Panasonic TC-21FX20P Schematic

ORDER NO. MTV0601423CE

Colour Television

TC-21FX20P

GP41 Chassis

Specifications

Power Source : |

AC AUTO 110-240V, 50/60 Hz |

Sound |

31.5 MHz (D, K, K1) |

Power Consumption : |

67W |

|

32 MHz (I) |

Aerial Impedance : |

75Ω unbalanced |

|

32.5 MHz (B, G) |

|

Coaxial type |

|

33.5 MHz (M) |

Receiving System : |

17 Systems |

|

|

Receiving Channels : |

|

Colour |

33.57 MHz (PAL) |

VHF |

2-13 (U.S.A. STANDARD) |

|

33.6 MHz (SECAM) |

UHF |

14-69 (U.S.A. STANDARD) |

|

33.75 MHz (SECAM) |

CATV |

1-125 (U.S.A. STANDARD) |

|

34.42 MHz (NTSC) |

Video / Audio Terminals : |

|

High Voltage : |

27.5kV ±1.5V |

DVD |

|

|

at zero beam current |

Y |

1.0Vp-p, 75Ω |

Picture Tube : |

A51LYZ295X |

PB |

0.7Vp-p, 75Ω |

|

50.0cm (21 inches) |

PR |

0.7Vp-p, 75Ω |

|

Measured diagonally, |

AV 1,2,3 |

|

|

90° deflection |

Video In |

1Vp-p, 75Ω |

Audio Output : |

16.0W |

Audio In |

Approx. 0.5V, 47kΩ |

Dimensions : |

Height : 472 mm |

Monitor Out |

|

|

Width : 648 mm |

Video Out |

1Vp-p, 75Ω |

|

Depth : 488 mm |

Audio Out |

Approx. 0.5V, 1kΩ |

Mass : |

24 kg (Net Wt.) |

Intermediate Frequency : |

|

|

|

Video |

38.0 MHz |

Specifications are subject to change without notice. |

|

|

|

Mass and dimensions shown are approximate. |

|

© 2006 Matsushita Electric Industrial Co., Ltd. All rights reserved. Unauthorized copying and distribution is a violation of law.

TC-21FX20P

CONTENTS

|

Page |

|

|

Page |

1 Safety Precautions |

3 |

|

2.4. Adjustment for CRT CUT OFF |

7 |

1.1. General Guide Lines |

3 |

|

2.5. Adjustment Procedure |

8 |

1.2. Leakage Current Cold Check |

3 |

|

2.6. Adjustment |

9 |

1.3. Leakage Current Hot Check (Fig. 1) |

3 |

3 |

Conductor Views |

12 |

1.4. X-Radiation |

3 |

4 |

Schematic Diagram |

13 |

1.5. GP41 Chassis Block Diagram |

4 |

|

4.1. A Board |

15 |

2 Service Hints |

5 |

|

4.2. L Board |

20 |

2.1. Service Position for E-Board |

5 |

5 |

Parts Locations |

23 |

2.2. Factory Mode Adjustment |

5 |

6 |

Replacement Parts List |

24 |

2.3. Adjustment for White Balance |

7 |

|

6.1. Replacement Parts List |

25 |

2

TC-21FX20P

1 Safety Precautions

1.1.General Guide Lines

1.It is advisable to insert an isolation transformer in the AC supply before servicing this hot chassis.

2.When servicing, observe the original lead dress, especially the lead dress in the high voltage circuits. If a short circuit is found, replace all parts which have been overheated or damaged by the short circuit.

3.After servicing, see to it that all the protective devices such as insulation barriers, insulation papers, shields and isolation R-C combinations, are properly installed.

4.When the receiver is not to be used for a long period of time, unplug the power cord from the AC cord outlet.

5.Potential, as high as 29.0kV is present when this receiver is in operation. Operation of the receiver without the rear cover involves the danger of a shock hazard from the receiver power supply. Servicing should not be attempted by anyone who is not thoroughly familiar with the precautions necessary when working on high voltage equipment. Always discharge the anode of the picture tube to the receiver chassis before handling the tube. After servicing make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.2.Leakage Current Cold Check

1.Unplug the AC cord and connect a jumper between the two prongs on the plug.

2.Turn on the receiver’s power switch.

Measure the resistance value, with an ohmmeter, between the jumper AC plug and each exposed metallic cabinet part on the

receiver, such as screw heads, aerials, connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading should be between 4 MΩ and 20 MΩ . When the exposed metal does not have a return path to the chassis, the reading must be infinite.

1.3.Leakage Current Hot Check (Fig. 1)

1.Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2.Check a 2 kΩ non-inductive resistor and an AC/DC current meter, in series with each exposed metallic part on the receiver in turn and an earth such as a water pipe.

The current from any point should not exceed 0.7 mA peak AC or 2 mA DC. In the case of a measurement being outside of these limits specified, there is a possibility of a shock hazard and the receiver should be repaired and rechecked before it is returned to the customer.

Fig. 1

1.4.X-Radiation

Warning:

The potential sources of X-Radiation in TV set are the EHT section and the picture tube. When using a picture tube test jig for service, ensure that jig is capable of handling 29.0kV without causing X-Radiation.

Note: It is important to use an accurate periodically calibrated high voltage meter.

1.Set the brightness to minimum.

2.Use the remocon to get into Service Mode.

3.Measure the EHT. The meter reading should indicate 27.5±1.5kV. If the meter indication is out of tolerance, immediate service and correction is required to prevent the possibility of premature component failure.

4.To prevent the possibility X-Radiation, it is essential to use the specified picture tube, if service replacement becomes necessary.

3

4

G

G

MAIN

POWER

SWITCH

FRONT INPUTS

AV2 : V/L/R

GEOMAGNETIC

WOOFER

AMP

IC2401

GP41 CHASSIS BLOCK DIAGRAM

|

PP |

|

SCL |

EEPROM |

|

|

PVP |

SDA |

|||

SPEAKER |

IC1101 |

||||

IC1801 |

|||||

|

|

||||

|

CVBS IN |

R/G/B |

|

||

|

A |

|

AUDIO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

||||||||

|

|

|

AMP |

|

|

|

|

|

|

|

|

|

CVBS OUT |

R/G/B |

|

|

SCL SDA |

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

IC2301 |

|

|

|

|

|

|

|

|

|

AUDIO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OUT |

VCT-IF |

|

|

|

|

R |

|

|

|

CRT |

|

|

|

defl. |

CRT |

||||||

|

REAR INPUTS |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

|

|

DRIVE |

|

|

|

coil |

||||||||||||||

|

AV1 : V/L/R |

|

|

|

|

|

|

|

|

|

V_IN |

IC601 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

AV3 : YUV/V/L/R |

|

|

|

|

|

|

|

|

|

A_IN |

IF |

H |

V |

VM |

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MON_OUT |

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

FRONT INPUTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

AV2 : V/L/R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V OUT |

|

|

|

|

|

|

|

|

|

|

|

|

MON_OUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

TUNER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

V/L/R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H OUT |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

29" models PIP models

Diagram Block Chassis GP41 .5.1

21FX20P-TC

TC-21FX20P

2 Service Hints

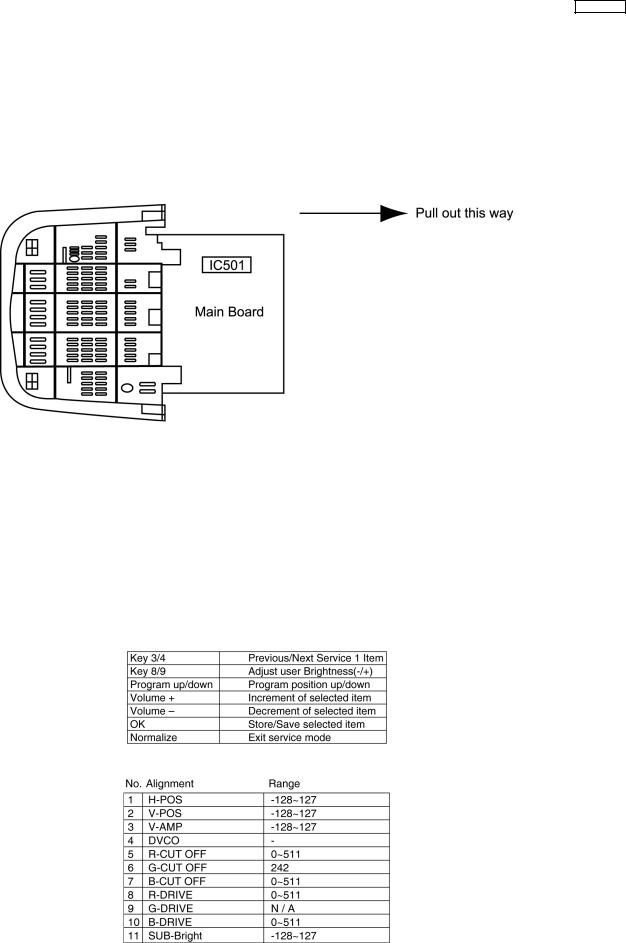

2.1.Service Position for E-Board

1.Remove the back cover.

2.Stand the TV set as shown in Fig. 2.

3.Remove the A-Board from the TV set by pulling the main board out as shown in Figure 2.

Fig. 2

2.2.Factory Mode Adjustment

1.Factory Mode Adjustment.

a)Set timer ON

b)Press remote’s RECALL ( ) and panel’s volume down key simultaneously to enter SERVICE 1.

) and panel’s volume down key simultaneously to enter SERVICE 1.

2.To Set Self-Check:

Press the volume down button on TV then press the Off Timer Button on remote control.

3.Service Mode 1 Controls

4. Service Mode 1 Function

5.Service Mode 2 Controls

To enter SERVICE 2; press channel key ‘1’ in SERVICE 1 entry screen.

5

TC-21FX20P

NOTE :- Service mode 2 options bit.

6.Service Mode 3 Controls

To enter SERVICE 3; press channel key ‘1’ in SERVICE 2 entry screen.

7.Service Mode 3 Function

6

TC-21FX20P

2.3.Adjustment for White Balance

Preparation:

1.Receive the white balance pattern and aging should have been performed over 30 minutes.

2.Set the picture menu to DYNAMIC NORMAL.

3.Degausse the CRT face.

4.Fix the CRT colour analyzer receiver unit to CRT face.

Adjustment of Low Light.

1.Adjustment Sub Bright, so that Y = 6.5 ± 1.0 nit.

2.Adjustment R-CUT OFF, so that X = 0.245 ± 0.015 nit.

3.Adjustment G-CUT OFF, so that Y = 0.274 ± 0.015 nit.

Adjustment of High Light

1.Adjustment Sub Bright, so that Y = 150 nit.

2.Adjustment R-Drive, so that X = 0.261 ± 0.015 nit.

3.Adjustment B-Drive, so that Y = 0.267 ± 0.015 nit.

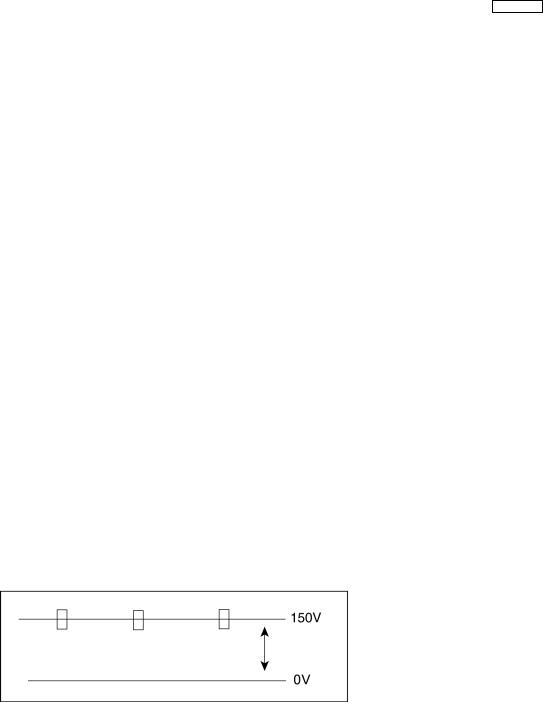

2.4.Adjustment for CRT CUT OFF

Preparation:

1.Connect the oscilloscope probe to TPL5.

2.Screen VR min.

3.Set the data Sub Bright, Bright.

4.In service Mode at “Bright” dac press [5] in factory mode to enter vertical line and adjust by volume down or up button.

5.Adjust “Screen VR” until 1-H Line appears.

7

TC-21FX20P

2.5.Adjustment Procedure

2.5.1.+B Voltage

Item / preparation

1.Operate the TV set.

2.Set control as follows : Brightness ........... minimum

Contrast ............... minimum

Adjustment procedure

1.Confirm the DC voltage at the indicated test points, as follows : TPA 15 : 3.35 ± 0.2V

TPA 16 : 141 ± 2V TPA 17 : 8.2 ± 0.5V TPA 18 : 1.9 ± 0.2V TPA 19 : 5.2 ± 0.2V TPA 20 : 175 ± 15V

2.5.2.High Voltage

Item / preparation

1.Receive the crosshatch pattern.

2.Set to 0 Beam.

Screen VR .......... minimum

Contrast .............. minimum

Adjustment procedure

1.Connect a DC voltage meter to TPA 16 and confirm the +B voltage is 141.0 ± 2V.

2.Connect a high frequency voltmeter to heater and confirm that voltage reads 6.3 ± 0.24 (VRMS).

3.Normalize the brightness and contrast.

8

TC-21FX20P

2.6.Adjustment

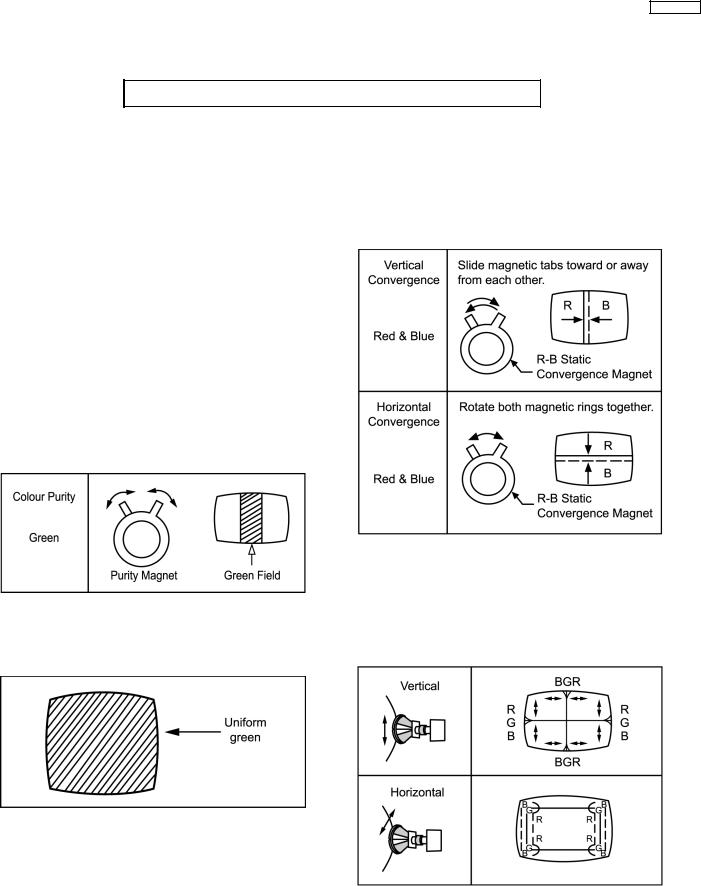

Before Colour Purity, Convergence and White Balance adjustment are attempted,

V. Height, H. Centre and Focus adjustments must be completed.

Colour Purity

1.Set the Brightness and Contrast controls to their maximum positions.

2.Operate the TV set for 60 minutes.

3.Fully degausse the picture tube by using an external degaussing coil.

4.Apply a crosshatch pattern signal and adjust the static convergence magnets to the approximately correct position.

5.Receive a black and white signal.

6.Set the control as follows: Red................minimum Green.............minimum Blue...............minimum

Press the Shipping button on the remote control twice to select CRT Adjustment Mode to select low light.

7.Loosen the clamp screw for the Deflection Yoke A in Fig. 10 and move the Deflection Yoke as close to the purity magnet as possible.

8.Adjust the purity magnetic rings so that a vertical green field is obtained at the centre of the screen.

Convergence

1.Apply a crosshatch pattern signal and Normalize Contrast control to the maximum positions.

2.Adjust Brightness until the grey position of the crosshatch pattern just becomes black.

3.Adjust the Red and Blue line at the centre of the screen by rotating the R-B static.

Fig. 6

9.Slowly push the Deflection Yoke and set it where a uniform green field is obtained.

Fig. 21

10.Re-adjust the Low Light controls to their correct settings and make sure that a uniform white field is obtained.

11.Tighten the clamp screw A in Fig. 10.

Fig. 8

4.Adjust Red and Blue with Green line at centre of the screen by rotating (RB)-G static convergence magnetic rings.

5.Lock convergence magnets with silicone sealer.

6.Remove the DY wedges and slightly tilt the Deflection Yoke vertically and horizontally to obtain the good overall convergence.

Fig. 9

7.Fix the Deflection Yoke by reinserting the DY wedges. Refer to Fig. 10.

8.If purity error is found, repeat “Colour Purity” adjustment.

9

Loading...

Loading...