Page 1

OmniDispenser

Technical

Guide

60-3007 Rev G

Includes hardware,

software, and

implementation steps

Page 2

This guide is CONFIDENTIAL and designed only for Omnicell Technical personnel and/or designated

representatives.

This guide and accompanying software and/or hardware described in it are protected under copyright laws and may

not be copied, wholly or in part, without the express written consent of Omnicell, Inc. The same proprietary and

copyright notices must be attached to any permitted copies as were attached to the original documents.

Omnicell, Inc.

1201 Charleston Road

Mountain View, CA 94043

(650) 251-6100

www.omnicell.com

Omnicell and the Omnicell design mark, OmniBuyer, OmniCenter, OmniRx, OmniSupplier, SafetyMed, SafetyPak,

SafetyStock, and Sure-Med are registered trademarks. Anesthesia TT, Anesthesia Workstation, Anywhere RN,

Executive Advisor, Flexbin, Medication Surveillance, OmniDispenser, OmniLinkRx, OmniScanner, OmniTrack,

Omni TT, Open Touch, OptiFlex, OptiFlex MobileTrack, Point-to-Point Medication Safety, SecureVault, See & Touch,

SinglePointe, TempCheck, Touch & Go, VSuite, and WorkflowRx are trademarks of Omnicell, Inc. in the United States

and internationally. All other trademarks and trade names are the property of their respective owners

Copyright 2009-2012 Omnicell, Inc. All rights reserved.

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 3

iii

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Competitive Advantages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Technical Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Dispense Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Restock Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Restock Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Rail Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Rails (Fixed and Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Dispensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Drawer Type and Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Module Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

ODMTall and ODMPlus3 Placement Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

ODMRx Placement Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Rail Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Options/Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Automatic Rail Configuration Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Communication with OmniCenter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Dispenser Configuration Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Addressing Scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Location Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Dispensing Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Dispense Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Multiple OmniDispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

FIFO for Multiple Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Dispense Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Dispense Transactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Returning Medications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Time-out Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Please Open Dispense Drawer Time-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Please Open Restock Door Time-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Forced Entry Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Inactive Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

EEPROM Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 4

iv Table of Contents

Software Functional Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Automatic Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Color Touch Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Restock Door Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Dispenser Drawer Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Dispenser Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Dispense Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Empty Dispenser Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Reset Wireway and Module Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Internal Bus Communications Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Dispense Setup Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Firmware Revision Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Emitter Full Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Check Stuck Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Emitter Bank Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Normal Restock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Supplemental Restock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Destock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Cycle Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Expiration/Recall. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Modify Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Select a Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Assigning an Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Replacing an Item Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Deleting an Item Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Unassigning All Bins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Setting Bin Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Countback Always Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

OmniCenter Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

User Access to Restock Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Pharmacy Drawer Configuration Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Dispensing Error Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

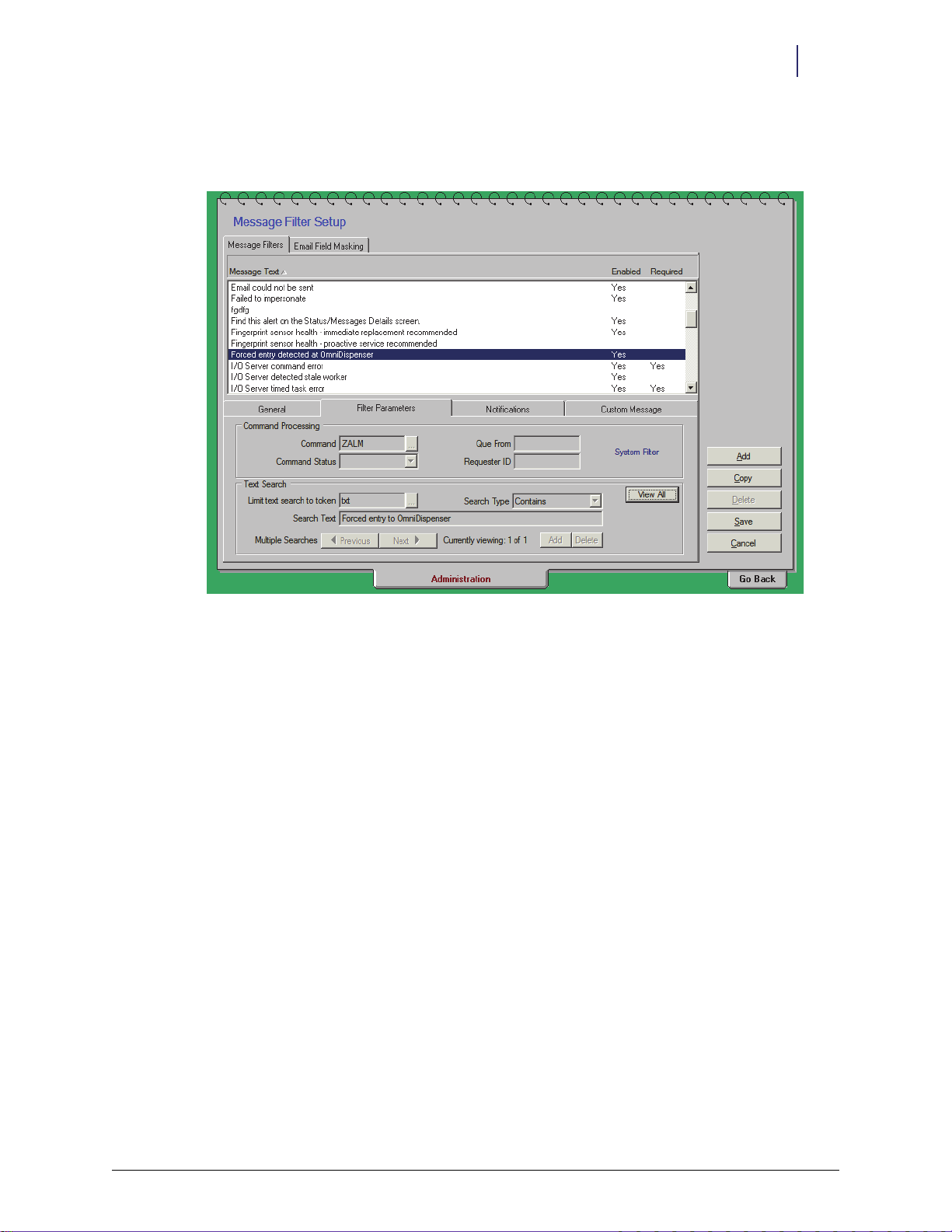

Message Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Forced Entry Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Message Filter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Configuring Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Install a Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Remove a Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Adjusting Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Installing Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Labeling Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 5

Table of Contents v

Loading Dispensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Oral Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Select a Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Loading the Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Syringes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Vials and Ampules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Selecting a Vial/Ampule Cassette or Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Loading a Vial/Ampule Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Loading a Vial/Ampule Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Configuring Cabinet Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Programing the OmniDispenser’s Pharmacy Drawers . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Cabinet Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Countback Always Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

FIFO Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Time-out Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Assigning Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Enabling User Access to Restock Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Field Service Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Replacing the Rail Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Access the OmniDispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Remove the Rail Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Install the New Rail Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Replacing/Adding/Removing Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Access the OmniDispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Remove Rails (B-E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Replace Rails (B-E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Add Optional Rails (B and E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Replacing the Restock Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Access the OmniDispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Remove the Restock Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Install the New Restock Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Replacing the Dispense Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Access the OmniDispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Remove the Dispense Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Install the New Dispense Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Replacing the Dispense Drawer Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Access the OmniDispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Remove the Drawer Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Install the New Drawer Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Install the Dispense Drawer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Replacing the Top Crossbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Access the OmniDispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Remove the Top Cross Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Install the New Cross Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 6

vi Table of Contents

Replacing the Rail Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

Access the OmniDispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

Remove the Rail Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Install the New Rail Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

Replacing the Carrier Controller Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

Access the OmniDispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

Remove the Carrier Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

Install the New Carrier Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

Field Replaceable Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glossary-1

Appendix A: Dispenser and Cassette Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Dispenser List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

5 ML Ampule Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

5 ML Vial Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Small Cassette Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Slim-Pak Dispenser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Double Cassette Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

ATC / 1ML / 2ML Cassette Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Cassette List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Order Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Dispensers/Cassettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Appendix B: Cassette Sizing Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Sizing Tool Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Oral Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Example: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

ATC or Strip Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Example: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Vials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Sizing Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Appendix C: Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Dispensing Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Loading Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Oral Solid Cassettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Vial/Ampule Cassettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

5ml Vial/Ampule Dispensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Syringe Dispensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

User Access Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 7

Table of Contents vii

Hardware Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

First Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Interpreting LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Rail Front LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Rail Controller Board LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Carrier Controller Board LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Diagnostic Results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Internal Bus Communication Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Dispense Setup Diagnostic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Firmware Revision Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

Emitter Full and Emitter Bank Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-11

OmniDispenser Module Communications Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . C-12

Appendix D: Medication to Cassette List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Dispenser/Cassette List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Oral Solid Medication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Injectable Medication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Non-Narcotic Medication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Appendix E: Part List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Index 1

Feedback Form. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

We Want to Hear From You . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

We need your input! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 8

viii Table of Contents

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 9

Introduction

About This Guide

This guide provides comprehensive technical information for the OmniDispenser module. It is

intended for use by Omnicell personnel, and is considered a confidential, internal document.

It is recommended that all Omnicell Field Operations and Technical Support personnel review

this guide prior to installing, implementing, troubleshooting, or servicing an OmniDispenser

module.

Product Overview

The OmniDispenser is an automated single-dose dispensing module, designed to fit within

OmniSupplier Color Touch and OmniRx Color Touch cabinets. This product allows facilities to

combine leading-edge unit-dose dispensing technology, with the convenience and flexibility of

Omnicell’s pharmacy and combination systems.

1-1

Competitive Advantages

Modeled after the Sure-Med unit-dose compartment, OmniDispenser provides:

Improved patient safety through medication error reduction.

Complete controlled substance unit-dose dispensing, including:

1 and 2 ml Ampules

1 and 2 ml Vials

Oral Solids

Syringes (SlimPak)

Superior convenience and ease of use:

Allows users to dispense multiple items into the dispense drawer, and retrieve them all at

once.

Allows use in combination with Omnicell pharmacy drawer types and supply storage

locations in a single cabinet.

No count-backs required for OmniDispenser dosing; increased nursing efficiency

Directed restock using Omnicell Guiding Light technology; decreased medication errors

Requirements

This section outlines general hardware and software requirements for the OmniDispenser

module. Please refer to “Technical Overview” on page 2-1 and “Implementation” on page 4-1 for

complete, detailed requirements and procedures.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 10

1-2 Introduction

Product Overview

Hardware

OmniDispenser modules can be ordered with new OmniSupplier Color Touch and OmniRx

Color Touch cabinets.

OmniDispenser modules can not be installed in the field, or otherwise retrofit into existing

cabinets.

A return bin is required (preferably external [Omnicell ERB]).

OmniDispenser requires a new dispenser type, designed with guiding light and restock button

technology.

The dispenser cassettes (plastic cassette that is filled and inserted into cassette dispensers) have

not changed.

Software

OmniDispenser is supported on Omnicell 7200 Color Touch systems and above. Minimum

software versions are as follows:

Color Touch: 5.4.5.x

OmniCenter: 7.0.5.x

OmniDispenser is supported on both Omnicell 7200 Plus and Omnicell 7200 Standard

servers.

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 11

Technical Overview

Restock

Door

Restock

LED/Button

Dispense

Drawer

Dispense

LED/Button

Restock

Door

Hardware Components

Note: See “Glossary” on page 1-1 for OmniDispenser related terms and definitions.

Dispense Drawer

The dispense drawer is used to retrieve dispensed medications. Users issue medications via the

Color Touch software, as usual. Once the medication is issued, it drops into the dispense drawer,

and the drawer LED flashes and unlocks. The user then pulls open the dispense drawer to retrieve

the medication.

During certain inventory or administrative applications, the user must press the dispense drawer

button to unlock the drawer.

2-1

Restock Door

The restock door grants access to the restock compartment, which houses the individual

dispensers. To access the restock compartment, the (authorized) user logs in, selects the desired

function, then presses the restock door button to select the module and/or open the restock door

(see the Software Functionality/User Interface section for details).

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Figure 2-1. OmniDispenser Module (installed on an OmniRx)

Page 12

2-2 Technical Overview

Cassette

Dispenser

Syringe

Dispenser

Dispenser

Button

Fixed Rai l

A, C, D

Optional Rail

B, E

Restock

Door

Tro ug h

Hardware Components

Once opened, the depression or trough at the base of the restock door can be used to catch

medications dispensed during inventory or diagnostics functions (see Figure 2-2). Though less

efficient, the user can also push the rail frame in and dispense into the dispense drawer, using the

Open Dispense Drawer and Open Restock Door buttons as needed to retrieve medications and/or

chose the next item.

Restock Compartment

The restock compartment houses the rail frame, fixed rails, any optional rails, and dispensers. The

restock compartment can only be accessed by authorized users. See “Implementation” on page 4-1

for details.

Rail Frame

After opening the restock door, the user slides the rail frame out to access the dispensers. The rail

frame is comprised of the entire outer rail—front, back, and sides.

Rails (Fixed and Optional)

Rails A, C, and D are fixed rails. Fixed rails are considered permanent and must be present for the

OmniDispenser to function properly.

Rails B and E are optional rails. Optional rails are held in place by a large front mounting screw,

for easy installation or removal. See “Implementation” on page 4-1 for instructions on installing or

removing optional rails.

Dispensers

The quantity, type, and layout of the dispensers are determined by the needs of the facility and

various configuration limitations. Each dispenser has a green button and guiding light LED to aid

in inventory and diagnostics functions.

Figure 2-2. Omni Dispenser Restock Compartment

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 13

System Information

Drawer Type and Name

From a software perspective, the OmniDispenser module (ODM) is considered a Pharmacy II

(high-density) drawer, and has the following attributes:

Drawer name is OmniDispenser.

Drawer type is 75 (0x4B).

Occupies 6 drawer positions.

As with any Pharmacy II drawer, the OmniDispenser module must be programmed upon

Note:

installation by using the dispense drawer button. See “Implementation” on page 4-1 for details.

Module Placement

There are three available OmniDispenser module types:

OmniDispenserTall (ODMTall)—OmniDispenser module designed to fit in 1-, 2-, and 3-cell

OmniSupplier Color Touch/auxiliary cabinets; includes a 1/2 door over the bottom zone [up to

6 shelf positions] (option kit #12-8009).

OmniDispenserPlus3 (ODMPlus3)—OmniDispenser “Tall” plus 3-drawer pharmacy carrier

(option kit #12-8008).

OmniDispenserRX (ODMRx)—OmniDispenser module designed to fit in an OmniRX Color

Touch cabinet (option kit #12-8010).

Technical Overview 2-3

System Information

The OmniDispenser module, by itself, occupies six (6) drawer positions. ODMTall occupies two

zones (OmniDispenser module plus 1/2 door). ODMPlus3 modules occupy nine (9) drawer

positions (OmniDispenser module plus 3-drawer carrier).

Each Color Touch main cabinet (brain) can support multiple OmniDispenser modules; there is a

theoretical software limitation of 126 Pharmacy II drawers and/or OmniDispensers per “brain”.

From a software standpoint, an ODM can be installed anywhere that it will fit within in a zone,

where Pharmacy II (high-density) drawers are supported. However, certain hardware limitations

and usage considerations apply:

ODMTall and ODMPlus3 Placement Rules

ODMs cannot be placed in the top-most zone—above the computer.

The first ODM installed should placed directly below the computer, in zone 1; subsequent

ODMs should be placed in the closest possible proximity to the Color Touch screen (main PC

Box)—ideally in the middle zones (zones 4 and 7 of a 3-cell cabinet).

If an ODM is to be placed below a supply zone, a top cover must also be ordered (option kit 12-

8011).

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 14

2-4 Technical Overview

System Information

Note: While it is possible to place ODMs in lower zones, it is not recommended. From an ergonomic

standpoint, retrieving medications and performing inventory functions is easiest for the user when the

ODM is placed in a middle zone—directly under the computer.

Figure 2-3. ODMTall Modules; ODMPlus 3 Modules (right: with 9 -drawer below); ODM Tall/ ODMPlus3

ODMRx Placement Rules

The first ODM installed should be placed in the top-most position.

An additional ODM can be placed below the first ODM, followed by a single drawer position

(for pharmacy drawer or dummy front). However, it is preferable to place any additional

modules in nearby auxiliary cabinets, rather than placing an ODM in the lower zone.

Figure 2-4. ODMRx

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 15

Rail Configuration

Options/Rules

Rails A, C, and D are considered fixed rails, and always present.

Rails B and E are optional, and can be ordered with the cabinet or purchased and installed at a

later date, as needed.

The following rail configurations are supported:

A, B, C, D, E—5 columns of 9 single-width dispensers (supports up to 45 single-width

dispensers).

A, B, C, D or A, C, D, E—1 column of double-width and 3 columns of single-width dispensers

(supports up to 9 double-width and 27 single-width dispensers with exception of doublecassette dispensers).

A, C, D—2 columns of double-width and 1 column of single-width dispensers (supports up to

18 double-width and 9 single-width dispensers with exception of double- cassette dispensers).

Note:

“Software Functional Overview” on page 3-1 for examples.

Technical Overview 2-5

System Information

Users can view the OmniDispenser module rail configuration via the Diagnostics screen. See

Figure 2-5. ODM Rail Assembly

Automatic Rail Configuration Detection

During startup, the cabinet software “interrogates” the OmniDispenser to determine the current

rail configuration (see Note). This also occurs when the user presses the Reload Hardware

Configuration or Reset Wireway and Module buttons. However, the cabinet must be powered

down prior to installing or removing rails. When the cabinet is rebooted, the new configuration is

automatically detected.

Since rails A (0), C (2), and D (3) are fixed rails, an error is generated if they are not present.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 16

2-6 Technical Overview

System Information

Communication with OmniCenter

OmniDispenser configuration information is sent to the OmniCenter, for bin assignment and

reporting purposes. This communication includes the drawer type (75 [0x4B]), rail configuration

and addressing.

Possible rail configurations/addresses that can be sent are as follows:

Rail Divider

Rail 0 (A) 0-8 Fixed—always present

Rail 1 (B) 9-17 Optional

Rail 2 (C) 18-26 Fixed—always present

Rail 3 (D) 27-35 Fixed—always present

Rail 4 (E) 36-44 Optional

Rail 10 (E) 0-16 Rail identifier sent when rail 1 (B) is not present. Uses rails A and B addresses, and may contain

Table 2-1. Rail Configurations

Address

Range Rail Type Description

double cassette dispenser. Not visible to the user.

Dispenser Configuration Options

The following rules apply to dispenser placement within the OmniDispenser:

Double-width dispensers can occupy any/all of the 9 rail positions in either the first (A) or the

fourth (D) columns, with the exception of double-cassette dispensers.

Double-cassette dispensers must be placed in the first (A) column, and can only occupy the

first 8 rail positions.

Addressing Scheme

Each OmniDispenser module has up to 45 assignable locations, as illustrated in the following

chart:

Row #

9 8 (A9) 17 (B9) 26 (C9) 35 (D9) 44 (E9)

8 7 (A8) 16 (B8) 25 (C8) 34 (D8) 43 (E8)

7 6 (A7) 15 (B7) 24 (C7) 33 (D7) 42 (E7)

6 5 (A6) 14 (B6) 23 (C6) 32 (D6) 41 (E6)

5 4 (A5) 13 (B5) 22 (C5) 31 (D5) 40 (E5)

4 3 (A4) 12 (B4) 21 (C4) 30 (D4) 39 (E4)

3 2 (A3) 11 (B3) 20 (C3) 29 (D3) 38 (E3)

2 1 (A2) 10 (B2) 19 (C2) 28 (D2) 37 (E2)

1 0 (A1) 9 (B1) 18 (C1) 27 (D1) 36 (E1)

Rail Divider ARail Divider

B (optional)

Rail Divider CRail Divider DRail Divider

E (optional)

Table 2-2. Addressing Scheme

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 17

Location Description

When dispenser locations are referred to various software functions and reports, the following

format is observed.

(Cabinet W), (Zone X), (Dispenser YZ), where:

W = Cabinet number from 0 to 13.

X = Zone number from 0 to 8.

Y = Column position from A to E

Z = Row position from 1 to 9.

Example: Cabinet 0, Zone 1, (Dispenser) A1

In most cases the dispenser position appears without a descriptor (A1). The letter refers to the

Note:

rail. The number refers to the dispenser position on that rail. Example: rail A, dispenser position 1

Dispensing Behavior

OmniDispenser dispensing behavior is similar to existing Sure-Med unit dose module, with a few

exceptions. These, and other behavioral considerations are noted in the following sections.

Technical Overview 2-7

System Information

Dispense Drawer

When the user issues an item, the OmniDispenser dispense drawer unlocks but does not pop

open. After the item (or items) is dispensed, the dispense drawer LED flashes and the user opens

the drawer to retrieve the medication(s).

Multiple OmniDispensers

There can be more than one OmniDispenser per “brain”. If multiple items are selected that reside

in the same cabinet, the dispense sequence takes place left to right, top to bottom (e.g. an item in

zone 4 dispenses before an item in zone 1). If multiple items are selected that reside in different

cabinets, the OmniDispenser module with the lowest cabinet number is dispensed first.

FIFO for Multiple Bins

The Always use FIFO (first in, first out) for Multiple Bins configuration option affects dispensing

behavior for OmniDispenser and Sure-Med unit dose modules (see the Implementation chapter,

Configuration Options section for more details). This option affects the dispense order for multibin items assigned across one or more unit-dose dispensers and/or other pharmacy bins (nonunit-dose).

If enabled, the software issues the item from the same bin until empty, then moves on to the next

bin, and so on. If disabled, the software issues from all dispenser locations first, before dispensing

from any drawer/non-dispenser locations. In this case, issues revert back to the dispenser(s)

immediately upon restock, regardless of the bin level of the currently indicated bin.

Note: If Always use FIFO... is enabled and a dispense error occurs on a multi-bin item, the software

moves on to the next bin in the sequence.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 18

2-8 Technical Overview

System Information

Dispense Errors

OmniDispenser firmware reports detailed dispense error and retry information to the

OmniCenter (ZALM command and log file). Possible error information includes:

Detector Gain at Max (emitters too dim).

Detector Gain at Min (emitters too bright).

Detector backoff puts gain at max

Detector bank failed

Bus communication failure

Emitter bank failed

Sideboard time-out

Total current exceeds module limits

12V input #1 exceeds current limit

12V input #2 exceeds current limit

When a dispense error occurs, it is automatically logged in the Item Bin record at the

OmniCenter. Performing a restock on a dispenser clears any existing error and notifies the

OmniCenter to remove the dispenser error flag from the Item Bin record.

If a dispenser is above reorder level but has a dispense error, the user can clear the error by

pressing the Clear Dispenser Error button during Modify Bin or Cycle Count. This is particularly

useful in cases where a dispense error is indicated, but the bin is full to capacity and can not be

restocked.

The presence of the Clear UD Dispenser Error button does not indicate a dispense error. This

button simply allows the user to clear errors for the selected dispenser, as needed.

Once pressed, any existing error is cleared and the button disappears until the next dispenser is

selected (or the same dispenser is selected again).

It is recommended that Cycle counts be performed at regular intervals (e.g. once per week)

Note:

instead of relying on restock to discover/resolve discrepancies for slow moving medications.

Dispense Transactions

All dispenses are logged as DISP transactions in the log file, for easier reference. Sample log

entries are as follows:

JT 00 INFO DISP 15:08:11.58 Dispense Time for Aux 1 Zone 1, Drawer 1 C3 = 1.930 seconds -- OK

JT 00 WARN DISP 15:08:44.92 Dispense Time for Aux 1 Zone 1, Drawer 1 C3 = 4.340 seconds -- Retried

JT 00 ERRO DISP 15:08:51.95 Dispense Time for Aux 1 Zone 1, Drawer 1 C3 = 5.440 seconds -- Failed

Returning Medications

Since users can not access the restock door/dispensers, OmniDispenser medications can not be

returned to the original bin. As such, all OmniDispenser items must be returned to a cabinet

return bin (preferably an Omnicell ERB, external return bin).

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 19

Time-out Behavior

Please Open Dispense Drawer Time-out

The Transaction Middle Time-out configuration setting determines the amount of time the user

has to open dispense drawer during a transaction. If the user does not open the dispense drawer

within the set amount of time, a warning sounds and the user is logged out. If any items were

dispensed during the transaction, a null transaction is sent to the OmniCenter (null type DN:

Dispense Drawer Not Opened).

The software does not monitor non-retrieved items, and does not check control level access for

subsequent users if the previous transaction timed-out with items left in the dispense drawer. If

items remain in the dispense drawer after the transaction times-out, the user can access the

dispense drawer via the Diagnostics function or retrieve the medications during the next issue

transaction.

This behavior does not apply during diagnostics functions.

Please Open Restock Door Time-out

The Inventory Time-out configuration setting determines the amount of time the user has to open

restock door during an inventory function. If the user does not open the restock door within the

set amount of time, a warning sounds and the user is logged out.

Technical Overview 2-9

System Information

Forced Entry Detection

Per usual functionality, if the Forced Entry Detection is enabled, and the restock door is opened

when it is supposed to be locked, a warning sounds and a null transaction (null type: FE) is sent to

the OmniCenter.

Inactive Access

Per usual functionality, when a user opens the OmniDispenser restock door, the inactive access

feature is enabled for all items in the module that are flagged for inactive access. The number of

times the user opens the restock door during a session is not recorded, only that they had access to

the items contained in the OmniDispenser.

EEPROM Configuration Settings

A number of configurable values are stored in OmniDispenser’s EEPROM. Most of these are

accessible directly through the cabinet software, via the Omni Config function. EEPROM settings

are pre-set in the manufacturing build process and should not be adjusted. If any future changes

are required, proper settings and instructions will be expressly communicated to the field and

Technical Support by Omnicell Engineering.

EEPROM settings are pre-set in the manufacturing build process and should not be adjusted

Note:

without direct instruction from Omnicell Engineering.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 20

2-10 Technical Overview

System Information

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 21

Software Functional Overview

This section provides an overview of the system behavior and user functions related to the

OmniDispenser module. For OmniDispenser setup and configuration information, see

“Implementation” on page 4-1.

Automatic Diagnostics

All OmniDispenser diagnostics run automatically during midnight processing. All diagnostics,

except the emitter diagnostic, run whenever the module is initialized.

If a failure occurs during automatic diagnostics, a ZALM message is sent to the OmniCenter. The

error is also logged at the OmniSupplier.

Color Touch Functionality

3-1

Diagnostics

Note: Omnicell personnel must be supervised by authorized pharmacy staff when performing any

functions that involve access to controlled medications.

The OmniDispenser diagnostics function is similar to Omnicell drawer diagnostics. The user

presses the Diagnostics button (under Admin Menus) on the Color Touch screen, then presses either

the restock door or dispense drawer button on the OmniDispenser.

While the OmniDispenser diagnostics are running, all door solenoids in the same cabinet are

locked. Those that were previously unlocked will be unlocked again once diagnostics are

complete. This is done to conserve power. The rail configuration displays for the selected

OmniDispenser module.

To access the following functions:

1. Log into the cabinet as an

2. Press Diagnostics from the Admin Menu.

Omnitech user.

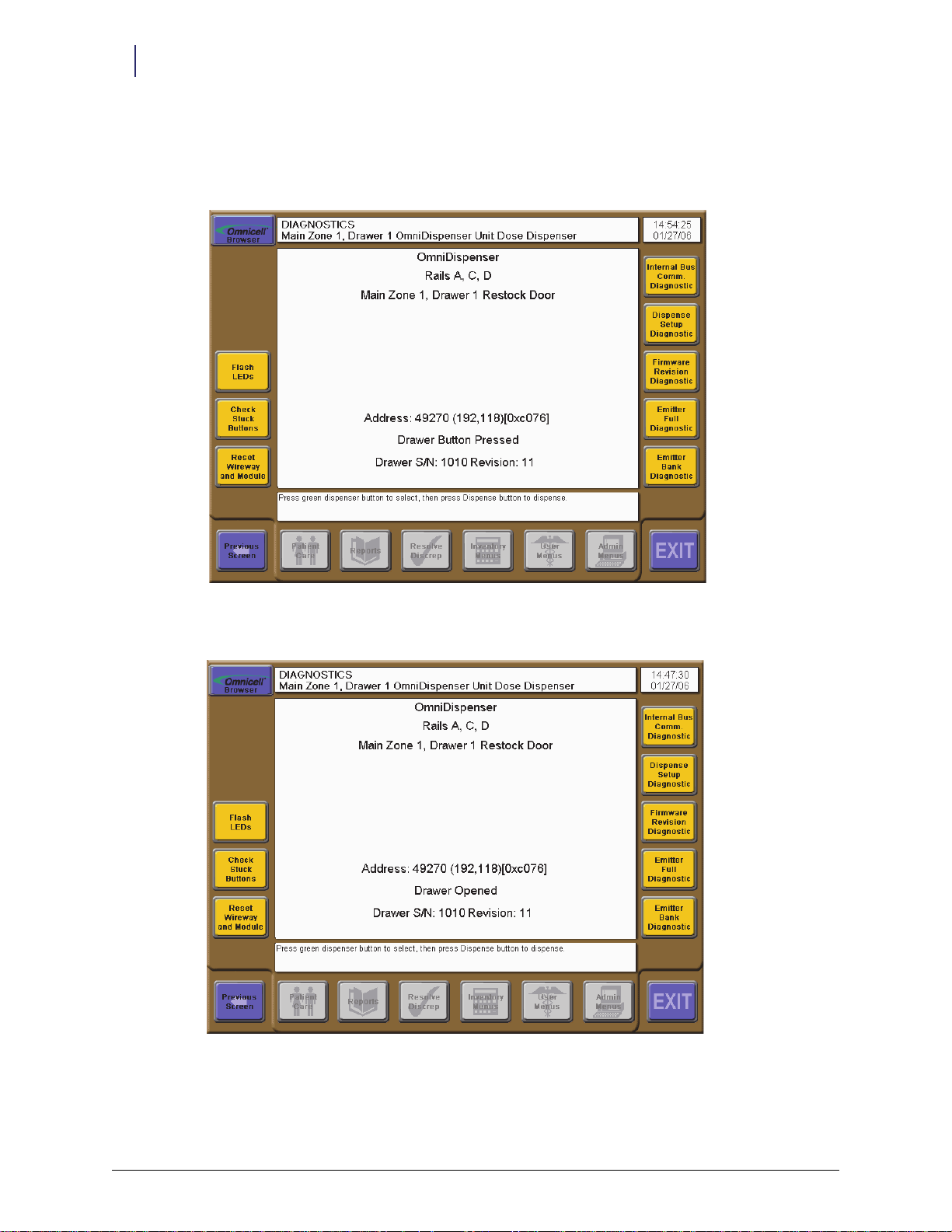

Restock Door Behavior

Note: In order to access the restock door, UD Access must be enabled for that user in the Users

database.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 22

3-2 Software Functional Overview

Color Touch Functionality

During the diagnostics function, the restock door behaves as follows:

When the user presses the restock door button, the restock door unlocks and the LED turns

on.

Figure 3-1. Restock door button pressed

When the user opens the restock door, the restock door LED flashes.

Figure 3-2. Restock door opened

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 23

Software Functional Overview 3-3

Color Touch Functionality

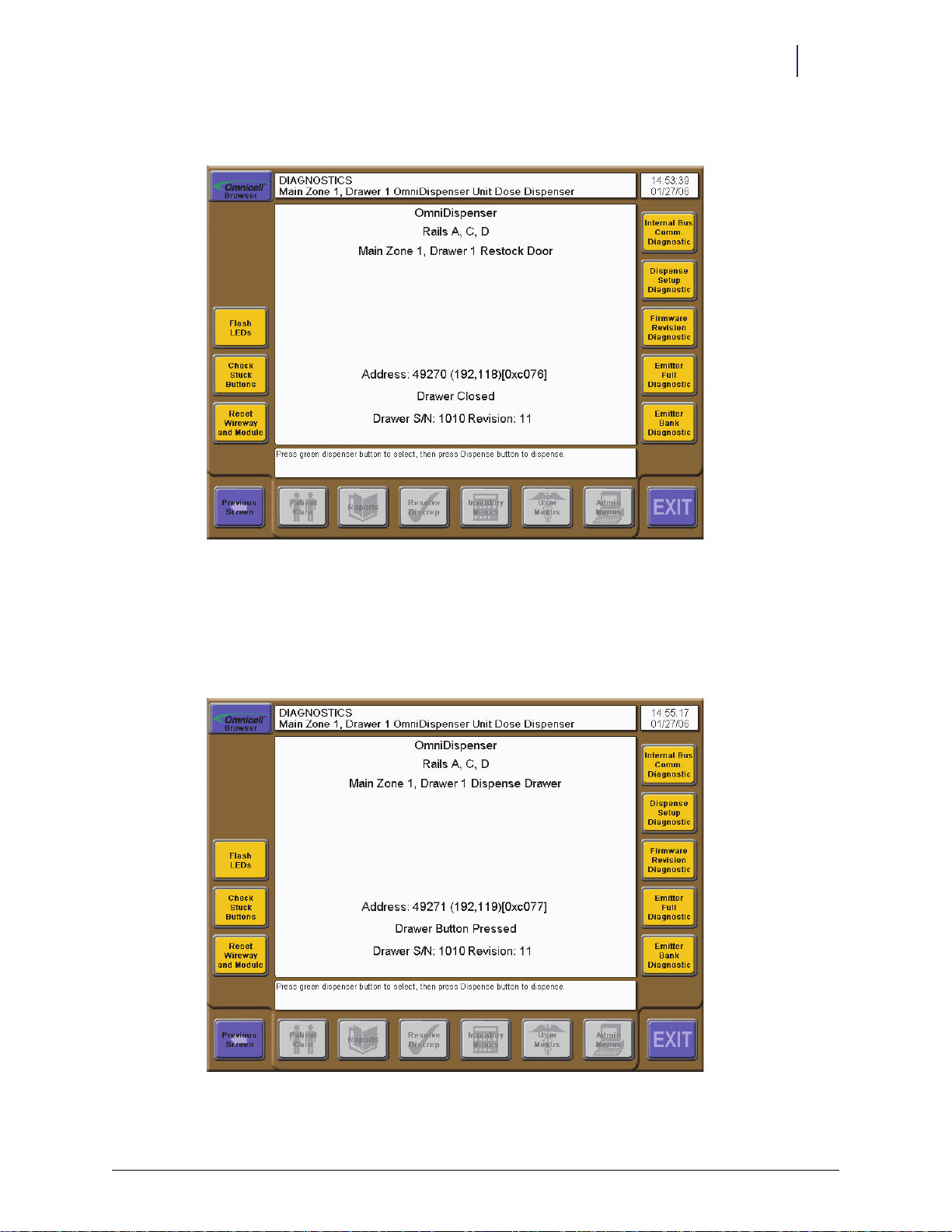

When the user closes the restock door, the restock door locks, and LED turns off.

Figure 3-3. Restock door closed

Dispenser Drawer Behavior

During the diagnostics function, the dispense drawer behaves as follows:

When the user presses the dispense drawer button, the dispense drawer unlocks and the LED

turns on.

Figure 3-4. Dispense drawer button pressed

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 24

3-4 Software Functional Overview

Color Touch Functionality

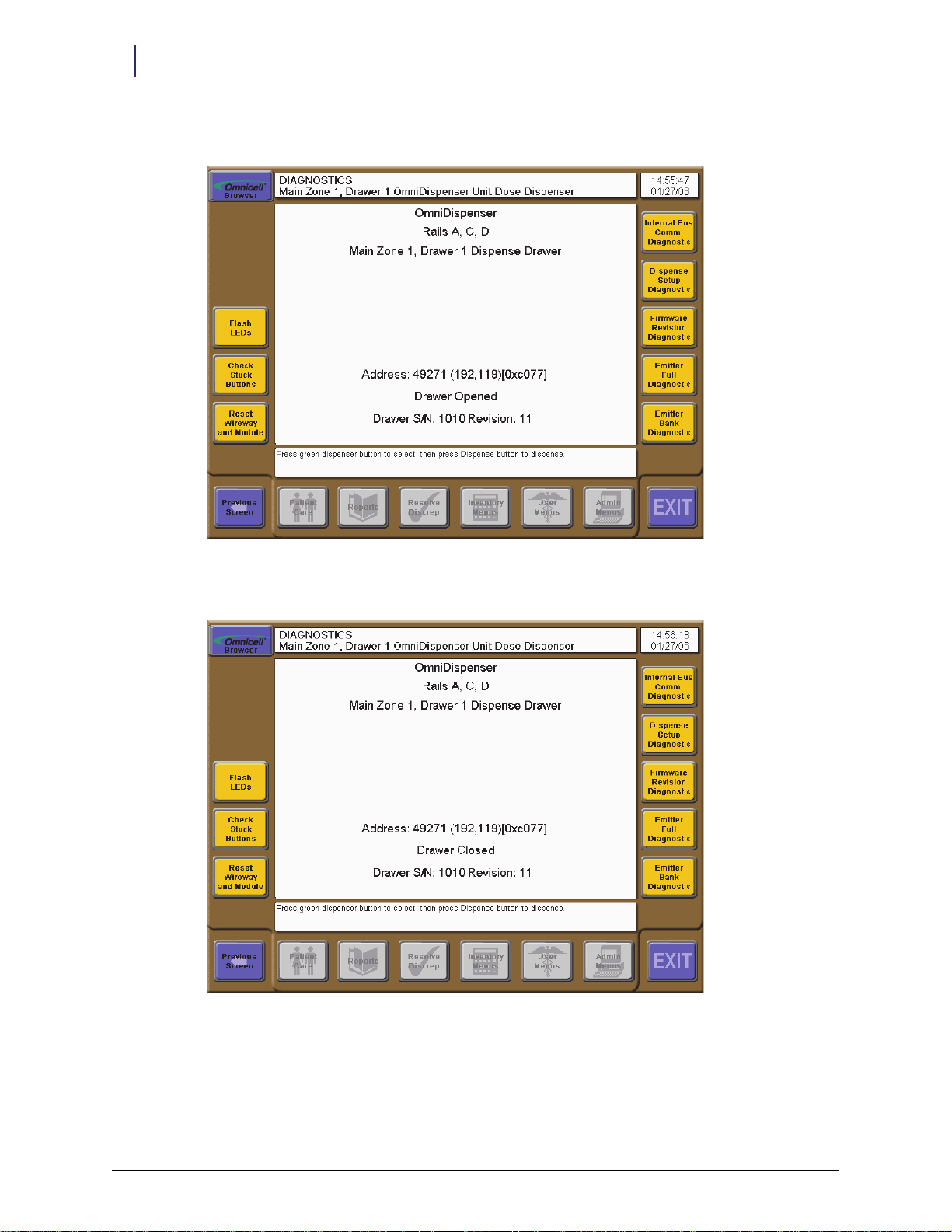

When the user opens the dispenser drawer, the dispense drawer LED flashes.

Figure 3-5. Dispense drawer opened

When the user closes the dispense drawer, the dispense drawer locks, and LED turns off.

Figure 3-6. Dispense drawer closed

Dispenser Behavior

During the diagnostics function, dispensers behave as follows:

When the user presses a dispenser button, the dispenser’s LED flashes.

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 25

Software Functional Overview 3-5

Color Touch Functionality

Dispense Function

The Dispense button displays on the Diagnostics window once the user has pressed a dispenser

button. The Dispense button remains available throughout the session, until the user opens the

dispense drawer or exits diagnostics.

Prior to pressing Dispense, the user should either position the rail frame so that selected dispenser

is over the trough in the restock door (recommended method) or push in the rail frame so that the

medication falls directly into the dispense drawer.

Pressing the Dispense button causes the dispenser to dispense one unit of medication. The results

of the dispense are displayed in the window and logged. These include status (

elapsed time, and any extended status from the firmware, if applicable.

OK /Retry / Fai l), the

Figure 3-7. Dispense Results

Dispense errors that occur while using the diagnostic function are not reported to the

Note:

OmniCenter.

If dispensing into the dispenser drawer, the user can press the Unlock Dispense Drawer button to

retrieve the medication, or select another function. If the user closes the restock door, the Unlock

Restock Door button also displays.

Any items dispensed must be placed back into the dispenser. There is no user interface for

replacing the items.

Empty Dispenser Function

The Empty Dispenser button displays on the Diagnostics window once the user has pressed a

dispenser button, as well as during various user functions where countback may be required. The

Empty Dispenser button remains available throughout the session, until the user opens the dispense

drawer or exits diagnostics.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 26

3-6 Software Functional Overview

Color Touch Functionality

Prior to pressing Empty Dispenser, the user should either position the rail frame so that selected

dispenser is over the trough in the restock door (recommended method) or push in the rail frame

so that the medication falls directly into the dispense drawer.

Pressing the Empty Dispenser button causes the selected dispenser to dispense until empty or until

an error occurs. The number of units dispensed is displayed only during Diagnostics. (There is no

quantity display for other functions.) If the quantity dispensed is greater than zero (0), a null

transaction is sent to the OmniCenter (null type DD).

If emptying into the dispenser drawer, the user can press the Unlock Dispense Drawer button to

retrieve the medication, or select another function. If the user closes the restock door, the Unlock

Restock Door button also displays.

Any items dispensed must be placed back into the dispenser. There is no user interface for

replacing the items.

Figure 3-8. Empty Dispenser Results

Reset Wireway and Module Function

Pressing the Reset Wireway and Module button resets the wireway and reloads the rail configuration

for the selected OmniDispenser module.

Internal Bus Communications Diagnostics

Pressing the Internal Bus Comm Diagnostic button causes the firmware internal bus communication

diagnostic to run. This diagnostic also runs automatically, during midnight processing, and

whenever the module is initialized (during startup or when programming the module). The

possible results are:

Pass

Internal bus communication time-out

Internal bus communication corruption

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 27

Software Functional Overview 3-7

Color Touch Functionality

If the diagnostic fails, the board with the first failure is identified. Subsequent failures, if any, are

not identified.

Figure 3-9. Internal Bus Communications Diagnostics Results

Dispense Setup Diagnostics

Pressing the Dispense Setup Diagnostic button causes the firmware dispense setup diagnostic to run.

This diagnostic also runs automatically, during midnight processing, and whenever the module is

initialized (during startup or when programming the module). The possible results are:

Pass

Time- out dur ing stop unsolicited messages phase

Corrupted communication during stop unsolicited messages phase

Time-out while turning on emitters

Corrupted communication while turning on emitters

Time-out while turning on detector

Corrupted communication while turning on detector

Detector side A at max gain

Detector side B at max gain

Detector side A at minimum gain

Detector side B at minimum gain

Detector side A backoff beyond maximum gain

Detector side B backoff beyond maximum gain

Time-out during internal dispenser command

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 28

3-8 Software Functional Overview

Color Touch Functionality

If the diagnostic fails, the bank number with the first failure is identified. Subsequent failures, if

any, are not identified. The bank numbers are as follows:

Bank 0 = dispensers A1, B1, C1, D1, E1

Bank 1 = dispensers A2, B2, C2, D2, E2

Bank 2 = dispensers A3, B3, C3, D3, E3

Bank 3 = dispensers A4, B4, C4, D4, E4

Bank 4 = dispensers A5, B5, C5, D5, E5

Bank 5 = dispensers A6, B6, C6, D6, E6

Bank 6 = dispensers A7, B7, C7, D7, E7

Bank 7 = dispensers A8, B8, C8, D8, E8

Bank 8 = dispensers A9, B9, C9, D9, E9

Figure 3-10. Dispense Setup Diagnostics Results

Firmware Revision Diagnostics

Pressing the Firmware Revision Diagnostic button causes the firmware revision diagnostic to run. This

diagnostic also runs automatically, during midnight processing, and whenever the module is

initialized (during startup or when programming the module). The possible results are:

Pass

Internal Bus Communication time-out

Internal Bus Communication corruption

Board Firmware lower than sideboard

Board Firmware higher than sideboard

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 29

Software Functional Overview 3-9

Color Touch Functionality

If the diagnostic fails, the board with the first failure is identified. Subsequent failures, if any, are

not identified. In this event, the boards with the lowest firmware versions must be replaced or

upgraded to match the board with the highest firmware version.

Figure 3-11. Firmware Revision Diagnostics Results

Emitter Full Diagnostics

Pressing the Emitter Full Diagnostic button causes the firmware emitter diagnostic to run. This

diagnostic also runs automatically, during midnight processing. Due to the length of the test (1 to

5 minutes), a message box asks the user for confirmation to run the test. The possible results are:

Pass

Internal bus communication time-out

Internal bus communication corruption

Detector failed

Emitters failed

Detector stuck

If the diagnostic fails, the bank number with the first failure is identified. Subsequent failures, if

any, are not identified. The bank numbers are as follows:

Bank 0 = dispensers A1, B1, C1, D1, E1

Bank 1 = dispensers A2, B2, C2, D2, E2

Bank 2 = dispensers A3, B3, C3, D3, E3

Bank 3 = dispensers A4, B4, C4, D4, E4

Bank 4 = dispensers A5, B5, C5, D5, E5

Bank 5 = dispensers A6, B6, C6, D6, E6

Bank 6 = dispensers A7, B7, C7, D7, E7

Bank 7 = dispensers A8, B8, C8, D8, E8

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 30

3-10 Software Functional Overview

Color Touch Functionality

Bank 8 = dispensers A9, B9, C9, D9, E9

Figure 3-12. Emitter Full Diagnostics Results

Check Stuck Buttons

If a drawer button is stuck, press Check Stuck Buttons for a diagnostic on the problem. The screen

will display the results.

Figure 3-13. Stuck Button DIagnostic

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 31

Software Functional Overview 3-11

Color Touch Functionality

Emitter Bank Diagnostics

Pressing the Emitter Bank Diagnostic button displays the emitter bank diagnostic window. The user

selects the banks to be tested, and once started, can cancel the test as needed, between banks. The

possible results are:

Pass

Internal bus communication time-out

Internal bus communication corruption

Detector failed

Emitters failed

Detector stuck

Figure 3-14. Emitter Bank Diagnostics Results

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 32

3-12 Software Functional Overview

Color Touch Functionality

Normal Restock

When a selected restock list contains OmniDispenser items, the applicable restock door and

dispenser LEDs flash. To select an item to restock, the user presses a flashing dispenser button.

Once pressed, the LED changes to steady on, and all other flashing LEDs are turned off. The user

presses the button once more when restock of the item is complete. Once complete, that dispenser

LED turns off, and the remaining LEDs resume flashing.

If a dispenser error occurs, the OmniCenter sets the restock record DISPERROR field to Y (Yes).

When the restock report is generated, the item appears on the report and is marked with an

asterisk (*). Additionally, the following message displays at the cabinet when the user restocks that

dispenser:

To perform a normal restock:

1. Log into the cabinet, then press Inventory Menus.

2. Press Normal Restock.

3. Select the desired restock from the list.

4. Press the flashing restock door button, then open the door.

5. Press a flashing dispenser button to select.

6. If the countback window is displayed, verify the current bin level as follows:

a. If needed, press Empty Dispenser to count the item. Refer to “Empty Dispenser Function” on

b. Press Ye s if the bin level displayed is correct.

This dispenser has reported errors, please check.

page 3-5 for details.

Figure 3-15. Normal Restock: Countback

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 33

Software Functional Overview 3-13

Color Touch Functionality

c. Press No if the bin level displayed is incorrect, then enter the actual countback amount.

Figure 3-16. Normal Restock: Restock Bin

7. Enter the restock quantity in the Actual Amount field.

8. Restock the item, then press the dispenser button again.

9. Repeat steps 5-8 until restock is complete, then close the restock door.

10. Press Exit to finish.

Supplemental Restock

To perform a supplemental restock of OmniDispenser items, the user first pre-selects the items.

When the user presses Restock Now, the restock door flashes and unlocks, and first applicable

dispenser LED flashes. The user presses the flashing dispenser button to restock that item. Once

pressed, the LED changes to steady on, and the LED of the next item, if any, flashes. The user can

then press the LED of the next item to restock or, if finished, close the restock door.

If any of the items in the OmniDispenser require a witness, witness information must be entered

before the restock door will unlock. Once entered, the witness applies to all witness-required items

for that restock.

To perform a supplemental restock:

1. Log into the cabinet, and press Inventory Menus.

2. Press Supplemental Restock.

3. Press the Restock Items button.

4. Select an item from the list.

5. Enter the Quantity to Restock.

6. Repeat steps 4-5 as needed, then press Restock Meds Now.

7. Enter witness, if required.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 34

3-14 Software Functional Overview

Color Touch Functionality

8. Open the restock door.

9. Press the flashing dispenser button.

10. If the countback window displays, verify the current bin level as follows:

a. If needed, press Empty Dispenser to count the item.

b. Press Ye s if the bin level displayed is correct.

c. Press No if the bin level displayed is incorrect, then enter the actual countback amount.

11. Enter the restock quantity in the Actual Amount field.

12. Restock the item, then press the next flashing dispenser button.

13. Repeat steps 10-12 until restock is complete; close the restock door to finish.

Destock

Per usual functionality, the user must pre-select the items they want to destock from the

OmniDispenser. Items are then removed similarly to the Remove Meds function.

To p erf or m a d e st oc k :

1. Log into the cabinet, and press Inventory Menus.

2. Press Destock.

3. Press the Destock Items button.

4. Select an item from the list.

5. Enter the Quantity to Remove.

6. Repeat steps 4-5 as needed, then press Destock Meds Now.

7. Enter witness, if required.

8. Remove the items from the dispense drawer.

9. Press Destock Items to destock additional items, or press Exit to finish.

Cycle Count

To cycle count items in an OmniDispenser, the user selects the Cycle Count function from the

Inventory menu, then presses the restock door button to select that module. The user can then

navigate to the item via Find Item, or open the restock door and either press a dispenser button

directly or use the Find Dispenser Item function. The Empty Dispenser function can be used, as needed,

to obtain a count. Cycle count is then completed as usual.

To perform a cycle count:

1. Log into the cabinet, and press Inventory Menus.

2. Press Cycle Count.

3. Press the restock door button and open the restock door.

4. Press Find Dispenser Item to navigate to an item, or press a dispenser button.

Note:

When a multi-bin item is selected, the Next Bin button displays. This allows the user to perform

the current function across all applicable bins.

A Clear Dispenser Error button displays during the Cycle Coun t function. This allows users to manually clear a

dispense error without having to initiate a restock. The button displays/re-displays whenever a bin is

selected, regardless if an error has occurred for that bin.

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 35

5. Enter witness, if required.

6. Count the item, using the Empty Dispenser function as needed.

7. Enter the quantity counted, then press OK.

8. If desired, press Flash Uncounted Bins to flash all remaining bins in that module.

Note:

will continue to flash until they are counted or the user exits the function.

9. Repeat steps 4-8 as needed, then press Exit to finish.

Note: It is recommended that cycle counts be performed at regular intervals (once a week) instead of

relying on restock to discover/resolve discrepancies for slow moving medications.

Expiration/Recall

To perform an expiration or recall for OmniDispenser items, the user selects the Expired/Recalled

function from the Inventory menu, then presses the restock door button to select that module. The

user can then navigate to the item via Find Item, or open the restock door and either press a

dispenser button directly or use the Find Dispenser Item function. Expirations/recalls are then

completed as usual.

To perform an expiration or recall:

Software Functional Overview 3-15

Color Touch Functionality

Once Flash Uncounted Bins is pressed (during Cycle Count), all uncounted bins in the module

Modify Bin

1. Log into the cabinet, and press Inventory Menus.

2. Press Expired/Recalled.

3. Press the restock door button and open the restock door.

4. Press Find Dispenser Item to navigate to an item, or press a dispenser button.

Note: When a multi-bin item is selected, the Next Bin button displays. This allows the user to perform

the current function across all applicable bins.

5. Enter witness, if required.

6. Enter the Quantity to Expire or Recall, then press OK.

7. Repeat steps 4-6 as needed, then press Exit to finish.

To access the bin modification functions:

1. Log into the cabinet.

2. Press Inventory Menus.

3. Press Modify Bin.

Note: A Clear Dispenser Error button displays during the Modify Bin function. This allows users to manually

clear a dispense error without having to initiate a restock. The button displays/re-displays whenever a

bin is selected, regardless if an error has occurred for that bin.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 36

3-16 Software Functional Overview

Color Touch Functionality

Select a Bin

There are two ways to select a dispenser:

Option 1:

1. Press the restock door button and open the door.

2. Press the button on the individual dispenser.

Option 2:

1. Press Find Item or open the restock door and press Find Dispenser Item.

Figure 3-17. Modify A Bin: Find Dispenser Item

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 37

2. Select the item from the list.

Software Functional Overview 3-17

Color Touch Functionality

Figure 3-18. Modify A Bin: Item List

3. If the item is in multiple locations, select the desired bin from the list.

Assigning an Item

To assign an item to an empty dispenser:

1. Press the restock door button and open the door.

2. Press the button on the dispenser.

3. Press the Assign Item button.

4. Proceed with bin assignment as usual.

Replacing an Item Assignment

There are two ways to replace an item in a dispenser:

Option 1:

1. Press the restock door button and open the door.

2. Press the button on the dispenser.

3. Press Assign Item.

4. Press Reassign Anyway or Assign Addition.

5. Proceed with bin assignment as usual.

Option 2:

1. Press Find Item or open the restock door and press Find Dispenser Item.

2. Select the desired item from the list.

3. If the item is in multiple bins, select the desired bin from the list.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 38

3-18 Software Functional Overview

Color Touch Functionality

4. Press Replace Item.

5. Proceed with bin assignment as usual.

Deleting an Item Assignment

There are two ways to delete an item from a dispenser:

Option 1:

1. Press the restock door button and open the door.

2. Press the button on the dispenser.

3. Press Delete Item.

Option 2:

1. Press Find Item or open the restock door and press Find Dispenser Item.

2. Select the desired item from the list.

3. If the item is in multiple bins, select the desired bin from the list.

4. Press Delete Item.

Unassigning All Bins

To unassign/delete all items in the OmniDispenser:

1. Press the restock door button and open the door.

2. Press Unassign All Dispenser Items.

Setting Bin Level

There are two ways to modify the quantity of an item:

Option 1:

1. Press the restock door button and open the door.

2. Press the button on the dispenser.

3. Press Set Bin Level.

4. Proceed with bin level modification as usual.

Option 2:

1. Press Find Item or open the restock door and press Find Dispenser Item.

2. Select the desired item from the list.

3. If the item is in multiple bins, select the desired bin from the list.

4. Press Set Bin Level.

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 39

5. Proceed with bin level modification as usual.

Software Functional Overview 3-19

Color Touch Functionality

Figure 3-19. Modify A Bin: Modify Options

Countback Always Configuration

Countback is not required for OmniDispenser items because users only have access to the

medication dose(s) being dispensed. The Enable Countback Always for Unit Dose Compartment

configuration option is disabled by default.

Countback may be required for inventory purposes. If the facility does not want to countback

OmniDispenser items, Countback Always must be set to Disable and Countback Req must be set to

(no) for each dispenser item.

N

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 40

3-20 Software Functional Overview

OmniCenter Functionality

OmniCenter Functionality

User Access to Restock Door

In order to access the OmniDispenser restock door (or Sure-Med unit dose compartment), the

UD Access field must be enabled in the Users table for each applicable user. See “Implementation”

on page 4-1 for more details.

Reports

Pharmacy Drawer Configuration Report

The Pharmacy Drawer Configuration Report displays detailed drawer or bin location

information—particularly for OmniDispenser items.

Figure 3-20. Pharmacy Drawer Configuration Report

Dispensing Error Report

The Dispensing Error Report includes dispensing errors and bin location information for

OmniDispenser hardware. Accordingly, the report description displayed on the OmniCenter Reports

tab reads:

Figure 3-21. Dispensing Error Report

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Lists all unit dose dispenser errors for a specified date range and OmniSupplier.

Page 41

Message Alerts

Increase security by setting up an alert for forced entry detection (available in Omnicell v 14.2 or

higher). Attempted tampering with the OmniDispenser drawer is detected by a sensor that sets off

an alarm and displays a warning on the cabinet screen. A corresponding alert can be configured to

be e-mailed to designated recipients.

The alarm functions the same for any type of dispense drawer access.

Forced Entry Detection

Enable forced entry detection at the cabinet:

OmniConfigs > Pharmacy > Forced En try Detection =

Verify this setting before setting up a message alert.

Message Filter Setup

1. Log into the OmniCenter as the administrator.

2. Click on the Administrator tab.

3. Select

4. Select

Software Functional Overview 3-21

OmniCenter Functionality

Yes

Setup from the Type menu.

Message Filter Setup from the Options Available menu.

Figure 3-22. Administration Tab

5. Click Continue.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 42

3-22 Software Functional Overview

OmniCenter Functionality

6. Create the tampering message.

a. Click the General sub-tab.

Figure 3-23. General Sub-Tab

b. Select Forced Entry to OmniDispenser from the Message Text list or click Add if message does not

already exist.

c. Check the Enabled box.

d. Set the priority level. (e.g. high)

e. Enter

Forced Entry to OmniDispenser in the Message Text field if not already populated from the

text message list.

f. Add a description if adding the message.

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 43

7. Select message parameters

a. Click the Filter Parameters sub-tab.

Software Functional Overview 3-23

OmniCenter Functionality

Figure 3-24. Parameters Sub-Tab

b. Type ZALM in the Command field.

c. Click Details.

d. Type

txt in the Limit Text Search To Token field.

e. Select Contains for the Search Type.

f. Enter

Forced Entry to OmniDispenser in the Search Text field.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 44

3-24 Software Functional Overview

OmniCenter Functionality

8. Create recipient list.

a. Select the Notification sub-tab.

b. Click Add.

c. Select the desired recipients for the message alert from a user list and/or select a default

printer. Refer to the OmniCenter User guide for the Omnicell software version running on

the cabinet for details.

d. Click Add.

Figure 3-25. Add Window

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 45

Software Functional Overview 3-25

9. Enter an optional custom message on the Custom Message sub-tab.

OmniCenter Functionality

Figure 3-26. Custom Message Sub-Tab

10. Click Save.

11. Click Go Back to return to the original window.

© 2012 Omnicell, Inc. OmniDispenser Technical Guide/60-3007 Rev G

Page 46

3-26 Software Functional Overview

OmniCenter Functionality

OmniDispenser Technical Guide/60-3007 Rev G © 2012 Omnicell, Inc.

Page 47

Overview

4-1

Implementation

This chapter provides the general steps necessary to implement OmniDispenser module (ODM)

at an existing pharmacy or mixed-use account. For additional implementation information, see

the applicable technical manual or contact an Omnicell Project Manager.

The needs and existing setup of each facility will determine the actual implementation

requirements and order in which they are performed. Implementation requirements include:

Adjusting/installing rails, as needed

Installing, labeling, an loading the dispensers

Configuring the cabinet software

Assigning items