Parkside PMNF 1350 C3 Original Instructions Manual

WALL CHASER PMNF 1350 C3

WALL CHASER

Translation of the original instructions

IAN 291805

MAUERNUTFRÄSE

Originalbetriebsanleitung

Before reading, unfold the page containing the illustrations and familiarise yourself with all

functions of the device.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB / IE / NI Translation of the original instructions Page

DE / AT / CH Originalbetriebsanleitung Seite

4

20

18

1 2

3

9

4

5

6

7

8

10

13

12

5

6

9

16

17

15

14

11

GB IE NI

Content

Introduction ................................. 4

Intended purpose .........................4

General description ......................5

Extent of the delivery ........................5

Functional description .......................5

Overview ........................................5

Technical data ..............................5

Notes on safety............................6

Symbols and icons ...........................6

General Safety Directions for Power

Tools ..............................................7

Safety instructions for cutting .............9

Additional safety instructions for all

applications ...............................10

Kickback and corresponding pre-

cautions ..................................... 10

Additional safety information ...........12

RESIDUAL RISKS ......................12

Assembly ................................... 12

Installing/changing disc .................12

Setting the groove depth .................13

Vacuuming ....................................13

Operation ..................................13

Turning on and off ..........................14

Handling ......................................15

Cleaning .......................................15

Storage ...................................... 15

Waste disposal and environmental

protection .................................. 15

Troubleshooting .........................16

Guarantee .................................17

Repair Service ............................18

Service-Center ............................ 18

Importer ....................................18

Replacement parts / Accessories 19

Original EG-Konformitäts-

erklärung ..................................39

Introduction

Congratulations on the purchase of your

new device. With it, you have chosen a

high quality product.

During production, this equipment has

been checked for quality and subjected to

a nal inspection. The functionality of your

equipment is therefore guaranteed.

The operating instructions constitute part of

this product. They contain important information on safety, use and disposal.

Before using the product, familiarise yourself with all of the operating and safety

instructions. Use the product only as de-

scribed and for the applications specied.

Keep this manual safely and in the event

that the product is passed on, hand over

all documents to the third party.

Intended purpose

The wall chaser is a tool for cutting mainly

mineral-based materials (such as concrete

or brick) without requiring the use of water.

This tool should only be used with diamond

cutting disks.

The tool should not be used in any other

application (e.g. cutting with coolant solutions, cutting harmful substances such as

asbestos).

The device is intended to be used by do-ityourselfers. It was not designed for heavy

commercial use. The tool is to be used by

adults. Children over the age of 16 may

not use the tool except under supervision.

The manufacturer is not liable for damages

caused by an improper use or incorrect

operation of this device.

4

NIIEGB

General description

See the fold-out pages for

illustrations.

Extent of the delivery

Carefully unpack the appliance and check

that it is complete. Dispose of the packaging material correctly.

- Device

- Protective hood

- 2 cutting disks (pre-mounted)

- Vacuum adapter (pre-mounted)

- Reducing adapter for vacuum

- Chuck key

- Hand chisel

- Instructions for use

Functional description

The wall chaser cuts two grooves in brickwork using two parallel diamond cutting

disks, without requiring the use of water.

Cabling grooves can be opened up by

removing the material in between the

grooves.

Please refer to the information from the

disc manufacturer.

Please refer to the descriptions below for

information about the operating devices.

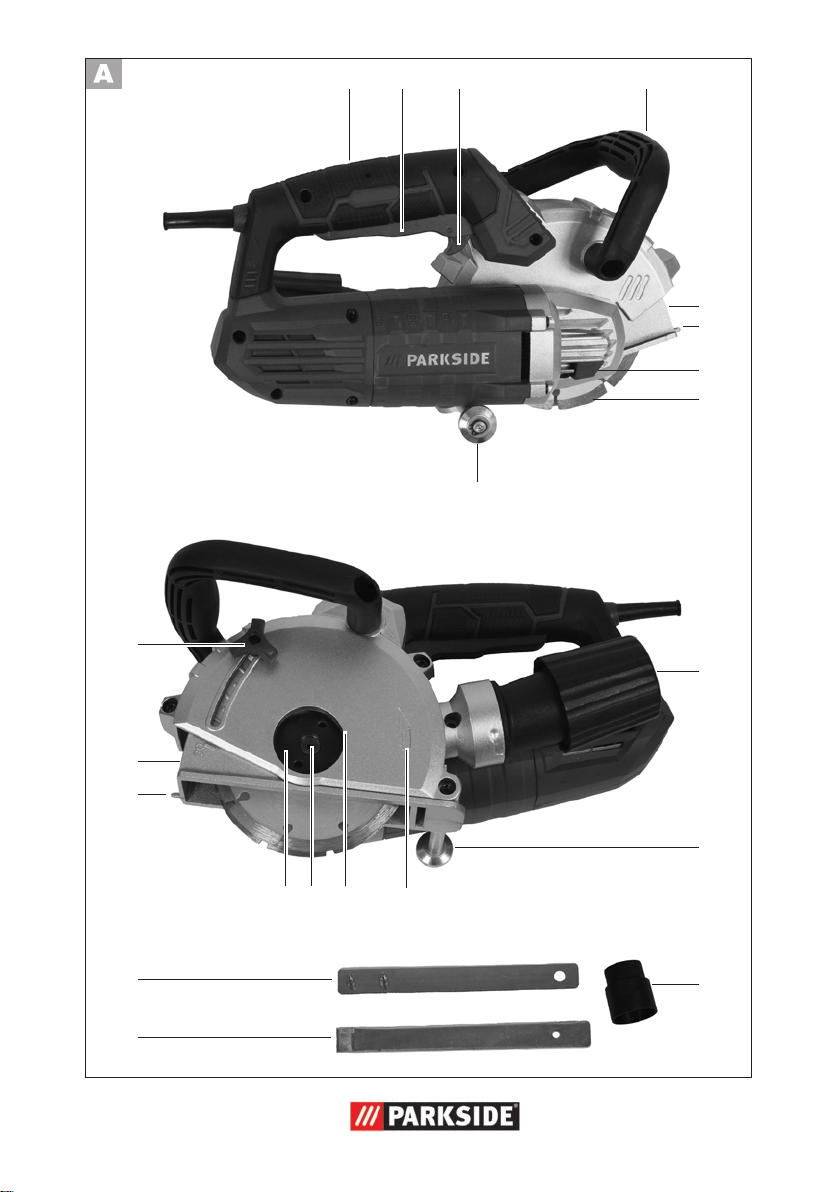

Overview

1 Handgrip

2 On/off switch

3 Switch block

4 Auxiliary handle

5 Maintenance coverage

6 Marking

7 Spindle stop button

8 Cutting disc

9 Start roller

10 Vacuum connector

11 Vacuum adapter

12 Hand chisel

13 Chuck key

14 Rotational direction marking

15 Protective guard opening

16 Mounting spindle

17 Threaded clamping ange

18 Retaining screw

19 Mounting ange

20 Spacer disks

21 Flange

Technical data

Wall chaser PMNF 1350 C3:

Rated input voltage

............................. 220 - 230 V~, 50 Hz

Power input ............................. 1350 W

Idling speed (n) .......................9000 min

Dimension of the cutting discs

............................... Ø 125 x 22,23 mm

Groove depth ........................ 0 - 30 mm

Groove width ............... 8 mm bis 26 mm

Spindle thread ................................ M14

Safety class ..........

II (Double insulation)

Protection category..........................IP X0

Sound pressure level

(L

) ......................90 dB(A); KpA= 3 dB

pA

Sound power level (L

measured ........... 101 dB(A); K

Vibration (a

) ....... 5,37 m/s2 K= 1,5 m/s

h

WA

)

WA

The vibration values represent maximum values which have been determined with the supplied blade. The actual vibration values may

vary depending on the used accessories.

The vibration values are still affected by the

handling for the user‘s.

-1

= 3 dB

2

5

GB IE NI

Cutting disc (included):

Idling speed n

0

................................... max.12250 min

Disc speed ....................... max. 80 m/s*

Outer diameter ................... Ø 125 mm

Bore hole ........................ Ø 22,23 mm

*

The grinding disc must keep a rotational

speed of 80 m/s.

Levels of noise and vibration were determined according to the norms and regulations

in the declaration of conformity.

The vibration emission value has been measured according to a standardised testing

method and may be used for comparison

with another electric tool.

The indicated vibration emission value may

also be used for an introductory assessment

of the exposure.

Warning:

The vibration emission value whilst

actually using the electrical tool may

vary from the given values independently of the type and way in which

the electric tool is used.

Try to keep the exposure to vibrations as low as possible. Examples

of measures to reduce vibration

exposure are the wearing of gloves

when using the tool and limiting the

working hours. For this purpose all

parts of the operating cycle have to

be considered (for example, times

when the electric tool is switched off

and times when it is switched on but

running without any load).

measures for the prevention of electric

shocks and the risk of injury and re.

-1

Please read all these instructions before using this electric tool and please

keep the safety instructions.

Symbols and icons

Symbols on the device:

Warning!

Warning! Electric shock hazard.

Always unplug the device before

working on it.

Read the manual!

Wear eye and ear protection.

Wear breathing protection.

Risk of cuts!

Wear cut-resistant gloves.

Wear safety shoes.

Do not use for wet grinding.

Safety class II (Double insulation).

Electrical machines do not belong

with domestic waste.

Other symbols on the

cutting disc:

Do not use defective discs.

Notes on safety

Caution! When using power tools,

observe the following basic safety

6

Symbols used in the instructions:

Hazard symbols with informa-

tion on prevention of personal

injury and property damage

.

NIIEGB

Hazard symbol with infor-

mation on the prevention of

personal injury caused by

electric shock.

Precaution symbol (explanation of

precaution instead of exclamation

mark) with information on prevention of harm / damage.

Notice symbol with information on

how to handle the device properly.

Switch the device off and remove

the mains plug. Allow the device to

cool down.

Connect the machine to the power

supply.

General Safety Directions for

Power Tools

WARNING! READ ALL SAFETY

DIRECTIONS AND INSTRUCTIONS. Omissions in the compliance

with safety directions and instructions

can cause electrical shock, re and/

or severe injuries.

Retain all safety directions and instructions for future use.

The term „power tool“ in the warnings refers

to your mains-operated (corded) power tool

or battery-operated (cordless) power tool).

Work area safety :

• Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

• Do not operate power tools in

explosive atmospheres, such as in

the presence of ammable Iiquids,

gases or dust. Power tools create

sparks which may ignite the dust or fumes.

• Keep children and bystanders

away while operating a power

tool. Distractions can cause you to lose

control.

Electrical safety :

CAUTION! The following states how

to avoid accidents and injuries due to

electric shock:

• Power tool plugs must match the

outlet. Never modify the plug in

any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodied plugs

and matching outlets will reduce risk of

electric shock

• Avoid body contact with earthed

or grounded surfaces, such as

pipes, radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is earthed

or grounded.

• Do not expose power tools to

rain or wet conditions. Water entering a power tool will increase the risk

of electric shock.

• Do not abuse the cord. Never

use the cord for carrying, pulling

or unplugging the power tool.

Keep cord away from heat, oil,

sharp edges or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

• When operating a power tool

outdoors, use an extension cord

suitable for outdoor use. Use of a

cord suitable for outdoor use reduces

the risk of electric shock.

7

GB IE NI

• If operating a power tool in a

damp location is unavoidable,

use a residual current device

(RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

Use a circuit breaker with a current limit

of 30 mA or less.

Personal safety:

CAUTION! The following states how

to avoid accidents and injuries:

• Stay alert, watch what you are

doing and use common sense

when operating a power tool.

Do not use a power tool while

you are tired or under the inuence of drugs, alcohol or medication. A moment of inattention white

operating power tools may result in

serious personal injury.

• Use personal protective equip-

ment. Always wear eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

• Prevent unintentional starting.

Ensure the switch is in the offposition before connecting to

power source and/or battery

pack, picking up or carrying the

tool. Carrying power tools with your

nger on the switch or energising power tools that have the switch on invites

accidents.

• Remove any adjusting key or

wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power

tool may result in personal injury.

• Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the power

tool in unexpected situations.

• Dress properly. Do not wear

loose clothing or jewellery. Keep

your hair, clothing and gloves

away from moving parts. Loose

clothes, jewellery or long hair can be

caught in moving parts.

• If devices are provided for the

connection of dust extraction

and collection facilities, ensure

these are connected and properly used. Use of dust collection can

reduce dust-related hazards.

Power tool use and care :

• Do not force the power tool. Use

the correct power tool for your

application. The correct power tool

will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the

switch does not turn it on and

off. Any power tool that cannot be

controlled with the switch is dangerous

and must be repaired.

• Disconnect the plug from the po-

wer source and/or the battery

pack from the power tool before making any adjust -ments,

changing accessories, or storing

power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentaIly.

• Store idle power tools out of the

reach of children and do not allow persons unfamiliar with the

power tool or these instructions

to operate the power tool. Power

tools are dangerous in the hands of untrained users.

• Maintain power tools. Check

for misalignment or binding

8

NIIEGB

of moving parts, breakage of

parts and any other condition

that may affect the power tool’s

operation. If damaged, have the

power tool repaired before use.

Many accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and

clean. Properly maintained cutting

tools with sharp cutting edges are less

Iikely to bind and are easier to control.

• Use the power tool, accessories

and tool bits etc. in accordance

with these instructions, taking

into account the working conditions and the work to be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

Service:

• Have your power tool serviced

by a qualied repair person

using only identical replacement

parts. This will ensure that the safety

of the power tool is maintained.

Safety instructions for

cutting

a) The protective guard on the de-

vice must be securely fastened,

and adjusted to ensure maximum safety, i.e. the smallest

possible section of the abrasive

surface should be visible to the

user. Ensure that you and all

persons in the vicinity keep out

of the plane of the rotating disk.

The protective guard is designed to

protect users from ying debris and

accidental contact with the abrasive

surface.

b) Only use diamond cutting disks

with this tool. Attaching the accessories to the device does not guarantee

safe operation.

c) The allowable rotation speed

of the attachment tools must be

at least as high as the highest

rotation speed indicated on the

electric tool. Accessories that run fas-

ter than the allowable speed can break

and y apart.

d) Schleifkörper dürfen nur für die

empfohlenen Einsatzmöglichkeiten verwendet werden. Zum

Beispiel: Schleifen Sie nie mit der

Seitenäche einer Trennscheibe.

Trennscheiben sind zum Materialabtrag

mit der Kante der Scheibe bestimmt.

Seitliche Krafteinwirkung auf diese

Schleifkörper kann sie zerbrechen.

e) Verwenden Sie immer unbeschä-

digte Spannansche in der richtigen Größe und Form für die von

Ihnen gewählte Schleifscheibe.

Geeignete Flansche stützen die Schleifscheibe und verringern so die Gefahr

eines Schleifscheibenbruchs.

f) Außendurchmesser und Dicke

des Einsatzwerkzeugs müssen

den Maßangaben Ihres Elektrowerkzeugs entsprechen. Falsch

bemessene Einsatzwerkzeuge können

nicht ausreichend abgeschirmt oder

kontrolliert werden.

g) The cutting disks and anges

must t the grinding spindle precisely. Disks that do not t the grin-

ding spindle precisely rotate unevenly,

vibrate sharply and can lead to loss of

control.

h) Never use damaged attachment

tools. Check attachment tools

such as grinding discs for chipping or cracks, grinding plates

9

GB IE NI

for cracks, wear or strong abrasion and wire brushes for loose

or broken wires before using

them. If the electric tool or the

attachment tool falls off, check

whether it is damaged or, use

an undamaged attachment tool.

If you have checked the attachment tool and attached it, keep

yourself and any nearby persons

beyond the level of the rotating

attachment tool and allow the device to run for 1 min. at the highest rotational speed. Damaged tools

usually break during this test period.

i) Wear personal safety equip-

ment. Depending on the application, use full face shields, eye

protection or safety goggles. In

so far as it is appropriate, wear

dust masks, ear protection,

gloves or special aprons which

keep small grinding and material particles away from you. Eyes

should be protected from the foreign

matter which can be caused to y during the various applications. Dust or

breathing masks should lter the dust

that is created during operation. If you

are exposed to loud noise for a long

time, you may suffer hearing loss.

j) Ensure that other people are at

a safe distance to your working

area. Anyone who enters the working area should wear personal

protective equipment. Broken bits from

the piece being worked or broken attach-

ment tools can y away and cause injuries

even beyond the direct working area.

k) Hold the electric tool only by the

insulated gripping surfaces when

performing work in which the

cutting tool may come into contact

with hidden wiring or its own

cord. Contact with a live wire can also

cause a charge in metal parts of the

device and result in an electric shock.

l) Keep the cord away from the ro-

tating attachment tool. If you lose

control of the device, the power cord

can become separated or caught and

your hand or arm may be pulled into

the rotating attachment tool.

m) Never put the electric tool down

before the attachment tool has

come to a full stop. The rotating at-

tachment tool can come into contact with

the surface upon which it is set, whereby

you could lose control of the electric tool.

n) Never allow the electric tool to

run while you are carrying it.

Your clothing may accidentally come

into contact with the rotating attachment

tool and get caught and the attachment

tool could drill into your body.

o) Clean the ventilation slots of

your electric tool routinely. The

motor air pulls dust into the housing

and, should too much metallic dust collect, could cause electrical hazards.

p) Never use the electric tool near

ammable material. Sparks could

ignite this material.

q) Do not use attachment tools

which require liquid coolant.

Using water or another liquid coolant

could lead to electrical shock.

Additional safety instructions

for all applications

Kickback and corresponding

precautions

Kickback is the sudden reaction from a

chopping or blocked grinder attachment

1 0

NIIEGB

such as a grinding disc, grinding plate,

wire brush etc. Chopping or blocking leads

to sudden stopping of the rotating attachment. This causes an uncontrolled electric

tool to accelerate in a direction counter to

the rotational direction of the attachment

tool. If, for example, a grinding disc cuts

into the workpiece or blocks it, the edge of

the grinding disc that digs into the workpiece can get caught and, through that,

break off the grinding disc or cause a kickback. The grinding disc then moves towards

or away from the operator, depending on

the direction of rotation of the disc at the

blocked spot. Here, the grinding discs can

also break. A kickback is caused by wrongly or incorrectly operating the electric tool.

It can be avoided by suitable cautionary

measures, such as described below.

a) Hold the electric tool very rmly and

bring your body and your arm into a

position in which you can resist the kickback force. Always use the supplemental

handle if available to give you the best

control over kickback force or reaction

time during acceleration. The operator

can master the kickback and reaction

force through suitable precautions.

b) Never bring your hands near a rotating

attachment tool. The attachment tool

can run over your hand in the kickback.

c) Keep your body away from the area

in which the electric tool would move

during a kickback. The kickback drives

the electric tool in the counter-direction

to the rotation of the grinding disc at

the blocked spot.

d) Work particularly cautiously in corner

areas or where there are sharp corners etc. Prevent the attachment tools

from recoiling from the workpiece and

jamming. The rotating attachment tool

tends to jam when near corners, sharp

edges or when it recoils from such. This

causes a loss of control or kickback.

e) Do not use chain or toothed saw bla-

des. Such attachment tools frequently

cause a kickback or loss of control over

the electric tool.

f) Avoid blocking the cutting disc or pres-

sing down too hard. Do not make any

excessively deep cuts. Overloading the

cutting disc increases wear and its tendency to tilt or block and, with that, to

kickback or break the grinder.

g) If the cutting disc jams, or you interrupt

your work, switch the device off and

hold it until the disc has come to a full

stop. Never try to pull the cutting disc

out of the cut while it is still running,

because it can kick back. Identify and

correct the cause of the jamming.

h) Do not switch the electric tool on again

as long as it is in the workpiece. Allow

the cutting disc to rst reach its full

rotational speed before you carefully

resume with the cutting. Otherwise, the

disc may catch, spring away from the

workpiece or cause a kickback.

i) Support plates or workpieces to reduce

the risk of kickback from a jammed cutting disc. Large workpieces may bend

under their own weight. The workpiece

must be supported on both sides of the

disc, near the cutting disc as well as

also at the edge.

j) Be particularly careful for pocket cuts in

existing walls or other areas where you

cannot see what is there. The cutting

disc may cause a kickback when it cuts

into gas or water lines, electrical lines

or other hidden objects.

1 1

GB IE NI

Additional safety information

a) Approved cutting disk types:

segmented diamond disks with a

maximum space of 10 mm between

segments, only with a negative cutting

angle.

Disk diameter: 125 mm

Disk thickness: 2,1 mm

RESIDUAL RISKS

Even if properly operating and handling

this electric tool, some residual risks will

remain. Due to its construction and build,

this electric tool may present the following

hazards:

a) Lung damage if suitable respiratory pro-

tection is not worn.

b) Hearing damage if suitable ear protec-

tion is not worn.

c) Damage to health due to

- touching the area of the grinding tool

which is not covered;

- ejection of parts of workpieces or

damaged grinding discs.

d) Health injuries which result from swin-

ging hand and arm, in the event that

the device is used over a longer period

of time or is not used and maintained

properly.

Warning! During operation, this

electric tool generates an electro-

magnetic eld which, under certain

circumstances, may impair the functionality of active or passive medical

implants. To reduce the risk of serious or lethal injuries, we recommend

that persons with medical implants

consult their doctor and the manufacturer of their medical implant

before operating the machine.

Assembly

Caution! Risk of injury!

- Ensure that you have sufcient

space in which to work, and that

you do not endanger other people.

- All hoods and protective devices

must be assembled properly before commissioning.

-

Installing/changing disc

1. Press the spindle stop button (7).

2. Turn the mounting spindle (16)

3. Release the clamping nut

(17) with the chuck key

(13). You can release the spindle

4. Remove the threaded clamping

5. Remove the cutting disk (8) by

6. Remove the ange (21) and the

7. Remove the second cutting disk

8. The take-up ange (19) can be

If you remove the take-up ange

Disconnect the mains plug before

changing the setting on the

device.

until the spindle lock xed the

mounting spindle. Keep and continue to hold down the spindle

lock button (7).

lock button (7.

ange (17) through the opening

in the protective guard (15).

lifting and pulling away the takeup spindle (16) until it reaches

the protective guard.

spacer disks (20) through the

opening in the protective guard

(15).

(8) as described in point 5.

left on the take-up spindle (16).

(19), make sure to position it cor-

1 2

NIIEGB

rectly. The take-up ange‘s (19)

contouring must face towards

the motor. If you turn the take-up

ange (19), the take-up spindle

(16) must turn with it.

9. Position the desired cutting disk

(8) on the take-up ange (19).

The label on the disc should always face the device.

10. Set the desired cutting width by

selecting the spacer disks (20).

Push the spacer disks onto the

take-up spindle (16). This is fol-

lowed by the ange (21). This is

followed by the second cutting

disk (8). All separator disks (20)

not used for setting the cutting

width must be pushed onto the

take-up spindle (16) after the

second cutting disk.

11. Reposition the threaded clam-

ping ange (17) on the take-up

spindle (16).

12. Press the spindle retaining tab

(7), and turn the take-up spindle

(16) until the spindle retainer

xes the take-up spindle (16).

Retighten the threaded clamping

ange (17) using the chuck key

(13). You can now release the

spindle retaining tab (7).

Setting the groove depth

1. Release the retaining screw (18).

2. Set the depth-stop to the required

depth. Adjust the protective

guard (5) to do this.

3. Reattach the protective guard (5)

with the retaining screw (18).

Vacuuming

During operation, the wall chaser generates a large quantity of dust. You should

therefore wear a dust mask, and always

connect an industrial vacuum cleaner.

If the vacuum system malfunctions, pause

operation and clear the malfunction!

Attaching the vacuum cleaner

Unscrew the suction connector (10) cap.

Insert the industrial vacuum cleaner’s hose

through the cap and screw the cap tight.

If your vacuum cleaner’s hose is the wrong

diameter for a direct connection, you can

insert the vacuum adapter (11) in between

with a single turn.

Always attach a vacuum cleaner. Damage

to the motor caused by failure to attach

a vacuum cleaner is not covered by the

warranty.

Operation

Caution! Risk of injury!

- Always remove the mains plug

before working on the tool.

- Only use grinding discs and accessories recommended by the manufacturer. Using other attachment

tools and other accessories can

represent a risk of injury for you.

- Only use grinding tools which

bear information about the

manufacturer, type of binding,

dimension and permitted number

of revolutions.

- Only use grinding discs where

the printed rotational speed is at

1 3

GB IE NI

least as high as what has been

specied on the name plate of

the device.

- Do not use any broken, cracked,

or otherwise damaged grinding

discs.

- Never operate the device without protective equipment.

- Support the plates or workpieces

in order to reduce the risk of

kickback from a jammed cutting

disc. Large workpieces may

bend under their own weight.

The workpiece must be supported on both sides of the disc, not

only near the cutting disc, but

also at the edge.

Keep your hands away from

the disc when the device is in

operation. Risk of injury.

Information on replacement:

• Never operate the device

without protective equipment.

• Ensure that the rotation speed stated on the grinding disc (8) is the

same or higher than the nominal

rotation speed of the device.

•

• Only use awless grinding discs

• Never re-drill a locating hole which

• Never use separate bushings or

• Do not use any saw blades.

Ensure that the grinding disc dimensions match those of the device.

(ringing test: when you strike the

grinding disc with a plastic hammer, it results in a clear sound).

is too small to make it larger.

adapters in order to make grinding discs with a hole that is too

large t the device.

Only replace the diamond

cutting disks in pairs.

Switch the device off and remove

the mains plug. Allow the device to

cool down.

Wear protective gloves when changing the discs in order to avoid cutting damages.

Turning on and off

Make sure that the power supply

voltage matches the voltage rating

indicated on the device‘s type plate.

Connect the machine to the power

supply.

1. To start the device, push the switch

lock (3) forwards. Press the on/off

switch (2).

2. To turn it off, release the on-off button.

The device turns off.

After switching on the device, wait until the

device has reached its max. speed. Only

then should you start with the work.

The disc still runs even after

the device has been switched

off. Risk of injury.

Trial run:

Always carry out a trial run before carry-

ing out your rst grinding procedure and

after every disc replacement. Switch the

device off immediately if the grinding disc

is not rotating smoothly, if considerable

vibration occurs or if you hear abnormal

noises.

1 4

Loading...

Loading...