris.

e component correctly when work beneath

er maintenance instructions are provided,

med. After the maintenance is performed,

cts away from moving fan blades. The fan

cts are struck, wear protective glasses in

ther debris may fly off objects when objects

i02415253

Ignition

Ignition systems can cause electrical shocks. Avoid

contacting the ignition system components and

wiring.

Systems

i02453806

Before Starting Engine

Inspect the engine for potential hazards.

Before starting the engine, ensure that no one is on,

underneath, or close to the engine. Ensure that the

area is free of personnel.

Ensure that the engine is equipped with a lighting

system that is suitable for the conditions. Ensure that

all lights work properly.

Page 12

12 SEBU8190

Safety Section

Engine Starting

All protective

be installed if the engine must be started in order

to perform service procedures. To help prevent an

accident that

around the parts carefully.

Do not bypass

disable the automatic shutoff circuits. The circuits are

provided in order to help prevent personal injury. The

circuits are

engine damage.

The initial s

has been serviced make provision to shut the engine

off, in order to stop an overspeed. This may be

accomplish

engine, or shutting off the ignition system.

Engine Star

If a warning tag is attached to the engine start switch

or to the controls, DO NOT start the engine or move

the contro

thewarningtagbeforetheengineisstarted.

guards and all protective covers must

is caused by parts in rotation, work

the automatic shutoff circuits. Do not

also provided in order to help prevent

tart-up of a new engine or a engine that

ed by shutting off the fuel supply to the

i02426322

ting

ls. Consult with the person that attached

i00659907

Engine Stopping

To avoid overhe

wear of the engine components, stop the engine

according to the instructions in this Operation and

Maintenance M

(Operation Section).

Use the Emerge

in an emergency situation. Do not use the Emergency

Stop Button for normal engine stopping. After an

emergency st

problem that caused the emergency stop has been

corrected.

On the initial start-up of a new engine or an engine

that has been serviced, make provisions to stop

the engine i

accomplished by shutting off the fuel supply to the

engine, or shutting off the ignition system.

ating of the engine and accelerated

anual, “Engine Stopping” topic

ncy Stop Button (if equipped) ONLY

op, DO NOT start the engine until the

f an overspeed occurs. This may be

i02436641

Electrical System

All protec

be installed if the engine must be started in order

to perform service procedures. To help prevent an

accident

around the parts carefully.

If there i

the exhaust system, refer to the purge procedure in

this Operation and Maintenance Manual, “Engine

Starting

Always start the engine according to the procedure

that is de

Manual, “Engine Starting” topic in the Operation

Section. Knowing the correct procedure will help to

prevent

Knowing the procedure will also help to prevent

personal injury.

To ensure that the jacket water heater (if equipped)

and/or the lube oil heater (if equipped) is working

proper

temperature during heater operation.

Engine

which can be harmful to your health. Always start the

engine and operate the engine in a well ventilated

area. I

vent the engine exhaust to the outside.

tive guards and all protective covers must

that is caused by parts in rotation, work

s a possibility that unburned gas remains in

” topic in the Operation Section.

scribed in the Operation and Maintenance

major damage to the engine components.

ly , check the water temperature and the oil

exhaust contains products of combustion

f the engine is started in an enclosed area,

Never disconnect any charging unit circuit or battery

circuit cable from the battery when the charging unit

is operating. A spark can cause the combustible

gases that are produced by some batteries to ignite.

To help prevent sparks from igniting combustible

gases that are produced by some batteries, the

negative “í” cable should be connected last from the

external power source to the negative “í” terminal

of the starting motor. If the starting motor is not

equipped with a negative “í” terminal, connect the

cabletotheengineblock.

Check the electrical wires daily for wires that

are loose or frayed. Tighten all loose electrical

connections before the engine is started. Repair all

frayed electrical wires before the engine is started.

See the Operation and Maintenance Manual for

specific starting instructions.

Grounding Practices

Note: All ground lines must return to the battery

ground.

Page 13

SEBU8190 13

Safety Section

Electrical System

Illustration 11

Typical example

(1) Starting motor to ground

(2) Battery negative to engine

g01217202

Correct grounding for the engine electrical system

is necessary for optimum engine performance

and reliability. Incorrect grounding will result in

uncontrolled electrical circuit paths and in unreliable

electrical circuit paths.

Uncontrolled electrical circuit paths can result in

damage to the crankshaft bearing journal surfaces

and to aluminum components.

The connections for the grounds should be tight and

free of corrosion. The engine alternator must be

grounded to the negative “-” battery terminal with

a wire that is adequate to handle the full charging

current of the alternator.

The power supply connections and the ground

connections for the engine electronics should always

be from the isolator to the battery.

Page 14

14 SEBU8190

Product Information Section

Model Views and Specifications

Product Information

Section

Model Views and

Specifications

i02415298

Model View Illustrations

The illustrations show various typical features of

4000 Series TRS Engine. The illustrations do not

show all of the options that are available.

Page 15

SEBU8190 15

Product Information Section

Model Views and Specifications

Illustration 1 2

Typical example

(1) Air filter

(2) Governor control unit

(3) Fuses for the ignition system

(4) Ignition

(5) Water temperature regulator

(6) O il filler cap

(7) Alternator

(8) Oil level gauge (dipstick)

g01207301

(9) Engine oil filters

(10) Relay

(11) Starting motor

(12) Charge air cooler

Page 16

16 SEBU8190

Product Information Section

Model Views and Specifications

Illustration 1 3

Typical example

(13) Ignition coil

(14) Zero pressure regulator

(15) Turbocharger

(16) Closed breather system

(17) The inspection cover for the Crankcase

(18) Drain plug

i02430841

Product Description

The Perkins Engines were developed in order to

provide gas engines for generator set applications.

The engines have the ability to burn a wide variety of

gaseous fuels.

Fuel System

The fuel is delivered to the zero pressure regulator.

The gas must be at a constant pressure and the gas

must be stable. The pressure must be within a range

of1.5to5kPa(0.21to0.72psi).Higherpressurewill

need to be reduced with an additional gas regulator.

g01215253

(19) Secondary water pump

The venturi must be selected for the engine. This

selection is based on the composition of the gas that

will be used.

Any change in the composition of the gas may require

a change to the venturi.

Theventuriislocatedinthegasmixerbody

immediately before the turbocharger. As air is

accelerated through the venturi gas is mixed with the

air. This mixture is compressed by the turbocharger.

the mixture passes through the charge cooler and

into the inlet manifold. The speed and the load is

governed by an electronically controlled throttle valve.

The air/fuel ratio is adjustable by the main adjustment

screw. This screw is located on the gas mixer body

before the venturi. This is the only means of adjusting

the exhaust emissions at full load.

Page 17

SEBU8190 17

Product Information Section

Model Views and Specifications

Ignition System

The engine is equipped with an Electronic Ignition

System (EIS). The EIS provides dependable firing

and low maintenance. The EIS provides precise

control of the following factors:

Voltage

•

Duration of the spark

•

Ignition timing

•

The TRS2 engine is equipped with protection from

detonation. The TRS1 engine may be equipped with

protection for detonation as an option.

The ignition timing is retarded when excessive

detonation is sensed. If detonation continues after full

retardation, then the engine must be shut down.

Lubrication System

The engine lubrication oil is supplied by a pump

that is driven by a gear. The oil is cooled and the

oil is filtered. A bypass valve provides unrestricted

flow of lubrication oil to the engine parts if the

oil filter elements become plugged. The bypass

valve will open if the oil filter differential pressure

reaches 34.4 to 48.2 kPa (5 to 7 psi). The engine oil

pressure operates in a range of 413.6 to 448.1 kPa

(60to65psi).

Battery chargi

•

The system is used when recovery of heat is not an

important fac

Cogeneration

Cogeneration uses energy from heat which would

otherwisebew

The following items are not supplied:

Water pumps

•

Water tempera

•

All water tube assemblies

•

This system is the responsibility of the OEM.

ng alternator

tor.

engine

asted.

ture regulator ( thermostat)

Engine Service Life

Engine effic

performance depend on adherence to proper

operation and maintenance recommendations. This

includes the

and coolants.

For the engin

refer to the Operation and Maintenance Manual,

“Maintenance Interval Schedule” in the Maintenance

Section.

iency and maximum utilization of engine

use of recommended lubricants, fuels,

e maintenance that is required,

Note: The engine lubrication oil is not filtered when

the bypass valve is open. Do not allow the engine

to operate when the bypass valve is open. This can

damage the engine components.

Cooling System

The water enters the engine from the oil cooler and

the water is passed through the cylinder block. The

water exits the cylinder head into the rail. The water

exits the engine from the water outlet.

Electrounit

This type of engine is supplied with the following

components:

Jacket water coolant pump

•

Water temperature regulator (thermostat)

•

Coolant pipe for the charge cooler

•

A water pump for the charge cooler

•

A water temperature regulator (thermostat) that

•

controls the system for the charge cooler

Specificat

ions

General Engine Specifications

Illustration 14

Six c ylinder

(A) Inlet v a lves

(B) E xhaus t valves

i02415458

g01216853

Page 18

18 SEBU8190

Product Information Section

Model Views and Specifications

Table 1

4006 Engine Specifications

Rated rpm 1500

Cylinders and arrangement In-line six cylinders

Bore 160 mm (6.2992 inch)

Stroke 190 mm (7.4803 inch)

Displacement

Compression ratio

Aspiration Turbocharged

Rotation (flywheel end) Counterclockwise

Inlet valve lash (cold) 0.40 mm (0.0157 inch)

Exhaust valve lash (cold) 0.40 mm (0.0157 inch)

Firing order 1,5,3,6,2,4

22.9 L (1397.4436 in3)

12:1

Illustration 15

Eight cylinder

(A) Inlet valves

(B) Exhaust valves

Table 2

g01207434

4008 Engine Specifications

Rated rpm 1500

Cylinders and arrangement

Bore

In-line eight cylinder

160 mm (6.2992 inch)

Stroke 190 mm (7.4803 inch)

Displacement

30.56 L

(1864.8855 in

Compression ratio 12:1

Aspiration Turbocharged

ion (flywheel end)

Rotat

Count

erclockwise

Inlet valve lash (cold) 0.40 mm (0.0157 inch)

Exhaust valve lash (cold) 0.40 mm (0.0157 inch)

ng order

Firi

7,6,8,5,2,3

1,4,

3

)

Page 19

SEBU8190 19

Product Information Section

Model Views and Specifications

Piston Positions for Valve Lash

Setting

Table 3

The six cylinder engine

Table 4

Top Center Position

1-6 6 1

2-5 2 5

3-4 4 3

1-6 1 6

2-5 5 2

3-4 3 4

Top Center Position

1-8 8 1

4-5 5 4

2-7 2 7

3-6 3 6

1-8 1 8

4-5 4 5

2-7 7 2

3-6 6 3

Engine cylinder with valves

on the rock

The eight cylinder engine

Engine cylinder with valves

on the rock

Set the bridge adjustment and

set valve lash.

Set the bridge adjustment and

set valve lash.

Page 20

20 SEBU8190

Product Information Section

Product Identification Information

Product Identification

Information

i02531889

Plate Locations and Film

Locations

Engine Identification

Perkins engines are identified by an engine serial

number.

A typical example of an engine serial number is

DGE F**** U00001M.

_________________________________________ MadeinStafford

D

G

____________________________________ Application (Table 5)

E

________________________________Type of engine (Table 6)

Perkins dealer

these numbers in order to determine the components

that were included in the engine. This permits

accurate iden

Serial Number

s and Perkins distributors require all of

tification of replacement part numbers.

Plate

_________________________ Number of cylinders (Table 7)

F

*****

_________________________________ _ Fixed build number

U

____________________________Built in the United Kingdom

00001

M

Table 5

Table 6

____________________________________Engine Number

____________________________________ Year of Manufacture

Application

G Genset

I

F TESI Gas Unit

E TESI Combined Heat and Power Unit

G 4016-E61 TRS

H

J

Gas

Type of engine (Gas)

TRS Combined Heat and Power Unit

TRS Gas Unit

Illustration 16

Serial number plate

The engine serial number plate contains the following

information:

Place of manufacture

•

Telephone number of manufacturer

•

Fax number of manufacturer

•

Type of engine

•

Engine serial number

•

Rated speed

•

Power output

•

Engine timing

•

Rating

•

g01266904

Table 7

Number of Cylinders

F 6

H 8

Page 21

SEBU8190 21

Product Information Section

Product Identification Information

Illustration 17

Location of the serial number plate for in-line engines

g01212991

The serial number plate (1) on an in-line engine is

located on the right side of the cylinder block. See

Illustration 17.

Page 22

22 SEBU8190

Operation Section

Lifting and Storage

Operation Section

Lifting and Storage

Product Lifting

i02427136

Some removals r

obtain proper balance and safety.

To remove the e

are on the engine.

Lifting eyes a

engine arrangement. Alterations to the lifting eyes

and/or the engine make the lifting eyes and the lifting

fixtures obs

that proper lifting devices are provided. Consult your

Perkins dealer for information regarding fixtures for

proper engin

equire lifting fixtures in order to

ngine ONLY, use the lifting eyes that

re designed and installed for the specific

olete. If alterations are made, ensure

elifting.

i02427139

Product Storage

Refer to Perkins Engine Company limited, Stafford

for information on engine storage.

There is three different levels of engine storage.

Level “A, B and C”.

Illustration 18

Typical example

NOTICE

Never ben

the eyebolts and the brackets under tension. Remember that the capacity of an eyebolt is less as the angle

between

comes less than 90 degrees.

When it i

angle, only use a link bracket that is properly rated for

the weight.

d the eyebolts and the brackets. Only load

the supporting members and the object be-

s necessary to remove a component at an

g01203936

Level “A ”

Level “A” will give protection for six month for diesel

engines and protection for one year for gas engines.

This is for engines that are transported by a container

or a truck.

Level “B ”

This level is additional to level “A”. Level “B ” will

give protection under normal storage condition from

í15° to +55°C (5.0000° to 99.0000°F) and “90%”

relative humidity for one year.

Level “C ”

This level is additional to level “B”. Level “C” will give

protection for five year in tropical temperatures or

arctic climates. Level “C” also meets MOD NES 724

level “J” for europe, when engines are stored in a

unheated building or in the open under waterproof

covers.

Use a hoist to remove heavy components. Use

an adjustable lifting beam to lift the engine. All

suppor

parallel to each other. The chains and cables should

be perpendicular to the top of the object that is being

lifted

ting members (chains and cables) should be

.

Page 23

SEBU8190 23

Operation Section

Gauges and Indicators

Gauges and Indicators

i02427382

Gauges and Indicators

Your engine m

the gauges that are described. For more information

about the gauge package, see the OEM information.

Gauges provide indications of engine performance.

Ensure that the gauges are in good working order.

Determine th

the gauges over a period of time.

Noticeable c

potential gauge or engine problems. Problems may

also be indicated by gauge readings that change

even if the r

Determine and correct the cause of any significant

change in the readings. Consult your Perkins dealer

or your Per

If no oil pressure is indicated, STOP the engine. If

maximum co

the engine. Engine damage can result.

ay not have the same gauges or all of

e normal operating range by observing

hanges in gauge readings indicate

eadings are within specifications.

kins distributor for assistance.

NOTICE

olant temperature is exceeded, STOP

Engine Oil

the engine oil pressure is 415 to 450 kPa

(60to65psi).

Pressure – The range for

Jacket Wat

Typical water temperature into the engine

is 71°C (160°F). Higher temperatures

may occur

temperature reading may vary according to load. The

reading should never exceed 96°C (204°F).

1. Ahighwat

cooling system.

indicator should be to the right side of “0” (zero).

under certain conditions. The water

er temperature switch is installed in the

Tachomet

speed (rpm).

Ammeter – This gauge indicates the

amount of charge or discharge in the

battery charging circuit. Operation of the

Service Hour Meter – The gauge indicates

operating hours of the engine.

er Coolant Temperature –

er – This gauge indicates engine

Page 24

24 SEBU8190

Operation Section

Features and Controls

Features and Controls

i02427696

Performance Parameters

Air/Fuel Ratio

The correct air/fuel ratio is very important for the

following considerations:

Margin of detonation

•

Control of emissions

•

Achieving optimum service life for the engine

•

If the air/fuel ratio is not appropriate for the fuel and

the operating conditions, a failure of the engine may

occur. The service life of the turbocharger, the valves,

and other components may be reduced.

Fuel Supply Pressure and Temperature

The fuel supply for the zero pressure regulator

must be at a constant pressure of 1.5 to 5 kPa

(0.21to0.72psi).Ifahigherpressureisrequireda

separate gas regulator must be installed into the fuel

line.

The minimum temperature for the gas into ZPR is

5 °C (41.0 °F). The maximum temperature into the

ZPRis40°C(104.0°F).

Zero Gas Pressure Regulator

The zero gas pressure regulator is a control valve that

operates on demand. The pitot tube in the regulator

outlet controls the flow. As the air is drawn through

the venturi a depression is created. Gas at higher

pressure is drawn in. This is mixed into the air flow.

This mixture then passes through the turbocharger.

As the engine load increases the pressure at the

outlet of the ZPR is reduced and the valve opens

supplying more gas.

i02427718

Sensors and Electrical

Components

Electronic Ignition System (EIS)

The Electronic Ignition System includes the following

components:

The control module for the ignition

•

Timing sensor

•

Ignition coil on each cylinder

•

Spark plugs

•

Ignition har

•

The ignition system generates high voltage. Do

not come in contact with the ignition system with

the engine in

personal injury or death.

The EIS contr

serviceable parts. The timing sensor uses the

magnets that are mounted on the camshaft in order

to generate

cylinder plus an index magnet in order to indicate the

start of each cycle. The EIS control module has a

output to e

each cylinder, the EIS sends a pulse to the primary

winding of the ignition coil. The coil increases the

voltage on

spark across the spark plug electrode.

The electr

following activities:

Ignition t

•

Protection from detonation (if equipped)

•

ness

operation. This voltage can ca use

ol module is a sealed unit with no

thetimingpulses.Onepulseforeach

ach ignition coil. To initiate combustion in

the secondary winding which creates a

onic ignition system provides control for the

iming

Air, Charge Cooler Water

Temperature and Altitude

Refer to technical date sheet for the charts for

the derate in order to determine the maximum

temperatures into the engine and the altitude derate.

Switches

The engine is installed with the following switches.

High cool

•

Low oil pressure switch

•

Overspeed switch and magnetic pickup

•

High press

•

ing water temperature switch

ureswitchforthemanifold

Page 25

SEBU8190 25

Operation Section

Features and Controls

Governor

The engine is installed with a digital governor that

includes the following components:

Digital governor

•

Actuator and throttle valve

•

Magnetic pickup

•

Wiring harness

•

The governor uses the magnetic pickup to sense

engine speed from the flywheel gear teeth. This

signal is fed into the governor, which drives an

actuator. This is connected to the throttle valve in

order to control the amount of combustion gas/air.

A Pandaros Packager service tool and cable are

required in order to make any adjustments to the

system.

Detonation System ( If Equipped)

The equipment for the detonation system is available

to sense detonation or knock which may be caused

by poor gas or may be caused by high combustion

temperatures.

The detonation system includes the following

components:

Detonation sensor on each cylinder

•

Control module for detonation

•

Wiring harness

•

The detonation system operates by measuring

vibrations on the crankcase. The signal is processed

in order to eliminate normal engine vibrations. If

detonation above a predetermined level is detected

the engine timing is retarded. If the engine continues

detonation the detonation system will operate in order

to stop the engine. If detonation ceases, the ignition

timing that is retarded will be gradually brought back

to a normal value.

i02427728

Alarms and Shutoffs

Engines may be e

protective devices that are not included in this section.

This section contains some general information about

thefunctiono

Alarms and shutoffs are electronically controlled.

The operatio

components which are actuated by a sensing unit.

The alarms and shutoffs are set at critical operating

temperature

protect the engine from damage.

The alarms fu

when an abnormal operating condition occurs. The

shutoffs function in order to shut down the engine

whenamorec

occurs. The shutoffs help to prevent damage to the

engine.

Shutoffs may cause unburned gas to remain in the

air inlet and in the exhaust manifold.

Unburned gas in the air inlet and exhaust system

may ignite

injury and/or property damage may result.

Before sta

burned gas, purge the unburned gas from the air

inlet and exhaust system. Refer to the topic on

purging u

section.

If an engi

always determine the cause of the shutoff. Make

the necessary repairs before attempting to start the

engine.

Become familiar with the following information:

Types of the alarm and shutoff controls

•

Location

•

Conditions which cause each control to function

•

Resetting procedure that is required before starting

•

the engine

rting an engine that may contain un-

nburned gas in the “Starting the Engine”

ne protective device shuts off the engine,

s of the alarm and shutoff controls

quipped with optional engine

f typical engine protective devices.

n of all alarms and shutoffs utilize

s, pressures, or speeds in order to

nction in order to warn the operator

ritical abnormal operating condition

when the engine is started. Personal

Testing Alarms and Shutoffs

The OEM will supply this system. Refer to the OEM

for more information.

Alarms must function properly in order to provide

timely warning to the operator. Shutoffs help to

prevent

to determine if the engine protective devices are

in good working order during normal operation.

Malfun

engine protective devices.

damage to the engine. It is impossible

ctions must be simulated in order to test the

Page 26

26 SEBU8190

Operation Section

Features and Controls

NOTICE

During testing

simulated.

, abnormal operating conditions must be

The tests must b

vent possible damage to the engine.

Periodic test

proper operation is recommended maintenance. To

prevent damage to the engine, only authorized

service perso

e performed correctly in order to pre-

ingofengineprotectivedevicesfor

nnel should perform the tests.

i02452757

Control Panel

Refer to the O

that is installed.

EM for information on the control panel

Page 27

SEBU8190 27

Operation Section

Engine Starting

Engine Starting

i02452805

Before Starting Engine

Before the en

daily maintenance and any other periodic

maintenance that is due. Refer to the Operation

and Maintena

Schedule” for more information.

For the maxim

•

thorough inspection within the engine compartment

before the engine is started. Look for the following

items: oil l

excessive dirt and/or grease. Remove any excess

dirt and/or grease buildup. Repair any faults that

were ident

Inspect the cooling system hoses for cracks and

•

for loose c

Inspect the alternator and accessory drive belts for

•

cracks, b r

Inspect the wiring for loose connections and for

•

worn wires

Open the fuel supply valve (if equipped).

•

Do not start the engine or move any of the controls

•

if there is a “DO NOT OPERATE” warning tag or

similar w

to the controls.

gine is started, perform the required

nce Manual, “Maintenance Interval

um service life of the engine, make a

eaks, coolant leaks, loose bolts, and

ified during the inspection.

lamps.

eaks, and other damage.

or frayed wires.

arning tag attached to the start switch or

If the engine is

•

maintain the coolant level within 13 mm (0.5 inch)

of the bottom of the filler pipe. If the engine is

equipped with

level in the sight glass.

Observe the a

•

the air cleaner when the diaphragm enters the red

zone, or when the red piston locks in the visible

position.

Remove any electrical loads.

•

not equipped with a header tank

a sight glass, maintain the coolant

ir cleaner service indicator. Service

i02427758

Cold Weather Starting

A jacket water heater is required for starting when the

temperature is below 10 °C (50 °F). The temperature

of the jacket water should be maintained at 40 °C

(104 °F).

Note: A oil pan immersion heater must not be

installed.

Extra battery capacity may be necessary in order to

start the engine.

Consult your Perkins dealer for more information on

the starting aids that are available for cold weather

starting.

i02427781

Starting

the Engine

Ensure th

•

clear.

All of the

•

damaged guards or for missing guards. Repair

any damaged guards. Replace damaged guards

and/or m

Check electrical cables and check the battery for

•

poor con

Reset all of the shutoffs or alarm components (if

•

equippe

Check the engine lubrication oil level. Maintain the

•

oil leve

mark on the engine oil level gauge.

Check th

•

in the header tank (if equipped). Maintain the

coolant level to the “FULL” mark on the header

tank.

at the areas around the rotating parts are

guards must be put in place. Check for

issing guards.

nections and for corrosion.

d).

l between the “ADD” mark and the “FULL”

e coolant level. Observe the coolant level

Engine exhaust contains products of combustion

which may

and operate the engine in a well ventilated area

and, if in an enclosed area, vent the exhaust to the

outside

For initial start-up of a new or rebuilt engine, and for

start-up of an engine that has been serviced, make

provision to shut the engine off should an overspeed

occur. This may be accomplished by shutting off the

fuel supply and/or the ignition to the engine.

be harmful to your health. Always start

.

NOTICE

Page 28

28 SEBU8190

Operation Section

Engine Starting

Purging Unburned Gas

Unburned gas in the air inlet and exhaust system

may ignite when the engine is started. Personal

injury and/or property damage may result.

Before starting an engine that may contain unburned gas, purge the unburned gas from the air

inlet and exhaust system. Refer to the topic on

purging unburned gas in the “Starting the Engine”

section.

The OEM will supply this system. Refer to the OEM

for more information.

Note: Using the “EMERGENCY STOP” button will

shut off both the fuel and the ignition.

Do not start the engine or move any of the controls

if there is a “DO NOT OPERATE” warning tag or

similar warning tag attached to the start switch or to

the controls.

Ensure that no one will be endangered before the

engine is started and when the engine is started.

Perform the procedures that are described in this

Operation and Maintenance Manual, “Before Starting

Engine” (Operation Section).

The following events cause unburned gas to remain

in the air inlet and in the exhaust manifold:

Emergency stop

•

Engine overspeed

•

Unsuccessful successive attempts to start the

•

engine

Unburned gas may remain in the air inlet and exhaust

system after several unsuccessful attempts to start

the engine. The unburned gas may increase to a

concentration that may ignite during a successive

attempt to start the engine.

Perform the following procedure in order to purge

the unburned gas:

1. Turn the manual gas shutoff valve to the CLOSED

position.

2. Disable the ignition system. Remove the fuses

from the ignition.

3. Turn the engine control switch to the START

position. Crank the engine for a minimum of six

seconds.

Final Checks and First Engine Start

Note: The fuel system must comply with all local

regulations.

The OEM will supply this system. Refer to the OEM

for more information.

1. The starting and the stopping of the engine must

be on no load.

2. The procedure for starting and stopping a radiator

cooled and CHP gas engine will be determined

by the OEM relative to each individual engine

installation.

3. Operate the engine at rated speed for ten minutes.

4. Inspect the engine for leaks in the oil system and

the coolant systems.

5. Stop the engine and check the engine oil and the

engine coolant level.

6. Operate the engine under normal working

conditions. Check the gauges in order to see the

condition of the engine.

7. If the engine fails to start after two attempts turn

off the gas supply and investigate the cause.

4. Enable the ignition by connecting the fuses that

was disconnected in Step 2.

5. Turn the manual gas shutoff valve to the OPEN

position.

6. Start the engine. Refer to the engine starting

procedure and refer to OEM in order to start the

engine.

Engine Starting Procedure

Note: The starting procedure may differ because of

the OEM system that is installed.

1. The signal is received.

2. Check that the gas pressure is in limits. If the gas

pressure is incorrect a warning is activated and

the electrical system will shut down. If the gas

pressure is in limits, go to the next step.

3. Activate the governor.

4. Activate the starter.

5. Operate the engine for three seconds in order to

purge the system.

Page 29

SEBU8190 29

Operation Section

Engine Starting

6. Activate the ga

Continue to operate the starter.

1. After the engi

Note: If the engine fails to start after the maximum

cranking time

2. The engine is now operating.

s valve and activate the ignition.

ne is started disengage the starter.

, the engine will be shut down.

Operation o f the Generator Set

Control Panel

For informati

set control panel, refer to the Operation and

Maintenance Manual for the generator and the

control pane

Automatic St

When the engine is in the AUTOMATIC mode, the

engine can start at any moment. To avoid personal

injury, alw

the engine is in the AUTOMATIC mode.

on on operation for a specific generator

l.

arting

ays remain clear of the the engine when

Manual starting

Refer to the

controls in order to manually start the engine.

OEM manual for information on the

i02428473

Starting with Jump Start

Cables

Do not use jump start cables in order to start the

engine. Charge the batteries or replace the batteries.

Refer to Operation and Maintenance Manual,

“Battery - Replace”.

i024285

After Starting Engine

For new in

rebuilt, carefully monitor the engine in order to detect

any unusual engine performance.

stallations and engines that are recently

29

Check for leaks in the air and in the fluid systems.

Page 30

30 SEBU8190

Operation Section

Engine Operation

Engine Operation

i02428569

Engine Operation

Proper opera

attaining the maximum service life and economy for

the engine. Follow the instructions in this Operation

and Maintena

operatingcostsandmaximizetheservicelifeofthe

engine.

Observe the gauges frequently while the engine is

operating. Record the data from the gauges in a log

regularly.

for normal engine operation. Comparing the data

over time will help to detect changes in engine

performan

Investigate any significant change in the gauge

readings.

action when discrepancies are found.

tion and maintenance are key factors in

nce Manual in order to minimize

Compare the data to the specifications

ce.

Monitor the engine operation and take

Partial load and Low Load

Operation

Extended operation at low load or reduced load will

cause the f

Carbon formation in the cylinder

•

ollowing results:

Detonation

•

Power los

•

Poor performance

•

Accelerated wear of components

•

Increase

•

The cylinder bore to glaze

•

s

d oil consumption

Page 31

SEBU8190 31

Operation Section

Engine Stopping

Engine Stopping

i02428635

Emergency Stopping

The OEM will s

Emergency shutoff controls are for EMERGENCY use

ONLY. DO NOT us

controls for normal stopping procedure.

Pressing the

unburned gas to remain in the air inlet and in the

exhaust manifold.

Unburned gas in the air inlet and exhaust system

may ignite w

injury and/or property damage may result.

Before star

burned gas, purge the unburned gas from the air

inlet and exhaust system. Refer to the topic on

purging unb

section.

upply the system.

NOTICE

e emergency shutoff devices or

Emergency Stop Button may cause

hen the engine is started. Personal

ting an engine that may contain un-

urned gas in the “Starting the Engine”

2. With the engine

and switch off the governor.

3. If an overspee

gas valve and the governor..

4. If another eng

valve.

stopped, switch off the ignition

d occurs, switch off the ignition, the

ine fault occurs switch off the gas

i02453745

Manual Stop Procedure

In order to manually stop the engine, refer to the

OEM for infor

the system that has been installed.

Stopping the

been operating under a load can result in overheating

and accelerated wear of the engine components.

Allow the engine to gradually cool before stopping the

engine.

mation. The procedure will depend on

NOTICE

engine immediately after the engine has

The emergen

for normal engine operation. Push the button for

emergency stopping. This shuts off both the fuel

and the ign

button is locked. To reset the button, turn the button

clockwise. The spring-loaded button will return to the

OUT posit

Do not use this method to stop the engine unless

an emergency has occurred. Continuous emergency

shutdownscancausedamagetosomeenginecomponents. This will leave unburned fuels in the combustion chambers and in the exhaust system. If an emergency shutdown occurs, purge the system by cranking

the engine for 5 to 10 seconds with the ignition shutoff.

cy stop button is in the OUT position

ition. The engine will not start when the

ion.

NOTICE

Typical Procedure in Order to Stop

the Engine

Note: The stopping procedure will differ because

of the different types of OEM controls that can be

installed.

1. In order to stop the engine, switch off the gas

valve.

Page 32

32 SEBU8190

Operation Section

Engine Stopping

i02508920

After Stopping Engine

Check the engin

•

the oil level between the “ADD” and “FULL” marks

on the “ENGINE STOPPED” side of the oil level

gauge.

If necessary, perform minor adjustments. Repair

•

any leaks and t

Note the service hour reading. Perform the

•

maintenance

and Maintenance Manual, “Maintenance Interval

Schedule” (Maintenance Section).

Only use antifreeze/coolant mixtures recommended in

the Refill Capacities and Recommendations section of

this manual.

age.

Allow the en

•

If freezing temperatures are expected, check the

•

coolant for

system must be protected against freezing to the

lowest expected outside temperature. Add the

proper cool

e crankcase oil level. Maintain

ighten loose bolts.

that is scheduled in this Operation

NOTICE

Failure to do so can cause engine dam-

gine to cool. Check the coolant level.

protection against freezing. The cooling

ant/water mixture, if necessary.

Perform all required periodic maintenance on all

•

driven equ

provided by the OEM of the driven equipment.

ipment. Refer to the instructions that are

Page 33

SEBU8190 33

Maintenance Section

Refill Capacities

Maintenance Section

Refill Capacities

i02478642

Refill Capacities

Lubrication System

The refill capacities for the engine crankcase reflect

the approximate capacity of the crankcase or sump

plus standard oil filters. Auxiliary oil filter systems will

require additional oil. Refer to the OEM specifications

for the capacity of the auxiliary oil filter. Refer to this

Manual, “Maintenance Section” for more information

on fluid recommendations.

TRS 4006

Table 8

TRS 4006

Refill Capacities

Compartment or System Liters Quarts

Crankcase Oil Sump

Total Lubrication System

(1)

These values are the approximate capacities for the crankcase

oil sump which includes the standard factory installed oil filters.

Engines with auxiliary oil filters will require additional oil. Refer

to the OEM specifications for the capacity of the auxiliary oil

filter.

(2)

The Total Lubrication System includes the capacity for the

Crankcase Oil Sump plus the capacity of factory installed oil

filters and other filters added to the lubrication system. Enter

the value for the capacity of the Total Lubrication Sy stem in

this row.

TRS 4008

Table 9

Compartment or System Liters Quarts

Crankcase Oil Sump

Total Lubrication System

(1)

These values are the approximate capacities for the crankcase

oil sump which includes the standard factory installed oil filters.

Engines with auxiliary oil filters will require additional oil. Refer

to the OEM specifications for the capacity of the auxiliary oil

filter.

(2)

The Total Lubrication System includes the capacity for the

Crankcase Oil Sump plus the capacity of factory installed oil

filters and other filters added to the lubrication system. Enter

the value for the capacity of the Total Lubrication Sy stem in

this row.

(1)

(2)

122.7 129.6

TRS 4008

Refill Capacities

(1)

(2)

166.6 176

Cooling System

To maintain the cooling system, the Total Cooling

System capacity must be known. The approximate

capacity is for the engine cooling system. External

System capacities will vary among applications.

Refer to the OEM specifications for the External

System capacity. This capacity information will be

needed in order to determine the amount of coolant

that is required for the Total Cooling System.

TRS 4006

Table 10

TRS 4006

Refill Capacities

Compartment or System Liters Quarts

Engine bloc

External System Per OEM

Total Cooling System

(1)

The E xternal System includes a radiator or an expansion

tank with the following components: heat exchanger and

piping. Refer to the OEM specifications. Enter the value for the

capacity of the External System in this row.

(2)

he Total Cooling System capacity includes the capacity of

T

he Engine plus the External System. Enter the value for the

t

apacity of the Total Cooling System in this row.

c

TRS 4008

able 11

T

Compartment or System Liters Quarts

Engine block only 48 64.4

External System Per OEM

Total Cooling System

(1)

The E xternal System includes a radiator or an expansion

tank with the following components: heat exchanger and

piping. Refer to the OEM specifications. Enter the value for the

capacity of the External System in this row.

(2)

The Total Cooling System capacity includes the capacity of

the Engine plus the External System. Enter the value for the

capacity of the Total Cooling System in this row.

k only

Refill Capacities

36 42.3

(1)

(2)

TRS 4008

(1)

(2)

Page 34

34 SEBU8190

Maintenance Section

Refill Capacities

i02481783

Fluid Recommendations

General Lubricant Information

Engine Oil

The engine oil recommendation for an application

can change due

of the oil. Refer to Perkins Engines Stafford for the

latest information.

Multigrade oils must not be used.

Recommendati

Engines that operate on natural gas should be

lubricated b

of 0.5% by weight. The total base number must be

between 5 and 7. The following SAE40 monograde

engine oils

Mobil Pegasus 705

•

Texaco/Caltex Geotex LA

•

Q8 Mahler MA

•

Castrol Duratec L

•

The oil change interval for Mobil Pegasus HPC40

•

is up to 2000 hours. Use scheduled oil analysis in

order to det

Mobil Pegasus 805

•

BP Energas NGL

•

Shell Mysel

•

Total Nateria MH40

•

Chevron HPLX low ash

•

to advances in the specification

on

y oils that have a nominal ash content

comply:

ermine the oil change interval.

la LA

Oil analysis

The oil analysis will complement the preventive

maintenance p

The oil analysis is a diagnostic tool that is used to

determine oil

rates. Contamination can be identified and measured

through the use of the oil analysis. The oil analysis

includes the

The Wear Rate Analysis monitors the wear of the

•

engine’s met

type of wear metal that is in the oil is analyzed. The

increase in the rate of engine wear metal in the

oil is as impo

metal in the oil.

Tests are co

•

contamination of the oil by water, glycol or fuel.

The Oil Cond

•

the oil’s lubricating properties. An infrared analysis

is used to compare the properties of new oil to the

propertie

allows technicians to determine the amount of

deterioration of the oil during use. This analysis

also allow

of the oil according to the specification during the

entire oil change interval.

rogram.

performance and component wear

following tests:

als. The amount of wear metal and

rtant as the quantity of engine wear

nducted in order to detect

ition Analysis determines the loss of

s of the used oil sample. This analysis

s technicians to verify the performance

Fuel Specification

A new engin

that conforms to the British natural gas specifications.

Refer to Perkins Engines Stafford in order to use a

differen

Cooling S

e is set to operate with clean natural gas

t specification of gas.

ystem Specifications

General Coolant Information

NOTICE

Never add coolant to an overheated engine. Engine

damage could result. Allow the engine to cool first.

Chevron/Ca

•

The oil has a lower total base number than the

recommended minimum value. The additive will

give the eq

The oil change interval for any of the oils must be

•

approved b

Engines which operate on landfill gas must use

•

the oil tha

Engines Stafford. These oils have a higher ash

content.

ltex HDAX 0% and 0.5% sulfated ash.

uivalent performance.

y Perkins Engines Stafford.

t is currently recommended by Perkins

NOTICE

If the engine is to be stored in, or shipped to an area

with below freezing temperatures, the cooling system

must be ei

ature or drained completely to prevent damage.

Frequently check the specific gravity of the coolant for

proper freeze protection or for anti-boil protection.