Page 1

1104

Oxygen Combustion Vessel

Operating Instruction Manual

209M

Page 2

1104 Oxygen Combustion Vessel

Table of Contents

Preface

Scope — 3

Related Instructions — 3

Purpose — 3

Description — 3

Accessories and Utilities — 3

Sample Preparation

— 3

Operation

Setting the Calorimeter Parameters — 4

Preparing the Fuse When the Combustion Cage is

Used — 5

Preparing the Fuse When the Combustion Cage is

Not Used — 5

Closing the Bomb — 6

Filling the Bomb Using a Calorimeter — 6

Filling the Bomb Manually — 7

Maintenance

— 7

Parts List

— 8

Drawings

1104 Oxygen Combustion Vessel — 9

1104 Oxygen Combustion Vessel - Head Assembly

— 10

Oxygen Filling Connection for the 1104 Oxygen

Combustion Vessel — 11

Note About Nomenclature:

Historically, burning a sample enclosed in a

high pressure oxygen environment is known

as Oxygen Bomb Calorimetry and the vessel

containing the sample is known as an Oxygen

Bomb. The terms bomb and vessel are used

interchangeably.

Customer Service

Questions concerning the installation or operation of this instrument

can be answered by the Parr Customer Service Department:

1-309-762-7716 • 1-800-872-7720 • Fax: 1-309-762-9453

E-mail: parr@parrinst.com • http://www.parrinst.com

2

Parr Instrument Company

Page 3

1104 Oxygen Combustion Vessel

Preface

Scope

These instructions cover the procedures to be fol-

lowed when using a Parr 1104 Oxygen Combustion

Vessel (or bomb) to determine caloric values of

solid or liquid combustible material in a Parr calorimeter. The user should study these instructions

carefully in order to obtain a complete understanding of the capabilities and limitations of an 1104

Oxygen Combustion Vessel, and to be well aware

of the precautions to be observed in its operation.

Calorimeter operations and the operation of various

oxygen vessel accessories are described in separate

instruction manuals listed below, copies of which

are available upon request.

Related Instructions

The following Parr publications are also included to

further your understanding of this instrument and

its component parts:

No. Description

201M Limited Warranty

205M Operating Instructions for the 1108 Oxy-

gen Combustion Vessel

207M Analytical Methods for Oxygen Bombs

230M Safety Precautions to be observed when

operating Pressure Reaction Equipment

483M Introduction to Bomb Calorimetry

Purpose

The Parr 1104 Oxygen Combustion Vessel is designed for combustion tests of explosives and other

fast burning, high-energy samples that burn with

extreme violence. The bomb is also recommended

for use with materials whose combustion characteristics are unknown or unpredictable. These instructions will provide the user with guidelines for the

safe operation and maintenance of the vessel. These

instructions must be supplemented with manual

205M, Operating Instructions for the 1108 Oxygen

Combustion Vessel, which contains information con-

cerning sample preparation and other application

information relevant to both vessel types.

Description

The 1104 Oxygen Combustion Vessel is a heavywalled, 240 mL vessel. It will handle samples liberat-

ing up to 12,000 calories using an oxygen charging

pressure up to 45 atm (665 psig). The sample is

contained in a combustion cage that is designed

to mufe the shock forces produced by explosive

samples. The capsule is anchored to the cage so the

explosion will not dislodge it.

Accessories and Utilities

• A minimum 99.5% purity oxygen source

providing 420 psig (3 Mpa) of pressure to the

bomb is required.

• To ignite the sample, 10 cm of NiCr fuse wire

(P/N 45C10) per test is needed.

Sample Preparation

Samples to be burned in the 1104 Oxygen Combustion Vessel are held in a thick-walled capsule (P/N

217A) within a heavy combustion cage that serves

to muffle the shock forces produced by high-energy

samples. While the combustion cage is essential

for fast burning, high-energy samples, it may not

be necessary to use the cage when testing samples

which do not burn violently. In some cases it may be

easier to secure complete combustion by substitut-

ing a lighter capsule (P/N 43AS) and omitting the

combustion cage. This substitution is described in

the Operation section of these instructions.

Manual 205M, Operating Instructions for the 1108

Oxygen Combustion Vessel, contains valuable infor-

mation concerning sample preparation. As a basic

rule, the 1104 Oxygen Combustion Vessel should

never be charged with a sample that will liberate

more than 12,000 calories when burned in oxygen.

Additionally, the oxygen charging pressure should

never exceed 45 atm (665 psig). Samples of smoke-

less powder weighing up to 4 grams have been

burned in this bomb, but the requirements for safe

operation vary so widely with different materials

that it is difcult to make general statements regarding allowable sample size. It is strongly recommended that the user make preliminary combustions with

small samples, then increase the sample size and

vary the oxygen pressure carefully to determine the

optimum charge.

Note: Although the high-strength of the bomb

is reassuring when working with fast burning or

explosive materials, the operator must ALWAYS

remember that he is dealing with extreme pressure and shock forces that require the exercise

of good judgment at all times.

www.parrinst.com

3

Page 4

1104 Oxygen Combustion Vessel

Sample Preparation (continued)

It is not advisable to test true explosives in the

presence of oxygen. Some of the end products of

the explosion will be combustible in high-pressure

oxygen, for example, mixed oxides of nitrogen and

carbon monoxide. With high-pressure oxygen available, these will burn to carbon dioxide and release

an undeterminable amount of heat that did not

come from the initial reaction of interest. This secondary combustion might give off nearly as much

energy as the preliminary explosion. To eliminate

this concern, it is recommended that the user ll the

bomb with nitrogen and then release the valve to

ush the vessel, repeating this process twice. This

will reduce the atmospheric oxygen trapped in the

bomb to a level that is insignicant, relative to the

primary reaction. It is advisable to leave a residual

pressure of at least 5 atmospheres on the bomb in

order to seal the inlet check valve.

Operation

Setting the Calorimeter Parameters

When using the 1104 Oxygen Combustion Vessel in

a calorimeter, the user must ensure that the correct

User ID is set in order to obtain the appropriate operating parameters. For the 6200 Isoperibol Calo-

rimeter, the User ID must be “62-1104”. For the 6100

Compensated Jacket Calorimeter, the User ID must

be “61-1104”.

1. From the Main Menu in the 6000 Series calorim-

eter, select “Program Info & Control”

2. From Program Info & Control, select “User Setup

ID”

3. Press “Clear”

4. Enter “62-1104” (or “61-1104”)

5. Press “Enter”

6. Press “Reload User Default Settings” and follow

the instrument prompts

For older models, please contact Parr for the appropriate software.

Bomb Head Assembly

4

Parr Instrument Company

Page 5

1104 Oxygen Combustion Vessel

Preparing the Fuse When the Combustion

Cage is Used

Set the bomb head on the support stand (P/N A38A)

and attach one end of a 10 cm length of fuse wire to

the hook on the straight electrode.

Run the wire through the slot in the cage, then up

through one of the holes in the top plate. Anchor

the free end under the head of one of the nearby

screws. Form the wire into a loop that will dip down

to the combustion capsule and check the position of

the wire to be sure that it does not touch the cage

at any point except the anchorage under the screw

head.

Capsule Support Loop

Set the capsule with its weighed sample in the bottom of the cage. Tighten the retaining screws to hold

the capsule rmly in place. Finally, bend the fuse

wire downward toward the surface of the charge.

Preparing the Fuse When the Combustion

Cage is Not Used

To replace the sample cage with the sample capsule,

unscrew the cage assembly from the bomb head

and replace it with a loop electrode (P/N 5A3). Use a

bushing (P/N 234A) in the bomb head and a lock nut

(P/N 235A) to anchor the electrode.

www.parrinst.com

5

Page 6

1104 Oxygen Combustion Vessel

Preparing the Fuse When the Combustion

Cage is Not Used (Continued)

Set the bomb head on the support stand (P/N A38A)

and attach one end of a 10 cm length of fuse wire

between the two electrodes.

Fasten one end of the wire to the loop electrode

(steps a thru d) then attach the other end to the

straight electrode (steps e thru h). Pull the loop

downward to tighten the connections then bend the

wire upward (step i). Place the capsule in the loop

holder and bend the wire down to the sample (step

j).

Note: Do not submerge the wire in liquid or

powder samples; better combustion will be obtained if the loop of the fuse is set slightly above

the surface. When using a sample that has been

pressed into a pellet, bend the wire so that the

loop is positioned about a centimeter above the

sample.

Closing the Bomb

Close the 1104 Oxygen Combustion Vessel by sliding the head into the cylinder and pushing it gently

until the head is pressed against the inside ledge

of the cylinder. Conrm that the compression ring

(P/N 212A2) is in place above the head. Ensure that

all the compression screws in the screw cap do not

protrude through the underside of the cap. Attach

the screw cap and turn it down by hand as far as it

will go. Progressively tighten the circle of compres-

sion screws in a star pattern until each bears rmly

against the compression ring.

Note: Do not use the spanner wrench (P/N 219A)

to seal the bomb. Extreme force is not required

when tightening the cap. It is important that the

screws be tightened uniformly so that the closing forces are evenly distributed.

Filling the Bomb Using a Calorimeter

The oxygen inlet connection on the 1104 Oxygen

Combustion Vessel differs from the connection used

on the 1108 Oxygen Combustion Vessel in that it is

Attaching Fuse Wire with Loop Electrode

6

Parr Instrument Company

Page 7

1104 Oxygen Combustion Vessel

threaded on instead of pushed on to the inlet valve.

The correct assembly to use when lling the 1104

from a calorimeter is P/N A19A15. Close the outlet

valve on the bomb head. Thread the end of the ll

connection on to the inlet valve of the 1104. Press

“O2 Fill” on the calorimeter to ll the vessel.

Filling the Bomb Manually

To ll the vessel directly the 1823 Oxygen Fill Connection must be used. Close the outlet valve on the

bomb head. Open the oxygen tank valve not more

than a quarter turn. Open the control valve on the

ll connection slowly and watch the bomb pressure rise to the desired lling pressure. Close the

control valve on the ll connection. The inlet check

valve will close automatically when the residual

pressure in the lling hose is released; leaving the

bomb lled to the highest pressure indicated on

the gage. Release the residual pressure in the ll-

ing hose by pushing downward on the toggle relief

lever attached to the ll connection. The gage should

now drop to zero. If the pressure drops slowly and

a large amount of gas escapes when the pressure

relief valve is opened, the check valve in the bomb

head is not operating properly. This trouble will have

to be corrected before the bomb can be used.

If too much oxygen should accidentally be introduced into the bomb, do not proceed with the

combustion. Detach the lling connection, exhaust

the bomb, remove the head and reweigh the sample

before repeating the lling operation.

When using the bomb in a calorimeter, insert the

lifting handle into the two holes in the side of the

screw cap and lower the bomb partially into the

calorimeter water bucket. Note that the bucket

should be lled with 1850 mL of water. Press the

banana plugs on the two ignition wires rmly into

the terminal sockets on the bomb head before the

head is immersed in the water. After connecting the

wires lower the bomb into the bucket. Remove the

lifting handle and shake off any drops of water back

into the bucket. The calorimeter should be standardized using an amount of Benzoic Acid that releases

approximately the same amount of energy as the

sample to be tested. An approximate EE value for

the 1104 in the 6000 Series instruments is 2500

cal/°C.

When using the bomb alone, it must be connected

to an ignition unit (P/N 2901). Always place the 1104

Oxygen Combustion Vessel behind a heavy shield

or barricade and completely submerge the bomb in

cold running water while ring. If the sample develops an unusually large amount of heat, it is recom-

mended that a cold stream of water be run against

the bomb to facilitate cooling.

Note: Do not fire the bomb at any point if there

is gas leakage.

The bomb must remain in the water bath until all

parts of the head and screw cap come to temperature equilibrium. Then remove the bomb from the

bath, wipe it with a clean towel and release the

residual gases through the needle valve before

unscrewing the compression screws and removing

the cap. If necessary, a spanner wrench (P/N 219A) is

provided to remove the screw cap of the vessel.

Maintenance

The chromium plated, steel alloy screw cap on the

bomb requires special care to keep the threads

from rusting and to prevent seizure. Always dry the

cap thoroughly after it has been used and store the

bomb with the screw cap removed from the cylin-

der. Keep a light coating of anti-seize lubricant (P/N

424HC2) on the threads of the cap but do not use

this or any lubricant on any other parts of the bomb.

Basic maintenance of the bomb including replacing

the O-ring, insulators, gaskets and spacers is recommended every 500 rings. If the bomb is used for

samples that contain a high amount of corrosive

materials, this maintenance should be completed

after every 250 rings.

Parr provides Oxygen Bomb repair services for the

1104 (P/N REPAIR.O7). A factory test is recommended after 5000 rings. This includes replacing all of

the seals, checking the dimensions of the cylinder,

screw cap and head, hydrostatically testing the seals

and proof ring the vessel using benzoic acid.

When returning a bomb to the factory, ship it to:

Parr Instrument Company

Attn: Repair Department

211 53rd Street

Moline, IL 61265-1720

Include a Purchase Order to cover the cost of the

repair, a person to contact (complete with a phone

number) and return shipping information. Individual

repair parts can be ordered from any Parr dealer or

directly from Parr.

www.parrinst.com

7

Page 8

1104 Oxygen Combustion Vessel

Parts List

1104 Oxygen Combustion Vessel Accessories

Part No. Description Part No. Description

A206A5 Head Assembly w/ Cage 424HC2 Anti-Seize Lubricant

A208A Screw Cap A19A15 Fill Connection

A207A Cylinder w/ Screw Cap 45C10 Fuse Wire, 10 cm

212A2 Compression Ring 219A Spanner Wrench

A206A6 Head Assembly w/ Loop TX18SK Socket Screw Key, 3/16

208AF Cap Screws 3415 1g Benzoic Acid pellets

56A Gasket for A19A15

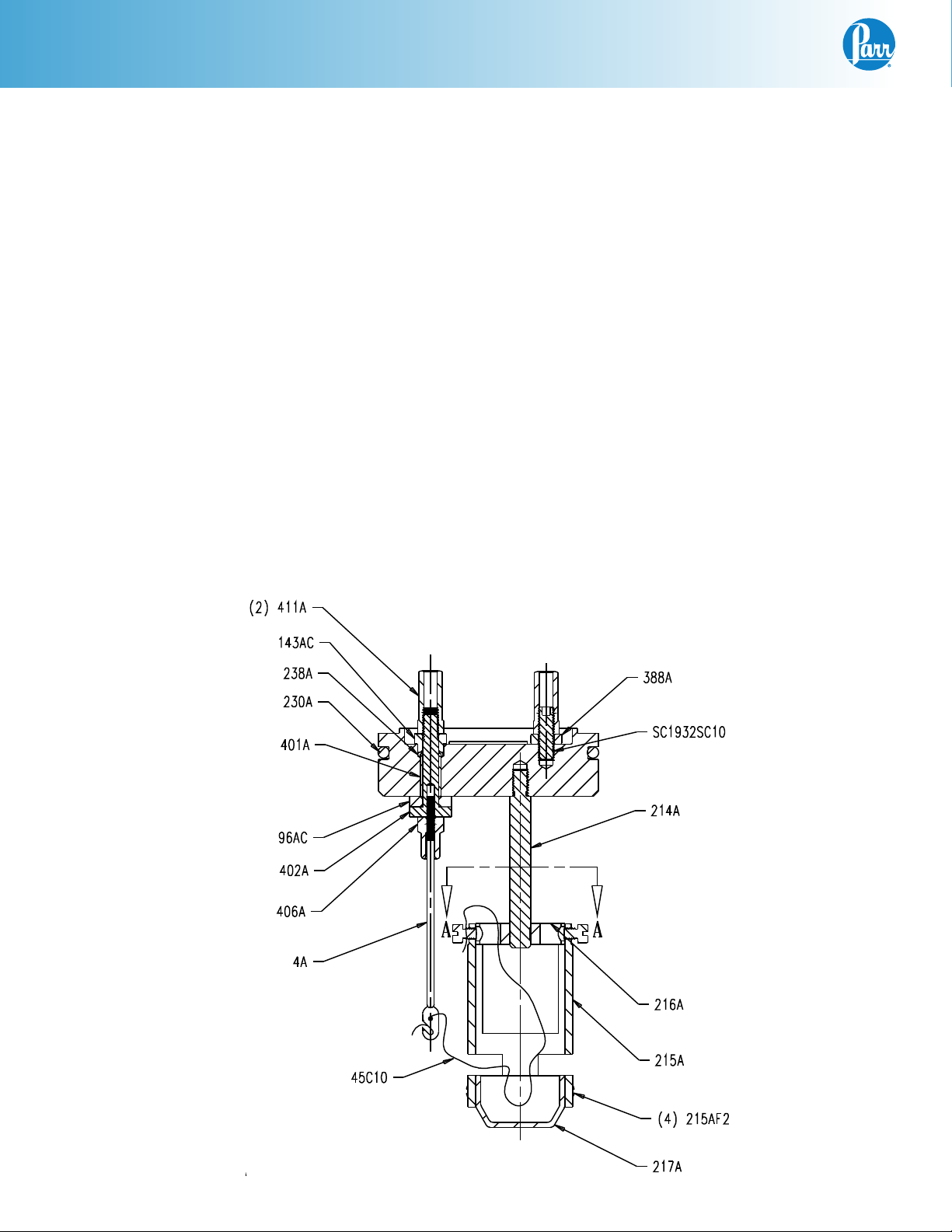

Head Assembly (Electrodes) Head Assembly (Valves)

Part No. Description Part No. Description

411A Terminal Nut

143AC Insulator 83A Valve Nut

238A O-Ring Gasket 209A Inlet Valve Body

230A Sealing Ring 13A2 Nut

401A Sleeve Insulator 84A3 Valve Spring

96AC Ceramic Washer 238A O-Ring Gasket

402A Electrode Core 109A Gasket

406A Lock Nut A11A2 Valve Stem

4A Straight Electrode 211A Valve Cover

388A Spacer

SC1932SC10 Socket Head Set Screw

Cage

214A Rod, Cage Support 397A Compression Nut

216A Disc, Cage Support 396A Outlet Valve Body

215AF1 Screw, Long 7VBCM Washer, Monel

215A Cage Tube 238A O-Ring Gasket

215AF2 Screw, Short 378A Packing Cup

217A Combustion Capsule, Heavy 20VB Valve Seat, Kel F

Loop Electrode

234A Bushing for 5A3 206A5 Bomb Head

235A Lock Nut 210A2 Outlet Valve Body

5A3 Loop Electrode 211A Valve Cover

43AS Capsule, SS

Gas Fill - Check Valve

Gas Release - Needle Valve

A420A Valve Needle

109A Gasket

8

Parr Instrument Company

Page 9

Drawings

1104 Oxygen Combustion Vessel

1104 Oxygen Combustion Vessel

212A2 REF

COMPRESSION RING

A206A5

HEAD ASSEMBLY

A208A

SCREW CAP REF

207A CYLINDER

www.parrinst.com

9

Page 10

1104 Oxygen Combustion Vessel

1104 Oxygen Combustion Vessel - Head Assembly

10

Parr Instrument Company

Page 11

1104 Oxygen Combustion Vessel

Oxygen Filling Connection for the 1104 Oxygen Combustion Vessel

www.parrinst.com

11

Page 12

Revision 04/04/13

Loading...

Loading...