Page 1

CNC SYSTEM

OSP-P300S/P300L

ALARM & ERROR LIST

(1st Edition)

Pub No. 5921-E (LE37-006-R1) Nov. 2011

Page 2

5921-E P-(i)

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine itself from

hazards arising from unforeseen accidents. However, operators must not rely exclusively on these safety

devices: they must also become fully familiar with the safety guidelines presented below to ensure accidentfree operation.

This instruction manual and the warning signs attached to the machine cover only those hazards which

Okuma can predict. Be aware that they do not cover all possible hazards.

1. Precautions Relating to Installation

(1) Please be noted about a primary power supply as follows.

Do not draw the primary power supply from a distribution panel that also supplies a major

noise source (for example, an electric welder or electric discharge machine) since this

could cause malfunction of the CNC unit.

If possible, connect the machine to a ground not used by any other equipment. If there is

no choice but to use a common ground, the other equipment must not generate a large

amount of noise (such as an electric welder or electric discharge machine).

(2) Installation Environment

Observe the following points when installing the control enclosure.

Make sure that the CNC unit will not be subject to direct sunlight.

Make sure that the control enclosure will not be splashed with chips, water, or oil.

Make sure that the control enclosure and operation panel are not subject to excessive

vibrations or shock.

The permissible ambient temperature range for the control enclosure is 5 to 40°C (41 to

104°F).

The permissible ambient humidity range for the control enclosure is relative humidity 50%

or less at 40°C (104°F) (no condensation).

The maximum altitude at which the control enclosure can be used is 1000 m (3281ft.).

2. Points to Check before Turning on the Power

(1) Close all the doors of the control enclosure and operation panel to prevent the entry of water,

chips, and dust.

(2) Make absolutely sure that there is nobody near the moving parts of the machine, and that there

are no obstacles around the machine, before starting machine operation.

(3) When turning on the power, turn on the main power disconnect switch first, then the CONTROL

ON switch on the operation panel.

Page 3

5921-E P-(ii)

SAFETY PRECAUTIONS

3. Precautions Relating to Manual/Continuous Operation

(1) Follow the instruction manual during operation.

(2) Do not operate the machine with the front cover, chuck cover, or another protective cover

removed.

(3) Close the front cover before starting the machine.

(4) When machining the initial workpiece, check for machine operations, run the machine under no

load to check for interference among components, cut the workpiece in the single block mode,

and then start continuous operation.

(5) Ensure your safety before rotating the spindle or moving a machine part.

(6) Do not touch chips or workpiece while the spindle is rotating.

(7) Do not stop a rotating part with hand or another means.

(8) Check that the condition of hydraulic chuck jaws as mounted, operating pressure, and

maximum permissible revolving speed.

(9) Check the condition and location of the cutting tool as mounted.

(10) Check the tool offset value.

(11) Check the zero offset value.

(12) Check that the SPINDLE OVERRIDE and FEEDRATE OVERRIDE dials on the NC operation

panel are set to 100%.

(13) When moving the turret, check the software limits for X- and Z-axes or the locations of limit

switch dogs to prevent interference with the chuck and tailstock.

(14) Check the location of the turret.

(15) Check the location of the tailstock.

(16) Cut workpieces with a transmitted power and torque within the permissible range.

(17) Chuck each workpiece firmly.

(18) Check that the coolant nozzle is properly located.

4. On Finishing Work

(1) On finishing work, clean the vicinity of the machine.

(2) Return the ATC, APC and other equipment to the predetermined retraction position.

(3) Always turn off the power to the machine before leaving it.

(4) To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the

main power disconnect switch.

Page 4

5921-E P-(iii)

SAFETY PRECAUTIONS

5. Precautions during Maintenance Inspection and When Trouble Occurs

In order to prevent unforeseen accidents, damage to the machine, etc., it is essential to observe the

following points when performing maitenance inspections or during checking when trouble has

occurred.

(1) When trouble occurs, press the emergency stop button on the operation panel to stop the

machine.

(2) Consult the person responsible for maintenance to determine what corrective measures need

to be taken.

(3) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

(4) Use only the specified replacement parts and fuses.

(5) Always turn the power off before starting inspection or changing parts.

(6) When parts are removed during inspection or repair work, always replace them as they were

and secure them properly with their screws, etc.

(7) When carrying out inspections in which measuring instruments are used - for example voltage

checks - make sure the instrument is properly calibrated.

(8) Do not keep combustible materials or metals inside the control enclosure or terminal box.

(9) Check that cables and wires are free of damage: damaged cables and wires will cause current

leakage and electric shocks.

(10) Maintenance inside the Control Enclosure

a. Switch the main power disconnect switch OFF before opening the control enclosure door.

b. Even when the main power disconnect switch is OFF, there may some residual charge in

the MCS drive unit (servo/spindle), and for this reason only service personnel are permitted

to perform any work on this unit. Even then, they must observe the following precautions.

MCS drive unit (servo/spindle)

The residual voltage discharges two minutes after the main switch is turned OFF.

c. The control enclosure contains the NC unit, and the NC unit has a printed circuit board

whose memory stores the machining programs, parameters, etc. In order to ensure that the

contents of this memory will be retained even when the power is switched off, the memory

is supplied with power by a battery. Depending on how the printed circuit boards are

handled, the contents of the memory may be destroyed and for this reason only service

personnel should handle these boards.

Page 5

(11) Periodic Inspection of the Control Enclosure

a. Cleaning the cooling unit

The cooling unit in the door of the control enclosure serves to prevent excessive

temperature rise inside the control enclosure and increase the reliability of the NC unit.

Inspect the following points every three months.

Is the fan motor inside the cooling unit working?

The motor is normal if there is a strong draft from the unit.

Is the external air inlet blocked?

If it is blocked, clean it with compressed air.

6. General Precautions

(1) Keep the vicinity of the machine clean and tidy.

(2) Wear appropriate clothing while working, and follow the instructions of someone with sufficient

training.

(3) Make sure that your clothes and hair cannot become entangled in the machine. Machine

operators must wear safety equipment such as safety shoes and goggles.

5921-E P-(iv)

SAFETY PRECAUTIONS

(4) Machine operators must read the instruction manual carefully and make sure of the correct

procedure before operating the machine.

(5) Memorize the position of the emergency stop button so that you can press it immediately at any

time and from any position.

(6) Do not access the inside of the control panel, transformer, motor, etc., since they contain high-

voltage terminals and other components which are extremely dangerous.

(7) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

Page 6

7. Symbols Used in This Manual

The following warning indications are used in this manual to draw attention to information of

particular importance. Read the instructions marked with these symbols carefully and follow them.

5921-E P-(v)

SAFETY PRECAUTIONS

Page 7

5921-E P-(i)

INTRODUCTION

INTRODUCTION

Before using this NC unit, read this manual thoroughly in order to ensure correct use.

This manual explains how to use and maintain the control so that it will deliver its full performance and

maintain accuracy over the long term.

You must pay particular attention to the cautions given in this manual; read them carefully and make sure you

fully understand them before operating the NC.

Page 8

5921-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 1 CLASSIFICATION OF ALARMS ...........................................................1

1-1. Alarm Classifications ......................................................................................................... 1

1-2. Object Number and Object Message ................................................................................ 2

1-2-1. Alarm Codes........................................................................................................ 3

1-2-2. Bit conversion method......................................................................................... 3

1-2-3. How to check alarm contents .............................................................................. 4

SECTION 2 ALARM P...............................................................................................5

SECTION 3 ALARM A.............................................................................................74

SECTION 4 ALARM B...........................................................................................249

SECTION 5 ALARM C...........................................................................................464

SECTION 6 ALARM D...........................................................................................544

SECTION 7 ERROR..............................................................................................645

SECTION 8 APPENDIX ........................................................................................754

8-1. Factor Classification Code/Factor Parameter................................................................ 754

8-1-1. Factor Classification Code/Factor Parameter (for Machine) ........................... 754

Page 9

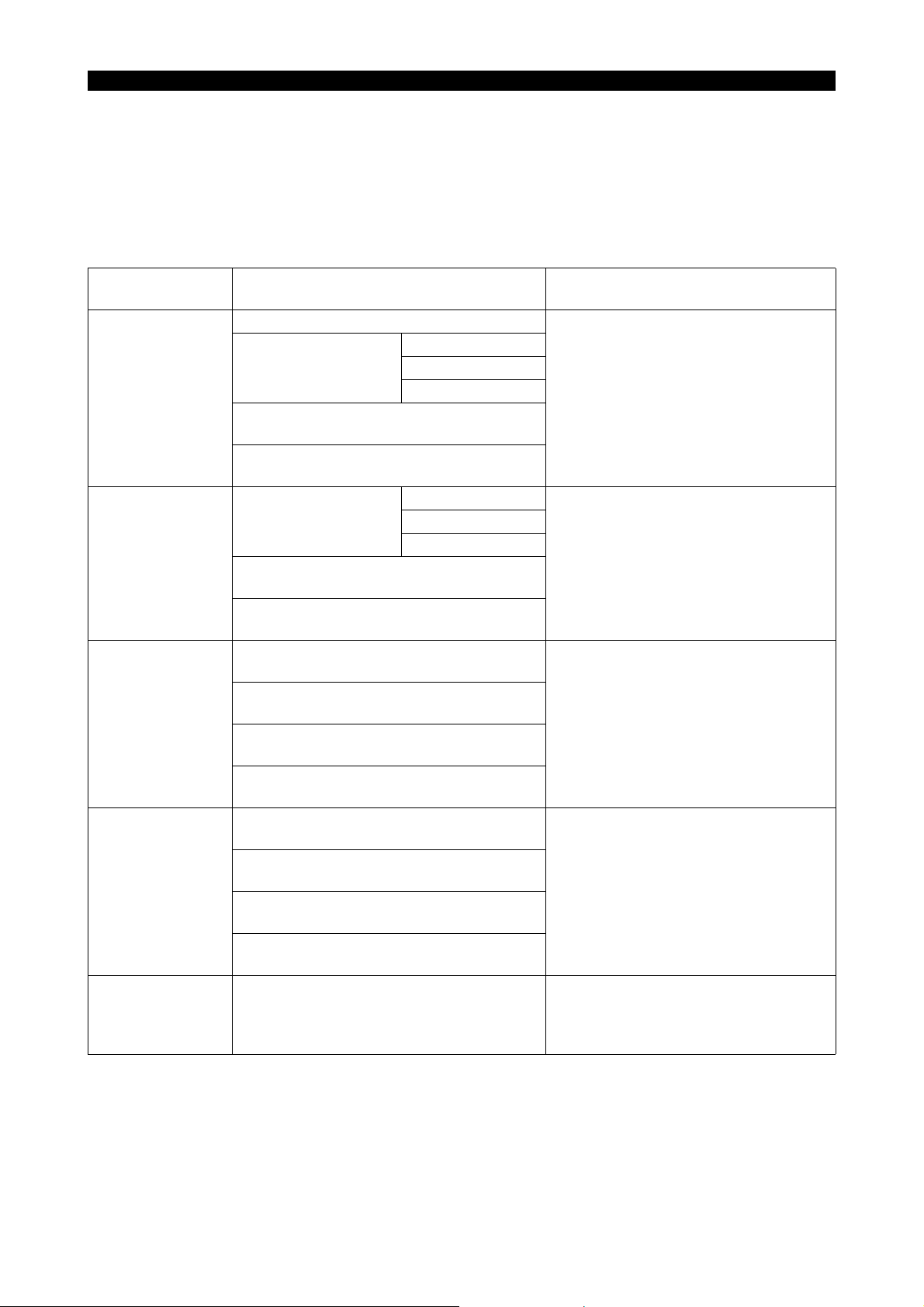

SECTION 1 CLASSIFICATION OF ALARMS

SECTION 1 CLASSIFICATION OF ALARMS

Alarms related with the OSP are classified into five types such as Alarm P, A, B, C and D.

1-1. Alarm Classifications

5921-E P-1

Alarm

P Stops NC operation. All NC functions are inoperative.

A

B The commands in the active block are

C The part program being run is executed to

D This alarm does not have any influence on

Machine Conditions When ALARM Lamp

Comes ON

axis feed

Stops;

Shuts off power supply to X- and Z-axis

servo drives.

Alarm display is displayed on the operation

panel.

Stops;

Shuts off power supply to X- and Z-axis

servo drives.

Alarm display is given on the operation

panel.

completed.

Spindle rotation and coolant supply do not

stop.

Power supply to X- and Z-axis servo drives

is not shut off.

Alarm display is given on the operation

panel.

the end (up to M02 command).

Spindle rotation and coolant supply do not

stop.

Power supply to X- and Z-axis servo drives

is not shut off.

Alarm display is given on the operation

panel.

the machine operation.

Alarm display is given on the operation

panel.

spindle rotation

coolant supply

axis feed Operations for display are possible.

spindle rotation

coolant supply

Operative NC Functions Thereafter

Concerning the control, cancel the alarm

by turning power on again after turning it

off once.

The machine remains inoperative until

the control is reset and the alarm

canceled.

Operations for display are possible.

The machine remains inoperative until

the control is reset and the alarm

canceled.

Operations for display are possible.

No new program can be run until the

control is reset and the alarm is

canceled.

Operations on the operation panel are all

operative. Alarm cannot be canceled

unless the cause of the alarm is

removed.

Page 10

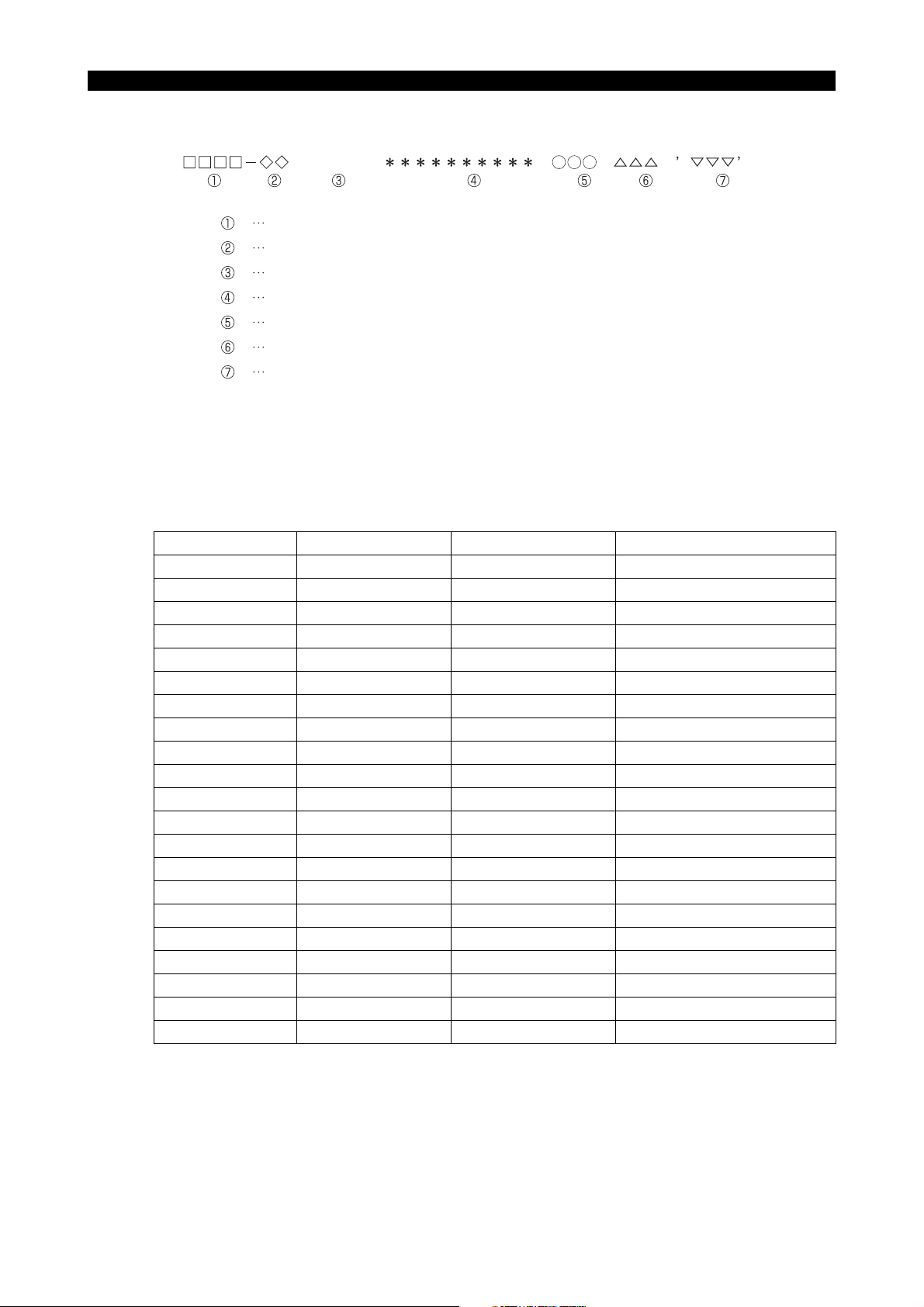

SECTION 1 CLASSIFICATION OF ALARMS

LE37006R0100300020001

Display Format of Alarm P, A, B, C and D

ALARM-A

Alarm number

Object number

Alarm level

Alarm message

Object message

Alarm code

Alarm character-string

1-2. Object Number and Object Message

The object number and the object message show the programming system and the control axis

where the alarm has occurred by the number and message as shown in the table blow:

5921-E P-2

Object No. Meaning Object message Notes

None No classification None

01 System 1 “A side” or “1-A sd” 1st spindle and turret A

02 System 2 “B side” or “1-B sd” 1st spindle and turret B

03 System 3 “2-A sd” 2d spindle and turret A

04 System 4 “2-B sd” 2d spindle and turret B

11 1st X-axis “XAaxis” or “X-axis”

12 1st Y-axis “YAaxis” or “Y-axis”

13 1st Z-axis “ZAaxis” or “Z-axis”

16 1st W-axis “W-axis”

19 1st C-axis “C-axis” or “Caxis1”

20 1st S-axis “SPDL” or “SPDL-1”

21 1st T-axis “TAaxis” or “T-axis”

22 1st M-axis “MAaxis” or “M-axis”

31 2d X-axis “XBaxis”

32 2d Y-axis “YBaxis”

33 2d Z-axis “ZBaxis”

39 2d C-axis “Caxis2”

40 2d S-axis “SPDL-2” Sub spindle, pick-off spindle

41 2d T-axis “TBaxis”

42 2d M-axis “MBaxis”

53 3d Z-axis “ZCaxis” LT series

As indicated above, the object numbers and messages to be used are determined by the machine

specifications.

Page 11

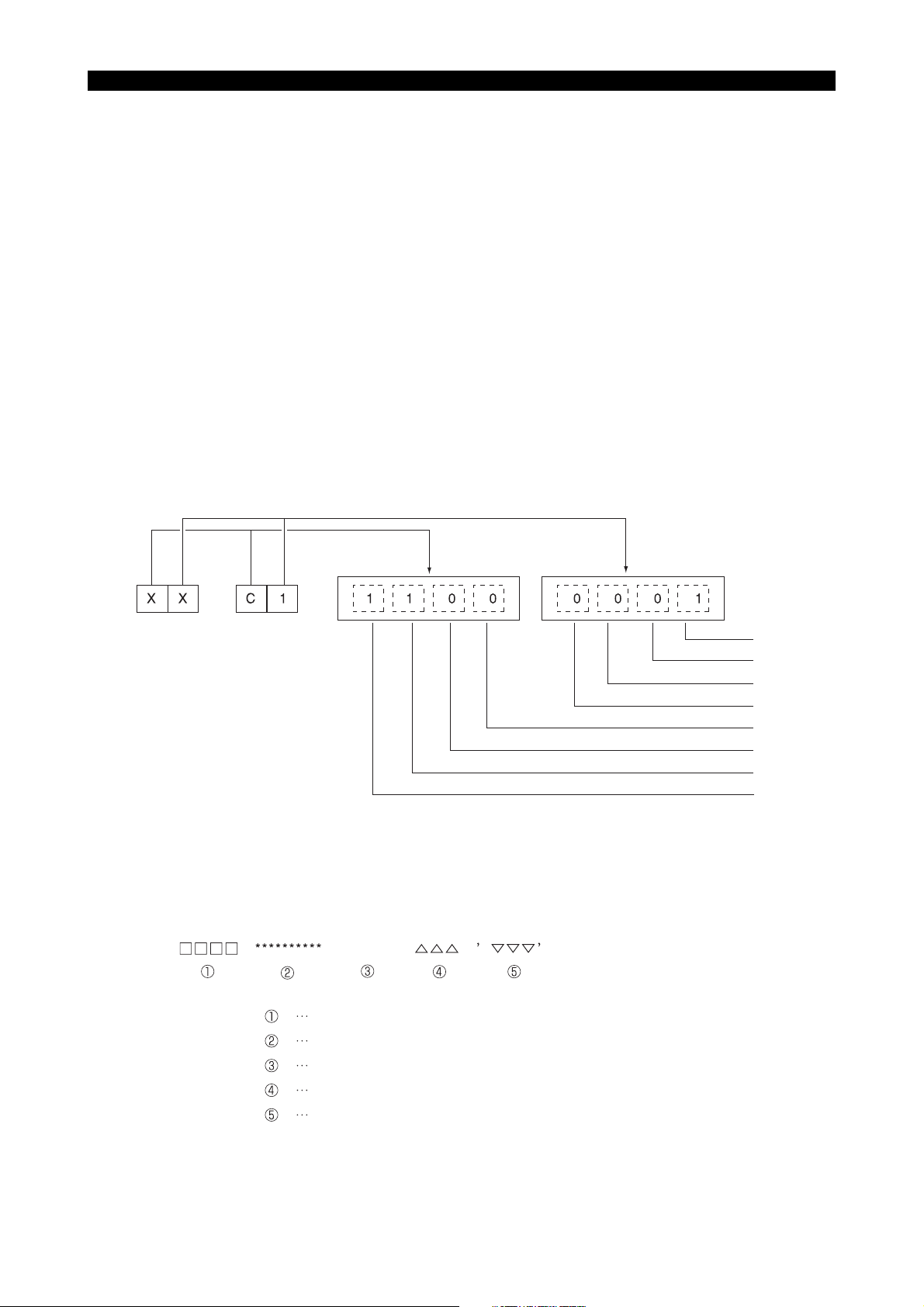

1-2-1. Alarm Codes

In this manual, alarm codes are explained using such as "X", "XX", and "XXYY".

Explanation is given in the following methods:

(1) The alarm code indicated in this text can be used directly as the key to find the contents of error.

(2) The alarm code indicated in this text should first be converted into bit expression (pattern),

which is then used as the key to find the contents of error.

In the case of 2), the procedure to convert the alarm code into bit pattern is shown below.

1-2-2. Bit conversion method

5921-E P-3

SECTION 1 CLASSIFICATION OF ALARMS

Alarm Code

(Expressed in

hexadecimal)

0 0000 8 1000

1 0001 9 1001

2 0010 A 1010

3 0011 B 1011

4 0100 C 1100

5 0101 D 1101

6 0110 E 1110

7 0111 F 1111

Bit Pattern

Alarm Code

(Expressed in

hexadecimal)

Bit Pattern

Page 12

1-2-3. How to check alarm contents

LE37006R0100300060001

The method to find the details of the alarm indicated by the bit pattern is explained below using an

example.

Example:

[Code] XX

XX

bit1->EC I/O power shut off error

bit2->ECC error

bit3->Not used

bit4->Not used

bit5->EDRQ INT signal

bit6->ECP INT signal

bit7->ECP RUN signal

bit0->Battery error

If an alarm occurs, a hexadecimal number is displayed.

If "$C1" is displayed, for example, first convert this "$C1" into bits.

5921-E P-4

SECTION 1 CLASSIFICATION OF ALARMS

After the conversion, it is known that Bit0, Bit6, and Bit7 are ON.

See the information above and you will find that these error codes

correspond to "battery error", "ECP INT signal", and "ECP RUN signal",

respectively.

Error Display Format

ERROR

Error number

Error message

Indication of ERROR

Error code

Error character-string

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

Page 13

SECTION 2 ALARM P

0700 NC start-up error ........................................................................................... 10

0701 P100-Menu initialization failure ..................................................................... 10

0702 Power failure upon start-up ........................................................................... 11

0703 Load information file not found ..................................................................... 11

0704 File load error ................................................................................................ 11

0705 Default scheduling table error ....................................................................... 12

0706 Backup data file error .................................................................................... 12

0707 DTL link/unlink error ..................................................................................... 12

0708 RT thread stack overflow .............................................................................. 13

0709 Hardware exception ...................................................................................... 13

0710 System call error ........................................................................................... 13

0711 AlarmService library error .............................................................................14

0712 AlarmService internal error (exception) ........................................................ 14

0713 AlarmService error ........................................................................................ 14

5921-E P-5

SECTION 2 ALARM P

0714 Blue screen ................................................................................................... 14

0715 P100-Menu error ........................................................................................... 15

0716 Floating point exception ................................................................................ 15

0717 PLC control error .......................................................................................... 15

0718 Real time thread time over ............................................................................ 15

0719 HXCP thread error ........................................................................................ 15

0720 AlarmService internal error ........................................................................... 16

0721 DeviceNet error ............................................................................................. 16

0723 DeviceNet I/O data link file read ................................................................... 17

0725 M code data file ............................................................................................ 17

0726 Safety speed data error ................................................................................ 17

0727 MCS firmware doesn't support POS2 unit .................................................... 17

0728 FL-net error ................................................................................................... 18

0729 Non-responsive software detected. .............................................................. 18

0731 R Spec. error ................................................................................................18

0732 Unable to execute lost motion compensation ............................................... 18

0735 MCS DD encoder link error ........................................................................... 18

0736 MCS DD encoder error ................................................................................. 19

0737 MCS DD encoder (slave sensor) detected error ........................................... 19

0738 MCS DD encoder initialization failure ........................................................... 20

0739 MCS DD encoder (slave sensor) initialization failure .................................... 21

0741 MCS firmware version error .......................................................................... 22

0742 Relocation detection error ............................................................................. 22

0744 MCS power supply unit overload .................................................................. 22

Page 14

SECTION 2 ALARM P

0750 The spec.-code or select-soft. was wrong .................................................... 22

0752 VDU communication error ............................................................................ 23

0753 VDU detected error ....................................................................................... 23

0754 VDU initialization failure ................................................................................ 24

0755 SIO link error ................................................................................................. 24

0756 PSC optical scale encoder error ................................................................... 25

0757 MF-SAFETY Error ........................................................................................ 25

0758 Safety I/O Error ............................................................................................. 26

0759 Safety Servo Link Error ................................................................................. 28

0782 Magnetic encoder speed detection error ...................................................... 29

0783 MCS Rotary encoder 5 initialization failure ................................................... 29

0784 MCS Rotary encoder 5 error ......................................................................... 30

0785 MCS Rotary encoder 4 initialization failure ................................................... 30

0786 MCS Rotary encoder 4 error ......................................................................... 30

0787 MCS Rotary encoder 3 initialization failure ................................................... 30

0788 MCS Rotary encoder 3 error ......................................................................... 30

0789 MCS Rotary encoder 2 error ......................................................................... 31

5921-E P-6

0790 MCS Rotary encoder 1 initialization failure ................................................... 31

0791 MCS Rotary encoder 1 error ......................................................................... 31

0792 MCS Linear scale 4 initialization failure ........................................................ 32

0793 MCS Linear scale 4 error .............................................................................. 32

0794 MCS Linear scale 3 initialization failure ........................................................ 32

0795 MCS Linear scale 3 error .............................................................................. 33

0796 MCS Linear scale 2 initialization failure ........................................................ 33

0797 MCS Linear scale 2 error .............................................................................. 33

0798 MCS Linear scale 1 initialization failure ........................................................ 33

0799 MCS Linear scale 1 error .............................................................................. 33

0800 Spindle D/A control data file read ................................................................. 34

0801 TCP/IP board detected error ......................................................................... 34

0802 Load information file not found ..................................................................... 35

0803 File load error ................................................................................................ 35

0804 MSB file mismatch ........................................................................................ 35

0805 MOP-Tool parameter PBU load .................................................................... 35

0806 MOP-Tool tool data PBU load ...................................................................... 35

0807 ACP panel status receipt error ...................................................................... 36

0808 Speed change ratio failure ............................................................................ 36

0810 NC I/O data file read ..................................................................................... 36

0812 MCS initialization error .................................................................................. 36

0813 MCS Communication error ........................................................................... 38

0814 MCS data file corrupt .................................................................................... 39

Page 15

SECTION 2 ALARM P

0815 PLC real-time task loop error ........................................................................ 40

0816 PLC initialization error ................................................................................... 40

0817 MCS error ..................................................................................................... 41

0818 ADP initialization failure ................................................................................ 41

0820 Machine data file read .................................................................................. 41

0821 Spindle gear ratio .......................................................................................... 42

0822 Wheel data file read ...................................................................................... 42

0823 AXIS CONSTRUCTION DATA setting error ................................................. 42

0824 Unit connection mistake ................................................................................ 43

0825 AXIS CONSTRUCTION name not set .......................................................... 43

0826 AXIS CONSTRUCTION DATA file read ....................................................... 43

0827 Control axis not found ................................................................................... 43

0828 Wire feed axis No. error ................................................................................ 43

0833 MCS option program file not sent ................................................................. 44

0834 MCS servo data error ................................................................................... 44

0835 MCS communication error ............................................................................ 44

0836 Program request illegal ................................................................................. 45

5921-E P-7

0837 Loader spec. code data error ........................................................................ 45

0838 Loader backup data file read error ................................................................ 45

0839 Specification conditions failure ..................................................................... 45

0840 SuperHi-NC specification mismatch ............................................................. 46

0841 FCP4 board detected error ........................................................................... 46

0842 Safety monitor spec. error ............................................................................ 46

0845 Specification code setting failure .................................................................. 46

0846 Thermal deviation comp. backup data file read ............................................ 47

0847 DNC-DT preload task start error ...................................................................47

0848 PSCB error ...................................................................................................47

0849 Synchronous axis tandem control initialization failure .................................. 47

0850 MCS Undefined alarm number ..................................................................... 48

0851 MCS Inverter unit fault .................................................................................. 48

0852 Mistake in data from MCS to NC .................................................................. 49

0853 MCS CON APA deviation ............................................................................. 50

0854 MCS Power supply unit error ........................................................................ 50

0855 MCS Converter link error .............................................................................. 51

0856 MCS DC-bus voltage alarm .......................................................................... 51

0857 MCS Motor overcurrent ................................................................................ 51

0858 MCS Power unit overheat ............................................................................. 51

0859 MCS Power unit overload ............................................................................. 52

0860 MCS Supply voltage flutter ........................................................................... 52

0861 MCS Inverter capacity differs from spec. ...................................................... 52

Page 16

SECTION 2 ALARM P

0862 MCS Winding change failure ........................................................................ 52

0863 MCS Encoder link error ................................................................................ 53

0864 MCS Encoder detected error ........................................................................ 53

0865 MCS Encoder initialization failure ................................................................. 54

0866 MCS Encoder with shaft detected error ........................................................ 54

0867 MCS Encoder with shaft initialization failure ................................................. 54

0868 MCS ABSO SCALE error .............................................................................55

0869 MCS ABSO SCALE initialization failure ........................................................ 55

0870 MCS Magnetic encoder alarm ...................................................................... 55

0871 MCS Resolver alarm ..................................................................................... 55

0872 MCS Pulse generator count over .................................................................. 56

0873 MCS Motor overheat ..................................................................................... 56

0874 MCS Servo link error .................................................................................... 56

0875 MCS Servo link disconnection ......................................................................57

0876 Mistake in data from NC to MCS .................................................................. 57

0877 MCS Servo data error ................................................................................... 57

0878 MCS Illegal command ................................................................................... 58

5921-E P-8

0879 MCS CON speed over .................................................................................. 58

0880 MCS Speed command over .......................................................................... 59

0881 MCS DIFF over ............................................................................................. 59

0882 MCS APA speed over ................................................................................... 59

0883 MCS Full-closed APA error ........................................................................... 59

0884 MCS Over speed .......................................................................................... 60

0885 MCS Speed deviation over ........................................................................... 60

0886 MCS Collision detected ................................................................................ 60

0887 MCS Urgent-stop time over .......................................................................... 61

0888 MCS Belt is broken ....................................................................................... 61

0889 MCS Axis change control error ..................................................................... 61

0890 MCS Independent encoder initialization failure ............................................ 61

0891 MCS Calculated current position lies outside range ..................................... 62

0892 MCS Motor overload ..................................................................................... 62

0893 MCS Safety speed monitor E-Link error ....................................................... 62

0894 MCS ABSO SCALE sub-slider detected error ..............................................62

0895 MCS Tandem control communication error .................................................. 63

0896 MCS Full abso scale link error ...................................................................... 63

0897 MCS Full abso scale error ............................................................................ 64

0898 MCS Full abso scale initialization failure ...................................................... 64

0899 MCS Axis stop signal error ........................................................................... 65

0940 Time sharing task control .............................................................................. 65

0941 Real-time task control ................................................................................... 65

Page 17

SECTION 2 ALARM P

0942 Real-time task loop error .............................................................................. 65

0943 Main processor name incorrect .................................................................... 66

0944 Slave processor name incorrect ................................................................... 66

0945 Memory board/battery life ............................................................................. 66

0951 SMP error ..................................................................................................... 66

0952 Not equipped with processor board .............................................................. 67

0954 Peripheral processor start ............................................................................. 67

0955 Spec. code: data file ..................................................................................... 67

0956 Backup data file read .................................................................................... 68

0957 Graphic backup data file read ....................................................................... 68

0958 Pitch compensation data file read ................................................................. 68

0965 Configuration file format error ....................................................................... 69

0971 Cache data: Initialization error ...................................................................... 69

0988 Cache data: Operation error ......................................................................... 69

0989 CPU information table data incorrect ............................................................ 69

0990 TASK generate error ..................................................................................... 70

0991 TASK information table data incorrect ..........................................................70

5921-E P-9

0992 PLC backup data file read ............................................................................ 70

0993 TCP/IP board illegal ...................................................................................... 71

0994 TCP/IP configuration file ............................................................................... 71

0995 Machine axis data file ................................................................................... 71

0996 PLC axis data file .......................................................................................... 71

0997 PLC monitor backup data file read ............................................................... 72

0998 PLC sequence program load ........................................................................ 72

0999 Synchronous tap data file read ..................................................................... 73

Page 18

0700 NC start-up error

An error occurred when NC started up.

[Object]

None

[Character-string]

None

[Code]

0x10000000: NC Configuration read error

0x10003000: Spec code read error

0x20000000: ServoLink board initializing error

0x3XXX00YY: NC data file read error

XXX:

0x002: HD backup status file

0x004: Parameter data file

0x008: Machine data file

0x010: PLC backup data file

0x020: PLC-HMI data file

0x040: Alarm History data file

0x080: PLC AXIS data pbu file

0x100: POT TOOL data pbu file (M/C only)

0x200: MOP TOOL Tool data file (M/C only)

0x400: MOP TOOL Parameter file (M/C only)

0x800: Thermal deviation compensation data file

YY:

0x01: File read open error

0x02: File read error

0x03: Version check error

0x04: Check sum error

0x05: Double check sum error

0x06: Backupped Memory error

0x07: File write open error

0x08: File write error

0x40000000: Axis information initializing error

-More than 8 axis

0x50000000: PLC data file read error

-Read failed M code data file

0x60000000: I/O Initializing error

-PLC variable backup file read error

-I/O forced data file read error

0x70000000: ServoLink Initializing error

0x80000000: Operation buffer get error

0x90000000: PBU data file read error

0xA0000000: Shared memory size definition error

0xA1XXXXXX: AlarmService start error

XXXXXX: Error code of AlarmService library function

0xA2400002: Alarm History read error

0xA3000000: Thread monitor initializing error

0xA9000000: Initialization processing of the safety logic was not completed within 20 seconds

0xA9000001: Axis construction definition file open error

0xA9000002: Axis construction definition file read error

0xA9000003: Axis construction definition file mismatch

0xFFFFFFFF: Debug information file read error

5921-E P-10

SECTION 2 ALARM P

0701 P100-Menu initialization failure

An error occurred in P100-Menu while system startup.

[Object]

None

[Character-string]

None

[Code]

1: NC Control file was not found.

2: PLC Control file was not found.

3: NC-HMI was not found

Page 19

4: 3D real sim file was not found.

5: MacMan file was not found.

6: Version mismatch between P100-Menu and PLC Control

7: Version mismatch between P100-Menu and MacMan

8: Version mismatch between P100-Menu and NC Control

11: Conf-P100-menu read error

12: An error occurred at RTOS

13: An error occurred at UPS Service

21: NC Control start failure

22: Error in obtaining shared objects

23: PLC Control start failure

24: NC-HMI start failure

25: 3D real sim start failure

26: MacMan start failure

101: Startup sequence 0x10 receive failure

200: Startup sequence 0x10 send failure

201: Startup sequence 0x20 receive failure

300: Startup sequence 0x20 send failure

301: Startup sequence 0x30 receive failure

400: Startup sequence 0x30 send failure

401: Startup sequence 0x60 receive failure

500: Startup sequence 0x60 send failure

501: Startup sequence 0x70 receive failure

600: Startup sequence 0x70 send failure

601: Startup sequence 0x7C receive failure

700: Startup sequence 0x7C send failure

701: AlarmService start failure

702: Activation sequence 0x80 receive failure

[Probable Faulty Locations]

1.Execution file name failure

2.Data file name failure

3.RTOS failure

4.UPS function failure

5.Software failure

6.Software Version failure

5921-E P-11

SECTION 2 ALARM P

0702 Power failure upon start-up

[Object]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

1.Power failure during while system startup

2.Power shutoff during while system startup

0703 Load information file not found

A load information file was not found.

[Object]

None

[Character-string]

None

[Code]

None

0704 File load error

An object file was not loaded correctly.

[Object]

None

[Character-string]

Page 20

None

[Code]

1:A file was not found

2:The attribute of file was not correct.

3:The load address information of file was not correct

4:An error occurred when file was loaded

FFFFFFFF:The details of alarm was displayed by message from OS

0705 Default scheduling table error

A default scheduling table error was detected.

[Object]

None

[Character-string]

None

[Code]

0x00010001: RTIN default scheduling table error (element number)

0x00010002: RTIN default scheduling table error (end element)

0x00020001: TSMN default scheduling table error (element number)

0x00020002: TSMN default scheduling table error (initial attribute)

[Probable Faulty Locations]

1.NC software failure

0706 Backup data file error

5921-E P-12

SECTION 2 ALARM P

Error occurred when load/save the backup file.

[Object]

None

[Character-string]

None

[Code]

XXXXYYYY

XXXX

0x0002:HD backup status file

0x0004:Low speed NC backup data file

0x0008:High speed NC backup data file

0x0010:PLC backup data file

0x0020:PLC-HMI data file

0x0040:Alarm history data file

0x0080:PLC axis data file

0x0100:POT TOOL data file

0x0200:MOP TOOL Tool data file (M/C only)

0x0400:MOP TOOL Parameter data file (M/C only)

0x0800:Thermal deviation compensation data file

YYYY

1:File read open error

2:File read error

3:Version check error

4:Check sum error

5:Double check sum error

6:Backup memory check error

7:File write open error

8:File write error

0707 DTL link/unlink error

An error occurred in DTL link or unlink.

[Object]

None

[Character-string]

None

[Code]

1:RTIN refresh error

Page 21

2:TSMN refresh error

[Probable Faulty Locations]

1.Hardware failure

2.Software failure

0708 RT thread stack overflow

Stack overflow of RT thread was detected.

[Object]

None

[Character-string]

Occurred RT thread name

[Code]

None

[Probable Faulty Locations]

1.NC software failure

0709 Hardware exception

Hardware exception was occurred.

[Object]

None

[Character-string]

Occurred RT thread name

[Code]

Hardware exception code

0x5555: CPU Diagnose error

0x8100:Divide by 0 error

0x8101:Unexpected Single Step Interrupt

0x8102:Unexpected NMI

0x8103:Unexpected Debug Interrupt

0x8104:Overflow error

0x8105:Array Bounds error

0x8106:Invalid Opcode error

0x8107:NPX Device not present

0x8108:Double Fault error

0x8109:Unknown Device error

0x810A:Invalid TSS error

0x810B:Segment not Present error

0x810C:Stack Fault error

0x810D:General Protection error

0x810E:Page Fault error

0x8110:Unknown Device error 1

0x8111:Alignment error

[Probable Faulty Locations]

1.Hardware failure

2.Software failure

[Note]

Alarm information is also displayed also in the console window.

5921-E P-13

SECTION 2 ALARM P

0710 System call error

An error occurred in the INtime system call.

[Object]

None

[Character-string]

Occurred RT thread name

[Code]

XXXXYYYY

XXXX:INtime system call code

YYYY:Return value or status of INtime system call

[Probable Faulty Locations]

Page 22

NC software failure

[Note]

Alarm information is also displayed also in the console window.

0711 AlarmService library error

An error occurred in the AlarmService library function.

[Object]

None

[Character-string]

Occurred thread name

[Code]

XXYYYYYY

XX:AlarmService library function code

YYYYYY:AlarmService library function error code

[Probable Faulty Locations]

NC software failure

[Note]

Alarm information is also displayed also in the console window.

0712 AlarmService internal error (exception)

An error occurred inside of AlarmService.

[Object]

None

[Character-string]

"ALMS"

[Code]

AlarmService internal error code

[Probable Faulty Locations]

NC software failure

[Note]

Alarm information is also displayed also in the console window.

5921-E P-14

SECTION 2 ALARM P

0713 AlarmService error

P100-Menu detected AlarmService error.

[Object]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

1.NC software failure

0714 Blue screen

Blue screen (kernel stop error) occurred.

[Object]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

1.Win32 application failure

2.Windows failure

3.Windows driver failure

Page 23

0715 P100-Menu error

An abnormal condition of P100-Menu was detected.

[Object]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

1.P100-Menu failure

0716 Floating point exception

Floating point exception was occurred.

[Object]

None

[Character-string]

Occurred RT thread name

[Code]

XXXXYYZZ

XXXX:Exception code

YY:Not used (0 fixed)

ZZ:FPU status word

bit5:PE (Precision Exception Flag)

bit4:UE (Underflow Exception Flag)

bit3:OE (Overflow Exception Flag)

bit2:ZE (Zero Divide Exception Flag)

bit1:DE (Denormalized Operand Exception Flag)

bit0:IE (Invalid Operation Exception Flag)

[Probable Faulty Locations]

NC software failure

5921-E P-15

SECTION 2 ALARM P

0717 PLC control error

Error occurred on PLC Control.

[Object]

None

[Character-string]

None

[Code]

XXXXYYYY

XXXX:PLC Control status

YYYY:PLC Control error code

[Probable Faulty Locations]

1.PLC software failure

0718 Real time thread time over

Real time-type thread did not finish within the stated time

[Object]

None

[Character-string]

RT thread name that was exceeded the stated time

[Code]

None

[Probable Faulty Locations]

1.NC software failure

0719 HXCP thread error

Page 24

An abnormal condition of HXCP thread was detected.

[Object]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

1.NC software failure

0720 AlarmService internal error

An error occurred inside of AlarmService.

[Object]

None

[Character-string]

"ALMS"

[Code]

AlarmService internal error code

[Probable Faulty Locations]

1.NC software failure

2.P100-Menu failure

5921-E P-16

SECTION 2 ALARM P

0721 DeviceNet error

Error occurred on DeviceNet.

[Index]

None

[Character-string]

CH* SC$

* : Channel number where the error occurred.

S : Sequence counter

[Code]

XXYYZZZZ

XX Slave station MacID where the error occurred

YY Slave station

0x00 Normal or nonexistent slave station

0x46 Duplicate MacID error

0x48 Communication stop

0x49 Discrimination information was not compatible with scan list

0x4D Data size was not compatible with scan list

0x4E No response in the connection check.

0x4F Other slave stations are nonexistence on network

0x50 Idle condition

0x53 Error received in the connection check

0x54 Timeout occurred in the connection check

0x56 Turn into the idle mode

0x5B Bus off

0x5C Network power supply off

( XXXX became 0xFFFF,if its not caused by slave station, such as communication delay.)

ZZZZ Scanner error status

bit 0 Memory check error

bit 1 Scan list initialize error

bit 2 Scan list mismatch error(MacID)

bit 3 Scan list mismatch error(Input data)

bit 4 Scan list mismatch error(Output data)

bit 5 Duplicate MacID error

bit 6 Network power supply status error

bit 7 Memory parity error

bit 8 Input data reception error(single)

bit 9 Input data reception error(dowble)

bit10 Output data transmission error(single)

bit11 Output data transmission error(dowble)

Page 25

bit12 Slave station communication delay error(single)

bit13 Slave station communication delay error(dowble)

bit14 Bus off

bit15 Diagnostic information access error

[Probable Faulty Locations]

1)Hardware failure

2)Software failure

0723 DeviceNet I/O data link file read

The NC failed to read DeviceNet IO data link file.

[Code]

I/O data file load status (in hexadecimal)

2 ->File open error (no file)

3 ->File read error (no data)

4 ->File attribute error (not "PBU1")

5 ->File close error

6 ->File size error (too small)

7 ->File size error (too large)

100->Wrong PLC machine type

200->Wrong PLC class

300->Wrong file version

1002 ->DN SCAN LIST CHANGE FILE OPEN ERROR

1003 ->DN SCAN LIST CHANGE FILE READ ERROR (NO DATA)

1004 ->DN SCAN LIST CHANGE FILE ATTRIBUTE ERROR (NO 'PBU1')

1005 ->DN SCAN LIST CHANGE FILE CLOSE ERROR

1006 ->DN SCAN LIST CHANGE FILE SIZE ERROR (SIZE SMALL)

5921-E P-17

SECTION 2 ALARM P

0725 M code data file

Establishment data of reading M-code file is bad.

[Code]

1->The denial data is bad.

[Character string]

The number is M-code which is established bad data.

[Measures to Take]

Please correct the bad data of M-code.

0726 Safety speed data error

The safety speed data was in abnormal state in the machine without the CE marking safety speed monitor.

[Index]

Axis name or none (spindle)

[Character-string]

None

[Code]

X

X=1:The guard number of the safety speed data was outside the range from -0 to 9.

[Measures to Take]

Change the safety speed monitor data file for axis control.

Relevant specifications:Without CE mark safety speed monitor type

[Related Specifications]

Without CE mark safety speed monitor type

0727 MCS firmware doesn't support POS2 unit

This alarm occurs when the firmware ROM version of the NC axis/ machine(PLC) axis MIV unit is not 511 or later when the new

POS unit is installed.

[Character-string]

None

[Code]

None

Page 26

0728 FL-net error

An error occurred during startup of the FL-net card.

[Object]

None

[Character-string]

None

[Code]

Y000XXX

Y:0

XXXX:

7F00:System error

7F01:Flash memory error

7F02:DRAM test error

7F03:NICE test error

7F04:EEPROM sum check error

7F05:CPU BUS error

7F06:illegal Instruction

Y:1

XXXX:

0004:Timeout error for 4 sec or longer

Y:F

XXXX:

FFFF: FL-net card is not mounted

[Probable Faulty Locations]

FL-net card is defective.

5921-E P-18

SECTION 2 ALARM P

0729 Non-responsive software detected.

Non-answered software was detected.

[Object]

None

[Character-string]

None

[Code]

NT Process name

[Probable Faulty Locations]

NC software failure

0731 R Spec. error

It is the illegal of "R SPEC".

[Index]

None

[Code]

1:"NON R SPEC" of NC is OFF, and "R-SPEC" of SVDN-ID is OFF.

2:"NON R SPEC" of NC is ON, and "R-SPEC" of SVDN-ID is ON.

3:When there are 2 SVDN-boards in the machine, "R-SPEC" of one board is ON, other is OFF.

4X:"NON R SPEC" of NC is OFF, and "R-SPEC" of SVDN-ID is ON, and Restriction-Spec is ON.

0732 Unable to execute lost motion compensation

0735 MCS DD encoder link error

An error occurred in the encoder communication link.

[Object]

Axis name or none (spindle)

[Character-string]

None

[Code]

XXYYZZZZ

Page 27

XX = $FF (fixed)

YY = $00: Error is detected at the DD encoder.

$01: Error is detected at the DD encoder(slave sensor).

ZZZZ = Encoder link error status at the time of error detection

bit15: Undefined

bit14: Undefined

bit13: Error in communication with the DD encoder (slave sensor)

bit12: Error in communication with the DD encoder

bit11: MT buffer error

bit10: Transmission loop error in AT mode

bit9 : Data over error in data receiving part of interface

bit8 : Undefined

bit7 : Undefined

bit6 : Modulation code error

bit5 : CRC error

bit4 : Format error

bit3 : Double transmission error

bit2 : Double reception error

bit1 : Parity error

bit0 : Time-out error

This alarm occurs only at ICB-H.

[Probable Faulty Locations]

DD encoder of DD encoder (slave sensor) of the pertinent axis Encoder link cables or connectors Inverter unit control board

0736 MCS DD encoder error

5921-E P-19

SECTION 2 ALARM P

The DD encoder has become undetectable.

[Object]

Axis name or none (spindle)

[Character-string]

None

[Code]

XXYYZZZZ

XX = Positional data status

bit7 : Error bit (1:error)

bit6 : Absolute position sensor margin error.(0:Normal, 1:Warning)

bit5 : Gap-Warning (1:Gap-small,Toggle:Gap-big)

bit4 : Inclination-Warning (1:CCW-big, Toggle:CW-big)

bit3 : Auto set mode (0:Normal, 1:Auto mode)

bit2 : Communication error (Toggle by detecting)

bit1,0: Error bit number of absolute position code.(It is indicated by 2bits.)

YY = Alarm code

01: Stop command has stopped.

02: Control parameter error

04: Absolutization error

05: Initialization speed too high

08: Auto-set-data error

0D: Speed too high

0E: Synchronization error

20: Absolutization mismatch (Only Format-5)

21: Communication-error of Master-sensor (Only Format-5)

3E: Code-error by Absolute-position-sensor

3F: Check-errotr by Absolute-position-code

40: Inclination-error (for plus)

41: Inclination-error (for minus)

42: Gap is narrow

43: Gap is wide

ZZZZ = 0000 fixed

This alarm occurs only at ICB-H.

[Probable Faulty Locations]

DD encoder

0737 MCS DD encoder (slave sensor) detected error

The DD encoder (slave sensor) has become undetectable.

Page 28

[Object]

Axis name or none (spindle)

[Character-string]

None

[Code]

XXYYZZZZ

XX = Positional data status

bit7 : Error bit (1:error)

bit6 : Absolute position sensor margin error.(0:Normal, 1:Warning)

bit5 : Gap-Warning (1:Gap-small,Toggle:Gap-big)

bit4 : Inclination-Warning (1:CCW-big, Toggle:CW-big)

bit3 : Auto set mode (0:Normal, 1:Auto mode)

bit2 : Communication error (Toggle by detecting)

bit1,0: Error bit number of absolute position code.(It is indicated by 2bits.)

YY = Alarm code

01: Stop command has stopped.

02: Control parameter error

04: Absolutization error

05: Initialization speed too high

08: Auto-set-data error

0D: Speed too high

0E: Synchronization error

20: Absolutization mismatch (Only Format-5)

21: Communication-error of Master-sensor (Only Format-5)

3E: Code-error by Absolute-position-sensor

3F: Check-errotr by Absolute-position-code

40: Inclination-error (for plus)

41: Inclination-error (for minus)

42: Gap is narrow

43: Gap is wide

ZZZZ = 0000 fixed

This alarm occurs only at ICB-H.

[Probable Faulty Locations]

DD encoder (slave sensor)

5921-E P-20

SECTION 2 ALARM P

0738 MCS DD encoder initialization failure

An error occurred in the initialization of the DD encoder.

[Object]

Axis name or none (spindle)

[Character-string]

None

[Code]

XXYYZZZZ

XX = Encoder link initialization sequence number (1B) at the time of the error detection

0: Reset

1: Network address setting

2: Request to send the basic information for communication

3: Change of communication software version

4: Acquisition of device information

5: Parameter change

6: Position detection start

7: AT mode start

YY = Error content (1B)

0: Communication error

1: Transmission start time over

2: Transmission finish time over

3: Reception finish time over

4: Abnormal response address

5: Abnormal response code

6: Parameter error

ZZZZ = Data (2B)

If YY = 0,

The encoder link error status C2ERR at the time of error detection appears.

If YY = 1, 2 or 3,

Page 29

The transmitted frame information QC2MTINF appears.

If YY = 4,

The network address of the responding device appears.

If YY = 5,

Alarm code + positional data status

Refer to MCS DD Encoder error (alarm 1136).

If YY = 6,

Parameter number at which the error is detected

1: Reception of insufficient number of parameters

2: Basic information for communication being incompatible

3: Multi-turn detection range over

4: Communication protocol version being incompatible

5: Positional data format being incompatible

6: Abbreviated data mode being incompatible

However, when abnormal voltage is detected at the encoder fuse

XXYY = $FFFF fixed

ZZZZ = Detected voltage value of the encoder fuse (12[V] = $9980)

Normal range: 10.6[V] to 13.8[V]

Allowable range: $8800 to $B000

This alarm occurs only at ICB-H.

[Probable Faulty Locations]

DD encoder

Encoder link cables and connectors

Inverter unit control board

5921-E P-21

SECTION 2 ALARM P

0739 MCS DD encoder (slave sensor) initialization failure

An error occurred in the initialization of the DD encoder (slave sensor).

[Index]

Axis name or none (spindle)

[Character-string]

None

[Code]

XXYYZZZZ

XX = Encoder link initialization sequence number (1B) at the time of the error detection

0: Reset

1: Network address setting

2: Request to send the basic information for communication

3: Change of communication software version

4: Acquisition of device information

5: Parameter change

6: Position detection start

7: AT mode start

YY = Error content (1B)

0: Communication error

1: Transmission start time over

2: Transmission finish time over

3: Reception finish time over

4: Abnormal response address

5: Abnormal response code

6: Parameter error

ZZZZ = Data (2B)

If YY = 0,

The encoder link error status C2ERR at the time of error detection appears.

If YY = 1, 2 or 3,

The transmitted frame information QC2MTINF appears.

If YY = 4,

The network address of the responding device appears.

If YY = 5,

Alarm code + positional data status

Refer to MCS DD Encoder error (alarm 1136).

If YY = 6,

Parameter number at which the error is detected

1: Reception of insufficient number of parameters

2: Basic information for communication being incompatible

3: Multi-turn detection range over

Page 30

4: Communication protocol version being incompatible

5: Positional data format being incompatible

6: Abbreviated data mode being incompatible

However, when abnormal voltage is detected at the encoder fuse

XXYY = $FFFF fixed

ZZZZ = Detected voltage value of the encoder fuse (12[V] = $9980)

Normal range: 10.6[V] to 13.8[V]

Allowable range: $8800 to $B000

This alarm occurs only at ICB-H.

[Probable Faulty Locations]

DD encoder (slave sensor)

Encoder link cables and connectors

Inverter unit control board

0741 MCS firmware version error

The MCS software version was not correct.

[Object]

None

[Code]

1-> The MCS software version of the XA axis is not since ICBH590 in the premium thread cutting function spec.

[Probable Faulty Locations]

Specification code error

MCS software version error

[Measures to Take]

Reinstall the software or reissue the install disk.

MCS software Upgrade

5921-E P-22

SECTION 2 ALARM P

0742 Relocation detection error

Relocation detection error occurred

[Character-string]

ComErr :Communication error

PBU :PBU data error

PJ :PJ discord

PwdTout :Password application timeout

PwdChk :Password check error

PwdTerm:Password application terminate

[Code]

ComErr:

bit2 Atmega error

bit1 RTC error

bit0 Relocation detection module error

PwdChk:

Password check error code

0744 MCS power supply unit overload

Power Supply Unit over load

[Object]

Axis name or none (spindle)

[Character-string]

None

[Code]

1(fixed)

[Probable Faulty Locations]

Power unit

Overload operation

0750 The spec.-code or select-soft. was wrong

The combination of NC-software and PLC-software was wrong.

Or, the combination of specification-code was wrong.

Page 31

SECTION 2 ALARM P

[Object]

None

[Character-string]

None

[Code]

1:PLC-software is not effective for the specification of "TOOL OFFSET 999"

4:It can't be combined with spindle command unit 0.1.

5:Overlapped PLC axis number

[Probable Faulty Locations]

(1)Mistake of select for specification-code

(2)Mistake of select for PLC-software-version

0752 VDU communication error

An error occurred in the VDU(Vibration Detect Unit) communication link, disabling the VDU from detecting acceleration.

[Object]

Axis name or none (spindle)

[Character-string]

None

[Code]

XXYYZZZZ

XX = FF [HEX] (fixed)

YY = 00 [HEX] (fixed)

ZZZZ = VDU link error status at the time of error detection.

(Each bit represents the kind of communication error.)

bit 15 Undefined

bit 14 Undefined

bit 13 Undefined

bit 12 1: Error in communication with VDU(AT mode)

bit 11 1: Error in communication with VDU(MT mode)

bit 10 1: Transmission loop error in AT (auto) mode

bit 9 1: Data over error in data receiving part of interface

bit 8 Undefined

bit 7 Undefined

bit 6 1: Modulation code error

bit 5 1: CRC error

bit 4 1: Format error

bit 3 1: Double transmission error

bit 2 1: Double reception error

bit 1 1: Modulation code error

bit 0 1: Time-out error

[Probable Faulty Locations]

- VDU

- Encoder link cables

- VFA unit

5921-E P-23

0753 VDU detected error

The VDU(Vibration Detect Unit) has become unable to detect acceleration data.

[Object]

Axis name or none (spindle)

[Character-string]

None

[Code]

XXYYZZZZ

XX = VDU error status

bit7 1: Error bit (1 is error)

bit6 1: Empty bit

bit5 1: Latest acceleration data is overflow(Y axis)

bit4 1: Latest acceleration data is overflow(X axis)

bit3 1: Empty bit

bit2 1: Error in communication (toggled detecting each error)

bit1 1: Previous acceleration data is overflow(Y axis)

Page 32

bit0 1: Previous acceleration data is overflow(X axis)

YY = VDU alarm code

01: Stop command halt

02: Control parameter error

07: User parameter check sum error

0E: Synchronous miss error

15: Acceleration sensor signal error (X axis)

16: Acceleration sensor signal error (Y axis)

17: Acceleration sensor signal error (X and Y axis)

ZZZZ= 0 (fixed)

[Probable Faulty Locations]

- VDU

0754 VDU initialization failure

An error occurred in initialization of VDU(Vibration Detect Unit).

[Object]

Axis name or none (spindle)

[Character-string]

None

[Code]

XXYYZZZZ

XX = Encoder link sequence number at the time of error detection

0: Reset

1: Network address setting

2: Request of basic information on communication

3: Change of communication version

4: Acquisition of device information

5: Parameter change

6: AT (auto) mode start

YY = Error content

0: Communication error

1: Transmission start time over

2: Transmission finishes time over

3: Reception finishes time over

4: Abnormal response address

5: Abnormal response code

6: Parameter error

ZZZZ = Additional data

If YY=0,

the encoder link error status C2ERR at the time of error detection appears.

If YY=1, 2, or 3,

the transferred frame information C2MTINF appears.

If YY=4,

the network address of the responding device appears.

If YY=5,

the received frame information C2RXINF appears.

If YY=6,

the number of parameter that caused the alarm appears.

1 = Not all the necessary parameters are received.

2 = Basic information on communication is incompatible.

4 = Protocol version on communication is incompatible.

[Probable Faulty Locations]

- VDU

- Encoder link cables

- VFA unit

5921-E P-24

SECTION 2 ALARM P

0755 SIO link error

An error occurred in the SIO link.

[Object]

None

[Character-string]

None

Page 33

[Code]

During steady processing

FFFFFFFF:

Recieved the same data from MFU twice

XXXXYYYY:

XXXX: command & data length

0303: recieved error with frame 0

YYYY:The second byte of reception data

1303: recieved error with frame 1

YYYY:The second byte of reception data

05FF: Error status besides 0

YYYY:Error status

During setup processing

XXYYZZZZ:

XX: frame

YY: command

00: reset

01: intelligence

02: time-out time setting

05: file-transfer

ZZZZ: error cause

0007: Data reception response is not sent within 0.15 second after data transmission.

0008: Data transmission does not end within 0.15 second.

0009: Communication error occurred after reception of data.

000A: Communication error occurred while the NC was waiting for data reception.

000B: Communication error occurred while the NC was waiting for data transmission.

000C: Data transmission was attempted during data transmission.

000D: Data transmission was attempted in the state of communication error.

000E: An error command was received.

000F: Transmission command and reception command were not same.

[Probable Faulty Locations]

1.SSIO card

2.Safety module

3.I/O slave

5921-E P-25

SECTION 2 ALARM P

0756 PSC optical scale encoder error

An error was detected by the position encoder of optical scale.

[Character-string]

None

[Code]

XXYYZZ

XX:Value of the J-type endoder and value of the optical scale are too different.

bit1:It is too different by a negative sign.

bit0:It is too different by a positive sign.

YY:Pulse count value of optical scale

bit0:A-phase pulse and B-phase pulse have changed at the same time.

ZZ:The amplitude of the optical scale signal is wrong.

bit1:The amplitude of B-phase is wrong.

bit0:The amplitude of A-phase is wrong.

[Probable Faulty Locations]

- Breakdown of optical scale

- Breakdown of optical scale cable

[Measures to Take]

- Exchange of optical scale

- Exchange of optical scale cables

0757 MF-SAFETY Error

An error was detected by the MF-SAFETY.

[Object]

None

[Character-string]

None

Page 34

[Code]

0x1000XXXX->CPU Exception was occurred in the MF-SAFETY

XXXX->Exception number

0x1100XXXX->NMI was occurred in the MF-SAFETY

XXXX->NMI code

bit15->An error was occurred

bit9 ->Voltage drop for CPU1

bit8 ->Watchdog timer overflow in CPU0

bit1 ->Voltage drop for CPU0

bit0 ->Watchdog timer overflow in CPU1

0x1200XXXX->CPU bus error was occurred in the MF-SAFETY

XXXX->CPUID

bit15->CPUID (0:CPU0, 1:CPU1)

0x130000XX->No response in CPU1 request

XX->CPU1 request number

0x170000XX->Normal process in the MF-SAFETY did not end within a specific period.

XX->End time of normal process (1bit=62.5us)

0x1800XXXX->An Error was detected by the MF-SAFETY

XXXX->Error Code

bit15->MFU I/O unit error

bit14->MFU I/O Bus parity error

bit12->Synchronization error

bit11->Wrongly set synchronous signal timing

0x19000000->Stack overflow in the MF-SAFETY CPU

0x1A00XXXX->Illegal address is in the label table

XXXX->Index of label table

0x1B000000->NC starts up with software update mode in the MF-SAFETY

0x1C0000XX->Mode setting is mismatch between NC and MF-SAFETY

XX->Mismatch location

01->MF-SAFETY mode setting is wrong

02->NC mode setting is wrong

[Probable Faulty Locations]

MF-SAFETY

MF-SAFETY mode setting

NC mode setting

I/O unit in MFU

[Measures to Take]

Replace the MF-SAFETY unit

Replace the I/O unit in MFU

Switch(SW1) of the MF-SAFETY turns off

Update the MF-SAFETY software (safety logic)

5921-E P-26

SECTION 2 ALARM P

0758 Safety I/O Error

An error occurred in Safety IO link (SIO link) or in safety I/O unit.

[Object]

None

[Character-string]

None

[Code]

0x20000000->Safety transmission data was mismatch between CPU0 and CPU1while initialization of SIO link

0x21XX0000->Command was not received while initialization of SIO link

XX->Expecting command

00->Reset Command

01->Information gathering Command

02->Time-out time setting Command

0x22XXYYYY->Communication error was occurred while initialization of SIO link

XX->Expecting command

00->Reset Command

01->Information gathering Command

02->Time-out time setting Command

YYYY->SIO controller error status

bit15->An error was occurred

bit10->Reception buffer size setting was too big

bit9 ->Disconnection error

Page 35

bit8 ->Modulation code error

bit7 ->CRC error

bit6 ->Format error

bit5 ->Double transmission error

bit4 ->Double reception error

bit3 ->Parity error was occurred when SIO controller read transmission buffer

bit2 ->Parity error was occurred when CPU read transmission buffer

bit1 ->Parity error was occurred when CPU read reception buffer

bit0 ->Time-out error

0x23XXYYYY->Error command was received while initialization of SIO link

XX->SIO link slave address which error was detected

YYYY->Error status

bit15->An error was occurred

bit10->Reception buffer size setting was too big

bit9 ->Disconnection error

bit8 ->Modulation code error

bit7 ->CRC error

bit6 ->Format error

bit4 ->Double reception error

bit3 ->Parity error was occurred when SIO controller read transmission buffer

bit2 ->Parity error was occurred when CPU read transmission buffer

bit1 ->Parity error was occurred when CPU read reception buffer

bit0 ->Time-out error

0x24XX00YY->Illegal command was received while initialization of SIO link

XX->Expecting command

XX->Reception command

0x25XX0000->Safety IO slave information did not match the scan file list

XX->Mismatch frame offset

0x2F000000->SIO link was disconnected

0x31000000->The command was not received within a specific period

0x3200XXXX->Communication error was detected by the MF-SAFETY

XXXX->SIO controller error status

bit15->An error was occurred

bit10->Reception buffer size setting was too big

bit9 ->Disconnection error

bit8 ->Modulation code error

bit7 ->CRC error

bit6 ->Format error

bit5 ->Double transmission error

bit4 ->Double reception error

bit3 ->Parity error was occurred when SIO controller read transmission buffer

bit2 ->Parity error was occurred when CPU read transmission buffer

bit1 ->Parity error was occurred when CPU read reception buffer

bit0 ->Time-out error

0x33XXYYYY->Error command was received in SIO link safety frame

XX->SIO link slave address which error was detected

YYYY->Error status

bit15->An error was occurred

bit10->Reception buffer size setting was too big

bit9 ->Disconnection error

bit8 ->Modulation code error

bit7 ->CRC error

bit6 ->Format error

bit4 ->Double reception error

bit3 ->Parity error was occurred when SIO controller read transmission buffer

bit2 ->Parity error was occurred when CPU read transmission buffer

bit1 ->Parity error was occurred when CPU read reception buffer

bit0 ->Time-out error

0x34XX0000->Safety protocol could not be established on the SIO link

XX->slave address

0x35XXYYZZ->Could not communicate safety SIO frame, after established safety protocol

XX->slave address

YY->

00->Reset command was received

01->Unexpected command was received

02->Undefined command was received

03->Connection ID was in err

04->CRC error

5921-E P-27

SECTION 2 ALARM P

Page 36

08->FailSafeData command was received

ZZ->Reception safety data

0x36000000->Safety transmission data was mismatch between CPU0 and CPU1

0x37XX0000->Safety frame was not renewal

XX->slave address

0x3FXXYYZZ->Safety physical output data was mismatch between CPU0 and CPU1

XX->Index of physical output

YY->Output data in CPU0

ZZ->Output data in CPU1

0x41X000YY->An error was occurred in MFU I/O unit

X->Slot number

YY->I/O unit error status

<MF-EC1>

bit7->Overcurrent Protection circuit was worked in output circuit

bit6->Overcurrent protection was occurred in input circuit

bit4->I/O bus check error

bit2->Data was mismatched between order and monitor

bit1->A parity error was occurred when I/O bus1 was written

bit0->A parity error was occurred when I/O bus0 was written

<MF-P2A16S>

bit6->Overcurrent protection was occurred in input circuit

bit5->Self-check error

bit4->I/O bus check error

<MF-P2M2S>

bit7->Overcurrent Protection circuit was worked in output circuit

bit6->Overcurrent protection was occurred in input circuit

bit4->I/O bus check error

bit2->Data was mismatched between order and monitor

bit1->A parity error was occurred when I/O bus1 was written

bit0->A parity error was occurred when I/O bus0 was written

0x42XYZZWW->MFU I/O unit input of CPU0 and CPU1 was mismatched longer than a specific period

X->Slot number

Y->I/O unit safety input number (1-4)

ZZ->Input data in CPU0

WW->Input data in CPU1

0x43XYZZWW->MFU I/O unit written data was mismatch between CPU0 and CPU1

X->Slot number