Perkins Engine 1200 Service Manual

PRELIMINARY

®

Part No 479-0227

Troubleshooting Guide

GB

1200 Series Marine Auxiliary Engines

PRELIMINARY

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to observe basic

safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations

before an accident occurs. A person must be alert to potential hazards, including human factors that can affect

safety. This person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result

in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you verify that you

are authorized to perform this work, and have read and understood the operation, lubrication, maintenance

and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings are not

heeded, bodily injury or death could occur to you or to other persons.

The hazards are identied by the “Safety Alert Symbol” and followed by a “Signal Word” such as “DANGER”,

“WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

WARNING

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or pictorially presented.

A non-exhaustive list of operations that may cause product damage are identied by “NOTICE” labels on the

product and in this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The warnings in

this publication and on the product are, therefore, not all inclusive. You must not use this product in any manner

different from that considered by this manual without rst satisfying yourself that you have considered all safety

rules and precautions applicable to the operation of the product in the location of use, including site-specic rules

and precautions applicable to the worksite. If a tool, procedure, work method or operating technique that is not

specically recommended by Perkins is used, you must satisfy yourself that it is safe for you and for others. You

should also ensure that you are authorized to perform this work, and that the product will not be damaged or

become unsafe by the operation, lubrication, maintenance or repair procedures that you intend to use.

The information, specications, and illustrations in this publication are on the basis of information that was available

at the time that the publication was written. The specications, torques, pressures, measurements, adjustments,

illustrations, and other items can change at any time. These changes can affect the service that is given to the

product. Obtain the complete and most current information before you start any job. Perkins dealers have the most

current information available.

WARNING

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts or parts with equivalent

specications including, but not limited to,

physical dimensions, type, strength and material.

Failure to heed this warning can lead to

premature failures, product damage, personal

injury or death.

In the United States, the maintenance, replacement, or repair of the emission control devices and systems

may be performed by any repair establishment or individual of the owner’s choosing.

PRELIMINARY

479-0227 Table of Contents

Chapter Page

Electronic Troubleshooting .......................................................................1

Engine Governor ..............................................................................................................5

Timing Considerations ......................................................................................................5

Fuel Injection ....................................................................................................................5

Customer Parameters and Engine Speed Governing ......................................................5

ECM Lifetime Totals ..........................................................................................................6

Programmable Parameters ..............................................................................................6

Passwords ........................................................................................................................6

Electronic Service Tools .................................................................................................11

Required Service Tools ...................................................................................................11

Optional Service Tools ....................................................................................................11

Perkins Electronic Service Tool ......................................................................................11

Connecting the Electronic Service Tool and the Communication Adapter II ...................12

Shutdown........................................................................................................................12

Warning Lamp ................................................................................................................12

Lamp Check ...................................................................................................................12

Sensor locations on the left side of the engine ...............................................................15

Harness Wire Identication.............................................................................................17

Programming Parameters........................................................................21

Test ECM Mode ..............................................................................................................21

Program a new Electronic Control Module (ECM)..........................................................21

Rerate the engine. ..........................................................................................................22

Unlock parameters. ........................................................................................................22

Clear engine events and certain diagnostic trouble codes. ............................................22

Flash Programming a Flash File.....................................................................................22

PRELIMINARY

Table of Contents 479-0227

Installing Injector Codes .................................................................................................23

Customer Specied Parameters .............................................................25

Equipment ID ..................................................................................................................25

Rating Number ...............................................................................................................25

Engine Location ..............................................................................................................25

Coolant Level Switch ......................................................................................................25

System Operating Voltage Conguration .......................................................................26

Customer Password 1 ....................................................................................................26

Customer Password 2 ....................................................................................................26

CAN Communication Protocol Write Security ................................................................26

System Conguration Parameters..........................................................27

Symptom Troubleshooting ......................................................................29

Probable Causes ............................................................................................................29

Diagnostic Codes ...........................................................................................................29

Electronic Service Tool ...................................................................................................29

ECM Parameters ............................................................................................................29

Electrical Connectors......................................................................................................29

Air Intake and Exhaust System ......................................................................................30

Valve Lash ......................................................................................................................30

Turbocharger ..................................................................................................................30

Fuel Supply.....................................................................................................................30

EFLP Flow Test at the Secondary Fuel Filter Inlet .........................................................32

Check the Return Fuel Lines ..........................................................................................32

Low Compression (Cylinder Pressure) ...........................................................................32

Electronic Injectors .........................................................................................................32

PRELIMINARY

479-0227 Table of Contents

Individual Malfunctioning Cylinders ................................................................................32

Alternator Is Noisy ..........................................................................................................33

Assembly after Repair ....................................................................................................34

Coolant Temperature Gauge ..........................................................................................36

Coolant Level..................................................................................................................36

Raw Water Cooling .........................................................................................................36

Keel Cooling ...................................................................................................................36

Radiator Fins ..................................................................................................................36

Radiator Cap and/or Pressure Relief Valve ....................................................................36

Restriction in the Coolant System ..................................................................................36

Valve Lash ......................................................................................................................37

Low Compression (Cylinder Pressure) ...........................................................................37

Injectors ..........................................................................................................................38

Pistons ............................................................................................................................38

Communication Adapter and/or Cables ..........................................................................39

Electrical Power Supply to the Diagnostic Connector ....................................................39

Electronic Service Tool and Related Hardware ..............................................................39

Electrical Power Supply to the Electronic Control Module (ECM) ..................................40

Data Link ........................................................................................................................40

Visible Faults ..................................................................................................................40

Air Intake and Exhaust System ......................................................................................41

Speed/timing Sensors ....................................................................................................41

Fuel System....................................................................................................................41

Glow Plugs .....................................................................................................................43

Low Compression (Cylinder Pressure) ...........................................................................43

Battery Cables and/or Batteries......................................................................................43

Starting Motor Solenoid or Starting Circuit .....................................................................43

PRELIMINARY

Table of Contents 479-0227

Starting Motor and/or Flywheel Ring Gear .....................................................................43

Electrical Power Supply ..................................................................................................43

Internal Engine Fault ......................................................................................................44

Multiple Starts or Cold Operation ...................................................................................44

Incorrect Maintenance Intervals .....................................................................................44

Dirt in Engine Oil.............................................................................................................44

Incorrect Oil ....................................................................................................................44

Contaminated Oil ............................................................................................................44

Leaks in Air Intake System .............................................................................................44

Dirt in Fuel .....................................................................................................................44

Low Oil Pressure ............................................................................................................45

Pistons ............................................................................................................................45

Connecting Rod and Main Bearings ...............................................................................45

Throttle Position Sensor .................................................................................................46

Air Intake and Exhaust System ......................................................................................46

Air Intake ........................................................................................................................47

Electrical Connectors......................................................................................................47

Fuel Supply.....................................................................................................................47

Throttle Position Sensor .................................................................................................48

Accessory Equipment .....................................................................................................49

Power Mode Control (If Equipped) .................................................................................49

Fuel Supply.....................................................................................................................49

Low Compression (Cylinder Pressure) ...........................................................................50

Electronic Unit Injectors ..................................................................................................50

ECM Parameters ............................................................................................................51

Throttle Signal for the Throttle Position Sensor ..............................................................51

Air Intake and Exhaust System ......................................................................................51

PRELIMINARY

479-0227 Table of Contents

Engine Supports .............................................................................................................52

Low Compression (Cylinder Pressure) ...........................................................................52

Display on the Control Panel ..........................................................................................52

Coolant Temperature Sensor Circuit ..............................................................................53

Low Coolant Temperature ..............................................................................................53

Cooling System ..............................................................................................................53

Glow Plugs .....................................................................................................................53

Fuel Quality ....................................................................................................................53

Valve Lash ......................................................................................................................53

Low Compression (cylinder pressure) ............................................................................53

Recommended Actions...................................................................................................54

Misreading of Fuel Level ................................................................................................54

Fuel Quality ....................................................................................................................54

Quality of Oil ...................................................................................................................54

Low Engine Temperature ................................................................................................54

Prolonged Operation at Idle Speed ................................................................................55

Engine Operating Speed ................................................................................................55

Air Inlet and Exhaust System .........................................................................................55

Cooling Fan ....................................................................................................................55

Reduced Pressure of Intake Air ......................................................................................55

Excessive Valve Lash .....................................................................................................55

Failure of the Primary Speed/Timing Sensor ..................................................................55

Electrical Connections ....................................................................................................57

Fuel Filters ......................................................................................................................57

Fuel Rail Pressure Sensor..............................................................................................57

Return Fuel Lines ...........................................................................................................58

High Ambient Air T emperature ........................................................................................59

PRELIMINARY

Table of Contents 479-0227

Intake Air Restriction and/or High Altitude ......................................................................59

Intake Air Restriction.......................................................................................................59

High Altitude ...................................................................................................................59

Intake Air from a Heated Area ........................................................................................59

Turbocharger ..................................................................................................................60

Oil Leaks.........................................................................................................................61

Engine Crankcase Breather ...........................................................................................61

Oil Level..........................................................................................................................61

Air Intake and Exhaust System ......................................................................................61

Turbocharger ..................................................................................................................62

Low Compression (cylinder pressure) ............................................................................62

Measuring Fuel Dilution ..................................................................................................63

Verifying Fuel Dilution .....................................................................................................63

Recommended Actions...................................................................................................64

Probable Causes ............................................................................................................65

Display on the Control Panel ..........................................................................................66

Electrical Connectors......................................................................................................67

ECM Connection ............................................................................................................67

Troubleshooting with Codes ...................................................................69

Troubleshooting with an Event Code .....................................................73

Diagnostic Functional Tests ....................................................................75

Communication...............................................................................................................83

PRELIMINARY

479-0227 Electronic Troubleshooting

Electronic Troubleshooting

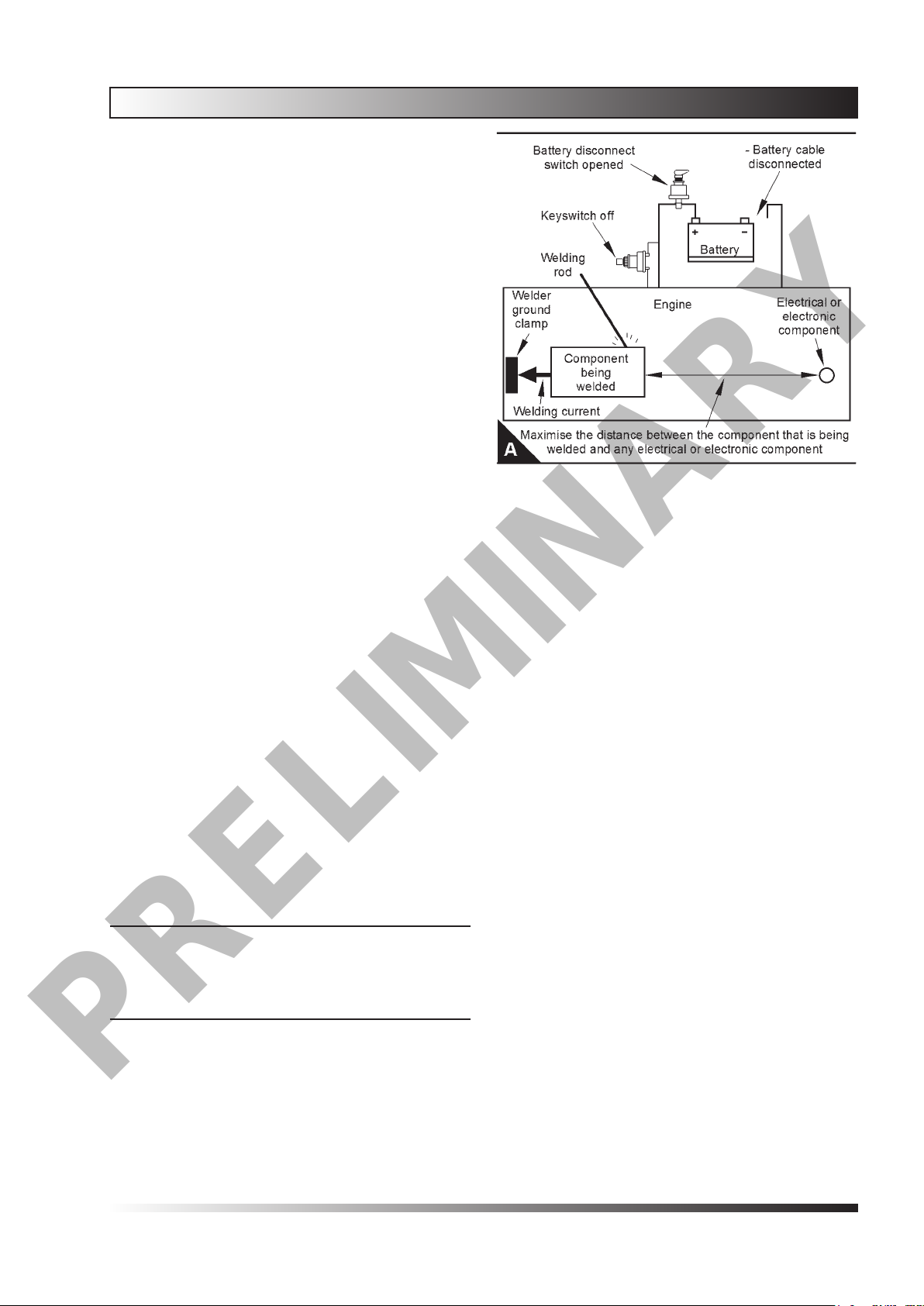

Welding Precaution

Correct welding procedures are necessary in order

to avoid damage to the following components:

• Electronic Control Module (ECM) on the engine

• Sensors

• Associated components

Components for the driven equipment should

also be considered. When possible, remove the

component that requires welding. When welding

on an engine that is equipped with an ECM

and removal of the component is not possible,

the following procedure must be followed. This

procedure minimizes the risk to the electronic

components.

Service welding guide (typical diagram)

1. Stop the engine. Remove the electrical power

from the ECM.

2. Ensure that the fuel supply to the engine is

turned off.

3. Disconnect the negative battery cable from the

battery. If a battery disconnect switch is installed,

open the switch.

4. Disconnect all electronic components from

the wiring harnesses. Include the following

components:

• Electronic components for the driven

equipment

• ECM.

• Sensors.

• Electronically controlled valves.

• Relays.

NOTICE

Do not use electrical components (ECM or ECM

sensors) or electronic component grounding points

for grounding the welder.

5. When possible, connect the ground clamp for

the welding equipment directly to the engine

component that will be welded. Place the

clamp as close as possible to the weld. Close

positioning reduces the risk of welding current

damage to the engine bearings, to the electrical

components, and to other components.

6. Protect the wiring harnesses from welding debris

and/or from welding spatter.

7. Use standard welding procedures to weld the

materials together.

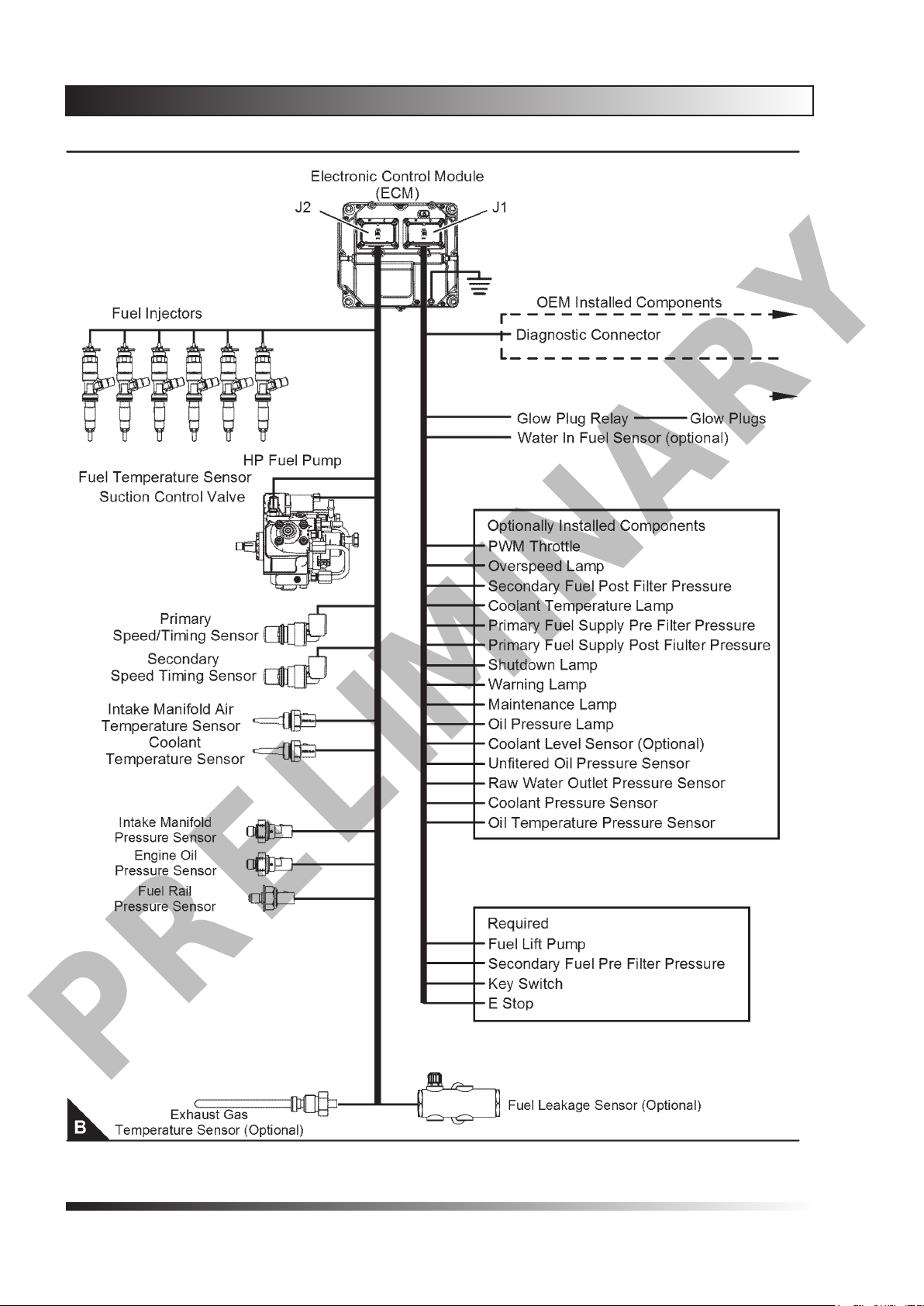

System Overview

The engine has an electronic control system.

The control system consists of the following

components:

• Electronic Control Module (ECM)

• Software (ash le)

• Wiring

• Sensors

• Actuators

The following information provides a general

description of the control system. Refer to Systems

Operation, Testing, and Adjusting for detailed

information about the control system.

Page 1

PRELIMINARY

Electronic Troubleshooting 479-0227

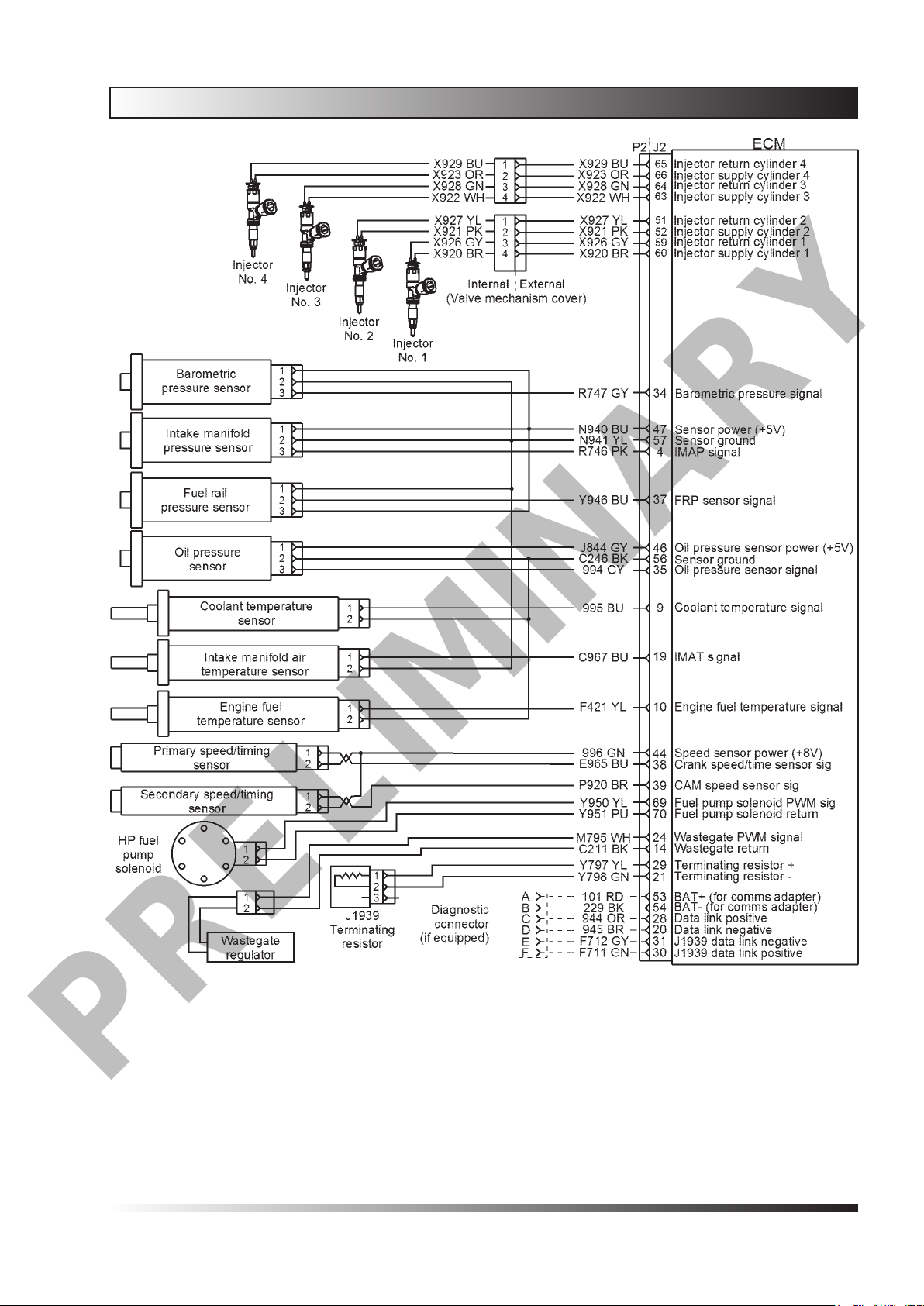

Electronic Circuit Diagram

Illustration shows the E70M conguration

Page 2

PRELIMINARY

479-0227 Electronic Troubleshooting

Illustration shows the E44M conguration

Page 3

PRELIMINARY

Electronic Troubleshooting 479-0227

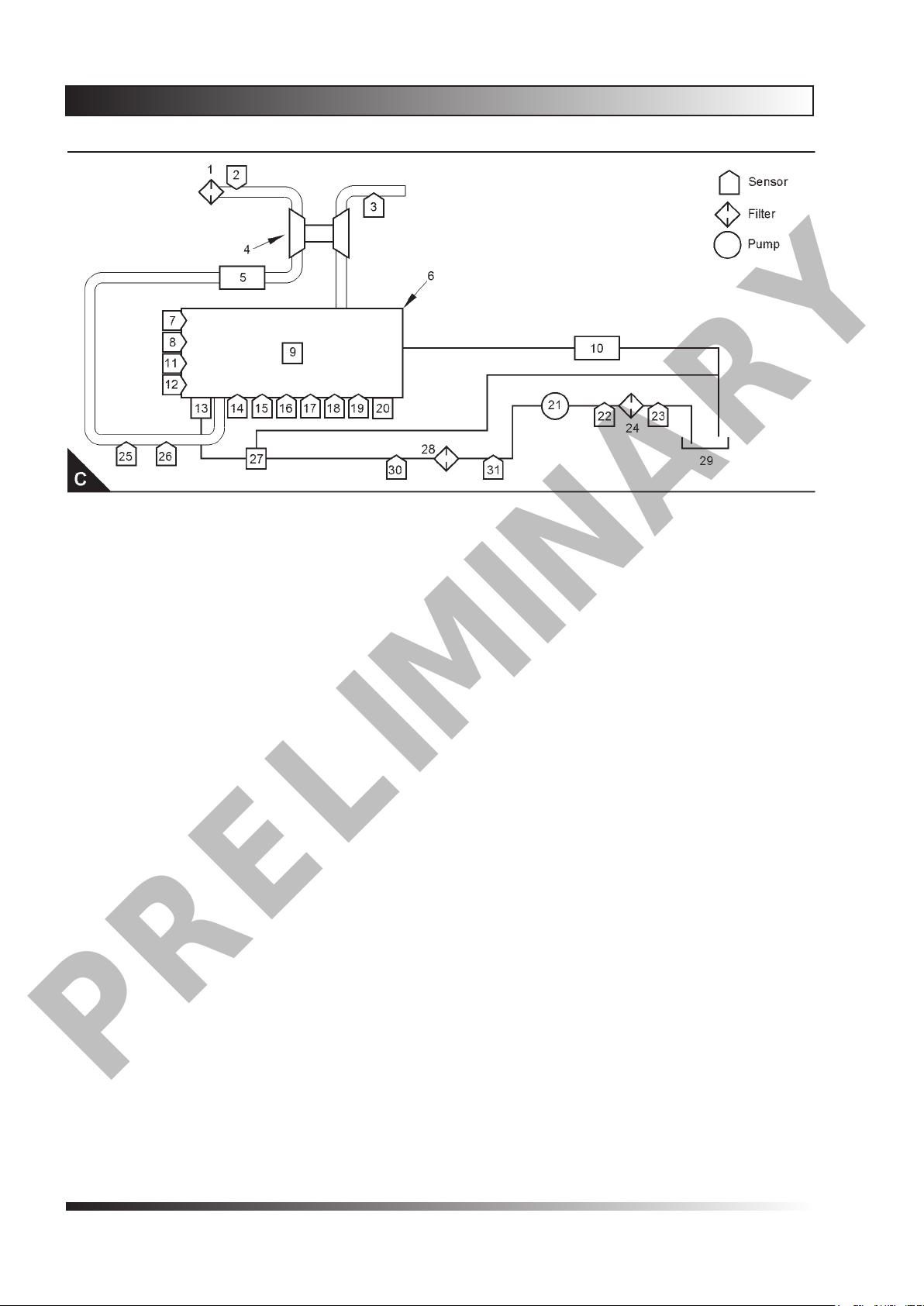

Block Diagram

(1). Air cleaner

(2). Air inlet temperature sensor

(3). Exhaust gas temperature sensor (if fuel

temperature sensor

(4). Turbocharger

(5). Air-to-air aftercooler

(6). Engine

(7). Coolant temperature sensor

(8). Primary speed/timing sensor

(9). Fuel injectors

(10). Return fuel cooler (optional)

(11). Sea water pressure sensor (if equipped)

(12). Secondary speed/timing sensor

(13). High-pressure fuel pump/transfer pump/fuel

temperature sensor

(21). Electric fuel lift pump

(22). Post-primary fuel lter pressure sensor

(23). Pre-primary fuel lter pressure sensor

(24). Primary fuel lter

(25). Intake manifold pressure sensor

(26). Intake manifold air temperature sensor

(27). Transfer pump inlet regulator

(28). Secondary fuel lter

(29). Fuel tank

(30). Post-secondary fuel lter pressure sensor

(31). Pre-secondary fuel lter pressure sensor

(14). Fuel rail pressure sensor

(15). Pre-lter oil pressure sensor (if equipped)

(16). Post lter oil pressure sensor

(17). Coolant pressure sensor

(18). Oil temperature sensor (if equipped)

(19). Fuel leakage detection sensor (if equipped)

(20). ECM

Page 4

PRELIMINARY

479-0227 Electronic Troubleshooting

System Operation

Engine Governor

The ECM governs the engine. The ECM determines

the timing, the injection pressure, and the amount of

fuel that is delivered to each cylinder. These factors

are based on the actual conditions and on the

desired conditions at any given time during starting

and operation.

The desired engine speed is typically determined by

one of the following conditions:

• The position of the throttle

• CAN input, set to default

Timing Considerations

Once the governor has determined the amount of

fuel that is required, the governor must determine

the timing of the fuel injection. Fuel injection timing

is determined by the ECM after considering input

from the following components:

• Coolant temperature sensor

• Intake manifold air temperature sensor

• Intake manifold pressure sensor

pressure, the ECM increases the “FRC Fuel Limit”.

A higher intake manifold pressure indicates that

there is more air in the cylinder. When the ECM

increases the “FRC Fuel Limit” , the ECM allows

more fuel into the cylinder.

The “Rated Fuel Limit” is a limit that is based on the

power rating of the engine and on the engine rpm.

The “Rated Fuel Limit” is like the rack stops and the

torque spring on a mechanically governed engine.

The “Rated Fuel Limit” provides the power curves

and the torque curves for a specic engine family

and a specic engine rating. All of these limits are

determined at the factory. These limits cannot be

changed.

Customer Parameters and Engine Speed Governing

A unique feature with electronic engines is customer

specied parameters. These parameters allow

the owner of the machine to ne-tune the ECM for

engine operation. Fine-tuning the ECM allows the

machine owner to accommodate the typical usage

of the machine and the power train of the machine.

Many of the customer parameters provide additional

restrictions on the actions that will be performed by

the ECM in response to input from the operator.

The ECM adjusts timing for optimum engine

performance and for fuel economy. Actual timing

and desired timing cannot be viewed with the

electronic service tool. The ECM determines the

location of top centre of the number one cylinder

from the signals that are provided by the engine

speed/timing sensors. The ECM determines when

injection should occur relative to top center. The

ECM then provides the signal to the injector at the

desired time.

Fuel Injection

The ECM sends a high voltage signal to the injector

solenoids in order to energize the solenoids. By

controlling the timing and the duration of the high

voltage signal, the ECM can control the following

aspects of injection:

• Injection timing

• Fuel delivery

The ash le inside the ECM establishes certain

limits on the amount of fuel that can be injected. The

“FRC Fuel Limit” is a limit that is based on the intake

manifold pressure. The “FRC Fuel Limit” is used

to control the air/fuel ratio for control of emissions.

When the ECM senses a higher intake manifold

Some parameters are intended to notify the operator

of potential engine damage (engine monitoring

parameters). Other parameters are used to enhance

the engine installation into the machine. Other

parameters are used to provide engine operating

information to the owner of the machine.

Page 5

PRELIMINARY

Electronic Troubleshooting 479-0227

Other ECM Functions for

Performance

The ECM can also provide enhanced control

of the engine for machine functions. Refer to

Troubleshooting, “Customer Specied Parameters”

for additional information.

ECM Lifetime Totals

The ECM maintains total data of the engine for the

following parameters

• “Total Operating Hours”

• “Engine Lifetime Hours”

• “Total Idle Time”

• “Total Idle Fuel”

• “Total Fuel”

• “Total Max Fuel”

• “Engine Starts”

• “Lifetime Total Engine Revolutions”

• “Average Load Factor”

The “Total Operating Hours” is the operating hours

of the engine. The operating hours do not include

the time when the ECM is powered but the engine is

not running.

operating information. “Average Load Factor”

compares actual operating information of the engine

to the maximum engine operation that is available.

“Average Load Factor” is determined by using “Total

Max Fuel” , “Total Idle Fuel” and “Total Fuel” . All of

these parameters are available with the electronic

service tool. These parameters are available within

the menu for “Current Totals”.

Programmable Parameters

Certain parameters that affect engine operation

may be changed with the electronic service tool.

The parameters are stored in the ECM, and the

parameters are protected from unauthorised

changes by passwords. These parameters are

either system conguration parameters or customer

parameters.

System conguration parameters are set at the

factory. System conguration parameters affect

emissions or power ratings within an engine family.

Factory passwords must be obtained and factory

passwords must be used to change the system

conguration parameters.

Customer parameters are variable. Customer

parameters can be used to adjust the following

characteristics of the engine within preset limits:

• Rpm ratings

• Power ratings

The “Engine Lifetime Hours” is the number of hours

when electrical power has been applied to the

engine. These hours will include the time when the

ECM is powered but the engine is not running.

“Total Idle Time” and “Total Idle Fuel” can include

operating time when the engine is not operating

under a load.

Fuel Information can be displayed in US gallons or

in litres.

“Total Fuel” is the total amount of fuel that is

consumed by the engine during operation.

“Total Max Fuel” is the maximum amount of fuel that

could have been consumed by the engine during

operation.

“Engine Starts” is the total number of times when

the engine has been started.

“Lifetime Total Engine Revolutions” is the total

number of revolutions that have been completed by

the engine crankshaft.

“Average Load Factor” provides relative engine

Customer passwords may be required to change

customer specied parameters.

Some of the parameters may affect engine

operation in an unusual way. An operator might not

expect this type of effect. Without adequate training,

these parameters may lead to power complaints

or performance complaints even though the

performance of the engine is to the specication.

Refer to Troubleshooting, “Conguration

Parameters” for additional information on this

subject.

Passwords

System conguration parameters are protected

by factory passwords. Factory passwords are

calculated on a computer system that is available

only to Perkins distributors. Since factory passwords

contain alphabetic characters, only the electronic

service tool may change system conguration

parameters. System conguration parameters affect

the power rating family or emissions.

Customer parameters can be protected by

Page 6

PRELIMINARY

479-0227 Electronic Troubleshooting

customer passwords. The customer passwords are

programmed by the customer. Factory passwords

can be used to change customer passwords if

customer passwords are lost.

Refer to Troubleshooting, “Factory Passwords” for

additional information on this subject.

Glossary

Active Diagnostic Code – An active diagnostic code

alerts the operator or the service technician that an

electronic system malfunction is currently present.

Refer to the term “Diagnostic Code” in this glossary.

Alternating Current (AC) – Alternating current is an

electric current that reverses direction at a regular

interval that is reoccurring.

Before Top Centre (BTC) – BTC is the 180 degrees

of crankshaft rotation before the piston reaches the

top dead centre position in the normal direction of

rotation.

Breakout Harness – A breakout harness is a test

harness that is designed to connect into the engine

harness. This connection allows a normal circuit

operation and the connection simultaneously

provides a Breakout T in order to measure the

signals.

Bypass Circuit – A bypass circuit is a circuit that is

used as a substitute circuit for an existing circuit. A

bypass circuit is typically used as a test circuit.

CAN Data Link (see also J1939 CAN Data Link)

– The CAN Data Link is a serial communications

port that is used for communication with other

microprocessor-based devices.

Code – Refer to “Diagnostic Trouble Code”.

Communication Adapter Tool – The communication

adapter provides a communication link between the

ECM and the electronic service tool.

Coolant Temperature Sensor – The coolant

temperature sensor detects the engine coolant

temperature for all normal operating conditions and

for engine monitoring.

Data Link – The data link is a serial communication

port that is used for communication with other

devices such as the electronic service tool.

Derate – Certain engine conditions will generate

event codes. Also, an engine derate may be applied.

The map for the engine derate is programmed into

the ECM software. The engine derate can be one

or more of three types: reduction of rated power,

reduction of rated engine speed and reduction of

rated machine speed for OEM products.

Desired Engine Speed – The desired engine speed

is input to the electronic governor within the ECM.

The electronic governor uses the signal from the

throttle position sensor, the engine speed/timing

sensor, and other sensors in order to determine the

desired engine speed.

Diagnostic Trouble Code – A diagnostic trouble code

is sometimes referred to as a fault code. These

codes indicate an electronic system malfunction.

Diagnostic Lamp – The diagnostic lamp is also

called the warning lamp. The diagnostic lamp

is used to warn the operator of the presence of

an active diagnostic code. The lamp may not be

included in all applications.

Digital Sensor Return – The common line (ground)

from the ECM is used as ground for the digital

sensors.

Digital Sensors – Digital sensors produce a pulse

width modulated signal. Digital sensors are supplied

with power from the ECM.

Digital Sensor Supply – The power supply for the

digital sensors is provided by the ECM.

Direct Current (DC) – Direct current is the type of

current that ows consistently in only one direction.

DT, DT Connector, or Deutsch DT – This connector

is a type that is used on this engine. The connectors

are manufactured by Deutsch .

Duty Cycle – Refer to “Pulse Width Modulation” .

Electronic Engine Control – The electronic engine

control is a complete electronic system. The

electronic engine control monitors the engine

operation under all conditions. The electronic engine

control also controls the engine operation under all

conditions.

Electronic Control Module (ECM) – The ECM is the

control computer of the engine. The ECM provides

power to the electronics. The ECM monitors data

that is input from the sensors of the engine. The

ECM acts as a governor in order to control the

speed and the power of the engine.

Electronic Service Tool – The electronic service tool

allows a computer (PC) to communicate with the

ECM.

Engine Monitoring – Engine Monitoring is the part

of the electronic engine control that monitors the

sensors. Engine monitoring also warns the operator

of detected faults.

Page 7

PRELIMINARY

Electronic Troubleshooting 479-0227

Engine Oil Pressure Sensor – The engine oil

pressure sensor measures engine oil pressure. The

sensor sends a signal to the ECM that is dependent

on the engine oil pressure.

Engine Speed/Timing Sensor – An engine speed/

timing sensor is a hall effect switch that provides a

digital signal to the ECM. The ECM interprets this

signal as the crankshaft position and the engine

speed. Two sensors are used to provide the speed

and timing signals to the ECM. The primary sensor

is associated with the crankshaft and the secondary

sensor is associated with the camshaft.

Event Code – An event code may be activated in

order to indicate an abnormal engine operating

condition. These codes usually indicate a

mechanical problem instead of an electrical system

problem.

Failure Mode Identier (FMI) – This identier

indicates the type of failure that is associated with

the component. The FMI has been adopted from the

SAE practice of J1587 diagnostics. The FMI follows

the parameter identier (PID) in the descriptions of

the fault code. The descriptions of the FMIs are in

the following list.

0. The data is valid but the data is above the normal

operational range.

1. The data is valid but the data is below the normal

operational range.

2. The data is erratic, intermittent, or incorrect.

3. The voltage is above normal or the voltage is

shorted high.

4. The voltage is below normal or the voltage is

shorted low.

5. The current is below normal or the circuit is open.

14. There is a special instruction for the device.

15. The signal from the device is high (least severe).

16. The signal from the device is high (moderate

severity).

17. The signal from the device is low (least severe).

18. The signal from the device is low (moderate

severity).

19. There is an error in the data from the device.

31.Condition exists.

Flash File – This le is software that is inside the

ECM. The le contains all the instructions (software)

for the ECM and the le contains the performance

maps for a specic engine. The le may be

reprogrammed through ash programming.

Flash Programming – Flash programming is the

method of programming or updating an ECM with an

electronic service tool over the data link instead of

replacing components.

FRC – See “Fuel Ratio Control” .

Fuel Pump – See “High Pressure Fuel Pump” .

Fuel Rail – This item is sometimes referred to

as the High Pressure Fuel Rail. The fuel rail

supplies fuel to the electronic unit injectors. The

high-pressure fuel pump and the fuel rail pressure

sensor work with the ECM in order to maintain the

desired fuel pressure in the fuel rail. This pressure

is determined by calibration of the engine in order

to enable the engine to meet emissions and

performance requirements.

Fuel Rail Pressure Sensor – The fuel rail pressure

sensor sends a signal to the ECM that is dependent

on the pressure of the fuel in the fuel rail.

6. The current is above normal or the circuit is

grounded.

7. The mechanical system is not responding

properly.

8. There is an abnormal frequency, an abnormal

pulse width, or an abnormal time period.

9. There has been an abnormal update.

10. There is an abnormal rate of change.

11. The failure mode is not identiable.

12. The device or the component is damaged.

13. The device requires calibration.

Fuel Ratio Control (FRC) – The FRC is a limit that

is based on the control of the ratio of the fuel to air.

The FRC is used for purposes of emission control.

When the ECM senses a higher intake manifold air

pressure, the FRC increases the FRC Limit.

Full Load Setting (FLS) – The FLS is the

parameter that represents the fuel system

adjustment. This adjustment is made at the factory

in order to ne-tune the fuel system. This parameter

must be programmed.

Full Torque Setting (FTS) – The FTS is the

parameter that represents the adjustment for the

engine torque. This adjustment is made at the

factory in order to ne-tune the fuel system. This

Page 8

PRELIMINARY

479-0227 Electronic Troubleshooting

adjustment is made with the FLS. This parameter

must be programmed.

Glow Plug – The glow plug is an optional starting

aid for cold conditions. One glow plug is installed

in each combustion chamber in order to improve

the ability of the engine to start. The ECM uses

information from the engine sensors such as the

coolant temperature to determine when the glow

plug relay must provide power to each glow plug.

Each of the glow plugs then provides a hot surface

in the combustion chamber in order to vaporize

the mixture of air and fuel. The result is improved

ignition during the compression stroke of the

cylinder.

Glow Plug Relay – The glow plug relay is controlled

by the ECM in order to provide high current to the

glow plugs that are used in the starting aid system.

Harness – The harness is the bundle of wiring

(loom) that connects all components of the

electronic system.

Hertz (Hz) – Hertz is the measure of electrical

frequency in cycles per second.

High Pressure Fuel Pump – The pump supplies

fuel under pressure to the fuel rail (high-pressure

fuel rail).

High Pressure Fuel Rail – See “Fuel Rail” .

Injector Codes – Injector codes contain 30

characters. The codes are supplied with new

injectors. The code is input through the electronic

service tool into the ECM. The injector codes

compensate for manufacturing tolerances of the

injector and for variances over the life of the injector.

Intake Manifold Air Temperature Sensor – The

intake manifold air temperature sensor detects the

air temperature in the intake manifold. The ECM

monitors the air temperature and other data in the

intake manifold in order to adjust injection timing

and other performance functions.

Intake Manifold Pressure Sensor – The Intake

Manifold Pressure Sensor measures the pressure

in the intake manifold. The pressure in the intake

manifold may be different to the pressure outside

the engine (atmospheric pressure). The difference

in pressure may be caused by an increase in air

pressure by a turbocharger (if equipped).

J1939 CAN Data Link – This data link is a SAE

standard diagnostic communications data link that is

used to communicate between the ECM and other

electronic devices.

Logged Diagnostic Codes – Logged diagnostic

codes are codes which are stored in the memory.

These codes are an indicator of possible causes for

intermittent problems. Refer to the term “Diagnostic

Trouble Codes” for more information.

NOx Reduction System – The NOx Reduction

System recycles a portion of the exhaust gases

back into the inlet air in order to reduce the oxides of

nitrogen (NOx) in the exhaust gases. The recycled

exhaust gas passes through a cooler before being

introduced into the inlet air.

OEM – OEM is an abbreviation for the Original

Equipment Manufacturer. The OEM is the

manufacturer of the machine or the vehicle that

uses the engine.

Open Circuit – An open circuit is a condition that is

caused by an open switch, or by an electrical wire

or a connection that is broken. When this condition

exists, the signal or the supply voltage can no longer

reach the intended destination.

Parameter – A parameter is a value or a limit that

is programmable. The parameters help determine

specic characteristics or behaviors of the engine.

Password – A password is a group of numeric

characters or a group of alphanumeric characters

that is designed to restrict access to parameters.

The electronic system requires correct passwords

in order to change some parameters (Factory

Passwords). Refer to Troubleshooting, “Factory

Passwords” for more information.

Personality Module – See “Flash File”

Power Cycling – Power cycling refers to the action

of cycling the keyswitch from any position to the

OFF position, and to the START/RUN position.

Pressure Limiting Valve (PLV) – The PLV is

a valve in the fuel rail that prevents excessive

pressure. The PLV will reduce the pressure to a safe

level that will limit engine operation but the reduced

pressure will not stop the engine.

Primary Speed/Timing Sensor – This sensor

determines the position of the crankshaft during

engine operation. If the primary speed/timing sensor

fails during engine operation, the secondary speed/

timing sensor is used to provide the signal.

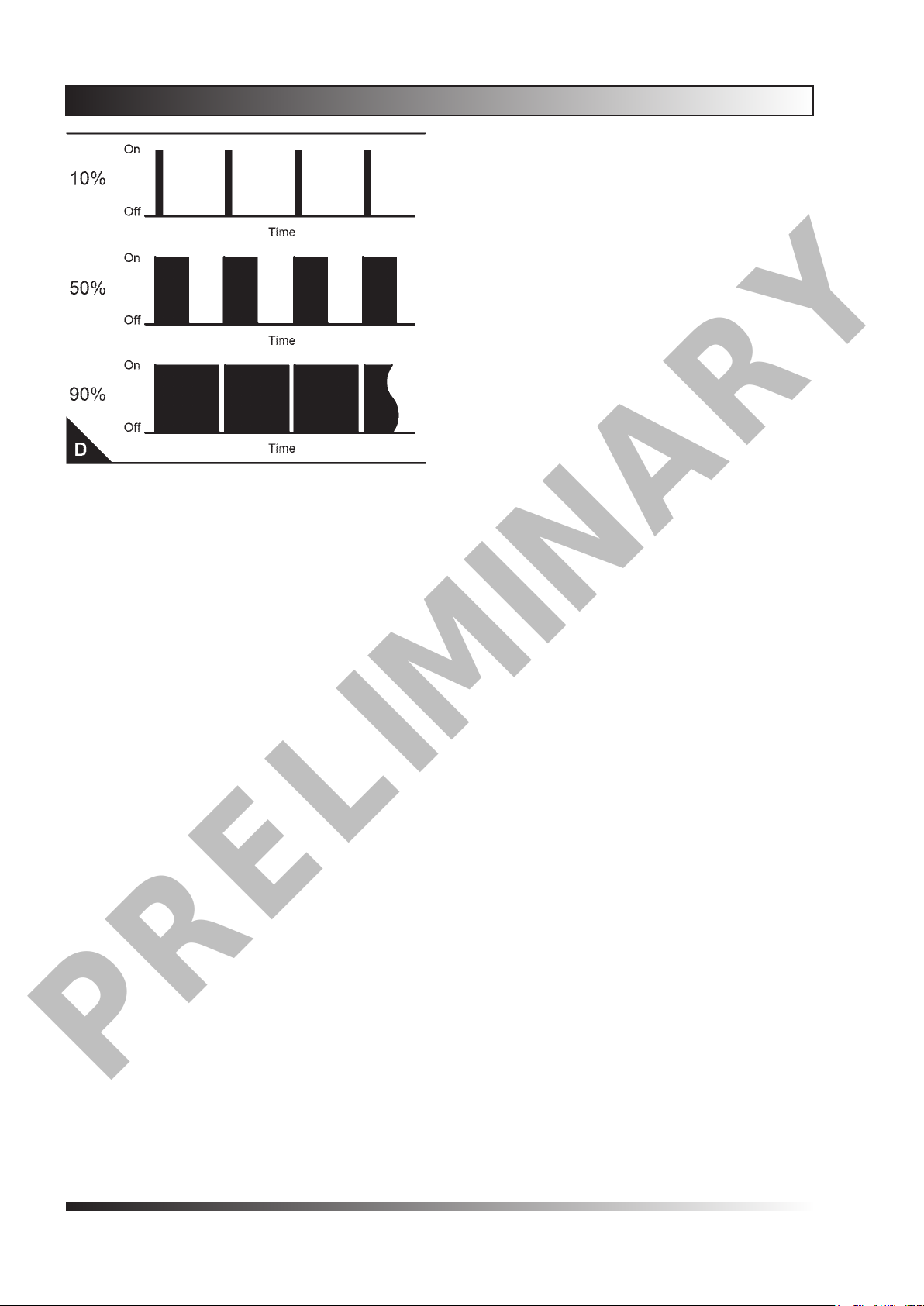

Pulse Width Modulation (PWM) – The PWM is a

signal that consists of pulses that are of variable

width. These pulses occur at xed intervals. The

ratio of “TIME ON” versus “TIME OFF” can be

varied. This ratio is also referred to as a duty cycle.

Page 9

PRELIMINARY

Electronic Troubleshooting 479-0227

a sensor to the ECM.

Suction Control Valve (SCV) – The SCV is a

control device in the high-pressure fuel pump. The

ECM controls the pressure in the fuel rail by using

the SCV to control the amount of fuel that enters the

chambers in the pump.

Supply Voltage – The supply voltage is a

continuous voltage that is supplied to a component

in order to provide the electrical power that is

required for the component to operate. The power

may be generated by the ECM or the power may be

battery voltage that is supplied by the engine wiring.

Suspect Parameter Number (SPN) – The SPN

is a J1939 number that identies the specic

component of the electronic control system that has

experienced a diagnostic code.

Rated Fuel Limit – This limit is based on the power

rating of the engine and on the engine rpm. The

Rated Fuel Limit enables the engine power and

torque outputs to conform to the power and torque

curves of a specic engine model. These limits are

in the ash le and these limits cannot be changed.

Reference Voltage – Reference voltage is a

regulated voltage and a steady voltage that is

supplied by the ECM to a sensor. The reference

voltage is used by the sensor to generate a signal

voltage.

Relay – A relay is an electromechanical switch. A

ow of electricity in one circuit is used to control the

ow of electricity in another circuit. A small current

or voltage is applied to a relay in order to switch a

much larger current or voltage.

Secondary Speed/Timing Sensor – This sensor

determines the position of the camshaft during

engine operation. If the primary speed/timing sensor

fails during engine operation, the secondary speed/

timing sensor is used to provide the signal.

Sensor – A sensor is a device that is used to detect

the current value of pressure or temperature, or

mechanical movement. The information that is

detected is converted into an electrical signal.

Short Circuit – A short circuit is a condition that has

an electrical circuit that is inadvertently connected to

an undesirable point. An example of a short circuit

is a wire which rubs against a vehicle frame and

this rubbing eventually wears off the wire insulation.

Electrical contact with the frame is made and a short

circuit is created.

Signal – The signal is a voltage or a waveform that

is used in order to transmit information typically from

System Conguration Parameters – System

conguration parameters are parameters that affect

emissions and/or operating characteristics of the

engine.

Tattletale – Certain parameters that affect the

operation of the engine are stored in the ECM.

These parameters can be changed by use of

the electronic service tool. The tattletale logs the

number of changes that have been made to the

parameter. The tattletale is stored in the ECM.

Throttle Position – The throttle position is the

interpretation by the ECM of the signal from the

throttle position sensor or the throttle switch.

Throttle Position Sensor – The throttle position

sensor is a sensor that is connected to a throttle

device such as an accelerator pedal or a hand lever.

This sensor sends a signal to the ECM that is used

to calculate desired engine speed.

Throttle Switch – The throttle switch sends a signal

to the ECM that is used to calculate desired engine

speed.

Top Center Position – The top center position

refers to the crankshaft position when the engine

piston position is at the highest point of travel. The

engine must be turned in the normal direction of

rotation in order to reach this point.

Total Tattletale – The total tattletale is the total

number of changes to all the parameters that are

stored in the ECM.

Wastegate – The wastegate is a device in a

turbocharged engine that controls the maximum

boost pressure that is provided to the inlet manifold.

Wastegate Regulator – The wastegate regulator

Page 10

PRELIMINARY

479-0227 Electronic Troubleshooting

controls the pressure in the intake manifold to a

value that is determined by the ECM. The wastegate

regulator provides the interface between the ECM

and the wastegate.

Electronic Service Tools

Perkins electronic service tools are designed to help

the service technician:

• Retrieve diagnostic codes.

• Diagnose electrical problems.

• Read parameters.

• Program parameters.

• Install injector trim codes.

Required Service Tools

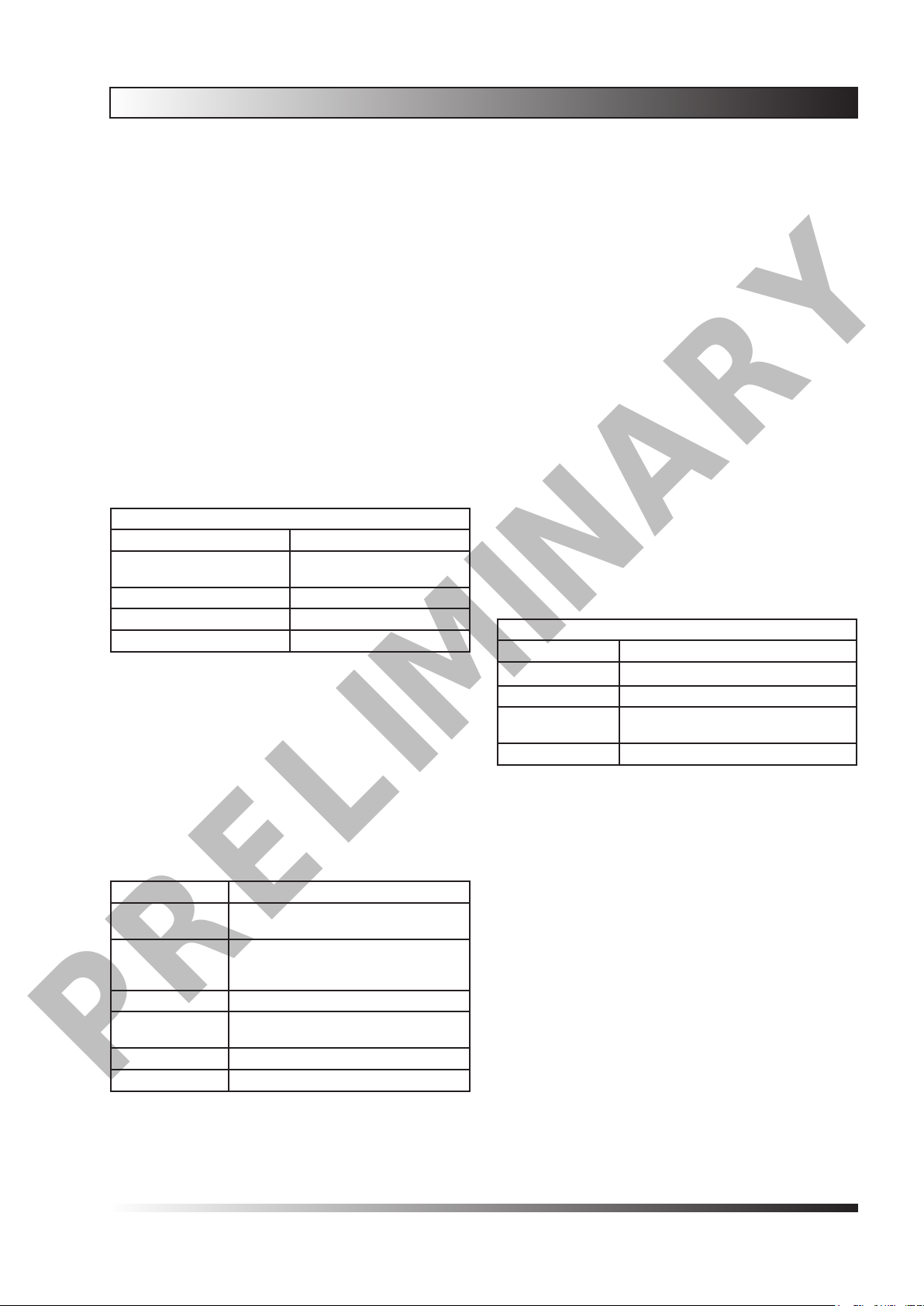

Required Service Tool

Part Number Description

CH11155 Crimp Tool

12-AWG to 18-AWG

2900A019 Wire Removal Tool

27610285 Removal Tool

- Suitable Digital Multimeter

Two short jumper wires are needed to check

the continuity of some wiring harness circuits

by shorting two adjacent terminals together in

a connector. A long extension wire may also be

needed to check the continuity of some wiring

harness circuits.

Optional Service Tools

Optional service tools that can be used when the

engine is serviced.

• Status of all pressure sensors and temperature

sensors

• Programmable parameter settings • Active

diagnostic codes and logged diagnostic codes

• Logged events

• Histograms

The Electronic Service Tool can also be used to

perform the following functions:

• Diagnostic tests

• Sensor calibrations

• Programming of ash les and injector trim codes

• Parameter programming

• Copy conguration function for ECM replacement

• Data logging

• Graphs (real time)

Service tools that are required in order to use the

Electronic Service Tool.

Service Tools for the use of the Electronic Service Tool

Part Number Description

(1)

(1)

27610261 Communication Adapter (Electronic

27610164 Adapter cable as

(1)

Refer to Perkins Engine Company Limited

Note: For more information on the Electronic

Service Tool and the PC requirements, refer to the

documentation that accompanies the software for

the Electronic Service Tool.

Single Use Programme Locense

Data Subscription for all Engines

Service Tool to the ECM interface)

Part Number Description

U5MK1092 Spoon Probe Kit

-

or

-

- Suitable Battery Load Tester

- Suitable Temperature Adapter

2900A038 Bypass Harness As

2900A036 Stub as

Multimeter

Suitable Digital Pressure Indicator

or

Engine Pressure Group

Multimeter

Perkins Electronic Service Tool

The Perkins Electronic Service Tool can display the

following information:

Page 11

PRELIMINARY

Electronic Troubleshooting 479-0227

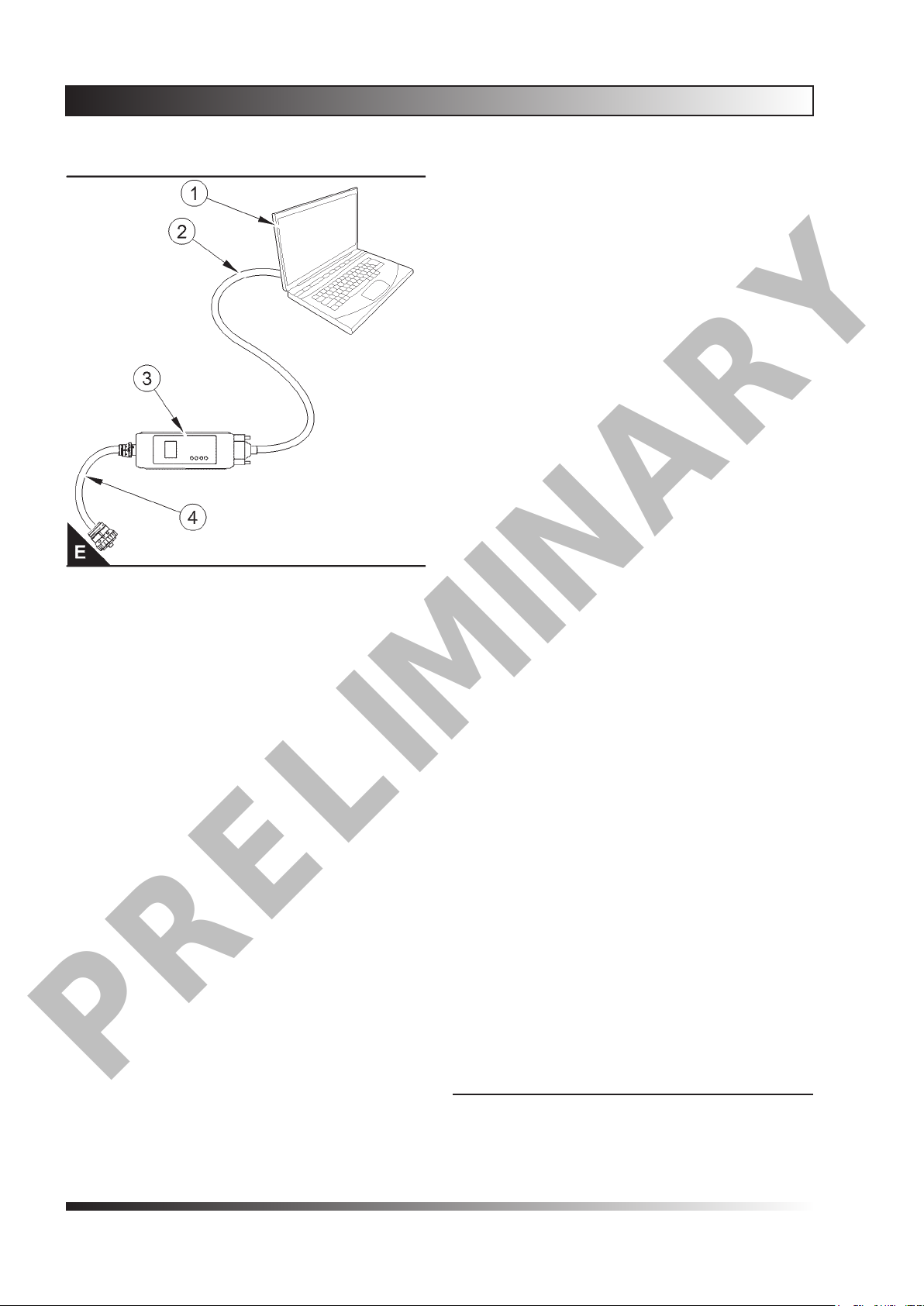

Connecting the Electronic Service Tool and the Communication Adapter II

(1). Personal Computer (PC)

(2). Adapter Cable (Computer Serial Port)

(3). Communication Adapter II

(4). Adapter Cable Assembly

Indicator Outputs

Six lamps are possible as outputs. The following

lamps will normally be installed in a typical

installation, (customer to supply).

• Shutdown.

• Warning.

• Overspeed.

• Coolant temperature.

• Oil pressure.

• Maintenance.

Functions of lamp outputs

Shutdown

Lamp check - When the keyswitch is turned to ON,

the lamp will come on for 5 seconds. The lamp will

then go off unless there is an active warning.

Flashing - The lamp will be ashing when the engine

is derated because of an active diagnostic code. An

example of an active code is ‘System Voltage High’.

On - The lamp will be on when the shutdown level

in the engine protection strategy has been reached.

The ‘Warning’ lamp will also be on.

Note: Items (2), (3) and (4) are part of the

Communication Adapter II kit.

Use the following procedure in order to connect

the Electronic Service Tool and the Communication

Adapter II.

1. Turn the keyswitch to the OFF position.

2. Connect cable (2) between the “COMPUTER”

end of communication adapter (3) and the

RS232 serial port of PC (1).

Note: The Adapter Cable Assembly(4) is required to

connect to the USB port on computers that are not

equipped with an RS232 serial port.

3. Connect cable (4) between the “DATA LINK” end

of communication adapter (3) and the service

tool connector.

4. Place the keyswitch in the ON position. If the

Electronic Service Tool and the communication

adapter do not communicate with the Electronic

Control Module (ECM), refer to the diagnostic

procedure Troubleshooting, “Electronic Service

Tool DoesNot Communicate”.

Warning Lamp

Lamp check - When the keyswitch is turned to ON,

the lamp will come on for come on for 5 seconds.

The lamp will then go off unless there is an active

warning.

Flashing - The lamp will be ashing when a

‘warning’ or a ‘warning and derate’ is active. This

situation includes low oil pressure.

On - The lamp will be on when the shutdown level

has been reached. The ‘Shutdown’ lamp will also be

on.

Lamp Check

Lamp check - When the keyswitch is turned ON, the

lamp will come on for 2 seconds. The lamp will then

go off unless there is an actice warning.

Replacing the ECM

NOTICE

Care must be taken to ensure that uids are

contained during performance of inspection,

maintenance, testing, adjusting and repair of the

Page 12

PRELIMINARY

479-0227 Electronic Troubleshooting

product. Be prepared to collect the uid with suitable

containers before opening any compartment or

disassembling any component containing uids.

Dispose of all uids according to local regulations

and mandates.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

The engine is equipped with an Electronic Control

Module (ECM). The ECM contains no moving

parts. Follow the troubleshooting procedures in this

manual in order to be sure that replacing the ECM

will correct the fault. Verify that the suspect ECM is

the cause of the fault.

Note: Ensure that the ECM is receiving power

and that the ECM is properly grounded before

replacement of the ECM is attempted. Refer to the

schematic diagram.

NOTICE

If the ash le and engine application are not

matched, engine damage may result.

Perform the following procedure in order to replace

the ECM.

1. Connect the electronic service tool to the

diagnostic connector.

2. Use the “Copy Conguration ECM Replacement”

function from the electronic service tool. If the

“Copy Conguration” is successful, proceed

to Step 4. If the “Copy Conguration” failed,

proceed to Step 3.

Note: Record any Logged Faults and Events for

your records.

3. Record the following parameters:

• Record all of the parameters on the

“Conguration” screen.

• Record all of the parameters on the “Throttle

Conguration” screen.

A test ECM can be used in order to determine if the

ECM on the engine is faulty. Install a test ECM in

place of the suspect ECM. Install the ash le with

the correct part number into the test ECM. Program

the parameters for the test ECM. The parameters

must match the parameters in the suspect ECM.

Refer to the following test steps for details. If the

test ECM resolves the fault, reconnect the suspect

ECM. Verify that the fault returns. If the fault returns,

replace the ECM.

Note: If an ECM is used as a test ECM, select “Test

ECM Mode” on the electronic service tool before the

engine serial number is entered.

Use the electronic service tool to read the

parameters in the suspect ECM. Record the

parameters in the suspect ECM. Install the ash le

into the new ECM. After the ECM is installed on the

engine, the parameters must be programmed into

the new ECM.

Note: When a new ECM is not available, an ECM

can be used from an engine that is not in service.

The ECM must have the same serial number sufx.

Ensure that the replacement ECM and the part

number for the ash le match the suspect ECM. Be

sure to record the parameters from the replacement

ECM. Use the “Copy Conguration ECM

Replacement” function in the electronic service tool.

• Record all of the parameters on the “Mode

Conguration” screen.

• Record the serial numbers of the electronic

unit injectors. The injector serial numbers

are shown on the “Injector Trim Calibration”

screen.

Note: If the parameters cannot be read, the

parameters must be obtained elsewhere. Some

parameters are stamped on the engine information

plate, but most parameters must be obtained from

the TMI data on the Perkins secured web site.

4. Remove power from the ECM.

5. Remove the ECM. Refer to Disassembly and

Assembly, “Electronic Control Module - Remove

and Install”.

6. Install the replacement ECM. Refer to

Disassembly and Assembly, “Electronic Control

Module - Remove and Install”.

7. If the replacement ECM is used as a test ECM,

select “Test ECM Mode” on the electronic service

tool.

8. Download the ash le.

a. Connect the electronic service tool to the

diagnostic connector.

b. Select ‘WinFlash’ from the ‘Utilities’ menu

of the electronic service tool.

Page 13

PRELIMINARY

Electronic Troubleshooting 479-0227

c. Select the downloaded ash le.

9. If necessary, use the electronic service tool to

clear the rating interlock . To clear the rating

interlock, enter the factory password when

the electronic service tool is rst connected.

Activating the Test ECM mode will also clear the

rating interlock .

10. Use the electronic service tool to program the

parameters. Perform the following procedure.

a. If the “Copy Conguration” procedure was

successful, use the “Copy Conguration,

ECM Replacement” function to load the

conguration le into the ECM.

Note: During the following procedure, factory

passwords may be required.

b. If the “Copy Conguration” procedure

failed, congure the parameters

individually. The parameters should match

the parameters from step 3.

Perform the “Fuel System Verication Test” .

cleared by use of the electronic service tool.

Logged codes may not indicate that a repair is

needed. The fault may have been temporary. The

fault may have been resolved since the logging

of the code. If the system is powered, an active

diagnostic trouble code may be generated whenever

a component is disconnected. When the component

is reconnected, the code is no longer active.

Logged codes may be useful to help troubleshoot

intermittent faults. Logged codes can also be used

to review the performance of the engine and the

electronic system.

Sensors and Electrical Connectors

The Electronic Control Module (ECM) and most of

the engine sensors are located on the left side of the

engine. For the remaining sensors that are attached

to the engine, see the following illustrations.

Note: In the following illustrations, some

components have been removed in order to improve

visibility.

11. Check for logged diagnostic codes. Factory

passwords are required to clear logged events.

Self-Diagnostics

The Electronic Control Module (ECM) can detect

faults in the electronic system and with engine

operation. A self-diagnostic check is also performed

whenever power is applied to the ECM.

When a fault is detected, a diagnostic trouble code

is generated. This code conforms to the SAE J1939

standard. An alarm may also be generated.

Diagnostic Trouble Code – When a fault in the

electronic system is detected, the ECM generates a

diagnostic trouble code. The diagnostic trouble code

indicates the specic fault in the circuitry.

Diagnostic codes can have two different states:

• Active

• Logged

Active Code – An active diagnostic code indicates

that an active fault has been detected by the control

system. Active codes require immediate attention.

Always service active codes prior to servicing

logged codes.

Logged Code – Many generated codes are stored

in the permanent memory of the ECM. The codes

are logged for 100 operating hours unless a code is

Page 14

PRELIMINARY

479-0227 Electronic Troubleshooting

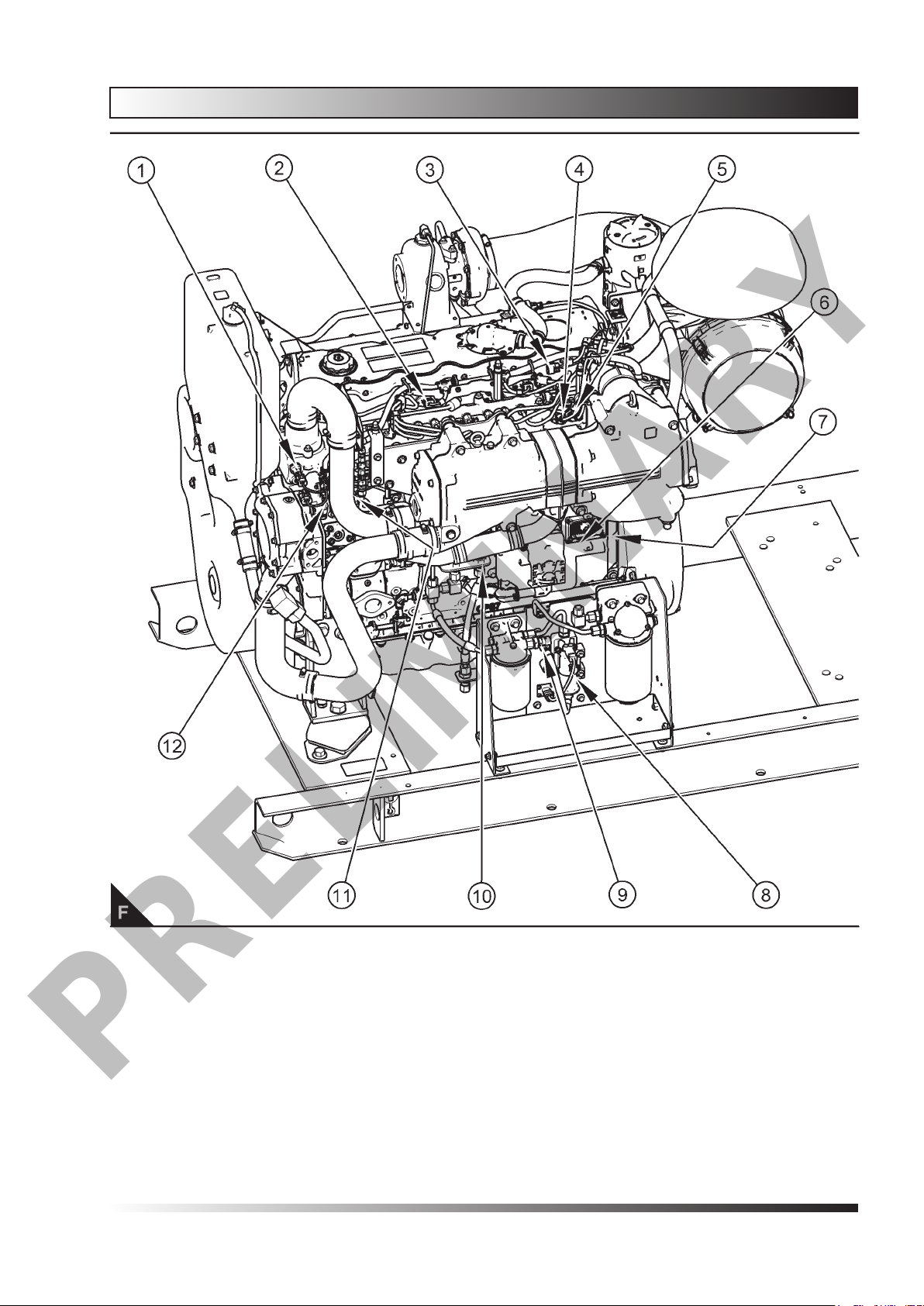

Sensor locations on the left side of the engine

(1). Coolant temperature sensor

(2). Glow plug

(3). Fuel pressure sensor (rail)

(4). Inlet manifold temperature sensor

(5). Inlet manifold pressure sensor

(6). Electronic Control Module (ECM)

(7). Primary speed/timing sensor

(8). Electric priming/lift pump

(9). Low pressure fuel sensor

(10). Oil pressure sensor

(11). Solenoid for high pressure fuel pump

(12). Fuel temperature sensor

Page 15

PRELIMINARY

Electronic Troubleshooting 479-0227

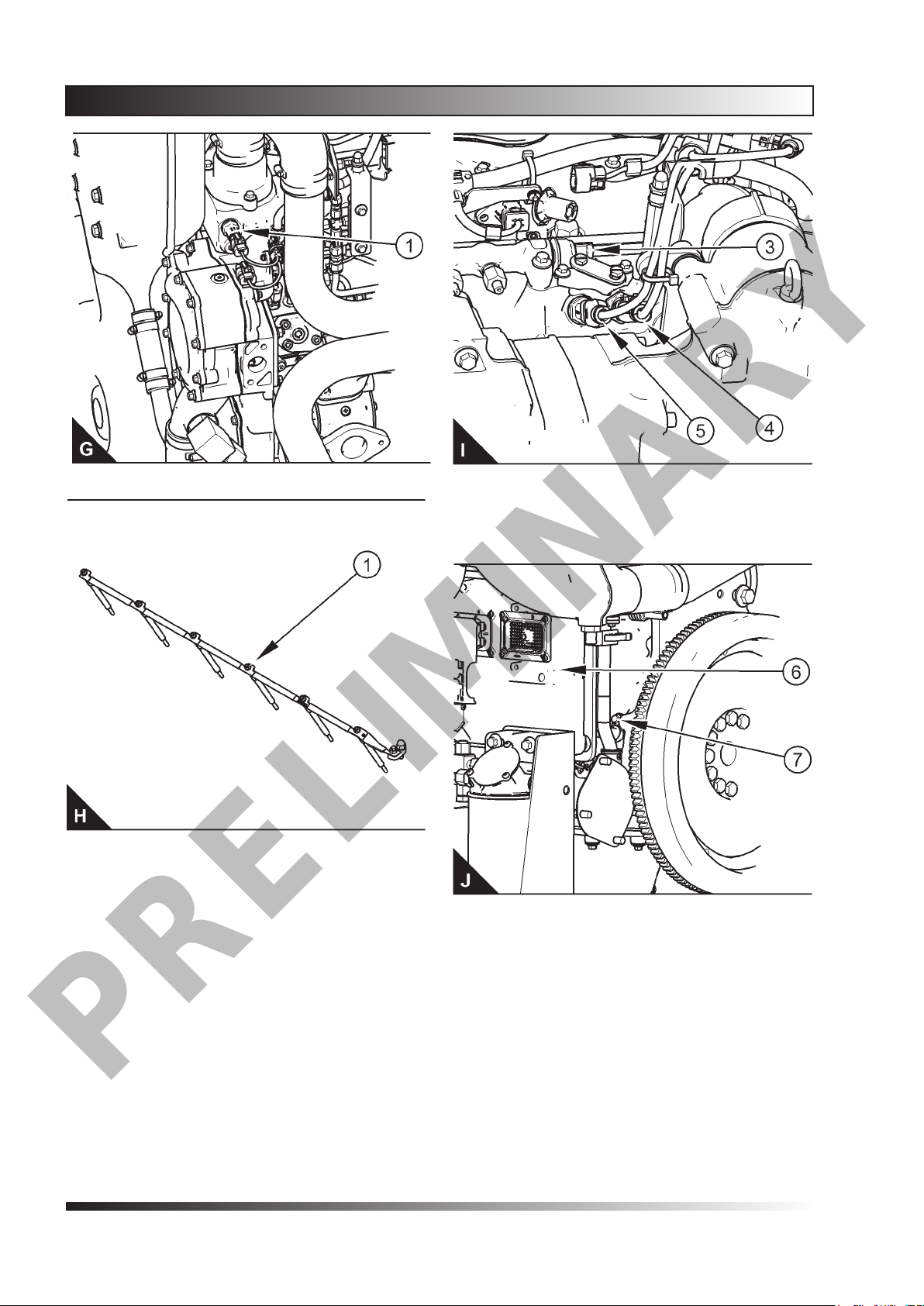

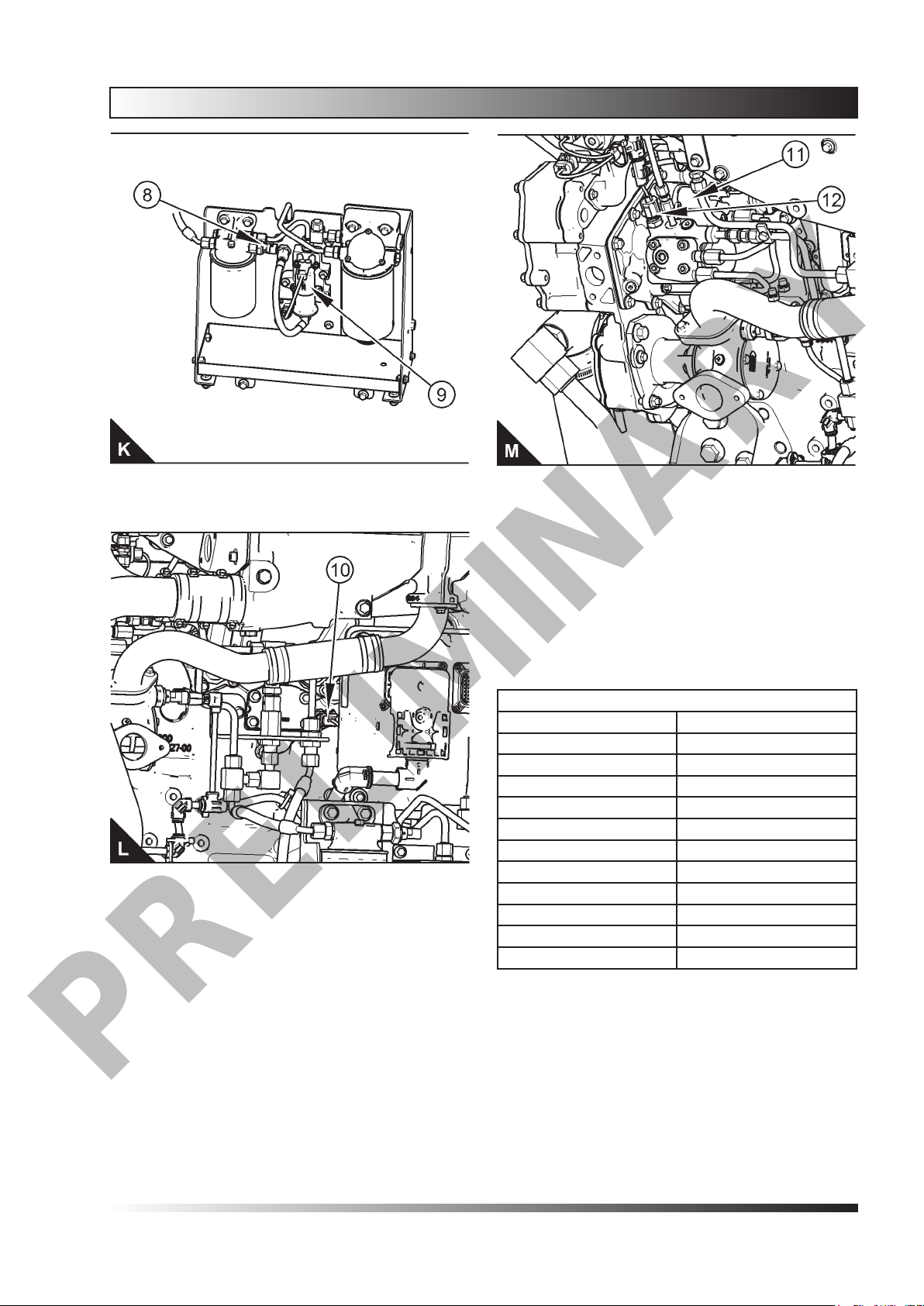

(1). Coolant sensor

(2). Glow plug

(3). Fuel sensor (rail)

(4). Inlet manifold temperature sensor

(5). Inlet manifold pressure sensor

(6). Electronic Control Module (ECM)

(7). Primary speed/timing sensor

Page 16

PRELIMINARY

479-0227 Electronic Troubleshooting

(8). Low pressure fuel sensor

(9). Electric priming/lift pump

(10). Oil pressure sensor

(11). Solenoid for high pressure fuel pump

(12). Fuel temperature sensor

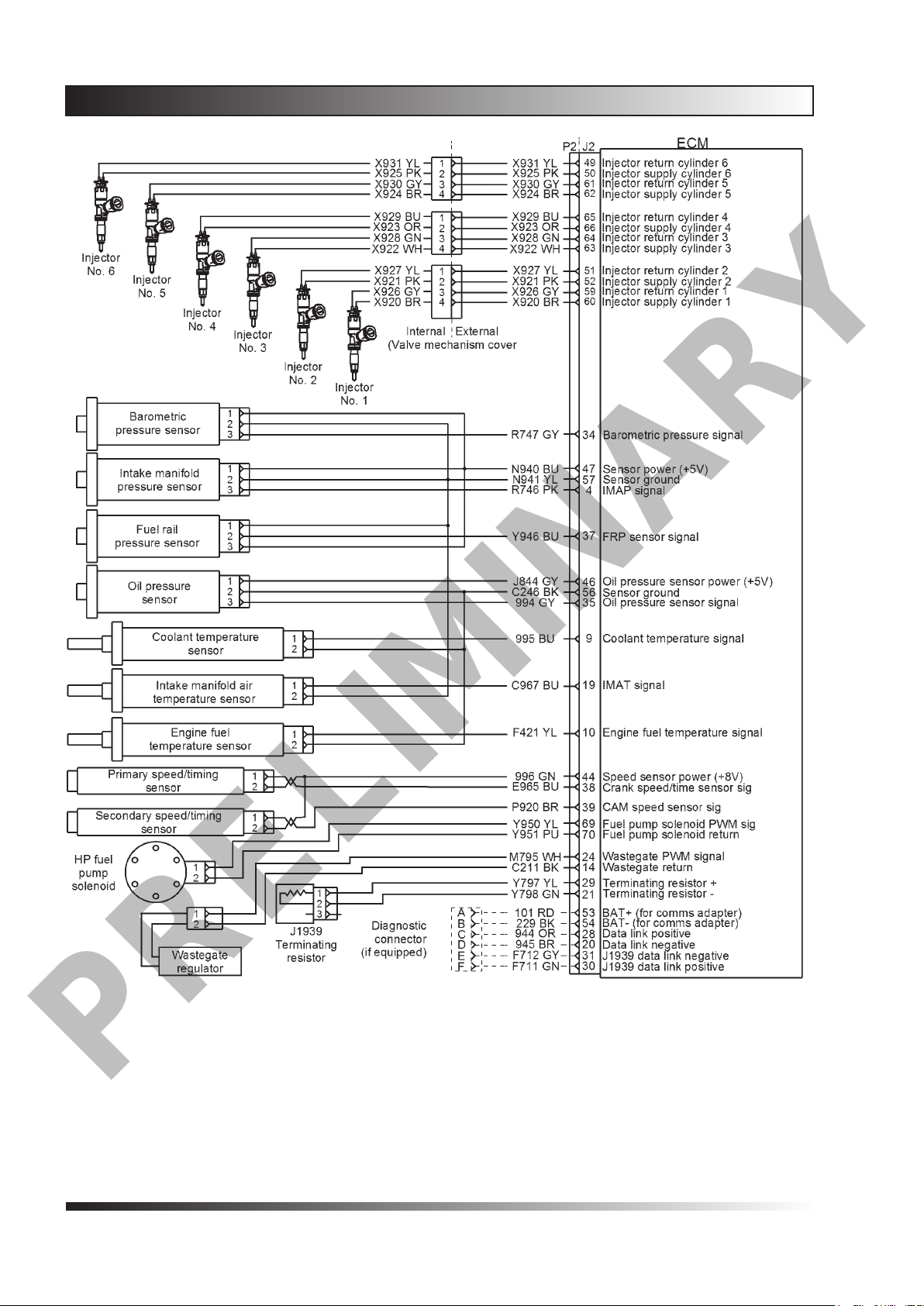

Engine Wiring Information

Harness Wire Identication

Perkins identies all wires with 11 solid colors. The

circuit number is stamped on the wire at a 25 mm (1

inch) spacing. The table lists the wire colors and the

color codes.

Colour Codes for the Harness Wire

Colour Code Colour

BK Black

BR Brown

RD Red

OR Orange

YL Yellow

GN Green

BU Blue

PU Purple

GY Grey

WH White

PK Pink

For example, a wire identication of X925-PK(Pink)

on the schematic would signify a pink wire with the

circuit number X925. X925-PK(Pink) identies the

power supply for the No. 1 injector.

Note: Always replace a harness wire with the same

gauge of wire and with the same color code.

Note: In the following diagrams, “Px” signies a plug

and “Jx” signies a jack.

Page 17

PRELIMINARY

Electronic Troubleshooting 479-0227

Schematic diagram of the 6 cyclinder engine

connections to the J2 connector on the ECM

Page 18

PRELIMINARY

479-0227 Electronic Troubleshooting

Page 19

PRELIMINARY

Electronic Troubleshooting 479-0227

ECM Harness Connector

Terminals

The Electronic Control Module (ECM) uses

connectors that have 70 terminals to interface to the

wiring harness. A more in depth explanation of the

connector can be found in the Users Handbook &

Installation Information manual.

Page 20

PRELIMINARY

479-0227 Programming Parameters

Programming Parameters

Programming Parameters

The electronic service tool can be used to view

certain parameters that can affect the operation of

the engine. The electronic service tool can also be

used to change certain parameters. The parameters

are stored in the Electronic Control Module (ECM).

Some of the parameters are protected from

unauthorized changes by passwords. Parameters

that can be changed have a tattletale number.

The tattletale number is incremented whenever a

parameter is changed.

Test ECM Mode

“Test ECM Mode” is a feature in the software that

can be used to help troubleshoot an engine that may

have a fault in the Electronic Control Module (ECM).

This feature allows a standard ECM to be used as a

test ECM. This feature eliminates the need to stock

a test ECM.

1. Search for the latest ash le for the engine.

Note: If a newer software version is available for the

engine, install the newest software on the suspect

ECM. If the new software does not eliminate the

fault, continue with this procedure.

2. Use the “Copy Conguration” feature on the

electronic service tool to copy the parameters

from the suspect ECM.

Note: If the “ECM Replacement” feature cannot

be used, record the programmed values into the

“Customer Specied Parameters Worksheet”. Also

record the system conguration parameters.

6. Use the “Copy Conguration” feature on the

electronic service tool to program the test ECM.

Note: If the “ECM Replacement” feature cannot be

used, program the test ECM with the values from

the “Customer Specied Parameters Worksheet”

and the values from the System Conguration

Parameters.

7. Program the engine serial number into the test

ECM.

Note: The “Test ECM Mode” must be activated

before the engine serial number is programmed into

the ECM.

8. Verify that the test ECM eliminates the fault.

When the “Test ECM Mode” is activated, an

internal timer sets a 24 hour clock. This clock

will count down only while the ECM is powered

and the keyswitch is in the ON position. After

the ECM has counted down the 24 hour period,

the ECM will exit the “Test ECM Mode” . The

parameters and the engine serial number will be

set.

If the test ECM eliminates the fault, the engine

can be released while the “Test ECM Mode” is still

active.

Once an ECM has been activated in the “Test ECM

Mode” , the ECM will stay in the “Test ECM Mode”

until the timer times out. If the ECM is used as a

test ECM for more than one engine, the “Test ECM

Mode” must be reactivated. Anytime prior to the

“Test ECM Mode” timing out, the ECM can be reset

to 24 hours.

Factory Passwords

3. Disconnect the suspect ECM. Temporarily

connect the test ECM to the engine. Do not

mount the test ECM on the engine.

4. Flash program the test ECM with the newest

software that is available.

5. Start the “Test ECM Mode” on the electronic

service tool. Access the feature through the

“Service” menu. The electronic service tool will

display the status of the test ECM and the hours

that are remaining for the “Test ECM Mode” .

Note: “Test ECM Mode” can only be activated if

the engine serial number has not already been

programmed during normal operation of the ECM.

If the engine serial number is programmed and

the ECM is not in “Test ECM Mode” , the ECM can

never be used as a test ECM.

Operating the engine with a ash le not designed

for that engine will damage the engine. Be sure the

ash le is correct for your engine.

Note: Factory passwords are provided only to

Perkins authorized distributors.

Factory passwords are required to perform each of

the following functions:

Program a new Electronic Control Module (ECM).

When an ECM is replaced, the system conguration

parameters must be programmed into the new

ECM. A new ECM will allow these parameters to

be programmed once without factory passwords.

NOTICE

Page 21

PRELIMINARY

Programming Parameters 479-0227

After the initial programming, some parameters are

protected by factory passwords.

Rerate the engine.

Rerating the engine may require changing the

interlock code, which is protected by factory

passwords.

Unlock parameters.

Factory passwords are required in order to

unlock certain system conguration parameters.

Refer to Troubleshooting, “System Conguration

Parameters”.

Clear engine events and certain diagnostic trouble codes.

Most engine events require factory passwords in

order to clear the code from ECM memory. Clear

these codes only when you are certain that the

fault has been corrected. For example, the 190-

15 Engine Overspeed requires the use of factory

passwords in order to clear the code from ECM

memory.

Since factory passwords contain alphabetic

characters, the electronic service tool must be

used to perform these functions. In order to obtain

factory passwords, proceed as if you already have

the password. If factory passwords are needed,

the electronic service tool will request the factory

passwords. The electronic service tool will display

the information that is required to obtain the

passwords.

Flash Programming

Flash Programming – A method of loading a ash

le into the Electronic Control Module (ECM)

3. Turn the keyswitch to the ON position. Do not

start the engine.

4. Select “WinFlash” from the “Utilities” menu on the

electronic service tool.

Note: If “WinFlash” will not communicate with the

ECM, refer to Troubleshooting, “Electronic Service

Tool Does Not Communicate”.

5. Flash program the ash le into the ECM.

a. Select the engine ECM under the

“Detected ECMs” .

b. Press the “Browse” button in order to

select the part number of the ash le that

will be programmed into the ECM.

c. When the correct ash le is selected,

press the “Open” button.

d. Verify that the “File Values” match the

application. If the “File Values” do not

match the application, search for the

correct ash le.

e. When the correct ash le is selected,

press the “Begin Flash” button.

f. The electronic service tool will indicate

when ash programming has been

successfully completed.

6. Use the electronic service tool to check for

diagnostic code 631-2. If this diagnostic code

is active and the ash le is not being installed

in order to change the engine rating, repeat

this procedure from 1. If this diagnostic code is

active and the ash le is being installed in order

to change the engine rating, factory passwords

must be obtained before the ash le will be

accepted.

The electronic service tool is used to ash program

a ash le into the ECM. The ash programming

transfers the ash le from the PC to the ECM.

Flash Programming a Flash File

1. Obtain the part number for the new ash le.

Note: If you do not have the part number for the

ash le, use “PTMI” on the Perkins secured web

site.

Note: You must have the engine serial number in

order to search for the part number of the ash le.

2. Connect the electronic service tool to the

diagnostic connector.

7. Access the “Conguration” screen under

the “Service” menu in order to determine

the parameters that require programming.

Look under the “Tattletale” column. All of the

parameters should have a tattletale of 1 or more.

If a parameter has a tattletale of 0, program that

parameter.

8. Start the engine and check for proper operation.

Check that there are no active diagnostic codes.

“WinFlash” Error Messages

If any error messages are displayed during ash

programming, click on the “Cancel” button in order

to stop the process. Access the information about

the “ECM Summary” under the “Information” menu.

Page 22

Loading...

Loading...