Page 1

Safety Check Instruction

SCI.991007-1.4

Product name:

Hardware version:

CelonLab ENT (100...120 V~)

30

REF no.:

WB991007

LAB991.025.007

The unit must undergo a safety check at annual intervals in accordance with the national statutory regulations. Please follow these test

instructions. All tests must be done with fully functional and calibrated test equipment and by technicians trained in the service / maintenance

of electrical medical devices. Record the test results in the “safety check report” for reference in future tests and provide the user of the unit

with a signed report. If the unit fails to meet any of the checks, contact the manufacturer.

During service / maintenance take care of the different hardware versions which may be applicable (see below).

The hardware version of the unit can be identified by the serial number which can be found on the type plate at the back side of the unit. The

table below shows the serial number range to identify the hardware version.

Hardware version

Serial number (SN)

30 … 31

A22701LE01.0001 ... A58702LE01.9999

32 … ≥ 35

1000-1001 … 6172-9999

From hardware version 35 the serial number itself includes already the hardware version. This code was introduced for units manufactured

since February 2005.

Example: 1234W35-567

Recommended test equipment and accessories

Electrical safety tester (Example: Unimet 1000 ST, Bender)

Electrosurgical analyzer (Example: QA-ES, Metron)

Load resistor 100 Ω, 25 W (or more), 5 % tolerance, low inductive part, short time load

Connection cables, HF-output (banana) to electrosurgical analyzer or load resistor

Power cord

Footswitch

Hardware version

© Celon AG Page 1 / 9

, Issue date: 01.09.2008

Page 2

Safety Check Instruction

SCI.991007-1.4

1. Inspection of the unit and the accessories

No.

Procedure

010

Accompanying documents are present and legible:

- Instructions for Use

- EMC-Guidelines

- final test report (incl. test protocols according to the final test report)

- optional (depending on the country): medical device information (“Medizinproduktebuch”)

020

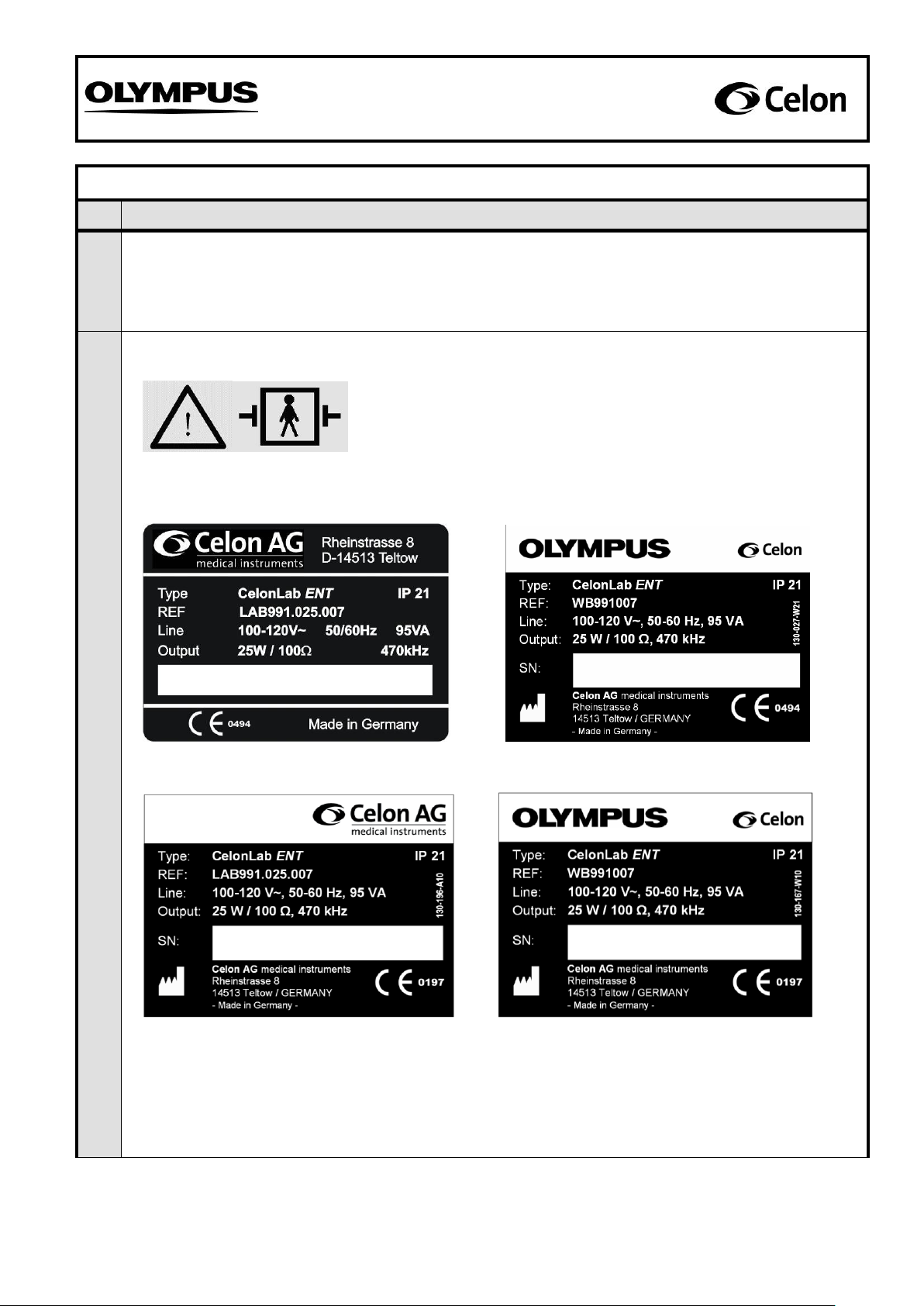

Labels present and legible:

Sample of symbol: “Unit is defibrillator-safe”

Visible on the front panel (see fig. 2)

Sample of symbol: “Caution! Read the Instructions for Use!”

Visible on the front panel (see fig. 2)

Samples of type plates: Details of the manufacturer, supply voltage, supply frequency, moisture

protection class (IP), reference number, serial number (e.g. 1234W34-567), power input, power

output, and output frequency.

Visible on the back of the unit (see fig. 1)

SN: 3580-1001

3580A34-567

1234W34-567

1234W34-567

© Celon AG Page 2 / 9

, Issue date: 01.09.2008

Page 3

Safety Check Instruction

SCI.991007-1.4

No.

Procedure

020

030

Unit and accessories are externally undamaged:

- Enclosure and front panel have no serious destructions

040

Lift up the unit and shake it gentle. No clatter noise should be audible.

Documentation

050

Document the test results in “SCR.991007.

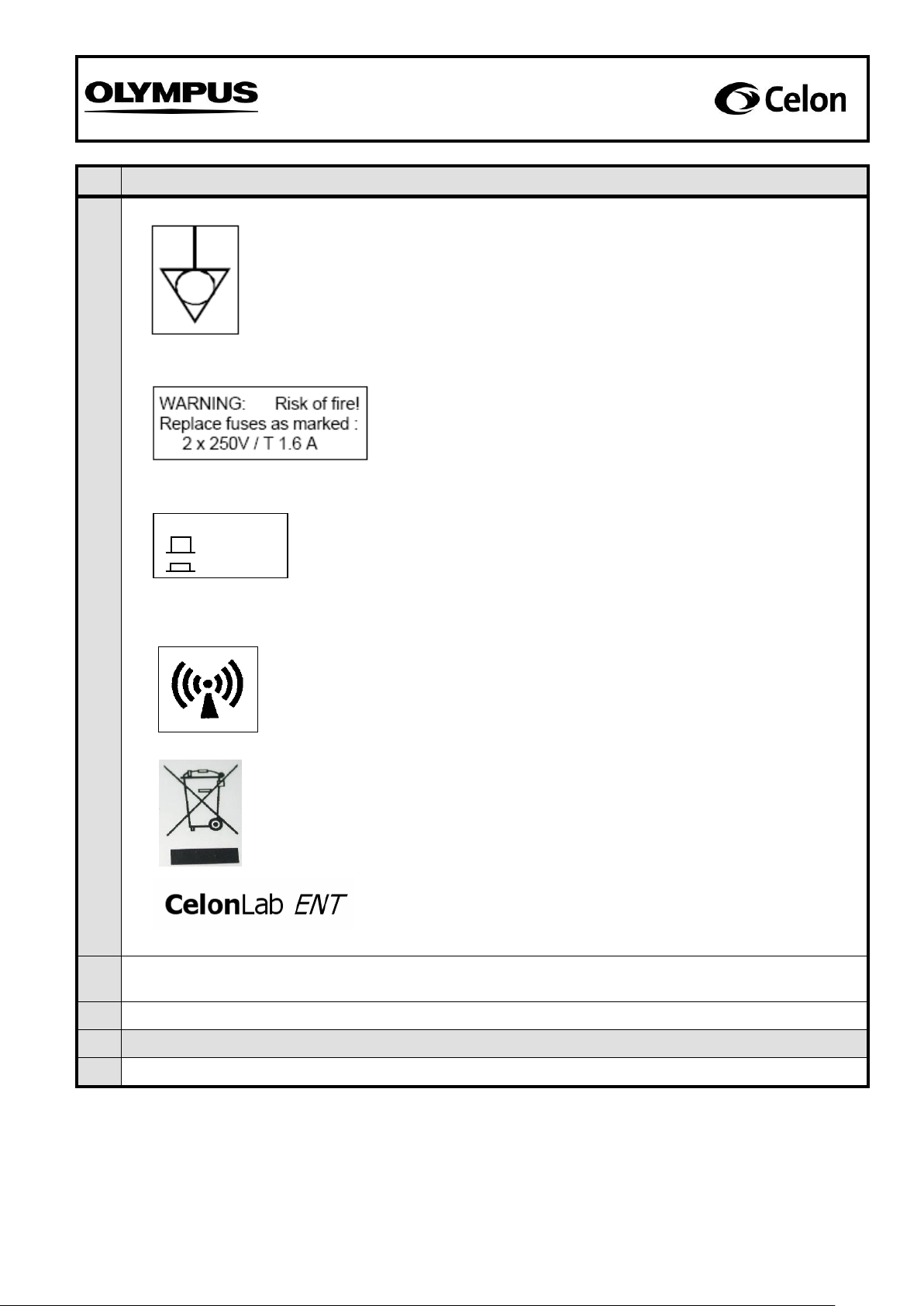

Sample of symbol: Connection for equipotential bonding

Visible on the back of the unit (see fig. 1)

Samples of label for power fuses:

Visible on the back of the unit (see fig. 1)

Sample of symbol: “Non-ionizing radiation”

Visible on the back of the unit (see fig. 1)

Sample of label for volume switch:

Visible on the back of the unit (see fig. 1)

Sample of label: Product name

Visible on the front panel (see fig. 2)

SPEAKER VOLUME

HIGH

LOW

Sample of symbol: “Waste electrical and electronic equipment”

Visible on the back of the unit, only applicable for

units within the European Union and sold after

August 13th, 2005. (see fig. 1)

© Celon AG Page 3 / 9

, Issue date: 01.09.2008

Page 4

Safety Check Instruction

SCI.991007-1.4

Fig. 1: Sample of the backside of the CelonLab ENT power control unit

Fig. 2: Sample of the front panel of the CelonLab ENT power control unit

© Celon AG Page 4 / 9

, Issue date: 01.09.2008

Page 5

Safety Check Instruction

SCI.991007-1.4

2. Display function check

No.

Procedure

Test accessories: Power cord

060

Connect the unit via power cord with a rated supply voltage. Switch on the unit and wait several seconds

until the power level display shows “1”.

070

Press the “UP“-button of the power setting (increasing the power) ten times.

The power level display has to be increased by 1 per step until “10” (starting from “1”) is shown.

080

Press the “UP“-button of the power setting (increasing the power) and hold it down.

The power level display has to be increased step-by-step until “25” is shown.

090

Press the “DOWN“-button of the power setting (reducing the power) ten times.

The power level display has to be reduced by 1 per step until “15” (starting from “25”) is shown.

100

Press the “DOWN“-button of the power setting (reducing the power) and hold it down.

The power level display has to be reduced step-by-step until “1” is shown.

Documentation

110

Document the test results in “SCR.991007”.

3. Power output

No.

Procedure

Test equipment: Electrosurgical analyzer (Example: QA-ES, Metron)

Connection cables, HF-output (banana) to the electrosurgical analyzer

Test accessories: Power cord

Footswitch

120

Connect the unit via the power cord with a rated supply voltage. Connect the footswitch with the unit.

130

Connect the unit via the connection cables at the HF-output 1 and 2 (see fig. 3) with the electrosurgical

analyzer according to the analyzer’s instructions for use and measure the following parameter:

Attention: Start measuring after the display shows the appropriate value and make sure to

release the footswitch before starting with a new measurement.

140

The power output at 5 (output load 100 Ω) has to be in the range of 4 W P 6 W.

150

The power output at 10 (output load 100 Ω) has to be in the range of 8 W P 12 W.

160

The power output at 15 (output load 100 Ω) has to be in the range of 12 W P 18 W.

170

The power output at 20 (output load 100 Ω) has to be in the range of 16 W P 24 W.

180

The power output at 25 (output load 100 Ω) has to be in the range of 20 W P 30 W.

Documentation

190

Document the test results in “SCR.991007”.

© Celon AG Page 5 / 9

, Issue date: 01.09.2008

Page 6

Safety Check Instruction

SCI.991007-1.4

4. Valid resistance range

No.

Procedure

Test equipment: Electrosurgical analyzer (Example: QA-ES, Metron)

Connection cables, HF-output (banana) to the electrosurgical analyzer

Test accessories: Power cord

Footswitch

200

Connect the unit via the power cord with a rated supply voltage. Connect the footswitch with the unit.

210

Connect the unit via the connection cables at the HF-output 1 and 2 (see fig. 3) with the electrosurgical

analyzer according to the analyzer’s instructions for use. Set the power level of the unit to “12” and

measure the following parameter:

Attention: Start check procedure, if not already done, after setting the power level to “12”and

make sure to release the footswitch before starting with a new check procedure.

Short circuit detection

220

The following signals and warnings have to occur at an output load of 10 Ω (unit shut off):

- The blue LED (signal lamp “power output”) is dark.

- The red LED (signal lamp “resistance too low”) is blinking.

- An alarm signal (pulsed tone) is audible.

230

The following signals have to occur with a load resistor of 25 Ω (normal function of the unit):

- The blue LED (signal lamp “power output”) glows.

- The red LED (signal lamp “resistance too low”) is dark.

- A continuous signal is audible.

HF-output 1

HF-output 2

Fig. 3: Sample of the front panel of the power control unit showing the HF-outputs.

© Celon AG Page 6 / 9

, Issue date: 01.09.2008

Page 7

Safety Check Instruction

SCI.991007-1.4

No.

Procedure

Upper shut off limit

240

The following signals have to occur with a load resistor of 325 Ω (normal function of the unit):

- The blue LED (signal lamp “power output”) glows.

- The red LED (signal lamp “resistance too low”) is dark.

- A high frequency continuous signal is audible.

250

The following signals have to occur with a load resistor of 450 Ω (unit does not shut off):

- The blue LED (signal lamp “power output”) glows.

- The red LED (signal lamp “resistance too low”) is dark.

- A pulsed signal with a high audio frequency is audible (end of treatment).

Documentation

260

Document the test results in “SCR.991007”.

5. High frequency leakage current (according to IEC 60601-2-2)

No.

Procedure

Test equipment: Electrosurgical analyzer (Example: QA-ES, Metron)

Load resistor 100 Ω, 25 W (or more), 5 % tolerance, low inductive part, short time

load

Connection cables, HF-output (banana) to the electrosurgical analyzer and the load

resistor

Test accessories: Power cord

Footswitch

270

Measurement of the high frequency leakage current according to 19.3.101 a) 3) (bipolar application) as

described in IEC 60601-2-2. The output being loaded and unloaded at rated load.

Connect the unit via the power cord with a rated supply voltage. Connect the footswitch with the unit.

280

Connect the load resistor (100 Ω) with the HF-output 1 and 2 and with the electrosurgical analyzer

according to the analyzer’s instructions for use to measure high frequency leakage currents. Set the

power level of the unit to “25” and measure the following parameter:

Attention: Start measuring, if not already done, after setting the power level to “25”and make

sure to release the footswitch before starting with a new measurement.

290

High frequency leakage current of HF-output 1 at output load 100 Ω: ≤ 35.4 mA.

300

High frequency leakage current of HF-output 2 at output load 100 Ω: ≤ 35.4 mA.

310

Disconnect the load resistor (100 Ω) from the HF-output 1 and 2.

320

Connect the HF-output 1 and 2 with the electrosurgical analyzer according to the analyzer’s instructions

for use to measure high frequency leakage currents. Set the power level of the unit to “25” and measure

the following parameter:

Attention: Start measuring, if not already done, after setting the power level to “25”and make

sure to release the footswitch before starting with a new measurement.

330

High frequency leakage current of HF-output 1 with open output: ≤ 35.4 mA.

340

High frequency leakage current of HF-output 2 with open output: ≤ 35.4 mA.

Documentation

350

Document the test results in “SCR.991007”.

© Celon AG Page 7 / 9

, Issue date: 01.09.2008

Page 8

Safety Check Instruction

SCI.991007-1.4

6. Earth resistance (according to IEC 60601-1 and IEC 62353)

No.

Procedure

Test equipment: Electrical safety tester (Example: Unimet 1000 ST, Bender)

Test probe

Test accessories: Power cord

Footswitch

360

Connect the unit with an electrical safety tester according to the tester’s instructions for use and measure

the following parameters against metal parts which can be touched:

370

Protective earth resistance: ≤ 0.3 Ω

Documentation

380

Document the test results in “SCR.991007”.

7. Current and power consumption

No.

Procedure

Test equipment: Electrical safety tester (Example: Unimet 1000 ST, Bender)

Load resistor 100 Ω, 25 W (or more), 5 % tolerance, low inductive part, short time

load

Connection cables, HF-output (banana) to the load resistor

Test accessories: Power cord

Footswitch

390

Connect the unit with an electrical safety tester according to the tester’s instructions for use. Connect

HF-output 1 and 2 of the unit (see fig. 3) via the connection cables with the 100 Ω load resistor. Set the

power level of the unit to “25” and press the footswitch to measure the following parameters:

Attention: Start measuring, if not already done, after setting the power level to “25”and make

sure to release the footswitch before starting with a new measurement.

400

Current consumption under load at 100...120 V~: IL 1.0 A

410

Power consumption under load at 100...120 V~: SL 110 VA

Documentation

420

Document the test results in “SCR.991007”.

© Celon AG Page 8 / 9

, Issue date: 01.09.2008

Page 9

Safety Check Instruction

SCI.991007-1.4

8. Inspection label

No.

Procedure

430

Cover or exchange an inspection label (as shown below) at the enclosure back of the unit and mark the

due date of the next periodic safety check (month/year). The unit must undergo a safety check at annual

intervals.

Documentation

440

Document the test results in “SCR.991007”.

© Celon AG Page 9 / 9

, Issue date: 01.09.2008

Loading...

Loading...