Parkside PNTS 250 C2 Translation Of The Original Instructions

WET & DRY BENCH GRINDER PNTS 250 C2

WET & DRY BENCH GRINDER

Translation of the original instructions

IAN 321438_1901

NASS-/TROCKENSCHLEIFER

Originalbetriebsanleitung

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions

of the device.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit

allen Funktionen des Gerätes vertraut.

GB / IE /NI Translation of the original instructions Page X5

DE / AT / CH Originalbetriebsanleitung Seite 21

max. 2 mm

13

7 6

14 15

1

32

4

5

4

78911 1012 6

3

16

5

6

17 212018 19

13

10

13

22

11

9

5

25

23 24

5

24

23

22

4

GB

IE

NI

Content

Introduction .................................5

Intended use ................................ 5

General description ...................... 6

Scope of delivery .............................. 6

Function description ...........................6

Summary ......................................... 6

Technical specications ................. 7

Safety Instructions........................7

Symbols and icons ............................ 7

General safety instructions.................. 8

Further Safety Instructions ................. 10

Residual risks .................................. 11

Assembly ................................... 11

Assemble/set workpiece suppor ts ..... 12

Assemble/adjust spark protection ..... 12

Screw device on to workbench ......... 12

Fill water into the water tank ............. 12

Operation .................................. 12

Switching on and off ....................... 13

Grinding with the dry grinding disc ... 13

Grinding with the wet grinding disc .. 13

Change grinding disc ...................... 14

Cleaning and maintenance ......... 15

Cleaning ........................................ 16

General maintenance ...................... 16

Storage ......................................16

Waste disposal and

environmental protection ...........16

Replacement parts/accessories ... 17

Trouble Shooting ........................ 18

Guarantee .................................19

Repair Service ............................ 20

Service-Center ............................ 20

Importer .................................... 20

Translation of the original

EC declaration of conformity ......38

Exploded Drawing ..................... 41

Introduction

Congratulations on the purchase of your

new device. With it, you have chosen a

high quality product.

During production, this equipment has

been checked for quality and subjected to

a nal inspection. The functionality of your

equipment is therefore guaranteed.

The operating instructions constitute

part of this product. They contain

important information on safety, use

and disposal. Before using the product, familiarise yourself with all of

the operating and safety instructions.

Use the product only as described

and for the applications specied.

Keep this manual safely and in the

event that the product is passed on,

hand over all documents to the third

party.

Intended use

The wet/dry grinder is suitable for sharpening tools (e.g. knives, scissors, chisels),

and deburring and grinding smaller metal

workpieces.

The device is not intended for all other

types of applications (e.g. grinding with

unsuitable grinding tools, grinding with a

coolant solution, grinding hazardous materials such as asbestos).

The equipment is intended for use in the

eld of DIY. It is not designed for commer-

cial use.

The equipment is designed for use by

adults. Young people under the age of 16

are permitted to use the equipment only

under supervision. The manufacturer shall

not be liable for damages caused by use

other than for the intended purpose or by

incorrect operation.

5

GB

IE

NI

General description

The illustrations can be found

on the front and rear fold-out

pages.

Scope of delivery

Unpack the equipment and check that it is

complete. Dispose of the packaging material correctly.

• Device with pre-assembled grinding

discs

• Spark protection

• Assembly material for mounting the

spark protection on the machine

- adjusting screw incl. washer and

snap ring, nut

• Workpiece support

• Assembly material for mounting the

workpiece support on the machine

- star grip nut, washer, lock washer

and screw

• Rubber cap for water tank

• Instruction Manual

Function description

The wet/dry grinder is a combined device

that is equipped with a dry grinding disc

and a wet grinding disc with different

grain sizes for coarse and ne grinding.

The device is provided with a spark protec-

tion and protective hoods for the protection

of the user.

For the function of the operating parts,

please refer to the descriptions below.

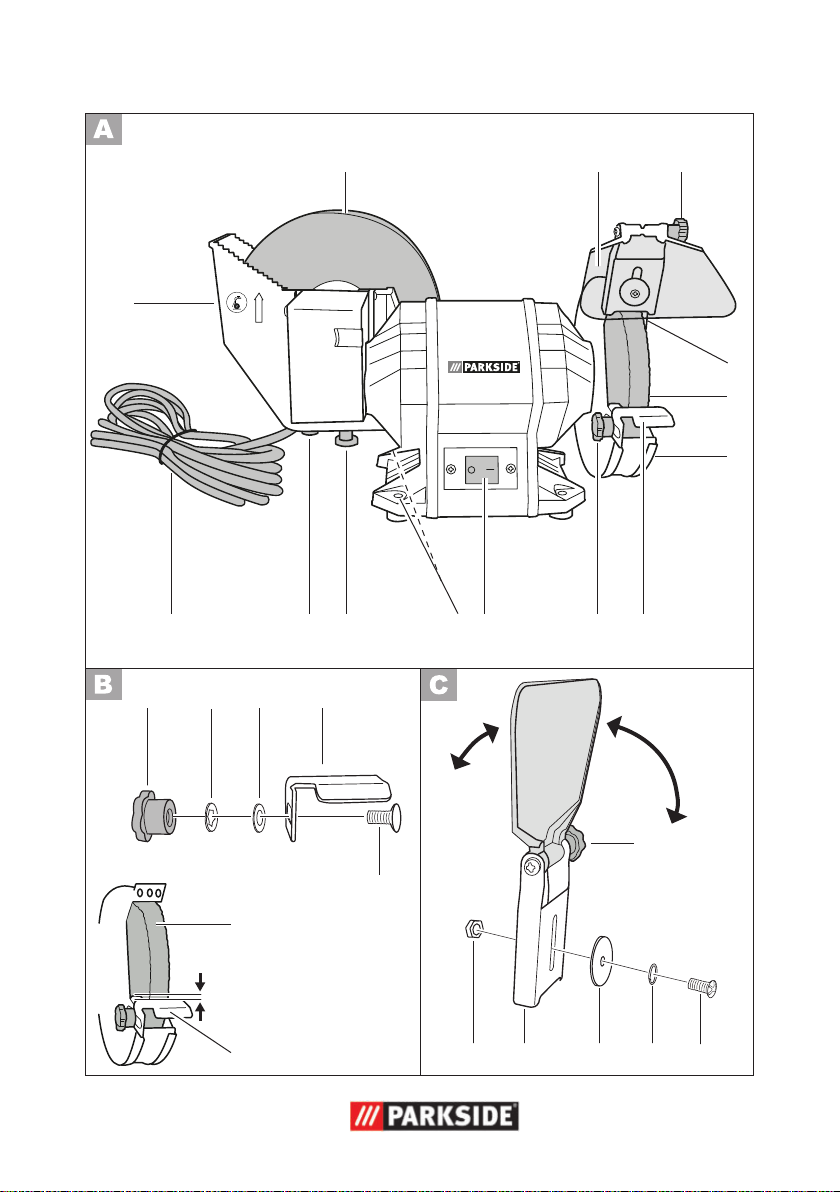

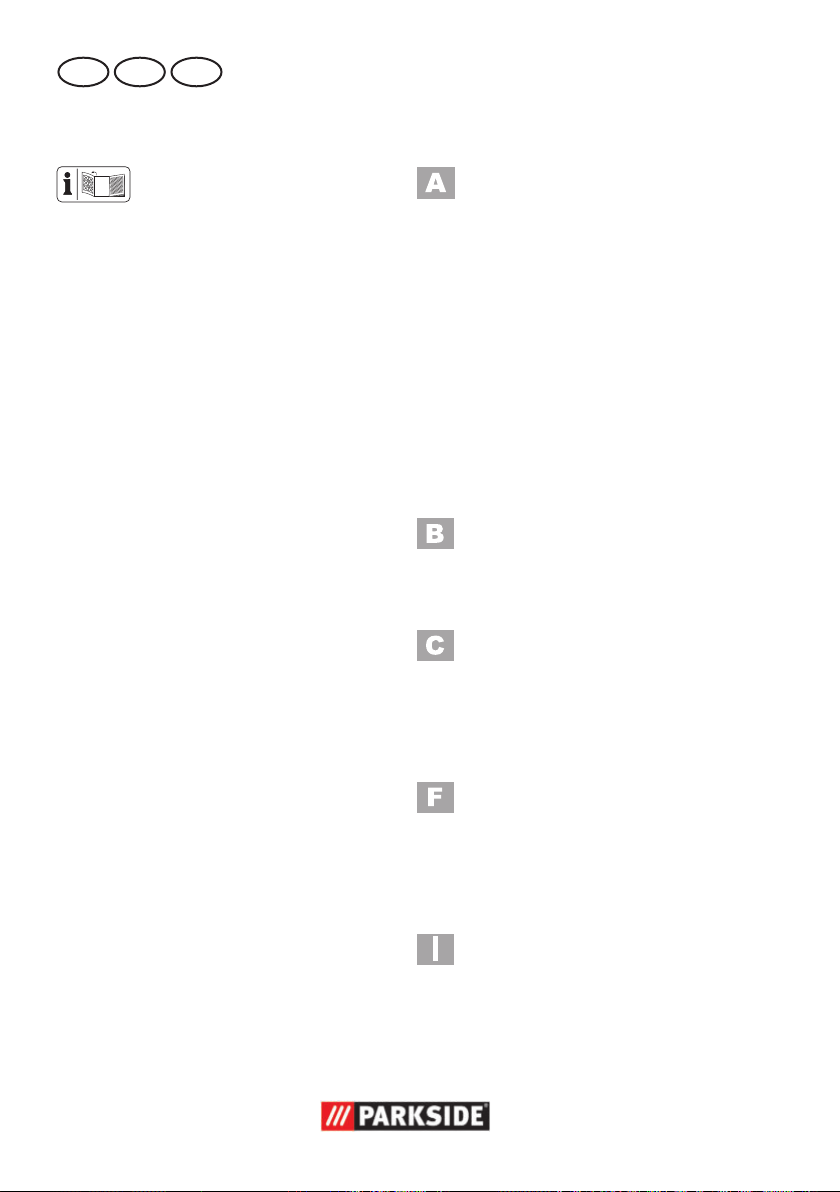

Summary

1 Wet grinding disc

2 Spark protection

3 Adjusting screw nut for spark

protection

4 Dry grinding disc cover

5 Dry grinding disc

6 Workpiece support

7 Star grip nut to mount/adjust the

workpiece support

8 On/off switch

9 Drillholes for table mounting

10 Rubber foot (water tank)

11 Rubber cap for water tank

12 Power cable

13 Water tank

14 Lock washer

15 Washer

16 Mounting screw for workpiece

support

17 Nut

18 Spark protection holder

19 Washer

20 Spring ring

21 Adjusting screw for spark protec-

tion fastener

22 Grinding disc nut

23 Clamping ange

24 Intermediate layers made of

cardboard

25 Protective hood for dry grinding

disc

26 Clamping ange made of plastic

27 Clamping ange made of plastic

28 Gear unit housing

29 Washer

6

GB

IE

NI

Technical specications

Wet & Dry Bench Grinder .....PNTS 250 C2

Nominal input voltage U ...230 V~, 50 Hz

Power consumption P ................... 250 W

(S2 30 min)*

Safety class .......................................... I

Mechanical rating ............................IPX0

Idling speed n

wet grinding disc ...... approx. 128 min

dry grinding disc .... approx. 2950 min

Weight (incl. accessories) .. approx. 8.6 kg

Sound pressure level

(LpA) ..................... 80 dB (A); KpA= 3 dB

Sound power level

(LWA) .................... 93 dB(A); KWA= 3 dB

Vibration total value (ah) .........

Wet grinding disc

Outer diameter ...................... Ø 200 mm

Bore hole ................................Ø 20 mm

Thickness ....................................40 mm

Grain size .........................................80

Speed n

Working speed vs ................ max. 40 m/s

Dry grinding disc

Outer diameter ...................... Ø 150 mm

Bore hole .............................Ø 12.7 mm

Thickness ....................................20 mm

Grain size .........................................36

Speed n

Working speed vs ................ max. 35 m/s

* A break is introduced after 30 minutes of

uninterrupted operating duration until the device temperature differs 2 K (2°C) less than

room temperature.

Noise and vibration values have been

determined according to the standards and

regulations mentioned in the declaration of

conformity.

0

2.5 m/s

............................ 3820 min

max

............................ 4500 min

max

-1

-1

-1

-1

The stated vibration emission value was

measured in accordance with a standard

testing procedure and may be used to compare one power tool to another.

The stated vibration emission value may

also be used for a preliminary exposure

assessment.

Warning!

The vibration emission value may

differ during actual use of the

power tool from the stated value

depending on the manner in which

the power tool is used.

Try to keep the exposure to vibrations as low as possible. Examples

2

of measures to reduce vibration

exposure are the wearing of gloves

when using the tool and limiting the

working hours. For this purpose all

parts of the operating cycle have to

be considered (for example, times

when the electric tool is switched

off and times when it is switched on

but running without any load).

Safety Instructions

Symbols and icons

Symbols in the manual:

Warning symbols with in-

formation on damage and

injury prevention.

Instruction symbols with information

on preventing damage.

Connect the machine to the power

supply..

Pull out the mains plug.

7

GB

IE

NI

Help symbols with information on

improving tool handling.

Symbols on the device:

Warning!

Risk of injury from the rotating tool!

Keep hands away.

Risk of electric shock! Disconnect

from the mains before carrying out

maintenance and repair work.

Read the instruction manual.

Wear ear protection.

Wear eye protection.

Wear breathing protection.

Wear cut-resistant gloves.

Use grinding disc only for dry

grinding.

Use grinding disc only for grinding

with water.

Do not dispose of electrical equip-

ment in household waste.

Other symbols on the discs:

Never use faulty grinding discs.

Graphical symbol on the packaging:

Corrugated cardboard

General safety instructions

WARNING!

When using power tools, observe

the following basic safety measures

for the prevention of electric shocks

and the risk of injury and re.

Please read all these instructions

before using the electric tools and

please keep the safety instructions.

The term “power tool” used in the safety instructions refers to mains-operated electric

tools (with a mains cable) and to batteryoperated electric tools (without a mains

cable).

Safe operation:

• Keep work area clear. Cluttered

areas and benches invite injuries.

• Consider work area environ-

ment.

- Do not expose tools to rain. Do not

use tools in damp or wet locations.

Water entering a power tool will increase the risk of electric shock.

- Keep work area well lit.

- Do not use tools in the presence of

ammable liquids or gases.

Power tools create sparks which may

ignite the dust or fumes.

• Guard against electric shock.

Avoid body contact with earthed or

grounded surfaces (e.g. pipes, radiators, ranges, refrigerators).

• Keep other persons away.

Do not let persons, especially children,

not involved in the work touch the tool

or the extension cord and keep them

away from the work area.

• Store idle tools. When not in use,

tools should be stored in a dry lockedup place, out of reach of children.

8

GB

IE

NI

• Do not force the tool. It will do

the job better and safer at the rate for

which it was intended.

• Use the right tool.

- Do not force small tools to do the job

of a heavy duty tool.

- Do not use tools for purposes not

intended; for example do not use circular saws to cut tree limbs or logs.

Use of the power tool for operations dif-

ferent from those intended could result

in a hazardous situation.

• Dress properly.

- Do not wear loose clothing or jewellery, they can be caught in moving

parts.

- Anti-slip footwear is recommended

when working outdoors.

- Wear protective hair covering to contain long hair.

• Use protective equipment.

- Use safety glasses.

- Use face or dust mask if working operations create dust.

• Connect dust extraction equip-

ment. If the tool is provided for the

connection of dust extraction and collecting equipment, ensure these are

connected and properly used.

• Do not abuse the cord. Never

yank the cord do disconnect it from the

socket. Keep the cord away from heat,

oil and sham edges.

• Secure work. Where possible use

clamps or a vice to hold the work. It is

safer than using your hand.

• Do not overreach. Keep proper foot-

ing and balance at all times.

This enables better control of the power

tool in unexpected situations.

• Maintain tools with care.

Many accidents are caused by poorly

maintained power tools.

- Keep cutting tools sharp and clean

for better and safer performance.

- Follow instruction for lubricating and

changing accessories.

- Inspect tool cords periodically and if

damaged have them repaired by an

authorized service facility.

- Inspect extension cords periodically

and replace if damaged.

- Keep handles dry, clean and free

from oil and grease.

• Disconnect tools. When not in use,

before servicing and when changing

accessories disconnect tools from the

power supply.

Such preventive safety measures reduce

the risk of starting the power tool acci-

dentaIly.

• Remove adjusting keys and

wrenches. Form the habit of checking

to see that keys and adjusting wrenches

are removed from the tool before turning it on. A wrench or a key left attached to a rotating part of the power

tool may result in personal injury.

• Avoid unintentional starting.

Ensure switch is in “off” position when

plugging in.

• Use outdoor extension leads.

When the tool is used outdoors, use

only extension cords intended for outdoor use and so marked.

• Stay alert, watch what you are

doing and use common sense

when operating a power tool.

Do not use a power tool while you are

tired or under the inuence of drugs,

alcohol or medication. A moment of

inattention white operating power tools

may result in serious personal injury.

• Check damaged parts.

This will ensure that the safety of the

power tool is maintained.

9

GB

IE

NI

- Before further use of tool, it should be

carefully checked to determine that it

will operate properly and perform its

intended function.

- Check for alignment of moving parts,

binding of moving parts, breakage of

parts, mounting and any other conditions that may affect its operation.

- A guard or other part that is damaged should be properly repaired or

replaced by an authorized service

centre unless otherwise indicated in

this instruction manual.

- Have defective switches replaced by

an authorized service centre.

- Do not use the tool if the switch does

not turn it on and off. There is a risk

of injury.

• Warning.

The use of any accessory or attachment

other than one recommended in this

instruction manual may present a risk of

personal injury.

• Have your tool repaired by a

qualied person. This electric tool

complies with the relevant safety rules.

Repairs should only be carried out by

qualied persons using original spare

parts, otherwise this may result in considerable danger to the user.

Further Safety Instructions

• Connect the device only to a power

point with a residual current protective

device (RCD) with a measured residual

current of not more than 30 mA.

• Keep the mains cable and extension

cable away from the grinding disc. In

the event that it is damaged or severed,

immediately disconnect the plug from

the socket.

Do not touch the cable before it has

been disconnected from the mains.

Risk of electric shock.

• The replacement of the plug or the connection line must always be executed

by the manufacturer of the electric tool

or his/her customer service in order to

avoid any hazards.

• Only switch the device on once it is

safely xed to the worktop.

• For your own safety only use accessories and attachments which were

stated in the operating instructions or

recommended or specied by the tool

manufacturer.

• Only use grinding tools recommended

by the manufacturer. Do not use any

saw blades. Ensure that the dimensions

match those of the device.

• Only use grinding discs where the

printed rotational speed is at least as

high as what has been specied on the

name plate of the device.

• Carry out a visual inspection of the

grinding disc before use. Do not use

any damaged or deformed grinding

discs. Replace any damaged or worn

grinding discs.

• Never operate the device without spark

protection or protective hoods.

Periodically readjust the spark protec-

tion in order to offset the wear and

tear of the grinding disc (distance max.

2mm).

• Replace the grinding disc if the spark

protection and the workpiece support

can no longer be readjusted to a distance of max. 2 mm at the latest.

• Make sure that the sparks produced by

grinding do not present a danger, e.g.

reach people or ignite ammable substances.

10

GB

IE

NI

• Always wear safety goggles, safety

gloves, respiratory protection and ear

protection when grinding.

• Never keep the ngers between the

grinding disc and spark protection or in

close proximity to the protective hoods.

There is a risk of crushing.

• The rotating parts of the device cannot

be covered due to functional reasons.

Therefore, proceed cautiously and hold

the workpiece rmly in order to avoid

slipping which could cause your hands

to come into contact with the grinding

disc.

• The workpiece gets hot during grinding. Do not touch the machined area,

allow it to cool down. There is a risk of

burning. Do not use coolants or the like.

• If you are tired or have consumed alcohol or tablets, do not work with the

device. Always have a break on time.

• Switch the device off and remove the

mains plug

- to loosen a blocked insertion tool,

- if the connection line is damaged or

entangled,

- in case of unusual sounds.

• Only operate the equipment in an upright, standing position and ensure you

have secure footing.

Residual risks

Even if properly operating and handling

this electric tool, some residual risks will

remain. Due to its construction and build,

this electric tool may present the following

hazards:

a) Lung damage, if suitable respiratory

protection is not worn.

b) Hearing damage, if suitable ear protec-

tion is not worn.

c) Damages to health due to

- touching the area of the grinding tool

which was not covered;

- the ejection of pieces from workpiece

or damaged grinding discs.

d) Damage to your health caused by

swinging your hands and arms when

operating the appliance for longer periods of time or if the unit is not held or

maintained properly.

Warning! During operation, this

electric tool generates an electro-

magnetic eld which, under certain

circumstances, may impair the

functionality of active or passive

medical implants. To reduce the risk

of serious or lethal injuries, we recommend that persons with medical

implants consult their doctor and

the manufacturer of their medical

implant before operating the machine.

Assembly

Caution!

Risk of injury!

- Ensure that you have sufcient space

in which to work, and that you do

not endanger other people.

- Always fasten the device on to the

work surface with screws featuring

the sufcient length and thickness in

order to maintain control of the device.

- All covers and protective devices

must be assembled properly before

commissioning.

- Disconnect the mains plug before

changing the setting on the device.

11

GB

IE

NI

Assemble/set work-

piece supports

1. Screw the workpiece supports (6) on to

the device.

To do this, use the screw (16), washer

(15), toothed washer (14) and star nut

(7) supplied.

2. Set the workpiece support (6) of the dry

grinding disc with the star grip nut (7)

so that the distance between the dry

grinding wheel (5) and the workpiece

support (6) must not exceed 2mm.

Periodically readjust the workpiece

support in order to offset the wear

and tear of the grinding disc (distance max. 2 mm).

Assemble/adjust spark

protection

1. Screw the spark protection holder (18)

onto the protective hood ( 25). For

this, use the adjusting screw (21) includ-

ing the snap ring and washer (20/19)

and the nut (17).

2. Adjust the spark protection holder (18)

with the aid of the adjusting screw (21):

The distance between the dry grinding

wheel ( 5) and the spark arrester

holder (18) must not exceed 2 mm.

Periodically readjust the spark pro-

tection in order to offset the wear

and tear of the grinding disc (dis-

tance max. 2mm).

3. Fold down the spark arrester into work-

ing position. Loosen the adjusting nut

(3) and tilt the spark arrester to the desired position.

Retighten the adjusting nut (3).

Despite the spark protection, you

should always wear protective

glasses when working in order to

avoid eye injuries.

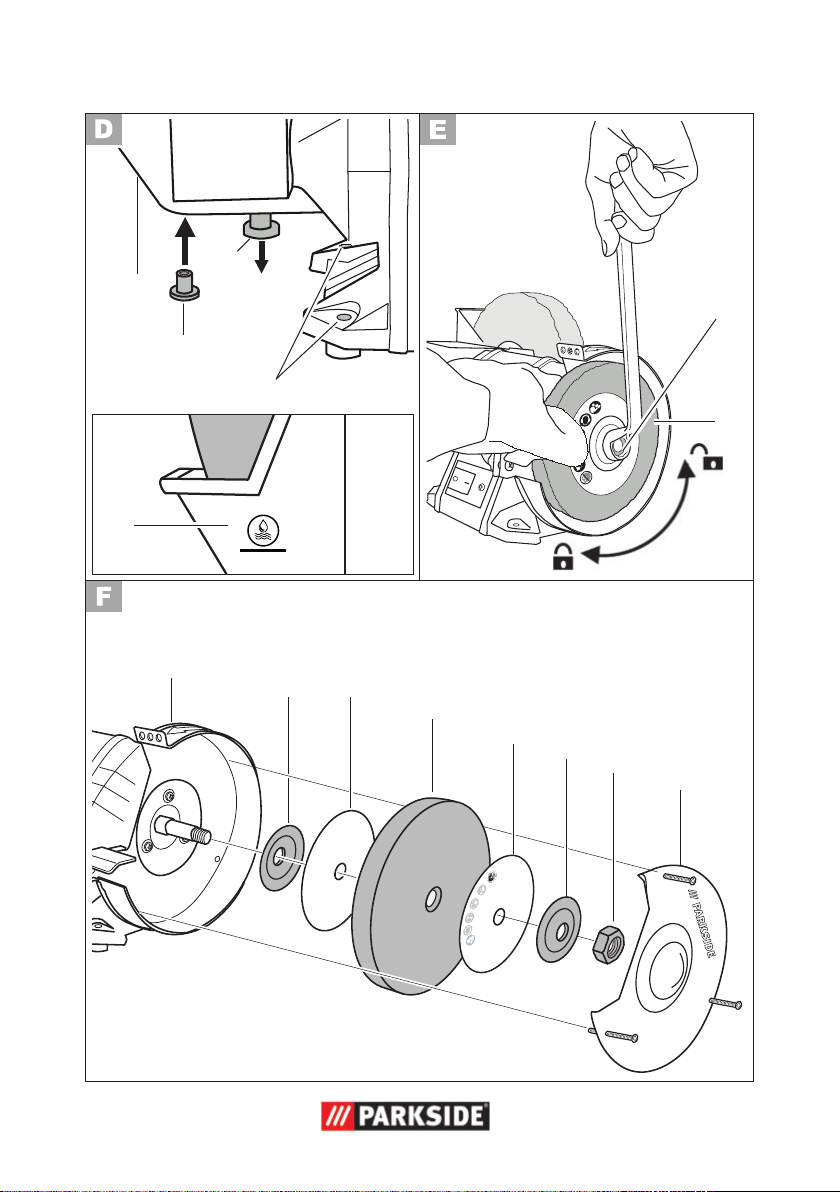

Screw device on to

workbench

1. Remove the rubber foot (10) of the water container.

2. Screw the device onto the at workbench with 4 screws and nuts. Insert the

screws through the 4bore holes (9) on

the base of the device.

The screws and nuts required for as-

sembly are not part of the scope of

delivery.

Fill water into the wa-

ter tank

1. Insert the rubber closure (11) into the

drain opening of the water tank (13).

2. Fill water into the water tank (13) up to

the water level mark .

Operation

Caution!

Risk of injury!

- Always disconnect the plug from the

mains socket before working.

- Use only grinding discs and accessories recommended by the manufac-

turer. The use of other insertion tools

and other accessories may cause risk

of injury.

- Only use grinding tools which bear

information about the manufacturer,

type of binding, dimension and permitted number of revolutions.

12

GB

IE

NI

- Only use grinding discs where the

printed rotational speed is at least as

high as what has been specied on

the name plate of the device.

- Do not use broken, cracked or otherwise damaged grinding discs.

- Never operate the device without the

visual protection disc.

- Always inspect the grinding disc before starting the device:

Check the distance between the

spark protection holder and grinding

disc as well as workpiece support

and grinding disc (distance maximum

2 mm).

- The grinding disc must be replaced

once the spark protection holder and

workpiece support on the grinding

disc do not have distance of max.

2mm.

- Switch on the equipment only when

it is safely installed on the work surface.

Keep your hands away from

the grinding disc when the

device is in operation. Injury

hazard!

Despite the spark protection, you

should always wear protective

glasses when working in order to

avoid eye injuries.

Switching on and off

Ensure that the mains voltage

matches the specications on the

rating plate.

Connect the equipment to the

mains.

1. To switch on, press the “I” On switch

( 8) and the device starts up.

2. To switch off, press the “0” off switch

( 8) and the device switches off.

After switching on the device, wait until the

device has reached its max. speed. Only

then must you start with the grinding.

The disc will continue to

run after the equipment is

switched off. There is a risk

of injury.

Test run:

Before starting work and after each

change of grinding disc, carry out a test

run of at least 60 seconds with no load.

Switch off the equipment immediately if the

disc runs lumpy, substantial vibrations occur, or abnormal noises are generated.

Grinding with the dry

grinding disc

• Place the workpiece on the workpiece

support ( 6) and slowly bring it to its

desired angle on the dry grinding disc (

5).

• Move the workpiece slightly from side

to side in order to achieve an optimal

grinding result. This way, the dry grinding disc is worn uniformly. Occasionally, allow the workpiece to cool down.

• Fold the spark protection device ( 2)

downwards while grinding in order to

avoid injury from sparks.

Grinding with the wet

grinding disc

• Check the water level in the water tank:

The wet grinding disc ( 1) is to be

13

GB

IE

NI

submerged in water up to the water

level mark

( 13).

• Stand in front of the wet grinding disc

( 1).

• Hold the workpiece with both hands

and lower it slowly onto the wet grinding disc.

• The workpiece can also be supported

on the teeth of the water tank ( 13).

on the water tank

Change grinding disc

Information

on replacement:

- Never operate the device without

protective equipment.

- Ensure that the rotation speed stated

on the grinding disc is the same or

higher than the nominal rotation

speed of the device.

- Ensure that the grinding disc dimensions match those of the device.

- Only use awless grinding discs

(sound test: an undamaged grinding

disc hanging freely on a string will

result in a clear sound if it is tapped

with a plastic hammer).

- Never re-drill a locating hole which is

too small to make it larger.

- Never use separate bushings or

adapters in order to make grinding

discs whose hole is too large t the

device.

- Do not use any saw blades.

- To clamp the grinding tools only use

the clamping ange provided. The

pads between the clamping ange

and the grinding tools must be made

of elastic materials e.g., rubber, soft

cardboard etc.

- Always reassemble the device completely after replacing the grinding

disc.

Switch the device off and remove

the mains plug.

Allow the device to cool down.

Wear protective gloves when

changing the grinding discs in order to avoid cutting damages.

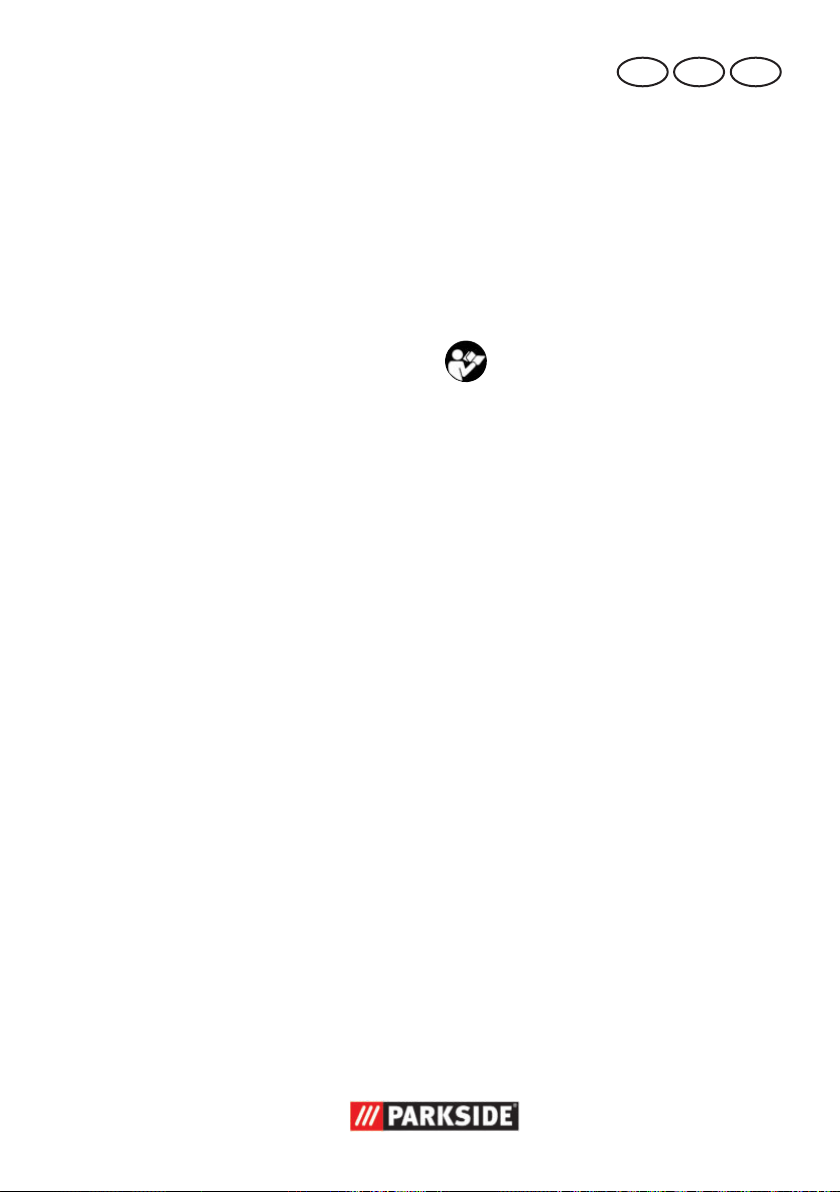

Change dry grinding disc:

1. Remove the spark protection (

2) (see „Assemble/adjust

spark protection”).

2. Loosen the xing screws and re-

move the dry grinding disc cover

( 4) from the protective hood

(25).

3. Unscrew the grinding disc

nut (22) with a screw wrench

(AF19mm) and hold against

the grinding disc with one hand

wearing a glove.

Unscrew the nut (right-hand

thread): turn counter-clockwise.

4. Remove the clamping ange (23)

and the dry grinding disc (5).

5. Fit on the new dry grinding disc

(5) with the intermediate cardboard layers (24) and the clamp-

ing ange (23), and screw the

grinding disc nut (22) manually

onto the nut (right-hand thread):

turn clockwise.

6. Tighten the grinding disc nut

with a screw wrench (AF19mm)

applying modest manual force.

7. Screw the dry grinding disc

cover (4).

8. Adjust the spark protection holder ( 18) and the workpiece

support ( 6) - The distance

from the dry grinding wheel (5)

must not exceed 2 mm (see „As-

sembly“).

14

Loading...

Loading...