Okuma LVT300 Technical Information

LVT300

CNC LATHE

TECHNICAL INFORMATION

Information No.2059-LVT300

(Revised by OEG)

(January 2001)

OKUMA Corporation

For Internal Use Only

OEG TECHNICAL INFORMATION

OEG Doc. G-L0022-03

OEG Doc. No G-L0022-03

OEG Technical Information

Date: 23.01.2001

Any technical information is subject to change without notice.

Okuma Europe GmbH

Original Written by:

Original Doc. No.: L-0022-03-Revision Reference.doc

REVISION REFERENCE (G-L0022-01 G-L0022-02)

NEW PAGE PAGE TITLE REVISED ITEMS

1-2 LVT300-Vertical CNC Lathe 1. Addition: Note

1-4 Spec. Comparison Between

Dynamic Turn LVT300/300M and ist Competitors

1. Revision: Table

2-2 Machine Specifications 1. Revision: Swing over cross-slide

(∅280 to ∅320)

2. Revision: Z-axis travel (310 to

360mm)

3. Revision: ID tool shank dia. indexing

time (0.1 to 0.15 sec)

4. Revision: Weight (5,500 to 6,000kg)

3-2 Kit Specifications 1. Revision: Table

4-1-1 Layout-Chip Side Disposal 1. Addition: New Page

9-2 Servo System Mechanism 1. Revision: Drawing

11-1 Table of Machine Constants 2. Revision: Start up time

12-1 Machining Capacity and

Accuracy

1. Addition: New Page

13-1 Machine Operation Time

Tab le

1 Revision: Feed axis starting time

2. Revision: Turret index time

14-1 Working Range Diagram 1. Revision: Drawing

14-2 Working Range Diagram 1. Revision: Drawing

14-3 Working Range Diagram 1. Revision: Drawing

14-4/14-5 Notes for Work Length

Range

1. Addition: New Pages

21-1-2 LVT300 System Layout

Example

1. Revision: Note

21-2-2 Work Changing Time Chart 1. Revision: Time Chart

21-3 – 21-9 2. Elimination: Pages

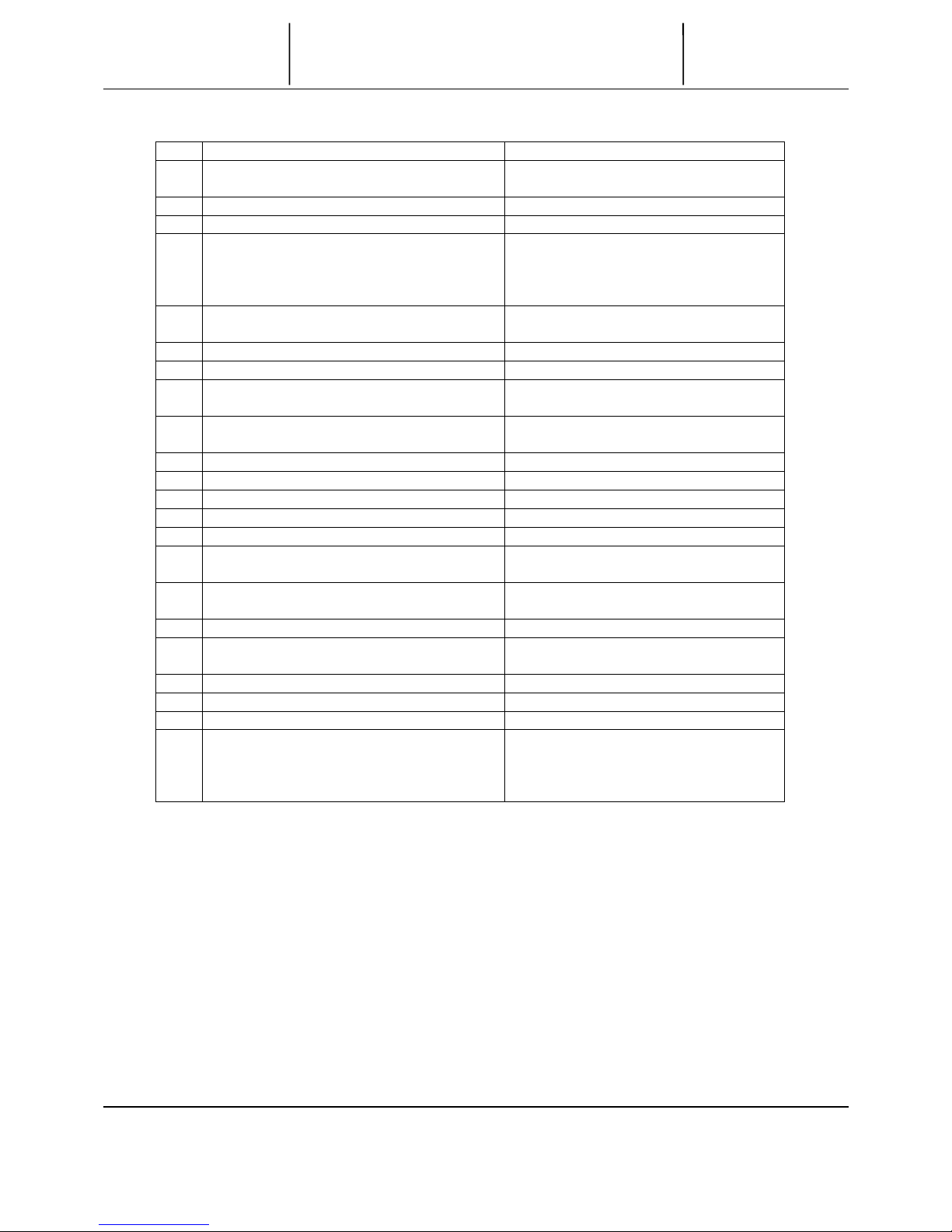

REVISION REFERENCE (G-L0022-02 G-L0022-03)

NEW PAGE PAGE TITLE REVISED ITEMS

4-2 Foundation Plan 1. Revision: Drawing

000-2 LT9910T.doc

No. Item Content

1 Technical Information for Sales Promotion - Features

- Spec Comparison with Competitors

2 Machine Specifications - Specification Table

3 Specifications - Specifications for Machine

4 Dimensional Drawings - Dimensional Drawings (Standard)

- Chip Side Disposal

- Foundation Plan

- CE *

5 Spindle Dimensions - Standard Spindle

- Spindle Rear End Dimensions

6 Bed Dimensions

7 Turret Dimensions - V12VDI Turret

8 Spindle Power/Torque Transmission

Diagram

- Standard Spindle

9 Mechanical Drawings - Turret

- Servo System Mechanism

10 Hydraulic Circuit Diagram

11 Machine Constants Table

12 Machining Capacity/Accuracy *

13 Operation Time Table *

14 Working Range Diagrams

15 Tooling (VDI) - Tooling System

- Tool Interference Diagram

16 Hydraulic Chuck Installation Drawing - Chuck Installation Drawing

17 Touch Setter *

18 Lubrication Chart - Lubrication list

- Oil Specifications

19 Chip Conveyor *

21 System Layout Example

22 Power Requirements

The final drawings or optional

specifications indicated with * will be

delivered later, because they are

under preparation.

Any technical information is subject to change without notice.

OKUMA Corporation

TTTTechnical SSSSheet

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

INFORMATION NO.

2059-LVT300

P-(i)

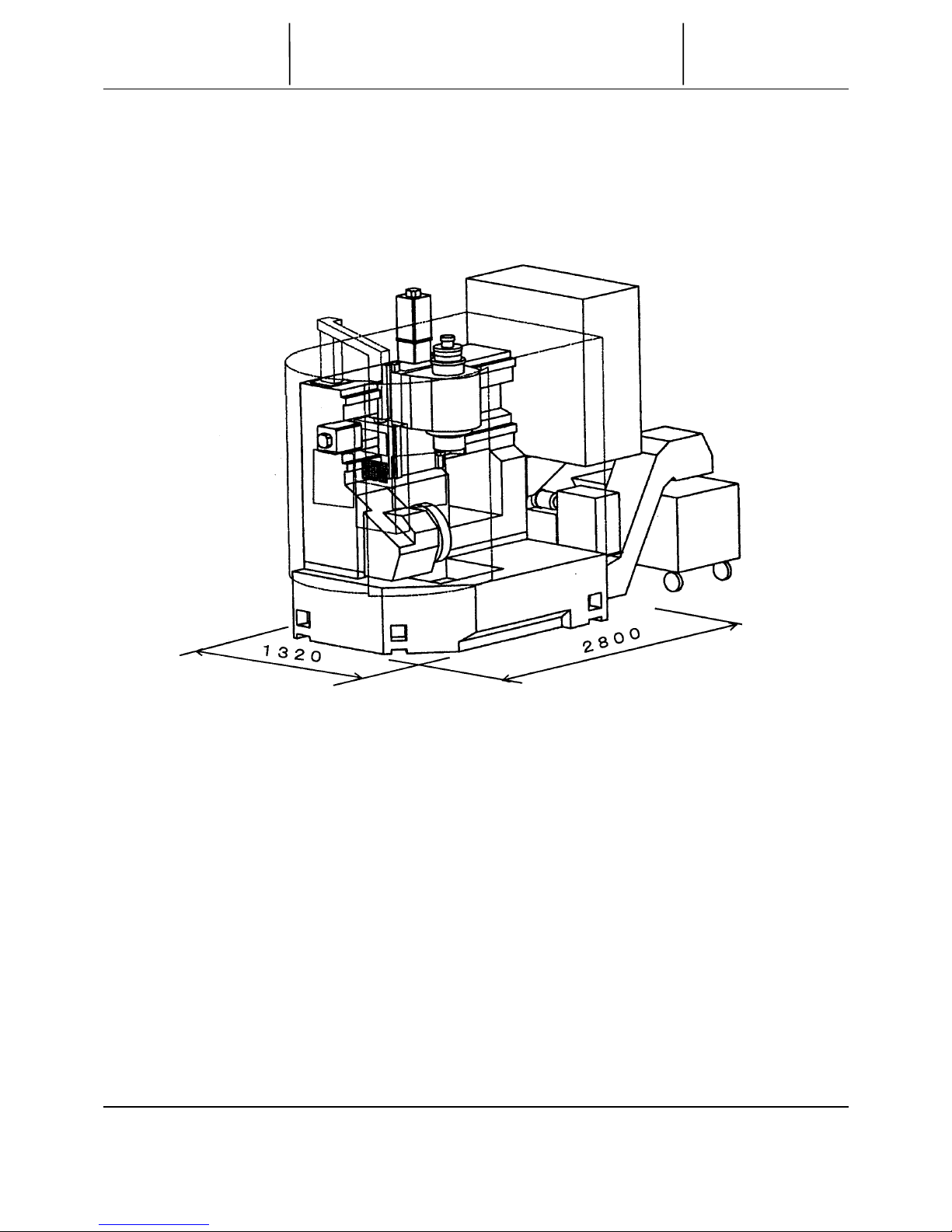

* Vertical CNC lathe equipped with the spindle loading function provides

flexibility in your line construction.

* Having a smaller machine width, this next-generation machine ensures

easy workpiece change.

●Applicable to line construction

* Vertical spindle capable of loading workpieces

* Minimum machine width:

Only 1.3 m though the machine is equipped with an 8-inch chuck.

●High productivity

* High feedrate by linear guides employed for all the feed axes Rapid feedrate:

X: 60 m/min (197 fpm), Z: 30 m/min (98 fpm)

* High-speed integral motor/spindle:

4,000 min

-1

, 22/15 kW (30/20 hp)

* V12 NC turret indexed at high speed: 0.15 sec/stat.

●High accuracy

* Thermally stabilized bed with box construction

* Coolant and chip discharged directly under the machine

* Gearless headstock and high-precision servo

* Thermal deviation compensation function

●Minimum cost

* Loading system not needed

TTTTechnical SSSSheet

LVT 300

LVT 300LVT 300

LVT 300

VERTICAL CNC LATHE

VERTICAL CNC LATHEVERTICAL CNC LATHE

VERTICAL CNC LATHE

INFORMATION NO.

2059-LVT300

1-2

Any technical information is subject to change without notice.

OKUMA Corporation

(51.97)

(110.24)

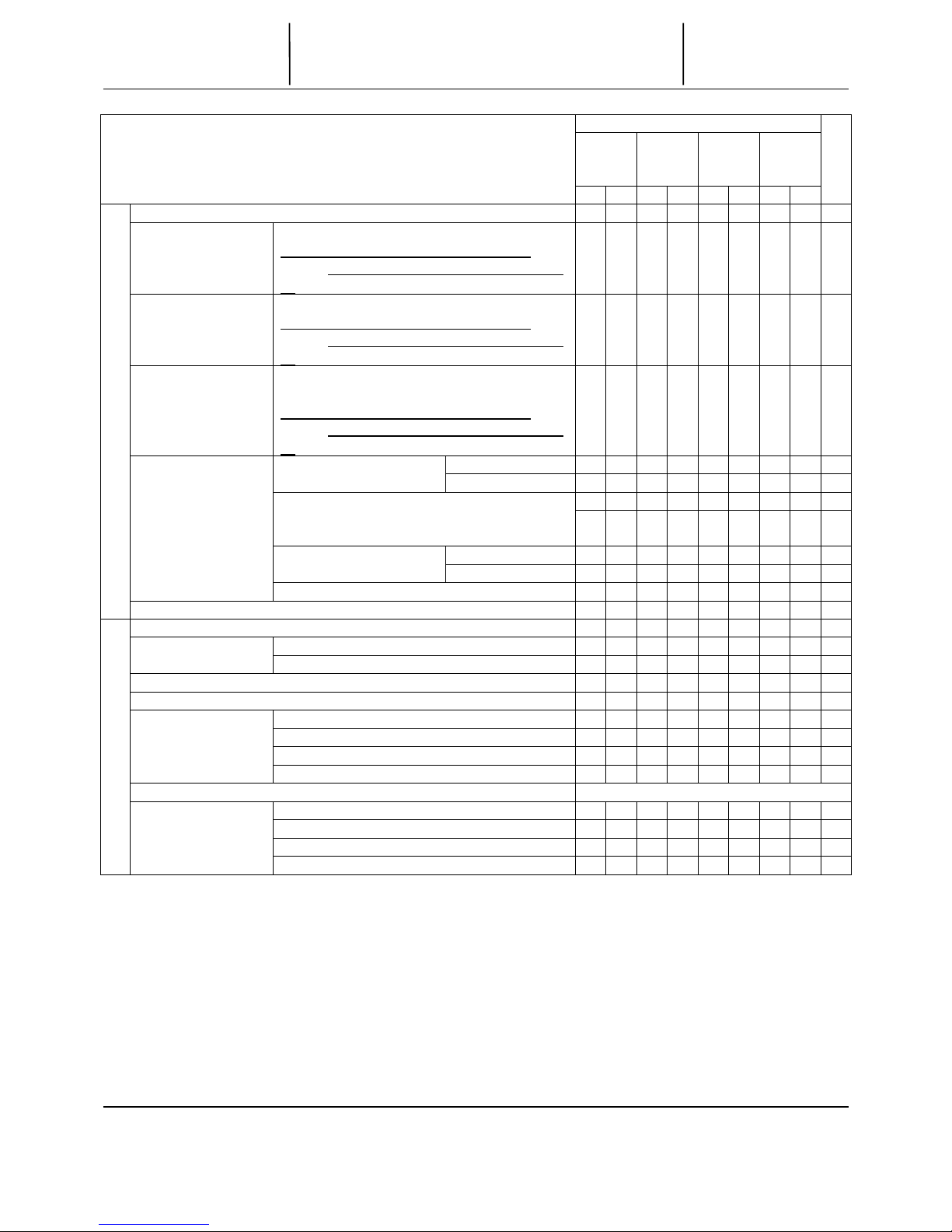

SPEC COMPARISON BETWEEN DYNAMIC TURN LVT300/300-M AND ITS COMPETITORS

Manufacturer OKUMA HITACHI SEIKI EMAG INDEX

Model LVT300 LVT300-M CS20 VSC200 VSC250 V200

Outside view

Standard chuck 8” ∅210 (8.27) (8”) ∅200 (7.87) ∅200/250 (7.87/9.84) ∅200 (7.87)

Swing over saddle mm (in.) ∅320 (12.6) (Limited by Z-axis cover) ∅400 (15.75)

Max. turning dia. mm (in.) ∅280 (11.02) ∅400 (15.75) ∅ 200 ∅200 ∅420 × 180 (16.54 )

Max. workpiece length mm (in.) 200 (11.02 × 7.87) 0 (15.75 × 5.91) 180 200 180 (7.09)

Capacity

Max. loading capacity kg (lb) 20 (44) 20 (44)

X-axis mm (in.) 210 (8.27) (machining travel) +

845 (33.27) (loading/unloading travel)

190 (7.48) (machining travel)

+1,120 (44.09)

(loading/unloading travel)

550 (21.65) 685 (26.97) 520 (20.47)

Z-axis mm (in.) 360 370 (14.57) 200 (7.87) 200 (7.87) 200 (7.87)

Travels

Work changing time sec 5.5 15 5 to 7 5 to 7

Spindle speed min

-1

4,000 5,000 6,500 6,000 5,000 (7,500)

Speed range (2 auto ranges) First gear

Spindle nose JIS A2-6 JIS A2-6 DIN55026 A5 DIN55026 A6 ISO 702/1 type 5(4)

Front bearing dia. ∅100 (3.94) ∅100 (3.94) ∅100 (3.94) ∅100 (3.94) ∅100 (∅75) {3.94 (2.95)}

Spindle bore mm (in.) ∅62 (2.44) ∅59 (2.32)

Spindle drive motor Output: kW (hp) Built-in motor: VAC 22/15 (20 min: cont.) AC11/7.5 AC34 AC39 Built-in motor: 29/20 (21/13)

Torque: Nm (lbf-ft) 412 208 153 460 140

Type V12VDI NC non-lift turret

V12 multi-function NC non-lift turret

12-angle base holder V12 V12 14

No. of tools 12 12 (for L and M) 12 12 12 14

Tool shank height/boring bar shank dia.

o25/∅40 (VDI holder shank dia.) ∅40) o25/∅32 ∅40 (DIN69880) ∅40 (DIN69880) o25

Turret

Indexing time sec 0.15 (1 index) 0.2 (1 index)

Spindle speed min

-1

-

4,500 3,000 6,000

Rotary tool

spindle

Rotary tool spindle drive motor kW (hp)

-

5.5/3.3 (7.5/4.4) 3.7 (5) 12.5 (16.67) 9.5 (12.67)

X-axis mm/min (fpm) 60 (2.36) 30 (1.18) 60 (2.36) 45 (1.77) 30 (1.18)Feedrate

Z-axis mm/min (fpm) 30 (1.18) 30 (1.18) 30 (1.18) 30 (1.18) 30 (1.18)

Motor Coolant pump kW (hp) 0.25 (0.333) 1.1 (1.5)

Height mm (in.) 2,500 (98.43) 2,743 (107.99) 2,800 (110.24) 2,650 (104.33)

Floor space mm × mm

(in. × in.)

1,320 × 2800

(51.97 × 110.06)

2,838 × 2,587

(111.73 × 101.85)

1,350 × 2,890

(53.15 × 113.78)

1,350 × 3,100

(53.15 × 122.05)

2,080 × 1,900

(81.89 × 74.80)

Machin e

size

Weight kg (lb) 5,500 (12,100) 6,000 (13,200) 5,000 (11,000) 6,500 (14,300) 6,500 (14,300)

Remarks

Indications in ( ) are for optional specifications.

Any technical information is subject to change without notice.

OKUMA Corporation

TTT

T

echnical

SSS

S

heet

SPEC COMPARISON BETWEEN DYNAMIC TURN

SPEC COMPARISON BETWEEN DYNAMIC TURN

SPEC COMPARISON BETWEEN DYNAMIC TURN

SPEC COMPARISON BETWEEN DYNAMIC TURN

LVT300/300-M AND ITS COMPETITORS

LVT300/300-M AND ITS COMPETITORS

LVT300/300-M AND ITS COMPETITORS

LVT300/300-M AND ITS COMPETITORS

INFORMATION NO.

2059-LVT300

1-4

002-2 LT9910E.doc

Model

LVT300

Swing over cross-slide

mm (in.)

∅320 (12.60)

Max. turning dia.

mm (in.)

∅280 (11.02)

Max. turning length

mm (in.)

200 (7.87)

Capacity

Recommended work weight

kg (lb)

20 (44)

*

X-axis

mm (in.)

210 (8.27) (for machining) + 845 (33.27) (for loading/unloading)

Z-axis

mm (in.)

360 (330 up to #0074)

Travels

Spindle speed

min

-1

40 to 4,000, [60 to 6,000]

Speed range Auto 2 ranges

Spindle nose JIS A2-6

Spindle bore

mm (in.)

∅62 (2.44)

Spindle

Front bearing ID

mm (in.)

∅100 (3.94)

Type V12 VDI NC non-lift

No. of tools 12

OD tool shank

mm (in.)

o25 × 25 (0.98 × 0.98) (VDI toolholder shank dia.: 40

(1.57))

ID tool shank dia.

mm (in.)

∅40 (1.57) (VDI toolholder shank dia.: ∅40 (1.57))

Turret

ID tool shank dia.

sec

0.15 Indexing time (per station)

Rapid traverse m/min (fpm) X: 60 (197), Z: 30 (98)

Spindle drive

kW (hp)

VAC22/15 (30/20) (20 min/cont.) [37/25 (50/33.3)]

Axis drive

kW (hp)

X-axis: 4, Z-axis: 6

Motors

Coolant pump

kW (hp)

0.25 (0.333)

Height

mm (in.)

2,500 (98.43)

Required floor space

mm × mm

(in. × in.)

1,320 × 3,200

(51.97 × 125.98) (Control panel included)

Machine

Specs

Weight

kg (lb)

5,500 (12,100)

NC

OSP-U100L

Values in [ ] are for high-speed and power-up specifications (optional).

*The max. load of the head stock is 70kg

(= Chuck + Cylinder + Draw Bar + Jaws •••• washers + workpiece)

OKUMA

OKUMA OKUMA

OKUMA Corporation

TTTTechnical SSSSheet

MACHINE SPECIFICATIONS

MACHINE SPECIFICATIONSMACHINE SPECIFICATIONS

MACHINE SPECIFICATIONS

INFORMATION NO.

2059-LVT300

2-2

003-2 LT9910.doc

SPECIFICATION FOR LVT300 CNC LATHE

o Estimated Spec

o Delivery Spec

Date

・ ・

Company

name

NC OSP-U100L

Standard specifications

T

Model

∅280 (110.24)

×

200 (7.87)

8-inch solid chuck

(N-08A601A)

with standard soft jaws (1 set)

Solid hydraulic cylinder

Spindle motor

VAC 22/15 kW (30/20 hp)

(20 min/cont.)

¡

Chucking

(RNKP120-25)

A

Spindle speed

40 to 4000 min

-1

¡ OD toolholder

C

Turret

V12 NC turret (VDI)

¡ ID toolholder base

H40

Hydraulic unit

¡

10-H40

Coolant supply system

¡

12-H40

Chip shield

¡

16-H40

Chip pan (rear discharge)

¡

20-H40

Standard

e

q

ui

p

ment

Work lamp (fluorescent)

¡

25-H40

Boring bar sleeve

32-H40

MT.No.1

MT.No.2

Machine-related equipment

Standard

accessories

Foundation washers

Leveling jack screws

Machine lifting hooks

Hand tools

¡

Drill sleeve

MT.No.3

NC OSP-U100L ¡

Tooling

Plug tool

Optional specifications Qty Optional accessories

Qty

Specifications for high speed/power-up spindle (A2-6)

Speed range to 6,000 min

-1

[37/25 kW (50/33.3 hp)]

Chip conveyor o Side disposal o Rear disposal

o L-type o H-type o Special

Chip bucket o L-type o H-type

o Special

TTTTechnical SSSSheet

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

INFORMATION NO.

2059-LVT300

3-2

Any technical information is subject to change without notice.

OKUMA Corporation

OSP-U100L CNC Standard Specifications

Axis Control X,Z simultaneous 2-axis turning, simultaneous 3-axis multi-processing

Position feedback Full-range absolute positioning (zero point return is not required)

Tape format N4, G2, X+53, Z+53, I+53, K+53, F+53, S4, T4, M2

Reader/puncher interface RS-232C

Floppy disk input/output

3.5” floppy disk drive (internal), input and output a program via OSP formatted floppy disk

auto ISO/EIA code recognition; absolute, incremental or both

Programming Auto ISO/EIA code recognition: absolute, Incremental or both

Min command units X-axis: 1 µm (0.00004 in) [dia], Z-axis: 1 µm (0.00004 in)

Max command units 8-digit decimal, ±99999.999 mm(±3937 in)

Programmable units 1 µm (0.00004 in), 10 µm (0.00004 in), 1mm (0.04 in) [freely selectable]

Decimal point data 1 µm (0.00004 in), 10 µm (0.00004 in), 1mm (0.04 in) increments

Feed Feedrates are listed in the machine space, override: 0~200%, dwell: 0.01~99999.99 sec

Tooling Tool selection: 12 sets, tool offset (compensation): 32 sets, max compensation value:

±99999.999 mm (±3937 in)

Auto tool compensation: calculated from manually input wear and tear measurement values

Spindle VAC motor operation Direct spindle speed commands (S4), fixed cutting speed

Spindle speed override (50~200%), optimum turning speed designation

M-spindle motor operation (multimachining)

Direct input of the motor speed

Display NOTE 1) Color display panel, six LED for display of operation conditions

Manual operation

Spindle (inching: clockwise or counter-clockwise turning), tool rotation, pulse handle,

X-Z-axis manual feed

Multitasking Program writing, editing during work

Self-diagnostics

Automatic diagnostics and display of program, operation, machine, and NC system

Problems

Door interlock Safety function to interlock machine movement when door is opened or closed

NC torque limiter Instant detection of machine collision to reduce machine damage

Hi-G Control Calculation of the speed-control and torque properties of a motor for high-speed, high

stability positioning

Features

Other Buffer resister, zero offset, tool interference, software limit, chuck barrier, tailstock barrier,

droop control, single block, machine lock, block delete, optional stop, dry-run, stroke

end-limit cancel, etc.

Program selection 1 program from the registered list of programs

Sequence number search Advance to an appointed sequence number in a selected program

Sequence restart Restart from an Interrupted sequence

Manual interrupt/auto return Manual operation during automatic operation: return to interrupt point

Threading slide hold Slide hold during threading (optional for [G34/G35] non-fixed cycles)

Programming Editing, tape read verify, listing, etc. via the screen editor

Memory operation Tape less operation: Tape storage capacity: 160m (525 ft), max program length: 320m

(1050 ft)

Useful Help Alarm help, display of G, M-code contents

Useful PLC Display of PLC ladder drawings and PLC data

Operation

Data management

Output of tool offset, zero offset, measurement data to tape or floppy disk (tape readers

and punchers are optional)

Nose R compensation (2B) Automatic compensation for nose R dimension errors Including arbitrary shapes and arcs

Arc radius designation Circular interpolation by ordering the radius L and end points X, and Z

Arbitrary angle chamfering Simple programming of arbitrary angle chamfers (C, R)

Taper angle designation Taper interpolation by designating either the X-, or Z-axis and the starting point angle

mm/min (ipm)Programming Both mm/rev (ipr) and mm/min (ipm) feedrate units usable

Schedule program Non-stop operation possible by setting the sequence order of several work programs

Zero offsets via G-codes Program zero point offsets are possible

Threading Thread feed: 0.001~1000.000mm(0.00004~39.37in): possible to set the threading lead pitch

Chamfering ON/OFF, fixed cycle threading, non-fixed threading cycle

(the thread lead indicates the CNC limit value, the max thread lead differs per machine

specification)

Custom fixed cycle Threading cycle, grooving cycle, drilling cycle

User task 1 GOTO, IF statements, arithmetic, common variable, local variable

(system operation variables)

Programming Function

Control In/Out Comments can be added into programs

Note 1: The display screen varies with machine model. LU series, LT15, LT25 … 14” color CRT

Other models controlled by OSPU100L… 10.4” color TFT

Any technical information is subject to change without notice.

OKUMA Corporation

TTTTechnical SSSSheet

CNC

CNCCNC

CNC STANDARD SPECIFICATIONS

STANDARD SPECIFICATIONSSTANDARD SPECIFICATIONS

STANDARD SPECIFICATIONS

INFORMATION NO.

2059-LVT300

3-4

Specifications

NML ANM

Onetouch

IGF

Onetouch

IGF-M

OSP-U100L Optional specifications

EDEDEDED

Single

Auto programming function LAP4

●●●●●●●●

Arc threading

●●●●

Inch/metric switching

●●●●

User Task 2

Sub-programming, calculation, function

operations

●●●●●●●●

I/O variables: 8 variables each (incl. the

above functions)

64 sets

Tool offset function

(std. 32 sets)

96 sets

Common variables: 1000 (std. 200)

Threading phase matching (spindle orientation separately

selected)

Slide hold during thread cutting (G34, G35)

Multifunction lathe Coordinate conversion

▲▲▲▲ ●●

spec Contour generation

▲▲▲▲ ●●

Flat turning

Programming

One-touch IGF (incl. LAP4, animation)

●

One-touch IGF with IGF convert function

●

One-touch IGF multifunction spec

●

One-touch IGF multifunction spec with IGF convert function

●

IGF-L3 (incl. LAP4, animation)

IGF-L3 with IGF convert function

IGF-L3 multifunction spec

Interactive functions

IGF-L3 multifunction spec with IGF convert function

Program store capacity 640 m

●●●

Standard 320 m 1280 m

●●●●

2560 m

●

5120 m

10240 m

Operation buffer capacity 640 m

Standard 320 m 1280 m

Program capacity

Any technical information is subject to change without notice.

OKUMA Corporation

TTTTechnical SSSSheet

OPTIONAL SPECIFICATIONS

OPTIONAL SPECIFICATIONSOPTIONAL SPECIFICATIONS

OPTIONAL SPECIFICATIONS

INFORMATION NO.

2059-LVT300

3-6-1

Specifications

NML ANM

Onetouch

IGF

Onetouch

IGF-M

OSP-U100L Optional specifications

EDEDEDED

Single

Animated simulation (incl. cycle time calculation function)

●●●●●●

Cycle time over check

●●●●●●●●

Load monitor function (spindle, feed axis)

●●●●●●

Tool life management function

●●●●

Operation end buzzer

Chucking error detection Included in machine specifications

Work counter Counting only ( pc)

Cycle stop ( pc)

Start disabling ( pc)

Hourmeter Power ON time

Spindle rotating time

NC running time

NC operation monitor (incl. counter, integrating function)

●●●●●●●●

NC work counter (alarm stop at count-up)

Operation end lamp (yellow rotating beacon)

Alarm lamp (red rotating beacon)

Monitoring function

3-step status indicator lamp type A (type B)

●●●●●●●●

In-process work gauging Included in machine specifications

Z-axis auto zero offset by touch sensor

C-axis auto zero offset by touch sensor

Measurement data Standard channel

printout

RS232C

Additional channel

Printer ( )

Post-process work

Quantitative compensation system [5 steps,

7 steps]

gauging interface BDC system

CEJ MATIC (for export)

RS232C (incl. dedicated channel)

Touch setter gauging [M, A] Included in machine specifications

Size catcher A (without calipers)

B (with 150 mm calipers)

Gauging function

Any technical information is subject to change without notice.

OKUMA Corporation

TTTTechnical SSSSheet

OPTIONAL SPECIFICATIONS

OPTIONAL SPECIFICATIONSOPTIONAL SPECIFICATIONS

OPTIONAL SPECIFICATIONS

INFORMATION NO.

2059-LVT300

3-6-2

Specifications

NML ANM

Onetouch

IGF

Onetouch

IGF-M

OSP-U100L Optional specifications

EDEDEDED

Single

Additional RS232C channel (std. 1 channel)

RS232C

Maker

connection cable

Type

Printer

Maker

Type

Printer cable RS232C interface cable

Maker

Type

DNC-A

Standard channel

●●●●

Channel added

DNC-B (incl. dedicated channel)

DNC-C [C1, C2, C3] (incl. dedicated

channel)

DNC-[P1,P2,P3]

Standard channel

* Channel added

Connection with

DNC

(User is requested

to prepare cables

and connect the

system.)

DNC-[T1,T2,T3] *

External input/output, communication function

Spindle orientation (electrical control)

●●●●

Auto power shutoff M02, alarm

function

Warm-up function (Warm-up operation by calendar timer)

Tool retraction cycle

External program A (pushbutton) 8 kinds

select B (rotary switch) 8 kinds

C1 (digital switch) BCD2 digits

C2 (digital switch) BCD4 digits

Interface with Okuma loader (OGL) Included in loader specifications

Interface with other Type B (machine-mastered)

maker’s Type C (robot/loader-mastered)

robot/loader Type D

Automation, untended operation

Type E

Any technical information is subject to change without notice.

OKUMA Corporation

TTTTechnical SSSSheet

OPTIONAL SPECIFICATIONS

OPTIONAL SPECIFICATIONSOPTIONAL SPECIFICATIONS

OPTIONAL SPECIFICATIONS

INFORMATION NO.

2059-LVT300

3-6-3

Specifications

NML ANM

Onetouch

IGF

Onetouch

IGF-M

OSP-U100L Optional specifications

EDEDEDED

Single

Bar feeder Bar feeder unit Included in machine specifications

Interface only

Maker

Type

Cycle time Operation time reducing function

●●●●●●●●

reducing Chuck open/close during spindle rotation

function *

Tailstock auto advance/retract during spindle

rotation

Automation, untended operation

Position feedback by ABSO SCALE (XA, ZA, XB, ZB) *

1/10 µm control *

Pitch error compensation (XA, ZA, XB, ZB)

High speed, high

accu

r

acy

Thin-type monochromatic operation panel (not selectable for some

machine models)

Earth leakage breaker

External M code signal [2 sets, 4 sets, 8 sets ( )]

Others

Note 1: NML, ANM, E, and D are abbreviation of NORMAL, ANIMATION, ECONOMY, and DELUX.

Note 2: When selecting a kit specification, encircle E or D of the required kit. To add a function or specification to

the selected kit, put a circle in the corresponding kit column. W hen selecting a function or specification

without selecting a kit, put a circle in the corresponding “Single” column.

Note 3: Installation of the items indicated with * requires technical consultation including review of the machine

specifications.

Note 4: For the specifications given in [ ], select a required specification by encircling.

Note 5: The functions indicated with ▲ are provided only for the multifunction model.

Note 6: When you need the 3-step status indicator lamp type B, encircle “Type B”.

Any technical information is subject to change without notice.

OKUMA Corporation

TTTTechnical SSSSheet

OPTIONAL SPECIFICATIONS

OPTIONAL SPECIFICATIONSOPTIONAL SPECIFICATIONS

OPTIONAL SPECIFICATIONS

INFORMATION NO.

2059-LVT300

3-6-4

TTTTechnical SSSSheet

DIMENSIONAL DRAWINGS

DIMENSIONAL DRAWINGSDIMENSIONAL DRAWINGS

DIMENSIONAL DRAWINGS

(MACHINE WITH L-TYPE TURRET)

(MACHINE WITH L-TYPE TURRET)(MACHINE WITH L-TYPE TURRET)

(MACHINE WITH L-TYPE TURRET)

INFORMATION NO.

2059-LVT300

4-1

10-547-700-002

Any technical information is subject to change without notice.

OKUMA Corporation

Any technical information is subject to change without notice.

OKUMA Corporation

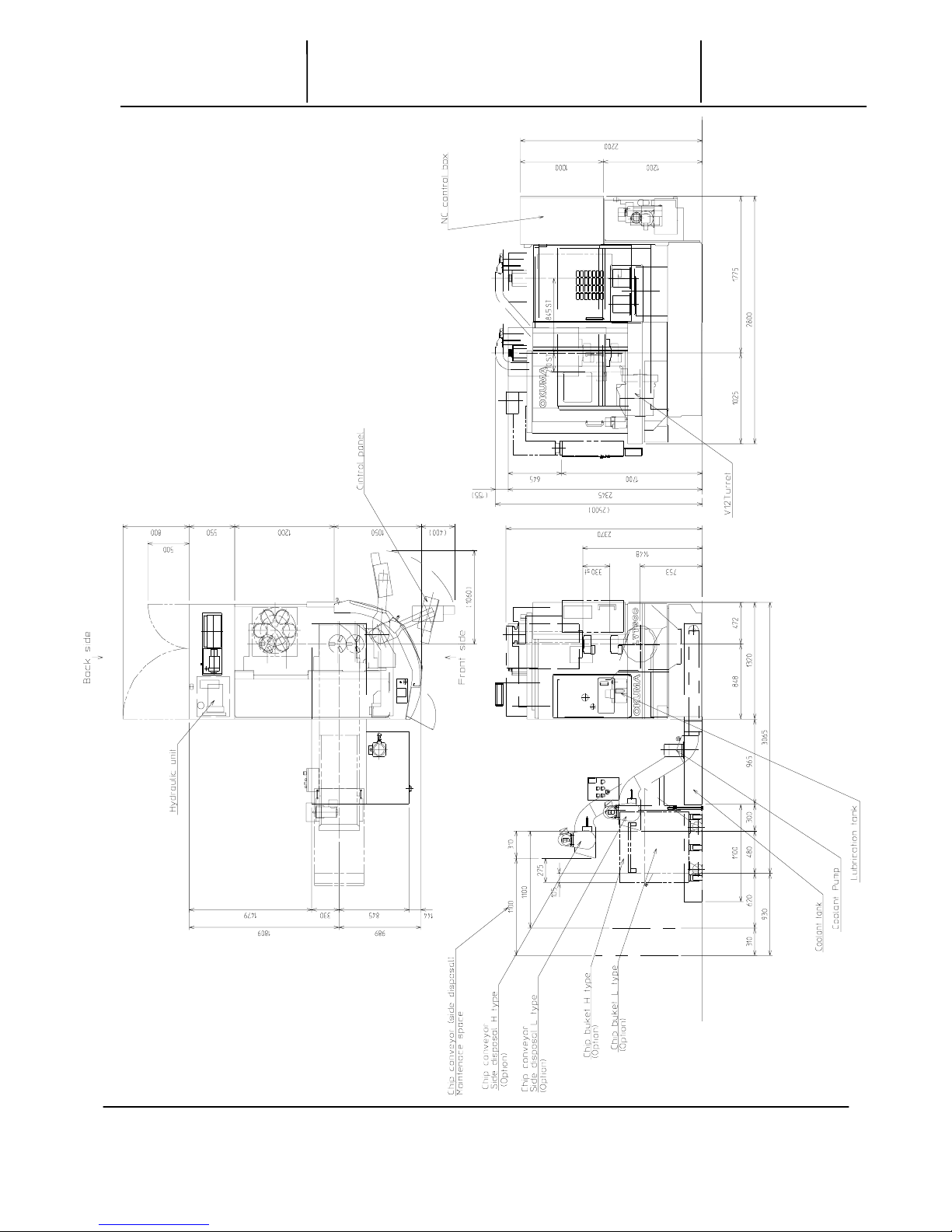

TTTTechnical SSSSheet

LAYOUT

LAYOUTLAYOUT

LAYOUT

CHIP SIDE DISPOSAL

CHIP SIDE DISPOSALCHIP SIDE DISPOSAL

CHIP SIDE DISPOSAL

INFORMATION NO.

2059-LVT300

4-1-1

10-547-700-028

TTTTechnical SSSSheet

FOUNDATION PLAN

FOUNDATION PLANFOUNDATION PLAN

FOUNDATION PLAN

INFORMATION NO.

2059-LVT300

4-2

Any technical information is subject to change without notice.

OKUMA Corporation

13-547-720-001

005-1 LT9910q.doc

φ100主軸(標準主軸)

φ100 standard spindle

LB300、LU15と主軸は共通。(参考図 00-535.010.004-3,-011-3)

This spindle is also used in LB300 and LU15.

(Refer to the drawings in 00-535.010, 004-3 and -011-3.)

(

00-547-010-004

)

TTTTechnical SSSSheet

主主主主 軸軸軸軸 寸寸寸寸 法法法法 図図図図

SPINDLE DIMENSIONS

SPINDLE DIMENSIONSSPINDLE DIMENSIONS

SPINDLE DIMENSIONS

INFORMATION NO.

2059-LVT300

5-1

Any technical information is subject to change without notice.

OKUMA Corporation

Loading...

Loading...