Page 1

C. ADJUSTMENT METHOD

C-5050 ZOOM

C. ADJUSTMENT METHOD

[1] TABLE FOR SERVICING TOOLS ..........................................................................C-2

[2] EQUIPMENT ...........................................................................................................C-2

[3] ADJUSTMENT ITEMS AND ORDER .....................................................................C-2

[4] SETUP ....................................................................................................................C-2

[5] CONNECTING THE CAMERA TO THE COMPUTER............................................C-3

[6] USB STORAGE INFORMATION REGISTRATION.................................................C-4

[7] ADJUST SPECIFICATIONS ...................................................................................C -4

1. AF LED ANGLE ADJUSTMENT ..........................................................................C-4

2. LENS ADJUSTMENT..........................................................................................C-5

3. AWB ADJUSTMENT ...........................................................................................C-5

4. CCD WHITE POINT DEFECT DETECT ADJUSTMENT ....................................C-5

5. CCD BLACK POINT DEFECT DETECT ADJUSTMENT IN LIGHTED..............C-6

6. LCD PANEL ADJUSTMENT...............................................................................C-6

6-1. LCD H AFC ADJUSTMENT .......................................................................C-6

6-2. LCD RGB OFFSET ADJUSTMENT............................................................C-6

6-3. LCD GAIN ADJUSTMENT .........................................................................C-7

6-4. LCD RED BRIGHTNESS ADJUSTMENT..................................................C-7

6-5. LCD BLUE BRIGHTNESS ADJUSTMENT ................................................C-7

7. SETTING DESTINATION ....................................................................................C-7

[8] ADJUSTMENT ITEMS ............................................................................................C-8

CHECKING OF LENS UNIT ...........................................................................................C-9

SIMENS STAR CHART.................................................................................................C-12

Rev .1

C-1 Ver.1

Page 2

C. ADJUSTMENT METHOD C-5050 ZOOM

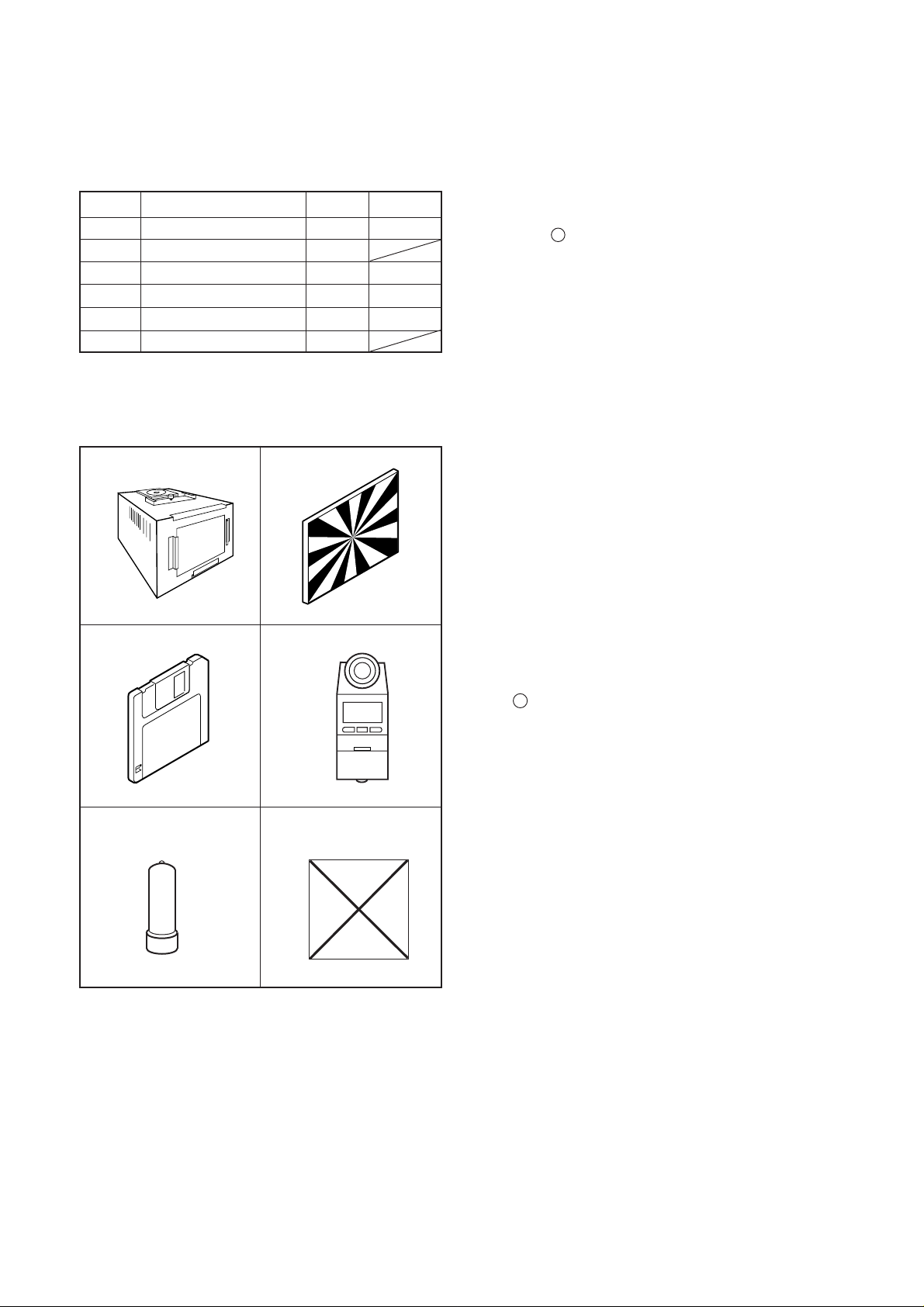

[1] T able for Servicing Tools

Ref. No.

J-1

J-2

J-3

J-4

J-5

J-6 1

Note: J-1 color viewer is 100 ± 10 VAC only.

Pattern box (color viewer)

Siemens star chart

Calibration software

Chroma meter

Spare lamp

Target board

Name Part code

Number

1

1

1

1

1

J-1 J-2

KC0336

VJ8-0196

KC0337

KC0339

[2] Equipment

1. Oscilloscope

2. Digital voltmeter

3. AC adaptor

4. PC (IBM R -compatible PC, Pentium processor, Window

98 or Me or 2000 or XP)

[3] Adjustment Items and Order

1. AF LED Angle Adjustment

2. Lens Adjustment

3. AWB Adjustment

4. CCD White Point Defect Detect Adjustment

5. CCD Black Point Defect Detect Adjustment in Lighted

6. LCD Panel Adjustment

6-1. LCD H AFC Adjustment

6-2. LCD RGB Offset Adjustment

6-3. LCD Gain Adjustment

6-4. LCD Red Brightness Adjustment

6-5. LCD Blue Brightness Adjustment

7.Setting Destination

Note:

1. If the lens, CCD, board and changing the part in item 2-

5 replace, it is necessary to adjust again. Item 5 adjustment should be carried out after item 3.

J-3

J-5

J-4

J-6

[4] Setup

1. System requirements

Windows 98 or Me or 2000 or XP

IBM R -compatible PC with pentium processor

CD-ROM drive

3.5-inch high-density diskette drive

USB port

40 MB RAM

Hard disk drive with at least 15 MB available

VGA or SVGA monitor with at least 256-color display

2. Installing calibration software

1. Insert the calibration software installation diskette into

your diskette drive.

2. Open Explorer.

3. Copy the DscCalDI_130 folder on the floppy disk in the

FD drive to a folder on the hard disk.

3. Installing USB driver

Install the USB driver with camera or connection kit for PC.

4. Pattern box (color viewer)

Turn on the switch and wait for 30 minutes for aging to take

place before using Color Viewre. It is used after adjusting

the chroma meter (KC0337) adjust color temperature to

3100 ± 20 K and luminosity to 900 ± 20 cd/m

handling the lamp and its circumference are high temperature during use and after power off for a while.

2

. Be careful of

Rev .1

C-2 Ver. 1

Page 3

C. ADJUSTMENT METHODC-5050 ZOOM

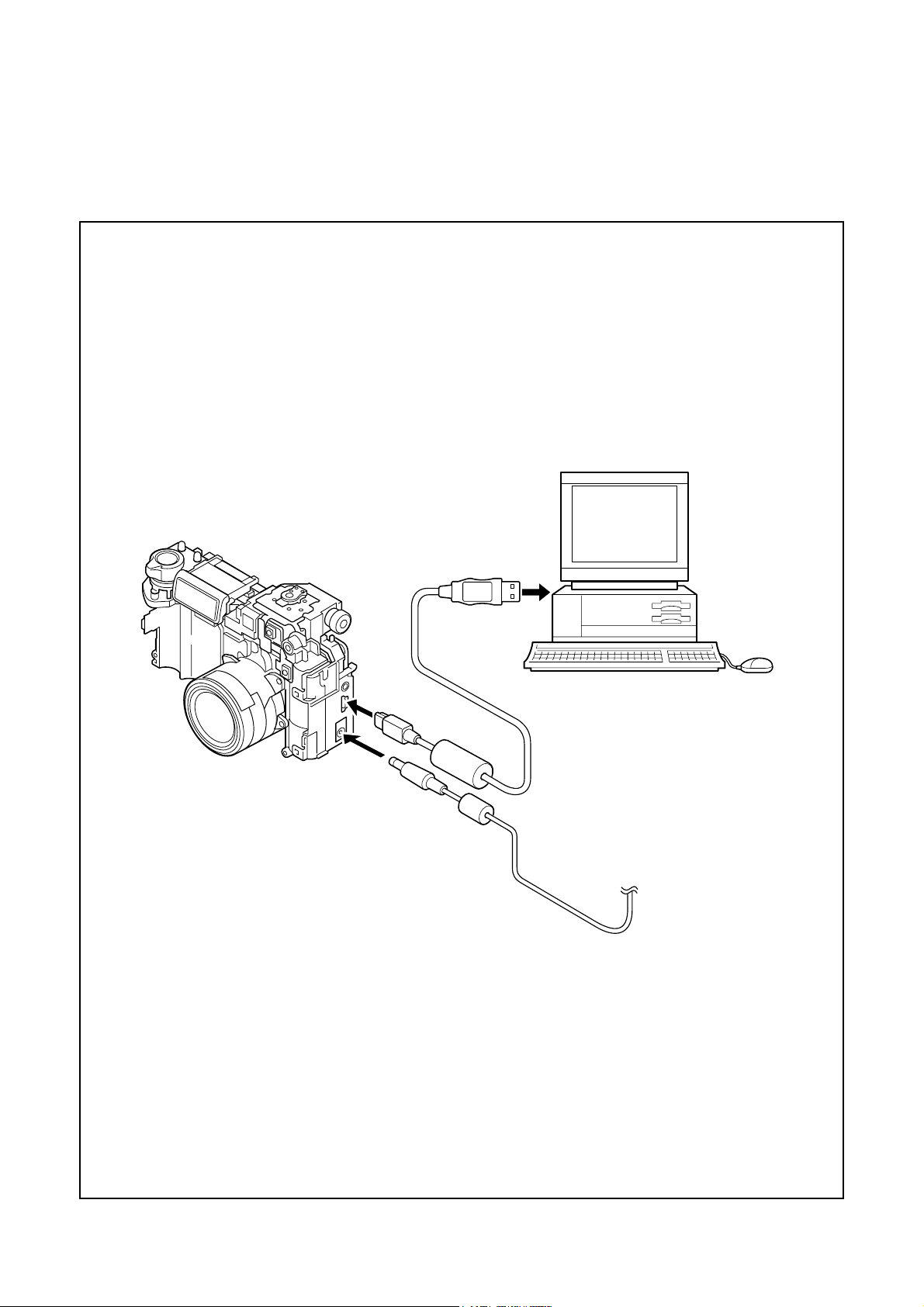

[5] Connecting the camera to the computer

1. Line up the arrow on the cable connector with the notch on the camera's USB port. Insert the connector.

2. Locate a USB port on your computer.

To USB port

USB cable

AC adaptor

C-3 Ver. 1

Page 4

C. ADJUSTMENT METHOD C-5050 ZOOM

7

y

[6] USB Storage Information Registration

USB storage data is important for when the camera is connected to a computer via a USB connection.

If there are any errors in the USB storage data, or if it has

not been saved, the USB specification conditions will not be

satisfied, so always check and save the USB storage data.

Preparation:

POWER switch: ON

Adjustment method:

1. Connect the camera to a computer. (Refer to [5] Connecting the camera to the computer on the page C-3.)

2. Double-click on the DscCalDi130.

3. Click on the Get button in the USB storage window and

check the USB storage data.

VID: OLYMPUS

PID: C5050Z

Serial:

Rev. : 1.00

4. Check the “Serial” in the above USB storage data. If the

displayed value is different from the serial number printed

on the base of the camera, enter the number on the base

of the camera. Then click the Set button.

5. Next, check VID, PID and Rev. entries in the USB storage data. If any of them are different from the values in

3. above, make the changes and then click the corresponding Set button.

Calibration

AWB

Focus

UV Matrix

Cal Mode

Cal Data

USB storage

VID

Get

PID

Set

OK

OK

Upload

Firmware

Image

Initialize

EVF

LCD Type

LCD

R Bright

RGB Offset

Tint

VCO

H AFC Test

Serial

Set

Set

Rev.

B Bright

Gain

Phase

Set

Set

VCOMDC

VCOMPP

Setting

Language

Video Mode

[7] Adjust Specifications

1. AF LED Angle Adjustment

[CP1 board (Side B)]

CL423(CSYNC)

CL404

(XENB)

CL403(R)

0 cm

TP301

TP302

CL402(B)

CL405(G)

70 cm

Target board

LED

spot

width

of 1cm

black

line

white

or gra

Target

mark

Setting the adjustment mode

1. Open the card cover of the camera.

2. Turn on the power switch.

3. Push the LCD button and OK button more than 3 seconds simultaneously. Display “CAMERA CONTROL OFF

ON RESET NO”.

4. Push the below arrow button, and select “ON”.

5. Push the OK button.

6. Close the card cover of the camera.

C-4 Ver. 1

Page 5

C. ADJUSTMENT METHODC-5050 ZOOM

Adjustment condition:

1. This adjustment should be carried out in a fairly dark

place so that the shape of the LED spot can be checked.

2. After adjustment, the readjustment is necessary to replace the lens, FPC unit and CA1 board.

3. Do not see the light of AF LED directly.

4. Do not adjust long time.

Adjustment method:

1. Set the camera so that the target board is at a distance

of 1 meters from LED. (Light up the target board.)

2. Connect TP301 and TP302. Connect the camera and

computer by USB cable.

3. Turn on the power, and double-click on the DscCalDi130.

4. Click the LCD “Test”, and select the “Monitor”.(The

through image will be displayed on the monitor.)

5. Carry out the pre-focus adjustment. After adjusting, the

target mark will appear on the monitor.

6. Turn off the light of target board.

7. Turn the screws on FPC unit to adjust so that the center of the LED spot appears inside the circle above the

target mark on the target board surface.

8. After adjusting, click the LCD “Test”, and select the “LCD

OFF”. (The lens will be stowed.)

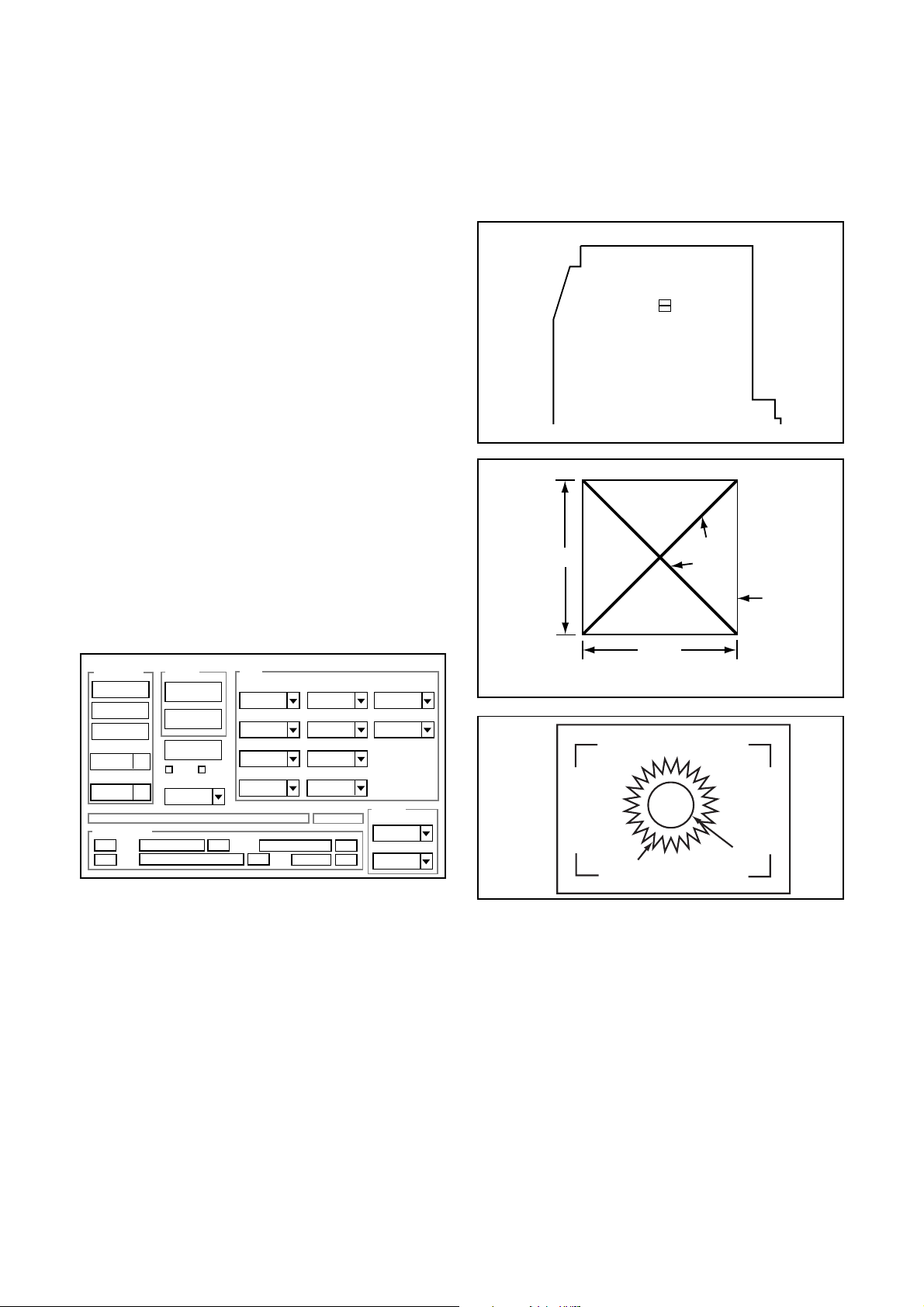

2. Lens Adjustment

Adjustment method:

1. Set the siemens star chart 150 cm ± 3 cm so that it becomes center of the screen.

2. Double-click on the DscCalDi130.

3. Click the “Focus”, and Click the “Yes”.

4. Lens adjustment value will appear on the screen.

5. Click the OK.

3. AWB Adjustment

Camera

Pattern box

(color viewer)

Camera

Approx.

150 cm ±3 cm

Siemens

star chart

Preparation:

POWER switch: ON

Adjustment condition:

Siemens star chart (A3)

Fluorescent light illumination with no flicker (incandescent

light cannot be used.)

Illumination above the subject should be 400 lux ± 10%.

Preparation:

POWER switch: ON

Setting of pattern box:

Color temperature: 3100 ± 20 (K)

Luminance: 900 ± 20 (cd/m

2

)

Adjusting method:

1. Set the camera 0 cm from the pattern box. (Do not enter

any light.)

2. Double-click on the DscCalDi130.

3. Click the “AWB”, and click the “Yes”.

4. AWB adjustment value will appear on the screen.

5. Click the OK.

4. CCD White Point Defect Detect Adjustment

Preparation:

POWER switch: ON

Adjustment method:

1. Double-click on the DscCalDi130.

2. Select “CCD Defect” on the LCD “Test”, and click the

“Yes”.

3. After the adjustment is completed, the number of defect

will appear.

C-5 Ver. 1

Page 6

C. ADJUSTMENT METHOD C-5050 ZOOM

5. CCD Black Point Defect Detect Adjustment In

Lighted

6-1. LCD H AFC Adjustment

Preparation:

POWER switch: ON

Adjusting method:

1. Double-click on the DscCalDi130.

2. Select 0 on the LCD “H AFC”.

3. Apply a trigger using CL423, and adjust LCD “H AFC” so

that the time A from the rising signal at CL423 to the falling signal at CL404 is 4.80 ± 0.1 µsec.

○○○○○○○○

○○

A

CL404

Camera

Pattern box

(color viewer)

Preparation:

POWER switch: ON

Setting of pattern box:

Color temperature: 3100 ± 20 (K)

Luminance: 900 ± 20 (cd/m

2

)

Adjusting method:

1. Set the camera 0 cm from the pattern box. (Do not enter

any light.)

2. Double-click on the DscCalDi130.

3. Select “CCD Black” on the LCD “Test”, and click the “Yes”.

4. After the adjustment is completed, the number of defect

will appear.

6. LCD Panel Adjustment

[CP1 board (Side B)]

CL423(CSYNC)

CL402(B)

CL405(G)

TP301

TP302

CL404

(XENB)

CL403(R)

CL423

Enlargement

○○○○○○○○

○○

A

CL404

CL423

6-2. LCD RGB Offset Adjustment

Adjusting method:

1. Adjust LCD “RGB Offset” so that the amplitude of the

CL405 waveform is 3.9 V ± 0.1 Vp-p.

3.9 V ±

0.1 Vp-p

CL405 waveform

C-6 Ver. 1

Page 7

C. ADJUSTMENT METHODC-5050 ZOOM

6-3. LCD Gain Adjustment

Adjusting method:

1. Adjust LCD “Gain” so that the amplitude of the CL405

waveform is 6.4 V ± 0.2 Vp-p.

Note:

6-2. LCD RGB Offset adjustment should always be carried

out first.

6.4 V ±

0.2 Vp-p

CL405 waveform

6-4. LCD Red Brightness Adjustment

Adjusting method:

1. Adjust LCD “R Bright” so that the amplitude of the CL403

waveform is (VG-0.1) ± 0.1 Vp-p with respect to the CL405

(VG) waveform.

Note:

6-2. LCD RGB Offset adjustment and 6-3. LCD Gain adjustment should always be carried out first.

6-5. LCD Blue Brightness Adjustment

Adjusting method:

1. Adjust LCD “B Bright” so that the amplitude of the CL402

waveform is (VG+0.2) ± 0.1 Vp-p with respect to the CL405

(VG) waveform.

Note:

6-2. LCD RGB Offset adjustment and 6-3. LCD Gain adjustment have done.

VG

CL405 waveform

(VG + 0.2)

± 0.1Vp-p

CL405 waveform

CL403 waveform

VG

(VG-0.1) ±

0.1 Vp-p

CL402 waveform

7. Setting Destination

Preparation:

POWER switch: ON

Adjustment method:

1. Double-click on the DscCalDi130.

2. Select CODE on the Setting “Factory Code”.

CODE is indicated on serial label.

Completing the adjustment mode

1. Open the card cover of the camera.

2. Turn on the power switch.

3. Push the LCD button and OK button more than 3 seconds simultaneously. Display “CAMERA CONTROL OFF

ON RESET NO”.

4. Push the above arrow button, and select “OFF”.

5. Push the OK button.

6. Close the card cover of the camera.

C-7 Ver. 1

Rev .1

Page 8

C. ADJUSTMENT METHOD C-5050 ZOOM

[8]Adjustment Items

Adjustment items

1. AF LED Angle Adjustment

2.Lens Adjustment

3. AWB Adjustment

4. CCD White Point Defect Detect Adjustment

5. CCD Black Point Defect Detect Adjustment

in Lighted

6-1. LCD H AFC Adjustment

6-2. LCD RGB Offset Adjustment

6-3. LCD Gain Adjustment

6-4. LCD Red Brightness Adjustment

6-5. LCD Blue Brightness Adjustment

7. Setting Destination

Changed repair parts

CCD LENS CA1 FPC CP1

Rev.1

C-8 Ver. 1

Page 9

C-5050ZOOM C.ADJUSTMENT METHOD

CHECKING OF LENS UNIT

1. Check Item

1)Backlash Pulse of LD

2)LD ERROR Pulse

3)Basklash Pulse of ZOOM

4)ZOOM ERROR Pulse

2. Tools

Part No.

1

2

3

4

5

KC0331

KC0334

KC0338

Description

Lens Checker LCK1

Connector Cable P5

Clip Connector 17

(Include FPC-Adaptor)

FPC-Adaptor

14-PINS for K-FPC

FPC-Adaptor

16-PINS for S-FPC

Q’ty

1

1

2

1

1

3. Checking Prosedure

Fi x 2 FPC-Adaptors (14 and 16 PINS) to ClipConnector

17.

Connect Connector Cable P5, Clip Connector 17

and Lens Checker LCK-1

1) AUTO

I. Tum on Lens Checker LCK-1

080-10

FPC-Adaptor 14

PINS for K-FPC

FPC-Adaptor 16

PINS for S-FPC

The last 2 digits are mean-

ing the number of Pin.

Ex.) 080-14 :14PINS

Lens Checker LCK-1

Connector Cable P5

Initial Setting

II. Set AUTO / MANU SW at AUTO

III.Set Dial SW at 5

IV. Set CW / CCW SW at CW

LCK-1 Ver.1 0 Auto

PUSH START SW

(0 : Number of Dial SW 0-5)

V. Connect the both FPCs (K-FPC and S-FPC) to

Clip Connectors. Hold a lens unit by hand, and keep

it horizontally.

VI. Push START SW. (More than 0.2 sec.)

LCK-1 Ver.1 0 Auto

ZOOM RESET

Clip Connector 17

C-9Ver. 1

Page 10

C.ADJUSTMENT METHOD

C-5050ZOOM

When an error occurs, an error is indicated, and it stops.

LCK-1 Ver.1 0 Auto

LD RESET

LCK-1 Ver.1 0 Auto

LD BACKLASH CHK

LB*

* is BACKLASH PULSE of LD

LCK-1 Ver.1 0 Auto

LD D CHK

LB1 D *

* is LD ERROR PULSE

LCK-1 Ver.1 0 Auto

ZOOM BACKLASH CHK

LB1 D1 ZB *

* is BACKLASH PLUSE of ZOOM

In case of GOOD

LCK-1 Ver.1 0 Auto

PUSH START SW

LB1 D1 ZB1 D12

GOOD

In case of NG :

LCK-1 Ver.1 0 Auto

PUSH START SW

LB D6

NO GOOD ZM D Err

ERROR is indicated

(The indication which isn’t being explained is the condition

of PR and PI.)

When CW/CCW SW is set at CCW, the automatic check of

the motor chosen with a LD/ZOOM SW is done.

2) Manual

I. Set AUTO/MANU SW at MANU

LCK-1 Ver.1 0 Manu

LD CW

LCK-1 Ver.1 0 Auto

ZOOM D CHK

LB1 D1 ZB1 D * *

* * is ZOOM ERROR PULSE (ZOOM AREA : SET-UP AREA)

The contents chosen with the LD/ZOOM SW and the CW/

CCW SW indicated in LCD.

II. Push START SW (More than 0.2 sec.)

LCK- Ver.1 0 Manu

LD CW

MOVE

When a motor works, “MOVE” is indicated in LCD.

C-10 Ver. 1

Page 11

C-5050ZOOM C.ADJUSTMENT METHOD

LD Motor

When PI signal 500 pulses (500pps) are changed,LD motor

stops

CW : Turn Out CCW : Tum In

ZOOM Motor

When PI signal 2200 pulses (300pps) are changed, ZOOM

motor stops

CW : W to T CCW : T to W

4. Others

Turn off LCK-1 promptly if something is wrong.

5, ERROR Indication

PI, PR Err : PI or PR Pulse does not change.

LD BK Err : LD BACKLASH PULSE is out of standard.

LD D Err : LD Pulse Error

ZD BK Err : ZOOM BACKLASH PULSE is out of

standard

ZD D Err : ZOOM Pulse Error

C-11Ver. 1

Page 12

C. ADJUSTMENT METHOD C-5050 ZOOM

C-12 Ver. 1

Loading...

Loading...