Parkside PAH 1700 A1 Translation Of The Original Instructions

DEMOLITION HAMMER PAH 1700 A1

DEMOLITION HAMMER

Translation of the original instructions

IAN 285765

ABBRUCHHAMMER

Originalbetriebsanleitung

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE / NI Translation of t he original instructions Page 1

DE / AT / CH Originalbetriebsanleitung Seite 11

A

B

Contents

Introduction ......................................................2

Intended use ................................................................ 2

Depicted components ......................................................... 2

Package contents ............................................................ 2

Technical data .............................................................. 2

Symbols used on the appliance ................................................. 3

General Power Tool Safety Warnings ................................3

1. Work area safety .......................................................... 3

2. Electrical safety ........................................................... 3

3. Personal safety ............................................................ 4

4. Power tool use and care .................................................... 4

5. Service .................................................................. 5

Safety instructions specific to hammers ........................................... 5

Before use .......................................................5

Greasing .................................................................. 5

Checking the oil level ......................................................... 5

Mount the auxiliary handle .................................................... 5

Use the additional handle ..................................................... 5

Fitting the chisel ............................................................. 6

Removing the chisel .......................................................... 6

Use .............................................................6

Switching on and off .........................................................7

Maintenance and cleaning ..........................................7

Topping up the oil ........................................................... 7

Replacing the carbon brushes .................................................. 7

Disposal .........................................................7

Kompernass Handels GmbH warranty ...............................8

Service .................................................................... 9

Importer ................................................................... 9

Translation of the original Conformity Declaration .....................10

PAH 1700 A1

GB│IE│NI

│

1 ■

DEMOLITION HAMMER

PAH 1700 A1

Introduction

Congratulations on the purchase of your new appliance. You have chosen a high-quality product. The

operating instructions are part of this product. They

contain important information about safety, usage

and disposal. Before using the product, please

familiarise yourself with all operating and safety instructions. Use the product only as described and for

the range of applications specified. Please also pass

these operating instructions on to any future owner.

Intended use

The demolition hammer is suitable for chiselling into

concrete, stone and plaster.

Any other usage or modification of the appliance

is deemed to be improper and carries a significant

risk of accidents.

The manufacturer accepts no responsibility for

damage(s) attributable to misuse.

The appliance is not intended for commercial use.

Depicted components

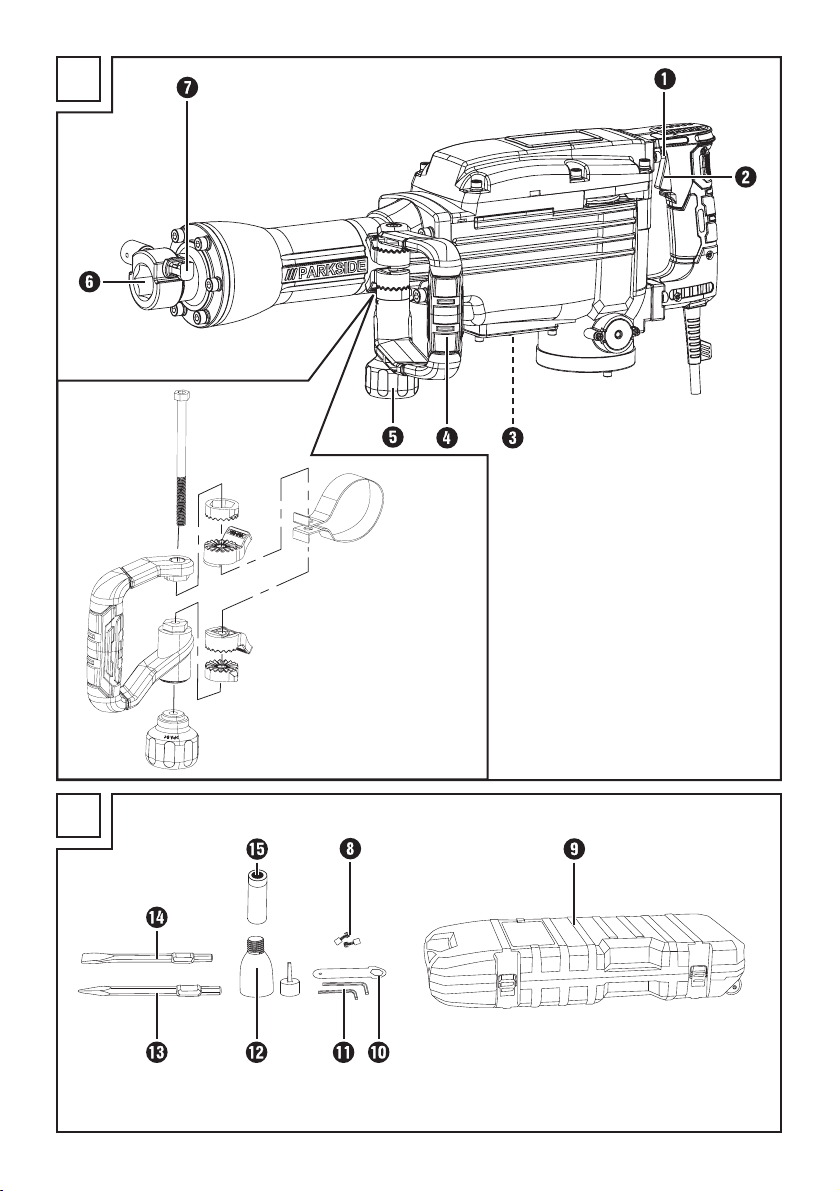

Figure A:

Locking switch

ON/OFF switch

Oil inspection window

Additional handle

Knurled nut for additional handle

Tool holder

Locking pin

Figure B:

Carbon brushes

Carrying case (with castors)

Assembly wrench

Hex key

Oil bottle

Pointed chisel

Flat chisel

Grease

Package contents

1 demolition hammer PAH 1700 A1

1 additional handle

1 flat chisel

1 pointed chisel

1 carrying case (with castors)

1 set of carbon brushes

50 g grease

1 oil bottle

1 assembly wrench

1 hex key 5 mm

1 hex key 6 mm

1 set of operating instructions

Technical data

Nominal power: 1700 W

Nominal voltage: 230 V ∼ 50 Hz

(AC)

Stroke rate: 1900 bpm

Stroke energy: 50 joule

Attachment socket: hexagonal (30 mm)

Noise emission value:

Noise measurement value determined in accordance with EN 60745. The A-rated noise level of

the tool is typically:

Chiselling:

Sound pressure level: L

Uncertainty K: 1.5 dB

Sound power level: L

Uncertainty K: 1.5 dB

Wear hearing protection!

Guaranteed sound power level

LWA in dB.

Total vibration value:

Total vibration value (vector total of three directions) determined in accordance with EN 60745:

Main handle:

Chiselling: a

h(CHeq)

Additional handle:

Chiselling: a

h(CHeq)

= 83.7 dB(A)

pA

= 103.7 dB(A)

WA

= 17.5 m/s2, K = 1.5 m/s

= 19.4 m/s2, K = 1.5 m/s

2

2

■ 2│GB

│IE│

NI

PAH 1700 A1

NOTE

► The vibration level specified in these instruc-

tions has been measured in accordance with

a standardised measuring procedure and

can be used for equipment comparisons. The

specified vibration emission value can also

be used to make an initial exposure estimate.

WARNING!

► The vibration level varies in accordance with

the use of the power tool and may be higher

than the value specified in these instructions

in some cases. Regular use of the power tool

in this way may cause the user to underestimate the vibration. Try to keep the vibration

loads as low as possible. Measures to reduce

the vibration load are, e.g. wearing gloves

and limiting the working time. Wherein all

states of operation must be included (e.g.

times when the power tool is switched off and

times where the power tool is switched on but

running without load).

Symbols used on the appliance

■ Read the operating instructions.

■

■

■

■

■

Wear hearing protection.

Wear a dust mask.

Wear safety goggles.

Wear safety gloves.

Earth before use.

General Power Tool

Safety Warnings

WARNING!

► Read all safety warnings and all instruc-

tions. Failure to follow the warnings and

instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1. Work area safety

a) Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools cre-

ate sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or ground-

ed surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

■

Caution!

CAUTION!

Fill with oil before first use!

FILL WITH OIL

BEFORE FIRST

USE.

PAH 1700 A1

GB│IE│NI

│

3 ■

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entan-

gled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

3. Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate

conditions will reduce personal injuries.

revent unintentional starting. Ensure that the

c) P

electric tool is switched off before you connect

it to the power supply, pick it up or carry it.

Carrying power tools with your finger on the

switch or energising power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

4. Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

c) Remove the plug from the socket before

making adjustments to the appliance, changing accessories or putting the appliance

into storage. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalign-

ment or binding of moving parts, breakage of

parts and any other condition that may affect

the power tool’s operation. If damaged, have

the power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

Keep cutting tools sharp and clean. Properly

f)

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

■ 4│GB

│IE│

NI

PAH 1700 A1

5. Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

Safety instructions specific to hammers

■ Wear hearing protection. Exposure

to loud noise can lead to hearing loss.

■ Use the additional handles supplied with the

appliance. Loss of control can lead to injuries.

■ Hold the appliance by the insulated handles

when you are carrying out work during which

the deployed tool may come into contact with

concealed power cables or its own power

cable. Contact with a live wire may electrify

exposed metal parts of the power tool and

could give the operator an electric shock.

Checking the oil level

NOTE

► Before operating the appliance, check whether

there is enough oil (e.g. SAE 20W—50) in the

appliance. Operation without sufficient oil will

cause irreparable damage to the appliance.

♦ Hold the appliance with the tool holder

facing upwards.

♦ Look in the oil inspection window

underside of the appliance to see whether there

is sufficient oil in the appliance (see fig. 1).

on the

■

Wear a dust mask.

Before use

WARNING! RISK OF INJURY!

► Switch off the appliance and pull out the

power plug before starting any work on the

appliance.

NOTE

► Periodically check the tightness of the hexa-

gon socket head screws on the unit. Use the

included hex key

Greasing

WARNING!

► Before every use, check whether there is

enough grease (e.g. multi-purpose grease,

bearing grease, etc.) in the appliance and

on the chisel. Operation without grease will

cause irreparable damage to the appliance.

♦ Grease the tool holder

grease .

♦ Grease the appropriate chisel shaft

with the supplied grease .

.

with the supplied

/

Fig. 1

If you cannot see any oil in the oil inspection

window

described in the section “Topping up the oil”.

, top up the oil (SAE 20W—50) as

Mount the auxiliary handle

The additional handle is not mounted on

delivery.

♦ Mount the additional handle

exploded view (see fold-out page).

as shown in the

Use the additional handle

♦ You can position the additional handle as

you wish.

♦ Undo the knurled nut

♦ Turn the additional handle

pliance axis and/or up to 360° forwards or

backwards into the desired position.

♦ Retighten the knurled nut

.

around the ap-

.

PAH 1700 A1

GB│IE│NI

│

5 ■

Loading...

Loading...