Page 1

CNC SYSTEM

OSP-P200M/P200MA/P20M

OSP-P200M-R/P200MA-R/P20M-R

PROGRAMMING MANUAL

(10th Edition)

Pub No. 5228-E-R9 (ME33-018-R10) Oct. 2010

Page 2

5228-E P-(i)

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine itself from

hazards arising from unforeseen accidents. However, operators must not rely exclusively on these safety

devices: they must also become fully familiar with the safety guidelines presented below to ensure accidentfree operation.

This instruction manual and the warning signs attached to the machine cover only those hazards which

Okuma can predict. Be aware that they do not cover all possible hazards.

1. Precautions Relating to Installation

(1) Please be noted about a primary power supply as follows.

• Do not draw the primary power supply from a distribution panel that also supplies a major

noise source (for example, an electric welder or electric discharge machine) since this

could cause malfunction of the CNC unit.

• If possible, connect the machine to a ground not used by any other equipment. If there is

no choice but to use a common ground, the other equipment must not generate a large

amount of noise (such as an electric welder or electric discharge machine).

(2) Installation Environment

Observe the following points when installing the control enclosure.

• Make sure that the CNC unit will not be subject to direct sunlight.

• Make sure that the control enclosure will not be splashed with chips, water, or oil.

• Make sure that the control enclosure and operation panel are not subject to excessive

vibrations or shock.

• The permissible ambient temperature range for the control enclosure is 5 to 40°C.

• The permissible ambient humidity range for the control enclosure is relative humidity 50%

or less at 40°C (no condensation).

• The maximum altitude at which the control enclosure can be used is 1000 m (3281ft.).

2. Points to Check before Turning on the Power

(1) Close all the doors of the control enclosure and operation panel to prevent the entry of water,

chips, and dust.

(2) Make absolutely sure that there is nobody near the moving parts of the machine, and that there

are no obstacles around the machine, before starting machine operation.

(3) When turning on the power, turn on the main power disconnect switch first, then the CONTROL

ON switch on the operation panel.

Page 3

3. Precautions Relating to Operation

(1) After turning on the power, carry out inspection and adjustment in accordance with the daily

inspection procedure described in this instruction manual.

(2) Use tools whose dimensions and type are appropriate for the work undertaken and the machine

specifications. Do not use badly worn tools since they can cause accidents.

(3) Do not, for any reason, touch the spindle or tool while spindle indexing is in progress since the

spindle could rotate: this is dangerous.

(4) Check that the workpiece and tool are properly secured.

(5) Never touch a workpiece or tool while it is rotating: this is extremely dangerous.

(6) Do not remove chips by hand while machining is in progress since this is dangerous. Always

stop the machine first, then remove the chips with a brush or broom.

(7) Do not operate the machine with any of the safety devices removed. Do not operate the

machine with any of the covers removed unless it is necessary to do so.

(8) Always stop the machine before mounting or removing a tool.

5228-E P-(ii)

SAFETY PRECAUTIONS

(9) Do not approach or touch any moving part of the machine while it is operating.

(10) Do not touch any switch or button with wet hands. This is extremely dangerous.

(11) Before using any switch or button on the operation panel, check that it is the one intended.

4. Precautions Relating to the ATC

(1) The tool clamps of the magazine, spindle, etc., are designed for reliability, but it is possible that

a tool could be released and fall in the event of an unforeseen accident, exposing you to

danger: do not touch or approach the ATC mechanism during ATC operation.

(2) Always inspect and change tools in the magazine in the manual magazine interrupt mode.

(3) Remove chips adhering to the magazine at appropriate intervals since they can cause

misoperation. Do not use compressed air to remove these chips since it will only push the chips

further in.

(4) If the ATC stops during operation for some reason and it has to be inspected without turning the

power off, do not touch the ATC since it may start moving suddenly.

5. On Finishing Work

(1) On finishing work, clean the vicinity of the machine.

(2) Return the ATC, APC and other equipment to the predetermined retraction position.

(3) Always turn off the power to the machine before leaving it.

(4) To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the

main power disconnect switch.

Page 4

5228-E P-(iii)

SAFETY PRECAUTIONS

6. Precautions during Maintenance Inspection and When Trouble Occurs

In order to prevent unforeseen accidents, damage to the machine, etc., it is essential to observe the

following points when performing maintenance inspections or during checking when trouble has

occurred.

(1) When trouble occurs, press the emergency stop button on the operation panel to stop the

machine.

(2) Consult the person responsible for maintenance to determine what corrective measures need

to be taken.

(3) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

(4) Use only the specified replacement parts and fuses.

(5) Always turn the power off before starting inspection or changing parts.

(6) When parts are removed during inspection or repair work, always replace them as they were

and secure them properly with their screws, etc.

(7) When carrying out inspections in which measuring instruments are used - for example voltage

checks - make sure the instrument is properly calibrated.

(8) Do not keep combustible materials or metals inside the control enclosure or terminal box.

(9) Check that cables and wires are free of damage: damaged cables and wires will cause current

leakage and electric shocks.

(10) Maintenance inside the Control Enclosure

a. Switch the main power disconnect switch OFF before opening the control enclosure door.

b. Even when the main power disconnect switch is OFF, there may some residual charge in

the MCS drive unit (servo/spindle), and for this reason only service personnel are permitted

to perform any work on this unit. Even then, they must observe the following precautions.

• MCS drive unit (servo/spindle)

The residual voltage discharges two minutes after the main switch is turned OFF.

Page 5

c. The control enclosure contains the NC unit, and the NC unit has a printed circuit board

whose memory stores the machining programs, parameters, etc. In order to ensure that the

contents of this memory will be retained even when the power is switched off, the memory

is supplied with power by a battery. Depending on how the printed circuit boards are

handled, the contents of the memory may be destroyed and for this reason only service

personnel should handle these boards.

(11) Periodic Inspection of the Control Enclosure

a. Cleaning the cooling unit

The cooling unit in the door of the control enclosure serves to prevent excessive

temperature rise inside the control enclosure and increase the reliability of the NC unit.

Inspect the following points every three months.

• Is the fan motor inside the cooling unit working?

The motor is normal if there is a strong draft from the unit.

• Is the external air inlet blocked?

If it is blocked, clean it with compressed air.

7. General Precautions

5228-E P-(iv)

SAFETY PRECAUTIONS

(1) Keep the vicinity of the machine clean and tidy.

(2) Wear appropriate clothing while working, and follow the instructions of someone with sufficient

training.

(3) Make sure that your clothes and hair cannot become entangled in the machine. Machine

operators must wear safety equipment such as safety shoes and goggles.

(4) Machine operators must read the instruction manual carefully and make sure of the correct

procedure before operating the machine.

(5) Memorize the position of the emergency stop button so that you can press it immediately at any

time and from any position.

(6) Do not access the inside of the control panel, transformer, motor, etc., since they contain high-

voltage terminals and other components which are extremely dangerous.

(7) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

Page 6

8. Symbols Used in This Manual

The following warning indications are used in this manual to draw attention to information of

particular importance. Read the instructions marked with these symbols carefully and follow them.

DANGER

indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING

indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION

indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

CAUTION

5228-E P-(v)

SAFETY PRECAUTIONS

indicates a potentially hazardous situation which, if not avoided, may result in damage to your

property.

SAFETY INSTRUCTIONS

indicates general instructions for safe operation.

Page 7

5228-E P-(i)

INTRODUCTION

INTRODUCTION

Thank you very much for choosing our NC system. This NC system is an expandable CNC with various

features. Major features of the NC system are described below.

(1) Compact and highly reliable

The CNC system has become compact and highly reliable because of advanced hardware technology,

including the computer boards equipped with high-speed microprocessors, I/O link, and servo link. The

"variable software" as a technical philosophy of the OSPs supported by a flash memory. Functions may

be added to the CNC system as required after delivery.

(2) NC operation panels

The following types of NC operation panels are offered to improve the user-friendliness.

• Thin color operation panels (horizontal)

• Thin color operation panels (vertical)

One or more of the above types may not be used for some models.

(3) Machining management functions

These functions contribute to the efficient operation of the CNC system and improve the profitability from

small quantity production of multiple items and variable quantity production of variations. Major control

functions are described below.

a. Reduction of setup time

With increase in small-volume production, machining data setting is more frequently needed. The

simplified file operation facilitates such troublesome operation. The documents necessary for setup,

such as work instructions, are displayed on the CNC system to eliminate the necessity of controlling

drawings and further reduce the setup time.

b. Production Status Monitor

The progress and operation status can be checked on a real-time basis on the screen of the CNC

system.

c. Reduction of troubleshooting time

Correct information is quickly available for troubleshooting.

(4) Help functions

When an alarm is raised, press the help key to view the content of the alarm.

This helps take quick action against the alarm.

To operate the CNC system to its maximum performance, thoroughly read and understand this instruction

manual before use.

Keep this instruction manual at hand so that it will be available when you need a help.

Screens

Different screens are used for different models. Therefore, the

screens used on your CNC system may differ from those shown

in this manual.

Page 8

5228-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 1 PROGRAM CONFIGURATIONS .............................................................1

1. Program Types and Extensions............................................................................................... 1

2. Program Name ........................................................................................................................ 2

3. Sequence Name...................................................................................................................... 3

4. Program Format....................................................................................................................... 4

4-1. Word Configuration........................................................................................................... 4

4-2. Block Configuration .......................................................................................................... 4

4-3. Program............................................................................................................................ 5

4-4. Programmable Range of Address Characters.................................................................. 5

5. Mathematical Operation Functions.......................................................................................... 6

6. Optional Block Skip.................................................................................................................. 8

7. Program Branch Function (Optional) ....................................................................................... 9

8. Comment Function (Control OUT/IN) ...................................................................................... 9

9. Message Function (Optional)................................................................................................. 10

10.Operation Methods and Program Storage Memory Capacity ................................................ 10

SECTION 2 COORDINATE SYSTEMS AND COORDINATE COMMANDS .............13

1. Coordinate System ................................................................................................................ 13

1-1. Coordinate Systems and Values .................................................................................... 13

1-2. Machine Zero and Machine Coordinate System ............................................................ 13

1-3. Work Coordinate System................................................................................................ 14

1-4. Local Coordinate System ............................................................................................... 14

2. Coordinate Commands.......................................................................................................... 15

2-1. Numerically Controlled Axes .......................................................................................... 15

2-2. Unit Systems .................................................................................................................. 16

2-3. Travel Limit Commands (G22, G23) (Optional) .............................................................. 21

2-4. Home Position Command (G30) .................................................................................... 23

2-5. Absolute and Incremental Commands (G90, G91) ........................................................ 24

2-6. Coordinate Recalculation Command (G97).................................................................... 25

SECTION 3 FEED FUNCTIONS................................................................................26

1. Rapid Feed ............................................................................................................................ 26

2. Cutting Feed .......................................................................................................................... 26

2-1. Feed per Minute (G94) ................................................................................................... 26

2-2. Feed per Revolution (G95) ............................................................................................. 26

2-3. F1-digit Feed Function (Optional)................................................................................... 27

2-4. F0 Command During Cutting Feed................................................................................. 28

3. Exact Stop Check Function (G09, G61, G64)........................................................................ 29

4. Automatic Acceleration and Deceleration.............................................................................. 30

Page 9

5228-E P-(ii)

TABLE OF CONTENTS

5. Following Error Check ........................................................................................................... 31

6. Positioning (G00)................................................................................................................... 32

7. Uni-directional Positioning (G60)........................................................................................... 33

8. Linear Interpolation (G01)...................................................................................................... 34

9. Plane Selection (G17, G18, G19) .......................................................................................... 35

10.Circular Interpolation (G02, G03)........................................................................................... 37

11.Helical Cutting (G02, G03) (Optional).................................................................................... 40

SECTION 4 PREPARATORY FUNCTIONS...............................................................41

1. Dwell Command (G04) .......................................................................................................... 41

2. Programmable Mirror Image (G62) (Optional)....................................................................... 42

3. Work Coordinate System Selection (G15, G16) .................................................................... 44

4. Work Coordinate System Change (G92) ............................................................................... 45

5. Unit System Check (G20, G21) (Optional) ............................................................................ 45

6. Coordinate System Conversion Functions ............................................................................ 46

6-1. Parallel Shift and Rotation of Coordinate Systems (G11, G10)...................................... 46

6-2. Copy Function (COPY, COPYE) .................................................................................... 48

7. Workpiece Geometry Enlargement / Reduction Function (G51, G50) (Optional).................. 50

SECTION 5 S, T, AND M FUNCTIONS .....................................................................52

1. S Code Function.................................................................................................................... 52

2. T Code Function .................................................................................................................... 52

3. M Code Function ................................................................................................................... 53

3-1. Examples of M Codes .................................................................................................... 53

SECTION 6 OFFSET FUNCTIONS...........................................................................56

1. Tool Length Offset Function (G53 - G59) .............................................................................. 56

2. Cutter Radius Compensation (G40, G41, G42)..................................................................... 57

2-1. Cutter Radius Compensation Function........................................................................... 57

2-2. Tool Movement in Start-up ............................................................................................. 59

2-3. Tool Movement in Cutter Radius Compensation Mode .................................................. 62

2-4. Tool Movement when Cutter Radius Compensation is Canceled .................................. 67

2-5. Changing Compensation Direction in Cutter Radius Compensation Mode .................... 71

2-6. Cutter Radius Compensation Type A ............................................................................. 74

2-7. Notes on Cutter Radius Compensation .......................................................................... 81

3. Cutter Radius Compensation Mode Override Function ......................................................... 90

3-1. Automatic Override at Corners ....................................................................................... 90

3-2. Circular Arc Inside Cutting Override ............................................................................... 92

4. Tool Radius Compensation G39 Command.......................................................................... 93

4-1. Parameter....................................................................................................................... 93

4-2. Corner Circular Interpolation .......................................................................................... 94

4-3. Corner Circular Interpolation Command Automatic Insertion ......................................... 96

Page 10

5228-E P-(iii)

TABLE OF CONTENTS

5. Three-dimensional Tool Offset (G43, G44) (Optional)........................................................... 98

5-1. Three-dimensional Tool Offset Start-up ......................................................................... 98

5-2. Three-dimensional Tool Offset Vector............................................................................ 99

5-3. Canceling Three-dimensional Tool Offset .................................................................... 101

5-4. Actual Position Data Display And Feedrate.................................................................. 101

5-5. Relationship with Other G Functions ............................................................................ 102

5-6. Relationship to Other Tool Offset Functions................................................................. 102

SECTION 7 FIXED CYCLES ...................................................................................103

1. Table of Fixed Cycle Functions ........................................................................................... 104

2. Fixed Cycle Operations ....................................................................................................... 105

2-1. Determining the Positioning Plane and the Cycle Axis................................................. 106

2-2. Controlling the Return Level ......................................................................................... 107

2-3. Fixed Cycle Mode......................................................................................................... 107

2-4. Cycle Operation Conditions.......................................................................................... 108

3. General Rules for Programming Fixed Cycles .................................................................... 109

3-1. Programming Format (General Command Format) ..................................................... 109

3-2. Command Items Necessary for Fixed Cycle Function Commands .............................. 111

3-3. Absolute Programming Mode and Incremental Programming Mode............................ 112

3-4. Positional Relationship among Return Point Level, Point R Level and Point Z

Level ............................................................................................................................. 113

3-5. Axis Shift....................................................................................................................... 113

3-6. Z-axis G01 Mode Return Function ............................................................................... 114

3-7. Relationships between Fixed Cycle Functions and Other Functions ........................... 115

3-8. Notes for Programming a Fixed Cycle.......................................................................... 116

4. Specification of Return-point Level (G71)............................................................................ 117

5. High Speed Deep Hole Drilling Cycle (G73)........................................................................ 118

6. Reverse Tapping Cycle (G74) ............................................................................................. 119

7. Fine Boring (G76) ................................................................................................................ 120

8. Fixed Cycle Cancel (G80).................................................................................................... 121

9. Drilling Cycle (G81, G82).....................................................................................................122

10.Deep Hole Drilling Cycle (G83)............................................................................................ 123

11.Tapping Cycle (G84)............................................................................................................ 125

12.Boring Cycle (G85, G89) ..................................................................................................... 126

13.Boring Cycle (G86) .............................................................................................................. 127

14.Back Boring Cycle (G87) ..................................................................................................... 128

SECTION 8 COORDINATE CALCULATION FUNCTION (PATTERN FUNC-

TION) ...................................................................................................129

1. Table of Functions ............................................................................................................... 129

2. General Rules of Coordinate Calculation ............................................................................ 130

2-1. Programming Format for Coordinate Calculation ......................................................... 130

2-2. Plane on Which Coordinate Calculation is Performed, and Motion Axes..................... 132

Page 11

5228-E P-(iv)

TABLE OF CONTENTS

2-3. Positioning at Calculated Pattern Points ...................................................................... 132

2-4. Others........................................................................................................................... 132

3. Omit (OMIT)......................................................................................................................... 133

4. Restart (RSTRT).................................................................................................................. 134

5. Line at Angle (LAA).............................................................................................................. 135

6. Grid (GRDX, GRDY)............................................................................................................ 136

7. Double Grid (DGRDX, DGRDY) .......................................................................................... 137

8. Square (SQRX, SQRY) ....................................................................................................... 139

9. Bolt Hole Circle (BHC)......................................................................................................... 141

10.Arc (ARC) ............................................................................................................................ 142

SECTION 9 AREA MACHINING FUNCTIONS........................................................143

1. List of Area Machining Functions......................................................................................... 143

2. Area Machining Operations ................................................................................................. 143

2-1. Basic Operations .......................................................................................................... 143

2-2. Tool Movements ........................................................................................................... 144

3. Area Machining Plane and Cycle Axis................................................................................. 146

4. General Rules...................................................................................................................... 147

4-1. Programming Format (General Command Format) ..................................................... 147

4-2. Area Machining Functions and Commands to be Used ............................................... 148

4-3. Data Entry in Incremental/Absolute Mode .................................................................... 149

4-4. Relationship among Present Point, Point R Level, and Finish Surface Level .............. 149

4-5. Definition of Machining Area (I, J) ................................................................................ 150

4-6. Notes on Area Machining ............................................................................................. 150

5. Face Milling Functions (FMILR, FMILF) .............................................................................. 151

6. Pocket Milling (PMIL, PMILR).............................................................................................. 156

6-1. Zigzag Pattern Pocket Milling Function (PMIL) ............................................................ 156

6-2. Spiral Pattern Pocket Milling Function (PMILR) ........................................................... 160

7. Round Milling Functions (RMILO, RMILI)............................................................................ 164

SECTION 10SUBPROGRAM FUNCTIONS.............................................................170

1. Overview.............................................................................................................................. 170

1-1. Calling a Subprogram................................................................................................... 170

2. Simple Call (CALL) .............................................................................................................. 173

3. Subprogram Call after Axis Movement (MODIN, MODOUT)............................................... 175

4. G and M Code Macro Functions.......................................................................................... 180

5. Program Call Function Using Variables............................................................................... 183

5-1. Outline .......................................................................................................................... 183

5-2. Program Call function by Variables .............................................................................. 183

5-3. Program Registration Function..................................................................................... 185

SECTION 11USER TASK.........................................................................................186

Page 12

5228-E P-(v)

TABLE OF CONTENTS

1. User Task 1 ......................................................................................................................... 186

1-1. Branch Function ........................................................................................................... 186

1-2. Variable Function.......................................................................................................... 189

1-3. Math Functions ............................................................................................................. 195

1-4. System Variables.......................................................................................................... 196

2. User Task 2 ......................................................................................................................... 234

2-1. I/O Variables................................................................................................................. 234

2-2. Math Functions ............................................................................................................. 240

SECTION 12SCHEDULE PROGRAMS...................................................................243

1. Overview.............................................................................................................................. 243

2. PSELECT Block................................................................................................................... 244

3. Branch Block........................................................................................................................ 247

4. Variables Setting Block........................................................................................................ 248

5. Schedule Program End Block.............................................................................................. 248

SECTION 13OTHER FUNCTIONS..........................................................................249

1. Table Index Specification.....................................................................................................249

1-1. 5-Degree Index Commands ......................................................................................... 249

1-2. 1-Degree Index Commands ......................................................................................... 250

1-3. 0.001 Degree Commands (Optional)............................................................................ 252

2. Angular Commands............................................................................................................. 254

3. Manual Shift Amount Cancel Command.............................................................................. 255

4. Print Format Function .......................................................................................................... 258

SECTION 14FILE MANAGEMENT ..........................................................................259

1. Files ..................................................................................................................................... 259

2. Various Files........................................................................................................................ 260

SECTION 15APPENDIX ..........................................................................................261

1. G Code Table (Including Optional Functions)...................................................................... 261

2. Table of Mnemonic Codes (Including Optional Functions) .................................................. 265

3. M Code Table ...................................................................................................................... 268

4. Table of Reserved Local Variable Words ............................................................................ 277

5. Table of System Variables................................................................................................... 278

Page 13

SECTION 1 PROGRAM CONFIGURATIONS

SECTION 1 PROGRAM CONFIGURATIONS

1. Program Types and Extensions

For OSP-E100M/E10M, four kinds of programs are used: schedule programs, main programs,

subprograms, and library programs. The following briefly explains these four kinds of programs.

Schedule Program

When more than one type of workpiece is machined using a pallet changer or other loading and

unloading equipment, multiple main programs are used. A schedule program is used to specify the

order in which the main programs are executed and the number of times the individual main

program is executed. Using a schedule program makes it possible to carry out untended operation

easily.

It is not necessary to assign a program name. The END code must be specified at the end of a

schedule program. For details, refer to SECTION 12, “SCHEDULE PROGRAMS”.

Main Program

A main program contains a series of commands to machine one type of workpiece. Subprograms

can be called from a main program to simplify programming.

A main program begins with a program name which begins with address character “O” and ends

with M02 or M30.

5228-E P-1

Subprogram

A subprogram can be called from a main program or another subprogram. There are two types of

subprograms: those written and supplied by Okuma (maker subprogram), and those written by the

customer (user subprogram).

The program name, which must start with “O”, is required at the beginning of the subprogram. The

RTS command must be specified at the end of the subprogram. For details, refer to SECTION 10,

“SUBPROGRAM FUNCTIONS”.

Library Program

Subprograms and G code macros which are used frequently may be stored as library programs.

Since library programs are automatically stored in the operation buffer area when the power is

turned on, they can be accessed at any time.

When a library program is stored in the operation buffer area, both a file name and an extension are

stored. The file name format is shown below.

• Program file format

Main file name: Begins with alphabetic characters (max. 16 characters)

••• .

ExtensionMain file name

ME33018R1000300010001

• Extensions

SDF: Schedule program file

MIN: Main program file

MSB: Maker subprogram file

SSB: System subprogram file

SUB: User subprogram file

LIB: Library program file

Page 14

2. Program Name

All programs are assigned a program name or a program number, and a desired program can be

called and executed by simply specifying the program name or number.

A program name that contains only alphabetic characters is called a program label and the one that

contains only numbers is called a program number. In this manual, both of them are referred to as a

program name.

Program Name Designation

Enter letters of the alphabet (A to Z) or numbers (0 to 9) following address character “O”. Note

•

that no space is allowed between “O” and a letter of the alphabet or a number. Similarly, no

space is allowed between letters of the alphabet and numbers.

• Up to four characters can be used.

• An alphabetic character can only be used in a program name if it begins with an alphabetic

character. Although a program beginning with an alphabetic character can contain a number in

it, one that begins with a number cannot contain an alphabetic character.

• Although all of the four characters may be numeric, program names of the type “OO***” (***:

alphanumeric) cannot be used since this kind of program name is used for system operation,

automating functions, etc.

5228-E P-2

SECTION 1 PROGRAM CONFIGURATIONS

• A block which contains a program name must not contain other commands.

• A program name may not be used for a schedule program.

• The program name assigned to a main program / subprogram must begin with address

character “O”.

• Since program names are handled in units of characters, the following names are judged to be

different program names.

• O0123 and O123

• O00 and O0

• All program names must be unique.

If program name “O1” is used for more than one program, the operation to call program “O1”

may call a program differing from the desired one.

Page 15

3. Sequence Name

All blocks in a program are assigned a sequence name that begins with address character “N”

followed by an alphanumeric sequence.

Functions such as a sequence search function, a sequence stop function and a branching function

can be used for blocks assigned a sequence name.

A sequence name that contains only alphabetic characters is called a sequence label and the one

that contains only numbers is called a sequence number. In this manual, both of them are referred

to as a sequence name.

Sequence Name Designation

Enter letters of the alphabet (A to Z) or numbers (0 to 9) following address character “N”.

•

• Up to five characters can be entered in succession to the address.

• Both alphabetic characters and numbers may be used in a sequence name. If an alphabetic

character is used in a sequence name, however, the sequence name must begin with an

alphabetic character.

• Although a sequence name must be specified at the beginning of a block, an optional block skip

code may be placed before a sequence name.

5228-E P-3

SECTION 1 PROGRAM CONFIGURATIONS

• Sequence numbers may be specified in any order.

• Since sequence names are handled in units of characters, the following names are judged to be

different sequence names.

• N0123 and N123

• N00 and N0

• When a sequence label is used, place a space or a tab after the sequence label.

Page 16

4. Program Format

4-1. Word Configuration

A word is defined as an address character followed by a group of numeric values, an expression, or

a variable name. If a word consists of an expression or a variable, the address character must be

followed by an equal sign “=”.

Examples:

5228-E P-4

SECTION 1 PROGRAM CONFIGURATIONS

X - 100

Address Numeric value

Word

Y = 100∗SIN[50]

Address

• An address character is one of the alphabetic characters A through Z and defines the meaning

of the entry specified following it. In addition, an extended address character, consisting of two

alphabetic characters, may also be used.

• Refer to SECTION 11, “Variable Function” for more information on variables.

• Hexadecimals may be used for numeric values.

Example: X#1000H (same as X4096)

4-2. Block Configuration

A group consisting of several words is called a block, and a block expresses a command. Blocks

are delimited by an end of block code.

• The end of block code differs depending on the selected code system, lSO or EIA:

ISO: LF

ElA: CR

• A block comprises several words.

Expression

Word

Z = VC1+VC2

Address

Variable

Word

ME33018R1000300040001

• A block may contain up to 158 characters.

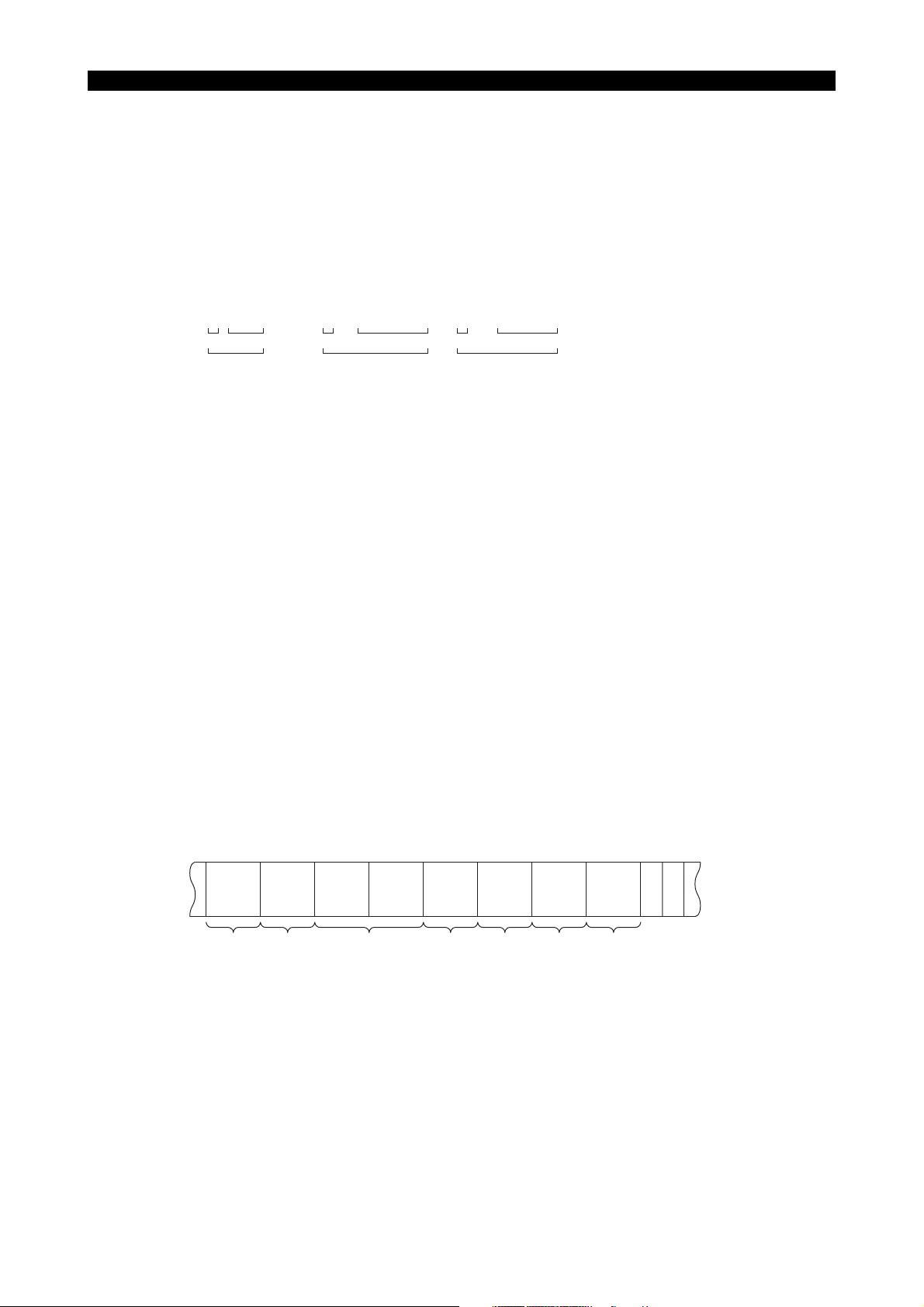

A block consists of the following commands, for example.

N__ G__ X__ Y__ F__ S__ T__ M__

Feedrate

Sequence No.

Preparatory function

Coordinate values

Spindle speed

LC

FR

Tool No.

Miscellaneous function

ME33018R1000300050001

Page 17

SECTION 1 PROGRAM CONFIGURATIONS

4-3. Program

A program consists of several blocks.

4-4. Programmable Range of Address Characters

The programmable ranges of numerical values of individual address characters are shown in the

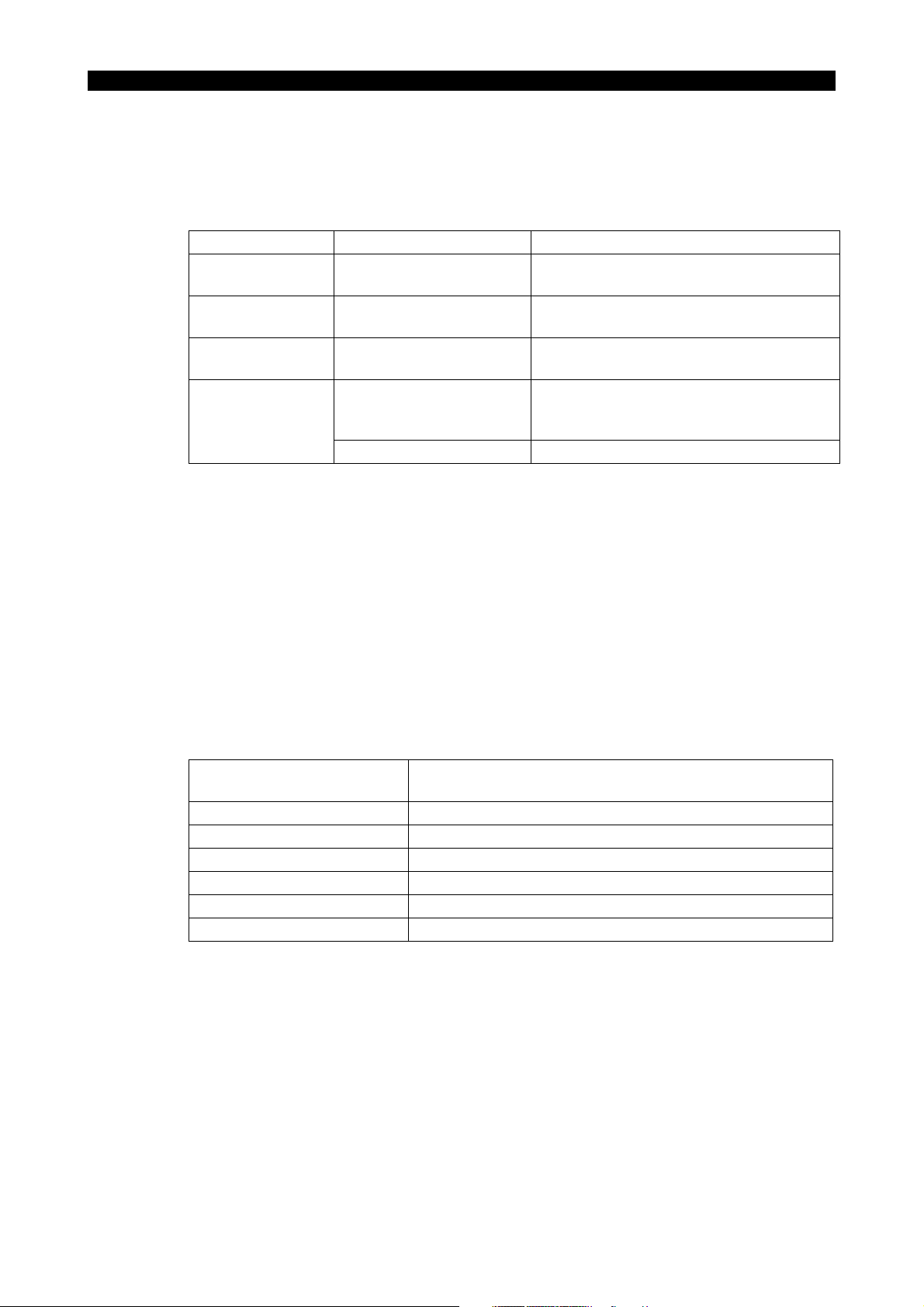

following table.

5228-E P-5

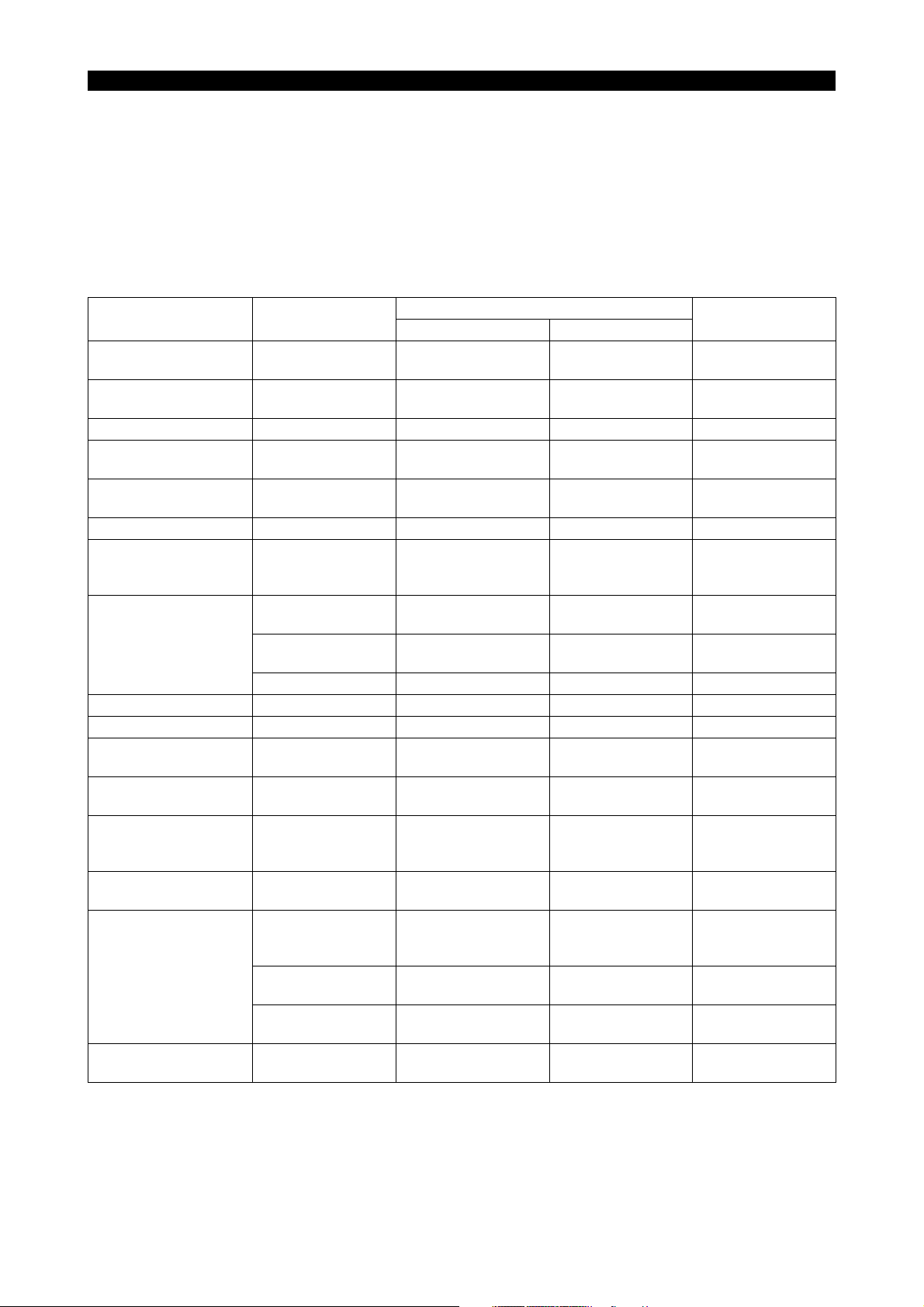

Address Function

O Program name 0000 - 9999 Same as metric

N Sequence name 00000 - 99999 Same as metric

G Preparatory function 0 - 399 Same as metric Mnemonics available

X, Y, Z, U, V, W

I, J, K

R Radius of arc ±99999.999mm ±9999.9999inch

A, B, C

F

S Spindle speed 0 - 65535 Same as metric

T Tool number 1 - 9999 Same as metric

M

H

D

P

Q

R

Coordinate values

(linear axis)

Coordinate values of

center of arc

Coordinate values of

rotary axis

Feed per minute

Feed per revolution

Dwell time period 0.001 - 99999.999 sec Same as metric

Miscellaneous

function

Tool length offset

number

Cutter radius

compensation

number

Dwell time period

(during fixed cycle)

Second dwell time

period (during fixed

cycle)

Depth of cut (during

fixed cycle)

Repetition time

(schedule program)

Cut starting level

(during fixed cycle)

±99999.999mm ±9999.9999inch

±99999.999mm ±9999.9999inch

±360.0000deg Same as metric

0.001 - 500.000

1 to maximum tool data

1 to maximum tool data

0.001 - 99999.999 sec Same as metric

0.001 - 99999.999 sec Same as metric

±99999.999mm ±9999.9999inch

Programmable Range

Metric Inch

0.1 - 24000.0

mm/min

mm/rev

0 - 511 Same as metric

number

number

0 - 99999.999

mm

1 - 9999 Same as metric

0.01 - 2400.00

inch/min

0.0001 - 50.0000

inch/rev

Same as metric

Same as metric

0 - 9999.9999inch

Alphabetic characters

Alphabetic characters

specification

±9999.9999deg

Remarks

available

available

Multi-turn

*: An alarm occurs when any of the following addresses is specified more than once within a block:

X, Y, Z, U, V, W, A, B, C, F.

Page 18

SECTION 1 PROGRAM CONFIGURATIONS

5. Mathematical Operation Functions

Mathematical operation functions are used to convey logical operations, arithmetic operations, and

trigonometric functions. A table of the operation symbols is shown below. Operation functions can

be used together with variables to control peripherals or to pass on the results of an operation.

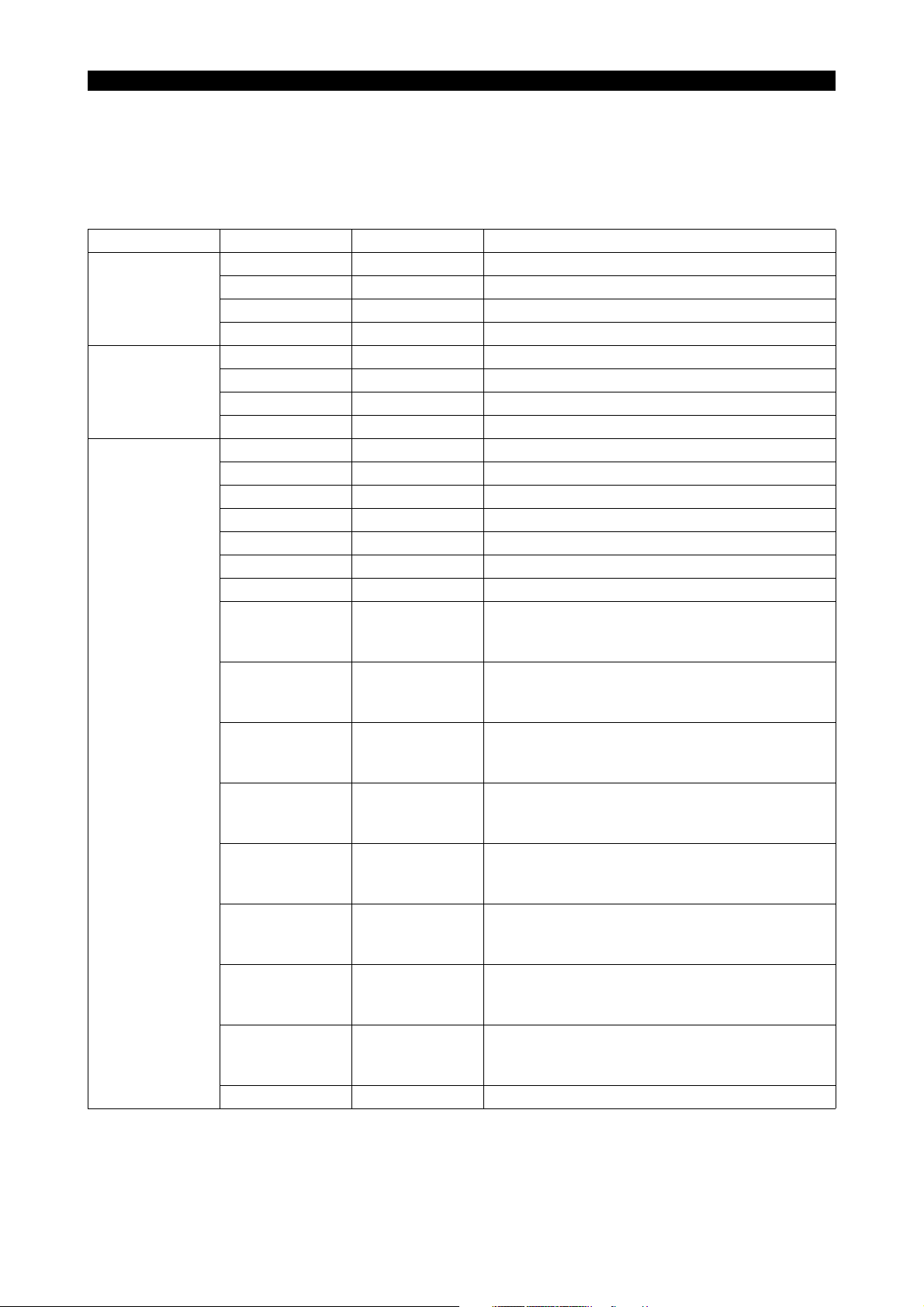

Category Operation Operator Remarks

Exclusive OR EOR 0110 = 1010 EOR 1100 (See *3.)

Logical operation

Arithmetic

operation

Trigonometric

functions, etc.

Logical OR OR 1110 = 1010 OR 1100 (See *3.)

Logical AND AND 1000 = 1010 AND 1100 (See *3.)

Negation NOT 1010 = NOT 0101

Addition + 8 = 5 + 3

Subtraction - 2 = 5 - 3

Multiplication * 15 = 5 * 3

Division / (slash) 3 = 15/5

Sine SIN 0.5 = SIN [30] (See *4.)

Cosine COS 0.5 = COS [60] (See *4.)

Tangent TAN 1 = TAN [45] (See *4.)

Arctangent (1) ATAN 45 = ATAN [1] (value range: -90° to 90°)

Arctangent (2) ATAN2 30 = ATAN 2 [1,(Square root 3)] (See *1.)

Square root SQRT 4 = SQRT [16]

Absolute value ABS 3 = ABS [-3]

Decimal to

hexadecimal

conversion

Hexadecimal to

decimal

conversion

Integer

implementation

(rounding)

Integer

implementation

(truncation)

Integer

implementation

(raising)

Unit integer

implementation

(rounding)

Unit integer

implementation

(truncation)

Unit integer

implementation

(raising)

Remainder MOD 2 = MOD [17, 5]

BIN 25 = BIN [$25]

($ represents a hexadecimal number.)

BCD $25 = BCD [25]

ROUND 128 = ROUND [1.2763 x 102]

FIX 127 = FIX [1.2763 x 102]

FUP 128 = FUP [1.2763 x 102]

DROUND 13.265 = DROUND [13.26462] (See *2.)

DFlX 13.264 = DFlX [13.26462] (See *2.)

DFUP 13.265 = DFUP [13.26462] (See *2.)

5228-E P-6

Page 19

SECTION 1 PROGRAM CONFIGURATIONS

Category Operation Operator Remarks

Brackets

*1. The value of ATAN2 [b, a] is an argument (range: -180° to 180°) of the point that is expressed

*2. In this example, the setting unit is mm.

*3. Blanks must be placed before and after the logical operation symbols (EOR, OR, AND, NOT).

*4. Numbers after function operation symbols (SIN, COS, TAN, etc.) must be enclosed in

Opening bracket [ Determines the order of calculation.

Closing bracket ]

by coordinate values (a, b).

brackets “[ ]”. ( “a”, “b”, and “c” are used to indicate the contents of the corresponding bits.)

(Expression in inner brackets is calculated first.)

Logical Operations

Exclusive OR (EOR) c = a EOR b

•

If the two corresponding values agree, EOR outputs 0.

If the two values do not agree, EOR outputs 1.

abc

000

011

101

110

5228-E P-7

• Logical OR (OR) c = a OR b

If both corresponding values are 0, OR outputs 0.

If not, OR outputs 1.

abc

000

011

101

111

• Logical AND (AND) c = a AND b

If both corresponding values are 1, AND outputs 1.

If not, AND outputs 0.

abc

000

010

100

111

• Negation (NOT) b = NOT a

NOT inverts the value (from 0 to 1, and 1 to 0).

ab

01

10

Page 20

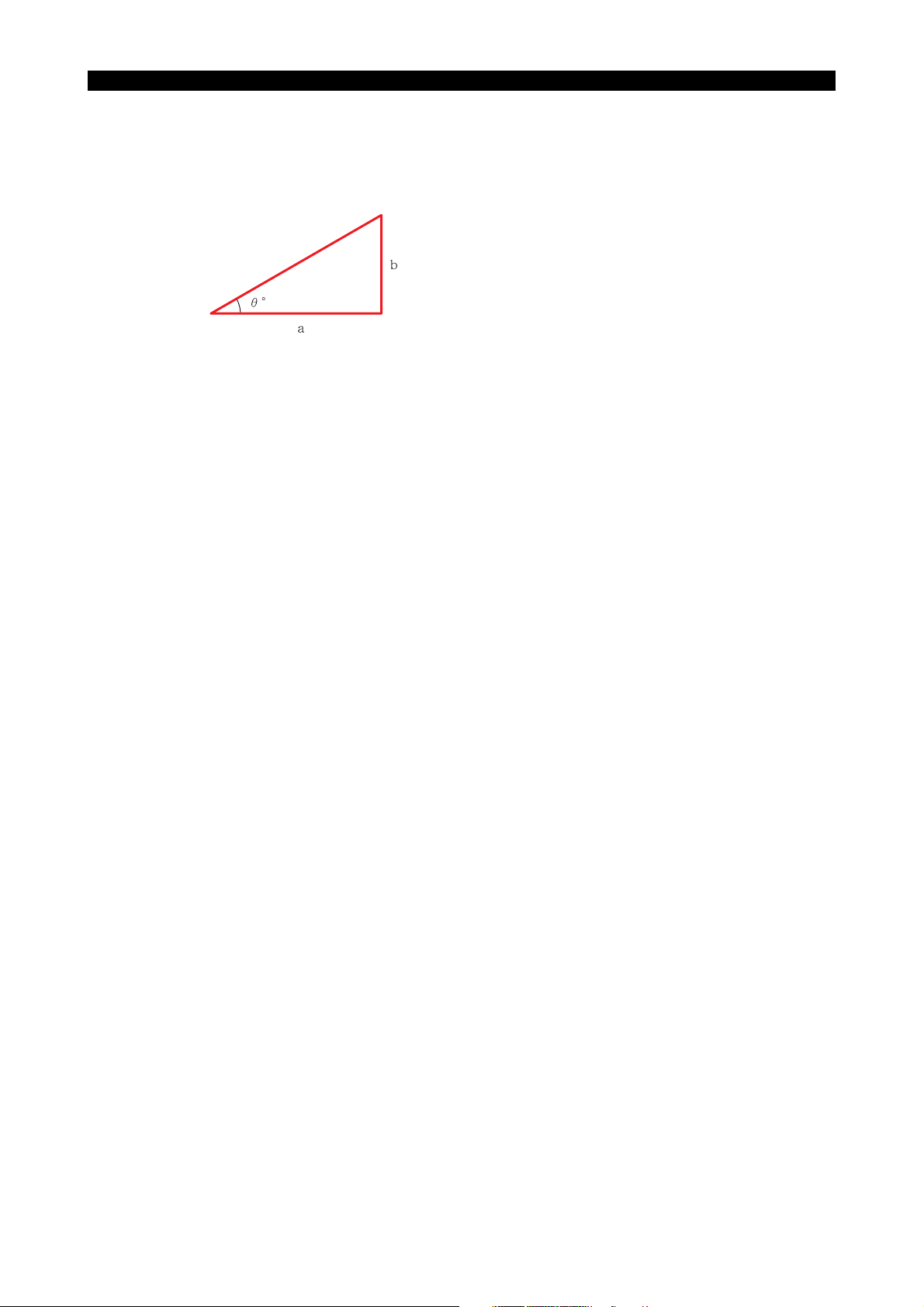

• Arc tangent (1) (ATAN)

θ = ATAN [b/a]

Arc tangent (2) (ATAN2)

θ = ATAN2 [b/a]

• Integer implementation (ROUND, FIX, FUP)

Converts a specified value into an integer (in units of microns) by rounding off, truncating, or

raising the number at the first place to the right of the decimal point.

6. Optional Block Skip

5228-E P-8

SECTION 1 PROGRAM CONFIGURATIONS

ME33018R1000300080001

[Function]

Blocks preceded by “/n” are ignored in automatic operation mode if the BLOCK SKIP switch on the

machine panel is set ON. If the switch is OFF, these blocks are executed normally. The optional

block skip function allows an operator to determine if a specific block should be executed or ignored

in automatic mode operation.

When the block skip function is called, the entire block will be ignored.

[Details]

• In the standard specification, one optional block skip can be specified; as an option, up to nine

are possible. These are distinguished in code as follows: “/1”, “/2”, “/3”. Note that “/” has the

same meaning as “/1” when this option is selected.

• A slash code “/” must be placed at the start of a block. If it is placed in the middle of a block, an

alarm is activated. A sequence name may precede a slash code “/”.

• A slash code “/” may not be contained in the program name block.

• Blocks which contain a slash code “/” are also subjected to the sequence search function,

regardless of the BLOCK SKIP switch position.

• Sequence stop is not executed at a block which contains a slash code “/” in single block mode

operation if the BLOCK SKIP switch is ON. The succeeding block is executed, and then the

operation stops.

• This function is also available in the schedule program.

Page 21

SECTION 1 PROGRAM CONFIGURATIONS

7. Program Branch Function (Optional)

[Function]

The program branch function executes or ignores the program branch command specified in a part

program according to the ON/OFF setting of the PROGRAM BRANCH switch on the machine panel.

The function corresponds to maximum two program branch switches, PROGRAM BRANCH 1 and

PROGRAM BRANCH 2 (extended to maximum nine switches by additional option). If the switch is

ON, the program branches when the following command is read.

• IF VPBR1 N*** The program branches to N*** block if the PROGRAM BRANCH 1 switch is

ON.

• IF VPBR2 N*** The program branches to N*** block if the PROGRAM BRANCH 2 switch is

ON.

Example:

5228-E P-9

IF VPBR1 N100

G00 X100 Z100

G00 Y100N100

IF VPBR1 N200

G00 X200 Z200

G00 Y200

N200

M02

Branching to N100 if PROGRAM BRANCH 1 switch is ON.

Branching to N200 if PROGRAM BRANCH 2 switch is ON.

[Details]

• In operation method B (large-volume program operation mode), use a sequence label name to

specify the branch destination.

• The program branch function has the same restrictions as the branch function of User Task 1.

• A program branch command (IF VPBR1 N*** or IF VPBR2 N***) must be specified in a block

without other commands.

8. Comment Function (Control OUT/IN)

A program may be made easier to understand by using comments in parentheses.

ME33018R1000300100001

• A comment must be parenthesized to distinguish it from general operation information. All

information placed in parentheses is regarded by the machine as comments.

• Comments are displayed in the normal character size.

Example:

N100 G00 X200 (FIRST STEP)

Comment

ME33018R1000300110001

Page 22

9. Message Function (Optional)

[Function]

For conditional branching it may be necessary to display a message, depending on the processing

at the destination of the branching. The message function is used in such cases, and the message

is displayed in enlarged characters.

[Format]

MSG (message statement)

[Details]

• The display of a message statement on the screen is twice the size of normal characters.

• If the MSG code is not followed by a message statement, the comment statement given last up

to the present block will be displayed.

• Up to 128 characters may be used in a message statement.

• The message function is possible only during machine operation mode.

• The following code can be used in the program to return the screen to he previous status after

the message has been displayed: NMSG

5228-E P-10

SECTION 1 PROGRAM CONFIGURATIONS

10. Operation Methods and Program Storage Memory Capacity

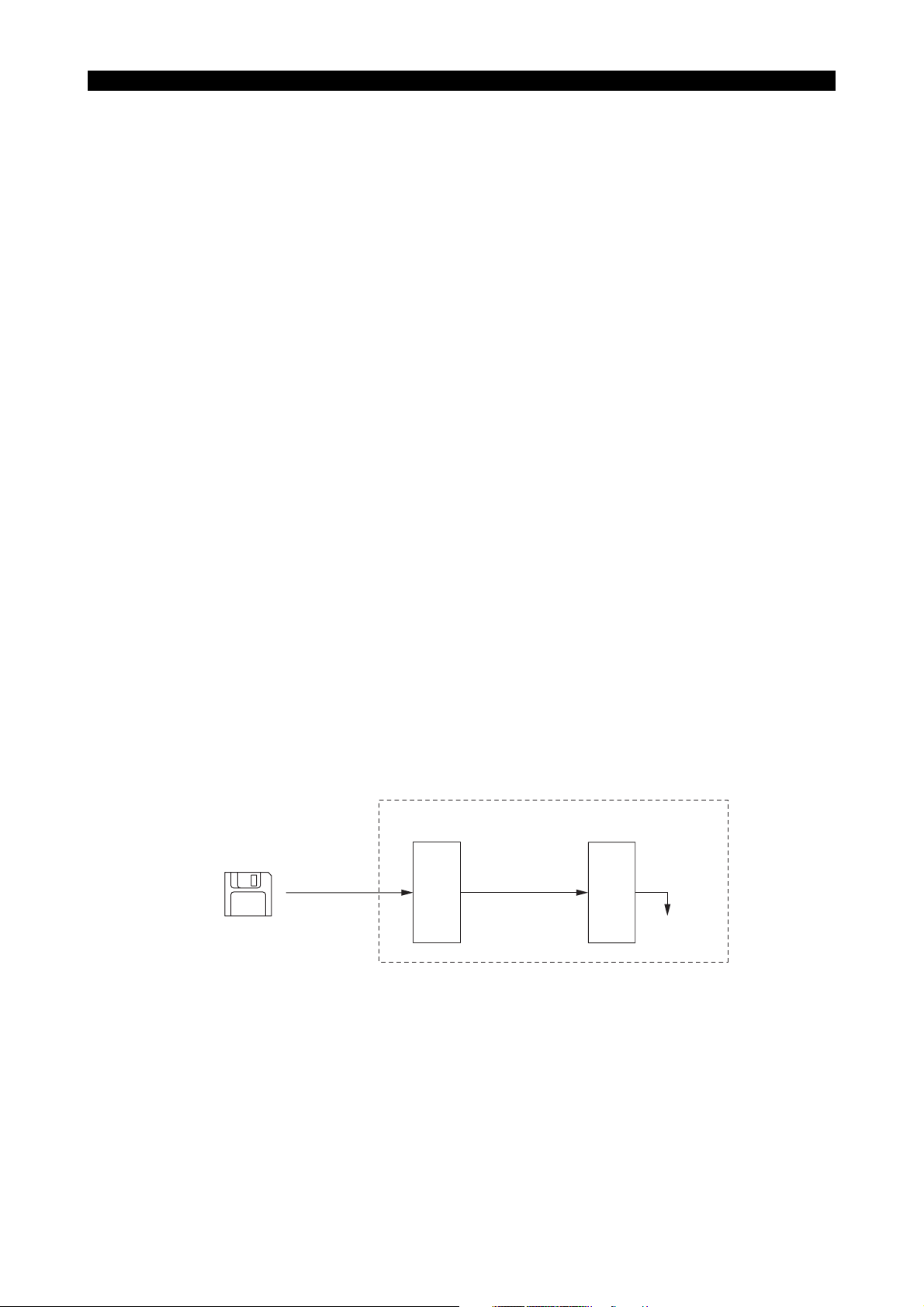

(1) Operation Capacity

The NC has a memory to store machining programs. The memory capacity is selected

depending on the size of the user program. On execution of a program, the program is

transferred from the memory to the operation buffer (RAM).

If the program size is larger than the operation buffer capacity, (for example, if the program size

is larger than 320 m (1050 ft.) although the operation buffer capacity is 320 m (1050 ft.)), the

program cannot be transferred from the memory to the operation buffer in batch (at one time).

Depending on the size of a program in comparison to the operation buffer capacity, two types of

operation methods are available (operation method A and operation method B), and restrictions

apply in programming according to the operation method used.

Machining program Memory

Program selection

Operation buffer

(RAM)

Operation

ME33018R1000300130001

Page 23

5228-E P-11

SECTION 1 PROGRAM CONFIGURATIONS

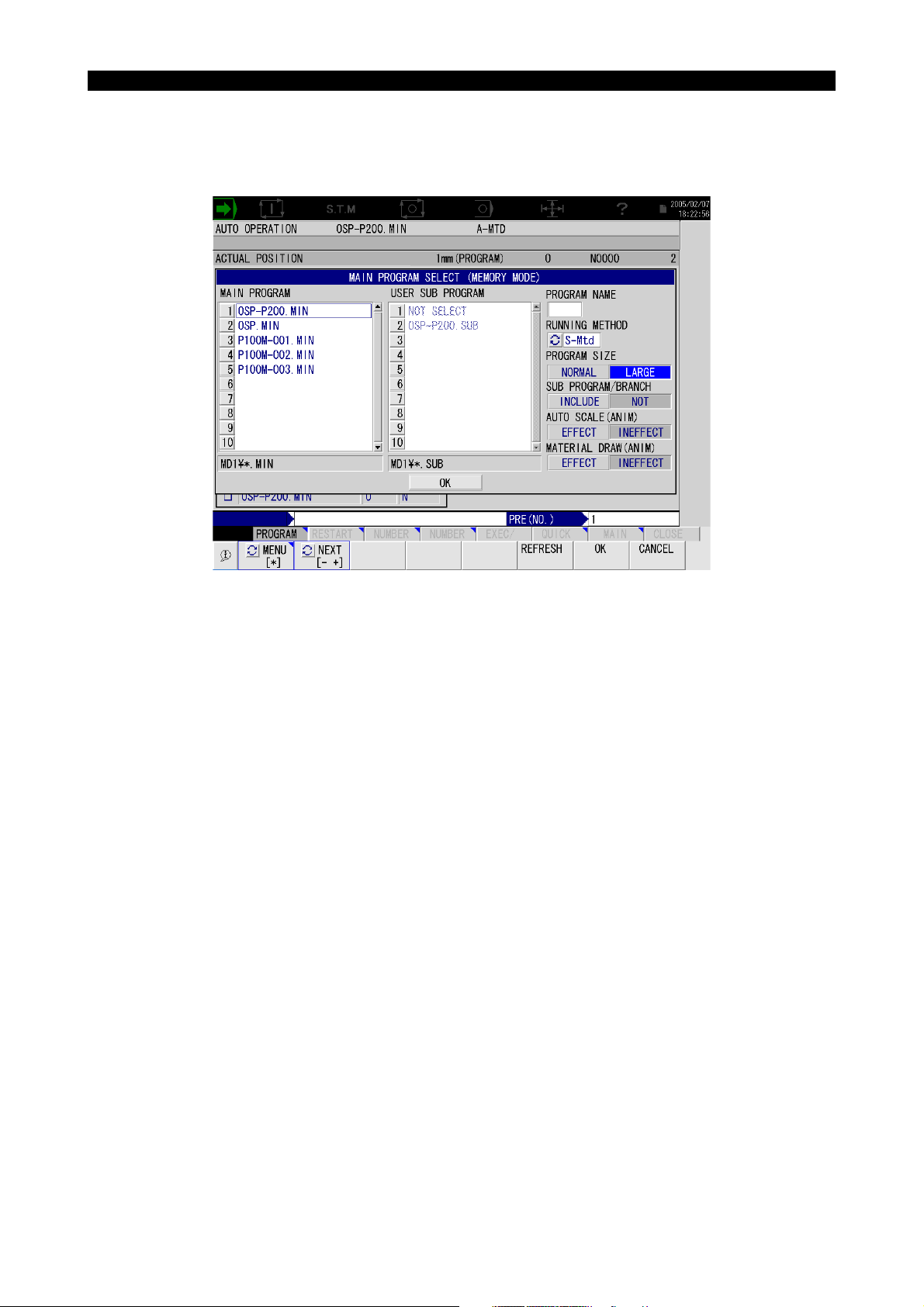

(2) Operation Methods

Select the operation method using the pop-up window MAIN PROGRAM SELECT (MEMORY

MODE) that appears when calling a program to be run. The operation method can be also

selected by the setting at the NC optional parameter (word) No. 11.

ME33018R1000300130002

• When A-Mtd is selected

Program running method A becomes effective.

The program to be executed is transferred to the operation buffer in batch.

This method is used when the program is smaller than the operation buffer capacity.

• When B-Mtd is selected

Program running method B becomes effective.

The program to be executed is called to the operation buffer in several segments.

This method is used when the program is larger than the operation buffer capacity.

Since schedule programs, subprograms, and library programs are generally called to the

operation buffer in batch, these programs must be created with restriction placed on their

capacities.

• When S-Mtd is selected

Program running method S becomes effective.

This method is used to execute a large program which does not use branch or subprogram

call functions.

Page 24

5228-E P-12

SECTION 1 PROGRAM CONFIGURATIONS

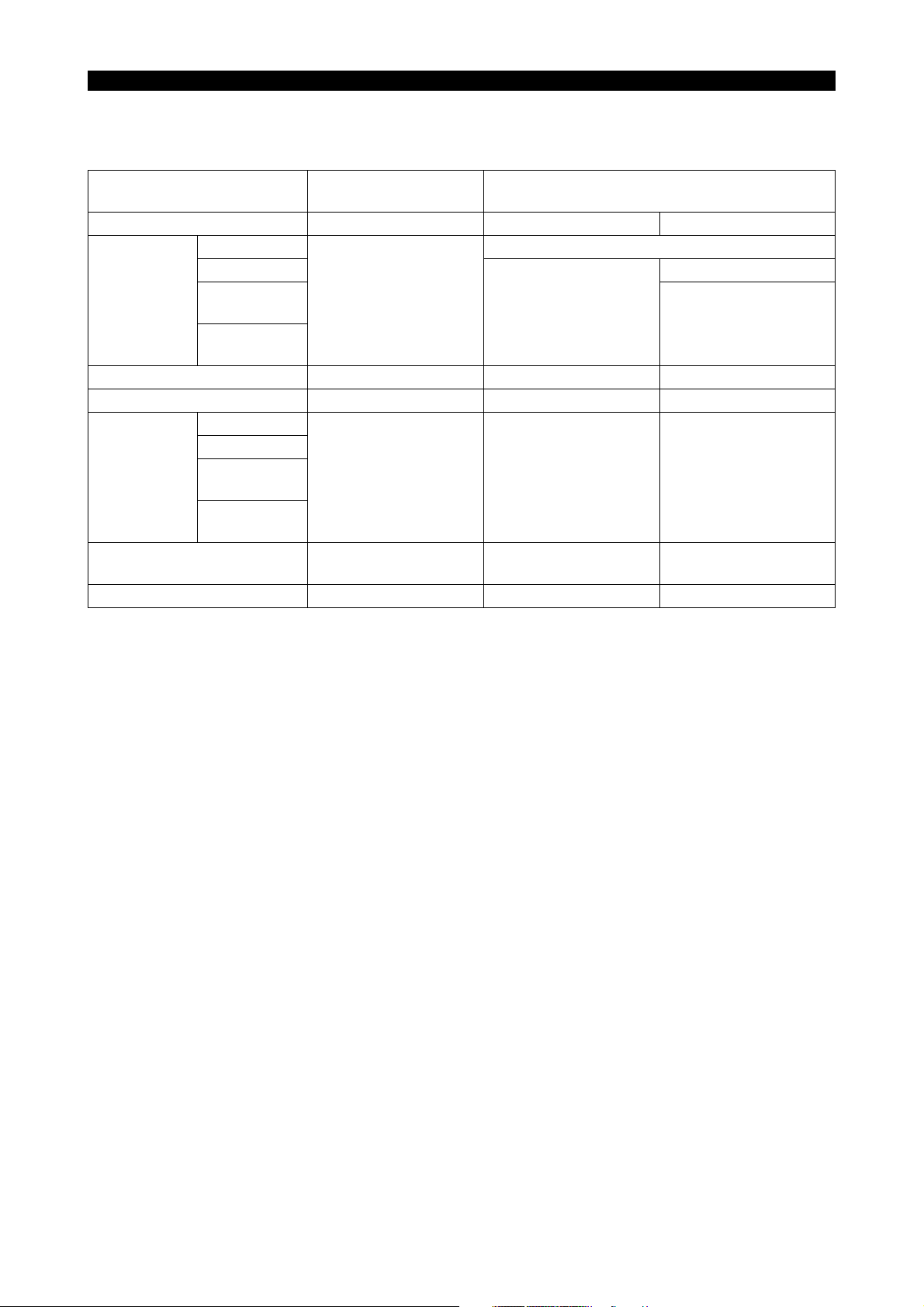

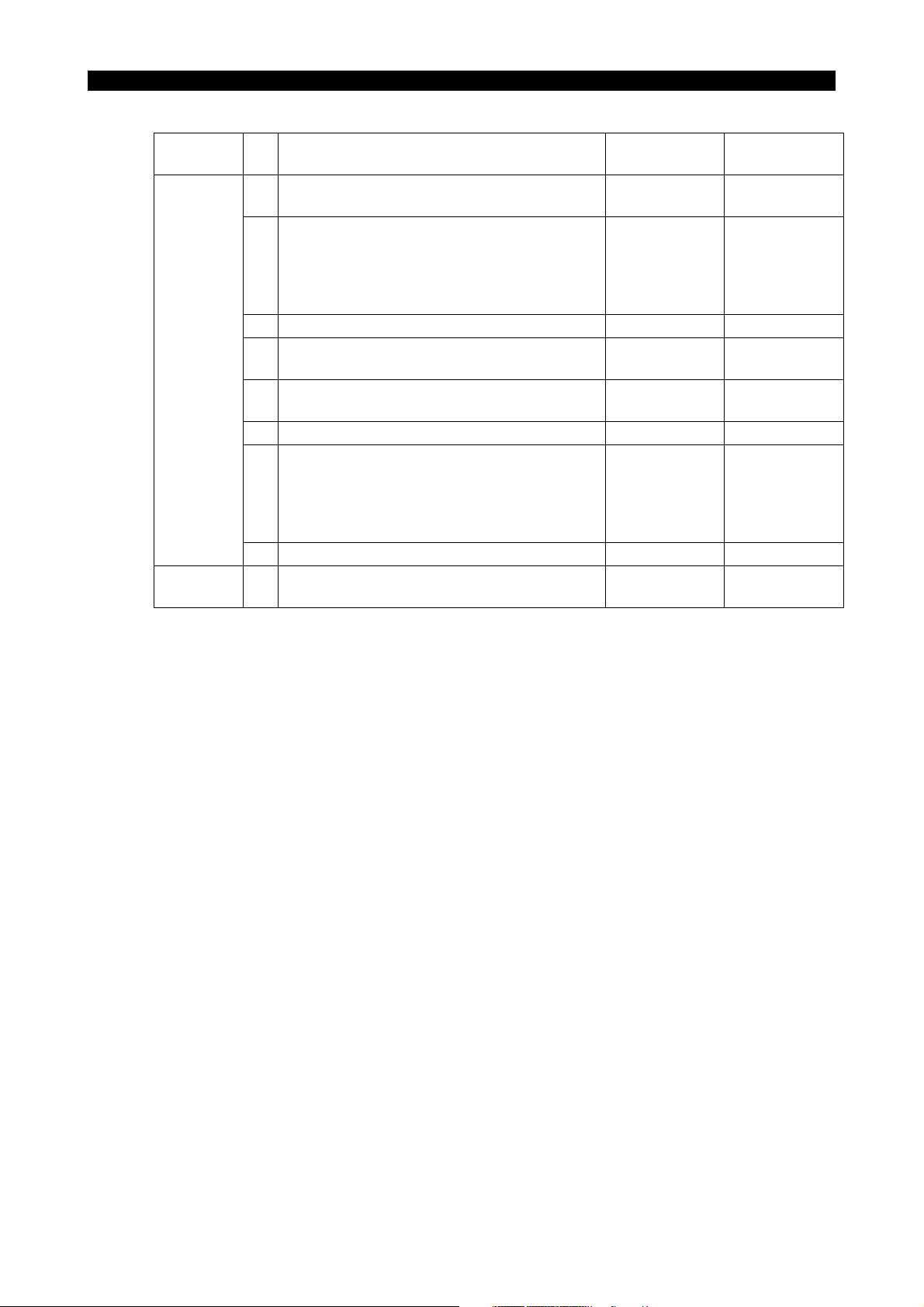

• When selecting an operation method, also select the program size and whether the

program has a sub program branch or not (only in the case of operation A and B). The

table below shows the relation between the operation method and the program size.

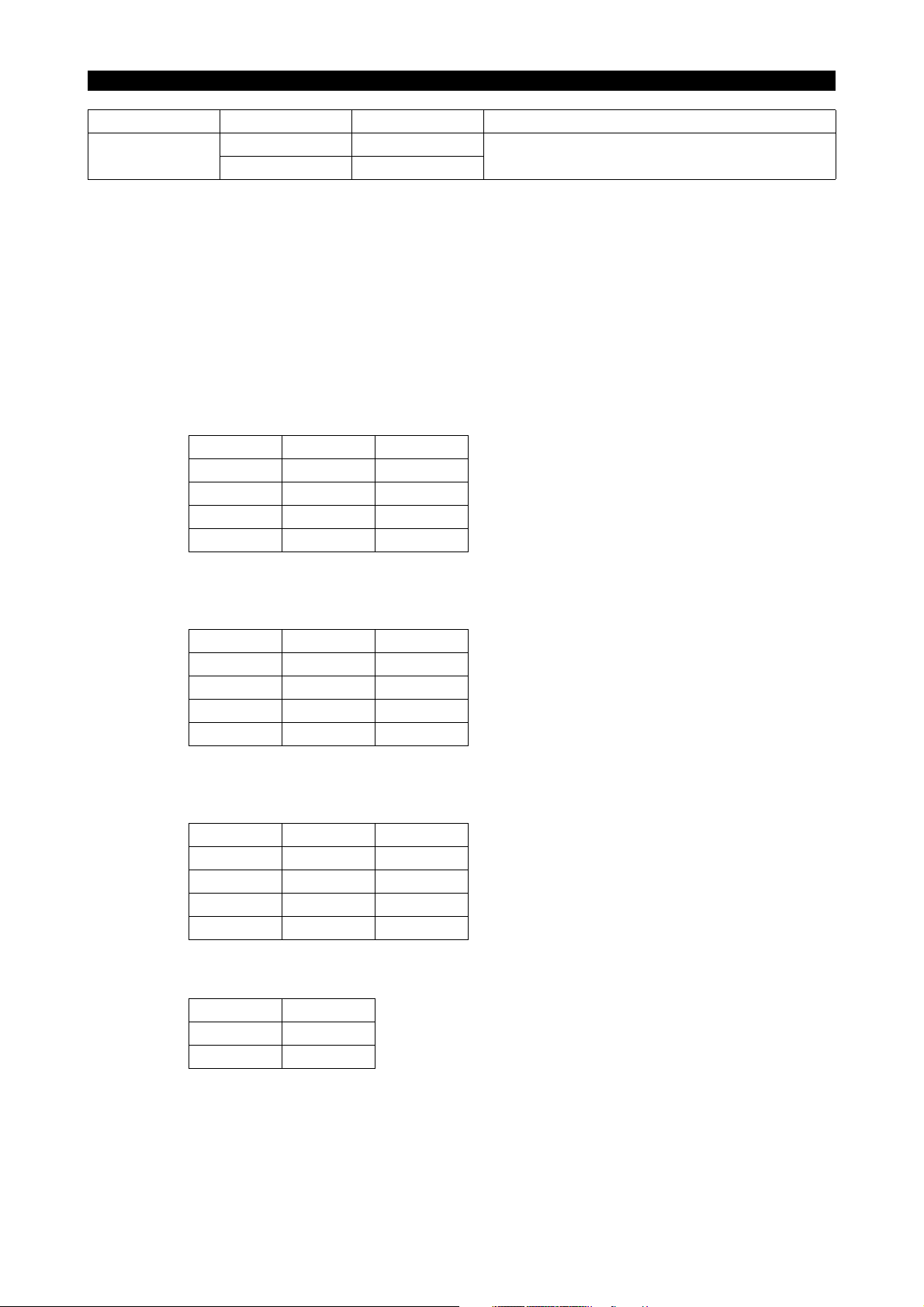

Item

Program running method Method A Method B Method S

Main program

Sub program

Program size

limit

Sub program function Usable Usable Unusable (alarm)

Branch function Usable Usable Unusable (alarm)

Destination of

a jump

specified in

branch

command

Main program sequence label

limit

Program selection time *1 *1 Completed immediately

Library

program

Schedule

program

Main program

Sub program

Library

program

Schedule

program

Program of normal

size

Total program size is

2MB.

Sequence label or

sequence number

Unlimited Unlimited Unlimited

Large program

2GB

Total program size is

about 1.8 MB.

Sequence label or

sequence number

-

Total program size is

about 1.8 MB.

-

*1. Time varies with the selected program size.

(3) Programming Restrictions for the Operation Method

For details of restrictions that must be taken into consideration when writing a program, refer to

SECTION 12, “PSELECT BLOCK”.

(4) Others

• The maximum capacity for running the main program is about 2 GB when the operation

method B is selected.

• The library program capacity is equivalent to the designated library program buffer size.

This means that the library program buffer size is always contained in the operation

capacity even if a library program is not registered.

• The number of subprograms and library programs stored in memory is independent of the

operation buffer size. They are always 126 and 65, respectively.

Page 25

5228-E P-13

SECTION 2 COORDINATE SYSTEMS AND COORDINATE COMMANDS

SECTION 2 COORDINATE SYSTEMS AND COORDI-

NATE COMMANDS

1. Coordinate System

1-1. Coordinate Systems and Values

In order to move a cutting tool to a target position, a coordinate system must be established to

specify the target position using coordinate values in the coordinate system.

The OSP-P200M uses three types of coordinate system (machine coordinate system, work

coordinate system, and local coordinate system). These coordinate systems are briefly explained

below.

• Machine coordinate system

The machine coordinate system is set by the machine tool manufactures. Although the setting

may be changed by the user, machine dependent setting values such as pitch error

compensation data and travel limit values must be changed accordingly.

• Work coordinate system

A work coordinate system is set by the user.

• Local coordinate system

A local coordinate system set temporarily by the commands in a program.

The user can select the coordinate system to be used as needed from the coordinate systems

indicated above.

The coordinate value is represented by components of the axes which make up the coordinate

system. Usually, a maximum of six axis components is used (the number differs depending on

the NC unit specifications.)

Example:

X__Y__Z__W__A__C__

The number of programmable axes, that is, the number of axis components used to define a

coordinate value varies depending on the machine specifications. This manual, therefore, uses

the following designation to indicate a coordinate value.

IP__

1-2. Machine Zero and Machine Coordinate System

The reference point specific to the individual machine is referred to as the machine zero and the

coordinate system having the machine zero as the origin is referred to as the machine coordinate

system.

The machine zero is set for each individual machine using system parameters.

Since the travel end limits and the home positions are set in the machine coordinate system, the

user should not change the location of the machine zero at his/her own discretion.

A cutting tool may not always be moved to the machine zero.

ME33018R1000400010001

Page 26

SECTION 2 COORDINATE SYSTEMS AND COORDINATE COMMANDS

1-3. Work Coordinate System

The coordinate system used to machine workpieces is referred to as the work coordinate system.

• Work coordinate systems are established and stored with work coordinate system numbers in

the memory before starting operation. The desired work coordinate system may be called at

the start of machining.

• Work coordinate systems are set by specifying the distance from the machine zero to the origin

of a work coordinate system as an offset value (work zero offset).

• For details, see SECTION 4, “Selection of Work Coordinate System” and SECTION 4, “Change

of Work Coordinate System”.

1-4. Local Coordinate System

Programming the entire operation of a workpiece using only a work coordinate system may

sometimes be difficult on some portions of the workpiece. In such cases, programming is facilitated

by setting a new coordinate system appropriate for a specific workpiece portion.

The new coordinate system is referred to as a local coordinate system.

5228-E P-14

• The desired local coordinate system can be established by specifying the origin in reference to

the origin of the presently selected work coordinate system and the angle of rotation on the

specified plane about the origin of the local coordinate system to be set with G11. Once a local

coordinate system has been established, all coordinate values are executed in the newly set

local coordinate system.

To change the local coordinate system to another one, the position of the origin of the new local

coordinate system and the angle of rotation about the origin should be specified with G11.

As explained above, a local coordinate system can be established only by specifying the

coordinate values of the origin and the angle of rotation in a program.

• To designate coordinate values in the work coordinate system, cancel the local coordinate

system by specifying G10.

• For details, refer to SECTION 4, “Parallel Shift and Rotation of Coordinates System”.

Coordinate system parallel shift amount

(Specified in a program)

Work zero offset amount

(Set by zero point data)

Machine zero offset amount

(Set by system parameter)

Rotating angle of local coordinate system

Local coordinate system zero point

Work coordinate system zero point

Machine zero

Zero point for position encoder

ME33018R1000400040001

Page 27

SECTION 2 COORDINATE SYSTEMS AND COORDINATE COMMANDS

2. Coordinate Commands

2-1. Numerically Controlled Axes

• The following table lists the addresses to be specified to control the axes.

Address Contents

Basic axis X, Y, Z

Parallel axis U, V, W

Rotary axis A, B, C

Circular

interpolation

parameters

• An axis movement command consists of an axis address, a sign indicating the direction of the

axis movement, and a numeric value which describes the axis movement. Refer to “Absolute

and Incremental Commands” for the designation of numeric values.

l, J, K

R Addresses specifying the radius of an arc

5228-E P-15

Addresses corresponding to the three axes

orthogonal to one another

Addresses of three orthogonal axes parallel

to the basic axes

Addresses of rotary axis in a plane right

angle to the basic axis

Addresses specifying distances, parallel to

an individual axis, from a start point to the

center of an arc

• In this manual, to simplify the explanation for axis designation, “Xp”, “Yp”, and “Zp” are used

instead of the actual axis addresses. They represent the axis as follows:

Xp X-axis and the axis parallel to X-axis (U-axis)

Yp Y-axis and the axis parallel to Y-axis (V-axis)

Zp Z-axis and the axis parallel to Z-axis (W-axis)

• The maximum number of controllable axes is six. This capability varies depending on the NC

model.

• The following table shows the number of simultaneously controllable axes in each of the axis

movement modes.

Number of Simultaneously Controllable Axes

(“n” represents the number of controllable axes.)

Positioning n

Linear interpolation n

Circular interpolation 2

Helical cutting 3

Manual operation 1

Pulse handle operation 1

In pulse handle operation, the optional 3-axis control function is available.

Page 28

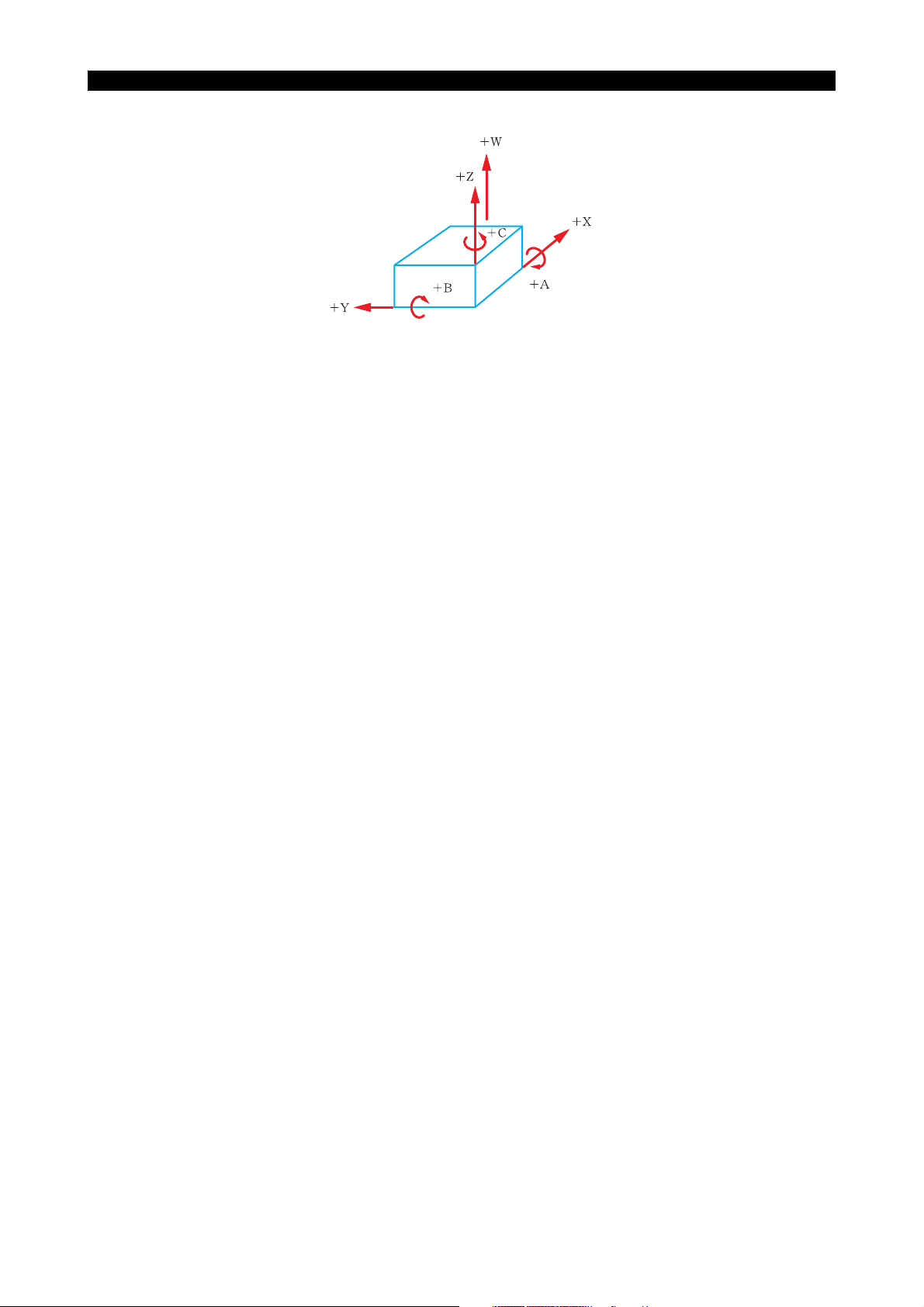

• The positive directions of the linear and rotary axes are defined as follows:

The definition of the coordinate axes and directions conforms to ISO R841.

ISO: International Organization of Standardization

2-2. Unit Systems

The unit systems that can be used in a program are described below. Note that the unit system

selected for programming and the unit system used for setting data such as zero point, tool data,

and parameters are independent of each other. The unit systems to be used for inputting the data

are set at NC optional parameter (INPUT UNIT SYSTEM).

5228-E P-16

SECTION 2 COORDINATE SYSTEMS AND COORDINATE COMMANDS

ME33018R1000400050001

2-2-1. Minimum Input Unit

The minimum input unit is the smallest unit of a value that may be entered in a program. For a linear

axis, the minimum input unit is 0.001 mm or 0.0001 inch.

For the NC with metric / inch switchable specification, the unit system can be selected by the setting

at LENGTH UNIT SYSTEM of NC optional parameter (INPUT UNIT SYSTEM).

For a rotary axis, the minimum input unit is 0.001 degree or 0.0001 degree. Either 0.001 degree or

0.0001 degree can be selected by the setting at ANGLE of NC optional parameter (INPUT UNIT

SYSTEM).

2-2-2. Basic Input Unit

The input unit may be changed to the “basic” unit by the setting at LENGTH of NC optional

parameter (INPUT UNIT SYSTEM). The fundamental units are then 1 mm, 1 inch, 1 degree, and 1

second.

Page 29

SECTION 2 COORDINATE SYSTEMS AND COORDINATE COMMANDS

2-2-3. Numeric Values (inch / metric switchable as optional function)

As the unit for specifying program values, “mm”, “deg.”, “sec”, etc. are used. For these units, a

decimal point may be used.

• Cautions on using a decimal point value

a. A decimal point value must not be used for addresses O, N, G, and M.

b. If a decimal point is not entered in a numeric value, the decimal point is assumed to exist at

the end of the specified numeric value.

c. If a value is set below the specified minimum input unit, the data is processed in the

following manner.

• For addresses S, T, H, D, Q, etc. that require integer type data, the value below the

minimum input unit is truncated.

• For addresses that use real data, the value below the minimum input unit is rounded.

• The input unit of dimension commands is determined by the setting at NC optional parameter

(INPUT UNIT SYSTEM) or NC optional parameter (bit) No. 3, bit 0 to bit 7 and No. 4, bit 0. How

these bits set the input unit is shown below.

5228-E P-17

• NC optional parameter (INPUT UNIT SYSTEM) screen

ME33018R1000400090001

Page 30

SECTION 2 COORDINATE SYSTEMS AND COORDINATE COMMANDS

• NC optional parameter (bit) No. 3, bit 0 to bit 7 and No. 4, bit 0

5228-E P-18

Parameter

No.

3

40

Bit

No.

Sets the unit system of length, “inch” or “mm”.

0

(*2)

1 Sets the unit of 1 mm, 1 inch, 1 deg., and 1 sec.

2 Sets unit of length, “0.01 mm” or “0.001 mm”. 0.01 mm 0.001 mm

Sets the unit of feedrate, 0.1 mm/min, 0.01

3

inch/min, or 1 mm/min, 0.1 inch/min

Sets the unit of feedrate, 0.001 mm/rev, 0.0001

4

inch/rev, or 0.01 mm/rev, 0.001 inch/rev

5 Sets the unit of time, “0.01 sec” or “0.1 sec”. 0.01 sec 0.1 sec

Sets the unit place at “1 mm”, “1 inch”, “1 deg”,

6

and “1 sec” when decimal point input is

selected.

7 Sets the unit time, “0.001 sec” or “0.1 sec”.(*1) 0.001 sec 0.1 sec

Sets the unit of angle, “0.001 deg” or “0.0001

deg”.

Contents

With

Check Mark

inch mm

Unit of 1 mm,

1 inch, 1 deg.,

and 1 sec is

selected.

0.1 mm/min

0.01 inch/min

0.001 mm/rev

0.0001 inch/rev

Unit place is set

at “1 mm”,

“1 inch”,

“1 deg”, and

“1 sec”.

0.0001 deg 0.001 deg

Without

Check Mark

Conforms to the

setting for bit 2

to bit 5 and bit 7

of No. 3 and bit

0 of No. 4.

1 mm/min

0.1 inch/min

0.01 mm/rev

0.001 inch/rev

Conforms to the

setting for bit 1

to bit 5, and bit

7.

*1: The unit of time is always “0.01 sec” if “1” is set for bit 5.

*2: The setting for bit 0 is valid only when the inch/mm switchable specification is selected.

Page 31

SECTION 2 COORDINATE SYSTEMS AND COORDINATE COMMANDS

• Examples of parameter setting are given below.

(●: With check mark, O: Without check mark)

• mm system

• inch system

5228-E P-19

ME33018R1000400090002

ME33018R1000400090003

An asterisk (*) in the table indicates setting of “0” or “1” is allowed.

• µm / mm unit system

The unit system that handles the data in units of mm (inch) for real data and in units of microns

(1/10000 inch) is called the “µm / mm unit system”. For this unit system, the unit is determined

depending on whether or not a decimal point is used in the data when YES is selected at REAL

NUMBER of NC optional parameter (INPUT UNIT SYSTEM). If a decimal point is used, the unit

of “mm (inch)” is set and if a decimal point is not used, the unit of “microns (1/10000 inch)” is

set.

Example 1:

X100.

X100

If an expression or a variable is used for the command of this unit system, the values are

always treated as real data.

Example 2: Local variables

PX 100=

100mm

100µm

PX=X

100mm

PX 100.=

ME33018R1000400090004

PX=X

100mm

ME33018R1000400090005

(The value is not “100 µm”.)

Page 32

5228-E P-20

SECTION 2 COORDINATE SYSTEMS AND COORDINATE COMMANDS

The following is a comparison how a numeric value is interpreted according to whether or not a

decimal point is used when “µm / mm unit system” is selected.

Command Element Value

X 100 100 µm–

X= 100 100 µm–

X 100. 100 mm Decimal point

X= 100. 100 mm Decimal point

X 100+100 200 mm Expression

X= 100.+100 200 mm Expression

X= 100+100. 200 mm Expression

X 100+100*2 300 mm Expression

X= 100+100*2 300 mm Expression

X= 100+100*2.5 350 mm Expression

PK= 100

X= 100+PK

PK= 100.

X= 200-PK

X= 200-100 100 mm Expression

X -100 -100 µm–

X -100. -100 mm Decimal point

X +100 100 µm–

X +100. 100 mm Decimal point

X= ROUND[100] 100 mm (*1) Expression

X= FIX[100.] 100 mm (*1) Expression

X= FUP[-100] -100 mm (*1) Expression

X= ROUND[100.] 100 µm (*2) –

X= FIX[100.] 100 µm (*2) –

X= FUP[-100.] -100 µm (*2) –

200 mm Variable

100 mm Variable

“mm unit system”

element

LA1=4 F=FIX[LA1] 4 mm/min

Variable

(*1) Decimal point is selected for designation of ROUND/FIX/FUP real number command.

(*2) Integer is selected for designation of ROUND/FIX/FUP real number command.

Page 33

SECTION 2 COORDINATE SYSTEMS AND COORDINATE COMMANDS

2-3. Travel Limit Commands (G22, G23) (Optional)

Since the NC is equipped with absolute position encoders, it is possible to set the travel limit with the

software. That is, if the travel limit is set as an absolute value by the software, the limit switch

usually used to detect the travel limit may not be used. If the travel limit is set in this manner, it is

possible to change the travel limit position by changing the travel limit value in a program.

Note that two types of travel limit, one set by the manufacture (factory-set travel limit) and the other

set by the user (user-set travel limit), are provided.

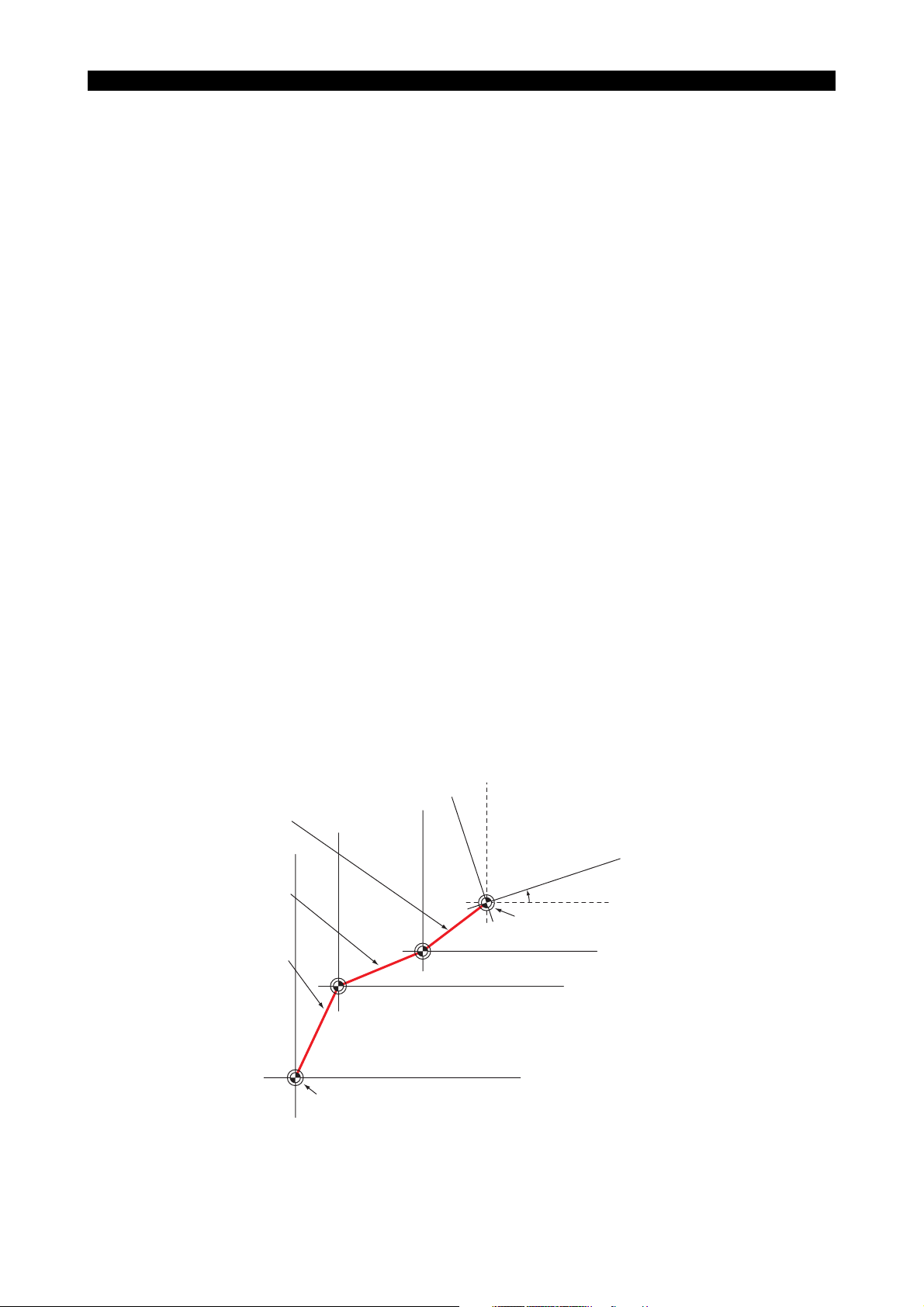

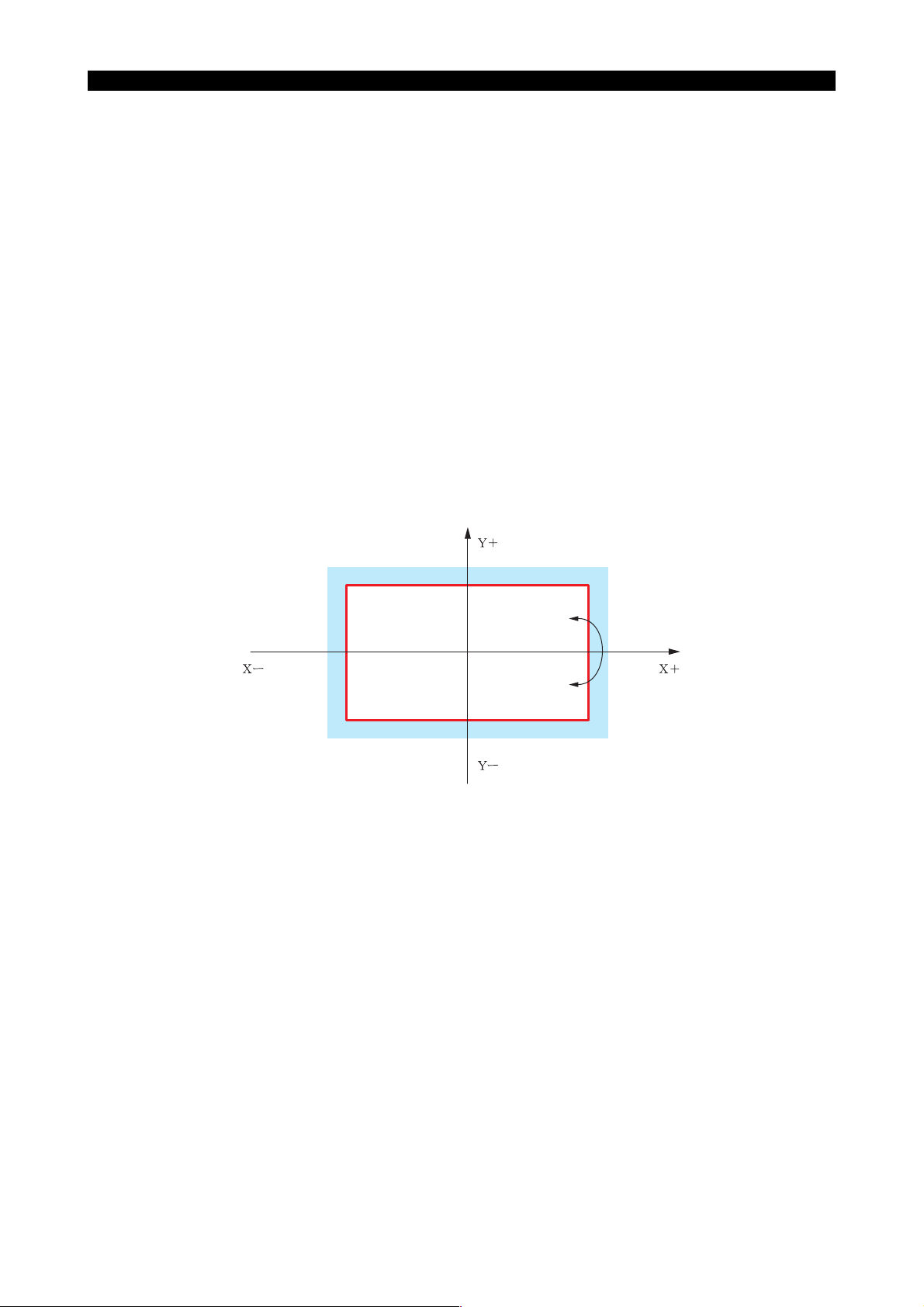

(1) Factory-Set Travel Limit (Soft-Limit)

• The travel limit is set in accordance with the maximum travel distance from the machine

zero of each axis. The travel limits are set both in the positive (P) and negative (N)

directions using the system parameters.

• The area inside of the set values (from the N direction travel limit to the P direction travel

limit) is available for operation (operation permitted area). The outside area is called the

operation inhibited area and axis movements into this area are not allowed.

• The travel limit function always monitors the programmed tool path. If the tool path enters

the operation inhibited area, even if the end point lies in the operation permitted area, this

function disables the tool movement.

5228-E P-21

Operation inhibited area

End point

Start point

ME33018R1000400100001

(2) User-Set Travel Limit (Programmable Limit) (Optional)

The travel limit may be set by the user either with user parameters or by programs using the

programmable travel limit function. Since both settings (user parameter and programmed

command) establish an identical area and since the data is stored in the same area, the data

entered last becomes the valid data, updating the previously set data. For example, when the

travel limits are set using a program after setting them with the user parameters, the travel limit

setting data is replaced with the data set for the user parameters. When setting the travel limits,

both positive (P) and negative (N) direction limit data must be set.

The area between the P and N travel limits is defined as the operation permitted area and that

outside the travel limits is defined as the operation inhibited area.

Page 34

5228-E P-22

SECTION 2 COORDINATE SYSTEMS AND COORDINATE COMMANDS

• Setting the travel limits by a program

[Programming format]

G22 X__Y__Z__α__β__γ__I__J__K__P__Q__R__

X

...........

Y

...........

Z

...........

α

...........

β

...........

γ

...........

I

...........

J

...........

K

...........

P

...........

Q

...........

R

...........

The numeric values entered are processed as coordinate values in the work coordinate

system.

“α”, “β”, and “γ” above do not represent an address. In actual programming, use axis

addresses of the 4th to 6th axis (A, B, C, U, V, and W).

X Programmable limit in the P direction of X-axis

Y Programmable limit in the P direction of Y-axis

Z Programmable limit in the P direction of Z-axis

α Programmable limit in the P direction of 4th-axis

β Programmable limit in the P direction of 5th-axis

γ Programmable limit in the P direction of 6th-axis

I Programmable limit in the N direction of X-axis

J Programmable limit in the N direction of Y-axis

K Programmable limit in the N direction of Z-axis

P Programmable limit in the N direction of 4th-axis

Q Programmable limit in the N direction of 5th-axis

R Programmable limit in the N direction of 6th-axis

ME33018R1000400100002

[Details]

• An alarm occurs if the command indicated above is executed for the machine equipped with a

multi-turn type rotary axis.

• The data set using G22 is backed up and is therefore valid even after the power is turned off.

• If the setting data is outside the factory-set soft limits, an alarm will occur.

• Which of the travel limits - the limits set with the system parameters (soft-limit) or the limits set

with user parameters or by a program (programmable limits) - becomes valid as the operation

permitted area can be set by specifying an appropriate G code.

G22: Selects the travel limits set with user parameters or those newly set by G22 are as the

travel limits and checks the program according to the selected operation permitted area.

G23: Cancels the G22 mode and selects the travel limits set with the system parameters. The

program is checked according to the selected operation permitted area.

If G22 is specified independently, the programmable limit values set with user parameters

become valid.

• For setting the travel limits with user parameters, refer to User Parameter, SECTION 4