Page 1

ISSUE 1

MAINTENANCE MANUAL

CLV-180

FR-1700

Page 2

CLV-180

INTRODUCTION

Introduction

This manual is intended for Olympus-certified technicians. Use of this manual by other individuals is

prohibited.

Precautions

Before Repair

(1) Notify the site manager of the intent to repair the unit and obtain his/her approval before

commencing.

(2) During repair, there is a risk of injury from the various tools and parts in the vicinity, as well as

from fluid leakage on the floor. Inform the relevant people to restrict access to the repair area.

(3) To prevent potentially dangerous health risks, avoid working in a closed room, i.e., select a

well-ventilated location when using organic solvents.

(4) In general, it is advisable to record the function and operation settings before repair, to enable

restoration of the settings after service.

(5) If the original settings cannot be known due to mechanical problems present at the time the unit

was accepted for repair, apply the factory-set values, or the safest settings (such as the lowest

output levels). In such a case, inform the user that the settings have been changed.

(6) Guard against static electricity.

Use a conductive mat or wristband to discharge static electricity to prevent damaging the boards

or other electrical components if it is necessary to touch them.

During Repair

(1) To prevent potentially dangerous health risks, thoroughly rinse any bodily areas that have come

into contact with organic solvents as soon as possible.

(2) When using organic solvents, handle flames such as those in alcohol lamps with caution,

because these solvents may ignite if exposed to flame.

In addition, always replace the lids back onto organic solvent containers before leaving the

work-bench.

(3) Beware of electric shock.

Turn off the power and unplug the power cord before removing the cover of the unit.

(4) Beware of residual voltages.

The unit may contain residual charges in capacitor components. Take care to avoid electric

shock when opening the top cover.

(5) To avoid personal injury and damage to the unit, heavy units should always be assembled or

disassembled by at least two people.

(6) Repair with extreme caution to avoid injury.

Use extra caution around metal parts because the edges may be sharp.

(7) Reassemble parts according to their original configuration. This regards the following items

especially:

a) Insulators, such as insulating tubes and mylar sheets.

b) Cable rerouting, clamps, and cores.

1

ISSUE1 INTRODUCTION

Page 3

CLV-180

c) Shield parts and cover screws with toothed washers.

Failure to attach parts in their original configurations, even if it does not impair product

function, poses the risk of noise radiation and reduced electrical safety.

(8) Use specified parts.

The parts and components of this product are designed to operate under certain anticipated

vibration, heat, chemical exposure, and voltage conditions. Always replace parts with those

specified in the parts list.

(9) Always tighten nuts/screws to the specified torque and only use components of the specified

dimensions.

(10) Do not reuse O-rings, E-rings, or packing. Always use new ones.

(11) When reusing components, remove sealing tape or sealing compound, and clean the

components before use.

(12) Check that no screws or nuts are loose.

After Repair

(1) After repair, inform the site manager of the nature of the problems, the cause, the

countermeasures taken, and the parts replaced.

(2) Always notify the site manager if, during repair, liquid disinfectants, cleaners, or alcohol were

used. Inform the site manager that before using the unit, it is necessary to verify the

concentration levels of disinfectants to ensure that they have not been diluted.

(3) Restore the original unit settings as they were recorded before repair. Request the presence of

site manager to verify the settings with you.

Copyright

© 2005 Olympus Medical Systems Corp. All rights reserved.

Unauthorized reproduction or distribution in part or in whole is prohibited.

Trademarks

OLYMPUS is a registered trademark of the Olympus Corporation.

The company names, product names, and proprietary technical terms in this document are the

trade-marks or registered trademarks of their respective owners.

2

ISSUE1 INTRODUCTION

Page 4

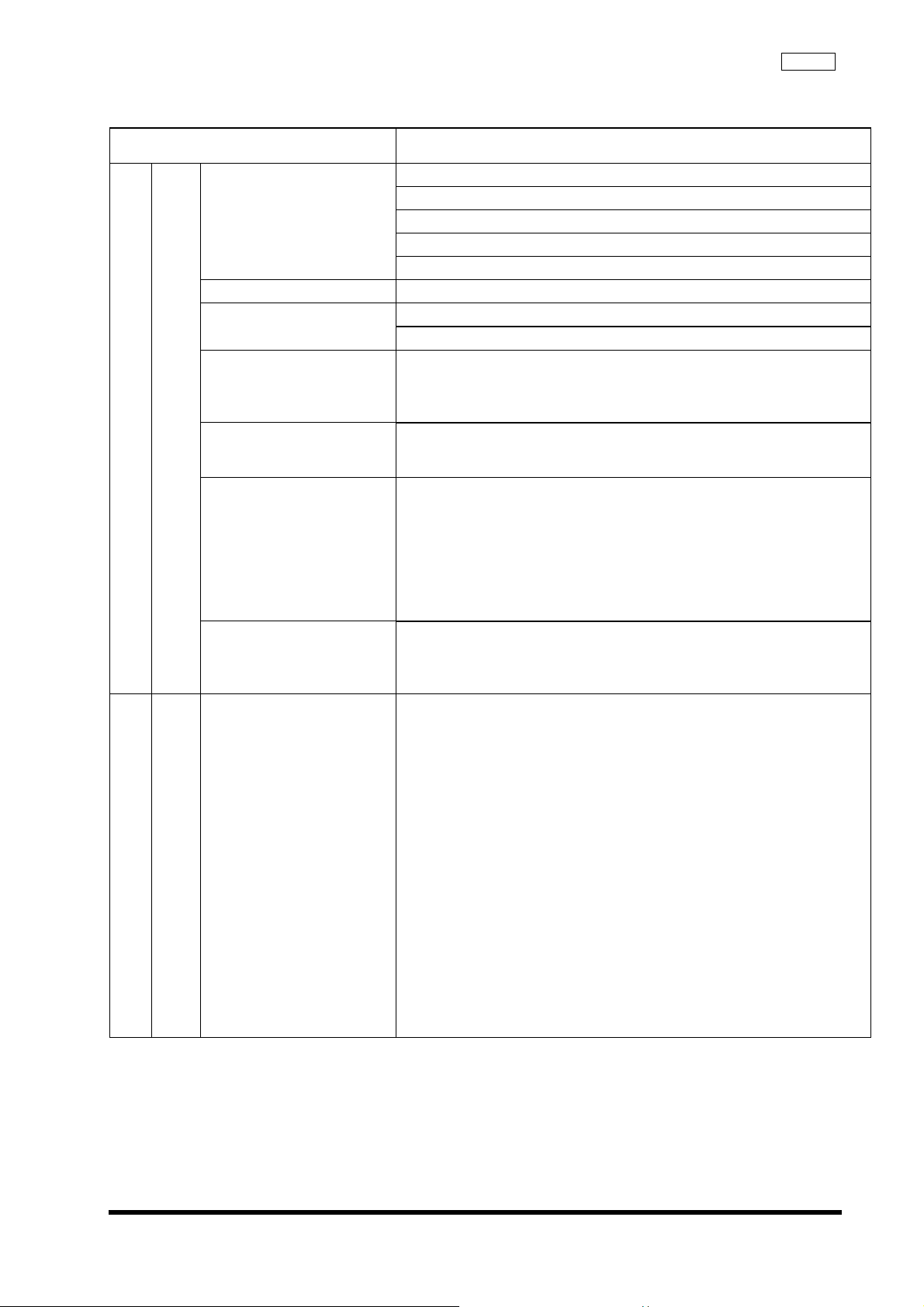

Contents

Chapter 1: Product Specifications………………………………………...1-1

1 Product Outline…………………………………..…………………………………………..1-2

2 Features……… ……… ………….……… …………..…………………… …… ……… ……..1-2

3 Operational Conditions……………………………..……………………………………...1-3

4 Specifications……… ….… ……… … …….………… ..…………………… ……… …….…1-4

5 Nomenclature and Functions…………………………………………..……………………..1-9

5-1 Front panel………………………………………………….…………………………….... 1-9

5-2 Control panel(buttons)……………………………………………………………………1-10

5-3 Control panel(indicators)………………………………………………………………...1-12

5-4 Rear and side panels……………………………………………………………………..1-14

Chapter 2: Troubleshooting………………………………………..…….2-1

1 Contents……… ……… ……… ……… ……… … ……… …………………………………… .2-2

2 Troubleshooting…………………………...…………………………………………………….2-2

2-1 Power input failure…………………………………………………………..………….2-3

2-2 Lamp failure…… ……… ……… ……… … ………… ……………………..…… …….2-4

2-3 Lamp malfunction…………….…… …… …………………….…………..… ……….2-4

2-4 Scope connection failure………………………………………………………………….2-5

2-5 High-brightness malfunction……………………………………………………………..2-6

2-6 Cooling Fan malfunction………………………………………………………………….2-7

2-7 Shield malfunction at Scope removal…………………………………………………..2-7

2-8 Pump malfunction………………………………………………………………………….2-8

2-9 Filter Change Malfunction………………………………………………………………..2-9

2-10 Outgoing light failure……………………………………………………………………2-11

2-11 Manual Brightness failure……………………………………………………………...2-11

2-12 Automatic Brightness failure………………………………………………………….2-12

2-13 Panel Malfunction……………………………………………………………………….2-13

2-14 Emergency Lamp malfunction………………………………………………………..2-15

2-15 Back-up malfunction…………………………………………………………………..2-16

2-16 Lamp Life Meter Reset malfunction…………………………………………………2-16

2-17 Transillumination malfunction……………………………………………………….2-16

Chapter 3: Precaution on disassemble and reassembly……..…..….3-1

1 Warning… … … … … … … … ..………………… … … … … … … … ..… … … ……………….3-2

2 Caution… ………… … … … … … ………… … … … … .…… … … … … … …… ………… … .3-2

Chapter 4: Assemble procedure…… ………… … ………..…..….4-1

1 Jigs and Tools………… ……… …………… …… ……………………………………… ….4-2

2 Areas…………… ………………………………………….…………………………………….4-2

3 Disassembling and Reassembling procedure……………………………………………….4-3

Chapter 5: Parts List… … ....… … … … … … … … … … ..… ..… .5-1

1 Exploded Parts Diagram…………………………..…………………………………………….5-2

2 Parts List… … … … … … … … … … … … … … .… … … … … … … … .… .… ..… … … … ..…… … … .5-10

Page 5

SpecificationCLV-180

Chapter 1: Products Specifications

ISSUE1

1-1

Page 6

SpecificationCLV-180

PRODUCT SPECIFICATIONS

1 Product Outline

Intended use:

When used in conjunction with an OLYMPUS endoscope, video system center, video monitor,

accessories, and other related equipment, this product supports examination and endoscopic treatment

by enabling observation through a fiberscope or through a video monitor.

Compatibility:

This product may be used in conjunction with EVIS 100/130/140 series videoscopes, EVIS EXERA

145/160 series videoscopes, EVIS EXERA II 165/180 series videoscopes, V series videoscopes, VISERA

series videoscopes, rigid light guides, fiberscopes, as well as EVIS EXERA II CV-180/165, and

endoscopic ultrasound systems.

Durability:

With adherance to the conditions listed below, this product has a usable life of 6 years from the

manufactured/shipped date.

Conditions: During this product’s usable life, the user must perform inspection before using, and

regular subsequent inspections as outlined in the attached materials and the operation

manual. Should the inspections reveal that repairs are required, the user must have

those repairs performed.

2 Features

(1) This is a light source unit for exclusive use with the EVIS EXERA II VIDEO SYSTEM CENTER

CV-180/165. However, this product is not to be used for surgery if used with the CV-165

(high-intensity function is not available).

(2) A mechanical detection unit is installed in the endoscope socket, enabling automatic switching to

the maximum amount of light appropriate for any endoscope connected. It is capable of

distinguishing between GI-type scope connectors, LG connectors for use with the SP high-intensity

function, and LG connectors for use with the non-SP, high-intensity function.

(3) When videoscopes or OES fiberscopes (including OES connectors used with BF and CHF type

endoscopes) are attached, the unit is capable of generating 1.3 times the output light intensity of

the CLV-U4 EVIS 100 mode and the OES mode (OAI, OLA). It produces 1.6 times more maximum

permissible illumination (white light) for the LG (non-OAI, OLA regions).

(4) When connected to a surgical fiberscope not compatible with the high-intensity RF connector, it

produces an output light intensity of the maximum permissible illumination (white light) for the LG

equivalent to the CLV-U4 EVIS 100 mode and the OES mode.

(5) When used with an endoscope and light guide compatible with the high-intensity RF connector, the

high-intensity mode is available, creating a brighter illumination. Compared to the illumination of the

CLV-U40 EVIS 100 mode or OES mode, approximately 2 times the maximum illumination (white

light) is produced. In high-intensity mode, it is also possible to select equal brightness or double

brightness of the CLV-U40 through the brightness mode switch.

(6) The optical filter used in NBI (narrowband imaging) observation has been loaded. NBI observations

are enabled when an NBI-compatible endoscope is connected to the unit.

(7) The optical filter used in PDD (photodynamic diagnosis) observation can be loaded (OE market).

One other optical filter for specialized observations may be loaded if required.

(8) The following modes may be selected:

a. Auto-ignition mode: the examination lamp automatically illuminates when the power is turned on.

b. Manual ignition mode: the examination lamp will illuminate when the lamp switch is pressed once

power has been turned on.

(9) The examination lamp can be manually turned off by continously pressing the LAMP switch for

approximately 1 second.

(10) Heat exhaust is through the rear (rear heat exhaust).

(11) The system automatically switches to the emergency lamp if the examination lamp does not come

on after pressing the lamp switch. As an emergency response, this will provide sufficient brightness

required for endoscope removal in situations when the examination lamp does not come on or if it

turns off. This will be indicated on the panel.

(12) Brightness can be adjusted using the 17 steps of automatic and manual brightness available.

(13) The air supply can be stopped completely as well as changed between high, medium or low supply.

(14) Disconnection of the emergency lamp will be automatically indicated on the panel.

(15) The transillumination switch enables the transmitted light illumination function (for GI endoscopes

ISSUE1

1-2

Page 7

SpecificationCLV-180

only).

(16) Panel settings are retained, and the light source unit will display at the previous settings the next

time the unit is turned on. However filter switch settings are not backed up, and will revert to the

regular filter.

(17) The exterior and the operating panel may be disinfected with ethanol (70% ethyl or isopropyl

alcohol) or with a mild detergent.

(18) This product has passed the OLYMPUS Eco-Product standard (Environmentally-friendly design

standard).

3 Operational Conditions

(1) Applicable video system centers: CV-180, CV-165

(2) Operational environment:

i) Use in a medical facility under the supervision of a medical doctor.

ii) Do not apply this light source directly to the heart.However, it may be used with the heart when

used in combination with a TYPE CF applied part indicated by a mark on the instrument.

iii) The outer casing of the unit must be grounded for safety.

iv) Do not use the light source in a combustible atmosphere.

v) Do not use the light source with the following electronic equipment or endoscopes:

a. Any devices designed to apply electronic treatment of a patient for which safe usage with

the CLV-180 has not yet been confirmed.

b. Any devices not designed to apply electronic treatment of a patient for which safety (e.g.,

leakage currents) has not yet be confirmed.

vi) Power supply:

Voltage: 100 – 120 V AC

Frequency: 50/60Hz

Input current: 500 VA

Power fluctuation: Within ±10%

Frequency fluctuation: Within ±1 Hz

vii) Environment

a. Operating environment

Ambient temperature: 10 – 40°C

Relative humidity: 30 – 85%

Air pressure: 700 – 1060 hPa

b. Storage environment

Ambient temperature: 25 – 70°C

Air pressure: 700 – 1060 hPa

ISSUE1

1-3

Page 8

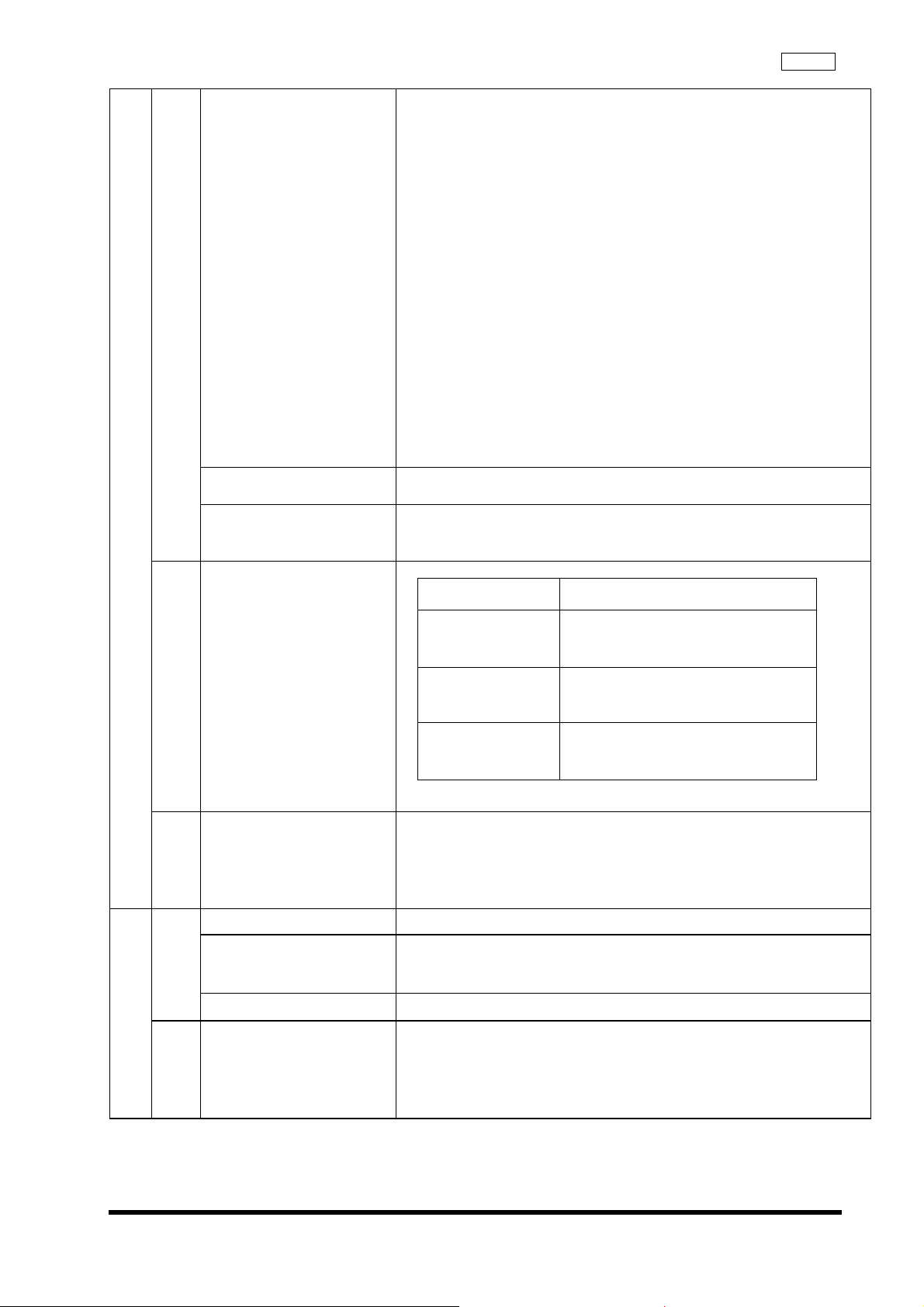

4 Specifications

Item Specification

SpecificationCLV-180

1. Videoscopes

2. EUS Videoscopes 1. EUS 130, 140, 160 series videoscopes

4. Light guide for use

with rigid

endoscopes

5. Rigid endoscopes

(Model names

omitted)

6. High-intensity

1. Type of endoscopes

1. Compatible endoscopes

compatible

fiberscopes

(for stiff eyepiece

endoscopes)

7. High-intensity

compatible

videoscopes

Illumination light path Emergency lamp

1. Optics

2. Illumination function

1. EVIS 100, 130, 140 series videoscopes

2. EVIS EXERA 145, 160 series videoscopes

3. V series videoscopes

4. EVIS EXERA II 165, 180 series videoscopes

5. VISERA series videoscopes

1. OES 10, 20, 30, 40, 60 series fiberscopes 3. Fiberscopes

2. E, E2, E3 series fiberscopes

High-intensity compatible light guides

Note: The high-intensity mode can be set by pressing the

high-intensity mode selection switch when connecting the

light guide.

Not compatible with rigid products other than those with

high-intensity compatible light guides.

CHF-CB30L, CHF-CB30S, URF-P3

(LF-TP, LF-DP, LF-GP) *1

(ENF-GP) *2

*1 Applicable when used in combination with the following

light guides: A3290, A3291, A3292, A3293, A3294, A3295,

A3296, A3297, A3298.

*2 Applicable when using in combination with light guide

A3293.

LTF-V, LTF-V2, LTF-V3

A4940A, A4941A, A4942A, A4943A, A4800A, A4801A,

A4802A, A4803A, A4804A, A4805A, A50000A, A50001A,

A50010A, A50011A, A50020A, A50021A

Condenser lens

Optical filters

Turret board (emergency lamp, filter, etc.)

Diaphram

Light-adjustment mesh turret

(1) Each of the optical filters on the turret plate are

automatically placed in the light path according to the

normal observation mode (GI/SP), special observation

mode (GI/SP), or high-intensity mode (SP) settings.

(2) In accordance with the various observational modes

above, the mesh filter with desired aperture ratio mounted

on the mesh turret can be automatically placed in the light

path.

(3) The emergency lamp is automatically placed in the light

path when the examination lamp malfunctions.

(4) There are four special filter frames provided to enable the

use of special filters.

ISSUE1

1-4

Page 9

SpecificationCLV-180

Examination lamp

(1) Type: Xenon short arc lamp with an eliptic mirror

(2) Model: MD-631

(3) Life: 500 hours (when lit continuously)

(4) The lamp will either illuminate when the power is switched

on (auto-ignition funtion), or it can be turned on by

pressing the LAMP switch on the front panel. The lamp

can be turned off by pressing the LAMP switch

2. Illumination light

Emergency lamp

(1) Type: Halogen 35 W (with reflector)

continuously for one second.

(2) Life: Average of at least 500 hours

Method (1) Manual adjusment only for fiberscopes and rigid-type

endoscopes (excluding when used with a CV-180 and

camera head).

(2) Automatic and manual adjustment available for

videoscopes.

(3) Automatic adjustment is available when the CV-180 and

camera head are used with rigid endoscopes and

light-source cables.

NBI special observation

mode

(1) The filter mode switch enables selection of the NBI special

observation mode when a light adjustment cable and the

CV-180 are connected to an NBI-compatible endoscope.

(2) When the NBI special observation mode is selected, the

NBI special filter is placed in the illumination light path.

Note: The CV-180 power switch must be ON.

PDD normal observation

mode (OE)

PDD is option 1 for

non-OE regions

(1) PDD normal observation mode will be activated when the

light guide is connected to a light adjustment cable

equipped with the PDD function, and a camera head for

exclusive use during PDD special observation are

connected to the CV-180.

(2) During PDD normal observation mode, the PDD normal

filter is placed in the illumination light path.

2. Illumination function

Note: The CV-180 power switch must be ON.

・ The PDD normal filter and PDD special filter are

required for the PDD function.

ISSUE1

PDD special observation

mode (OE)

PDD is option 1 for

non-OE regions

3. Brightness adjustment

PDD special observation

mode (OE)

(Fiberscope)

PDD is option 1 for

non-OE regions

Optional observation

mode (OE)

PDD is option 2 for

non-OE regions

(1) From the PDD normal observation mode, the PDD special

observation mode may be selected by pressing the filter

mode switch.

(2) During PDD special observation mode, the PDD special

filter is inserted in the illumination light path.

(3) Press the switch again to insert the PDD normal filter. The

filters can be exchanged by pressing the switch.

Note: The CV-180 power switch must be ON.

(1) With the CV turned OFF, attach the light-supply cable with

the PDD function. When the light guide is attached,

pressing the filter mode switch will select the PDD special

observation mode.

(2) During PDD special observation mode, the PDD special

filter is inserted in the illumination light path.

Note: The normal filter is used for PDD observation during

observation through a fiberscope, rather than the

PDD normal filter.

(1) This function is reserved for experimental use.

1-5

Page 10

SpecificationCLV-180

available through the endoscope distal end when

High-intensity mode (1) When a high-intensity compatible endoscope is inserted, the

high-intensity mode may be selected by pressing the

high-intensity switch. High-intensity mode may not be

selected with endoscopes that are not high-intensity

compatible.

(2) When a high-intensity compatible endoscope is inserted, the

high-intensity mode switch illuminates. This enables the

selection of the high-intensity mode (LED above the switch

illuminates) or the normal mode (LED above the switch goes

out).

(3) The current settings for the high-intensity mode switch are

retained when the power is turned OFF. When a

high-intensity compatible endoscope is inserted, illumination

will either be the high-intensity mode or normal mode,

depending on the settings retained by the system. Initial

factory setting: normal mode.

(4) When the high-intensity mode is terminated (normal mode),

3. Brightness adjustment

illumination is equivalent to the CLV-U40 EVIS 100 and OES

mode.

(5) High-intensity mode provides approximately twice the amount

of illumination as the SP normal observation mode.

Manual adjustment (1) Mechanical diaphram (set on the panel)

(2) 17 steps

Automatic adjustment (1) Mechanical diaphram with constant illumination control

(image illumination)

(2) 17 steps

2. Illumination function

Front panel display

method in special

Observation mode Front panel display method

observation mode

NBI special

observation mode

・The NBI LED lights up (white)

PDD normal

observation mode

PDD special

observation mode

・The PDD LED lights up (green)

(OE only)

・The PDD LED lights up (white)

(OE only)

Equipment (1) Forced air cooling with a fan (rear exhaust)

4. Cooling

Air supply pump (1) Diaphragm system

Air supply pressure (1) Three air supply pressure levels (high, medium, low and

stop)

(2) Maximum air supply pressure: less than 53.9 kPa

Control (1) Through air supply switch settings

1. Air

Water supply (1) Supply is

a water supply container is attached.

3. Air/Water supply

function

2. Water

ISSUE1

1-6

Page 11

SpecificationCLV-180

switch)

Endoscope and light guide One-touch connection

Light-supply cable (MAJ-1411) Connector on the rear-panel

(Light-supply cable for CV connection)

Expansion cable (MAJ-202/972) System connector on the rear-panel

(compatible with Endo GATE/Endo ALPHA)

4. Connection

Foot switch (MAJ-1391) Foot switch connector on the rear-panel

Emergency lamp indicator Indicates if the emergency lamp is disconnected or if the

emergency lamp is in use (when the main lamp will not illuminate).

・Lit up: Emergency lamp in use (the main lamp will not illuminate).

・Blinking: Emergency lamp is disconnected or has been removed.

indication

5. Emergency

Setting retention (1) Settings prior to powering off the unit are retained.

・Manual / automatic brightness settings

・Airflow settings

・Light intensity level

・High-intensity mode setting

・Special observation function display

6. Panel

・Lamp life indicator (with the power ON, the indicator may

be reset when the examination lamp is extinguished by

continuously pressing the counter reset switch.)

Switch illumination system

(not including counter reset

On endoscope removal (1) When the endoscope is removed, the light emanating from

1. Dimming

Exterior

2. Disinfection

Temperature switch (1) To ensure safety, when the internal temperature rises

3. Alarm

7. Safety

Protection Class 1 unit (3P power supply)

(1) All switches illuminated

(not including counter reset switch)

the scope connector is dimmed by the dimmer plate

located in the endoscope socket.

(1) Disinfect with ethanol for disinfection (70% ethyl or

isopropyl alcohol) or with a mild detergent.

above the specified value, the temperature switch turns off

and the electrical current supply to the lamp is terminated.

The unit detects that the temperature switch has shut off,

and sounds an alarm.

ISSUE1

4. Electrical

shock

Region

1. EU/ EFTA Y

2. Japan N

regulations

5. Applicable

3. USA Y

Sold

MDD

Class:II a (rule: 11-1)

CE marking: CEO197

Pharmaceutical Law (Application of the Pharmaceutical law to assist Asian

market response)

FDC laws

1-7

Page 12

SpecificationCLV-180

4. Canada Y

5. Singapore Y

6. Other Y

Common to all

countries

Class: II

Singaporean medical device regulations

K-FDA (Korea)

SDA (China)

IEC 60601-1 (Medical electrical equipment - Part 1: General requirements

for safety): 1988 + A1, A2

IEC 60601-1-1 (Medical electrical equipment - Part 1-1: General

requirements for safety): 2000

IEC 60601-1-2 (Medical electrical equipment - Part 1-2: General

requirements for safety - Collateral standard: Electromagnetic compatibility

- requirements and tests): 2001

IEC 60601-2-18 (Medical electrical equipment - Part 2: Particular

requirements for the safety of endoscopic equipment): 1996 + A1

ISO 14971(Medical devices -- Risk management): 2000

ISO 9000-3(Software engineering -- Guidelines for the application of ISO

9001:2000 to computer software): 1997

ISO 8600-1(Optics and photonics -- Medical endoscopes and endotherapy

devices -- Part 1: General requirements): 1997

ISO 7000(Graphical symbols for use on equipment) : 2004

IEC 60417-1: 2002, -2: 1998(Graphical symbols for use on equipment)+

A1, A2

Canadian Medical Device and Equipment Regulation

EU/EFTA

EN 980 (Graphical symbols for use on equipment): 2003

2. Japan JIS T1005 (Style manual for instruction manuals): 1983

JIS T0601-1 (Medical electrical equipment -- Part 1: General requirements

for safety): 1999

6. Applicable external regulations

JIS T0601-1-1(Medical electrical equipment -- Part 1-1: General

requirements for safety -- Collateral standard: Safety requirements for

medical electrical systems): 1999

JIS T0601-1-2(Medical electrical equipment -- Part 1: General

requirements for safety -- 2. Collateral standard: Electromagnetic

compatibility -- Requirements and tests): 2002

3. USA UL 60601-1: 2003

4. Canada CAN/CSA-C22.2 No.601.1-M90: 1990

CAN/CSA-C22.2 No.601.1-S1: 1994

5. Other Olympus Eco-Product Standard

Ambient temperature 10 – 40°C

Relative humidity: 30 – 85%

Air pressure 700 to 1060hPa

Usage environment Do not use in a combustible atmosphere

Type of protection against

electrical shocks

8. Other

However, this instrument may be applied to the heart if it is used with equipment classified as

TYPE CF applied part. (indicated by the symbol)

Class 1

Degree of protection: Type BF applied part

Voltage 100 – 240 V AC

1. Usage restrictions

Frequency 50/60 Hz

Power fluctuation

Frequency fluctuation

Within ±10%

Within ±1 Hz

Power consumption 500VA

1-8

ISSUE1

Page 13

SpecificationCLV-180

User servicing Examination lamp, fuses

OLYMPUS servicing Emergency lamp replacement, special filter attachment

2. Par need replacment

Weight

Dimensions 383 (W) × 536 (D) × 162 (D) mm (maximum)

Panel Panel selection varies by region

3. Other

Power cord Cord set with a 3-prong hospital grade

Fuse Fuse capacity

Warranty period As specified in the applicable laws for each country

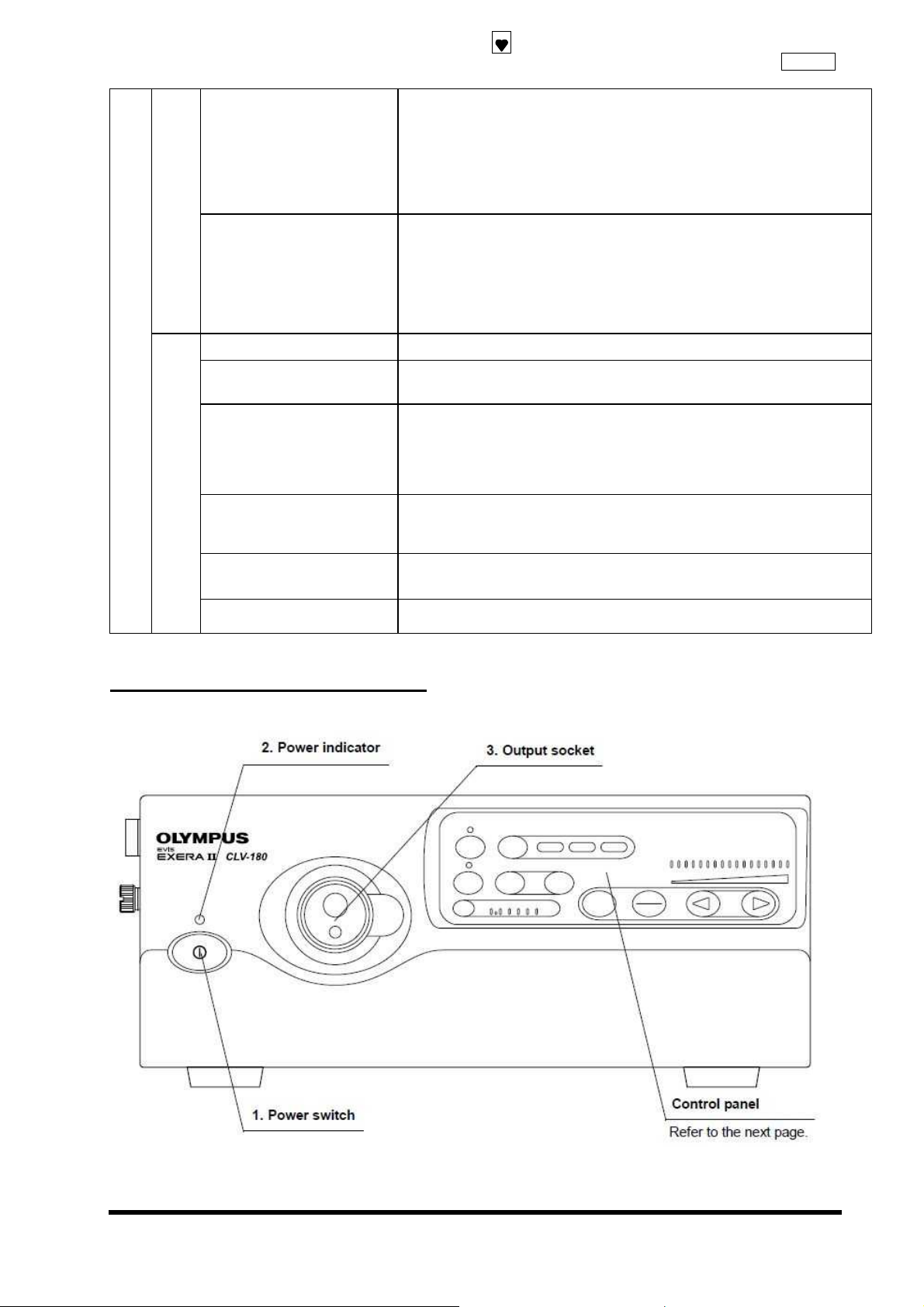

5 Nomenclature and Functions

5-1 Front panel

Approximately 15.4㎏

370 () × 475 (D) × 150 (D) mm (standard)

AC 100 - 240 English (3E, 6E, 6LA)

AC 100 - 240 Symbol (6S)

AC 100 - 120 English (3OA)

AC 100 English (1J)

With plug (1J, 3OA, 3E)

Plug-less (6E, 6S,6LA)

Littel (manufacturer) 215008: 8A

ISSUE1

1-9

Page 14

SpecificationCLV-180

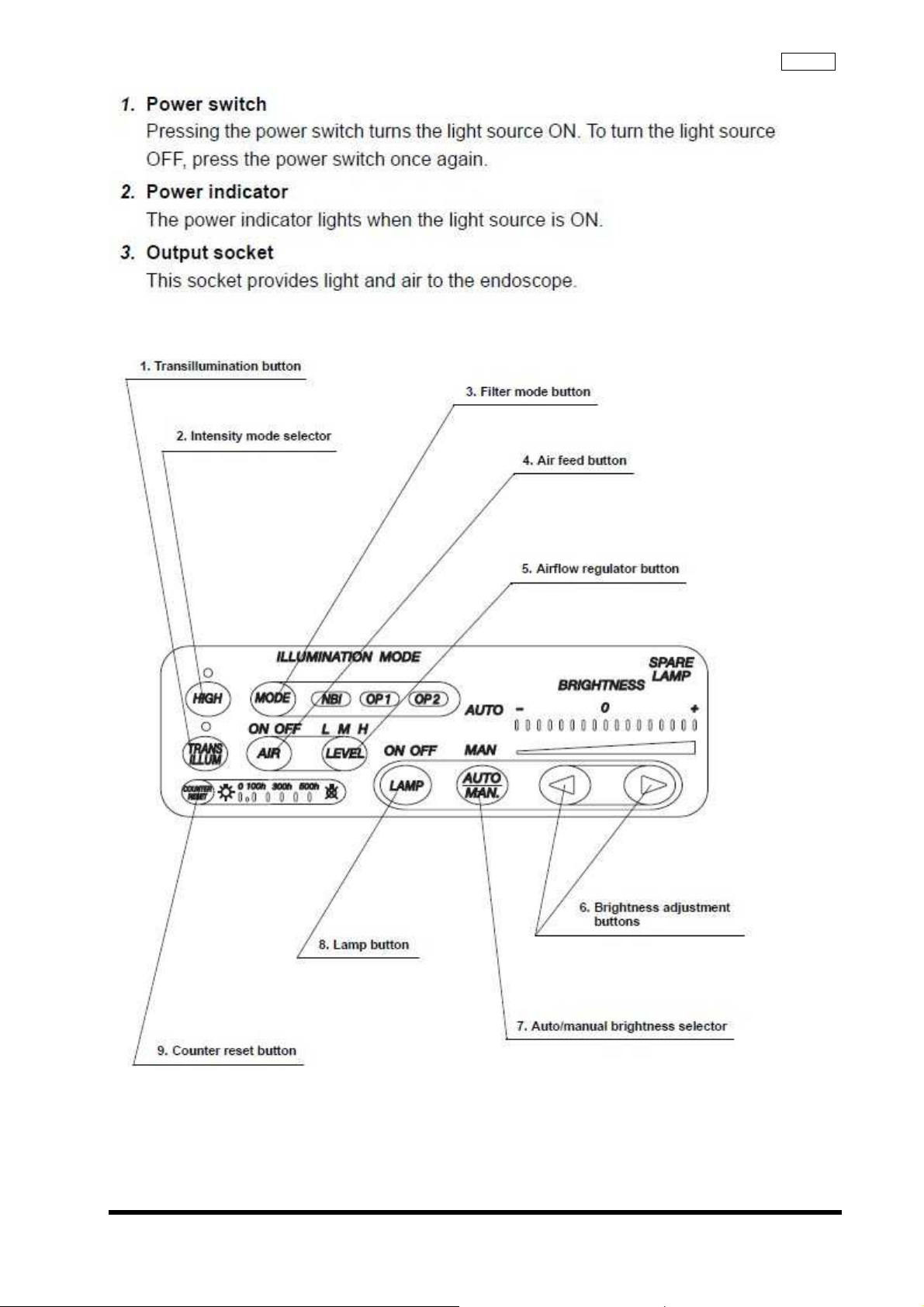

5-2 Control panel (buttons)

ISSUE1

1-10

Page 15

SpecificationCLV-180

(1) Transillumination button

When pressing this button, light emitted from the endoscope’s distal end becomes brighter for 7

seconds, then returns automatically to its original brightness level.

(2) Intensity mode selector

Press to switch between the high-intensity mode and normal intensity mode when using an

endoscope compatible with the high-intensity mode.

(3) Filter mode button

Pressing this button activates the NBI observation function.

(4) Air feed button

Pressing this button starts or stops the air feed from the endoscope’s distal end.

(5) Airflow regulator button

This button is use to control the pressure of the air being fed from the endoscope.

(6) Brightness adjustment buttons

These buttons are pressed to adjust the brightness level.

(7) Auto/manual brightness selector

This selector is pressed to select automatic or manual brightness control.

(8) Lamp button

This button is pressed to turn ON or OFF the examination (xenon) lamp.

(9) Counter reset button

After replacing the examination (xenon) lamp, the lamp hour meter is reset by pressing this button

for 1.

ISSUE1

1-11

Page 16

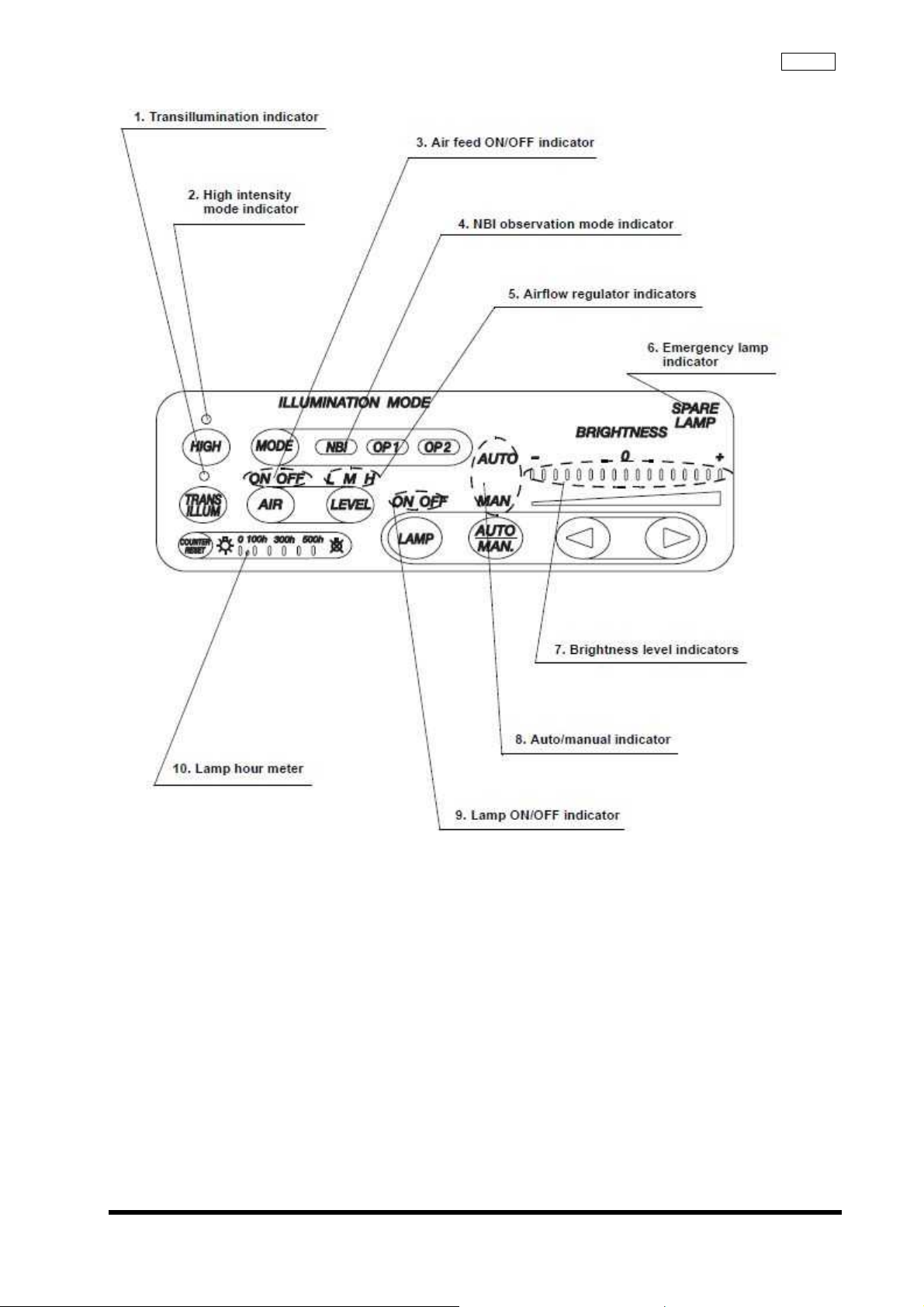

5-3 Control panel (Indicators)

SpecificationCLV-180

ISSUE1

1-12

Page 17

SpecificationCLV-180

(1) Transillumination indicator

This indicator lights when the transillumination function is activated.

(2) High intensity mode indicator

The indicator lights when high-intensity mode is selected.

(3) Air feed ON/OFF indicator

This indicator lights when the air feed from the endoscope’s distal end is activated.

(4) NBI observation mode indicator

This indicator lights in green to indicate that the light source can perform the NBI observation.

This indicator lights in green continuously when an endoscope with the NBI observation

compatibility is connected and the light source is ready for the NBI observation. Also, the indicator

lights in white when NBI observation mode is active.

The "OP.1" and "OP.2" are prepared for future use.

(5) Airflow regulator indicators

One of these indicators lights to indicate the current airflow pressure level setting ("L" (Low), "M"

(Medium) or "H" (High)).

(6) Emergency lamp indicator

This indicator lights when the emergency lamp (halogen) is in use, and blinks when the emergency

lamp (halogen) is disconnected or not mounted.

(7) Brightness level indicators

These indicators display the current brightness level.

(8) Auto/manual indicator

This indicator displays the brightness selector setting ("auto" or "manual").

(9) Lamp ON/OFF indicator

This indicator lights when the examination lamp (xenon lamp bulb) lights.

(10) Lamp hour meter

This indicator displays the total working hours of the examination (xenon) lamp.

ISSUE1

1-13

Page 18

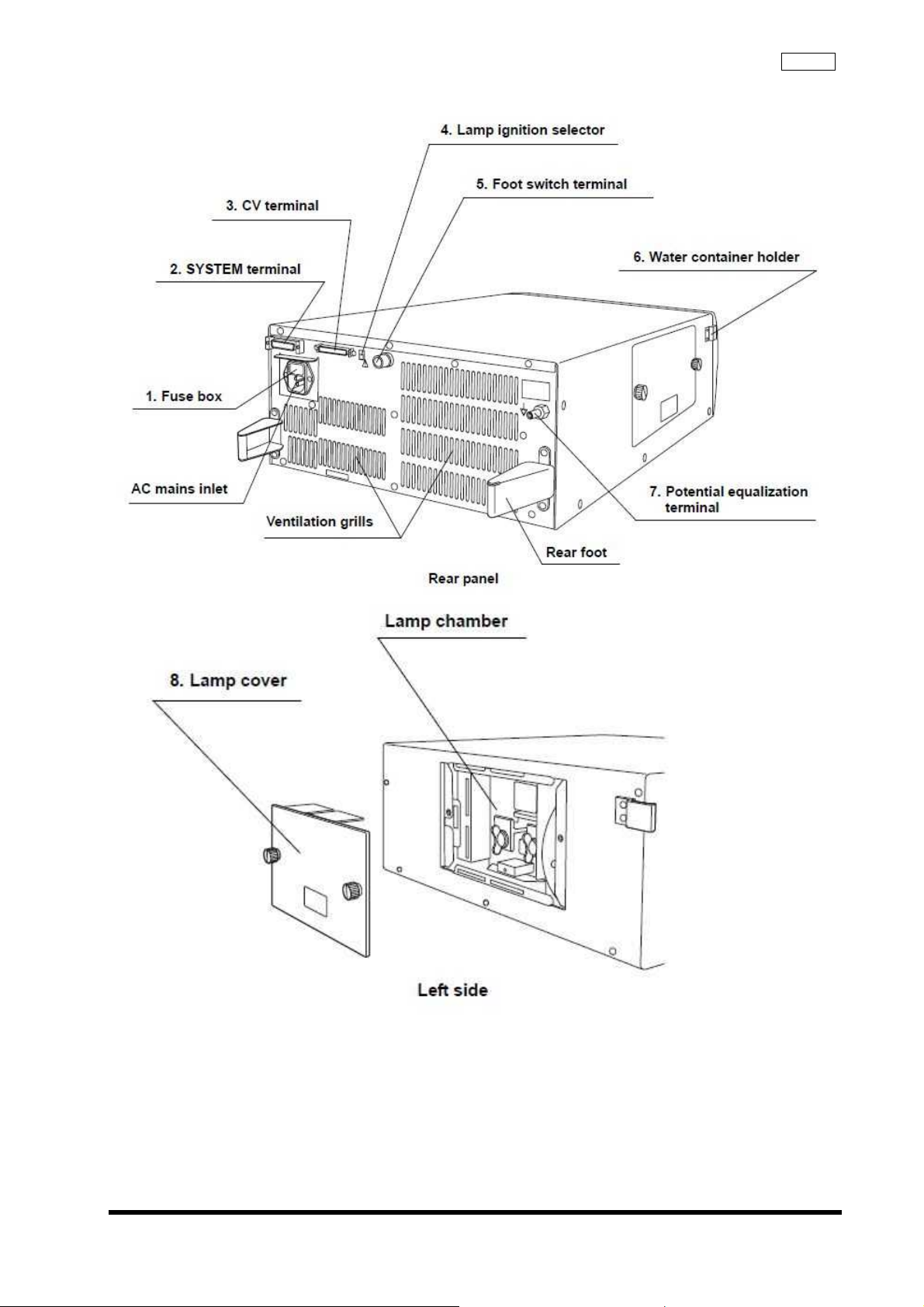

5-4 Rear and side panels

SpecificationCLV-180

1-14

ISSUE1

Page 19

SpecificationCLV-180

(1) Fuse box

The fuses protect the light source from electrical surges.

(2) SYSTEM terminal

The terminal accepts connection from an external unit.

(3) CV terminal

This terminal is the receptacle for the light source cable to connect the light source to the EVIS

EXERA II video system center.

(4) Lamp ignition selector

This selector is set to select automatic or manual ignition of the examination lamp. When the

automatic ignition is selected, turning ON the light source lights the examination lamp

simultaneously. When the manual ignition is selected, pushing the lamp button on the control panel

lights the examination lamp.

(5) Foot switch terminal

This connector is the receptacle for the foot switch (MAJ-1391) for use in the naked-eye PDD

observation.

(6) Water container holder

This holder is used for the installation of the water container.

(7) Potential equalization terminal

For safety, this terminal is connected to a potential equalization terminal of the other equipment

connected with the light source, and the electric potential of their equipment are made the same.

(8) Lamp cover

This cover has to be removed to replace the examination lamp.

ISSUE1

1-15

Page 20

Chapter 2: Troubleshooting

2-1

ISSUE1

TroubleshootingCLV-180

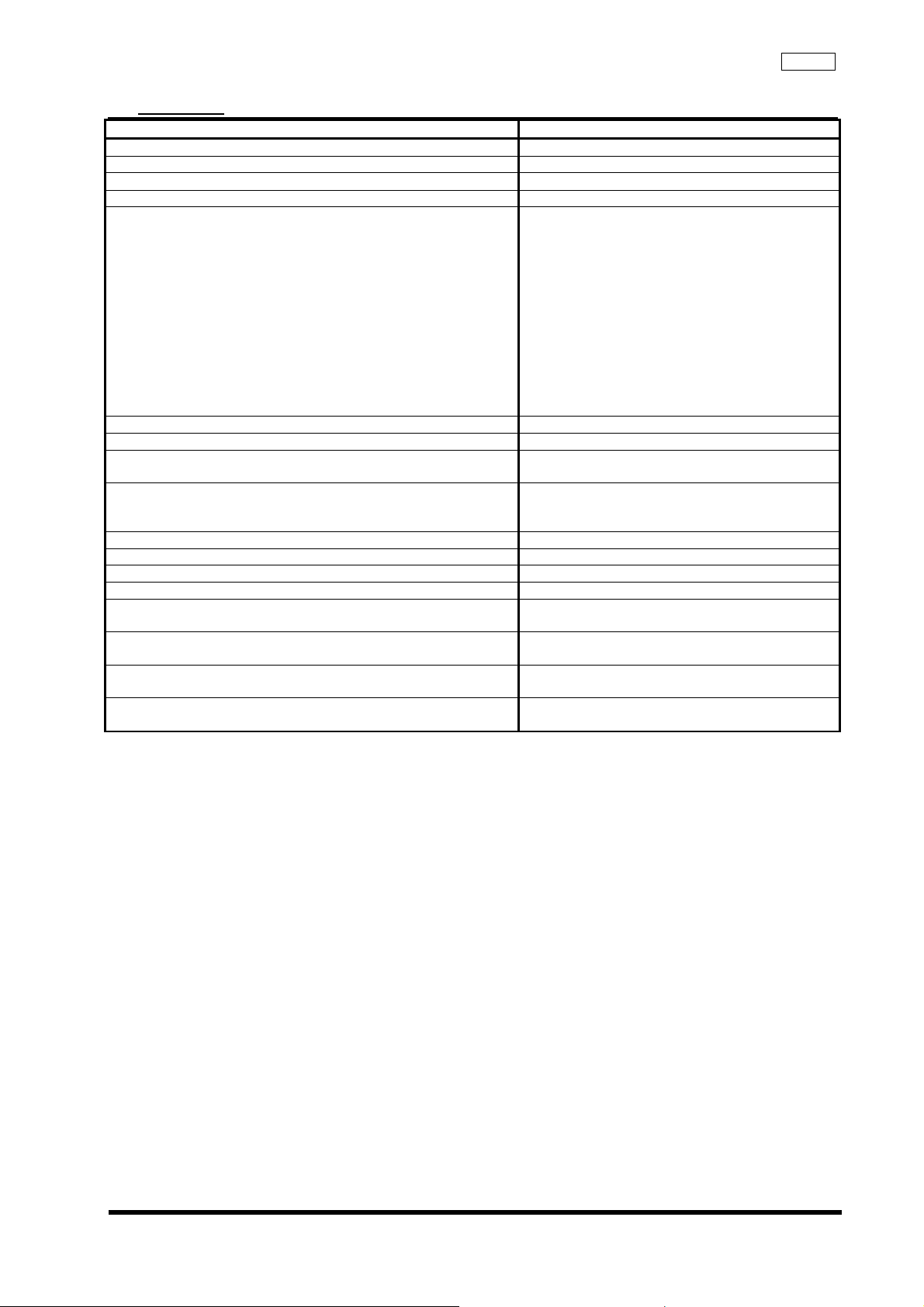

Page 21

TroubleshootingCLV-180

1.

Contents

Symptom Failure Mode

2-1 No power Power input failure

2-2 Xenon Lamp not lit Lamp failure

2-3 Lamp going out Lamp going out

2-4 Scope not mounting Scope connection failure

2-5 Incapability of discriminating GI, SP, or high-brightness

SP

<GI Scope>

AIR button or Transillumination button cannot be

selected when GI Scope is connected.

<SP>

AIR button, Transillumination button, and

high-brightness button can be selected when SP

Scope is connected.

<High-brightness SP>

High-brightness button cannot be selected when

high-brightness Scope and Light Guide are

connected.

2-6 Cooling fan not working Cooling fan malfunction

2-7 Exit light from Light Source when Scope is removed Shield failure at scope removal

2-8 Pump not working when Pump ON switch is pushed, or

no change in air supply volume

2-9 Turret Board not rotating when Special Light

Observation Scope is connected and Mode switch is

pushed

2-10 No light from Scope Exit light failure

2-11 View area is dark or excessively light Manual Brightness failure

2-12 View area is dark or excessively light Automatic Brightness failure

2-13 No change in LED display when switch is pushed Panel malfunction

2-14 Emergency Lamp is not automatically lit when Xenon

Lamp is put out

2-15 Values set before shutdown are not saved when power

shuts down

2-16 Time not changing to "0" when Lamp Life Meter Reset

switch is pushed

2-17 No change in light quantity when Trans Illumination

switch is pushed

Scope discrimination failure

Pump malfunction

Filter changing malfunction

Emergency Lamp malfunction

Back up malfunction

Lamp Life Meter Reset malfunction

Transillumination malfunction

2-2

ISSUE1

Page 22

2. Troubleshooting CLV-180

④

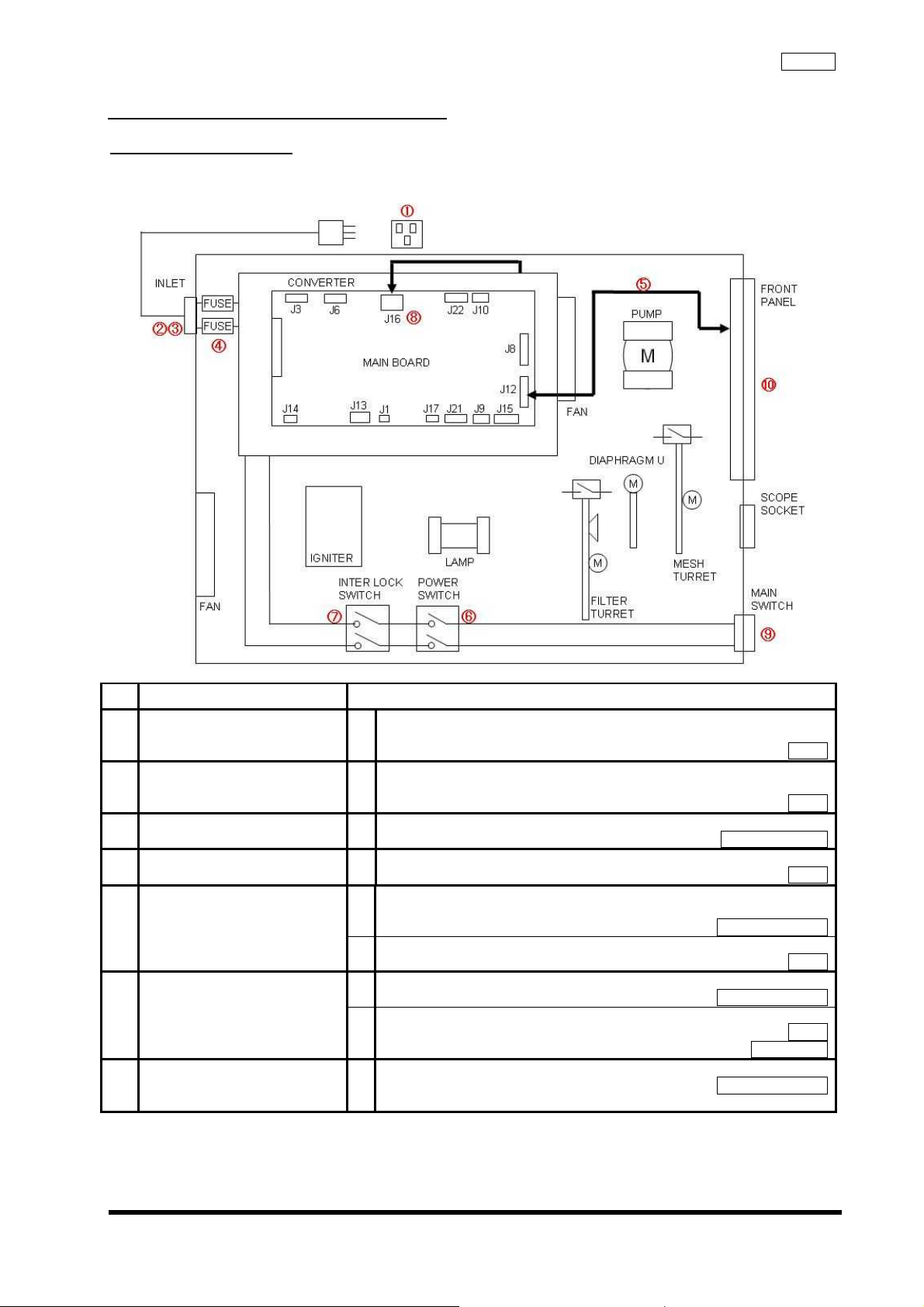

2-1 Power input failure

Incapable to input power

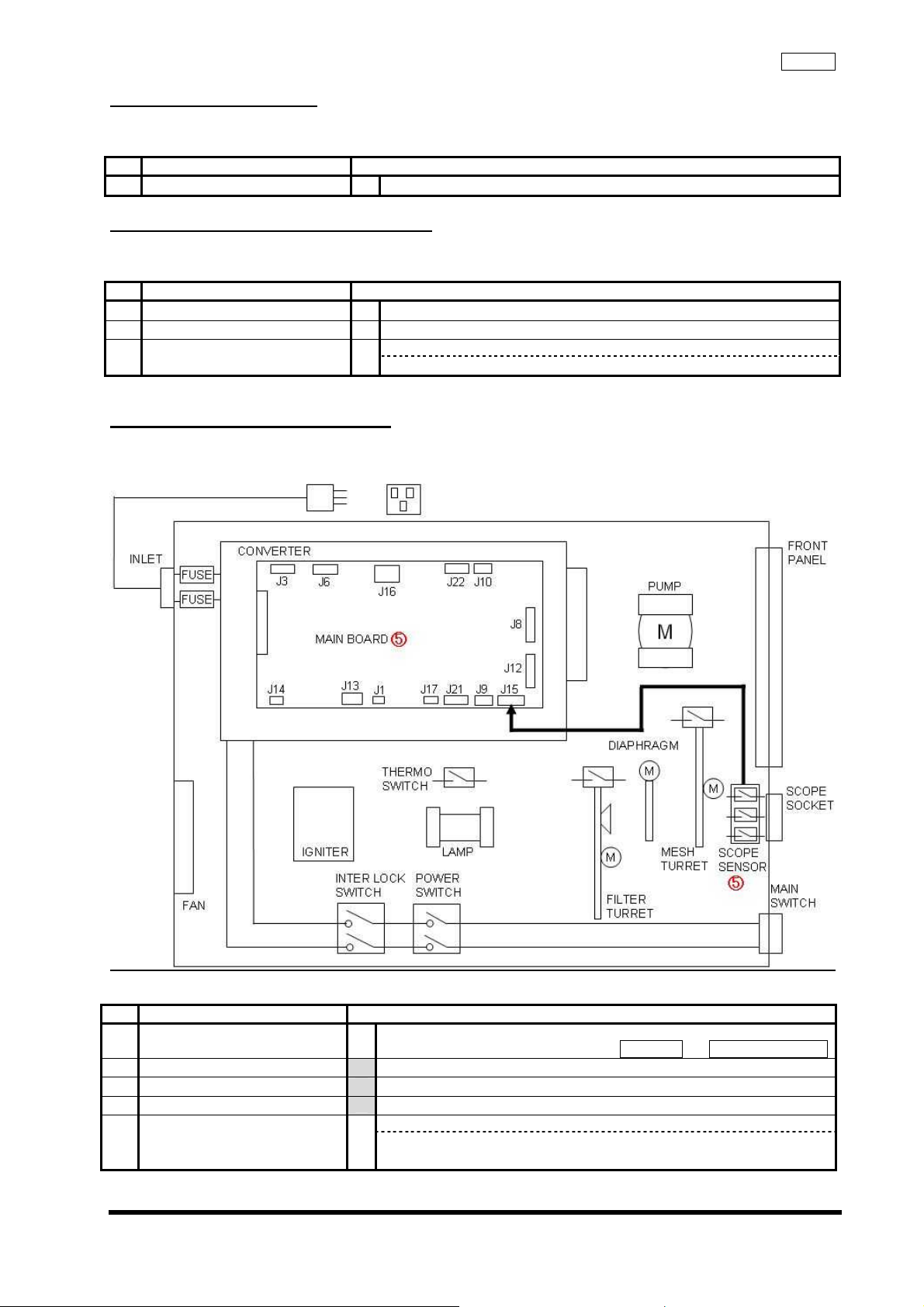

2-1-1 Block diagram

TroubleshootingCLV-180

2-1-2 Estimated location of failure

No

①

②

③

⑤

⑥

⑦

Estimated failure location Inspection method

Input voltage 1 Verify the voltage of wall socket.

* Conformity with commercial power voltage standard.

Power Cable 1 Connect the Power Cable to wall socket and verify voltage at inlet side.

* Conformity with commercial power voltage standard.

Body Inlet Plug 1 Confirm that the inlet plug is not bend or distorted.

Visual inspection

Fuse 1 Confirm that the fuse was not burned out.

Power Switch

Interlock Switch

Flat Cable 1 Verify connection of the Flat Cable

1 Confirm that the Power Switch inside the equipment is pushed when

the Main Switch on the Front Panel is pushed.

Visual Inspection

2 Confirm conductivity of the Power Switch when power is ON.

1 Confirm that the switch is pushed by the Lamp Door.

Visual Inspection

2 Confirm conductivity of the Interlock Switch when power is ON.

Visual Inspection

Main Board (J12) <--> Front Panel

Tester

Tester

Tester

Tester

Tester

Interlock Jig

2-3

ISSUE1

Page 23

TroubleshootingCLV-180

Main Board

⑧

Converter

Power Switch LED 1

⑨

Front Panel Unit 1

⑩

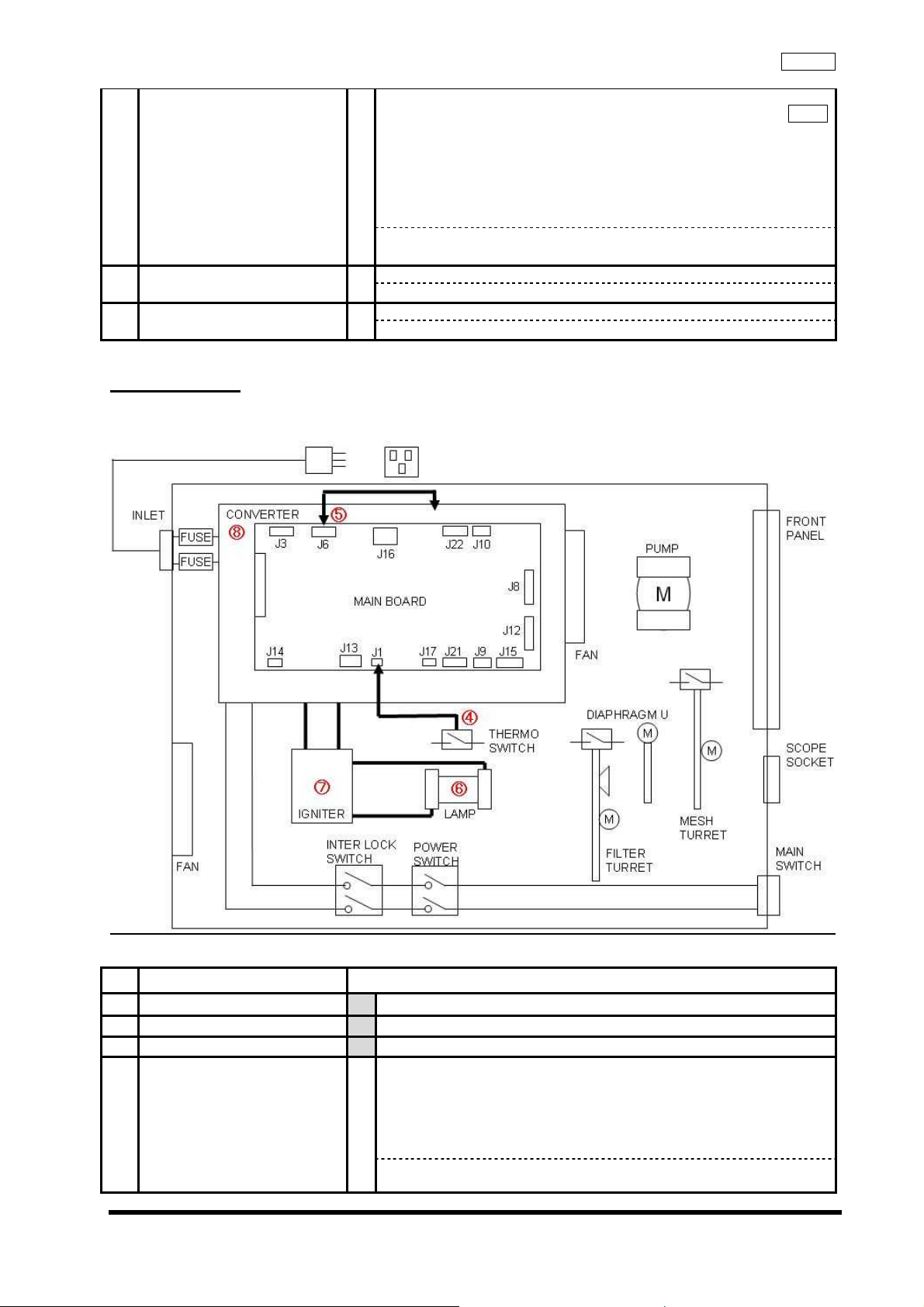

2-2 Lamp failure

Xenon Lamp of light source not lit

2-2-1 Block diagram

Confirm that the input voltage to Main Board J16 is correct.

1

J16 (Main Board) <- -> Converter)

1pin : DC +15V±0.75V

2pin : DC +12V±0.6V

3pin : DC + 5V±0.25V

4pin : GND

5pin : DC -15V±0.75V

YES → Replace Main Board

NO→ Replace Converter

Confirm that the Power Switch LED is lit:

NO → Replace the Power Switch LED

Confirm that the Front Panel of LED is lit:

NO → Replace the Front Panel

Tester

2-2-2 Estimated location of failure

No Estimated failure location Inspection method

Power input failure Refer to 2-1

①

Emergency Lamp Malfunction Refer to 2-16

②

Panel malfunction Refer to 2-13

③

Thermo Switch /

④

Main Board

ISSUE1

Status of Thermo Switch when buzzer is sounding

1

Thermo Switch

・ Less than 85℃

Conductive

・ 85℃ or higher

Non-conductive

Within standard -> Replace Main Board

Out of standard -> Replace Thermo Switch

2-4

Page 24

②

Main Board 1

⑤

Surrounding the Lamp

⑥

Xenon Lamp /

⑦

Igniter

Converter

⑧

1 Verify Lamp attachment.

2 Check the area surrounding the Lamp House.

1

1 Xenon Lamp not lit even after procedures 1-7

Confirm that the signals in the Main Board are correct:

Main Board J6/2Pin

HIGH : XENON Lamp lit*HIGH : approx. 5 V

LOW : XENON Lamp not lit

H -> L when the Ignition Button is pushed ON to turn on Lamp

L -> H when the Ignition Button is pushed OFF to turn off Lamp

(Long push)

NO →Replace Main Board

・ Confirm that Lamp is attached properly.

・ Confirm that heat compound is applied properly.

・ Confirm that the area surrounding the Xenon lamp contacts is clean.

* Cleaning is required if the discoloration is found.

・ No unnecessary objects (e.g. metal chip)

・ No leakage of high voltage pulse

・ Check connection with Terminal F and Terminal R

・ Confirm there is enough distance between Round Terminal and Lamp

House

Clattering noise at ignition

YES →Replace Xenon Lamp

NO →Igniter

YES →Replace Converter

2-3 Lamp malfunction

Lamp going out

2-3-1 Estimated location of failure

No

①

③

④

⑤

Estimated location failure Inspection method

Log 1 Verify frequency of Lamp failure errors.

* Refer to EVIS communication Checker for verification method.

CLV-180 Communication Cable

Power input failure Refer to 2-1

Emergency Lamp malfunction Refer to 2-16

Cooling Malfunction Refer to 2-6

Lamp failure Refer to 2-2

2-4 Scope connection failure

Scope not mounting

2-4-1 Estimated location of failure

No

①

②

ISSUE1

Estimated location failure Inspection Metod

Scope 1 Confirm that Scope is a compatible one.

Scope Socket 1 Confirm that the Scope Socket is free of abnormalities.

* Insert Heat Cover Positioning Jig to Scope Socket and confirm that

it's not caught inside.

2-5

TroubleshootingCLV-180

Evis communication checker

Heat Cover Positioning Jig

Page 25

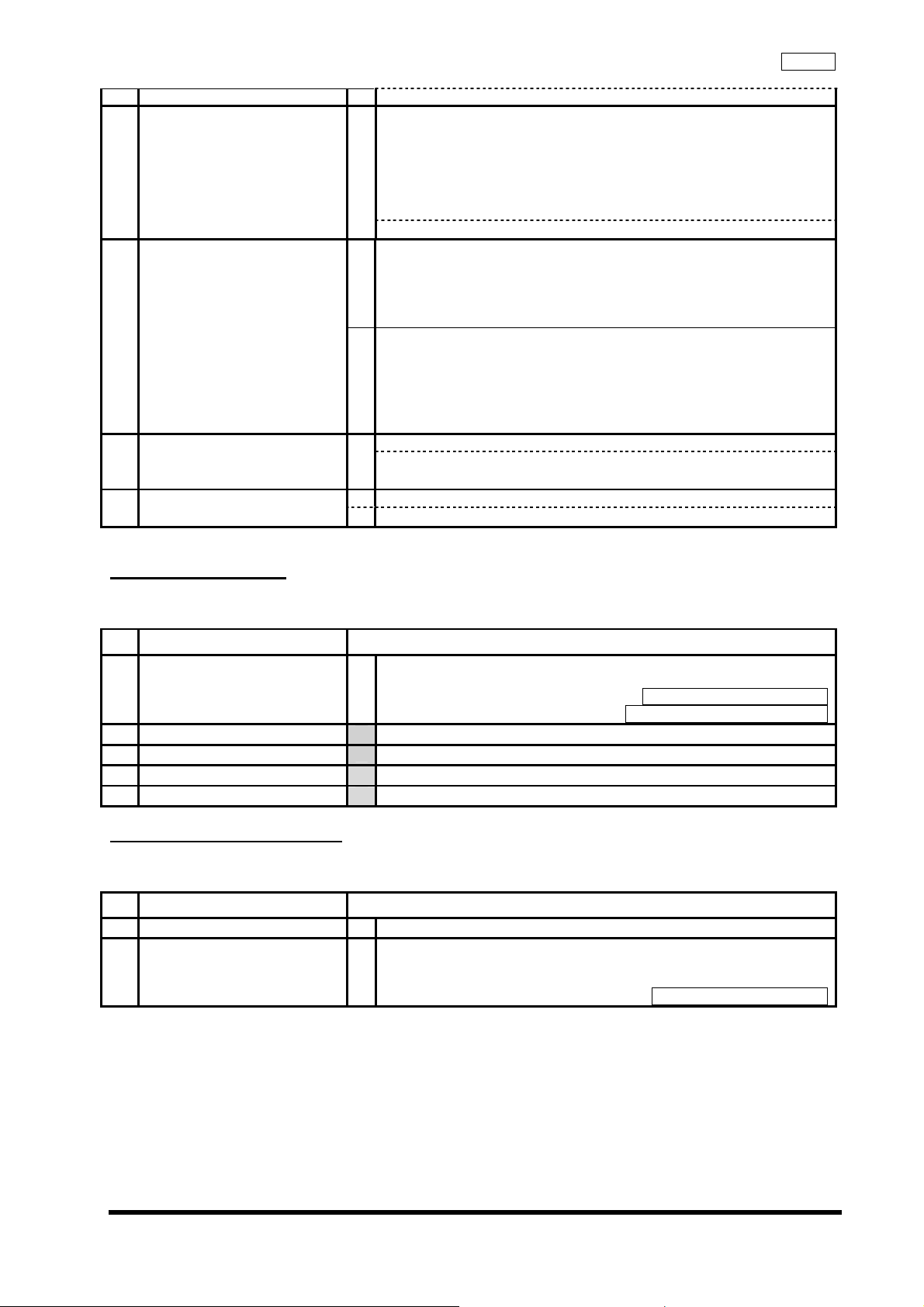

2-5 High-brightness malfunction

Not changing to high-brightness function mode

2-5-1 Block diagram

TroubleshootingCLV-180

2-5-2 Estimated location of malfunction

No

①

②

③

Estimated location failure Inspection Method

High-brightness scope 1 Confirm that scope is compatible for high-brightness.

Panel malfunction Refer to 2-13

Scope Sensor /

Main Board

Confirm following status of J15 connector on Main Board when

1

high-brightness scope is connected:

Main Board J15

When high-brightness scope is connected

Pin 2: HIGH

Pin 5: LOW

Pin 8: LOW

Pin 9: GND

* HIGH: approx. 5 V

YES → Replace Main Board

NO → Replace Scope Sensor

Tester

2-6

ISSUE1

Page 26

2-6 Cooling Fan malfunction

Cooling Fan not rotating

2-6-1 Block diagram

TroubleshootingCLV-180

2-6-2 Estimated location of failure

No

①

②

③

Estimated location failure Inspection Method

Connector 1 Verify connection of connector.

<Lamp House Fan>

Converter <--> (J16) Main Board (J14) <--> Fan

Lamp House Fan /

Main Board

Converter 1

Confirm output of +12 V at Main Board J14/Pin 1.

1

YES → Replace Lamp House Fan

NO → Replace Main Board

Confirm output of +12 V at connector of Converter Fan.

NO → Replace Converter

2-7 Shield malfunction at Scope removal

Light not changing to minimum or no change in volume when removing Scope

2-7-1 Estimated location of failure

No

①

Estimated location failure Inspection Method

Shield Plate 1

Confirm Shield Plate function.

*Insert Heat Cover Positioning Jig to Scope Socket and verify

movement of Shield Plate

NO → Replace Shield Plate

Heat Cover Positioning Jig

2-7

ISSUE1

Page 27

TroubleshootingCLV-180

2-8 Pump malfunction

No movement of the pump, or no change in air supply volume when switching the pump ON.

2-8-1 Block diagram

2-8-2 Estimated location of failure

No

①

②

③

④

Estimated location failure Inspection Method

Scope 1 Confirm that scope is compatible GI scope.

*EVIS 100,130, 160, 180 Series

Scope Sensor

Harness/

Tube

Pump 1 Confirm that air supply pressure / volume conform standards when

1 Set Pump Switch to "H".

Confirm following status of J15 on Main Board:

2

J15 on MAIN BOARD

When GI scope is connected

Pin 2: LOW

Pin 5: HIGH

Pin 8: LOW

Pin 9: GND

* HIGH: approx. 5 V

NO → Replace Scope Sensor

1 Verify Harness connection.

Main Board (J12) <--> Front Panel

2 Verify hose connection.

3 Check stuffing of Reverse Stop Valve

4 Verify rubber of Air Supply Mouthpiece.

changing air supply setting to L, M, and H.

Max pressure (at H)

53.9 kPa or less (air supply pressure locked)

Volume

L: 0.5 L/min or more (output pressure: set as 19.6-20.6 kPa)

M: 0.68 L/min or more (output pressure: set as 21.6-22.6 kPa)

H: 1 L/min or more (output pressure: set as 26.5-27.5 kPa)

Air Flow Checker

2-8

ISSUE1

Page 28

TroubleshootingCLV-180

⑤

Main Board /

Pump

Confirm that the output voltage of Main Board J17/Pin 1 conforms to

1

standards when changing air supply setting to L, M, and H.

Main Board J17/Pin 1

Air supply level: Output voltage

L: +5 V

M: +8 V

H: +12 V

YES → Replace Pump

NO→ Main Board

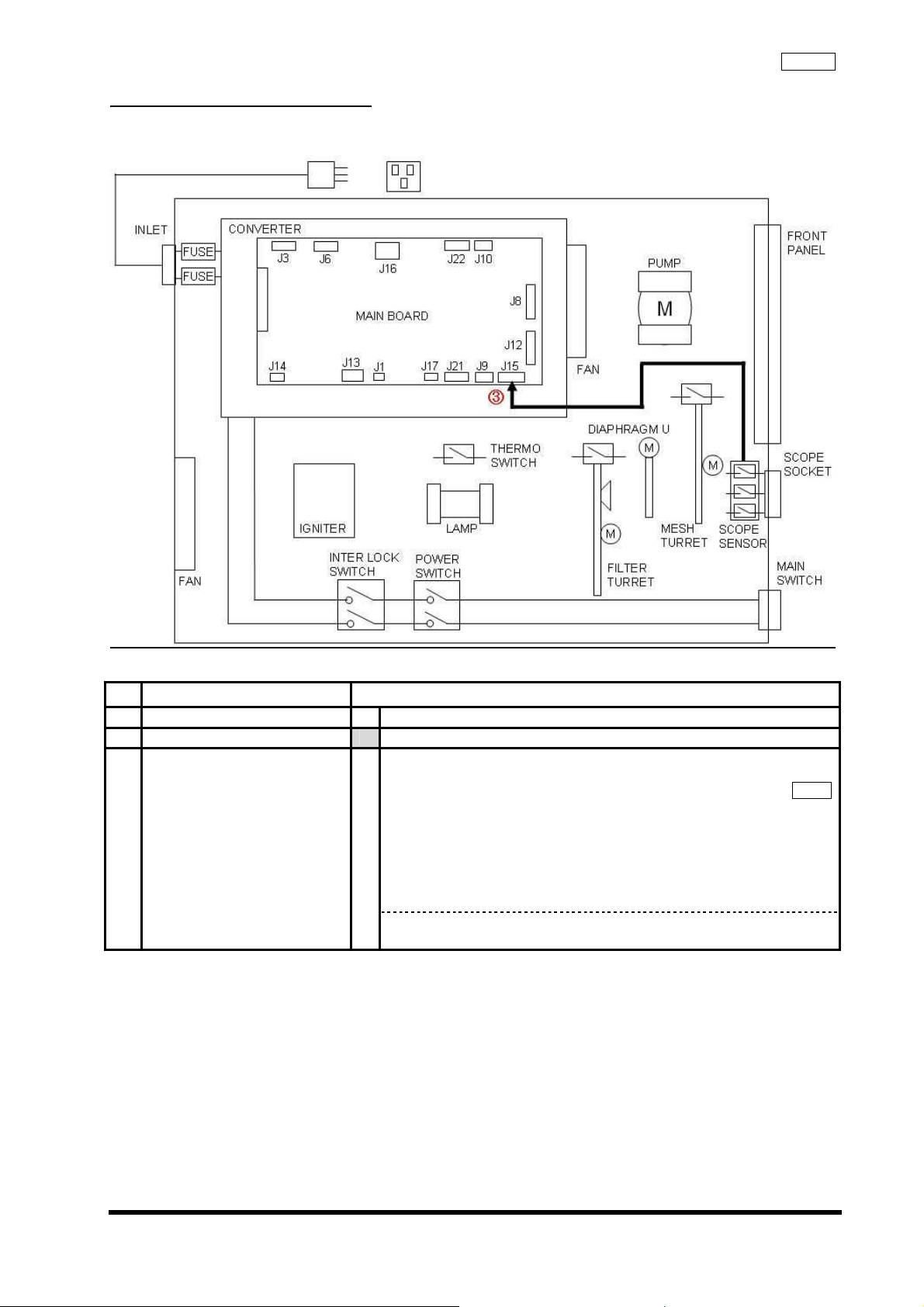

2-9 Filter Change Malfunction

Turret Board not rotating when Mode Switch is pushed

2-9-1 Block diagram

2-9-2 Estimated location of failure

No

①

②

③

④

⑤

⑥

ISSUE1

Estimated location failure Inspection Method

Light Source Cable 1 Verify connection of CV and Light Source Cable (MAJ-1411).

Scope /

Camera Head

Panel Lamp failure 1 Refer to 2-13

Harness 1 Verify connection of Harness.

Filter Limit Switch 1

Mesh Limit Switch 1

1 Confirm that scope or camera head is compatible with special light.

Main Board (J22) <--> Mesh Turret Unit

Main Board (J21) <--> Filter Turret Unit

Main Board (J10) <--> Mesh Limit Switch Unit

Main Board (J9) <--> Filter Limit Switch Unit

Main Board (J12) <--> Front Panel

Confirm that J9/Pin 1 change to LOW when Filter Limit Switch is

pushed.

NO → Replace Filter Limit Switch

Confirm that J10/Pin 1 change to LOW when Mesh Limit Switch is

pushed.

NO → Replace Mesh Limit Switch

2-9

Visual Inspection

Visual Inspection

Page 29

TroubleshootingCLV-180

Filter Turret Unit /

⑦

Main Board

1 Enter Brightness Manual Mode.

Input power by pushing "AIR Switch" and "Brightness UP Switch".

Set Filter position at will through MODE Switch and generate control

2

signal through AIR Switch. Then confirm following wave form at J21 of

Main Board:

Oscilloscope

J21 Connector

Pin 1:φ1

Pin 2:φ2

Pin 5:φ3

Pin 6:φ4

Mesh Turret Unit /

⑧

Main Board

(Range:5 V 10 ms)

YES → Filter Turret Unit

NO → Main Board

1 Enter Brightness Manual Mode.

Input power by pushing "AIR Switch" and "Brightness UP Switch".

Set Filter position at will through Counter Reset Switch and generate

2

control signal through AIR Switch. Then confirm following wave form at

J22 of Main Board:

Oscilloscope

J22Connector

Pin 1:φ1

Pin 2:φ2

Pin 5:φ3

Pin 6:φ4

(Range:5 V 10 ms)

YES → Mesh Turret Unit

NO → Main Board

2-10

ISSUE1

Page 30

2-10 Outgoing light failure

④

No light going out from Scope

2-10-1 Estimated location of failure

No

①

②

③

④

⑤

Estimated location failure Inspection Method

Scope 1 Confirm that Scope is a compatible one.

Power input failure Refer to 2-1

Lamp failure Refer to 2-2

Filter change malfunction Refer to 2-9

Manual Brightness failure Refer to 2-11

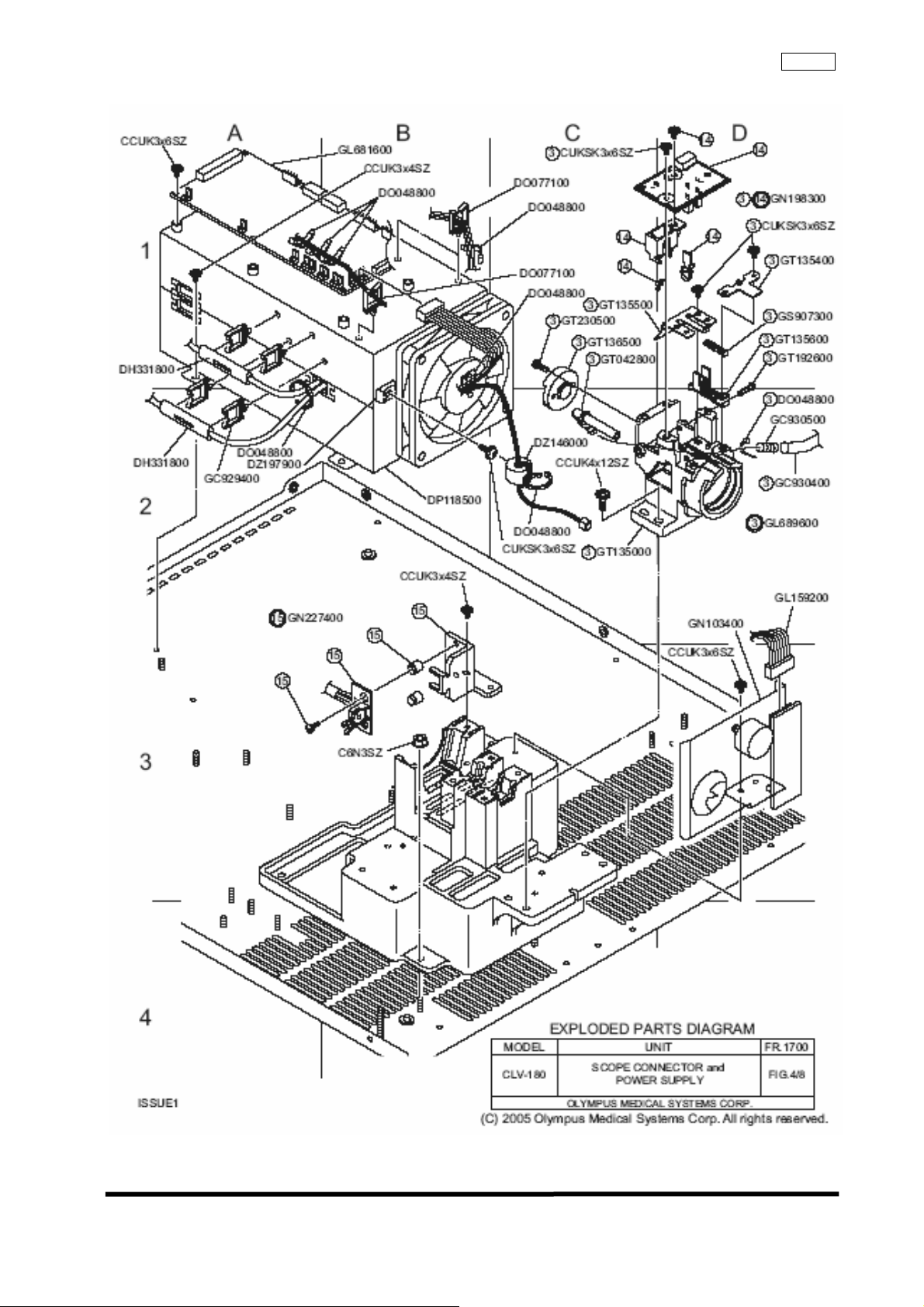

2-11 Manual Brightness failure

View field is dark or excessively light.

2-11-1 Block diagram

TroubleshootingCLV-180

2-11-2 Estimated location of failure

No

①

②

③

ISSUE1

Estimated location failure Inspection Method

Harness 1 Verify connection of Harness.

Main Board (J12) -> Front Panel

Main Board (J8) -> Iris Unit

Panel light malfunction Refer to 2-13

Iris Unit 1 Confirm that Iris Unit is mounted without distortion or inclination.

Iris Wing Positioning Jig

Scope Sensor 1 Confirm the following status of Main Board at J15 when Scope Dummy

is connected to Scope Socket:

・GI ScopeGI Scope Dummy

J15

Pin 2:L

Pin 5:H

Pin 8:L

・SP ScopeHeat Cover Positioning Jig

Pin 2:L

Pin 5:L

2-11

Page 31

Pin 8:H

・High-brightness SP ScopeHigh brightness SP Scope Dummy

Pin 2:H

Pin 5:L

Pin 8:L

*H:approx. 5 V

NO:Replace Scope Sensor

⑤

Iris Unit /

Main Board

Confirm following status of J8 when Brightness is set to manual and

1

light quantity from minimum to maximum:

J8

Pin 2 :Voltage change minus to plus.

YES:Replace Iris Unit

NO :Replace Main Board

2-12 Automatic Brightness failure

View field is dark or excessively light

2-12-1 Estimated location of failure

No

1 Light Source Cable

2 Manual Brightness failure Refer to 2-11

3 Main Board

Estimated location failure Inspection Method

Confirm connection to system capable of automatic Brightness.

CV-180

Confirm following status of J8 when scope move to the distance from

vicinity:

J8

Pin 2 :Voltage change minus to plus.

TES :Replace Iris Unit

NO:Replace Main Board

TroubleshootingCLV-180

CV-180

Light Source Cable

2-12

ISSUE1

Page 32

2-13 Panel Malfunction

@ No change in LED when switch is pushed, or LED display not lit.

@ The whole Front Panel blinks not accepting buttons.

2-13-1 Block diagram

TroubleshootingCLV-180

2-13-2 Estimated location of failure

No

1 HARNESS

3 MAIN BOARD

Estimated location failure Inspection Method

HARNESS

FRONT PANEL

1 Verify connection of Harness.

Main Board (J12) -> Front Panel

LED not completely lit when POWER is switched ON. 2 FRONT PANEL

1

No LED lit : Replace Harness

Some LED lit : Replace Front Panel

1 Confirm that the Pin corresponding to Main Board J12 change to H

when button is pushed.

*H: approx. DC +5 V

Tester

J12

Pin 5 :AIR

Pin 6 :MODE

Pin 7 :AUTO/MANUAL

Pin 8 :BRIGHTNESS UP

Pin 9 :BRIGHTNESS DOWN

Pin 10:LEVEL

Pin 11:TRANSILLUMINATION

Pin 12:LUMP

Pin 13:COUNTER RESET

Pin 14:HIGH

2-13

ISSUE1

Page 33

TroubleshootingCLV-180

4

SCORP SENSOR

THERMO SENSOR

MAIN BOARD

YES : Replace MAIN BOARD

NO : Replace FRONT PANEL

Front Panel blinks immediately after switching Power ON not accepting

1

buttons.

・ Pin of Thermo Sensor not conductive:

Replace Thermo Sensor

Signals from Scope Sensor are not the following when each type of

scope is connected to Scope Socket:

Replace Scope Sensor

Main Board J15

・GI Scope GI Scope Dummy

J15

Pin 2:L

Pin 5:H

Pin 8:L

・SP ScopeHeat Cover Positioning Jig

Pin 2:L

Pin 5:L

Pin 8:H

・High brightness SP ScopeHigh brightness SP Scope Dummy

Pin 2:H

Pin 5:L

Pin 8:L

*H:approx. 5 V

・ None of the above cases applicable: Replace Main Board

2-14

ISSUE1

Page 34

2-14 Emergency Lamp malfunction

Emergency Lamp not lit automatically when Xenon Lamp is off.

2-14-1 Block diagram

TroubleshootingCLV-180

2-14-2 Estimated location of failure

No

①

②

③

④

Estimated location failure Inspection Method

EMRGENCY LAMP

HARNESS

Panel malfunction Refer to 2-13

Filter change malfunction Refer to 2-9

CONVERTER

MAIN BOARD

Confirm that Emergency Lamp on Front Panel is blinking.

1

YES : Replace EMRGENCY LAMP

Replace HARNESS(CONVERTER → EMERGENCY LAMP)

Confirm status of following pins at Main Board J6 when Emergency

1

Lamp is not blinking:

・(When Xenon Lamp is OFF)

2 : H(Xenon Lamp ON order: ON order at L. L maintain while ON)

3 : H(Emergency Lamp ON: L when ON)

6 : H(Xenon Lamp ON: L when ON)

7 : L(Emergency Lamp: L when no break down)

Replace MAIN BOARD

・(When Emergency Lamp is ON)

2 : H

3 : L

6 : H

7 : L

Replace CONVERTER

・(When Xenon Lamp is working normally)

2 : L

3 : H

6 : L

7 : L

Replace CONVERTER or MAIN BOARD

・Others

Replace CONVERTER or MAIN BOARD

2-15

ISSUE1

Page 35

2-15 Back-up malfunction

②

Settings are not saved after switching Power OFF

2-15-1 Estimated location of failure

No

①

Estimated location failure Inspection Method

MAIN BOARD 1 Replace MAIN BOARD

2-16 Lamp Life Meter Reset malfunction

Not changing to "0" when Lamp Life Meter Reset switch is pushed.

2-16-2 Estimated location of failure

No

①

②

③

Estimated location failure Inspection Method

XENON LAMP 1 Confirm that Xenon Lamp is OFF.

Panel malfunction Refer to 2-13

MAIN BOARD

Dose not reset when pushing Reset switch.

YES : Replace MAIN BOARD

2-17 Transillumination malfunction

No change in light quantity when Transillumination switch is pushed.

2-17-1 Block diagram

TroubleshootingCLV-180

2-17-2 Estimated location of failure

No

①

③

④

⑤

ISSUE1

Estimated location failure Inspection Method

Scope 1 Confirm that GI Scope is connected.

Panel Malfunction Refer to 2-13

Filter Change Malfunction Refer to 2-9

Manual Brightness malfunction Refer to 2-11

SCOPE SENSOR

MAIN BOARD

Transillumination switch lit:

NO → SCORP SENSOR 交換

YES → MAIN BOARD

2-16

GI Scope or GI Scope Dummy

Page 36

Precautions on disassembly and assembly CLV-180

Chapter 3: Precaution on

disassembly and reassembly

ISSUE 1

3-1

Page 37

Precautions on disassembly and assembly CLV-180

1. Warning

(1) To prevent potentially dangerous health risks, select a well-ventilated location when using organic solvents.

(2) To prevent potentially dangerous health risks, rinse your body well under running water to wash away

organic solvents if any adhere to your body.

(3) When using organic solvents, handle flames such as those in alcohol lamps with caution since these

solvents may ignite if exposed to flame. In addition, be sure to put the lids on containers of organic solvents

before leaving the workbench.

2. Caution

(1) Attach parts in their original configurations during reassembly. Pay particularly close attention to the following

items:

a) Insulators, such as insulating tubes and mylar sheets

b) Cable rerouting, clamps, and cores

c) Shielded parts and covered screws with toothed washers

Failure to attach parts in their original configurations, even if it does not impair

product functions, poses the risk of noise radiation and reduced electrical safety.

(2) Exercise extreme caution to prevent possible injuries during reassembly. Be particularly careful to avoid

injuring yourself on the sharp edges of metal parts.

(3) Always use the specified components. The product is comprised of components designed to withstand

anticipated vibration, heat, and voltage. When replacing any component, make sure the replacement

component has the same characteristics as the original component, and always use the specified

components.

(4) Use the specified jigs and tools. The use of any unspecified jigs or tools may damage the AR-TZ2 or the

components under repair and prevent it from functioning properly or performing optimally.

(5) Be careful to avoid electrocution. Only remove the cover enclosing the OTV-SP1C after turning off the power

and unplugging the power cord, unless it is critically important not to do so.

(6) Be careful about residual voltage. Even if the unit is turned off before the cover is opened, keep in mind that

the capacitor may still hold a charge, so take care to avoid electrocution.

(7) Guard against static electricity. If it is necessary to touch the boards or other electrical components, to

prevent damaging them, use a conductive mat or wristband to discharge static electricity.

ISSUE 1

3-2

Page 38

Disassembly and Reassembly ProcedureCLV-180

Chapter 4: Disassembly and

Reassembly procedure

ISSUE1

4-1

Page 39

1. Jigs and Tools

No. Name Specification Remark

1 Box bit Size 5.5 mm

2 Phillips bit (No1)

3 Phillips bit (No2)

4 Open head 10 mm, 14 mm

5 Torque driver 0.02~0.15 [Nm]

6 Torque driver 0.2~1.2 [Nm]

7 Torque driver 0.6~2.6 [Nm]

8 Long-nose Pliers

9 Nipper

10 Tweezers

11 Filter retaining jig

12 Diaphragm positioning jig

13 Heat cover positioning jig

2. Areas

Disassembling procedure is described by 3 areas.

Disassembly and Reassembly ProcedureCLV-180

ISSUE1

A

B

C

4-2

Page 40

Disassembly and Reassembly ProcedureCLV-180

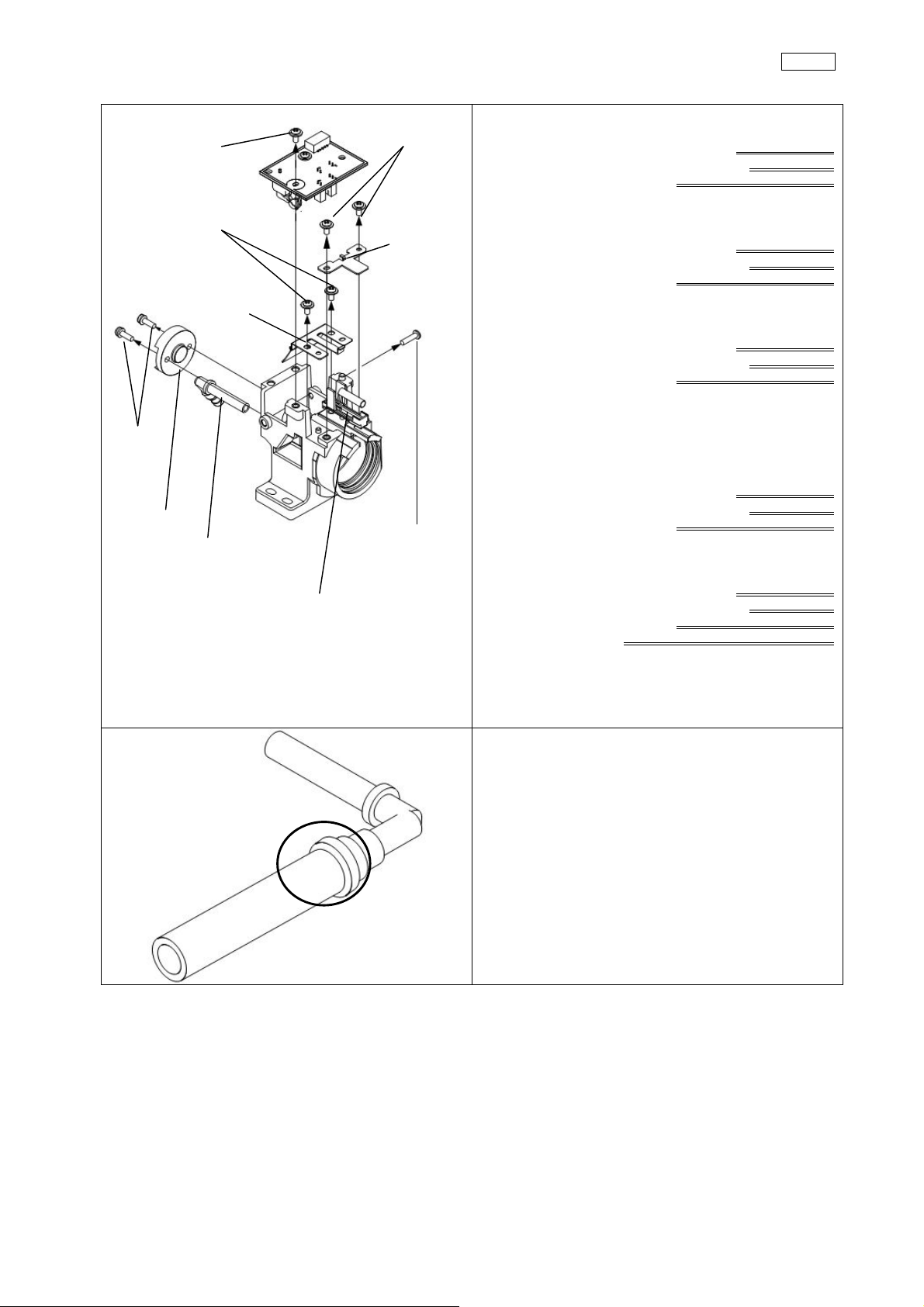

3. Disassembling and Reassembling procedure

3-1 First step

DOOR 260 EU

3-2 Area A

TOP COVER

13 screws

W03O002A

(Thermo switch)

1 screw 2 screws

Shield plate

Switch board collar

Switch board

Switch washer

2 screws

3-2-1 NSW bracket

Switch board spring

NSW bracket U

[3-2-1]

Heat sink eco U

[3-2-2]

3 screws

Switch

(interlock)

Rear panel U

[3-2-3]

11 screws 6 nuts

Shield case 260 eco U

[3-2-4]

W03O003A

(FAN)

2 screws

Lamp base U

[3-2-5]

4 nuts

Igniter U

[3-2-6]

3 nuts

Igniter COVER

2 nuts

1 screw

W03O018A

(Main switch)

Extending knob

ISSUE1

4-3

Page 41

3-2-2 Heat sink eco U

Disassembly and Reassembly ProcedureCLV-180

Sink shaft

1 e-ring

Hinge board

Spring collar

2 screws

Magnet holder eco

Magnet

2 screws

Snap lock

Mini catch

6 screws

GT washer

Xenon lamp

Hex bolt

3-2-3 Shield case 260 eco U

SHIELD MYLAR 1

Knob washer

SHIELD MYLAR 2

HS guide x 2

4 screws

Gasket 2

Caution plate

Mini clamp

Cable holder

ISSUE1

4-4

Page 42

3-2-4 Lamp base U

Disassembly and Reassembly ProcedureCLV-180

Sink retainer spring

2 screws

Pole spacer

Pole F

1 screw

Discharge spring

W12M020A

(resistance)

1 screw

Discharge plate

W12M019A(cable)

1 screw

3-2-5 Igniter U

UPCL16PS50

(Igniter)

Igniter BL

Pole R

3 screws

Sink spring

2 screws

Discharge coil

Discharge base U

1 e-ring

W03O001A

(CONDENSER H)

Sink spring

2 screws

Discharge spindle

Discharge base

1 screw

Core x 2

2 binders

ISSUE1

3 nuts

W03O006A

(+IGNITER H)

W03O007A

(-IGNITER H)

W03O008A

(+RELAY H)

W03O009A

(-RELAY H)

4-5

Page 43

3-3 Area B

Disassembly and Reassembly ProcedureCLV-180

6 screws

3-4 Area C

Front panel

[3-4-1]

3 screws

M limit SW U

IPF Power supply U MAIN BOARD

4 nuts

S socket U

[3-4-3]

4 screw

M turret U

Side clamp

Connector cover

Terminal

Binder

180 MESH BK BASE

2 screws

Pump 260 eco U

[3-4-2]

4 nuts

Turret U

[3-4-4]

4 screws

W04Q001A

(scope detection cable )

W03Q011A

(filter turret cable )

W03Q011A

(filter turret cable )

4 screws

W03Q011A

(filter turret cable )

Limit SWBK eco U

1 screws

Lens retainer U

2 screws

4 screws

ISSUE1

UPNS180U

(Diaphragm)

2 screws

4-6

Page 44

3-4-1 Front panel U

6 screws

180 FP chassis

Disassembly and Reassembly ProcedureCLV-180

Binder

(Cord holder)

180 shielding plate

4 screws

FP sheet

5 screws

Gasket F 260

Core holder 180

2 screws

3-4-2 Pump 260 eco U

Upper P case

4 screws

F panel 180 U

Core

Binder

P packing

Pump U

2 screw

Pump

UPCL18ZZ

(LED Board)

1 screw

Switch collar LL

Switch spring

Main switch

Valve U

Pump board eco

Rubber foot

Tubes

Pump base

4-7

ISSUE1

Page 45

3-4-3 S socket U

Disassembly and Reassembly ProcedureCLV-180

Heat cover

2 screws

SS board repair U

1 screw 2 screws

Plastic screw

3-4-4 Turret U

Cramp base eco

2 screws

F frame board

2 screws

Attachment U

Retaining bracket 180

Turret BK eco U

1 screw

Binder

1 screw

Hinge 180

2 screws

Edge saddle

1 screw

Slide detection spring

Slide detection 180

T stopper pin

1 screw

H lamp shield

2 screws

H lamp retainer

3 screws

Filters

3-4-4 Turret U

5 screws

W03O010A

(Lamp harness)

H Lamp spring

Emergency lamp

M turret repair U T stopper pin 180

1 screw

Limit SW U

4-8

ISSUE1

Page 46

3-1 First step

Disassembly and Reassembly ProcedureCLV-180

(1) Loosen the knot and take off 260EU

260EU

SWITCH

BLOCK

WRENCH

TOP COVER

C6N3SZ

(2) Take off WRENCH

(3) Take off 2 NUTS (C6N3SZx2) and SWITCH BLOCK

BOX bit(size 5.5 mm)

Torque driver

Tightening torque 0.6 Nm

(4) Take off 13 SCREWS (HCBK3x6SAx10: 10 on the

right and left side、3 on the back) and TOP COVER

→3-2 Area A

→3-3 Area B

→3-4 Area C

Phillips bit (No.2)

Torque driver

Tightening torque 0.6 Nm

3-2 Area A

CUKSK3X6SZ

THERMO SWITCH

ISSUE1

(1) Take off 1 SCREW (CUKSK3X6SZ) and THERMO

SWITCH

Phillips bit (No.2)

Torque driver

Tightening torque 0.6 Nm

4-9

Page 47

Disassembly and Reassembly ProcedureCLV-180

Blue

CCUK3x4SZ

HEAT SINK U

Green

(2) Take off only junction part of FASTEN TERNMINAL

(3) Take off 2 SCREWS (CCUK3x4SZx2) and NSW

BRACKET U

Phillips bit (No.2)

Torque driver

Tightening torque 0.6 Nm

(4) Take off HEAT SINK U

→Go to 3-2-2

CBK2.5x6SA HCBK3x6SA

REAR PANEL U

C6N3SZ

CCUK3X4SZ

SHIELD PLATE

(5) Take off 9 SCREWS (HCBK3x6SA:7, CBK2.5x6SA:2)

and REAR PANEL U

→Go to 3-2-3

Phillips bit (No.1)

Torque driver

Tightening torque 0.33 Nm

Phillips bit (No.2)

Torque driver

Tightening torque 0.6 Nm

(6) Take off 3 SCREWS (CCUK3X4SZ) and SHIELD

PLATE

Philips bit (No.2)

Torque driver

Tightening torque 0.6 Nm

(7) Take off 6 NUTS (C6N3SZ) and SHIELD CASE 260 U

→Go to 3-2-4

Box bit(Size 5.5 mm)

Torque driver

(Tightening torque:0.6 Nm)

4-10

ISSUE1

Page 48

Disassembly and Reassembly ProcedureCLV-180

CUKSK3x6SZ CUKSK4x6SZ

(10) C6N3SZ

IGNITER

COVER

(9) C6N3SZ

IGNITER U

(8) Take off 2 SCREWS (CUKSK3x6SZ, CUK¥SK4x6SZ) ,

and adjust HARNESS which is connected with LAMP

BASE U

Phillips bit (No.2)

Torque driver

Tightening torque 0.6 Nm

(9) Take off 2 NUTS (C6N3SZ) and IGNITER COVER

Box bit (Size 5.5 mm)

Torque driver

(Tightening torque:0.6 Nm)

(10) Take off 3 NUTS (C6N3SZ) and IGNITER U

*At same time, take off HARNESS from POWER

SUPPLY

→Go to 3-2-6

Box bit (Size 5.5 mm)

Torque driver

(Tightening torque:0.6 N m)

Connected with HARNESS Take off HARNESS

C6N3SZ

LAMP BASE U

Connected with HARNESS

ISSUE1

(11) Take off 5 NUTS (C6N3SZ) and LAMP BASE U

*One of NUTS is connected with HARNESS

→Go to 3-2-5

BOX bit(size 5.5 mm)

Torque driver

Tightening torque0.6 Nm

4-11

Page 49

Disassembly and Reassembly ProcedureCLV-180

(15)CCUK4x45SZTake off CONNECTOR

FERRITE CORE

FAN BK

ECO

CORE

STAND

(14)CCUK3x4SZ (13)C6N3SZ (16)CUKSK3x6SZ

3-2-1 NSW bracket

CCUK3x4SZ

INTERLOCK

SWITCH

EXTENDING

KNOB

MAIN SWITCH

3-2-2 Heat sink eco U

(12) Take off FAN CABLE from J14 of MAIN BOARD

(13) Take off 1 NUTS (C6N3SZ) and FERRITE CORE

BOX bit(size 5.5 mm)

Torque driver

Tightening torque 0.6 Nm

(14) Take off 2 SCREWS (CCUK3x4SZ) and FAN ECO U

Phillips bit (No.2)

Torque driver

Tightening torque 0.6 Nm

(15) Take off 2 SCREWS (CCUK4x45SZ) and FAN BK

ECO

Phillips bit (No.2)

Torque driver

Tightening torque 1.4 Nm

(16) Take CORE out and take off SCREW (CUKSK3x6SZ)

and CORE STAND

Phillips bit (No.2)

Torque driver

Tightening torque 0.6 Nm

(1) Take off 1 SCREW (CCUK3x4SZ) and SW PLATE

SPRING

Phillips bit( No.2 )

Torque driver

Tightening torque 0.6 Nm

(2) Take off EXTENDING KNOB from MAIN SWITCH

(3) Take SWITCH (INTERLOCK SW)and MAIN SWITCH

from N SWITCH BK

*Take off by pushing the trap on each upper and

lower side

(1) Unlock HEAT SINK F ECO U

4-12

ISSUE1

Page 50

CCUK3x6SZ

WASHER

KNOB WASHER

ER5SA

Disassembly and Reassembly ProcedureCLV-180

(2) Take off ER5SA from SINK SHAFT in HEAT SINK F

ECO U

Long-nose Pliers

(3) Pull SINK SHAFT, then take off KNOB WASHER

from SINK SHAFT

(4) Take off 2 SCREWS (CCUK3x6SZ), HINGE PLATE

and SPRING COLLAR

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(6)CSK2.5x6SA

SNAP

LOCK

XENON LAMP

MINI CATCH

(5)CSK2.5x6SA

GT

(5) Take off 2 SCREWS (CSK2.5x6SA), MAGNET

HOLDER ECO and MAGNET

Phillips bit (№1)

Torque driver

Tightening torque 0.33 Nm

(6) Take off 6 SCREWS (CSK2.5x6SA) , SNAP LOCK

and MINI CATCH

Phillips bit (№1)

Torque driver

Tightening torque 0.33 Nm

(7) Take off 3 HEX BOLT, GT WASHER and XENON

LAMP

Hex wrench(size 2.5 mm)

Tightening torque 0.8 Nm

HEX BOLT

(8) SINK SHAFT Take off ER5SA from SINK SHAFT

on HEAT SINK F ECO U

Long-nose Pliers

(9) Pull SINK SHAFT, and take off KNOB

WASHER from SINK SHAFT

ER5SA

KNOB WASHER

4-13

ISSUE1

Page 51

3-2-3 Rear panel

(1)

(3)

CCUK2.5x6SZ

(2)

RETAINING

BASE

(5)

6N6SN

EndoAlpha

CONNECTOR

(4)

FOOT SW

CONNECTOR

TERMINAL

REAR

FOOT

Disassembly and Reassembly ProcedureCLV-180

(1) Take off NUT, WASHER and FOOT SW CONNECTOR

Open head (size 14 mm)

Torque driver

Tightening torque 1.2 Nm

(2) Take off 1 NUT(C6N3SZ) and GROUND CODE, and 1

WASHER

BOX bit (size 5.5 mm)

Torque driver

Tightening torque 0.6 Nm

(3) Take off 2 SCREWS (CCUK2.5x6SZ), EndoAlpha

CONNECTOR and RETAINING BASE

Phillips bit (№2)

Torque driver

Tightening torque 0.4 Nm

(4) Take off 4 SCREWS(CBK3x4SA) and REAR FOOT

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(5) Take off 2 NUTS(6N6SN), 1 WASHER and TERMINAL

Open head(size 10 mm)

Torque wrench

Tightening torque 5 Nm

4-14

ISSUE1

Page 52

3-2-4 Shield case 260 eco U

CCUK3x6SZ

CCUK3x6SZ

CCUK3x6SZ

CABLE HOLDER

CAUTION PLATE

Disassembly and Reassembly ProcedureCLV-180

(1) Take off GASKET 2

(2) Take off CABLE HOLDER

(3) Take off MINI CLAMP

(4) Take off CAUTION PLATE

MINI

CLAMP

GASKET 2

SHIELD MYLAR 2 CCUK3x6SZ

SHIELD MYLAR 1

3-2-4 Lamp base U

(1)

(2)

(3)

(5) Take off 4 SCREWS(CCUK3x6SZ), HS GUIDE

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(6) Take off SHIELD MYLAR 1

(7) Take off SHIELD MYLAR 2

(1) Take off 2 SCREWS(CCUK3x6SZ) and take off SINK

SPRING from POLE F

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(2) Take off 2 SCREWS(CCUK3x6SZ) and take off SINK

SPRING from POLE R

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(3) Take off 3 SCREWS (CCUK3x6SZ)

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

4-15

ISSUE1

Page 53

CCUK3x6SZ

SPRING

CCUK3x6SZ

CCUK2x4SZ

PLATE

DISCHARGE COIL

POLE SPACER

HARNESS

DISCHARGE

ISSUE1

(5) (6)

(8)

DISCHARGE

(10) ER2.5SN

(4)

(11)

DISCHARGE

COIL

(9)

Disassembly and Reassembly ProcedureCLV-180

(4) Take off 1 SCREW (CCUK3x6SZ) and take POLE F

and POLE SPACER off together.

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(5) First take off 1 SCREW (CCUK3x4SZ), and adjust

HARNESS、and then take off POLE R

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(6) Take off 2 SCREWS (CCUK3x4SZ) and SINK

RETAINER SPRING

Phillips bit (№2)

Torque driver

(7) Take off 1 SCREW (CCUK3x6SZ) , HARNESS and

DISCHARGE SPRING

(8) Take off 1 SCREW (CCUK3x6SZ)、HARNESS and

DISCHARGE PLATE

(9) Take off ER2.5SN, DISCHARGE BASE U and

DISCHARGE COIL

(10) Take off 1 SCREW (CCUK2x4SZ), DISCHARGE

SPINDLE

4-16

Tightening torque 0.6Nm

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

Long-nose Pliers

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

Page 54

3-2-5 Igniter U

on BASE

Tightened with STUD

(1) (2)

(3)

3-3 Area B

Disassembly and Reassembly ProcedureCLV-180

(1) Take off 1 NUT (6N15BN) and take off components as

follows :

1 WASHER

- IGNITER HARNESS *terminal hole M3

BOX bit(size 8 mm)

Torque driver

Tightening torque 2.0 Nm

(2) Take off 1 NUT (6N15BN) and take off HARNESS as

follows:

W03O008A (Red)

1 WASHER

CONDENSER HARNESS

+ IGNITER HARNESS *terminal hole M4

BOX bit (size 8 mm)

Torque driver

Tightening torque 2.0 Nm

(3) Take off 1 NUT (6N15BN) and take off HARNESS as

follows:

Take off IGNITER

W03O009A (Black)

1 WASHER

CONDENSER HARNESS

BOX bit(size 8 mm)

Torque driver

Tightening torque 2.0 Nm

(1) Cut the BINDER and take off HARNESS from

BINDER

Nipper

(2) Take off each HARNESS connected to MAIN BOARD

4-17

ISSUE1

Page 55

Disassembly and Reassembly ProcedureCLV-180

(3) Take off 8 SCREWS (CCUK3x6SZ:6, CBK2.5x6SA:2)

and MAIN BOARD

Phillips bit (№1)

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

HCBK3x6SA

(4) Take off 7 SCREWS (HCBK3x6SA) and REAR

PANEL U

Phillips bit (№1)

Torque driver

Tightening torque 0.33 Nm

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(5) Take off CORE

*Pull CONNECTOR by pushing upper side

Phillips bit (№1)

Torque driver

Tightening torque 0.33 Nm

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

ISSUE1

4-18

Page 56

Disassembly and Reassembly ProcedureCLV-180

(6) Take off 4 NUTS (C6N3SZ) and CONVERTER

BOX bit(size 5.5 mm)

Torque driver

Tightening torque 0.6 Nm

(7) Take off IGNITER HARNESS which comes from

CONVERTER

*upper:red、lower:black

3-4 Area C

(1) Take off FLAT CABLE which comes from FRONT

PANEL

4-19

ISSUE1

Page 57

Disassembly and Reassembly ProcedureCLV-180

(2) Take off SCREW (CCUK3x6SZ)

(tightened with GROUND STRAP)

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(3) Take off 2 SCREWS (CCUK3x4SZ) and FRONT

PANEL

→Go to 3-4-1

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

FRONT PANEL

VALVE U

(4) Cut 4 BINDERS (left figure) and take off TUBE from

VALVE U

Nipper

4-20

ISSUE1

Page 58

Disassembly and Reassembly ProcedureCLV-180

(5) Take off 1 NUT (C6N3SZ, left figure) and CABLE

from BINDER

BOX bit(size 5.5 mm)

Torque driver

Tightening torque 0.6 Nm

(6) Take off 4 NUTS (C6N3SZ) and PUMP 260 ECO U

→Go to 3-4-2

BOX bit(size5.5mm)

Torque driver

Tightening torque 0.6 Nm

C6N3SZ

(7) Cut the BINDER which holds CABLE connected with

S SOCKET U, M LIMIT SWITCH, and take off

CABLE from MINI CRAMP

Nipper

4-21

ISSUE1

Page 59

Disassembly and Reassembly ProcedureCLV-180

counterclockwise for Reassembly in order to align

(8) Take off 2 SCREWS (CCUK3x4SZ) and M LIMIT

SWITCH

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(9) Take off 4 SCREWS (CCUK3x4SZ) and M TURRET

U

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(10) Take off 4 SCREWS (CCUK3x4SZ) and 180 MESH

BK BASE

Phillips bit(№2)

Torque driver

Tightening torque 0.6 Nm

CCUK3x4SZ

180 MESH

BK BASE

CCUK4x12SZ

(11) Take off 4 SCREWS (CCUK4x12SZ) and S SOCKET

180U

*Fix the S SOCKET 180U by pushing

the optical axis .

→ go to 3-4-3

Phillips bit (№2)

Torque driver

Tightening torque 1.4 Nm

ISSUE1

4-22

Page 60

Disassembly and Reassembly ProcedureCLV-180

1-T

2-T

(15)CCUK3x4SZ

DIAPHGRAM

HARNESS

LENS

RETAINER 3

LENS

RETAINER 2

CUKSK3x6SZ

(12) Take off DIAPHRAGM HARNESS from

DIAPHRAGM U

(13) Take off 2 SCREWS (CCUK3x6SZ) and

DIAPHRAGM U

Phillips bit (№2)

Torque driver

Tightening torque 1.4 Nm

DIAPHRAGM POSITIONING JIG(for reassembly)

*Push the side that has no slit on JIG towards the rear

and make the DIAPHGRAM stay inside the slit as seen

from above.

(14) Take off EMERGENCY HARNESS from MINI

CRAMP

(15) Take off 4 SCREWS (CCUK3x4SZ) 、 LENS

RETAINER 2 and LENS RETAINER 3

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(16) Take off 1-T and 2-T from LENS BASE

(17) Take off 2 SCREWS (CUKSK3x6SZ) and LENS

RETAINER U

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(18) Take off 3-T and 4-T from LENS BASE

LENS RETAINER U

4-T

3-T

(19)Take off 1 SCREW (CCUK3x4SZ) and LIMIT SW U

Phillips bit (№2)

Torque driver

Tightening toque 0.6 Nm

4-23

ISSUE1

Page 61

Disassembly and Reassembly ProcedureCLV-180

3-4-1 Front panel U

(2) CCUK3x4SZ

GASKET F260

CCUK3x8SZ

180 FP CHASSIS

CORE HOLDER

180

180

SHIELDING

PLATE

(20)Take off 3 SCREWS (CCUK3x8SZ) and TURRET

180U

→Go to 3-4-4

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(1) Take off 6 SCREWS (T2CCUK3x8SZ) and 180 FP

CHASSIS

Phillips bit (№2)

Torque driver

Tightening torque 0.3 Nm

(2) Take off 2 SCREWS (CCUK3x4SZ) and CORE

HOLDER 180

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(3) Cut BINDER and take off CORE

Nipper

(4) Take off BINDER

(5) Take off 9 SCREWS(CCUK3X4SZ), 180

SHIELDING PLATE and FP SHEET

* In case of trading FP CHASSIS, take off GASKET

F260

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

FP

SHEET

4-24

ISSUE1

Page 62

Disassembly and Reassembly ProcedureCLV-180

CONNECTOR

T2CCUK3x8SZ

LED BOARD

SWITCH

SPRING

3-4-2 Pump 260 eco U

LED COVER

MAIN SWITCH

(6) Take off CONNECTOR (left figure) and CABLE

CABLE

(7) Take off 1 SCREW (T2CCUK3x8SZ), LED BOARD

and LED COVER

Phillips bit (№2)

Torque driver

Tightening torque 0.3 Nm

(8) Take off SWITCH COLLAR LL, SWITCH SPRING,

MAIN SWITCH

Tweezers

SWITCH

COLLAR LL

(1)Cut BINDER (left figure) and take off TUBE

Nipper

4-25

ISSUE1

Page 63

T2CCUK3x14SZ

UPPER P

CASE

P PACKING

CCUK3x8SZ

Disassembly and Reassembly ProcedureCLV-180

(2) Take off 4 SCREWS(T2CCUK3x14SZ), FLAT CLIP ,

UPPER P CASE and P PACKING

Phillips bit (№2)

Torque driver

Tightening torque 0.3 Nm

FLAT CLIP

(3)Take off 2 SCREWS (CCUK3x8SZ) and take out

PUMP

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

PUMP

(4)Cut BINDER(left figure) and take off TUBE

Nipper

4-26

ISSUE1

Page 64

TUBE SSS

CCUK3x6SZ

RUBBER

FOOT

PUMP

PLATE

Disassembly and Reassembly ProcedureCLV-180

(5)Take off TUBE SSS from TUBE, which was taken

off from PUMP

(6) Take off 2 SCREWS (CUKSK3x6SZ) and PUMP

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(7) Take off RUBBER FOOT from PUMP BASE

(8) Pull RUBBER FOOT from PUMP PLATE ECO

Long-nose Pliers

SUPPORT COIL S

ISSUE1

PUMP

BASE

(9) Take off TUBE S from VALVE U and pull SUPPORT

COIL S

4-27

Page 65

3-4-3 S socket 180U

(1) CCUK3x4SZ

(3) CCUK3x6SZ

(2) CCUK3x6SZ

RETAINING

BRAKET

180

Disassembly and Reassembly ProcedureCLV-180

(1) Take off 1 SCREW (CCUK3x4SZ) and SS BOARD

REPAIR U

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

(2) Take off 2 SCREWS (CCUK3x6SZ) and RETAINING

BRACKET180

Phillips bit (№2)

Torque driver

Tightening torque 0.6 Nm

HINGE 180