Page 1

No. 434M

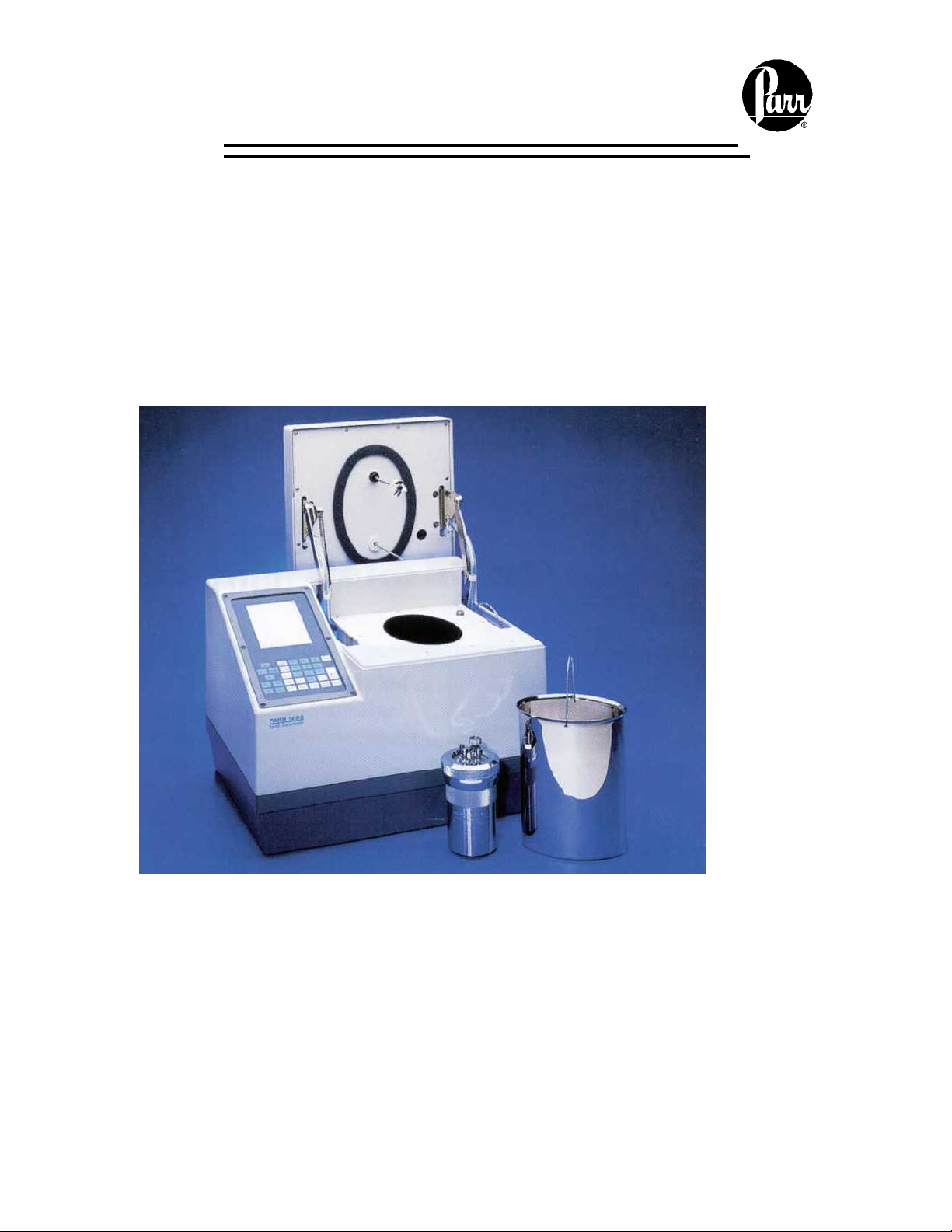

1356 ISOPERIBOL BOMB CALORIMETER

Service Manual

Page 2

Page 3

1. Calorimeter Operation

Operation……………………………………………………………………5

Corrections Fixed………………………………………………………… 6

Corrections and Final Report

Data Entry

Report Option …………………………………………………………… 7

Generate Report……………………………………………………………. 7

Display Reports …………………………………………………………… 8

Clear Memory

Edit Memory

Calorimeter Standardization ………………………………………………9

Heat of Combustion Calculation ………………………………………… 9

Calculations ……………………………………………………………….. 9

Correction Thermochemical……………………………………………….. 9

Details Thermochemical Calculation ……………………………………. 10

Sample Spiking ……………………………………………………………. 10

Spiking Sample Calculations ……………………………………………….11

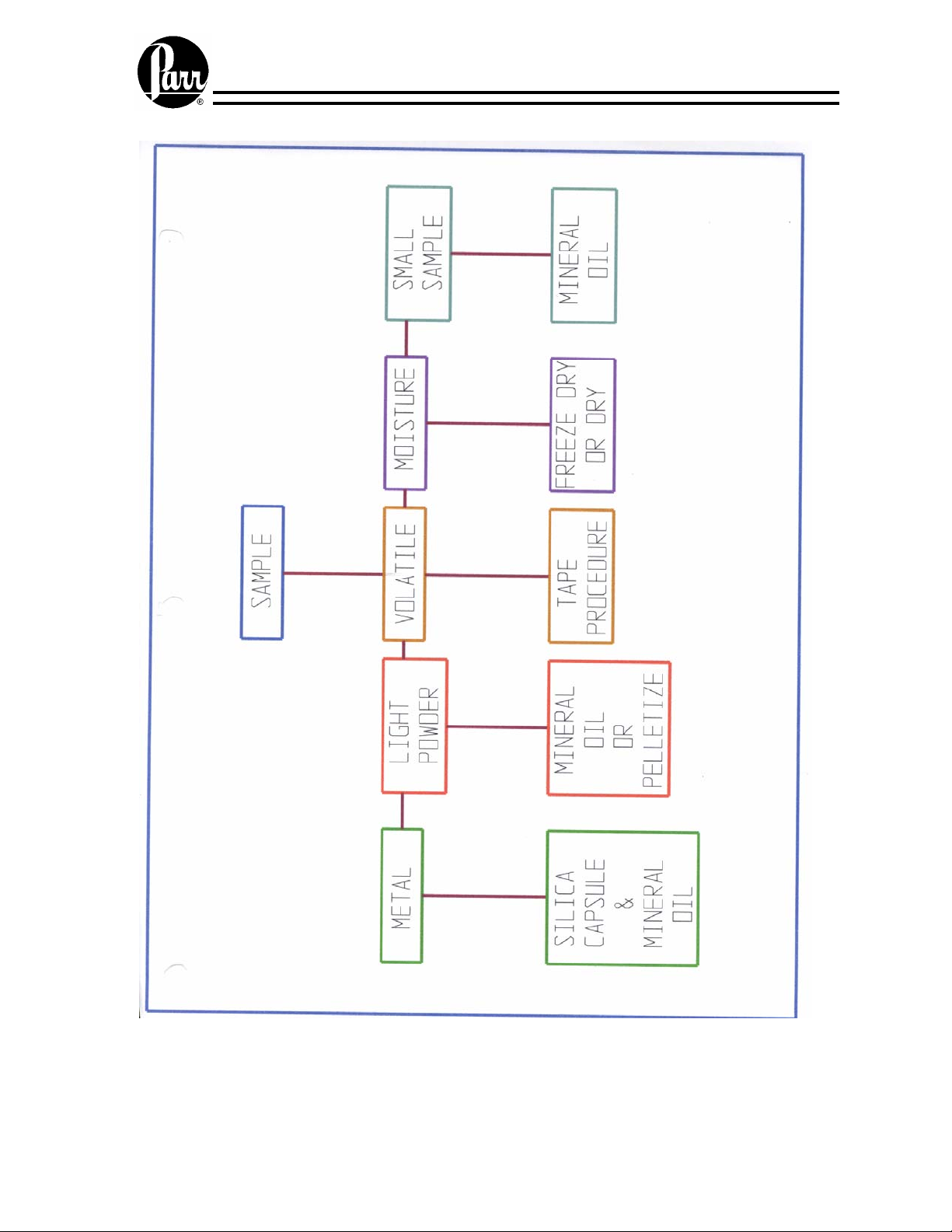

Sample handling ………………………………………………………….12

2. 1108 Bomb Maintenance and Safety Instructions

Bomb Maintenance ……………………………………………………….. 11

500 Firings…………………………………………………………………. 11

3. Parts Replacement

Motor………………………………………………………………………. 14

Battery…………………………………………………………………….. 14

Cover adjustment………………………………………………………….. 14

Thermistor………………………………………………………………….. 15

Controller………………………………………………………………… 15

Controller Combined …………………………………………………….. 15

Keyboard

Cover Replacement………………………………………………………. 16

Support Rod ………………………………………………………………. 17

4. Error Messages

Preperiod/Postperiod

Misfire …………………………………………………………………… 19

Exceeded Calibration Limit………………………………………………. 19

Oxygen Charge Low……………………………………………………… 19

5. Miscellaneous

Misfire-wire intact

1356 Precison

Calculate Tests per Oxygen Cylinder

Volatile Spiking

Sulfuric acid correction …………………………………………………… 21

Use of inert gas-heat capacity

ISO/BSI corrections

…………………………………………………………………. 7

………………………………………………………………8

………………………………………………………………. 8

………………………………………………………………….. 16

……………………………………………………. 18

………………………………………………………… 19

……………………………………………………………… 20

…………………………………………………………… 21

……………………………………………………… 23

………………………………………………. 7

…………………………………….. 20

…………………………………………….. 22

Page 4

MSDS sheet benzoic acid…………………………………………………. 41

Data Logger 1356 ………………………………………………………… 24

Screen Bubbles ……………………………………………………………. 24

Stirrer Harness A1573E2………………………………………………….. 24

Replacing LCD Display and Keypad……………………………………. 25

Replacement I/O Board ……………………………………………………. 25

Longer Post Periods

Power Supply Board Replacement

CPU Board Replacement………………………………………………….. 27

6. Parts

5 year………………………………………………………………………. 27

Parts Information

5000 tests

Assembly Hinge ………………………………………………………….. 29

1563 Water Handling……………………………………………………… 30

7. Diagrams

Front View 1356 Calorimeter…………………………………………….. 32

Upper Link…………………………………………………………………. 33

Lower Link………………………………………………………………… 33

Left Linkage Bracket ……………………………………………………… 34

Right Mounting Plate ………………………………………………………35

Left Mounting Plate……………………………………………………….. 35

Right Linkage Bracket…………………………………………………….. 36

Cover Assembly 1356…………………………………………………. 37

Hinge Assembly…………………………………………………………… 37

1563 Flow Diagram……………………………………………………….. 38

1563 Electrical Diagrams………………………………………………….. 39

………………………………………………………………… 28

………………………………………………………. 25

……………………………………….. 26

………………………………………………………….. 27

4

Page 5

1. Calorimeter Operation

A. Operating the Calorimeter

All operations required to standardize the Calorimeter, or test an unknown sample, should

proceed step-wise in the following manner:

1. Turn on the calorimeter, go to menu page 1 and press YES key on line 3 to

activate the pump and heater.. The bomb parts should be wetted and then dried in

the manner used at the conclusion of a test. This serves to wet all sealing parts, as

well as leaving the bomb with the same amount of residual water which will exist

in all subsequent testing.

Prepare the sample and charge the oxygen bomb by attaching the hose to the

bomb and pressing the O2 Fill key.

The throughput of the 1356 Calorimeter can be increased by using multiple

bombs and water buckets. With this arrangement, the calorimeter can operate

almost continuously since the operator will be able to empty a bomb and recharge

it while a run is in progress. A bomb and bucket for the next run will be ready to

go into the calorimeter as soon as it is opened. Each bomb and bucket

combination will have to be standardized separately and the proper energy

equivalent for each set must be used for the heat of combustion calculation.

2. Fill the calorimeter bucket by first tarring the dry bucket on a solution or trip

balance; then add 2000 (+/- 0.5) grams of water. Distilled water is preferred, but

de-mineralized or tap water containing less than 250 ppm of dissolved solids is

satisfactory. The water temperature should be approximately 1 to 2ºC below the

room temperature. It is not necessary to use exactly 2000 grams, but the amount

selected must be duplicated within +/-0.5 gram for each run. Instead of weighing

the bucket, it can be filled from an automatic pipette, or from any other

volumetric device if the repeatability of the filling system is within +/-0.5 ml. Try

to make the starting temperature as repeatable as possible.

3, To speed and simplify the bucket filling process, and to conserve water and

energy, Parr offers a closed-circuit Water Handling System (No. 1563). This

provides a water supply, cooled to the starting temperature and held in an

automatic pipette ready for delivery in the exact amount needed to fill the bucket.

A 1552 Water Cooler is required when using the 1563 Water Handling System.

Instructions for this automatic system are given in Operating Instruction No. 245

and 246M.

4. Set the bucket in the calorimeter. Attach the lifting handle to the two holes in the

side of the screw cap and partially lower the bomb in the water. Handle the bomb

carefully during this operation so that the sample will not be disturbed. Push the

two ignition lead wires into the terminal sockets on the bomb head. Orient the

wires away from the stirrer shaft so they do not become tangled in the stirring

mechanism. Lower the bomb completely into water with its feet spanning the

circular boss in the bottom of the bucket. Remove the lifting handle and shake any

drops of water back into the bucket. Check for any bubbles coming from the

bomb, if bubbles are seen, do not fire the bomb. Resolve the problem.

5. Close the calorimeter cover

5

Page 6

Press the START key . The calorimeter will prompt for a Cal ID. The calorimeter

will then prompt for sample identification number by displaying Sample ID on

the display. Enter the correct sample ID by using any number, up to six digits, to

identify the sample. The calorimeter will check its memory and will not accept

duplicate sample ID numbers. Enter this value. The system will now prompt for a

sample weight, enter the sample wieght.

6. The calorimeter will now take over and conduct the test. During the time it is

establishing the initial equilibrium, it will display the PRE-PERIOD. Once the

bomb has been fired, the POSTPERIOD will be displayed. The calorimeter will

check to make certain that a temperature rise occurs and will then look for the

final equilibrium conditions to be met. If it fails to meet either the initial or final

equilibrium conditions, or if it fails to detect a temperature rise within the allotted

time, the calorimeter will terminate the test and advise the user of the error.

7. At the conclusion of the test, the calorimeter will signal the user and print the

results.

8. Open the cover, detach the lead wires from the bomb and remove the bucket with

the bomb. Remove the bomb from the bucket and open the knurled valve knob on

the bomb head to release the residual gas pressure before attempting to remove

the cap. This release should proceed slowly over a period of not less than one

minute to avoid entrainment losses. After all pressure has been released, unscrew

the cap, lift the head out of the cylinder and place it on the support stand.

Examine the interior of the bomb and fuel capsule for soot or other evidence of

incomplete combustion. If such evidence is found, the test will have to be

discarded.

9. Wash all interior surfaces of the bomb with a jet of distilled water and collect the

washings in a beaker.

10. Use Fixed Corrections or remove all unburned pieces of fuse wire from the bomb

electrodes; straighten them and measure their combined length in centimeters.

Subtract this length from the initial length of 10 centimeters and multiply this

burned length by 2.3 calories per cm (for Parr 45C10 Fuse Wire) to obtain the

fuse correction. The scale on the fuse wire card can be used to obtain this value

directly. If fixed corrections are used no entry is required.

11. Use fixed corrections or titrate the bomb washings with a standard sodium

carbonate solution using methyl orange, red or purple indicator. A 0.0709N

sodium carbonate solution is recommended for this titration to simplify the

calculation. This is prepared by dissolving 3.76 grams of Na2CO3 in the water and

diluting to one liter. NaOH or KOH solutions of the same normality may be used.

Enter the titer value for the acid correction. If fixed acid corrections has been

programmed, no entry is required.

12 Analyze the bomb washings to determine the sulfur content of the sample if it

exceeds 0.1 percent. Methods for determining sulfur are discussed in Operating

Instructions No. 207M.

13. Turn off the calorimeter at the power switch.

6

Page 7

B. Entering Corrections and Obtaining the Final Report

Final reports for each test can be obtained via the REPORT key, whenever the user is

prepared to enter the corrections for acid, sulfur and fuse.

Refer to the Reporting Generation for the steps necessary to initiate a report from the

calorimeter.

C. Manual Entry

During the reporting process, the calorimeter will prompt the user to enter the following

values:

Fuse Correction: Key in the Fuse Wire Correction and press the ENTER key. The default

setting for this value is to be entered in calories.

Acid Correction: Key in the Acid Correction and press the ENTER key. The default

setting for this value is to be entered in milliliters of standard alkali required to titrate

total acid or calories.

Sulfur Correction: Key in the Sulfur Correction and press the ENTER key. The default

setting for this value is entered as percent sulfur in the sample.

Enter these values when requested by the corresponding prompt. After the last entry has

been made, the calorimeter will automatically produce a final report. If values for these

corrections are not available, the user can use the SKIP key to pass over any of these

corrections. However, a final report will not be printed until an entry is made for each of

the three correction factors.

D. Fixed Corrections

In many cases, fixed values for fuse and acid can be used without introducing a

significant error since the corrections are both relatively small and constant. Fixed sulfur

corrections can also be used whenever a series of samples will be tested with a

reasonably constant sulfur content. Details for applying fixed corrections are found in the

Details Thermochemical Calculation Any value setup as a fixed correction will be

automatically applied and the calorimeter will not prompt the user for this value.

E. Report Option Selection

Data can be transferred over the RJ45 port to a 40 or 80 column printer to provide a

printed report. This port can also be used to transmit data to a host computer. In this case,

the data will have to be received, stored and formatted by programs residing in the host

computer. If you wish to transfer data to a computer ask for software from Parr, we can

quote a price for the software.

The default setting sends the calorimetric reports to the printer.

F. Report Generation

There are two kinds of calorimeter reports, which can be issued; preliminary and final.

Preliminary reports are generated at the conclusion of a test run when one or more of the

calorimeter corrections (FUSE, ACID, SULFUR, SPIKE) is not fixed. A final report

contains all of the final or fixed calorimetric corrections needed in order to give either an

energy equivalent or heat of combustion value.

7

Page 8

Reports may be obtained by pressing the REPORT key. To obtain a block of reports

between two specified sample numbers, press the REPORT key. Enter the first sample

number to the display, and press the ENTER key. The system will then prompt for the

last sample ID, if only one report is desired enter the same sample ID, followed by the

ENTER key. If a block of reports is desired enter the last sample in the block followed by

the ENTER key. During the reporting process, the printed reports will indicate whether

the reports are final or preliminary. The preliminary reports will require corrections to be

entered.

Preliminary reports will remain preliminary and the energy equivalent or heat of

combustion value, which is reported will reflect the fixed constants as set by the operator.

The printing of large numbers of reports may be avoided at any time using the RESET

key. The reset action will take effect after the current report has been completely

transmitted.

G. Displayed Reports

Reports may also be obtained through the display on the 1356 Calorimeter. The

procedure for obtaining reports on the display is the same as for obtaining printed reports.

The calorimeter will hold data for 500 tests within its memory. These tests may be either

preliminary, final, determination or calibration reports. Once the memory of the

calorimeter is filled, any attempt to start a new analysis will cause the calorimeter to

display MEMORY FULL, to avoid this error message go to Menu page 7 and line 6.

Change the Overwrite from OFF to On, then the oldest test will be deleted and replaced

by the most recent test. The alternative is to clear memory of tests.

H. Clearing Memory

This capability allows the user to delete Sample ID numbers and all related data and

results for a single report, a sequence of reports or for all reports.

To clear a single report, press the CLEAR MEM key. The calorimeter will prompt for the

first sample number in the block and then prompt for the last sample number in the block,

then press the ENTER key. To clear all reports, use the sequence procedure with 1 as the

first sample number and 999999 as the last number of the sequence.

I. Editing Memory

The user is able to add data and information to the previously gathered information for a

test by using the Memory Editing procedures described in the manual on page 8-1.

Press the F3 key. The calorimeter will then prompt for the first sample number, which is

keyed in and press the Enter key. The calorimeter will then prompt for the las t sample

number in the block, enter the ID and press the Enter key. If one wishes to edit one

sample, then enter the same number for the first and last sample ID. Highlight the data

field to be edited by pressing the Up or Down Arrow key

8

Page 9

Press the Clear key, enter the new value on the keyboard and press the Enter key. This

sequence is canceled by pressing the RESET key. Press the Escape key, when one is

done editing. If more than 1 sample is to be edited, the screen will display the next

sample’s information.

J. Standardizing the Calorimeter

The calorimeter will calculate the average EE value from standardization tests that have

been made.

K. Calculating the Heat of Combustion

While the Model 1356 Calorimeter will automatically make all of the calculations

necessary to produce a gross heat of combustion for the sample. It is important that the

user understand these calculations to ensure that the instrument is set up so that the

calculations match the procedures used and that the units are consistent throughout the

entire procedure and calculations.

L. General Calculations

Basically, the calculation of the gross heat of combustion is done using the following

equation:

Where:

Hc =Gross heat of combustion.

T =Observed temperature rise.

EE =Energy equivalent of the calorimeter being used.

e1 =Heat produced by burning the nitrogen entrapped in the bomb to form nitric acid.

e2 =Extra heat produced due to burning sulfur to sulfur trioxide and forming sulfuric

acid instead of sulfur dioxide.

e3 =Heat produced by the burning fuse wire.

m =Mass of the sample.

For convenience and by tradition, these calculations are made in calories, grams,

and degrees Celsius, and then converted to other units if required. The other units desired

are set on Menu page 2, line 2.

Temperature rise

automatically. Corrections for heat leaks are applied automatically. Similarly, the method

for extrapolating the end point of the test is discussed in the dynamic method description.

Energy equivalent

abbreviated as EE) is determined by standardizing the calorimeter as described in the

Standardization Section of the calorimeter manual. It is an expression of the amount of

energy required to raise the temperature of the calorimeter one degree. It is commonly

expressed in calories per degree Celsius. Since it is directly related to the mass of the

calorimeter, it will change whenever any of the components of the calorimeter (i.e. the

bomb, bucket, or amount of water) is changed.

M. Thermochemical Corrections

Nitric acid correction

. The 1356 Calorimeter produces a corrected temperature rise reading

. The energy equivalent (represented by W in the above formula, or

. In the high pressure oxygen environment within the oxygen bomb,

9

Page 10

nitrogen that was present as part of the air trapped in the bomb is burned to nitric oxide

which combines with water vapor to form nitric acid. All of this heat is artificial since it

is not a result of the sample burning.

Sulfur correction. In the oxygen rich atmosphere within the bomb, sulfur in the sample is

oxidized to sulfur trioxide, which combines with water vapor to form sulfuric acid. This

liberates additional heat over the normal combustion process, which converts sulfur to

sulfur dioxide. The sulfur correction removes this excess heat from the calculations.

Fuse wire correction. The wire used for a fuse to ignite the sample is partially consumed

in the combustion. Thus, the fuse generates heat both by the resistance it offers to the

electric firing current and by the heat of combustion of the wire that is actually burned. It

is normally assumed that the heat generated by the electrical resistance will be the same

when standardizing the bomb and when testing an unknown sample, and can therefore be

ignored. Significant variances can, however, occur in the amounts of fuse wire actually

burned in each test. So this energy is subtracted to account for the heat of combustion of

the metal.

N. Thermochemical Calculation Details

Traditionally, standard solutions and procedures have been established to simplify the

calculations and thermochemical calculations.

ACID and SULFUR Corrections. In certain ASTM methods, the amount of sodium

carbonate used to titrate the bomb washings is equated with e1.

Users may find it convenient to enter a fixed value for the acid correction and avoid the

need to determine this correction for each test. To enter Fixed Acid Corrections,go to

Menu page 5 and turn on line 1 Fixed Fuse for Standardization or line 4 for

Determination. Total errors of more than 3 calories will seldom occur when using Fixed

Acid Corrections.

Fixed Sulfur Corrections can be entered if a series of samples contain a constant amount

of sulfur. For Standizations, line 3 is always ON. For determination runs to enter Fixed

Sulfur Corrections, turn on Line 6 and enter the estimated value.

O. Spiking Samples

It is sometimes necessary to add a spiking material to samples, which are very small,

have a low heat of combustion, or have a high moisture content to add sufficient heat to

drive the combustion to completion. Benzoic acid is an excellent material for spiking for

all of the same reasons that it is a good standard material. White oil is also an excellent

material; particularly for liquid samples. The 1356 Calorimeter can automatically

compensate for the addition of spiking materials to these samples.

When Use Spiking is turned on, on Menu page 2.3 and line 1, the heat of combustion of

the spiking material must be entered on Menu page 2.3, line 2.

During data entry when using a spike, the calorimeter will prompt for both the sample

weight and the spike weight.

10

Page 11

Spiking Calculations

[{EE x T(temp rise)}-e1-e2-e3-[mass(oil) x Heat Combustion(oil)]/sample m grams

2. 1108 Oxygen Bomb Maintenance and Safety Instructions

Oxygen Bomb Maintenance

Under normal usage Parr oxygen bombs will give long service if handled with reasonable

care. However, the user must remember that these bombs are continually subjected to

high temperatures and pressures which apply heavy stresses to the sealing mechanism.

The mechanical condition of the bomb must therefore be watched carefully and any parts

that show signs of weakness or deterioration should be replaced before they fail.

Otherwise, a serious accident may occur.

Do not fire the bomb if gas bubbles are observed anywhere indicating a possible gas

leak. Disassemble the parts and install new seals immediately.

Keep the 397A compression nut on the valve needle tightened firmly at all times.

Frequent tightening is important. This nut, if slightly loose, may allow a leak to develop

during the rapid pressure rise upon ignition. This type of leak may not be detectable

before firing; but if it develops, the hot gases can ignite the 20VB valve seat and burn

through the head.

Do not use extreme force when closing the needle valve. A moderate but firm turn on

the valve knob should be sufficient to stop all gas flow. Excessive needle pressure will

deform and possibly close the gas passage. If this happens, unscrew the valve body and

replace the 20VB valve seat. Accumulated salt deposits may also clog the gas passage,

making it difficult to release pressure at the end of a run. To avoid this, clean the passage

through the valve needle and deflector nut with a small drill.

Firings 500

All O-rings and 20VB valve seats should be replaced after 500 firings for the standard

1108 Oxygen Bomb and 250 firings for the 1108CL Oxygen Bomb for chlorine content

of samples is 25% or greater.

A Parr 475A service clamp offers a convenient means for clamping the bomb head firmly

in a vise without damaging the head when replacing any of the bomb head parts.

When replacing the 230A head gasket, stretch the new O-ring and let it snap into place to

be sure that it moves freely in its groove and is not twisted.

To replace the valve seat, unscrew the 397A compression nut; remove the valve stem and

the old seat, and disassemble all of the parts. Drop a new 20VB valve seat into the body

and push it down into place. Slide a 7VBCM Monel washer, two 238A O-rings and

the 378A packing cup onto the valve needle with the needle pointed upward; then adjust

the parts on the needle so that the tip of the needle is flush with or slightly recessed into

the bottom of the packing cup. Insert this assembly into the 369A outlet valve body and

press it firmly against the valve seat by tightening and 397A compression nut to 100

inch-pounds of torque.

The 238A sealing ring in the insulated electrode should be replaced with the same

frequency as the 20VB valve seat. Also keep the 411A terminal nut tight at all times. As

11

Page 12

Sample preparation

12

Page 13

the 238A sealing ring ages and hardens it becomes a partial electrical conductor,

permitting misfires and producing unwanted heating effects. Periodic replacement will

eliminate this potential problem.

The threads on the screw cap should be checked routinely for any burrs or other

deformity. After long use, the threads on the screw cap may become worn to the point

where they will no longer provide a safe closure for the bomb, and the screw cap will

have to be replaced. The following procedure can be used to check the extent to which

the threads have become worn.

Assemble the bomb with the head in the cylinder and count the number of turns required

to bring the screw cap down firmly against the head. Then open the bomb; remove the

head and replace the screw cap, but turn it down to only one-half of the turns previously

counted. This will usually be about four turns. With the screw cap in this position, use a

dial gage to measure the vertical deflection when lifting the screw cap upward. If this

measurement exceeds 1/32 inch (0.030”), the screw cap is unsafe and should be

discarded. The cylinder can then be returned to the factory for inspection. If the threads

on the cylinder are in good condition, a new screw cap can be custom-fitted to the

cylinder.

Never under any circumstances use oil on valves or fittings which handle

compressed oxygen. This precaution applies to all of the oxygen bomb parts as well as to

the oxygen filling connection.

The 1108CL Bombs will resist chlorine, fluorine or bromine in the presence of moisture.

If samples yielding appreciable amounts of these elements are burned in a Parr bomb, the

bomb should be emptied and washed as quickly as possible after each combustion.

If the interior of the bomb cylinder should become etched, the resistance of the metal to

further attack can be improved by restoring the surface to its original highly polished

condition. Bombs needing polishing or other repair work can be returned to the factory.

A periodic overhaul and test at the factory will help to keep any Parr oxygen bomb in

first-class condition.

Parr oxygen bombs can be returned at any time for repair and testing. A factory test is

recommended after every 5000 firings, or sooner if the bomb has been subject to any of

the following conditions: (a) fired with an excessive charge, (b) ignition of any internal

components, (c) machined by any source other than the factory, (d) damaged by corrosive

vapors that might have exceeded 80% of the corrosion allowance, or (e) any changes in

the threads on the bomb cylinder and/or screw cap. When returning a bomb to the

factory, ship it to Parr Instrument Company, 211-53rd Street, Moline, Illinois 61265, with

the package marked for the attention of the Repair Department. A purchase order

covering the repair work should be included with the shipment or mailed to the same

address, as no repairs will be started without specific instructions. Be sure to include a

return shipping address and the name and telephone number of the individual to be

contacted if questions arise concerning excessive repair costs or other problems.

Individual repair parts can be ordered from any Parr dealer or direct from the factory.

13

Page 14

2. Parts Replacement

Keyboard

A bad keyboard panel will result in the calorimeter responding to only some rows or

columns of keys and ignoring others. If the keyboard has failed completely, the

calorimeter will respond to no key activation. Keyboard. In either case, the calorimeter

will power-up to the main menu..

Instructions for Adjusting Cover

1. Turn off instrument and open cover.

2. Loosen 8 set screws that secure the lower link assemblies, S shaped, to the

assembly shaft rod, Hinge Assembly

3. Carefully move the cover to the closed position.

4. From the rear of the calorimeter, with a nut driver or socket wrench, loosen the

six kep nuts that secure the support rod mounting place to the calorimeter chassis

5. Align cover so that cover has a uniform alignment with calorimeter chassis, front

side and rear. No air gap should exist between rear portion of cover and the

calorimeter chassis.

6. Position the lower linkage assemblies to outer most position against the support

rod mounding plate.

7. Now secure the nuts on the support rod mounting plates, alternating between left

and right hand plates until all six nuts have been tightened.

Raise the cover and recheck the lower linkages to be sure they are at outer most

position adjacent to the respective mounting plates. Secure the 8 set screws.

8. Lower cover and recheck cover adjustment.

Motor Replacement

Remove the stirrer shaft assembly from the motor coupler.

From the bottom side of the cover, remove the 12 button head socket screws that secure

the top cover of the metal plate. Remove the motor’s electrical leads from the terminal

strip and note the terminal connection for each lead wire. Remove the 2 round head

screws that secure the motor to the cover and transfer the coupler to the new motor.

1404E Battery

The controller must be removed from the calorimeter. Remove the 6 screws that secure

the beige rectangular ring on the keypad. Remove the thermistor connectors from the

controller and remove the two orange connectors from the side of the controller. Remove

the power cord. Swing the controller out of the opening in the calorimeter. Remove the

ribbon connector from the display board and remove the power cord for the display, 2

wires, red and black. Remove the 4 nuts that secure the smart link connectors

on the back panel. Remove the 7 phillip screws that secure the left side panel to the

control module at the side and bottom of the left side chassis. The battery is secured to

14

Page 15

the left side panel via velcro and is located between the power supply board at the front

and the cpu board and is connected electrically to the cpu board. Remove the connector

and replace the battery.

Bucket Thermistor Replacement

Open the calorimeter cover, and turn off the instrument. Use a 5/64 Allen wrench to

remove the 12 button head screws which secure the cover to the bottom plate of the

cover assembly Front View 1356 Calorimeter

be removed with the cover in a not fully pushed back position. Before removing the last

screw, grasp the cover assembly so that it does not drop and become damaged Remove

the 2 cable clips which secure the thermistor cable to the hinge assembly. With the cover

closed, remove the nut and plastic ferrule which secures the probe to the cover water

jacket assembly, Cover Assembly 1356. Remove the probe from cover through the cover

and jacket hinge openings. Disconnect the BNC connector from the microprocessor case

Front View 1356 Calorimeter

thermistor probe and secure to the cover with the previously removed nut and ferrule.

Controller Removal

The 1356 Calorimeter Controller can be physically separated into two halves. The upper

logic pack consists of the keyboard, and display. The lower half consists of power supply

board, microprocessor board and the I/O board.

1. Disconnect the power cord from the rear of the controller, remove the thermistor

connectors, remove the 2 orange connectors..

2. Remove the six screws located on the display bezel.

3. Remove the bezel.

4. Separate the logic pack from the power pack by lifting the logic pack up from the

lower edge.

5. Unplug the 4 conductor, shielded, thermistor probe cable from the logic pack at

P4. Note that the red wire of the cable goes to Pin 1 in the logic pack.

Unplug the two ribbon cables using the two ejectors on the mating sockets.

Combined Controller Removal

The 1356 Calorimeter Controller can be physically separated into two halves. The upper

logic pack consists of the keyboard, and display. This display is attached to the lower

power pack with one ribbon cable that is connected to the cpu board and a two wire cable

that is connected to the power board. Six screws are used to mate the display to the lower

unit.

1. Disconnect the power cord and any Smart Link and/or printer cables from the rear

of the controller.

2. Disconnect the two orange connector plugs from the side of the controller.

3. Disconnect the BNC connectors attached to the ends of the bucket and jacket

thermistor probes.

. Reversing the above removal procedure, install the new

). The screws at the rear of the cover must

15

Page 16

4. Remove the six screws located on the display bezel and remove the bezel.

5. Push the rear of the controller near the bottom of the case, which will force the

display panel up.

6. Grab hold of the front edge of the controller which has been forced up in the

preceding step, and guide it out of the front of the calorimeter case, tilting where

necessary to provide clearance of the BNC jacks.

7. The display and lower half may now be separated, if desired, by following the

procedure given for the logic pack removal. If the controller is returned to Parr,

they may be secured together with screws. Otherwise, they must be separated to

avoid damage in transit.

Keypad

When any row or column of keys fail on the keyboard panel of a 1356 Calorimeter, the

panel is not repairable and must be replaced. A replacement keyboard panel can be

ordered from Parr (Parr Part No. 1601E). Replace the keyboard panel by removing the

controller from the 1356. For removal see;. Controller Combined .

Instructions for Replacing Support Rod Mounting Plates

1. Turn off instrument, disconnect harness plugs from the controller and open cover.

2. Loosen 8 set screws that secure the lower link assemblies, S shaped, to the

assembly shaft rod.

3. Remove the socket head machine screws from the lower linkages which connect

to cover brackets. These flat head machine screws and retaining washers have been

fastened with Loctite which may require more than normal effort to loosen them. Care

must be exercised in this step as the cover may slip down and possibly bend the

thermistor probe.

4. Remove the round head machine screw that secures the tube clips to the lower

linkages.

5. Carefully move the cover to the closed position.

6. Remove 2 socket head machine screws that secure the upper linkage to the

support rod mounting plates.

7. From the rear of the calorimeter, with a nut driver or socket wrench remove the

six kep nuts that secure the support rod mounting plate to the calorimeter chassis.

8. Remove 2 snap rings that secure the retaining pin to the upper U bracket and gas

spring, and remove retaining pin.

9. The lower linkages that were previously loosened via set screws can now be

moved toward the center on the shaft assembly rod.

11. Lower the shaft assembly rod and remove both support rod mounting plates from

the shaft assembly rod.

16

Page 17

12. Position the new mounting plates on the shaft assembly rod. Raise the shaft

assembly rod to position the support rod mounting plate over the machine screws

attached to the calorimeter chassis.

13. Secure the mounting plates with previously removed kep nuts, finger tight.

14. With previously removed flat head machine screws and retaining washers, secure

the upper linkage to the support rod mounting plates.

15. Use the retaining pin to secure the gas spring to the U bracket. Reattach the snap

rings on the retaining pin.

16. Push the lower linkages to the outer most position on the shaft assembly rod.

Raise cover to open position.

17. Attach tube clips to the lower linkage assembly with the nut and washer between

the two linkage assemblies.

18. Reattach lower linkage arms to the cover bracket with the flat head machine

screws and retaining washers. Position the lower linkage assemblies to outer most

position against the support rod mounting plate.

18. Position the lower linkage assemblies to outer most position against the support

rod mounting plate.

19. Lower the cover and align cover so that cover has a uniform alignment with

calorimeter chassis, front, side and rear. No air gap should exist between rear portion of

cover and the calorimeter chassis.

20. Now secure the nuts on the support rod mounting plates, alternating between left

and right hand plates until all six nuts have been tightened.

21. Raise the cover and recheck the lower linkages to be sure they are at outer most

position adjacent to respective mounting plates. Secure the 8 set screws.

Reattach cable connector, lower cover and recheck cover adjustment.

4. Messages Error

Error: Pre-period/Post-period Time Limit Violated

Pre-period or Post-period Time Limit Violation. The causes are listed in order of

probability.

1. The stirrer motor does not work or is intermittent, which is generally due to

weak torque capability. With cover open and stirrer operating, one should

not be able to stop stirring with gentle force of two fingers. Another test is to

open and close the lid, if the motor stops during this process, replace the

A1537E2 wiring harness

2. The bucket tipped so as to touch the wall of test chamber.

3. Water in the bottom of test chamber.

4. The bucket temperature is started at temperatures which are more than 1-2

degrees C below the room temperature.

5. Bad motor cable, Parr A1537E2 or feet on the bomb are worn so water circulates

under the bomb.

6. Oxygen leak in the bomb or foam insulation has deteriorated.

7. Bucket thermistor probe bent and touching the bucket.

17

Page 18

8.

Misfire Error

Ignition Problems on the 1356 Calorimeter are generally attributed to one of three

possible sources, after having checked the fuse.

1. Breakdown of insulator and O-ring on the insulated electrode assembly. Any

reading on an ohm meter when set on RX1 scale when the ohm meter leads are connected

to the ignition terminals of oxygen bomb head is an indication of insulation breakdown.

2. The ignition lead wires have broken internal wire strands which may be detected

by connecting the ohm meter to the ends of the wire, and flexing the wire. Any change in

the reading of approximately from 0-20 ohms would indicate broken strands of wire.

Readings for bad ignition wires generally go to infinity on flexing the wire.

3. The third possibility is the connection termination of the 11 pin Wago connector

to the A1135DD control unit. The wire terminations for ignition wire are not fully

inserted into the orange connector. The voltage output from the 11 pin connector on the

A1135DD control unit may be confirmed with volt meter measurement at pins 6 and 7.

When one turns on line 1 of menu page 9.2 and voltage on large blue capacitor inside the

controller should ramp to approximately 30 volts. If system does not show any ramping,

the charging circuit is at fault. If capacitor charges but the fuse wire does not burn, the

discharge circuit is at fault.

4. Improperly formed fuse wire may cause misfire. The fuse should be attached by

raising the cap, inserting the wire through the eyelet and then pull the cap downward to

complete the assembly. The bottom portion of fuse wire should touch sample before any

portion of wire touches the capsule.

Error: Calibration Limit Exceeded

This error is generally attributed to a calibration test that caused the range of calibration

tests to be larger than 12 calories/C. The cause of this may be due to the fact that:

1. The oxygen bomb has 500 firings and requires the replacement of O-rings and

valve seat.

2. The operator may have used the wrong bomb, that is each bomb is required to

have its own EE value.

3. An operator is different than the person that established the original EE value, it

may be necessary for each operator to have their own EE value.

4. The EE value may be an outlier and discarded after using a statistical review

procedure.

5. Discard the first calibration test

6. Be sure that bucket is dried after each run as well as the bomb and the probe and

stirrer.

7. All tests should be made at the same starting temperature.

18

Page 19

Low Oxygen Charge

Low Oxygen Pressure - signifies low oxygen pressure in the line filling the bomb. The

pressure switch must reach 27 (400 psi) atmospheres in this line otherwise there is the

display of this error message. Our recommended oxygen line pressure to the calorimeter

is 440-450 psi to allow for some pressure drop in the line to the calorimeter’s oxygen

solenoid

The most common cause is low oxygen pressure in the oxygen cylinder. Another

common reason for this error message is partially plugged orifice at the input of the

oxygen solenoid block and generally occurs when replacing the oxygen tank. We

recommend wiping the threads on the oxygen cylinder before attaching the oxygen

Regulator to the replacement tank. Close the valve for the oxygen tank. The problem may

be resolved by reversing oxygen connections at the solenoid block assembly. .Move the

connection from the input connector of the block to the output connector of the block

assembly. Cycle the oxygen fill process with the tank valve open to flush any particles

which may be blocking the orifice. After the completion of the fill process, close the

oxygen tank valve to avoid emptying the tank. If the error 78 message occurs at the end

of this process, oxygen is not flowing to the solenoid block assembly or the pressure

switch is faulty. If oxygen is being supplied to the block, then failure of the pressure

switch to close may be confirmed with an ohm meter measurement of approximately zero

resistance across pins 10 and 11 of the 11 position Wago Connector during the fill

process with the oxygen connections still in the reversed position. If one does not have a

filter in the oxygen line to the calorimeter, we recommend that a 359VB filter be

installed.

5. Miscellaneous

Accuracy & Precision-1356 Calorimeter

There are several considerations on must review to obtain the utmost accuracy and

precision. The water should be measured as accurate as possible, if one measures the

water to .5 ml or grams, this should be sufficient for most work.

1. The water residue in the bucket and on the bomb should be removed after each test.

2. The sample should be weighed to a minimum of .1 mg, preferably to .01 mg for each

test.

3. The acid titer should be made after each calibration test.

The fuse wire should be measured after each test.

4. The calibration tests should be reviewed to ensure that good work is being done. The

range of the calibration tests should not be greater than 12 cal/C. to give a relative

standard deviation of .20% which all 1356 calorimeters are capable of obtaining.

5. The starting temperature of each test should be T temperature +/- 1 C. for the best

accuracy

19

Page 20

Oxygen Use

P1A Oxygen Cylinder volume of cylinder 43.8 liters pressure of cylinder 2490 psi

V x P = 109062 liters-psi

Amount of gas per test = .350 liters x 450 psi = 158 psi-liter

No. of tests = 109062 psi-liter/158 psi-liter= 700 tests per cylinder

Spiking Volatile Waste Samples

Determine the heating value of mineral oil based on a minimum of 6 combustion tests.

Store this value in menu page 2.3 line 2. Go to menu page 2.3 and turn on line 1. Entered

value must be in cal/g and typical value is 11000 cal/g.

Cut a square portion from the 517A tape, which is chlorine free and apply to the fuel

capsule. Trim to the circumference of the capsule leaving one tab to fold back so that

material can be added to the capsule. The amount of tape used for covering the capsule

will be .0502 gm +/- .002 g. The tape will have a heat of combustion value of

approximately 6300 cal/g, and correction for the tape would be 316 calories +/- 12.6

calories. If this variation is insignificant relative to your application, then you might add

this value to fixed fuse correction and enter the sum on menu page 5 line 4, and turn on

fixed fuse..

If this value is significant, you might consider adding your fuse and acid correction and

entering the total for a fuse correction. Then one can use the nitric acid entry as means for

correcting for the tape. Menu page 5 line 5 should be off. Take the heat value of the tape

divided by 14.1 and multiply the result by the weight of the tape and enter this value on

Menu page 5 line 5. This assumes that a fixed value is used for the sulfur correction is

turned on. When requesting a report, the system will prompt for the nitric acid value. The

entry will be the weight of the tape.

Recommended procedure for all waste samples would be:

1. Cut, add tape to crucible, trim and leave tab to fold back.

2. Add .45 g of mineral oil

3. Add .1 g of sample

4. Seal capsule, load into bomb, and proceed as normal

Acid Sulfuric Calculations

The factor used to convert percent sulfur concentration to calorie correction in the heat of

combustion calculation for liquid hydrocarbon fuels is different than the factor for solid

fuels. The following table lists the differences between fuels.

20

Page 21

1. Solid Fuels (D2015)

Heat of Formation of .... 29KJ/mole

Sulfuric Acid for a Fuel with 5% sulfur and 5% hydrogen

S02(g) + 1/2 02(g) + H20(1) >H2S04 in 15 moles H20

e2 = 23.7 BTU/LB x %S x 1gm = x BTU gm/LB or

e2 = 13.17 cal/gm x %S x 1gm = x cal

2. Liquid Hydrocarbon Fuels (D240)

Heat of Formation of......301.KJ/moleSulfuric Acid for a fuel with .8% sulfur and 20%

hydrogen.

S02(g) + 1/2 02(g) + 651H20 > H2S04 650H20(1)

e2 = 14 cal/gm x %S x 1gm = x cal

GAS EFFECTS CALORIMETRY

There are occasions when the calorimeter is used to test

heat powders or similar materials in an inert atmosphere.

The question then becomes what is the effect on the heat

capacity when this change is made.

360 ml oxygen bomb x30atms/10800 ml or 10.8 liters

1. Oxygen

1.429 gm/liter x 10.8 liters = 15.43 gms

.219 cal

gm K K

2. Argon

1.784 gm/liter x 10.8 liter = 19.27 gms

.124 cal x 19.27 gm = 2.39 cal

gm K K

3. Helium

.1785 gm

1.24 cal x 1.93 gm = 2.39 cal

gm K K

x 10.8 liter = 1.93 gm

x 15.43 = 3.38 cal

21

Page 22

4. Nitrogen

1.251 gm x 10.8 liter = 13.51 gm

.249 cal x 13.51 gm = 3.36 cal

gm K K

oxygen 3.4 cal/C

argon 2.4 cal/C

helium 2.4 cal/C

nitrogen 3.4 cal/C

ISO/BSI Bomb Washing Titration

The reaction is carried out stoichiometricly to a phenolpthalein endpoint (V2)

(2HNO3 +H2SO4) +2 Ba(OH)2 + 4H20

Excess Na2C03 (20 ml 0.1N) is back titrated with HCl using methyl orange (V1)

Ba(NO3)2 + Na2CO3 (excess)=BaCO3 (P) + 2NaNO3

Assume heat of formation of H2SO4 is _72 kcal/mole(-301kJ/mole)

Assume heat of formation of HNO3 is –14 kcal/mole (-59.8kJ/mole)

Mwt. H2SO4=98, eqwt=49

Mwt HNO3=63

4.184J=1 calorie

So, for H2SO4, 301 kJ/mole*0.1N/2*0.001liter=15.1 J.ml of 0.1N H2SO4

For HNO3 59.8 kJ/mole*0.1N*0.001 liter=5.9J/ml of .1N HNO3. (ISO uses 6 J/ml

ISO calculations

Nitric acid correction in joules:

5.9*(20-V1)

Sulfuric acid correction in joules:

15.1*(V1+V2-20)

Add them:

7.2 V1+ 15.1 V2-184

22

Page 23

1356 Data Logger

To log data one may either log the data to the internal ram disc, or send the data

directly to the printer or to the computer. To log the bucket temperature at a

specified time interval: from the main menu, go to page 9, Diagnostics page and

select Data Logger Controls, item 7; select the time interval for logging on line 2;

then go to line 3 and turn on the Bucket temperature; go to line 4, turn on the

computer format; then go to line 5 to set the destination of the data.

The data will appear as follows;

0,20000713, 072508, 20.235234, 19.988185

0,20000713, 072518, 20.235251, 19.988425

0,20000713, 072528, 20.239104, 19.988681

where 0 is the Calorimeter ID, the date is July 13, 2000, the time starts at

7:25:08 AM, jacket temperature is 20.235234 C., and the bucket temperature is

19.988185 C.

1356 Bubbles in screen

Remove the 2 Wago connectors from the controller. Replacing LCD Display and

Keypad Remove the 6 screws that secure the rectangular ring on the display-keyboard.

Lift the controller out of the calorimeter. Gently lift the keyboard-display unit from the

lower control box and disconnect the cables to the display unit. Remove the 4 nuts that

secure the circuit board to the keypad assembly. Remove the 4 hex standoffs between the

circuit board and keypad assembly. Disconnect the ribbon from the keypad to the circuit

board. Remove the nuts that secure the display to the keypad assembly. Remove the

display and circuit board from the keypad plate. Remove the protective plastic cover from

the keypad plate. Reassemble.

A1573E2 Stirrer Harness

This is assembled from 3.2 feet of XA2202L and 2 pieces of 553E2.

Remove the cover of the 1356 calorimeter. Remove the wires from the terminal block,

noting from which terminals they were removed. Locate the red and black wires at the

locations 1 and 2 on the 11 position connector at the side of the controller. Adjacent to

the wires are 2 openings, insert a small screw driver into the opening adjacent to the

wires and remove the wires from the harness assembly. Attach the connectors for the

wires at the terminal block and thread through the hinge assembly, through the harness

cover, through the square ferrite filter and attach to the connector. Open the clamping

mechanism with a screw driver, insert the wires, and remove the screw driver to secure

the wires. Reattach the connector to the controller

LCD display, keypad and display board replacement.

This work should be done by a person using a ground strap attached to their body.

Turn the instrument off. Disconnect power cord from back of the instrument.

Disconnect the thermistor connections. Remove the cable to the printer at the back

of the controller.

23

Page 24

The 1356 Calorimeter Controller can be physically separated into two halves. The upper

part consists of the keyboard, LCD display, keypad and display driver board. This top

assembly is attached to the lower power half with two cables; display driver cable and a

power cable. Turn the instrument off.

1. Disconnect the power cord, terminal cable, balance cable, printer cable and any

Smart Link cables from the rear of the controller.

2. Disconnect the two orange cables attached to the lower portion and adjacent to the

probe connection lug. Note which cable goes to the display.

3. Push the rear of the controller near the bottom of the case, which will force the

display panel up.

4. Grab hold of the front edge of the controller which has been forced up in the

preceding step, and guide it out of the front of the calorimeter case, tilting where

necessary to provide clearance of the BNC jacks.

5. Carefully lift the top and remove the two cables.

6. Attach the two cables to the new assembly.

Steps to replace an I/O Board in an A1135DD

1) Turn off power and remove power cord.

2) Turn calorimeter around to gain access to the back.

3) Disconnect the two temperature probes (BNC) from the controller.

4) Disconnect the two wiring harnesses (orange connectors) from the controller.

5) Remove the 6 painted Phillip screws holding the retaining plate (557DD) to the

display of the controller.

Remove controller from the calorimeter.

6) Disconnect the BNC connectors attached to the ends of the bucket and jacket

thermistor probes.

7). Remove the six screws located on the display bezel and remove the bezel

Warning: It is highly recommended that all Electro-static Discharge (ESD)

abatement procedures are used. Failure to do so can damage the circuit boards and

void your warrant

8) Remove the 5 phillip screws that secure the right side panel and the 2 screws that

are located on the bottom.

9) Disconnect the cable to the thermistor probes. Disconnect the harness at the top

front portion of the board . Disconnect the harness at the top rear portion of the board.

Disconnect the orange connector at the bottom rear portion of the board.

10) Unscrew the 6 screws that secure the I/O board to the right side panel.

11) Install the new I/O circuit board.

24

Page 25

Lengthening Post Period for 1356 Calorimeter

Gain entry to the factory menu by pressing the following three keys simultaneously from

the main menu.

1. Hidden key above the Enter key and below the Start key, Shift the Up Arrow key. At

the password prompt, enter 1234567890.

Press 2 to access the L parameters submenu. The password is 61265.

Parameter set 1 is for the 1108 bomb.

1. Turn calorimeter around to gain access to the back.

2. Disconnect the two temperature probes (BNC) from the controller.

3. Disconnect the two wiring harnesses (orange connectors) from the controller.

4. Remove the 6 painted Phillip screws holding the retaining plate (557DD) to the

display of the controller.

5. Parameter set 2 is for the 1107 bomb.

Parameter set 3 is for the 1104 bomb.

Parameter set 4 is unused.

6. Press the menu entry that corresponds to the bomb model number being used.

Change item 9 (Post period timeout) as required in order to eliminate post period timeout

error messages, when slow burning samples are tested. This value corresponds to the

number of ten second time intervals after ignition. The calorimeter will issue a post

period timeout error messages if the post period time exceeds this value

.

Steps to Replace a Power Supply Board in an A1135DDXX

Turn off power and remove power cord.

Remove controller from the calorimeter.

Warning: It is highly recommended that all Electro-static Discharge (ESD)

abatement procedures are used. Failure to do so can damage the circuit boards and

void your warranty.

1.. At an ESD approved workstation remove the display. Disconnect the two cables

attached to the display. Set the display to the side. Care should be taken to avoid

scratching the display.

1. Remove the screws holding the left panel to the chasis. Note: there are two screws

on the bottom of the unit. The power supply board is at the front of the side panel.

2. Remove the harness from the top of the board, the cable from the board to the fan and

the harness at the bottom of the board..

3. Remove the four screws holding the power supply board to the panel.

4. Install the replacement power supply board.

5. Reassemble unit by following these instructions in reverse.

Steps to replace a CPU Board in an A1135DDXX

Turn off power and remove power cord.

Remove controller from the calorimeter.

Warning: It is highly recommended that all Electro-static Discharge (ESD)

abatement procedures are used. Failure to do so can damage the circuit boards and

void your warranty.

1. Disconnect the two temperature probes (BNC) from the controller.

2. Disconnect the two wiring harnesses (orange connectors) from the controller.

3. At an ESD approved workstation remove the display. Disconnect the two cables

25

Page 26

attached to the display. Set the display to the side. Care should be taken to avoid

scratching the display.

4. Remove the 5 screws holding the left panel to the chasis. Note: there are two

screws on the bottom of the unit. The power supply board is at the front of the side panel

and the cpu board is at the rear of the side panel.

7. Remove the display cable from the cpu board. Remove the 2 wire cable from the

battery to the cpu board. Remove the ribbon connector between the I/O board and the

cpu board at the cpu board. Remove the connector at the bottom of the cpu board for

the harness between the I/O board and the cpu board. Remove the 4 screws that

secure the cpu board to the side panel.

6. Install the replacement cpu board.

7. Reassemble unit by following these instructions in reverse.

26

Page 27

1356 Calorimeter Parts List

Item Description Item Description

421A

A476A3

393DD

1027DD

539DD

549DD

558DD

581DD

A391DD

A555DD

A570DD

A596DDEB

A596DDEE

A598DD

A1135DDEA

A1135DDEF

A1043DD

893E

Vessel lifter

Slip connector, 1/8NPTF

Bucket support

Coupler, stirrer shaft

Top plate

Gas spring

Cover seal

Retainer ring

Oval bucket

Air Can Assbly

Oxygen regulator

Oxygen solenoid assembly, 115V

Oxygen solenoid assembly, 230V

Pressure switch assembly

Controller, 115V

Controller, 230V

Stirrer motor assembly

Thermistor, 1/8 OD, 7.8"L

997E3

A297E

A719E

1404E

1601E

1609E

A16313E

1633E

A1635E

A1641E

A1573E2

A1750E

A1770E2

697HC2

HX0012TB024

213VB

214VB

TX06SK

TX25SK

Fuse

Lead wire

Cord set, 115 V

Battery

Keypad

Display

Power Supply Harness

Power Supply

I/O Board

Display Driver

Motor Stiring Harness

Fan

Cpu board programmed

Gas filter

Tubing, oxyen

Compression nut 1/8 OD

Ferrule set, 1/8 OD

1/6 Allen Wrench

1/4 Allen Wrench

Parts Information

5 Year Recommended Spare Parts

Qty. Part No. Description

1

1

1

1

1

6

1

25FT

A1043DD

A596DDEB

A598DD

893E

180HW

214VB

359VB

HX0012TB024

Stirrer motor assembly, DC

Solenoid assembly, oxygen

Pressure switch assembly

Thermistor

Solenoid, 1/8 NPTF

Ferrule set, brass; 1/8T

Filter, in-line; 1/8T

Tubing, 1/8 OD, pressure; nylon

27

Page 28

Recommended Spare Parts Per 5000 Tests

Qty.

3 PKG (2)

3 PKG (2)

1 PKG (12)

3 PKG (12)

1 PKG (2)

1 PKG (2)

1

3 PKG (2)

1 PKG (2)

1

5 PKG (2)

5 PKG (2)

5 PKG (12)

3 PKG (2)

1 PKG (2)

7 PKG (3)

1 PKG (6)

6

1 PKG (2)

5pkg

5

2 PKG (6)

1 PKG (6)

Part No. Description

4A10

5A10

230A

238A

378A

388A

400A

401A

402A

403A

404A2

406A

415A

96AC

143AC

45C10

149C

263C

264C

A297E

7VBCM

20VB

3415

Straight Electrode w/sleeve

Loop electrode w/sleeve

O-ring, NBR, 2-3/8ID x 1/8CS

O-ring, NBR, 3/16ID x 1/16CS

Packing cup

Spacer

Valve needle

Sleeve insulator

Electrode core

Check valve

Deflector nut

Lock nut, SS

O-ring, 7/16 x 1/16CS, NBR

Electrode insulator

Insulator, delrin

Fuse wire, Ni alloy, 10cm

In-line filter

Printer paper, 40cm

Ribbon, replacement

Lead wire

Monel washer

Valve seat, Kel-F

Benzoic acid, bottle of 100

External Connections

183VB Ferrule,3/8” Cooler 2

214VB Ferrule,1/8” A570DD 1

HJ0025TB035 Cooler to 1563 20 ft

HX0012TB024 1356 to Oxygen 25 ft

1563 Water Handling System

218VB Ferrule, ¼” 16

226VB Ferrule, 5/8” 2

HJ0025TB035 7 Ft

HX0062TB062 4 in

JR0056TB125A 54 in

28

Page 29

Parts Hinge Assembly

Qty Part No Description

1 A525DD Lower RH Link

1 A526DD Lower LH Link

2 527DD Link Upper

1 A530DD2 Lift Shaft

1 A535DD3 Right Mounting Plate

1 A536DD3 Left Mounting Plate

6 536DD2 Washer

6 537DD2 Retaining washers

1 A545DD2 RH Mounting

1 A546DD2 LH Mounting

1 549DD Gas Spring

2 567DD Spacer

1 579DD Pin

6 581DD Retaining Ring

1 616DD Lower trunion

2 A618DD Strut Strap

2 619DD Strut Strap

1 621DD Upper Trunion

1 622DD Threaded Rod

6 632DD Bushing Pivot

6 SA1632FS08 Screws

1 SN3118HX Jam Nut

29

Page 30

Parts List 1563 Water Handling System

Part No. Description

108C

110C

148C

149C

186DD

612DD

A633DDEA

A633DDEF

894DD

34E2

138E

178E

185E

201E

379E

458E

967E

982E

1356E

246M

89HW

167HW

172HW2

174HW

179HW

180HWEA

A183HW

209HW

205VB

BA0025TB030

HJ0025TB035

HX0062TB062

JR0056TB125A

SA1632RD08

SA1932RD06

Polyethylene spout

Black latex tubing

Stopcock plug, teflon

In-line filter

Cable clip, 5/16 dia.

Pad, motor mount

Pump motor assembly, 120V

Pump motor assembly, 240V

Plastic feet

Cord set w/115V plug 18-3SJT

Fuse holder

Strain relief bushing black

Fuse slo-blo 5 amp 250V

Terminal ring; 310 stud 14-16 Ga

Cable tie

Terminal ring; #5-6 stud, 18-22 Ga

Capacitor, 0.005uF, 2000 VDC

Thermoswitch (1563)

Switch, toggle; DPST w-on/off

1563 Water handling System Instruction Manual

Solenoid valve 120/60 brass

Pipette, glass w/stopcock

Cap, receiver cover; It. Gray

Pipette support

Clamp, hose; adjustable

Solenoid, 1/8 NPTF; 120/60 (N.O.)

Shaft support

Pump mounting plate

Manifold, 1/4OD x 1/4OD

1/4OD x 50' copper tube

Tubing Nylon, ¼ 0D X.034W

Tubing, Bev-A-Line; 5/8OD

5/16ID x .125W latex black

8-32 x ½ RHMS 18-8 SS

10-32 x 3/8 RHMS18-8 SS

30

Page 31

1356 Calorimeter Front View

L Shaped

Upper Link

SA1332RD06

Cover

Bracket

31

SA1332RD06

Lower Link

S Shaped

Page 32

527DD Linkage Upper

Linkage Lower 526DD

32

Page 33

A546DD2 Left Bracket Linkage

33

Page 34

A535DD3 Right Mounting Plate

A536DD3 Left Mounting Plate

34

Page 35

A545DD2 Right Bracket Linkage

35

Page 36

1356 Cover Assembly

Assembly Hinge Mechanism

36

Page 37

Diagram Flow

Page 38

Electrical Diagrams Water Handling

Page 39

MSDS-Benzoic Acid

-----------------------------------------------------------------------

1 - PRODUCT IDENTIFICATION

----------------------------------------------------------------------PRODUCT NAME: BENZOIC ACID

FORMULA: C6H5COOH

FORMULA WT: 122.12

CAS NO.: 65-85-0

NIOSH/RTECS NO.: DG0875000

PRODUCT CODES: 5077,0080,0077,0076

EFFECTIVE: 03/20/86

REVISION #01

PRECAUTIONARY LABELLING

BAKER SAF-T-DATA(TM) SYSTEM

HEALTH - 1 SLIGHT

FLAMMABILITY - 1 SLIGHT

REACTIVITY - 1 SLIGHT

CONTACT - 1 SLIGHT

HAZARD RATINGS ARE 0 TO 4 (0 = NO HAZARD; 4 = EXTREME HAZARD).

LABORATORY PROTECTIVE EQUIPMENT

SAFETY GLASSES; LAB COAT

PRECAUTIONARY LABEL STATEMENTS

CAUTION MAY BE HARMFUL IF SWALLOWED

MAY CAUSE IRRITATION

DURING USE AVOID CONTACT WITH EYES, SKIN, CLOTHING. WASH THOROUGHLY

AFTER HANDLING. WHEN NOT IN USE KEEP IN TIGHTLY CLOSED CONTAINER.

SAF-T-DATA(TM) STORAGE COLOR CODE: ORANGE (GENERAL STORAGE)

-----------------------------------------------------------------------

2 - HAZARDOUS COMPONENTS

-----------------------------------------------------------------------

COMPONENT % CAS NO. NOT APPLICABLE

-----------------------------------------------------------------------

3 - PHYSICAL DATA

----------------------------------------------------------------------BOILING POINT: 249 C (480 F) VAPOR PRESSURE(MM HG): <1

MELTING POINT: 122 C (252 F) VAPOR DENSITY(AIR=1): 4.2

SPECIFIC GRAVITY: 1.32 EVAPORATION RATE: <1

(H2O=1) (BUTYL ACETATE=1)

SOLUBILITY(H2O): SLIGHT (0.1 TO 1 %) % VOLATILES BY

VOLUME: N/A

APPEARANCE & ODOR: WHITE CRYSTALS WITH A FAINT, PLEASANT ODOR.

-----------------------------------------------------------------------

4 - FIRE AND EXPLOSION HAZARD DATA

-----------------------------------------------------------------------

FLASH POINT (CLOSED CUP:121 C (250 F) NFPA 704M RATING: 2-1-

FLAMMABLE LIMITS: UPPER - N/A % LOWER - N/A %

39

Page 40

FIRE EXTINGUISHING MEDIA

USE ALCOHOL FOAM, DRY CHEMICAL OR CARBON DIOXIDE.

(WATER MAY BE INEFFECTIVE.)

SPECIAL FIRE-FIGHTING PROCEDURES

FIREFIGHTERS SHOULD WEAR PROPER PROTECTIVE EQUIPMENT AND SELFCONTAINED BREATHING APPARATUS WITH FULL FACEPIECE OPERATED IN POSITIVE

PRESSURE MODE.

TOXIC GASES PRODUCED

CARBON MONOXIDE, CARBON DIOXIDE

-----------------------------------------------------------------------

5 - HEALTH HAZARD DATA

-----------------------------------------------------------------------

TOXICITY: LD50 (ORAL-RAT)(MG/KG) - 2350

LD50 (ORAL-MOUSE)(MG/KG) - 2370

LD50 (IPR-MOUSE)(MG/KG) - 1460

CARCINOGENICITY: NTP: NO IARC: NO Z LIST: NO OSHA REG: NO

EFFECTS OF OVEREXPOSURE DUST MAY IRRITATE OR BURN MUCOUS MEMBRANES.

CONTACT WITH SKIN OR EYES MAY CAUSE IRRITATION.

INGESTION MAY CAUSE GASTROINTESTINAL IRRITATION.

INGESTION MAY CAUSE NAUSEA AND VOMITING.

TARGET ORGANS

NONE IDENTIFIED

MEDICAL CONDITIONS GENERALLY AGGRAVATED BY EXPOSURE

NONE IDENTIFIED

ROUTES OF ENTRY

NONE INDICATED

EMERGENCY AND FIRST AID PROCEDURES

INGESTION:IF SWALLOWED AND THE PERSON IS CONSCIOUS, IMMEDIATELY GIVE

LARGE AMOUNTS OF WATER. GET MEDICAL ATTENTION.

INHALATION: IF A PERSON BREATHES IN LARGE AMOUNTS, MOVE THE

EXPOSED

PERSON TO FRESH AIR. GET MEDICAL ATTENTION.

EYE CONTACT: IMMEDIATELY FLUSH WITH PLENTY OF WATER FOR AT LEAST 15

MINUTES. GET MEDICAL ATTENTION.

SKIN CONTACT: IMMEDIATELY WASH WITH PLENTY OF SOAP AND WATER FOR AT

LEAST 15 MINUTES.

-----------------------------------------------------------------------

6 - REACTIVITY DATA

-----------------------------------------------------------------------

STABILITY: STABLE HAZARDOUS POLYMERIZATION: WILL NOT OCCUR

CONDITIONS TO AVOID: HEAT, FLAME, OTHER SOURCES OF IGNITION,

MOISTURE

INCOMPATIBLES: STRONG BASES, STRONG OXIDIZING AGENTS, ALKALIES

DECOMPOSITION PRODUCTS: CARBON MONOXIDE, CARBON DIOXIDE

40

Page 41

-----------------------------------------------------------------------

7 - SPILL AND DISPOSAL PROCEDURES

-----------------------------------------------------------------------

STEPS TO BE TAKEN IN THE EVENT OF A SPILL OR DISCHARGE

WEAR SUITABLE PROTECTIVE CLOTHING. CAREFULLY SWEEP UP AND REMOVE.

DISPOSAL PROCEDURE

DISPOSE IN ACCORDANCE WITH ALL APPLICABLE FEDERAL, STATE, AND LOCAL

ENVIRONMENTAL REGULATIONS.

-----------------------------------------------------------------------

8 - PROTECTIVE EQUIPMENT

----------------------------------------------------------------------VENTILATION: USE ADEQUATE GENERAL OR LOCAL EXHAUST

VENTILATION TO KEEP FUME OR DUST LEVELS AS LOW AS

POSSIBLE.

RESPIRATORY PROTECTION: NONE REQUIRED WHERE ADEQUATE VENTILATION

CONDITIONS EXIST. IF AIRBORNE CONCENTRATION

IS HIGH, USE AN APPROPRIATE RESPIRATOR OR DUST

MASK.

EYE/SKIN PROTECTION: SAFETY GLASSES WITH SIDESHIELDS, RUBBER GLOVES

ARE RECOMMENDED.

-----------------------------------------------------------------------

9 - STORAGE AND HANDLING PRECAUTIONS

----------------------------------------------------------------------SAF-T-DATA(TM) STORAGE COLOR CODE: ORANGE (GENERAL STORAGE)

SPECIAL PRECAUTIONS

KEEP CONTAINER TIGHTLY CLOSED. SUITABLE FOR ANY GENERAL CHEMICAL

STORAGE AREA.

-----------------------------------------------------------------------

10 - TRANSPORTATION DATA AND ADDITIONAL INFORMATION

----------------------------------------------------------------------DOMESTIC (D.O.T.)

PROPER SHIPPING NAME BENZOIC ACID

HAZARD CLASS ORM-E

UN/NA NA9094

LABELS NONE

REPORTABLE QUANTITY 5000 LBS.

INTERNATIONAL (I.M.O.)

PROPER SHIPPING NAME CHEMICALS, N.O.S. (NON-REGULATED)

Revision 2-20-03

41

Loading...

Loading...