Page 1

CNC SYSTEM

OSP-E100M

OSP-E10M

OPERATION MANUAL

(6th Edition)

Pub No. 4290-E-R4 (ME32-083-R6) Aug. 2002

Page 2

SAFETY PRECAUTIONS

4290-E P-(i)

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine

itself from hazards arising from unforeseen accidents. However, operators must not rely exclusively

on these safety devices: they must also become fully familiar with the safety guidelines presented

below to ensure accident-free operation.

This instruction manual and the warning signs attached to the machine cover only those hazards

which Okuma can predict. Be aware that they do not cover all possible hazards.

1. Precautions Relating to Machine Installation

(1) Install the machine at a site where the following conditions (the conditions for achievement of

the guaranteed accuracy) apply.

• Ambient temperature:17 to 25°C

• Ambient humidity:40% to 75% at 20°C (no condensation)

• Site not subject to direct sunlight or excessive vibration; environment as free of dust, acid,

corrosive gases, and salt spray as possible.

(2) Prepare a primary power supply that complies with the following requirements.

• Voltage: 200 V

• Voltage fluctuation: ±10% max.

• Power supply frequency: 50/60 Hz

• Do not draw the primary power supply from a distribution panel that also supplies a major

noise source (for example, an electric welder or electric discharge machine) since this could

cause malfunction of the CNC unit.

Eeoemm1pl001

Eeoemm1pl002

• If possible, connect the machine to a ground not used by any other equipment. If there is no

choice but to use a common ground, the other equipment must not generate a large amount

of noise (such as an electric welder or electric discharge machine).

(3) Installation Environment

Observe the following points when installing the control enclosure.

• Make sure that the CNC unit will not be subject to direct sunlight.

• Make sure that the control enclosure will not be splashed with chips, water, or oil.

• Make sure that the control enclosure and operation panel are not subject to excessive vibra-

tions or shock.

• The permissible ambient temperature range for the control enclosure is 0 to 40°C.

• The permissible ambient humidity range for the control enclosure is 30 to 95% (no conden-

sation).

• The maximum altitude at which the control enclosure can be used is 1000 m (3281ft.).

Page 3

SAFETY PRECAUTIONS

2. Points to Check before Turning on the Power

4290-E P-(ii)

(1) Close all the doors of the control enclosure and operation panel to prevent the entry of water,

chips, and dust.

(2) Make absolutely sure that there is nobody near the moving parts of the machine, and that there

are no obstacles around the machine, before starting machine operation.

(3) When turning on the power, turn on the main power disconnect switch first, then the CONTROL

ON switch on the operation panel.

3. Precautions Relating to Operation

(1) After turning on the power, carry out inspection and adjustment in accordance with the daily

inspection procedure described in this instruction manual.

(2) Use tools whose dimensions and type are appropriate for the work undertaken and the machine

specifications. Do not use badly worn tools since they can cause accidents.

(3) Do not, for any reason, touch the spindle or tool while spindle indexing is in progress since the

spindle could rotate: this is dangerous.

(4) Check that the workpiece and tool are properly secured.

(5) Never touch a workpiece or tool while it is rotating: this is extremely dangerous.

(6) Do not remove chips by hand while machining is in progress since this is dangerous. Always

stop the machine first, then remove the chips with a brush or broom.

(7) Do not operate the machine with any of the safety devices removed. Do not operate the

machine with any of the covers removed unless it is necessary to do so.

Eeoemm1pl003

Eeoemm1pl004

(8) Always stop the machine before mounting or removing a tool.

(9) Do not approach or touch any moving part of the machine while it is operating.

(10) Do not touch any switch or button with wet hands. This is extremely dangerous.

(11) Before using any switch or button on the operation panel, check that it is the one intended.

4. Precautions Relating to the ATC

(1) The tool clamps of the magazine, spindle, etc., are designed for reliability, but it is possible that

a tool could be released and fall in the event of an unforeseen accident, exposing you to danger:

do not touch or approach the ATC mechanism during ATC operation.

(2) Always inspect and change tools in the magazine in the manual magazine interrupt mode.

(3) Remove chips adhering to the magazine at appropriate intervals since they can cause misoper-

ation. Do not use compressed air to remove these chips since it will only push the chips further

in.

(4) If the ATC stops during operation for some reason and it has to be inspected without turning the

power off, do not touch the ATC since it may start moving suddenly.

Eeoemm1pl005

Page 4

5. On Finishing Work

4290-E P-(iii)

SAFETY PRECAUTIONS

(1) On finishing work, clean the vicinity of the machine.

(2) Return the ATC, APC and other equipment to the predetermined retraction position.

(3) Always turn off the power to the machine before leaving it.

(4) To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the

main power disconnect switch.

Eeoemm1pl006

6. Precautions during Maintenance Inspection and When Trouble Occurs

In order to prevent unforeseen accidents, damage to the machine, etc., it is essential to observe the

following points when performing maintenance inspections or during checking when trouble has

occurred.

(1) When trouble occurs, press the emergency stop button on the operation panel to stop the

machine.

(2) Consult the person responsible for maintenance to determine what corrective measures need

to be taken.

(3) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

(4) Use only the specified replacement parts and fuses.

Eeoemm1pl007

(5) Always turn the power off before starting inspection or changing parts.

(6) When parts are removed during inspection or repair work, always replace them as they were

and secure them properly with their screws, etc.

(7) When carrying out inspections in which measuring instruments are used - for example voltage

checks - make sure the instrument is properly calibrated.

(8) Do not keep combustible materials or metals inside the control enclosure or terminal box.

(9) Check that cables and wires are free of damage: damaged cables and wires will cause current

leakage and electric shocks.

(10) Maintenance inside the Control Enclosure

a) Switch the main power disconnect switch OFF before opening the control enclosure door.

b) Even when the main power disconnect switch is OFF, there may some residual charge in

the MCS drive unit (servo/spindle), and for this reason only service personnel are permitted

to perform any work on this unit. Even then, they must observe the following precautions.

• MCS drive unit (servo/spindle)

The residual voltage discharges two minutes after the main switch is turned OFF.

c) The control enclosure contains the NC unit, and the NC unit has a printed circuit board

whose memory stores the machining programs, parameters, etc. In order to ensure that the

contents of this memory will be retained even when the power is switched off, the memory is

supplied with power by a battery. Depending on how the printed circuit boards are handled,

the contents of the memory may be destroyed and for this reason only service personnel

should handle these boards.

Page 5

(11) Periodic Inspection of the Control Enclosure

a) Cleaning the cooling unit

The cooling unit in the door of the control enclosure serves to prevent excessive temperature rise inside the control enclosure and increase the reliability of the NC unit. Inspect the

following points every three months.

• Is the fan motor inside the cooling unit working?

The motor is normal if there is a strong draft from the unit.

• Is the external air inlet blocked?

If it is blocked, clean it with compressed air.

7. General Precautions

4290-E P-(iv)

SAFETY PRECAUTIONS

(1) Keep the vicinity of the machine clean and tidy.

(2) Wear appropriate clothing while working, and follow the instructions of someone with sufficient

training.

(3) Make sure that your clothes and hair cannot become entangled in the machine. Machine opera-

tors must wear safety equipment such as safety shoes and goggles.

(4) Machine operators must read the instruction manual carefully and make sure of the correct pro-

cedure before operating the machine.

(5) Memorize the position of the emergency stop button so that you can press it immediately at any

time and from any position.

(6) Do not access the inside of the control panel, transformer, motor, etc., since they contain high-

voltage terminals and other components which are extremely dangerous.

(7) If two or more persons must work together, establish signals so that they can communicate to

confirm safety before proceeding to each new step.

8. Symbols Used in This Manual

The following warning indications are used in this manual to draw attention to information of particular importance. Read the instructions marked with these symbols carefully and follow them.

Indicates an imminent hazard which, if not avoided, will result in death or serious

DANGER

injury.

Eeoemm1pl008

Eeoemm1pl009

WARNING

CAUTION

NOTICE

Indicates hazards which, if not avoided, could result in death or serious injury.

Indicates hazards which, if not avoided, could result in minor injuries or damage to

devices or equipment.

Indicates precautions relating to operation or use.

Page 6

INTRODUCTION

4290-E P-(i)

INTRODUCTION

Thank you very much for choosing our CNC system. This numerical control system is a expandable

CNC with various features including a multi-main CPU system. Major features of the CNC system

are described below.

(1) Expandable CNC with a multi-main CPU system

A multi-main CPU system on which up to seven engines (main CPUs) can be mounted is used.

An excellent performance and cost effectiveness have been realized as a leader of increasingly

rapid and accurate machine tools. The CNC system can be adapted to any models and variations by changing the construction of the main CPUs. The machine is controlled by a built-in

PLC.

(2) Compact and highly reliable

The CNC system has become compact and highly reliable because of advanced hardware

technology, including UCMB (Universal Compact Main Board), I/O link, and servo link. The

'variable software' as a technical philosophy of the OSPs supported by a flash memory. Functions may be added to the CNC system as required after delivery.

(3) NC operation panels

The following types of NC operation panels are offered to improve the user-friendliness.

• Color CRT operation panels

• Thin color operation panels (horizontal)

• Thin color operation panels (vertical)

One or more of the above types may not be used for some models.

(4) Machining management functions

These functions contribute to the efficient operation of the CNC system and improve the profitability from small quantity production of multiple items and variable quantity production of variations. Major control functions are described below.

Eeoemm1an001

a) Reduction of setup time

With increase in small-volume production, machining data setting is more frequently

needed. The simplified file operation facilitates such troublesome operation. The documents

necessary for setup, such as work instructions, are displayed on the CNC system to eliminate the necessity of controlling drawings and further reduce the setup time.

b) Production Status Monitor

The progress and operation status can be checked on a real-time basis on the screen of the

CNC system.

c) Reduction of troubleshooting time

Correct information is quickly available for troubleshooting.

(5) Help functions

When an alarm is raised, press the help key to view the content of the alarm.

This helps take quick action against the alarm.

To operate the CNC system to its maximum performance, thoroughly read and understand this

instruction manual before use.

Keep this instruction manual at hand so that it will be available when you need a help.

Screens

Different screens are used for different models. Therefore, the

screens used on your CNC system may differ from those shown

in this manual.

Page 7

CONSTRUCTION OF THIS MANUAL

4290-E P-(i)

CONSTRUCTION OF THIS MANUAL

This instruction manual consists of five chapters.

Eeoemm1i1001

FUNDAMENTALS

This chapter describes the specifications, part names, and functions. Description of the part names

and functions includes explanation of switches on the NC operation panels, screen transition, and

basic operations on each screen.

OPERATION

This chapter describes how to operate the machine from the NC operation panel for different operation modes (manual, MDI, and automatic). The on-screen operating procedures are described in

each operation mode.

DATA OPERATION

This chapter describes file operations, programming operations, parameter and data setting and

other data related operations.

Just like the chapter of Operation, descriptions are given by data setting mode (zero setting, tool

data setting, parameter setting, and programming).

APPENDIX

Appendix includes view of operation panels, tables of EIA/ISO codes, and lists of G codes, M codes,

and system variables.

SPECIAL FUNCTIONS (separate manual)

Some of the functions of the machine and CNC system are described. A description of the concept

necessary for functional operations is added for your further understanding.

Page 8

4290-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

FUNDAMENTALS

SECTION 1 PART NAMES AND FUNCTION..................................................................1

1. Operation Panels .......................................................................................................................... 1

1-1. Basic Construction of Operation Panels ................................................................................ 1

1-2. Guide to Controls on Operation Panels ................................................................................. 2

2. SCREENS .................................................................................................................................. 12

2-1. Mode Transition Charts ....................................................................................................... 12

2-2. Screen Operations............................................................................................................... 22

3. One-touch Window Close Operation .......................................................................................... 25

OPERATION

SECTION 1 TURNING THE POWER ON AND OFF.....................................................26

1. Turning the Power ON ................................................................................................................ 26

2. Turning the Power OFF .............................................................................................................. 26

3. Emergency Stop ......................................................................................................................... 26

SECTION 2 OPERATION MODES................................................................................27

1. Operation Mode Basic Screen .................................................................................................... 27

1-1. Screen Display .................................................................................................................... 27

1-2. Pop-up Windows ................................................................................................................. 28

SECTION 3 MANUAL OPERATION..............................................................................30

1. Axis Feed Operations ................................................................................................................. 30

1-1. Manual Rapid Traverse Operation ...................................................................................... 30

1-2. Manual Cutting Feed Operation .......................................................................................... 31

1-3. Pulse Handle Feed .............................................................................................................. 32

2. Spindle Operation ....................................................................................................................... 33

2-1. Starting the Spindle ............................................................................................................. 33

2-2. Stopping the Spindle ........................................................................................................... 33

2-3. Releasing the Spindle.......................................................................................................... 33

2-4. Spindle Orientation .............................................................................................................. 33

3. Indexing the Swivel Head and the Attachment ........................................................................... 34

4. ATC............................................................................................................................................. 35

4-1. ATC Operation..................................................................................................................... 35

4-2. Manual Tool Change Operation .......................................................................................... 43

Page 9

4290-E P-(ii)

TABLE OF CONTENTS

4-3. Manual Magazine Operation ............................................................................................... 45

4-4. Manual Tool Change during Automatic Operation .............................................................. 46

5. APC ............................................................................................................................................ 47

5-1. APC Operation .................................................................................................................... 47

5-2. Automatic APC Operations.................................................................................................. 49

5-3. Manual APC Operation........................................................................................................50

6. Others ......................................................................................................................................... 51

SECTION 4 MDI OPERATION ......................................................................................52

1. Procedure for MDI Operation...................................................................................................... 52

2. Automatic Operation and MDI Operation.................................................................................... 53

3. Subprogram Call in MDI Operation............................................................................................. 54

SECTION 5 AUTOMATIC OPERATION........................................................................55

1. Program Files ............................................................................................................................. 55

2. Program Selection ...................................................................................................................... 57

2-1. Selection of Main/Subprogram ............................................................................................ 57

2-2. Schedule Program Function ................................................................................................ 60

3. Cycle Start and Slide Hold .......................................................................................................... 62

3-1. Cycle Start ........................................................................................................................... 62

3-2. Slide Hold ............................................................................................................................ 63

4. Resetting the NC ........................................................................................................................ 65

5. Sequence Number Search and Mid-Cycle Start ......................................................................... 66

5-1. Sequence Number Search .................................................................................................. 66

5-2. Mid-Cycle Start (Start after Sequence Number Search) ..................................................... 69

6. Return Search and Sequence Restart ....................................................................................... 70

6-1. Return Search ..................................................................................................................... 70

6-2. Sequence Restart ................................................................................................................ 73

7. Sequence Stop (Option) ............................................................................................................. 74

8. Single Block ................................................................................................................................ 76

9. Optional Block Skip..................................................................................................................... 77

10.Program Branch.......................................................................................................................... 77

11.Optional Stop .............................................................................................................................. 77

12.Mirror Image Function................................................................................................................. 78

12-1.Mirror Image (Local Coordinate System)............................................................................ 78

12-2.Mirror Image Function in Work Coordinate System............................................................ 81

13.Override ...................................................................................................................................... 84

13-1.Feedrate Override .............................................................................................................. 84

13-2.Spindle Override ................................................................................................................ 84

14.Manual Intervention and Restart................................................................................................. 85

Page 10

4290-E P-(iii)

TABLE OF CONTENTS

15.Pulse Handle Shift Operation ..................................................................................................... 88

16.Lock Functions............................................................................................................................ 89

16-1.Machine Lock ..................................................................................................................... 89

16-2.Axis Command Cancel ....................................................................................................... 89

16-3.Auxiliary (S.T.M) Function Lock.......................................................................................... 89

17.Dry Run....................................................................................................................................... 90

18.Library Program Registration ...................................................................................................... 91

18-1.Registering a library program ............................................................................................. 92

18-2.Erasing a library program ................................................................................................... 93

18-3.Initializing library program storage buffer area ................................................................... 93

18-4.Specifying the library program storage buffer area size ..................................................... 93

19.Editing Selected Program ........................................................................................................... 94

19-1.Quick Edit Function ............................................................................................................ 94

19-2.Editing the Main Program ...................................................................................................96

20.Operation End Lamp (Option)..................................................................................................... 97

21.Operation End Buzzer (Option) .................................................................................................. 97

22.Alarm Lamp (Option) .................................................................................................................. 97

23.Automatic Power OFF (Option) .................................................................................................. 97

24.Work Counter (Option)................................................................................................................ 98

25.Hour Meter (Option).................................................................................................................... 99

25-1.POWER ON TIME Hour Meter .......................................................................................... 99

25-2.NC RUNNING TIME Hour Meter ....................................................................................... 99

25-3.CUTTING TIME Hour Meter ............................................................................................... 99

25-4.SPINDLE REVOLUTION TIME Hour Meter ...................................................................... 99

SECTION 6 NC OPERATION PANEL/SCREEN DISPLAY.........................................100

1. Actual Position Display ............................................................................................................. 100

1-1. ACTUAL POSITION display screen 1/4 (normal display screen) ...................................... 100

1-2. ACTUAL POSITION display screen 2/4

(RELATIVE ACTUAL POSITION display screen) ............................................................. 103

1-3. ACTUAL POSITION display screen 3/4 (Detail display screen)........................................ 106

1-4. ACTUAL POSITION display screen 4/4 ............................................................................ 107

2. Main Program Display .............................................................................................................. 108

2-1. Main program display screen with machine conditions ..................................................... 108

2-2. Main program display screen with subprogram ................................................................. 109

2-3. Main program display screen with valid G/M code ............................................................ 110

3. Schedule Program Display ....................................................................................................... 111

3-1. Schedule program display screen with machine conditions .............................................. 111

3-2. Schedule program display screen with main program....................................................... 112

4. MDI Program Display................................................................................................................ 113

Page 11

4290-E P-(iv)

TABLE OF CONTENTS

5. Block Data Display.................................................................................................................... 114

SECTION 7 HELP FUNCTION ....................................................................................116

1. Help Screen .............................................................................................................................. 117

1-1. Operation with the function menu...................................................................................... 118

1-2. Selecting Operation from the CONTENTS Screen............................................................ 118

2. The Head CONTENTS Screen of POCKETMANUAL .............................................................. 119

3. Search ...................................................................................................................................... 120

4. Terminating the HELP Screen .................................................................................................. 121

5. Supplement............................................................................................................................... 121

DATA OPERATION

SECTION 1 DATA SETTING MODES.........................................................................122

1. Guide to Modes ........................................................................................................................ 122

SECTION 2 ZERO SETTING.......................................................................................123

1. Work Coordinate System Zero Point ........................................................................................ 123

2. Zero Offset Setting.................................................................................................................... 123

2-1. Basic Procedure for Setting Zero Offset Data ................................................................... 123

2-2. Other Operations ............................................................................................................... 125

SECTION 3 TOOL DATA SETTING ............................................................................126

1. Tool Data Setting Operation ..................................................................................................... 126

1-1. Basic Tool Data Setting Operation .................................................................................... 126

1-2. Other Operations ............................................................................................................... 129

2. Tool Shape ............................................................................................................................... 130

3. ATC Pot Number/Tool Number Correspondence ..................................................................... 133

3-1. Memory Random ATC ....................................................................................................... 133

3-2. ATC with Fixed Addresses (Including Multi-magazine) ..................................................... 137

3-3. Collective clear (TOOL CANCEL) and collective setting (TOOL SET) .............................. 141

SECTION 4 PARAMETER SETTING ..........................................................................142

1. Types of Parameter .................................................................................................................. 142

2. Basic Parameter Setting Operations ........................................................................................ 143

2-1. Parameter Setting Screens ............................................................................................... 143

2-2. Setting Parameters ............................................................................................................ 144

2-3. Other Operations ............................................................................................................... 146

3. SETTING THE PARAMETERS ................................................................................................ 149

3-1. General Parameters ..........................................................................................................149

Page 12

4290-E P-(v)

TABLE OF CONTENTS

3-2. NC Optional Parameters ................................................................................................... 163

3-3. Machine User Parameter................................................................................................... 194

3-4. Machine System Parameter .............................................................................................. 223

SECTION 5 PARAMETER I/O FUNCTION .................................................................231

1. Parameter Input/Output Operations.......................................................................................... 231

1-1. Input................................................................................................................................... 232

1-2. Output................................................................................................................................ 233

1-3. Verify ................................................................................................................................. 238

1-4. Correspondence between Q Numbers and Parameters ................................................... 241

1-5. Tape Format ...................................................................................................................... 244

1-6. Supplementary Explanation of Parameter Input/Output Function ..................................... 245

SECTION 6 PROGRAM OPERATIONS......................................................................247

1. Basic Screen in the Program Operation Mode ......................................................................... 247

1-1. DIRECTORY Screen ......................................................................................................... 247

1-2. PROGRAM EDITING Screen ............................................................................................ 248

2. Program File Operations........................................................................................................... 252

2-1. Changing the Directory Display ......................................................................................... 252

2-2. Creating a New File ........................................................................................................... 257

2-3. Displaying a Program Source............................................................................................ 258

2-4. Copying a File.................................................................................................................... 259

2-5. Renaming a File ................................................................................................................ 261

2-6. Deleting a File.................................................................................................................... 262

2-7. Protecting a File................................................................................................................. 263

2-8. File Operations .................................................................................................................. 264

3. Program Editing Operations ..................................................................................................... 277

3-1. Copy .................................................................................................................................. 279

3-2. Delete ................................................................................................................................ 280

3-3. Paste ................................................................................................................................. 281

3-4. 1 Line Insert ....................................................................................................................... 281

3-5. 1 Character Delete ............................................................................................................ 282

3-6. Overwr/Insert ..................................................................................................................... 282

3-7. Another File ....................................................................................................................... 283

3-8. Find.................................................................................................................................... 286

3-9. Replace ............................................................................................................................. 288

3-10.Line Jump ......................................................................................................................... 290

3-11.Sequence No. Arrange ..................................................................................................... 292

3-12.File Insert .......................................................................................................................... 294

3-13.Save ................................................................................................................................. 296

Page 13

4290-E P-(vi)

TABLE OF CONTENTS

3-14.Quit / Stop......................................................................................................................... 297

3-15.Select & Quit..................................................................................................................... 298

3-16.Power Failure Measures in Direct Editing Mode .............................................................. 299

4. Device Information Operations .................................................................................................300

5. Initialization ............................................................................................................................... 301

6. RS232C .................................................................................................................................... 303

6-1. Input/Output Operation ......................................................................................................304

6-2. Tape Format ...................................................................................................................... 310

6-3. Specifications for RS232C Interface.................................................................................. 312

6-4. Connection with External Device....................................................................................... 314

7. Preference Setting Operations .................................................................................................322

7-1. Date/Time .......................................................................................................................... 323

7-2. File Pattern ........................................................................................................................ 324

7-3. File Format ........................................................................................................................ 325

7-4. Sort .................................................................................................................................... 326

7-5. % Code Operation ............................................................................................................. 327

7-6. Edit Mode Property ............................................................................................................ 328

7-7. Display Property ................................................................................................................ 329

APPENDIX

SECTION 1 APPENDED FIGURES ............................................................................330

1. Optional Parameter................................................................................................................... 330

Page 14

FUNDAMENTALS

Page 15

SECTION 1 PART NAMES AND FUNCTION

SECTION 1 PART NAMES AND FUNCTION

1. Operation Panels

1-1. Basic Construction of Operation Panels

4290-E P-1

The machine has eight human-machine interfaces with different applications:

(1) NC Operation Panel

Used for operations other than those in the manual mode, such as file operations and data setting.

(2) Machine Operation Panel

Features the switches and keys used mainly for manual operation.

(3) Option Panel

Used with special machine specifications that require additional switches and indicating lamps.

The arrangement of the switches and indicating lamps differs depending on the selected

optional specification.

(4) Manual Tool Change Panel

Used for changing tools manually.

The arrangement of the switches differs depending on the machine model.

(5) Manual Magazine Operation Panel

Used for operating the magazine manually.

The arrangement of the switches differs depending on the machine model.

(6) APC Operation Panel (for Parallel Type 2-Pallet APC)

Used for operating the pallet changer manually.

The arrangement of the switches differs depending on the machine model.

(7) AAC Operation Panel

Used for changing attachments manually.

(8) Manual Attachment Tool Change Panel

Used for changing tools manually for attachment.

Eeoemm1b2001

Page 16

SECTION 1 PART NAMES AND FUNCTION

1-2. Guide to Controls on Operation Panels

1-2-1. Operation Mode Selection Keys

4290-E P-2

(1) AUTO Key

Pressed to select the automatic operation mode, in which a part program stored in the memory disk (MD) is read to the working memory

of the NC and executed.

(2) MDI Key

Pressed to select the MDI operation mode, in which a program is

written one block at a time from the keyboard of the NC operation

panel and executed in the same way as in automatic operation.

(3) MANUAL Key

Pressed to select the manual operation mode, in which the manual

operation switches on the machine operation panel, pulse handle

operation box, etc., are used to operate the machine.

1-2-2. Data Setting Mode Selection Keys

(1) EDIT AUX. Key

Pressed to select the program operation mode, in which program

files and data files can be edited, punched, printed, displayed, and

deleted.

(2) PARAMETER Key

Pressed to select the parameter mode, in which the following

parameters are set: system parameter, user parameter, common

variables, NC optional parameter, machine system parameter and

machine user parameter.

Eeoemm1b2002

Eeoemm1b2003

P

(3) ZERO SET Key

Pressed to select the zero set mode, in which the zero offset data is

set.

(4) TOOL DATA Key

Pressed to select the tool data mode, in which the tool length offset

data, cutter radius compensation data, ATC tool data, and tool management data can be set, changed, or displayed.

(5) MacMan Key

Pressed to select the MacMan mode, in which the machining management function can be used.

MacMan

Page 17

1-2-3. NC Status Indicating Lamps

4290-E P-3

SECTION 1 PART NAMES AND FUNCTION

S.T.M

Eeoemm1b2004

?

(1) RUN Lamp

This lamp is lit while the machine is actually operating in the automatic or MDI mode.

(2) S.T.M Lamp

This lamp is lit while S (spindle), T (tool), or M (miscellaneous) operation is being executed.

(3) SLIDE HOLD Lamp

This lamp goes on when the [SLIDE HOLD] button is pressed.

(4) PROGRAM STOP Lamp

This lamp is lit during a program stop (M00) or optional stop (M01) in the automatic or MDI

mode.

It blinks during dwell (G04).

(5) LIMIT Lamp

This lamp goes on when an axis reaches the variable limit position.

(6) ALARM Lamp

This lamp goes at the occurrence of an alarm.

Note that it does not light when a warning message is displayed due to erroneous operation.

Page 18

SECTION 1 PART NAMES AND FUNCTION

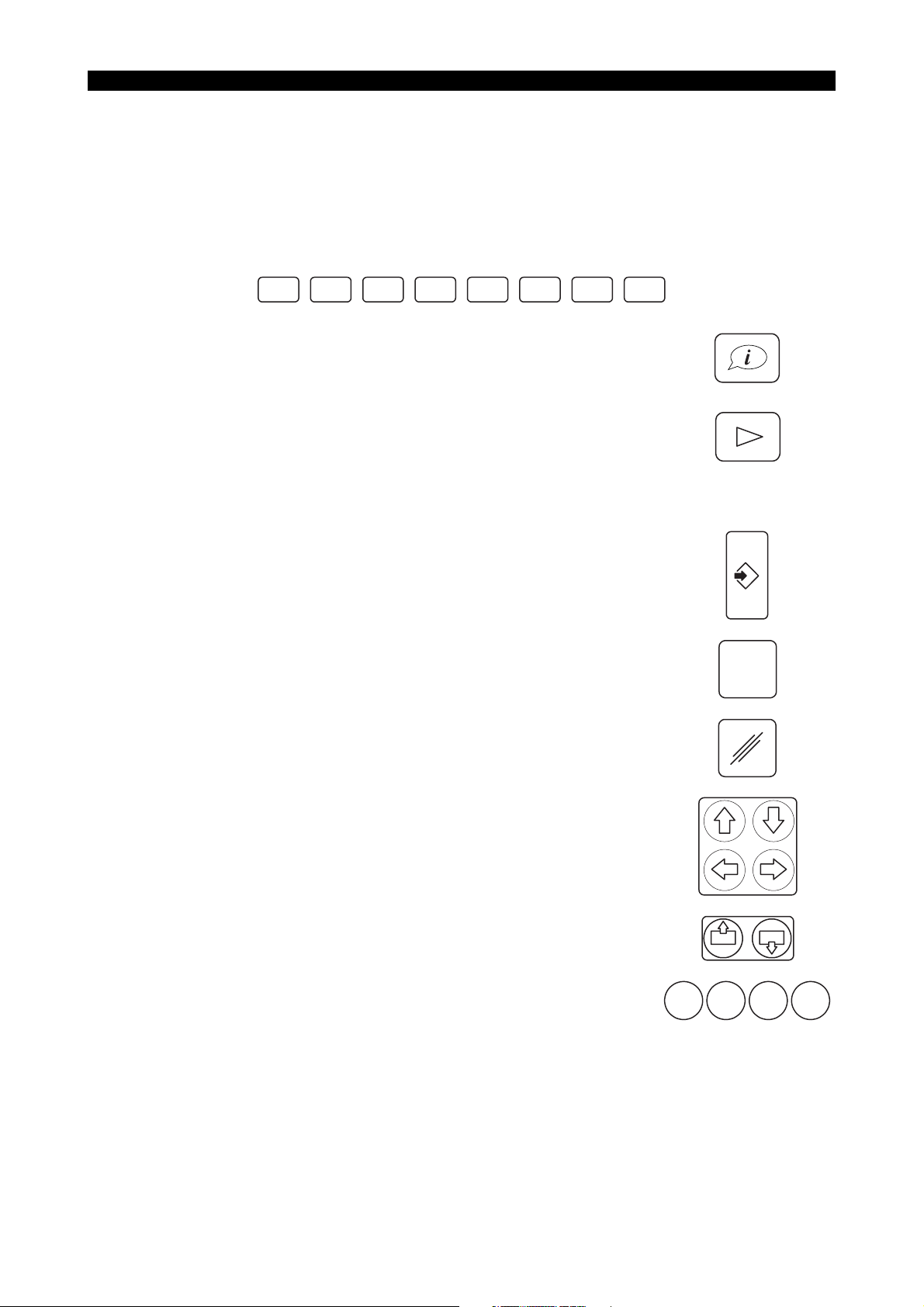

1-2-4. Other Controls on the NC Operation Panel

4290-E P-4

(1) Function Keys: F1 to F8

When the operator selects an operation mode, the functions (operations) available in the

selected mode are displayed on the bottom line of the screen. The function keys (F1 to F8) correspond to the displays for individual functions, and the functions are executed by pressing the

corresponding function key.

Only those functions that are valid in the current step of an operation and the currently selected

mode are displayed.

F1 F2 F3 F4 F5 F6

(2) Help Key

This key is located to the left of function key [F1].

It is used to display descriptions of alarms which occur during

machine operation, and the alarm history.

(3) Extend key

This key is located to the right of function key [F8].

It is functional only when a triangular mark is displayed at the right

end of the function menu. It is used when all of the accessible items

in a function menu cannot be displayed at one time; pressing the

[Extend] key changes the function menu.

(4) WRITE Key

Press this key to select an operation, and to confirm data after inputting it.

F7 F8

Eeoemm1b2005

(5) BS (Backspace) Key

Used when you have made a mistake in inputting data. Pressing this

key deletes the character input last.

(6) CANCEL Key

Used when you have made a mistake in inputting data. Pressing this

key deletes a line of data that has not been confirmed.

(7) Cursor Keys

These keys move the screen cursor in the directions indicated on

the keys.

(8) Page Keys

If the information called out is displayed in more than one page, the

page keys are used to change the display page.

(9) Operator Keys

These keys are used when multiple data have to be input with operators during program editing or when setting data.

BS

+

P

-

P

/

*

Page 19

SECTION 1 PART NAMES AND FUNCTION

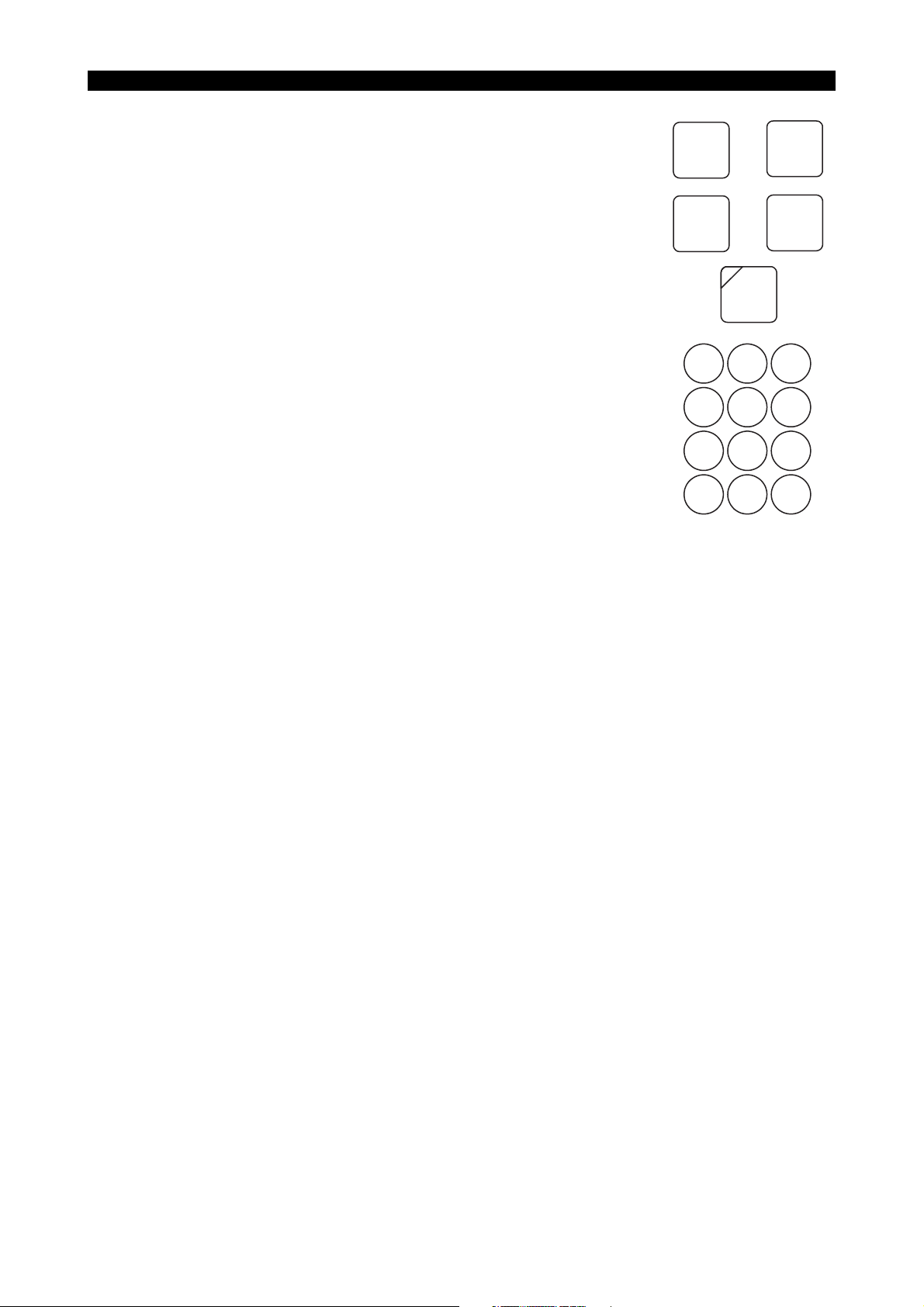

(10) Character Keys

Character keys are used to input characters for data input, program

operation, and file editing operations.

To input the character shown at the upper right corner of a key top,

press the key while holding down the [UPPER CASE] key.

While the [CAPS LOCK] key is pressed (indicating lamp at the upper

left corner of the key lit), these input upper case letters of the alphabet (A to Z). When the [CAPS LOCK] key is not pressed, lower case

letters (a to z) are input.

(11) Ten Keys

The ten keys are used to input numbers for data input, program

operations, and file editing operations.

!

A

SHIFT

7

4

1

0

4290-E P-5

to

+

CAPS

LOCK

8

5

2

.

;

Z

!

A

9

6

3

=

Page 20

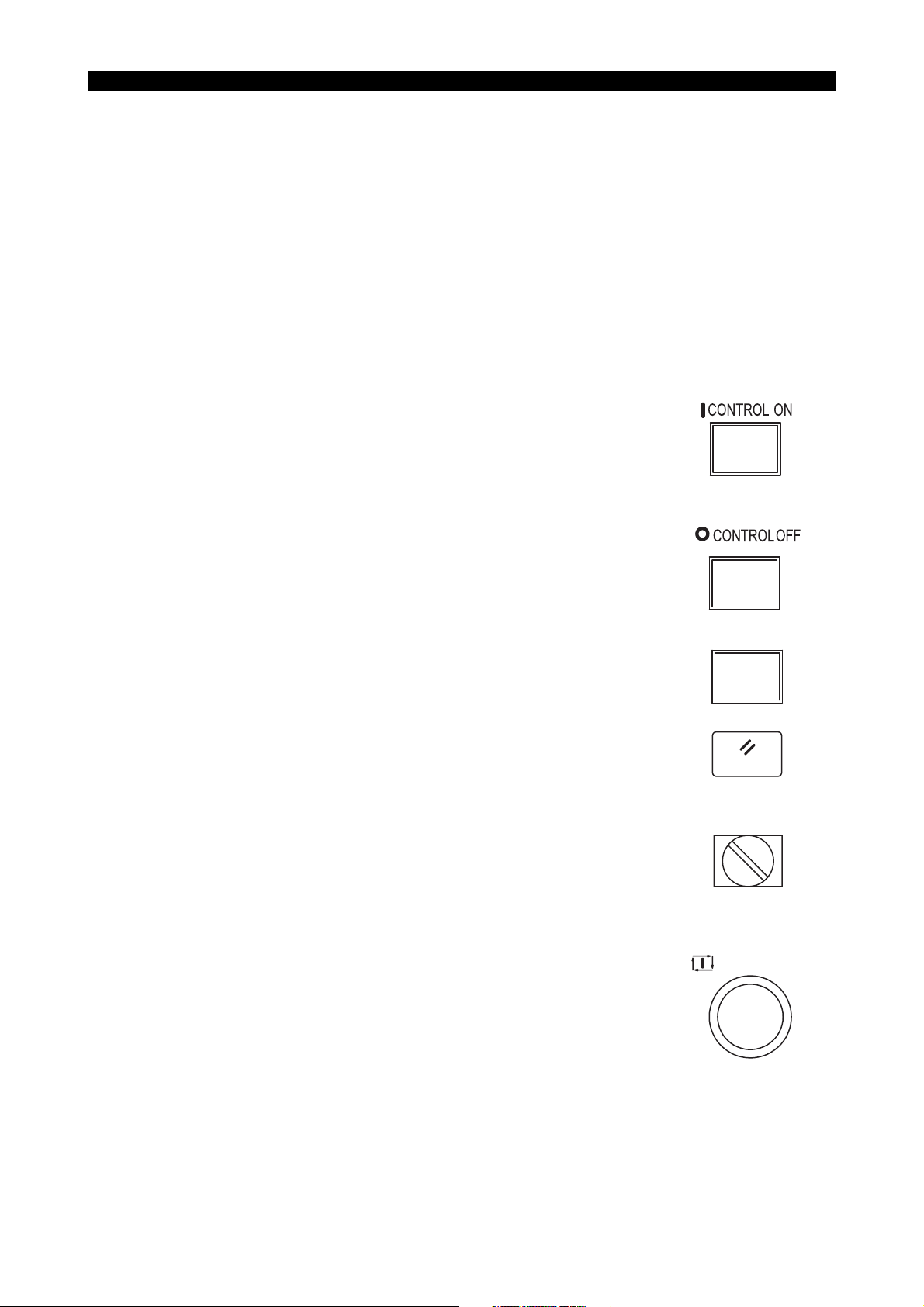

1-2-5. Controls on the Machine Operation Panel

4290-E P-6

SECTION 1 PART NAMES AND FUNCTION

The flat keys on the machine operation panel have the features indicated below depending on

whether or not they have indicating lamps.

< Flat keys with an indicating lamp >

The indicating lamp in a key indicates if the function of the key is valid or not.

• Indicating lamp lit: Key function is valid.

• Indicating lamp unlit: Key function is invalid.

< Flat keys without an indicating lamp >

The function of the key is in effect only while the key is held down. While the key is not being

pressed, the function is not in effect.

(1) CONTROL ON Switch

It operates only after the main switch of the machine has been

turned on.

The pilot lamp in this switch lights when the control power is turned

on.

If the [EMERGENCY STOP] button is pressed, the pilot lamp in this

switch goes off. To recover from the emergency stop state, press

the [CONTROL ON] switch again.

(2) CONTROL OFF Switch

When shutting off the power, turn off the control power first by pressing the [CONTROL OFF] switch before turning off the main switch of

the machine.

Eeoemm1b2006

(3) RESTART Switch

This switch is used, for example, to restart the operation which has

been interrupted due to the door interlock function. To restart the

suspended operation, press the [RESTART] switch and then the

[CYCLE START] button.

(4) RESET Switch

Used to recover normal operation when the machine is in the

stopped state due, for example, to an alarm.

(5) NC PANEL Switch

When the UNLOCK position is selected, all operations at the NC

and machine operation panels are enabled.

When the EDIT LOCK position is selected, operations in the program operation (EDIT AUX) mode and (PARAMETER) mode are

disabled.

When the LOCK position is selected, all operations at the NC operation panel are disabled.

(6) CYCLE START Button

The [CYCLE START] button is used to start machine operation as

directed by the commands that have been given.

The CYCLE START signal is output when this button is released

after being pressed.

RESTART

RESET

NC PANEL

EDIT

UNLOCK LOCK

LOCK

CYCLE START

Page 21

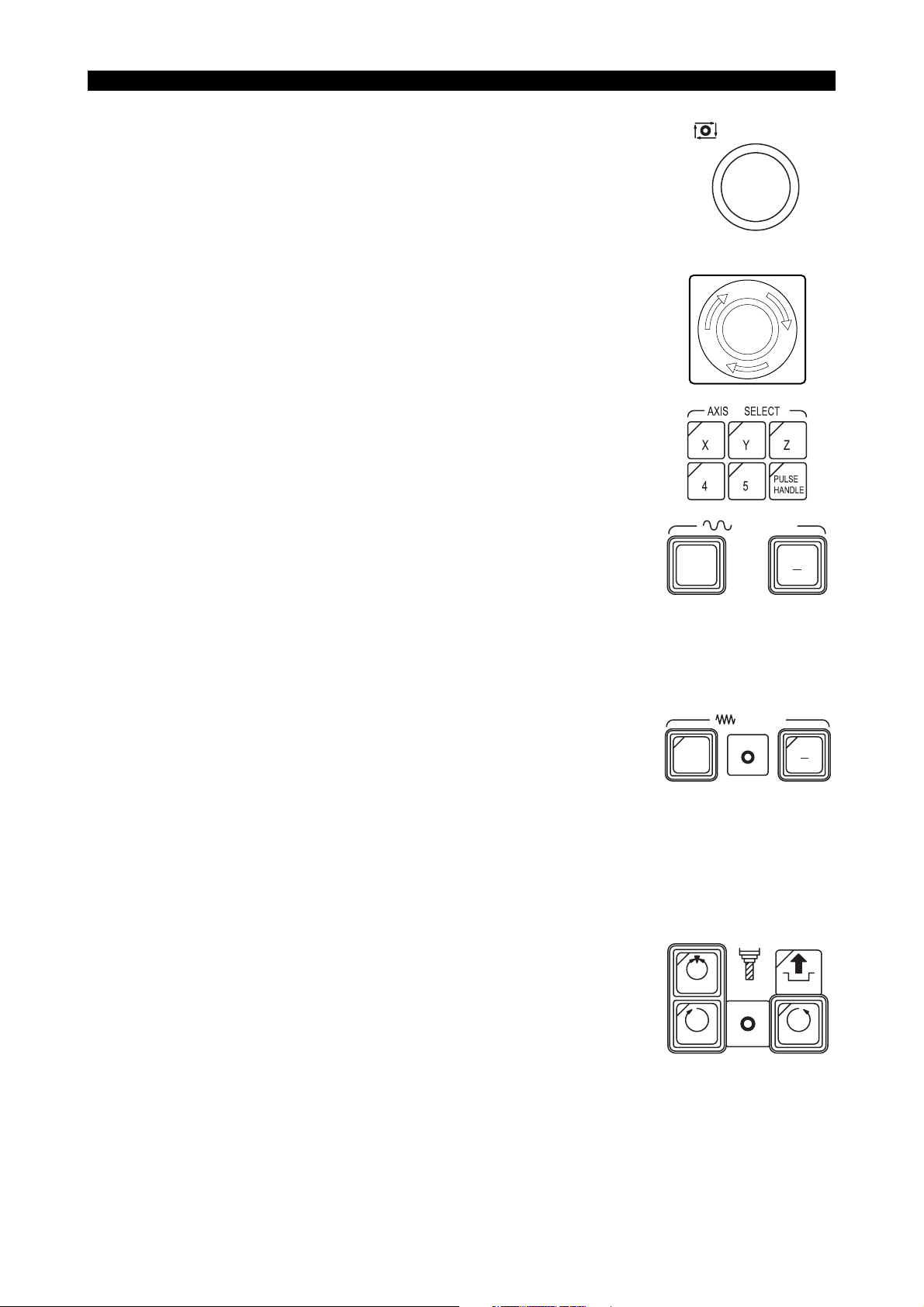

SECTION 1 PART NAMES AND FUNCTION

(7) SLIDE HOLD Button

Pressing this button stops motion on the X-, Y-, and Z-axis immediately. To resume axis movements, press the [CYCLE START] button.

If none of the X-, Y-, and Z-axes is moving when this button is

pressed, the slide hold state is established when the current

sequence is completed, or when the next axis motion starts.

4290-E P-7

SLIDE HOLD

(8) EMERGENCY STOP Button

This shuts off the power supply to the machine with the NC power

kept active.

To release the emergency stop state, unlock the [EMERGENCY

STOP] button and press the [CONTROL ON] button.

(9) AXIS SELECT Keys

These keys are used to select the axis to be moved manually (rapid

feed, cutting feed).

To move an axis using the pulse handle, select [PULSE HANDLE].

(10) RAPID Keys

These keys are used to move the axis selected by the [AXIS

SELECT] key at a rapid traverse rate in the direction indicated in a

key.

The selected axis moves at a rapid traverse rate only while the

[RAPID] key is held pressed.

[Supplement]

Rapid traverse rate differs depending on the machine model and specifications.

EMG. STOP

RAPID

+

(11) JOG Keys

These keys are used to move the axis selected by the [AXIS

SELECT] key at a cutting feedrate in the direction indicated in a key.

Once a key is pressed, the axis keeps moving even if it is released.

To stop axis feed, press the [STOP] key.

[Supplement]

Cutting feedrate differs depending on the machine model and specifications.

(12) SPINDLE STOP Key

Used to stop the spindle manually.

(13) SPINDLE CW Key

Used to start the spindle in the forward (CW) direction.

(14) SPINDLE CCW Key

Used to start the spindle in the reverse (CCW) direction.

(15) SPINDLE ORIENTATION Key

Used to stop the spindle at the preset angular position.

To execute spindle orientation, press the [SPINDLE ORIENTATION] key while pressing the [INTERLOCK RELEASE] button.

JOG

+

ORIENTATION

SPINDLE

CW CCW

RELEASE

STOP

Page 22

SECTION 1 PART NAMES AND FUNCTION

(16) SPINDLE RELEASE Key

Used to set the spindle free (neutral position).

[Supplement]

Spindle speeds differ depending on the machine model and specifications.

4290-E P-8

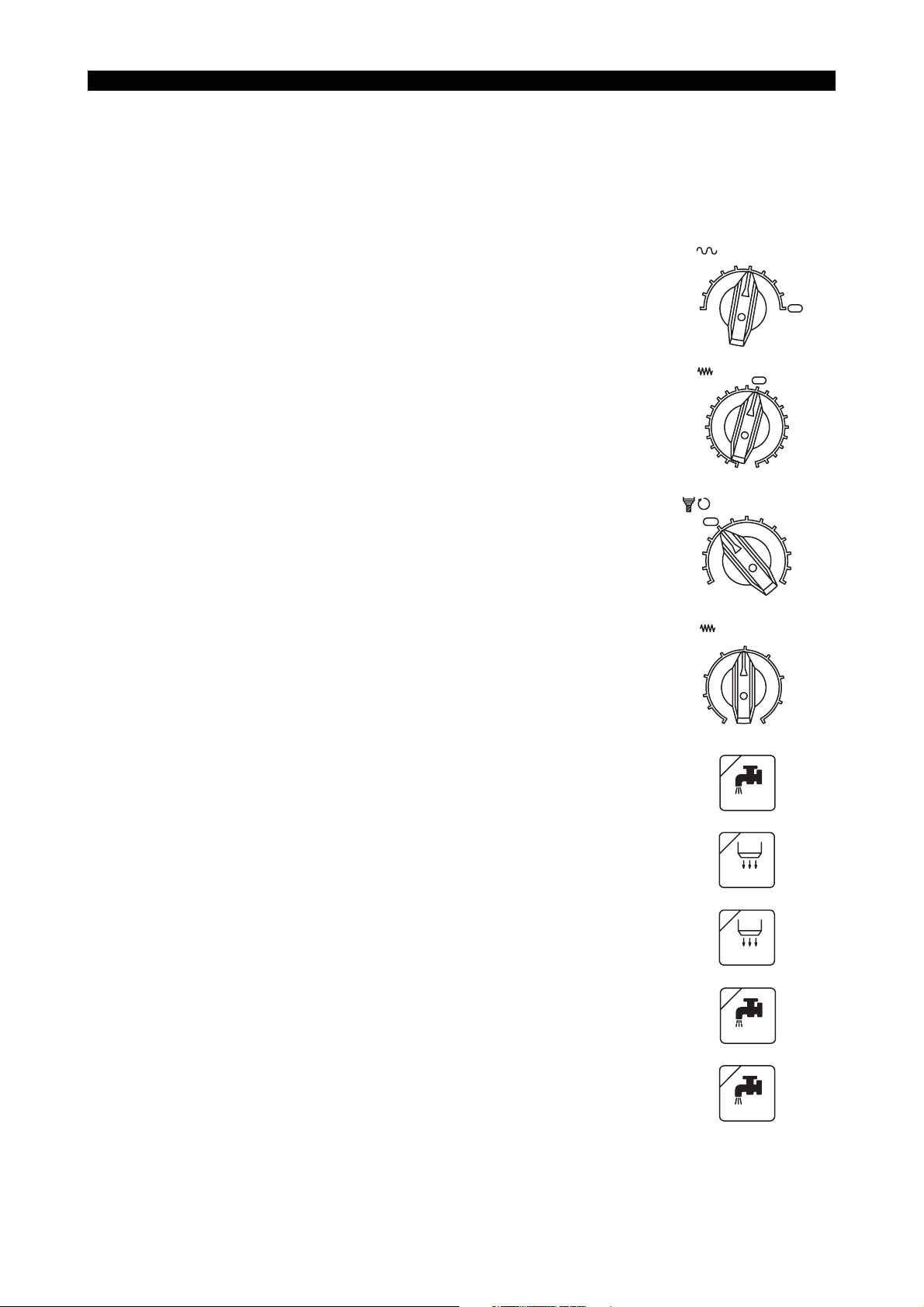

(17) RAPID OVERRIDE Dial

Used to set the desired override value to be applied to the rapid

traverse rate.

(18) FEEDRATE Override Dial

Used to set the desired override value to be applied to the feedrate

specified in a program.

(19) SPINDLE OVERRIDE Dial

Used to set the desired override value to be applied to the spindle

speed specified in a program.

(20) JOG SPEED Dial

The [JOG SPEED] dial is used to set jog feedrate (cutting feedrate).

(21) COOLANT Key

Used to turn on coolant supply.

RAPID

OVERRIDE

%

5030

10

5

1

0

70

60

50

40

30

20

10

%

100

90

80

70

50

500

20

8

200

100

4

50

2

0.04

FEEDRATE

%

95

90

80

5

0

SPINDLE

120

110

(inch/min)

(mm/min)

1000

1

70

80

100

105

110

170

180

200

OVERRIDE

130

140

JOG

SPEED

40

2000

10000

90

120

130

150

160

150

200

80

4000

6000

400

100

140

160

180

160

240

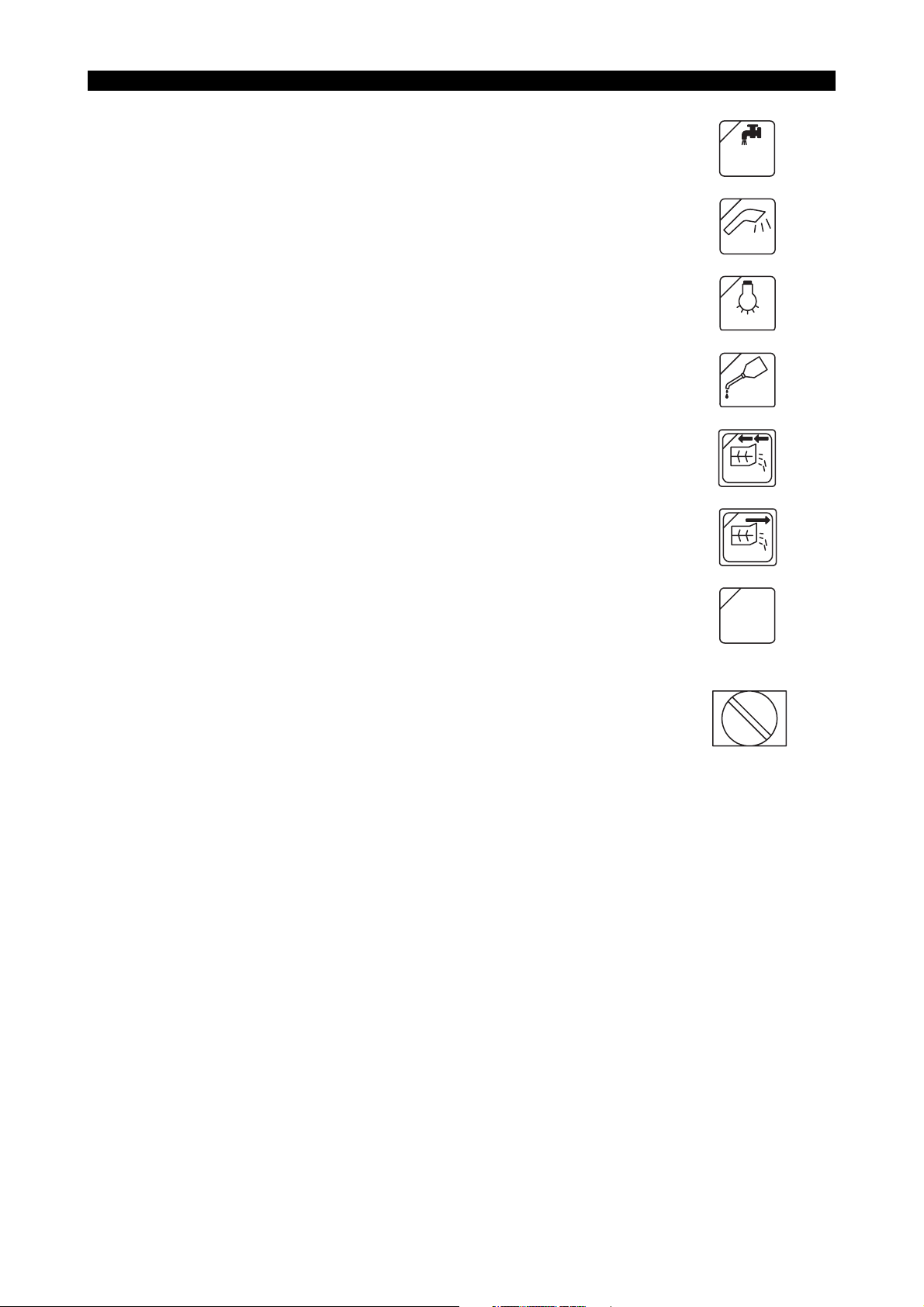

(22) A.B NOZ. Key

(23) A.B ADAPT. Key

(24) OIL MIST Key

(25) OIL HOLE Key

COOLANT

NOZB.A

.

ADAPTB

.

.A

MISTOIL

OIL HOLE

Page 23

(26) OIL HOLE HIGH Key

(27) SHOWER Key

(28) LIGHT Key

(29) LUB. Key

(30) CHIP CON. Reverse Key

Used to operate the chip conveyor in the reverse direction.

The chip conveyor operates only while the key is pressed.

(31) CHIP CON. Forward Key

Used to operate the chip conveyor in the forward direction.

4290-E P-9

SECTION 1 PART NAMES AND FUNCTION

OIL HOLE

HIGH

SHOWER

LIGHT

LUB.

CHIP CON

.

(32) DISPLAY OFF Key

While this function is in effect, the indicating lamp at the upper left

corner of the key is lit.

(33) Door Interlock Mode Selector Switch

For details of the door interlock function, refer to the Instruction

Manual for Safety Door Interlock Function separately issued.

CONCHIP

DISPLAY

OFF

PRODUCTION

SETTING

.

TEST

Page 24

1-2-6. Mode Selection Keys

4290-E P-10

SECTION 1 PART NAMES AND FUNCTION

These switches are used to select the operation mode for program operation.

Eeoemm1b2007

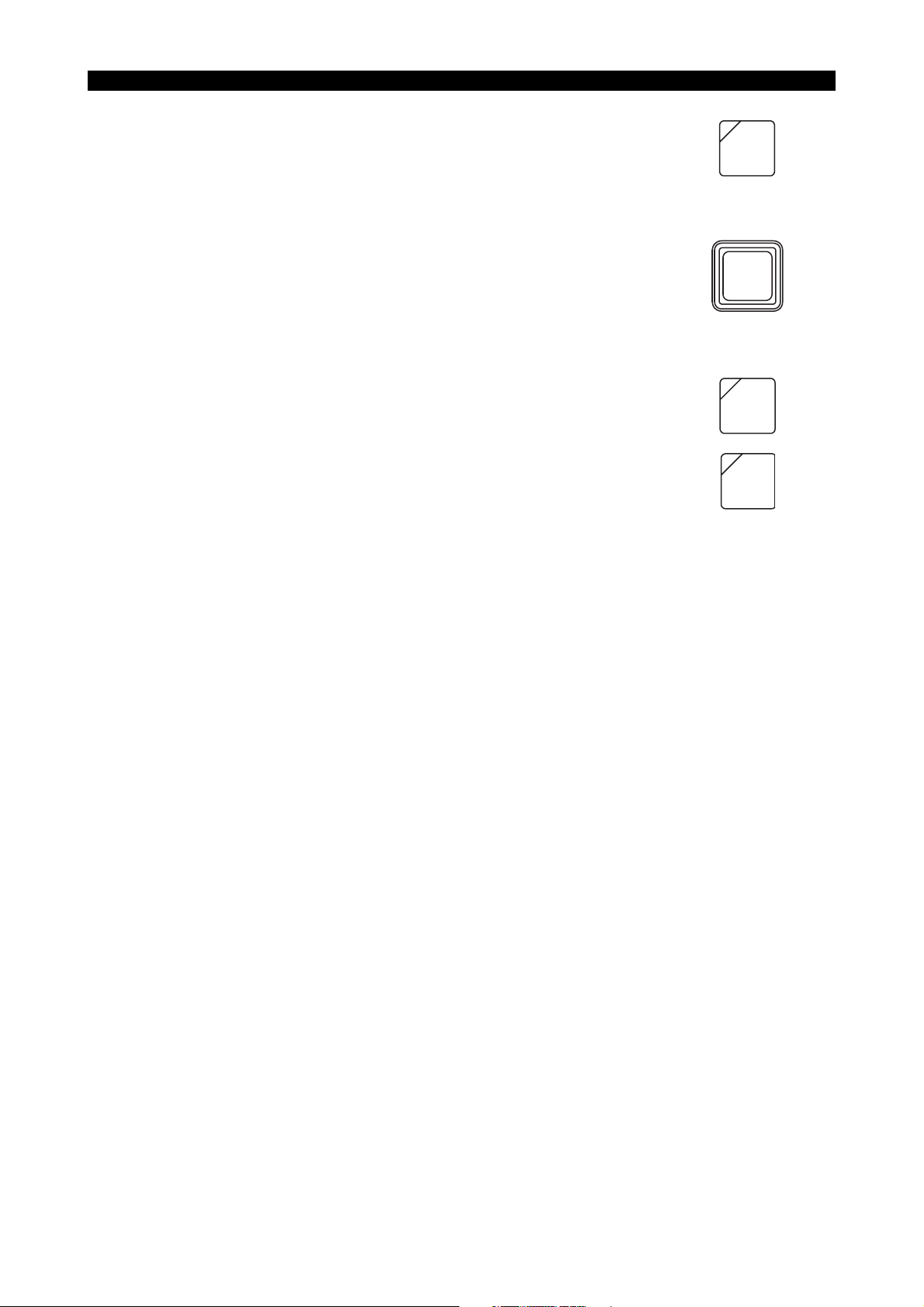

(1) SINGLE BLOCK Key

Used to execute a program block by block.

When this key is valid, the indicating lamp at the upper left corner

lights.

The [CYCLE START] button has to be pressed to execute each successive block.

SINGLE

BLOCK

When the [SINGLE BLOCK] key is invalid (indicating lamp at the

upper left corner unlit), program blocks are executed continuously.

(2) BLOCK SKIP Key

Used to ignore the commands between a slash (/) code and “CR”

code.

When this key is valid, the indicating lamp at the upper left corner

lights.

BLOCK

SKIP

When the [BLOCK SKIP] key is invalid (indicating lamp at the upper

left corner unlit), commands entered after a slash code (/) are executed.

[Supplement]

A slash code (/) must be placed at the start of a program block or immediately after the

sequence number (or sequence name) of a block.

(3) PROGRAM BRANCH Key

Used to execute a program branch instruction in a part program.

The indicating lamp at the upper left corner of the key is lit when the

program branch function is valid.

When the [PROGRAM BRANCH] key is invalid (indicating lamp at

the upper left corner of the key unlit), a program branch instruction in

PROGRAM

BRANCH

1

a part program is not executed.

(4) OPTIONAL STOP Key

Used to stop program operations including spindle rotation and coolant supply.

When this key is valid, the indicating lamp at the upper left corner

lights.

Pressing the [CYCLE START] button in this condition recovers the

OPTIONAL

STOP

state before the stop and starts continuous program execution.

When the [OPTIONAL STOP] key is invalid (indicating lamp at the

upper left corner unlit), program execution proceeds even if a block

containing M01 is executed.

PROGRAM

BRANCH

2

(5) CYCLE STOP Key

Used to stop the operation after the completion of a main program

while the operation is controlled by a schedule program.

When this key is valid, the indicating lamp at the upper left corner

lights.

When the [CYCLE STOP] key is invalid (indicating lamp at the upper

left corner unlit), the operation continues even after the completion

of a main program while the operation is controlled by a schedule

program.

CYCLE

STOP

Page 25

4290-E P-11

SECTION 1 PART NAMES AND FUNCTION

(6) AXIS COM. CANCEL Key

Used to cancel the operation of the specified axis. Designation of an

axis made using a parameter.

When the [AXIS COM. CANCEL] key is valid, the indicating lamp at

AXIS

COM.

CANCEL

the upper left corner lights.

(7) S.T.M LOCK Key

Used to lock miscellaneous functions and enable only axis movements.

S

LOCK

(8) DRY RUN Key

Used to execute axis feed commands (commands in G01, G02, G03

mode, etc.) at the feedrate set with the JOG SPEED dial. The feedrate commands specified in a program are disregarded.

When the [DRY RUN] key is valid, the indicating lamp at the upper

left corner lights.

DRY

RUN

When the [DRY RUN] key is invalid (indicating lamp at the upper left

corner unlit), the axes are fed at the feedrates specified in the program.

[Supplement]

To change the dry run function ON/OFF state, press the [DRY RUN] key while holding down

the [INTERLOCK RELEASE] key.

MT

...

(9) MACHINE LOCK Key

Used to execute a program without actual machine operations.

When the [MACHINE LOCK] key is valid, the indicating lamp at the

upper left corner lights.

If a program is executed with the machine lock function ON, the

actual position display is updated according to the commands as the

program is run. The block data display is also updated. Resetting

MACHINE

LOCK

the CNC restores the display prior to the machine lock.

When the [MACHINE LOCK] key is invalid (indicating lamp at the

upper left corner unlit), commands specifying machine operations

are actually executed.

[Supplement]

To change the machine lock function ON/OFF state, press the [MACHINE LOCK] key while

holding down the [INTERLOCK RELEASE] key.

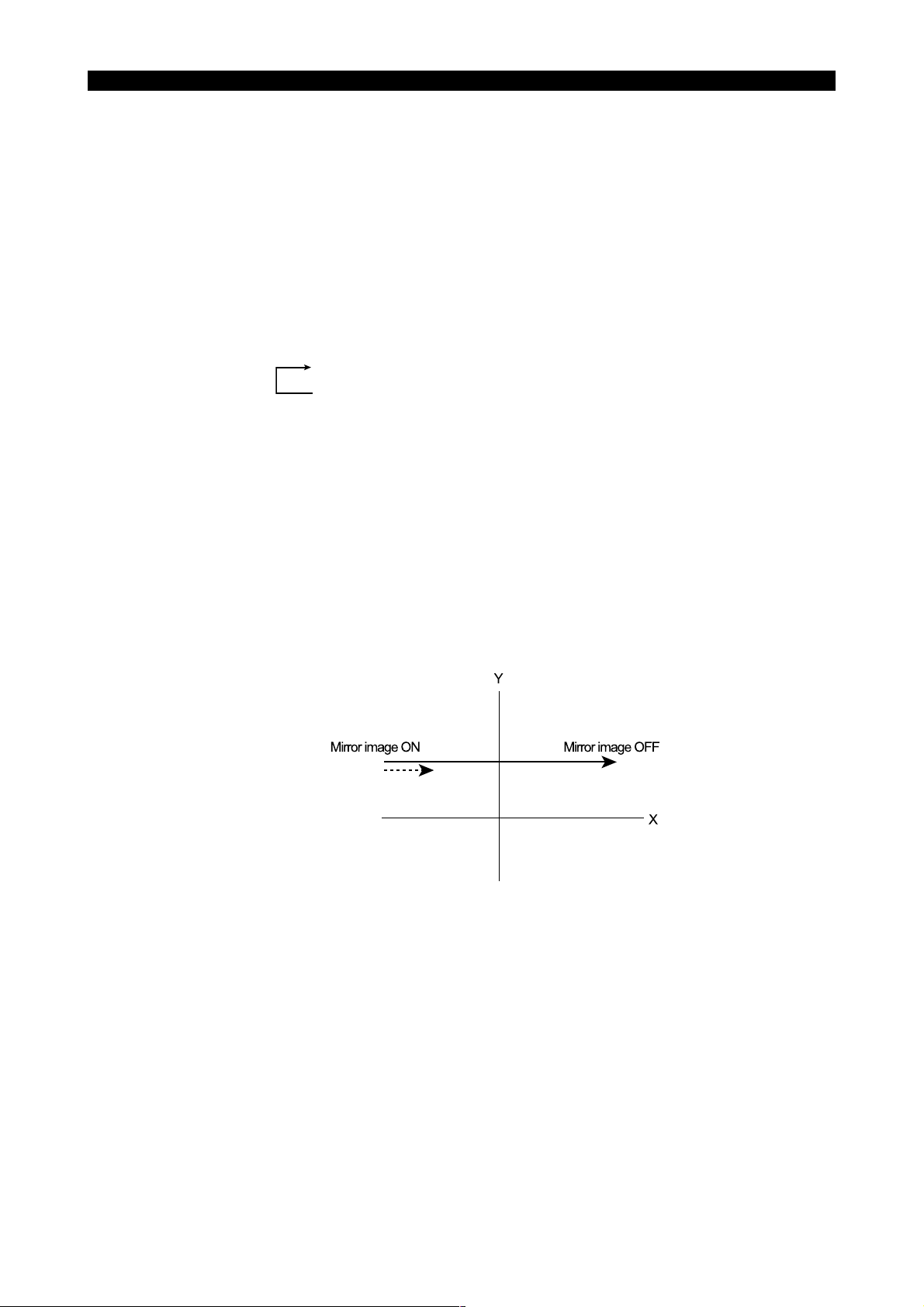

(10) MIRROR IMAGE Keys

Used to reverse the sign of the coordinate value.

When the [MIRROR IMAGE] key is valid, the indicating

lamp at the upper left corner lights.

When the [MIRROR IMAGE] key is invalid (indicating

MIRROR

IMAGE

X

MIRROR

IMAGE

Y

MIRROR

IMAGE

Z

lamp at the upper left corner unlit), the sign of the specified coordinate value is not reversed.

MIRROR

IMAGE

4

[Supplement]

To change the mirror image function ON/OFF state, press the [MIRROR IMAGE] key while

holding down the [INTERLOCK] key.

Page 26

SECTION 1 PART NAMES AND FUNCTION

(11) INTERLOCK RELEASE Key

This key must be held down when the corresponding mode key is

pressed in order to establish or cancel the dry run mode, machine

lock mode or mirror image mode.

The indicating lamp at the upper left corner of the key is lit, and the

key function is valid, only while the key is pressed.

(12) SEQUENCE RESTART Key

Used during program operation to start a part program from part

way through.

When performing manual operation by interrupting an automatic

operation by pressing the [MID AUTO MANUAL] key, the axes can

be returned to the position where automatic operation was interrupted by pressing the [SEQUENCE RESTART] key.

(13) MID AUTO MANUAL Key

Used to interrupt automatic or MDI mode operation to perform manual operation.

(14) PULSE HANDLE SHIFT Key

Used to add axis movements performed by turning the pulse handle

to the operation executed according to the commands in a part program.

4290-E P-12

INTER

LOCK

RELEASE

SEQUENCE

RESTART

MID.

AUTO

MANUAL

PULSE

HANDLE

SHIFT

2. SCREENS

2-1. Mode Transition Charts

Note that the screens displayed depend on the machine specifications.

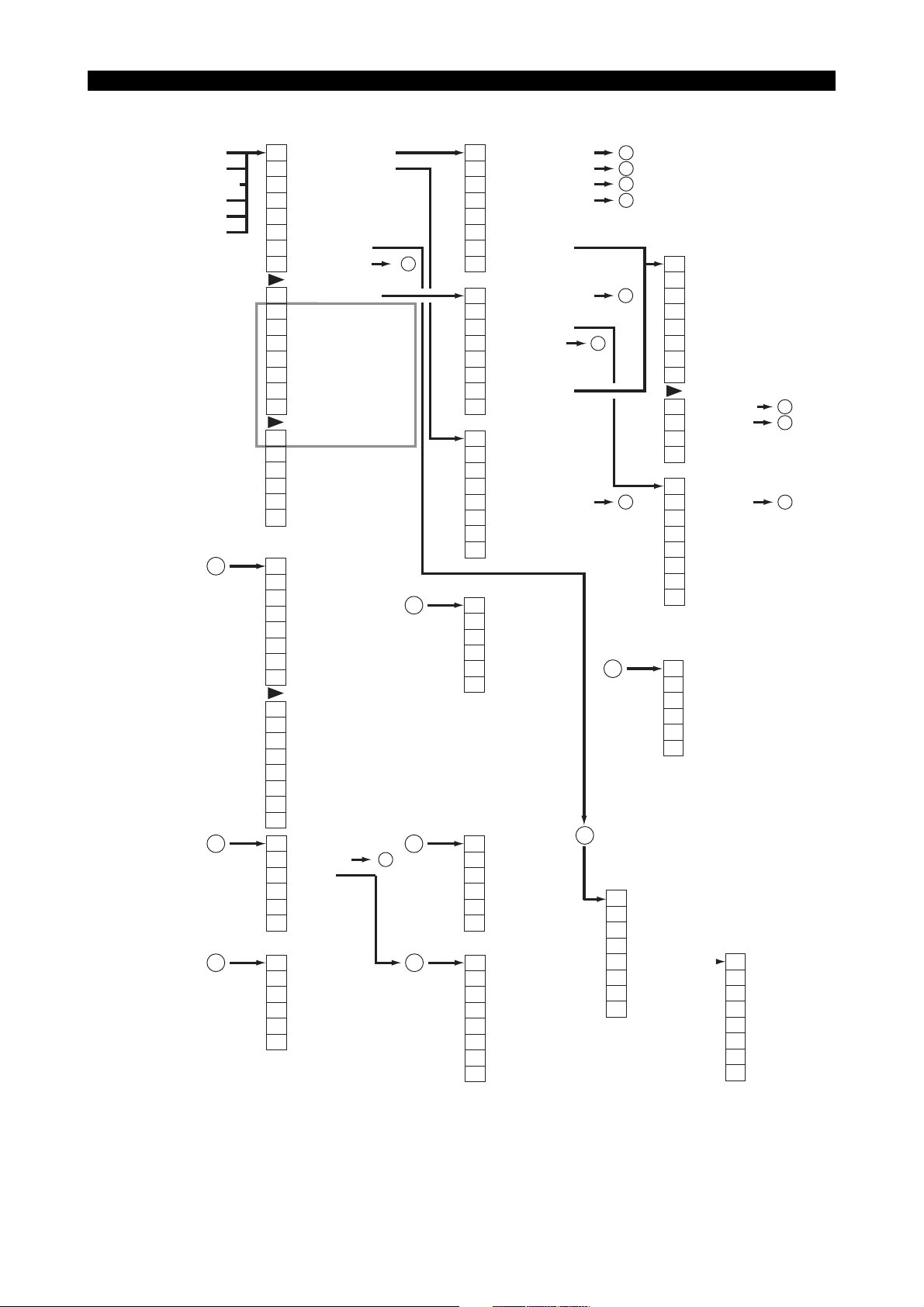

Eeoemm1b2008

Page 27

SECTION 1 PART NAMES AND FUNCTION

2-1-1. Operation Modes (Automatic / MDI / Manual)

4290-E P-13

ACTUAL POSITION

MAIN PROGRAM

SCHEDULE PROGRAM

MDI PROGRAM

FEED AXIS DATA

BLOCK DATA

1

2

3

F1

MAIN PRG_OPER

F2

ACT_POSI ENLARGE

F3

LOAD ON/OFF

F4

ANIMATE ON/OFF

F5

PROGRAM ON/OFF

F6

QUICK EDIT

F7

NC OPR MONITOR

F8

DISPLAY CHANGE

F1

SCHEDULE PRG_OPR

F2

LIBRARY PROGRAM

F3

F4

PROGRAM MESSAGE

F5

TOOL ON/OFF

F6

TOOL LIST DISPLAY

F7

F8

DISPLAY CHANGE

F1

PARAM.F1 SET

F2

F3

:

F7

F8

F1

F2

F3

F4

F5

F6

F7

F8

F1

F2

F3

F4

F5

F6

F7

F8

F1

F2

F3

:

F7

F8

F1

F2

F3

:

F7

F8

* Refer to next page.

ACTUAL POSITION

MAIN PROGRAM

SCHEDULE PROGRAM

MDI PROGRAM

ANIMATED SIMULATE

CLOSE

MENU CHANGE

DISPLAY PROPERTY

CLOSE

FILE NAME

SORT

OK

CANCEL

OK

CANCEL

F1

PROGRAM SELECT

F2

RESTART

F3

NUMBER STOP

F4

NUMBER SEARCH

F5

EXEC/READ

F6

QUICK EDIT

F7

MAIN PRG_EDIT

F8

1

* Displayed only when [F4] (RELATIVE ACT. POSI) is selected.

4

5

3

6

CLOSE

F1

PROGRAM SELECT

F2

F3

PROGRAM ENTRY

F4

NUMBER SEARCH

F5

SCHEDULE PRG_EDIT

F6

QUICK EDIT

F7

MAIN PRG_EDIT

F8

CLOSE

F1

ACT. POSI (WORK)

F2

ACT. POSI (LOCAL)

F3

MACHINE ACT. POSI

F4

RELATIVE ACT. POSI

F5

POSI SET RELATIVE*

F6

SHIFT ON/OFF

F7

F8

CLOSE

F1

F2

:

F6

ENTRY

F7

ENTRY CANCEL

F8

CLOSE

F1

F2

:

F6

LAST

F7

OK

F8

CLOSE

F1

FILE NAME

F2

SIZE

F3

DATE (UP)

F4

DATE (DOWN)

F5

EXT.

F6

F7

UNSORT

F8

CLOSE

18

3

7

F1

F2

F3

F4

F5

F6

F7

F8

2

Eeoemm1b2020

5

4

3

F1

F2

F3

2

F4

F5

F6

F7

F8

F1

F2

:

F8

F1

F2

7

F3

F4

F5

F6

F7

F8

F1

F2

F3

:

F7

F8

SET

ADD

RELATION PARA.

BACKUP

CLOSE

COPY

DELETE

PASTE

1 LINE INSERT

1-CHAR DELETE

OVER WR/INSERT

PROGRAM SELECT

QUIT

FIND/REPLACE

JUMP

FILE NAME

SORT

ENTRY

ENTRY CANCEL

CLOSE

CLOSE

F1

MENU

F2

F3

:

:

:

F7

BACKUP

F8

CLOSE

EIOEMM1B2025R01

10

11

3

Page 28

ACTUAL POSITION

MAIN PROGRAM

SCHEDULE

MDI PROGRAM

FEED AXIS DATA

BLOCK DATA

* Refer to previous page.

F1

MAIN PRG_OPER

F2

ACT_POSI ENLARGE

F3

LOAD ON/OFF

F4

ANIMATE ON/OFF

F5

PROGRAM ON/OFF

F6

QUICK EDIT

F7

NC OPR MONITOR

F8

DISPLAY CHANGE

4290-E P-14

SECTION 1 PART NAMES AND FUNCTION

F1

TOOL LIST SELECT

F2

LACK & DISUSED

F3

16

F4

F5

DATA CHANGE

F6

F7

F8

CLOSE

10

F1

SCHEDULE PRG_OPER

F2

LIBRARY PROGRAM

F3

F4

PROGRAM MESSAGE

F5

TOOL ON/OFF

F6

TOOL LIST DISPLAY

F7

F8

DISPLAY CHANGE

F1

PARAM. F1 SET

F2

F3

:

F7

F8

F1

F2

F3

F4

F5

F6

FIND

F7

REPLACE

F8

CLOSE

11

F1

REGIS.

F2

ERASE

F3

INIT

F4

BUFFER SIZE

F5

F6

F7

F8

1

F1

F2

F3

F4

F5

F6

F7

F8

CLOSE

F1

F2

:

F6

F7

F8

TOP PAGE

LAST PAGE

FORWARD

BACK

TOP

CANCEL

2

3

CLOSE

F1

F2

F3

F4

F5

F6

F7

F8

F1

F2

F3

F4

F5

F6

F7

F8

YES

NO

SET

ADD

ACCEL

DECEL

BACKUP

CLOSE

EIOEMM1B2026R01

Page 29

4290-E P-15

SECTION 1 PART NAMES AND FUNCTION

ANIMATED SIMULATION

< > : 3D MODE

F1

MAIN PRG_OPER

F2

TRACE/ANIMATE <TRACE/MATERIAL>

F3

MATERIAL DRAWING

F4

ERASE

F5

PROGRAM ON/OFF

F6

QUICK EDIT

F7

HIGH DRAW

F8

DISPLAY CHANGE

F1

SCHEDULE PRG_OPER

F2

ACT_POSI ENLARGE

F3

LOAD ON/OFF

F4

TOOL ON/OFF

F5

SPLIT/SOLID <SECTION ON/OFF>

F6

<TRNSPRNT ON/OFF>

F7

AUTO SCALE

F8

DISPLAY CHANGE

F1

2D/3D CHANGE

F2

RESTART

F3

GRAPHIC DATA

F4

AREA CHANGE

F5

<ANGLE CHANGE>*

F6

<SECTION CHANGE>

F7

NC OPR MONITOR

F8

DISPLAY CHANGE

Displayed only when a solid

*

drawing is selected with

SPLIT/SOLID in 2D mode.

1

5

8

1

F1

PROGRAM SELECT

F2

RESTART

F3

NUMBER STOP

F4

NUMBER SEARCH

F5

EXEC/READ

F6

QUICK EDIT

F7

MAIN PRG_EDIT

F8

CLOSE

F1

PROGRAM SELECT

F2

F3

PROGRAM ENTRY

F4

NUMBER SEARCH

F5

SCHEDULE PRG EDIT

F6

QUICK EDIT

F7

MAIN PRG_EDIT

F8

CLOSE

F1

ACT. POSI (WORK)

F2

ACT. POSI (LOCAL)

F3

MACHIN ACT. POSI

F4

RELATIVE ACT. POSI

F5

POSI SET RELATIVE*

F6

SHIFT ON/OFF

F7

F8

CLOSE

* Displayed only when [F4] (RELATIVE ACT. POSI)

is selected.

F1

MAGNI.

F2

REDUCE

F3

F4

PLANE/SIDE <NONE>

F5

F6

F7

F8

CLOSE

5

4

3

3

7

2

F1

COPY

F2

DELETE

F3

PASTE

F4

1 LINE INSERT

F5

1-CHAR DELETE

F6

OVER WR/INSERT

F7

PROGRAM SELECT

F8

QUIT

F1

FIND/REPLACE

F2

JUMP

:

F8

F1

F2

FILE NAME

F3

SORT

F4

F5

F6

ENTRY

F7

ENTRY CANCEL

F8

CLOSE

10

11

3

6

F1

DOWN ROTARY

F2

UP ROTARY

F3

RIGHT ROTARY

F4

LEFT ROTARY

F5

F6

F7

F8

CLOSE

F1

Y-Z PL.

F2

Z-X PL.

F3

X-Y PL.

F4

F5

F6

F7

F8

CLOSE

EIOEMM1B2027R01

Page 30

4290-E P-16

SECTION 1 PART NAMES AND FUNCTION

GAUGING RESULTS

F1

MAIN PRG_OPER

F2

ACT_POSI ENLARGE

F3

LOAD ON/OFF

F4

ANIMATE ON/OFF

F5

PROGRAM ON/OFF

F6

QUICK EDIT

F7

F8

DISPLAY CHANGE

F1

SCHEDULE PRG_OPER

F2

TOOL/ZERO

F3

TOOL

ON/OFF

F4

MSB ZERO ON/OFF

F5

MSB TOOL ON/OFF

F6

SENSstat ON/OFF

F7

VARIOUS ON/OFF

F8

DISPLAY CHANGE

F1

PROGRAM SELECT

F2

RESTART

F3

NUMBER STOP

F4

NUMBER SEARCH

F5

EXEC/READ

F6

QUICK EDIT

F7

MAIN PRG_EDIT

F8

1

7

1

CLOSE

F1

PROGRAM SELECT

F2

F3

PROGRAM ENTRY

F4

NUMBER SEARCH

F5

SCHEDULE PRG_OPER

F6

QUICK EDIT

F7

MAIN PRG_EDIT

F8

CLOSE

F1

ACT. POSI (WORK)

F2

ACT. POSI (LOCAL)

F3

MACHINE ACT. POSI

F4

RELATIVE ACT. POSI

F5

POSI SET RELATIVE*

F6

SHIFT ON/OFF

F7

F8

CLOSE

* Displayed only when [F4] (RELATIVE ACT. POSI)

is selected.

2

5

4

3

F1

COPY

F2

DELETE

F3

2

3

7

PASTE

F4

1 LINE INSERT

F5

1-CHAR DELETE

F6

OVER WR/INSERT

F7

PROGRAM SELECT

F8

QUIT

F1

FIND/REPLACE

F2

JUMP

:

F8

F1

F2

FILE NAME

F3

SORT

F4

F5

F6

ENTRY

F7

ENTRY CANCEL

F8

CLOSE

10

11

3

6

NC AXIS DATA

DIAGNOSIS

PLC DATA DISPLAY

F1

STANDARD

F2

MAGNI.

F3

F4

F5

F6

F7

F8

DISPLAY CHANGE

F1

REFER/CHANGE

F2

F3

F4

F5

F6

F7

F8

DISPLAY CHANGE

F1

(BIT ON)

F2

(BIT OFF)

F3

(FORCED ON/OFF)

F4

SEARCH

F5

F6

ID CHANGE

F7

F8

DISPLAY CHANGE

MEMORY DATA

1

M CODE DISPLAY

1

PLC MODULE SKIP

F1

F2

:

F6

F7

OK

F8

1

CANCEL

F1

REFER/CHANGE

F2

ADDRESS UP

F3

ADDRESS DOWN

F4

F5

F6

F7

F8

DISPLAY CHANGE

F1

F2

F3

F4

SEARCH

F5

F6

F7

F8

DISPLAY CHANGE

F1

F2

F3

F4

LABEL/PROGRAM

F5

F6

F7

F8

DISPLAY CHANGE

1

1

1

EIOEMM1B2028R01

Page 31

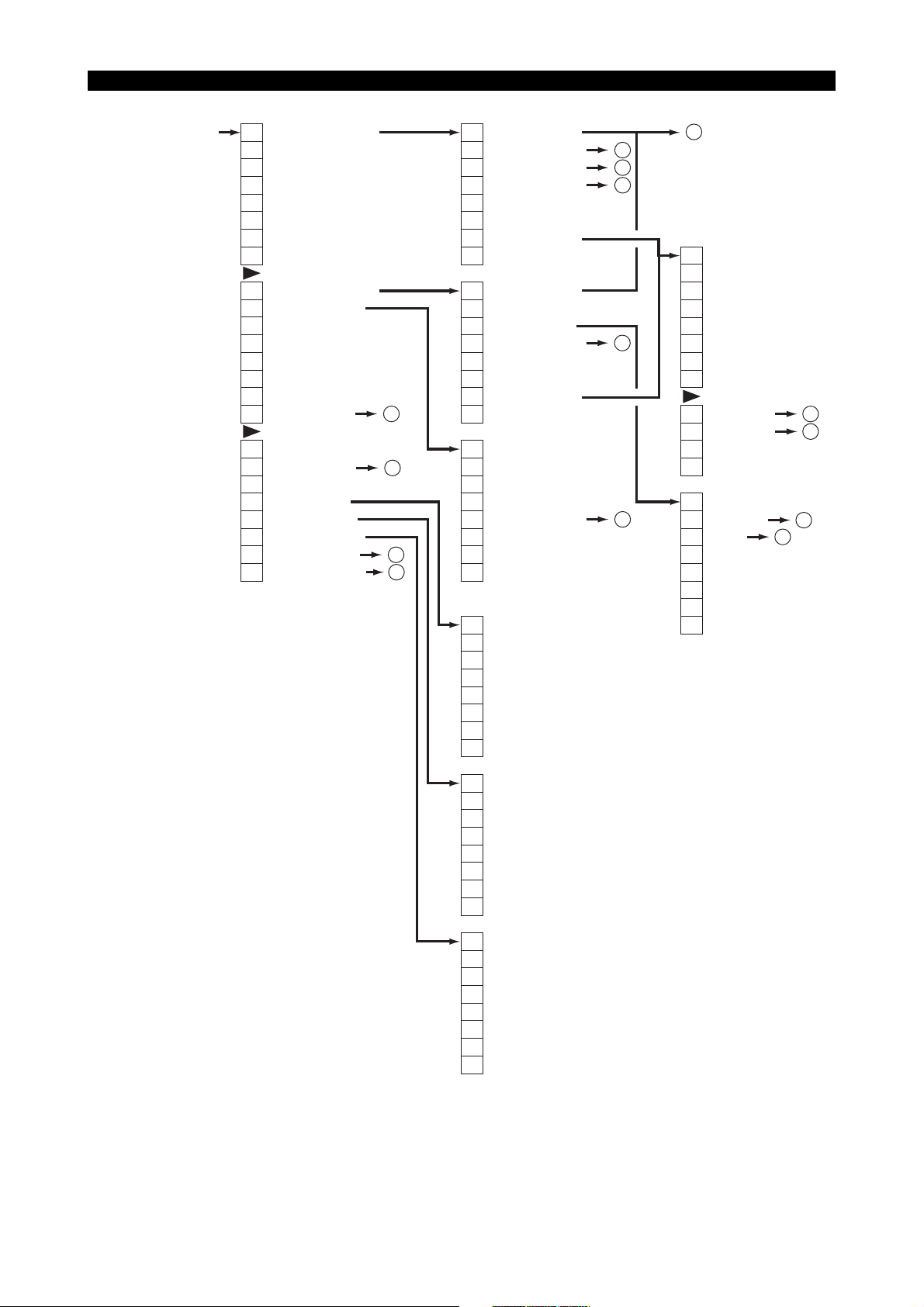

4290-E P-17

SECTION 1 PART NAMES AND FUNCTION

SPEC CODE

I/O CHECK

PLC DATA DISPLAY

ATC/APC CONDITION

MACHIN DIAGNOSIS

Hi-CUT GUIDE

RS232C CHECK

(CONTROL+D)

CHANGE MODE

(PLC CONTROL MODE)

F1

F2

F3

F4

F5

F6

F7

F8

DISPLAY CHANGE

F1

SEND BUFFER (or RECEIVE BUFFER)

F2

F3

F4

F5

F6

F7

F8

DISPLAY CHANGE

F1

SET

F2

F3

F4

F5

F6

F7

F8

DISPLAY CHANGE

1 1

1

1

PLC DATA TRACE

ATC TOOL SET/DISPLAY

(Memory random)

F1

TRACE START

F2

TRACE QUIT

F3

TRACE SELECT*

F4

DISPLAY POSITION

F5

DATA1/DATA8

F6

CHANGE COND

F7

F8

DISPLAY CHANGE

*Displayed only when

DATA8 is selected with [F5] (DATA/DATA8).

F1

SET (or MENU)

F2

F3

LABEL/IDENT

:

F7

F8

CLOSE

F1

F2

F3

F4

POT SEARCH

F5

TOOL SEARCH

F6

F7

F8

DISPLAY CHANGE

3

1

PLC LADDER MONITOR

F1

MODULE CALL

F2

PAGE SELECT

F3

DISPLAY OPTION

F4

SEARCH

F5

ROLE UP

F6

ROLE DOWN

F7

F8

DISPLAY CHANGE

F1

BIT ON

F2

BIT OFF

F3

F4

F5

F6

F7

F8

SYSTEM VARIABLE

1

F1

AXIS DATA

F2

ZERO OFFSET

F3

TOOL OFFSET

F4

SYSTEM PARA.

F5

HOME POSITION

F6

VNCOM

F7

F8

DISPLAY CHANGE

F1

MSB ZERO OFFSET

F2

MSB TOOL OFFSET

F3

F4

F5

F6

VARIOUS DATA

F7

F8

DISPLAY CHANGE

1

1

EIOEMM1B2006r01

Page 32

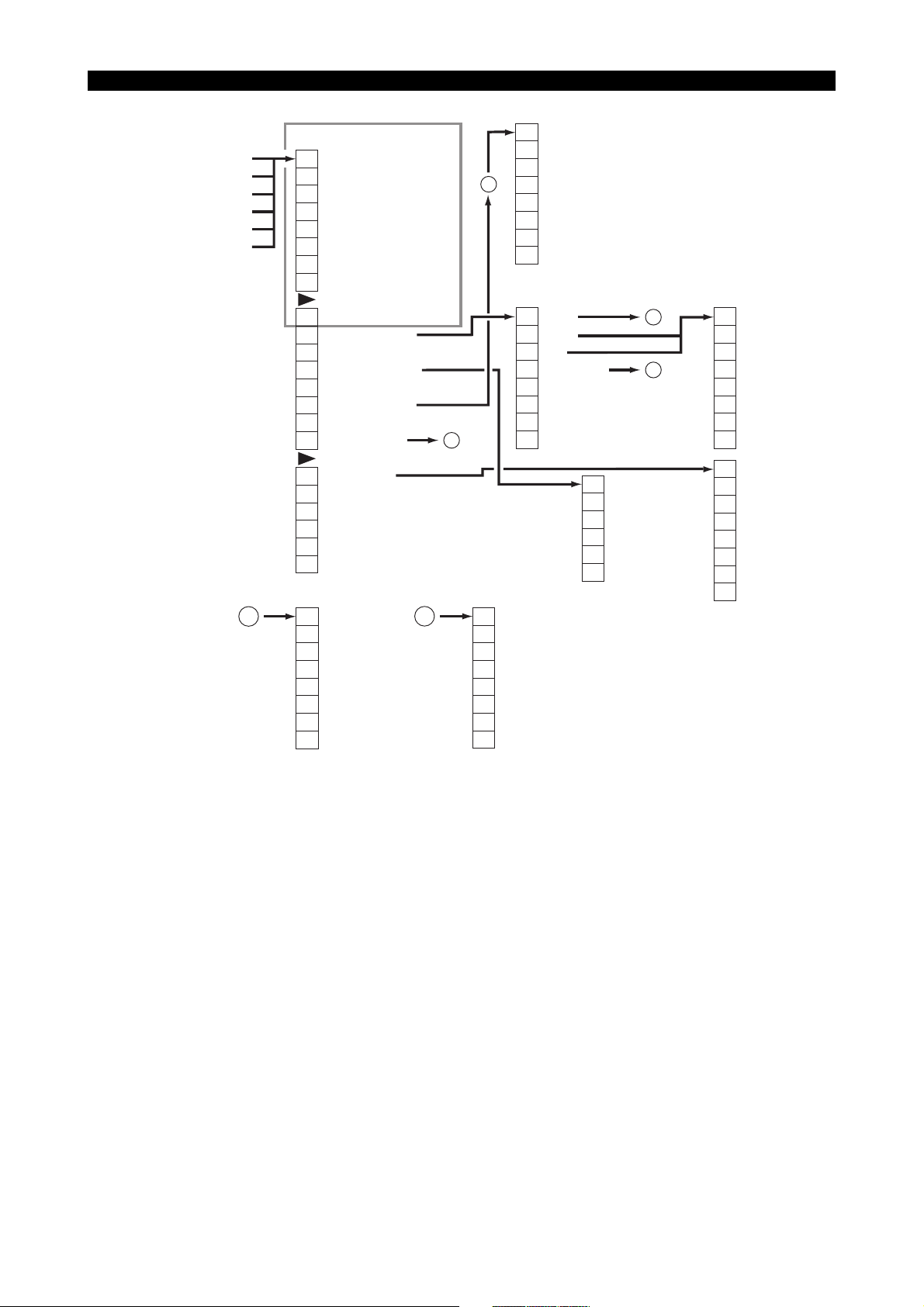

2-1-2. Zero Set Mode

4290-E P-18

SECTION 1 PART NAMES AND FUNCTION

F1

SET

F2

ADD

F3

CAL

F4

FIND

F5

BACK UP

F6

F7

F8

F1

F2

F3

:

F7

DATA IN/OUT

F8

F1

F2

F3

F4

F5

F6

F7

F8

Eeoemm1b2010

OK

CANCEL

12

EIOEMM1B2007R01

Page 33

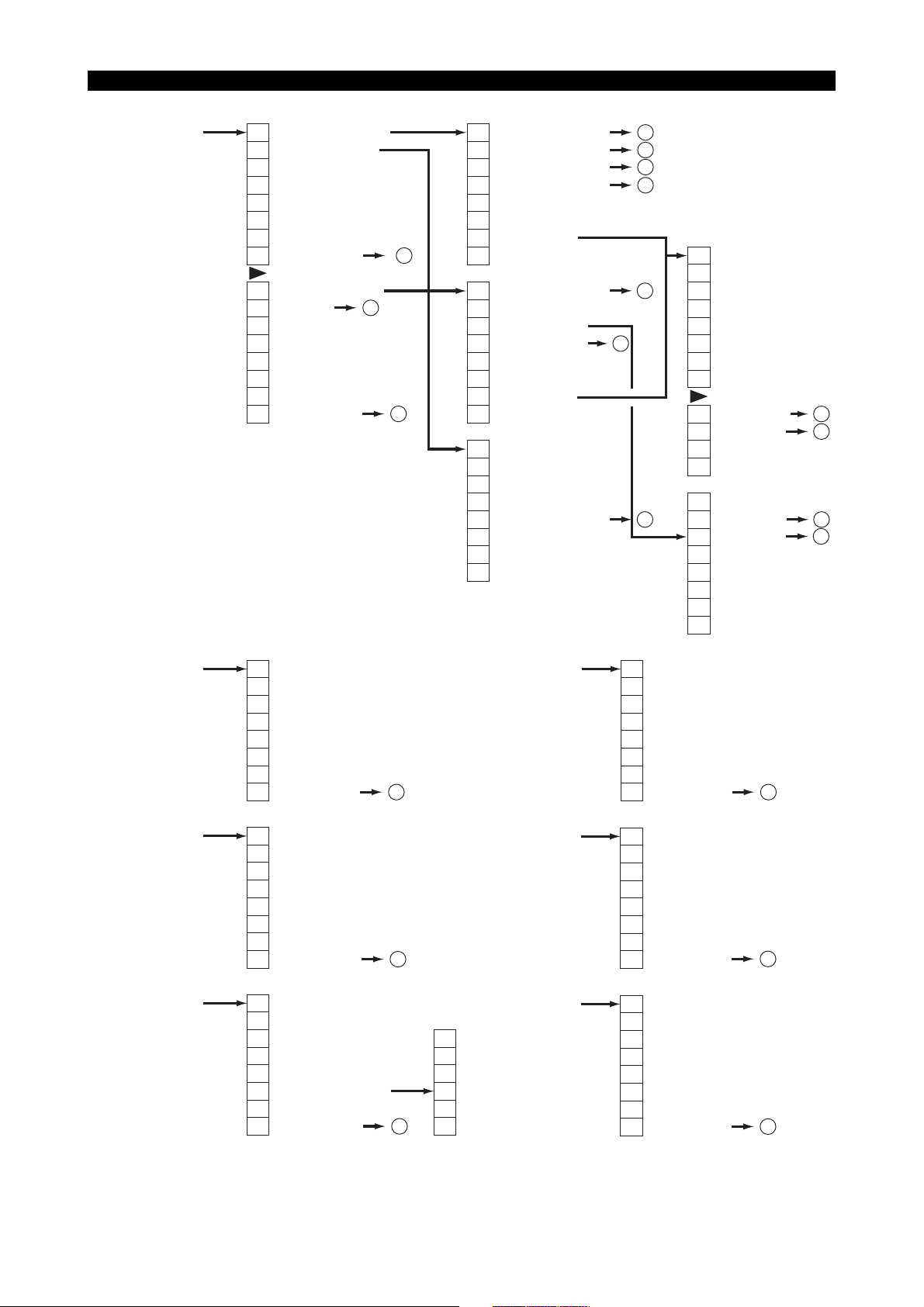

2-1-3. Tool Data Setting Mode

4290-E P-19

SECTION 1 PART NAMES AND FUNCTION

TOOL OFFSET

/ COMPENSATION

TOOL MANAGEMENT

F1

SET

F2

ADD

F3

CAL

F4

FIND

F5

BACK UP

F6

ITEM ↑

F7

ITEM ↓

F8

DISPLAY CHANGE

:

F6

TOOL LIST

F7

DATA IN/OUT

F8

DISPLAY CHANGE

F1

SET (or MENU)

F2

F3

H/D COMP NO. 2, 3 (or LIFE SETTING)

F4

FIND

F5

BACK UP

F6

ITEM ↑

F7

ITEM ↓

F8

DISPLAY CHANGE

:

F4

SORT

F5

F6

TOOL LIST

F7

DATA IN/OUT

F8

DISPLAY CHANGE

17

16

12

16

12

TOOL SHAPE

DEFINITION

3

9

9

POT NO./TOOL NO.

TABLE (MEMORY-

3

RANDOM)

9

9

F1

SET

F2

F3

F4

F5

BACK UP

F6

ITEM ↑

F7

ITEM ↓

F8

DISPLAY CHANGE

F1

F2

:

F7

DATA IN/OUT

F8

F1

SET

F2

F3

F4

POT SEARCH

F5

TOOL SEARCH

F6

ITEM ↑

F7

ITEM ↓

F8

DISPLAY CHANGE

F1

TOOL CANCEL

F2

TOOL SET

:

F6

F7

F8

DISPLAY CHANGE

Eeoemm1b2021

9

F1

F2

F3

F4

DUMMY TOOL SET

F5

12

TOOL NO. CLEAR

F6

F7

OK

F8

CANCEL

3

3

9

13

9

Window that appears

during command

execution

9

17

F1

F2

F3

F4

F5

F6

F7

F8

CANCEL

F1

F2

:

F8

CLOSE

F1

MENU CHANGE

:

F8

CLOSE

F1

TOOL NO.

F2

GROUP NO.

:

F8

CLOSE

F1

(CHECK MARK)

F2

:

F6