Page 1

PNEUMATIC SAW PDKS 6.3 A1

IAN 285212

DRUCKLUFT-SÄGE

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

PNEUMATIC SAW

Operation and Safety Notes

Translation of the original instructions

TRYKLUFTSSAV

Brugs- og sikkerhedsanvisninger

Oversættelse af den originale driftsvejledning

SCIE PNEUMATIQUE

Instructions d‘utilisation et consignes de sécurité

Traduction des instructions d‘origine

PERSLUCHTZAAG

Bedienings- en veiligheidsinstructies

Vertaling van de originele gebruiksaanwijzing

Page 2

GB / IE / NI Operation and Safety Notes Page 5

DK Brugs- og sikkerhedsanvisninger Side 15

FR / BE Instructions d‘utilisation et consignes de sécurité Page 25

NL / BE Bedienings- en veiligheidsinstructies Pagina 37

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 49

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Før du læser, vend begge sidene med billeder frem og bliv bekendt med alle apparatets funktioner.

Avant de lire le mode d‘emploi, ouvrez les deux pages contenant les illustrations et familiarisez-vous ensuite

avec toutes les fonctions de l‘appareil.

Vouw vóór het lezen de beide pagina‘s met de afbeeldingen open en maak u vertrouwd met alle functies

van het apparaat.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

Page 3

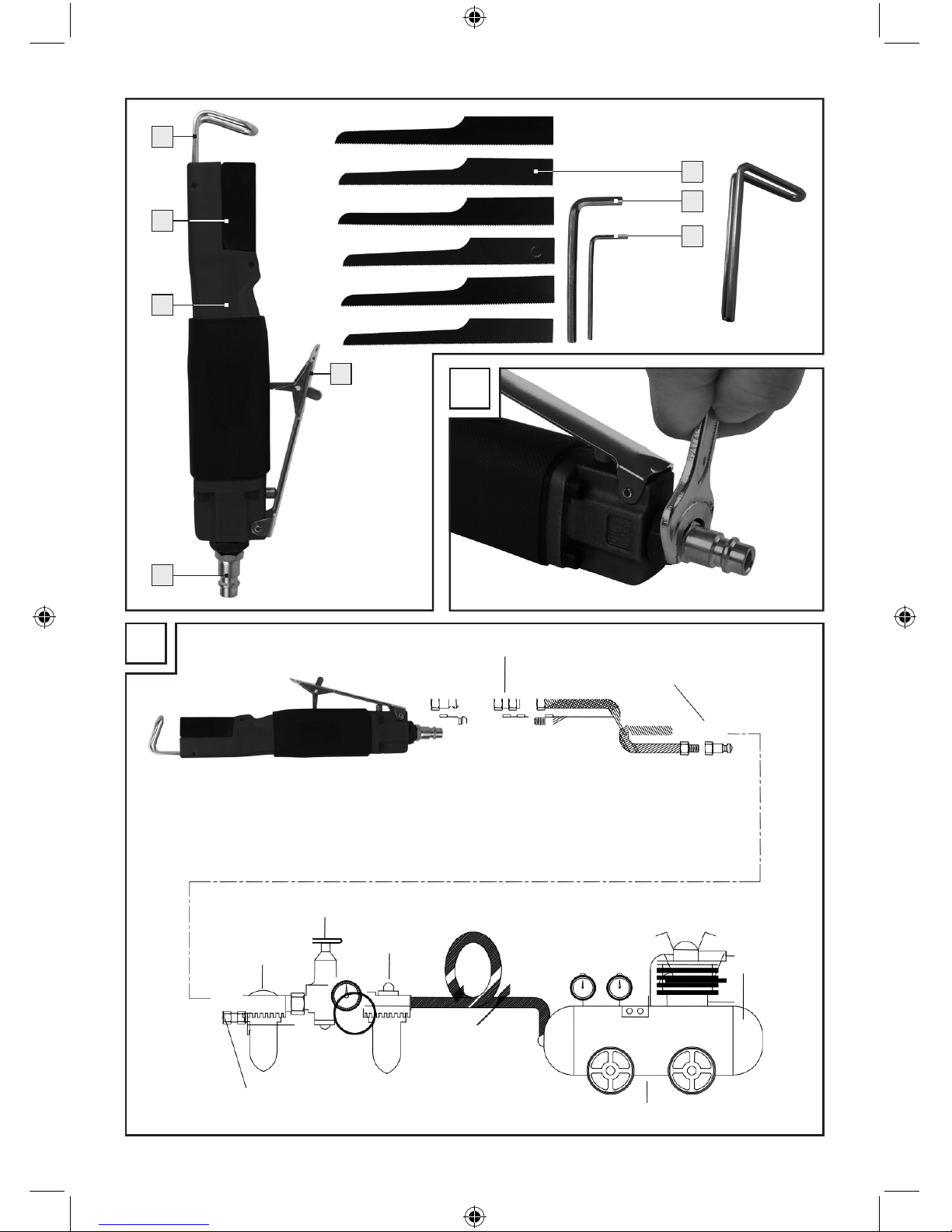

A

2

3

1

5

8

6

7

4

2 x

B

Pressurised air hose / Druckluftschlauc h

Quick-release socket /

Schnellverschluss-Stecker

Quick-release socket /

Schnellverschluss-Stecker

Pressure regulator / Druckregler

Lubricator /

Öler

Filter / Filter

Quick-opening sleeve / Schnellverschluss-Muffe

Compressor / Kompressor

Page 4

D

FE

C

HG

I

Page 5

5 GB/IE/NI

Table of contents

Introduction ................................................................................................................................... Page 6

Intended use ........................................................................................................................................ Page 6

Features ...............................................................................................................................................Page 6

Technical Data ....................................................................................................................................Page 6

Scope of delivery ................................................................................................................................ Page 7

General safety rules ..............................................................................................................Page 7

Risks due to projected parts ...............................................................................................................Page 7

Hazards from entanglement ............................................................................................................... Page 7

Operating hazards .............................................................................................................................Page 7

Hazards due to repetitive motions ..................................................................................................... Page 8

Risks associated with accessories ......................................................................................................Page 8

Hazards in the work environment ...................................................................................................... Page 8

Hazards due to dust and vapours .....................................................................................................Page 8

Noise hazards ..................................................................................................................................... Page 9

Hazard due to vibration ..................................................................................................................... Page 9

Additional safety instructions for pneumatic machinery ...................................................................Page 9

Before use .......................................................................................................................................Page 10

Installation ...........................................................................................................................................Page 10

Start-up .............................................................................................................................................Page 10

Connecting the compressed air tool .................................................................................................. Page 10

Cutting .................................................................................................................................................Page 10

After initial use ...........................................................................................................................Page 11

Replacing the saw blade .................................................................................................................... Page 11

Adjusting / replacing the blade guard ............................................................................................... Page 11

Cleaning and storage ...........................................................................................................Page 11

Lubricating the air saw ........................................................................................................................ Page 11

Storing the air saw .............................................................................................................................. Page 11

Maintenance ................................................................................................................................. Page 12

Warranty and service information ...........................................................................Page 12

Warranty terms ...................................................................................................................................Page 12

Extent of warranty ............................................................................................................................... Page 12

Processing of warranty claims ............................................................................................................ Page 13

Environmental instructions and disposal information ..............................Page 13

Declaration of Conformity ................................................................................................ Page 14

Page 6

6 GB/IE/NI

Introduction

Pneumatic saw PDKS 6.3 A1

Introduction

Congratulations!

You have chosen high-quality device by

our company. Familiarise yourself with

the product before using it for the first time. In addition, please carefully refer to the operating instructions

and the safety advice below. Initial operation of this

tool must be performed by trained personnel.

KEEP OUT OF THE REACH OF CHILDREN!

Intended use

The air saw is an air-powered tool for handyman use.

It is designed for bodywork, automotive and shop

use. The user should wear safety goggles to protect

from fragments and safety gloves to protect from

accidental contact with potentially sharp edges. K

eep

these instructions in a safe place. When passing this

product on to others, please also include all the documents. Any use other than the intended is prohibited

and potentially dangerous. Damages resulting from

noncompliance or misuse are not covered by the

warranty and are not included in the manufacturer‘s

liability. This device has been designed for household use and may not be used for commercial or

industrial purposes.

Features

Check that all the items are present and that the

product is in perfect condition immediately after

unpacking. Never use the product if it is defective.

1

Saw blade

2

Socket head wrench 4 mm

3

2 mm socket head wrench for installing /

removing the stop bracket

8

4

Trigger with safety stop

5

Threaded plug nipple

6

Housing

7

Cover (socket head screw)

8

Stop bracket

Technical Data

Max. working pressure: 6,3 bar

Max. speed: 8500

rpm

Air intake: ¼

Stroke: 10 mm

Weight: 620 g

Noise and vibration

ATTENTION!

Always wear hearing protection!

Noise parameter per EN15744:2008

Noise level L

pA

: 80.2 dB(A)

Sound power level L

WA

: 91.2 dB(A)

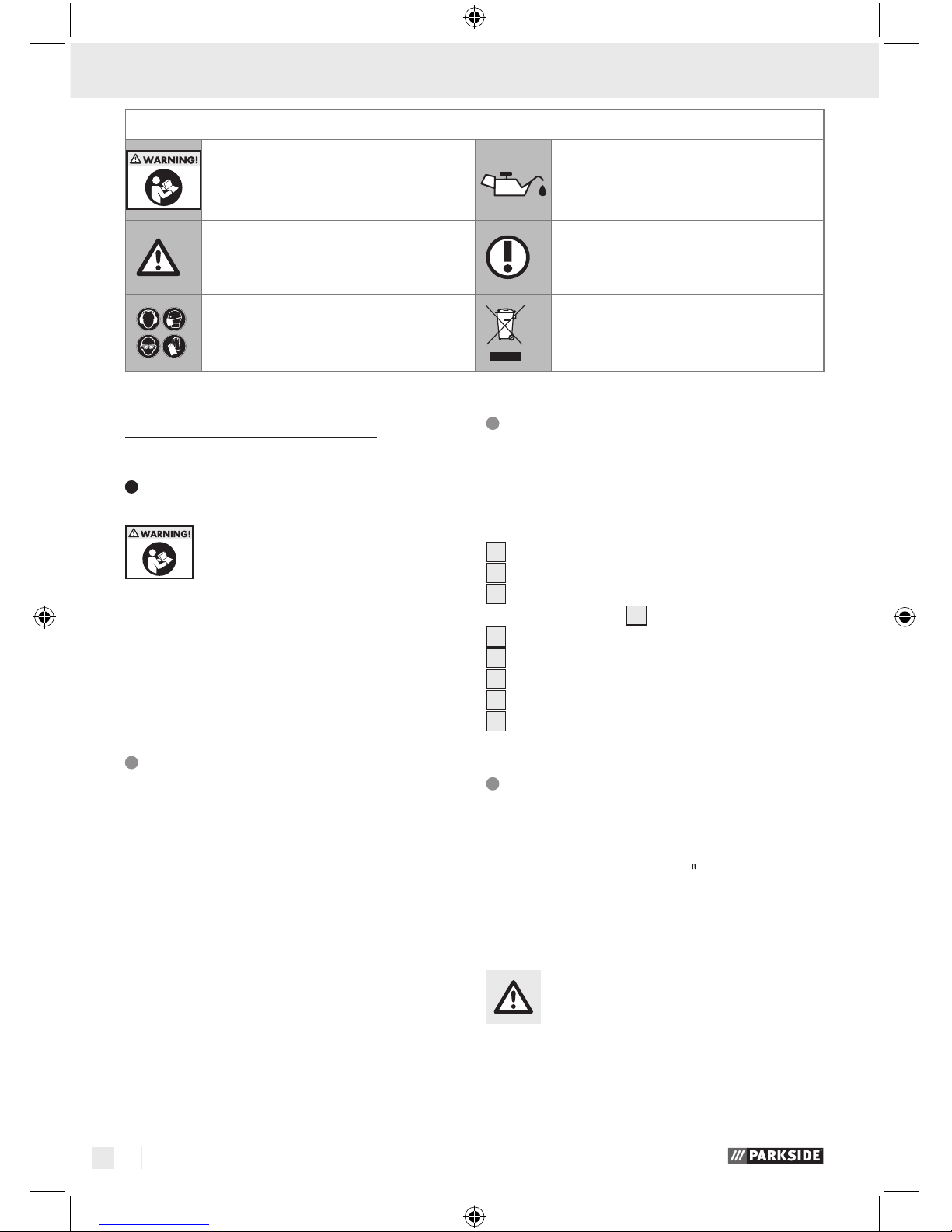

These original operating instructions / the device uses the following pictograms:

Please read the operating instructions!

Oil daily

Observe the warning and safety

instructions!

Note

Wear ear protection, dust mask, safety glasses and protective gloves.

Dispose of packaging and device in

an environmentally-friendly way!

Introduction / General safety rules

Page 7

7 GB/IE/NI

Uncertainty K = 3 dB

Vibration parameters per EN 12096, ISO

28927-7

Hand-arm vibration level: 5.8 m / s

2

Uncertainty K: 0.6 m / s

2

Scope of delivery

1 Pneumatic saw

1 2 mm socket head wrench for installing / removing

the stop bracket

8

1 Socket head wrench 4 mm

6 Saw blades (3 saw blades for wood (HCS),

3 saw blades for metal (BIM))

2 Blade guards

1 Set of instructions for use

General safety rules

Multiple hazards! Read and understand

the safety notices before setting up, operating,

repairing, maintaining and replacing accessories

on circular, oscillating or reciprocating saws,

as well as before working near the machine.

Failure to observe this may result in severe

physical injuries.

Circular, oscillating and reciprocating saws

should only be set up, adjusted and used by

adequately qualified and trained persons.

Do not modify these circular, oscillating and re-

ciprocating saws. Modifications may reduce the

effectiveness of safety measures and increase

operator risks.

Never lose the safety notices – and pass on to

the user.

Never use a damaged circular, oscillating or

reciprocating saw.

The machines must be inspected regularly to ver-

ify the machine is labelled with clearly legible

rated values and markings. If necessary, the user

must contact the manufacturer for replacement

labels.

Risks due to projected parts

If the work-piece, one of the accessories or the

tool itself breaks, parts may be projected at

great speed.

Always wear impact-proof eye protec-

tion when using circular, oscillating,

or reciprocating saws. The level of

required protection required should be assessed

individually for each application.

It must be ensured that the work-piece is prop-

erly secured.

Be sure sparks and metal cuttings are directed

so they do not produce a hazard.

Be sure the saw blade is installed correctly

and firmly.

Hazards from entanglement

Failure to keep loose fitting clothing, jewellery,

necklaces / scarves (etc.), hair or gloves away

from the machine or accessories can pose a risk

of suffocation, scalping and / or cuts.

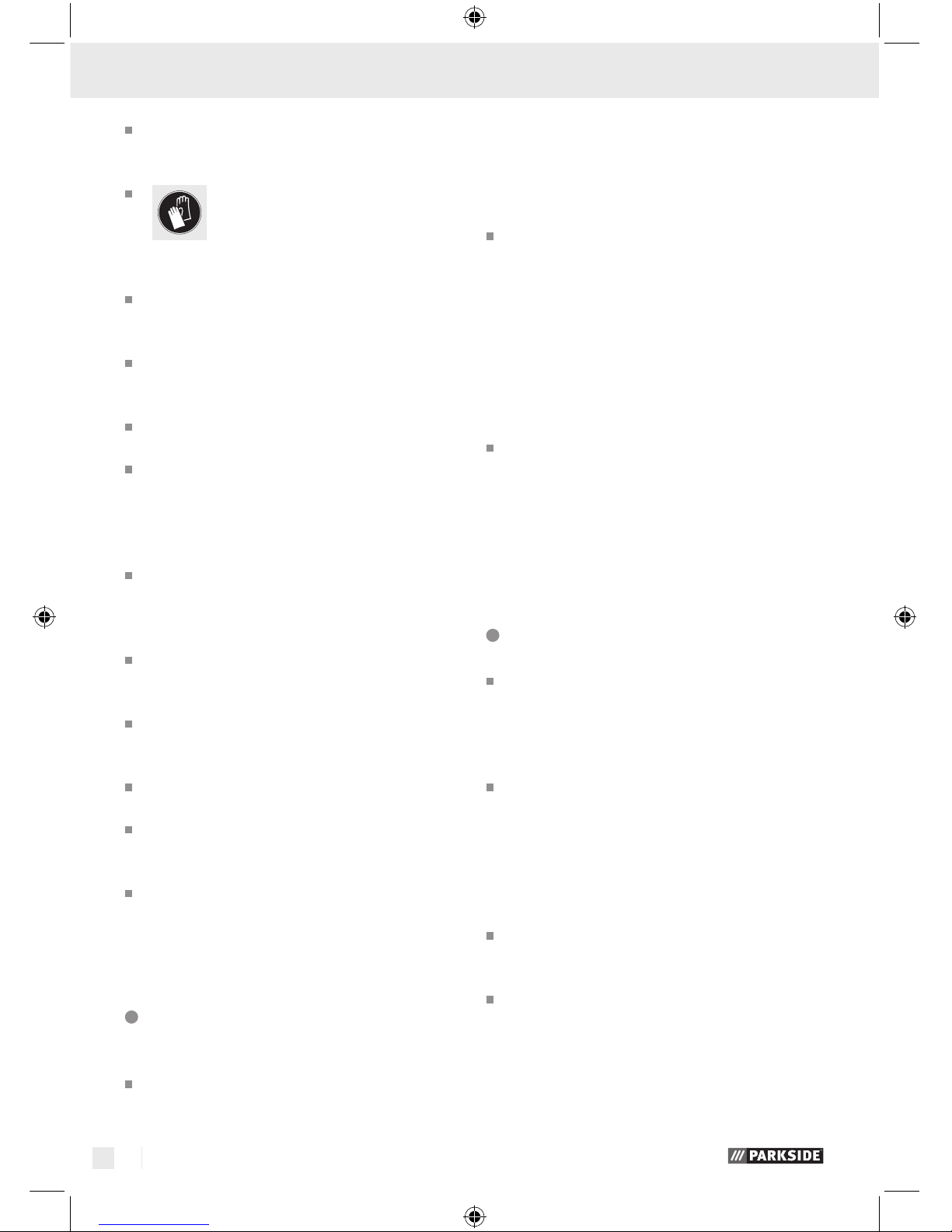

Operating hazards

Avoid contact with the saw blade to prevent cuts

to the hands or other body parts.

Guards must be safely installed and in good

working order.

Defective, bent or severely worn guards must

be replaced with guards recommended by the

manufacturer.

Be sure the retractable guard does not snap

from the fully opened position to the fully closed

position after being released.

Never lock or tie guards in an open position or

otherwise disable.

When using the machine the user‘s

hands may be exposed to hazards

such as cuts as well as abrasion and

heat. Wear suitable gloves to protect hands.

The operator and the maintenance personnel

must be physically capable of managing the

size, weight and power of the machine.

Page 8

8 GB/IE/NI

General safety rules

Hold the machine correctly: be prepared

to counteract typical or sudden movements –

keep both hands ready.

Be sure your body is well balanced and you

maintain a solid grip.

Prevent injuries from cutting: Avoid con-

tact with the saw blade when the machine is

connected to the air supply. Wear protective

equipment such as gloves, apron and helmet.

Uncontrolled machine movement can

cause injuries: Always be sure to hold the

guide plate (if attached) firmly against the

work piece.

Cutting with these machines will create sharp

edges. Wear gloves to protect your hands.

In the event of power failure release the start-

or stop control.

Only use the lubricants recommended by the

manufacturer.

Protective equipment such as safety goggles

must be used; suitable gloves and protective

clothing are recommended.

Be aware the rotating built-in tool will start up

after activating the start- and stop control.

Hazards due to

repetitive motions

When using circular, oscillating or reciprocating

saws for work related tasks the operator may

experience discomfort of the hands and arms,

as well as the neck and shoulders or other

body parts.

When using circular, oscillating or reciprocating

saws the operator should maintain a comfortable

posture, ensuring a secure grip and avoiding

uncomfortable postures or postures making it

difficult to maintain balance. The operator should

change his posture when working for extended

periods to help prevent discomfort and fatigue.

If the operator experiences symptoms such as

persistently or repeatedly feeling unwell, discomfort, palpitations, pain, tingling, numbness, a

burning sensation or stiffness, these warning si

gns

should not be ignored. The operator should consult a suitably qualified healthcare professional.

Risks associated with

accessories

Disconnect circular, oscillating and reciprocating

saws from power before installing or replacing

tools or accessories.

Only use accessory and material sizes and

types recommended by the manufacturer of the

circular, oscillating or reciprocating saw. Never

use other sizes and types of accessories and

materials.

Avoid direct contact with accessories before

and after using the equipment, as these may

be warm or sharp.

Inspect the saw blade prior to use. Do not use

saw blades which may have been dropped or

with chipped, cracked or otherwise defective

parts.

Hazards in the work

environment

Slipping, tripping and falling are the main causes

of injuries at the workplace. Keep in mind that

surfaces may have become slippery during

machine use, and remember tripping hazards

caused by the air- or hydraulic hose.

Proceed with caution in unfamiliar surroundings.

There may be hidden dangers due to electrical

cables or other supply lines.

These circular, oscillating or reciprocating saws

are not suitable for use in explosive environments

and are not insulated against contact with electric lines.

Verify there are no electric lines, gas lines, etc.

which may pose a hazards if damaged by use

of this equipment.

Hazards due to dust

and vapours

Dust and vapour produced when using circular,

oscillating and reciprocating saws can be dangerous to the health (e.g. cancer, birth defects,

asthma and / or dermatitis; it‘s imperative to

Page 9

9 GB/IE/NI

General safety rules

perform a risk assessment in this respect and implement the respective regulatory mechanisms.

The risk assessment should include dust generat

ed

by machine use and the dust already present in

the area, which is possibly being blown around.

Operate and maintain the circulating, oscillating

and reciprocating saws as recommended in these

instructions to minimise the risk of releasing dust

and vapours.

Exhaust air must be extracted so as to minimise

dust being blown about in dusty environments.

If dust or vapours are produced, controlling these

at their point of release is a priority.

Any machine parts or accessories to collect,

extract or eliminate airborne dust or vapours

should be used and maintained according to

manufacturer instructions.

Select, maintain and replace consumables /

machine tools as recommended in the instructi

ons

for use to prevent an unnecessary increase in

the production of dust or vapours.

Warnings regarding the risk of explosion or fire

related to the materials being worked on must

be observed.

Use respiratory protection as in-

structed and as required by occupational health and safety regulations.

Working on certain materials emits dust and

vapour, resulting in a potentially explosive environment.

Noise hazards

With inadequate ear protection the impact of

high noise levels may result in permanent hearing damage, hearing loss and other problems,

e.g. tinnitus (ringing, whistling or buzzing in the

ear). A risk assessment and implementing the

respective regulatory mechanisms for these

hazards is imperative.

Suitable regulatory mechanisms to minimise the

risk include measures such as using insulation

to prevent pinging sounds on work pieces.

Use hearing protection.

Operate and maintain circular, oscillating and

reciprocating saws as recommended in the instructions for use to prevent an unnecessary increase in the noise level.

Select, maintain and replace consumables /

tools as recommended in the instructions for

use to prevent an unnecessary increase in the

noise level.

If the circular, oscillating or reciprocating saws

feature a silencer, always ensure it is installed

and functional when the machine is in use.

Hazard due to vibration

Exposure to vibration may cause damage to

the nerves and disturb blood circulation in hands

and arms.

Wear warm clothing and keep your hands warm

and dry when working in cold environments.

If you notice numbness, tingling or pain in your

fingers or hands, or the skin in your fingers or hands

turns white, stop using the circular, oscillating

or reciprocating saw and consult a physician.

Operate and maintain the circular, oscillating

or reciprocating saws as recommended in these

instructions for use to prevent an unnecessary

increase in vibration.

Select, maintain and replace the consumables /

machine tools according to these instructions to

prevent an unnecessary increase in vibration.

Whenever possible, use a support, clamp or

equaliser to support the weight of the machine.

Hold the machine firmly, but not too tightly,

maintaining the necessary hand reaction forces,

as the vibration hazard typically increases when

firming the grip.

Attaching the saw blade incorrectly can cause

excess vibration.

Additional safety instructions

for pneumatic machinery

Compressed air can result in serious injuries.

Always close the air supply, release pressure

from the hose, and disconnect the machine

Page 10

10 GB/IE/NI

General safety rules / Before use / Start-up

from the compressed air supply, when the machine is not in use, before switching accessories or when performing repairs.

Never aim the air flow at yourself or others.

Hoses flapping about can result in serious

injuries. Therefore always inspect hoses and

their fasteners for damage and a secure fit.

When using universal swivel couplings (coup-

ling discs), always use locking pins; Whip-check

hose safety cables must be used for protection

in the event the connection between the hose

and the machine or in between hoses fails.

Be sure not to exceed the maximum pressure

specified on the machine.

Never carry pneumatic tools by the hose.

Before use

Installation

The device itself is fully functional at delivery. Using

the device may require (unless already installed) installing a threaded plug nipple

5

(note the data

under technical details for the fit / size).

Wrap the threaded plug nipple 5 with Teflon

tape (not included) before screwing it into the

air tool. Wrap the tape around the thread as

tight as possible. This will minimise the likelihood

of air leaking and optimise the work process.

Now screw the threaded plug nipple 5 into

the power tool.

Tighten the threaded plug nipple 5 to the air

tool with a size 14 key using moderate force

(see Fig. A).

Adjusting the compressed air supply and

connections

Only use filtered, lubricated and regulated

compressed air.

Connect to the compressed air system using the

method shown in Figure B. This will increase

the effectiveness and life of the tool.

Set your compressor to the working pressure

specified for the device under technical data.

Please note, on average the pressure for 10 m

of hose will decrease by about 0.5 bar.

Excessive pressure is

dangerous! Never exceed the specified

pressure!

Add a few drops of air tool oil or SAE 10–20

engine oil to the compressed air connection of

the air tool before first use and in regular interva

ls.

Using other oil (particularly higher viscosity) will

result in damage or even total loss of the device.

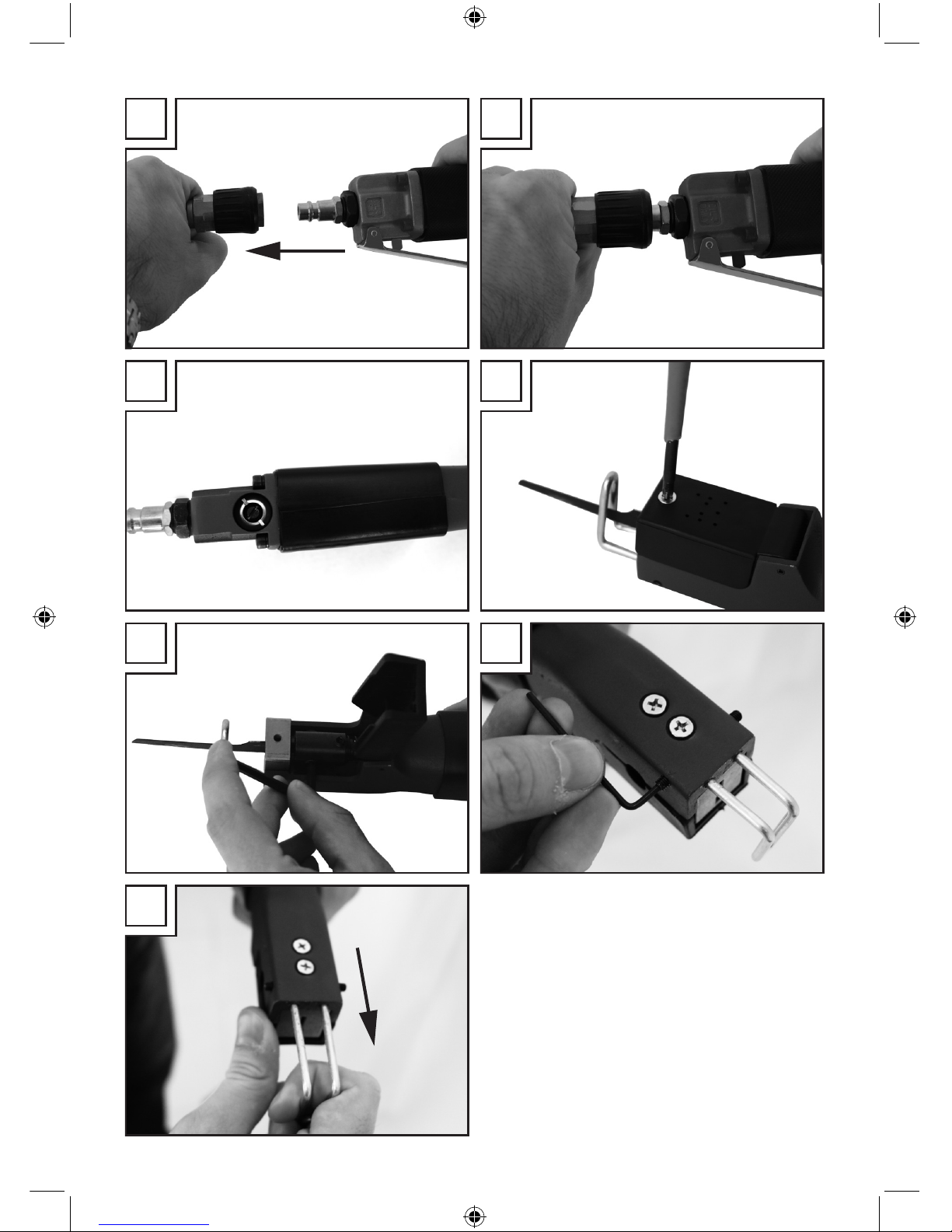

Start-up

Connecting the

compressed air tool

Verify the work piece is correctly supported.

Connect to compressed air by pushing on the

quick couple of the hose using a little force

(see Fig. C).

Always verify the compressed air hose is properly

connected (see Fig. D). A loose hose whipping

about out of control presents a major hazard.

The threaded plug nipple

5

must be firmly

seated for the same reason. This must also be

checked.

Use the screw on the air inlet (see Fig. E) to

adjust the tool pressure.

Cutting

Note: The trigger 4 features a safety stop. Using

the trigger

4

requires pushing the lever on the trig-

ger

4

(safety stop) forward whilst pushing down

on the trigger

4

.

Activate the trigger 4 to operate the saw.

Note: Metal slivers flying about can be very

dangerous!

Note: If the compressed air supply is temporarily cut off due to power failure or temporary

compressor failure, immediately release the

trigger

4

. You must now first pull the saw all

the way out of the work piece to continue working. You can then continue working.

Always check the saw blade position after

2 minutes of continuous operation.

Page 11

11 GB/IE/NI

Start-up / After initial use / Cleaning and storage

After finishing the task, release the trigger 4 to

stop the saw from running.

After initial use

Once the task has been finished the device must be

disconnected from the compressed air connection.

This first requires the pressure to be completely released from the lines.

Briefly activate the trigger 4 on the device to

release any remaining compressed air.

Replacing the saw blade

Immediately replace the saw blade 1 if dull, wa

rped

or defective.

Always be sure the compressed air supply is dis-

connected when replacing the saw blade

1

!

First open the front cover 7 with a screwdriver

(see Fig. F).

Use the included socket head wrench 2 to

loosen the socket head screws on the saw blade

holder (see Fig. G) and remove the saw blade.

Then insert the new saw blade 1 into the saw

blade holder and tighten the socket head screws

again.

Ensure the saw blade 1 is correctly seated in

the saw blade holder and cannot be pulled out.

Then close the cover 7 with the screwdriver.

Adjusting/replacing the blade

guard

To adjust the blade guard 8, loosen the two

outside screws (see Fig. H) with the included

2 mm hexagon socket wrench

3

. After loosening the screws you will be able to pull on the

blade guard to adjust it (see Fig. I).

You will now be able to adjust or replace the

blade guard.

After replacing or adjusting the blade guard,

tighten the previously loosened screws with the

hexagon socket wrench.

Cleaning and storage

To ensure a long life and trouble-free operation, it‘s

important to observe the following instructions.

Always disconnect the tool from the compressed

air supply before cleaning.

Clean your tool with a dry, soft cloth or lightly

blow it out with compressed air. Never use

caustic cleaners.

Lubricating the air saw

Note: Regular lubrication is required

to ensure the longest possible life to

air tools.

Turn the tool over so the air connection is facing

up and add a few drops of air tool oil or SAE

10–20 engine oil to the tool‘s air connection.

Activate the trigger 4 to allow the oil to dis-

perse better.

Hold a rag or absorbent paper towel in front

of the exhaust opening and run the tool on idle

for a few seconds.

ATTENTION! Remove the compressed

air connection before performing maintenance!

Excess oil will be blown out.

Keep persons or objects away from the discharge.

Storing the air saw

Store the air tool in a dry location, protected from

the weather and out of the reach of children.

Be sure moisture does not enter the inside of

the air tool.

Page 12

12 GB/IE/NI

Maintenance / Warranty and service information

Maintenance

The device should be regularly maintained (after

about 1–2 uses).

Always wear suitable work gloves.

Maintenance must be performed by trained per-

sons. Adhering to these maintenance instructions

will ensure a long life and proper operation of

this quality product.

Disconnect equipment from the compressed air

source when performing maintenance and care.

Check the condition of wear and tear items

and accessories with every maintenance.

Note: Daily cleaning and regular lubrication

are absolutely required for smooth operation.

Only use special tool oil with a high viscosity

(thin) for this purpose. Oil for compressed air

equipment or motor oil SAE10–20 are suitable.

ATTENTION! Do not use any other (especially

high viscosity) lubricant. Otherwise there will

be a danger of functional disturbance or permanent damage.

Operate the device with clean air. Corrosion

residue, dust and dirt from the supply line impact

performance and result in technical problems.

Such contamination can be countered using a

service unit with filter, reducer valve and oiler.

If necessary, clean your device with a damp cloth.

Do not use chemical cleaners containing aggres-

sive substances such as petrol, thinner, etc., as

these may damage the plastic.

Ensure fluids do not enter the saw.

Regularly check all screws, the stop bracket and

saw blade are firmly seated. Further regularly

check the speed and vibration level of the device.

Regularly check the condition of the saw blade.

The saw blade must not be defective or deformed.

Warranty and service

information

Creative Marketing Consulting GmbH

warranty

Dear customer,

the warranty for this device is 3 years from the date

of purchase. In the event of product defects, you

have legal rights against the retailer of this product.

Your statutory rights are not limited in any way by

our warranty detailed below.

Warranty terms

The warranty period begins on the date of purchase.

Please retain the original receipt safely. This document

is required as your proof of purchase.

Should this device show any defect in materials or

manufacture within 3 years from the date of purch

ase,

we will repair or replace it - at our discretion - free

of charge. This warranty is conditional on the defective device and the receipt of purchase being presented within the three year warranty period, and

that there is a brief written description of the nature

of the defect and of the date it arose.

If the defect is covered by our warranty, we will

return the repaired device or replacement thereof.

A repair or exchange of the device does not extend

a new warranty period.

Extent of warranty

The appliance has been manufactured to strict quality

guidelines and meticulously examined before delivery.

The warranty applies to faults in material or manufacture. This warranty does not apply to product parts

subject to normal wear and tear and which can therefore be considered as wear items, or to damage to

fragile parts, e.g. switches, storage batteries or

glass parts.

This warranty becomes void if the device has been

damaged or improperly used or maintained. All instructions provided in the instructions for use must

Warranty and service ... / Environmental instructions and disposal information

Page 13

13 GB/IE/NI

Warranty and service ... / Environmental instructions and disposal information

be followed strictly to constitute proper use of the

product. Purposes and practices which the operating instructions warn of or advise against must be

avoided without fail.

This product is intended for private, non-commercial

use only. Any incorrect or improper use of the device,

use of force and changes not performed by our authorized service branch will void the warranty.

Processing of warranty claims

Please follow the instructions below to ensure quick

processing of your claim:

Please have your receipt and the item number

(e.g. IAN) ready as your proof of purchase when

enquiring about the product.

The item number can be found on the type plate, engraving, the cover page of your instructions (bottom

left) or the decal at the back or bottom.

In the event of malfunctions or other defects, please

first contact the service department below by phone

or e-mail.

A product determined defective may then be returned

t

o the specified service address free of charge, incl

uding the proof of purchase (receipt) and information

about the defect and when it occurred.

Notice:

Visit www.lidl-service.com to download

this and many other manuals, product

videos and software.

How to contact us:

GB, IE, NI

Name: C. M. C. GmbH

Internet address: www.cmc-creative.de

E-mail: service.gb@cmc-creative.de

service.ie@cmc-creative.de

service.ni@cmc-creative.de

Phone: 0-808-189-0652 (standard

rates for German landlines)

Registered office: Germany

IAN 285212

Please note that the following address is not a

service address.

Please first contact the service point named above.

Address:

C. M. C. GmbH

Katharina-Loth-Str. 15

DE-66386 St. Ingbert

GERMANY

Environmental instructions

and disposal information

Don‘t waste, recycle!

Device, accessories and packaging should

be recycled in an environmentally friendly

manner.

Do not dispose of the air tool with your household

waste, or throw it into the fire or water. If possible,

devices which are no longer functioning should be

recycled. Contact your local retailer for information.

Page 14

14 GB/IE/NI

Declaration of Conformity

Declaration of Conformity

We,

C. M. C. GmbH

Responsible for documentation: Marc Uhle

Katharina-Loth-Str. 15

DE-66386 St. Ingbert

GERMANY

declare in our sole responsibility the product

Pneumatic saw

Item number: 2053

Year of manufacture: 2017 / 34

IAN: 285212

MODEL: PARKSIDE PNEUMATIC SAW

PDKS 6.3 A1

meets the basic safety requirements of European

Directives

Machinery Directive

EC directive 2006 / 42 / EC

and its amendments.

The conformity assessment is based on the following

harmonised standards:

DIN EN ISO 11148-12:2012

St. Ingbert, 31.05.2017

i. A. Marc Uhle

- Quality Control Manager -

Page 15

15 DK

Indholdsfortegnelse

Indledning .......................................................................................................................................Side 16

Formålsbestemt anvendelse ................................................................................................................Side 16

Udstyr ....................................................................................................................................................Side 16

Tekniske data........................................................................................................................................Side 16

Leverede dele .......................................................................................................................................Side 17

Generelle sikkerhedsregler .............................................................................................Side 17

Farer i forbindelse med omkringflyvende dele ...................................................................................Side 17

Farer ved infiltration .............................................................................................................................Side 17

Farer under driften ...............................................................................................................................Side 17

Farer ved gentagne bevægelser .........................................................................................................Side 18

Farer ved tilbehørsdele ........................................................................................................................Side 18

Farer på arbejdspladsen .....................................................................................................................Side 19

Fare på grund af støv og dampe ........................................................................................................Side 19

Farer i forbindelse med larm ...............................................................................................................Side 19

Farer i forbindelse med svingninger ....................................................................................................Side 20

Yderligere sikkerhedshenvisninger til pneumatiske maskiner ............................................................Side 20

Inden ibrugtagning ..................................................................................................................Side 20

Montage ...............................................................................................................................................Side 20

Ibrugtagning .................................................................................................................................Side 21

Tilslutning af trykluftværktøj .................................................................................................................Side 21

Savning .................................................................................................................................................Side 21

Efter ibrugtagningen ..............................................................................................................Side 21

Udskiftning af savklinge .......................................................................................................................Side 21

Justér / veksel anslagsbøjle ..................................................................................................................Side 22

Rengøring og opbevaring .................................................................................................Side 22

Smøring af trykluft-sav ..........................................................................................................................Side 22

Opbevaring af trykluft-sav ...................................................................................................................Side 22

Vedligeholdelse ..........................................................................................................................Side 22

Henvisninger til garanti og serviceafvikling......................................................Side 23

Garantibetingelser ...............................................................................................................................Side 23

Garantiomfang .....................................................................................................................................Side 23

Afvikling af garantisager .....................................................................................................................Side 23

Miljøhenvisninger og bortskaffelsesangivelser .............................................Side 24

EG-konformitetserklæring .................................................................................................Side 24

Page 16

16 DK

Indledning

Trykluftssav PDKS 6.3 A1

Indledning

Hjerteligt tillykke!

De har valgt et produkt af høj kvalitet

fra vores firma. Gør Dem fortrolig med

apparatet inden første ibrugtagning. Læs derfor den

efterfølgende betjeningsvejledning og sikkerhedsanvisningerne omhyggeligt igennem. Kun instruerede

personer må tage dette produkt i brug.

OPBEVARES UTILGÆNGELIGT FOR BØRN!

Formålsbestemt anvendelse

Trykluft-saven er et trykluftdrevet værktøj til den håndværksmæssige indsats. Den er koncioeret til indsatsen

i karosserifremstillingen, kraftfartøjs- og værkstedsområdet. Brugeren bør beskytte sig med et par beskyttelsesbriller mod brudstykker og med handsker

imod tilfældig kontakt med eventuelle skarpe kanter.

Opbevar denne vejledning omhyggeligt. Hvis De

giver produktet videre til tredjemand, så skal vejledningen også følge med. Enhver anvendelse, der

afviger fra den formålsbestemte anvendelse, er

forbudt og indebærer potentielle farer. Skader, der

opstår på grund af manglende overholdelse eller

fejlagtig anvendelse, dækkes ikke af garantien, og

hører ikke til producentens ansvarsområde. Dette

produkt er konciperet til privat brug og må ikke

benyttes kommercielt eller industrielt.

Udstyr

Kontrollér altid umiddelbart efter udpakningen, at

produktets tilstand er fejlfri. Benyt ikke produktet,

når dette er defekt.

1

Savklinge

2

Umbrakonøgle 4 mm

3

Umbrakonøgle 2 mm til montage / demontage

af anslagsbøjlen

8

4

Aftrækshåndtag med udløsningssikring

5

Gevindstiknippel

6

Kabinet

7

Afdækning (umbracoskrue)

8

Anslagsbøjle

Tekniske data

Maks. arbejdstryk: 6,3 bar

Maks omdrejningstal: 8500 min

-1

Luftindslip: ¼

slaglængde: 10 mm

Vægt: 620 g

Støj og vibration

OBS! Bær altid et høreværn!

Støjværdier iht. EN15744:2008

Lydtryksniveau L

pA

: 80,2 dB(A)

Lydtrykseffekt L

WA

: 91,2 dB(A)

Usikkerhed K = 3 dB

I denne originaldriftvejledning / ved apparatet anvendes følgende piktogrammer:

Læs betjeningsvejkledning!

Smøres dagligt

Følg advarsels- og sikkerhedsanvisningerne!

Henvisning

Bær høreværn, en åndedræts- / støvbeskyttelsesmaske, beskyttelsesbriller

og beskyttelseshandsker.

Bortskaf emballagen og maskinen

miljøvenligt!

Indledning / Generelle sikkerhedsregler

Page 17

17 DK

Vibrationsværdier iht. EN 12096, ISO 28927-7

Hånd-arm-vibrationsniveau: 5,8 m / s

2

Usikkerhed K: 0,6 m / s

2

Leverede dele

1 trykluft-sav

1 umbrakonøgle 2 mm til montage / demontage af

anslagsbøjlen

8

1 umbrakonøgle 4 mm

6 savklinger (3 savklinger til træ (HCS), 3 savklinger

til metal (BIM))

2 anslagsbøjler

1 betjeningsvejledning

Generelle

sikkerhedsregler

Flere farer! Sikkerhedshenvisningerne skal

læses og være forstået inden opstilling, driften,

reparationen, vedligeholdelsen og udskiftningen

af tilbehørsdele ved rundsavs- og de svingende

savmaskiner med frem- og tilbagegående savklinge, samt inden påbegyndelse af arbejdet i

nærheden af maskinen. Er dette ikke tilfældet,

så kan dette føre til alvorlige personskader.

Rundsavs- og de svingende savmaskiner eller de

savmaskiner med frem- og tilbagebevægende

savklinge bør udelukkende opstilles, indstilles

eller anvendes af tilsvarende kvalificeret eller

skolet betjeningspersonale.

Disse rundsavs- og svingendesavmaskiner eller

de savmaskiner med fremad- eller tilbagebevægende savklinge må ikke ændres. Ændringer

kan forringe sikkerheden og forhøje risici for

betjeningspersonalet.

Sikkerhedshenvisningerne må ikke gå tabt –

og skal gives videre til brugerpersonen.

Benyt aldrig beskadigede rundsave og svin-

gende savmaskiner eller savmaskiner med

frem- og tilbagegående savklinge.

Maskinerne skal regelmæssigt gennemgå en

inspektion, for at kontrollere at maskinen er

kendetegnet med de påkrævede tydeligt

læsbare afmålingsværdier oo mærkninger.

Brugeren skal kontakte producenten for at få

nødvendige ersatningsskilte.

Farer i forbindelse med

omkringflyvende dele

Ved et brud hos værktøjet eller tilbehørsdele

eller endda ved selve maskinværktøjet kan dele

med høj hastighed slynges ud.

Under driften af rundsaven og svin-

gende savmaskiner eller savmaskiner

med frem- og tilbagegående savklinge skal man altid bære en slagfast øjenbeskyttelse. Graden af den krævede sikkerhed

bør til hver enkelt anvendelse vurderes særskilt.

Det skal kontrolleres om emnet er fastgjort sikkert.

Det skal sikres at gnister og metalspåner styres

på sådan en måde, at disse ikke forårsager fare.

Det skal sikres, at savklingen eller savskæret er

fastspændt korrekt og fast.

Farer ved infiltration

Der kan bestå kvælnings-. skalperings- og /

eller snitfare, når løst siddende beklædning,

smykker, halskæder / halstørklæder (o.l.), hår

eller handsker ikke holdes fjern fra maskinen

og dens tilbehørsdele.

Farer under driften

Undgå kontakt med savklingen for at forhindre

at hænder eller andre kropsdele skæres.

Beskyttelseshætter skal være sikkert anbragt på

pladsen og i god funktionel stand.

Defekte, bøjede eller kraftigt slidte beskyttelses-

hætter skal erstattes med af maskinproducenten

anbefalede beskyttelseshætter.

Sørg for at beskyttelseshætten, som kan trækkes

tilbage, bevæger sig fra den fuldstændig åbnede

position hurtigt tilbage i dens lukkede position

efter man har sluppet den.

Page 18

18 DK

Generelle sikkerhedsregler

Beskyttelseshætter, som kan trækkes tilbage,

må aldrig sættes, bindes fast eller på anden

må deaktiveres i en åben position.

Ved maskinens indsats kan betjene-

rens hænder være udsat for farer

som f.eks. snit samt afskrabninger

og varme. Bær handsker som beskyttelse for

hænderne.

Betjeneren og vedligeholdelsespersonalet skal

fysisk være i stand til at håndtere maskinens

størrelse, masse og ydelse.

Hold maskinen korrekt: Vær beredt til at

modvirke de normale eller pludselige bevægelser - Hold begge hænder klare.

Vær opmærksom på, at deres krop er i balance

og at De har sikker hold.

Undgå kvæstelser gennem skæren og

afskæren: Undgå kontakten med savklingen

eller savbladet eller –skær når lufttilførslen er

tilsluttet på maskinen. Bær beskyttelsesudstyr

som handsker, forklæde og hjelm.

Kvæstelser kan forårsages gennem

maskinens ukontrollerede bevægelser: Garantér altid af føringspladen (når

anbragt) holdes fast mod værkstykket.

Skærearbejde med denne maskine fører til skarpe

hjørner. Bær handsker for at beskytte hænderne.

Frigiv kommandoindretningen til igang- og stil-

standssættelse i tilfælde af en afbrydelse hos

energiforsyningen.

Anvend kun de af producenten anbefalede

smøremidler.

Der skal anvendes sikkerhedsudstzr som sikker-

hedsbriller; egnede handsker og beskyttelsesbeklædning er anbefalelsesværdig.

Vær Dem bevidst om, at roterende indbygget

værktøj starter op, efter at kommandoindretningen til igang- og stilstandssættelsen er blevet

frigivet.

Farer ved gentagne

bevægelser

Ved anvendelsen af rundsave og svingende

savmaskiner eller savmaskiner med frem og

tilbagevægende savklinge til gennemførelse af

arbejdsrelateret arbejde, kan det muligvis komme

til ubehagelige oplevelser i hænderne og armene, samt i hals- og skulderområdet eller på

andre kropsdele hos brugeren.

Ved anvendelsen af rundsave og svingende

savmaskiner eller savmaskiner med frem- og

tilbagebevægende savklinge bør brugeren indtage en bekvem kropsholdning; derved være

opmærksom på sikker hold og undgå ugunstige

kropsholdninger eller sådanne, hvor det er svært

at holde balancen. I løbet af langvarende arbejde bør betjeningspersonen ændre kropsholdningen, hvilket kan være nyttigt i forbindelse

med undgåelse af ubehageligheder og træthed.

Hvis betjeningspersonen føler symptomer som

f.eks. vedvarende eller gentagende optræden

af ildebefindende, skavanker, slag, smerter,

kriblen, døvhed, brænden eller stivhed i sin krop,

bør disse tegn ikke ignoreres. Betjeningspersonen bør meddele arbejdsgiveren dette og opsøge en kvalificeret læge.

Farer ved tilbehørsdele

Fjern rundsaven og den svingende savmaskine

samt savmaskinerne med fremdad- og tilbagegående savklinge inden monteringen eller

udskiftningen af maskinværktøjerne eller fra

tilbehørsdele fra energiforsyningen.

Anvend udelukkende tilbehørsdele og forbrugs-

materialer med de af producenten af rundsave

og svingende savmaskine eller savmaskiner

med frem- og tilbagegående savklinge anbefalede størrelser og typer. Anvend ikke nogen andre størrelser og typer af tilbehørsdelene og

forbrugsmaterialerne.

Undgå inden og efter anvendelsen af maskin-

værktøjet direkte kontakt med tilbehørsdele, da

de kan være varme eller skarpkantede.

Kontrollér savklingen inden brugen. Brug ikke

nogen savklinger, som måske er faldet ned

eller på hvilke dele er slået af, revnet eller på

anden vis beskadiget.

Page 19

19 DK

Generelle sikkerhedsregler

Farer på arbejdspladsen

Udskridning, snublen og styrt er hovedårsager

for skader på arbejdspladsen. Vær opmærksom

på overflader som er blevet glatte gennem brugen af maskinen og gennem den luft- og hydraulikslangebetingede snublefare.

Vær forsigtig i ukendte omgivelser. Der kunne

være gemte risici på grund af strøm- eller andre

forsyningsledninger.

Disse rundsavs- og svingende savmaskiner eller

disse savmaskiner med fremad- og tilbagegående savklinge er ikke bestemt til indsatsen i

eksplosionsfarlige atmosfærer og ikke isoleret

mod berøring med elektriske ledninger.

Sørg for at ikke nogen elektriske ledninger,

gasrørledninger, osv. er tilstede, som i tilfælde

af beskadigelsen i forbindelse med anvendelsen

af maskinen, kan føre til en fare.

Fare på grund af støv og dampe

Den / De ved indsats af rundsave og svingende

savmaskiner med fremad- og tilbagegående

savklinge opstående støv og dampe kan forårsage sundhedsskader (som f.eks. kræft, fødselsfejl, astma og / eller dermatitis); det er uundgåeligt

at gennemføre en risikovurdering iht. disse farer

og at implementere tilsvarende reguleringsmekanismer.

I risikovurderingen bør den ved maskinanven-

delsen opstående støv og den derved muligvis

ophvirvlende tilstedeværende støv inddrages.

Rundsavene og svingende savmaskiner eller de

savmaskiner med fremad- og tilbagegående

savklinge skal drives og vedligeholdes efter de

i denne vejledning indeholdte anbefalinger, for

af reducere frisættelsen af støv og dampe til

det mindste.

Returluften skal afledes på sådan en måde, at

ophvirvlingen af støv i støvholdige omgivelser

reduceres til det mindste.

Såfremt støv eller dampe opstår, så skal hoved-

opgaven være, at kontrollere disse på stedet

for deres frisættelse.

Alle til opfangning, udsugning eller undertryk-

kelse af flyvestøv eller dampe foresete indbygnings- eller tilbehørsdele hos maskinen, bør

indsættes og vedligeholdes iht. producentens

tilsvarende anvisninger.

Forbrugsmaterialerne / Maskinværktøjer skal

udvælges tilsvarende iht. driftvejledningens

anbefalinger, vedligeholdes og erstattes for at

undgå en unødvendig intensivering af støv- og

dampudviklingen.

Advarsler over eksplosionens risiko eller ild iht.

materialet, som skal forarbejdes, skal være givet.

Anvend udstyret til åndedrætsbeskyt-

telse efter anvisningerne og som

krævet iht. arbejds- og sundhedsfor-

skrifterne.

Arbejdet med bestemt materiale forårsager

emissioner med støv og damp, som fører til en

potentiel eksplosiv omgivelse.

Farer i forbindelse med larm

Et højt støjniveau kan føre til varige høreskader,

døvhed og andre problemer som f.eks. tinnitus

(ringen, susen, piben eller summen i øret), hvis

der bæres utilstrækkeligt høreværn. Derfor er risikovurderingen og implementeringen iht. tilsvarende reguleringsmekansimer til disse farer

uundgåelig.

Til de reguleringsmekanismer, som er egnede

til at formindske risikoen, hører forholdsregler

som f.eks. anvendelsen af isoleringsstoffer, for

at undgå at der optræder ringelyde ved værkstykkerne.

Anvend høreværnsudstyr.

Rundsavene og svingende savmaskiner eller

savmaskinerne med fremad og tilbagegående

savklinge skal drives og vedligeholdes efter de

i driftvejledningen indeholdte anbefalinger, for

at undgå en unødvendig forhøjelse af støjniveauet.

Forbrugsmaterialerne / Maskinværktøjerne skal

udvælges, vedligeholdes og erstattes tilsvarende

Page 20

20 DK

Generelle sikkerhedsregler / Inden ibrugtagning

iht. driftvejledningens anbefalinger, for at undgå

en unødvendig forhøjelse af støjniveauet.

Sørg alid for, hvis rundsavene og de svingende

savmaskiner eller savmaskinerne er udstyret

med en lyddæmper, at denne er på sin plads

og funktionsdygtig, når maskinen er i drift.

Farer i forbindelse

med svingninger

Indflydelsen af svingninger kan forårsage ska-

der på nerverne og forstyrrelserne i hændernes

og armenes blodcirkulation.

Bær varmt tøj ved arbejdet i kolde omgivelser

og hold dine hænder varme og tørre.

Hvis De konstaterer en døvhedsfølelse, kriblen

eller smerter i deres fingre eller hænder eller

huden ved deres fingre eller hænder misfarver

til til hvid farve, så indstil arbejdet med rundsavene og svingende savmaskiner eller savmaskinerne med fremad- og tilbagående savklinge

og konsultér en læge.

Rundsavene og svingende savmaskiner eller de

savmaskiner med frem- og tilbagegående savklinge skal drives og vedligeholdes efter de i

denne driftvejledning indeholdte anbefalinger,

for at undgå en unødvendig forstærkning af

svingningerne.

Forbrugsmaterialerne / maskinværktøjerne skal

udvælges, vedligeholdes og erstattes tilsvarende

iht. denne driftvejlednings anbefalinger for at

undgå en unødvendig forstærkning af svingningerne.

Brug for at holde maskinens masse, når som

helst det er muligt, en stander, en spænder

eller en udligningsanordning.

Ηold maskinen med et ikke alt for fast, men sik-

kert greb under overholdelse af de påkrævede

hånd-reaktionskræfter, da svingningsrisikoen

som regel bliver større med tiltagende gribekraft.

Savklingens uhensigtsmæssige fastgørelse kan

forårsage et forhøjet svingningsniveau.

Yderligere sikkerhedshenvis-

ninger til pneumatiske

maskiner

Trykluft kan forårsage alvorlige personskader.

Sørg for, i tilfælde af at maskinen ikke bruges,

samt inden udskiftningen af tilbehørsdele eller

inden udførelsen af reparationsarbejder, at lufttilførslen er lukket, at luftslangen ikke står under

tryk og at maskinen er adskilt fra lufttilførslen.

Ret aldrig luftstrømmen imod Dem selv eller

andre personer.

Løstsiddende slanger kan forårsage alvorlige

personskader. Kontrollér derfor altid om slangerne og deres fastgørelsesmidler er ubeskadigede eller har løsnet sig.

Hvis der anvendes universal-drejekoblinger

(klovkoblinger), så skal låsestifter indsættes;

whipcheck-slangesikringer skal anvendes, for

at give beskyttelse i tilfælde af svigt i forbindelse med slangens forbindelse med maskinen og

slangerne iblandt hinanden.

Sørg for, at det på maskinen angivne højeste

tryk ikke overskrides.

Luftdrevne maskiner må aldrig bæres ved

slangen.

Inden ibrugtagning

Montage

Selve apparatet er allerede fuldt fuktionsdygtig i

leveret stand. For at kunne benytte apparatet, skal de

i givet fald (såfremt ikke allerede integreret) montere

endnu en gevindstiknippel

5

(vær opmærksom på

pasnøjagtigheden / størrelsen af de i de tekniske

detaljer angivne data).

Vikkel teflonbånd (ikke indeholdt i leveringen)

omkring gevindstikniplen

5

, inden De skruer

denne ind i trykluftapparatet. De skal vikle båndet så stramt som muligt rundt om gevindet.

Sandsynligheden for, at der slipper luft ud, er

dermed minimal, og arbejdsprocessen bliver

optimeret.

Skru nu gevindstikniplen 5 ind i trykluftappa-

ratet.

Page 21

21 DK

Inden ibrugtagning / Ibrugtagning / Efter ibrugtagningen

Spænd gevindstikniplen 5 ved hjælp af en

14´er nøgle med moderat kraft fast i trykluftapparatet (se afbildning A).

Indstilling af tryklufttilførsel og tilslutninger

Anvend kun filtreret, smurt og reguleret trykluft.

Anvend den i afbildning B viste tilslutningsme-

tode på trykluftsystemet. Denne forhøjer værktøjets effekt og levetid.

Indstil deres kompressor på det i de tekniske

data angivne arbejdstryk til apparatet. Vær

opmærksom på, at trykket i gennemsnit aftager

med omkring 0,5 bar ved 10 m slange.

For højt tryk er farligt!

Overskrid aldrig det angivne tryk!

Giv inden den første anvendelse og i regelmæs-

sige afstande nogle dråber trykluftapparatolje

eller motorolje SAE 10–20 i trykluftapparatets

tryklufttilslutning. Anvendelsen af andre oljer

(især af tyktflydende) vil føre til fejlfunktioner,

skader eller endda en totalskade hos apparatet.

Ibrugtagning

Tilslutning af trykluftværktøj

Kontrollér om værkstykket understøttes rigtigt.

Etablér tryklufttilslutningen, idet De trykker slan-

gens hurtigtilslutningskobling på med lidt kraft

(se afbildning C).

Kontrollér absolut at trykluftslangen (se afbild-

ning D) sidder fast. En slange, der er løs eller

slår ukontrolleret om sig, er et faremoment. Af

samme grund skal gevindstikniplen

5

sidde

fast. Også det skal kontrolleres.

Via skruen ved luftindsugningen (se afbildning E)

kan lufttrykket ved apparatet varieres.

Savning

Henvisning: Aftrækshåndtaget 4 råder over en

udløsningssikring. For at kunne betjene udtrækshåndtaget

4

så skal De trykke det lille håndtag ved ud-

trækshåndtaget

4

(udløsningssikring) fremad og

samtidig trykke udtrækshåndtaget

4

nedad.

Betjen udtrækshåndtaget 4, for at starte saven.

Henvisning: Omkringflyvende metalsplinter

kan være meget farlige!

Henvisning: Når trykluftforsyningen afbry-

des gennem et strømsvigt eller et midlertidigt

kompressorudfald, så skal de med det samme

slippe udtrækshåndtaget

4

. Ønsker De at

fortsætte deres arbejde, så skal De først trække

saven helt ud af værkstykket. Derefter kan De

fortsætte med deres arbejde.

Kontrollér henholdsvis efter 2 minutters varig

drift om savklingen sidder fast.

Når De har afsluttet deres arbejde, så slip ud-

trækshåndtaget

4

, for at afslutte savens kørsel.

Efter ibrugtagningen

Efter at arbejdet er afsluttet, så skal apparatet skilles

fra tryklufttilslutningen.

Til det skal i første omgang trykket slippes fuldstændigt ud af ledningerne.

For at reducere eventuelle tilstedeværende re-

ster af trykluft, skal De kort betjene apparatets

udtrækningshåndtag

4

.

Udskiftning af savklinge

Er savklingen 1 sløv, bøjet eller defekt, så skal

den omgående udskiftes.

Vær ved udskiftning af savklingen 1 altid op-

mærksom på, at trykluftforsyningen er afbrudt!

Åben i første omgang med hjælp af en skrue-

trækker den forreste afdækning

7

(se afbild-

ning F).

Løsne efterfølgende med hjælp af den vedlagte

umbrakonøgle

2

umbrakoskruerne på savklin-

geoptaget (se afbildning G) og fjern savklingen.

Sæt efterfølgende den nye savklinge 1 ind i

savklingeoptaget og spænd umbrakoskruen

fast igen.

Sørg for at savklingen 1 sidder korrekt i sav-

klingegoptaget og ikke lader sig trække ud mere.

Page 22

22 DK

Efter ibrugtagningen / Rengøring og opbevaring / Vedligeholdelse

Luk derefter igen afdækningen 7 med hjælp

af en skruetrækker.

Justér/veksel anslagsbøjle

Til justering af anslagsbøjlen 8 skal begge

udvendige skruer (se afbildning H) løsnes ved

hjælp af den vedlagte 2 mm indvendige sekskantsnøgle

3

. Efter løsningen af skruerne kan

anslagsbøjlen løsnes via træk (se afbildning I).

Nu er en justering eller et komplet skift af an-

slagsbøjlen mulig.

Lås efter vekslingen eller justeringen af anslags-

bøjlen de forinden løsnede skruer ved hjælp af

den indvendige sekskantsnøgle.

Rengøring og opbevaring

For at garantere en lang levetid og en fejlfri drift, er

det vigtigt at efterfølgende anvisninger overholdes.

Inden de rengør deres værktøj, så skal det prin-

cipielt fjernes fra trykluftkilden.

Rengør deres værktøj med en tør blød klud el-

ler blæs det let ud med trykluft. Anvend under

ingen omstændighed ætsende regøringsmidler.

Smøring af trykluft-sav

Henvisning: For en muligst lang

levetid er det for trykluftapparater

unndgåeligt, at de skal smøres re-

gelmæssigt.

Vend værktøjet, så tryklufttilslutningen viser

opad og giv nogle dråber trykluftapparatolje

eller motorolje SAE 10–20 i trykluftapparatets

tryklufttilslutning.

Betjen aftrækshåndtaget 4, så oljen bedres

kan fordele sig.

Hold en klud eller en sugeegnet papirklud foran

åbningerne til afgangsluft og sæt apparatet for

få sekunder i tomgangsdrift.

OBS! Fjern tryklufttilslutningen inden

vedligeholdelsesarbejder!

Overskydende olje blæses ud.

Hold udslippet fjern fra personer eller genstande.

Opbevaring af trykluft-sav

Opbevar trykluftværktøjet så det er beskyttet

mod vejrlig indflydelse, i tørre rum, som børn

ikke kan nå.

Vær opmærksom på, at der ikke trænger fugt

ind i trykluftapparatets indre.

Vedligeholdelse

Ved apparatet bør regelmæssigt (ca. efter 1-2 arbejdsgange) foretages en vedligeholdelse.

Bær altid egnede arbejdshandsker.

Vedligeholdelsen må kun gennemføres af instru-

erede personer. En lang levetid og en fejlfri drift

hos dette kvalitetsprodukt garanteres gennem

en overholdelse iht. de her angivne vedligeholdelseshenvisninger.

Apparatet skal kobles fra trykluftskilden, når der

foretages eftersyn og plejning.

Kontrollér forbrugsmaterialets og tilbehørets

tilstand ved hvert eftersyn.

Henvisning: Til deres apparats gnidningsfrie

funktion er en daglig rengøring og en regelmæssig smøring tvingende påkrævet. Anvend

hertil venligst kun specielt værktøj med høj viskositet (tyndtflydende). Egnet er olie til trykluftmaskiner eller motorolie SAE10-20.

OBS! Anvend ikke andre (specielt sejtflydende)

smøremidler. Ellers er der fare for at funktionsforstyrrelser eller varige skader.

Driv apparatet med ren luft. Korrosionsrester,

støv og snavs fra forsyningsledningen påvirker

ydelsen og skaber tekniske problemer. Sådan

en forurening kan modvirkes med hjælp af en

vedligeholdelsesenhed med filter, reduktionsenhed og smører.

Rengør deres apparat i givet fald med en fug-

tig klud.

Page 23

23 DK

Vedligeholdelse / Henvisninger til garanti og serviceafvikling

Benyt ikke nogen kemiske regøringsmidler, som

indeholder aggressive stoffer, som benzin,

fortynder o.a., da de kan angribe kunststoffet.

Vær opmærksom på, at der ikke kommer væsker

ind i saven.

Kontrollér regelmæssigt om alle anslagsbøjlens

og savklingens skruer sidder fast. Kontrollér tilmed regelmæssigt apparatets omdrejningstal

og svingningsniveau.

Kontrollér regelmæssigt savklingens tilstand.

Savklingen må hverken være defekt eller deformeret.

Henvisninger til garanti og

serviceafvikling

Creative Marketings garanti

Consulting GmbH

Kære kunde, De får 3 års garanti fra købsdatoen

af på dette apparat. I tilfælde af mangler ved dette

produkt, har De juridiske rettigheder over for sælgeren af dette produkt. Disse juridiske rettigheder

begrænses ikke af vores garanti, der beskrives i det

følgende.

Garantibetingelser

Garantifristen begynder fra købsdatoen af. Opbevar

den originale kassebon på et sikkert sted. Denne

kassebon er nødvendig som dokumentation for købet.

Hvis der inden for tre år fra købsdatoen opstår en

materiale- eller fabrikationsfejl, så repareres eller

erstattes produktet - efter vores valg - af os uden

omkostninger for Dem. Denne garantiydelse forudsætter, at det defekte apparat og købsbeviset (kassebon) forelægges inden udløbet fristen på tre år,

sammen med en beskrivelse af, hvori manglen består

og hvornår den er opstået.

Hvis defekten dækkes af vores garanti, modtager

De derefter det reparerede eller et nyt apparat. Ved

reparation eller udskiftning af apparatet begynder

der ikke en ny garantiperiode.

Garantiomfang

Køleboksen er produceret omhyggeligt efter strenge

kvalitetskrav og inden levering afprøvet samvittighedsfuldt.

Garantien gælder for materiale- eller fabrikationsfejl.

Garantien omfatter ikke produktdele, der udsættes

for normal slitage og dermed kan betragtes som

sliddele, eller beskadigelser af følsomme komponenter som f.eks. kontakter, batterier eller dele af

glas.

Garantien bortfalder, hvis apparatet bliver beskadiget eller ikke anvendes eller vedligeholdes korrekt.

Til en korrekt anvendelse af produktet skal alle

henvisninger, der er opført i betjeningsvejledningen,

overholdes nøjagtigt. Anvendelsesformål og handlinger, der frarådes eller advares imod i betjeningsvejledningen, skal ubetinget undgås.

Produktet er kun beregnet til privat og ikke til erhvervsmæssig brug. Ved misbrug og uhensigtsmæssig behandling, anvendelse af vold og ved indgreb, som

ikke er foretaget af vores autoriserede service-afdeling, ophører garantien.

Afvikling af garantisager

For at kunne sikre en hurtig behandling af deres

anliggende skal følgende henvisninger følges:

Opbevar venligst kassebonen og artikelnummeret

(f.eks. IAN) som købsdokumentation, så disse kan

forelægges på forspørgsel.

Artikelnummeret er angivet på typeskiltet, med en

indgravering på forsiden af vejledningen (forneden

til venstre) eller på en mærkat bag- eller undersiden.

Hvis der forekommer funktionsfejl eller andre mangler, skal De først kontakte nedenstående serviceafdeling telefonisk eller via e-mail.

Et prdoukt, der er rigistreret som defekt, kan De derefter sende portofrit til den oplyste serviceadresse

med vedlagt købsbevis (kassebon) og angivelse af,

hvori manglen består og hvornår den er opstået.

Page 24

24 DK

... / Miljøhenvisninger og bortskaffelsesangivelser / EG-konformitetserklæring

Henvisning:

På www.lidl-service.com kan De downloade denne og mange yderligere

håndbøger, produktvideoer og software.

Kontaktinformationer:

DK

Navn: C. M. C. GmbH

Internetadresse: www.cmc-creative.de

E-Mail: service.dk@cmc-creative.de

Telefon: +49 (0) 6894 9989752

(normal takst tysk fastnet)

Sæde: Tyskland

IAN 285212

Bemærk, at følgende adresse ikke er en serviceadresse.

Kontakt først ovenforstående serviceafdeling.

Adresse:

C. M. C. GmbH

Katharina-Loth-Str. 15

DE-66386 St. Ingbert

TYSKLAND

Miljøhenvisninger og

bortskaffelsesangivelser

Råstofgenindvinding i stedet for

bortskaffelse af affald!

Apparat, tilbehør og emballage skal

afleveres til miljøvenlig genbrug.

Kast trykluftværktøjet ikke i husholdningsaffaldet,

ilden eller i vandet. Hvis det er muligt, så bør det

ikke mere funktionsdygtige apparat genbruges.

Spørg om råd hos deres lokale forhandler.

EG-konformitetserklæring

Vi, virksomheden

C. M. C. GmbH

Dokumentansvarlig: Marc Uhle

Katharina-Loth-Str. 15

DE-66386 St. Ingbert

TYSKLAND

erklærer på eget ansvar, at produktet

Trykluftssav

Artikelnummeret: 2053

Byggeår: 2017 / 34

IAN: 285212

Model: PARKSIDE TRYKLUFTSSAV PDKS

6.3 A1

opfylder de væsentlige sikkerhedskrav, som er

fastlagt i de europæiske retningslinjer

Maskinretningslinje

EG-retningslinje 2006 / 42 / EG

og deres ændringer.

Følgende harmoniserede normer blev taget i betragtning i forbindelse med konformitetsvurderingen:

DIN EN ISO 11148-12:2012

St. Ingbert, 31.05.2017

på vegne af Marc Uhle

- Leder kvalitetssikring -

Page 25

25 FR/BE

Table des matières

Introduction ................................................................................................................................... Page 26

Utilisation conforme ............................................................................................................................Page 26

Équipement .......................................................................................................................................... Page 26

Caractéristiques techniques ................................................................................................................ Page 26

Contenu de la livraison ....................................................................................................................... Page 27

Règles générales de sécurité .......................................................................................... Page 27

Risques liés aux pièces projetées ....................................................................................................... Page 27

Risques liés au happement ................................................................................................................. Page 27

Risques liés au fonctionnement ...........................................................................................................Page 28

Risques liés aux mouvements répétés ................................................................................................ Page 28

Risques liés aux accessoires ............................................................................................................... Page 28

Risques liés au lieu de travail .............................................................................................................Page 29

Risques liés à la poussière et aux vapeurs ........................................................................................ Page 29

Risques liés au bruit .............................................................................................................................Page 29

Risques liés aux oscillations ................................................................................................................ Page 30

Mesures de sécurité supplémentaires pour les machines pneumatiques ........................................Page 30

Avant la mise en service .....................................................................................................Page 31

Montage .............................................................................................................................................. Page 31

Mise en service ........................................................................................................................... Page 31

Raccordement de l‘outil à air comprimé ...........................................................................................Page 31

Coupes circulaires ............................................................................................................................... Page 31

Après la mise en service ..................................................................................................... Page 32

Remplacer la lame de la scie ............................................................................................................. Page 32

Réglage / remplacement de l‘étrier de butée .................................................................................... Page 32

Nettoyage et entretien ........................................................................................................ Page 32

Graissage de la scie à air comprimé ................................................................................................Page 32

Stockage de la scie à air comprimé .................................................................................................. Page 33

Maintenance ................................................................................................................................. Page 33

Remarques sur la garantie et le service après-vente ................................ Page 33

Conditions de garantie ....................................................................................................................... Page 33

Étendue de la garantie .......................................................................................................................Page 34

Faire valoir sa garantie ....................................................................................................................... Page 34

Indications relatives à l‘environnement et à la mise au rebut ..........Page 35

Déclaration de conformité EG ........................................................................................ Page 35

Page 26

26 FR/BE

Introduction / Règles générales de sécurité

Introduction

Scie pneumatique PDKS 6.3 A1

Introduction

Félicitations!

Vous avez opté pour un produit de

grande qualité proposé par notre

entreprise. Avant la première mise en service, vous

devez vous familiariser avec toutes les fonctionnalités

du produit. Veuillez lire attentivement le mode

d’emploi ci-dessous et les consignes de sécurité. La

mise en service de ce produit est réservée à des

personnes habilitées.

TENIR HORS DE PORTÉE DES ENFANTS!

Utilisation conforme

Cette scie est un outil à air comprimé destiné à

l‘emploi artisanal. Cet outil est conçu pour une utilisation dans la construction de carrosseries, d‘automobiles ainsi qu‘en atelier. L‘utilisateur doit se protéger

des fragments de matériau par le port de lunettes

de protection et porter des gants de protection en

cas de contact accidentel avec des arrêtes coupantes

éventuelles. Veuillez conserver soigneusement cette

notice. Fournissez également tous les documents en

cas de remise du produit à un tiers. Toute application divergeant de l‘utilisation conforme à l‘usage

prévu est interdite et potentiellement dangereuse.

Les dommages résultant du non-respect des consignes

ou d‘une utilisation incorrecte ne sont pas couverts

par la garantie et ne relèvent pas de la responsabilité du fabricant. Le produit est conçu pour un usage

privatif et ne doit pas être utilisé à des fins commerciales ou industrielles.

Équipement

Immédiatement après le déballage, veuillez toujours contrôler le bon état de l’appareil. N‘utilisez

le produit que s‘il ne présente aucun défaut.

1

Lame de scie

2

Clé à six pans creux 4 mm

3

Clé à six pans creux 2 mm pour le montage

et / ou le démontage de l‘étrier de butée

8

4

Levier déclencheur avec sécurité de déclenche-

ment

5

Raccord fileté

6

Boîtier

7

Revêtement (vis à six pans creux)

8

Étrier de butée

Caractéristiques techniques

Pression de service max.: 6,3 bar

Régime max.: 8500 min

-1

Entrée d‘air: ¼

Levée: 10 mm

Poids: 620 g

Les pictogrammes suivants sont utilisés dans le présent mode d’emploi / sur

l‘appareil:

Lire la notice d'utilisation!

Doit être lubrifié chaque jour

Respectez les avertissements et les

consignes de sécurité!

Remarque

Veuillez porter un casque auditif,

un masque respiratoire / antipoussière, des lunettes et des gants de

protection.

Mettez l’emballage et l’appareil au

rebut de manière écophile!

Page 27

27 FR/BE

Bruit et vibration

ATTENTION! Porter un casque

auditif!

Indicateurs de bruit conformément à la norme

EN 15744:2008

Niveau de pression

acoustique L

pA

: 80,2 dB(A)

Niveau de puissance

acoustique L

WA

: 91,2 dB(A)

Incertitude K= 3 dB

Indicateurs de vibration conformément à la norme

EN 12096, ISO 28927-7

Niveau de vibration dans

les mains et les bras: 5,8 m / s

2

Incertitude K: 0,6 m/s

2

Contenu de la livraison

1 Scie à air comprimé

1 Clé à six pans creux 2 mm pour le montage et /

ou le démontage de l‘étrier de butée

8

1 Clé à six pans creux 4 mm

6 Lames de scie (3 lames pour bois (HCS), 3

lames pour métal (BIM))

2 Étriers de butée

1 Mode d‘emploi

Règles générales de

sécurité

Risques multiples! Les consignes de sécurité

doivent être lues et comprises avant l‘installation,

l‘utilisation, la réparation, la maintenance et le

changement d‘accessoires des machines circulaires ou des scies oscillantes, scies sauteuses

et scies sabres avant de travailler à proximité

de ces machines. Dans le cas contraire, cela

peut conduire à des blessures physiques graves.

Les machines circulaires ou des scies oscillantes,