ELECTRICAL SYSTEM

GI

MA

CONTENTS

PRECAUTIONS ...............................................................4

Supplemental Restraint System (SRS) ″AIR

BAG″ and ″SEAT BELT PRE-TENSIONER″...............4

Wiring Diagrams and Trouble Diagnosis.....................4

HARNESS CONNECTOR................................................5

Description...................................................................5

STANDARDIZED RELAY................................................7

Description...................................................................7

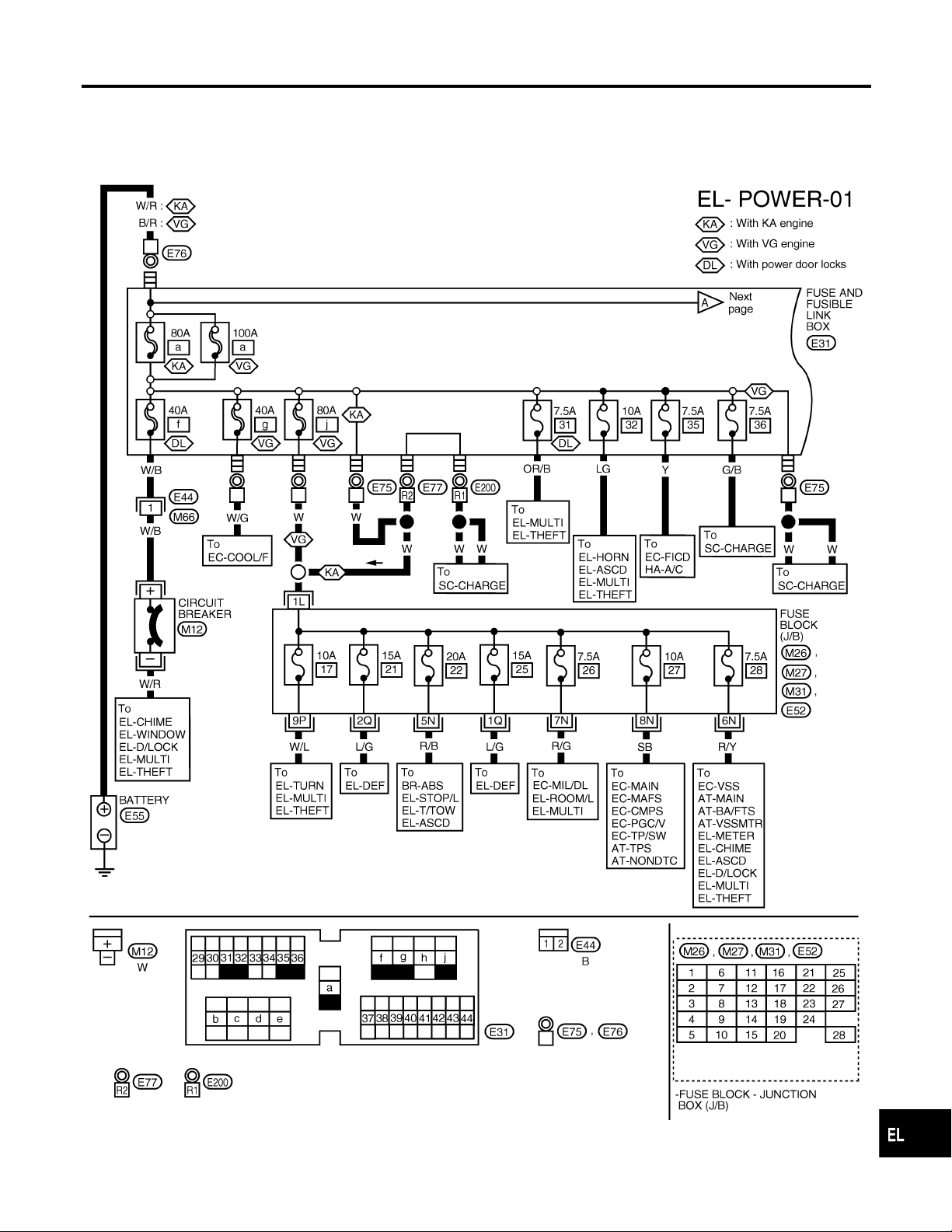

POWER SUPPLY ROUTING...........................................9

Circuit Diagram............................................................9

Wiring Diagram - POWER - ......................................11

Inspection...................................................................16

GROUND........................................................................17

Ground Distribution....................................................17

COMBINATION SWITCH ..............................................31

Check.........................................................................31

Replacement..............................................................32

STEERING SWITCH......................................................33

Check.........................................................................33

HEADLAMP (FOR USA)...............................................34

System Description....................................................34

Wiring Diagram - H/LAMP -.......................................35

Trouble Diagnoses.....................................................36

Bulb Replacement .....................................................37

Aiming Adjustment.....................................................38

HEADLAMP (FOR CANADA) - DAYTIME LIGHT

SYSTEM - ......................................................................40

System Description (For Canada).............................40

Circuit Diagram..........................................................42

Wiring Diagram - DTRL -...........................................43

Trouble Diagnoses.....................................................46

Bulb Replacement .....................................................47

Aiming Adjustment.....................................................47

PARKING, LICENSE AND TAIL LAMPS .....................48

Wiring Diagram - TAIL/L -..........................................48

STOP LAMP ..................................................................49

Wiring Diagram - STOP/L - .......................................49

BACK-UP LAMP............................................................50

Wiring Diagram - BACK/L -.......................................50

SECTION

FRONT FOG LAMP.......................................................51

System Description....................................................51

Wiring Diagram - F/FOG -.........................................52

Aiming Adjustment.....................................................53

Removal and Installation...........................................54

Bulb and Lens Replacement.....................................54

TURN SIGNAL AND HAZARD WARNING LAMPS.....55

System Description....................................................55

Wiring Diagram - TURN -..........................................57

Trouble Diagnoses.....................................................59

Electrical Components Inspection.............................59

TRAILER TOW...............................................................60

System Description....................................................60

Wiring Diagram - T/TOW -.........................................61

Trouble Diagnoses.....................................................62

ILLUMINATION..............................................................63

System Description....................................................63

Wiring Diagram - ILL -...............................................64

INTERIOR ROOM LAMP...............................................66

Component Parts and Harness Connector

Location .....................................................................66

System Description....................................................67

Wiring Diagram - ROOM/L -......................................69

METERS AND GAUGES...............................................72

Component Parts and Harness Connector

Location .....................................................................72

System Description....................................................73

Combination Meter ....................................................75

Wiring Diagram - METER - .......................................77

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode..........................78

Trouble Diagnoses.....................................................79

Electrical Components Inspection.............................85

WARNING LAMPS........................................................87

Circuit Diagram..........................................................87

Wiring Diagram - WARN -.........................................88

Electrical Components Inspection.............................95

WARNING CHIME.........................................................96

EL

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CONTENTS (Cont’d)

Component Parts and Harness Connector

Location .....................................................................96

System Description....................................................97

Wiring Diagram - CHIME - ........................................99

Trouble Diagnoses...................................................101

FRONT WIPER AND WASHER..................................110

System Description..................................................110

Wiring Diagram - WIPER -......................................113

Trouble Diagnoses (With intermittent wipers).........115

Removal and Installation.........................................118

Washer Nozzle Adjustment .....................................119

Washer Tube Layout ...............................................120

REAR WIPER AND WASHER....................................121

System Description..................................................121

Wiring Diagram - WIP/R -........................................122

Removal and Installation.........................................123

Washer Nozzle Adjustment .....................................124

Washer Tube Layout ...............................................125

Check Valve.............................................................125

HORN...........................................................................126

Wiring Diagram - HORN - .......................................126

CIGARETTE LIGHTER................................................127

Wiring Diagram - CIGAR -.......................................127

AUDIO..........................................................................128

System Description..................................................128

Wiring Diagram - AUDIO -.......................................129

Trouble Diagnoses...................................................130

Inspection.................................................................130

AUDIO ANTENNA.......................................................132

Location of Antenna.................................................132

Fixed Antenna Rod Replacement............................132

REAR WINDOW DEFOGGER.....................................133

Component Parts and Harness Connector

Location ...................................................................133

System Description..................................................134

Wiring Diagram - DEF -...........................................136

Trouble Diagnoses...................................................137

Electrical Components Inspection...........................141

Filament Check........................................................142

Filament Repair .......................................................143

DOOR MIRROR...........................................................144

Wiring Diagram - MIRROR - ...................................144

AUTOMATIC SPEED CONTROL DEVICE (ASCD)...145

Component Parts and Harness Connector

Location ...................................................................145

System Description..................................................147

Circuit Diagram........................................................149

Wiring Diagram - ASCD - ........................................150

Fail-safe System......................................................154

Trouble Diagnoses...................................................155

Electrical Component Inspection.............................168

ASCD Wire Adjustment ...........................................170

POWER WINDOW.......................................................171

System Description..................................................171

Wiring Diagram - WINDOW -..................................173

Trouble Diagnoses...................................................177

POWER DOOR LOCK.................................................178

Component Parts and Harness Connector

Location ...................................................................178

System Description..................................................179

Circuit Diagram........................................................183

Wiring Diagram - D/LOCK -.....................................184

Trouble Diagnoses...................................................188

MULTI-REMOTE CONTROL SYSTEM.......................202

Component Parts and Harness Connector

Location ...................................................................202

System Description..................................................203

Circuit Diagram........................................................206

Wiring Diagram - MULTI - .......................................207

Trouble Diagnoses...................................................211

ID Code Entry Procedure........................................223

Remote Controller Battery Replacement.................224

THEFT WARNING SYSTEM.......................................225

Component Parts and Harness Connector

Location ...................................................................225

System Description..................................................227

Circuit Diagram........................................................230

Wiring Diagram - THEFT -.......................................231

Trouble Diagnoses...................................................235

SMART ENTRANCE CONTROL UNIT.......................254

Description...............................................................254

Circuit Diagram........................................................255

Smart Entrance Control Unit Inspection Table........257

ELECTRICAL UNITS LOCATION...............................259

Engine Compartment...............................................259

Passenger Compartment.........................................260

HARNESS LAYOUT....................................................262

How to Read Harness Layout.................................262

Outline......................................................................263

Main Harness...........................................................264

Engine Room Harness ............................................266

Engine Control Harness ..........................................272

Engine No. 2 Harness.............................................276

Body Harness..........................................................278

Body No. 2 and Chassis Harness...........................279

Room Lamp Harness...............................................280

Front Door Harness.................................................281

Rear Door Harness..................................................282

Back Door Harness .................................................283

Air Bag Harness ......................................................284

BULB SPECIFICATIONS............................................285

Headlamp.................................................................285

Exterior Lamp ..........................................................285

Interior Lamp............................................................285

EL-2

CONTENTS (Cont’d)

WIRING DIAGRAM CODES (CELL CODES).............286

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL-3

SC

IDX

PRECAUTIONS

Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

Supplemental Restraint System (SRS) “AIR

BAG” and “SEAT BELT PRE-TENSIONER”

The Supplemental Restraint System “AIR BAG” and “SEAT BELT PRE-TENSIONER” used along with a seat

belt, helps to reduce the risk of severe injury to the driver and front passenger in certain types of collisions.

The Supplemental Restraint System consists of a driver air bag module (located in the center of the steering

wheel), a front passenger air bag module (located on the instrument panel on the passenger side), seat belt

pre-tensionsers, a diagnosis sensor unit, a crash zone sensor (4WD models), a warning lamp, wiring harness

and spiral cable.

Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

쐌 To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be performed by an authorized NISSAN dealer.

쐌 Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see RS section.

쐌 Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses (except “SEAT BELT PRE-TENSIONER”) covered with yellow insulation, either just before the harness connectors or for the complete harness,

are related to the SRS.

NGEL0001

Wiring Diagrams and Trouble Diagnosis

When you read wiring diagrams, refer to the following:

쐌 GI-10, “HOW TO READ WIRING DIAGRAMS”

쐌 EL-9, “POWER SUPPLY ROUTING” for power distribution circuit.

When you perform trouble diagnosis, refer to the following:

쐌 GI-34, “HOW TO FOLLOW TEST GROUP IN TROUBLE DIAGNOSIS”.

쐌 GI-23, “HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT”.

Check for any Service bulletins before servicing the vehicle.

NGEL0002

EL-4

HARNESS CONNECTOR

Description

Description

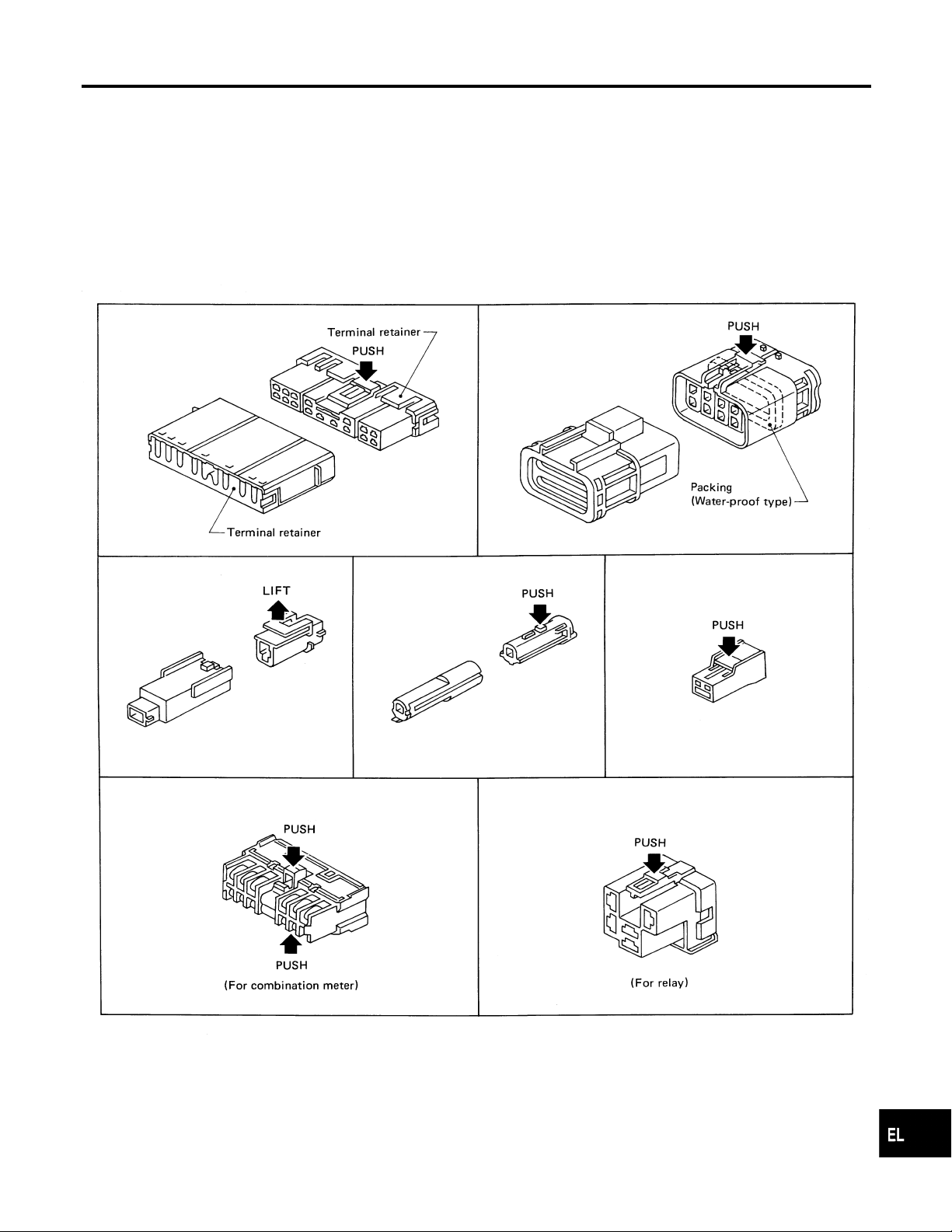

HARNESS CONNECTOR (TAB-LOCKING TYPE)

쐌 The tab-locking type connectors help prevent accidental looseness or disconnection.

쐌 The tab-locking type connectors are disconnected by pushing or lifting the locking tab(s). Refer to the

illustration below.

Refer to EL-6 for description of the slide-locking type connector.

CAUTION:

Do not pull the harness when disconnecting the connector.

[Example]

NGEL0003

NGEL0003S01

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-5

SEL769D

HA

SC

IDX

Description (Cont’d)

HARNESS CONNECTOR

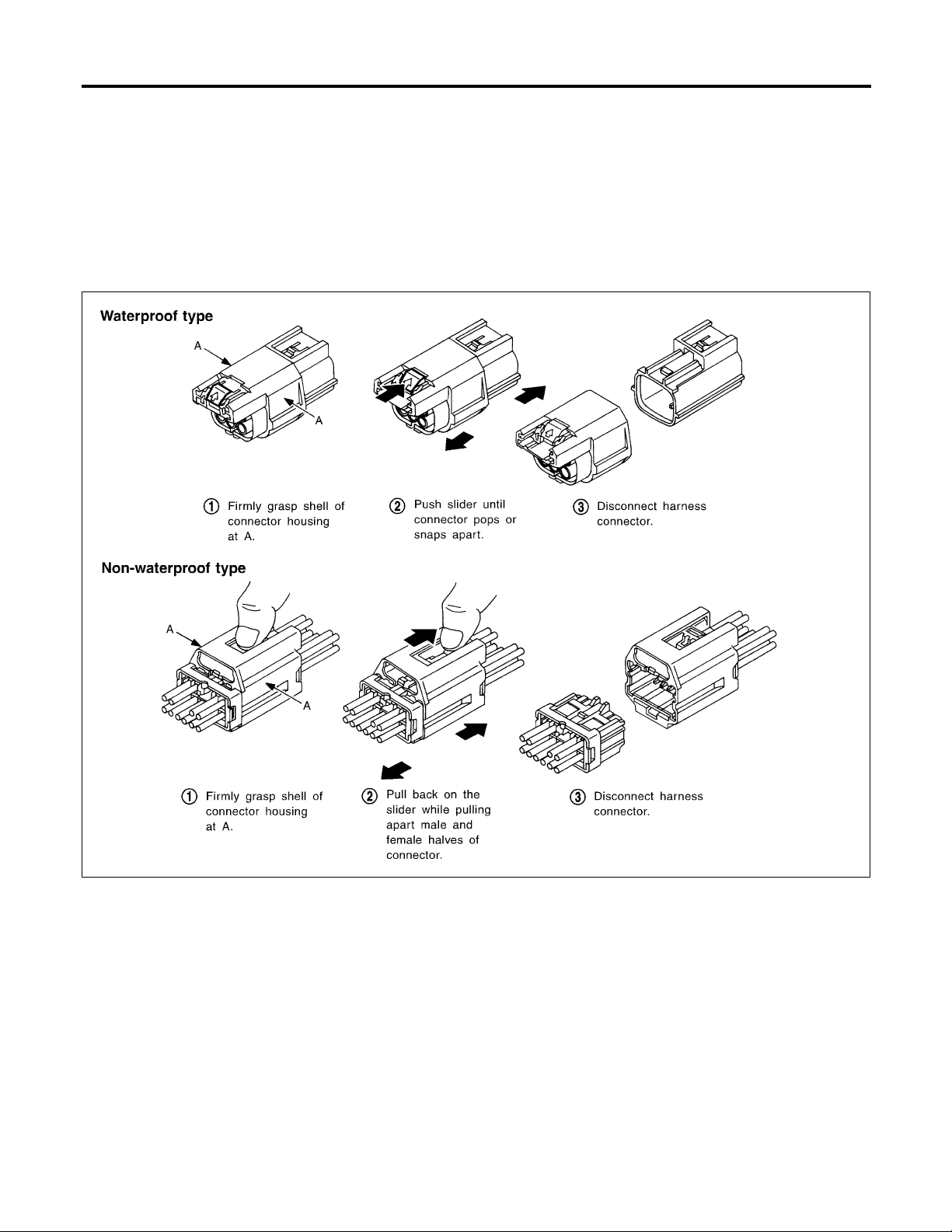

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)

=NGEL0003S02

쐌 A new style slide-locking connector is used on certain systems and components, especially those related

to OBD>

쐌 The slide-locking type connectors help prevent incomplete locking and accidental looseness or disconnec-

tion.

쐌 The slide-locking type connectors are disconnected by pushing or pulling the slider. Refer to the illustra-

tion below.

CAUTION:

Do not pull the harness or wires when disconnecting the connector.

Be careful not to damage the connector support bracket when disconnecting the connector.

EL-6

AEL299C

STANDARDIZED RELAY

Description

Description

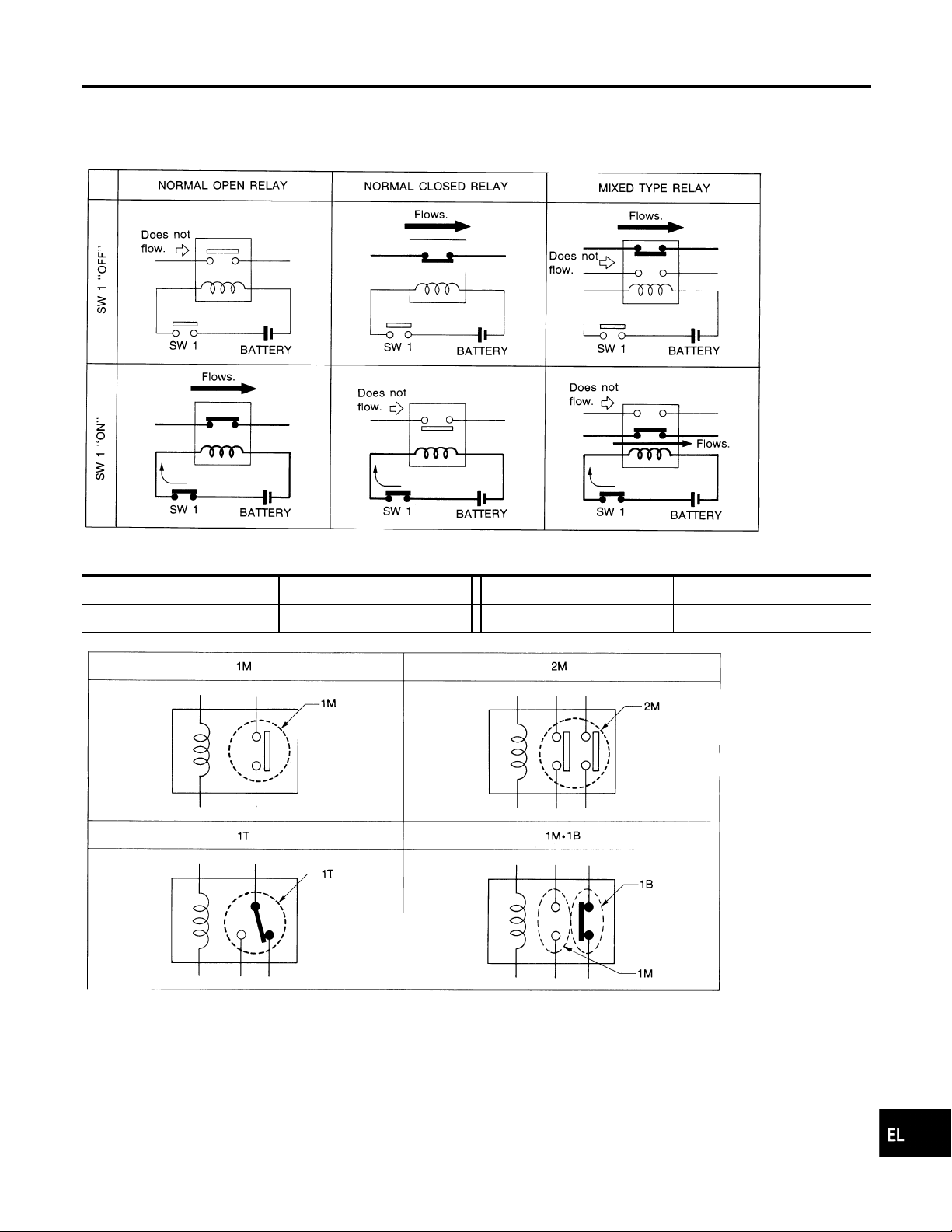

NORMAL OPEN, NORMAL CLOSED AND MIXED TYPE RELAYS

Relays can mainly be divided into three types: normal open, normal closed and mixed type relays.

NGEL0004

NGEL0004S01

SEL881H

GI

MA

EM

LC

EC

FE

CL

MT

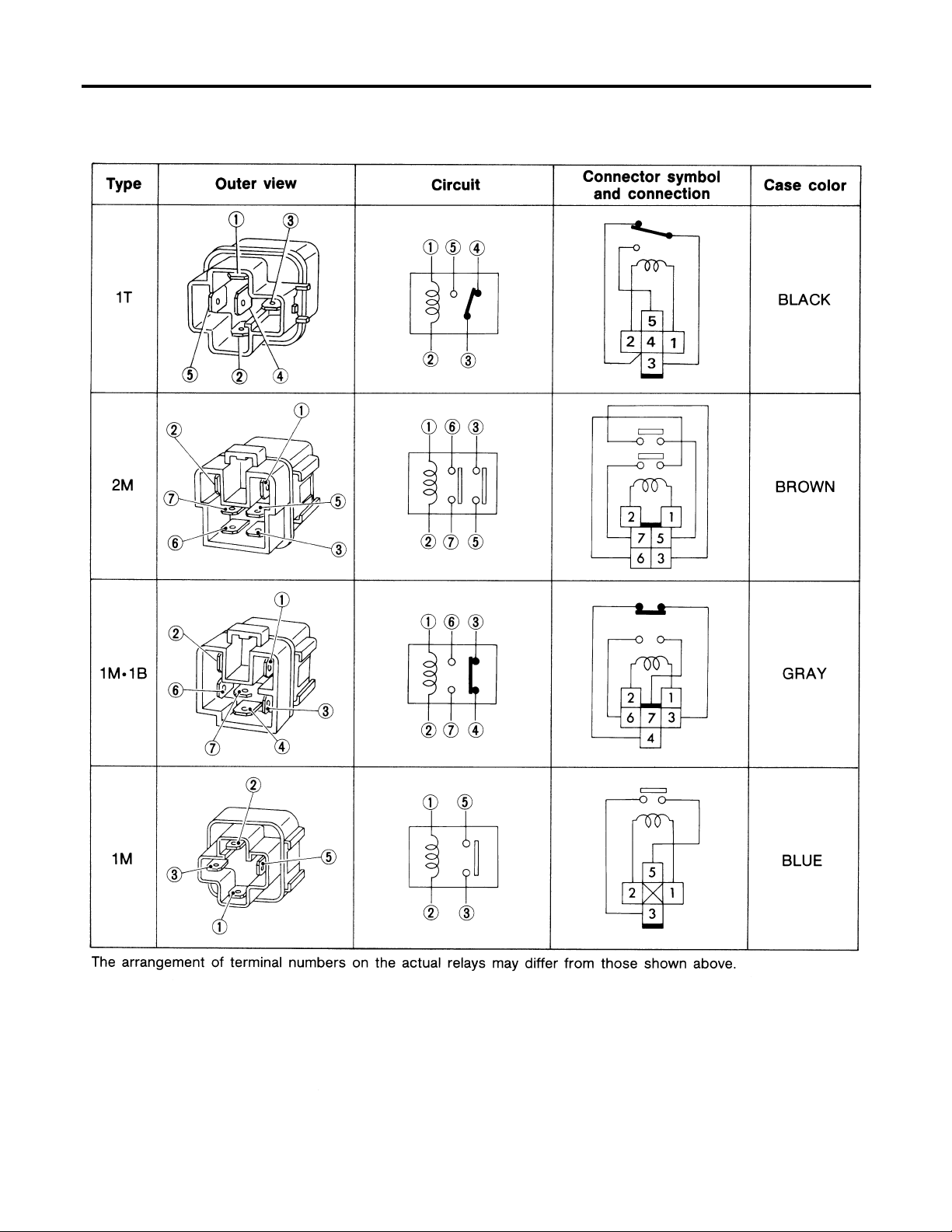

TYPE OF STANDARDIZED RELAYS

1M 1 Make 2M 2 Make

1T 1 Transfer 1M·1B 1 Make 1 Break

NGEL0004S02

SEL882H

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-7

HA

SC

IDX

Description (Cont’d)

STANDARDIZED RELAY

EL-8

SEL661TA

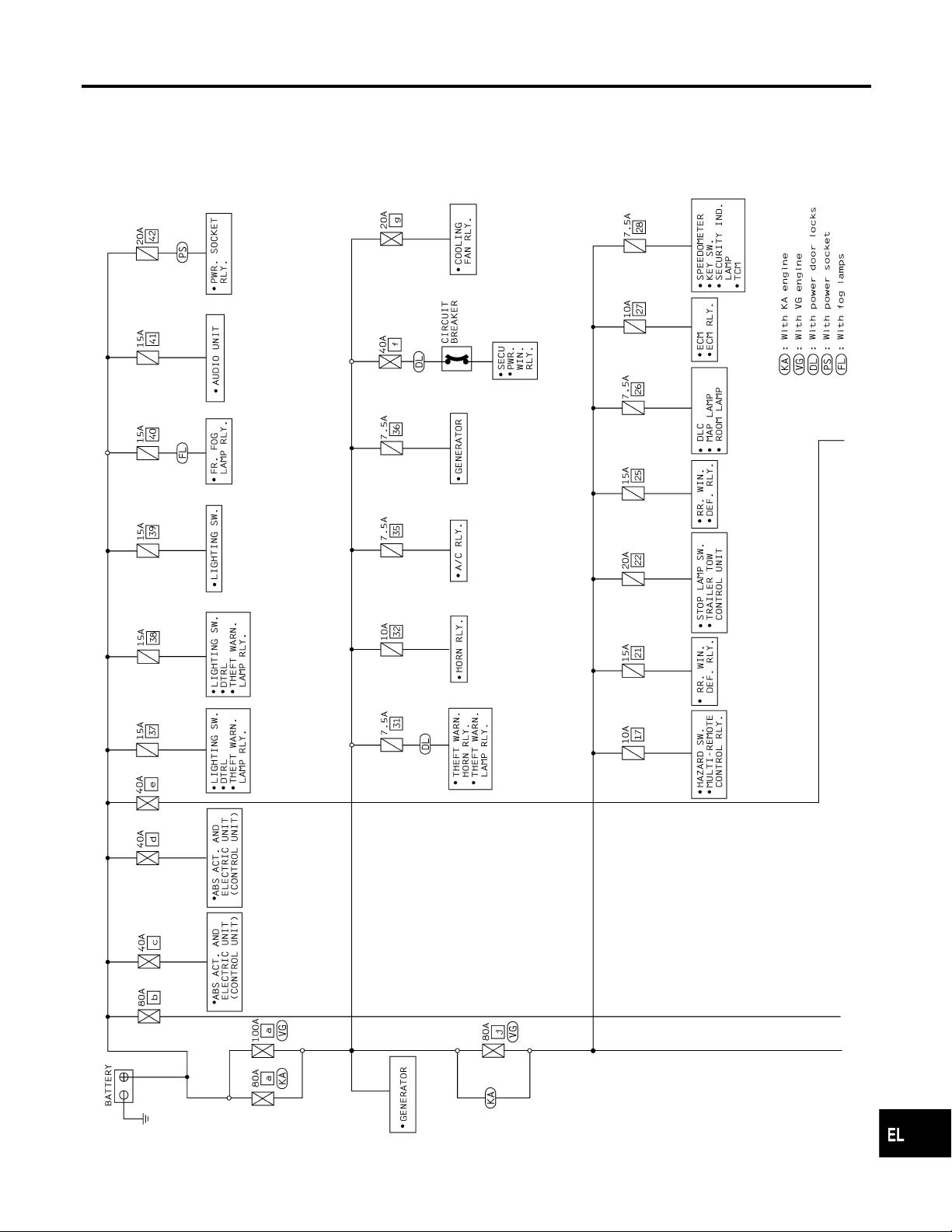

POWER SUPPLY ROUTING

Circuit Diagram

Circuit Diagram

NOTE:

For detailed ground distribution information, refer to “GROUND DISTRIBUTION”, EL-17.

NGEL0005

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-9

AEL409C

HA

SC

IDX

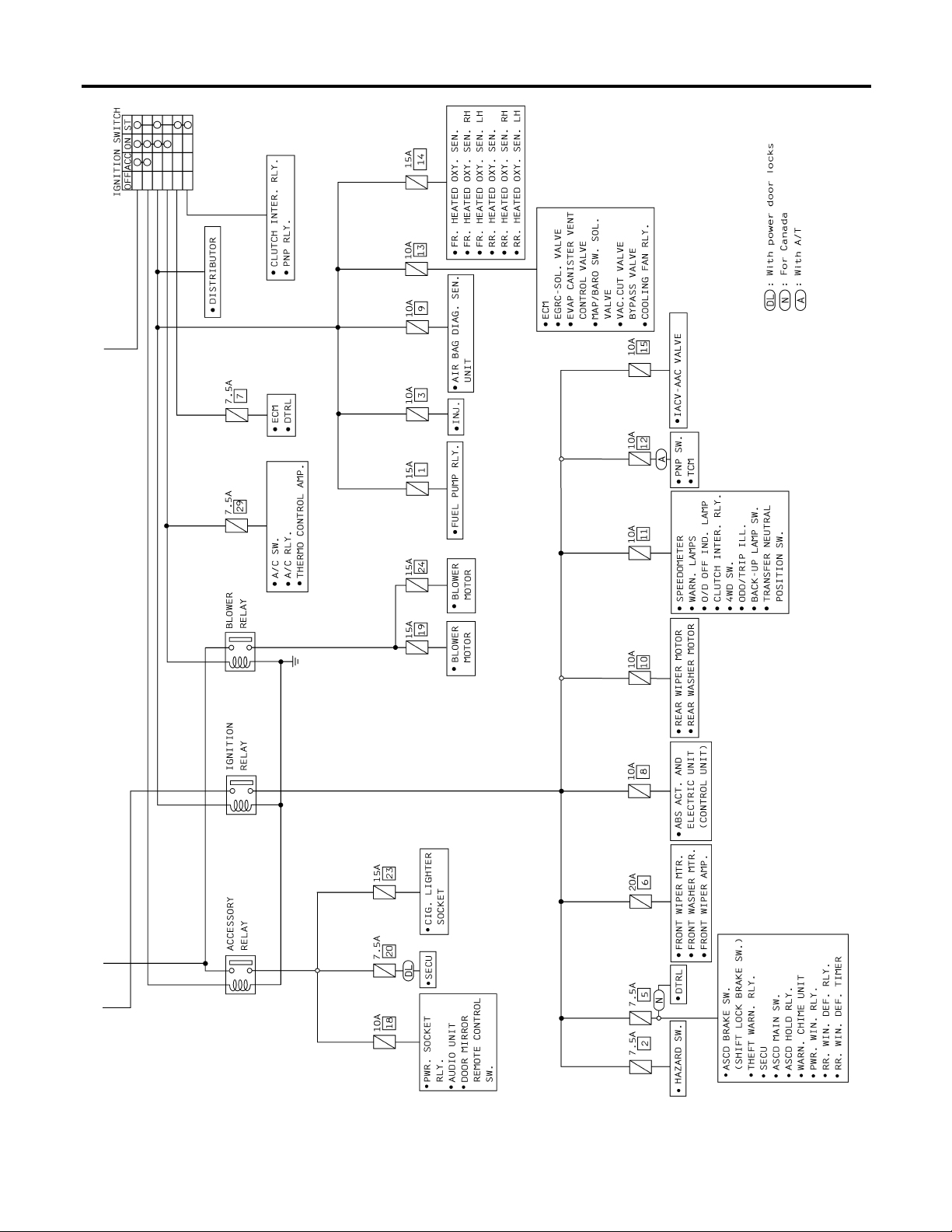

Circuit Diagram (Cont’d)

POWER SUPPLY ROUTING

EL-10

AEL410C

POWER SUPPLY ROUTING

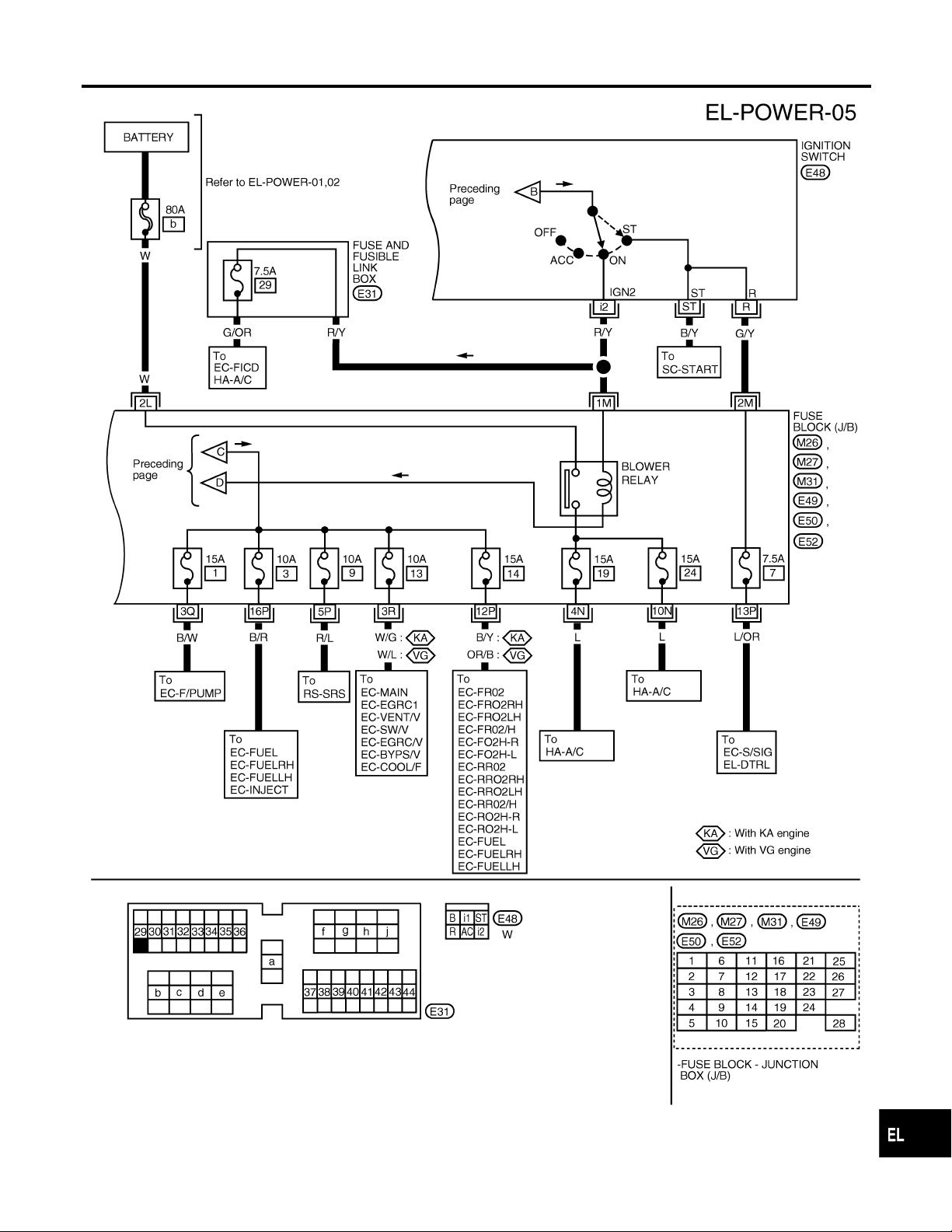

Wiring Diagram — POWER —

Wiring Diagram — POWER —

BATTERY POWER SUPPLY — IGNITION SW. IN ANY POSITION

NOTE:

For detailed ground distribution information, refer to “GROUND DISTRIBUTION”, EL-17.

=NGEL0006

NGEL0006S01

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-11

HA

SC

AEL411C

IDX

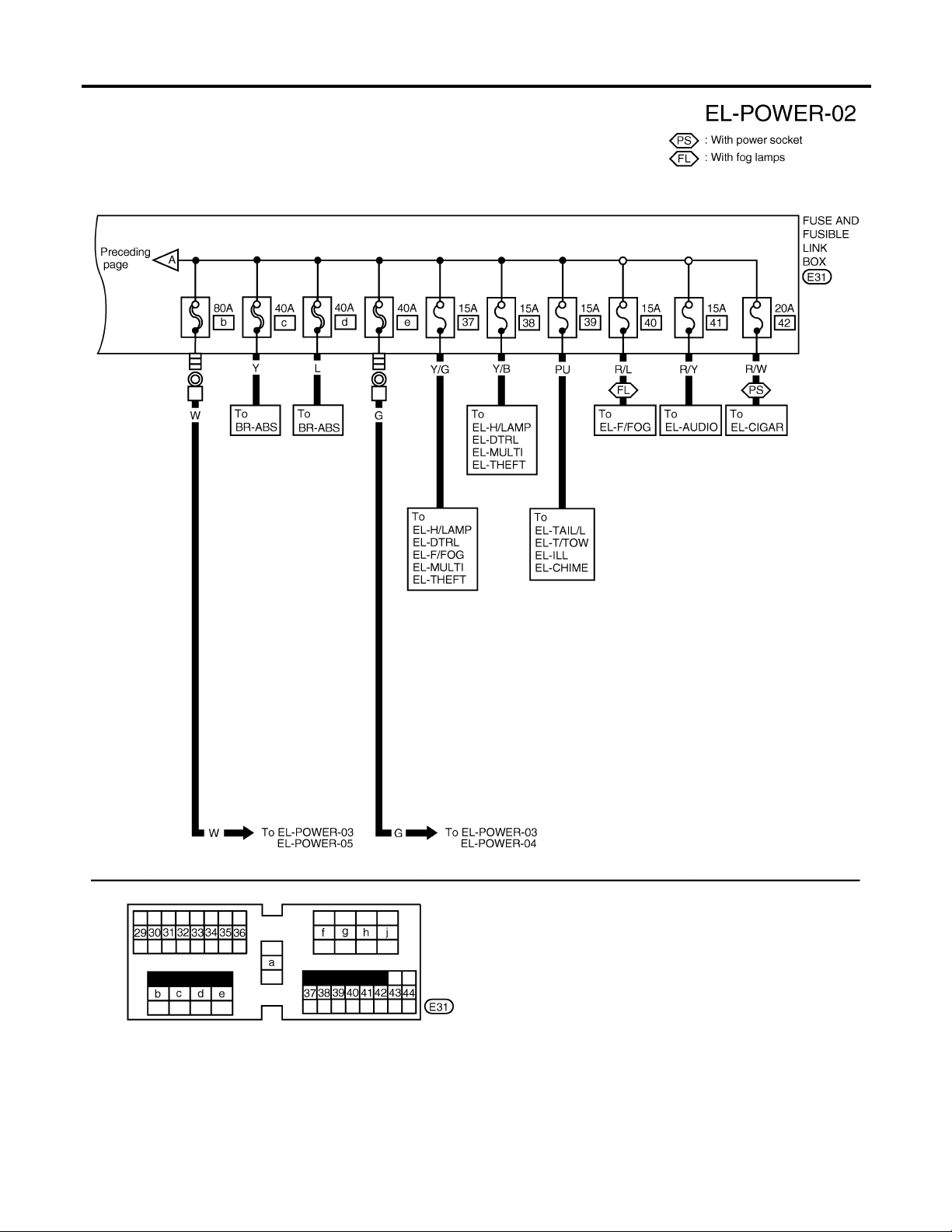

Wiring Diagram — POWER — (Cont’d)

POWER SUPPLY ROUTING

EL-12

AEL412C

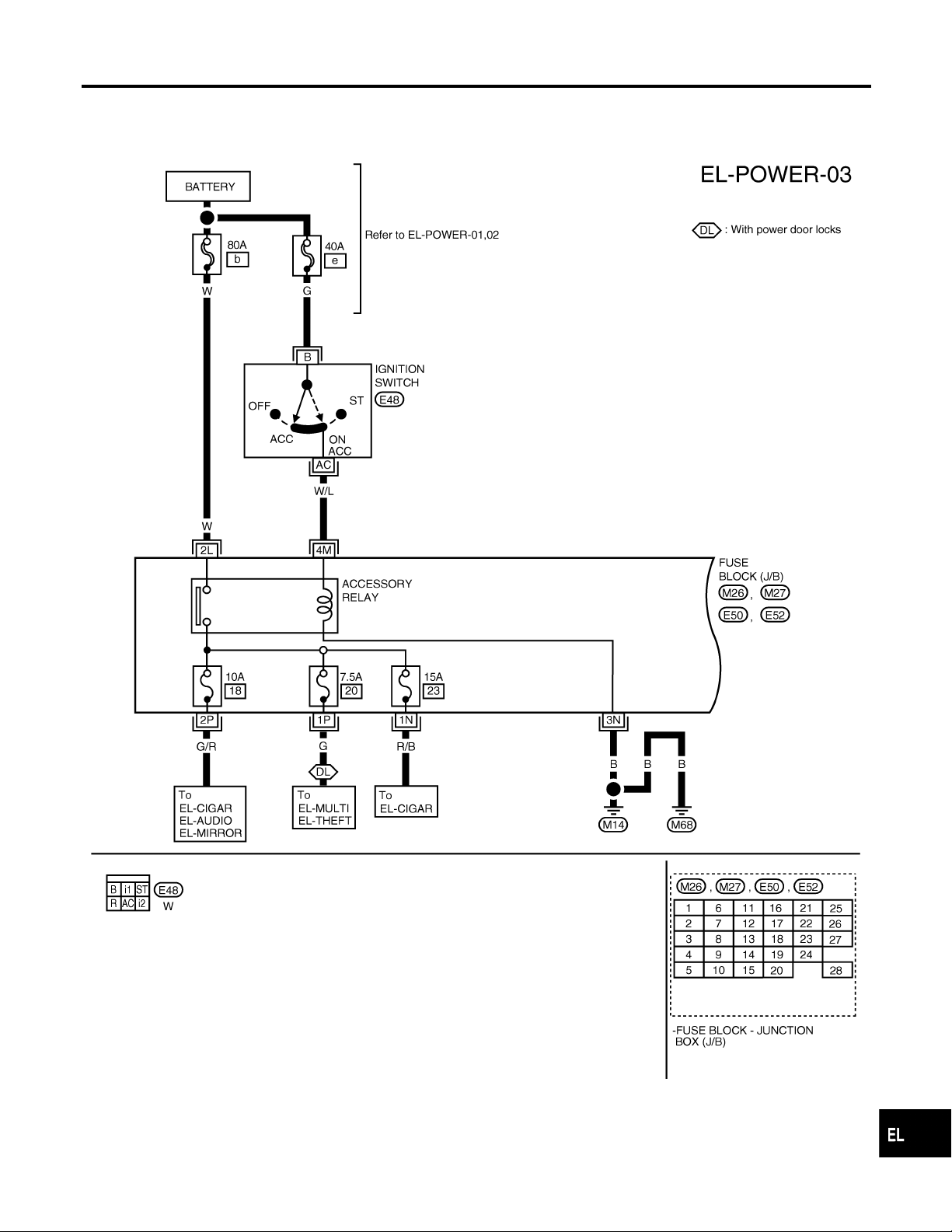

POWER SUPPLY ROUTING

Wiring Diagram — POWER — (Cont’d)

ACCESSORY POWER SUPPLY — IGNITION SW. IN ACC OR ON

NOTE:

For detailed ground distribution information, refer to “GROUND DISTRIBUTION”, EL-17.

=NGEL0006S02

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-13

AEL413C

HA

SC

IDX

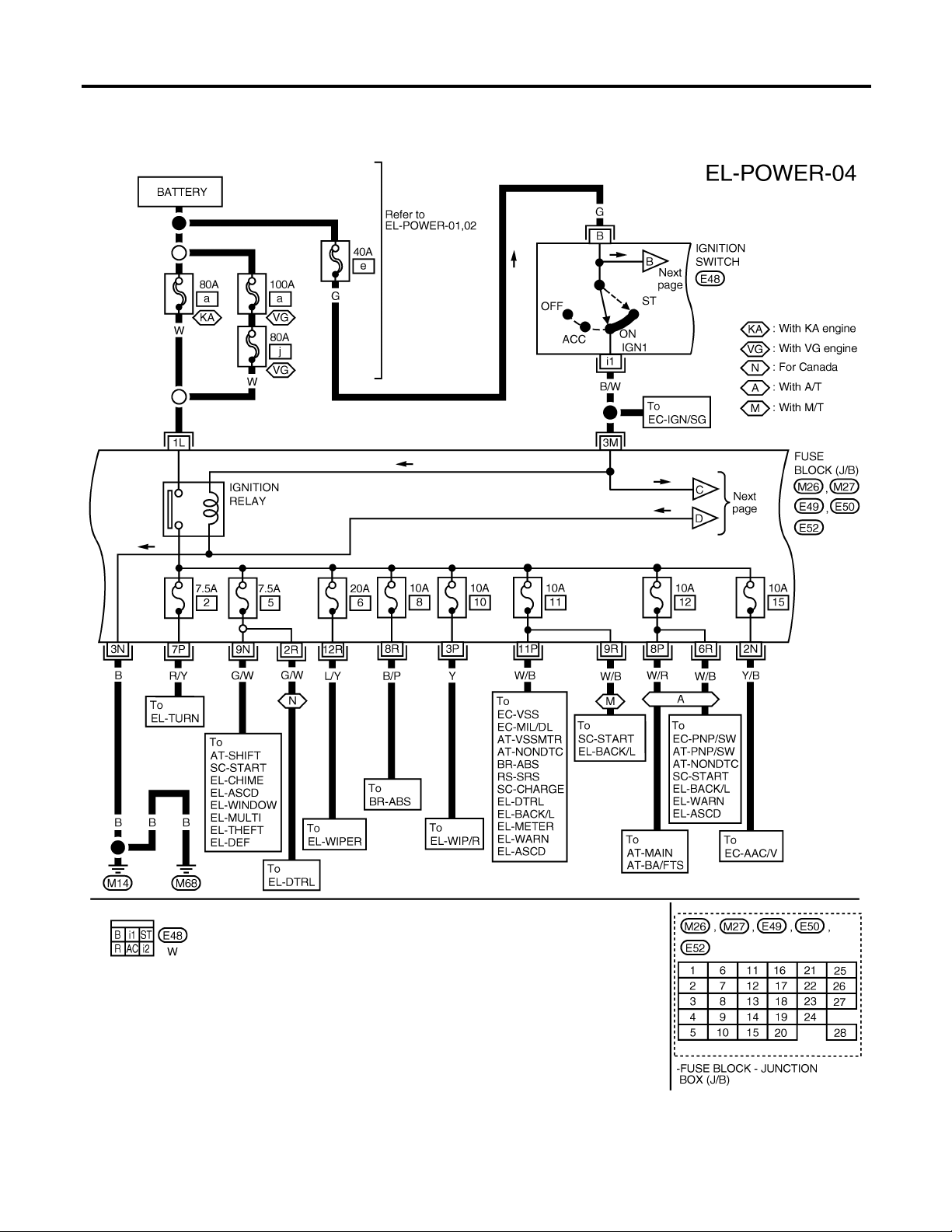

Wiring Diagram — POWER — (Cont’d)

POWER SUPPLY ROUTING

IGNITION POWER SUPPLY — IGNITION SW. IN ON AND/OR START

NOTE:

For detailed ground distribution information, refer to “GROUND DISTRIBUTION”, EL-17.

=NGEL0006S03

EL-14

AEL414C

POWER SUPPLY ROUTING

Wiring Diagram — POWER — (Cont’d)

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

EL-15

BT

HA

SC

AEL415C

IDX

Inspection

POWER SUPPLY ROUTING

CEL083

MEL944F

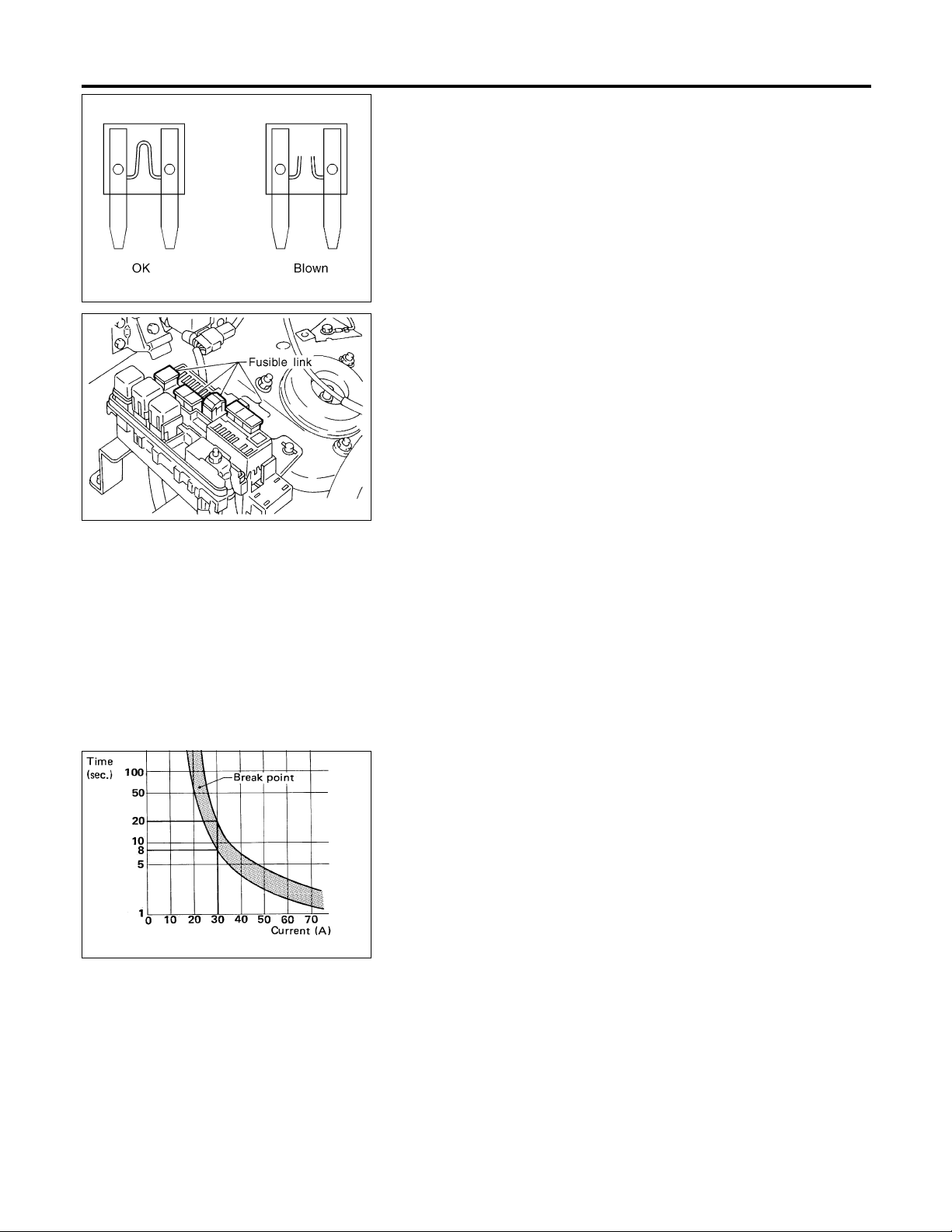

Inspection

FUSE

NGEL0007

NGEL0007S01

쐌 If fuse is blown, be sure to eliminate cause of problem

before installing new fuse.

쐌 Use fuse of specified rating. Never use fuse of more than

specified rating.

쐌 Do not partially install fuse; always insert it into fuse

holder properly.

쐌 Remove fuse for “ELECTRICAL PARTS (BAT)” if vehicle is

not used for a long period of time.

FUSIBLE LINK

NGEL0007S02

A melted fusible link can be detected either by visual inspection or

by feeling with finger tip. If its condition is questionable, use circuit

tester or test lamp.

CAUTION:

쐌 If fusible link should melt, it is possible that critical circuit

(power supply or large current carrying circuit) is shorted.

In such a case, carefully check and eliminate cause of

problem.

쐌 Never wrap outside of fusible link with vinyl tape. Impor-

tant: Never let fusible link touch any other wiring harness,

vinyl or rubber parts.

SBF284E

CIRCUIT BREAKER

NGEL0007S03

For example, when current is 30A, the circuit is broken within 8 to

20 seconds.

Circuit breakers are used in the following systems.

EL-16

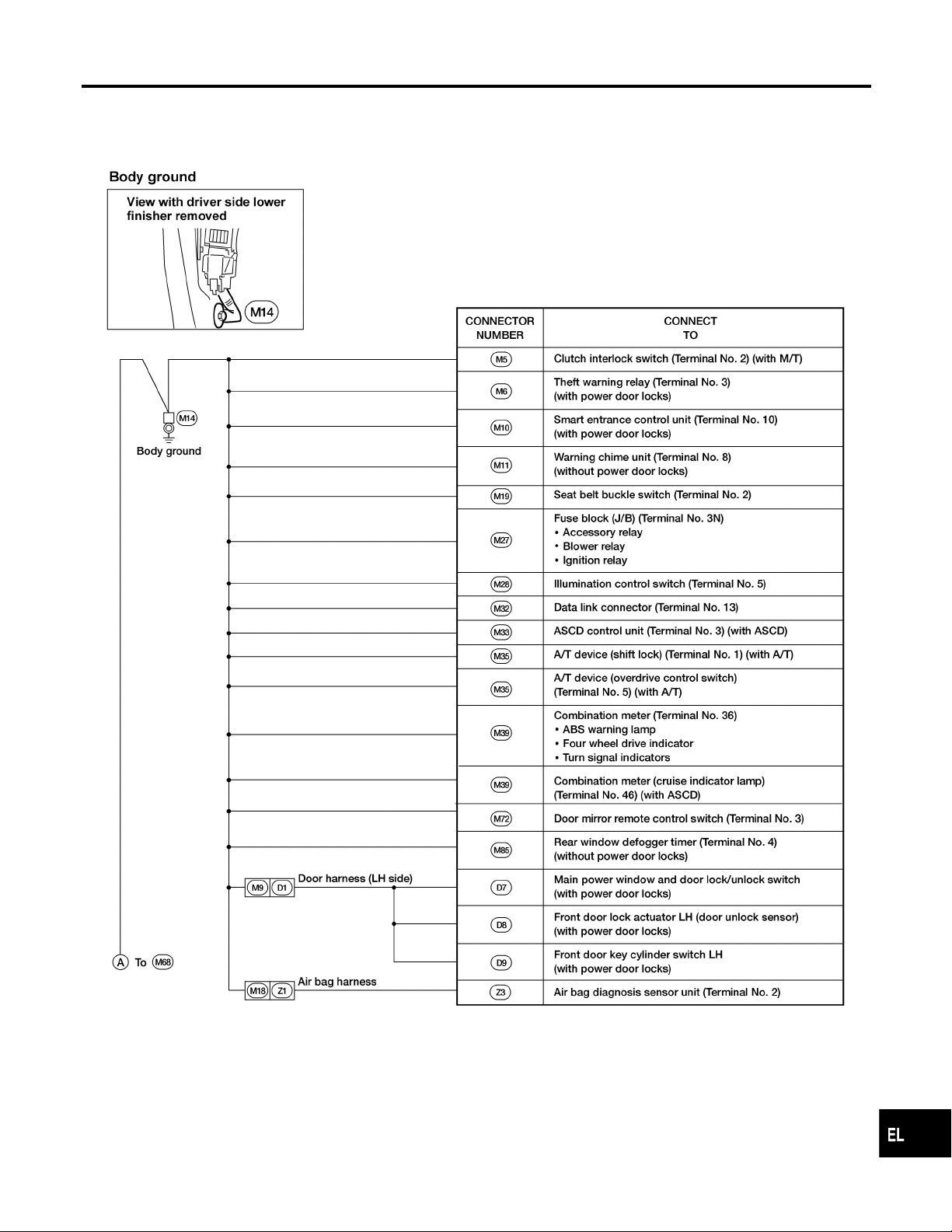

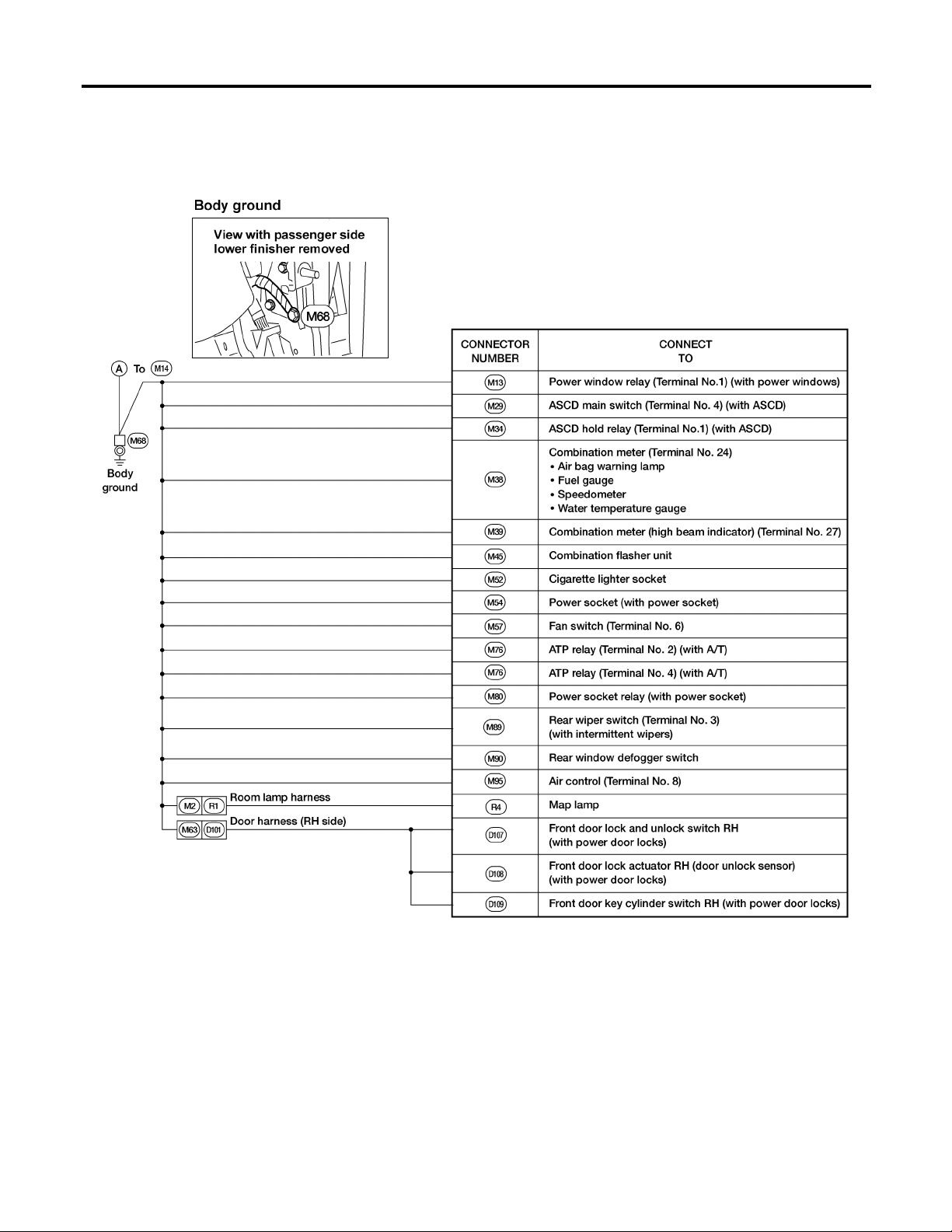

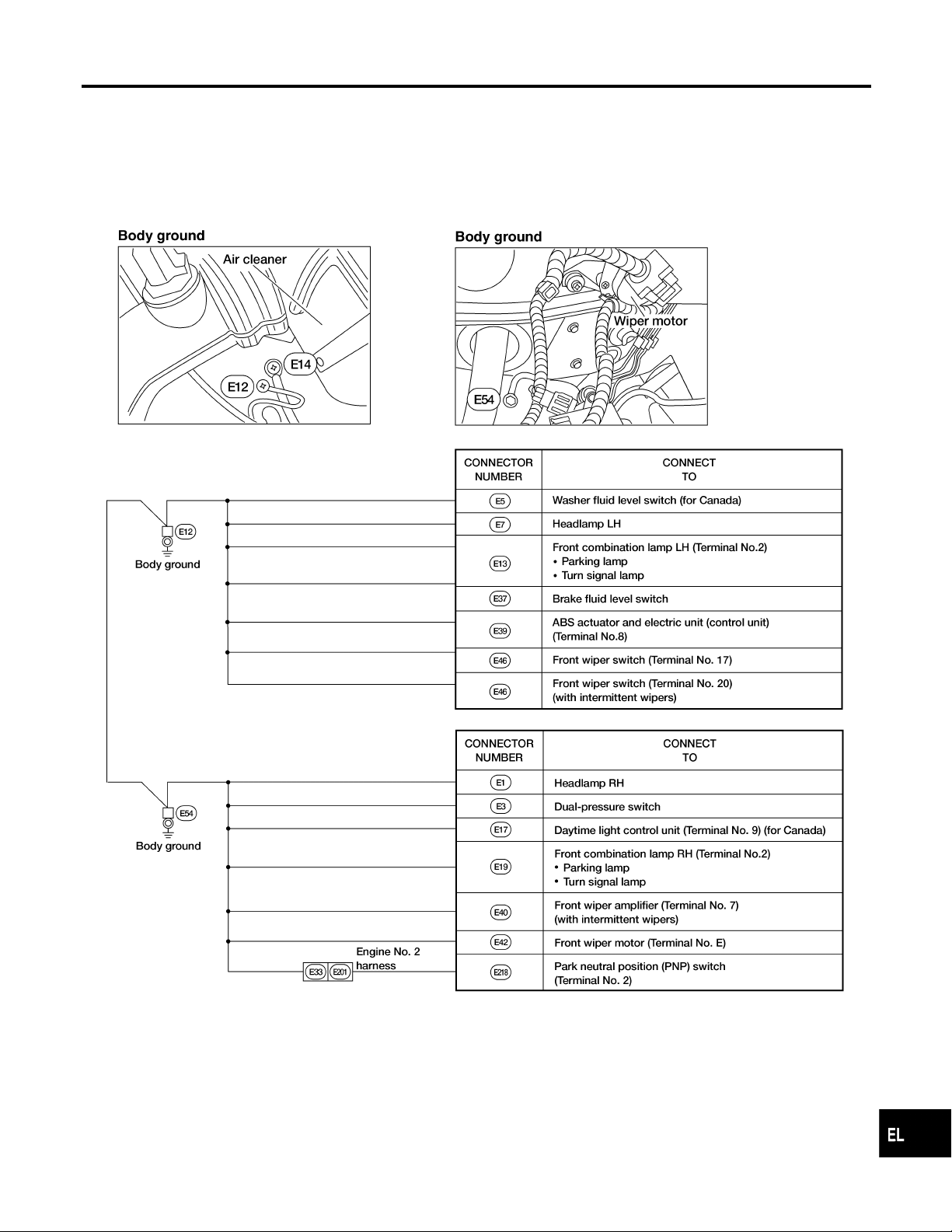

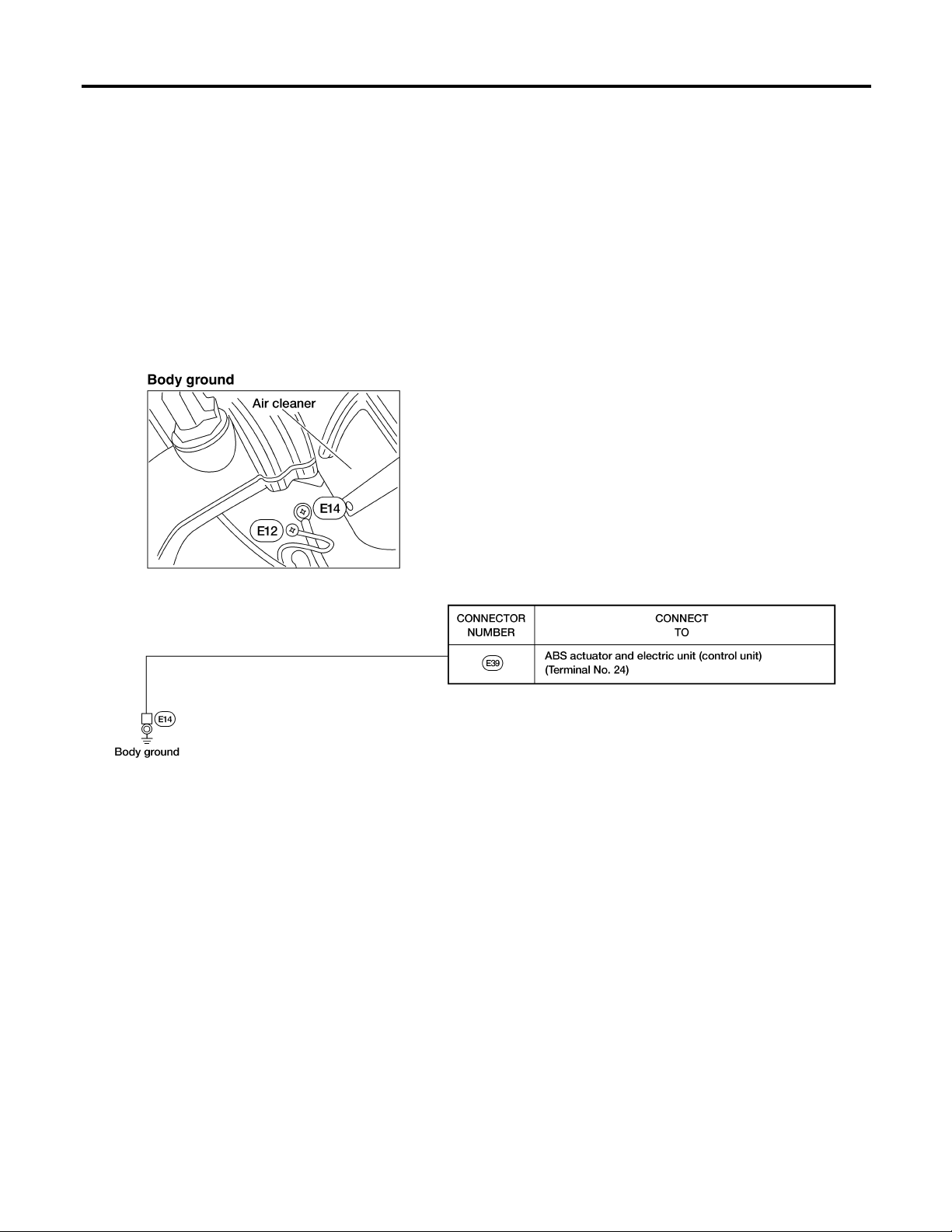

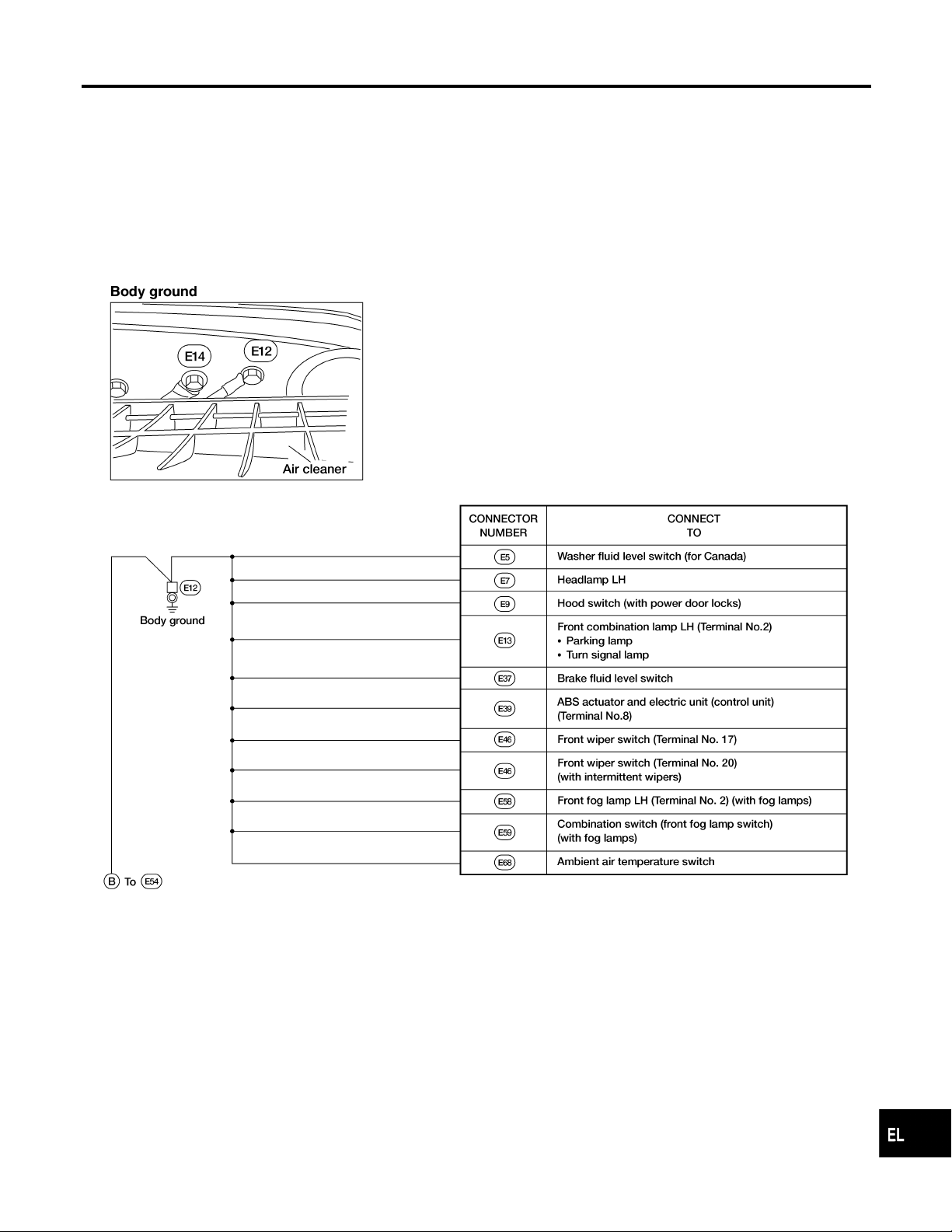

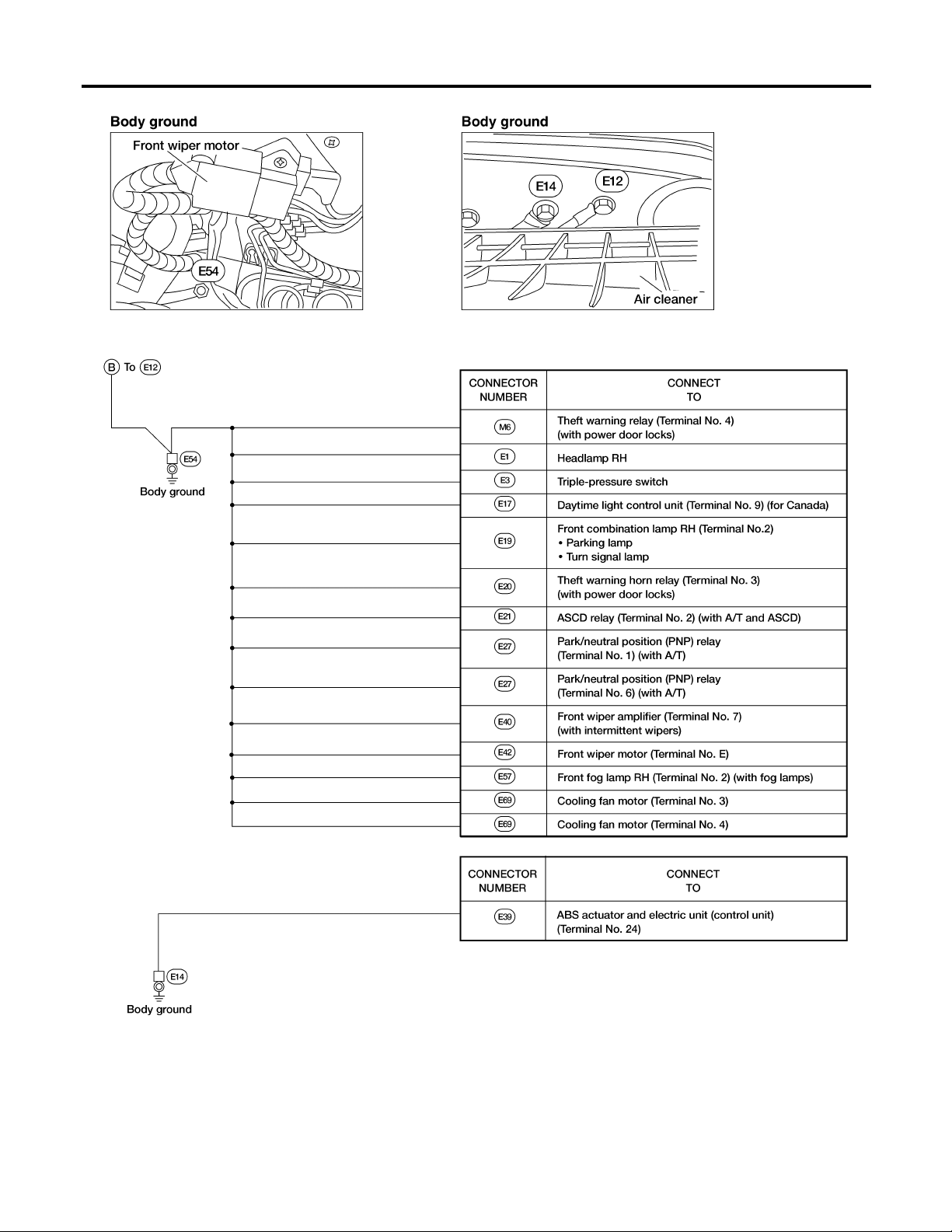

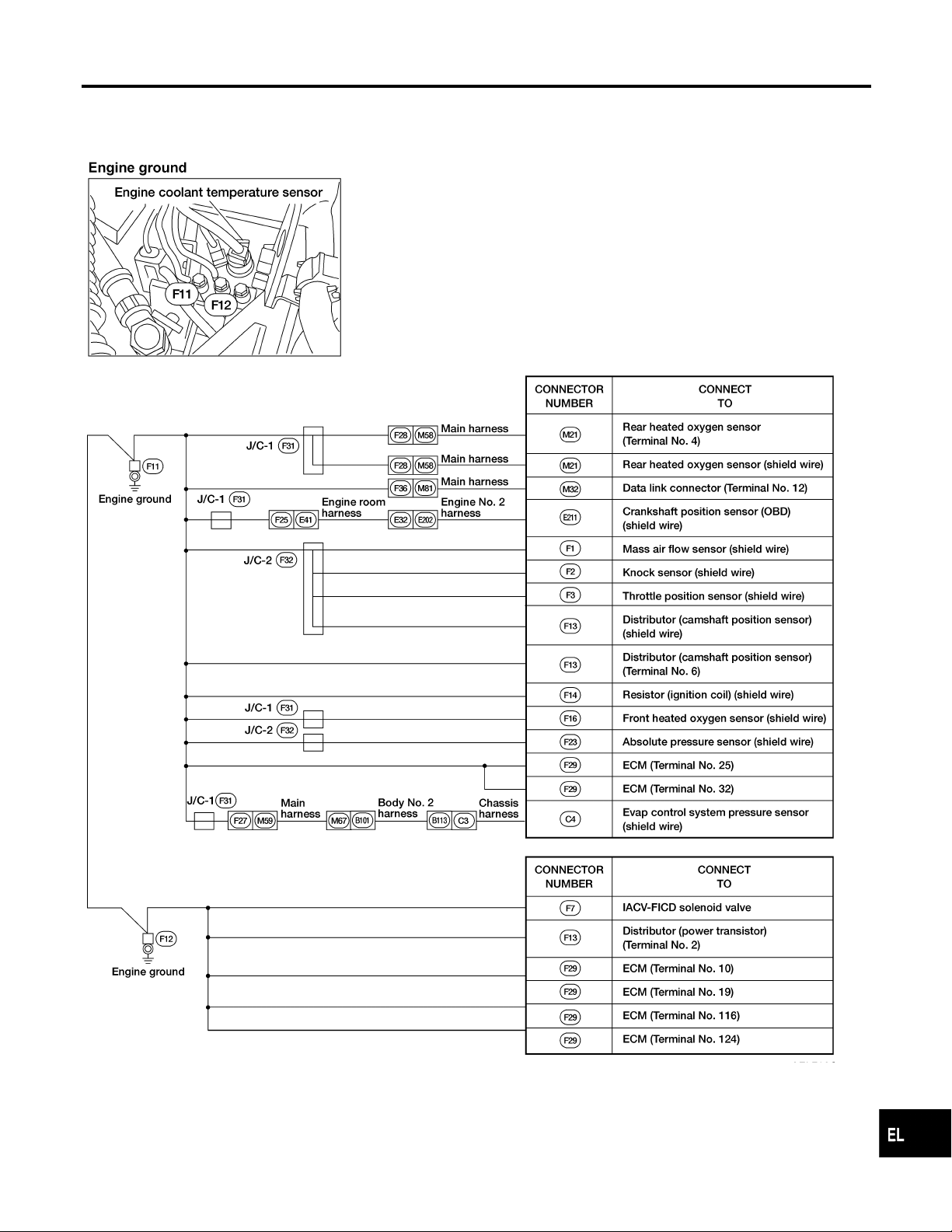

GROUND

Ground Distribution

Ground Distribution

MAIN HARNESS

NGEL0171

NGEL0171S01

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-17

AEL706C

HA

SC

IDX

Ground Distribution (Cont’d)

GROUND

EL-18

AEL707C

GROUND

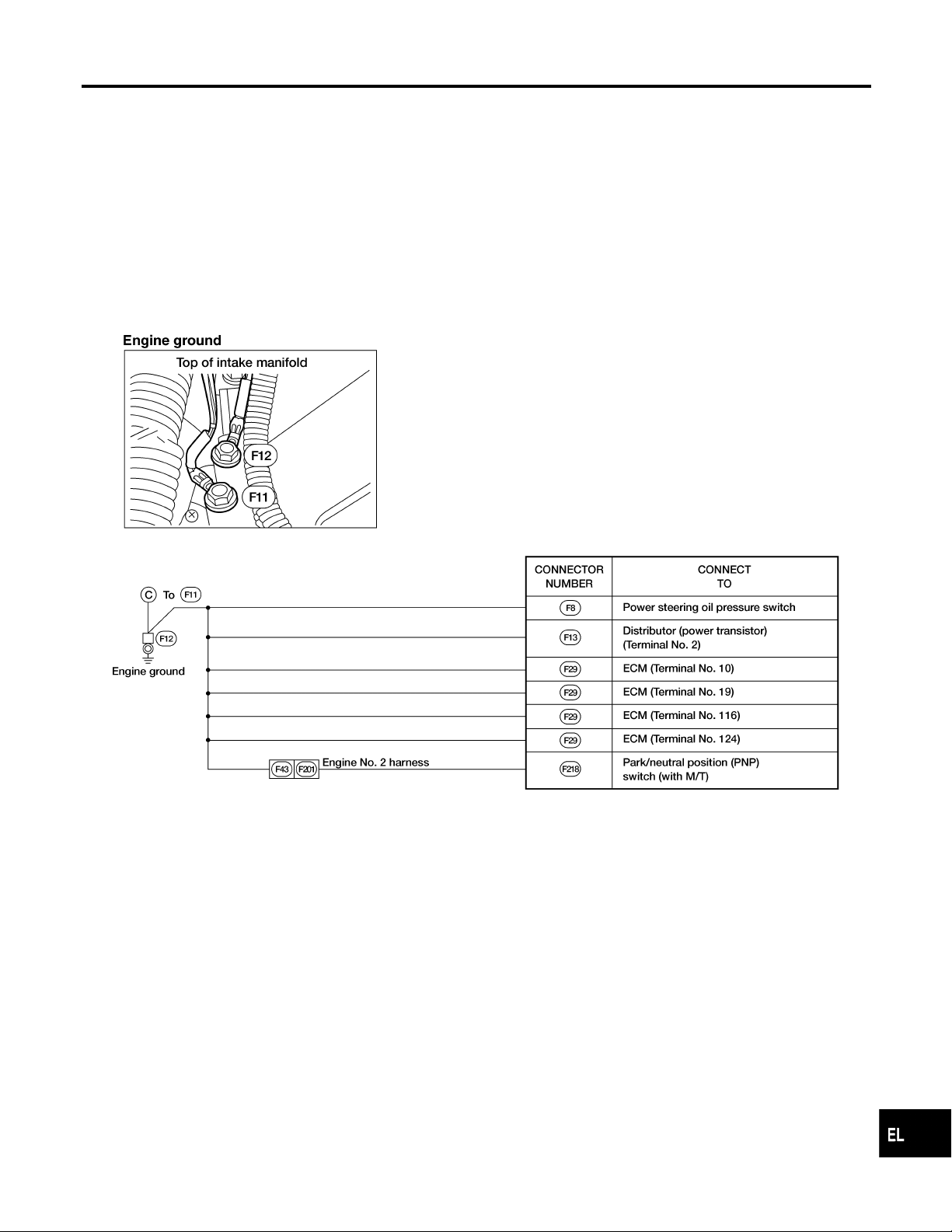

Ground Distribution (Cont’d)

ENGINE ROOM HARNESS

KA24DE

NGEL0171S02

NGEL0171S0201

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-19

HA

AEL708C

SC

IDX

Ground Distribution (Cont’d)

GROUND

EL-20

AEL709C

GROUND

Ground Distribution (Cont’d)

VG33E

NGEL0171S0202

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-21

AEL711C

HA

SC

IDX

Ground Distribution (Cont’d)

GROUND

EL-22

AEL712C

GROUND

Ground Distribution (Cont’d)

ENGINE NO. 2 HARNESS

KA24DE

NGEL0171S08

NGEL0171S0801

GI

MA

EM

LC

EC

FE

CL

MT

AEL710C

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-23

HA

SC

IDX

Ground Distribution (Cont’d)

GROUND

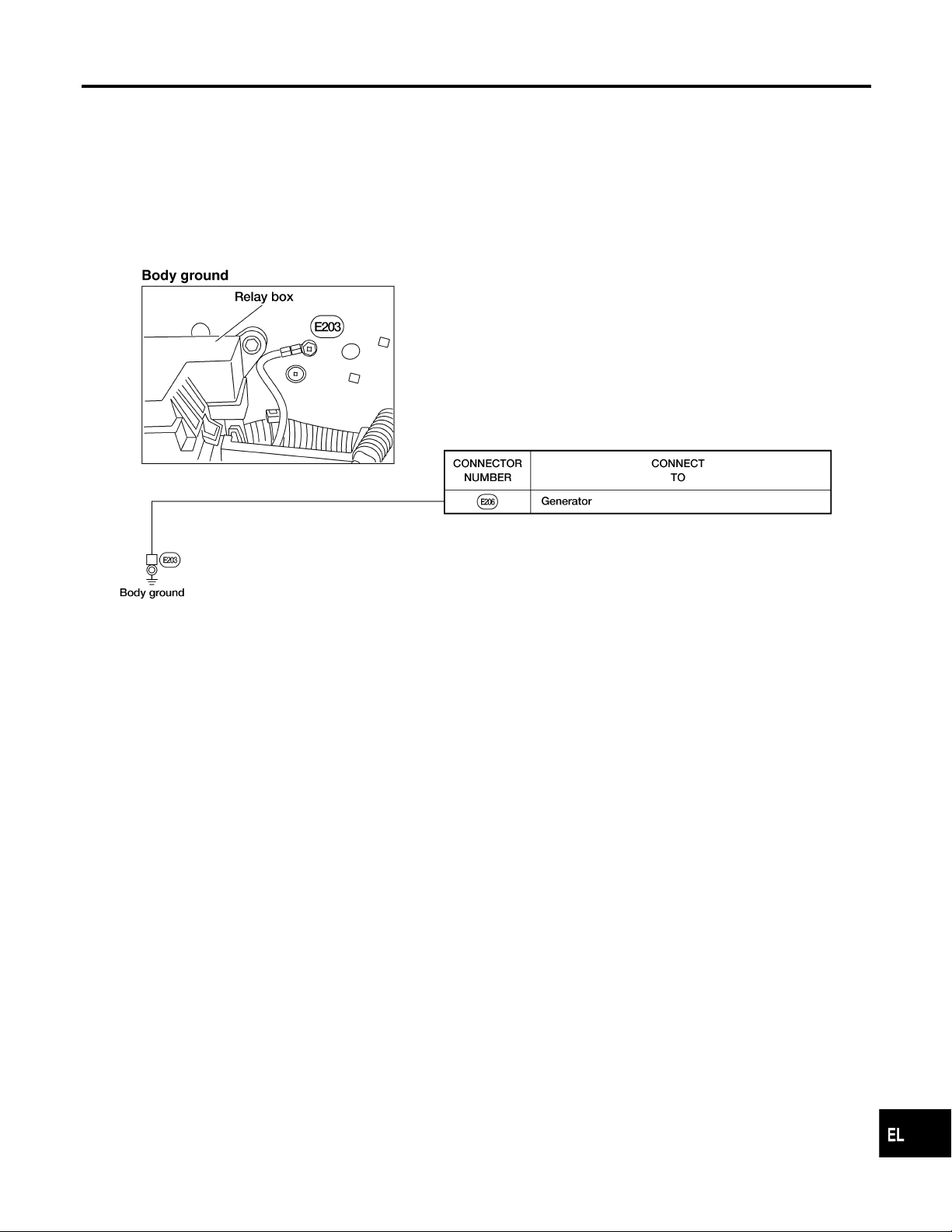

GENERATOR HARNESS

VG33E

NGEL0171S03

NGEL0171S0301

EL-24

AEL697C

GROUND

Ground Distribution (Cont’d)

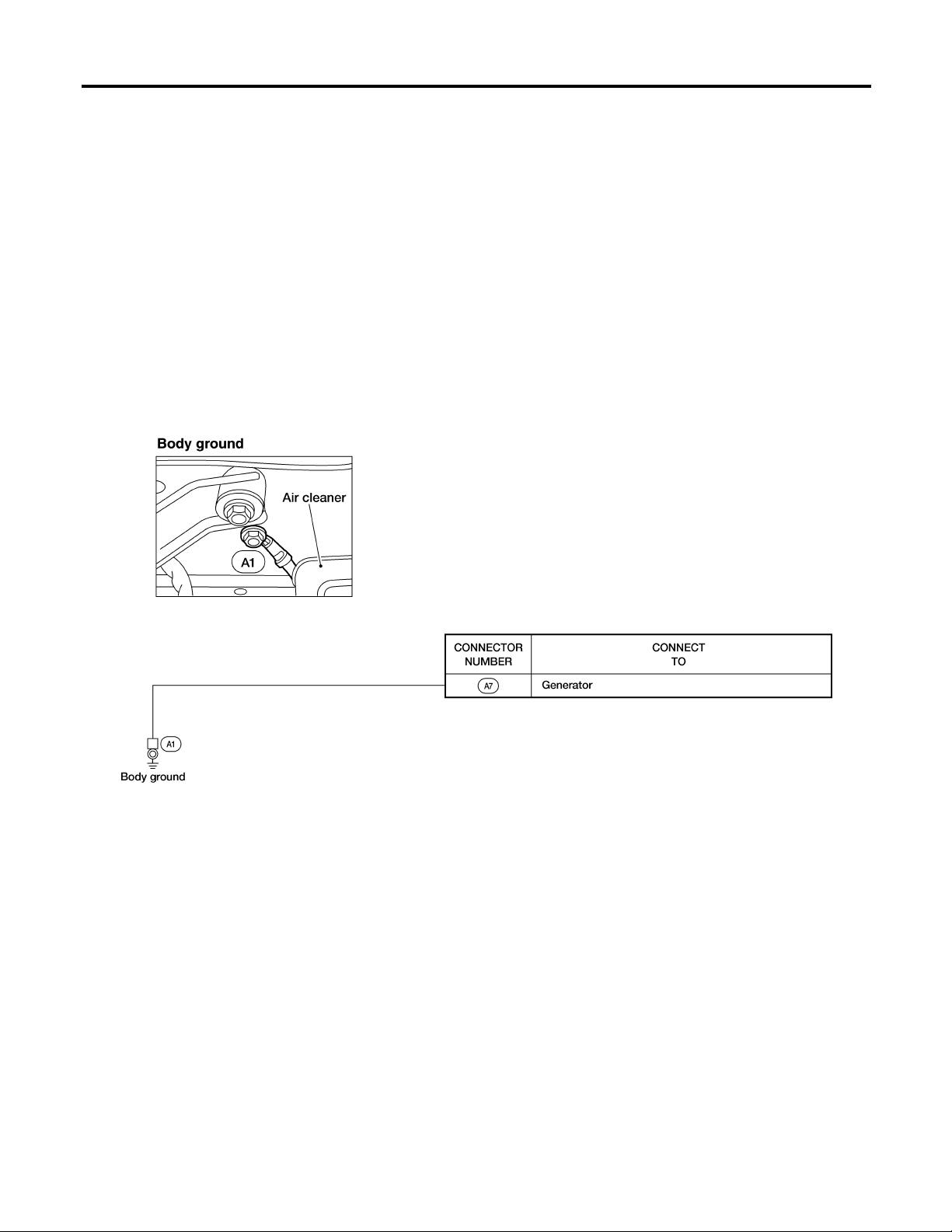

ENGINE CONTROL HARNESS

KA24DE

NGEL0171S04

NGEL0171S0401

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-25

HA

AEL713C

SC

IDX

Ground Distribution (Cont’d)

GROUND

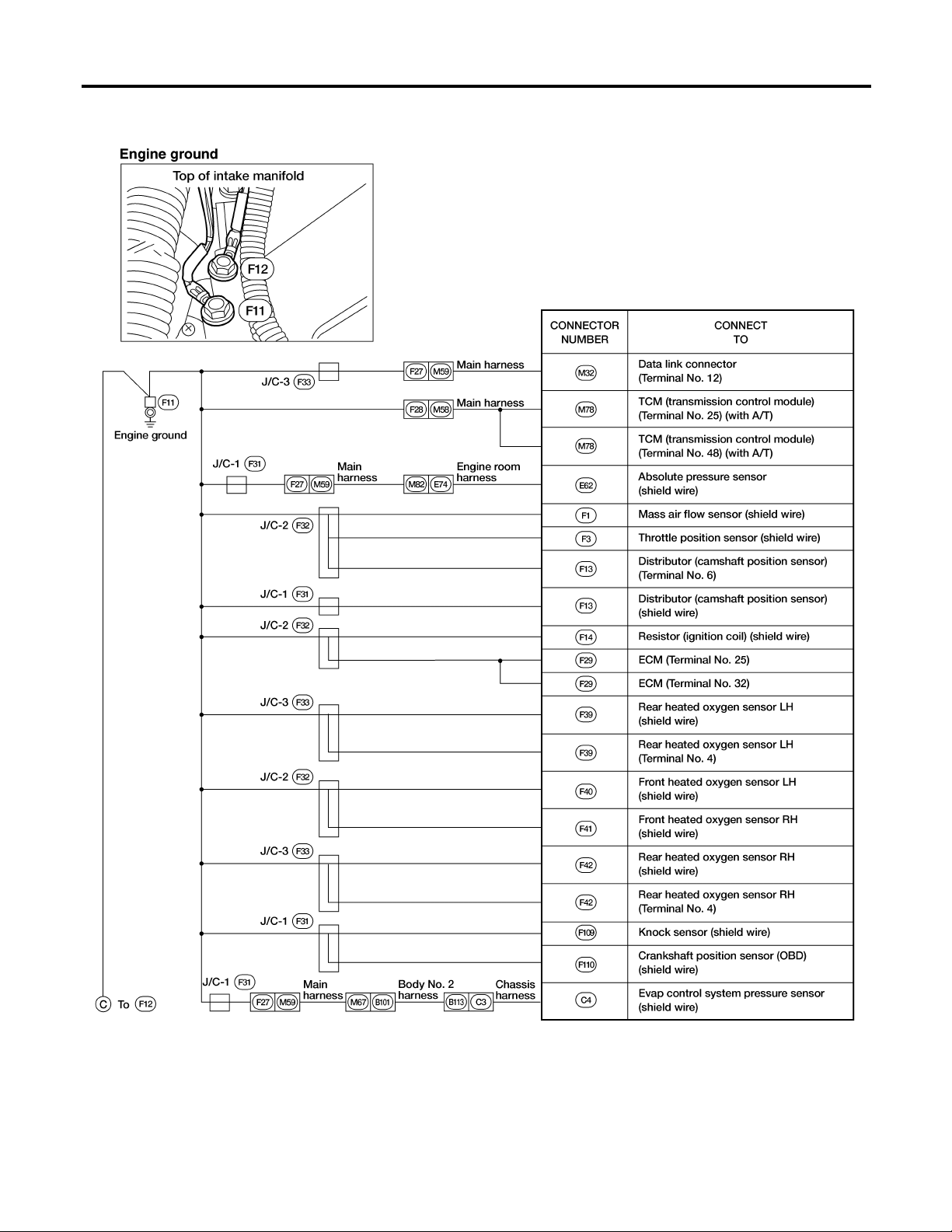

VG33E

NGEL0171S0402

EL-26

AEL714C

GROUND

Ground Distribution (Cont’d)

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

EL-27

AEL715C

BT

HA

SC

IDX

Ground Distribution (Cont’d)

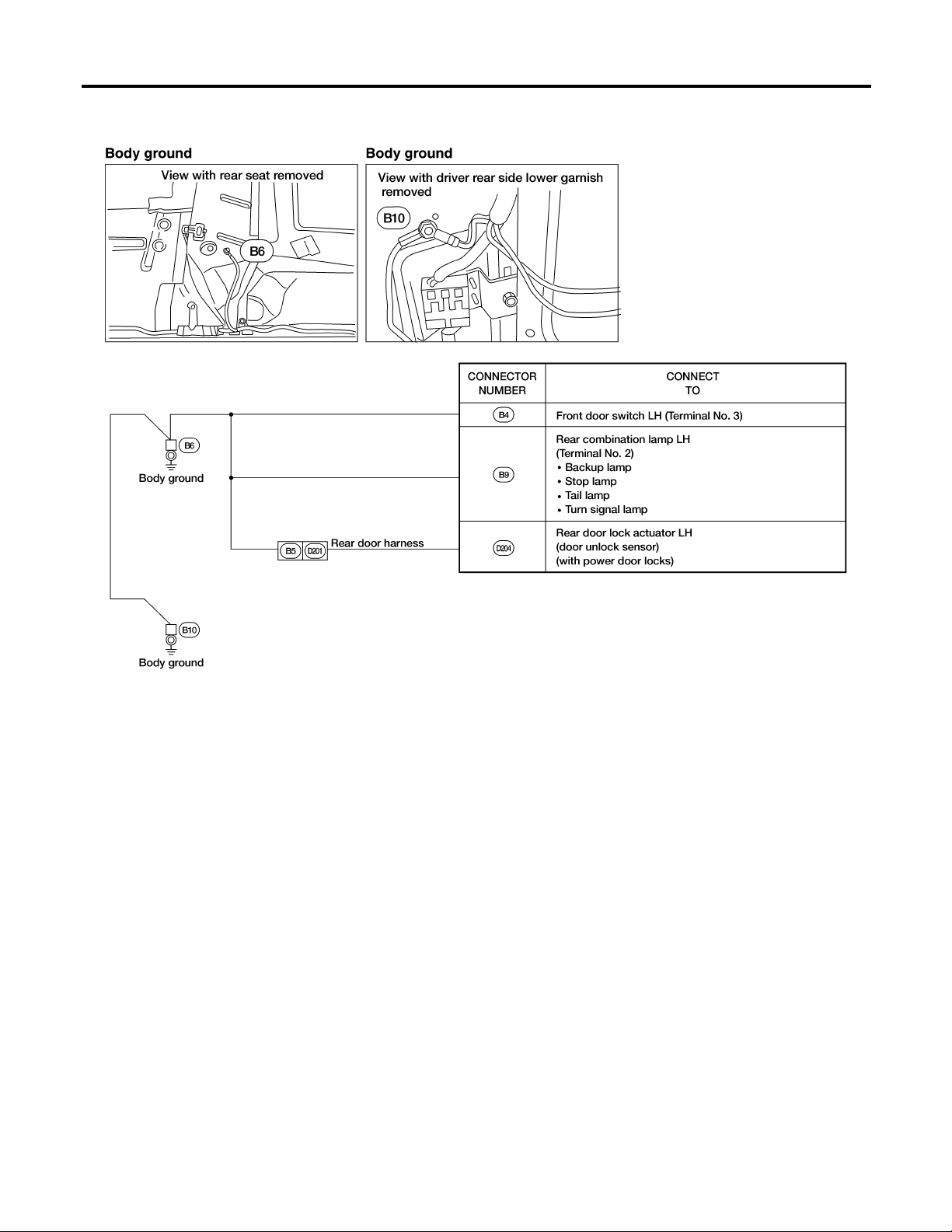

GROUND

BODY HARNESS

NGEL0171S05

AEL716C

EL-28

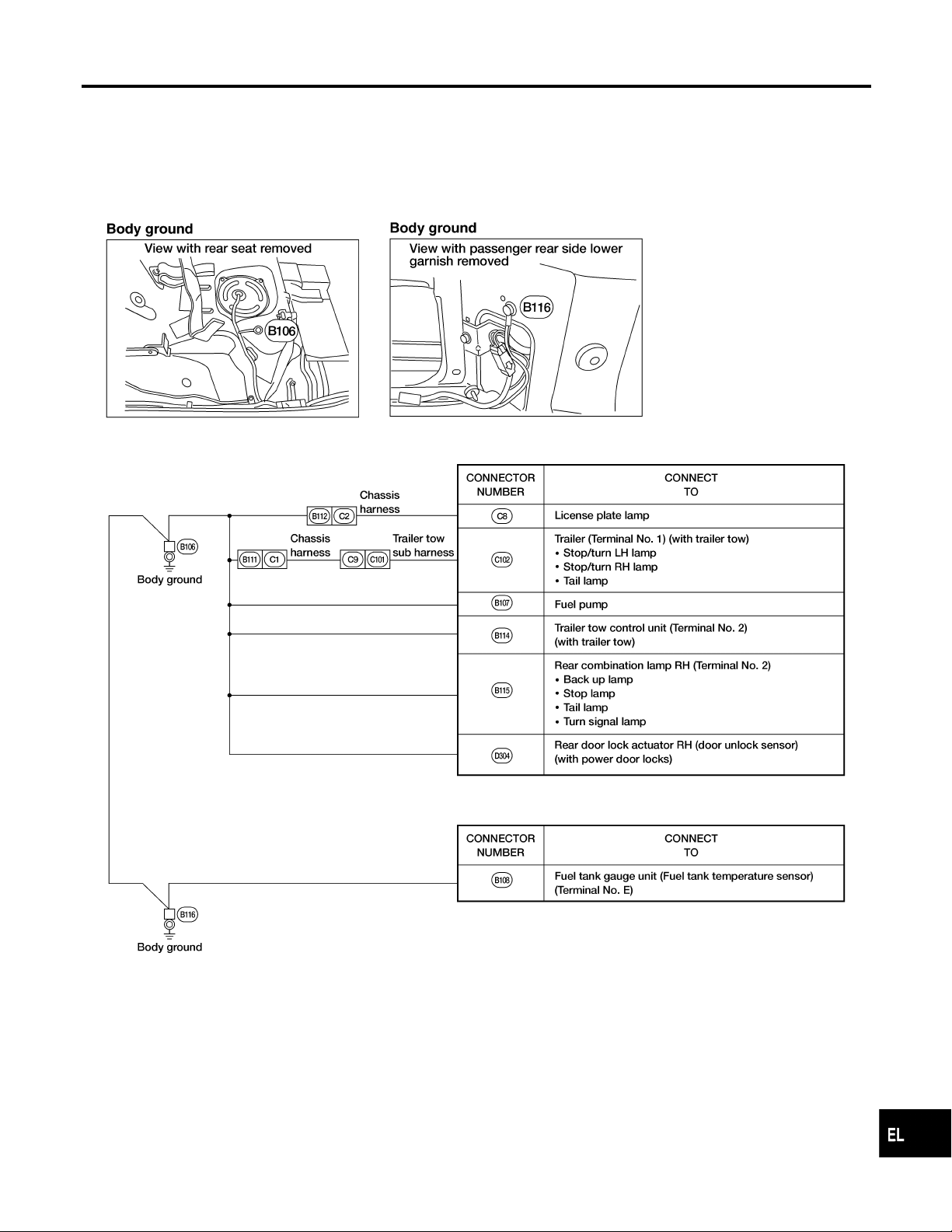

GROUND

Ground Distribution (Cont’d)

BODY NO. 2 HARNESS

NGEL0171S06

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-29

AEL717C

HA

SC

IDX

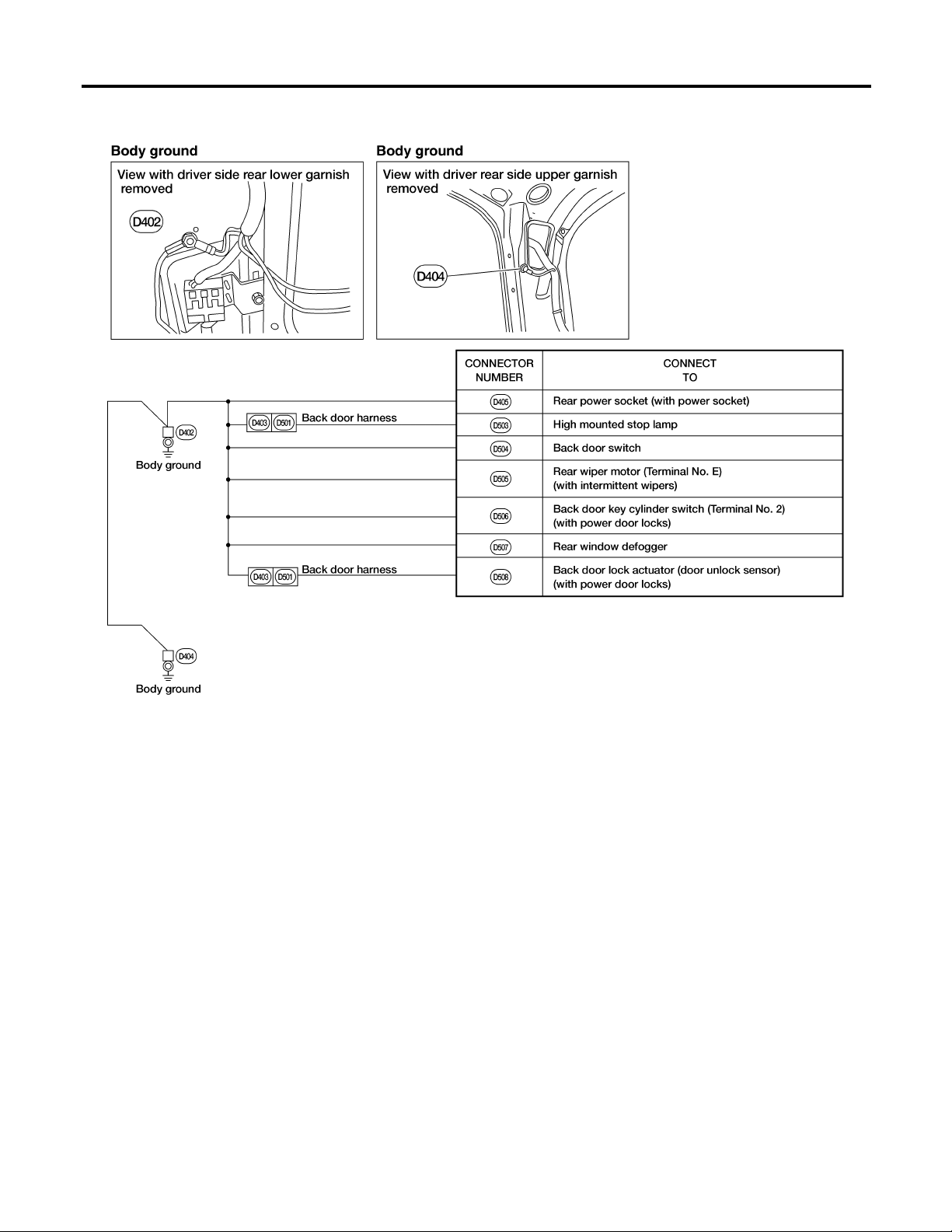

Ground Distribution (Cont’d)

GROUND

BACK DOOR NO. 2 HARNESS

NGEL0171S07

AEL718C

EL-30

COMBINATION SWITCH

Check

Check

NGEL0009

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-31

HA

SC

AEL122C

IDX

Replacement

COMBINATION SWITCH

SEL865L

MEL205B

Replacement

NGEL0010

For removal and installation of spiral cable, refer to RS-16,

[“Driver Air Bag Module and Spiral Cable”, “SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)”].

쐌 Each switch can be replaced without removing combination

switch base.

쐌 To remove combination switch base, remove base attaching

screws.

쐌 Before installing the steering wheel, align the turn signal can-

cel tab with the notch of the combination switch. Refer to RS

RS-16,[“Driver Air Bag Module and Spiral Cable”, “SUPPLE-

MENTAL RESTRAINT SYSTEM (SRS)”].

ARS152

EL-32

STEERING SWITCH

Check

Check

NGEL0011

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-33

HA

SC

AEL603B

IDX

System Description

HEADLAMP (FOR USA)

System Description

NGEL0012

The headlamps are controlled by the lighting switch which is built into the combination switch.

Power is supplied at all times

쐌 through 15A fuse (No. 37, located in the fuse and fusible link box)

쐌 to lighting switch terminal 5 and

쐌 through 15A fuse (No. 38, located in the fuse and fusible link box)

쐌 to lighting switch terminal 8.

LOW BEAM OPERATION

NGEL0012S01

With the lighting switch in the headlamp ON (2ND) position and LOW BEAM (B) position, power is supplied

쐌 from lighting switch terminal 10

쐌 to headlamp LH terminal D and

쐌 from lighting switch terminal 7

쐌 to headlamp RH terminal D.

Ground is supplied to headlamp LH/RH terminal E through body grounds E12 and E54.

With power and ground supplied, the low beams illuminate.

HIGH BEAM OPERATION/FLASH-TO-PASS OPERATION

NGEL0012S02

With the lighting switch in the FLASH TO PASS (C) position or the headlamp ON (2ND) position and HIGH

BEAM (A) position, power is supplied

쐌 from lighting switch terminal 6

쐌 to headlamp RH terminal M and

쐌 from lighting switch terminal 9

쐌 to headlamp LH terminal M and

쐌 to combination meter terminal 26 for the high beam indicator.

Ground is supplied to terminal 27 of the combination meter through body grounds M14 and M68.

Ground is supplied to headlamp LH/RH terminal E through body grounds E12 and E54.

With power and ground supplied, the high beams and the high beam indicator illuminate.

THEFT WARNING SYSTEM

NGEL0012S03

The theft warning system will flash the high beams if the system is triggered. Refer to “System Description”,

“THEFT WARNING SYSTEM”, EL-227.

EL-34

HEADLAMP (FOR USA)

Wiring Diagram — H/LAMP —

Wiring Diagram — H/LAMP —

NGEL0013

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-35

HA

SC

AEL347C

IDX

Trouble Diagnoses

HEADLAMP (FOR USA)

Symptom Possible cause Repair order

Neither headlamp LH nor headlamp

RH operate.

Headlamp LH does not operate,

but headlamp RH operates properly.

Headlamp RH does not operate,

but headlamp LH operates properly.

High beam LH does not operate,

but low beam LH operates.

Low beam LH does not operate,

but high beam LH operates.

Trouble Diagnoses

1. Lighting switch 1. Check lighting switch.

1. Bulb

2. Headlamp LH ground circuit

3. 15A fuse

4. Lighting switch

1. Bulb

2. Headlamp RH ground circuit

3. 15A fuse

4. Lighting switch

1. Bulb

2. Open in high beam LH circuit

3. Lighting switch

1. Bulb

2. Open in low beam LH circuit

3. Lighting switch

1. Check bulb.

2. Check continuity between headlamp LH terminal E

and grounds E12 and E54.

3. Check 15A fuse (No. 38, located in fuse and fusible

link box). Verify battery positive voltage is present at

terminal 8 of lighting switch.

4. Check lighting switch.

1. Check bulb.

2. Check continuity between headlamp RH terminal E

and grounds E12 and E54.

3. Check 15A fuse (No. 37, located in fuse and fusible

link box). Verify battery positive voltage is present at

terminal 5 of lighting switch.

4. Check lighting switch.

1. Check bulb.

2. Check R/G wire between lighting switch and headlamp LH for an open circuit.

3. Check lighting switch.

1. Check bulb.

2. Check R wire between lighting switch and headlamp LH for an open circuit.

3. Check lighting switch.

NGEL0014

High beam RH does not operate,

but low beam RH operates.

Low beam RH does not operate,

but high beam RH operates.

High beam indicator does not work. 1. Bulb

1. Bulb

2. Open in high beam RH circuit

3. Lighting switch

1. Bulb

2. Open in low beam RH circuit

3. Lighting switch

2. High beam indicator ground circuit

3. Open in high beam circuit

1. Check bulb.

2. Check R/W wire between lighting switch and headlamp RH for an open circuit.

3. Check lighting switch.

1. Check bulb.

2. Check R/B wire between lighting switch and headlamp RH for an open circuit.

3. Check lighting switch.

1. Check bulb in combination meter.

2. Check continuity between combination meter terminal 27 and grounds M14 and M68.

3. Check R/G wire between lighting switch and combination meter for an open circuit.

EL-36

HEADLAMP (FOR USA)

Bulb Replacement

AEL722C

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replaceable halogen bulb. The bulb can be replaced from the engine compartment side without removing the headlamp body.

쐌 Grasp only the plastic base when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Unclip the bulb retaining clip, and then remove it.

4. Remove the headlamp bulb carefully. Do not shake or rotate

the bulb when removing it.

5. Install in the reverse order of removal.

CAUTION:

Do not leave headlamp reflector without bulb for a long period

of time. Dust, moisture, smoke, etc. entering headlamp body

may affect the performance of the headlamp. Remove headlamp bulb from the headlamp reflector just before a replacement bulb is installed.

=NGEL0015

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-37

HA

SC

IDX

Aiming Adjustment

HEADLAMP (FOR USA)

Aiming Adjustment

=NGEL0016

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester.Aimers should be

in good repair, calibrated and operated in accordance with respective operation manuals.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

1) Keep all tires inflated to correct pressures.

2) Place vehicle and tester on one and same flat surface.

3) See that there is no-load in vehicle (coolant, engine oil

filled up to correct level and full fuel tank) other than the

driver (or equivalent weight placed in driver’s position).

AIMER ADJUSTMENT MARK

NGEL0016S01

When using a mechanical aimer, adjust adapter legs to the data

marked on the headlamps.

Adjustment value for mechanical aimer

AEL615C

AEL671B

Mechanical aimer level

Horizontal side −4 to 4

Vertical side −4 to 4

LOW BEAM

NGEL0016S02

1. Turn headlamp low beam on.

2. Use a #2 cross-recessed screwdriver to adjust the aim of the

lamp.

쐌 Cover the opposite lamp.

EL-38

HEADLAMP (FOR USA)

Aiming Adjustment (Cont’d)

If the vehicle front body has been repaired and/or the headlamp

assembly has been replaced, check aiming. Use the aiming chart

shown in the figure.

쐌 Upper edge and left edge of high intensity zone should be

within the range shown at left. Adjust headlamps accordingly.

쐌 Dotted lines in illustration show center of headlamp.

“H”: Horizontal center line of headlamps

“W

”: Distance between each headlamp center

L

GI

MA

EM

LC

EC

FE

CL

SEL866L

MT

AT

TF

PD

AX

SU

BR

ST

RS

EL-39

BT

HA

SC

IDX

HEADLAMP (FOR CANADA) — DAYTIME LIGHT SYSTEM —

System Description (For Canada)

System Description (For Canada)

NGEL0017

The headlamp system for Canada vehicles contains a daytime light control unit that activates the high beam

headlamps at approximately half illumination whenever the engine is running. If the parking brake is applied

before the engine is started the daytime lights will not be illuminated. The daytime lights will illuminate once

the parking brake is released. Thereafter, the daytime lights will continue to operate when the parking brake

is applied. If the daytime light control unit receives a ground signal from the generator, the daytime lights will

not be illuminated. The daytime lights will illuminate once a battery positive voltage signal is sent to the daytime light control unit from the generator.

Power is supplied at all times

쐌 through 15A fuse (No. 38, located in the fuse and fusible link box)

쐌 to daytime light control unit terminal 3 and

쐌 to lighting switch terminal 8.

Power is also supplied at all times

쐌 through 15A fuse (No. 37, located in the fuse and fusible link box)

쐌 to daytime light control unit terminal 2 and

쐌 to lighting switch terminal 5.

With the ignition switch in the ON or START position, power is supplied

쐌 through 7.5A fuse [No. 5, located in the fuse block (J/B)]

쐌 to daytime light control unit terminal 12.

With the ignition switch in the START position, power is supplied

쐌 through 7.5A fuse [No. 7, located in the fuse block (J/B)]

쐌 to daytime light control unit terminal 1.

Ground is supplied to daytime light control unit terminal 9 through body grounds E12 and E54.

HEADLAMP OPERATION

Low Beam Operation

NGEL0017S01

NGEL0017S0101

When the lighting switch is turned to the headlamp ON (2ND) position, LOW BEAM (B), power is supplied

쐌 from lighting switch terminal 7

쐌 to headlamp RH terminal D and

쐌 to daytime light control unit terminal 4.

Ground is supplied to headlamp RH terminal E through body grounds E12 and E54.

Also, when the lighting switch is turned to the headlamp ON (2ND) position, LOW BEAM (B), power is supplied

쐌 from lighting switch terminal 10

쐌 to headlamp LH terminal D.

Ground is supplied

쐌 to headlamp LH terminal E

쐌 from daytime light control unit terminal 7

쐌 through daytime light control unit terminal 9

쐌 through body grounds E12 and E54.

With power and ground supplied, the low beam headlamps illuminate.

High Beam Operation/Flash-to-pass Operation

NGEL0017S0102

When the lighting switch is turned to the headlamp ON (2ND) position, HIGH BEAM (A) or FLASH TO PASS

(C) position, power is supplied

쐌 from lighting switch terminal 6

쐌 to headlamp RH terminal M and

쐌 to daytime light control unit terminal 8.

Also, when the lighting switch is turned to the headlamp ON (2ND) position, HIGH BEAM (A) or FLASH TO

PASS (C) position, power is supplied

쐌 from lighting switch terminal 9

쐌 to combination meter terminal 26 for the high beam indicator and

쐌 to daytime light control unit terminal 5

쐌 through daytime light control unit terminal 6

EL-40

HEADLAMP (FOR CANADA) — DAYTIME LIGHT SYSTEM —

System Description (For Canada) (Cont’d)

쐌 to headlamp LH terminal M.

Ground is supplied in the same manner as low beam operation.

Ground is supplied to combination meter terminal 27 through body grounds M14 and M68.

With power and ground supplied, the high beam headlamps and HI BEAM indicator illuminate.

GI

DAYTIME LIGHT OPERATION

With the engine running, the lighting switch in the OFF or 1ST position and parking brake released, power is

supplied

쐌 to daytime light control unit terminal 3

쐌 through daytime light control unit terminal 6

쐌 to headlamp LH terminal M

쐌 through headlamp LH terminal E

쐌 to daytime light control unit terminal 7

쐌 through daytime light control unit terminal 8

쐌 to headlamp RH terminal M.

Ground is supplied to headlamp RH terminal E through body grounds E12 and E54.

Because the high beam headlamps are now wired in series, they operate at half illumination.

OPERATION (FOR CANADA)

After starting the engine with the lighting switch in the OFF or parking lamp (1ST) position, the headlamp high

beams automatically turn on. Lighting switch operations other than the above are the same as conventional

light systems.

Engine With engine stopped With engine running

OFF 1ST 2ND OFF 1ST 2ND

Lighting switch

ABCABCABCABCABCABC

High beam X X O X X O O X O 왕* 왕*O왕* 왕*O O X O

Headlamp

Low beam XXXXXXXOXXXXXXXXOX

Clearance and tail lamp X X X OOOOOOXXXOOOOOO

NGEL0017S02

NGEL0017S03

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

License and instrument illumination

lamp

A: HIGH BEAM position

B: LOW BEAM position

C: FLASH TO PASS position

O : Lamp ON

X : Lamp OFF

왕 : Lamp dims. (Added functions)

*: When starting the engine with the parking brake released, the daytime lights will come ON.

When starting the engine with the parking brake pulled, the daytime lights won’t come ON.

XXXOOOOOOXXXOOOOOO

AX

SU

BR

ST

RS

BT

HA

SC

EL-41

IDX

Circuit Diagram

HEADLAMP (FOR CANADA) — DAYTIME LIGHT SYSTEM —

Circuit Diagram

NGEL0019

AEL348C

EL-42

HEADLAMP (FOR CANADA) — DAYTIME LIGHT SYSTEM —

Wiring Diagram — DTRL —

Wiring Diagram — DTRL —

NGEL0020

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-43

HA

SC

AEL349C

IDX

HEADLAMP (FOR CANADA) — DAYTIME LIGHT SYSTEM —

Wiring Diagram — DTRL — (Cont’d)

EL-44

AEL350C

HEADLAMP (FOR CANADA) — DAYTIME LIGHT SYSTEM —

Wiring Diagram — DTRL — (Cont’d)

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

EL-45

BT

HA

SC

AEL351C

IDX

HEADLAMP (FOR CANADA) — DAYTIME LIGHT SYSTEM —

Trouble Diagnoses

Trouble Diagnoses

DAYTIME LIGHT CONTROL UNIT INSPECTION TABLE

Terminal

No.

1 L/OR Ignition switch start signal Ignition switch in START position 12

2 Y/G Power source for head-

3 Y/B Power source for head-

4 R/B Lighting switch headlamp

5 R/G Lighting switch headlamp

6 R/Y Headlamp LH high beam Lighting switch in the FLASH TO PASS (C) position

Wire

color

Item Condition

lamp RH

lamp LH

RH low beam output

LH high beam output

(Approximate value)

All other conditions 0

— 12

— 12

Lighting switch in the headlamp ON (2ND) position

and LOW BEAM (B) position

All other conditions 0

Lighting switch in the FLASH TO PASS (C) position

or headlamp ON (2ND) position and HIGH BEAM (A)

position

All other conditions 0

or headlamp ON (2ND) position and HIGH BEAM (A)

position

NGEL0021

NGEL0021S01

Voltage

12

12

12

With parking brake released, engine running and

lighting switch in OFF or parking and tail lamp ON

(1ST) positions

CAUTION:

Block wheels and ensure selector lever is in P or

N position.

All other conditions 0

7 B/W Headlamp LH control

(ground)

8 R/W Lighting switch headlamp

RH high beam output

9 B Ground ——

Lighting switch in the FLASH TO PASS (C) position

or headlamp ON (2ND) position

All other conditions 6

Lighting switch in the FLASH TO PASS (C) position

or headlamp ON (2ND) position and HIGH BEAM (A)

position

With parking brake released, engine running and

lighting switch in OFF or parking and tail lamp ON

(1ST) positions

CAUTION:

Block wheels and ensure selector lever is in P or

N position.

All other conditions 0

12

0

12

6

10 Y Parking brake switch Parking brake released 12

Parking brake set 0

11 Y/B Generator

(L terminal)

When engine is running 12

All other conditions 0

EL-46

HEADLAMP (FOR CANADA) — DAYTIME LIGHT SYSTEM —

Trouble Diagnoses (Cont’d)

12 G/W Ignition switch on signal Ignition switch OFF, ACC positions 0

Ignition switch ON, START positions 12

Bulb Replacement

Refer to “HEADLAMP (FOR USA)”, EL-37.

Aiming Adjustment

Refer to “HEADLAMP (FOR USA)”, EL-38.

NGEL0022

NGEL0023

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL-47

SC

IDX

Wiring Diagram — TAIL/L —

PARKING, LICENSE AND TAIL LAMPS

Wiring Diagram — TAIL/L —

NGEL0024

EL-48

AEL352C

STOP LAMP

Wiring Diagram — STOP/L —

Wiring Diagram — STOP/L —

NGEL0025

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-49

HA

SC

AEL353C

IDX

Wiring Diagram — BACK/L —

BACK-UP LAMP

Wiring Diagram — BACK/L —

NGEL0026

EL-50

AEL354C

FRONT FOG LAMP

System Description

System Description

Power is supplied at all times

쐌 through 15A fuse (No. 40, located in the fuse and fusible link box)

쐌 to front fog lamp relay terminal 5 and

쐌 through 15A fuse (No. 37, located in the fuse and fusible link box)

쐌 to lighting switch terminal 5.

With the lighting switch in the headlamp ON (2ND) position and LOW BEAM (B) position, power is supplied

쐌 through lighting switch terminal 7

쐌 to front fog lamp relay terminal 2.

FRONT FOG LAMP OPERATION

The front fog lamp switch is built into the combination switch. The lighting switch must be in the headlamp ON

(2ND) position and LOW BEAM (B) position for front fog lamp operation.

With the front fog lamp switch in the ON position:

쐌 ground is supplied to front fog lamp relay terminal 1

쐌 through front fog lamp switch terminal 2

쐌 through front fog lamp switch terminal 1

쐌 through body grounds E12 and E54.

The front fog lamp relay is energized and power is supplied

쐌 through front fog lamp relay terminal 3

쐌 to front fog lamp LH/RH terminal 1.

Ground is supplied to front fog lamp LH/RH terminal 2 through body grounds E12 and E54.

With power and ground supplied, the front fog lamps illuminate.

NGEL0027

NGEL0027S01

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL-51

SC

IDX

Wiring Diagram — F/FOG —

FRONT FOG LAMP

Wiring Diagram — F/FOG —

NGEL0028

EL-52

AEL355C

FRONT FOG LAMP

Aiming Adjustment

AEL160C

MEL327G

Aiming Adjustment

Before performing aiming adjustment, make sure of the following.

1) Keep all tires inflated to correct pressure.

2) Place vehicle on level ground.

3) See that vehicle is unloaded (except for full levels of coolant,

engine oil and fuel, and spare tire, jack, and tools). Have the

driver or equivalent weight placed in driver’s seat.

Loosen front fog lamp adjusting nuts and adjust aiming by moving

front fog lamps.

1. Set the distance between the screen and the center of the front

fog lamp lens as shown at left.

2. Turn front fog lamps ON.

3. Adjust front fog lamps so that the top edge of the high intensity zone is 100 mm (4 in) below the height of the fog lamp

centers as shown at left.

쐌 When performing adjustment, if necessary, cover the

headlamps and opposite fog lamp.

4. Tighten the front fog lamp adjusting nuts.

NGEL0029

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

MEL328G

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL-53

IDX

Removal and Installation

FRONT FOG LAMP

Removal and Installation

=NGEL0184

1. Disconnect front fog lamp harness connector and separate

front fog lamp connector from front fog lamp bracket.

AEL616C

2. remove mounting nut and remove lens and housing assembly

from front fog lamp bracket.

3. Install in reverse order of removal. Ensure top of lens faces up.

4. Tighten mounting nut.

:5-6N·m (0.51 - 0.61 kg-m, 44.3 - 53.1 in-lb)

AEL345C

AEL346C

Bulb and Lens Replacement

NGEL0185

1. Remove the two metal clips on sides of fog lamp.

2. Pull out and support fog lamp lens.

3. Disconnect fog lamp bulb connector.

4. Lift retaining spring.

5. Remove fog lamp bulb.

쐌 Fog lamp bulb cannot be separated from wire and is serviced

as an assembly.

6. For lens replacement, disconnect ground connector from bulb

retainer and remove lens.

7. Install in reverse order of removal. Ensure top of lens faces up.

DO NOT TOUCH BULB.

EL-54

TURN SIGNAL AND HAZARD WARNING LAMPS

System Description

System Description

TURN SIGNAL OPERATION

With the hazard switch in the OFF position and the ignition switch in the ON or START position, power is supplied

쐌 through 7.5A fuse [No. 2, located in the fuse block (J/B)]

쐌 to hazard switch terminal 2

쐌 through the hazard switch terminal 1

쐌 to combination flasher unit terminal B

쐌 through combination flasher unit terminal L

쐌 to turn signal switch terminal 1.

Ground is supplied to combination flasher unit terminal E through body grounds M14 and M68.

LH Turn

With the turn signal switch in the LH position, power is supplied from turn signal switch terminal 3 to

쐌 front combination lamp LH terminal 1

쐌 combination meter terminal 11 and

쐌 rear combination lamp LH terminal 3.

Ground is supplied to front combination lamp LH terminal 2 through body grounds E12 and E54.

Ground is supplied to rear combination lamp LH terminal 2 through body grounds B6 and B10.

Ground is supplied to combination meter terminal 36 through body grounds M14 and M68.

With power and ground supplied, the combination flasher unit controls the flashing of the LH turn signal lamps.

RH Turn

With the turn signal switch in the RH position, power is supplied from turn signal switch terminal 2 to

쐌 front combination lamp RH terminal 1

쐌 combination meter terminal 28 and

쐌 rear combination lamp RH terminal 3.

Ground is supplied to the front combination lamp RH terminal 2 through body grounds E12 and E54.

Ground is supplied to the rear combination lamp RH terminal 2 through body grounds B106 and B116.

Ground is supplied to combination meter terminal 36 through body grounds M14 and M68.

With power and ground supplied, the combination flasher unit controls the flashing of the RH turn signal lamps.

HAZARD LAMP OPERATION

Power is supplied at all times to hazard switch terminal 3 through:

쐌 10A fuse [No. 17, located in the fuse block (J/B)].

With the hazard switch in the ON position, power is supplied

쐌 through hazard switch terminal 1

쐌 to combination flasher unit terminal B

쐌 through combination flasher unit terminal L

쐌 to hazard switch terminal 4.

Ground is supplied to combination flasher unit terminal E through body grounds M14 and M68.

Power is supplied through hazard switch terminal 5 to

쐌 front combination lamp LH terminal 1

쐌 combination meter terminal 11 and

쐌 rear combination lamp LH terminal 3.

Power is supplied through hazard switch terminal 6 to

쐌 front combination lamp RH terminal 1

쐌 combination meter terminal 28 and

쐌 rear combination lamp RH terminal 3.

Ground is supplied to front combination lamp LH/RH terminal 2 through body grounds E12 and E54.

Ground is supplied to rear combination lamp LH terminal 2 through body grounds B6 and B10.

Ground is supplied to rear combination lamp RH terminal 2 through body grounds B106 and B116.

Ground is supplied to combination meter terminal 36 through body grounds M14 and M68.

With power and ground supplied, the combination flasher unit controls the flashing of the hazard warning

lamps.

NGEL0030

NGEL0030S01

NGEL0030S0101

NGEL0030S0102

NGEL0030S02

EL-55

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

TURN SIGNAL AND HAZARD WARNING LAMPS

System Description (Cont’d)

MULTI-REMOTE CONTROL SYSTEM OPERATION

NGEL0030S03

Power is supplied at all times

쐌 through 10A fuse [No. 17, located in the fuse block (J/B)]

쐌 to multi-remote control relay terminals 2, 5 and 7.

Ground is supplied to multi-remote control relay terminal 1 through smart entrance control unit terminal 7, when

the multi-remote control system is triggered through the smart entrance control unit.

Refer to “MULTI-REMOTE CONTROL SYSTEM”, EL-202.

The multi-remote control relay is energized.

Power is supplied through multi-remote control relay terminal 3 to

쐌 front combination lamp LH terminal 1

쐌 combination meter terminal 11 and

쐌 rear combination lamp LH terminal 3.

Power is supplied through multi-remote control relay terminal 6 to

쐌 front combination lamp RH terminal 1

쐌 combination meter terminal 28 and

쐌 rear combination lamp RH terminal 3.

Ground is supplied to front combination lamp LH/RH terminal 2 through body grounds E12 and E54.

Ground is supplied to rear combination lamp LH terminal 2 through body grounds B6 and B10.

Ground is supplied to rear combination lamp RH terminal 2 through body grounds B106 and B116.

Ground is supplied to combination meter terminal 36 through body grounds M14 and M68.

With power and ground supplied, the smart entrance control unit controls the flashing of the hazard warning

lamps.

EL-56

TURN SIGNAL AND HAZARD WARNING LAMPS

Wiring Diagram — TURN —

Wiring Diagram — TURN —

NGEL0032

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-57

HA

SC

AEL356C

IDX

TURN SIGNAL AND HAZARD WARNING LAMPS

Wiring Diagram — TURN — (Cont’d)

EL-58

AEL357C

TURN SIGNAL AND HAZARD WARNING LAMPS

Trouble Diagnoses

Symptom Possible cause Repair order

Turn signal and hazard warning

lamps do not operate.

Turn signal lamps do not operate

but hazard warning lamps operate.

Hazard warning lamps do not operate but turn signal lamps operate.

Front turn signal lamp LH or RH

does not operate.

Rear turn signal lamp LH does not

operate.

Trouble Diagnoses

1. Hazard switch

2. Combination flasher unit

3. Open in combination flasher unit

circuit

1. 7.5A fuse

2. Hazard switch

3. Turn signal switch

4. Open in turn signal switch circuit

1. 10A fuse

2. Hazard switch

3. Open in hazard switch circuit

1. Bulb

2. Front turn signal lamp ground

circuit

1. Bulb

2. Rear turn signal lamp LH

ground circuit

NGEL0033

1. Check hazard switch.

2. Refer to combination flasher unit check.

3. Check wiring to combination flasher unit for open

circuit.

1. Check 7.5A fuse [No. 2, located in fuse block (J/B)].

Turn ignition switch ON and verify battery positive

voltage is present at terminal 2 of hazard switch.

2. Check hazard switch.

3. Check turn signal switch.

4. Check G wire between combination flasher unit and

turn signal switch for open circuit.

1. Check 10A fuse [No. 17, located in fuse block

(J/B)]. Verify battery positive voltage is present at

terminal 3 of hazard switch.

2. Check hazard switch.

3. Check G wire between combination flasher unit and

hazard switch for open circuit.

1. Check bulb.

2. Check front turn signal lamp ground circuit.

1. Check bulb.

2. Check rear turn signal lamp LH ground circuit.

GI

MA

EM

LC

EC

FE

CL

MT

AT

Rear turn signal lamp RH does not

operate.

LH and RH turn indicators do not

operate.

LH or RH turn indicator does not

operate.

1. Bulb

2. Rear turn signal lamp RH

ground circuit

1. Ground circuit 1. Check ground circuit.

1. Bulb 1. Check bulb in combination meter.

1. Check bulb.

2. Check rear turn signal lamp RH ground circuit.

Electrical Components Inspection

COMBINATION FLASHER UNIT CHECK

쐌 Before checking, ensure that bulbs meet specifications.

쐌 Connect a battery and test lamp to the combination flasher

unit, as shown. Combination flasher unit is properly functioning if it blinks when power is supplied to the circuit.

SEL122E

NGEL0034

NGEL0034S01

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL-59

SC

IDX

System Description

TRAILER TOW

System Description

NGEL0161

Power is supplied at all times

쐌 through 15A fuse [No. 22, located in the fuse block (J/B)]

쐌 to trailer tow control unit terminals 3 and 4.

Ground is supplied

쐌 to trailer tow control unit terminal 2 and

쐌 to trailer harness connector terminal 1

쐌 through body grounds B106 and B116.

TRAILER TAIL LAMP OPERATION

NGEL0161S01

With the lighting switch in the parking and tail lamp ON (1ST) or

headlamp ON (2ND) position, power is supplied

쐌 from lighting switch terminal 12

쐌 to trailer harness connector terminal 2.

TRAILER STOP, TURN SIGNAL AND HAZARD LAMP

OPERATION

The trailer stop, turn signal and hazard lamps are all controlled by

the trailer tow control unit. The trailer tow control unit regulates the

amount of voltage supplied to the trailer lamps. If either turn signal

or the hazard lamps are turned on and the trailer tow control unit

gets a brake lamp input, the trailer tow control unit supplies more

voltage to the trailer lamps to make them illuminate brighter.

Power is supplied to trailer tow control unit terminals 3 and 4

through 15A fuse (No. 22, located in the fuse block) at all times.

Stop lamp input is supplied to trailer tow control unit terminal 1.

Left turn signal and hazard lamp input is supplied to trailer tow

control unit terminal 6.

Right turn signal and hazard lamp input is supplied to trailer tow

control unit terminal 5.

Based on the stop lamp, turn signal lamp and hazard lamp inputs

to the trailer tow control unit, power is supplied to trailer stop/turn

lamp LH

쐌 from trailer tow control unit terminal 7

쐌 to trailer harness connector terminal 3.

Power is also supplied to trailer stop/turn lamp RH

쐌 from trailer tow control unit terminal 8

쐌 to trailer harness connector terminal 4.

NGEL0161S02

EL-60

TRAILER TOW

Wiring Diagram — T/TOW —

Wiring Diagram — T/TOW —

NGEL0162

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-61

HA

SC

AEL358C

IDX

Trouble Diagnoses

TRAILER TOW

Trouble Diagnoses

TRAILER TOW CONTROL UNIT INSPECTION TABLE

Terminal

No.

1 BR/R Stop lamps signal

2 B Ground ——

3 R/B Power supply — 12

4 R/B Power supply — 12

5 G/R RH turn lamps

6 G/Y LH turn lamps

7 Y Stop/LH turn lamp (output)

Wire

color

Item Condition

When brake pedal is depressed 12

When brake pedal is released 0

When RH turn lamps or hazard lamps operate 12 (intermittently)

All other conditions 0

When LH turn lamps or hazard lamps operate 12 (intermittently)

All other conditions 0

When brake pedal is depressed 12

When LH turn lamps or hazard lamps operate 12 (intermittently)

All other conditions 0

When brake pedal is depressed 12

Voltage

(Approximate

value)

NGEL0163

NGEL0163S01

8 G Stop/RH turn lamp (output)

When RH turn lamps or hazard lamps operate 12 (intermittently)

All other conditions 0

EL-62

ILLUMINATION

System Description

System Description

Power is supplied at all times

쐌 through 15A fuse (No. 39, located in the fuse and fusible link box)

쐌 to lighting switch terminal 11.

The lighting switch must be in the parking and tail lamps ON (1ST) or headlamps ON (2ND) position for illumination.

The illumination control switch controls the amount of current to the illumination system. As the amount of

current increases, the illumination becomes brighter.

The following chart shows the power and ground connector terminals for the components included in the illumination system.

Component Connector No. Power terminal Ground terminal

Illumination control switch M28 1 5

Air control M56 2 1

Audio unit M51 8 7

Hazard switch M53 7 8

Rear wiper switch M89 4 5

Rear window defogger switch M90 5 6

Combination meter M39 40 41

Main power window and door lock/unlock

switch

ASCD main switch M29 5 6

D7 3 8

NGEL0035

GI

MA

EM

LC

EC

FE

CL

MT

AT

A/T device M35 4 3

The ground for all of the components are controlled through terminals 4 and 5 of the illumination control switch

and body grounds M14 and M68.

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL-63

SC

IDX

Wiring Diagram — ILL —

ILLUMINATION

Wiring Diagram — ILL —

NGEL0037

EL-64

AEL359C

ILLUMINATION

Wiring Diagram — ILL — (Cont’d)

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

EL-65

BT

HA

SC

AEL360C

IDX

INTERIOR ROOM LAMP

Component Parts and Harness Connector Location

Component Parts and Harness Connector

Location

NGEL0194

EL-66

AEL428C

INTERIOR ROOM LAMP

System Description

System Description

MODELS WITHOUT POWER DOOR LOCKS

Room Lamp

Power is supplied at all times

쐌 through 7.5A fuse [No. 26, located in the fuse block (J/B)]

쐌 to front room lamp terminal + and

쐌 to rear room lamp terminal +.

With the front/rear room lamp switch in the ON position, ground is supplied through the case of the front/rear

room lamp.

With one or more doors open, with the front/rear room lamp switch in the DOOR position, ground is supplied

쐌 to front/rear room lamp terminal DR

쐌 through front door switch LH terminal 1 and/or

쐌 through front door switch RH, rear door switch LH/RH and/or back door switch terminal +.

Ground is supplied to back door switch terminal – through body grounds D402 and D404.

MODELS WITH POWER DOOR LOCKS

Room Lamp

Power is supplied at all times

쐌 through 7.5A fuse [No. 26, located in the fuse block (J/B)]

쐌 to front room lamp terminal + and

쐌 to rear room lamp terminal +.

With the front/rear room lamp switch in the ON position, ground is supplied through the case of the front/rear

room lamp.

With the front door LH open and the front/rear room lamp switch in the DOOR position, ground is supplied

쐌 to front/rear room lamp terminal DR

쐌 through front door switch LH terminal 1.

With the front door RH open and the front/rear room lamp switch in the DOOR position, ground is supplied

쐌 to smart entrance control unit terminal 35

쐌 through front door switch RH terminal + and

쐌 to front/rear room lamp terminal DR

쐌 through smart entrance control unit terminal 9

쐌 through smart entrance control unit terminal 10

쐌 through body grounds M14 and M68.

With rear door LH/RH and/or back door open and the front/rear room lamp switch in theDOOR position, ground

is supplied

쐌 to smart entrance control unit terminal 16

쐌 through rear door switch LH/RH and/or back door switch terminal + and

쐌 to front/rear room lamp terminal DR

쐌 through smart entrance control unit terminal 9

쐌 through smart entrance control unit terminal 10

쐌 through body grounds M14 and M68.

NGEL0038

NGEL0038S01

NGEL0038S0106

NGEL0038S06

NGEL0038S0601

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

Room Lamp Timer Operation

When the room lamp switch is in the DOOR position, the smart entrance control unit keeps the room lamp

illuminated for about 30 seconds when:

쐌 unlock signal is supplied from multi-remote controller

쐌 key is removed from ignition key cylinder while front door LH is closed

쐌 driver’s door is opened and then closed while ignition switch is not in the ON position.

The timer is canceled and room lamp turns off when:

쐌 front door LH is locked with multi-remote controller, or

쐌 ignition switch is turned ON.

The smart entrance control unit turns off the room lamp if it is left on for 30 minutes.

NGEL0038S0603

EL-67

BT

HA

SC

IDX

System Description (Cont’d)

INTERIOR ROOM LAMP

Map Lamp

Power is supplied at all times

쐌 through 7.5A fuse [No. 26, located in the fuse block (J/B)]

쐌 to map lamp terminal +

Ground is supplied

쐌 to map lamp terminal –

쐌 through body grounds M14 and M68.

With map lamp switch in ON position, lamp illuminates.

NGEL0038S0602

EL-68

INTERIOR ROOM LAMP

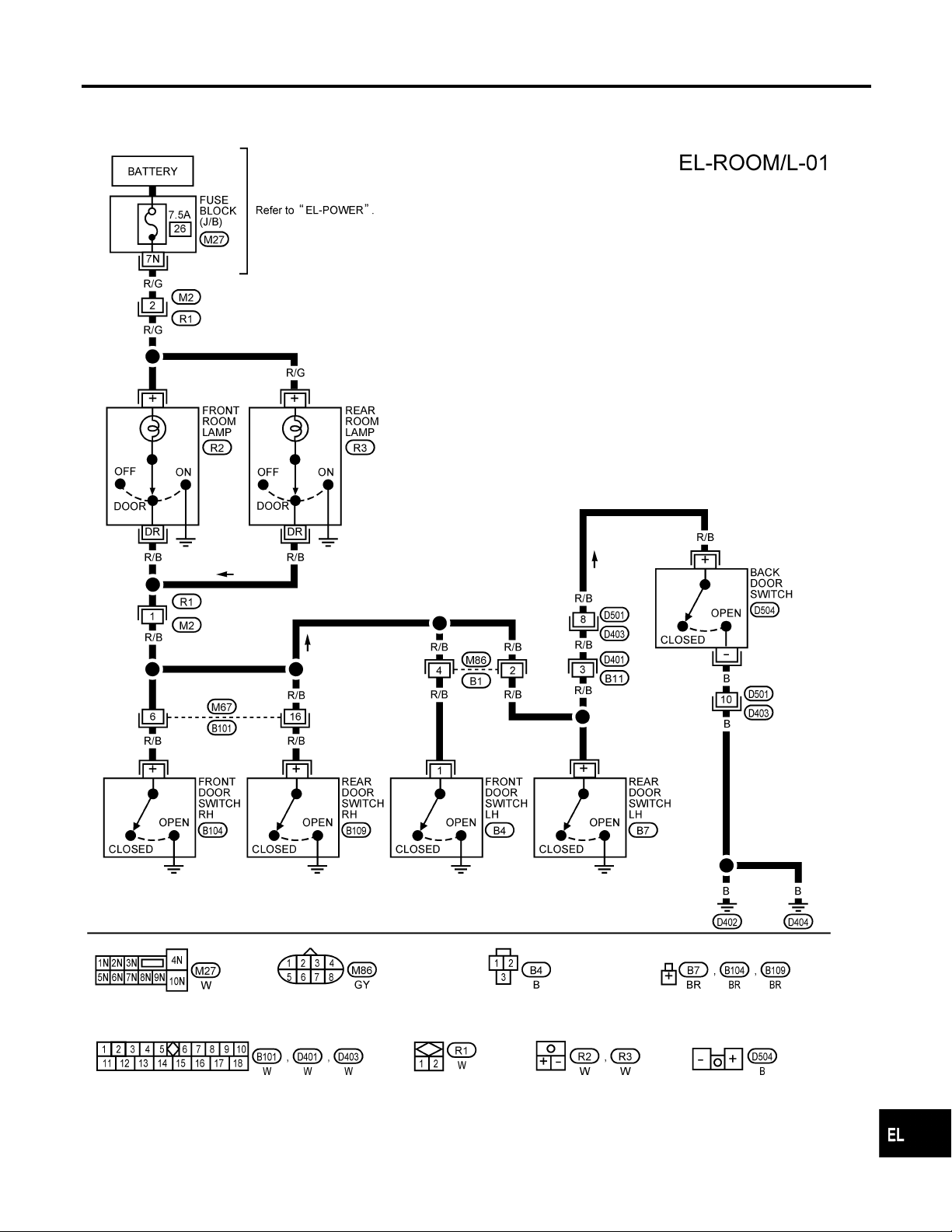

Wiring Diagram — ROOM/L —

Wiring Diagram — ROOM/L —

MODELS WITHOUT POWER DOOR LOCKS

NGEL0040

NGEL0040S01

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-69

HA

SC

AEL775C

IDX

Wiring Diagram — ROOM/L — (Cont’d)

INTERIOR ROOM LAMP

MODELS WITH POWER DOOR LOCKS

NGEL0040S02

EL-70

AEL386C

INTERIOR ROOM LAMP

Wiring Diagram — ROOM/L — (Cont’d)

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

EL-71

BT

HA

SC

AEL623C

IDX

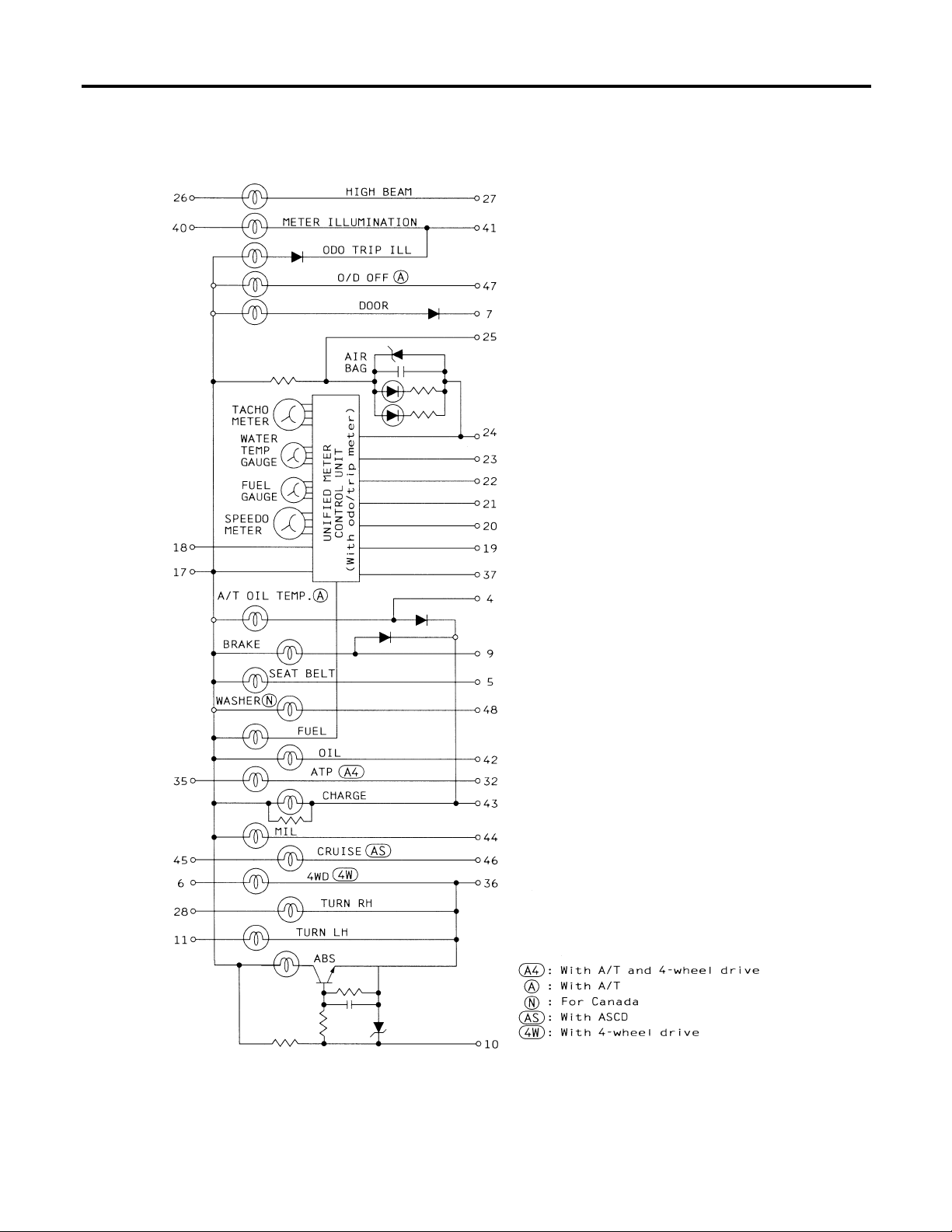

METERS AND GAUGES

Component Parts and Harness Connector Location

Component Parts and Harness Connector

Location

NGEL0041

EL-72

AEL429C

METERS AND GAUGES

System Description

System Description

UNIFIED CONTROL METER

쐌 Speedometer, odo/trip meter, tachometer, fuel gauge and water temperature gauge are controlled totally

by unified meter control unit combined with speedometer and odo/trip meter.

쐌 Digital meter is adopted for odo/trip meter.*

*The record of the odo meter is kept even if the battery cable is disconnected. The record of the trip meter

is erased when the battery cable is disconnected.

쐌 Odo/trip meter segment can be checked in diagnosis mode.

쐌 Meter/gauge can be checked in diagnosis mode.

HOW TO CHANGE THE DISPLAY FOR ODO/TRIP METER

NGEL0042

NGEL0042S06

NGEL0042S07

GI

MA

EM

LC

EC

FE

CL

MT

SEL253V

NOTE:

Turn ignition switch ON to operate odo/trip meter.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

쐌 through 7.5A fuse [No. 28, located in the fuse block (J/B)]

쐌 to combination meter terminal 18.

With the ignition switch in the ON or START position, power is supplied

쐌 through 10A fuse [No. 11, located in the fuse block (J/B)]

쐌 to combination meter terminal 17.

Ground is supplied

쐌 to combination meter terminal 24

쐌 through body grounds M14 and M68.

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank. The reading on the gauge is based on the

resistance of the fuel tank gauge unit.

The fuel gauge is regulated by a variable ground signal supplied

쐌 to combination meter terminal 20 for the fuel gauge

쐌 through fuel tank gauge unit terminal G

쐌 through fuel tank gauge unit terminal E

쐌 through body grounds B106 and B116.

NGEL0042S08

NGEL0042S03

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL-73

IDX

System Description (Cont’d)

METERS AND GAUGES

WATER TEMPERATURE GAUGE

NGEL0042S01

The water temperature gauge indicates the engine coolant temperature. The reading on the gauge is based

on the resistance of the thermal transmitter.

The water temperature gauge is regulated by a variable ground signal supplied

쐌 to combination meter terminal 19

쐌 through thermal transmitter terminal 1.

As the temperature of the coolant increases, the resistance of the thermal transmitter decreases and the

needle on the gauge moves from C to H.

TACHOMETER

NGEL0042S02

The tachometer indicates engine speed in revolutions per minute (rpm).

The tachometer is regulated by a signal

쐌 to combination meter terminal 21 for the tachometer

쐌 from ECM terminal 3.

SPEEDOMETER

NGEL0042S04

The vehicle speed sensor provides a voltage signal to the combination meter for the speedometer.

The voltage is supplied

쐌 to combination meter terminals 22 and 23 for the speedometer

쐌 from vehicle speed sensor terminals 1 and 2.

The unified meter control unit converts the voltage to the vehicle speed and displays it on the speedometer.

EL-74

METERS AND GAUGES

Combination Meter

Combination Meter

NGEL0043

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-75

HA

SC

AEL773C

IDX

Combination Meter (Cont’d)

METERS AND GAUGES

EL-76

AEL774C

METERS AND GAUGES

Wiring Diagram — METER —

Wiring Diagram — METER —

NGEL0045

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-77

HA

SC

AEL362C

IDX

METERS AND GAUGES

Meter/Gauge Operation and Odo/Trip Meter Segment Check in Diagnosis Mode

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode

DIAGNOSIS FUNCTION

쐌 Odo/trip meter segment can be checked in diagnosis mode.

쐌 Meters/gauges can be checked in diagnosis mode.

NGEL0151

NGEL0151S01

HOW TO ALTERNATE DIAGNOSIS MODE

NGEL0151S02

1. Turn ignition switch ON and change odo/trip meter to TRIP A

or TRIP B.

2. Turn ignition switch OFF.

3. Turn ignition switch ON while pressing and holding odo/trip

meter switch.

4. Confirm that trip meter indicates “000.0”.

5. Push odo/trip meter switch more than 3 times within 5 seconds.

6. All odo/trip meter segments should be turned on.

NOTE:

If some segments are not turned on, speedometer (unified

meter control unit) with odo/trip meter should be replaced.

At this point,the unified metercontrol unit is in diagnosis mode.

SEL110V

SEL111V

7. Push odo/trip meter switch. Indication of each meter/gauge

should be as shown in figure at left while pushing odo/trip

meter switch if it is not malfunctioning.

NOTE:

It takes about 1 minute for indication of fuel gauge to become

stable.

EL-78

METERS AND GAUGES

Trouble Diagnoses

Trouble Diagnoses

PRELIMINARY CHECK

NGEL0046

NGEL0046S04

GI

MA

EM

LC

EC

FE

CL

MT

*1: Meter/Gauge Operation and Odo/

Trip Meter Segment Check in

Diagnosis Mode (EL-78)

*2: METER/GAUGE RESISTANCE

CHECK (EL-85)

*3: POWER SUPPLYAND GROUND

CIRCUIT CHECK (EL-81)

*4: Symptom Chart 1 (EL-80)

*5: Symptom Chart 2 (EL-80)

AT

TF

PD

AX

SU

BR

ST

RS

AEL533C

BT

HA

EL-79

SC

IDX

Trouble Diagnoses (Cont’d)

METERS AND GAUGES

Symptom Possible causes Repair order

Speedometer and/or odo/

trip meter indicate(s) malfunction in Diagnosis

mode.

Multiple meters/gauges

indicate malfunction in

Diagnosis mode.

Tachometer, fuel gauge or

water temp. gauge indicates malfunction in Diagnosis mode.

Symptom Possible causes Repair order

Speedometer and odo/trip

meter are malfunctioning.

SYMPTOM CHART

NGEL0046S05

Symptom Chart 1 (Malfunction is Indicated in

Diagnosis Mode)

쐌 Speedometer (unified meter control unit) 쐌 Replace speedometer (unified meter control unit).

쐌 Meter/Gauge

쐌 Speedometer (unified meter control unit)

1. Check resistance of meter/gauge indicating malfunction. If the resistance is NG, replace the meter/gauge.

Refer to “METER/GAUGE RESISTANCE CHECK”,

EL-85.

2. If the resistance is OK, replace speedometer (unified

meter control unit).

NGEL0046S0501

Symptom Chart 2 (No Malfunction is Indicated in

Diagnosis Mode)

쐌 Sensor

- Speedometer, Odo/Trip meter

쐌 Speedometer (unified meter control unit)

1. Check vehicle speed sensor.

Refer to INSPECTION/VEHICLE SPEED SENSOR,

EL-82.

2. Replace speedometer (unified meter control unit).

NGEL0046S0502

Multiple meters/gauges

are malfunctioning (except

speedometer, odo/trip

meter).

Tachometer, fuel gauge or

water temp. gauge is malfunctioning.

쐌 Speedometer (unified meter control unit) 쐌 Replace speedometer (unified meter control unit).

쐌 Sensor/Engine revolution signal

- Tachometer

- Fuel gauge

- Water temp. gauge

쐌 Speedometer (unified meter control unit)

1. Check the sensor for malfunctioning meter/gauge.

Refer to INSPECTION/ENGINE REVOLUTION

SIGNAL, EL-83.

Refer to INSPECTION/FUEL TANK GAUGE UNIT,

EL-84.

Refer to INSPECTION/THERMAL TRANSMITTER,

EL-85.

2. Replace speedometer (unified meter control unit).

Before starting trouble diagnoses above, perform PRELIMINARY

CHECK, EL-79.

EL-80

METERS AND GAUGES

Trouble Diagnoses (Cont’d)

AEL535C

POWER SUPPLY AND GROUND CIRCUIT CHECK

Power Supply Circuit Check

Terminals Ignition switch position

(+) (−) OFF ACC ON

18 Ground

17 Ground 0V 0V Battery voltage

If NG, check the following.

쐌 7.5A fuse [No. 28, located in fuse block (J/B)]

쐌 10A fuse [No. 11, located in fuse block (J/B)]

쐌 Harness for open or short between fuse and combination

meter

Battery volt-

age

Battery volt-

age

Ground Circuit Check

Terminals Continuity

=NGEL0046S07

NGEL0046S0701

Battery voltage

NGEL0046S0702

GI

MA

EM

LC

EC

FE

CL

MT

AT

AEL536C

24 - Ground Yes

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL-81

SC

IDX

Trouble Diagnoses (Cont’d)

METERS AND GAUGES

INSPECTION/VEHICLE SPEED SENSOR

1 CHECK VEHICLE SPEED SENSOR OUTPUT

1. Remove vehicle speed sensor from transmission.

2. Check voltage between combination meter terminals 22 and 23 while quickly turning speed sensor pinion.

Voltage: Approx. 0.5V

OK or NG

OK 䊳 Vehicle speed sensor is OK.

NG 䊳 GO TO 2.

2 CHECK VEHICLE SPEED SENSOR

Check resistance between vehicle speed sensor terminals 1 and 2.

=NGEL0046S03

AEL537C

Resistance: Approx. 285Ω

OK or NG

OK 䊳 Check harness and connector between speedometer and vehicle speed sensor.

NG 䊳 Replace vehicle speed sensor.

AEL538C

EL-82

METERS AND GAUGES

Trouble Diagnoses (Cont’d)

INSPECTION/ENGINE REVOLUTION SIGNAL

1 CHECK ECM OUTPUT

1. Start engine.

2. Check voltage between combination meter terminals 21 and 24 at idle and 2,000 rpm.

Higher rpm = Higher voltage

Lower rpm = Lower voltage

Voltage should change with rpm.

OK or NG

OK 䊳 Engine revolution signal is OK.

NG 䊳 Harness for open or short between ECM and combination meter

NGEL0046S02

GI

MA

EM

LC

EC

AEL539C

FE

CL

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

EL-83

HA

SC

IDX

Trouble Diagnoses (Cont’d)

METERS AND GAUGES

INSPECTION/FUEL TANK GAUGE UNIT

1 CHECK GROUND CIRCUIT FOR FUEL TANK GAUGE UNIT

Check harness continuity between fuel tank gauge unit harness connector terminal E and ground.

Does continuity exist?

Yes 䊳 GO TO 2.

No 䊳 Repair harness or connector.

2 CHECK GAUGE UNITS

Refer to “FUEL TANK GAUGE UNIT CHECK”, EL-86.

OK or NG

OK 䊳 GO TO 3.

NG 䊳 Replace fuel tank gauge unit.

=NGEL0046S08

AEL625C

3 CHECK HARNESS FOR OPEN OR SHORT

1. Disconnect combination meter harness connector M38 and fuel tank gauge unit harness connector.

2. Check continuity between combination meter harness connector terminal 20 and fuel tank gauge unit harness connector terminal G.

Continuity should exist.

3. Check continuity between combination meter harness connector terminal 20 and ground.

Continuity should not exist.

AEL626C

OK or NG

OK 䊳 Fuel tank gauge unit is OK.

NG 䊳 Repair harness or connector.

EL-84

METERS AND GAUGES

Trouble Diagnoses (Cont’d)

INSPECTION/THERMAL TRANSMITTER

1 CHECK THERMAL TRANSMITTER

Refer to “THERMAL TRANSMITTER CHECK”, EL-86.

OK or NG

OK 䊳 GO TO 2.

NG 䊳 Replace thermal transmitter.

2 CHECK HARNESS FOR OPEN OR SHORT

1. Disconnect combination meter harness connector M38 and thermal transmitter harness connector.

2. Check continuity between combination meter harness connector terminal 19 and thermal transmitter harness connector

terminal 1.

Continuity should exist.