Page 1

OmniRx Service Guide

67-2023 Rev D

Page 2

This guide is CONFIDENTIAL and designed only for Omnicell Technical personnel and/or designated

representatives.

This guide and accompanying software and/or hardware described in it are protected under copyright laws and may

not be copied, wholly or in part, without the express written consent of Omnicell, Inc. The same proprietary and

copyright notices must be attached to any permitted copies as were attached to the original documents.

Omnicell, Inc.

1201 Charleston Road

Mountain View, CA 94043

(650) 251-6100

www.omnicell.com

Omnicell and the Omnicell design mark, OmniBuyer, OmniCenter, OmniRx, OmniSupplier, SafetyMed, SafetyPak,

SafetyStock, and Sure-Med are registered trademarks. Anesthesia TT, Anesthesia Workstation, Anywhere RN,

Executive Advisor, Flexbin, Medication Surveillance, OmniDispenser, OmniLinkRx, OmniScanner, OmniTrack,

Omni TT, Open Touch, OptiFlex, OptiFlex MobileTrack, Point-to-Point Medication Safety, SecureVault, See & Touch,

SinglePointe, TempCheck, Touch & Go, VSuite, and WorkflowRx are trademarks of Omnicell, Inc. in the United States

and internationally. All other trademarks and trade names are the property of their respective owners

Copyright 2010 Omnicell, Inc. All rights reserved.

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 3

Table of Contents

Electronics Sled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Tools List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

LCD Screen Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Speaker Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Printer Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Seiko Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

APS Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Keyboard Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

PS/2 Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

USB Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

PC Tray Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

PowerCom2 Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

PowerCom3 Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Standardization Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Final Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

iii

Frames and Wireways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Wireway Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Manual Override Cable Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Drawers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Tools List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Matrix Drawers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Bin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Unlit Matrix Drawers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Lit Matrix Drawers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Double-Deep Matrix Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Matrix Drawers Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Supply Drawer Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Pharmacy Drawer Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Pharmacy Drawer Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Appendix A: Part List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 4

iv Table of Contents

Documentation Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Feedback-1

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 5

Tools List

Electronics Sled

This chapter provides detailed instructions to remove specific parts in the electronics sled. To

replace the item, reverse the removal steps with the new part.

The whole console is replaced when changing out the Seiko printer and PS/2 keyboard for the

APS printer and USB keyboard (with separate numeric pad) when spares are used up.

The following tools are required to install the electronics tray:

T8 Torx Driver

T10 Torx Driver

T15 Torx Driver

9/64” Allen wrench

Standard adjustable wrench

1-1

General Shutdown

Perform shutdown procedures before doing any service.

1. Perform a graceful shutdown of the electronics sled.

2. Unplug the power cable to the OmniRx.

3. Unlock the console with the #2036 key.

4. Lift the console from the rear of the OmniRx, then prop it up.

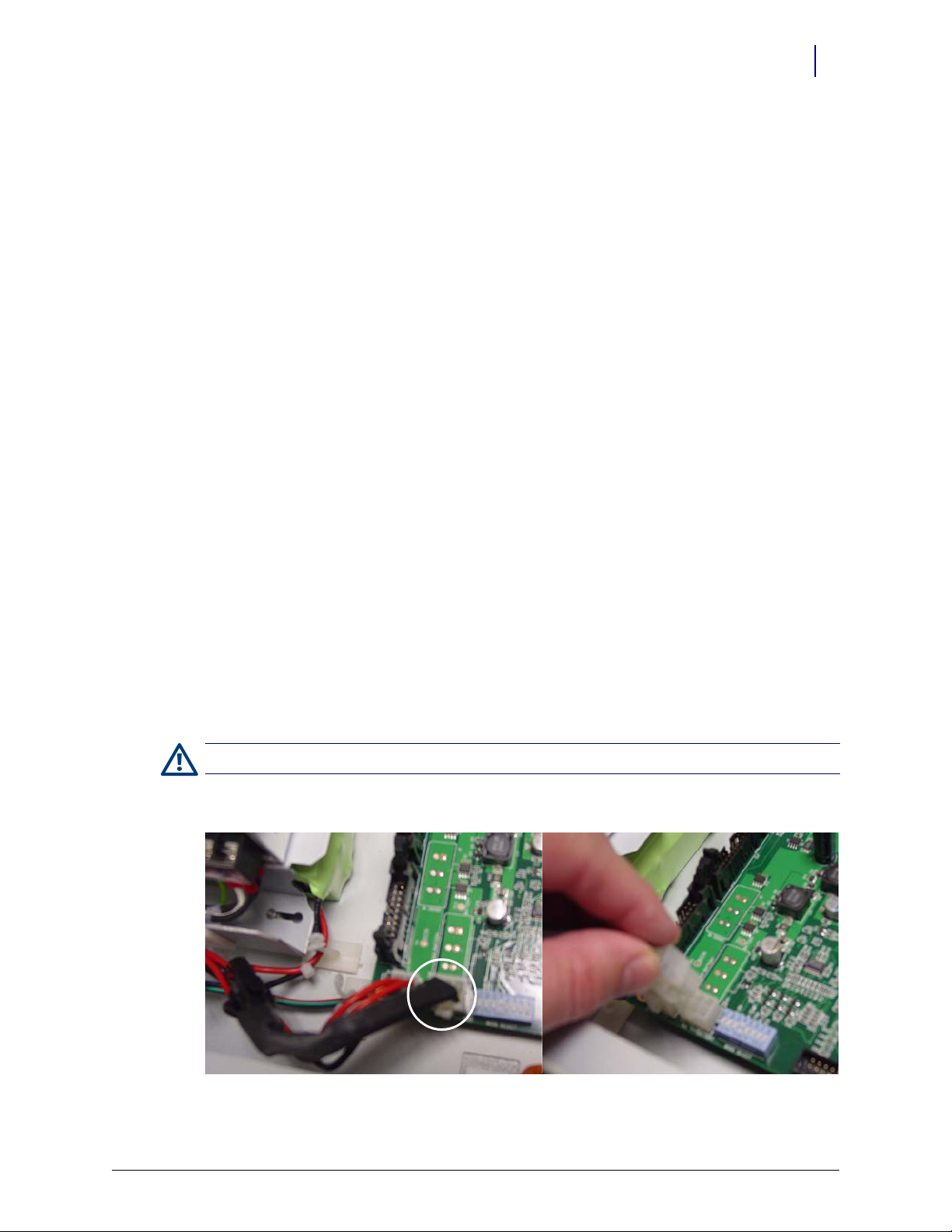

Caution: Use an ESD wrist band while working inside the sled.

5. Disconnect the black battery cable.

Figure 1-1. Battery cable

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 6

1-2 Electronics Sled

LCD Screen Removal

LCD Screen Removal

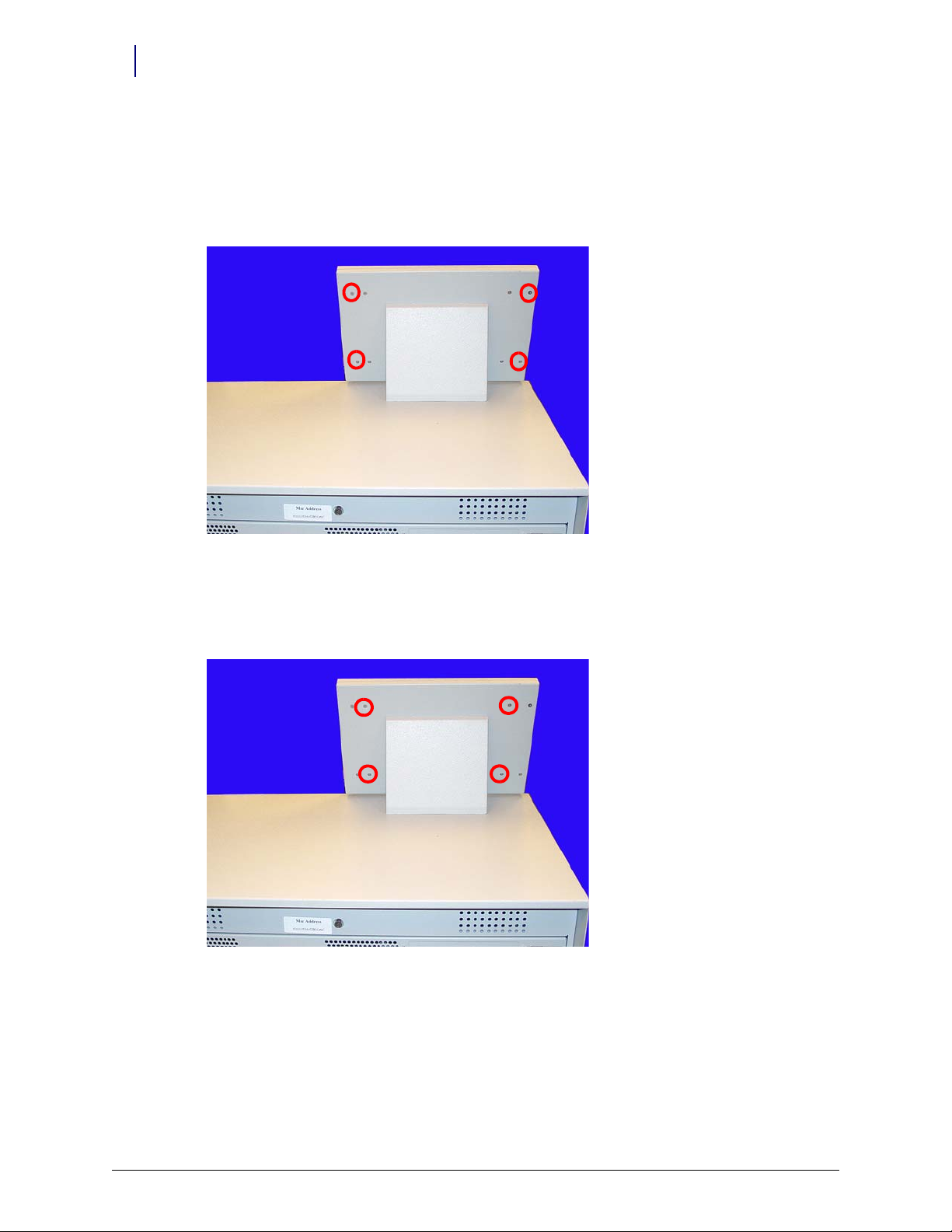

1. Lower the console into the closed position.

2. Remove the four outer screws that secure the LCD bezel to the console using a Torx T10

screwdriver.

Figure 1-2. Remove the four outer screws

3. Remove the bezel.

4. Remove the four inner screws at the back of the bezel. Hold onto the front of the LCD screen

while removing the screws so that the assembly does not fall.

Figure 1-3. Remove the four inner screws

5. Tilt the LCD assembly forward and disconnect the cables from the back of the LCD assembly.

a. Disconnect the inverter to power cable.

b. Disconnect the flat panel cable.

6. Remove the LCD assembly from the LCD housing.

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 7

Speaker Removal

1. Lift the console from the rear and prop it up if it is not already open.

2. Disconnect the speaker cable from the motherboard.

Figure 1-4. Disconnect the speaker cable from the motherboard

3. Remove the two screws that hold the speaker in place using a Torx T10 screwdriver.

Electronics Sled 1-3

Speaker Removal

Figure 1-5. Remove the speaker

4. Disconnect the speaker from the console top.

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 8

1-4 Electronics Sled

Printer Removal

Printer Removal

Seiko Printer

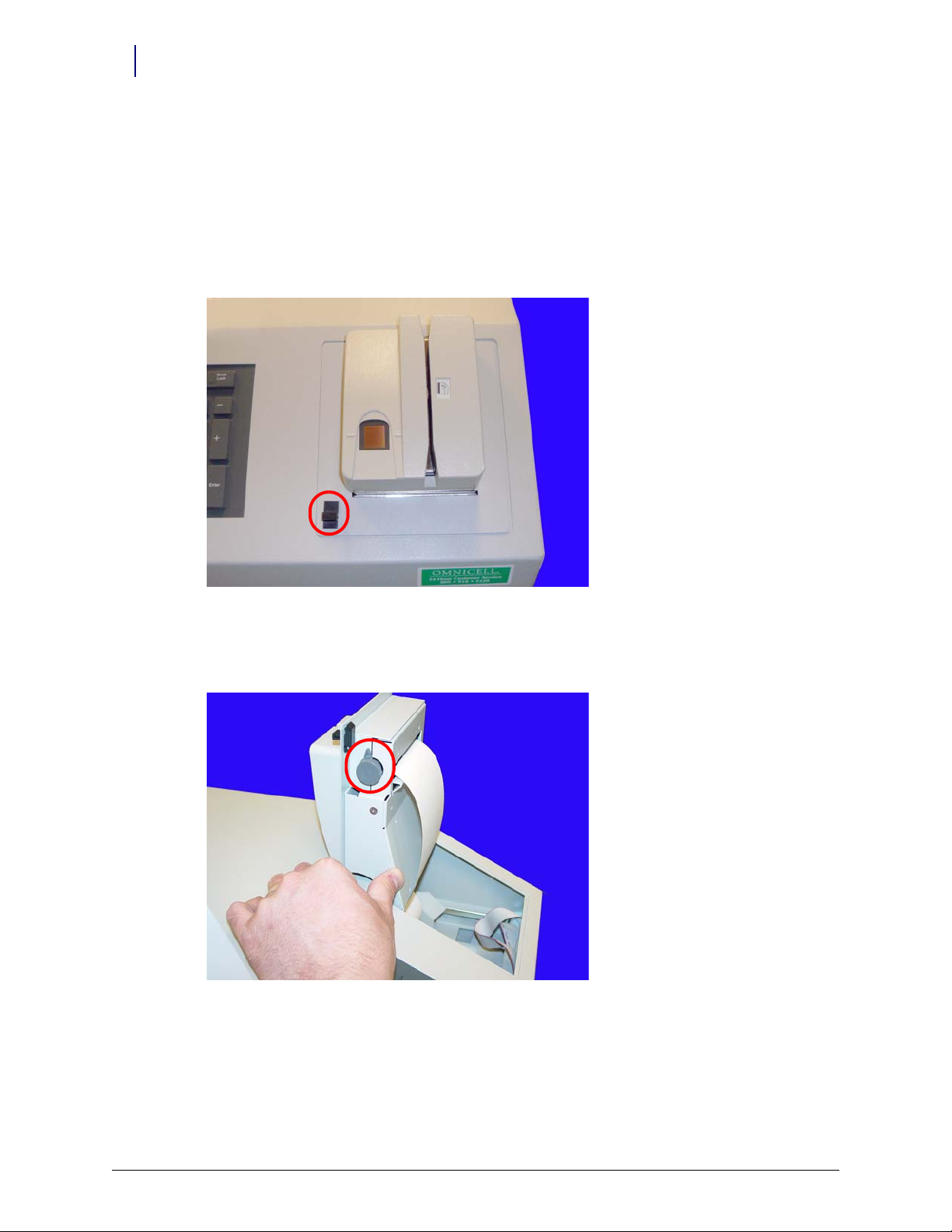

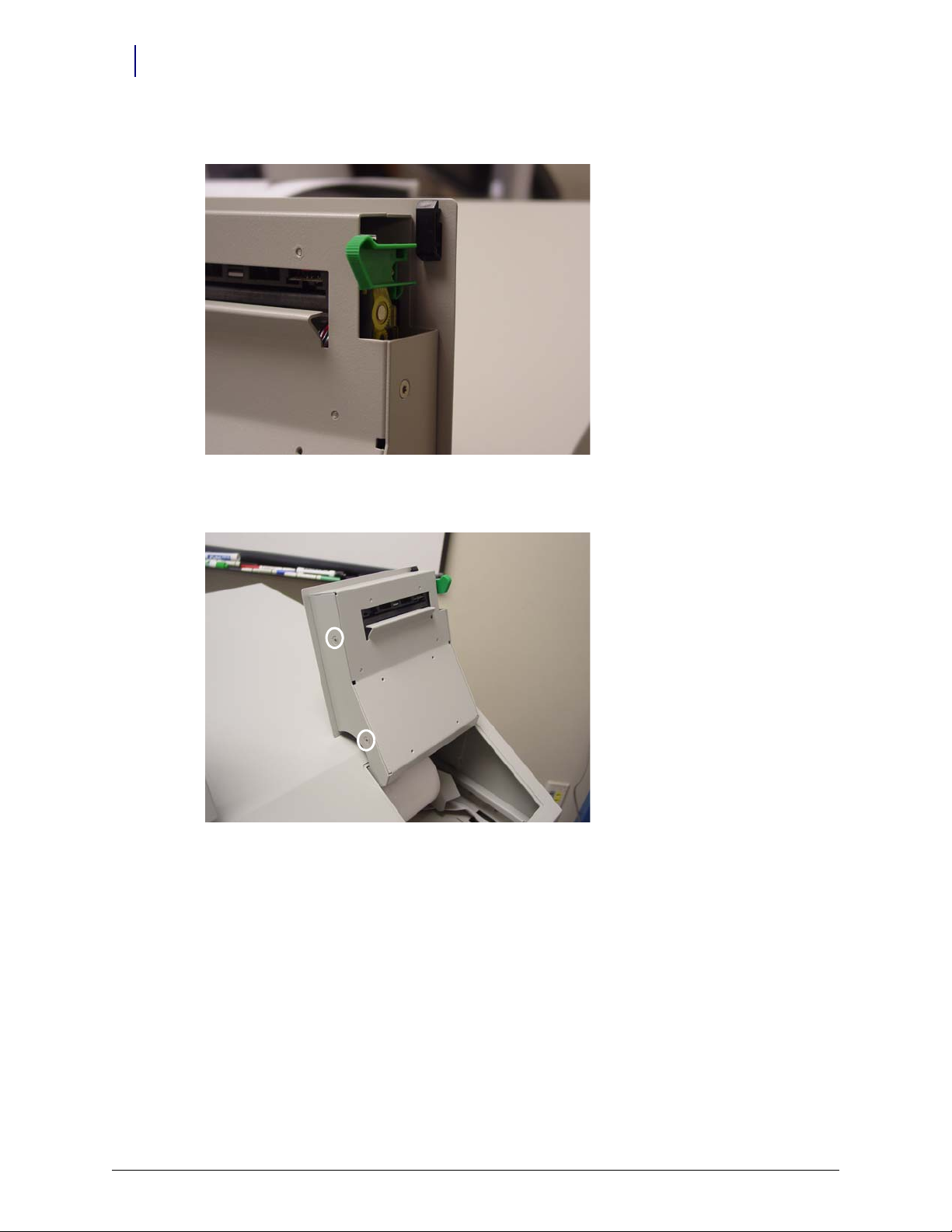

1. Lower the console into the closed position.

2. Open the printer cover by pushing the black release mechanism toward the rear of the

machine and lifting the cover.

Figure 1-6. Open the printer cover

3. Remove the paper from the printer.

4. Push the platen lever to the left to the disengaged position.

Figure 1-7. Turn the platen lever

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 9

Electronics Sled 1-5

Printer Removal

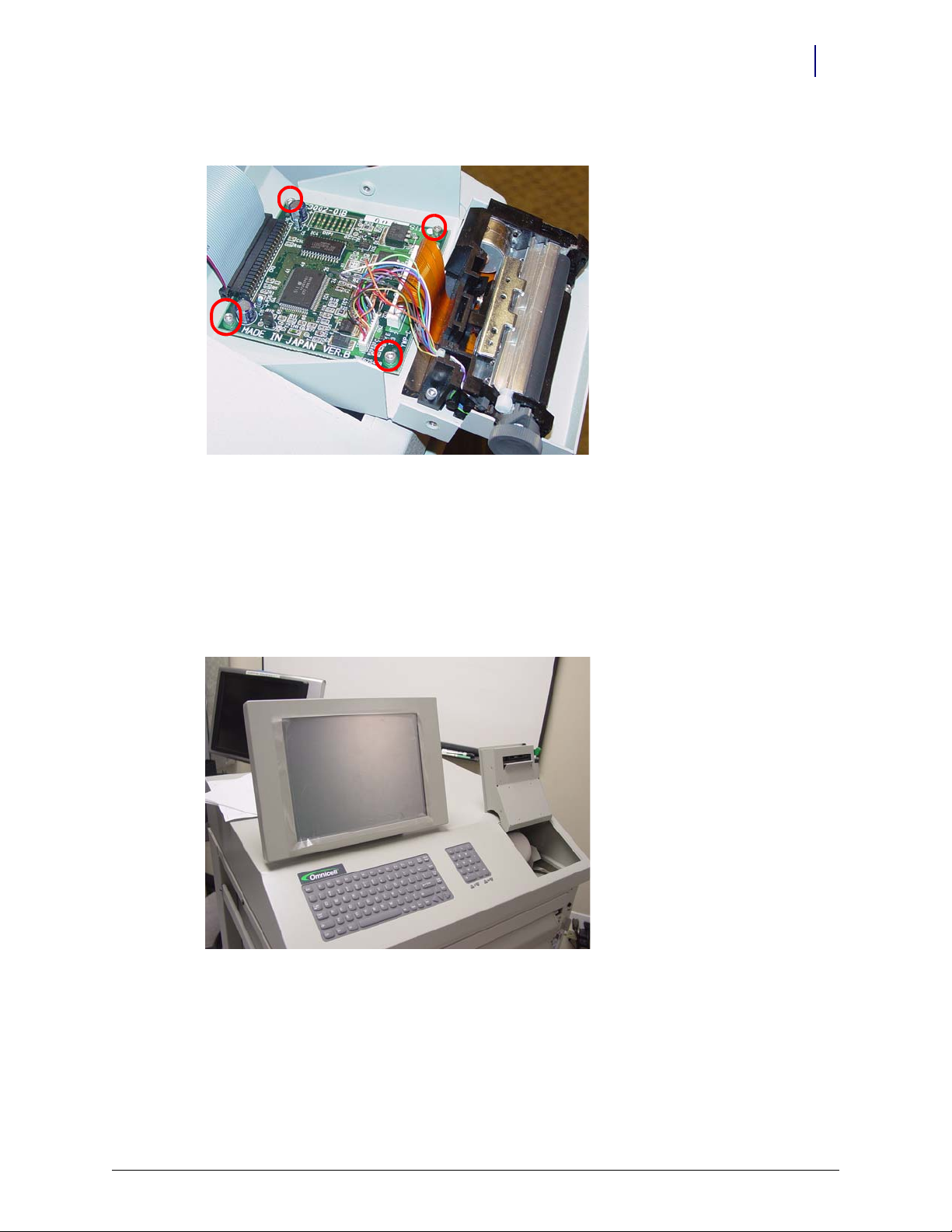

5. Remove the four screws (two on each side) that secure the printer assembly to the cover.

Figure 1-8. Remove the printer assembly screws

6. Remove the printer assembly.

7. Remove the four screws that secure the lower assembly to the frame.

Figure 1-9. Remove the lower assembly screws

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 10

1-6 Electronics Sled

A

B

Printer Removal

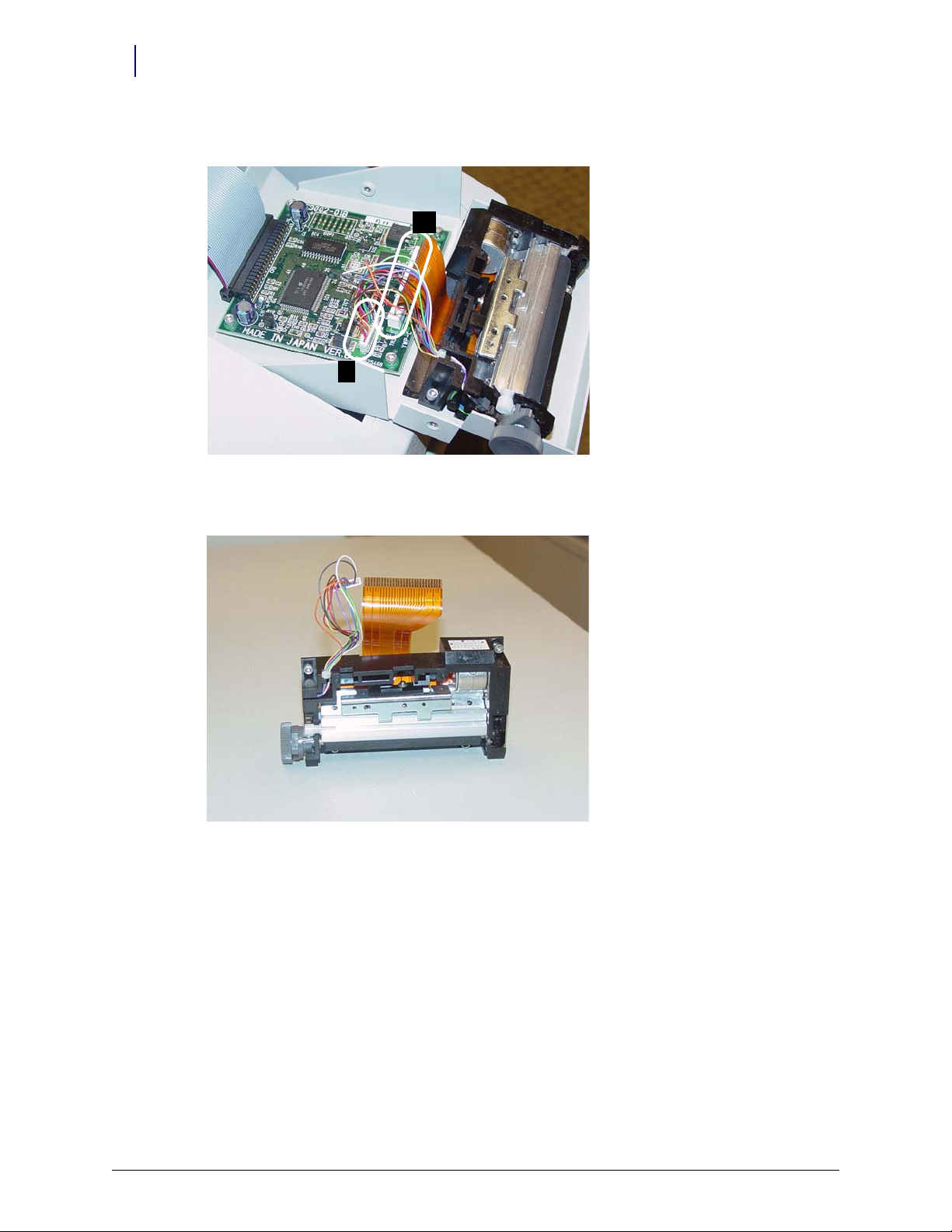

8. Disconnect the printer ribbon cable and the printer data cables from the printer PC Board.

Figure 1-10. Remove the printer cables

9. Remove the printer.

Figure 1-11. Remove the printer

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 11

10. Remove the four screws that secure the PC card to the frame.

Figure 1-12. Remove printer PC card screws

Electronics Sled 1-7

Printer Removal

APS Printer

11. Lift the card off the frame slightly, then remove the printer ribbon cable.

This service procedure is similar to the Seiko printer.

1. Open the printer cover by pushing the black release mechanism toward the rear of the

machine and lifting the cover.

Figure 1-13. Open the printer cover

2. Remove the paper from the printer.

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 12

1-8 Electronics Sled

Printer Removal

3. Lift the green platen lever on the right side to the disengaged position.

Figure 1-14. Lift the platen lever

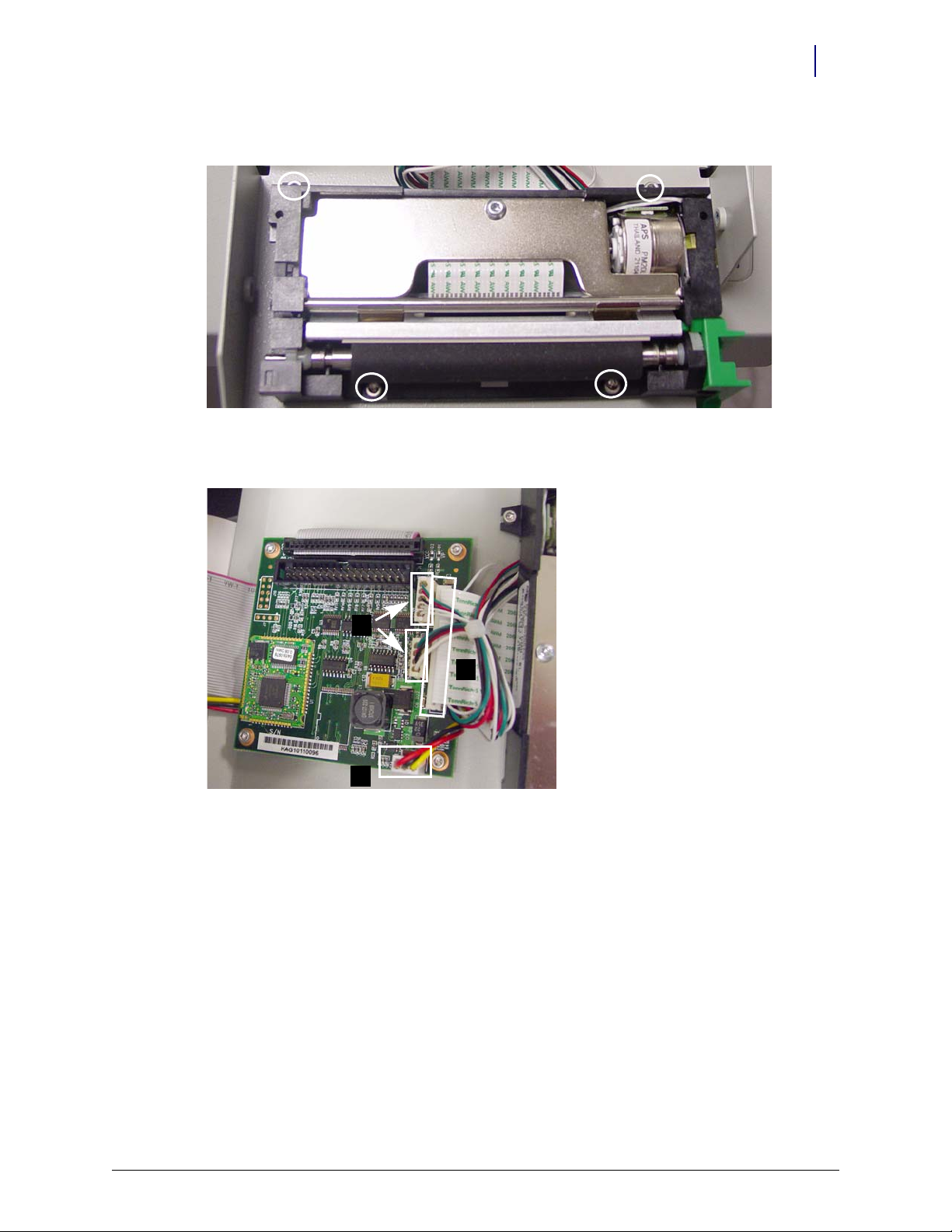

4. Remove the four screws (two on each side) that secure the printer assembly to the cover.

Figure 1-15. Remove the Screws Securing the Printer Assembly

5. Remove the printer assembly.

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 13

6. Remove the four screws that secure the lower assembly to the frame.

A

B

C

Figure 1-16. Remove the lower assembly screws (top screws partially hidden)

7. Disconnect the four printer cables from the printer PC Board.

Electronics Sled 1-9

Printer Removal

Figure 1-17. Remove the printer cables: (a) ribbon cable (b) 2 data cables (c) power cable)

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 14

1-10 Electronics Sled

Keyboard Service

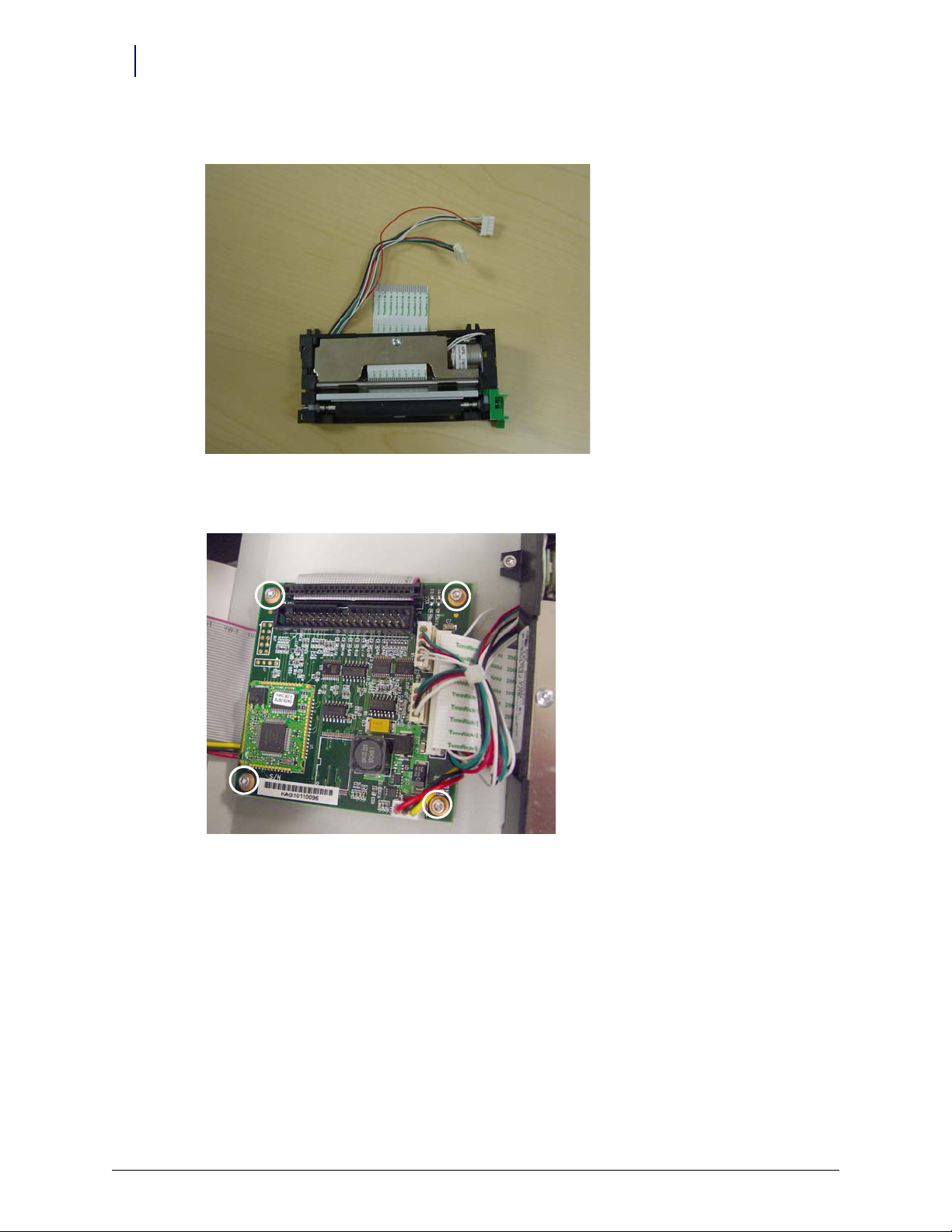

8. Remove the printer.

Figure 1-18. Remove the printer

9. Remove the four screws that secure the PC card to the frame.

Figure 1-19. Remove the printer PC card screws

10. Lift the card off the frame slightly, then remove the printer ribbon cable.

Keyboard Service

1. Disconnect all console cables.

2. Remove the console and set it upside down in a work area.

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 15

PS/2 Keyboard

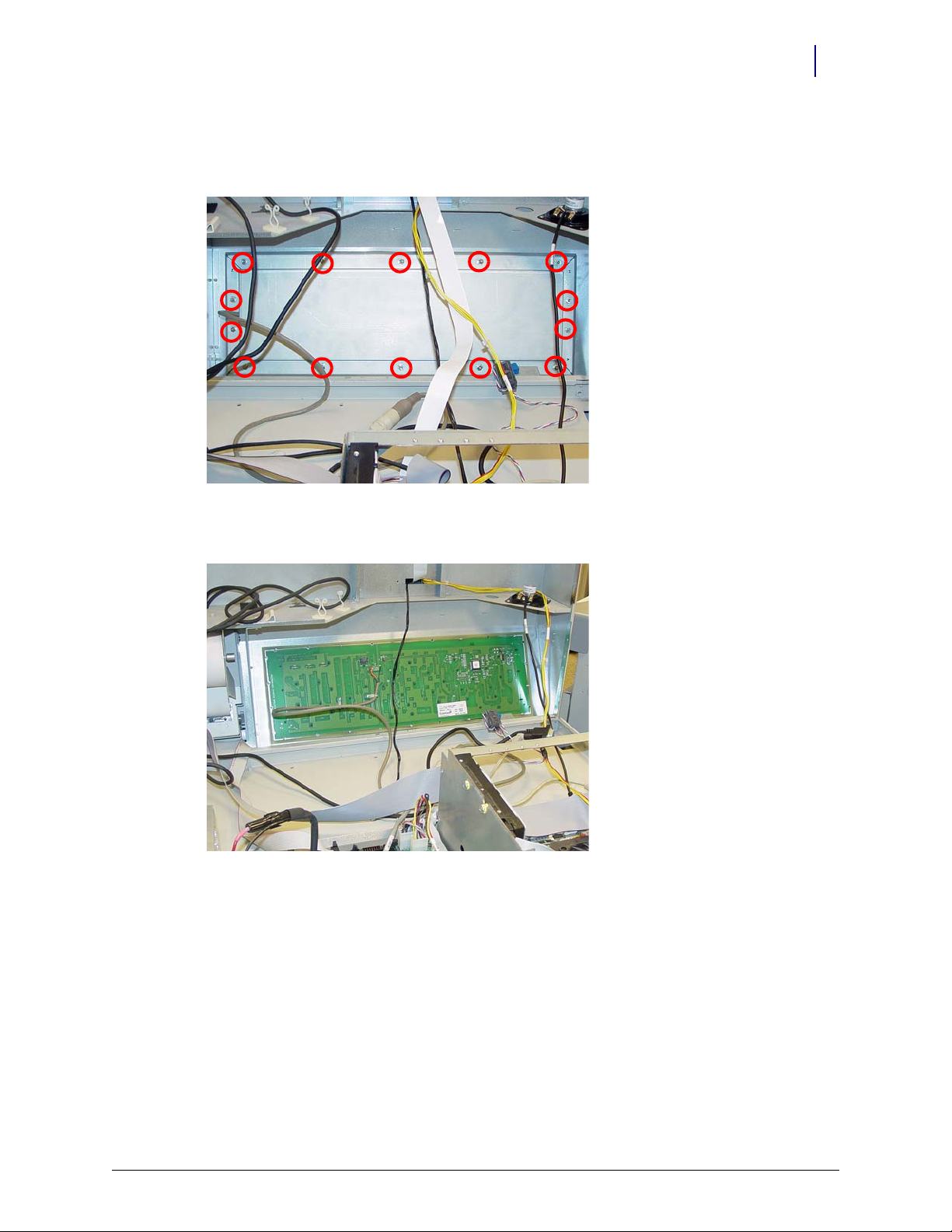

1. Remove the 14 nuts that secure the keyboard cover to the tray.

Figure 1-20. Remove the nuts that secure the keyboard cover to the tray

Electronics Sled 1-11

Keyboard Service

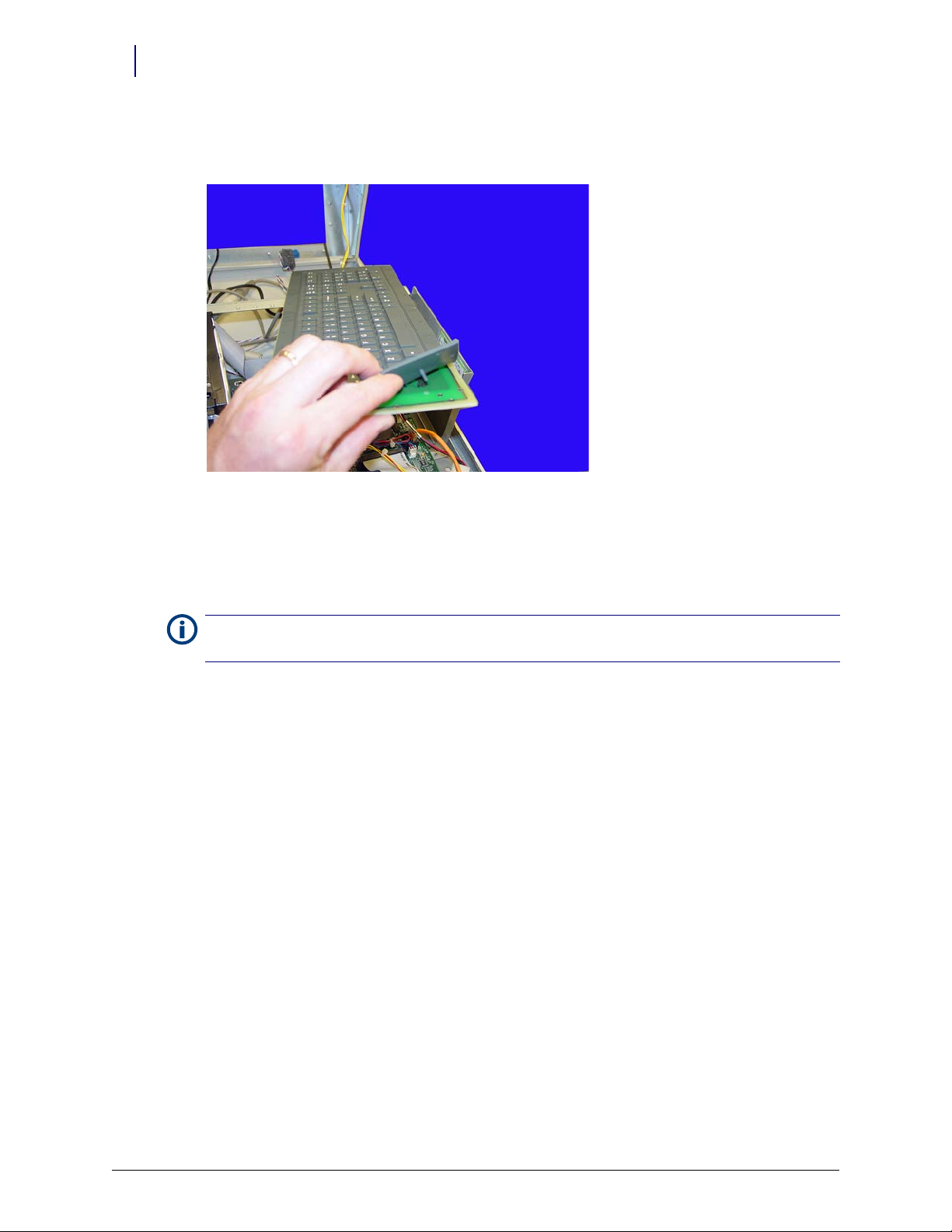

2. Remove the keyboard cover.

Figure 1-21. Remove the keyboard cover

3. Remove the keyboard from the tray.

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 16

1-12 Electronics Sled

Keyboard Service

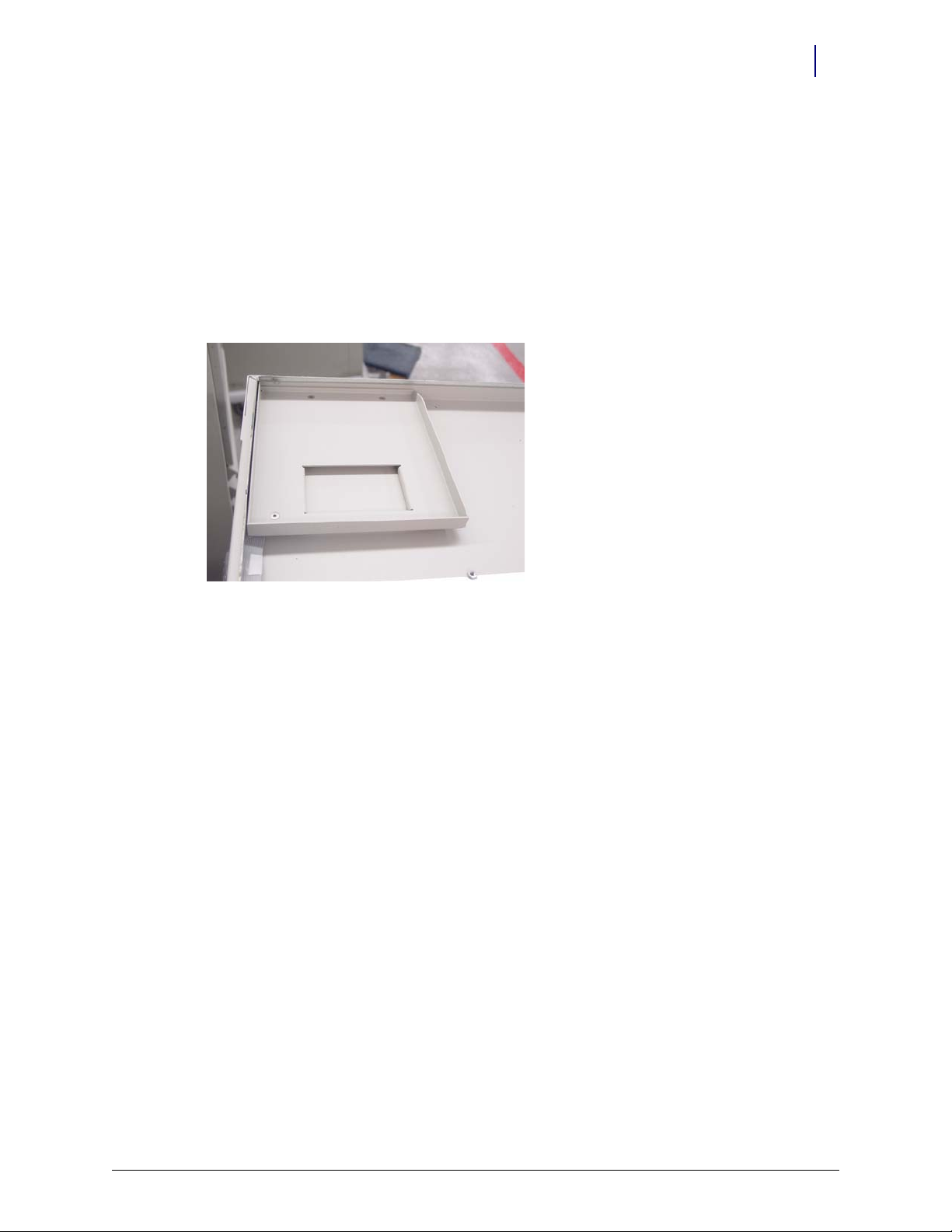

4. Hold the keypad with the elastomer facing up and gently pull the elastomer up and off the

Figure 1-22. Pull the elastomer up and off the keyboard

keyboard.

5. Gently place the new elastomer onto the keyboard and push the rubber tabs through the holes

on the keyboard.

6. Keeping the keypad upright, reach underneath the keyboard and gently pull the tabs until the

elastomer rests snugly on the keyboard.

To prevent ripples in the elastomer, pull the tabs through going left to right, right to left, bottom to top

Note:

or top to bottom. Do not pull the tabs through in a random order or in a circular pattern.

7. Remove any bubble or ripples in the elastomer and then place the new keypad and elastomer

back into place on the tray.

8. Replace the keyboard cover.

9. Replace the screws that secure the keyboard cover to the tray.

10. Set the console back in place, then prop it up.

11. Re-connect all the cables.

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 17

USB Keyboard

Electronics Sled 1-13

Keyboard Service

1. Disconnect the cables. The ribbon cable connects the numeric keypad with the keyboard. The

power cable connects the keyboard to the mother board.

2. Remove the 20 keyboard and keypad bracket nuts.

Figure 1-23. Keyboard and keypad bracket screws / cables

3. Remove the keyboard and keypad support bracket. Each contains a PC board and an overlay.

a. Separate parts and replace as needed.

Figure 1-24. Keyboard bracket, PC board, overlay and keypad bracket, PC board, overlay

b. Re-assemble the parts into the bracket.

4. Attach the bracket back on the console.

5. Attach the cables.

6. Set the console back in place, then prop it up.

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 18

1-14 Electronics Sled

PC Tray Upgrade

7. Re-connect all the cables.

PC Tray Upgrade

This section covers the replacement of the PowerCom2 tray with the PowerCom3 tray.

PowerCom2 Tray

1. Disconnect the LAN cable and the AUX cables from the rear of the electronics sled.

Figure 1-25. Location and labels for LAN and AUX cable connections on CT PC tray

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 19

2. Disconnect the following cables from the electronics tray:

a. LCD cable

b. Contrast cable

c. Inverter (backlight) cable

d. Touch screen cable

e. Keyboard cable

f. Speaker cable

g. Card reader cable (if applicable–not shown)

h. Fan power cable (if applicable)

i. Printer cable (free cable from any clips)

j. Cabinet power/comm cable

k. wireway cable

Electronics Sled 1-15

PC Tray Upgrade

Figure 1-26. Location of cables on the CT PC tray with PowerCom2 board

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 20

1-16 Electronics Sled

PC Tray Upgrade

3. Turn the two 1/4-turn fasteners securing the electronics sled counter-clockwise to unlock.

Figure 1-27. Lift and remove the CT PC tray

4. Lift and remove the PowerCom2 tray.

PowerCom3 Tray

1. Place the PowerCom3 tray into position inside the electronics sled.

2. Turn the two 1/4-turn fasteners securing the electronics tray clockwise to lock the tray into

place.

Figure 1-28. Place the CT PC tray into the OmniRx

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 21

3. Connect the wireway cable to the J10 of the PowerCom3 Board

.

Electronics Sled 1-17

PC Tray Upgrade

Figure 1-29. Connect the wireway cable to J10 of the PowerCom3 board

4. Connect the printer cable to J27 on the motherboard.

Figure 1-30. Connect the printer cable to J27 of the motherboard

Note:

Ensure that the red wire is connected closest to Pin 1.

5. Connect the fan power cable to J17 on the UPS board (if applicable).

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 22

1-18 Electronics Sled

PC Tray Upgrade

6. Connect the speaker cable to port J45 on the motherboard.

Figure 1-31. Connect the speaker cable to J45 of the motherboard

7. Connect the keyboard cable to port J42 on the motherboard.

Figure 1-32. Connect the keyboard cable to J42 of the motherboard

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 23

Electronics Sled 1-19

PC Tray Upgrade

8. Connect the touch screen data cable to J2 on the motherboard:

a. Connect the extension cable provided in the kit to the touch screen data cable (red wire to

red wire).

b. Wrap the joined connectors with electrical tape to ensure that the cables do not become

disconnected.

c. Connect the touch screen data cable extension to J2 on the motherboard.

Figure 1-33. Connect the touch screen data cable to J2 of the motherboard

9. Connect the inverter cable (backlight) to J32 on the motherboard.

Figure 1-34. Connect the backlight cable to J32 of the motherboard

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 24

1-20 Electronics Sled

PC Tray Upgrade

10. Connect the contrast cable to J31 on the motherboard.

Figure 1-35. Connect the contrast cable to J31 of the motherboard

11. Connect the LCD data cable to J37 on the motherboard

Figure 1-36. Connect the LCD data cable to J37 of the motherboard

12. If a card reader is present and needs to be reconnected:

a. Connect the card reader serial cable to J47 on the motherboard.

b. Connect the card reader power cable to the back of the card reader serial connector.

c. Insert card reader power cable pins into the disk drive power connector.

d. Align the red-stripe pin to the red cable and the gray-stripe pin to the gray cable in next

spot.

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 25

Standardization Changes

To standardize the peripherals that Omnicell products use, the Seiko printer and PS/2 keyboards

are being replaced by APS printers and USB keyboards with a numeric pad. The console is

swapped out in this procedure.

1. Lift and prop-up the console if it is not already open.

2. Disconnect all console cables.

3. Remove the console.

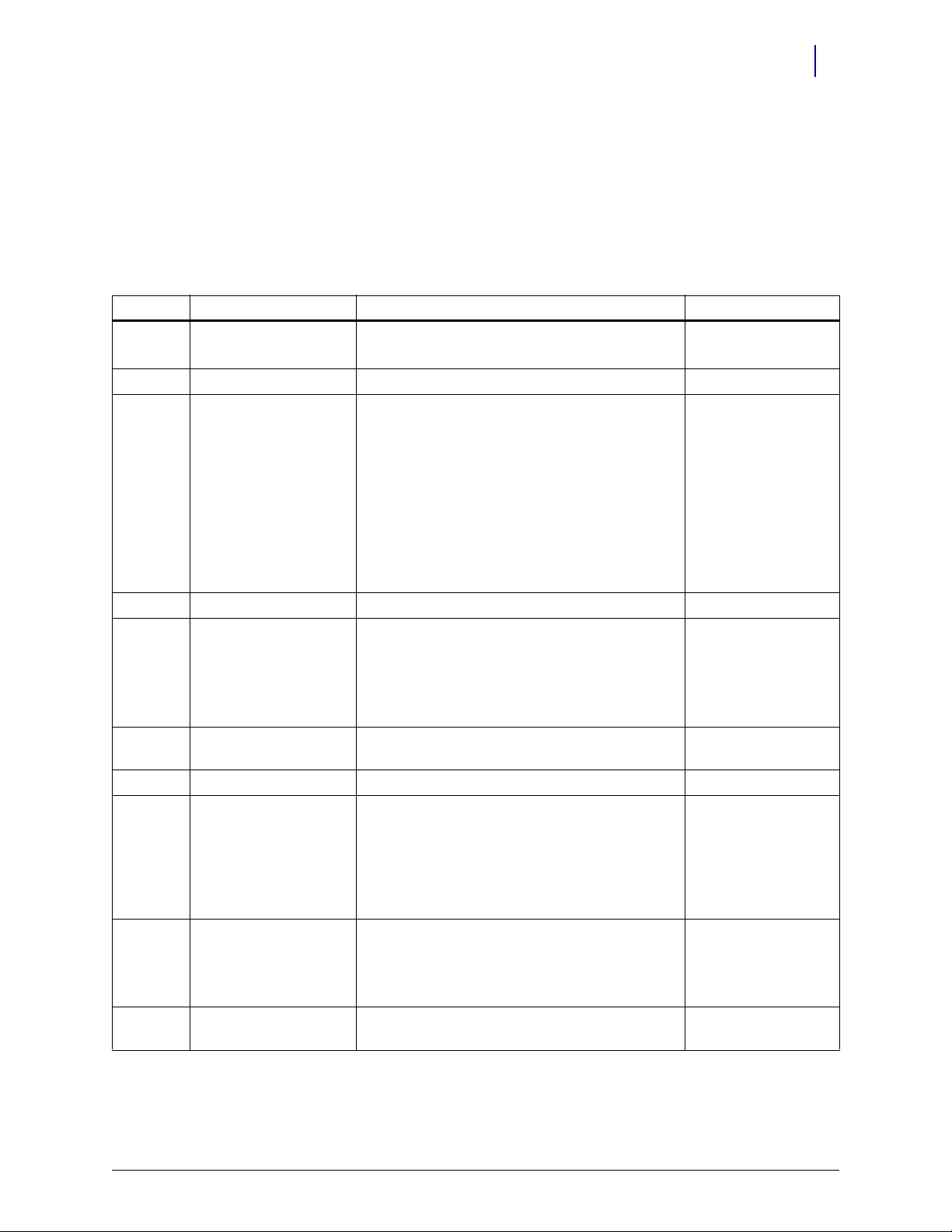

4. Replace the cable cover bracket with the new, wider one using three screws.

Electronics Sled 1-21

Standardization Changes

Final Steps

Figure 1-37. Cable cover bracket

5. Place new console into position, then prop it open.

6. Re-connect the cables. Most will go back where the old cables were with a couple of exceptions.

The contrast cable goes into J33 instead of J32.

The USB keyboard cable goes to the USB port (vs. the PS/2 connection).

Move the jumper on JP1 from pins 1-2 to 3-4.

After the service is performed, return the OmniRx to production status.

1. Lift and prop-up the console if it is not already open.

2. Re-connect the battery cable.

3. Close and lock the console.

4. Plug in the power cable, then restart the OmniRx.

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 26

1-22 Electronics Sled

Final Steps

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 27

Frames and Wireways

Wireway Removal

Important: A Pharmacist must be present when servicing drawers where medications are present.

1. Perform a graceful shutdown of the OmniRx. Refer to “General Shutdown” on page 1-1.

2. Unlock the two locks on the manual override cover with the #2202, 2232 keys.

3. Slide the cover to the right and remove the cover.

4. Remove all the drawers from the OmniRx. See “Pharmacy Drawer Removal” on page 3-8.

2-1

Figure 2-1. Remove the drawers from the OmniRx

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 28

2-2 Frames and Wireways

Wireway Removal

5. Remove all drawer slides by removing the two screws that secure the slide and slide mount

bracket to the frame.

Figure 2-2. Remove the drawer rails

6. Remove the two screws on the front of the frame that help secure the wireway.

Figure 2-3. Remove the two wireway screws on the front of the OmniRx

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 29

7. Remove the four screws on the side of the frame that secure the wireway.

Frames and Wireways 2-3

Wireway Removal

Figure 2-4. Remove the wireway screws on the side of the OmniRx

8. Pull the wireway far enough from the frame to access the SPC board connectors.

9. Disconnect the cables on top and bottom that connect the SPC board to the wireway.

Figure 2-5. Remove the ribbon cable and remove the SPC board from the wireway

10. Remove the SPC board from the wireway.

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 30

2-4 Frames and Wireways

Manual Override Cable Service

Manual Override Cable Service

Removal

1. Perform a graceful shutdown of the electronics sled.

2. Remove the manual override cover.

3. Remove all three drawers from the OmniRx. See “Pharmacy Drawer Removal” on page 3-8.

4. Open the printer cover.

5. Push the platen lever to the left to release the paper.

6. Open the lid to the electronics tray.

7. Remove the thermal printer paper and spool.

8. Remove the electronics tray. See “PC Tray Upgrade” on page 1-14.

9. Remove the four screws that secure the cable cover bracket.

Figure 2-6. Remove the four screws that secure the cable cover bracket to the frame

10. Remove the bracket.

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 31

11. Remove the two screws that secure the manual override cable.

Figure 2-7. Remove the two screws that secure the manual override cable to the frame

Frames and Wireways 2-5

Manual Override Cable Service

12. Remove the red handle on the front of the manual override cable.

Figure 2-8. Remove the red handle on the manual override cable

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 32

2-6 Frames and Wireways

Manual Override Cable Service

13. Remove the nut that secures the manual override cable to the front of the frame.

Figure 2-9. Remove the nut that secures the manual override cable to the frame.

14. Remove the screw that secures the manual override cable to the manual override assembly.

Figure 2-10. Remove the screw that secures the manual override cable to the frame

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 33

15. Loosen the nut that secures the cable to the back of the frame.

Figure 2-11. Loosen the nut that secures the cable to the frame anchor

Frames and Wireways 2-7

Manual Override Cable Service

Replacement

16. Pull the cable from the anchor on the back of the frame.

17. Pull the cable out from inside the OmniRx cabinet.

1. Feed the cable into the OmniRx cabinet.

2. Replace the screw that secures the manual override cable to the manual override assembly.

3. Place the manual override cable into the frame anchor so that the two screws are on opposite

side of the anchor bracket.

4. Tighten the screws.

5. Feed the front of the manual override cable through the hole on the front of the OmniRx

cabinet.

6. Replace the nut that secures the cable to the frame.

7. Replace the red handle.

8. Replace the two screws that secure the manual override cable to the inside of the front of the

frame.

9. Replace the printer support bracket.

10. Replace the thermal printer paper and the spool.

11. Replace the electronics sled and reattach all cables that had been removed.

12. Close the lid to the electronics tray.

13. Feed the printer paper through the printer.

14. Power up the OmniRx cabinet.

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 34

2-8 Frames and Wireways

Manual Override Cable Service

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 35

Overview

Drawers 3-1

Overview

Drawers

There are a variety of drawers available for the half-cell cabinets, offering different levels of control

for storing and tracking medications and pharmacy supplies.

The supply drawer provides low level security. It is typically used to store items that are frequently

used and require little security. The drawer is custom configured using individual dividers and has

a 24-line maximum capacity.

The Omnicell matrix drawer models have no lids, but are configured with dividers. Drawer liners

are used to configure matrix drawers to the required number of bins. The matrix drawers may or

may not be lit with guiding light technology.

Lit matrix drawers can be configured for 24 bins maximum. Unlit matrix drawers can be

configured for 96 bins maximum. The drawers are separated into four equal quadrants. Unlit

drawer quadrants contain up to 24 bins. Lit matrix drawer quadrants contain up to six bins.

Omnicell sensing lid drawers provide medium security. The system senses and records access to

the bins when a lid is lifted. These drawers are used to contain controlled substances.

Omnicell locking lid drawers provide the highest security. Users can only access one bin at a time

which contains the pre-selected medication. All other bin lids remain locked. Special censors

generate audible and visual feedback if entry is attempted into bins that are not pre-selected.

Tools List

The following tools are required to service a standard drawer:

T10 Torx Driver

T15 Torx Driver

2-sided tape

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 36

3-2 Drawers

Matrix Drawers

Matrix Drawers

Bin Configuration

Unlit Matrix Drawers

Each unlit matrix drawer can contain a maximum of 96 bins (24 per quadrant). Customers can

utilize the flexibility of this drawer and custom-configure it to meet specific needs and

requirements for the site. As with other matrix drawers, the dividers are designed to be snapped

off, enabling the bins to be custom-configured to fit site-specific needs.

Figure 3-1. Matrix drawer dividers

Dividers must be placed into the drawer in a specific order with each divider in a specific slot, so

Note:

separating the dividers by part number is recommended.

1. Make sure the customer has approved the layout of each drawer.

Note: It is recommended that a drawing be made of each drawer, showing the customer’s preferred

configuration for each quadrant of a given drawer.

2. Break the divider tabs according to the customer design and trim away excess plastic to ensure

a snug fit in the drawer.

3. Add the dividers to the bin liner. The dividers should snap into the bottom of the drawer and

the sides of each bin liner quadrant.

4. Use the gray circular labels provided with the kit to cover any un-used divider slots in the bin

liner.

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 37

Drawers 3-3

Matrix Drawers

Lit Matrix Drawers

Each lit matrix drawer can contain a maximum of 24 bins (six per quadrant). Customers can

utilize the flexibility of this drawer and custom-configure it to meet specific needs and

requirements for the site. As with other matrix drawers, the dividers are designed to be snapped

off, enabling the bins to be custom-configured to fit site-specific needs.

Dividers must be placed into the drawer in a specific order with each divider in a specific slot, so

Note:

separating the dividers by part number is recommended.

Figure 3-2. Lit matrix drawer

1. Make sure the customer has approved the layout of each drawer.

Note: It is recommended that a drawing be made of each drawer, showing the customer’s preferred

configuration for each quadrant of a given drawer.

2. Break the divider tabs according to the customer design and trim away excess plastic to ensure

a snug fit in the drawer.

3. Add the dividers to the bin liner. The dividers should snap into the bottom of the drawer and

the sides of each bin liner quadrant.

4. Use the gray circular labels provided with the kit to cover any un-used divider slots in the bin

liner.

5. Insert the light pipes into each notch provided in the dividers. The light pipe is installed on the

rear side of the bin divider and snaps into a slot on the bottom of the bin liner.

Note: Be sure to place a light pipe into every notch, even if the position will not be used for guiding light

purposes. The pipes provide support and help keep the dividers in place.

Double-Deep Matrix Drawer

The installation of a double deep 4-bin matrix drawer (OMD4) is the same a regular double deep

drawer. The OMD4 can replace an existing double deep drawer or it would replace two single

deep drawers.

1. Perform a graceful shutdown of the electronic sled.

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 38

3-4 Drawers

Matrix Drawers

2. Remove the existing double deep drawer, two existing drawers, two false drawer fronts or a

combination of drawer and false fronts that would take up two adjoining drawer spaces.

If two single deep drawers are removed, the lower set of slide mount brackets must be removed from

Note:

inside the carrier before continuing.

3. Insert the bin liner into the drawer, with the side numbered

4. Insert the right/left bin divider into the bin liner.

5. Insert the front/rear bin divider into the bin liner.

6. Connect the drawer cable and insert the drawer into the carrier.

Matrix Drawers Labels

Numerical bin labels are provided with matrix drawers to make bin identification and restock

easier for the customer.

1 and 2 facing the front.

Figure 3-3. Matrix drawer labelling system

The bottom of the bin liner on any matrix drawer is numbered according to its type (i.e. 1-96, 124, 1-4). These numbers are used to identify bin locations for the drawer. The drawer will be

numbered by using the lowest number in a specific bin.

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 39

In Figure 3-3, the bin in the lower right corner of the drawer would be Bin 7, the bin in the upper

left corner would be Bin 49, and the bin in the upper right corner would be Bin 85.

Once a bin has been configured, label the bin divider to correspond with the bin name corner. and

affix the label to the top of the right rear divider of that bin.

Supply Drawer Installation

1. Perform a graceful shutdown of the electronic sled.

2. Open the door in the zone where the supply drawer will be located.

3. Slide the two drawer brackets into the slots in the back of the frame.

4. Secure the slide mounting bracket to the frame with the screw provided. Use a Torx T15

screwdriver to tighten the screw.

5. Slide the supply drawer and housing onto the brackets until the drawer snaps into the latching

tabs located on the back of the bracket.

6. Connect the SPC board cable to the 10-pin connector on the rear of the SPC board in the

wireway of the frame.

7. Use a Torx T15 screwdriver to insert two screws - one on either side of the bottom of the

drawer - to secure the supply drawer to the drawer brackets.

8. Insert the switchpanel connector cover into the hole in the frame.

9. Set the DIP switches for the shelf and the zone settings. There are two DIP switches: The first

DIP switch (S1) sets the drawer zone and the second DIP switch (S2)sets the drawer location.

Drawers 3-5

Supply Drawer Installation

Note:

On switch S1, switch #8 must always be off for a supply drawer SPC.

Pharmacy Drawer Installation

Important: A Pharmacist must be present when servicing drawers where medications are present.

1. Unlock the manual override cover using the #2302 and 2232 keys.

2. Remove the cover by pushing it to the right and lifting it off.

3. Remove any false drawer front by removing the two screws securing the false drawer front

using a Torx T15 screwdriver.

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 40

3-6 Drawers

Pharmacy Drawer Installation

Note:

Figure 3-4. Remove the screws securing the false drawer front

Keep the screws securing the false drawer front. They will be used later in the procedure.

4. Remove the slide mounting bracket.

Figure 3-5. Remove the slide support bracket

5. Connect the drawer cable to the drawer connect board.

6. Use a piece of double-sided tape to attach the cable clamp to the drawer cable.

7. Line up the tape to the edges of the clamp and secure the clamp to the carrier with two screws

using a Torx T15 screwdriver.

8. Connect a slide to the left side of the carrier with the three screws provided using a Torx T15

screwdriver.

9. Connect the drawer controller cable to the drawer controller board at the rear end of the

drawer.

10. Replace the slide to the slide mounting bracket with three screws using a Torx T15 screwdriver.

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 41

11. Install the slide support bracket with slide attached.

Figure 3-6. Install the New Slide Support Bracket

Drawers 3-7

Pharmacy Drawer Installation

Note:

The washers must be used. They ensure that the screw threads do not protrude into the cable path.

12. Place the drawer controller cable between the two ends of the drawer controller cable clamp.

13. Secure the pharmacy drawer controller cable clamp and the drawer controller cable to the

pharmacy drawer. Use the two screws provided with a Torx T10 screwdriver.

14. Close the drawer and replace the pharmacy manual override cover.

15. Power up the cabinet.

16. Program the drawer at the OmniSupplier in Omni Configurations.

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 42

3-8 Drawers

Pharmacy Drawer Removal

Pharmacy Drawer Removal

1. Perform a graceful shutdown of the electronic sled.

2. Unlock the manual override cover using the #2202 and 2232 keys.

3. Remove the cover by pushing it to the right and lifting it off.

Figure 3-7. Remove the Manual Override Cover

4. Pull the manual override lever and open the desired pharmacy drawer.

5. Remove the two screws securing the drawer controller cable cover to the cable clamps using a

Torx T10 screwdriver.

Figure 3-8. Remove the Controller Cable Cover

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 43

6. Remove the cable clamp and disconnect the drawer cable.

Figure 3-9. Remove the Controller Cable

Drawers 3-9

Pharmacy Drawer Removal

7. Push the release levers on either side of the drawer up or down to release the drawer.

Figure 3-10. Push the Release Levers to Release the Drawer

8. Remove the pharmacy drawer from the module.

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 44

3-10 Drawers

Pharmacy Drawer Removal

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 45

Appendix A: Part List

Link back to the procedure that calls out the given part using the cross reference in the Where Used

column.

Part # Part Name Agile Description Where Used

12-3102

12-3113

13-1128-58 PowerCom2 tray MFG ASSY,CT PC BOX,W/PTR, 5.8 XP ETX CE [inactive]

13-1129

13-1142

13-1136

13-1143

13-1150

13-1152

13-1151

13-1153

14-1122 keyboard MFG,ASSY,KEYBOARD/LCD,W/PTR OMNIRX

14-1123

14-1291

14-1261 LCD assembly MFG ASSY, DISPLAY,ETX-REVC,LVDS,RX-CT

14-2040 PowerCom3 tray ELECTRONICS TRAY,ETX2,5.10.1.9,ANESTHESIA

14-7008

14-7009

14-7013

14-7015

14-7016

14-7021 double-deep matrix drawer

15-7020 false drawer front MFG,ASSY,DRAWER,FRONT,DUMMY RX2

supply drawer DRAWER ASSY,SUPPLY,OSD24,GREEN BUTTONS

DRAWER ASSY,SUPPLY,OSD24,BLUE BUTTONS

console MFG ASSY, LID, ETX, LVDS, RX-CT (old)

MFG ASSY, LID, LVDS, RX-CT, MOBILE CART (old)

MFG ASSY,LID W/O PTR,CE (old)

MFG ASSY, LID W/O PTR, MOBILE CART (old)

MFG ASSY, LID, ETX, LVDS, RX-CT (new)

MFG ASSY, LID, LVDS, RX-CT, MOBILE CART (new)

MFG ASSY,LID W/O APS PTR,CE (new)

MFG ASSY, LID W/O APS PTR, MOBILE CART (new)

printer, printer assembly

(printer) ribbon cable

[hard wired to printer, same P/N

as printer]

pharmacy drawer MODEL,OLL6,LARGE,LOCKING DRAWER,RX2

bin labels [comes with drawer]

MFG,ASSY,PRINTER,OMNIRX (old)

MFG ASSY,APS PRINTER,OMNIRX (new)

MODEL,OSL6,LARGE,SENSING DRAWER,RX2

MODEL,OSL12,REGULAR,SENSING DRAWER,RX2

MODEL,OSL24,24-BIN,SENSING DRAWER,RX2

MODEL,OLMD24,24-LIT,MATRIX MATRIX,DRAWER

MODEL OMD4,4-BIN MATRIX DRAWER,UNLIT

Supply Drawer

Installation

PC Tray Upgrade

Keyboard Service

Standardization

Changes

PS/2 Keyboard

Seiko Printer

APS Printer

LCD Screen

Removal

PC Tray Upgrade

Pharmacy Drawer

Installation

Double-Deep

Matrix Drawer

Matrix Drawers

Labels

Pharmacy Drawer

Installation

A-1

Table A-1. OmniRx Part List

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 46

A-2 Appendix A: Part List

Part # Part Name Agile Description Where Used

15-7075

15-7076

40-1045

71-7008

40-7035 wireway cable PCB ASSY,RX,DRAWER,CONNECT OMNIRX

41-1034 keyboard PCB PCB,KEYBOARD,QWERTY,USB KB,PS/2 MSE,84-KEY,CTPC

41-1035 keypad PCB PCB,KEYBOARD,NUMERIC,USB KB,PS/2 MSE,23-KEY,CTPC

41-7009 (wireway) SPC Board PCB,RX,DRAWER,CONNECT RX

42-1185 cabinet power cable CABLE,ASSY,POWER,SWITCH

42-1204 card reader cable CABLE,ASSY,POWER,CARD,READER CT,PC,BOX

42-1210 fan power cable CABLE,ASSY,FAN RETROFIT COOLING,OMNIRX

42-1229 flat panel cable; LCD data cable CABLE ASSY, LVDS LCD DISPLAY

divider (kit) KIT,DIVIDER,24-BIN,LIT,MATRIX

KIT,DIVIDER,4/96,BIN,UNLIT,MTR

PC card PCBA, PRINTER INTERFACE, APS

PCB ASSY,PRINTER,RIGHT ANGLE SHROUDED CONN (Seiko)

Bin Configuration

Seiko Printer

APS Printer

PowerCom2 Tray

USB Keyboard

USB Keyboard

Wire way R emo val

PowerCom2 Tray

PowerCom2 Tray

PowerCom2 Tray

LCD Screen

Removal

42-1232 battery cable CABLE,ASSY,BATTERY,18V,UPS,CT PC BOX,POWERCOM3

42-1302-02 [USB keyboard] power cable CABLE,ASSY,USB KEYBOARD,QWERT Y TO MOTHERBOARD,STD,CTPC

42-1304 (printer) power cable CABLE ASSY, POWER, APS PTR, CT PC BOX

42-1307 [keypad/keyboard] ribbon cable CABLE ASSY,NUMERIC TO KEYBD, OMNIRX/TT

42-2101 SPC board cable CABLE,ASSY,DRAWER,CONTROLLER TO,SPC

General Shutdown

USB Keyboard

APS Printer

USB Keyboard

Supply Drawer

Installation

42-7030 drawer cable CABLE,ASSY,DRAWER,OMNIRX

Pharmacy Drawer

Removal

42-7061 touch screen cable CABLE,ASSY,TOUCH,PAD,DATA ANESTHESIA

42-7087 contrast cable CABLE ASSEMBLY, POTENTIOMETER, OMNIRX

42-7088-12

42-7096-12

42-7092 inverter cable CABLE ASSY,ETX-REV C TO INVERTER,121PW181,RX

data cable

(sensors hard wired to printer)

CABLE ASSY,PRINTER,48" (Seiko)

CABLE ASSY, PRINTER, 34 PIN, 48" (APS)

PowerCom2 Tray

PowerCom2 Tray

Seiko Printer

APS Printer

LCD Screen

Removal

51-2064 manual override handle KNOB,PULL,MANUAL,OVERRIDE OMNIRX

Manual Override

Cable Service

51-7025 manual override cable CABLE,MANUAL OVERRIDE,OMNIRX

Manual Override

Cable Service

53-2081

53-7289

cable cover bracket COVER,CABLE,OMNIRX [old]

COVER,CABLE,OMNIRX [new]

Standardization

Changes

Manual Override

Cable Service

53-1082 keyboard cover BKT,COVER,KEYBD,OMNIRX

53-1105 LCD bezel BEZEL, NEC LVDS LCD DISPLAY

PS/2 Keyboard

LCD Screen

Removal

53-2078 wireway WIREWAY,OMNIRX

Wire way R emo val

Table A-1. OmniRx Part List

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 47

Appendix A: Part List A-3

Part # Part Name Agile Description Where Used

53-2081 drawer controller cable cover COVER,CABLE,OMNIRX

Pharmacy Drawer

Removal

53-2082 manual override cover COVER,MANUAL,OVERRIDE,OMNIRX

Wire way R emo val

Pharmacy Drawer

Installation

Pharmacy Drawer

Removal

53-7104

53-7123

slide mounting bracket BRACKET,SLIDE,MOUNT,OMNIRX

BRACKET,SLIDE,MOUNT,MAN. OVERRIDE,ATTACH

Wire way R emo val

Supply Drawer

Installation

Pharmacy Drawer

Installation

53-7106 cable clamp CABLE,CLAMP,SLIDE,MOUNT,OMNIRX

Pharmacy Drawer

Installation

Pharmacy Drawer

Removal

53-7128 override lever LEVER,MANUAL OVERRIDE RELEASE,3-DRAWER CARRIER

Pharmacy Drawer

Removal

53-7286 keyboard support bracket BRACKET,MOUNTING,KEYBOARD,OMNIRX

53-7288 keypad support bracket BRACKET,MOUNTING,NUMERIC KEYPAD,OMNIRX

57-7231 light pipe LIGHT PIPE, 2222, 3131,96 SDD

57-7035

57-7046

70-7000

70-7002

71-1145 elastomer OVERLAY, ELASTOMER, QWERTY, ENGLISH, CTPC

71-1188 keypad overlay OVERLAY,ELASTOMER,KEYPAD,LOW PROFILE,NUMERIC,GREY

71-1189 keyboard overlay OVERLAY,ELASTOMER,QWERTY, LOW PROFILE, ENGLISH

71-3001

71-3008

73-1001 speaker SPEAKER, 2.5", 8 OHM, 2W

80-0374 DIP switch SW,DIP,8-POS,SL,SPST,VERT,TH

bin liner LINER,MATRIX,96-BIN,RX

LINER,MATRIX,4-BIN,RX,VACUUM FORMED

(printer) ribbon cable

(flex cable hard wired to printer)

switchpanel connector cover SWITCHPANEL,DRAWER,GREEN

PRINTER,THERMAL,SEIKO LTP3345A-S576

PRINTER, THERMAL, APS CP305-80MM-BL-OMN

SWITCHPANEL,DRAWER,BLUE

USB Keyboard

USB Keyboard

Lit Matrix Drawers

Double-Deep

Matrix Drawer

Seiko Printer

APS Printer

PS/2 Keyboard

USB Keyboard

USB Keyboard

Supply Drawer

Installation

Speaker Removal

Supply Drawer

Installation

80-0802 speaker cable CONN,CABLE ASSY,MOLDED PLUG,3.5MM STEREO,SHL'D,PVC,36IN

82-6061 jumper JUMPER,SHUNT,0.1",15AU,RED

Speaker Removal

Standardization

Changes

91-7040 drawer slide SLIDE,OUTER HALF, DRAWER,RX,ACCURIDE C3834-156-1 [right side]

Wire way R emo val

Table A-1. OmniRx Part List

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 48

A-4 Appendix A: Part List

Part # Part Name Agile Description Where Used

92-1000

92-1002

92-1011

key CAM LOCK,#2036 [lid]

CAM LOCK,#2202 [manual ovveride cover]

CAM LOCK,#2232 [manual ovveride cover]

General Shutdown

Wire way R emo val

Pharmacy Drawer

Installation

Pharmacy Drawer

Removal

94-6005 (keyboard cover) nut NUT,HEX,4-40,SS

PS/2 Keyboard

USB Keyboard

94-6132 (supply drawer) screw

(drawer controller cable cover)

screw

SCREW,BH,TORX,8-32,X,3/16,SS

Supply Drawer

Installation

Pharmacy Drawer

Removal

94-6133 (slide mounting screw

(wireway) screw [front, side]

(manual override assembly)

screw

(clamp) screw

94-6137 (speaker) screw SCREW,BH,TORX,6-32,X,3/16,SS

94-6142 (manual override cable) screw SCREW,BH,TORX,4-40,X,1/4,SS

SCREW,BH,TORX,8-32,X,1/4,SS

Wire way R emo val

Pharmacy Drawer

Installation

Manual Override

Cable Service

Speaker Removal

Manual Override

Cable Service

94-6162 (LCD bezel) screw

(printer cover) screw

(printer assembly) screw

(console) screw

(cable cover bracket) screw

SCREW,FH,TORX,6-32,X,3/16,100,DEG,C'SINK

LCD Screen

Removal

Seiko Printer

APS Printer

Manual Override

Cable Service

Standardization

Changes

94-6165 (false drawer front) screw SCREW,BH,TORX,8-32,X,3/8,SS

Pharmacy Drawer

Installation

94-6167 (manual override cable) nut NUT,EX,SMALL,HEX,10-32,1/4,X 3/32,SS

Manual Override

Cable Service

94-6170 (electronics sled) fastener STUD,1/4,TURN,WING,HD,SOUTHCO

94-6173 (PC card) screw SCREW,SHCS,4-40,X,3/16,SS

PowerCom2 Tray

Seiko Printer

APS Printer

95-6015 paper PAPER,THERMAL,92M ROLL,80MM WIDE

Seiko Printer

APS Printer

Table A-1. OmniRx Part List

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 49

Index

IN-1

A

APS printer 1-7

AUX cables 1-14

B

bin configuration 3-2

bin liner 3-4

bracket 3-5

C

cable clamp 3-6, 3-9

cables 1-15

controller cable clamp 3-7

D

dividers 3-2

drawer controller cable 3-6, 3-7

drawer controller cable cover 3-8

drawer rails 2-2

drawers 3-1

E

elastomer 1-12

electronics sled 1-1

F

false drawer front 3-5

false drawer front 3-4

fan 1-17

K

keyboard 1-10

L

labels 3-4

LAN cable 1-14

LCD screen 1-2

locking lid drawers 3-1

matrix drawer 3-1

O

OMD4 3-3

P

PowerCom2 tray 1-14

PowerCom3 tray 1-16

printer 1-4

PS/2 keyboard 1-11

R

release levers 3-9

S

Seiko printer

sensing lid drawers 3-1

slide 3-6

slide support bracket 3-7

SPC board cable 3-5

speaker 1-3

supply drawer 3-1, 3-5

switchpanel connector 3-5

T

tools 1-1, 3-1

top module 1-21

U

USB printer 1-13

W

wireway 2-1

M

manual override assembly 2-6

manual override cable 2-4

manual override cover 2-1, 3-5, 3-8

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 50

IN-2 Index

OmniRx Service Guide/67-2023 Rev D © 2010 Omnicell, Inc.

Page 51

Documentation Feedback

This document is designed to provide relevant technical information to those responsible for the

implementation, service, and support of Omnicell products. The Documentation team needs your

input, so we can continue to improve our publications.

Sending Comments to the Technical Documentation Team

Did this document meet your needs? If so, please let us know what we’re doing right. If not, please

provide specific feedback. E-mail or fax your feedback as follows:

E-mail: Documentation Requests e-mail group at documentationrequests@omnicell.com (specify the

document title or PN).

Fax: Send this page, along with your feedback, to (650) 251-6266, attention: Documentation.

This document is designed to provide relevant technical information to Omnicell personnel

responsible for the implementation, service, and support of Omnicell Automation Systems.

Feedback Form

Name: E-mail:

Dept./Title: Phone:

Feed back:

© 2010 Omnicell, Inc. OmniRx Service Guide/67-2023 Rev D

Page 52

Loading...

Loading...