Page 1

687M

1” NPT Bottom Drain Valve Model A296VB2

Operating & Maintenance Instructions

Description

The Parr Instrument Company A296VB2 Bottom

Drain Valve has an extended tip stem. In the

closed position, the stem of the valve is flush

with the inside bottom of the vessel so that

there is minimal dead space between the

bottom of the vessel and the shut off point

of the valve. In the fully open position, the

stem is retracted to open a clear passage from

the vessel. When the valve is re-closed, any

material in this passage will be pushed back

into the reactor by the rising stem.

CAUTION! If abrasive particles are

run through the valve, it is necessary

to flush the valve after use.

If the valve is leaking, it is a good indication

that the seal may be worn, has been damaged,

or abrasive particles are interfering. The valve

should be disassembled, inspected, cleaned as

required, and seals replaced.

Disassembly of the Bottom Drain Valve

Installation and Operation

This valve is designed to be installed in the

bottom of Parr cylinders that are machined

specifically for installation with minimal dead

space. Pipe thread sealant tape should be

applied to the valve body threads and then

installed turning clockwise into the cylinder. The

valve should be tightened sufficiently to seal

the pipe treads and bring the stem of the valve

approximately even with the inside bottom of

the cylinder.

The valve is opened by turning the handle

counterclockwise. Opening the valve will

progressively increase the passage for product

flow until the valve is at the fully open position.

The valve is closed by turning the handle

clockwise until the plunger contacts and

compresses seal 1.

1. Retract the plunger to the fully

open position by turning the handle

counterclockwise.

2. Remove the (3) 1/4-28 socket head cap

screws (SHCS) from the screw shaft retainer

using the 3/16 socket screw key furnished

with the BDV.

3. Loosen the (3) 1/4-28 socket head cap

screws that compress seal 2 with the

retainer using the 3/16 socket screw key

furnished with the BDV.

4. Pull the screw shaft retainer and plunger

assembly out of the valve body.

5. Remove the (3) standoffs.

6. Remove the (3) 1/4-28 socket head cap

screws and remove the retainer.

7. Using a pick, remove the compression rings

and seal 2.

Use the extension bar (661VBGA) provided with

the A296VB2 to open and close the valve.

Parr Instrument Company www.parrinst.com

8. Using a pick, remove seal 1 from the valve

body.

Page 2

Bottom Drain Valve Model A296VB2

Assembly of Bottom Drain Valve

1. Before assembly, all parts of the valve

should be clean and in good condition.

NOTE: Assembly of the valve is easier if it

is removed from service and oriented so

that the threads going into the cylinder face

downwards.

2. Apply generous amounts of lubrication

using a high temperature thread lubricant.

See the “Lubrication of the Bottom Drain

Valve” section in this manual.

3. Install a 511VB3FH silver or 511VB3FG gold

faced (depending on BDV material) seal 1

into the cavity in the valve body. The plunger

may be used to help with the installation.

4. Install the compression ring, next install

the PTFE seal 2, and then install the second

compression ring.

Lubrication of the Bottom Drain Valve

Lubrication of the straight threads should be

done with a nickel based high temperature

thread lubricant. If SD2520SC10 shoulder bolt

is removed, re-install into plunger with semipermanent thread locker. Lubricate all other

internal and outer straight threads on the valve

body, retainers, and plunger.

The frequency of lubrication depends on the

amount of use the valve receives. If the valve

sits for a long period of time (one or more

months), it should be lubricated before use. If

the valve is used daily, then lubrication may be

required once a week.

Applications that include operating temperatures of 250 °C and above will require more

frequent lubrication of the valve threads.

5. Install the retainer and start the (3) 1/4-28

socket head cap screws.

6. Install the plunger assembly.

7. Tighten the retainer into valve body using

100 in-lbs torque on each of the (3) 1/4-28

socket head cap screws.

8. Install the (3) standoffs.

9. Install the (3) 1/4 flat socket head cap screws

with the plunger retracted away from seal 1.

10. Turn the handle clockwise until the plunger

contacts seal 1.

2

Parr Instrument Company

Page 3

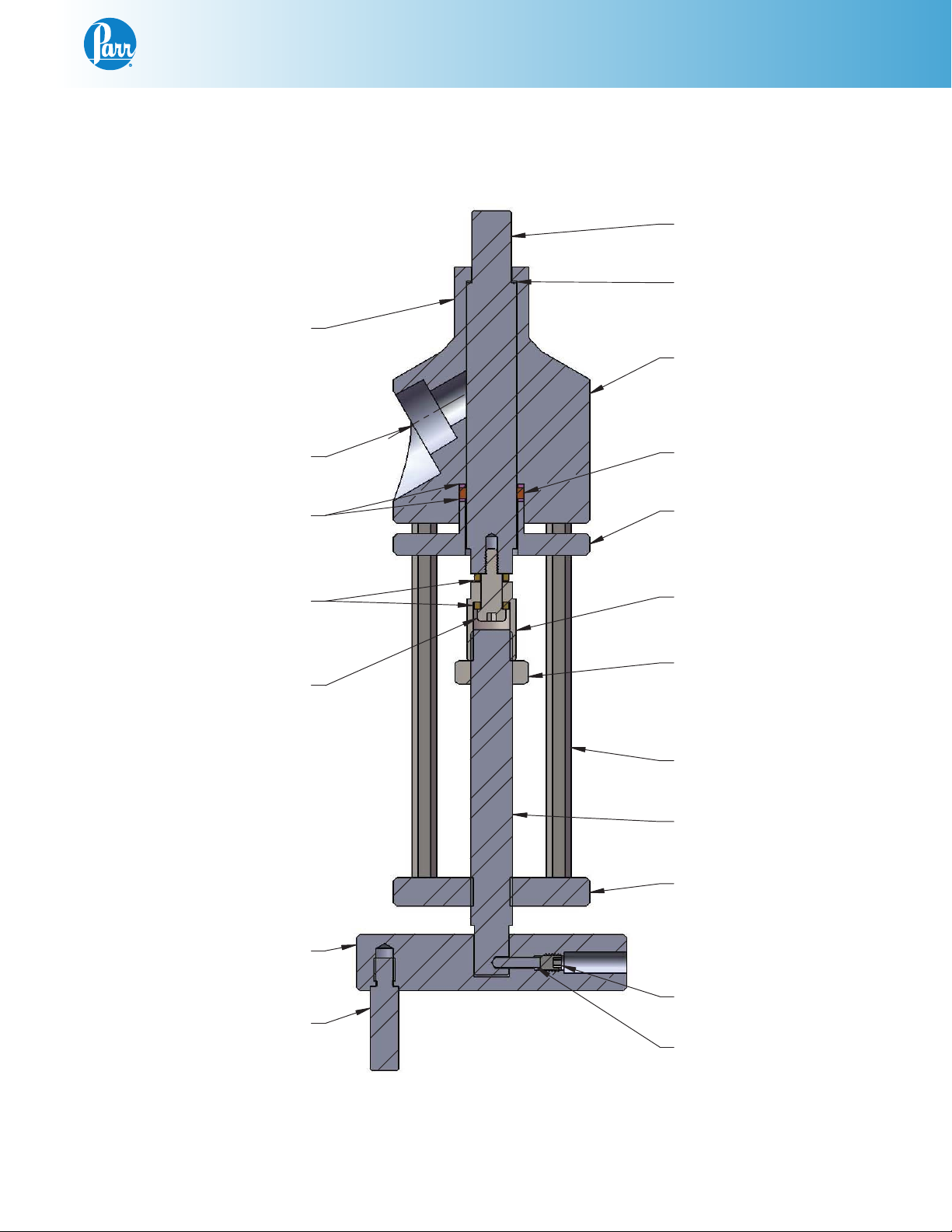

1" NPT

REF

Bottom Drain Valve Model A296VB2

A296VB2 Bottom Drain Valve

3550HC *

PLUNGER

511VB3 *

SEAL 1

3551HC *

VALVE BODY

1" NPT

REF

3553HC *

COMP RING (2)

3554HC

SHIM

SD2520SC10

1/4-20 X .375 SHSB

3558HC

HANDLE

638VBHA

SEAL 2

3552HC

RETAINER

(3) 1932HC2DE

1/4-28 X 1.00 SHCS

3556HC

RETAINING CAP

3555HC

3/4-10

JAM NUT

(3) 3560HC

STANDOFF

3559HC

SCREW SHAFT

3557HC

SCREW SHAFT

RETAINER

(3) 1932HC3DE

1/4-28 X .62 SHCS

3562HC

HANDLE TEE

*Available in other alloys

SC3118SC06

5/16 X .375 SHSS

3561HC

SET PIN

www.parrinst.com

3

Page 4

687M R00 12/08/14

Loading...

Loading...