OKI OKIFAX OF-7 Service Manual

OKIFAX

Facsimile Transceiver

! (“.,,

Field Service Handbook

OF-7

1

FIRST EDITION

July

17,199O

OKI

ELECTRIC INDUSTRY COMPANY, LTD.

PREFACE

This manual is intended to be used for installing and maintaining the OKIFAX OF-7 facsimile

transceiver (International Standard Version).

Maintenance of the OF-7 is assumed to be conducted to the following levels:

l

Component-level maintenance for mechanical portion

0

Unit-level maintenance for electric portion

0

Copyright 1990

This manual is subject to alteration without prior notification.

OKI

ELECTRIC INDUSTRY COMPANY, LTD.

CONTENTS

Page

CHAPTER

1.1

1.2

CHAPTER

CHAPTER

3.1

’ ~’

3.2

3.2.1

3.3

3.3.1

3.4

3.5

3.6

3.6.1

3.6.2

3.6.3

3.6.4

3.7

3.7.1

3.7.2

3.7.3

3.7.4

3.7.5

3.7.6

3.8

3.9

3.10

3.10.1

3.11

3.11.1

3.11.2

3.12

3.12.1

3.12.2

3.12.3

1. GENERAL INFORMATION

Features . . . . . . .

General Appearance

2.

SPECIFICATIONS 2

..__...__.______..________............_...._____________

.

-

3. INSTALLATION

..-

General

Installation Site

Environments

Unpacking

UnpackingProcedure

ContentsChecking

ACCordConnection

InitialSettings

General

DIPSwitchSl

SlideSwitchS2

Programming by Key Operation

Optional Settings

General

Polling Number (Password) Programming

Access Digit Programming

TWCSI

TechnicalSet-up

Line Monitor Acoustic Sound

Telephone and Line Connection

Frame Ground Connection

Accessory Installation

Thermal Recording Paper

Off-IineTest

Checkltems

Operation Procedure

On-lineTest ________._____.______.___________.__________________________

General

Reception

Transmission

....................................

..........................................................

..........................................................

.............................................................

...................................................

......................................................

....................................................

..........................................................

................................................................

...........................................................

.........................................................

.......................................................

................................................................

.

..............................................

(Tel. No.) Programming

........................................................

............................................

..........................................

...................................................

............................................................

............................................................

................................................................

________.___________.___._____________________________________

____.___________________1____._.___________________________

.........................

.

3-38

l-l

1

-

1

3-l

3 - 2

3-2

3-2

3-2

3-3

3-3

3-4

3-4

3-5

3-7

3 - 8

3 - 22

3-22

3 - 23

3-24

3 - 25

3-27

3 - 31

3 - 33

3 - 34

3 - 35

3 35

3-37

3-37

3 - 37

3-38

3-38

3-39

2

-i

Page

CHAPTER

4.1

4.2

4.2.1

4.2.2 ToneTest

4.2.3

4.2.4

4.2.5

4.2.6

4.2.7 ROMTest

4.2.8

4.3

CHAPTER

5.1

5.1.1

5.1.2

5.1.3

5.1.4

5.2

4. MAINTENANCE

Routine inspection

Self-Diagnosis Tests

LEDTest

High or Low Speed MODEM Transmission or

PBSendTest

PrintTest ________.______.__.______________________..____.___...........

image

RAMTestandClear _______...________________..........____._____...__..

LC Display Data in Error State

_________._______._______.__._______..__.._________.___..._._.. 4-4

Sensor Test

5. ADJUSTMENT

Electrical Adjustments

Ringing Signal Detection Sensitivity

Dial Tone and Busy Tone Detection Level

Dial Tone and Busy Tone Detection Level (2)

Line Monitor Acoustic Sound Adjustment

Image Sensor Output Waveform Check

.,

_____.___________________.____._._______._.___.____......_....

Recepti~on

___.____._.__________.___._.____.__________..___...........

___..___.___.._______.._.___..._____.....

_____.______.__________..__.___,__.___.____________..i........

_________._____.______________...____.......

.,.

(I)

.

_.

______.______.._____...__.........

Test

. . . . . . . . . . . .

4- 1

4 - 3

4-5

4 - 6

4-8

4-9

4-11

4-12

4-13

4-

14

5-l

5-l

5-3

5-5

5-7

5-7

CHAPTER

6.1

6.1.1

6.1.2

6.1.3

6.1.4 Abnormal Print-out

6.1.5 NoGood Local Copy

6.1.6

6.1.7

6.1.8 Transmission Communication Trouble

6.1.9

6.1.10

CHAPTER

7.1

7.1.1

7.1.2

7.2

7.3

6. TROUBLESHOOTING

Electrical Troubleshooting Flow Chart

Overall

NoGoodLCDOperation .______._._____._____._________._______________._

LitAlarmLED _._.___.__.____._______________________________._____...___

No Dial-Tone Detection

No Auto-Dialing

NoAuto-Reception ____._______________________..___..__________.__._.._

Reception Communication Trouble

_._.._._...______._________._________......____.______.__.______

_. _______..______.____________. _...__ _._____._ __.

__

_. __ _. _. _. _.

7. DISASSEMBLY & ASSEMBLY

General

Precautions for Parts Replacement

Tools

General Mechanical Structure

How to Disassemble and Reassemble

_______..___._.____.____.__.._____.______..._____...__......__..

_.___.__._.......__...._.___..____.______.__________.__._____._.._

_______..___.________._.____._______...

6 - 1

6-l

6-3

6-5

6 - 6

6-7

6 - 9

6-

12

_.

6-

14

6-16

6-

17

7-1

7-l

7-l

7 - 2

7 - 3

_

ii

_

Page

7.3.1

7.3.2

7.3.3

7.3.4

7.3.5

7.3.6

7.3.7

7.3.8

7.3.9

TopCover .________...........________..................................

PrintScanlJnit

MCNTorNCUPCBoard

OPE PC Board

PowerSupplyUnit

Image Sensor Unit, Document Exist Sensor

Separation Rubber, Feed Roller

Print Roller, Recording Paper Detector

Thermal

CHAPTER

8.1

Lab,\ 8.1.1

8.1.2

8.1.3

8.1.4

8.2 SignalFlow

PC

PC Board

Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overall Circuit Diagram

General Block Diagram

._._.............______...._._______________.____________

_____.........______..._..................................

HeadAss’y

. . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . .

..___...._______._._________.__..__....

..____...........__.__________....____..

.

.._._____..............._

8. BRIEFTECHNICAL DESCRIPTION

BoardandUnit

___._______________...______________~____.._._____________.___

____________.__.__________________........................__

. .._.._________..._..._.__.___________________________ B-l

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .

__._........_....

7-3

7-S

.

.

.

8-4

7-7

7-9

7-9

7 - 10

7-

12

7-

14

7- 16

8-1

8-l

8-1

B - 1

CHAPTER I:

GENERAL INFORMATION

CHAPTER 1.

GENERAL INFORMATION

1.1

1.2

Features

GeneralAppearance

.................................................

......................................

l-l

l-

2

CHAPTER 1.

GENERAL INFORMATION

1.1

Features

The

OKIFAX

(1)

(2) Sixteen-halftone transmission

(3)

(4)

(5)

(6)

(7)

(8) Acoustic monitor

(9) Local diagnosis

OF-7 has the following main features:

Direct contact image sensor

Ten one-touch key for auto dialing

One specified time delay transmission

Access digit for PTT line

Automatic response delay for auto receive

Activity report print out

(10)

Over heat protection

l-l

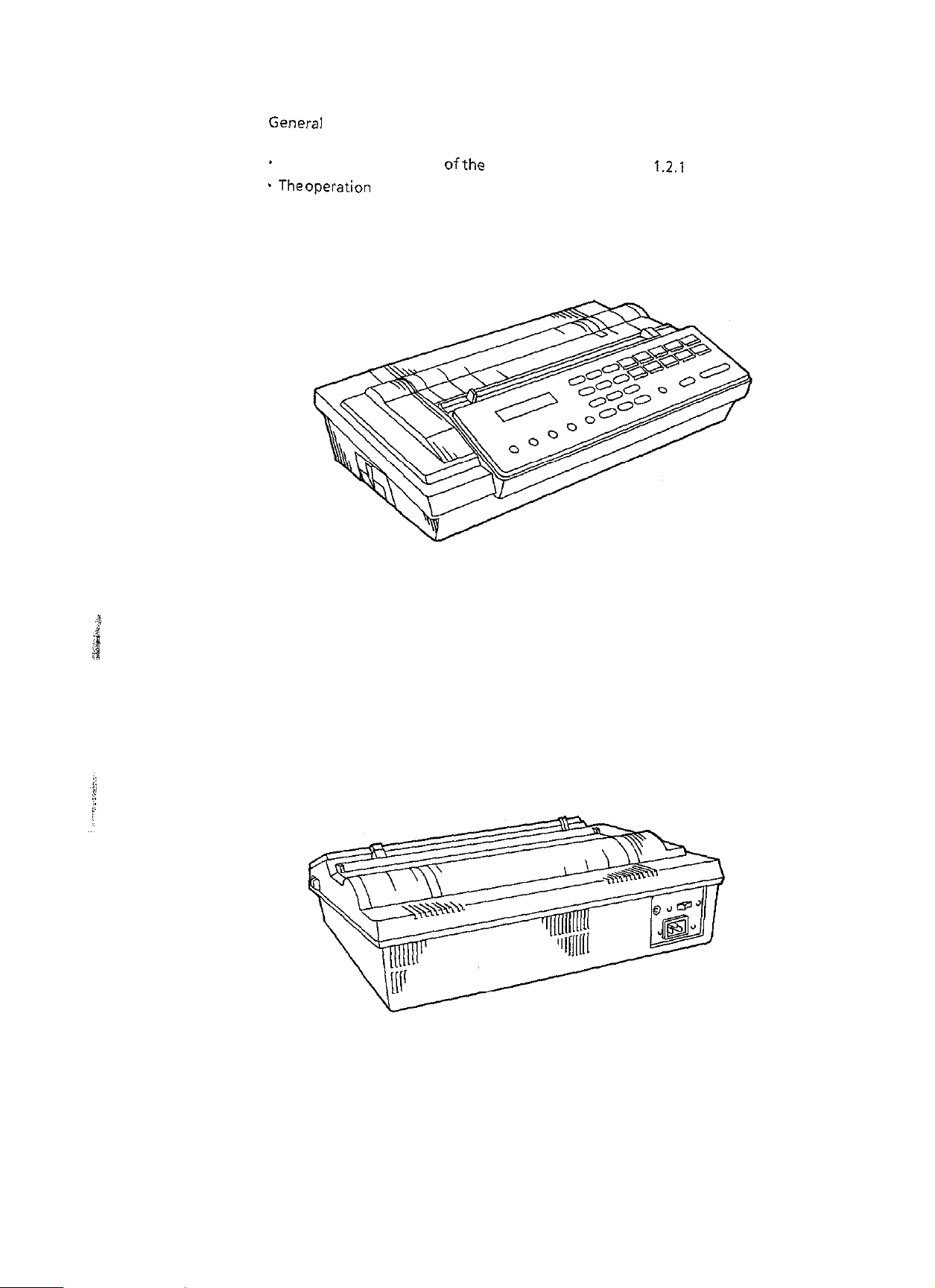

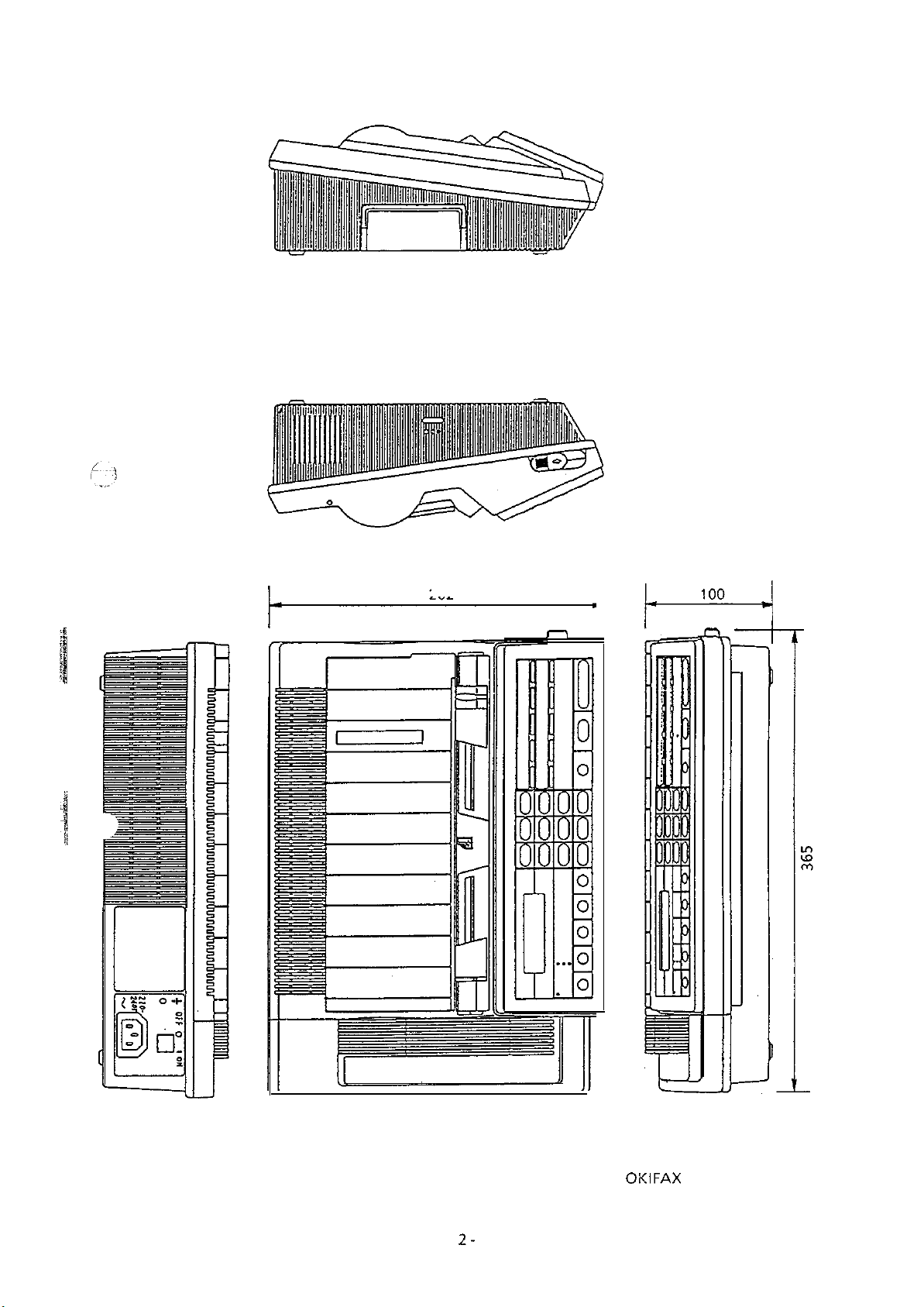

1.2

Genera1

I

The general appearance

.

Appearance

ofthe

OF-7 is shown in Figure

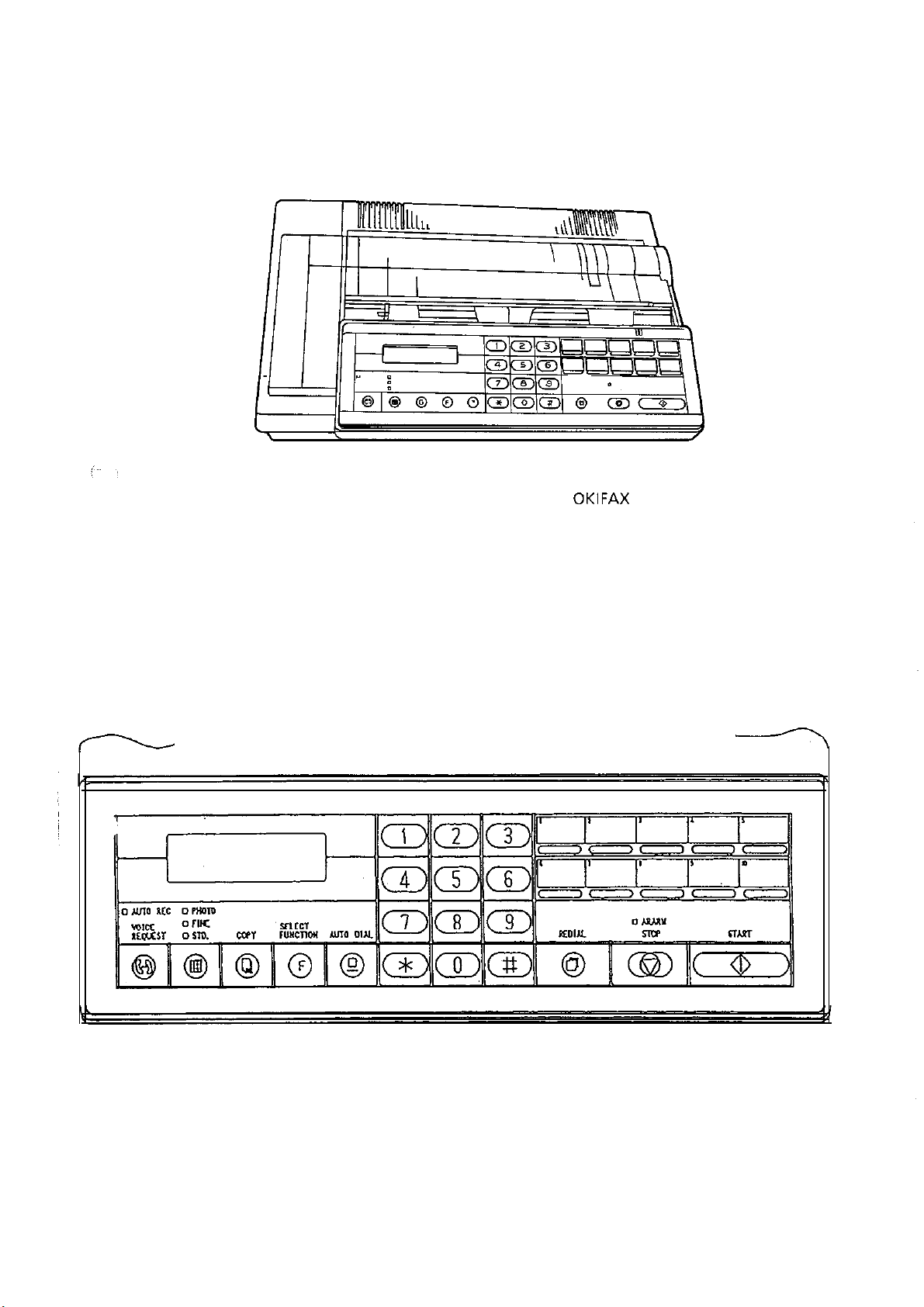

The

operation control Panel of the OF-7 is shown in Figure 1.2.3 and Figure 1.2.4.

1.2.1

and Figure 1.2.2 below,

Fig. 1.2.1

General appearance (frontview)

Fig. 1.2.2

General appearance (rear view)

1-2

Fig. 1.2.3

Operation control panel of the OKIFAX OF-7

Fig. 1.2.4 Operationcontrol panel (expansion)

1-3

CHAPTER

2:

SPECIFICATIONS

CHAPTER 2.

SPECIFICATIONS

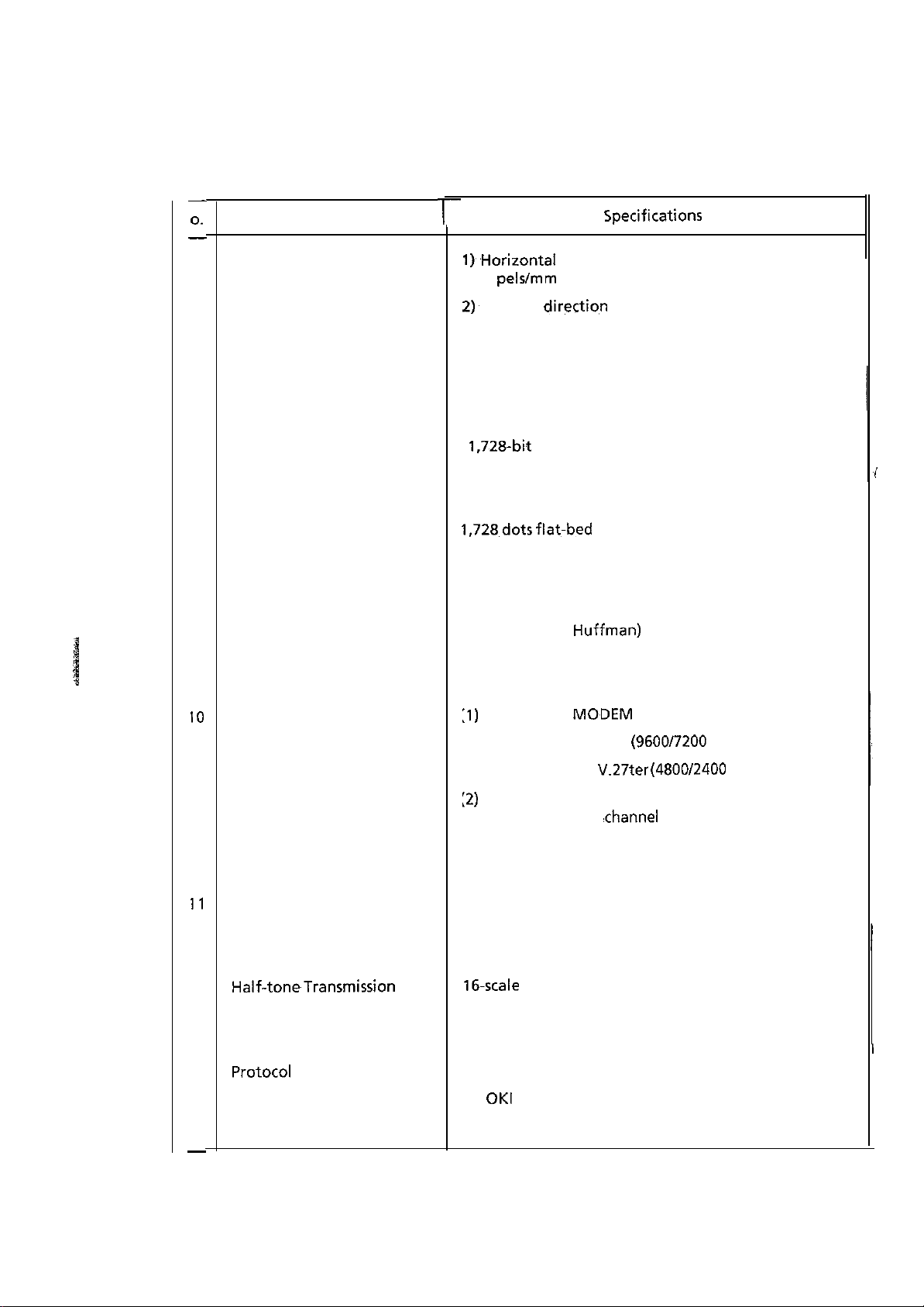

The table below

lo.

Type of Apparatus

1

Applicable Telephone Line

2

Communication’Mode

3

Transmission Mode

4

givesthe

item

specifications

.

CCITT Group 3 facsimile transceiver

Half-duplex

for

the OKIFAX OF-7.

‘Specifications

.

Desktop design

(1) GSTN (General Switched Telephone Network)

(2) PBX extensions

* PBX: Private Branch Exchange

CCITT

G3 mode

”

Document Size

5

(1) Width

Max.: 216

Min.: 148 mm (IS0 A5 size)

(2) Length

Max.: 1000 mm

Min.: 128 mm

mm,(American

lettersize)

2-l

-

0.

-

6

Resolution

Item

r

l),

,Horizontal direction

8

pelslmm

2).

Vertical

a) 3.85 lines/mm (STD)

b) 7.7 lines/mm (FINE)

directiqn

Scanning Method

7

Recording Method

8

Coding Scheme

9

MODEM

IO

1,728-bit Direct Contact image sensor

l,728,dotsflat-bed

One-dimensional coding scheme:

MH (Modified Huffman)

:l)

High-speed

CCITT Rec. V.29 (9600/7200 bps)

a)

CCITT Rec.

b)

:2)

Low-speed MODEM

CCITT Rec. V.21

thermal printing head

MO,DEM

V.27ter

(4800/2400 bps)

,channel

2 (300 bps)

Transmission Time (image)

11

12

13

-

17 seconds

16.scale

Dither algorithm

(1) CCITT Rec. T.30

(2)

gradation

OKI

special protocol

2-2

b.

14

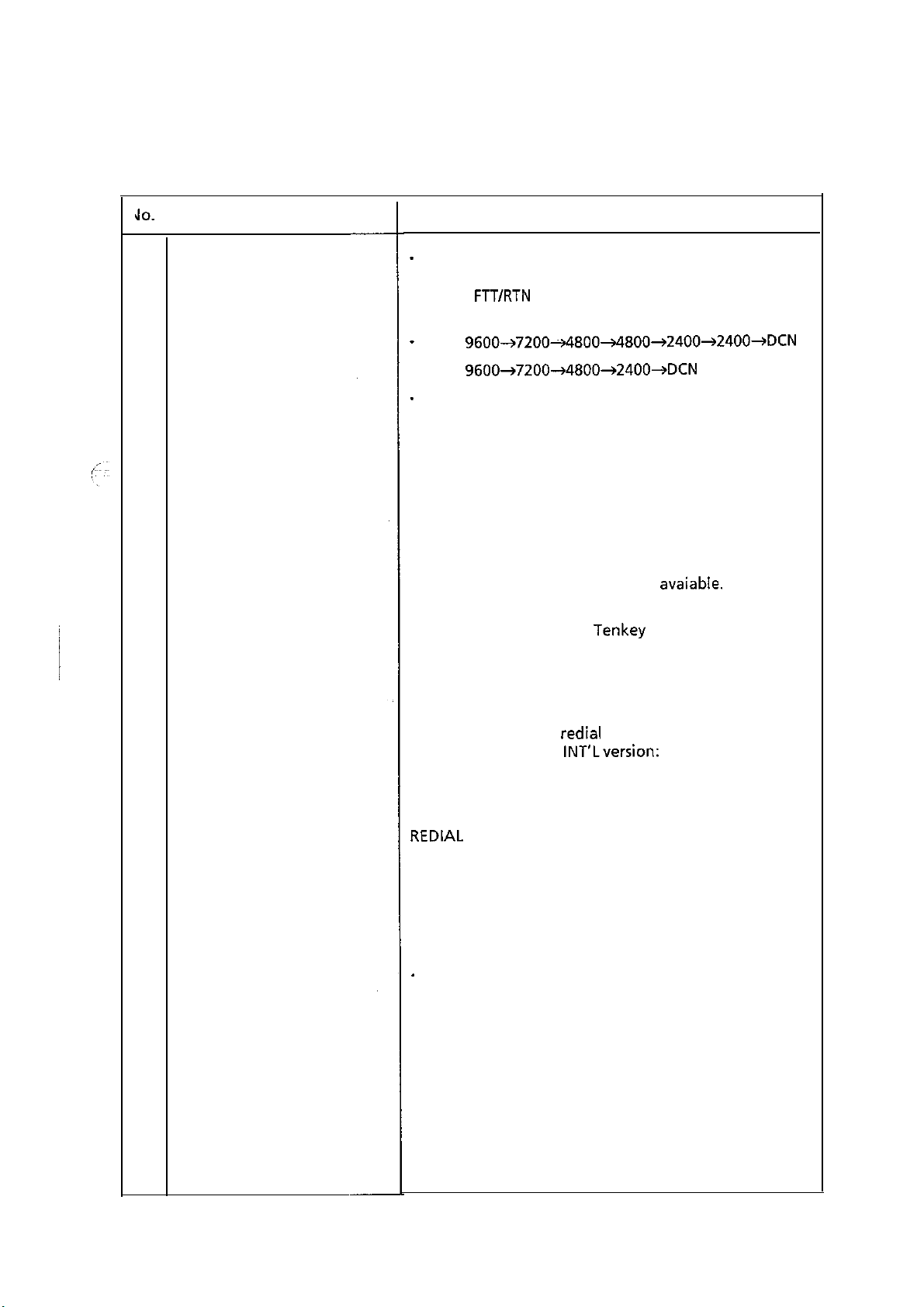

Fall-back

Item

Specifications

.

The automatic fall-back system will attempt

transmission in the following sequence in accordance

with an

FTT/RTN

response signal from a remote

machine.

.

FTT

9600+7200+%800+4800+2400+2400+DCN

15

Auto Dialing

Auto Redial

16

. RTN

.

The transmitter can transmit a DCN signal to the

9600+7200+4800+2400~DCN

remote station for disconnection after the second

2400 bps transmission is attempted.

(1) One-touch key

10 one-touch keys are provided.

(2) Two-digit location code

10 different location codes are

avaiable.

(3) Full-digit location

Operator can use the Tenkey pad for a full-digit

location number.

. Fixes the

number

of

redial

attempts in accordance

with PTT parameter INT’Lversion: 2 tries (fixed).

17

Manual Redial

18

Voice Request

19

Local Copy

REDIAL

key provided

. No limit on number of repeat attempts.

. VOICE REQUEST key provided

.

A voice request from the receiver/transmitter is

available only upon completion of the total message

transmission/ reception.

Copy reproduces document only with 7.7 lines/mm

resolution.

2-3

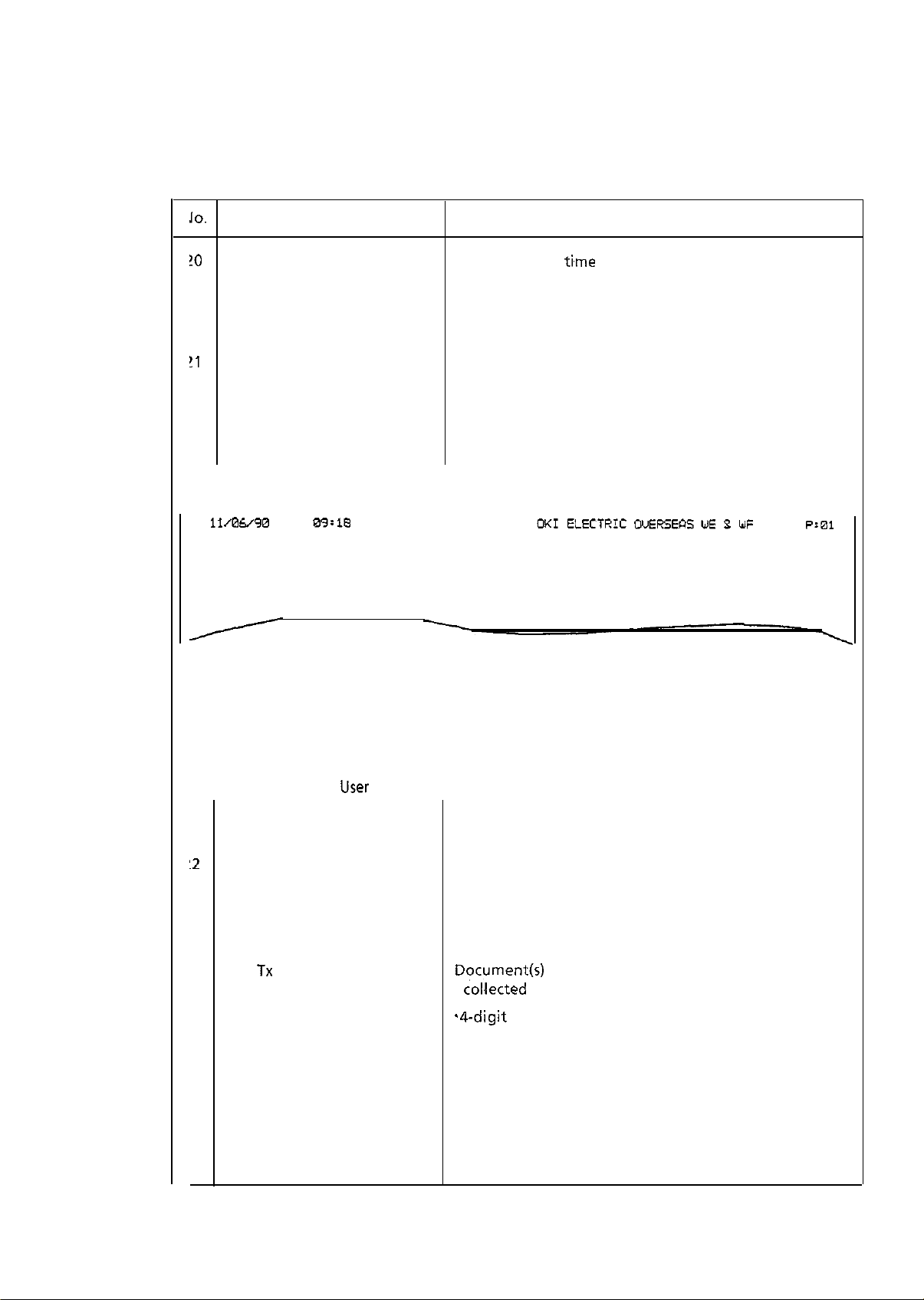

lo.

!O

!1

Delay Send

(Feeder)

Sender ID

Item

09:ie

Specifications

. One specified

ti,me

of the delay transmission is

available.

The OF-7 can transmit a programmed alphanumeric

message, such as company’s name, consisting of up to

32 characters.

Sender’s ID format (example)

:2

Personal ID

Poll

3

(To be polled)

Notes: (1) Sender ID print position

User or service personnel can select the sender ID print position that is

inside or outside of the top of every reproduced page at the remote

receiver.

(2) Sender ID data transmit or not

User

or service personnel can select the sender ID data transmit or not.

Upper 16 digits of the Sender ID are separately sent to

the remote machine to indicatethe “Personal ID.”

TX

Dpcument(s)

cokcted

. 4-digit

set on the feeder can be automatically

by a remote station.

poll number is provided.

2-4

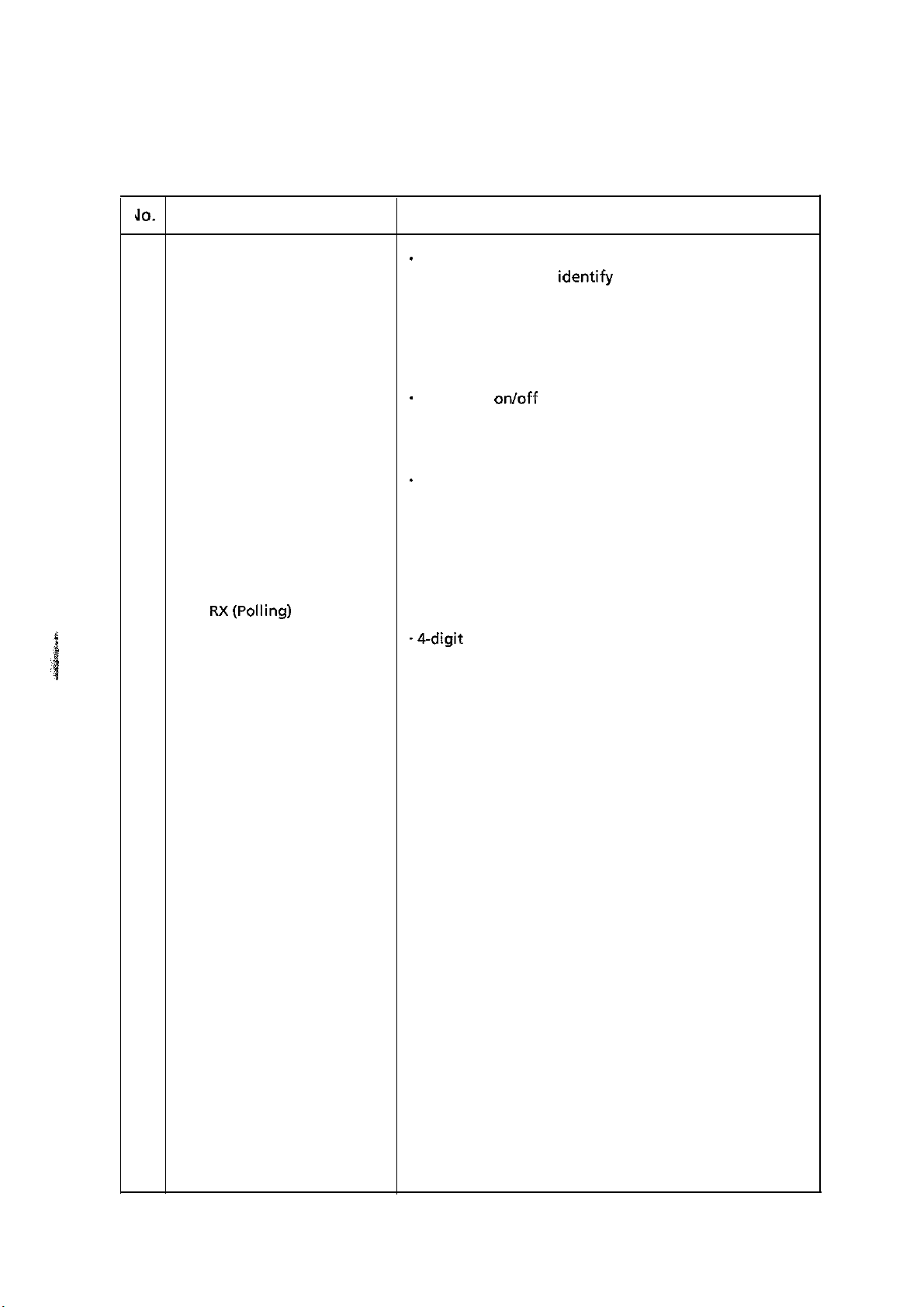

JO.

Item

Specifications

24

Access Digit

.

The OF-7 can set a digit-string (one to four digits) with

which the OF-7 can

identify

the originated call as

either PBX extension call or a call going out from PBX

to a PTT line.

25

Auto Receive

26

Automatic Response Delay

Selectable

.

Service personnel can selectthe delaytime of

on/off

by a key on the operation panel

.

automatic response time of the machine.

. 1 ring and 5 seconds, 30 seconds, stepped by 5 seconds.

Poll RX(Polling) Collection of message(s) from a remote station

27

.4-digit

password is provided.

2-5

UO.

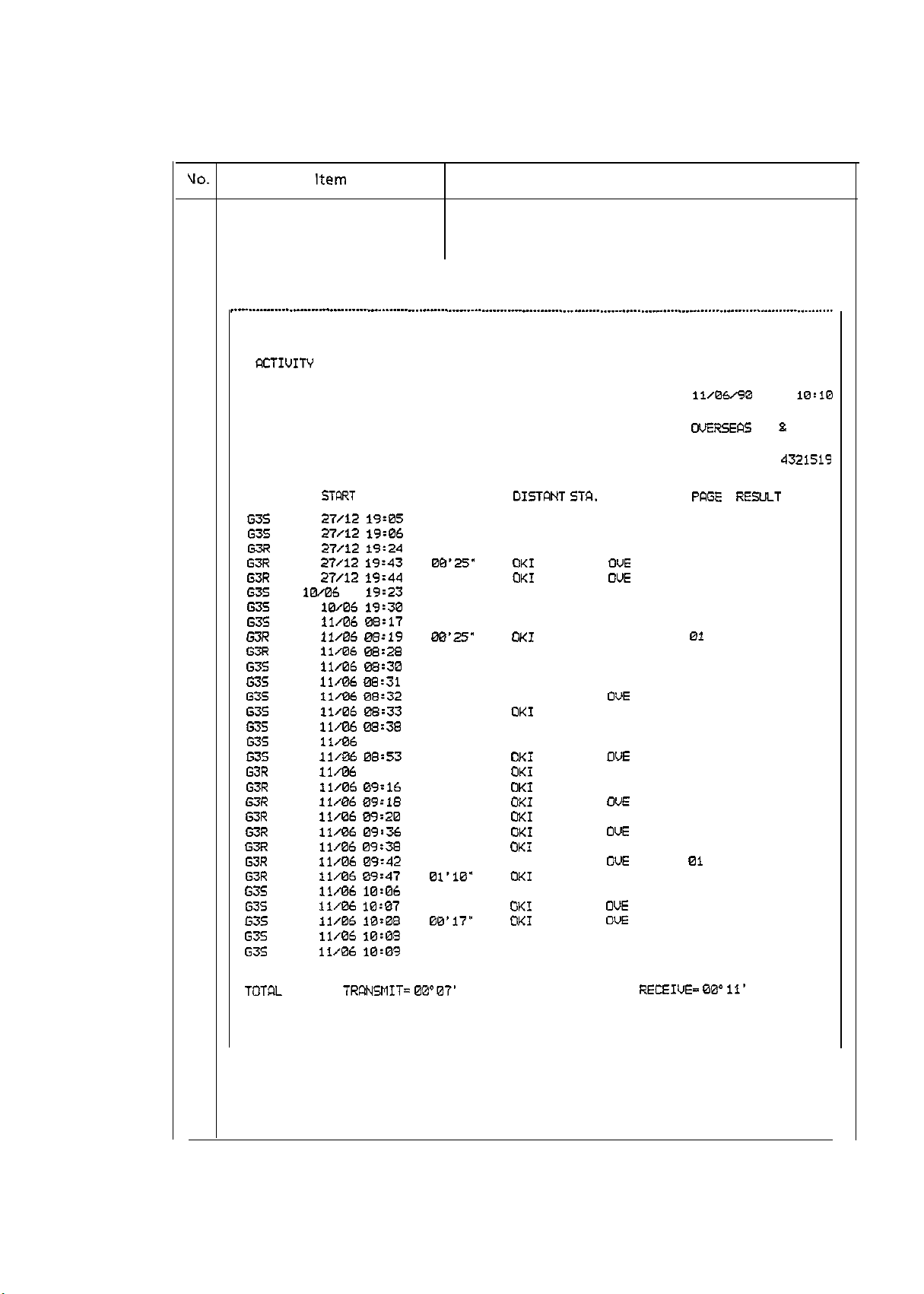

28

Activity Report

Item

Specifications

The OF-7 can print out the activity report manually or

automatically when 30 reports are recorded.

Activity Report format (example)

RCTIUITV

NODE

G35

635

m

G3R

G3R

635

635

635 11106 08:17

G3R

G3R

635

635

635

635

635

635 11106

635

G3R

G3R

G3R

G3R

G3R

G3R

G3R

G3R

635 11106 10:06

G3S

635

635

635

REPORT

STRRT

TIME

27112 19:05

27/12 19:06

27/12 13124

27/12 19143

27/12 19:44

lW06

19:23

10/06 19:30

IV06 08:19

lW06 08:28

11/06 OS:30

11/06

OS:31 00’25”

11/06 08132

11106 OS:33

11/06 OS:38

08-51 01’14” OK1 ELECTRIC OUE

11/06 OS:53

11106

09-15 00’25’

11x06 09:lb

11/06 09:18

lW06 09:20

11/06 09:36

11106 09:38

11/06 09142

11106 09:47 01’10”

11/06 i0:07

11/06 10:08 00’17”

11/06 10:08

11/06 10:03

11/06/90

OK1 ELECTRIC

TIME

00’29’ 6

00’23’ 2

00’22’ 01 OK

00’25”

00’25’

00’02” 6

00’30” OK1 ELECTRIC OUE 01 OK

06’21’ OK1 ELECTRIC OUE 01 OK

00’25’

00’43”

00’ 12”

00’26’ OK1 ELECTRIC

00’ 12’

00’34” OK1 ELECTRIC OUE

00’32”

00’25”

00’25” OKI ELECTRIC

00’25”

01’23”

02’24’

01’54” OK1 ELECTRIC

00’09’

00’17”

00’35’ OK1 ELECTRIC OUE

00’11”

DISTQNT STR.

OKI ELECTRIC O”E 01 OK

OK1

ELECTRIC

OK1

ELECTRIC GUE 01 OK

OK1

ELECTRIC OUE

OK1 ELECTRIC OUE

OKI ELECTRIC OUE

OK1

ELECTRIC

OK1

ELECTRIC WE

OK1

ELECTRIC OUE

OK1

ELECTRIC OUE

OK1

ELECTRIC

OK1

ELECTRIC OUE

OK1

ELECTRIC OUE

OI<I

ELECTRIC

WI

ELECTRIC WE

OK1 ELECTRIC OUE

ID

O”E

2

OUE

O’JE

OUE

OUE

OUE

6

OUE

WERSEQS

0081 3

PFlGE RESLkT

01 OK

03 OK

02 OK

03 OK

07 OK

01 OK

01 OK

01 OK

01 OK

01 OK

01 OK

01 OK

01 OK

01 OK

01 OK

01 OK

10:10

WE X WF

4321519

STOP

STOP

STOP

NG

STOP

NG

NE

STOP

NG

TOTQL

TIME

TRRNSMIT= 00’07’

2-6

TOTPL TIME

RECEIUE= 00’11’

Item

Specifications

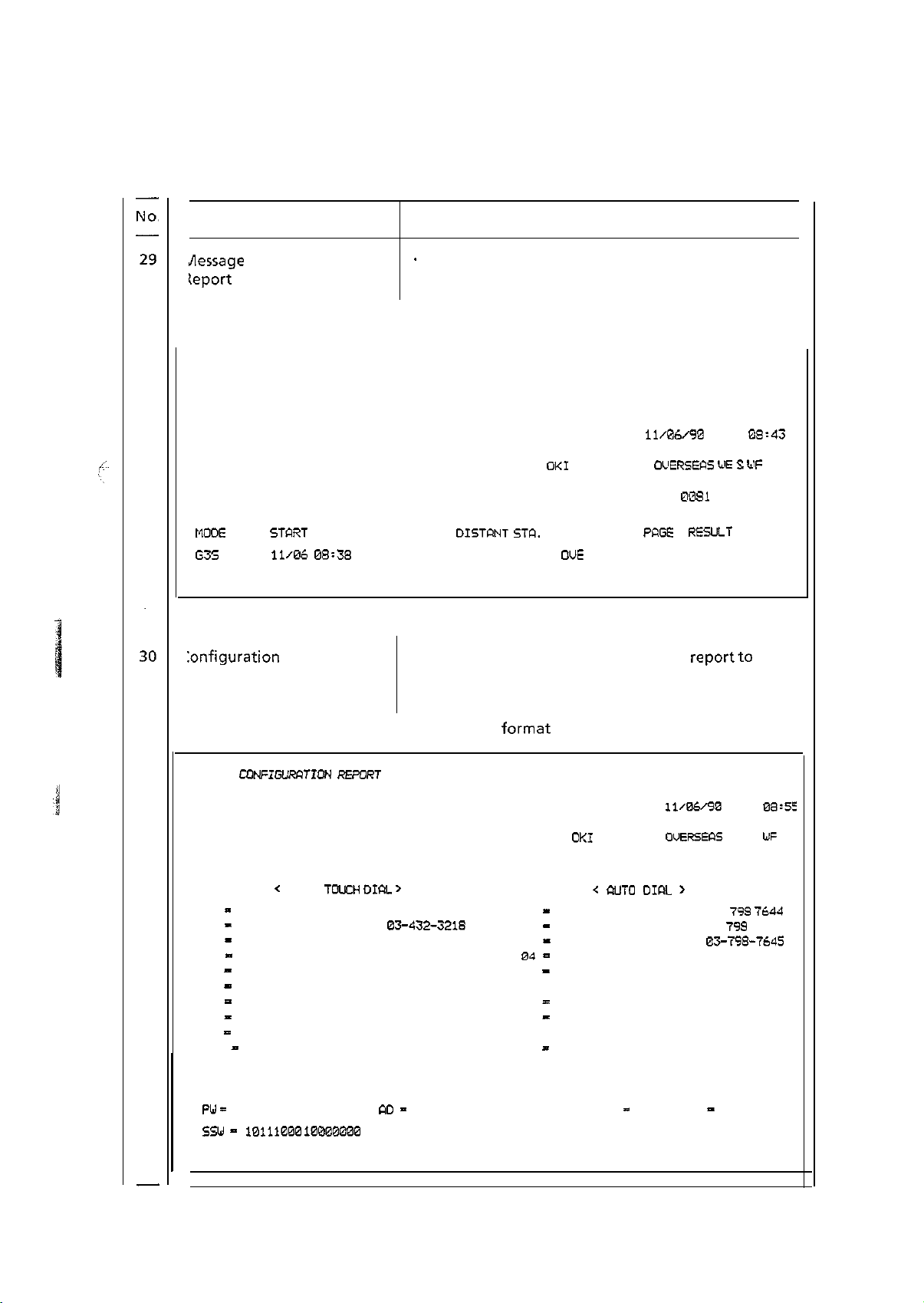

Jlessage

Confirmation

teport

CONFIRMRTION REPORT

ST’ART

MODE

G3S

TIME TIME

11106

OS:38 00’34’

:onfiguration Report

.

The OF-7 can manually print out a message

confirmation report after the message have been sent

Message Confirmation Report format (example)

11/06/90

OISTONT STQ.

OK1 ELECTRIC

OKI ELECTRIC

IO

OUE

OUERSEFIS lrlE S UF

POGE RESULT

03 OK

The OF-7 can print out a configuration reportto

confirm an initial setting, or rearrange the machine

configuration.

00s

3 4321519

05:43

CSM=IWRh-TIW

01

-

02

-

03

=

04

=

05

=

06

=

07

=

08

=

09

-

10 =

PW -

0000

SSW -

10H1000 i0000000

(

ONE

Configuration Report

REPORT

TOLCH 01% >

03 432 1519

03-432-3218

03-432-3219

QO =

41234

00000000 00010000 00100000 00010000 10000100

format

01

02

03

04

05

06

07

08

09

10

(example)

OKI

ELECTRIC

( !auTO OIQL )

=

=

=

=

=

=

-

=

=

REP = 2

11,06/96

OUERSEFIS

03 795 1644

03 799 7614

03-798-7645

RINT = 3

WE 8

08:5E

WF

-

2-7

-

UO.

-

Item

Specifications

Acoustic Monitor

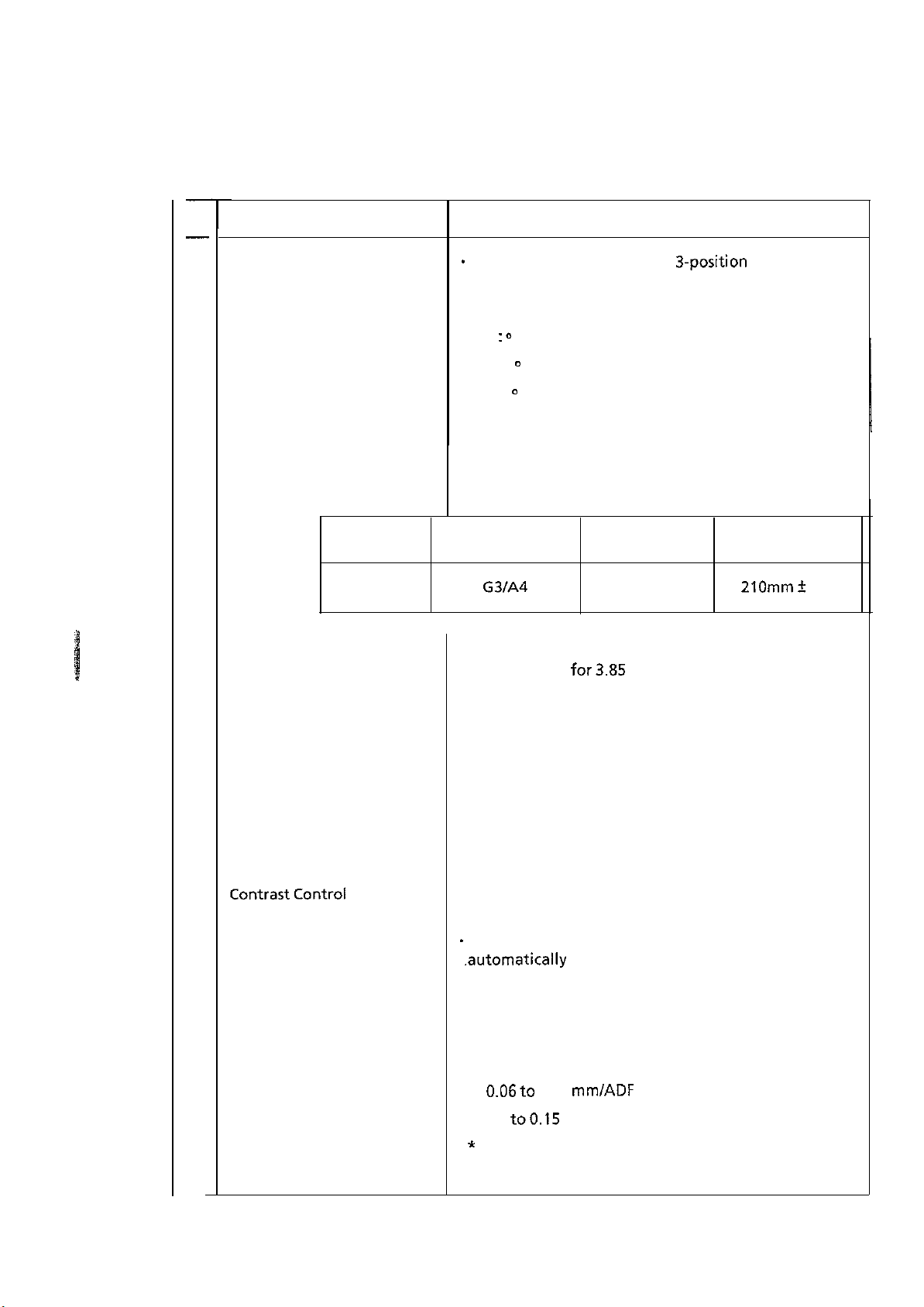

31

Effective Reading Width

32

One-line Minimum Scanning

33

.

Loudness is selectable with a

(high, normal, low)

Acoustic monitor ON/OFF is set by the service personnel.

ON : 0 Dialing-FAX signal reception

0

Stating the reception-before sending NSF

OFF: 0 Not monitered.

Document Communication

Width Mode/Paper Width

A4 size

(210 mm)

G3lA4 A4

10 millisecond

5 millisecond for 7.7 lines/mm

for365

Copy Size

lines/mm

3.position

Effective Reading

Width

ZlOmm+

slide switch.

1%

One-line Minimum Print

34

Time

35

36

Transmission Document

(1) Thickness

10 millisecond for 3.85 lines/mm

5 millisecond for7.7 lines/mm

Automatic paper-background sensing control is

provided.

.

The Light and Dark contrasts (low contrast) is

.automatically

enhanced to improve image quality.

The documents must be rectangular in shape, and

must be placed face down on the ADF stacker.

a)

0.06to

b) Up

0.13

too.15

mm/ADF

mm/single sheet

* Kind of documents must be a high quality paper,

2-a

No.

Item

Specifications

(2) Shape

(3) Opacity

(4) Automatic Document

Feeder (ADF)

Document Damage

37

Document Jam Detection

38

Documents must be rectangular in shape.

.

The machine will properly reproduce documents

whose opacity is more than 60% is normal mode/and

more than

.

Max. 5 documents/A4 size

7O%is

photo mode.

The document will not be marked, wrinkled or torn as a

result of being sent throuth the feeder or scanner.

(1) Within

lm

Transmission will stopand a line disconnectwill

occur when the end of the document is not

detected within lm after scanning begins.

Document Jam Removal

39

(2) 5 seconds

Notice will be given if the document does not reach

the scanning position within 5 seconds after the

document feed begins.

.

If document is not detected,the document feed begins

after pressing COPY key.

2-9

NO.

-

40

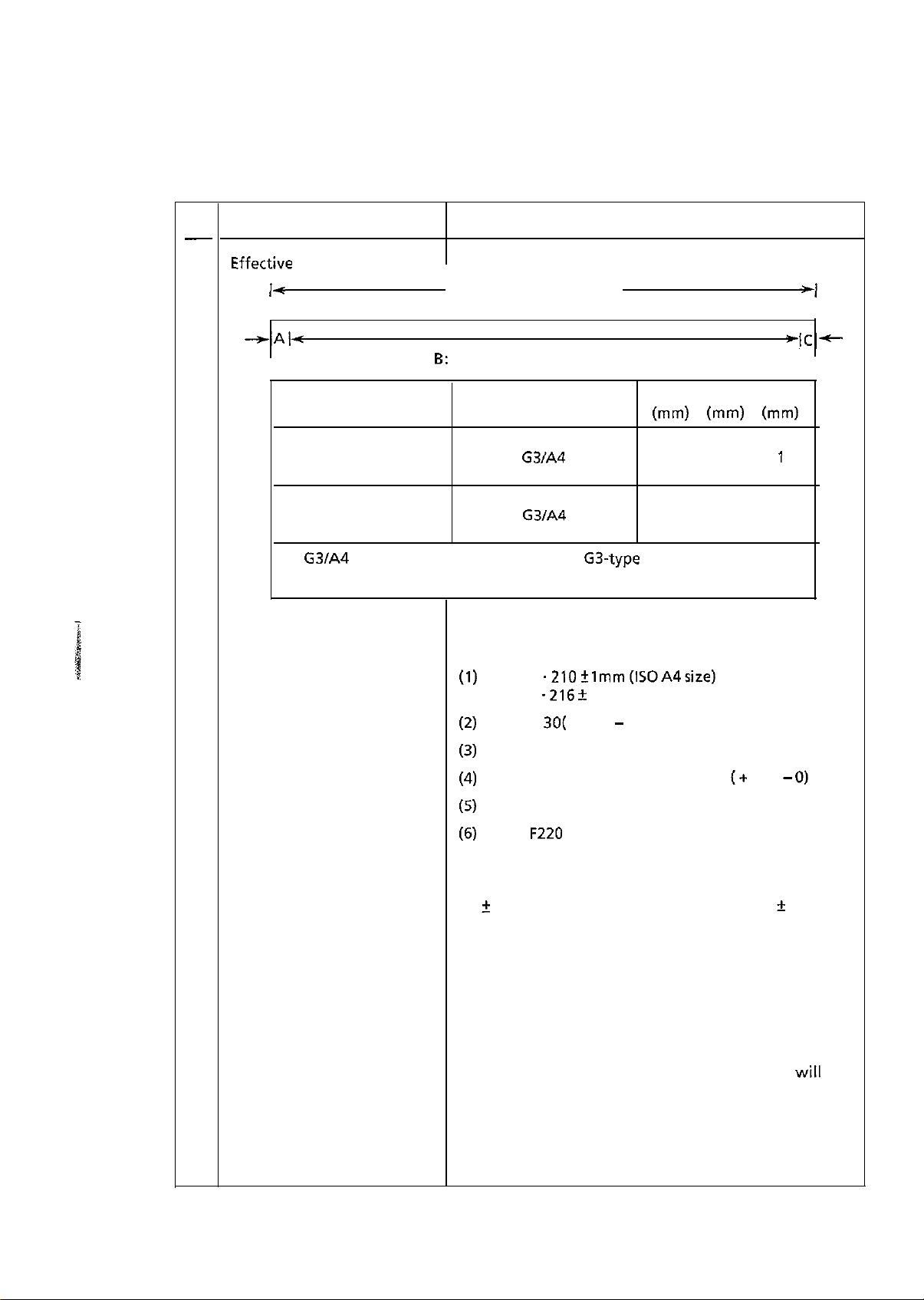

Effecthe

Item

Recording Width

Specifications

IN

Recording Paper Size

A4

(210 mm)

Letter

(216 mm)

* G3/A4 Denotes receiving a signal from G3-type machine transmitting

A4 documents.

41

Recording Paper . Highly thermosensitive paper

Recording paperwidth

6:

Effective recording width

Communication Mode*

G3/A4

G3IA4

Width: .ZlO?r

(1)

.216 ?:

Length:

(2)

Printing color: Black

(3)

Inside diameter of paper roll: 25.4 (+ 1 or - 0) mm

(4)

Outside diameter of paper roll: about 65 mm

(5)

Type:

(6)

30(

+ 2 or - 0) meters per roll

F220

KB (Mitsubishi), or equivalent

A

(mm) (mm) (mm)

1

4

lmm(ISOA4size)

1 mm (American letter size)

B C

208

208 4

1

42

Skewing of Recording Paper

Indication of Remaining

43

Recording Paper

Recording Paper Running

44

out

The maximum allowable skew of the recording paper

is ? 2 mm over a 30 meter roll of paper, and f 1 mm

over any advance of 2 meters.

The remaining recording paper may be viewed

through the window on the paper compartment

cover.

When the paper is running out, a photo sensor will

detect “No Paper” status, and LC Display will show

“NO PAPER”.

At the same time the machine will be occurred an

alarm tone, and ALARM lamp will be turned on.

2-10

Item

Specifications

Copy Density

Copy Uniformity Printed copies will exhibit a uniform density of the

Line interface Requirements

(1) Printed black image greaterthan 1.15 OD (Optical

density) unit.

(2) White background (unprinted area) no greater

than 0.2 OD unit.

printed and background area:

(1) From edge to edge: 0.2 OD unit

(2) From

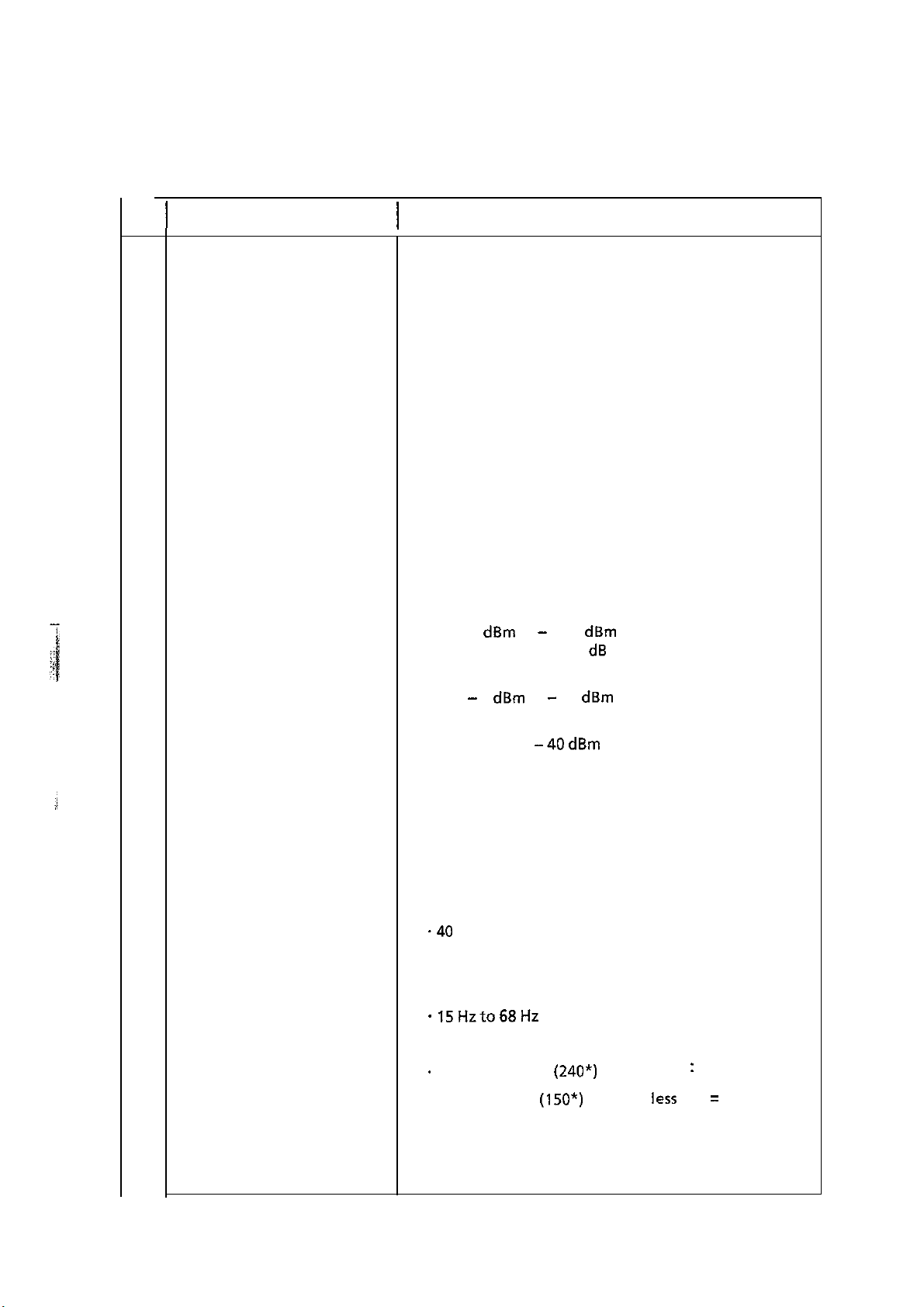

(1) Impedance

(2) Sending power level

(3) Receiving power level

copy

to

copy:

600 ohms balanced

0

dBm

*

a)

(factory setting: Germany)

to - 15.5

Adjustable in 0.5 dB steps

-

6

dBm

to - 46

dBm

dBm

0.3 OD unit

range

range

Ring Detection Sensitivity

b) OdBmto

(factory setting: without Germany)

c) OdBmto -34dBm

*

Adjustable by registor combinations

(1) Voltage range

.40

volts to 150 Vrms

. No operate below 17 volts

(2) Frequency range

. 15Hzto68Hz

(3) Ring voltage duration

.

Longer than 180

. No operate 90

Note: The ring-detect circuit will not activate on dial

pulse 10 pps, dial tone, or other spurious noises

on the telephone line.

-4OdBm

(240*)

(150*)

msec.

msec. or

* : In case that

PTT parameter

=

less

Norway.

2-11

\I0

-

Item

Specifications

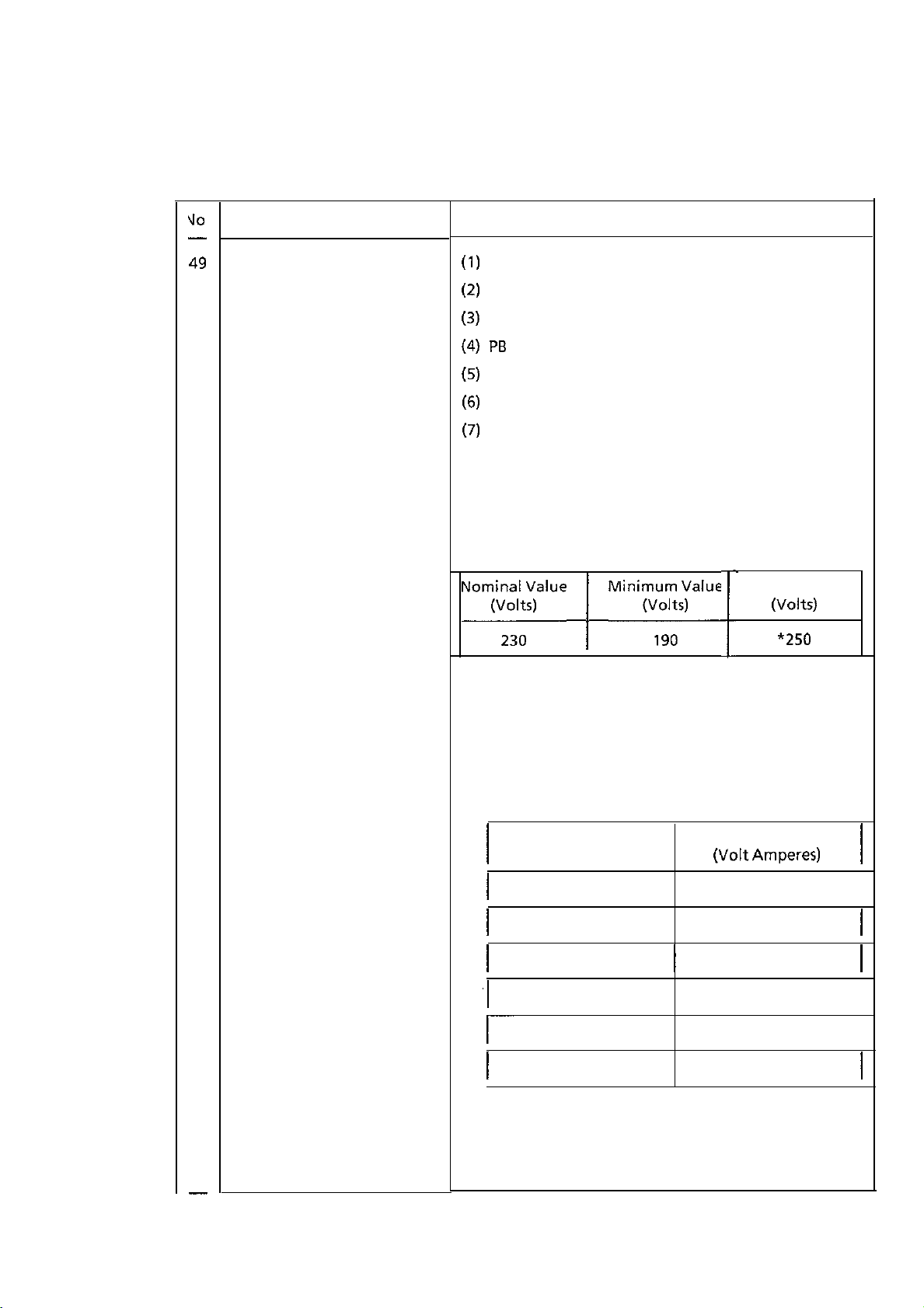

49

Local Diagnosis

50

AC Power

LED test

(1)

Tone sending test

(2)

High-speed MODEM test

(3)

PB

tone test

(4)

Print test

(5)

Image sensor test

(6)

ROM test

(7)

RAM test and RAM clear

(1) Voltage range

Nomiilue

Note:

The power supply will work at 260 volts actually,

but the maximum value shows 250 volts

according to PTT regulation.

1

Mini:ylue

Maximum Value

(Volts)

t

*250

(2) Frequency range

47 Hz to 63 Hz

(3) Power consumption

I

I

I

I

,I

I-~-~~~

I

-

Mode

Transmit

Receive

Receive (All Black)

Copy (Normal)

Copy (All Black)

Standby

Typical Power

(VoltAmperes)

1

60 VA

60 VA

200 VA

85 VA

210 VA

29 VA

I

I

I

I

I

I

I

2-12

IO.

Item

Specifications

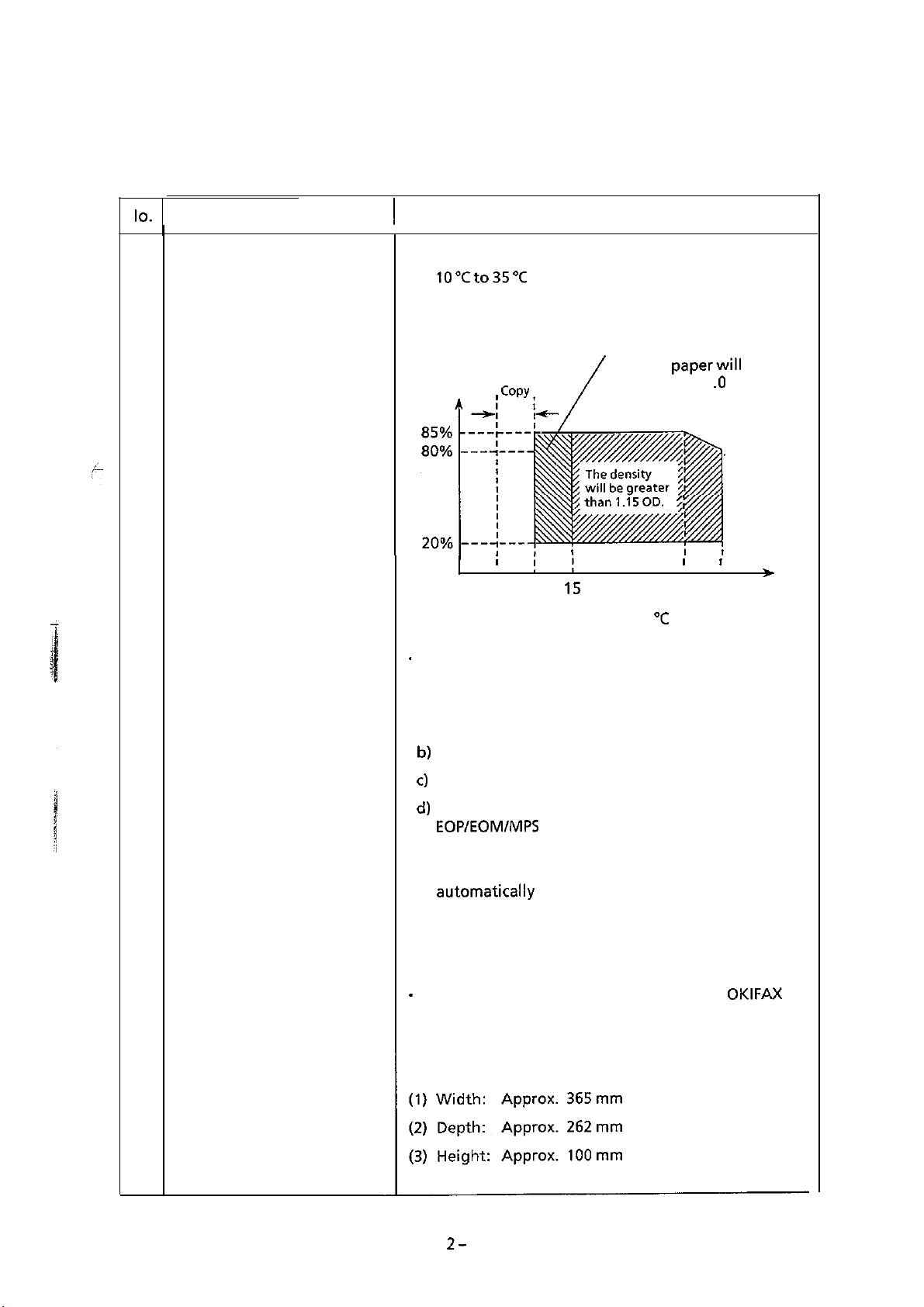

Ambient Conditions

Overheat Protection

(1) Temperature range

lO”Cto35”C

(2) Humidity range

20% to 85%

The density of a block

image printed on

thermal paperwill be

Degraded

.

The OF-7 can detect an overheating condition with the

Quality

, COPY.

i

10

5

greater than 1 .O OD unit.

/

than1.15OD. :

15

Temperature

“C

I

I

30 35

P

thermal print head’s electrical current volume, it will

interrupt the reception as follows:

General Appearance

Dimensions

a) Stop the printing

b)

Generate an alarm tone

c)

LC Display shows “HEATALARM”

d)

Return a DCN signal after responded to

EOPIEOMIMPS signal from the remote station.

* As the overheating condition is removed by natural

cooling, the alarm message on LC display will be

automatically

altered with the normal clock

indication.

.

General appearance and dimensions of the OKIFAX

OF-7isshownin Figure2.1.

2-

13

No.

1

item

Specifications

55

Weight

Reliability

56

(1)

MTBF

(2) Thermal Print Head

(3) Feeder Separation

Rubber

Approx. 5 kg

. The MTBF

hours of actual operation.

*

MTBF will be measurable at a confidence level of

95 percent under controlled laboratory conditions.

.

The MTBF will be based on 50 percent transmit and

50 percent receive activity.

. The life of any given element on the print head will be

greater than 3 x 107 cycles.

*

One cycle is defined as the sequence required to

print one black picture element.

. The separation rubber does not

for at least 10,000 document feeds.

for

the overall machine will exceed 6,000

req~uire

replacement

57

Accessories

(1) AC power code

(2) Thermal recording paper

(3) User’s guide

2-

14

262

I

-

/

f

Fig. 2.1 General appearance and dimensions of the

2-

15

Unit: mm

OKIFAX

OF-7

CHAPTER 3:

INSTALLATION

CHAPTER 3.

INSTALLATION

3.1

3.2

3.2.1

3.3

3.3.1

3.4

3.5

3.6

3.6.1

3.6.2

3.6.3

3.6.4

General

Installation Site

Environments

Unpacking

Unpacking Procedure

Contents Checking

AC Cord Connection

Initial Settings

General

DIPSwitch ___.________..______._______..____..________

SlideSwitchS2 ________..________._____________..._____... 3-7

Programming by Key Operation

..______.._______________........................

.

.

___.____.._.______...._______,.____....__......

. .

.

.

__.__.....____.__._______..._____..____..__.__...

..________.____.......

3-1

3 - 2

3 - 2

3-2

3 - 2

3 - 3

.

3 - 3

3 - 4

3-4

3-5

3-8

3.7

3.7.1

3.7.2

3.7.3

3.7.4

3.7.5

3.7.6

3.8

3.9

3.10

3.10.1

Optional Settings . .

General

Polling Number (Password) Programming

Access Digit Programming

TSVCSI

Technical Set-up

Linelmpedance

Telephone and Line Connection

Frame Ground Connection

Accessory Installation

Thermal Recording Paper

_____.___.._____._.______.......__.____.....___..

(Tel. No.) Programming

_______.___..___.______.._____.._____.....

.

________..............

.

..________....____,_____.._____..

.

3-22

_,.

3 - 22

3 - 23

3-

24

3 - 25

3 - 27

3-31

3-33

3 - 34

3 - 35

3-35

3.11

Off-line Test

.............................................

3 - 37

3.11.1 Check Items

3.11.2

Oaeration Procedure

3.12 Off-line Test

3.12.1

3.12.2

3.12.3

General

Reception

Transmwon .............................................

.................................................

..............................................

.....................................

.............................................

...............................................

3 - 37

3 - 37

3 - 38

3-38

3-38

3 - 39

CHAPTER 3.

INSTALLATION

3.1

General

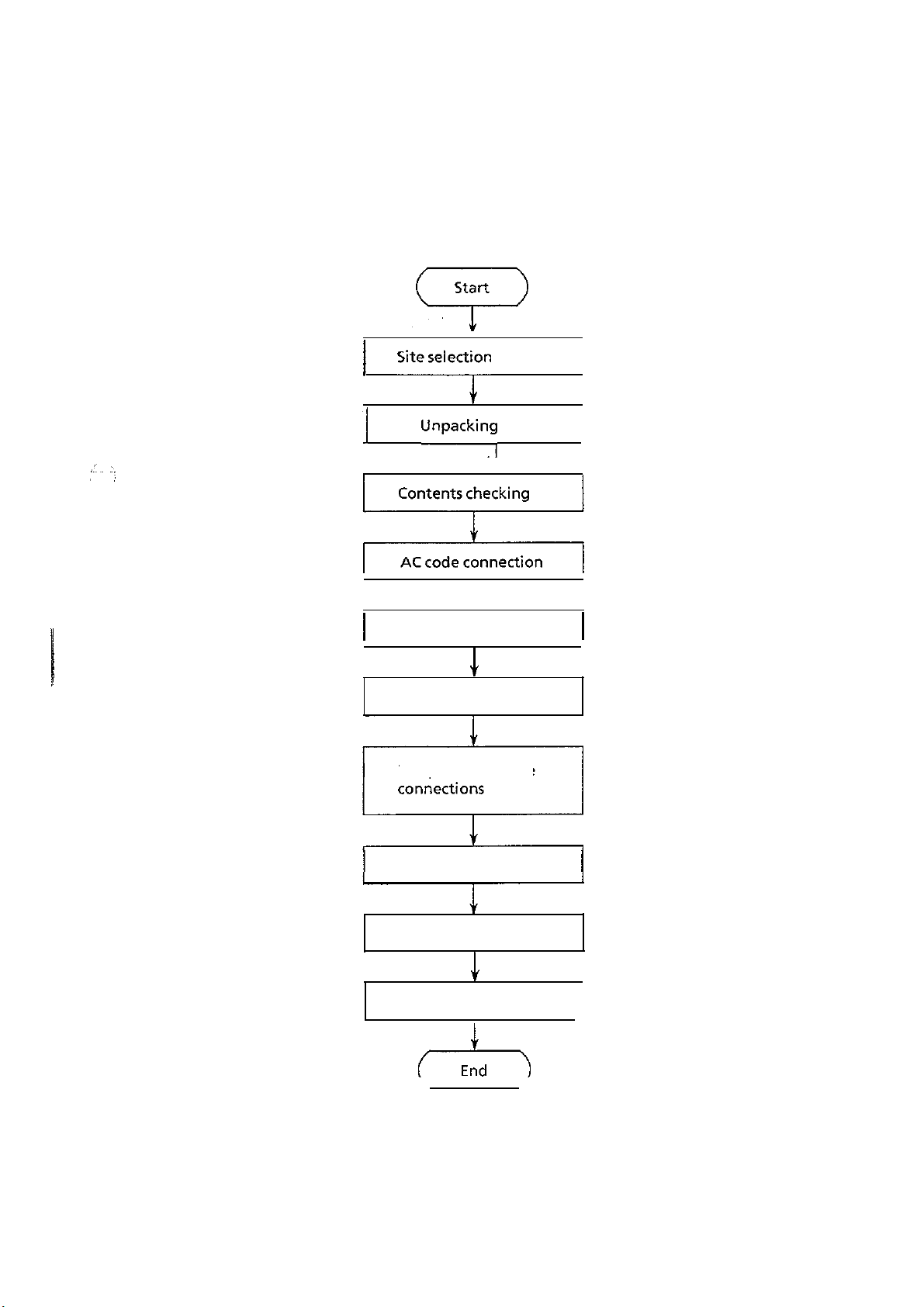

The following flow chart shows the general installation procedure.

1

1

Siteseiectiy

1

1

I

Unpackin,;

Initial settings

I

i

Optional settings

Telephone and line

Accessories installation

Off-line test

On-line test

3-l

Loading...

Loading...