Page 1

ORDER NO. MD0510379C1 A6

Speaker System

MODEL UNIT

SC-TM44 SA-TM44 Stereo

SB-TM44

Specifications

POTENCIA DE SALIDA (AMPLIFICADOR)

SC-TM44 Colour (S)... Silver Type

SB-TM44 Front Speaker

SA-TM44

SB-TM44

SC-TM44 Frontal (Bajo) 105 W RCM por canal (3Ω) 1kHz, 10% DAT

Amplificador SA-TM 44

Potencia de salida 4600 W (P.M.P.O)

Consumo de potencia 125 W

Alimentaciòn 127 V ca ±10% 60 Hz

Sencibilidad music port: 100 mV

Rango de sintonìa AM:

Rango de sintonìa FM:

Dimensiones

: 6.6 kg aprox

Peso

Notes: Specifications ar e subject to chan ge without notice. Mass and dimens ions are approximate.Total harmonic distortion is me asured by the digital spect rum analyzer.

© 2004 Matsushita Electric Industrial Co. Ltd.. All rights reserved. Unauthorized copying and distribution is a violation of law.

(b x h x l) 250 mm x 330 mm x 343mm

520-1710MHz (paso de 0,2 MHz)

87.9-107.9 MHz (paso de 0,2 MHz

87.5-108.0 MHz (paso de 0,1 MHz

(Alto)105 W RCM por canal (3Ω) 10kHz, 10% DAT

Bafles SB-TM 44

FRONTAL

Bocina Super Tweeter piezo type

ina Tweeter 6 cm

Boc

Bocina Woofer 16

IMPEDANCI

Fronta

o 3 Ω

Alt

jo 3 Ω

Ba

Dimensiones

Peso: 3.4 kg aprox

A

l - - - - - -

(b x h x l) 247 mm x 330 mm x 221mm

cm

Page 2

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers and insulation papers shields are properly

installed.

3. After servicing, check for leakage current checks to prevent from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the chassis, the reading must be

.

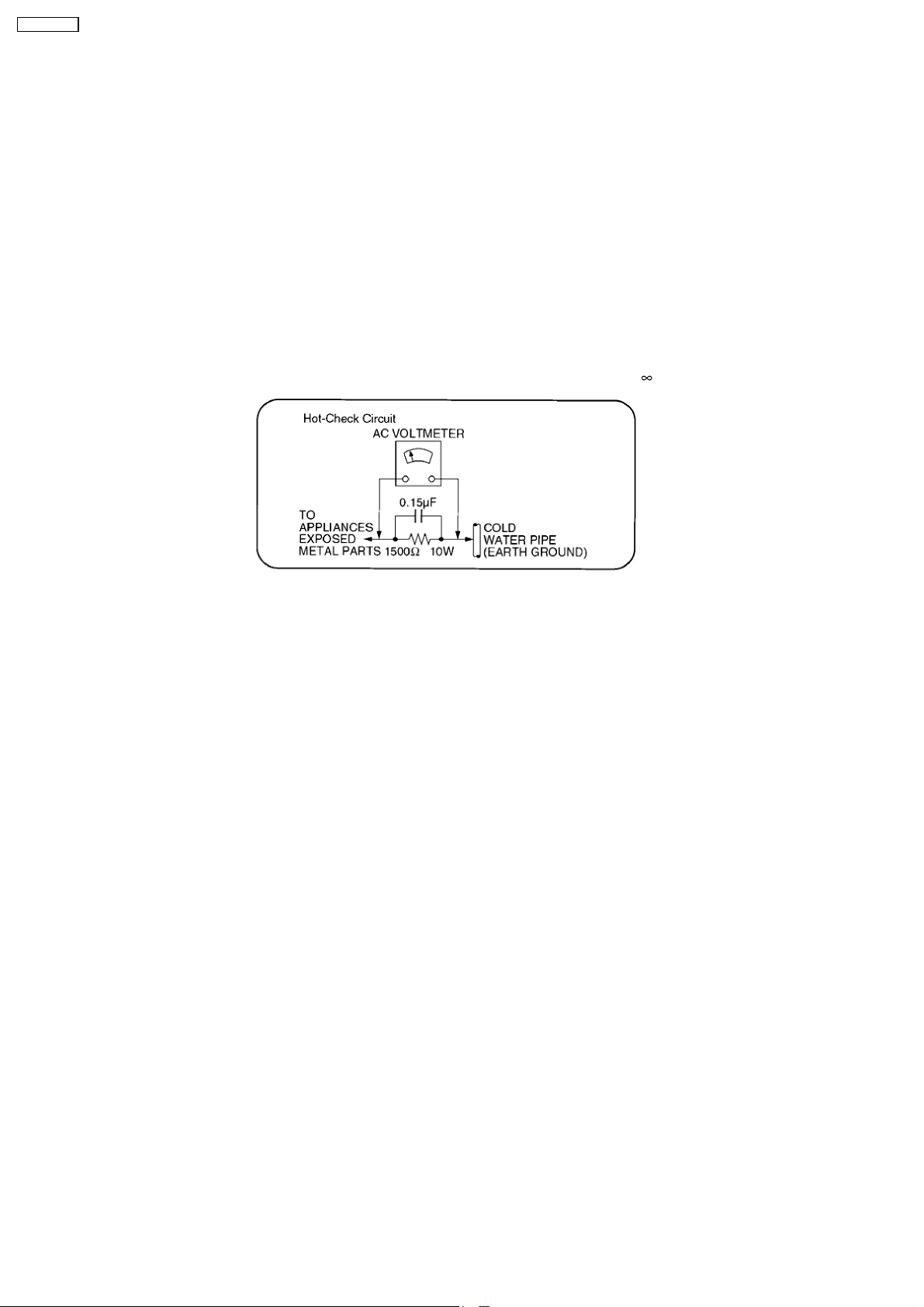

Fig. 1

1.1.2. Leakage Current Hot Check (See Figure 1)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transfo rmer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitor, between each expose d metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. Should the measurement is out of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is returned to

the customer.

1.2. Before repair and adjustment

Disconnect AC power, discharge Power Capacitors C5101, C5104, C5171, C5172, C5920, C5940 and C5950 through a 10Ω,5W

resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 120V, 60 Hz in NO SIGNAL mode (volume min at CD mode) should be ~ 300mA.

1.3. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connec tion wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

2

Page 3

3. Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium

foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize body motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

3

Page 4

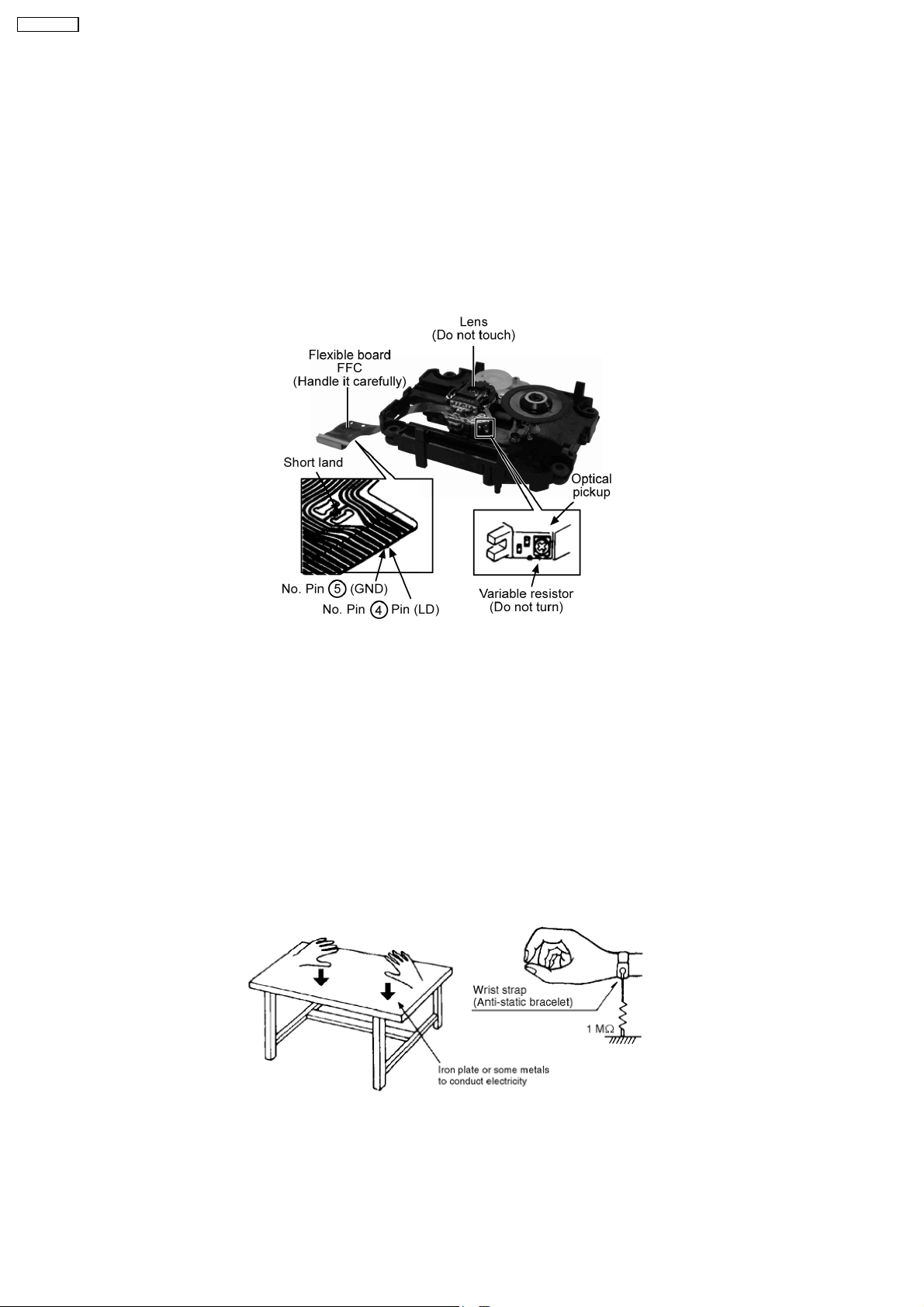

3 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break down due to potential difference caused by the static electricity of

clothes or our human body.

So, be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

· Way of handling the traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. To prevent the breakdown of the laser diode, an antistatic shorting pin is inserted into the flexible board (FFC board).

3. Do not to apply excessive stress to the flexible board (FFC board). When removing or connecting the short pin, finish the job

in as short time as possible.

4. Do not turn the variable resistor for laser power adjustment. (It is pre-adjusted during production time)

Grounding for electrostatic breakdown prevention

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) is place, and ground the

sheet.

Caution :

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your clothes touch the

traverse deck (optical pickup).

Caution when replacing the Traverse Deck

The traverse deck has a short point shorted with solder to protect the laser diode against electrostatics breakdown. Be sure to

remove the solder from the short point before making connections.

4

Page 5

4 Precaution of laser diode

CAUTION:

This unit utilizes a class 1 laser diode in the optical pickup unit .

Invisible laser radiation is emitted from the optical pickup lens.

Wavelength: 780nm

When the unit is turned on:

1. Do not look directly into the optical pickup lens.

2. Do not use optical instruments to look at the optical pickup lens.

3. Do not adjust the preset variable resistor on the optical pickup lens.

4. Do not disassemble the optical optical pickup unit.

5. If the optical pickup is replaced, use the manufacturer’s specified replacement pickup only.

6. Use of control or adjustments or performance of procedures other than those specified herein may result in hazardous radiation

exposure.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

n Use of caution label

5

Page 6

5 Handling the Lead-free Solder

5.1. About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

· Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher. Please

use a high temperature soldering iron. In case of soldering iron with temperature control, please set it to 700 ± 20°F (370 ±

10°C).

· Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

· W hen soldering or unsoldering, please completely remove all of the solder on the pins or solder area, and be sure to heat the

soldering points with the Pb free solder until it melts enough.

6

Page 7

6 New Features

6.1. CRS1 Mechanism Overview

6.1.1. General Feature

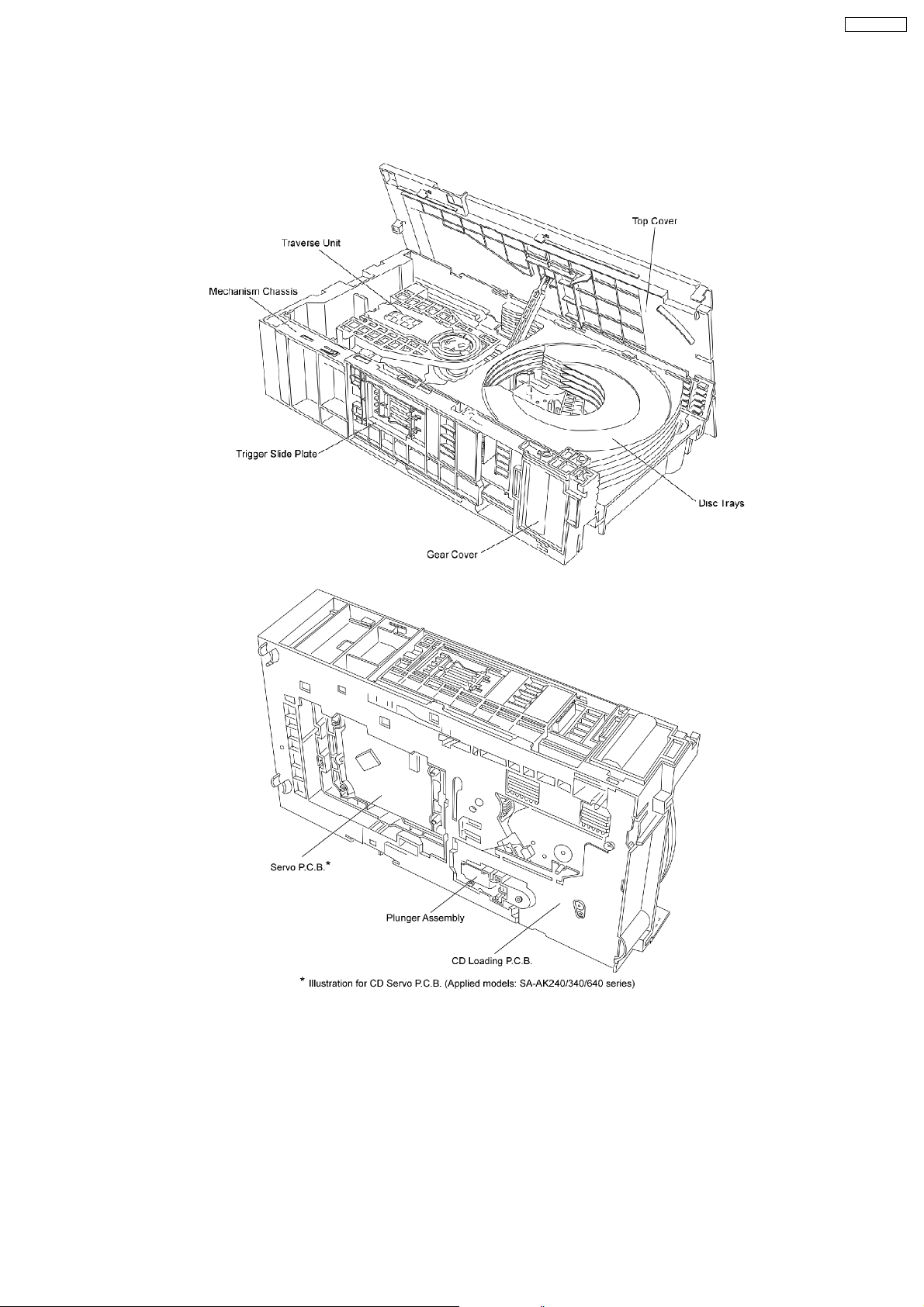

· This is a five disc changer mechanism for CD/DVD. The outline figure is shown below.

7

Page 8

· The mechanism has "CHANGE WHILE PLAY" function. It open other trays for disc exchanging while one tray is at PLAY

position performing recording or reproducing.

· The mechanism can quickly change all trays with "CHANGE ALL" function. All trays can be move to OPEN position with one

operation.

· There is no sensor to indicate presence of disc on any tray.

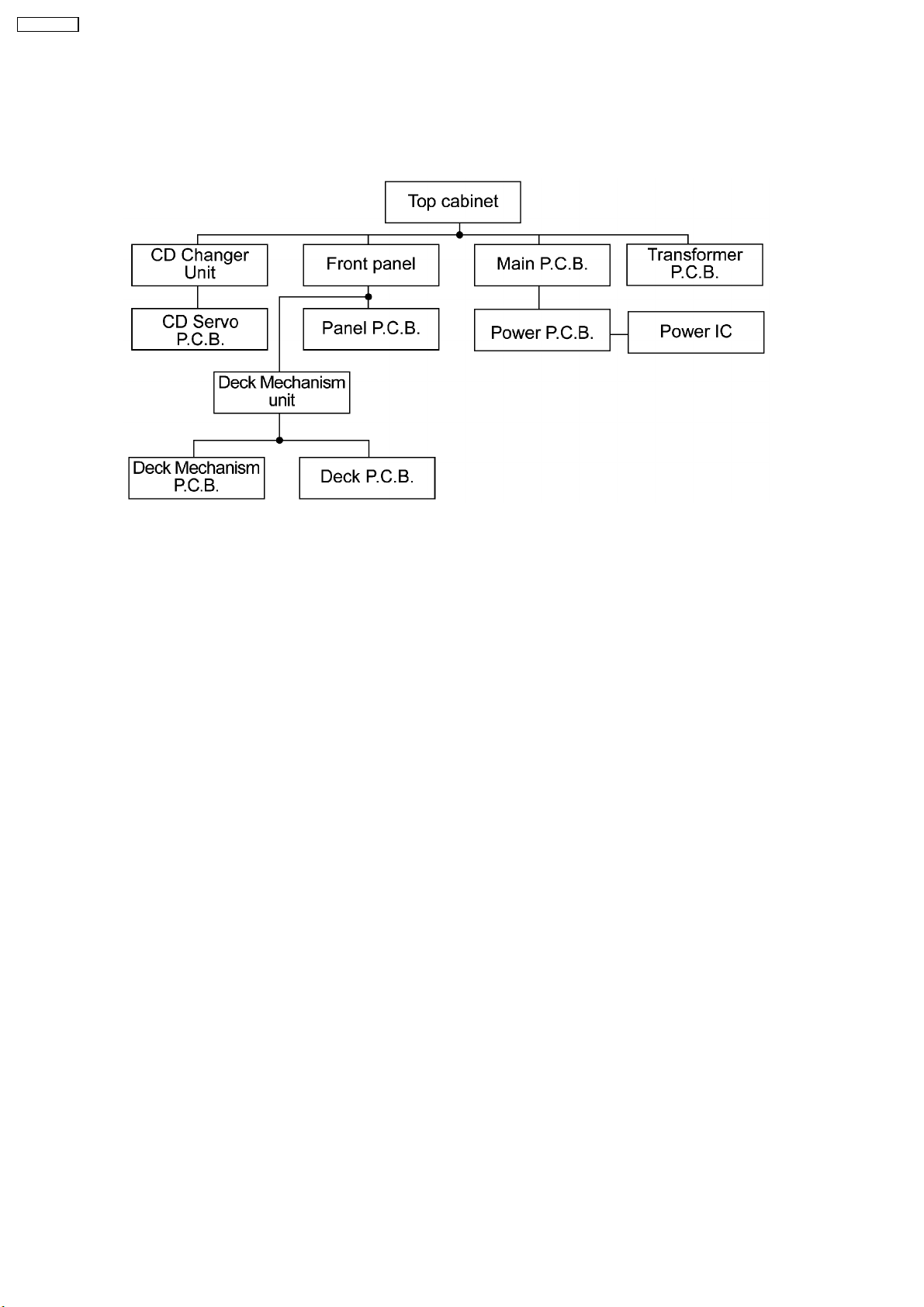

6.1.2. Hardware composition

· Below is the hardware components of the mechanism

Name Function

Open Switch (OPEN-SW) The switch is used to detect normal tray opening

The switch is used for detect tray being manually push/trigger when full open

Home Switch (HOME-SW) Is used to detect cam gear home position

Close Sensor (CLOSE-SENSOR) Used for normal single tray closing

Used to detect cam gear rotate to Play Driving position

Play Switch (PLAY-SW) Detect TRV clamping complete position

Stocking Switch (STOCK-SW) Detect tray completely transfer for play position to stocking position

UD Sensor (UD-SENSOR) Detect TRV vertical movement position

Top Switch (TOP-SW) Detect a default position of TRV vertical movement position

Driver IC To drive Motor

Motor Main driving source for changer

Plunger Switching the driving source from motor to:

1. Tray open/close

2. Drive tray to play/stock position and TRV vertical movement

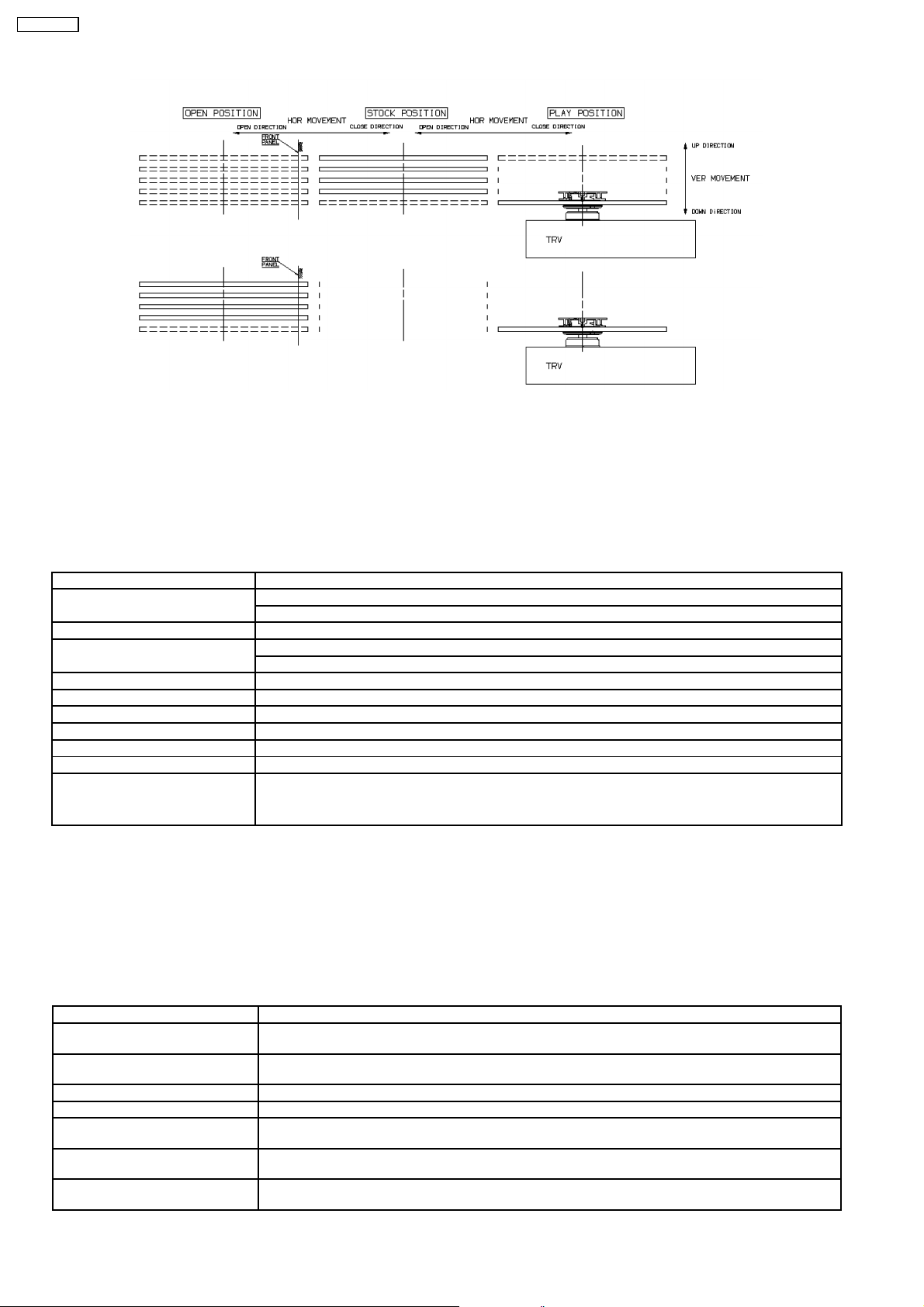

6.1.3. Mechanism Operation

· This mechanism has the following state:

1. Driving of a tray to open/close

2. Up/down operation of a traverse performs a state changes of tray.

By using the plunger to lift/release of a switching gear, and the cam gear to lift/release the function gear the motor can be link

to several gear trains to perform various operations.

· The functions that can be perform in this mechanism are described as below:

Condition Explanation

Open current playing tray The state to change current playing disc. All tray will be open at once and current tray at PLAY position

Open All The state where all trays being driven to OPEN position. The disc can be taken in or out from tray to tray

Stock The state where the trays are stored in STOCK position

Play The state where one of the tray 5 trays is being driven to PLAY position and clamped by traverse unit

Play & Open Tray-* The state where one of the tray is in playing position performing recording or reproducing, other trays can

Change The state when one of the opened tray being driven from OPEN position to STOCK position and other

Close All The state where all open trays will being driven from OPEN position to STOCK position, one by one from

will be expose.

by close tray one by one from top to bottom.

be used (OPEN position) for disc exchanging without stopping the recording or reproducing process.

opened trays remain still at OPEN position.

top to bottom

8

Page 9

Note: * represent tray number (from 1 ~ 5)

6.1.4. New CD Mechanism (CRS1)

Note:

This service manual does not contain the following information for the mention CD Mechanism drive:

· Schematic Diagram, Block Diagram and P.C.B. layout of CD Loading P.C.B.

· Part List for individual parts of the mechanism.

· Explode d View and Parts List for individual parts of the CD Mechanism drive.

Please refer to the original service manual (Order No. MD0509368C0) for the CD Mechanism Drive CRS1.

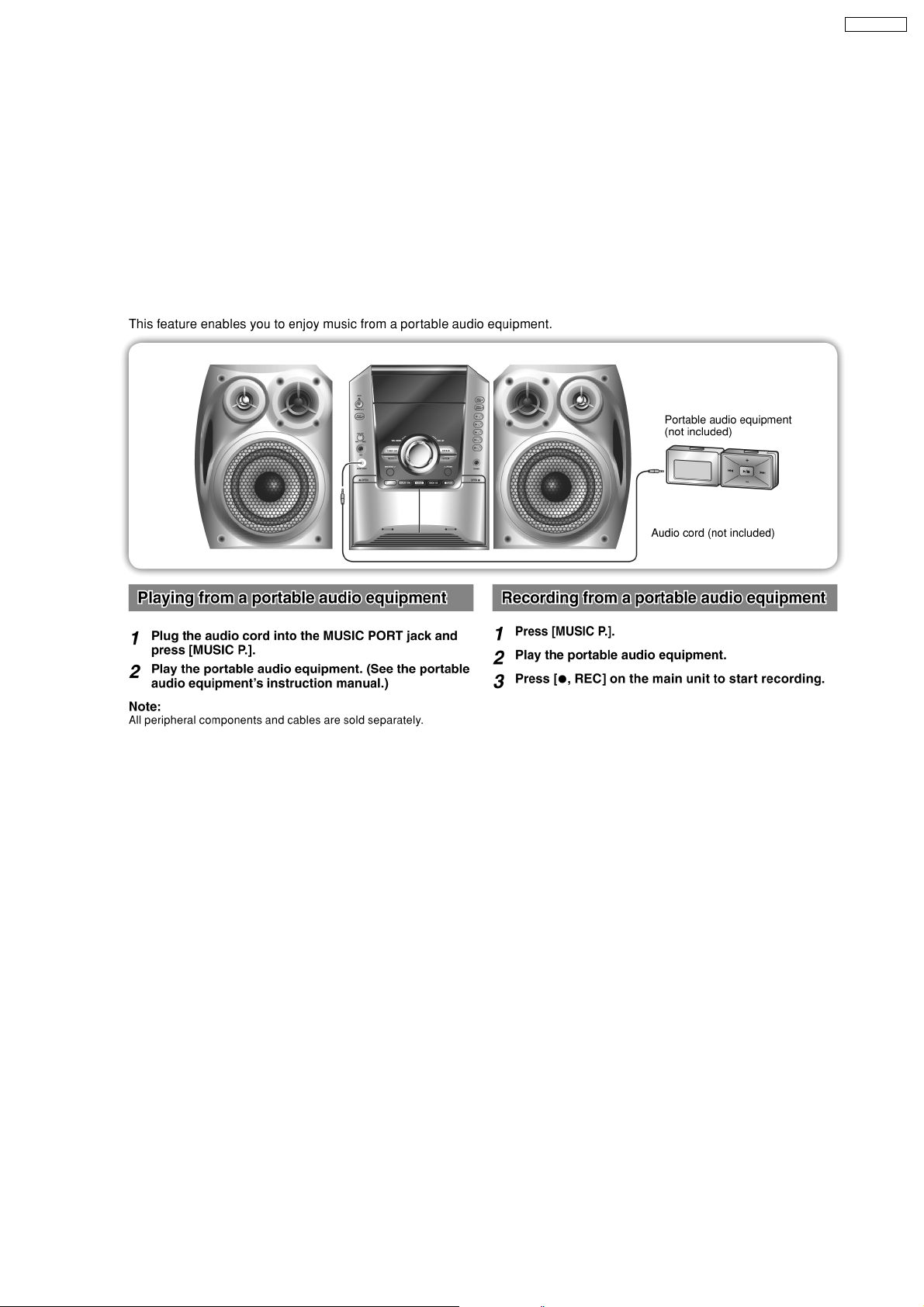

6.2. Music Port

With reference to page 17 of the operating instruction manual.

9

Page 10

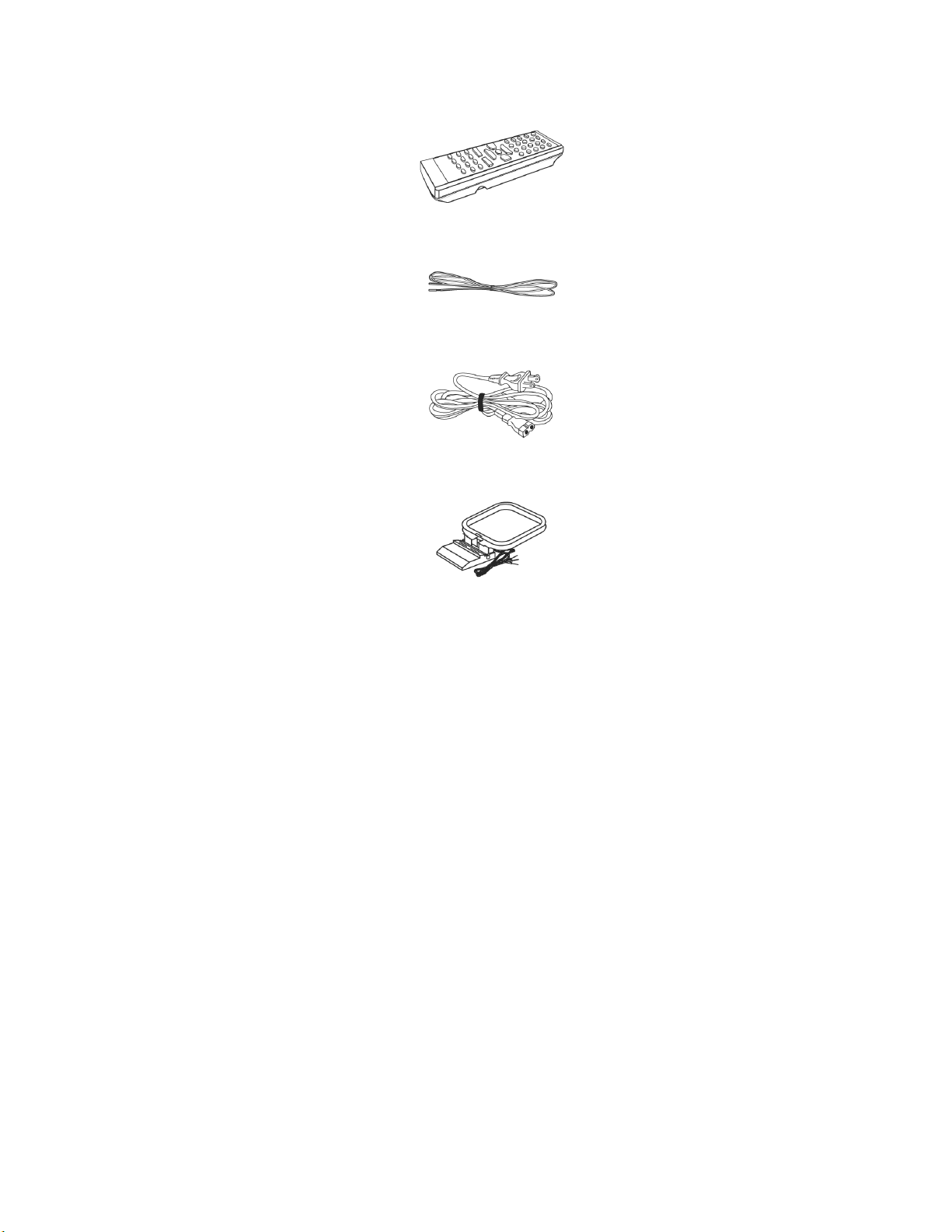

7 Accessories

Remote Control

N2QAHB000065

FM Antenna

Wire

RSA0006-L

AC Cord

SJA168-1A

AM Loop Antenna

N1DAAAA00001

Page 11

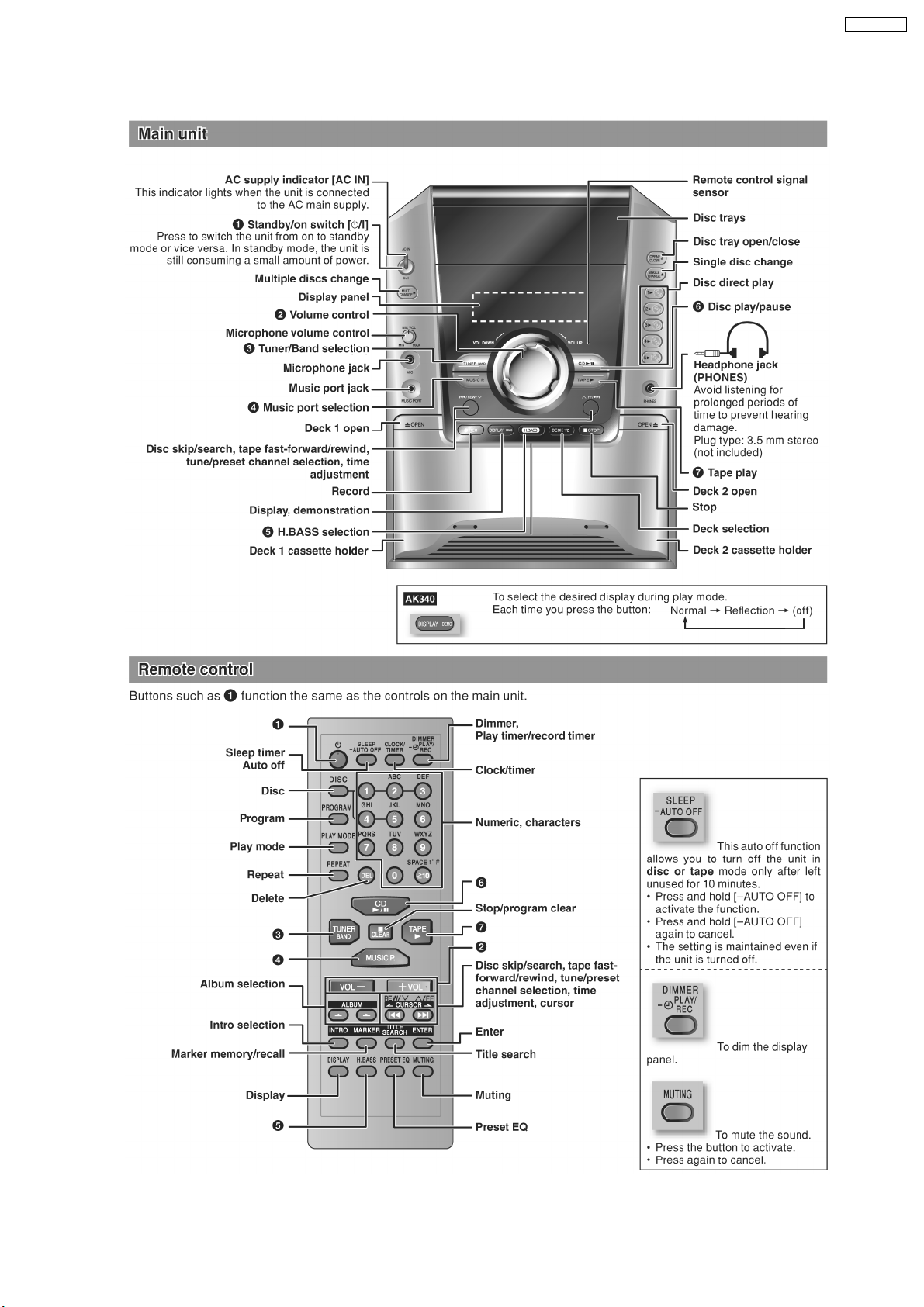

8 Operating Instructions Procedures

11

Page 12

12

Page 13

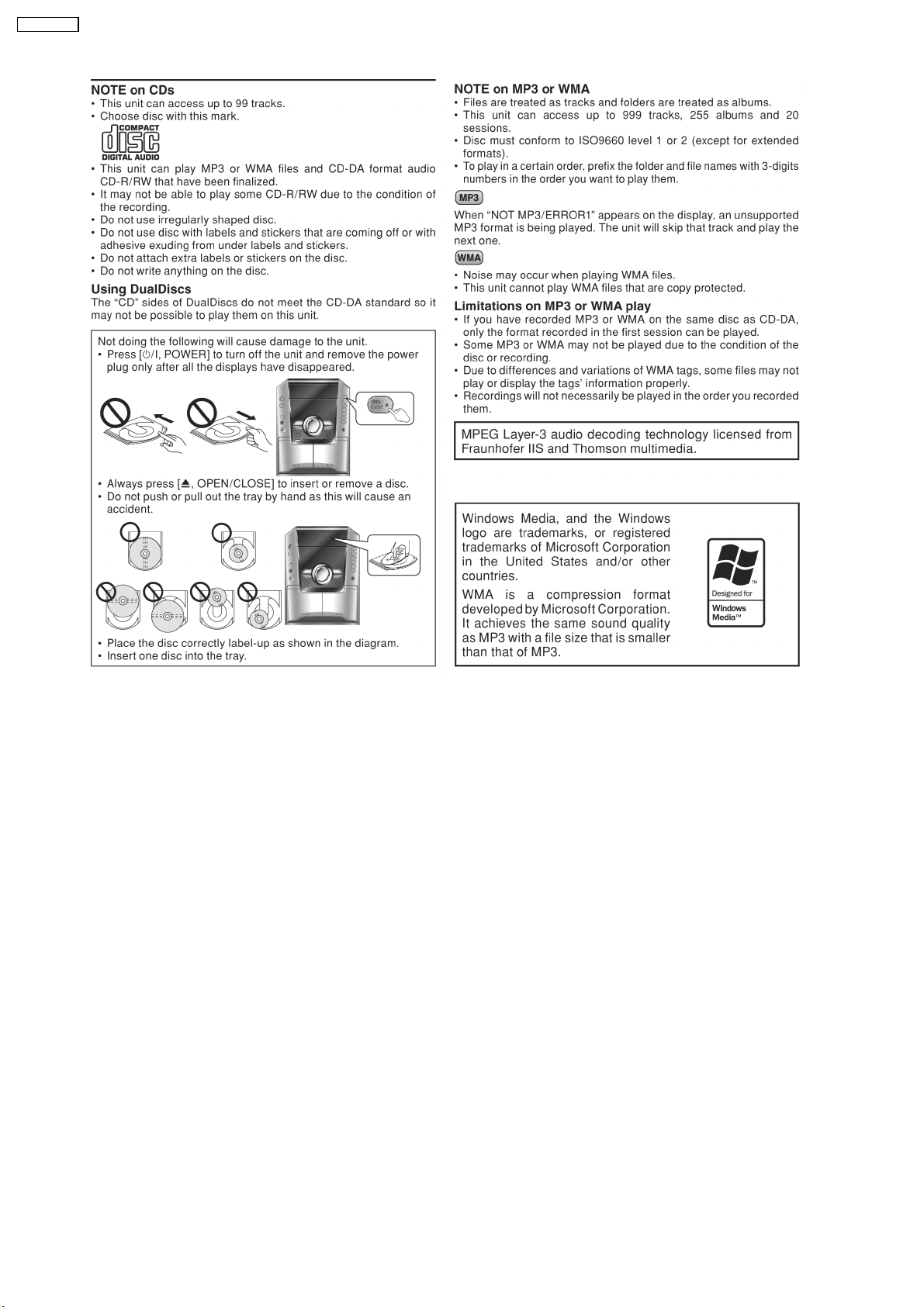

9 Self diagnosis and special mode setting

This unit is equipped with functions for checking and inspecting namely: Self-Diagnostic and Test Mode.

9.1. Special Mode Table

Item FL Display Key Operation

Mode Name Description Front Key

Self -Diagnostic

Mode

CD Test Mode To enter into checking the

CD Auto

Adjustment

To enter into self

diagnostic checking for

main unit.

reliability of changer unit.

To check the CD auto

adjustment result for

FLOCK, TLOCK and

CLVS.

1. Select [

] for TAPE mode (Ensure no tape is

inserted).

2. Press and hold [

seconds follow by [

To exit, press

main unit or remote control.

1. Select [ ] for CD mode.

2. Press and hold [

seconds follow by [

To exit, press

main unit or remote control.

In CD Test Mode:

1. Press [0] button on the remote control.

To exit, press

main unit or remote control.

]button for 3

].

button on

] button for 3

].

button on

button on

CD Changer

Reliability Test

(CRS1)

Doctor Mode To enter into Doctor

Cold Start To activate cold start

Changer

Reliability Test

To determine the

reliability of CD Changer

Unit.

(For more information,

refer to section 9.1.1)

Mode for checking of

various items and

displaying EEPROM and

firmware version.

upon next AC power up.

To check the function

operation of changer unit.

(For more information,

refer to 9.1.1)

1.

2.

1. All segments will light up for 1 second.

2. The Check Sum of EEPROM and firmware

version will be display.

* ROM correction

** Firmware version No:

In Self-Diagnostic Mode:

1. Select [

2. Press [

To exit, press

main unit or remote control.

(The tray will return to PLAY position and then

power off)

In any mode:

1. Press [

follow by [4] and [7] on remote control.

To exit, press [ENTER] button on remote

control or

unit or remote control.

In doctor mode:

1. Press [4] button on remote control.

To exit, press [ENTER] button on remote

control or

unit or remote control.

In doctor mode:

1. Press [DISC] on remote control.

To exit, press [ENTER] button on remote

control or

unit or remote control.

] for CD mode.

] button.

button on

] button on main unit

button on main

button on main

button on main

13

Page 14

Item FL Display Key Operation

Mode Name Description Front Key

FL Display Test To check the FL

segments display (All

segments will light up and

LED will blink at 0.5

second interval)

Tape Eject Test To check on the tape

eject function (For deck

1/2)

In doctor mode:

1. Press [PROGRAM] button on remote

In doctor mode:

1. Press [PROGRAM] button on remote

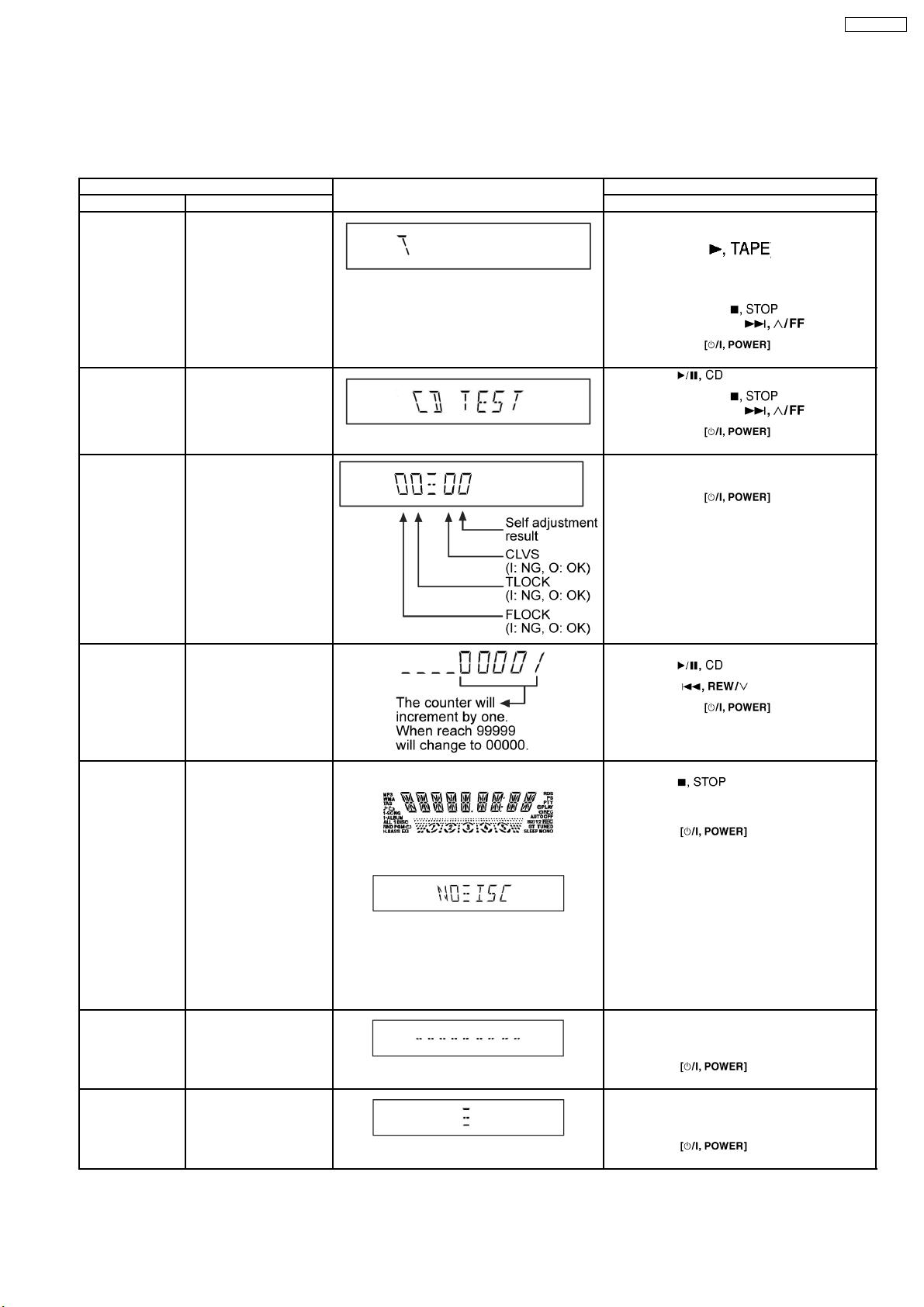

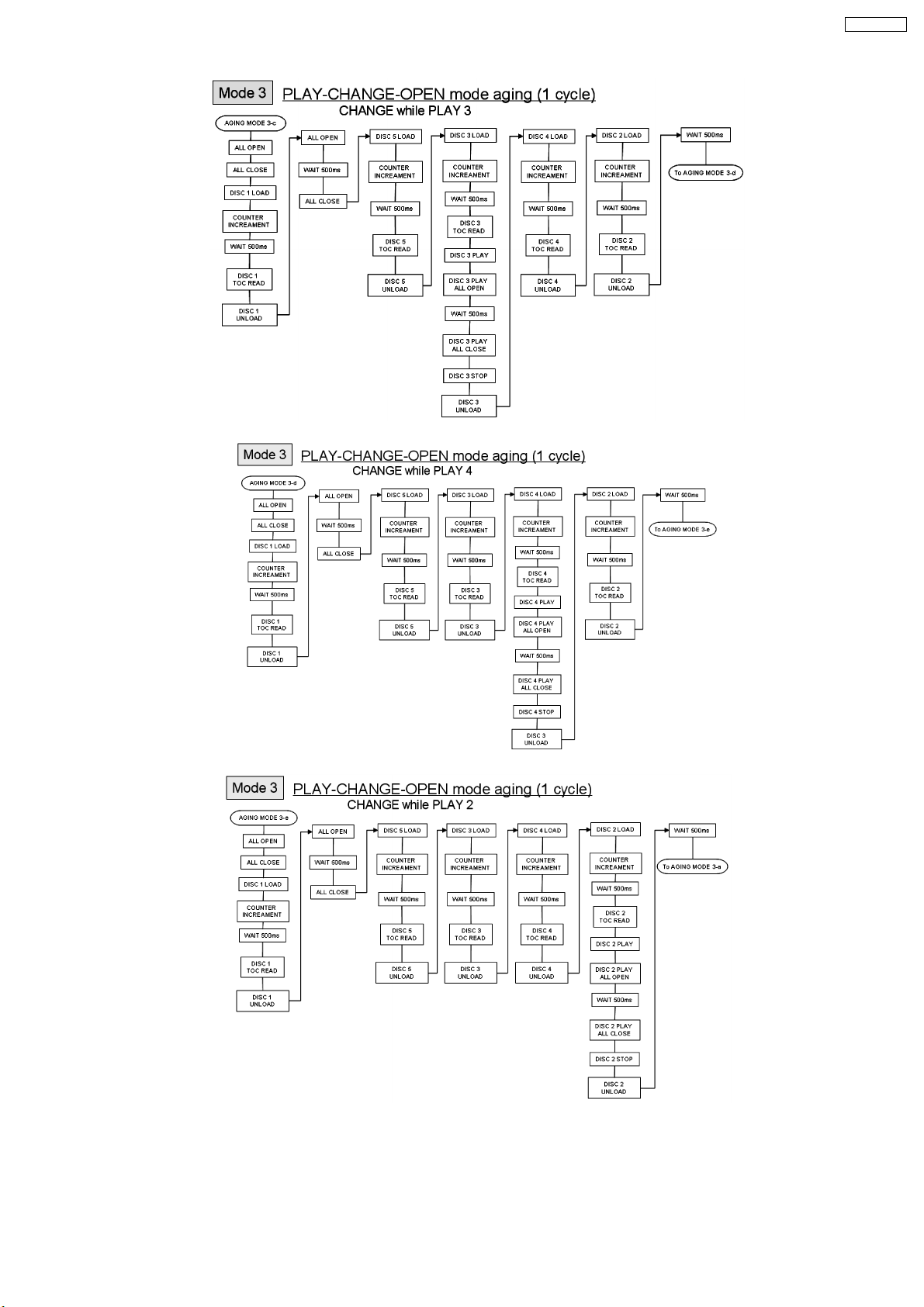

9.1.1. CD changer unit ageing test mode

Below is the process flow chart of ageing for the CD changer unit. (CRS1)

control.

control.

14

Page 15

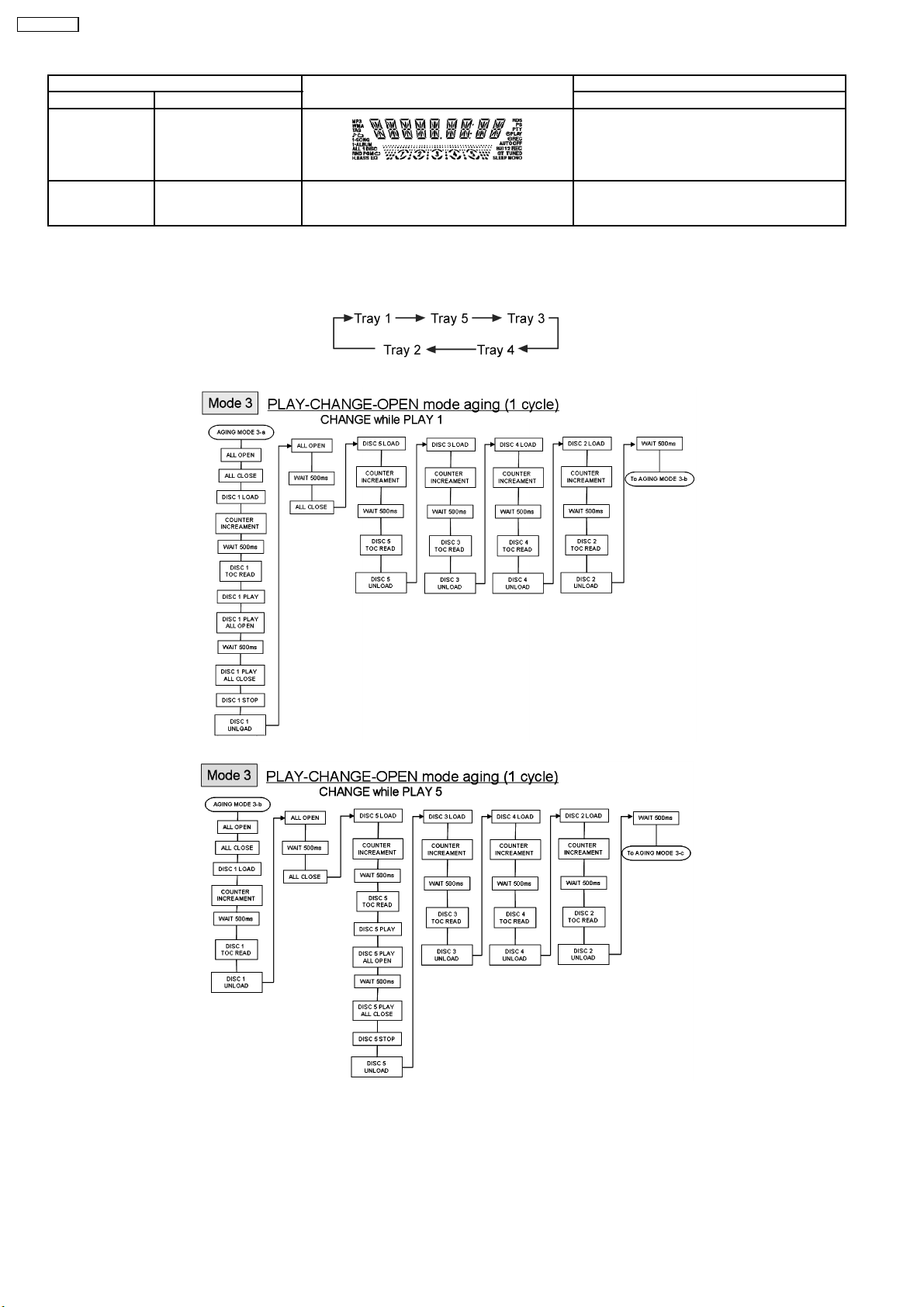

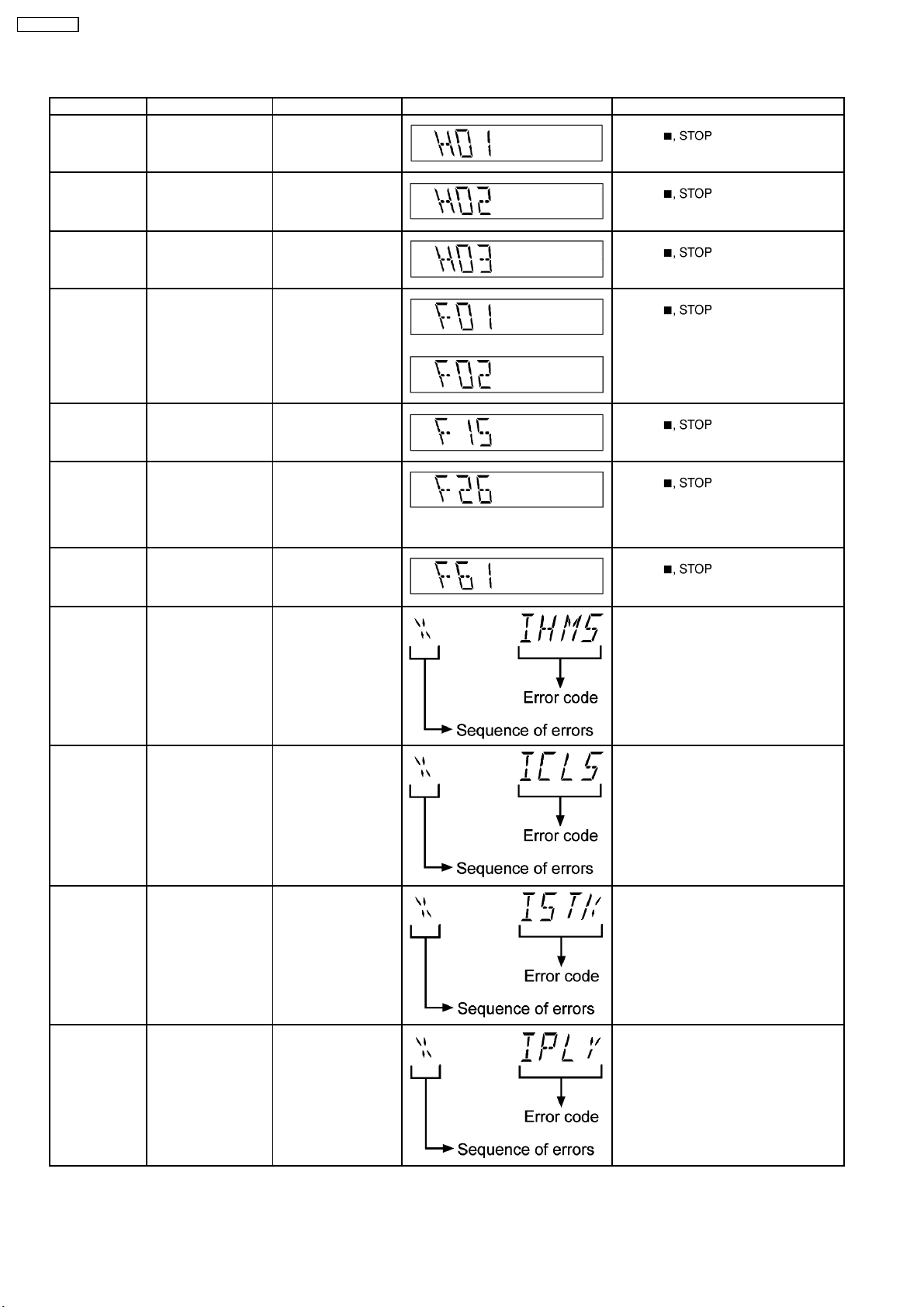

9.2. Error code Table

Self-Diagnosis Function (refer Section 9.1) provides information on any problems occuring for the unit and its respective

components by displaying the error codes. These error code such as U**, H** and F** are stored in memory and held unless it is

cleared.

15

Page 16

The error code is automatically display after entering into self-diagnostic mode.

Error Code Diagnosis Contents Description of error Automatic FL Display Remarks

H01 Mode SW, plunger

and capstan motor

abnormal

For deck mechanism unit (For deck 1/2).

Press [

next error.

] on main unit for

H02 Rec INH SW

H03 HALF SW abnormal For deck mechanism unit (For deck 1/2).

F01

F02

F15 RESET SW

F26 Transmission error

F61 Power Amp IC output

IHMS Cam gear

abnormal

Reel pulse abnormal

TPS error

abnormal

between CD Servo

LSI IC and

microprocessor IC

abnormal

abnormality

REST SW: ON is not

detected within the

specified time.

When set to CD mode,

the sense signal does

not turn “Low”, a fail

safe time after system

command

transmission is sent.

Upon power on,

PCONT=HIGH,

DCDET=L after

checking LSI.

Cam gear does not

rotate to “HOME”

position.

For deck mechanism unit (For deck 2).

Press [

next error.

Press [

next error.

For deck mechanism unit (For deck 1/2).

Press [

next error.

For CD unit (For Traverse).

Press [

next error.

For CD unit (For Traverse).

Press [

next error.

For power.

Press [

next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

] on main unit for

] on main unit for

] on main unit for

] on main unit for

] on main unit for

] on main unit for

ICSL Cam gear/gear units

abnormal

ISTK Drive rack/gear

assembly abnormal

IPLY Drive rack/gear

assembly abnormal

Cam gear does not

rotate to “PLAY”

driving position and

hence does not drive

playing tray to

“STOCK” position.

The tray drive rack

does not move to

“STOCK” position.

(Tray does not move

to “STOCK” position)

The tray drive rack

does not move to

“PLAY” position. (Tray

does not move to

“PLAY” position)

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

16

Page 17

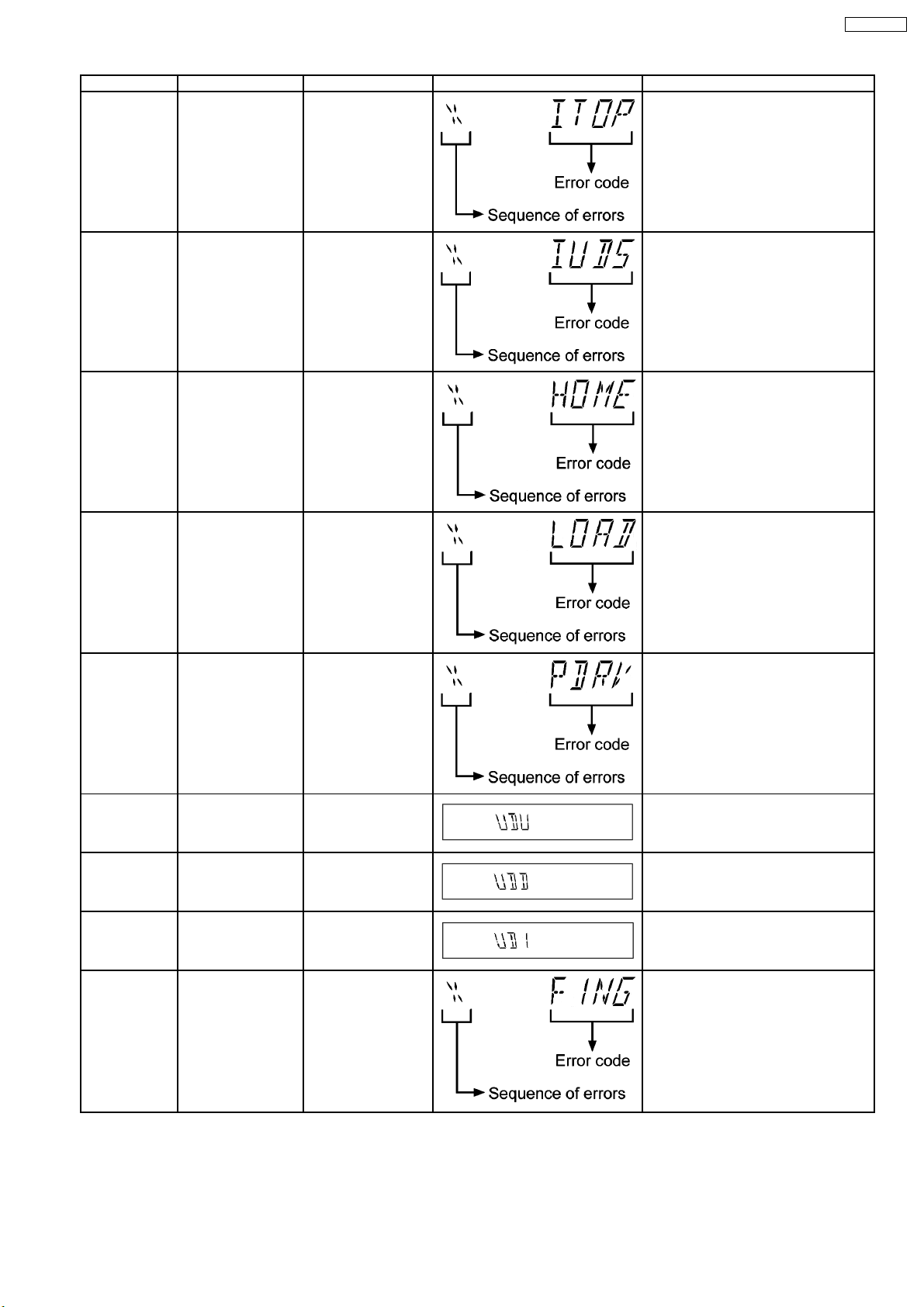

Error Code Diagnosis Contents Description of error Automatic FL Display Remarks

ITOP UD assembly UD Rack does not

move to front

direction. This lead to

UD base not raise to

top position.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

IUDS UD assembly After TOP SW is

HOME Cam gear/gear

assembly abnormal

LOAD Tray drive assembly

abnormal

PDRV Cam gear/gear

assembly abnormal

detected, UD rack

does not move into

tray 1 position.

Cam gear does not

move to “HOME”

position under

following conditions

1. After tray is load to

“PLAY” position.

2. After tray is unload

to “STOCK”

position.

Tray unit does not

move from “STOCK”

to “PLAY” position

Cam gear does not

move from “HOME” to

“PLAY” drive position.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

UDU UD base asssembly

abnormal

UDD UD base asssembly

abnormal

UD1 UD base asssembly

abnormal

F1NG Fail - safe mode. (For

open/close tray

unit(s))

UD Base assembly

does not move

upwards from tray 5 to

tray 2

UD Base assembly

does not move

downwards from tray 1

to tray 5.

UD Base assembly

does not move to tray

1.

When the tray open

operation is

performed, it fails to

open. It will

automatically close all

trays after the time-out

by the microprocessor.

During this time when

it fails, the error code

will appear.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

17

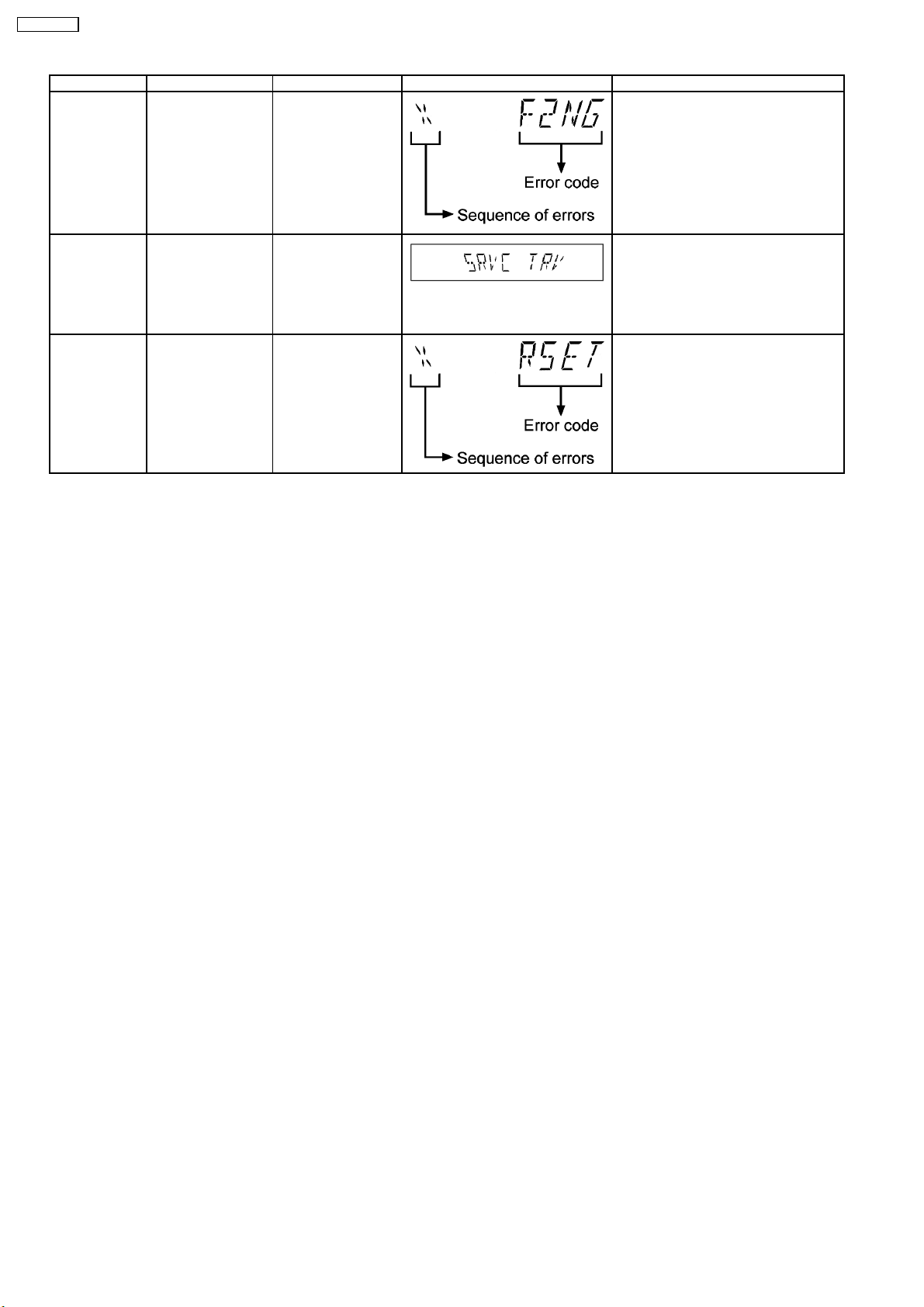

Page 18

Error Code Diagnosis Contents Description of error Automatic FL Display Remarks

F2NG Fail - safe mode. (For

open/close tray

unit(s))

SRVC_TRV To unlock the

traverse unit for

service

RSET Cam gear jam/close

sensor faulty

When the tray close

operation is

performed, it fails to

close. It will

automatically open all

trays after the time-out

by the microprocessor.

During this time when

it fails, the error code

will appear.

1. All trays set to

“STOCK” position

2. Mechanism set to

tray 5

3. Cam gear set to

“HOME” position

During tray re-open,

the cam gear will

rotate in the opposite

direction to reset the

cam gearposition.

When it fails, the error

code will appear.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

For CD changer unit (CRS1).

Press [SINGLE CHANGE] on main unit

for next error.

CRS1 Error Code display

1. The errors that occured in CRS1 Mechanism can be recalled and displayed, in the order of the occurence under self-diagnostic

(Refer to Section 9.1 for procedures to enter this mode.

· Only the first 5 errors will be memorized (in backup memory). The subsequence error shall be ignored and not memorize.

For system with EEPROM as memory backup,memory space in EEPROM is neccesary.

2. To display all error code memorized

In CRS1 Self-Diagnostic mode, press [SINGLE CHANGE] to display subsequence error code.

It shall repeat after reaching error no. 5.

e.g.:

[1____IHMS]→ [SINGLE CHANGE]

[2____ITOP]→ [SINGLE CHANGE]

[3____HOME]→ [SINGLE CHANGE]

[4____LOAD]→ [SINGLE CHANGE]

[5_____UDD]→ [SINGLE CHANGE]

3. To clear the error code memory

In CRS1 Self-Diagnostic mode, long press [SINGLE CHANGE] key (2s or more)1

18

Page 19

10 Assembling and Disassembling

10.1. Caution

Special Note:

This model uses a new CD changer unit CRS1. In this following section does not contain the necessary disassembly &

assembly information for the CD changer unit (CRS1) except the disasembly & assembly of traverse unit. Kindly refer to the

original service manual for the CD changer unit. (Order No. MD050 9368C0).

“ATTENTION SERVICER”

Some chassis components may have sharp edges. Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the main

components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

4. Refer to the Parts No. on the page of “Parts Location and Replacement Parts List” (Section 22), if necessary.

Warning :-

This product uses a laser diode. Refer to caution statement Precaution of Laser Diode.

Caution:

After replacing of CD Changer Unit, ageing test is necessary. Please confirm operation for CD Changer Unit.

Below is the list of disassembly sections

· Disasse mbly of Top Cabinet

· Disasse mbly of Rear Panel

· Disasse mbly of CD Changer Unit

· Disasse mbly of Main P.C.B.

· Disasse mbly of Transformer P.C.B.

· Disasse mbly of Power P.C.B.

· Disasse mbly of Front Panel Unit

· Disasse mbly of Panel P.C.B.

· Disasse mbly of Deck Mechanism Unit

· Disasse mbly for Deck P.C.B.

· Disasse mbly of Traverse Unit

· Disasse mbly of Optical Pickup Unit (CD Mechanism)

· Disasse mbly of Deck Mechanism

· Replacement for cassette lid

· Rectification for tape jam problem

19

Page 20

10.2. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart as below.

20

Page 21

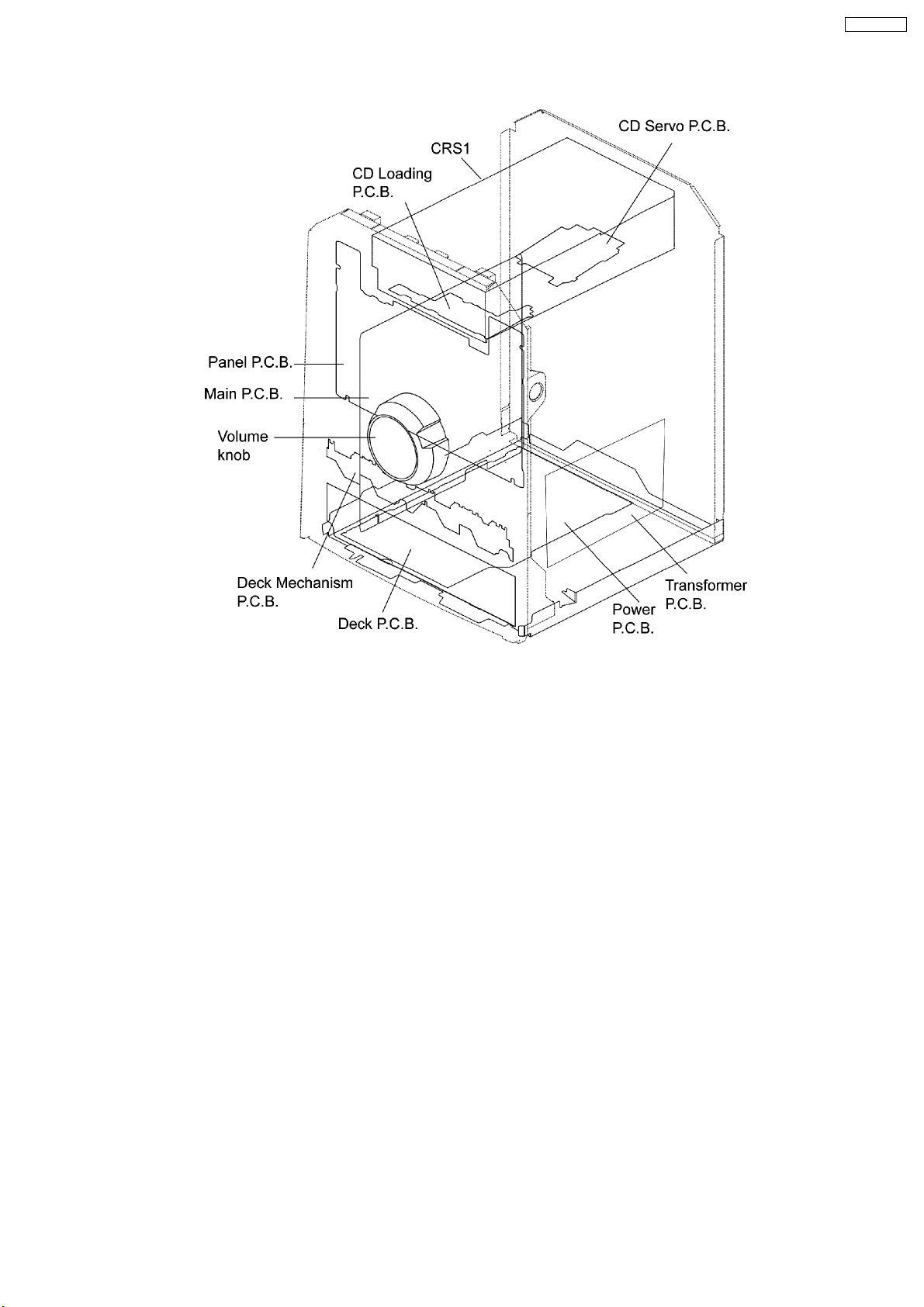

10.3. Main Parts Location

21

Page 22

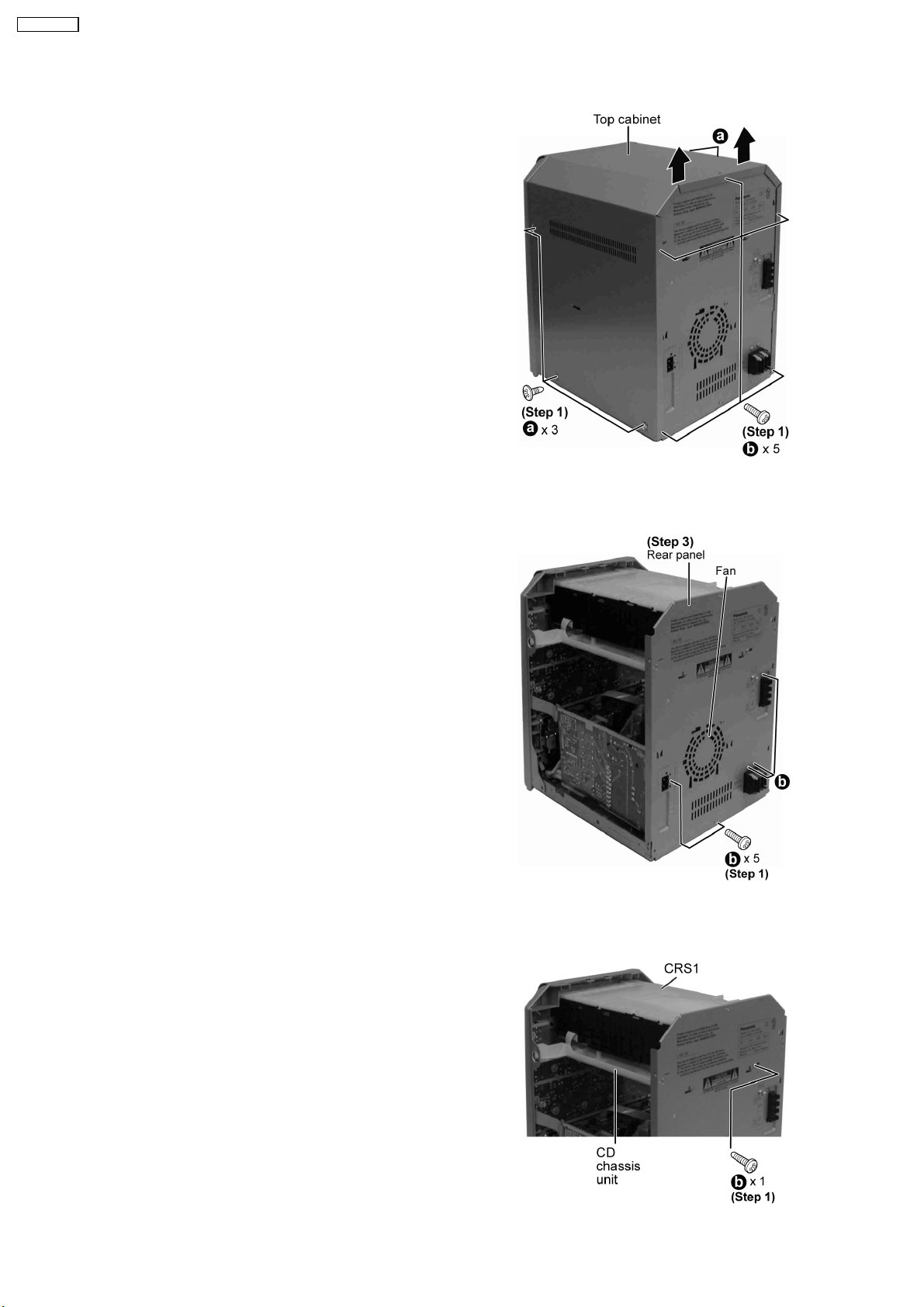

10.4. Disassembly of Top Cabinet

Step 1 Remove 3 screws at each side and 5 screws at rear

panel.

Step 2 Lift up both sides of the top cabine t, push the top

cabinet towards the rear to remove the top cabinet.

10.5. Disassembly of Rear Panel

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

Step 1 Remove 5 screws.

Step 2 Disconnect cable CN2810 (Fan) at Main P.C.B..

Step 3 Remove rear panel.

10.6. Disassembly of CD Changer Unit (CRS1)

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

Step 1 Remove 1 screw at rear panel.

22

Page 23

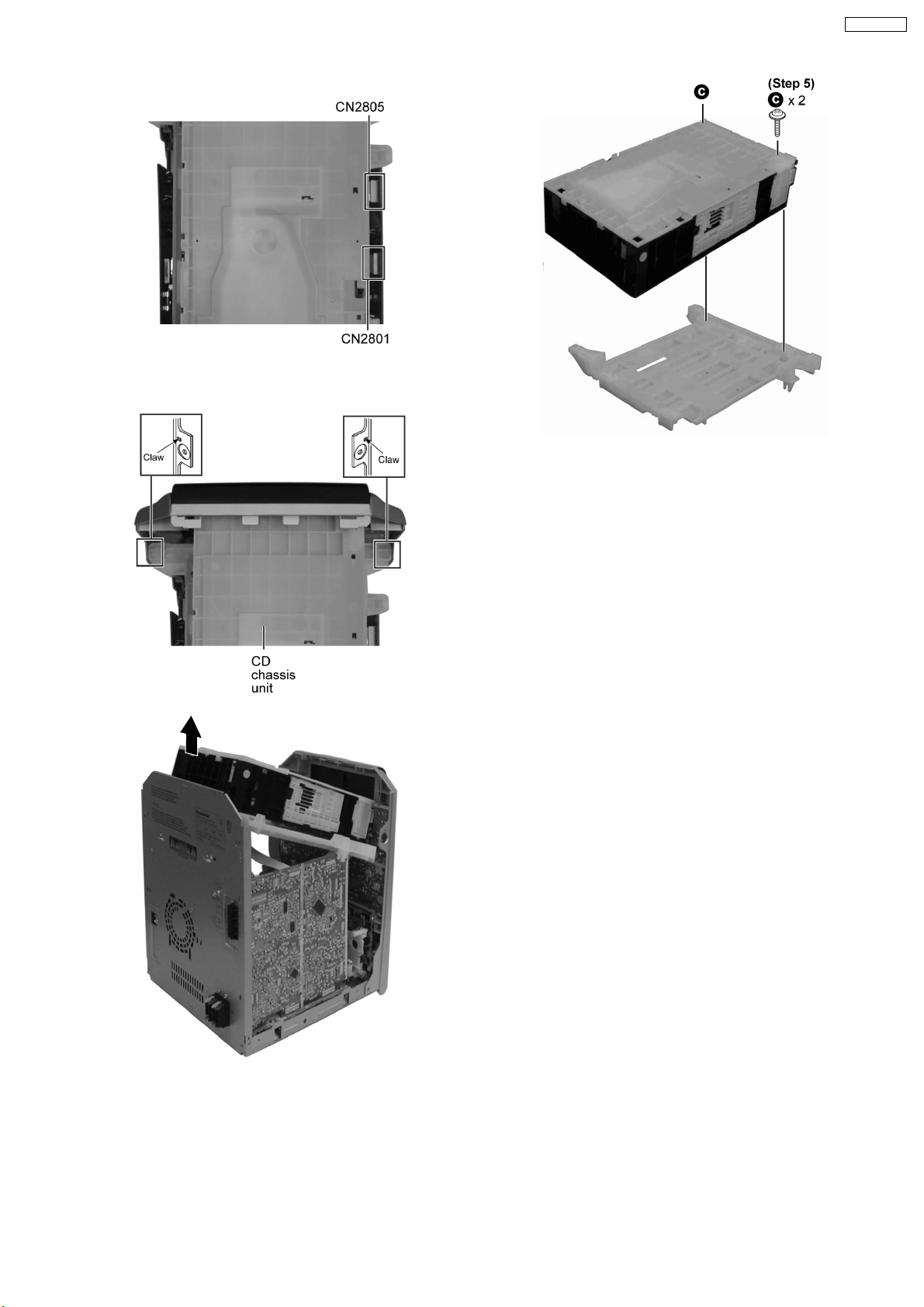

Step 2 Detach the FFC cables (CN2801 & CN2805).

Step 3 Release the claws on both ends.

Step 5 Remove 2 screws.

Step 6 Remove the Mecha Chassis.

Note:

For disassembly & assembly of traverse unit, please refer to

section 10.14 of this service manual.Please refer to original

Service Manual for the Disassembly and Assembly of the CD

Changer Unit (CRS1).

Step 4 Lift the CD changer unit upwards to remove it.

· Disasse mbly of Mecha Chassis

23

Page 24

10.7. Disassembly of Main P.C.B.

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 10.6 - Disassembly of CD Changer Unit

· Follow the (Step 1) - (Step 3) of Item 10.5 - Disassembly of Rear Panel

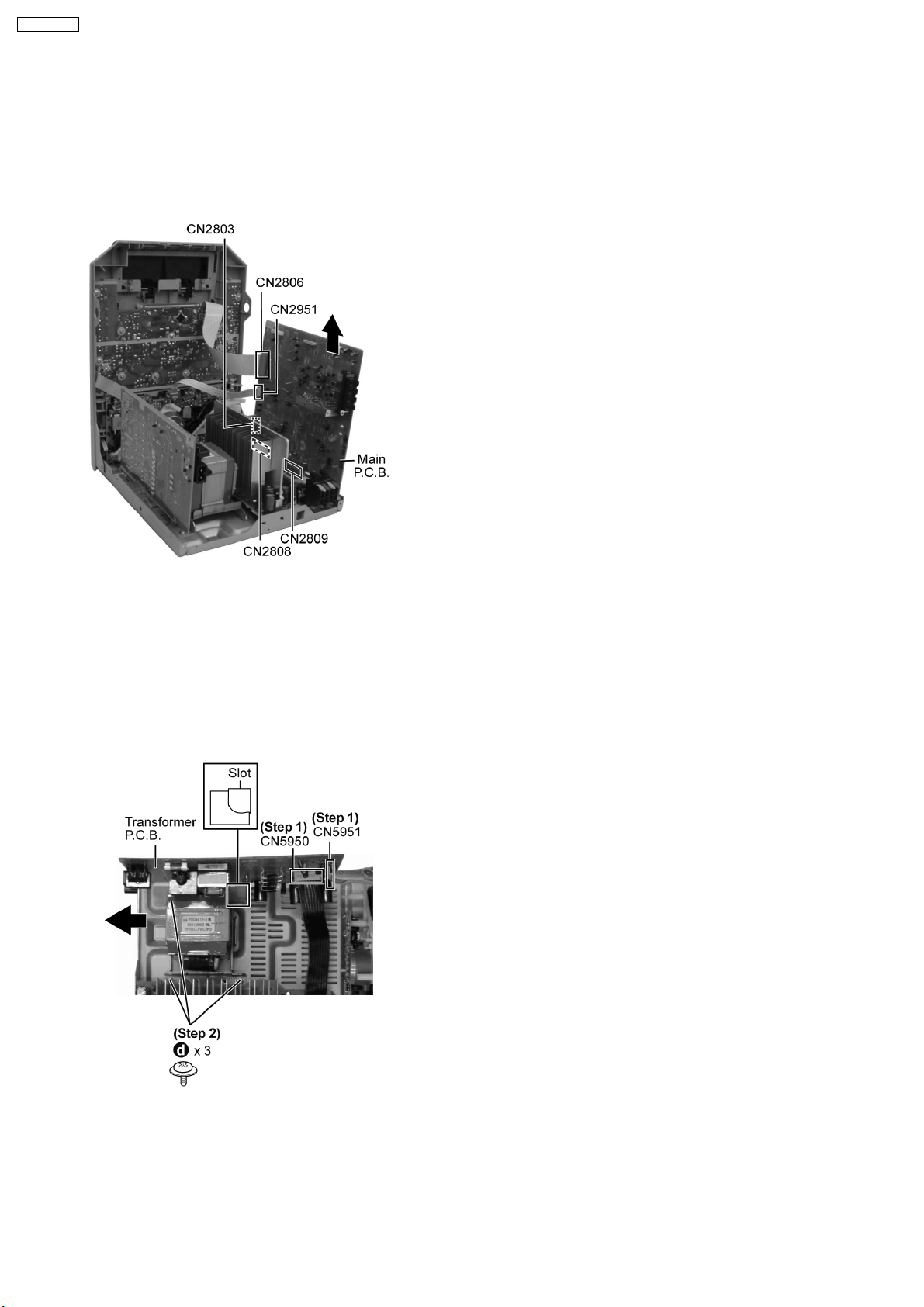

Step 1 Disconnect FFC cables (CN2803, CN2806 and

CN2951).

Step 2 Detach connectors (CN2808 & CN2809).

Step 3 Remove Main P.C.B..

10.8. Disassembly of Transformer P.C.B.

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 3) of Item 10.5 - Disassembly of Rear Panel

· Follow the (Step 1) - (Step 4) of Item 10.6 - Disassembly of CD Changer Unit

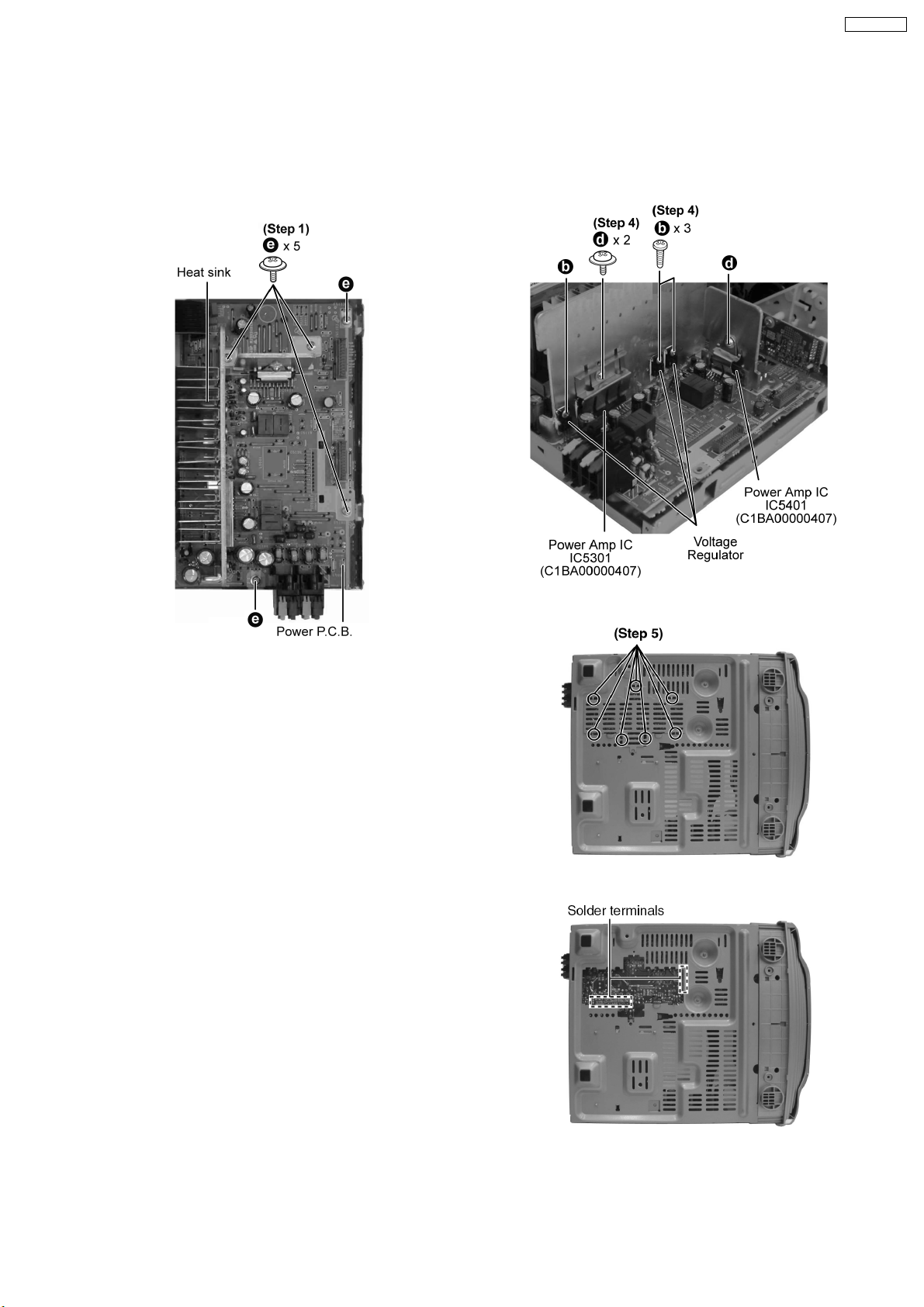

Step 1 Disconnect connectors (CN5950 & CN5951).

Step 2 Remove 3 screws (Mounting screws for transformer to

bottom chassis).

Step 3 Push the Transformer P.C.B. sidewards to remove it.

24

Page 25

10.9. Disassembly of Power P.C.B.

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 10.6 - Disassembly of CD Changer Unit

· Follow the (Step 1) - (Step 3) of Item 10.5 - Disassembly of Rear Panel

· Follow the (Step 1) - (Step 3) of Item 10.7 - Disassembly of Main P.C.B.

Step 1 Remove the 5 screws on Power P.C.B..

Step 2 Detach cable (CN5950) remove the 5 screws on Power

P.C.B..

Step 3 Remove Power P.C.B..

Note:

Insulate the Power P.C.B. with insulation material to avoid short

circuit.

· Replacement of the Power Amp IC or Voltage Regulator

Step 4 Remove 2 screws at the Power Amp IC and/or 3

screws to Voltage Regulator.

Step 5 Cut the joints with a metal cutter as shown below.

Step 6 Desolder the terminals to replace the components.

Step 7 Fix back the cut portion with a screw as shown.

25

Page 26

10.10. Disassembly of Front Panel Unit

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 10.6 - Disassembly of CD Changer Unit

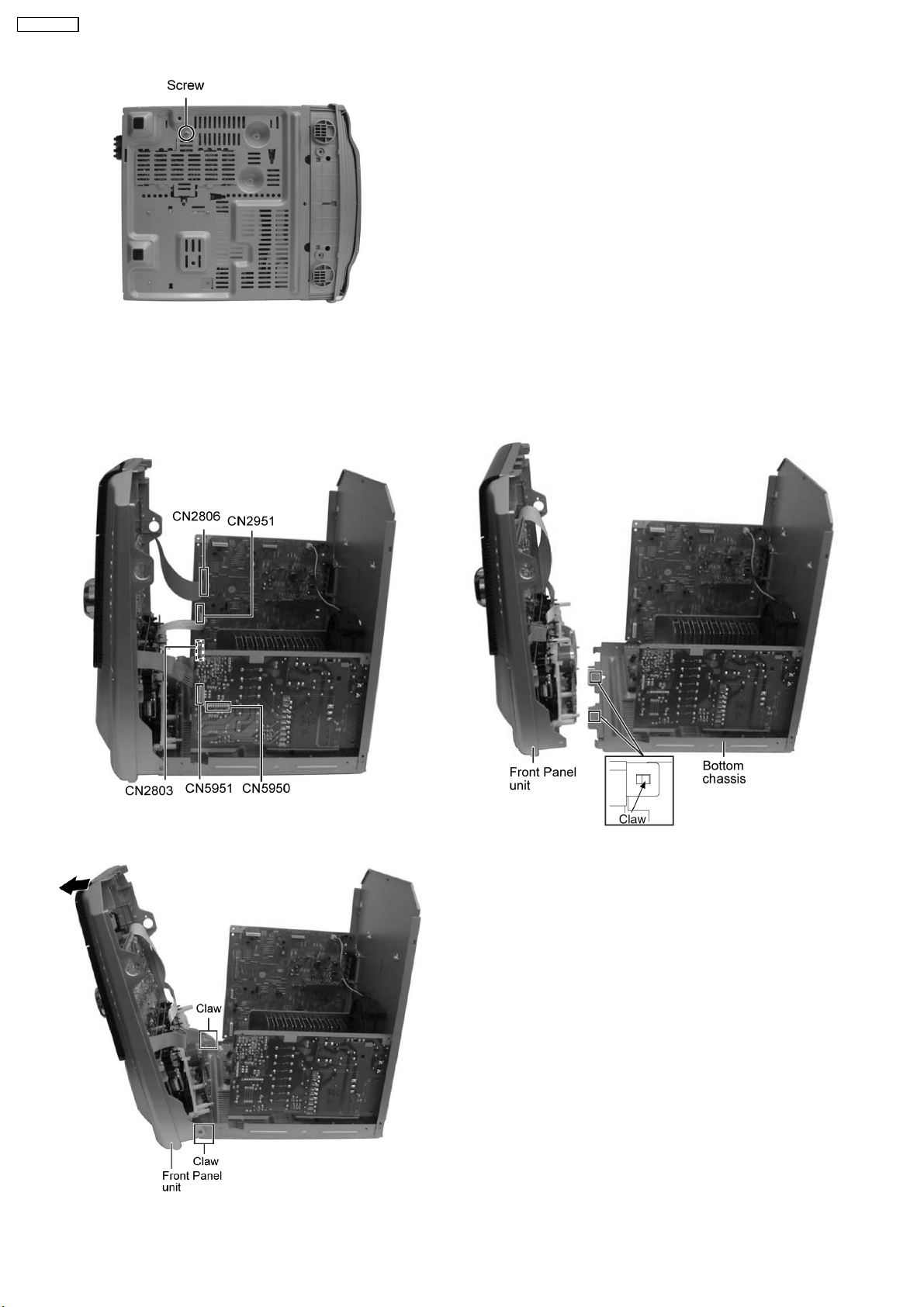

Step 1 Disconnect connectors (CN2803, CN2806, CN2951,

CN5950 & CN5951).

Step 3 Release 2 claws outwards.

Step 2 Bent the front panel unit slightly forward as arrow

shown.

Step 4 Remove the front panel unit.

Note: Ensure 2 claws located at the bottom chassis is seated

into the 2 slots at bottom of front panel at 2 catches (one on

each side) of bottom chassis to be aligned to front panel’s slot.

Assembly is secured upon hearing clicking sound.

26

Page 27

10.11. Disassembly for Panel P.C.B.

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 10.6 - Disassembly of CD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 10.10 - Disassembly of Front Panel Unit

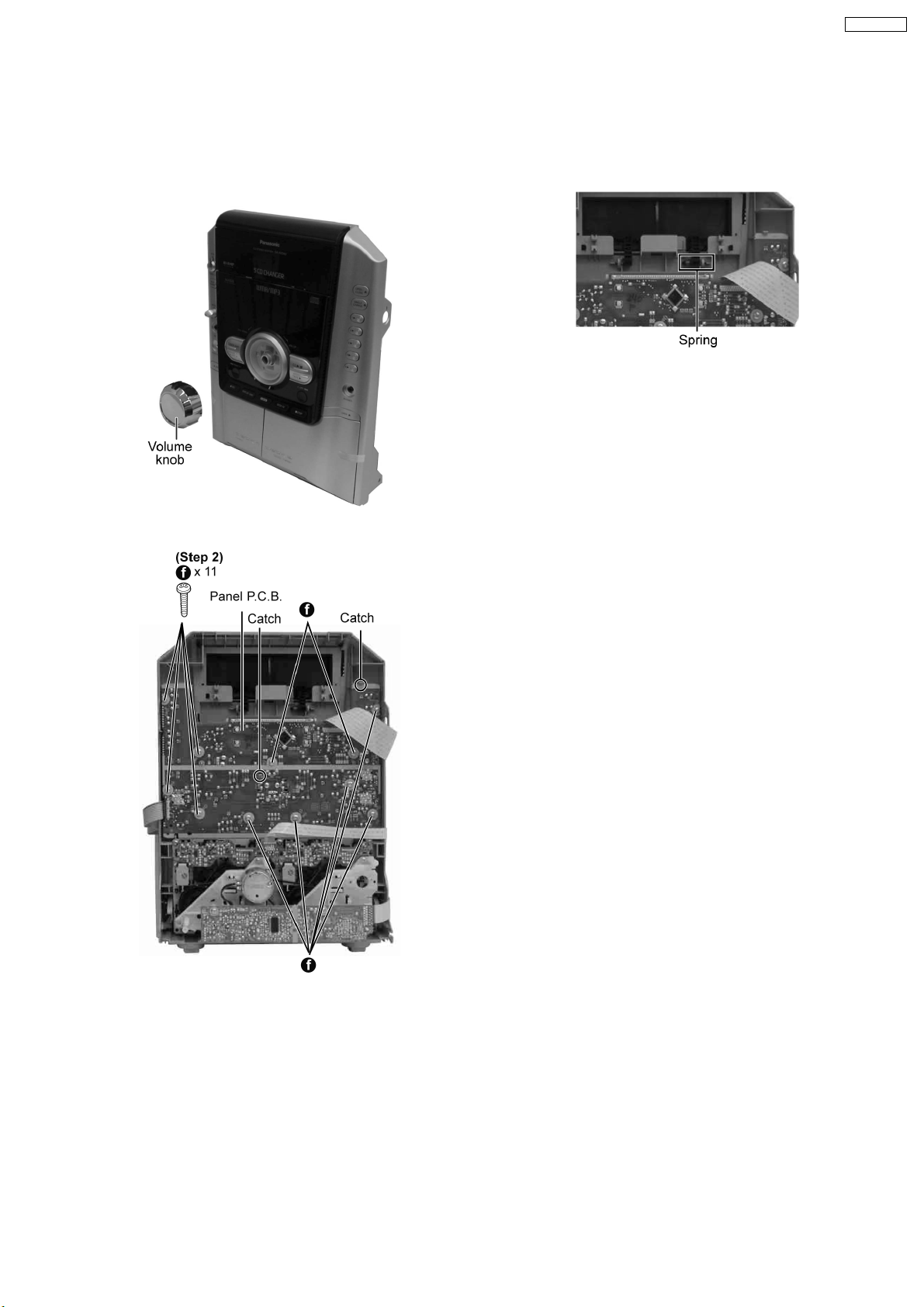

Step 1 Remove the volume knob.

Step 2 Remove Lid.

Note: Do not misplace the spring.

Step 2 Remove 11 screws.

Step 3 Release 2 catches.

Step 4 Remove Panel P.C.B..

10.11.1. Disassembly of Lid

Step 1 Lift the spring sideward.

27

Page 28

10.12. Disassembly of Deck mechanism unit

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 10.6 - Disassembly of CD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 10.10 - Disassembly of Front Panel Unit

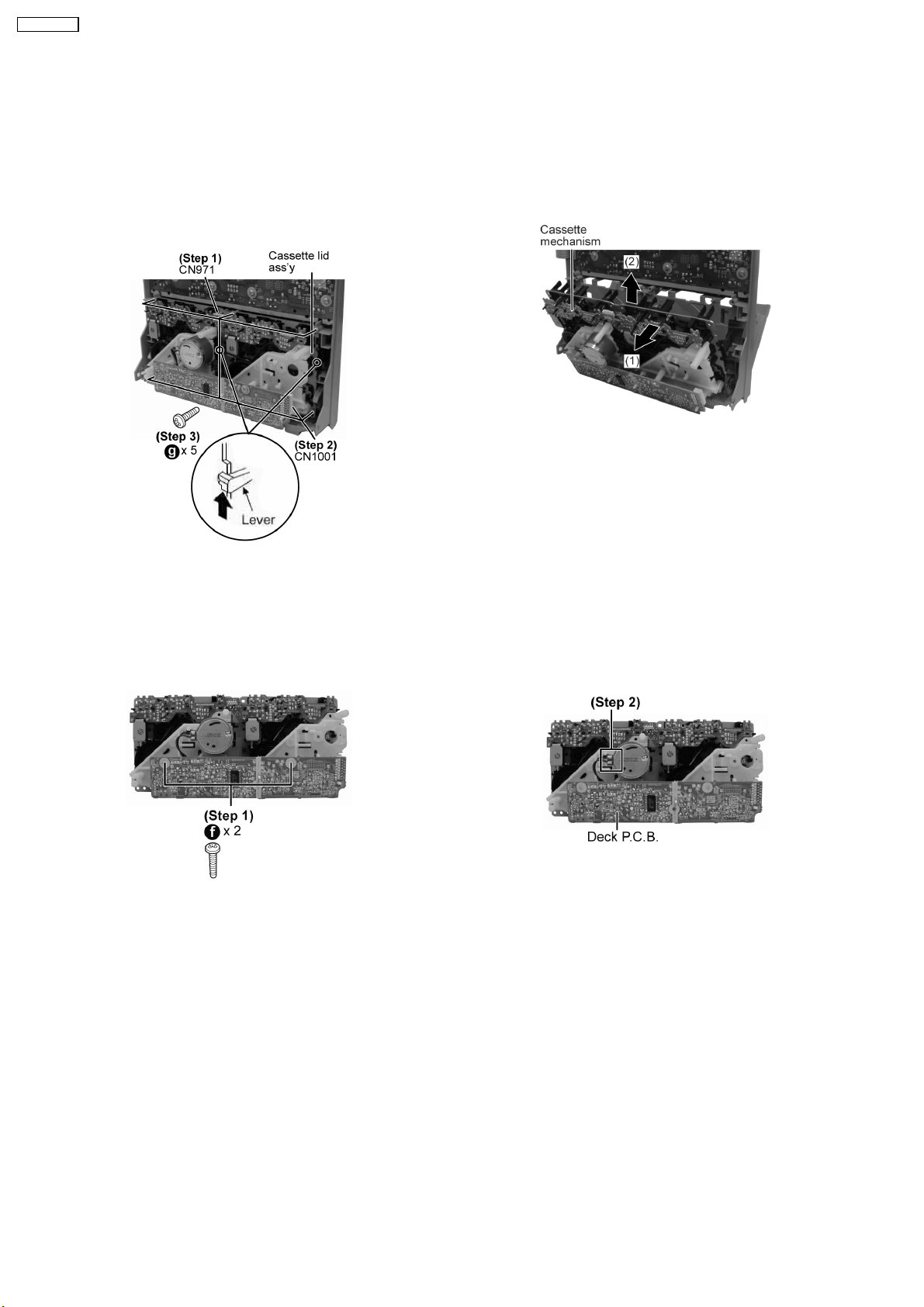

Step 1 Detach FFC cable (CN971).

Step 2 Disconnect FFC cable (CN1001).

Step 3 Remove the 5 screws.

Step 4 Push the lever upward, and then open the cassette lid

ass’y (For DECK1 and DECK2).

Step 5 Tilt the cassette mechanism unit in the direction of

arrow (1), and then remove it in the direction of arrow (2).

Note: For disassembly of parts for deck mechanism unit,

refer to Section 10.15.

10.13. Disassembly of Deck P.C.B.

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 10.6 - Disassembly of CD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 10.10 - Disassembly of Front Panel Unit

Step 1 Remove 2 screws.

Step 2 Desolder wire at deck motor terminals (W1002).

Step 3 Remove Deck P.C.B.

10.14. Disassembly of Traverse Unit

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 10.6 - Disassembly of CD Changer Unit22

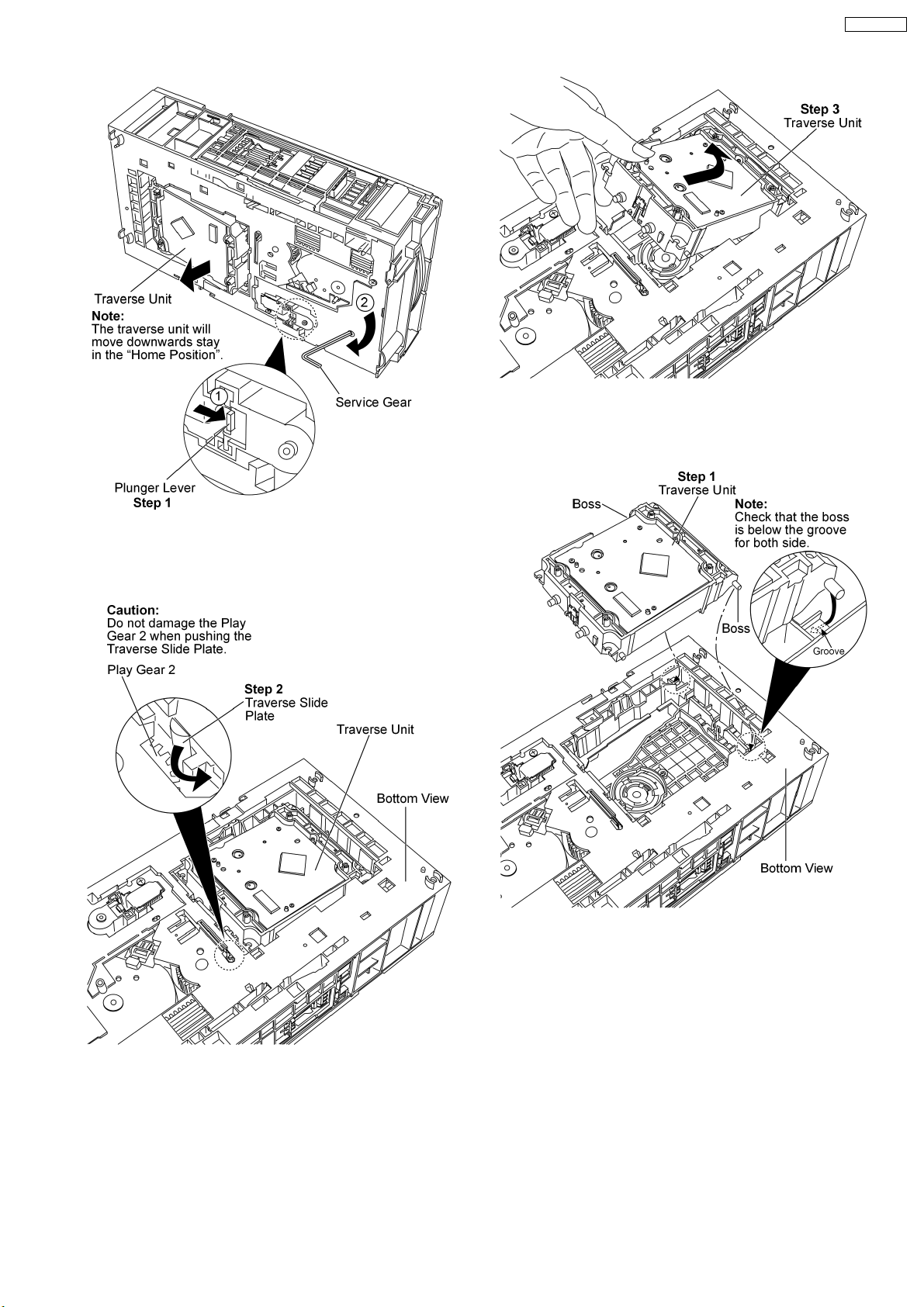

Important notes: Ensure all the trays are in the “STOCK”

position before proceeding to the disassemble of traverse

unit. For procedures to set the trays in “STOCK” position,

please refer to original Service Manual for CRS1, Section 7.

Disassembling Procedure When Tray In Play Position,

Order No. MD0509368C0.

28

Page 29

Step 1: Press and hold the plunger lever and rotate the

gear as arrows shown until it stop.

Step 3: Remove the traverse unit as arrow shown.

· Assembly of Traverse Unit

Step 2: Push the traverse slide plate as arrow shown to

release the traverse unit.

Caution: Do not exert strong force on the traverse

slide plate.

Step 1: Turn over the unit and install the traverse unit.32

29

Page 30

Step 2: Push the traverse slide plate as arrow shown to

lock the traverse unit.

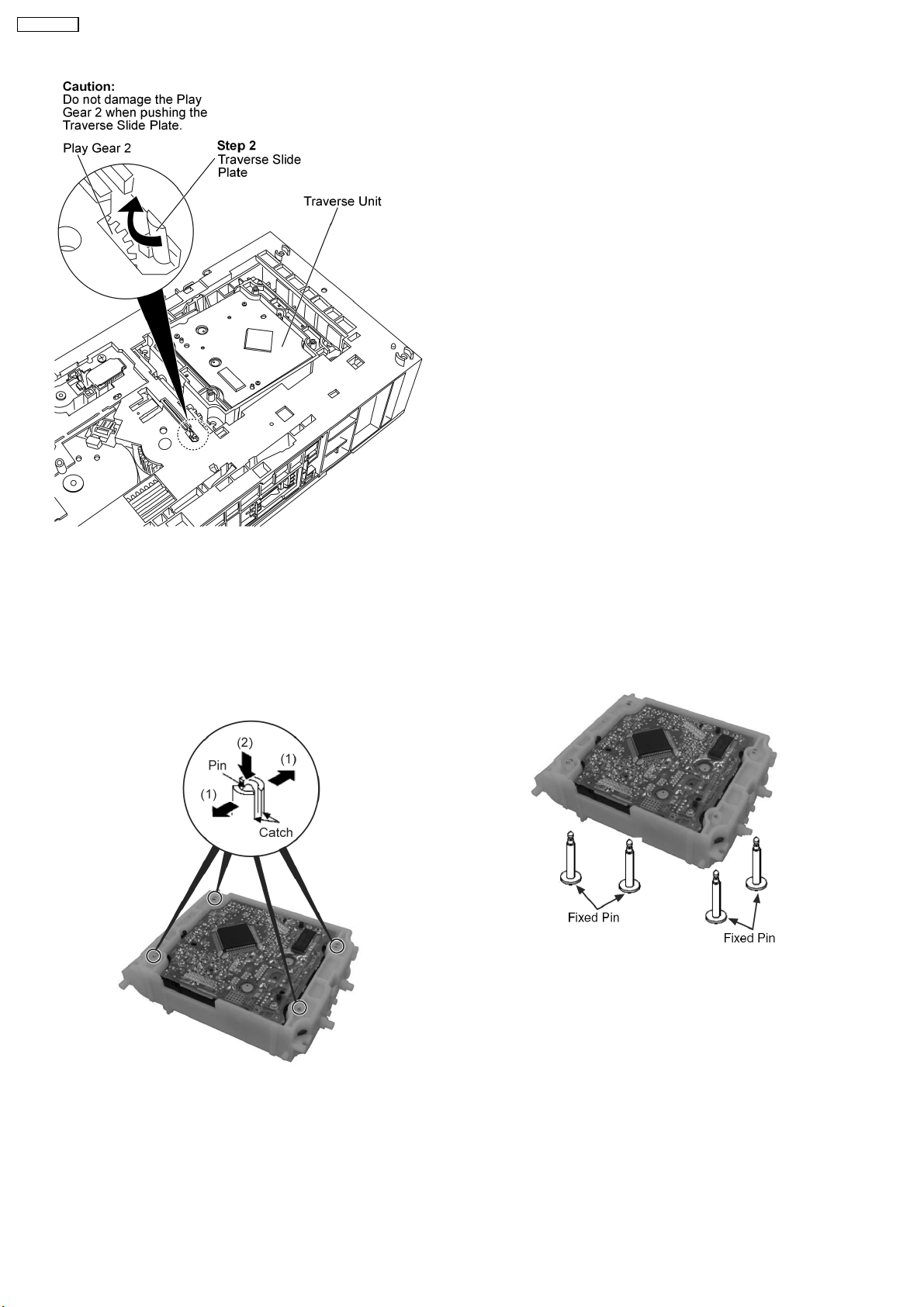

10.15. Disassembly of optical pickup unit (CD mechanism)

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 10.6 - Disassembly of CD Changer Unit

· Follow the (Step 1) - (Step 2) of Item 10.14 - Disassembly of Traverse Unit

Step 1 Pull out FFC.

Step 3 Remove 4 pins.

Step 2 Widening the catch, push the pin in.

30

Page 31

Step 4 Remove the traverse deck.

Note: As floating springs (4 pieces) come off at the same time,

be careful not to lose them.

Step 8 Remove the catch of the drive rack, and take out the

drive rack.

Step 5 Remove 3 screws.

Step 6 Remove the CD Servo P.C.B. and turn it over.

Note: Insert a short pin into FFC of the optical pickup.

Step 7 Rotate the traverse deck (B) to the arrow direction and

shift the optical pickup to the furthest backward.

Step 9 Place the convex part of an optical pickup to the

concave part of a traverse base, then take out the optical

pickup.

31

Page 32

10.16. Disassembly of Deck Mechanism

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 10.6 - Disassembly of CD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 10.10 - Disassembly of Front Panel Unit

· Follow the (Step 1) - (Step 5) of Item 10.12 - Disassembly of Deck Mechanism Unit

10.16.1. Disassembly of the pinch roller ass’y and head block

* The mechanism as shown below is for DECK1. For DECK

2, perform the same procedures.

32

Page 33

Step 1 Release the catch, and then remove the pinch roller (F).

Step 2 Release 2 claws and detach the head block connector.

Step 3 Remove 2 screws.

Step 4 Remove head block.

10.16.2. Disassembly of capstan motor ass’y, capstan belt A, capstan belt B and winding

belt

Step 1 Detach the head block connector (Deck P.C.B.).

Step 2 Desolder wire(W1002) at motor assembly.

Step 3 Remove Deck P.C.B.

Step 4 Remove 3 screws (for deck 1 & 2).

Step 5 Remove capstan belt A/B.

Step 6 Remove the flywheel R.

Step 7 Release the claw and remove the winding lever and

spring.

[Installation of the belt]

Step 1 The boss and marking should be positioned

horizontally.

33

Page 34

Step 2 Put the winding belt on the pulley temporarily.

Step 3 Install the flywheel F.

Step 4 Put the winding belt on the flywheel F.

Step 5 Install the winding lever and spring while pressing the

winding arm in the direction of arrow.

Step 6 Install the flywheel R.

Step 7 Put the capstan belt A temporarily as shown below.

Step 8 Put the capstan belt B on the motor ass’y pulley.

Step 9 Install the sub chassis to the mechanism, and then

tighten screws.

34

Page 35

Step 10 Install 3 screws.

Step 11 Put the capstan belt B as shown below.

Step 12 Put the capstan belt A on the motor ass’y pulley.

35

Page 36

10.17. Replacement for cassette lid

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

Step 1 Lift up the lever upward, open the cassette deck. (For

DECK1 and DECK2)

Step 2 Push up the cassette lid (L/R) in the direction of arrow.

(For DECK1 and DECK2).

10.18. Rectification for tape jam problem

· Follow the (Step 1) - (Step 2) of Item 10.4 - Disassembly of Top Cabinet

Step 1 If a cassette tape cannot be removed from the deck (the

tape is caught by the capstan or pinch roller during playback or

recording), rotate the flywheel F in the direction of the arrow to

remove it.

Step 2 Push the lever upward and open the cassette lid.

Remove the cassette tape.

36

Page 37

37

Page 38

11 Service Fixture and Tools

38

Service Tools

Extension FFC

(A) Deck P.C.B. - Main P.C.B. REEX0485 (14 Pins)

(B) Panel P.C.B. - Deck Mechanism P.C.B. REEX0484 (10 Pins)

12 Service Positions

Note: For description of the disassembly procedures, see the Section 10.

12.1. Checking and Repairing of Main P.C.B.

Page 39

12.2. Checking and Repairing of Transformer P.C.B.

39

Page 40

12.3. Checking and Repairing of Panel, Deck & Deck Mechanism P.C.B.

40

Page 41

12.4. Checking and Repairing of Power P.C.B.

41

Page 42

13 Adjustment Procedures

42

13.1. Cassette Deck Section

· Measurement Condition

−

− Reverse-mode selector switch:

− −

−

− Deck Tape Select: NORMAL

− −

−

− Make sure head, capstan and press roller are clean.

− −

−

− Judgeable room temperature 20 ± 5 °C (68 ± 9°F)

− −

· Measuring instrument

−

− EVM (DC Electronic voltmeter)

− −

−

− Digital frequency counter

− −

· Test Tape

−

− Tape speed gain adjustment (3 kHz, -10 dB);

− −

QZZCWAT

13.1.1. Tape Speed Adjustment (Deck 1/2)

1. Insert the test tape (QZZCWAT) to DECK 2 and playback

(FWD side) the middle portion of it.

2. Adjust Motor VR (DECK 2) for the output value shown

below.

Adjustment target: 2910 ~ 3090 Hz (NORMAL speed)

3. After alignment, assure that the output frequency of the

DECK 1 FWD are within ±60 Hz of the value of the output

frequency of DECK 2 FWD.

13.1.2. Bias Voltage Check

1. Set the unit “AUX” position.

2. Insert the Normal blank tape (QZZCRA) into DECK 2 and

the unit to “REC” mode (use “l REC/STOP” key).

3. Measure and make sure that the output is within the

standard value.

Bias voltage for Deck 2 14±4mV (Normal)

Fig. 2

Fig. 3

Fig. 1

13.1.3. Bias Frequency Adjustment (Deck 1/2)

1. Set the unit to “AUX” position.

2. Insert the Normal blank tape (QZZCRA) into DECK 2 and set the unit to “REC” mode (l use “REC/STOP” key).

3. Adjust L1002 so that the output frequency is within the standard value as below.

Standard Value: 89 ~ 110 kHz

Fig. 4

13.1.3.1. Cassette Deck Section

Below is the locations of test points for Deck P.C.B.:-

Page 43

13.2. Tuner Section

43

This section include details on the alignment of AM-IF and AM RF adjustment.

13.2.1. AM-IF Alignment

1. Set up the equipments as shown in Fig. 5.

2. Select [TUNER] mode on selector and set to [AM] mode.

3. Apply signal as shown in Fig. 5 from AM-SG.

4. Adjust Z2602 accordingly so that the output frequency is maximized at 450kHz in Fig. 6.

Fig. 5

Fig. 6

13.2.2. AM RF Adjustment

1. Set up the equipments as shown in Fig. 7.

2. Select [TUNER] on selector and set to [AM] mode.

3. Set AM-SG to 520kHz.

4. Receive 520kHz in the unit.

5. Adjust L2601 (OSC) so that the EVM-AC is maximized.

6. Set AM-SG to 600Hz.

7. Receive 600Hz in the unit.

8. Adjust L2601 (ANT) so that the EVM-SG is maximized.

9. Set AM-SG to 520kHz.

10. Receive 520kHz in the unit.

11. Adjust L2602 (OSC) so that the EVM-DC value is with 1.1±0.5V.

Page 44

Fig. 7

44

13.2.3. Adjustment Point

Below is the locations of alignment points on the Main (Tuner) P.C.B.

Page 45

14 Voltage and Waveform Chart

45

Note:

Circuit voltage and waveform described herein shall be regarded as reference information when probing defect point, because it

may differ from an actual measuring value due to difference of Measuring instrument and its measuring condition and product itself.

14.1. CD Servo P.C.B. & Main P.C.B.

Page 46

46

Page 47

14.2. Power P.C.B. and Transformer P.C.B.

47

Page 48

14.3. Waveform Chart

48

Page 49

49

Page 50

15 Wiring Connection Diagram

50

PHONE

9. . . . . .1

H6555/

W6555

JK6551

PbF

12

. . . . . . . .

1

CN2809

CN2808

12

. . . . . . . .

1

CN2803

14 . . . . . . .2

13 . . . . . . .1

MAIN P.C.B

B

SOLDER SIDE

CN2951

10 . . . 2

9 . . . 1

FM ANT

TUNER PACK

FAN

MOTOR

CN2806

30 . . . . . . . . . . . . 2

29 . . . . . . . . . . . . .1

AM ANT

TUNER PACK

H

P.C.B

BLACK

RED

To CRS1 (CN1)

JK2601

2

1

(To Fan)

CN2810

CN2801

2

. . . . . .

16

CN2805

15

1 2

1

. . . . . . . .

17

. . . . . . . . . .

14

. . . . . . .

2

1

CN5103

1

. . . . . . . . .

12

CN5102

1

. . . . . . . . .

12

JK5102 JK5101

LEFT

SPEAKER

E

POWER P.C.B

SOLDER SIDE

RIGHT

SPEAKER

H5104/

W5104

9

. . . . . . . .

1

PbF

PbF

SENSOR

VOLUME

CS1002

1

5

3

4

2

(DECK 2)

R/P HEAD

JK6751

MUSIC

PORT

MOTOR

-

+

2

1

W1002

Z6481

C

PANEL P.C.B

SOLDER SIDE

VR6491

JK6501 VR6511

MIC VOL

MIC

PbF

DECK MECHANISM P.C.B

G

SOLDER SIDE

F

CN6601

1

. . . . . . . . . . . . . . . . . . . .

2

. . . . . . . . . . . . . . . . . . . .

29

30

1 . . . 9

2 . . . 10

CN971

DECK P.C.B

SOLDER SIDE

PbF

PLAYBACK HEAD

CS1001

12345

(DECK 1)

PbF

CN5951

1

. . . . . . .

9

9 . . . . . . . . .1

CN5950

TRANSFORMER P.C.B

D

SOLDER SIDE

CN1001

2

1

. . . . . . . . . .

. . . . . . . . . .

14

13

CN7002

17

. . . . . . . . . . . .

16

. . . . . . . . .

2

1

M

TRAVERSE

MOTOR

T5950

(POWER TRANSFORMER)

A

CD SERVO P.C.B

SOLDER SIDE

M7301

SPINDLE MOTOR

CAUTION

RISK OF ELECTRIC SHOCK

AC VOLTAGE LINE.

PLEASE DO NOT TOUCH

THIS P.C.B

T5951

(SUB-TRANSFORMER)

. . . . . . . . . . .

15

16

M

M7302

CN7001

JK5950

2

1

. . . . . . . . . . .

PbF

AC IN

120V 60HZ

OPTICAL PICKUP

Page 51

margaiDkcolB 61

51525354555657

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

58

Page 59

17 Schematic Diagram

59

(All schematic diagrams may be modified at any time with the

development of the new technology)

17.1. Notes of Schematic Diagrams

S951 : MODE Switch

S952 : HALF Switch

S971 : MODE Switch

S972 : HALF Switch

S975 : RECINH_F Switch

S6101 : POWER Switch

S6102 : SINGLE DISC CHANGE Switch

S6103 : OPEN/CLOSE Switch

S6104 : CD1 Switch

S6105 : CD2 Switch

S6106 : CD3 Switch

S6107 : CD4 Switch

S6108 : CD5 Switch

S6201 : DECK 2 OPEN Switch

S6202 : DISPLAY/DEMO Switch

S6203 : DECK 1/2 Switch

S6204 : H.BASS Switch

S6205 : FF Switch

S6206 : REW Switch

S6207 : DECK 1 OPEN Switch

S6301 : CD Switch

S6302 : TAPE Switch

S6303 : STOP Switch

S6304 : REC Switch

S6305 : TUNER/BAND Switch

S6306 : MUSIC PORT Switch

S6308 : MULTI DISC CHANGE SWITCH

S7201 : REST SWITC H

VR6491 : VR VOLUME JOG

VR6511 : VR MIC VOLUME

· The voltage value and waveforms are the reference voltage

of this unit measured by DC electronic voltmeter (high

impedance) and oscilloscope on the basis of chassis.

Accordingly, there may arise some error in voltage values

and waveforms depending upon the internal impedance of

the tester or the measuring unit.

· Importance safety notice :

Components identified by

characteristics important for safety. Furthermore, special

parts which have purposes of fire-retardant (resistors), highquality sound (capacitors), low-noise (resistors), etc. are

used. When replacing any of components, be sure to use

only manufacturer´s specified parts shown in the parts list.

mark have special

Caution !

IC, LSI and VLSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care during

repair.

· Cover the parts boxes made of plastics with aluminium foil.

· Put a conductive mat on the work table.

· Ground the soldering iron.

· Do not touch the pins of IC, LSI or VLSI with fingers directly.

Page 60

tiucriCovreSDC)A( .2.71

60

Page 61

61

Page 62

ti

62

)B(.3.71

(ni

T

aM

ucriC)renu

Page 63

tiucriCniaM)B(.4.71

636465

Page 64

Page 65

Page 66

66

Page 67

TO

67

MAIN

CIRCUIT

(1B) ON

SCHEMATIC

DIAGRAM-2

TO

MAIN

CIRCUIT

(1A) ON

SCHEMATIC

DIAGRAM-2

TO

CD SERVO

CIRCUIT

(CN7002) ON

SCHEMATIC

DIAGRAM-1

CN2801

TO

DECK

MECHANISM

CIRCUIT

(CN971) ON

SCHEMATIC

DIAGRAM-7

CN2951

2B

2A

L

1

A_GND

2

R

3

CD_3.3V

4

CD_GND

5

LD_S

6

NC

7

+7.5V

8

PGND

9

MCLK

10

MDATA

11

MLD

12

BLKCK

13

STAT

14

/RST

15

/REST_S

16

17

PL2

10

PL1

9

DVREF

8

PL_GND

7

DECK-2

6

PHOTO_PB

5

PHOTO_RP

4

HALF_PB

3

VREF_GND

2

MODE_PB

1

TUNER RCH

PLLCE

TUNER LCH

PLL_DA

TUNER DQ/ST

PLL CLK

TUNER SD

+15V

TUNER DQ/ST

TUNER GND

VCC +7.5V

DET OUT

C21310R2131

C2231 0

3/4

R2121

W2563 0

10K

R2928

3.3K

3.3K

R2231

3.3K

0.1

C2901

1000P

C2906

R2221

3.3K

R2132

3.3K

R2232

R2929 10K

3.3K

R2930 10K

R2242

R2142

2.7K

2.7K

SA-AK340PL MAIN CIRCUIT

R2676 10K

C2678 0.01

B0ADCC000002

W2561

R2912 4.7K

R2914 4.7K

0

W2569

R2916 4.7K

R2918 10K

0

R2923 0

R2927 4.7K

W2570

0

R2931 10K

Q2958,Q2960

B1ACKD000006

PLUNGER ON/OFF SWITCH

Q2957,Q2959

B1GBCFLL0037

PLUNGER ON/OFF SWITCH

W2517 0

R2675

4.7K

D2677

B0BC7R500001

Q2901

Q2901

B1ACKD000006

CONTROL SWITCH

Q2902

D2901

R2924

10K

R2925

R2919

4.7K

R2958

Q2958

R2960

Q2960

22K

22K

4.7K

R2674

47K

D2677

R2902 33

C2903 0.01

R2901 10K

R2909 2.2K

C2904 16V100

R2910 330

R2920

4.7K

Q2906

W2565

0

Q2907

W2568 0W2567 0

Q2907

B1ABCF000176

CD STATUS INTERFACE

R2957

1K

R2959

1K

W2554 0

R2954

10K

R2955 270K

R2956 270K

R2151 0

R2251 0

R2673 47K

R2672 10K

R2671 10K

PLLCE_UP

DET_OUT

R2677

120

C2671

100P

C2673

0.01

C2674

100P

Q2902

B1AACF000064

VOLTAGESTABLISER CD3.3V

R2908

R2907

1K

R2921

4.7K

W2542

330

0

W2566

0

R2922

10K

MOT_12V

Q2957

C2957

100P

C2959

100P

Q2959

W2525

0

PHOTO_1

PHOTO_2

R2953

10K

PLL_DA

STIDO

PLL_CLK

+15V

T_GND

CD8V

SW5V

A_GND

CD7.5V

PGND

MCLK

MDATA

MLD

SW5V

BLKCK

STATUS

UP_GND

CD_RST

RESTSW

PLG2

PLG1

DVREF+

P_GND

SW5V

DECK2

W2534

0

SD

HALF_1

SW5V

R2856 47K

SPEED

CLOSE_SW

OPEN_SW

CHG_CW

CHG_CCW

ST_SW

PLAY_SW

CHG_PLR[88]

BOTTOM_SW

UP_SENSOR

DECK2

KEY3

KEY2

KEY1

PHOTO_2

PHOTO_1

VREF+

VCC

B1ABCF000176

INTERFACE SWITCH

UP_GND

SYS6V

UP_GND

VREF+

PCONT

MODE_1

R2855 47K

R2867

100K

Q2906

D2950 B0ACCK000005

R2966

4.7K

W2550

0

Q2950

B1ACKD000006

DECK SUPPLY

CONTROL SWITCH

Q2951

B1ACKD000006

SUPPLY CONTROL SWITCH

Q2952

B1GBCFLL0037

DECK SUPPLY (PCONT)

CONTROL SWITCH

PA_IN_L

PA_IN_R

UP_GND

B1ACKD000006

CONTROL SWITCH

B1GBCFJJ0051

CHANGER PLUNGER

ON/OFF SWITCH

R2866 47K

R2854 47K

R2857 47K

R2951

470K

Q2936

CD SUPPLY

Q2937

R2864

R2865 47K

100

R2852 100

R2853 100

R2858 100

R2859 100

R2860 100

R2862 100

R2861 100

Q2951

W2540

0

W2558

R2950

470K

R2952

1K

Q2952

CN2805

0

UP-GND

CHG_CCW

CCW

1

R2863

R2801

10K

Q2950

R2965

4.7K

P_GND

CHG_CW

P_GND

CW

2

47K

SPEED

81

CLOSE_SW

82

OPEN_SW

83

CHG_CW

84

CHG_CCW

85

ST_SW

86

PLAY_SW

87

CHG_PLR

88

BOTTOM_SW

89

UP_SENSOR

90

DECK2

91

KEY3

92

KEY2

93

KEY1

94

PHOTO_2

95

AVSS

96

PHOTO_1

97

VREF

98

AVCC

99

DEMO

100

DVREF+

CD8V

VC_8V

43

Page 68

W2526

1

1

0

4

0

/

68

0

R2863

47K

SPEED

81

CLOSE_SW

82

OPEN_SW

83

CHG_CW

84

CHG_CCW

85

ST_SW

86

PLAY_SW

87

CHG_PLR

88

BOTTOM_SW

89

UP_SENSOR

90

DECK2

91

KEY3

92

KEY2

93

KEY1

94

PHOTO_2

95

AVSS

96

PHOTO_1

97

VREF

98

AVCC

99

DEMO

100

MCLK

/RESTSW

HOME_SW

80

79

/RESTSW

HOME_SW

MDATA

7778

MCLK

VREF+

C2872 0.022

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

C2871 330P

MUTE_A

R2871 22K

R2873

22K

1

2

3

4

NC

VCC

EE_CS

EE_CLK

-9V

IC2871

W2576

0

W2536

0

W2537

0

W2547 0

W2548 0

GND

EE.DAT

R2827

A_GND

NC

8

7

6

5

MUTE_D_AMP

R2874 4.7K

C2874 330P

STANDBY

IDCDET

PCONT

MUTE_A

HP_L

HP_R

FAN

MOT_12V

R2945

10K

D2946

B0ADCJ000020

W2571

0

W2532 0

W2572

0

IC2871

E-EPROM IC

(NOT SUPPLIED)

C2945

16V47

3

1

2

R2851

47K

R2946

56K

C2944

100P

6.3V100

C2947

R2947

27

B1ACKD

FAN MOTOR ON

R2944

4.7K

R2942

5.6K

R2943

10K

R2949

47K

R2948

100

W2573

Q29

0

C29

R29

0.

82

ASP_DA

+15V

MTR(58)

R2844 10K

58

REC

MTR

PLG2

57

PLG1

56

PLG2

55

PLG1

ASP_CLK

MODE_1

R2842 10K W2523 0

54

53

NC

NC

MODE_1

EE_CS/EFP/EPH

HALF_1

R2841 10K

51

52

NC

HALF_1

STAND_BY

DCDET

PCONT/EFP/CS

EE_DAT

EE_CLK

MUTE_A

MUTE_DA

REG1

REG2

REG3

REG4

REG5

REG6

REG7

REG8

NC

NC

NC

NC

SW15V

LM_1

MLD

STATUS

76

MLD

MDATA

STATUS

CD_RST

H.BASS_LED

73

7475

CD_RST

H.BASS_LED

FL_CLK

72

FL_CLK

FL_CS

FL_DOUT

R2848 100

FL_CS

FL_DOUT

V_JOG_B

V_JOG_A

FL_RESET

R2847 100

68

697071

67

V_JOG_B

V_JOG_A

FL_RESET

IC2801

C2CBYY000053

MICROPROCESSOR

SW_LED

VOL_LED

R2849 1K

R2843 1K

66

65

SW_LED

VOL_LED

64

GND

W2557 0

VSS

VCC

REC(59)

DECK1_H

R2845 10K

R2846 4.7K

60

59

62

61

63

NC

NC

VCC

DECK1_H

R2801

10K

Q2950

R2965

4.7K

UP-GND

P_GND

CHG_CW

CHG_CCW

P_GND

CW

CCW

2

1

DVREF+

CD8V

HOME_SW

HOME_SW

VC_8V

43

5

ST-SW

ST-SW

678

LM_1

PA_LVL

1

2

LM_1

SW5V

OPEN_SW

CLOSE_SW

SW5V

CAM_SENSOR

OPEN_SW

9

TO CRS1

PLLCE

RDS_DA

3

4

5

PLLCE_UP

D_GND

PLAY_SW

PLAY_SW

D_GND

11 12 13 14 1510

RDS_CLK

MODE_A

6

MODE_A

UD_SENSOR

PLUNGER

F_HOP

BYTE

CNVSS

9

8

7

F_HOP

CNVSS

W2559

SPEED

BOTTOM_SW

W2560

SPEED

BOTTOM_SW

UD_SENSOR

10

XC_IN

11

0

W2555

0

XC_OUT

/RESET

12

W2543 0

IRESET

0

Q2937

X_OUT

VSS

1413

W2544

Q2936

D2936

XIN

VCC

/NMI

RMT

BLKCK

SYNC

ST/DOSDNC

SW_LV-1

SW_LV-2

ASP_DA

ASP_CLK

10DB_ATT

PLL_DAT

ASP_CLK

HP_L

HP_GND

HP_GND

HP_L

HP_R

HP_R

3029282726

PLL_DA

PLL_CLK

UP_GND

DGND

PLL_CLK

SW5V

PA_IN_L

W2539 0

SW5V

PA_IN_L

PA_IN_R

MOT_12V

PA_IN_GND

MOT10V

PA_IN_R

PA_IN_GND

R2820 100K

R2819 100K

R2818 100K

R2817 100K

R2830 100K

R2831 100K

R2832 100K

R2883

330K

R2882

X2801

10M

H0A327200115

FL_CS

J_VOl_B

FL_RESET

FL_RST

J_VOl_B

FL_CS

FL_CLK

FL_DOUT

FL_DOUT

FL_CLK

H_BASS_LED

H_BASS_LED

1011121416171819202122232425262729 2830 1315

J_VOLA

SW_LED

VOL_LED

J_VOLA

VOL_LED

SW_LED

TO

PANEL CIRCUIT (CN6601) ON

SCHEMATIC DIAGRAM-4

R2833 100K

KEY3

KEY3

C2883

C2882

W2552

KEY2

KEY2

W2549

0

R2810 22K

R2886

18P

1M

18P

0

RMT

KEY1

P-GND

VREF+

VREF+

RMT

P-GND

KEY1

IN OUT

SYNC

SYNC

GND

PCONT

PCONT

R2881

220

X2802

H2B100500004

SYS6V

SYS6V

123456789

16V100

C2852

C2803

C2853

0.1

1

Q2803

B1GBCFJJ0051

RESET (MICRO-P) SWITCH

D2803

B0ACCK000005

C2802

50V2.2

VREF+

18

16

17

W2545 0

C2821

100P

VCC

R2937

R2936

1K

10K

R2802 100

RMT

2019

R2803 10K

SYNC

BLKCK

MOT_12V

W2556

0

CN2806

15

0

B0EAKM000117

2524232221

STIDOSDASP_DA

MIC

+15V

MIC_GND

CHG_PLR(88)

MIC_GND

+15V

MIC

Page 69

69

Page 70

70

Page 71

tiucriClenaP)C(.5.71

71

Page 72

72

Page 73

tiucriCremrofsnarT)D(.6.71

73

Page 74

tiu

747576

woP)E(.7.71

criCre

Page 75

Page 76

Page 77

77

Page 78

tiuc

78

71

riCkceD)F(.8.

nahceMkceD)G(&tiuc

riCmsi

Page 79

79

Page 80

draoBtiucriCdetnirP81

80

oN .y

onhcetwenfotnempolevedehthtiwemitynatadeifidomebyamsmargaiddraobtiucriC:et

gol

.B.C.PovreSDC.1.81

Page 81

.B.C.PniaM)B(.2.81

Page 82

Page 83

.B.C.PlenaP)C(.3.81

82

Page 84

83

Page 85

.B.C.PremrofsnarT)D(.4.81

84

Page 86

85

Page 87

86

.B.C.PrewoP)E(.5.81

Page 88

PkceD)F(.6.81

87

.B.C.PmsinahceMkceD)G(&.B.C.

Page 89

88

Page 90

19 Illustration of ICs, Transistors and Diodes

89

C1BB00001121 (100P)

C2CBYY000053 (100P)

C0HBB0000057 (44P)

MN6627954MA (100P)

CNB13030R2AU (4P)

2

1

3

4

2

3

4

1

2SB0709AHL

B1ABCF000176

B1ABGC000005

B1ADCF000063

B1GBCFJJ0051

B1GDCFNA0001

B1GBCFLL0037

B1BACG000023

B1BCCG000002

E

C

B

1

BA5948FPE2

28

1

7

8

14

B1ADCF000001

B1GDCFJJ0047

B1AABC000003

B1AAGC000007

E

C

B

AN7348S-E1 (24P)

C1AA00000612

C1BA00000407

C0JBAB000011 (14P)

C1BB00000962 (24P)

C1CB00001937 (20P)

1

C0AABB000125

5

22

21

15

8

4

1

B1AACF000064

B

C

E

1

5

B1AAKD000014

B1AARC000003

B1ACKD000006

E

E

C

C

B

B

B1DEGM000026

1

.

.

.

.

. .

.

.

.

18

2SB0621AHA

E

C

B

B1CECC000003

B1AAAC000016

B1AAAD000015

B1GCCFJJ0016

B1GACFJJ0018

MAZ80560ML

Anode

A

Cathode

Ca

B

C

E

MA2C16500E

A

Anode

Ca

Cathode

G

S

D

B0BA6R800008

B0BA3R900006

B0BA5R700008

B0BA02400029

B0BA02400030

D

A

Anode

S

G

Ca

Cathode

B0BA01900005

Ca

A

Anode

B0EAKM000122

Ca

A

Anode

B0CDBB000015

B0CBAD000004

A

Cathde

Cathode

B0BA01500003

B0EAKM000117

Ca

A

Anode

B0ADCJ000020

Cathode

Ca

Cathode

Anode

B0BA01100004

B0BC5R600003

B0BC5R000009

Anode

A

Cathode

Ca

B0ADCC000002

B0BA02600018

A

Anode

B0BC9R000008

Anode

A

B3ACA0000302

Anode

Cathode

A

Ca

Cathode

Cathode

B0AACK000004

B0BC7R500001

B0EAMM000038

A

Anode

B0ACCK000005

Anode

Ca

Cathode

Anode

Ca

A

Cathode

Ca

Cathode

Ca

A

B3AAA0000583

Ca

Page 91

20 Terminal Function of IC's

90

20.1. IC7001 (MN6627954MA) Servo Processor,Digital Signal

Processor/Digital filter and D/A Converter

Pin No. Mark I/O Function

1 A11 O DRAM address signal O/P 11

2 A9 O DRAM address signal O/P 9

3 A8 O DRAM address signal O/P 8

4 A7 O DRAM address signal O/P 7

5 A6 O DRAM address signal O/P 6

6 A5 O DRAM address signal O/P 5

7 A4 O DRAM address signal O/P 4

8 NWE O Write Enable Signal (DRAM)

9 NCAS O DRAM CAS Control Signal

10 NRAS O DRAM ARS Control Signal

11 A3 O DRAM address Signal O/P 3

12 A2 O DRAM address Signal O/P 2

13 A1 O DRAM address Signal O/P 1

14 A0 O DRAM address Signal O/P 0

15 A10 O DRAM address Signal O/P 10

16 BA0 N.C. Motor O/P (0);/Serial I/P

17 BA1 N.C. Motor O/P (1);/Serial I/P

18 PRAMVSS33 - GND (DRAM)

19 PRAMVDD15 - Power Supply Voltage (DRAM)

20 PRAMVDD33 - Power Supply Voltage (+1.6V)

21 SPOUT O Spindle Drive O/P

22 PC I/O Spindle motor drive O/P signal

serial data/Monitoring I/P

23 TRVP O Traverse Drive O/P (+ve)

24 TRP O Tracking Drive O/P (+ve)

25 FOP O Focusing Drive O/P (+ve)

26 DVSS1 - GND

27 IOVDD2 I Digital Power Supply Voltage 2

(I/O)

28 DVDD1 - Digital Power Supply Voltage 1

(Built-In)

29 SRVMON0 N.C. Servo Monitor (0) O/P

30 SRVMON1 N.C. Servo Monitor (1) O/P

31 AVSS2 - GND

32 OSCIN I Oscillating Input

33 CTRCRS N.C. Tracking Cross Comparator

34 VREF - +Vref Supply Voltage

35 E I Tracking Input Signal 1

36 F I Tracking Input Signal 2

37 D I Focusing Input Signal 4

38 B I Focusing Input Signal 2

39 C I Focusing Input Signal 3

40 A I Focusing Input Signal 1

41 PD I APC Amp I/P

42 LD O Laser Drive Current O/P

43 CENV I Detection Capacitance

Connection terminal

44 RFENV O RF Envelope O/P

45 RFOUT O RF Summing Amp O/P

46 RFIN I SGC I/P

47 AVDD2 I Analog Power Supply voltage 2

(For DSL/PLL)

48 ARFDC O AGC Capacitive Connection

Terminal

49 ARFOUT O AGC Output

50 ARFFB I ARF Feedback Signal I/P

51 ARFIN I Audio RF Signal I/P

52 DSLF I Loop Filter Terminal (For DSL)

Pin No. Mark I/O Function

53 IREF I Reference I/P

54 PLLF I PLL Loop Filter Terminal (Phase

Compare)

55 PLLF0 O PLL Loop Filter Terminal (Speed

Compare)

56 OUTL O Audio O/P (LCH)

57 AVSS1 - GND

58 AVDD1 I Analog Power Supply Voltage 1

59 OUTR O Audio O/P (RCH)

60 DVSS3 I GND3 (Digital Circuit)

61 NSRVMONON I Servo Motor O/P Enabling

62 EXT0 N.C. Expansion O/P Port 0

63 EXT1 N.C. Expansion O/P Port 1

64 EXT2 N.C. Expansion O/P Port 2

65 FLAG N.C. Flag Signal O/P

66 TX N.C. Digital Audio Interface O/P

signal

67 MCLK I Micro-Computer Command

Clock I/P

68 MDATA I Micro-Computer Data I/P

69 MLD I Micro-Computer Load I/P

70 STAT O Status Signal O/P

71 BLKCK O Subcode Blk Clock

72 NRST O LSI Reset Signal

73 DQSYTXT N.C. Pack Signal O/P for CD-Text

data

74 SMCK N.C. Micro-Computer Clock O/P

75 PMCK N.C. IOCNT Serial data O/P

(Synchronous O/P)

76 DVDD2 - Digital Power Supply Voltage 2

(+1.5V)

77 IOVDD1 - Digital Power Supply Voltage 1

(For I/O)

78 DVSS2 - GND2 (For Digital Circuit)

79 NTEST2 I Test Mode Setting (ON:H)

80 X2 O Crystal Oscillating Circuit O/P

81 X1 I Crystal Oscillating Circuit I/P

82 NTEST I Test Mode Setting I/P (ON:H)

83 D2 I/O Data Signal O/P 2

84 D1 I/O Data Signal O/P 1

85 D0 I/O Data Signal O/P 0

86 D3 I/O Data Signal O/P 3

87 D4 I/O Data Signal O/P 4

88 D5 I/O Data Signal O/P 5

89 D6 I/O Data Signal O/P 6

90 D7 I/O Data Signal O/P 7

91 D15 I/O Data Signal O/P 15

92 D14 I/O Data Signal O/P 14

93 DRVDD I I/O Power Supply Voltage

(DRAM)

94 D13 I/O Data Signal O/P 13

95 D12 I/O Data Signal O/P 12

96 D11 I/O Data Signal O/P 11

97 D10 I/O Data Signal O/P 10

98 D9 I/O Data Signal O/P 9

99 D8 I/O Data Signal O/P 8

100 SDRCK O Clock Signal O/P

Page 92

20.2. IC7002 (BA5948FPE2) IC 4CH Drive

91

Pin No. Mark I/O Function

1 IN2 I Motor Driver 92 Input

2 PC2 I Turntable Motor Drive Signal

(“L”:ON)

3 IN1 I Motor Drive (1) Input

4 PC1 - Traverse Motor Drive Signal

(“L”): ON)

5-8 N.C. - No Connection

9 PGND1 - Ground Connection (1) for Drive

10 PVCC1 I Power Supply (1) for Drive

11 D1- O Motor Drive (1) reverse - action

output

12 D1+ O Motor Drive (1) forward - action

output

13 D2- O Motor Drive (2) reverse - action

output

14 D2+ O Motor Drive (2) forward - action

output

Pin No. Mark I/O Function

15 D3- O Motor Drive (3) reverse - action

16 D3+ O Motor Drive (3) forward - action

17 D4- O Motor Drive (4) reverse - action

18 D4+ O Motor Drive (4) forward - action

19 PVCC2 - Power Supply (2) for Driver

20 PGND2 - Ground Connection (2) for Driver

21-24 N.C. O No Connection

25 VCC I Power Supply terminal

26 VREF I Reference Voltage Input

27 IN4 I Motor Driver (4) Input

28 IN3 I Motor Driver (3) Input

20.3. IC2801 (C2CBYY000053) System Microprocessor

Pin No. Mark I/O Function

1 LM_1 - Level Meter

2 PA_LVL - No Connection

3 PLLCE O PLL Chip Select

4 RDS_DA I RDS Data Input

5 RDS_CLK I RDS Clock Input

6 MODE_A - No Connection

7 F_Hop O F_Hop for Digital Amp

8 BYTE - External Data Bus Width Select

Input (Connect to Ground)

9 CNVSS - Flash Mode Terminal (Connect

to Ground)

10 XC_IN - 32.768 kHz Sub Clock

11 XC_OUT - 32.768 kHz Sub Clock

12 /RESET - Reset Input (ACTIVE L)

13 X_OUT - 10 MHz Main Clock

14 VSS - Ground (0V)

15 XIN - 10 MHz Main Clock

16 VCC - Power Supply (+5V)

17 /NMI - Connect to Vcc (+5V)

18 RMT I Remote Control Input

19 BLKCK I CD Block Clock Input (Inverted)

20 SYNC I AC Failure Detect Input

21 ST/DO I Tuner IF Data/ Stereo Input

22 SD I Tuner Signal Detect Input

23 N.C. - No Connection

24 SW_LV-1 O Sub-Woofer Level 1

25 SW_LV-2 O Sub-Woofer Level 2

26 ASP_DA O ASP DATA

27 ASP_CLK O ASP CLOCK

28 10DB_ATT O No Connection

29 PLL_DAT O PLL DATA

30 PLL_CLK O PLLCLK

31 REG8 - To GND resistor

32 REG7 I Region Setting 7 (MIC)/Flash Rx

33 REG6 I Region Setting 6 (RDS)/Flash

Clock

34 REG5 O Chip Select/Flash Busy

35 REG4 I Latin Non Chip Select

36 REG3 I Region Setting 3 (Tuner)

37 REG2 I Region Setting 2 (Tuner)

38 REG1 I Region Setting 1 (Tuner)

39 MUTE_DA O Mute_DA for Digital Amp

40 MUTE_A O Audio Mute

41 EE_CS/EFP/EPH O EEPROM Chip Select

42 EE_CLK O EEPROM CLOCK

Pin No. Mark I/O Function

43 EE_DAT I/O EEPROM DATA

44 N.C. - No Connection

45 N.C. - No Connection

46 PCONT/EFP/CS O Main Transforme r Control

47 DCDET I DC Detect Input

48-49 N.C. - No Connection

50 STANDBY O Standby mode

51 N.C. - No Connection

52 HALF_1 I Deck 1 HALF PLAYBACK

53 MODE_1 I Deck 1 MODE PLYABACK

54 N.C. - No Connection

55 N.C. - No Connection

56 PLG1 O Deck 1 plunger control

57 PLG2 O Deck 2 plunger control

58 MTR O/I Deck motor control

59 REC O/I L when record circuit is

60 DECK1_H O H when DECK 1 P/B head is

61 N.C. - No Connection

62 VCC - Power Supply (+5V)

63 N.C. - No Connection

64 VSS - Ground (0V)

65 SW_LED O SUB WOOFER LED

66 VOL_LED O VOLUME_LED

67 V_JOG_A I Volume Jog A

68 V_JOG_B I Volume Jog B

69 FL_RESET O FL Driver reset

70 FL_CS I/O FL Driver Chip Select

71 FL_DOUT O Serial Data To FL Driver

72 FL_CLK I/O Serial Clock To FL Driver

73 H.BASS_LED O H.BASS LED

74 CD_RST O CD Reset Output

75 STATUS I CD Servo LSI Status Input

76 MLD O CD Command Load Output

77 MDATA O CD Command Data Output

78 MCLK O CD Command Clock Output

79 /RESTSW I CD Limit Switch Input for the

80 HOME_SW I Home Switch for CRS1

81 SPEED O SPEED is For CRS1 (cater)

82 CLOSE_SW I CLOSE SW is for CRS1

output

output

output

output

Output

INPUT

INPUT

(“L” for motor ON)

operating

selected

most Inner Point (Active Low)

Page 93

Pin No. Mark I/O Function

92939495969798

83 OPEN_SW I Open_Sw for CRS1

84 CHG_CW O CRS1 motor CW

85 CHG_CCW O CRS1 motor C CW

86 ST_SW I Stock_Sw for CRS1

87 PLAY_SW I Play_Sw for CRS1

88 CHG_PLR O Plunger for CRS1

89 BOTTOM_SW I Bottom_SW for CRS1

90 UP_SENSOR I UD-Sensor for CRS1

91 DECK2 I DECK CONDITION INPUT 2

92 KEY3 I KEY3 INPUT

93 KEY2 I KEY2 INPUT

94 KEY1 I KEY1 INPUT

95 PHOTO_2 I Rotation Detection Signal (Deck

96 AVSS - Analog Power Supply Input

97 PHOTO_1 I Rotation Detection Signal (Deck

98 VREF - Reference for A-D (5V)

99 AVCC - Analog Power Supply Input

100 DEMO I (H= default demo on, L= default

(R_INHF/MODE2/HALF2)

2)

(Connect to GND)

1)

demo off.)

Page 94

Page 95

Page 96

Page 97

Page 98

Page 99

Page 100

N2QAHB000065

99

SJA168-1A

RQTM0140-1

N1DAAAA00001

RSA0006-L

Loading...

Loading...