Panasonic NN-L530BF, NN-S560BF, NN-S560WF User Manual

Service Manual

ORDER NO. SIMMC 0001002C1

E1

Microwave Oven

© 2000 Shanghai Matsushita Microwave

Oven Co.,Ltd

All rights reserved. Unauthorized copying

and distribution is a violation of law.

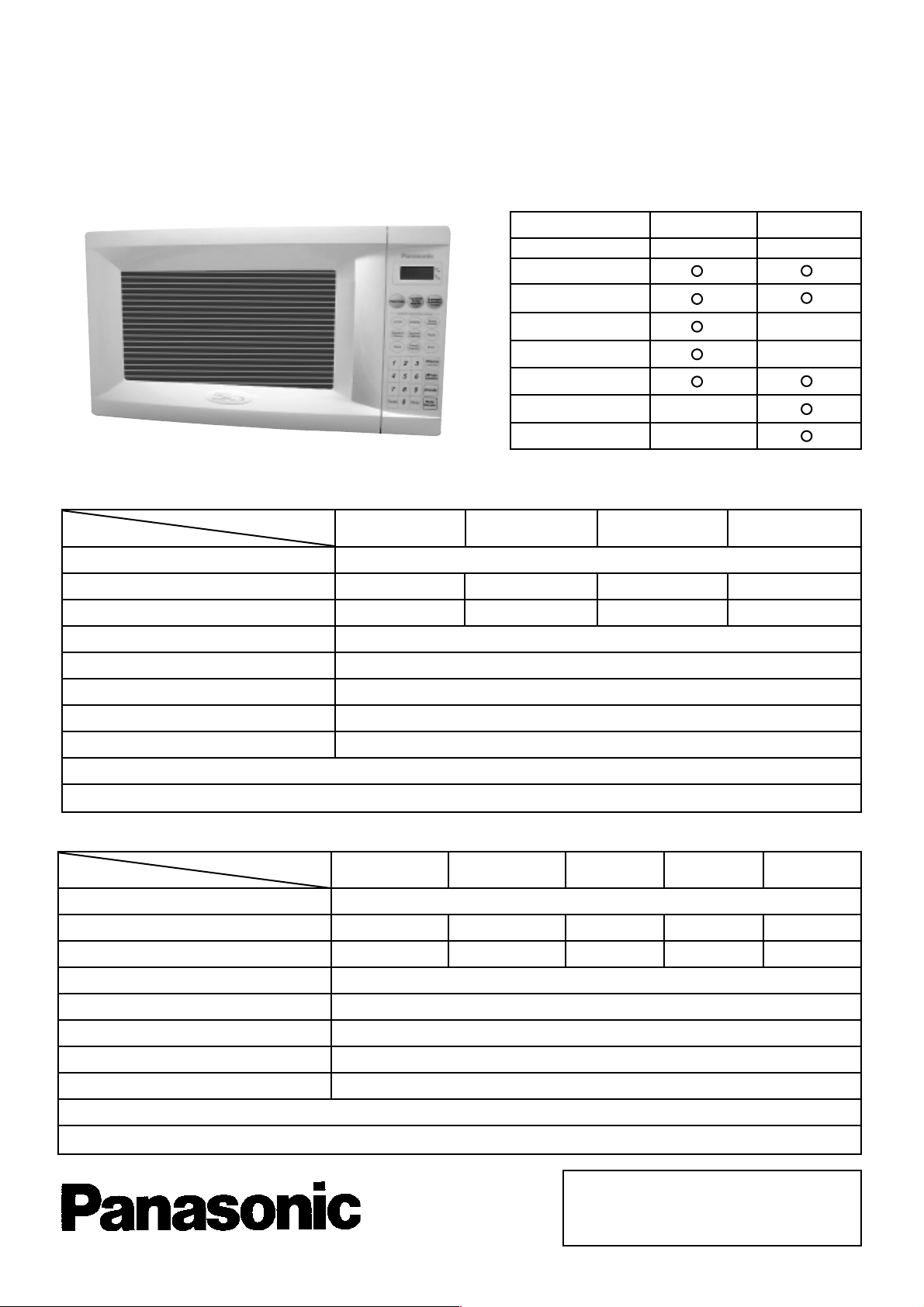

MODELS APH CPH

USA Canada

®

Specifications:

Power Source:

Power Requirement:

Output(IEC705-88):

Microwave Frequency:

Timer:

Outside Dimensions:

Oven Cavity Dimensions:

Weight:

Output power:IEC705-88 Test Procedure

Specifications subject to change without notice.

Specifications for APH :

Model:

*

120V AC Single Phase, 60Hz

*

2450MHz

*

99min.99sec

*

20

”(518mm)(W)

O

16

”(407mm)(D)

O

11”(301mm)(H)

*

14

”(375mm)(W)

O

15

”(386mm)(D)

O

8

”(225mm)(H)

*

26.5 lbs. (12.0kg)

1370W

1370W

1370W 1370W

1300W 1300W 1100W 1000W

NN-S560BF/WF NN-S550BF/WF NN-S540BF/WF NN-L530BF/WF

Specifications:

Power Source:

Power Requirement:

Output(IEC705-88):

Microwave Frequency:

Timer:

Outside Dimensions:

Oven Cavity Dimensions:

Weight:

Output power:IEC705-88 Test Procedure

Specifications subject to change without notice.

Specifications for CPH:

Model:

*

120V AC Single Phase, 60Hz

*

2450MHz

*

99min.99sec

*

20

”(518mm)(W)

O

16

”(407mm)(D)

O

11”(301mm)(H)

*

14

”(375mm)(W)

O

15

”(386mm)(D)

O

8

”(225mm)(H)

*

26.5 lbs. (12.0kg)

1370W 1370W 1370W 1370W 1370W

1200W 1100W 1100W 1100W 1000W

NN-S560BF/WF

NN-S540BF/WF

NN-L530WF NN-L520WF NN-S510WF

NN-S560BF/WF

NN-S550BF/WF

NN-S540BF/WF

NN-L530BF

NN-L530WF

NN-L520WF

NN-S510WF

*

RPH Model refer to the last page.

WARNING

CONTENTS

(Page) (Page)

-1-

FEATURE CHART ...........................................................................3 DISASSEMBLY AND PARTS REPLACEMENT PROCEDURE ............... 13

CONTROL PANEL ...........................................................................3 COMPONENT TEST PROCEDURE ........................................................16

OPERATION AND DIGITAL PROGRAMMER MEASUREMENTS AND ADJUSTMENTS ............................................... 18

CIRCUIT TEST PROCEDURE ........................................................5 PROCEDURE FOR MEASURING MICROWAVE ENERGY LEAKAGE... 19

SCHEMATIC DIAGRAMS ............................................................... 7 TROUBLESHOOTING GUIDE .................................................................20

DESCRIPTION OF OPERATING SEQUENCE ...............................9 EXPLODED VIEW AND PARTS LIST ...................................................... 24

CAUTIONS TO BE OBSERVED WHEN TROUBLESHOOTING ....11 SCHEMATIC DIAGRAM &

PARTS LIST OF DIGITAL PROGRAMMER CIRCUIT ............................. 25

PRECAUTIONS TO BE OBSERVED BEFORE AND

DURING SERVICING TO AVOID POSSIBLE EXPOSURE

TO EXCESSIVE MICROWAVE ENERGY

(A) Do not operate or allow the oven to be operated with the

door open.

(B) Make the following safety checks on all ovens to be serviced

before activating the magnetron or other microwave source,

and make repairs as necessary:

(1) Interlock operation

(2) Proper door closing

(3) Seal and sealing surfaces (arcing, wear, and other

damage)

(4) Damage to or loosening of hinges and latches.

(5) Evidence of dropping or abuse

(C) Before turning on microwave power for any service test or

inspection within the microwave generating compartments,

check the magnetron, waveguide or transmission line, and

cavity for proper alignment, integrity and connections.

(D) Any defective or misadjusted components in the interlock,

monitor, door seal, and microwave generation and trans-

mission systems shall be repaired, replaced, or adjusted

by procedures described in this manual before the oven is

released to the owner.

(E) A microwave leakage check to verify compliance with the

Federal Performance Standard should be performed on

each oven prior to release to the owner.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not

contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair

the product or products dealt with in this service information by anyone else could result in serious injury or death.

>

1.This product should be serviced only by trained, qualified personnel.

2.Though this product has been manufactured in compliance with:

“Federal Performance Standard 21 CFR Subchapter J”(D.H.H.S): U.S.A. models

or “Radiation Emitting Devices Act”(Health and Welfare Canada): Canadian models

it is very important all repairs should be made in accordance with procedures described in this manual to avoid being exposed

to excessive microwave radiation.

3.Check for radiation leakage before and after every servicing according to the “procedure for measuring radiation leakage.”

4.If the unit cannot be repaired on site, advise the customer not to use until unit is repaired.

5.Any serviceman who learns of any accident pertaining to microwave radiation leakage including the oven operating with

open door should immediately notify the appropriate address listed below and Center for Devices and Radiological Health,

DHHS.

IN U.S.A. Panasonic Services Company IN PUERTO RICO PSC

(PASC) 50 Meadowland Parkway, (PSC) San Gabriel Industrial Park

Secaucus, New Jersey 07094 65th Infantry Ave. Km.9.5

Attention: Technical Service Division. Carolina, Puerto Rico 00985

(201)348-7000 (787)750-4300

IN CANADA Panasonic Canada Inc.

(PCI) 5770 Ambler Drive, Mississauga,

Ontario, L4W2T3

(905)624-5010

6.There are special components used in the microwave oven which are important for safety. These parts are marked with

a on the replacement parts list. It is essential that these critical parts should be replaced only with the manufacture’s

specified parts to prevent microwave leakage, shock, fire, or other hazards. Do not modify the orginal design.

>

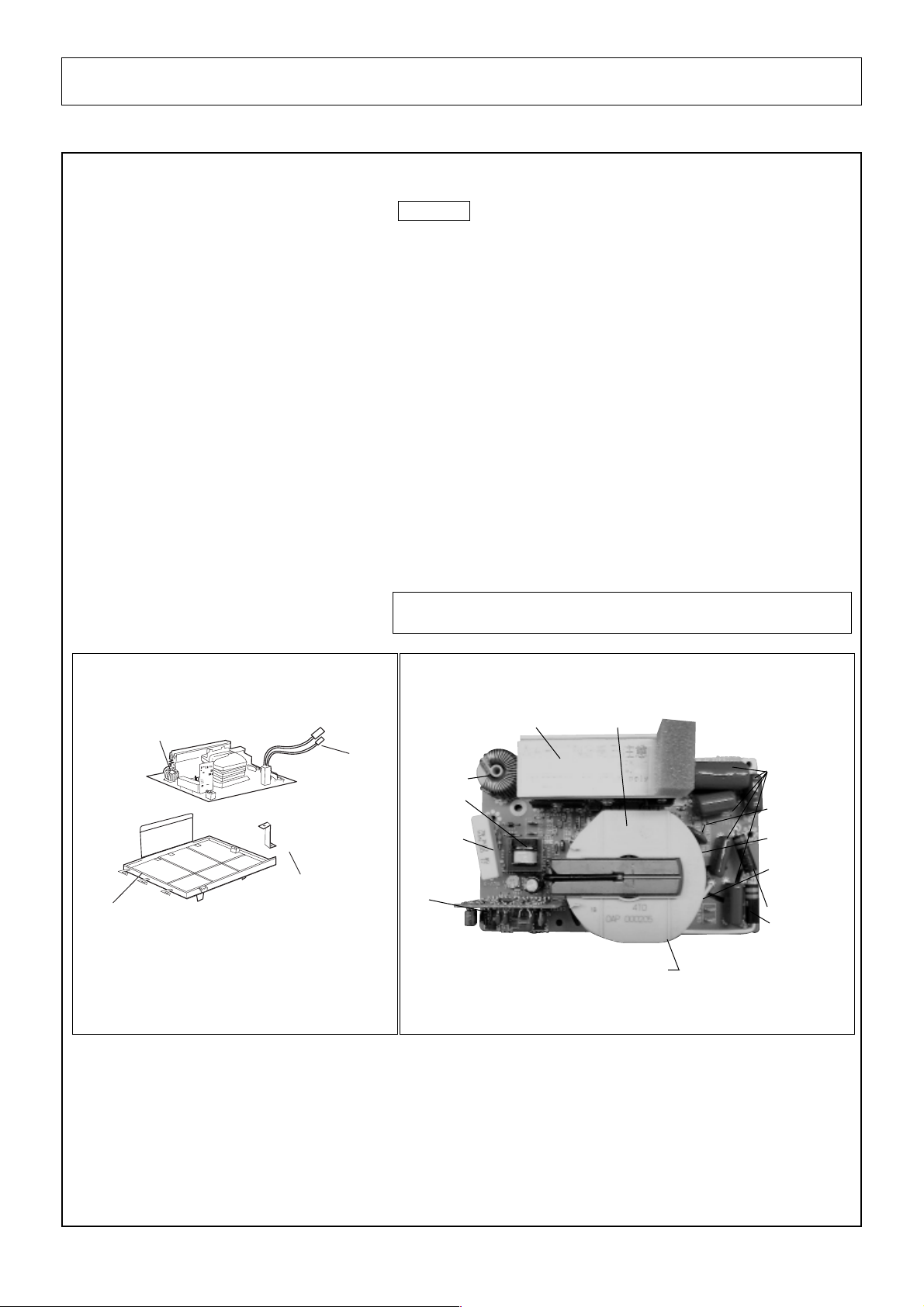

DANGER OF HIGH VOLTAGE AND HIGH TEMPERATURE (HOT/LIVE) OF THE INVERTER POWER SUPPLY (U)

INVERTER WARNING

This Inverter board looks like a regular PCB. However, this PCB drives the magnetron tube with extremely high voltage

and high current.

IT HAS: 1. Very high voltage and high current circuits.

It functions the same as the high voltage transformer and high voltage capacitor in ordinary microwave ovens.

2. Aluminum heat sink is energized with very high voltages and high heat energy.

3. Very high voltage may remain in circuitry even when oven is off. High voltage may remain in the capacitors

on the board.

DO NOT:

1. Do not touch circuitry because it has very hot (high voltage) circuitry. Even when replacing board, extreme

care should be taken to avoid possible electric shock hazards. High voltage may remain in circuit.

2. Do not touch aluminum heat sink because it is very hot in high voltage and also very hot in high heat energy.

3. Do not try to adjust or tamper with preset volume on the Inverter board because it is very dangerous to

adjust without proper test equipment.

4. Do not test oven while Inverter grounding plate or screws are loose. It is very dangerous to operate H.V.

Inverter Circuit (U) with loose mounting screws or if improperly grounded.

5. For USA only:

Do not try to repair Inverter PCB because it is very dangerous to repair it. Replace as whole High Voltage

Inverter Circuit unit and return fully re-packed with original shipping box and shipping materials.

INVERTER POWER SUPPLY DIAGRAM

NEW HV

- 2 -

*

*

*

*

*

HEAT SINK

(RECTIFIER BRIDGE)

CHOKE COIL

CURRENT

TRANSFORMER

SAND BAR

RESISTOR

HIGH VOLTAGE

TRANSFORMER

PCB

FILM CAPACITORS

VARISTOR

PRIMARY WINDINGS

SECONDARY

WINDINGS

HIGH VOLTAGE

DIODES

DO NOT TOUCH

LEAD

WIRE

GROUNDING

PLATE

*

4

INVERTER

SUPPORT

BRACKET OF ORIFICE

H.V INVERTER(U)

*

3

1

2

5

7

11

16

17

4

aa

aa

a

9

12

3

8

6

10

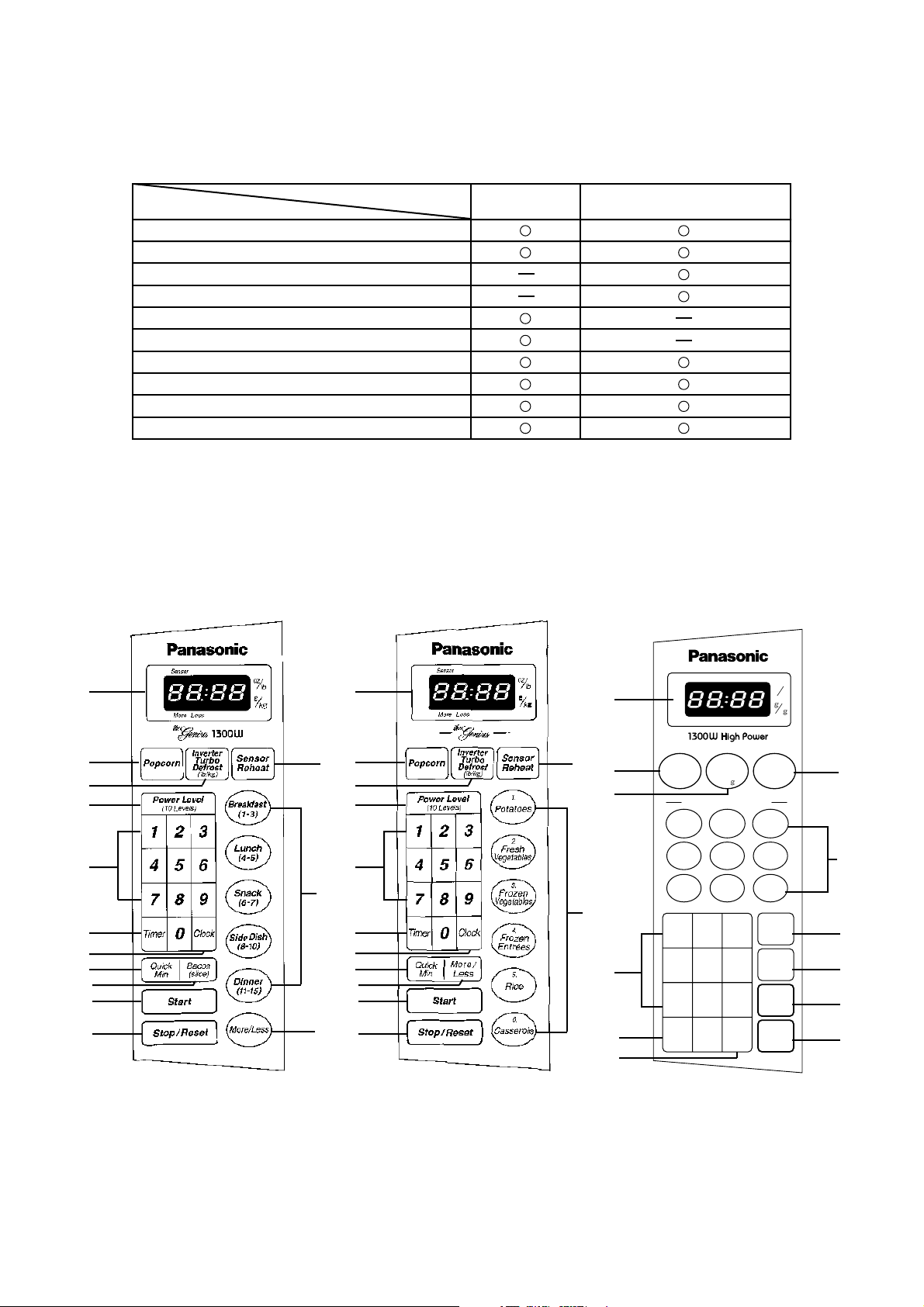

FEATURE CHART

- 3 -

CONTROL PANEL

FEATURE

Three Stage Cooking

Inverter Turbo Defrost

Auto Reheat

Inverter Auto Cook

Sensor Reheat

Sensor Cook

Quick Min

Popcorn

Timer

Digital Clock

MODEL

NN-S550WF NN-S540WF NN-S510WF

NN-S520WFNN-S530WF

NN-S560WF

NN-S560(CPH)

NN-S560(APH)

1

2

5

7

11

16

17

3

8

6

12

9

NN-S550

7

1

2

4

bb

bb

b

17

3

6

16

11

5

8

10

k

lb

oz

Popcorn

Inverter

Turbo

Defrost

(lb/k )

Auto

Reheat

(1-4servings)

Inverter Auto Cooking

Power

Level

(10 Levels)

Quick

Min

Start

Stop/

Reset

123

654

789

Clock

0

Timer

Froz.Veg.

11.

Froz.

Entrées

8.

Breakfast

(-)

13

Dinner

67

(-)

FreshVeg.

10.

Serving

/

Weight

Rice

12.

Potatoes

9.

Lunch

45

(-)

4

aa

aa

a

- 4 -

CONTROL PANEL

NN-L520

7

1

2

4b

17

3

13

6

16

11

5

8

14

15

NN-L530

1

2

4b

17

3

13

6

16

11

5

8

7

14

15

(1) Display Windows

(2) Popcorn Pad

(3) Inverter Turbo Defrost Pad

(4a) Sensor Reheat Pad

(4b) Auto Reheat Pad

(5) Power Level Pad

(6) Number Pads

(7) Timer Pad

(8) Clock Pad

(9) Sensor Cook Pad

(10) Inverter Auto Cooking Pads

(11) Quick Min Pad

(12) More /Less Pad

(13) Cooking Guide

(14) Auto Cook Pad

(15) Serving/Weight Pad

Before cooking: One tap clears your instructions.

During cooking: One tap temporarily stops the

cooking process. Another tap cancels all your

instructions and time of day or colon appears on

the display window.

(17) Stop/Reset Pad

One tap allows oven to begin functioning. If door is

opened or STOP/RESET Pad is pressed once during

oven operation, START Pad must again be pressed to

restart oven.

(16) Start Pad

5

MN-S510

7

1

2

4b

17

3

6

16

11

8

10

NN-S540

7

1

2

4b

17

3

6

16

11

5

8

10

- 5 -

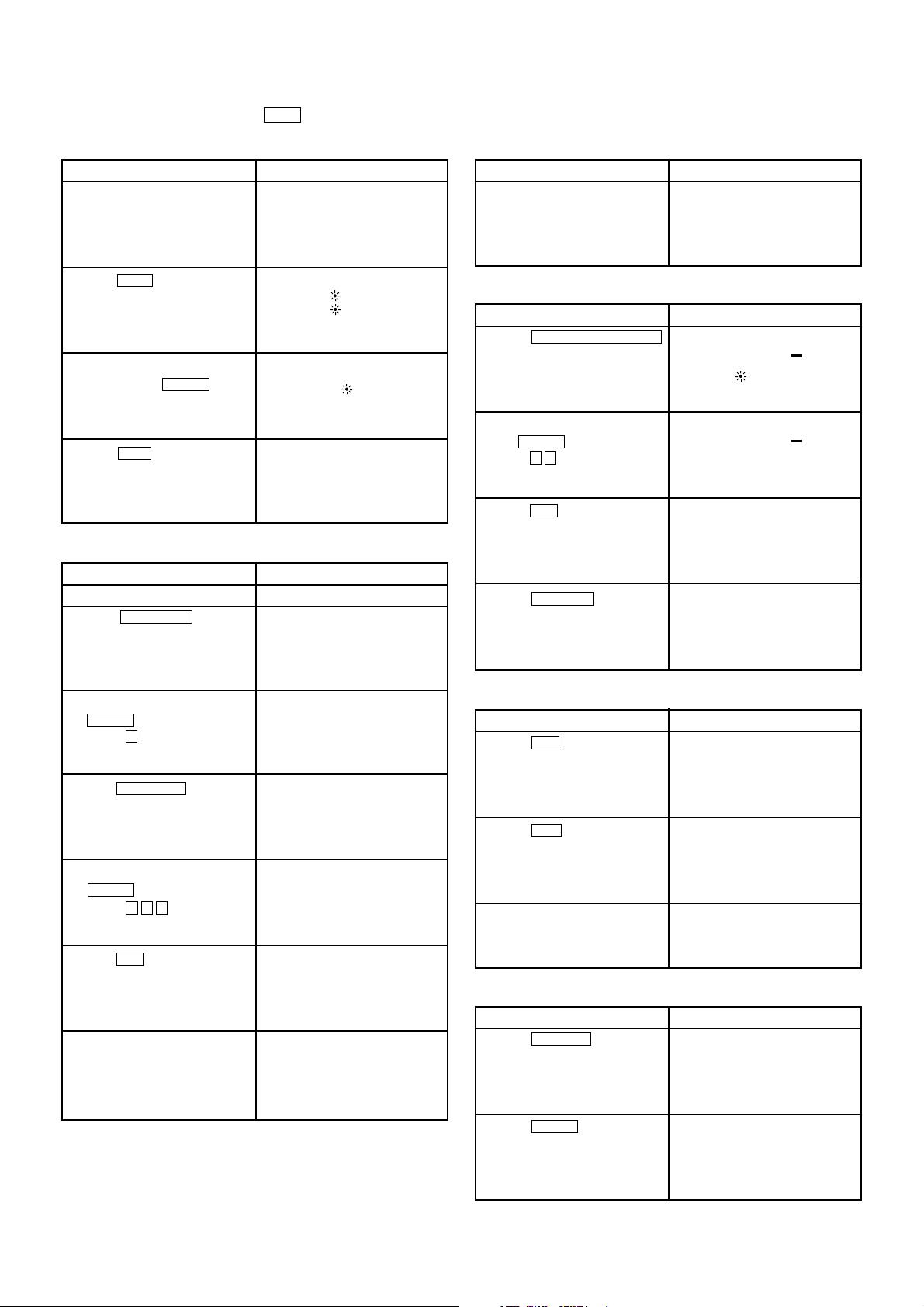

OPERATION AND DIGITAL PROGRAMMER CIRCUIT TEST PROCEDURE

When you pluge the power supply cord into the wall outlet, microwave oven automatically enter into the state of lb / oz. If you want

to use g / kg state, please press Start pad after pluging the power source.

1. Press Inverter Turbo Defrost

pad.

2. Set the weight for 1 lb by press-

ing Number pads.

1 lb = 1 0

3. Press Start Pad.

4. Press Stop/Reset Pad twice.

Oven shuts off.

8. When 2nd stage cooking time has

elapsed, oven beeps 5 times and

shuts off.

Time of day or colon if set appears

in the display.

3. Inverter Turbo Defrost

OPERATION SCROLL DISPLAY

OPERATION

SCROLL DISPLAY

Time of day or colon if set appears

in the display.

4.23

1.0

1. Press Rice pad twice.

2. Press Start pad.

Cooking begins as time counts

down.

3. When cooking time has elapsed,

oven beeps 5 times and shuts off.

4. Inverter Auto Cooking

OPERATION SCROLL DISPLAY

15.00

2. Press Power Level pad once

to set High power.

(1st stage)

3. Set for 5 seconds by pressing

Number pads.

5 sec.= 5

4. Press Power Level pad 4 times

to s et Medium power.

(2nd stage)

5. Set for 1 minute by pressing

Number pads.

1 min.= 1 0 0

6. Press Start pad.

7. When 1st stage cooking time has

elapsed. Oven beeps twice and

automatically switches to 2nd

stage cooking.

OPERATION

SCROLL DISPLAY

1. Plug the power supply cord into

wall outlet.

2. Press Clock pad.

3. Enter time of day (TOD) by press-

ing appropriate Number pads.

4. Press Clock pad. TOD has now

been resistered into the digital

programmer circuit and will count

up by minutes.

2. Time Cooking for Two Stage

OPERATION SCROLL DISPLAY

1. Place a water load in the oven.

88.88

11 25

11. 25

1.0 0

P 1 0

. 5

P 5

. 5

1.0 0

1. To Set Clock

1

Time of day or colon if set appers in

the display.

1. Press Auto Cook pad.

2. Press Number pads.

(Press 3 to select Bacon)

5. Auto Cook

OPERATION

SCROLL DISPLAY

3

6

- 6 -

OPERATION SCROLL DISPLAY

3. Press Serving / Weight pad.

(Select 4. 6. 10. 14 slices)

4. Press Start pad.

When cooking time has elapsed,

Oven beeps 5 times and shuts off.

4

4.10

Times of day or colon if set appears

in the display.

OPERATION

SCROLL DISPLAY

1. Press Popcom pad five times

for 3.5 oz serving.

(Select 1.75. 2.65. 2.85. 3.0 or

3.5 oz )

2. Press Start pad.

Cooking begin as times counts

down.

When cooking time has elapsed,

Oven beeps 5 times and shuts off.

3.5

1.45

Time of day or colon if set appears in

the display.

6. Popcorn

OPERATION

SCROLL DISPLAY

1. Pour 150 15cc (4.5 1/2 ozs)

of room temperature water in a

beaker, place the beaker in the

center of the oven.

Press Breakfast pad twice.

2. Press Start pad.

3.The steam sensor detects steam

about 1.5 to 4 minutes after the

start pad is pressed.

Sensor cooking (T1) automatically

switches to cooking time(T2).

“Sensor” disappears with beep

sounds and the remainder of

cooking time appears in the display

window.

NOTE: Cooking time will vary

depending on the water

temperature, the shape of

the beaker or the Power

source Voltage.

4.When cooking time has elapsed,

Oven beeps 5 times and shuts off.

2

Time of day or colon if set appears in

the display.

7. Sensor Cooking (NN-S560WFAPH/CPH,S560BFAPH/CPH)

OPERATION SCROLL DISPLAY

1. Press Auto Reheat pad twice

for two servings.

2. Press Start pad.Auto Reheat

cycle begins time counts down.

3.When cooking time has elapsed,

Oven beeps 5 times and shuts off.

2

2.00

Time of day or colon if set appears in

the display.

8. Auto Reheat

Press

Power Level

9. Power Level

Power Level Display Window

once

twics

3 times

4 times

5 times

6 times

7 times

8 times

9 times

10 times

P 10 (HIGH)

P 9

P 8

P 7 (MED. HIGH)

P 6 (MEDIUM)

P 5

P 4

P 3 (MEDIUM-LOW)

P 2

P 1 (LOW)

P 10

P 9

P 8

P 7

P 6

P 5

P 4

P 3

P 2

P 1

OPERATION SCROLL DISPLAY

1. Press Start pad 3 times

continuously. “Child” appears in

the display.

Child

10. To set Child satety Lock

OPERATION

SCROLL DISPLAY

1. Press Start / Reset pad 3 times

continuously.

11. To Reset Child Lock

Time of day or colon if set appears in

the display.

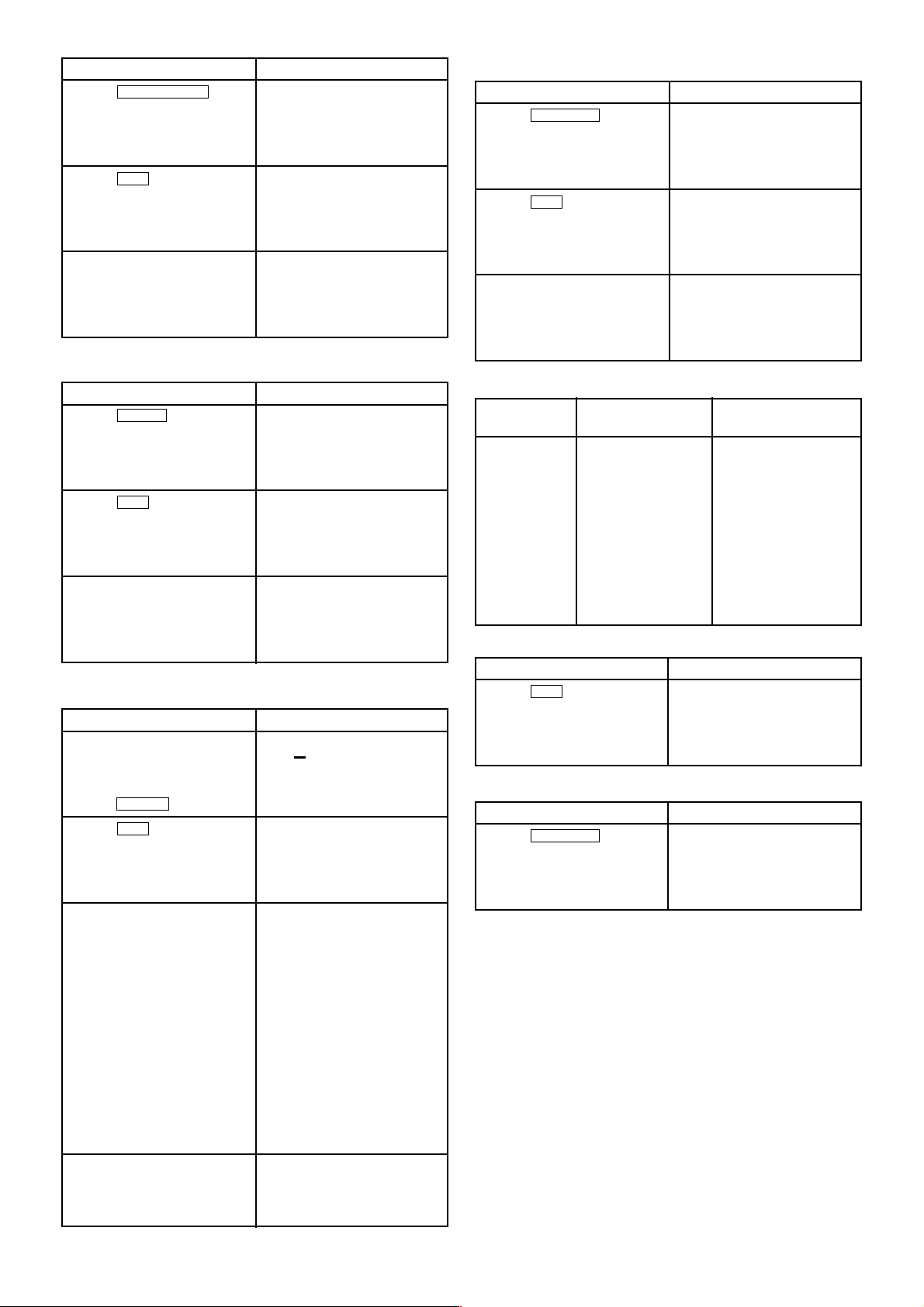

SCHEMATIC DIAGRAM (APH)

- 7 -

SCHEMATIC DIAGRAM (APH)

- 8 -

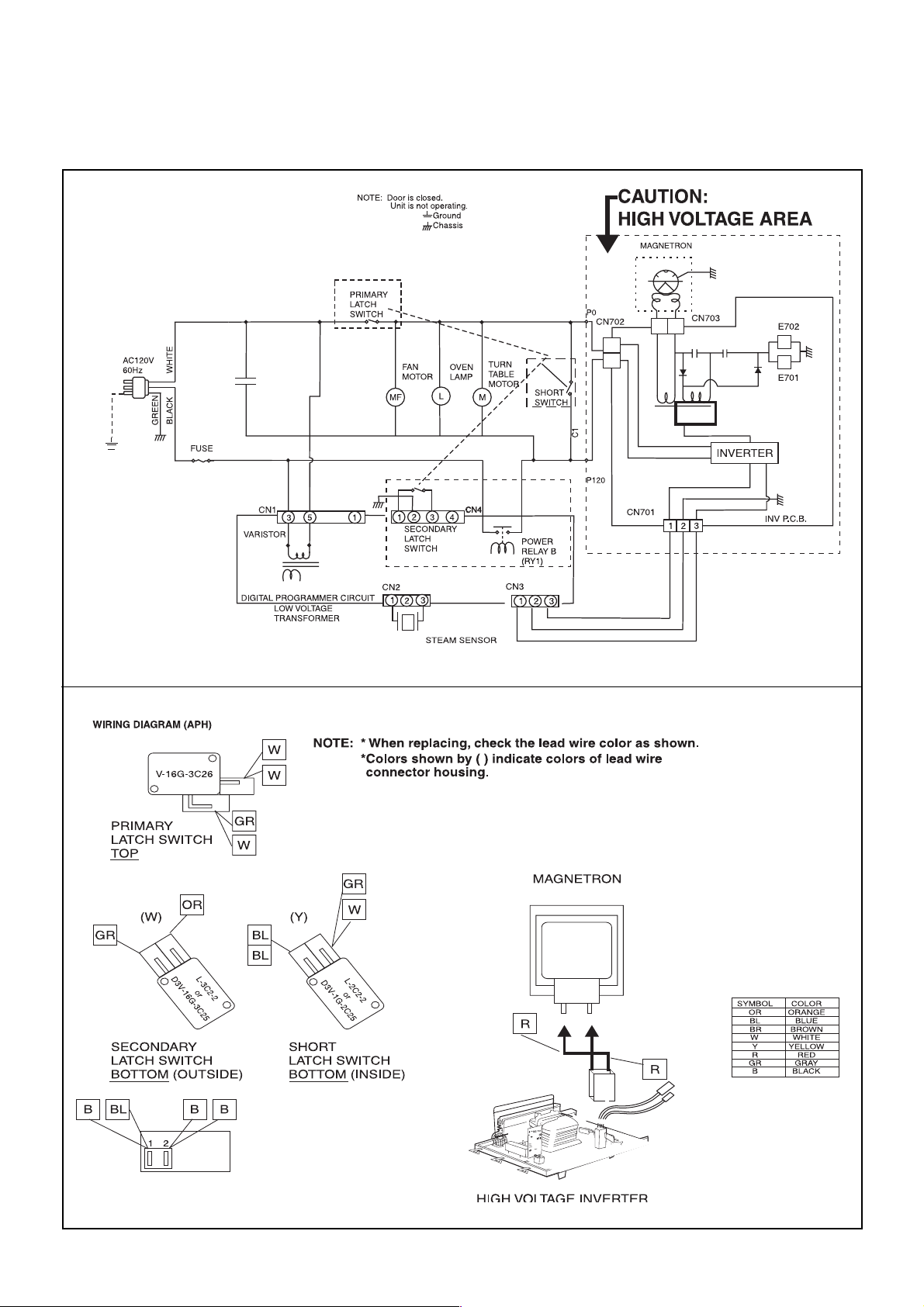

SCHEMATIC DIAGRAM (CPH)

SCHEMATIC DIAGRAM (CPH)

DESCRIPTION OF OPERATING SEQUENCE

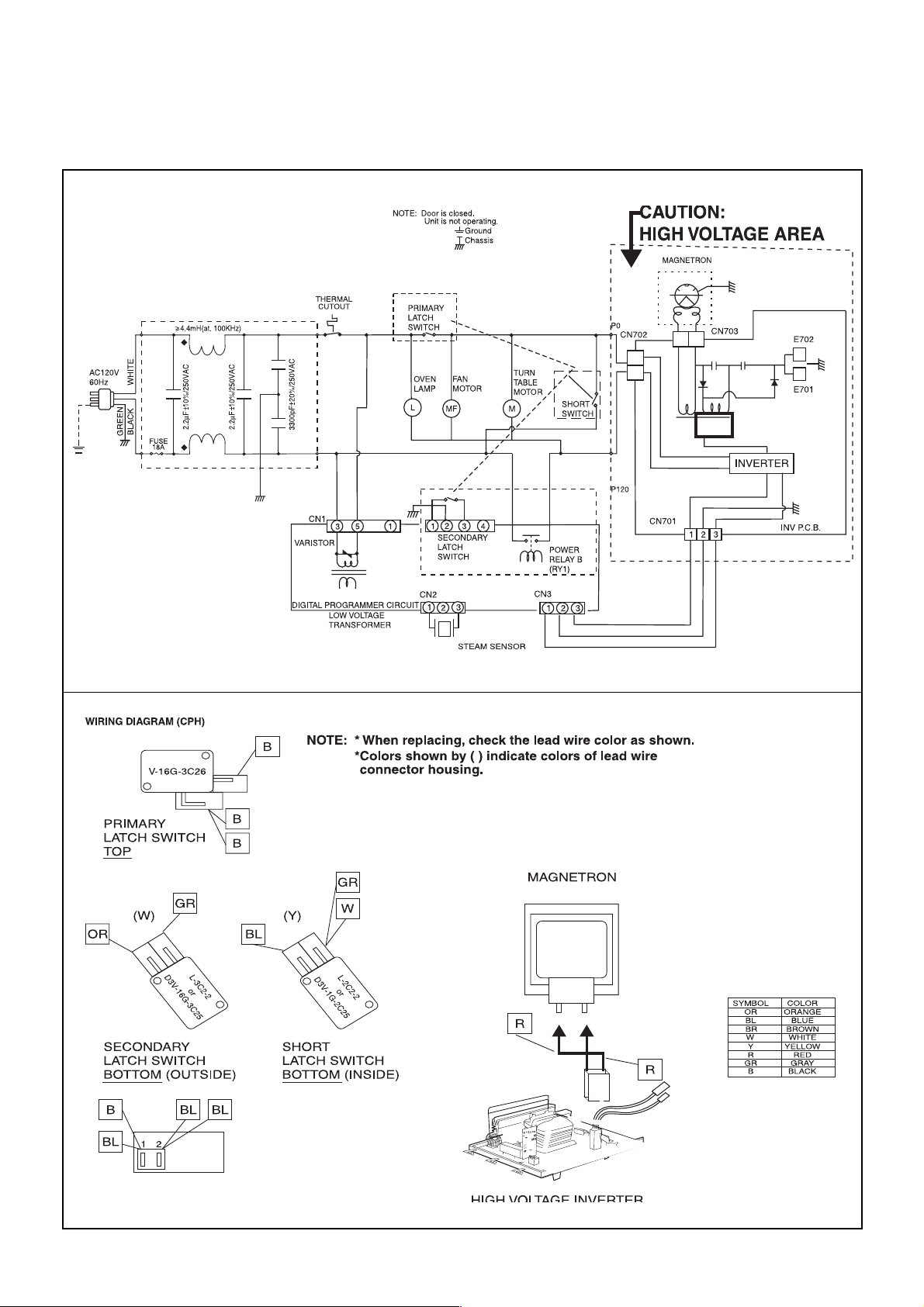

1. Variable power cooking control

The coil of power relay B (RY1) is energized intermittently by the digital

programmer circuit, when the oven is set at any power selection except

for High power position. The digital programmer circuit controls the

ON-OFF time of power relay B contacts in order to vary the output

power of the microwave oven from ”Low” to “High” power. One

complete ON and OFF cycle of power relay B is 22 seconds. The

relation between indications on the control panel and the output of the

microwave oven is as shown in table.

NOTE: The ON/OFF time ratio does not correspond with the

percentage of microwave power since approximately 2 sec-

onds are required for heating of magnetron filament.

2. Inverter Power Supply Circuit NEW H,V

This Inverter Power Supply Circuit supplies 4,000V DC to the magnetron

tube from the line voltage,120v 60Hz AC input. functions as the H.V.

transformer, the H.V.capacitor and H.V.Diode.

1. The AC input voLtage 120V 60HZ is rectified to DC voltage immediately.

2. DC voltage will be supplied to the switching devices called IGBT. These

devices will be switched ON-OFF by the 20 to 40 kHz PWM. (pulse

width modulation) signal from the microcomputer in the DPC.

3. This drives the High voltage transformer to increase up to 2,000V AC

and approximately 3V AC by means of transformer.

4. Then the half-wave doubler voltage rectifier circuit, consisting of the

HV diodes and Capacitors, generates the necessary 4,000V DC

needed for the magnetron.

5. Output power of the magnetron tube is always monitored by the

signal output from the current transformer built into the inverter ciruit.

6. Then this signal will be fed back to the microcomputer in the DPC to

determine operating conditions and output necessary to control PWM

signal to the inverter Power Supply to control output power.

3. Inverter Turbo Defrost

When this Auto Control feature is selected and the Start Pad is tapped:

(A) The digital programer circuit determines the power level and cooking

time to complete cooking and indicates the operating state in the

display window. Table shows the corresponding cooking times for

respective serving by categories.

(B) When cooking time the display window has elapsed, the oven tums

off automatically by a control signal from the digital programmer circuit.

- 9 -

POWER SETTING

OUTPUT

POWER(%)

APPROX.

ON-OFF TIME OF

POWER RELAY B (RY1)

ON (SEC) OFF (SEC)

HIGH

MEDIUM-HIGH

MEDIUM

MEDIUM-LOW

DEFROST

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

30%

22

22

22

22

22

22

22

22

15

8

22

0

0

0

0

0

0

0

0

7

14

0

Variable Power Cooking

P10

P9

P8

P7

P6

P5

P4

P3

P2

P1

P3

Inverter Turbo Defrost

SELECTED

WEIGHT

1.0LB

6.0LB

COOKING TIME

4 min.28 sec.

25 min.00 sec.

4. Sensor Cooking (NN-S560BFAPH/CPH NN-

S560WFAPH/CPH)

Auto sensor cooking is a revolutionary way to cook by microwave

without setting a power level or selecting a time.

All that is necessary is to select an Auto Sensor Program before starting

to cook.

Understanding Auto Sensor Cooking

As the food cooks, a certain amount of steam is produced. If the food

is covered, this steam builds up and eventually escapes from the

container. In Auto Sensor Cooking, a carefully designed instrument,

called the steam sensor element, senses this escape of steam. Then,

based upon the Auto Sensor Program Selected, the unit will

automatically determine the correct power level and the proper length

of time it will take to cook the food.

NOTE: Auto Sensor Cooking is successful with the foods and

recipes found in the Auto Sensor Cooking Guide. Because

of the vast differences in food composition, items not

mentioned in the Cooking Guide should be prepared in the

microwave oven using power select and time features. Please

consult variable Power Microwave cookbook for procedures.

Explanation of the Auto Sensor Cooking process

1) During the first 10 second period there is no microwave activity,

and when calculating the T2 time by using the formula below make

sure this 10 second is subtracted from the T1 time. In other words T1

time starts at the end of the 10 second period.

2) T1 time... The total amount of time it takes the microwave oven to

switch to T2 time after the 10 second period.

3) T2 time... When the steam escapes from the cooking container placed

in the oven, the steam sensor detects it and the microprocessor cal-

culates the balance of cooking time. This T2 time is then shown in the

display and begins counting down.

Balance of cooking time (T2 time)

The balance of cooking time which is called T2 time, can be calcu-

lated by the following formula.

T2 time (in sec.)=T1 time X K factor

NOTE: Remember, the T1 time starts after the 10 second period.

The coefficient K is programmed Into the mlcroprocessor

memory and they are listed in the following tables along with

the P1 and P2 powers.

NOTE: When "More" or "Less" pad is selected, the K factor varles

resulting In T2 time to be increased or decreased.

Example of calculating the T2 time

Example 1: If the T1 time is measured to be 2 minutes and 40 seconds

after the 10 second period, and the Auto program selected is

Frozen Vegetable:

T2 = T1 X K

=2 min. and 40 sec. X 0.1

=160 sec. X 0.1

=16 sec.

5. Sensor Reheat (NN-S560BFAPH/CPH,NN-S560WF

APH/CPH)

Auto Sensor Reheat is a quick and easy way to reheat refrigerator

and room temperature foods.

Simply press the reheat pad. There is no need to select power level

and cooking time.

NOTE: The Auto Sensor Reheat process is same as Auto Sensor

Cooking process.

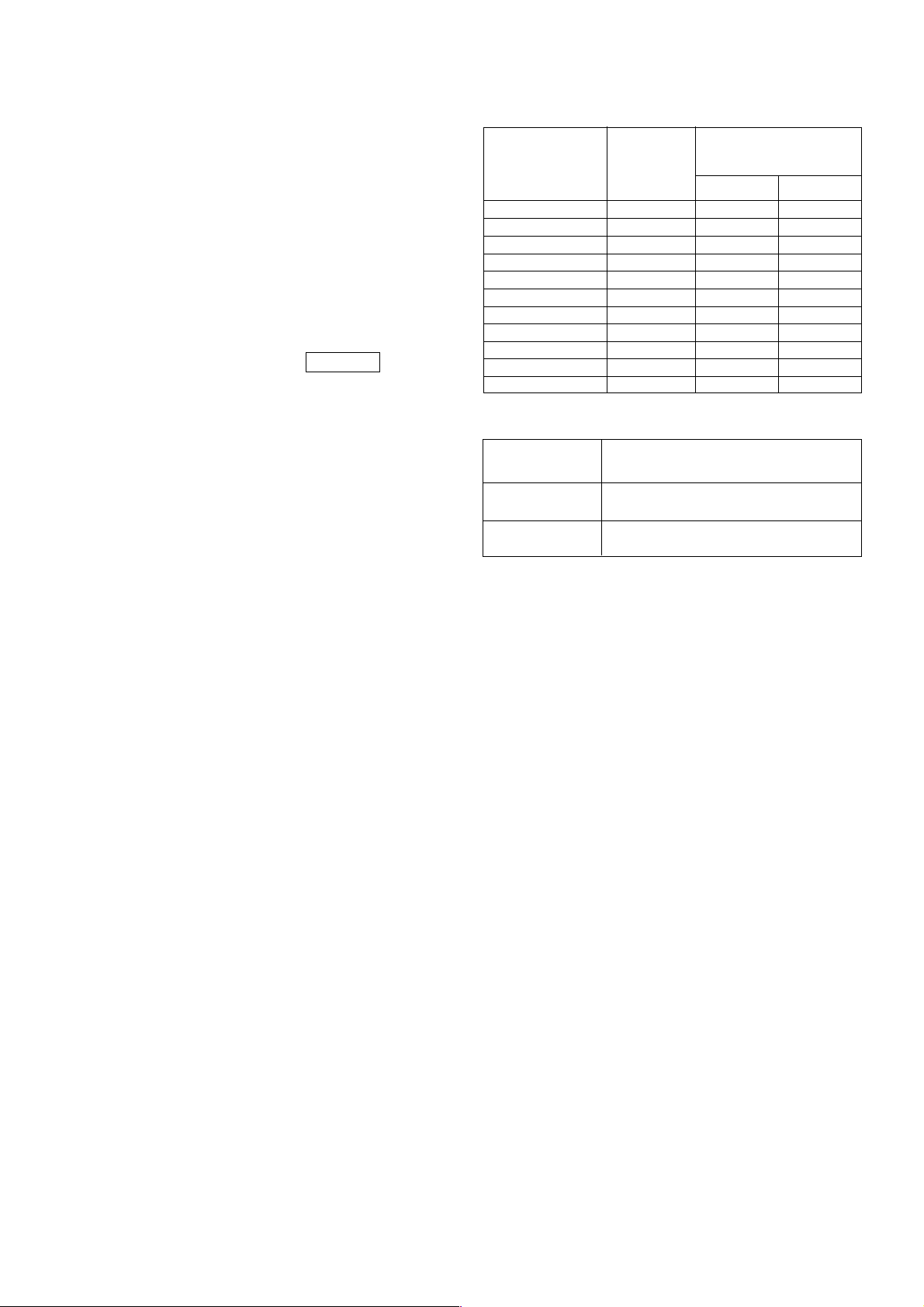

AUTO SENSOR COOKING/REHEAT PROCESS

Category

Frozen Vegetables

Sensor Cooking

P1

Power

HIGH

K Factor

Standard

0.1

P2

Power

LOW

- 10 -

Category

Sensor Recheat

Sensor Reheat (All Sensor Modeis)

P1

Power

HIGH

K Factor

Standard

0.1

P2

Power

LOW

Loading...

Loading...