Page 1

FlexLock Installation

and Configuration Guide

60-3002 Rev G

includes TempCheck installation,

FlexLock service, Helmer fridge

adjustments

Page 2

This guide is CONFIDENTIAL and designed only for Omnicell Technical personnel and/or designated

representatives.

This guide and accompanying software and/or hardware described in it are protected under copyright laws and may

not be copied, wholly or in part, without the express written consent of Omnicell, Inc. The same proprietary and

copyright notices must be attached to any permitted copies as were attached to the original documents.

Omnicell, Inc.

1201 Charleston Road

Mountain View, CA 94043

(650) 251-6100

www.omnicell.com

Omnicell and the Omnicell design mark, OmniBuyer, OmniCenter, OmniRx, OmniSupplier, SafetyMed, SafetyPak,

SafetyStock, and Sure-Med are registered trademarks. Anesthesia TT, Anesthesia Workstation, Anywhere RN,

Executive Advisor, Flexbin, Medication Surveillance, OmniDispenser, OmniLinkRx, OmniScanner, OmniTrack,

Omni TT, Open Touch, OptiFlex, OptiFlex MobileTrack, Point-to-Point Medication Safety, SecureVault, See & Touch,

SinglePointe, TempCheck, Touch & Go, VSuite, and WorkflowRx are trademarks of Omnicell, Inc. in the United States

and internationally. All other trademarks and trade names are the property of their respective owners

Copyright 1999-2010 Omnicell, Inc. All rights reserved.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 3

Table of Contents

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

FlexLock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

TempCheck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Procedure Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Kit/Parts Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Helmer Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Under Counter Refrigerator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

11 Cubic Foot / 20-25 Cubic Foot Refrigerator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

FlexLock Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Door Bracket Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Test Fit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Helmer Fridge Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Alignment Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Bracket Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

TempCheck Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Inner Housing and Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Retrofit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Electronics Sled Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

PC Box Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

External Return Bin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

FlexLock to FlexLock Chain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Retrofit TempCheck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

iii

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 4

iv Table of Contents

Software Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

FlexLock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

TempCheck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Service Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Service Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Alignment Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Replace TempCheck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

FlexLock Inner Housing Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Implementation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

OmniCenter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Bin Addressing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Item Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Color Touch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

FlexLock Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Cabinet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Implementation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

OmniCenter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Temperature Monitoring Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Color Touch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Cabinet Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Kit/Parts Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Service Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

FlexLock Manual Override/Cover Plate Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

FlexLock Manual Override. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Cover Plate Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Cable Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Electronic Sled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

PC Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

ERB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

FlexLock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Lock Assembly Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Depth Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Lock Pawl Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Vertical Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Final Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Inner Housing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Inner Housing Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 5

Table of Contents v

FlexLock Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Mounting Bracket Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Mounting Bracket Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Alignment Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Appendix A Parts/Kit List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Part Link Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Kit List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Compatible Refrigerators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Refrigerator Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Diagnostics and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

FlexLock Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

TempCheck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Temperature Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Misconfiguration Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IN-1

Documentation Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . FB-1

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 6

vi Table of Contents

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 7

FlexLock

1-1

Product Overview

FlexLock offers security for refrigerated medications or supplies. It can be attached to a

refrigerator storing thermal-sensitive medications or a supply cabinet. FlexLock is then

cabled to an Omnicell cabinet. The Color Touch screen can display the status of the

FlexLock (open/closed, locked/unlocked). A maximum of two FlexLocks can be attached to

one Omnicell cabinet due to power supply considerations. The FlexLock should be located

as close to the OmniSupplier as possible for best usage.

Other FlexLock features:

Up to 119 items can be assigned to each FlexLock.

An internal bin address is associated with each item. External bin numbers are not used.

An item cannot be assigned to the same FlexLock more than once.

An item cannot be assigned to more than one FlexLock.

An item cannot be assigned to a FlexLock and any other hardware locations at the same

time.

System Requirements

TempCheck

The TempCheck temperature sensor is an optional component of the Omnicell FlexLock

product. It can be included as part of a new FlexLock installation or retrofit to an existing

FlexLock.

TempCheck automates monitoring of the storage temperature for thermal-sensitive

medications. This product promotes increased patient safety, workflow efficiency, and

regulatory compliance.

Alerts warn the staff (pharmacy, RN, security) when the storage temperature is outside the

specified range for a better response time. Reports can be used to meet state and local

agency regulations. The Color Touch screen can display real-time storage temperature

readings through a diagnostics window.

A refrigerator or cabinet that fits the FlexLock template; extra

Color Touch Cabinets running Omnicell 7000 software or higher

Spacing: 12” length, 6” height, 6” depth (2” depth okay if refrigerator/cabinet can be slid

out to access the override lock)

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 8

1-2 Product Overview

TempCheck

System Requirements

Note:

OmniCenter and Color Touch Cabinets running Omnicell 10.0 software or higher

Email application enabled at the Omnicenter (SMTP server provided by the hospital IT

department)

FlexLock installed and configured with FlexLock assembly #14-7043 and manufacturing

assembly kit #20-6023

Retrofits for an existing FlexLock with TempCheck kit #20-6037

Refer to the Omnicell 10.0 Technical Release Guide for more information on Email setup.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 9

Hardware Installation

Procedure Overview

This chapter provides the procedure to install a FlexLock device on a refrigerator or cabinet.

FlexLock installation includes retrofitting cables.

The FlexLock can be cabled to:

Electronic Sled [Omni TT, OmniRX, Anesthesia Workstation, Sure-Med, half-cell]

PC Box cabinets [one-two-three cells]

External Return Bin [ERB] (in a chain configuration)

FlexLock (in a chain configuration)

Also included are installation steps for the optional TempCheck temperature probe—used with

FlexLock on a refrigerator. If doing a retrofit for an existing FlexLock, refer to “Retrofit

TempCheck” on page 2-45.

2-1

Tools Required

The following tools are required to perform the FlexLock installation:

T-10 Torx Driver

Cam Lock Keys #2202 and #2232 [FlexLock]

Cam Lock Keys #2202 and #2204 [ERB]

ESD Wrist Strap

1/4” Hex Driver (with various bit sizes)

T8 Torx Driver

5/16 Nut Driver

Screwdriver (for vertical alignment)

Needle-nose Pliers (helpful with pealing adhesive cover)

Standard Phillips screw driver

Kit/Parts Required

The initial FlexLock installation uses two kits. A third is needed for a TempCheck retrofit for an

existing Flexlock. Additional parts must be ordered from Helmer if attaching a FlexLock to one if

its refrigerators.

FlexLock Assembly #14-7043: Some FlexLock parts come pre-assembled for shipping

purposes. They need to be separated to do the installation.

Installation Kit #20-6023: Includes the TempCheck temperature probe

TempCheck Retrofit Kit #20-6037: Includes the FlexLock inner housing with the TempCheck

compatible PCBA #40-3013

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 10

2-2 Hardware Installation

Curved Door

Bracket Assembly

Square Door

Bracket Assembly

Cam Lock Keys

FlexLock Unit

with cable

Instruction CD

[obsolete]

Blue Screen

Power Cable

Standoffs

#94-6218

Alignment

Fixture

Bracket Cutout

AUX cabl es

#94-6233

#94-6158

#94-6138

#91-2052

#91-2051

Kit/Parts Required

Figure 2-1. FlexLock Kit #14-7043

Figure 2-2. FlexLock Installation Kit #20-6023 with TempCheck probe (#15-7105) [bottom]

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 11

Helmer Parts

Under Counter Refrigerator

1 Spacer (321240-1)

2 Philip screws (230322)

Hardware Installation 2-3

Kit/Parts Required

11 Cubic Foot / 20-25 Cubic Foot Refrigerator

Omnicell FlexLock handle: (20-25 cu. ft. = 321132-1) (11 cu. ft. = 321132-2)

Spacer block (321133-1)

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 12

2-4 Hardware Installation

Kit/Parts Required

Kits

Special accessories are available for facilities that install the Omnicell FlexLock on Helmer upright

refrigerators, undercounter refrigerators, and undercounter freezers.

FlexLock Compatible Door Handles (Upright Models)

The door handle features a cutout and spacer which enable the FlexLock to wrap around the front

and side of the door.

Available for single door upright refrigerators 11, 20, 25, and 26.5 cu ft. (326, 572, 714, 750 l)

Compatible with glass and solid doors

Factory or field installation

FlexLock Adapter Kit (Undercounter Models)

The adapter kit includes an extension bar that mounts to the door of the unit, allowing the

FlexLock to be properly installed.

Adapter kits available for undercounter refrigerators and freezers (5 cu ft. / 142 l)

Compatible with glass and solid doors; powder coated and stainless steel exteriors

Factory installed or field installation kits available

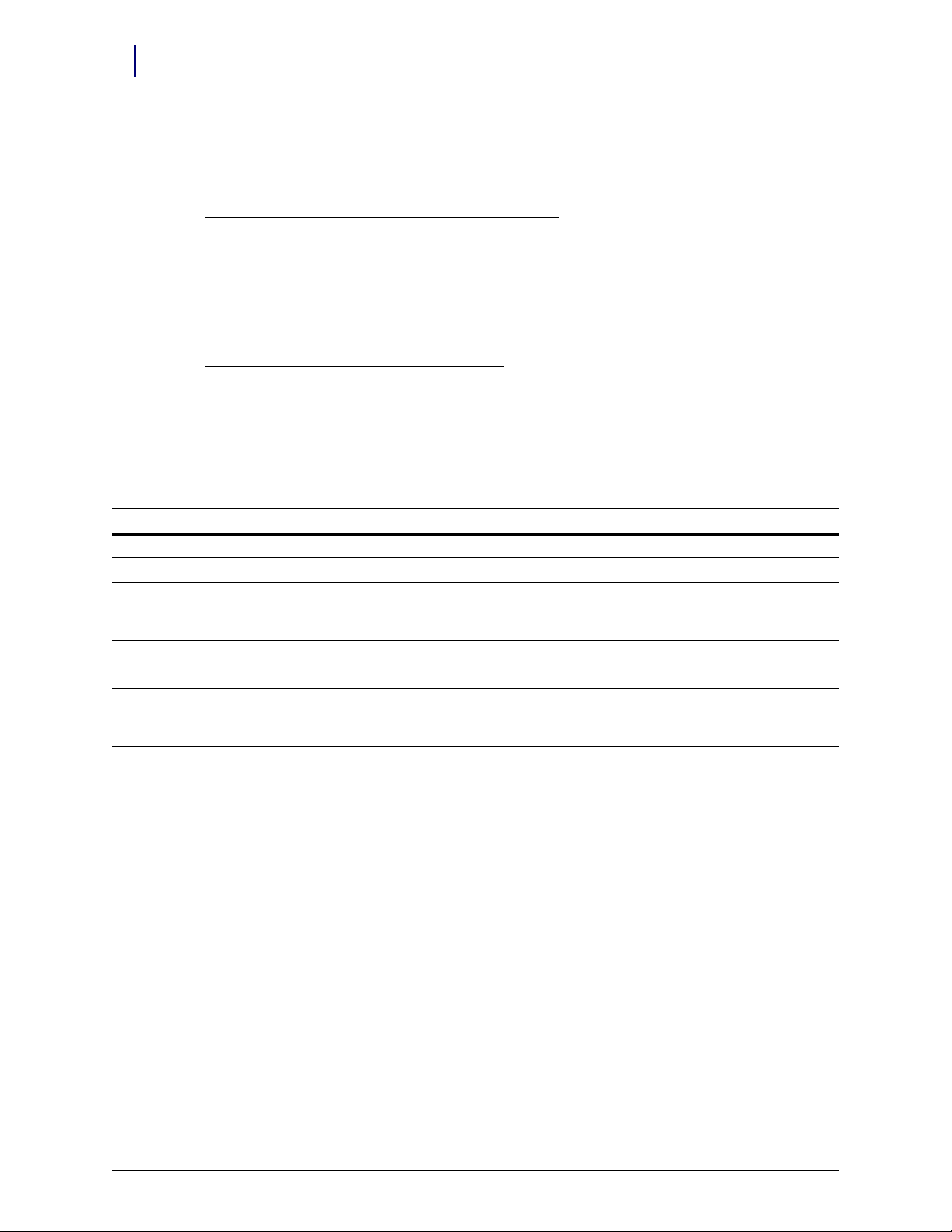

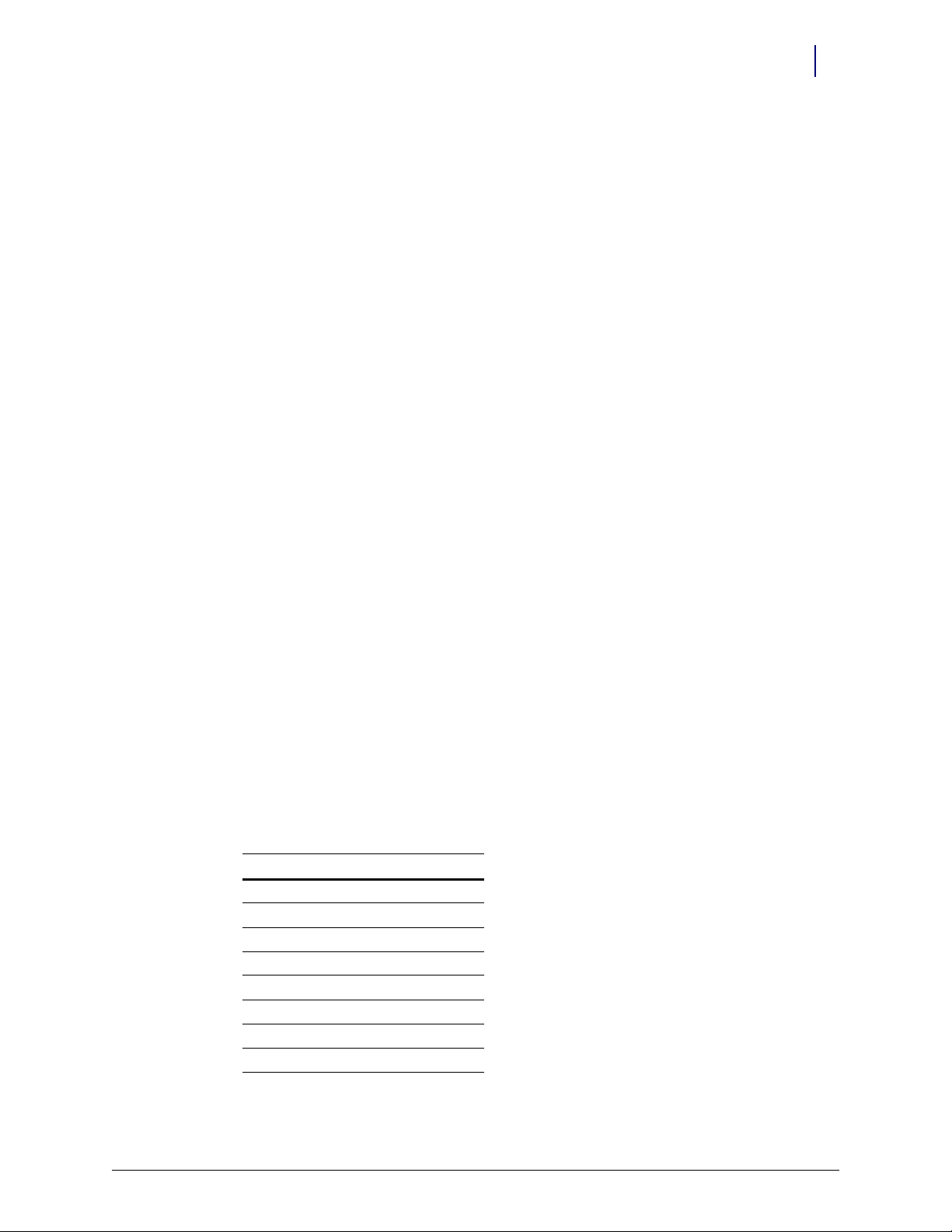

Part # Description Size/Model Notes

400848-2 Omnicell FlexLock Adapter Kit, Factory installed 5 cubic feet (model 142 l) for UC Refrigerators and Freezers

400782-2 Omnicell FlexLock Compatible Door Handle, Factory installed 11 cubic feet (model 326 l)

400782-1 Omnicell FlexLock Compatible Door Handle, Factory installed 20 cubic feet (model 572)

25 cubic feet (model 714)

26.5 cubic feet (model 750 l)

400848-1 Omnicell FlexLock Adapter Kit, Field installation 5 cubic feet (model 142 l) for UC Refrigerators and Freezers)

400875-2 Omnicell FlexLock Compatible Door Handle, Field installation 11 cubic feet (model 326 l)

400875-1 Omnicell FlexLock Compatible Door Handle, Field installation 20 cubic feet (model 572)

25 cubic feet (model 714)

26.5 cubic feet (model 750 l)

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 13

Installation Instructions

Preparation

1. Use the template pattern (see “Template” on page C-1) to see if the cabinet or refrigerator is

compatible with the FlexLock. There are two sides of the template—one for a square (90°

angle) door, the other for a rounded door (used by such manufacturers as Sanyo or Kenmore).

a. Align the template to the door and side surface.

b. Make sure there are no gaps.

Hardware Installation 2-5

Installation Instructions

Figure 2-3. Using the template pattern

Important:

pattern. See “Compatible Refrigerators” on page A-5 for space requirements and makes/models details.

2. Use an isopropyl alcohol/water mix to clean the refrigerator or cabinet surface where the

FlexLock is to be placed (side where door opens—not the hinged side).

FlexLock Assembly

1. Choose a location on the refrigerator or cabinet—allowing room for the Flexlock and

accessing the refrigerator/cabinet handle.

Note: If installing the TempCheck probe, make sure the cross bar of the mounting bracket is not in line

with a shelf inside the refrigerator. The TempCheck flex circuit should be able run along the inside wall

of the refrigerator.

2. Select the correct door adapter for the door type.

Do not attempt to install the FlexLock if the refrigerator door does not fit the template

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 14

2-6 Hardware Installation

Installation Instructions

Door Bracket Assembly

1. Remove the three T-8 screws which hold the cover plate to the door plate using a T-8 Torx

Driver and retain them for later use.

Figure 2-4. Removing the cover plate

2. Remove the cover plate.

3. Remove the four 5/16 nuts which hold the door plate to the plate adapter using a 5/16 nut

driver.

Figure 2-5. Removing the door plate from the plate adaptor

4. Remove the door plate.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 15

Hardware Installation 2-7

Installation Instructions

Test Fit

1. Test fit the door adapter against the door corner. Bend the adapter slightly to match the angle

of the refrigerator if needed. A close fit is required for strength.

Figure 2-6. Testing the door adapter fit

Figure 2-7. Bending the door adapter

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 16

2-8 Hardware Installation

Installation Instructions

2. Attach the door adapter to the correct door plate using four 5/16” Hex nuts. Hand tighten.

Figure 2-8. Assembling the door brackets

3. Test fit the door bracket assembly against the door corner.

Figure 2-9. Testing the door bracket assembly fit

Helmer Fridge Adjustment

If attaching the FlexLock to a Helmer refrigerator, extra steps and parts are needed. This setup can

take up to 15 minutes. Secure the contents of the refrigerator (if any) in a secure, temperature

controlled container/area during the procedure.

For the 11 cubic feet refrigerator, do the following steps:

1. Remove the existing handle from the door by removing the five mounting screws.

2. Secure the Omnicell Flexlock handle to the door using four of the original screws (two on top

and two at the bottom).

3. Secure the spacer block to the door using the middle screw. Make sure that one edge lines up

with the front face of door.

For the under counter refrigerator, do the following steps:

1. Remove two of the bottom door screws.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 17

Hardware Installation 2-9

2 - Lift up

1 - Slide back

Installation Instructions

2. Install the spacer by rotating it into position with the two screw holes aligning with the

mounting holes.

3. Make sure the spacer is flush with the front of the door. If the spacer is not flush, rotate the

spacer into position with the other two mounting holes to obtain the flush position.

4. Secure the spacer with two Phillips flat head screws provided with the kit.

Mounting Bracket

1. Use #2232 cam lock key to move the keyhole cover plate to the open (unlocked) position.

2. Remove the T-10 screw in back with a T-10 Torx driver.

3. Put on an ESD wrist strap and properly ground it.

Figure 2-10. Removing the back screw

4. Slide the outer housing back, then lift off.

Figure 2-11. Removing the outer housing

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 18

2-10 Hardware Installation

Installation Instructions

5. Remove the four 5/16” hex standoffs in each of the inner housing corners and retain them for

later use.

Figure 2-12. Removing the standoffs

6. Lift the inner housing off.

Figure 2-13. Removing the inner housing

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 19

Hardware Installation 2-11

Installation Instructions

Alignment Fixture

1. Place the mounting bracket so that the crossbar is toward the bottom and the threaded studs

are facing up.

Figure 2-14. Arranging the bracket assembly

2. Lay the alignment fixture over the right side of the mounting bracket. Align the fixture’s offset

stud holes with the bracket studs. The fixture’s cutout should be facing right.

Figure 2-15. Placing the alignment fixture on the mounting bracket

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 20

2-12 Hardware Installation

Installation Instructions

3. Use two of the standoffs (removed from the inner housing) to keep the fixture in place. Do not

tighten.

4. Slide in the door bracket assembly’s lock tab into the alignment fixture cutout.

5. Tighten the standoffs.

Figure 2-16. Completed bracket assembly with alignment fixture

Bracket Assembly

1. Fit the complete bracket assembly on the cabinet/refrigerator.

Figure 2-17. Fitting the whole bracket assembly

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 21

Hardware Installation 2-13

Installation Instructions

2. Turn the brackets over and remove the protective film from the adhesive strips for the

mounting bracket and the side of the inner door bracket. Leave the film cover on the strip that

will go on the front of the door.

Figure 2-18. Removing adhesive strip covers

3. Fit the door bracket assembly to the cabinet/refrigerator and press firmly on the mounting

bracket and the side of the door bracket assembly.

Figure 2-19. Bonding the bracket assembly

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 22

2-14 Hardware Installation

Installation Instructions

4. Remove the alignment fixture.

Figure 2-20. Bracket assembly without the alignment fixture

5. Open the refrigerator/cabinet door.

6. Press firmly on the mounting bracket to assure the adhesive has full contact.

Figure 2-21. Pressing the mounting bracket

7. Close the refrigerator/cabinet door.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 23

8. Remove the four 5/16” hex nuts to remove the door plate.

Figure 2-22. Removing the door plate

Hardware Installation 2-15

Installation Instructions

9. Bend the door adapter back slightly to peel off the adhesive strip cover.

Figure 2-23. Bending the door adapter

Figure 2-24. Stripping the adhesive cover

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 24

2-16 Hardware Installation

Installation Instructions

10. Press the door adapter firmly in place, to assure full contact from the adhesive.

Figure 2-25. Bonding the door adapter

Important:

take 20 minutes for 50% bond strength; 24 hours for 90% bond strength; 72 hours for 100% bond

strength. The process can be sped up by increasing the temperature 150° F for an hour.

If applicable, the TempCheck probe can be installed while waiting for the bonding process. Refer

to“TempCheck Installation” on page 2-18.

Wait until the bond is set before proceeding to the next step. At room temperature, it will

11. Re-attach the door plate to the door adapter and tighten the four 5/16” nuts.

Figure 2-26. Re-attaching the door plate

12. Open the door of the refrigerator/cabinet.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 25

13. Match the notches on the cover plate to the door plate openings.

Figure 2-27. Matching notches

14. Move the cover plate forward until it fits without gaps.

Hardware Installation 2-17

Installation Instructions

Figure 2-28. Placing the cover plate

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 26

2-18 Hardware Installation

Circuit

Contac ts

Installation Instructions

15. Secure the cover plate to the door plate with the three retained T-8 Torx screws to the side of

the front cover.

Figure 2-29. Securing the cover plate

TempCheck Installation

This section provides instructions for the optional installation of a TempCheck temperature probe

with a new FlexLock. If performing a TempCheck retrofit for an existing FlexLock, refer to

“Retrofit TempCheck” on page 2-45. If not using this optional feature, skip to the next

section—“Inner Housing and Cover” on page 2-20.

Note: Most refrigerators have doors that open from the left (door hinges on the right side). If the door opens

from the right side, some installation parts must be inverted.

1. Clean the intended path of the TempCheck probe flex circuit inside the refrigerator with a

isopropyl alcohol/water mix. The path should be level with the mounting bracket’s crossbar

and not in line with a refrigerator shelf. The probe is placed on the side closest to the

opening—opposite the hinges.

2. Align the contacts end of the flex circuit to the edge of the FlexLock mounting bracket and

temporarily attach it with adhesive tape. Avoid taping over the circuit contacts at the end.

Figure 2-30. Aligning the end of the Flex Circuit with bracket.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 27

Hardware Installation 2-19

Installation Instructions

3. Pull the flex circuit tight inside the refrigerator door.

4. Install the temperature sensor end inside the refrigerator. Remove the self-adhesive cover and

pull the flex circuit tight while sticking it in place.

Figure 2-31. Installing the sensor inside the refrigerator.

5. Remove the tape from the contacts end of the flex circuit.

6. Peel off the self-adhesive cover from the flex circuit.

7. Pull the flex circuit tight while carefully adhering it from inside the refrigerator to the mid

point of the mounting bracket.

8. Bend the exposed end of the flex circuit at a ninety degree angle. Bend up for refrigerators that

open from the left...or down for refrigerators that open from the right. The exposed contacts

should be facing the refrigerator wall in either case.

Figure 2-32. Bending the Flex Circuit end up (refrigerator opens from left)............or down (refrigerator opens from right).

Note: Be sure to complete the “Bracket Assembly” steps before going to the “Inner Housing and Cover”

section.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 28

2-20 Hardware Installation

Installation Instructions

Inner Housing and Cover

1. Place the inner housing over the mounting bracket’s threaded studs. If applicable, thread the

TempCheck flex circuit through the inner housing opening.

Figure 2-33. Placing the Inner Housing in position.

2. Place a washer on the threaded studs, then tighten the four standoffs.

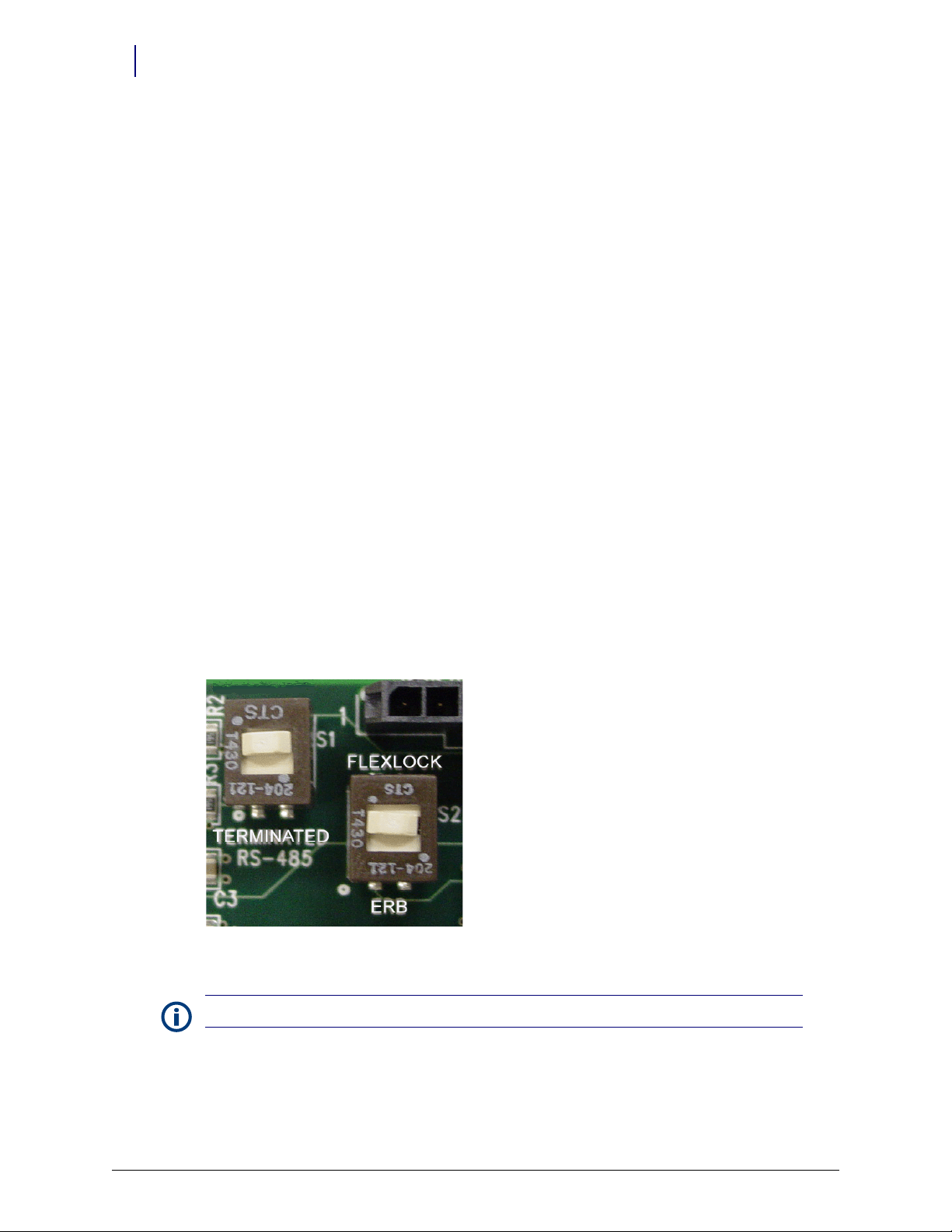

3. Set the PCBA S1 slide switch to either: (see Figure 2-34)

Terminated—if the FlexLock is at the end of the AUX daisy chain or the only AUX device

Not Terminated (not marked on PCBA)—if in the middle of a daisy chain with an External

Return Bin (ERB) or another FlexLock cabled to it

4. Set the PCBA S2 slide switch to FlexLock.

Figure 2-34. Checking the PCBA Switch Settings.

Note: The PCBA switch labels will be upside down when the inner housing is installed.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 29

Hardware Installation 2-21

ZIF Connector

ZIF Connector

1

2

Installation Instructions

5. If installing the TempCheck probe:

a. Pull out the Zero Insertion Force (ZIF) connector collar so that it is in the up (unlocked)

position.

b. Loop the TempCheck probe flex circuit around without twisting to plug it into the ZIF

connector. The flex circuit contacts should be facing down (if refrigerator opens from the

left) or up (if refrigerator opens from the right).

c. Insert the flex circuit into the connector, then evenly press the ZIF connector collar down

into the locked position.

Figure 2-35. Connecting the Flex Circuit in the Housing Assembly

6. Install the FlexLock housing cover by (1) placing it over the inner housing offset to the front,

then (2) sliding it back.

Figure 2-36. Placing the Housing Cover in position.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 30

2-22 Hardware Installation

1

2

3

standoffs

standoffs

release

housing

opening

shims

crosshair

crosshair

Installation Instructions

Alignment

1. Close the refrigerator (or cabinet) door to check the lock assembly for clearance in three

places.

The lock assembly should be vertically centered so that the gap at point 1 is the same as

point 2.

The lock tab should move in/out of the locking slot with no interference at point 3.

Figure 2-37. Checking the locking assembly.

2. If alignment adjustments are needed, remove the cover.

Figure 2-38. Alignment Features

3. To add space between the mounting bracket and the inner housing assembly:

a. Pull the ZIF connector collar up to release the TempCheck flex circuit if present.

b. Remove the four corner standoffs and washers.

c. Remove the inner housing. Thread the flex circuit out of the housing opening if present.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 31

Hardware Installation 2-23

washers/shims

Installation Instructions

d. Remove the standoff (2nd left on inner housing) holding the extra washers.

Figure 2-39. Washer/Shims under standoff

e. Remove the washers and replace the standoff.

f. Use the washers as shims by placing them on the four threaded studs.

g. Place the inner housing on the threaded studs now with shims.

h. Re-thread the TempCheck flex circuit back through the housing opening if present.

i. Place a washer on the threaded studs then tighten the four standoffs.

Figure 2-40. Adding space with shims

j. If installing the TempCheck probe:

1. Pull out the Zero Insertion Force (ZIF) connector collar so that it is in the up

(unlocked) position.

2. Loop the flex circuit around to plug it into the ZIF connector. The exposed metal

contact portion of the flex circuit end should be facing down.

3. Evenly press the ZIF connector collar down into the locked position.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 32

2-24 Hardware Installation

Installation Instructions

4. Set the vertical alignment if needed.

a. Loosen the standoffs as needed.

b. Use a screwdriver with the two cross hairs. The screwdriver slot adjustment sets the

c. Tighten the standoffs.

position up and down from neutral. The neutral position is when the cross hairs are aligned

in a cross formation.

Figure 2-41. Aligning the inner housing with the Cross Hair.

5. To adjust the inner plate of the Lock Pawl:

a. Loosening the middle and two right standoffs.

b. Adjust pawl horizontally as needed.

c. Re-tighten the standoffs.

6. Replace the housing cover.

7. Secure the housing cover with one T-10 Torx screw.

Figure 2-42. Securing the housing cover.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 33

Retrofit

Hardware Installation 2-25

Installation Instructions

This section provides instructions for various cable retrofits depending on how the FlexLock is

configured into the Omnicell system.

Electronics Sled Connection

This section provides instructions for attaching a FlexLock to the following cabinet types:

OmniTT

AnesthesiaTT

Anesthesia Workstation

Half Cell Cabinet

OmniRX

1. Power down the cabinet.

Caution:

2. Access the electronics sled.

Figure 2-43. Propping the sled cover

Note: The Anesthesia Workstation sled cover can be removed completely.

Put on an ESD wrist strap and ground it before working on the cabinet electronics.

a. Lift up the sled cover.

b. Prop open using a switch panel housing.

3. Remove both AUX cable connectors at the rear of the electronic sled by pushing down on the

AUX connector and pulling it out through the back.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 34

2-26 Hardware Installation

Installation Instructions

Figure 2-44. Removing the AUX connectors

4. Unplug the 4 pin connector from AUX J24 (US Logic/Windows 95) or J10 (ETX/Windows XP)

on the power-comm board.

5. Remove the cable.

Figure 2-45. AUX cable removed

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 35

Hardware Installation 2-27

Aux

Conne ctor

FlexLock

Connector

Power

Connector

Communications

Connector

Installation Instructions

6. Insert the black AUX connector from the Omnicell FlexLock retrofit AUX cable assembly into

the first opening.

Figure 2-46. #42-7052 AUX Cable Assembly

7. Refer to the following table when connecting the 4-pin and 3-pin cables.

Board Type Com 4-Pin Connection Power 3-Pin Connection

US Logic This motherboard does not support auxiliary cabinets, FlexLock or ERB.

OmniRx Power Com (40-7056) J10 J4, J5 (MAG), J16

Power Com2 (40-1015) J16 4-pin HDD power connector from

AC/DC power sup ply

Power Com3 (40-1021, 1050) J20 J4 / J5 / J6

a. Insert the 4-pin connector into the appropriate port (varies by board).

Figure 2-47. Connecting the communications cable

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 36

2-28 Hardware Installation

Installation Instructions

b. Insert the 3-pin (blue and yellow cables) connector from the retrofit AUX cable assembly

Figure 2-48. Connecting the power cable

8. Thread the Omnicell FlexLock cable (white) through the 2nd AUX opening.

9. Slip the metal retaining bracket (1” square) over the white connector and position it on the

inside rear of the metal rail.

into the appropriate port (varies by board).

Figure 2-49. Positioning the retaining bracket

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 37

Hardware Installation 2-29

Installation Instructions

10. Connect the FlexLock cable to the cable assembly.

Figure 2-50. Connecting the FlexLock cable

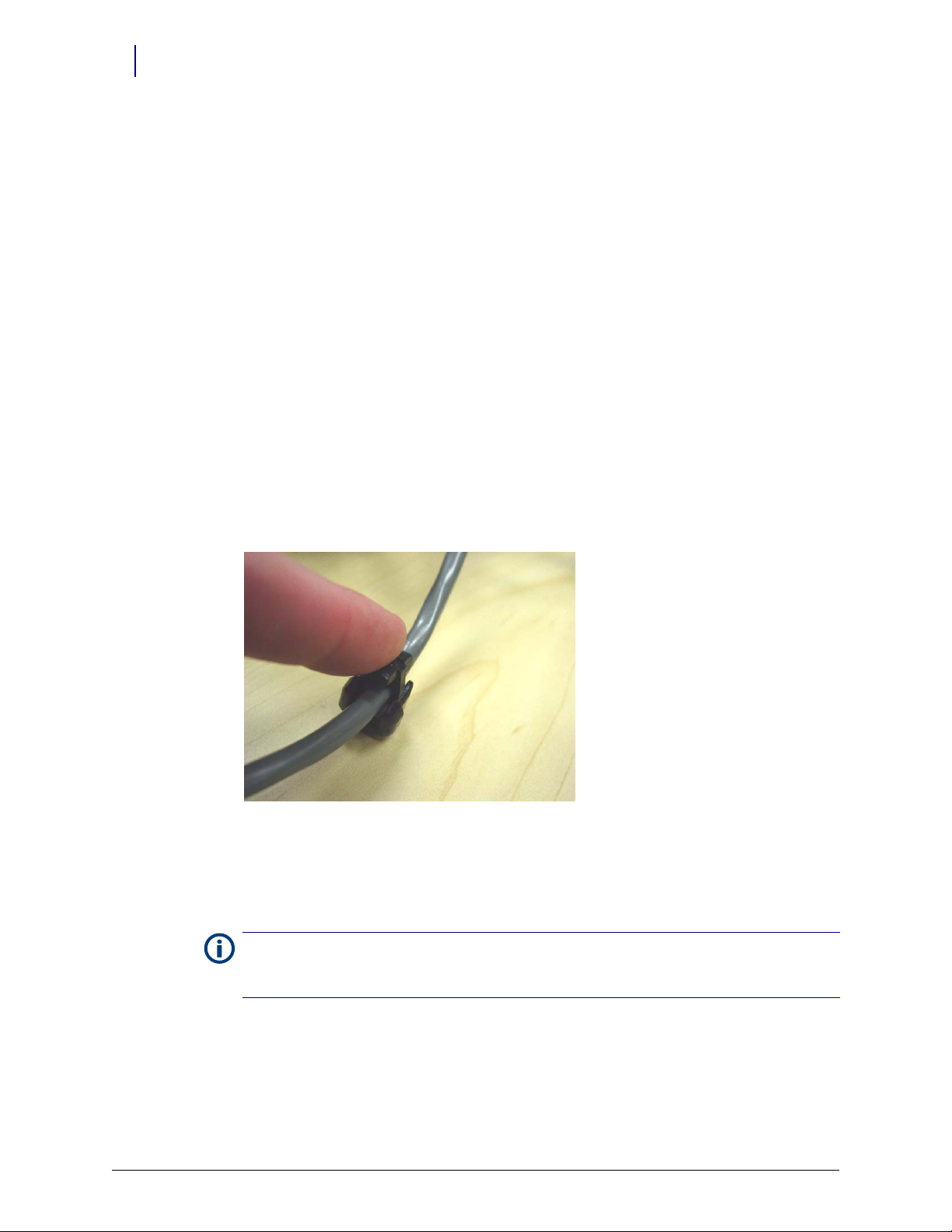

11. Snap on the black strain relief over the outside Omnicell FlexLock Power Comm cable and

push it half way through the 2nd AUX opening. The metal retainer should snap into the

groove of the black strain relief and secure the cable to the inside of the rear panel.

Figure 2-51. Snapping on the strain relief

12. Tuck all the cables out of the way. Use cable ties as needed.

13. Close the sled cover.

14. Remove the ESD wrist strap.

15. Switch the power on.

16. Proceed to “Software Implementation” on page 3-1 for software configuration instructions for

FlexLock and TempCheck if installed.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 38

2-30 Hardware Installation

Aux

Conne ctor

FlexLock/ER B

Conne ctor

Power

Conne ctor

Communications

Conne ctor

Installation Instructions

PC Box Connection

Use these steps when connecting a FlexLock to an OmniSupplier.

1. Power down the cabinet.

Caution: Put on an ESD wrist strap and ground it before working on the cabinet electronics.

2. Access the PC Box.

3. Remove both AUX cable connectors at the rear of the PC box by pushing down on the AUX

connector and pulling it out through the back.

Figure 2-52. Removing the AUX connectors from the PC box

4. Unplug the 4-pin connector from Aux Com J16 on the power-comm board.

5. Remove the AUX cable.

6. Insert the black AUX connector from the Omnicell FlexLock retrofit AUX cable assembly into

the first opening.

Figure 2-53. AUX Cable Assembly #42-7058

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 39

Hardware Installation 2-31

AUX COM

Installation Instructions

7. Insert the 4 pin header connector on the retrofit AUX cable assembly into J16, labeled AUX

COM on the UPS board.

Figure 2-54. Connecting the communication cable

8. Insert the power (blue and yellow cables) connector from the retrofit AUX cable assembly into

power supply connector.

Figure 2-55. Connecting the power cable

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 40

2-32 Hardware Installation

Installation Instructions

9. Thread the Omnicell FlexLock cable (white) through the 2nd AUX opening and connect it to

the cable assembly.

Figure 2-56. Connecting the FlexLock cable

10. Slip the metal retaining bracket (1” square) over the white connector and position it on the

inside rear of the metal rail.

11. Snap on the black strain relief over the outside Omnicell FlexLock Power Comm cable and

push it half way through the 2nd AUX opening. The metal retainer should snap into the

groove of the black strain relief and secure the cable to the inside of the rear panel.

Figure 2-57. Inside view of bracket and strain relief

12. Tuck all the cables out of the way. Use cable ties as needed.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 41

Hardware Installation 2-33

Strain Relief

AUX Con nector

Installation Instructions

13. Secure the PC Box.

Figure 2-58. Rear View of OmniSupplier PC Box

14. Remove the ESD wrist strap.

15. Switch the power on.

16. Proceed to “Software Implementation” on page 3-1 for software configuration instructions for

FlexLock and TempCheck if installed.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 42

2-34 Hardware Installation

Installation Instructions

External Return Bin

If connecting an External Return Bin (ERB) and a FlexLock at the same time, install the ERB first.

Refer to [Section 20] External Return Bin, Installation and Servicing Manual.

Note: The FlexLock can be installed without removing the ERB from the frame. The pictures in this

section show the ERB detached for clarity purposes.

1. Remove the internal I/O cover plate on the cable side of the ERB.

a. Remove the 4-40 flathead fastener below the ERB on the cable side with a T-8 Torx driver.

Figure 2-59. Removing the fastener

b. Open the access door using key #2204 to unlock the access door and key #2202 to override

the solenoid.

Figure 2-60. Opening the access door

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 43

c. Slide out the I/O cover plate on the cable side.

Figure 2-61. Sliding out the I/O cover plate

Note: The figures in this section are with the ERB removed from the frame for clarity.

Hardware Installation 2-35

Installation Instructions

2. Remove the black plug cover on the side adjacent to the cable assembly.

Figure 2-62. Removing the plug

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 44

2-36 Hardware Installation

Installation Instructions

3. Insert the FlexLock molex cable into the cutout.

Figure 2-63. Inserting the FlexLock cable

4. Pullout the ERB connector from behind the PCB/solenoid metal plate.

Figure 2-64. Accessing the ERB connector

5. Connect both 6 pin molex cables together inside the ERB.

Figure 2-65. Connecting the ERB and FlexLock cables

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 45

Hardware Installation 2-37

FlexLock

cable (in)

ERB cable

(out)

Installation Instructions

6. Insert a black strain relief to cover the cutout and secure the cable.

Figure 2-66. Securing the cable with a strain relief

7. Slide in the I/O cover over the cables and cable openings, into the slot in the back wall. Do not

pinch any wires.

Figure 2-67. Replacing the I/O cover plate

8. Secure the I/O cover plate with the 4-40 flathead fasteners on the bottom of the ERB on the

cable side.

Figure 2-68. Securing the I/O cover plate fastener

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 46

2-38 Hardware Installation

Installation Instructions

9. Open the return door to remove the PCB/solenoid metal mount.

a. Push the pawl of the solenoid to the left.

Figure 2-69. Accessing the pawl

b. Lift the top handle to open the return door.

Figure 2-70. Opening the return door

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 47

Hardware Installation 2-39

Installation Instructions

10. Remove the PCB/solenoid metal plate by loosening the two nuts on either side of the plate,

using a 5/16” nut driver.

Figure 2-71. Nut locations

Note: Do not completely remove the nuts, one full turn should be enough.

Figure 2-72. Loosening the metal plate nuts

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 48

2-40 Hardware Installation

Installation Instructions

11. Maneuver the metal plate around the sheet metal tabs and nuts. Remove the lower rim first.

Figure 2-73. Removing the metal plate

12. Set the S1 slide switch to Not Terminated (not labeled on the board) because the ERB will be in

the middle of the daisy chain configuration. The S2 slide switch should already be set to ERB.

Figure 2-74. Setting the switches

13. Replace the PCB/solenoid metal plate, then tighten the two nuts on either side of the plate,

using a 5/16” nut driver.

14. Close the return door.

15. Close and lock the access door with the cam keys.

16. Proceed to “Software Implementation” on page 3-1 for software configuration instructions for

FlexLock and TempCheck if installed.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 49

Hardware Installation 2-41

Installation Instructions

FlexLock to FlexLock Chain

1. Install the second Flexlock to a refrigerator or cabinet with the same procedures as the first.

2. Remove the Omnicell FlexLock cover plate of the 1st FlexLock using both keys.

Figure 2-75. Moving the key cover plate

3. Remove the 6-32 BH Torx screw.

Figure 2-76. Removing the housing cover screw

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 50

2-42 Hardware Installation

Installation Instructions

4. Open the refrigerator door, then remove the cover.

Figure 2-77. Removing the housing cover

5. Remove the black Heyco plug from the back of FlexLock #1 (this is adjacent to the black strain

relief located on the power/comm cable). There are small plastic snaps on the inside of plug

that can be pressed with a flat blade screwdriver to release the plug.

Figure 2-78. Removing the plug

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 51

Hardware Installation 2-43

Installation Instructions

6. Route the power/comm cable from FlexLock #2 into the available cutout on FlexLock #1.

Note: Cable limitation from Host to last FlexLock is 125 ft.

Figure 2-79. Routing the Flexlock cable

7. Connect the 6 plug connector into the available white 6 conductor plug.

Figure 2-80. Connecting the FlexLock cable

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 52

2-44 Hardware Installation

Installation Instructions

8. Install the large black strain relief over the FlexLock #2 power/comm cable.

Figure 2-81. Installing the strain relief

9. Snap the strain relief into the cutout.

Figure 2-82. Snapping the strain relief into the cutout

10. Tie up any loose internal wires with the existing Kurly lock or cable tie.

11. Set the S1 switch to Not Terminated (not marked on PCBA).

Figure 2-83. Checking the PCBA Switch Settings.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 53

12. Replace the cover on the first FlexLock and secure it with the 6-32 BH Torx screw.

13. Proceed to “Software Implementation” on page 3-1 for software configuration instructions for

FlexLock and TempCheck if installed.

Retrofit TempCheck

This section provides instructions if retrofitting an existing FlexLock with a TempCheck probe.

The retrofit kit #20-6037 is needed for this procedure.

1. Remove the screw that secures the FlexLock housing cover.

2. Remove the housing cover.

3. Remove the four standoffs that secure the FlexLock inner housing.

4. Follow steps in “TempCheck Installation” on page 2-18.

5. Follow the steps in “Inner Housing and Cover” on page 2-20 using the new inner housing from

the retrofit kit.

6. Proceed to “Software Implementation” on page 3-1 for software configuration instructions for

TempCheck.

Hardware Installation 2-45

Retrofit TempCheck

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 54

2-46 Hardware Installation

Retrofit TempCheck

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 55

Software Implementation

This chapter provides general instructions for implementing the FlexLock and its optional

feature, TempCheck. For additional information or assistance, contact Omnicell Technical

Support.

FlexLock

Implementation Overview

Software implementation for FlexLock includes the following:

Bin Addressing

Item Assignment

Reports

FlexLock Programming

Cabinet Configuration

3-1

OmniCenter

Bin Addressing

FlexLock bin addresses are handled essentially the same way that the bin addresses in a

Sure-Med universal compartment are currently treated. The drawer type is FlexLock. The

location displayed is entered by the user at the OmniSupplier. If a user-entered description

is not provided, the field displays Flexlock #1, Flexlock #2, and so on. Like universal

compartment bins, FlexLocks do not support multiple bins, so items that are assigned to a

FlexLock cannot be assigned elsewhere, and vice versa. Only pharmacy items are

supported.

The new Drawer Type information is as follows:

l

Field Value

draw type 46

draw_desc FlexLock

start_bin 0

stop_bin 118

bin_number nBin + 1

subdrawers .F.

multi_bin .F.

matrix .F.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 56

3-2 Software Implementation

FlexLock

Item Assignment

Items can be assigned to existing Remote Lock bins via the OmniCenter Database tab. The

Bin Assignment feature is accessed by selecting the Bins radio button on the Item Record.

Reports

The Pharmacy Drawer Configuration report and the Bin Assignment look-up list are used to

support FlexLock.

Color Touch

FlexLock Programming

1. Login at the Color Touch screen of the cabinet where the FlexLock is cabled.

2. Go to the configuration

a. Press Admin.

b. Press Omni Config.

c. Press Program FlexLock.

3. Press the button on the FlexLock. A confirmation window is displayed when the

FlexLock programming is complete.

Figure 3-1. Pressing the FlexLock button for programming

Cabinet Configuration

There are 5 software configurations for FlexLock. Four are maintained by the system. One

can be changed by the user. It is found in the Omni Config, Misc menu.

Misc_Options

Config Name: FlexLock_Timeout_Value

Menu Name: FlexLock Timeout Value

Description: Limit FlexLock access

Val ues :

Default:

Implementation: Set to the desired time out setting in seconds.

0-999 Seconds; 0 seconds = disabled

60 Seconds

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 57

Note: If the OmniSupplier CountBack Timeout configuration is set to 0 (disabled), the FlexLock

Timeout will also be disabled—regardless of its setting.

TempCheck

Implementation Overview

Implementation for FlexLock TempCheck includes the following:

Setting the Temperature Monitoring Parameters at the OmniCenter

Configuring the cabinet software via Color Touch

FLEXLOCK#_MONITORING

FLEXLOCK#_MONITORFREQ

FLEXLOCK#_LOWTEMPLIMIT

FLEXLOCK#_HIGHTEMPLIMIT

Software Implementation 3-3

TempCheck

OmniCenter

This section provides instructions for setting up the temperature monitoring parameters.

Temperature Monitoring Parameters

1. Login to OmniCenter as Omnicell Tech.

2. Select the Administrative tab.

3. Select Setup Administrative Type.

4. Double press Temperature Monitoring Setup.

Figure 3-2. Administration > Setup window

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 58

3-4 Software Implementation

TempCheck

5. Select temperature display type (Celsius; Fahrenheit).

6. Select number of months to store temperature readings. The default is

12.

7. Specify notice trigger (only when status changes; all alerts).

8. Check box for notification when status returns to normal if desired.

9. Press Add to specify destinations for alert.

10. Select output type on the Add window.

11. Specify search type, enter a string, then press Search. A matching list is displayed below.

12. Highlight the desired destinations, then press Add.

Figure 3-3. Temperature Monitoring Setup window

13. Repeat Steps 11-12 as needed.

14. Press Close when finished adding destinations.

15. Press Delete to remove a destination listing if needed.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 59

Color Touch

Software Implementation 3-5

TempCheck

There are four software configurations available if one or more FlexLocks with TempCheck

are connected to the system. The configurations are found in the Omni Config, FlexLock

Temperature Monitoring menu.

Cabinet Software Configuration

FlexTemp

Config Name: FLEXLOCK#_MONITORING

Menu Name: FlexLock # Monitoring

Description: Enables temperature monitoring for the TempCheck device

Val ues :

Default:

Implementation:

On; Off

Off

On to enable temperature monitoring.

Set to

Config Name: FLEXLOCK#_MONITORFREQ

Menu Name: FlexLock # Monitoring Frequency

Description: Specifies the frequency (in minutes) at which the cabinet will check the temperature.

Val ues :

Default:

Implementation: Set the desired number of minutes between each temperature check.

Config Name: FLEXLOCK#_LOWTEMPLIMIT

Menu Name: FlexLock # Low Temp Limit

Description: Specifies the temperature (ºC) below which a low temperature warning will occur.

Val ues :

Default:

Implementation: Set the desired low end of the acceptable temperature range. Alerts will be given if the sensor

Config Name: FLEXLOCK#_HIGHTEMPLIMIT

Menu Name: FlexLock # High Temp Limit

Description: Specifies the temperature (ºC) above which a high temperature warning will occur.

Val ues :

Default:

Implementation: Set the desired high end of the acceptable temperature range. Alerts will be given if the sensor

1-120 minutes

30 minutes

-9 to 129º C

2º C

encounters temperatures below this setting.

-8 to 130º C

8º C

encounters temperatures above this setting.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 60

3-6 Software Implementation

TempCheck

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 61

Service

Product Overview

The FlexLock can be connected to a cabinet or a workstation. It can also be daisy-chained to

an External Return Bin (ERB) or another FlexLock.

The cabinet or workstation acts as a host providing power to the FlexLock directly or

indirectly through a daisy-chained ERB or another FlexLock.

The host cabinet or workstation must be powered down to work on the FlexLock as it does

not have its own power switch. This is true even if the FlexLock to be serviced is in a daisychain and not directly connected to the host cabinet or workstation.

Some services require the disconnection of the FlexLock cables for replacement or to allow

the host equipment to be used while service is being completed on the FlexLock.

4-1

Service Overview

There are four types of services done on a FlexLock. They are listed below with the related

conditions when they are performed.

Alignment Adjustment

This service is done when the refrigerator door does not close properly.

TempCheck Replacement

Replace the TempCheck probe and flex circuit cable (if present) when:

FlexLock Inner Housing Replacement

This service is done when:

Complete FlexLock Replacement

The whole FlexLock assembly is replaced when:

Temperature readings are beyond hardware limit

Voltage problems occur and error messages are displayed

Upgrading an older FlexLock for TempCheck installation

Hardware failure occurs and error messages are displayed

FlexLock has poor adhesion to refrigerator or cabinet

Poor adhesion can be caused by an unclean or textured refrigerator/cabinet surface. It

can also be caused by not waiting long enough for the adhesion to bond before the

FlexLock is used.

Wrong door latch was used originally

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 62

4-2 Service

Standoffs

#94-6218

Blue Screen

Power Cable

CD

(obsolete)

Alignment

Fixture

TempCheck Probe

#15-7105

Bracket Cutout

AUX assy cables

#94-6138

#94-6233

#94-6158

#91-2052

#91-2051

Service Overview

Tools Required

Kit/Parts Required

Tool Required for

T-10 Torx Driver All Procedures

FlexLock Cam Lock Keys #2202 and #2232 All procedures

ERB Cam Lock Keys #2202 and #2204 Replacing Inner Housing, FlexLock (if connected to ERB)

ESD Wrist Strap All procedures

1/4” Hex Driver (with various bit sizes) Replacing FlexLock

T8 Torx Driver Replacing FlexLock

5/16 Nut Driver Replacing FlexLock

Screwdriver Adjusting alignment

Adhesive Cleaning Tool (safety blade) Replacing TempCheck, FlexLock

Table 4-1. Too ls Re quir ed

Figure 4-1. FlexLock Installation Kit #20-6023 with TempCheck probe

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 63

General Service Instructions

Kits/Parts Used for Description/Notes

#14-7043 Replacing FlexLock Contains Door Brackets, Cam Lock Keys with FlexLock unit/cable

#20-6023 Replacing FlexLock Includes the TempCheck temperature probe, cable for host equipment; See

“Appendix A Parts/Kit List” on page A-1 for details.

#20-6037 Replacing TempCheck,

Inner Housing

Table 4-2. Kit/Parts Required

Contains the FlexLock inner housing with the TempCheck compatible PCBA

#40-3013 and TempCheck probe; used for upgrading FlexLock for TempCheck

General Service Instructions

These instructions are called by the service procedures that follow.

Service Preparation

These steps are done before every service.

1. Contact the pharmacist so that a representative can be present when pharmacy items are

accessible during service.

2. Store the contents of the refrigerator elsewhere. The refrigerator door may be left open

for a long period of time depending on the type of service to be done. This could harm

thermal-sensitive medications.

3. Turn off the power to the FlexLock by performing a graceful shut-down the host cabinet

or workstation—even if the FlexLock to be serviced is daisy-chained to another FlexLock

or ERB.

4. Wear a properly grounded ESD strap. This will protect sensitive components from

electro-static discharge.

Service 4-3

FlexLock Manual Override/Cover Plate Removal

These two procedures are usually combined except for alignment adjustment.

FlexLock Manual Override

1. Use cam lock key #2232 to open the FlexLock override cover plate.

Figure 4-2. Unlocking the cover plate

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 64

4-4 Service

1

2

General Service Instructions

2. Use cam lock key #2202 to override the locking mechanism so that the refrigerator door

can be opened and closed.

Cover Plate Removal

1. Remove the 6-32 BH Torx screw with a T-10 Torx driver.

Cable Procedures

Figure 4-3. Removing the cover plate screw

2. Open the refrigerator door.

3. Slide the cover forward then out.

Figure 4-4. Removing the cover plate

The cable procedures vary by equipment type:

Electronic Sled

PC Box

ERB (as part of daisy-chain)

(another) FlexLock - part of daisy-chain

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 65

Service 4-5

General Service Instructions

Caution:

must be put on before accessing cables.

The host cabinet/workstation must be powered down and a properly grounded ESD strap

Electronic Sled

This section provides instructions for removing/connecting the FlexLock cable to the

following cabinet types:

OmniTT

AnesthesiaTT

Anesthesia Workstation

Half Cell Cabinet

OmniRX

1. Access the equipment.

a. Lift up the sled cover.

b. Prop open using a switch panel housing.

Figure 4-5. Propping the sled cover

Note: The Anesthesia Workstation sled cover can be removed completely.

2. Disconnect the FlexLock cable.

a. Disconnect the FlexLock cable from the power/communication cable inside the sled.

Refer to Figure 4-10.

b. Remove the strain relief and the retaining bracket. Refer to Figure 4-11 (strain relief)

and Figure 4-9 (retaining bracket).

c. Thread the cable out of the AUX opening.

3. Remove the power-communication cable.

a. Disconnect the cable from the board.

1. Remove the 4-pin (red and blue cables) connector from the AUX J24 (US Logic/

Windows 95) or J10 (ETX/Windows XP) slot on the power-comm board. See

Figure 4-7.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 66

4-6 Service

AUX

Conne ctor

AUX

Conne ctor

FlexLock

Conne ctor

Communications

Conne ctor

Power

Connector

General Service Instructions

2. Remove the 3-pin (black and yellow cables) connector from the J16 slot labeled

MAG on the UPS board. See Figure 4-8.

b. Disconnect the AUX connector.

c. Remove the cable from the sled.

Figure 4-6. #42-7052 AUX Cable Assembly

4. Replace the power-communication cable.

a. Insert the black AUX connector from the Omnicell FlexLock retrofit AUX cable

assembly into the one of the AUX openings from the inside the sled.

b. Insert the 4-pin connector (red/blue/black cables) into AUX J24 (US Logic/Windows

95) or J10 (ETX/Windows XP) on the power-comm board.

Figure 4-7. Connecting the communications cable

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 67

General Service Instructions

c. Insert the 3 pin (blue and yellow cables) connector from the retrofit AUX cable

assembly into J16 labeled MAG on the UPS board.

Figure 4-8. Connecting the power cable

Service 4-7

5. Connect the FlexLock cable.

a. Thread the Omnicell FlexLock cable through the AUX opening.

b. Slip the metal retaining bracket (1” square) over the white connector and position it

on the inside rear of the metal rail.

Figure 4-9. Positioning the retaining bracket

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 68

4-8 Service

General Service Instructions

c. Connect the FlexLock cable to the power-communication cable.

Figure 4-10. Connecting the FlexLock cable

d. Snap on the black strain relief over the outside Omnicell FlexLock Power Comm

cable and push it half way through the AUX opening. The metal retainer should snap

into the groove of the black strain relief and secure the cable to the inside of the rear

panel.

Figure 4-11. Snapping on the strain relief

6. Secure the equipment.

a. Route cables neatly—using cable ties as needed.

b. Remove the prop (if one is used), then close/replace the sled cover.

Note:

If the FlexLock cable was disconnected so the host equipment can be used during FlexLock

service (alignment adjustment or TempCheck replacement), the host cabinet/workstation can now be

powered up for use.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 69

General Service Instructions

AUX

Conne ctor

FlexLock

Conne ctor

Communications

Conne ctor

Power

Connector

PC Box

1. Access the equipment.

For more details on accessing the PC Box, refer to the Omnicell Hardware Installation Document,

Note:

Section 1: PC Box.

2. Disconnect the FlexLock cable.

a. Disconnect the FlexLock cable from the power-communication cable.

b. Remove the bracket and strain relief.

c. Thread the cable out of the AUX opening.

3. Remove the power-communication cable.

a. Disconnect the power-communication cable.

1. Remove the 4-pin header (blue and red cables) connector from J24 slot, labeled

AUX COM on the UPS board.

2. Remove the power (black and yellow cables) connector from the power supply

connector.

b. Remove the black AUX connector.

c. Remove the power-communication cable from the PC Box.

Service 4-9

Figure 4-12. AUX Cable Assembly #42-7058

4. Replace the power-communication cable.

a. Insert the black AUX connector from the Omnicell FlexLock retrofit AUX cable

assembly into the first opening.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 70

4-10 Service

General Service Instructions

b. Insert the 4-pin header connector (red/blue/black cables) on the retrofit AUX cable

assembly into J24, labeled AUX COM on the UPS board.

Figure 4-13. Connecting the communication cable

c. Insert the power (black and yellow cables) connector from the retrofit AUX cable

assembly into power supply connector.

Figure 4-14. Connecting the power cable

5. Connect the FlexLock cable.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 71

Service 4-11

General Service Instructions

a. Thread the Omnicell FlexLock cable through the AUX opening and connect it to the

power-communication cable.

Figure 4-15. Connecting the FlexLock cable

b. Slip the metal retaining bracket (1” square) over the white connector and position it

on the inside rear of the metal rail.

c. Snap on the black strain relief over the outside Omnicell FlexLock Power Comm

cable and push it half way through the 2nd AUX opening. The metal retainer should

snap into the groove of the black strain relief and secure the cable to the inside of the

rear panel.

Figure 4-16. Inside view of bracket and strain relief

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 72

4-12 Service

FlexLock

Cable

General Service Instructions

Figure 4-17. Rear View of OmniSupplier PC Box

6. Secure the equipment.

a. Route the cables neatly—using cable ties as needed.

b. Close and secure the PC Box drawer.

Note: For more details on securing the PC Box, refer to the Omnicell Hardware Installation Document,

Section 1: PC Box.

If the FlexLock cable was disconnected so the host equipment can be used during FlexLock service

(alignment adjustment or TempCheck replacement), the host cabinet/workstation can now be powered

up for use.

ERB

1. Access the equipment.

a. Remove the internal I/O cover plate on the cable side of the ERB.

1. Remove the 4-40 flathead fastener below the ERB on the cable side with a T-8

Torx d r ive r.

Figure 4-18. Removing the fastener.

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 73

General Service Instructions

b. Open the access door using key #2204 to unlock the access door and key #2202 to

override the solenoid.

Figure 4-19. Opening the access door

c. Slide out the I/O cover plate on the cable side.

Service 4-13

Figure 4-20. Sliding out the I/O cover plate

2. Disconnect the FlexLock cable.

a. Disconnect the FlexLock cable from the 6-pin connector. See Figure 4-23.

b. Remove the strain relief. See Figure 4-24.

c. Thread the cable out. See Figure 4-21 and Figure 4-22.

d. If disconnecting cables to allow the ERB to be used while servicing the other

FlexLock, set the S1 switch to Terminated. Refer to Step 3g on page 4-15.

Note:

The power-communication cable is not used when the FlexLock is daisy-chained to an ERB.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 74

4-14 Service

General Service Instructions

3. Connect the FlexLock cable.

a. Insert the FlexLock molex cable into the cutout.

Figure 4-21. Inserting the FlexLock cable

b. Pullout the ERB connector from behind the PCB/solenoid metal plate.

Figure 4-22. Accessing the ERB connector

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 75

c. Connect both 6 pin molex cables together inside the ERB.

ERB cable

(out)

FlexLock cab le

(in)

Figure 4-23. Connecting the ERB and FlexLock cables

d. Insert a black strain relief to cover the cutout and secure the cable.

Service 4-15

General Service Instructions

Figure 4-24. Securing the cable with a strain relief

e. Slide in the I/O cover over the cables and cable openings, into the slot in the back

wall. Do not pinch any wires. See Figure 4-20.

f. Secure the I/O cover plate with the 4-40 flathead fasteners on the bottom of the ERB

on the cable side. See Figure 4-18.

g. Access the PCB switches.

1. Open the return door to remove the PCB/solenoid metal mount.

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 76

4-16 Service

General Service Instructions

2. Push the pawl of the solenoid to the left.

Figure 4-25. Accessing the pawl

3. Lift the top handle to open the return door.

Figure 4-26. Opening the return door

4. Remove the PCB/solenoid metal plate by loosening the two nuts on either side of

the plate, using a 5/16” nut driver.

Figure 4-27. Nut locations

FlexLock Installation and Configuration Guide/60-3002 Rev G © 2010 Omnicell, Inc.

Page 77

General Service Instructions

Note: Do not completely remove the nuts, one full turn should be enough.

Figure 4-28. Loosening the metal plate nuts

5. Maneuver the metal plate around the sheet metal tabs and nuts. Remove the lower

rim first.

Service 4-17

Figure 4-29. Removing the metal plate

© 2010 Omnicell, Inc. FlexLock Installation and Configuration Guide/60-3002 Rev G

Page 78

4-18 Service

General Service Instructions

6. Set the S1 slide switch to Not Terminated (not labeled on the board) because the

ERB will be in the middle of the daisy chain configuration. The S2 slide switch

should already be set to ERB.

Figure 4-30. Setting the switches

4. Secure the equipment.

a. Replace the PCB/solenoid metal plate, then tighten the two nuts on either side of the

plate, using a 5/16” nut driver.

b. Close the return door.

c. Close and lock the access door with the cam keys.

Note:

If the FlexLock cable was disconnected so the host equipment can be used during FlexLock

service (alignment adjustment or TempCheck replacement), the host cabinet/workstation can now be

powered up for use.

FlexLock