Page 1

653M

Supplemental Instructions for the 1108V and 1108VCL

Oxygen Combustion Vessel for Vacuum Applications

Overview

These instructions act as a supplement to the 205M

to cover the procedures to be followed when using a

Parr 1108V Oxygen Combustion Vessel to determine

calorifi c values of solid or liquid combustible material in a Parr calorimeter, or when using an 1108V

vessel in a 1901 Oxygen Vessel Apparatus to prepare solid or liquid samples for chemical analysis.

The user should study these instructions carefully

in order to obtain a complete understanding of the

capabilities and limitations of an 1108V Vessel, and to

be well aware of the precautions to be observed in

its operation.

Adapted for Vacuum Applications

The 1108V differs from a standard 1108 oxygen combustion vessel in that the self-sealing check valve

has been replaced by a manual valve. This provides

a way to seal the vessel with a vacuum or low pressure in the vessel.

The following instructions take the place of Filling

the Vessel in the 205M 1108 Oxygen Combustion Vessel Operating Instruction Manual.

Evacuating the vessel

The instructions below describe a general procedure

for establishing a vacuum inside the vessel.

Attach the A233A2 Snap Coupling Assembly to the

vacuum pump. Slide the snap coupling assembly

over the gas inlet fi tting on the vessel head. Close

the outlet valve on the vessel head and open the

A344A2 valve needle.

Follow the instruction for the vacuum pump until the

desired pressure is obtained.

Close the A344A2 valve needle and remove any pressure or vacuum from the snap coupling assembly.

Remove the A233A2 Snap Coupling Assembly.

(Ref. 205M)

The instructions below describe a general procedure

on how to fi ll the 1108V with positive pressure based

on the 1824 Oxygen Filling Connection. Other fi lling

methods may vary.

Gas for the vessel can be drawn from commercial

tanks. Unscrew the protective cap from the tank and

inspect the threads on the valve outlet to be sure

they are clean and in good condition. Place the end

of the fi lling connection into the tank outlet and draw

up the connection tightly with a wrench.

The pressure connection to the vessel is made with

the A233A2 Snap Coupling Assembly attached to the

fi lling tubing which slides over the gas inlet fi tting on

the vessel head. Slide the snap coupling assembly

onto the inlet valve and push it down as far as it will

go. If it does not slide easily, a drop of water spread

around the inlet valve will lubricate the sealing rings.

Close the outlet valve on the vessel head. Using

a 5/16” open end wrench, open the A344A2 Valve

Needle. Make sure that the fi lling connection control valve is closed. Then open or ‘crack’ the gas

tank valve not more than one quarter turn. Open

the fi lling connection control valve slowly and watch

the gage as the vessel pressure rises to the desired

fi lling pressure (never more than 40 atm.); then close

the control valve. Close the A344A2 Valve Needle.

Release the residual pressure in the fi lling hose by

pushing downward on the lever attached to the relief

valve. The gage should now return to zero. If the

pressure drops slowly and a large amount of gas

escapes when the pressure relief valve is opened the

A344A2 valve in the head is not closed properly.

If too much pressure should be accidently be introduced into the vessel, DO NOT proceed with the

combustion. Detach the fi lling connection; exhaust

the vessel; remove the head and reweigh the sample

before repeating the fi lling operation.

Filling the Vessel with Gas

While the main use of an 1108V is to test self-oxidizing samples in a vacuum it can also easily be used

for positive pressure applications.

For testing samples in an inert atmosphere generally

5 atm of nitrogen or argon is suffi cient.

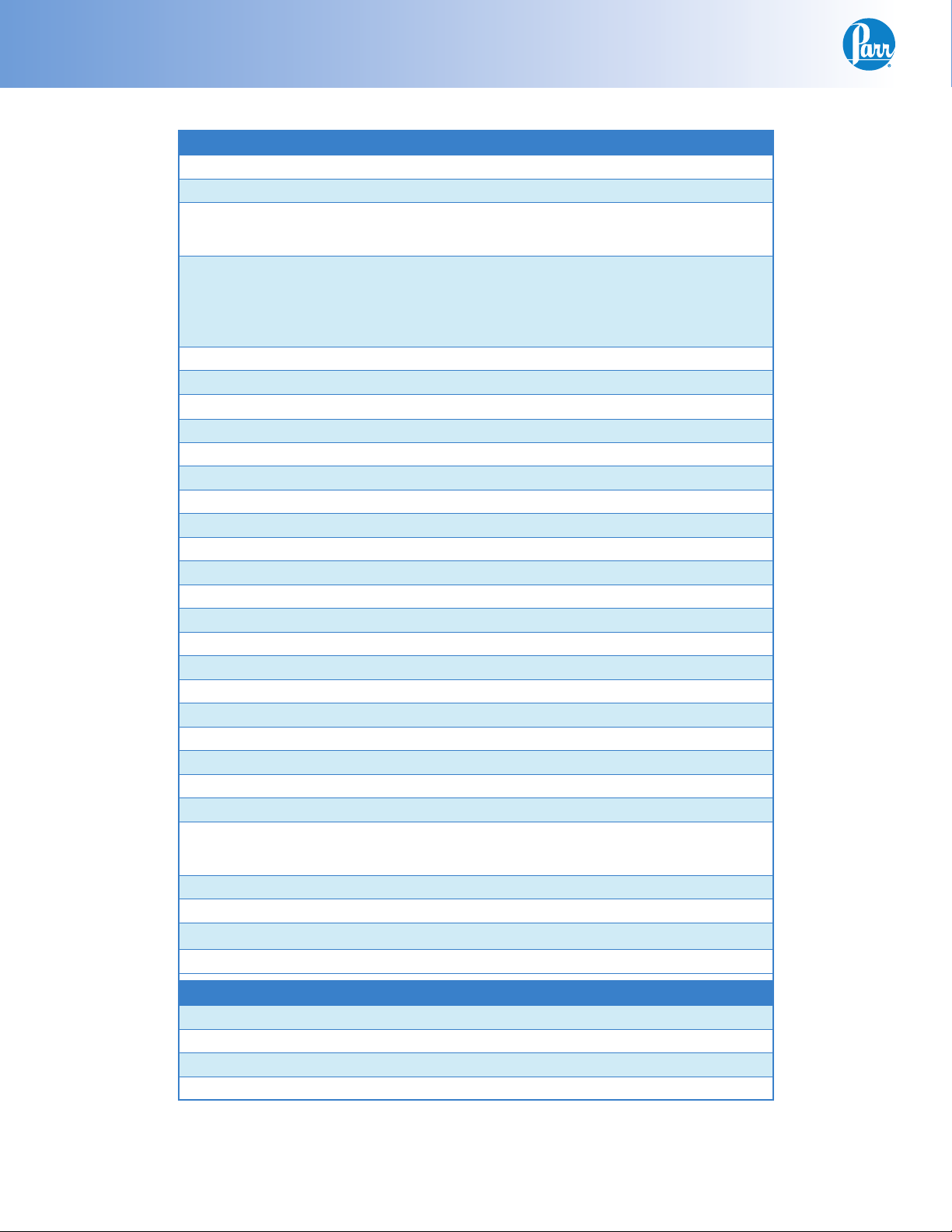

Drawings and Diagrams

1108V Parts Diagram Key, Parts for the 1108V Oxygen

Vessel, and Parts for the 1824 Oxygen Filling Connection Diagram replace the 1108 Parts Diagram Key,

Parts for the 1108 Oxygen Vessel, and Parts for the

1825 Oxygen Filling Connection respectively.

Page 2

1108V Oxygen Combustion Vessel

Key Item Description

1 103A Screw Cap

2 230A O-ring 2-3/8 ID Buna-N

3 394A12

1108V Parts Diagram Key*

Vessel Head, Bare

394A12CL

4 A101A

A101ACL

5 SC1332SC02 Set Screw

6 463A Needle Plug

7 344A2 Valve Needle

8 378A Packing Cup

9 411A Terminal Nut

10 143AC Insulator Delrin

11 238A O-ring 3/16 ID Buna-N

12 388A Spacer

13 SC1932SC10 Socket Head Set Screw

14 278A3 Adapter Bushing

15 404A2 Defl ector Nut

16 406A Lock Nut

17 5A10 Loop Electrode with Sleeve

18 4A10 Straight Electrode with Sleeve

19 401A Sleeve Insulator

20 96AC Electrode Insulator

21 402A Electrode Core

22 406A Lock Nut

23 407A Valve Knob

24 398A Lock Nut

25 400A

Vessel Head for Chlorine Service

Vessel Cylinder sold only with 103A Screw Cap as Part

No. AA101A

Vessel Cylinder for Chlorine Service sold only with 103A

Screw Cap as Part No. AA101ACL

Valve Needle

A420A

26 397A Compression Nut

27 396A Outlet Valve Body

28 7VBCM Washer Monel

29 20VB Valve Seat Kel-F

Valve Needle with Knob (Nos. 23, 24, 25)

Item Complete Assemblies

AA101A Vessel Cylinder with 103A Screw Cap

AA101ACL Vessel Cylinder for Chlorine Service with 103A Screw Cap

A416A3V Vessel Head Assembly

A416A3VCL Vessel Head Assembly for Chlorine Service

*1108V Parts Diagram Key and Parts for the 1108V Oxygen Vessel replace the 1108 Parts Diagram Key and

Parts for the 1108 Oxygen Vessel sections found in the 205M on pages 14-15.

2

Parr Instrument Company

Page 3

1108V Oxygen Combustion Vessel

Parts for the 1108V Oxygen Vessel*

www.parrinst.com

3

Page 4

1108V Oxygen Combustion Vessel

Parts for the 1824 Oxygen Filling Connection*

Item Description

4VB3 Packing gasket

6VBBB Packing cover, brass

8VB2 Packing nut

9VB1 Union nut, brass, CGA540

20VB Valve seat, PCTFE

21VBBB Lantern ring, brass

53A Oxygen gage, 3-1/2”, 0-60 atm

112VB4AK Valve needle

124VB Union nipple, brass, CGA540

A140VB Toggle relief valve

A150VB Valve knob

188A2 Filling connection body, bare

243VB Tube connector, male

438VB Elbow connector, 45°, male

A233A2 Snap coupling assembly

357HC O-ring for A223A2 Snap coupling assembly (2 required)

HX0012TB024 Pressure tubing, 1/8” OD, Nylon, 5-ft

*Parts for the 1824 Oxygen Filling Connection replaces Parts for the 1825 Oxygen Filling Connection

found in the 205M on page 17.

P

arr Instrument Company

211 53rd Street • Moline, Illinois 61265 USA 1-309-762-7716 • 1-800-872-7720 • Fax: 1-309-762-9453

Revision 04/09/13

E-mail: parr@parrinst.com • http://www.parrinst.com

Loading...

Loading...