Parkside PFDS 33 B2 Assembly Manual

FLUX-CORED WIRE WELDER PFDS 33 B2

FLUX-CORED WIRE WELDER

Assembly, operating and safety instructions

IAN 291492

FÜLLDRAHT-SCHWEISSGERÄT

Montage-, Bedienungs- und Sicherheitshinweise

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB / IE / NI Assembly, operating and safet y instructions Page 5

DE / AT / CH Montage-, Bedienungs- und Sicherheitshinweise Seite 25

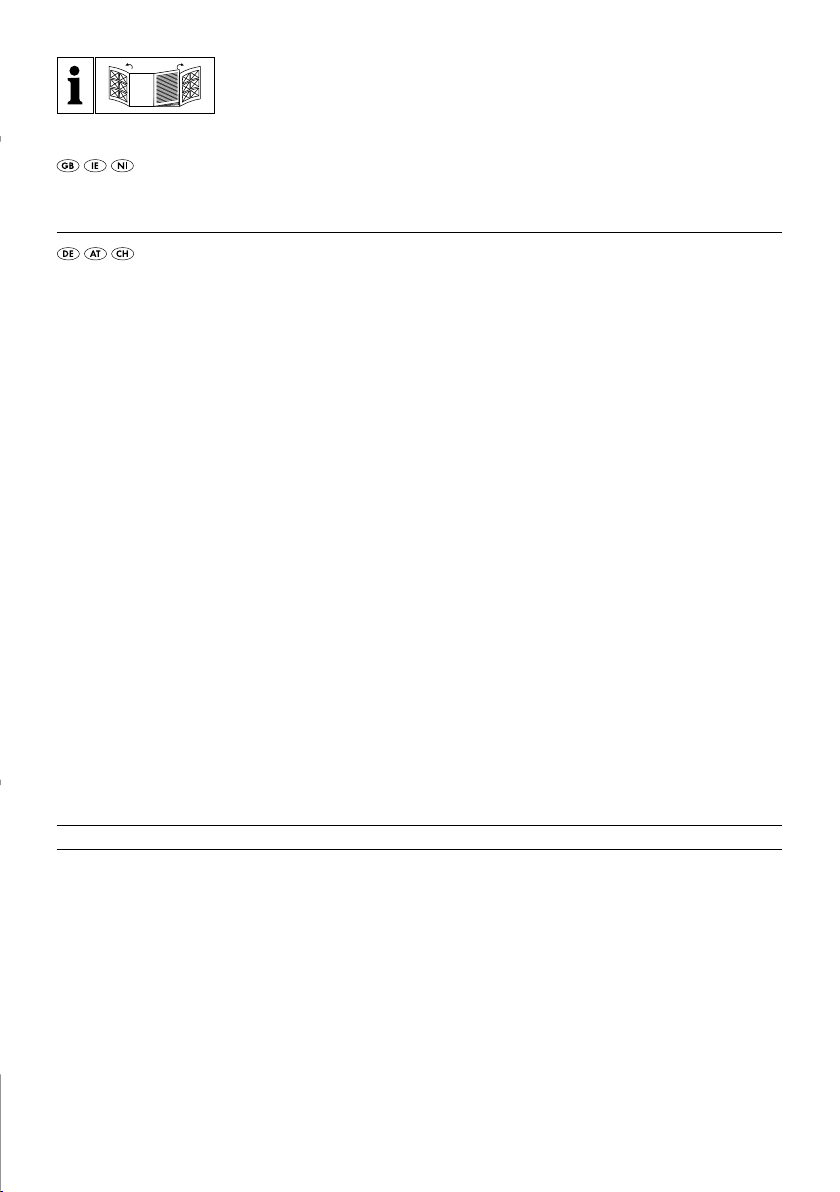

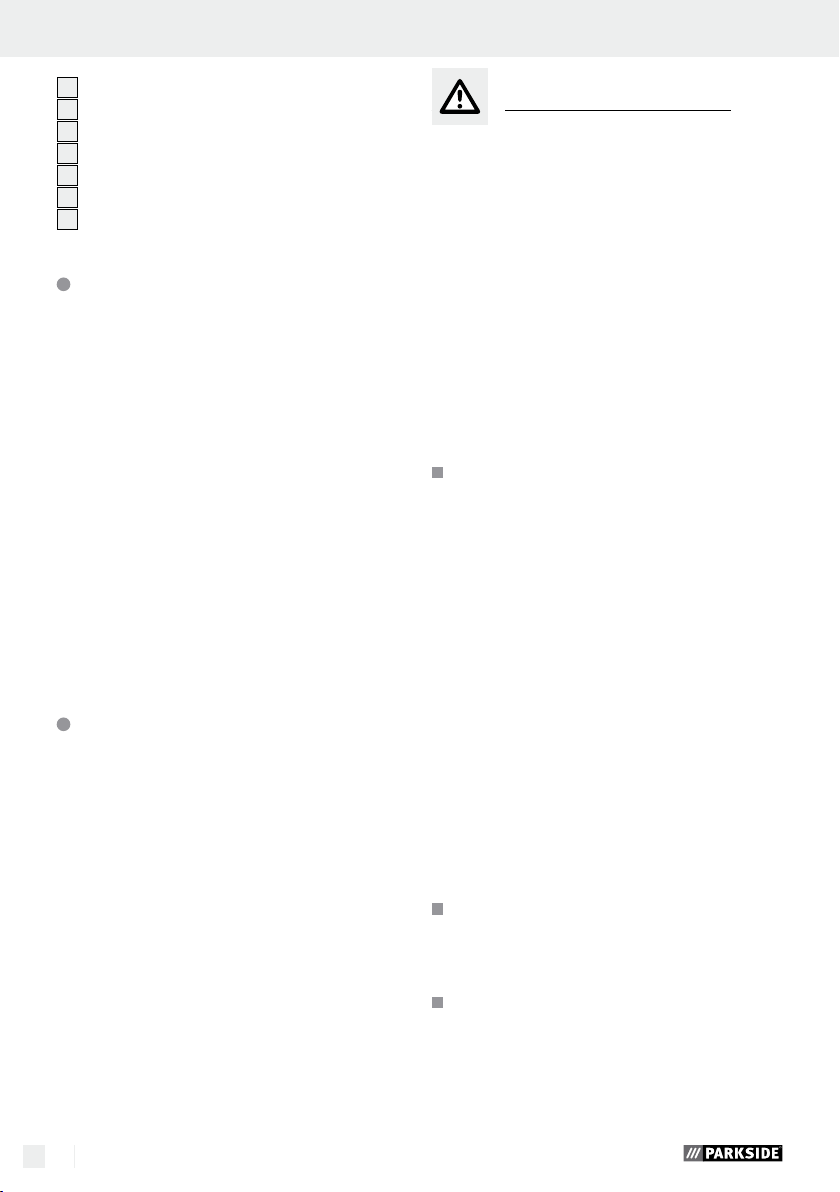

1 2

19

Ø 0,6

Ø 0,8

6

14 15

18

Ø 0,9

3459 8 710111213

16

17

A

B

21

20

24

16

2223

Table of contents

List of pictograms used ........................................................................................................ Page 6

Introduction ................................................................................................................................... Page 7

Intended Use ....................................................................................................................................... Page 7

Parts Description .................................................................................................................................. Page 7

Technical Data ....................................................................................................................................Page 8

Scope of Delivery ................................................................................................................................ Page 8

Safety instructions ................................................................................................................... Page 8

Safety hazards during arc welding ...................................................................................................Page 10

Safety notices specific to the welding shield ..................................................................................... Page 12

Tight and moist spaces .......................................................................................................................Page 13

Protective clothing ............................................................................................................................... Page 13

Protecting against rays and burns ...................................................................................................... Page 13

EMC Device Classification ................................................................................................................. Page 14

Before Use ...................................................................................................................................... Page 15

Assembly ......................................................................................................................................... Page 15

Assembling the welding helmet .......................................................................................................... Page 15

Inserting the flux-cored wire ...............................................................................................................Page 15

Initial Use.........................................................................................................................................Page 18

Switching the unit on and off .............................................................................................................. Page 18

Adjusting the welding current ............................................................................................................. Page 18

Adjusting the wire feeder .................................................................................................................... Page 18

Welding ............................................................................................................................................... Page 19

Creating a welding seam ................................................................................................................... Page 20

Maintenance and Cleaning .............................................................................................. Page 21

Environmental instructions and disposal information .............................. Page 21

Information about warranty and service processing ............................... Page 22

Warranty terms .........................................................................................................................Page 22

Extent of warranty ............................................................................................................................... Page 22

Processing of warranty claims ............................................................................................................ Page 22

Service ............................................................................................................................................... Page 23

EU Conformity Declaration ............................................................................................... Page 23

5 GB/IE/NI

List of pictograms used

Caution! Read instructions for

use!

Severe or fatal injuries may

occur.

Power input; phase number, as

well as

Caution! Danger of electric

shock!

1~ 50 Hz

Alternating current symbol and

rated value of the frequency

Important notice!

Do not dispose of electrical

equipment in household waste!

Dispose of the packaging and

unit in an environmentally-friendly

manner!

Do not use the unit outdoors

and never in rain!

Self-shielded flux-cored arc

welding

Electric shocks from welding

electrodes can prove fatal

IP21S

Protection type

Inhaling welding smoke can

pose a risk to your health.

Suitable for welding with

increased electric risk

Welding sparks can cause an

explosion or fire.

Single-phase transformer

Arc rays can damage the eyes

and injure the skin.

H

Insulation class

Electromagnetic fields can

interfere with the functionality of

pacemakers.

U

2

Standard working voltage

Attention, potential dangers!

I

1max

Highest rated value of mains

current

X %

Duty cycle

I

1eff

Effective value of highest mains

current

I

2

Rated value of welding current Earth terminal

Wire feeder

6 GB/IE/NI

Introduction

Flux-Cored Wire Welder PFDS 33 B2

Introduction

Congratulations! You have

chosen a high-quality unit from

our company. Familiarise yourself with the product before using it for the first time.

In addition, please carefully read the instructions for

use and the safety instructions below. Initial operation of this tool must be performed by trained personnel.

KEEP OUT OF THE REACH OF CHILDREN!

Intended Use

This unit is intended for self-shielded flux-cored arc

welding using the appropriate wire. Additional gas

is not required. The inert gas is contained in a powdered form in the wire, is therefore fed directly into

the arc, and this makes the tool wind-resistant while

working outdoors. Only suitable wire electrodes may

be used for the unit. Intended use also involves observing the safety instructions, assembly instructions

and operating instructions in the instruction manual.

The applicable accident prevention regulations are

to be adhered to as strictly as possible. The unit

may not be used:

- in insufficiently ventilated spaces,

- in a damp or wet environment,

- in explosive environments,

- for the purposes of thawing pipes,

- in the vicinity of people with pacemakers and

- in the vicinity of inflammable materials.

Only use the product as described and for the

specified purpose. Keep these instructions in a safe

place. When passing this product on to others, please

also include all the documents. Any use other than

the intended is prohibited and potentially dangerous.

Damages resulting from noncompliance or misuse

are not covered by the warranty and are not included

in the manufacturer's liability.

Residual risk

Even if you use the unit correctly, there will always

be residual risks. The following hazards can arise

due to the design and performance of this flux-cored

arc welding unit:

- Eye damage due to being dazzled,

- Touching hot parts of the unit or the work piece

(burns),

- In the case of insufficient protection, a risk of

accidents and fire exists due to sparks or slag,

- Harmful gas and smoke emissions in the case of a

lack of air and / or insufficient extraction in enclosed

spaces.

Reduce the residual risk by using the unit carefully

and correctly and following all the instructions as

stated.

Parts Description

1

Cover for wire feeder unit

2

Carrying strap

3

Mains plug

4

Earth cable with earth terminal

5

Main switch ON / OFF (including mains

control lamp)

6

Control lamp for overload protection

7

Burner nozzle

8

MIN / MAX switch for welding current setting

9

1 / 2 Switch for welding current setting

10

Adjustment wheel for wire feeder

11

Burner

12

Burner button

13

Cable assembly with direct connection

14

Welding nozzle (0.6 mm)

15

Welding nozzle (0.8 mm)

16

Handle

17

Welding nozzle (0.9 mm)

18

Flux-cored wire welding coil (wire reel)

Ø 0.9 mm / 450 g

19

Chipping hammer with wire brush

20

Welding helmet after assembly, consisting of:

21

Dark welding lens

22

Mask

23

Mounting clip

24

Protective glass locking mechanism

25

Roll holder

7 GB/IE/NI

26

Wire outlet

27

Adjusting knob

28

Pressing roller unit

29

Feed roller

30

Feed roller holder

31

Cable assembly intake

32

Torch neck

Technical Data

Mains connection: 230 V∼ / 50 Hz

(alternating current)

Welding current I

Duty cycle X: 10 % at 90 A

Open-circuit voltage U

Highest rated value

for the mains current: I

Effective value for highest

rated current: I

Welding wire drum max.: approx. 450 g

Welding wire diameter: 0.9 mm

Fuse: 16 A

Weight: 13.65 kg

Scope of Delivery

1 Flux-cored arc welding unit PFDS 33 B2

1 Burner nozzle (pre-installed)

3 Welding nozzles (1x 0.9 mm pre-installed; 1x

0.8 mm; 1x 0.6 mm)

1 Chipping hammer with wire brush

1 Flux-cored wire Ø 0.9 mm / 450 g

1 Welding helmet

1 Carrying strap

1 Instructions for use

: 40–90 A

2

welding current,

60 % at 40 A

welding current

: 32 V

0

14 A

1 max.

4.4 A

2 eff

Safety instructions

Please carefully read the instructions

for use and follow the specified notices. Familiarise yourself with the

tool, its proper use and the safety

notices using these instructions for

use. The nameplate contains all the

technical data for this welding tool,

please learn about the technical

facts of this tool.

This device may be used by

children aged 16 years and up,

as well as by persons with reduced

physical, sensory or mental capacities, or lacking experience

and / or knowledge, so long as

they are supervised or instructed

in the safe use of the device and

understand the associated risks.

Do not allow children to play with

the appliance. Cleaning and user

maintenance should not be performed by children without supervision.

Only have repairs and / or main-

tenance performed by electrically

skilled persons.

Only use the welding cables

included (PFDS 33 B2 H01N2D1x10 mm²).

8 GB/IE/NI

Safety instructions

During use the equipment should

not be located directly against a

wall, be covered, or be jammed

between other equipment to ensure ample air can be taken in

through the ventilation louvres.

Verify the equipment is correctly

connected to the mains voltage.

Avoid any tensile load on the

mains. Unplug the mains plug

from the socket before transferring the equipment to a different

location.

Always switch the equipment off

with the ON / OFF switch when

not in use. Set the electrode

holder down on an insulated

pad and allow to cool for

15 minutes before removing the

electrodes from the holder.

Pay attention to the condition of

the welding cables, the electrode

holders and the earth terminals.

Worn insulation and conducting

parts can produce hazards and

reduce the welding quality.

Arc welding produces sparks,

melted metal parts and smoke.

Therefore note: Remove any

flammable substances and / or

materials from the work area

and its immediate surroundings.

Ensure the work area is ventilated.

Do not weld atop containers, re-

ceptacles or pipes, which do or

did contain flammable liquids or

gasses.

Avoid any

direct contact with the welding

circuit. The no-load voltage between the electrode holder and

earth terminal can be dangerous, there is a risk of electric

shock.

Do not store or use the equipment

in a moist or wet environment or

in the rain. The Protection Provision

IP21S applies in this respect.

Protect the eyes with the appro-

priate safety glass (DIN Grad

9-10) to be installed in the

included welding shield. Use

gloves and dry protective clothing free from oil and grease to

protect the skin from ultraviolet

rays and the arc.

Do not use the

welding power source to thaw

pipes.

Remember:

The arc ray can damage the

eyes and cause burns to the skin.

Arc welding produces sparks and

drops of molten metal, the welded

work piece begins to glow and

remains very hot for a relatively

9 GB/IE/NI

long time. Therefore do not touch

the work piece with bare hands.

Arc welding releases noxious

fumes. Be careful not to inhale

these as best possible.

Protect yourself from the danger-

ous effects of the arc and keep

persons not involved in the work

at least 2 m away from the arc.

ATTENTION!

Depending on mains conditions

at the connection point, operating the welding equipment may

interfere with the voltage supply

for other loads. When in doubt,

please contact your power supply company.

Operating the welding equipment

may interfere with the functionality of other devices, e.g. hearing

aids, pacemakers, etc.

Safety hazards

during arc welding

Arc welding produces a variety of

safety hazards. It is therefore particularly important for the welder to

observe the following rules to avoid

putting himself and others in danger

and to prevent damage to persons

and the equipment

Only have work to the mains

voltage end, e.g. to cables, plugs,

outlets, etc. performed by a electrically skilled person in accordance with national and local

regulations.

In the event of an accident, im-

mediately disconnect the welding

equipment from the mains voltage.

If electrical contact voltage occurs,

immediately switch the equipment

off and have it inspected by an

electrically skilled person.

Always ensure good electrical

contacts on the welding current

end.

Always wear insulating gloves on

both hands whilst welding. These

will protect from electric shock

(no-load voltage of the welding

current), from hazardous rays

(heat and UV rays) and glowing

metal and weld splashes.

Wear solid, insulating shoes. The

shoes should also insulate when

exposed to moisture. Low shoes

are not suitable, as glowing metal

drops falling could cause burns.

Wear suitable protective clothing,

no synthetic garments.

Do not look into the arc with

unprotected eyes, only use a

welding shield with approved

protective glass per DIN. In

10 GB/IE/NI

Safety instructions

addition to light- and heat rays

which could result in blinding or

burns, the arc also emits UV rays.

Without adequate protection,

this invisible ultraviolet radiation

causes very painful conjunctivitis

which is only noticed a few hours

later. UV rays further cause burns

similar to a sunburn in unprotected

areas of the body.

Persons near the arc or assistants

must also be informed of the risks

and outfitted with the necessary

protection. If necessary, set up

protective panels.

Ensure an adequate supply of

fresh air whilst welding,

particularly in small spaces, as it produces

smoke and harmful gasses.

Do not weld containers in which

gasses, fuels, mineral oils, etc.

were stored - even if emptied a

long time ago - as residue poses

an explosion hazard.

Special regulations apply in rooms

posing fire- and explosion hazards.

Welded joints exposed to great

strain and needing to meet certain safety requirements must be

made by specially trained and

certified welders. Examples are

pressure vessels, running rails,

tow couplings, etc.

ATTENTION! Always connect

the earth terminal as close as

possible to the point of weld to

provide the shortest possible path

for the welding current from the

electrode to the earth terminal.

Never connect the earth terminal

to the housing of the welding

equipment!

Never connect the earth terminal

to earthed parts far away from

the work piece, e.g. a water pipe

in another corner of the room. This

could otherwise damage the

protective bonding system of the

room you are welding.

Do not use the welding equipment

in the rain.

Do not use the welding equipment

in a moist environment.

Only place the welding equip-

ment in a level location.

The output is rated at an ambient

temperature of 20 °C. The welding time may be reduced in

higher temperatures.

Danger of electric shock:

Electric shock from a weld-

ing electrode can be fatal.

Do not weld in rain or snow. Wear

dry insulating gloves. Do not touch

the electrode with bare hands. Do

not wear wet or damaged gloves.

11 GB/IE/NI

Protect yourself from electric shock

by insulating from the work piece.

Do not open the equipment housing.

Danger due to welding

smoke:

Inhaling welding smoke can jeopardize your health. Keep your head

out of the smoke. Use facilities in

open areas. Use ventilation to remove

smoke.

Danger due to electromagnetic fields:

Welding current produces electromagnetic fields. Do not use along

with medical implants. Never wrap

the welding cables around the

body. Consolidate welding cables.

Safety notices specific to

the welding shield

Danger due to welding

sparks:

Welding sparks can cause an

explosion or fire. Keep flammables

away from the welding area. Do

not weld next to flammables. Welding sparks can cause a fire. Keep a

fire extinguisher nearby and an observer ready to use it. Do not weld

on top of drums or any closed containers.

Danger due to arc rays:

Arc rays can damage the eyes and

injure the skin. Wear a hat and

safety goggles. Wear hearing

protection and a closed, high shirt

collar. Wear welding helmets and

proper filter sizes. Wear full personal protection.

Using a hot light source (e.g.

lighter) always check the welding shield is working properly

before starting to weld.

Welding splashes can damage

the glass shield. Replace damaged or scratched glass shields

immediately.

Promptly replace damaged or

heavily soiled / splashed components.

The equipment may only be

operated by persons who have

turned 16.

Familiarise yourself with the safety

instructions for welding. Also refer

to the safety instructions of your

welding equipment.

Always use the welding shield

when welding. Failure to use the

shield may result in serious injuries to the retina.

12 GB/IE/NI

Safety instructions

Always wear protective clothing

when welding.

Never use the welding shield

without protective glass, as the

optics can otherwise be damaged.

Replace the protective glass

early to ensure good visibility

and fatigue-proof working.

Tight and moist spaces

When working in tight, moist or

hot spaces, use insulating pads

and intermediate layers in addition to gauntlet gloves made from

leather or other insulating materials to insulate the body from

earth.

When using welding equipment

in electrically dangerous conditions, e.g. in tight spaces from

conductive walls (kettles, pipes,

etc.), in wet spaces (soaking of

work clothes), the output voltages

of the welding equipment may

not be higher than 48 Volts (rms

value) in open loop. Based on

the output voltage this welding

equipment may be used in these

conditions.

Protective clothing

Whilst working the welder must

be protected against rays and

burns all over the body with the

appropriate clothing and face

protection. Remember the following steps:

- Put on protective clothing before

welding.

- Put on gloves.

- Open windows or vent to ensure

air supply.

- Wear safety goggles and a

mask.

Wear gauntlet gloves made

from suitable material (leather)

on both hands. These must be in

good condition.

Wear suitable aprons to protect

the clothing from sparks and

burns. When required based on

the working method, e.g. welding

overhead, wear a protective suit

and, if necessary, a head guard.

Protecting against

rays and burns

Mark the work area with a

sign „Danger! Do not look into

flames!“ to indicate the risk to

the eyes. If possible, shield the

13 GB/IE/NI

work areas to protect persons

nearby. Keep unauthorised persons away from the welding area.

Walls in the direct vicinity of fixed

work areas should be neither

light coloured nor glossy.

Protect windows against rays

passing through or reflecting at

a minimum to head height, e.g.

with suitable paint.

EMC Device Classification

This is a welding unit with Class A

electromagnetic compatibility in accordance with the IEC 60974-10

standard. Therefore, it fulfils the applicable requirements for industrial

and domestic use. It may be connected to the public low voltage

electricity supply in residential areas.

Even when the flux-cored arc welding unit complies with standardized

emission thresholds, electric arc

welding units may cause electromagnetic interference in sensitive

systems and devices.

The user is responsible and must

undertake the appropriate safety

measures for interference which

results from arcs during the welding

process. In doing so, the user must

take the following into account in

particular:

- Power, control, signal and tele-

communications cables

- Computers and other microproces-

sor-controlled devices

- Televisions, radios and other play-

back devices

- Electronic and electric safety

equipment

- People with pacemakers or hearing

aids

- Measuring devices and calibration

devices

- Interference immunity of other

devices in the vicinity

- The time of day during which

welding work is being carried out.

To reduce potential interference

radiation, it is recommended that

you:

- Equip the mains connection with a

mains filter or shield it with a metal

pipe

- Regularly perform maintenance

work on the flux-cored arc welding

unit and keep it in good condition

- Weld cables should be as short

as possible, fully unwound and

run as parallel on the ground as

possible

- Potential equalization should be

provided

14 GB/IE/NI

Safety instructions / Before Use / Assembly

- The work pieces should be properly earthed

- Devices and systems susceptible

to interference radiation should be

removed from the welding area if

possible or shielded.

Before Use

Remove all parts from the packaging and inspect

whether the flux-cored arc welding unit or the

individual parts are visibly damaged. If this is

the case, do not use the flux-cored arc welding

unit. Contact the manufacturer using the service

address stated.

Remove all protective film and other transport

packaging.

Check that all items included in the scope of

delivery are present.

Assembly

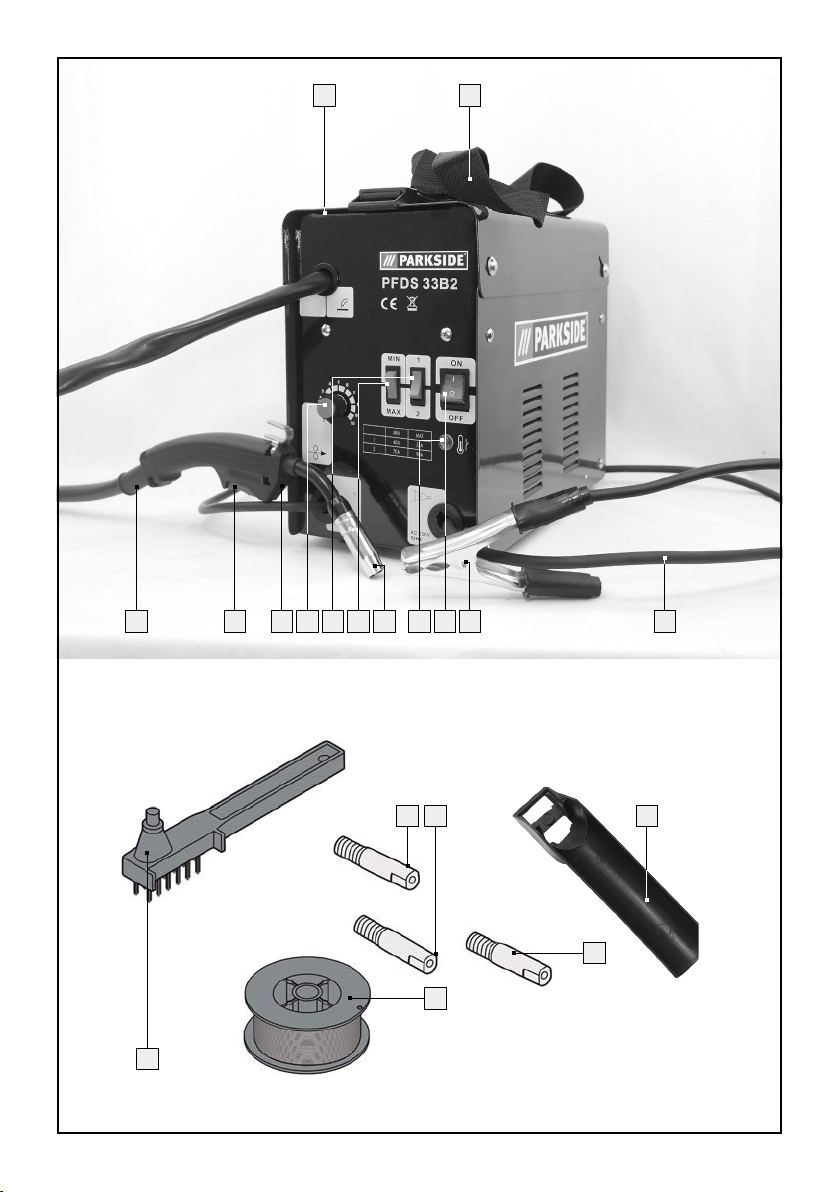

Assembling the

welding helmet

Insert the dark welding lens 21 into the mask

with the writing to the top

The marking on the dark welding lens

be visible from the front of the welding helmet.

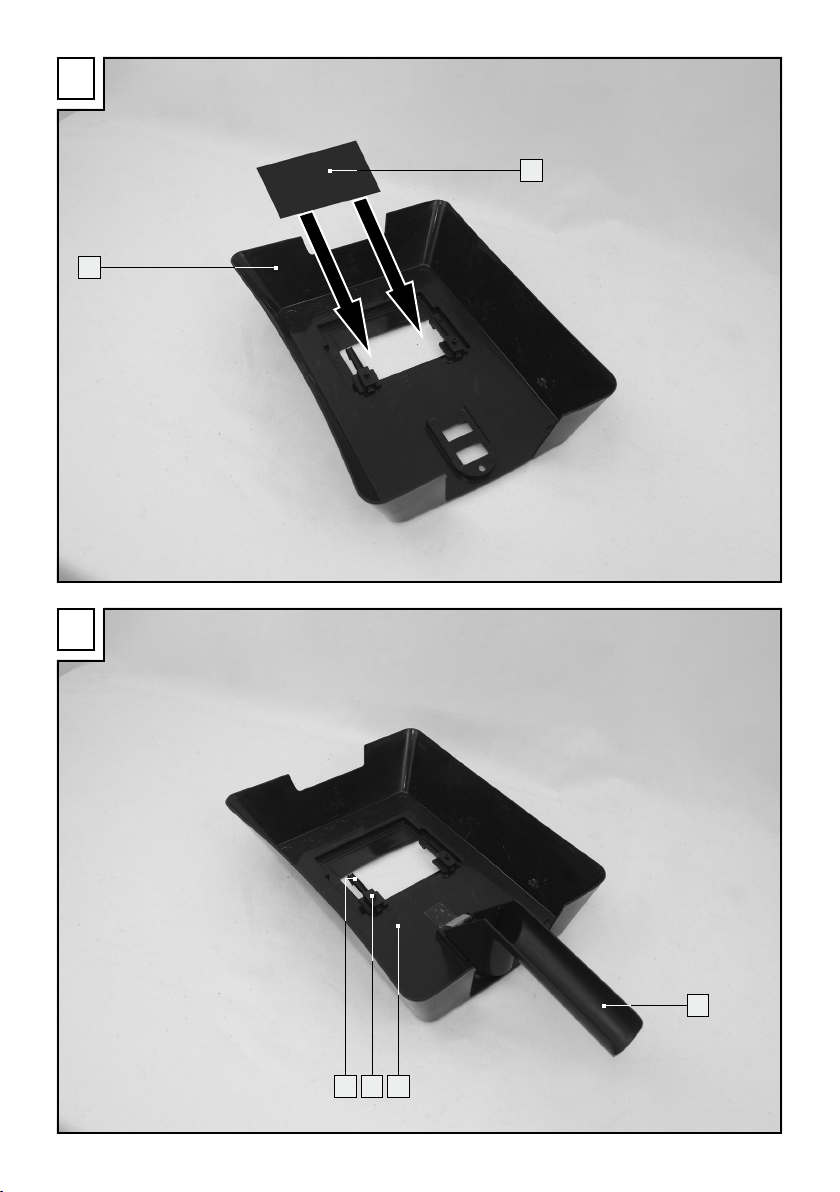

Push the handle 16 into the suitable notch on

the mask from the inside until it clicks in (See

Fig. B).

Inserting the flux-cored wire

22

(see Fig. A).

21

must

a diameter from 0.6 – 0.9 mm can be used with this

unit.

The feed roller, welding nozzle and wire cross-section

must always be compatible.

The unit is suitable for wire reels up to a maximum

of 450g.

Unlock and open the cover for the wire feeder

1

unit

by lifting the threaded rod up from the

slotted hole.

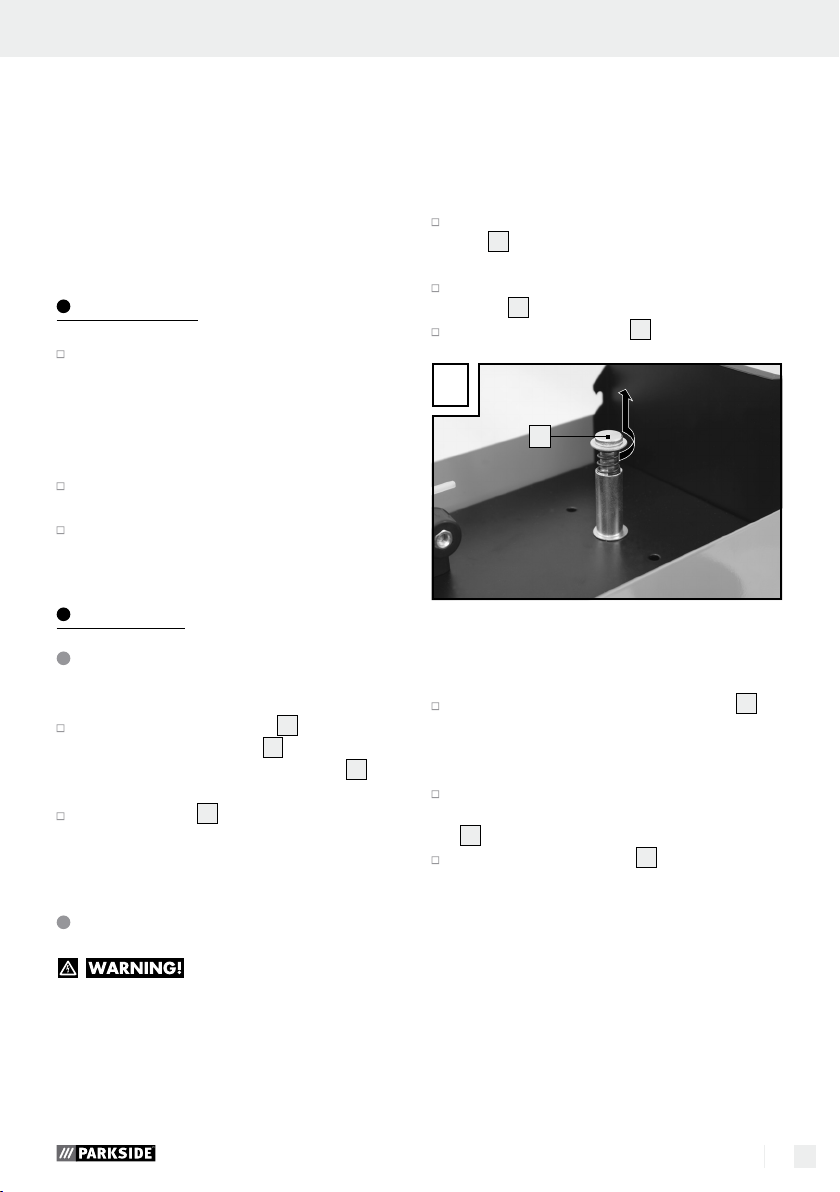

Unlock the roller unit by turning the roller

25

holder

Remove the roller holder 25 from the shaft (see

Fig. C).

clockwise (see Fig. C).

C

25

Note: Please ensure that the wire end does not

loosen and that the roll does not automatically

roll away. The wire end may only be loosened

during assembly.

Unwrap the flux-cored wire welding coil 18

completely so that it can be unrolled freely.

However, do not loosen the wire end just yet

(see Fig. D).

Place the wire reel onto the shaft. Ensure that

the roll uncoils on the side with the wire outlet

26

(see Fig. D).

Reattach the roller holder 25 and lock it by

pressing on it and turning it counterclockwise

(see Fig. D).

To prevent the hazard of an

electrical shock, injury or damage, pull the mains

plug from the socket before maintenance or preparing for work.

Note: Depending on the application, different

welding wires may be required. Welding wires with

15 GB/IE/NI

Loading...

Loading...