AUTOMATIC TRANSMISSION

GI

MA

CONTENTS

TROUBLE DIAGNOSIS - INDEX ....................................4

Alphabetical & P No. Index for DTC ...........................4

PRECAUTIONS ...............................................................6

Supplemental Restraint System (SRS) ″AIR

BAG″ and ″SEAT BELT PRE-TENSIONER″...............6

Precautions for On Board Diagnostic (OBD)

System of A/T and Engine...........................................6

Precautions..................................................................6

Service Notice or Precautions.....................................8

Wiring Diagrams and Trouble Diagnosis.....................9

PREPARATION .............................................................10

Special Service Tools................................................10

OVERALL SYSTEM ......................................................12

A/T Electrical Parts Location .....................................12

Circuit Diagram..........................................................13

Cross-sectional View .................................................14

Hydraulic Control Circuit............................................15

Shift Mechanism ........................................................16

Control System ..........................................................25

Control Mechanism....................................................26

Control Valve .............................................................31

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................33

Introduction................................................................33

OBD-II Function for A/T System................................33

One or Two Trip Detection Logic of OBD-II..............33

OBD-II Diagnostic Trouble Code (DTC)....................33

Malfunction Indicator Lamp (MIL)..............................37

CONSULT-II...............................................................37

Diagnostic Procedure Without CONSULT-II..............46

TROUBLE DIAGNOSIS - INTRODUCTION..................53

Introduction................................................................53

Work Flow..................................................................57

TROUBLE DIAGNOSIS - BASIC INSPECTION...........59

A/T Fluid Check.........................................................59

Stall Test....................................................................59

Line Pressure Test.....................................................62

Road Test...................................................................63

SECTION

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................81

Symptom Chart..........................................................81

TCM Terminals and Reference Value........................92

TROUBLE DIAGNOSIS FOR POWER SUPPLY..........96

Wiring Diagram - AT - MAIN......................................96

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH .........................................................................99

Description.................................................................99

Wiring Diagram - AT - PNP/SW...............................101

Diagnostic Procedure ..............................................102

Component Inspection.............................................104

DTC P0710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT.......................................................................105

Description...............................................................105

Wiring Diagram - AT - FTS......................................107

Diagnostic Procedure ..............................................108

Component Inspection.............................................110

DTC P0720 VEHICLE SPEED SENSOR.A/T

(REVOLUTION SENSOR) ...........................................111

Description............................................................... 111

Wiring Diagram - AT - VSSA/T................................113

Diagnostic Procedure ..............................................114

Component Inspection.............................................115

DTC P0725 ENGINE SPEED SIGNAL .......................116

Description...............................................................116

Wiring Diagram - AT - ENGSS................................117

Diagnostic Procedure ..............................................118

DTC P0731 IMPROPER SHIFTING TO 1ST GEAR

POSITION ....................................................................120

Description...............................................................120

Wiring Diagram - AT - 1ST......................................123

Diagnostic Procedure ..............................................124

Component Inspection.............................................125

DTC P0732 IMPROPER SHIFTING TO 2ND GEAR

POSITION ....................................................................126

Description...............................................................126

Wiring Diagram - AT - 2ND......................................129

Diagnostic Procedure ..............................................130

AT

EM

LC

EC

FE

CL

MT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS (Cont’d)

Component Inspection.............................................130

DTC P0733 IMPROPER SHIFTING TO 3RD GEAR

POSITION ....................................................................132

Description...............................................................132

Wiring Diagram - AT - 3RD......................................135

Diagnostic Procedure ..............................................136

Component Inspection.............................................136

DTC P0734 IMPROPER SHIFTING TO 4TH GEAR

POSITION ....................................................................138

Description...............................................................138

Wiring Diagram - AT - 4TH......................................142

Diagnostic Procedure ..............................................143

Component Inspection.............................................146

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE......................................................147

Description...............................................................147

Wiring Diagram - AT - TCV......................................149

Diagnostic Procedure ..............................................150

Component Inspection.............................................151

DTC P0744 IMPROPER LOCK-UP OPERATION......152

Description...............................................................152

Wiring Diagram - AT - TCCSIG...............................155

Diagnostic Procedure ..............................................156

Component Inspection.............................................159

DTC P0745 LINE PRESSURE SOLENOID VALVE...160

Description...............................................................160

Wiring Diagram - AT - LPSV....................................162

Diagnostic Procedure ..............................................163

Component Inspection.............................................164

DTC P0750 SHIFT SOLENOID VALVE A ..................165

Description...............................................................165

Wiring Diagram - AT - SSV/A..................................167

Diagnostic Procedure ..............................................168

Component Inspection.............................................169

DTC P0755 SHIFT SOLENOID VALVE B..................170

Description...............................................................170

Wiring Diagram - AT - SSV/B..................................172

Diagnostic Procedure ..............................................173

Component Inspection.............................................174

DTC P1705 THROTTLE POSITION SENSOR ...........175

Description...............................................................175

Wiring Diagram - AT - TPS......................................178

Diagnostic Procedure ..............................................179

Component Inspection.............................................183

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE..........................................................................184

Description...............................................................184

Wiring Diagram - AT - OVRCSV..............................186

Diagnostic Procedure ..............................................187

Component Inspection.............................................188

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE)....189

Description...............................................................189

Wiring Diagram - AT - BA/FTS................................191

Diagnostic Procedure ..............................................192

Component Inspection.............................................194

VEHICLE SPEED SENSOR.MTR................................195

Description...............................................................195

Wiring Diagram - AT - VSSMTR..............................197

Diagnostic Procedure ..............................................198

DTC CONTROL UNIT (RAM), CONTROL UNIT

(ROM)...........................................................................199

Description...............................................................199

Diagnostic Procedure ..............................................200

DTC CONTROL UNIT (EEPROM) ..............................201

Description...............................................................201

Diagnostic Procedure ..............................................202

TROUBLE DIAGNOSES FOR SYMPTOMS...............203

Wiring Diagram - AT - NONDTC.............................203

1. O/D OFF Indicator Lamp Does Not Come On....206

2. Engine Cannot Be Started In P and N Position..208

3. In ″P″ Position, Vehicle Moves Forward Or

Backward When Pushed.........................................209

4. In N Position, Vehicle Moves ..............................210

5. Large Shock. N -> R Position.............................212

6. Vehicle Does Not Creep Backward In R

Position....................................................................214

7. Vehicle Does Not Creep Forward In D, 2 Or 1

Position....................................................................217

8. Vehicle Cannot Be Started From D

9. A/T Does Not Shift: D

Kickdown: D

-> D2..................................................223

4

10. A/T Does Not Shift: D

11. A/T Does Not Shift: D

-> D2Or Does Not

1

-> D3.............................226

2

-> D4.............................229

3

...................220

1

12. A/T Does Not Perform Lock-up.........................232

13. A/T Does Not Hold Lock-up Condition..............234

14. Lock-up Is Not Released...................................236

15. Engine Speed Does Not Return To Idle (Light

Braking D

16. Vehicle Does Not Start From D

17. A/T Does Not Shift: D

-> D3).....................................................237

4

.......................239

1

-> D3, When

4

Overdrive Control Switch ON -> OFF .....................240

18. A/T Does Not Shift: D

-> 22, When Selector

3

Lever D -> 2 Position ..............................................241

19. A/T Does Not Shift: 2

-> 11, When Selector

2

Lever 2 -> 1 Position...............................................242

20. Vehicle Does Not Decelerate By Engine

Brake........................................................................243

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches

Circuit Checks) ........................................................243

A/T SHIFT LOCK SYSTEM.........................................251

Description...............................................................251

Wiring Diagram - SHIFT -........................................252

AT-2

CONTENTS (Cont’d)

Diagnostic Procedure ..............................................253

Component Check...................................................255

KEY INTERLOCK CABLE ..........................................256

Components.............................................................256

Removal...................................................................256

Installation................................................................257

ON-VEHICLE SERVICE ..............................................258

Control Valve Assembly and Accumulators.............258

Revolution Sensor Replacement.............................259

Rear Oil Seal Replacement.....................................259

Parking Components Inspection..............................259

Park/Neutral Position (PNP) Switch Adjustment .....260

Manual Control Linkage Adjustment........................260

REMOVAL AND INSTALLATION...............................261

Removal...................................................................261

Installation................................................................263

OVERHAUL .................................................................264

Components.............................................................264

Oil Channel..............................................................266

Locations of Needle Bearings, Thrust Washers

and Snap Rings.......................................................267

DISASSEMBLY............................................................268

REPAIR FOR COMPONENT PARTS .........................279

Oil Pump..................................................................279

Control Valve Assembly...........................................283

Control Valve Upper Body.......................................289

Control Valve Lower Body.......................................294

Reverse Clutch ........................................................296

High Clutch ..............................................................300

Forward and Overrun Clutches ...............................302

Low & Reverse Brake..............................................306

Forward Clutch Drum Assembly..............................310

Rear Internal Gear and Forward Clutch Hub..........312

Band Servo Piston Assembly..................................315

Parking Pawl Components......................................319

ASSEMBLY..................................................................321

Assembly (1)............................................................321

Adjustment...............................................................329

Assembly (2)............................................................331

SERVICE DATA AND SPECIFICATIONS (SDS).......338

General Specifications.............................................338

Shift Schedule..........................................................338

Stall Revolution........................................................338

Line Pressure...........................................................338

Return Springs.........................................................339

Accumulator O-ring..................................................340

Clutches and Brakes ...............................................340

Oil Pump and Low One-way Clutch........................342

Total End Play..........................................................342

Reverse Clutch Drum End Play ..............................343

Removal and Installation.........................................343

GI

MA

EM

LC

EC

FE

CL

MT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

AT-3

EL

IDX

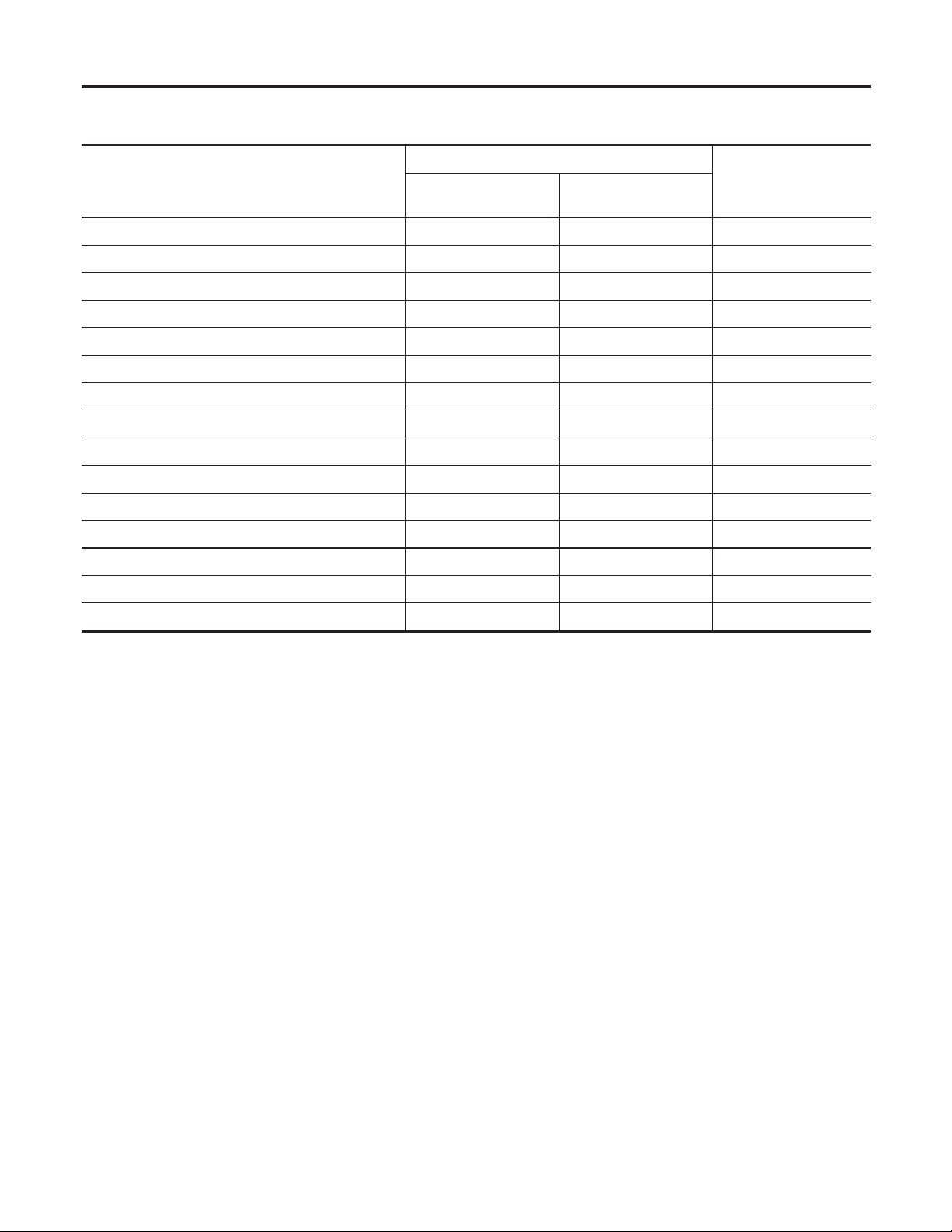

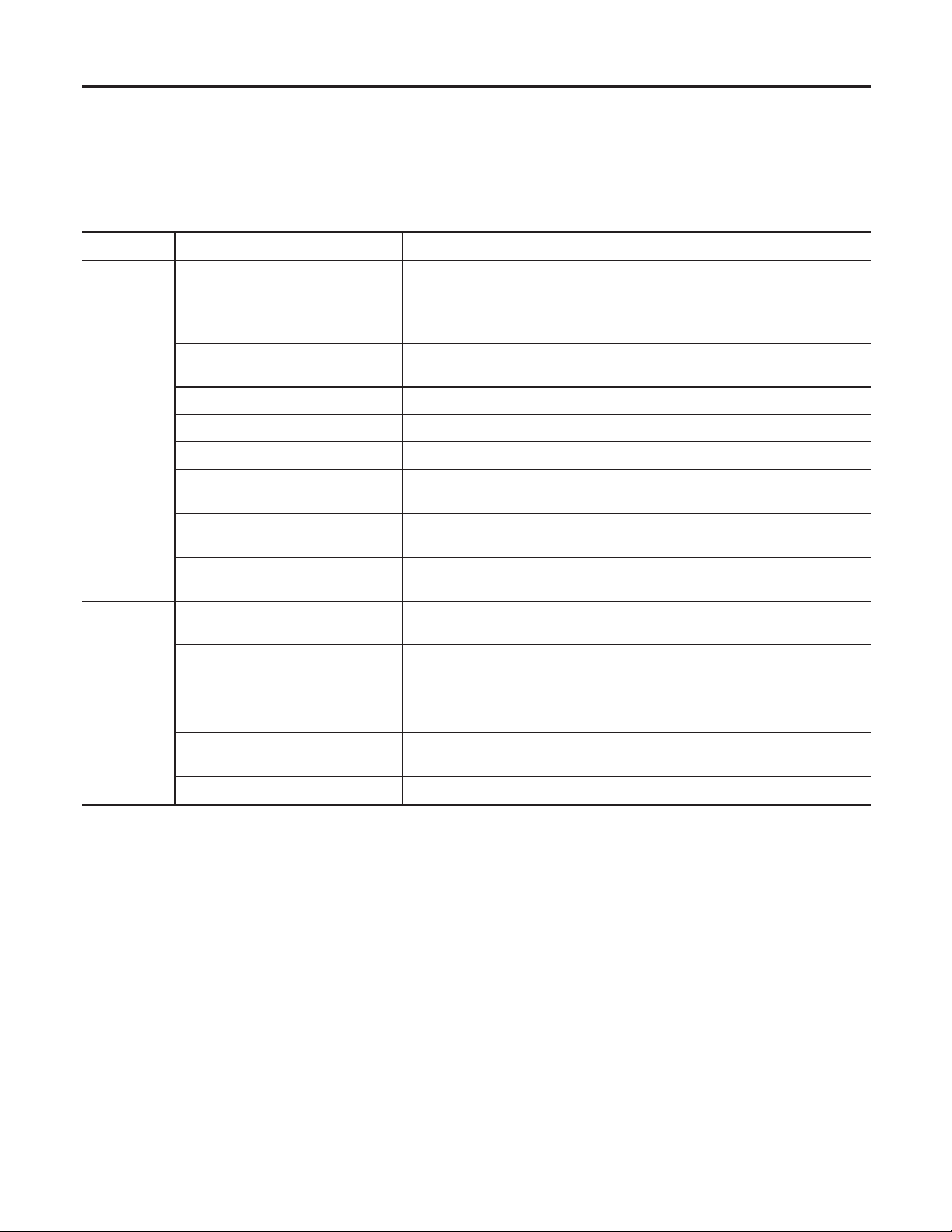

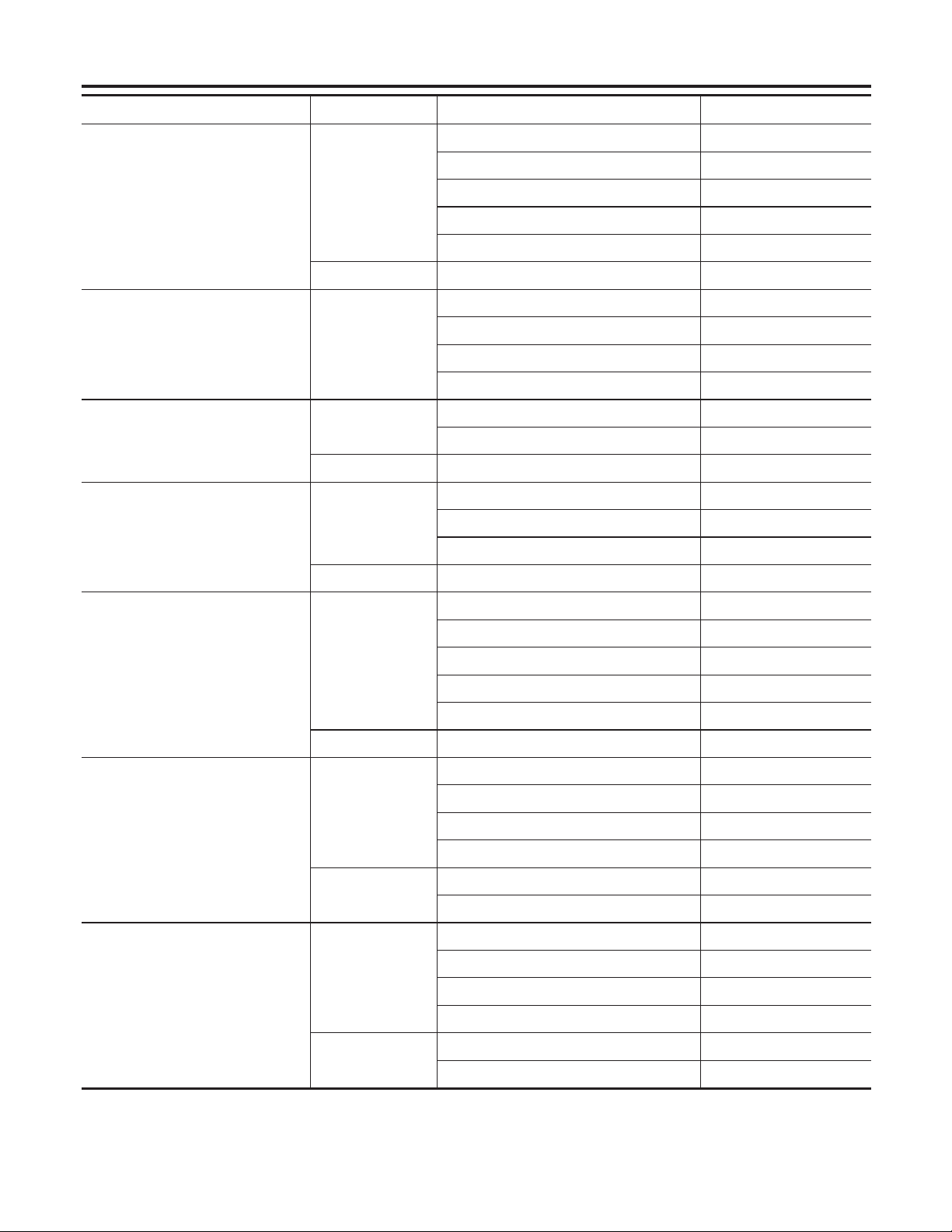

Alphabetical & P No. Index for DTC

TROUBLE DIAGNOSIS — INDEX

Alphabetical & P No. Index for DTC

ALPHABETICAL INDEX FOR DTC

Items

(CONSULT-II screen terms)

A/T 1ST GR FNCTN 1103 P0731 AT-120

A/T 2ND GR FNCTN 1104 P0732 AT-126

A/T 3RD GR FNCTN 1105 P0733 AT-132

A/T 4TH GR FNCTN 1106 P0734 AT-138

A/T TCC S/V FNCTN 1107 P0744 AT-152

ATF TEMP SEN/CIRC 1208 P0710 AT-105

ENGINE SPEED SIG 1207 P0725 AT-116

L/PRESS SOL/CIRC 1205 P0745 AT-160

O/R CLTCH SOL/CIRC 1203 P1760 AT-184

PNP SW/CIRC 1101 P0705 AT-99

SFT SOL A/CIRC*3 1108 P0750 AT-165

SFT SOL B/CIRC*3 1201 P0755 AT-170

ECM*1

DTC

CONSULT-II

GST*2

Reference page

NGAT0179

NGAT0179S01

TCC SOLENOID/CIRC 1204 P0740 AT-147

TP SEN/CIRC A/T*3 1206 P1705 AT-175

VEH SPD SEN/CIR AT*4 1102 P0720 AT-111

*1: In Diagnostic Test Mode II (Self-diagnostic results), these numbers are controlled by NISSAN.

*2: These numbers are prescribed by SAE J2012.

*3: When the fail-safe operation occurs, the MIL illuminates.

*4: The MIL illuminates when both the “Revolution sensor signal” and the “Vehicle speed sensor signal” meet the fail-safe condition at

the same time.

AT-4

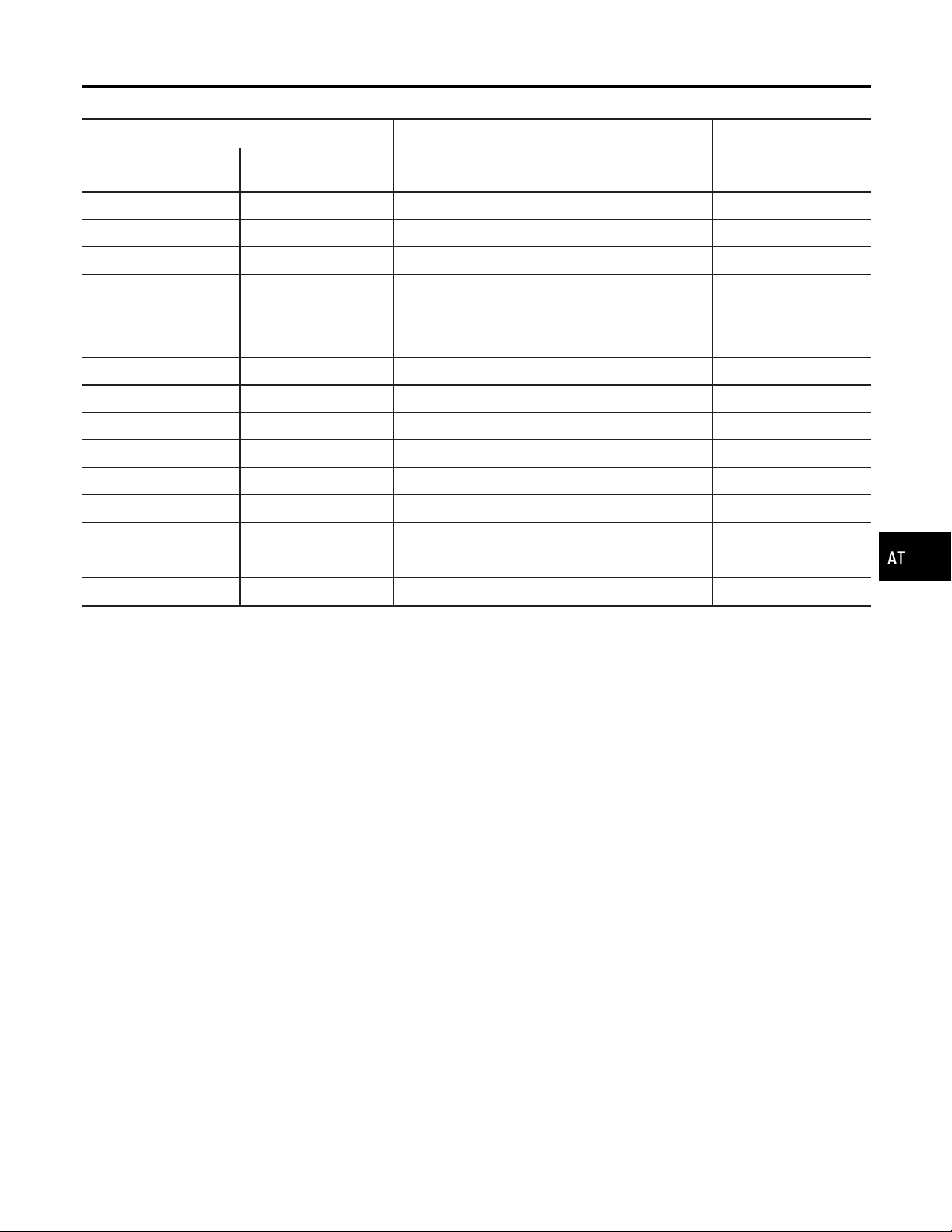

TROUBLE DIAGNOSIS — INDEX

Alphabetical & P No. Index for DTC (Cont’d)

P NO. INDEX FOR DTC

DTC

CONSULT-II

GST*2

P0705 1101 PNP SW/CIRC AT-99

P0710 1208 ATF TEMP SEN/CIRC AT-105

P0720 1102 VEH SPD SEN/CIR AT*4 AT-111

P0725 1207 ENGINE SPEED SIG AT-116

P0731 1103 A/T 1ST GR FNCTN AT-120

P0732 1104 A/T 2ND GR FNCTN AT-126

P0733 1105 A/T 3RD GR FNCTN AT-132

P0734 1106 A/T 4TH GR FNCTN AT-138

P0740 1204 TCC SOLENOID/CIRC AT-147

P0744 1107 A/T TCC S/V FNCTN AT-152

P0745 1205 L/PRESS SOL/CIRC AT-160

P0750 1108 SFT SOL A/CIRC*3 AT-165

P0755 1201 SFT SOL B/CIRC*3 AT-170

ECM*1

Items

(CONSULT-II screen terms)

=NGAT0179S02

GI

Reference page

MA

EM

LC

EC

FE

CL

MT

P1705 1206 TP SEN/CIRC A/T*3 AT-175

P1760 1203 O/R CLTCH SOL/CIRC AT-184

*1: In Diagnostic Test Mode II (Self-diagnostic results), these numbers are controlled by NISSAN.

*2: These numbers are prescribed by SAE J2012.

*3: When the fail-safe operation occurs, the MIL illuminates.

*4: The MIL illuminates when both the “Revolution sensor signal” and the “Vehicle speed sensor signal” meet the fail-safe condition at

the same time.

TF

PD

AX

SU

BR

ST

RS

BT

AT-5

HA

SC

EL

IDX

PRECAUTIONS

Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

Supplemental Restraint System (SRS) “AIR

BAG” and “SEAT BELT PRE-TENSIONER”

The supplemental Restraint System such as “AIR BAG” and “SEAT BELTPRE-TENSIONER” used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side), seat

belt pre-tensioners, a diagnosis sensor unit, a crash zone sensor, warning lamp, wiring harness and spiral

cable.

Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, refer to

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses (except “SEAT BELT PRE-TENSIONER”) covered with yellow insulation either just before the harness connectors or for the complete harness

are related to the SRS.

RS-16

.

NGAT0001

Precautions for On Board Diagnostic (OBD) System of A/T and Engine

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

I Be sure to turn the ignition switch OFF and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MIL to light up.

I Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

I Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

I Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system,

etc.

I Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

NGAT0002

SEF289H

Precautions

I Before connecting or disconnecting the TCM harness

connector, turn ignition switch OFF and disconnect negative battery terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if

ignition switch is turned off.

NGAT0003

AT-6

PRECAUTIONS

Precautions (Cont’d)

I When connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM

pin terminal, when connecting pin connectors.

GI

MA

EM

AAT470A

MEF040DA

SAT964I

I Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or not. (See page AT-92.)

I After performing each TROUBLE DIAGNOSIS, perform

“DTC (Diagnostic Trouble Code) CONFIRMATION PROCEDURE”.

The DTC should not be displayed in the “DTC CONFIRMATION PROCEDURE” if the repair is completed.

I Before proceeding with disassembly, thoroughly clean the out-

side of the transmission. It is important to prevent the internal

parts from becoming contaminated by dirt or other foreign matter.

I Disassembly should be done in a clean work area.

I Use lint-free cloth or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the operation of the transmission.

I Place disassembled parts in order for easier and proper

assembly.

I All parts should be carefully cleaned with a general purpose,

non-flammable solvent before inspection or reassembly.

I Gaskets, seals and O-rings should be replaced any time the

transmission is disassembled.

I It is very important to perform functional tests whenever they

are indicated.

I The valve body contains precision parts and requires extreme

care when parts are removed and serviced. Place disassembled valve body parts in order for easier and proper

assembly. Care will also prevent springs and small parts from

becoming scattered or lost.

I Properly installed valves, sleeves, plugs, etc. will slide along

bores in valve body under their own weight.

AT-7

LC

EC

FE

CL

MT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Precautions (Cont’d)

PRECAUTIONS

I Before assembly, apply a coat of recommended ATF to all

parts. Apply petroleum jelly to protect O-rings and seals, or

hold bearings and washers in place during assembly. Do not

use grease.

I Extreme care should be taken to avoid damage to O-rings,

seals and gaskets when assembling.

I Replace ATF cooler if excessive foreign material is found in oil

pan or clogging strainer. Refer to “ATF COOLER SERVICE”

(Refer to AT-9).

I After overhaul, refill the transmission with new ATF.

I When the A/T drain plug is removed, only some of the fluid is

drained. Old A/T fluid will remain in torque converter and ATF

cooling system.

Always follow the procedures under “Changing A/T Fluid” refer

to

MA-37

whenchangingA/Tfluid.

Service Notice or Precautions

FAIL-SAFE

NGAT0004

NGAT0004S01

The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of 1, 2 or D. The customer may complain of sluggish or poor acceleration.

When the ignition key is turned ON following Fail-Safe operation, O/D OFF indicator lamp blinks for about 8

seconds. (For “TCM SELF-DIAGNOSTIC PROCEDURE (No Tools)”, refer to AT-47.)

Fail-Safe may occur without electrical circuit damage if the vehicle is driven under extreme conditions (such

as excessive wheel spin followed by sudden braking). To recover normal shift pattern, turn the ignition key

OFF for 5 seconds, then ON.

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the “WORK FLOW” (Refer to AT-57).

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICE

NGAT0004S04

The torque converter should be replaced under any of the following conditions:

I External leaks in the hub weld area.

I Converter hub is scored or damaged.

I Converter pilot is broken, damaged or fits poorly into crankshaft.

I Steel particles are found after flushing the cooler and cooler lines.

I Pump is damaged or steel particles are found in the converter.

I Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

I Converter is contaminated with engine coolant containing antifreeze.

I Internal failure of stator roller clutch.

I Heavy clutch debris due to overheating (blue converter).

I Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

I The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

AT-8

PRECAUTIONS

Service Notice or Precautions (Cont’d)

I The threads in one or more of the converter bolt holes are damaged.

I Transmission failure did not display evidence of damaged or worn internal parts, steel particles or clutch

plate lining material in unit and inside the fluid filter.

I Vehiclehas been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such

as taxi, delivery or police use.

GI

MA

ATF COOLER SERVICE

Replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer.

Replace radiator lower tank (which includes ATF cooler) with a new one and flush cooler line using cleaning

solvent and compressed air.

OBD-II SELF-DIAGNOSIS

I A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the O/D OFF indicator or the malfunction indicator lamp (MIL). Refer to the table on

AT-38 for the indicator used to display each self-diagnostic result.

I The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM

memories.

Always perform the procedure “HOW TO ERASE DTC” on AT-35 to complete the repair and avoid

unnecessary blinking of the MIL.

I The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when

the O/D OFF indicator lamp does not indicate any malfunctions.

− Park/neutral position (PNP) switch

− A/T 1st, 2nd, 3rd, or 4th gear function

− A/T TCC S/V function (lock-up)

*: For details of OBD-II, refer to

I Certain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector. For description and how to disconnect, refer to

“Description”, “HARNESS CONNECTOR”.

EC-627

(“ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION”).

Wiring Diagrams and Trouble Diagnosis

When you read wiring diagrams, refer to the followings:

GI-10

I “HOW TO READ WIRING DIAGRAMS” refer to

I “POWER SUPPLY ROUTING” for power distribution circuit refer to

When you perform trouble diagnosis, refer to the followings:

I “HOW TO FOLLOW TEST GROUP IN TROUBLE DIAGNOSIS” refer to

I “HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT” refer to

.

EL-9

.

GI-34

.

GI-23

NGAT0004S02

NGAT0004S03

EL-5

NGAT0005

.

,

EM

LC

EC

FE

CL

MT

TF

PD

AX

SU

AT-9

BR

ST

RS

BT

HA

SC

EL

IDX

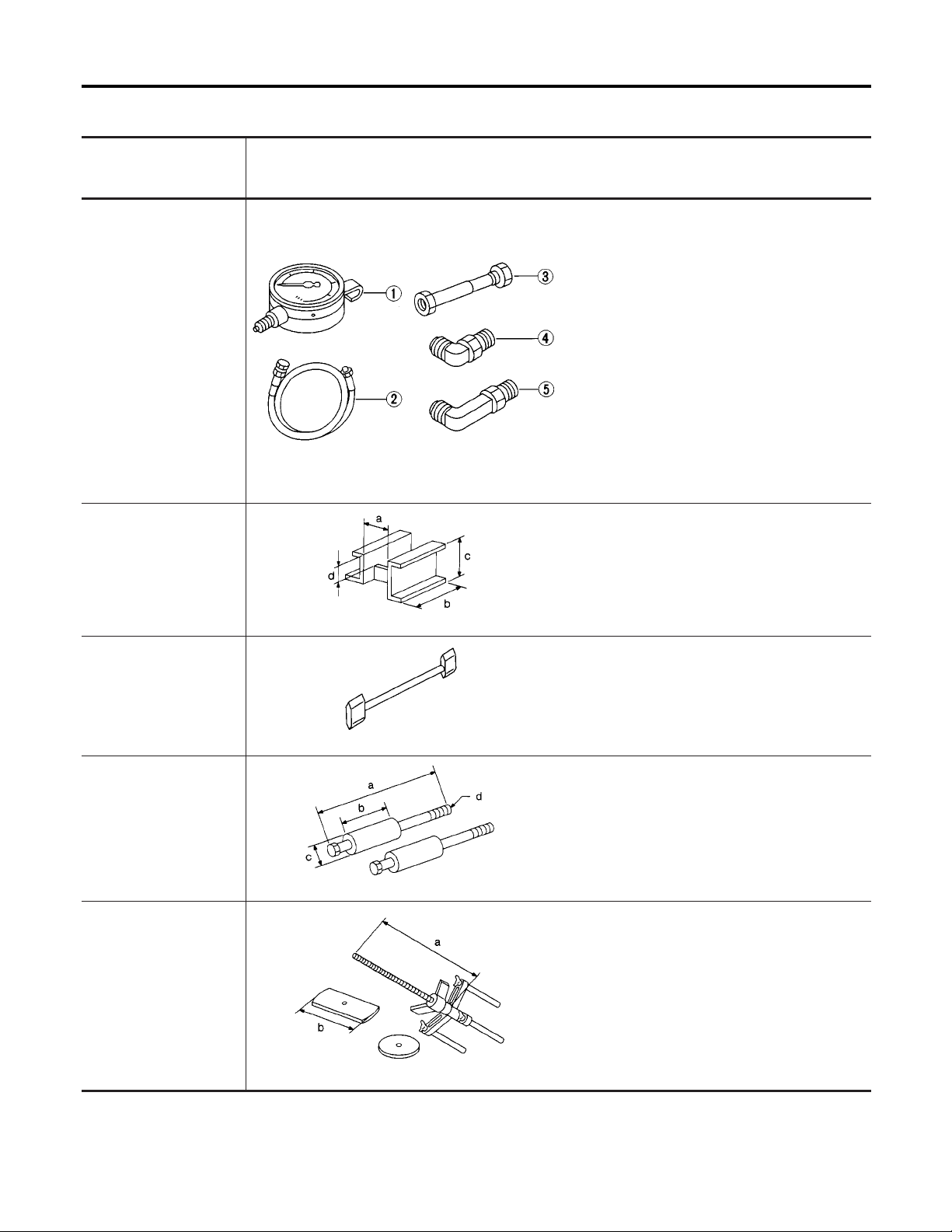

Special Service Tools

PREPARATION

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

ST2505S001

(J34301-C)

Oil pressure gauge set

1 ST25051001

(—)

Oil pressure gauge

2 ST25052000

(—)

Hose

3 ST25053000

(—)

Joint pipe

4 ST25054000

(—)

Adapter

5 ST25055000

(—)

Adapter

ST07870000

(J37068)

Transmission case stand

Description

Measuring line pressure

NT097

Disassembling and assembling A/T

a: 182 mm (7.17 in)

b: 282 mm (11.10 in)

c: 230 mm (9.06 in)

d: 100 mm (3.94 in)

NGAT0006

KV31102100

(J37065)

Torque converter oneway clutch check tool

ST25850000

(J25721-A)

Sliding hammer

KV31102400

(J34285 and J34285-87)

Clutch spring compressor

NT421

Checking one-way clutch in torque converter

NT098

Removing oil pump assembly

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in) dia.

d: M12 x 1.75P

NT422

Removing and installing clutch return springs

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

NT423

AT-10

Tool number

(Kent-Moore No.)

Tool name

PREPARATION

Special Service Tools (Cont’d)

Description

GI

ST33200000

(J26082)

Drift

(J34291)

Shim setting gauge set

NT091

NT101

Installing oil pump housing oil seal Installing rear

oil seal

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

Selecting oil pump cover bearing race and oil

pump thrust washer

MA

EM

LC

EC

FE

CL

MT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

AT-11

EL

IDX

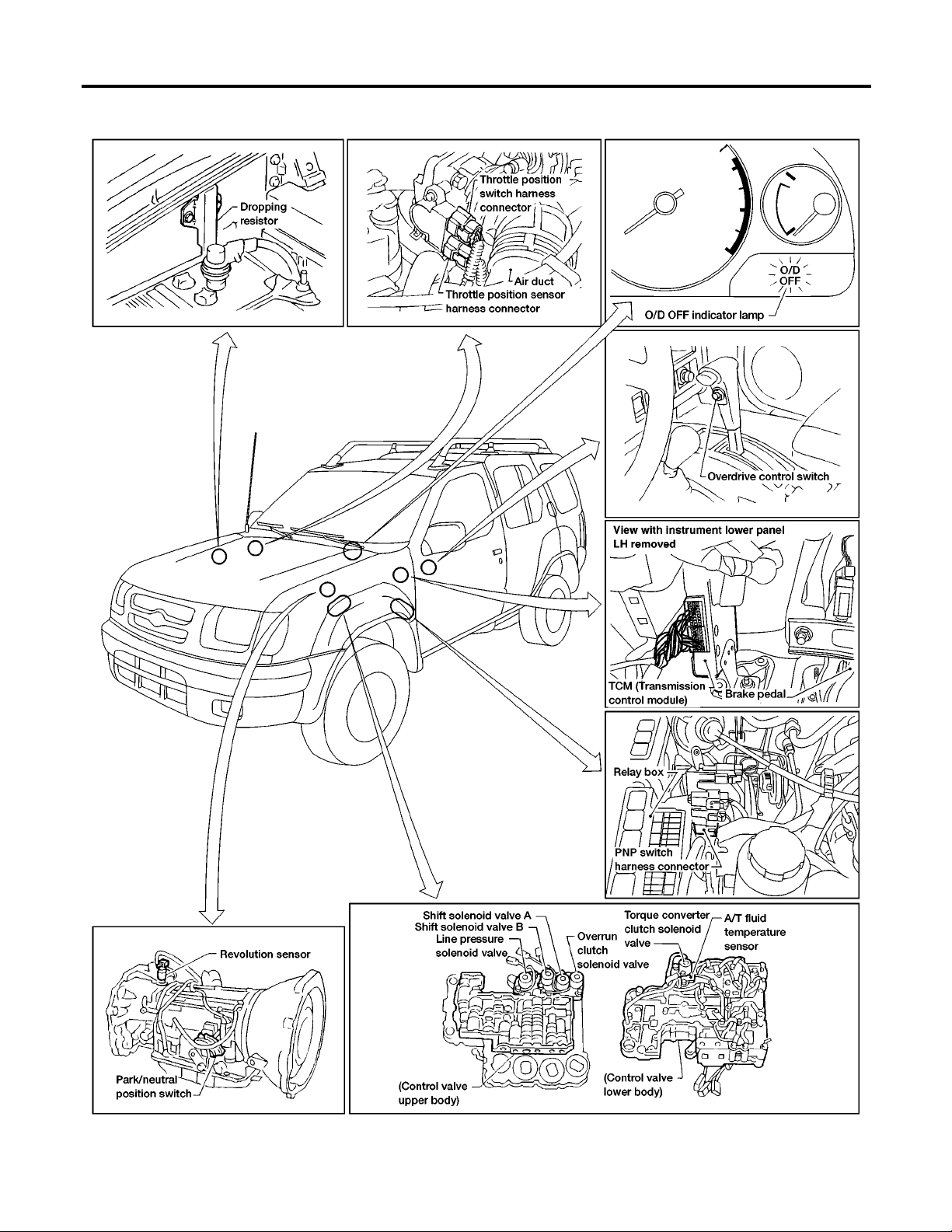

A/T Electrical Parts Location

OVERALL SYSTEM

A/T Electrical Parts Location

NGAT0007

AT-12

AAT622A

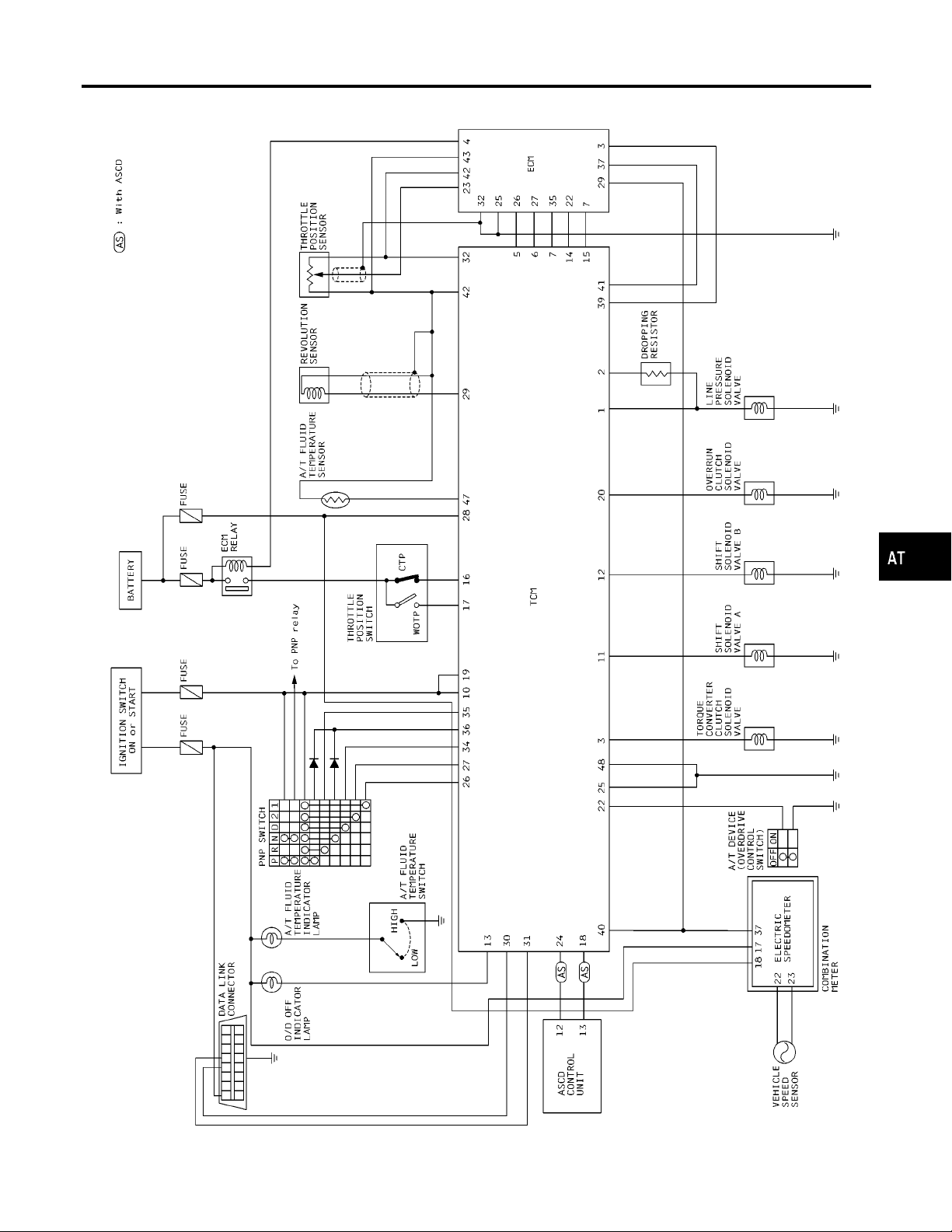

OVERALL SYSTEM

Circuit Diagram

Circuit Diagram

NGAT0008

GI

MA

EM

LC

EC

FE

CL

MT

TF

PD

AX

SU

BR

ST

RS

BT

HA

AT-13

AAT580A

SC

EL

IDX

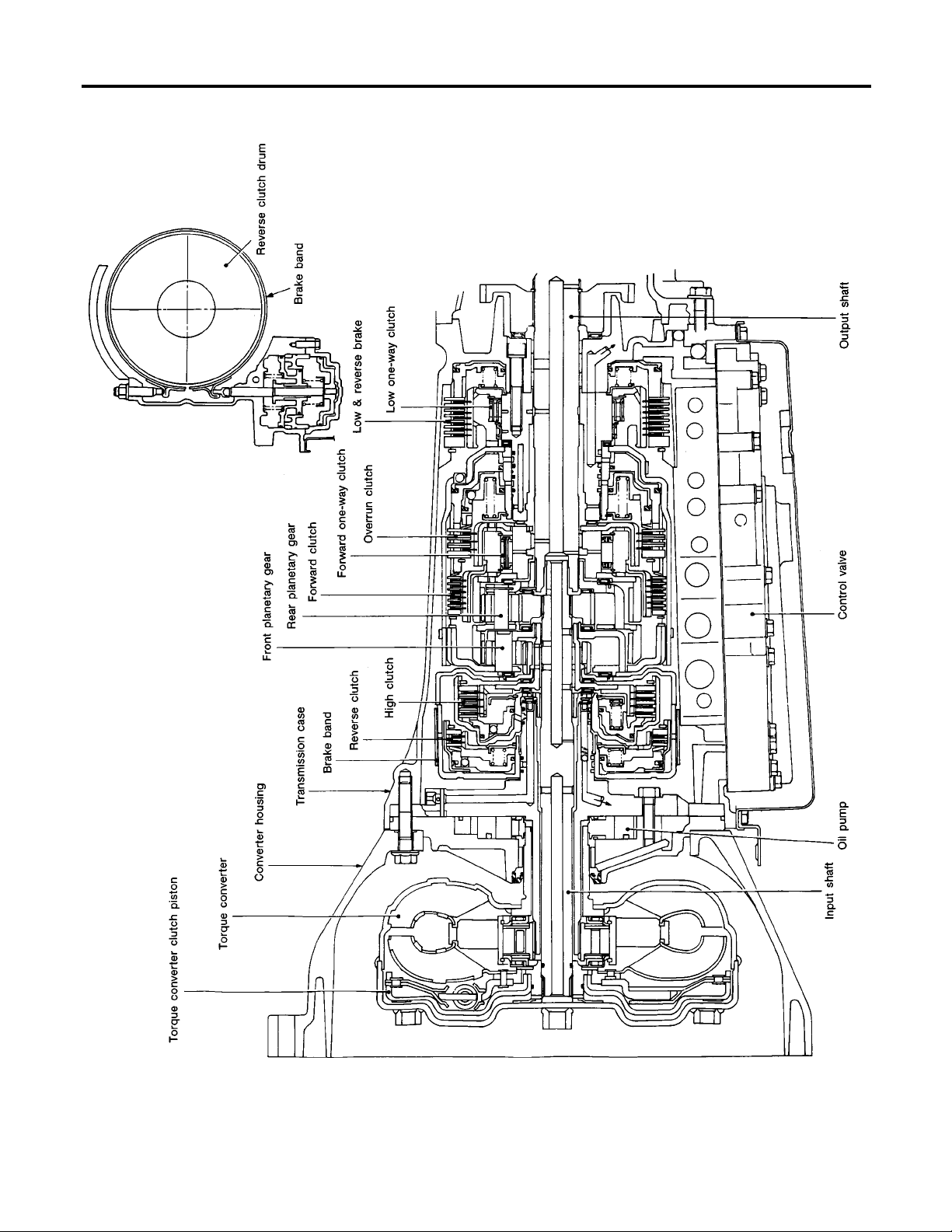

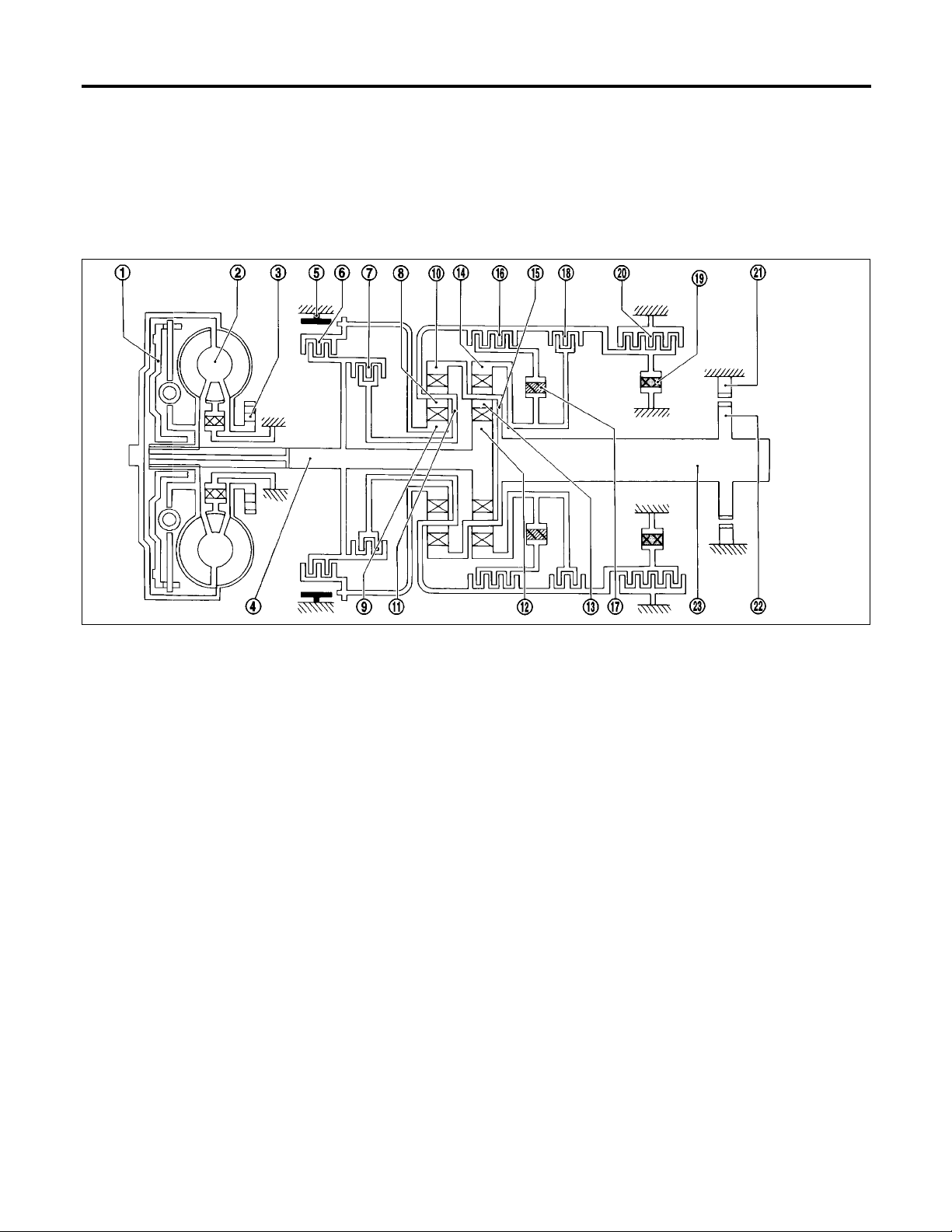

Cross-sectional View

OVERALL SYSTEM

Cross-sectional View

NGAT0010

AT-14

SAT125BA

OVERALL SYSTEM

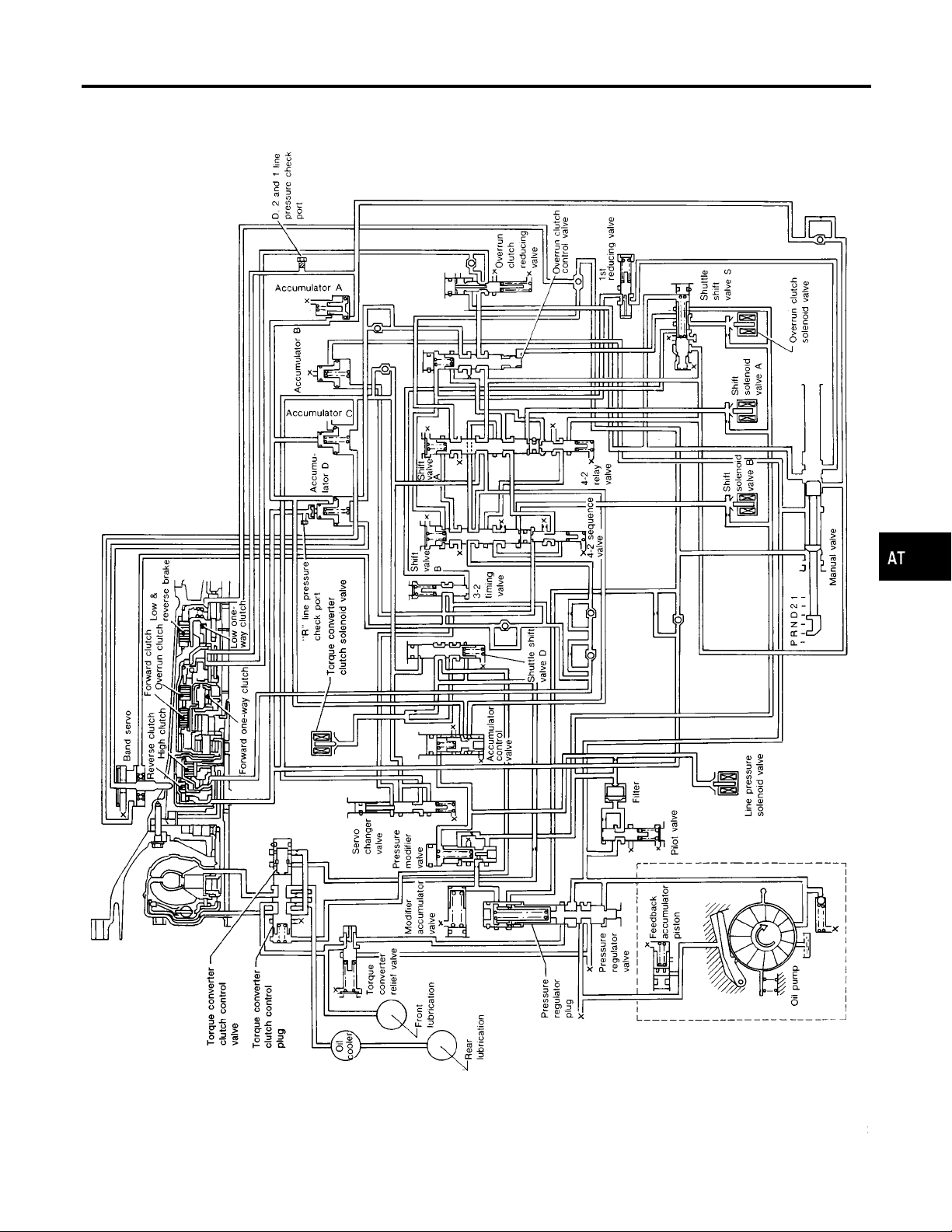

Hydraulic Control Circuit

Hydraulic Control Circuit

NGAT0011

GI

MA

EM

LC

EC

FE

CL

MT

TF

PD

AX

SU

BR

ST

RS

BT

HA

AT-15

SAT624GA

SC

EL

IDX

Shift Mechanism

OVERALL SYSTEM

Shift Mechanism

NGAT0012

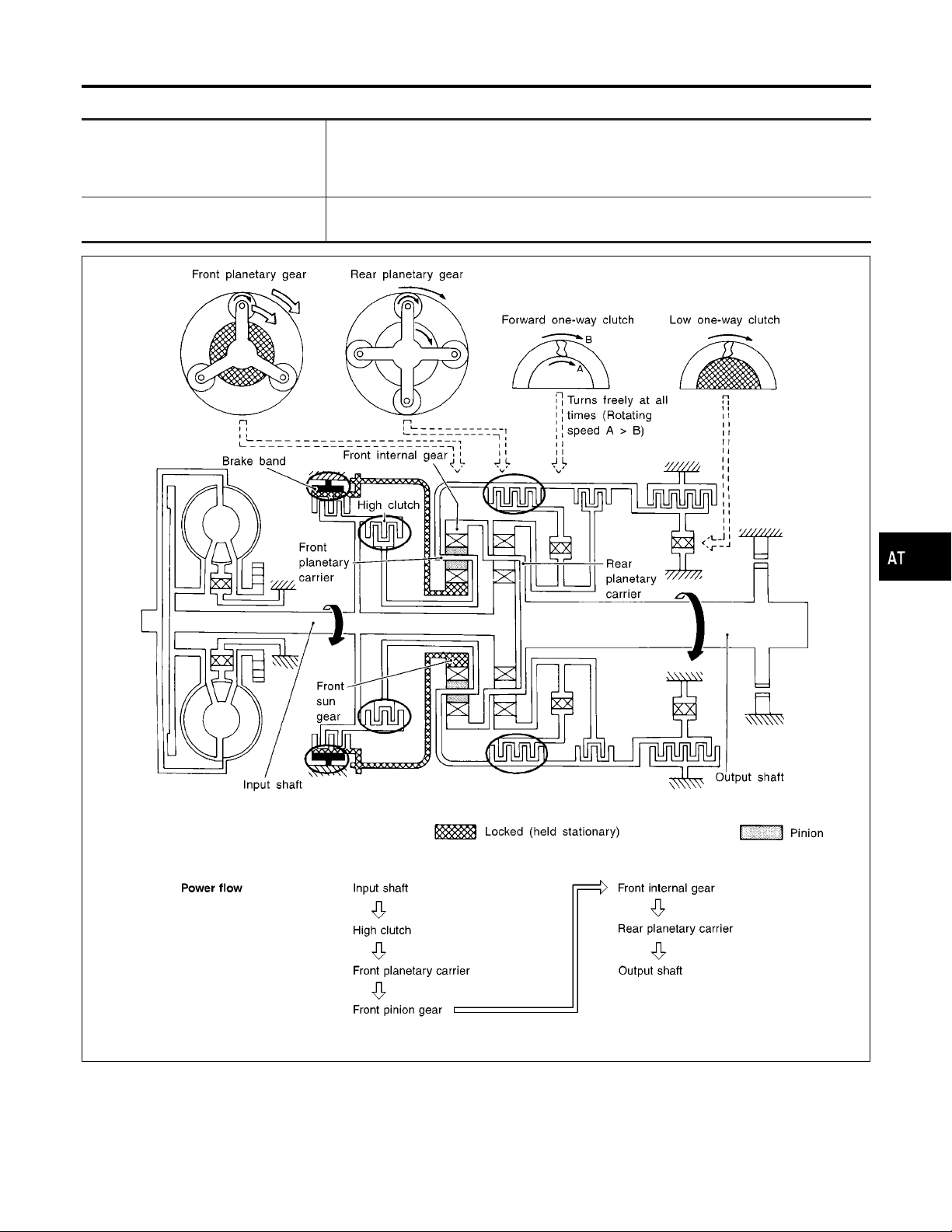

The automatic transmission uses compact, dual planetary gear systems to improve power-transmission

efficiency, simplify construction and reduce weight.

It also employs an optimum shift control and superwide gear ratios. They improve starting performance and

acceleration during medium and high-speed operation.

Two one-way clutches are also employed: one is used for the forward clutch and the other for the low clutch.

These one-way clutches, combined with four accumulators, reduce shifting shock to a minimum.

CONSTRUCTION

NGAT0012S01

1. Torque converter clutch piston

2. Torque converter

3. Oil pump

4. Input shaft

5. Brake band

6. Reverse clutch

7. High clutch

8. Front pinion gear

9. Front sun gear

10. Front internal gear

11. Front planetary carrier

12. Rear sun gear

13. Rear pinion gear

14. Rear internal gear

15. Rear planetary carrier

16. Forward clutch

SAT509I

17. Forward one-way clutch

18. Overrun clutch

19. Low one-way clutch

20. Low & reverse brake

21. Parking pawl

22. Parking gear

23. Output shaft

AT-16

OVERALL SYSTEM

Shift Mechanism (Cont’d)

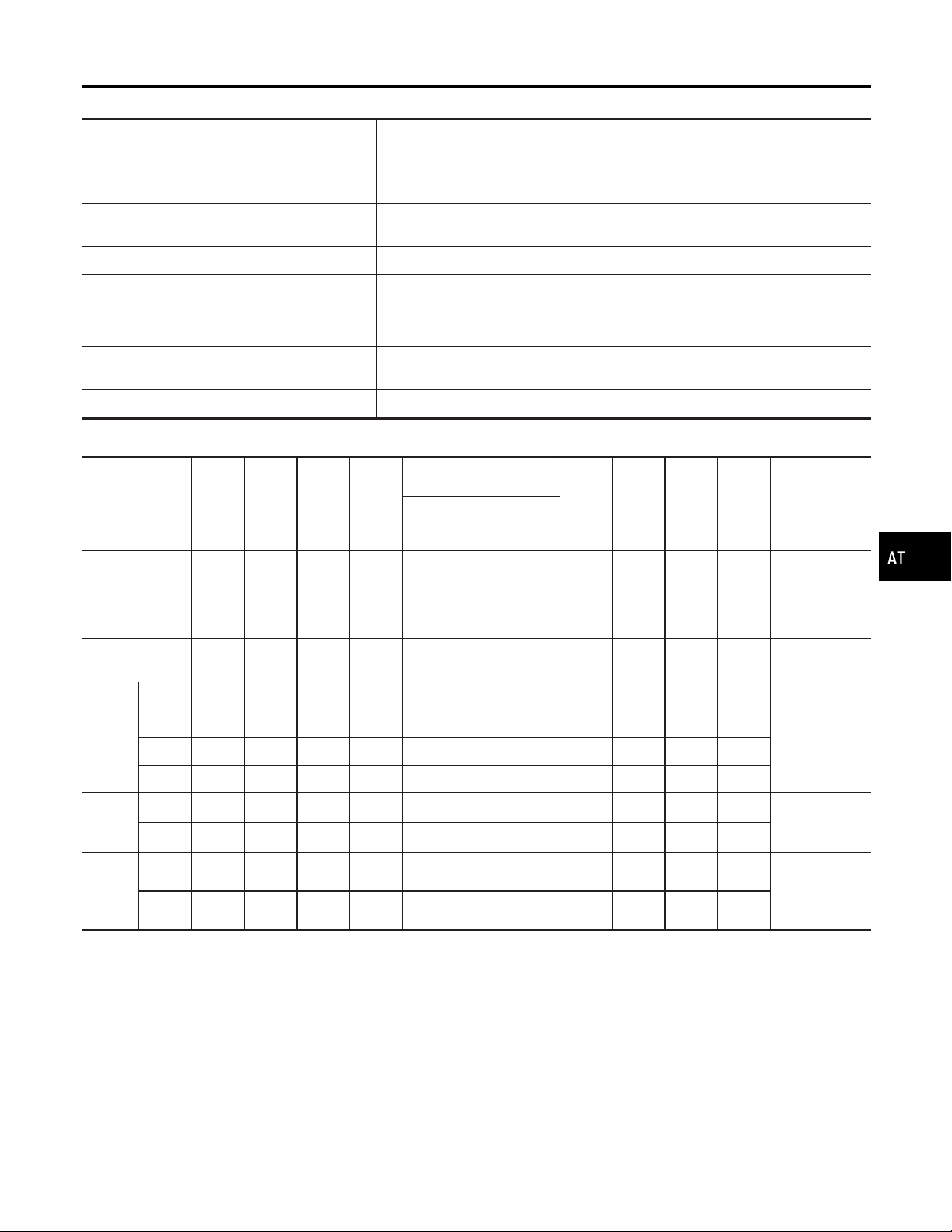

FUNCTION OF CLUTCH AND BRAKE

Clutch and brake components Abbr. Function

Reverse clutch 6 R/C To transmit input power to front sun gear 9.

High clutch 7 H/C To transmit input power to front planetary carrier 11.

Forward clutch 16 F/C To connect front planetary carrier 11 with forward one-way

clutch 17.

Overrun clutch 18 O/C To connect front planetary carrier 11 with rear internal gear 14.

Brake band 5 B/B To lock front sun gear 9.

Forward one-way clutch 17 F/O.C When forward clutch 16 is engaged, to stop rear internal gear

14 from rotating in opposite direction against engine revolution.

Low one-way clutch 19 L/O.C To stop front planetary carrier 11 from rotating in opposite direc-

tion against engine revolution.

Low & reverse brake 20 L & R/B To lock front planetary carrier 11.

CLUTCH AND BAND CHART

For-

ward

one-

way

clutch

Low

one-

way

clutch

Low &

reverse

brake

Lock-up Remarks

Shift position

Reverse

clutch

High

clutch

For-

ward

clutch

Over-

run

clutch

2nd

apply

Band servo

3rd

release

4th

apply

=NGAT0012S02

NGAT0012S03

GI

MA

EM

LC

EC

FE

CL

MT

P

R q q

N

1st q *1D B B

2nd q *1A q B

D*4

3rd qq*1A *2C C B *5q

4th q C *3C C qq

1st qq BB

2

2nd qqq B

1st qq BBq

1

2nd qqq B

*1: Operates when overdrive control switch is being set in OFF position.

*2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not contract

because oil pressure area on the “release” side is greater than that on the “apply” side.

*3: Oil pressure is applied to 4th “apply” side in condition *2 above, and brake band contracts.

*4: A/T will not shift to 4th when overdrive control switch is set in OFF position.

*5: Operates when overdrive control switch is OFF.

q : Operates.

A: Operates when throttle opening is less than 3/16, activating engine brake.

B: Operates during “progressive” acceleration.

C: Operates but does not affect power transmission.

D: Operates when throttle opening is less than 3/16, but does not affect engine brake.

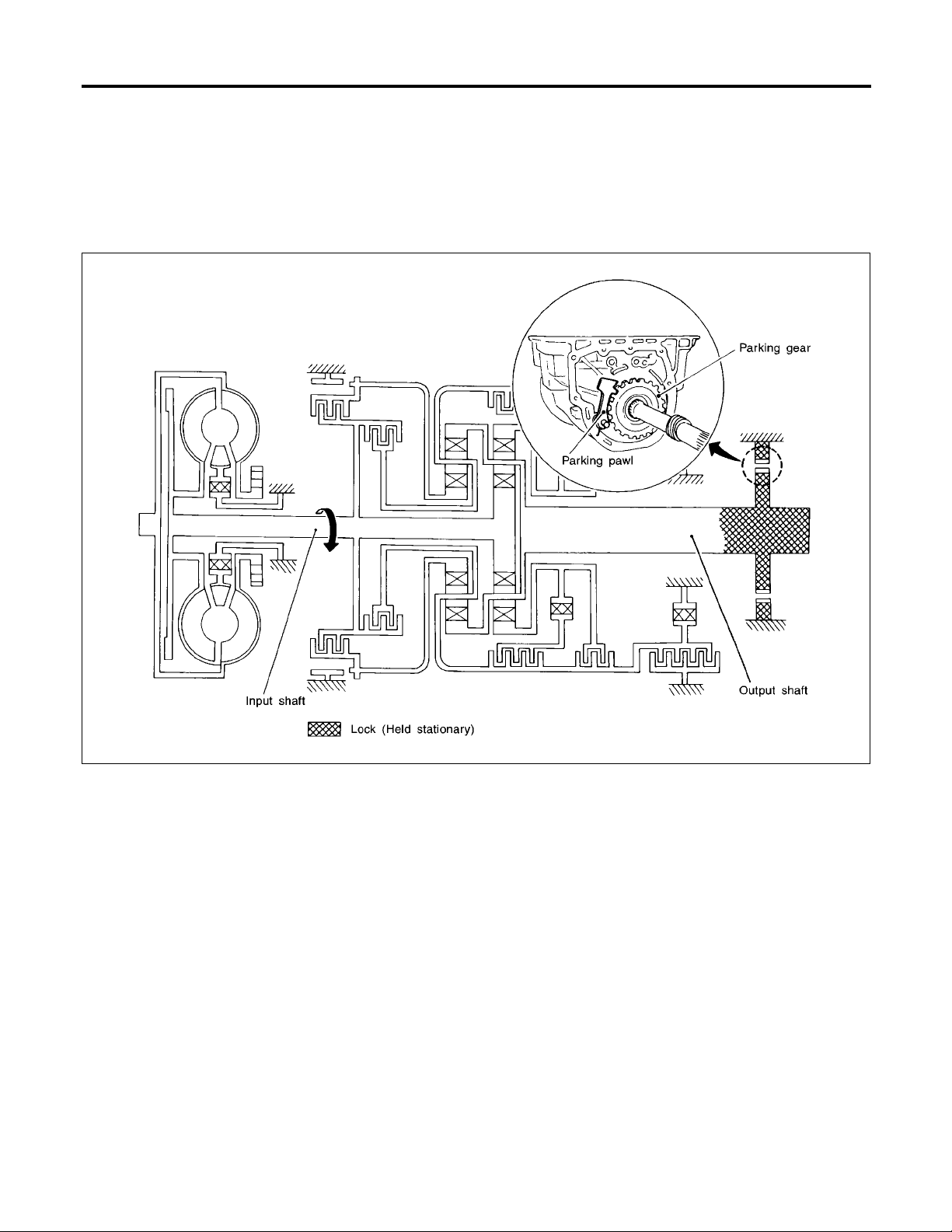

PARK

POSITION

REVERSE

POSITION

NEUTRAL

POSITION

Automatic

shift

1 k 2 k 3 k

4

Automatic

shift

1 k 2

Locks (held

stationary) in

1st speed

1 g 2

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

AT-17

IDX

Shift Mechanism (Cont’d)

OVERALL SYSTEM

POWER TRANSMISSION

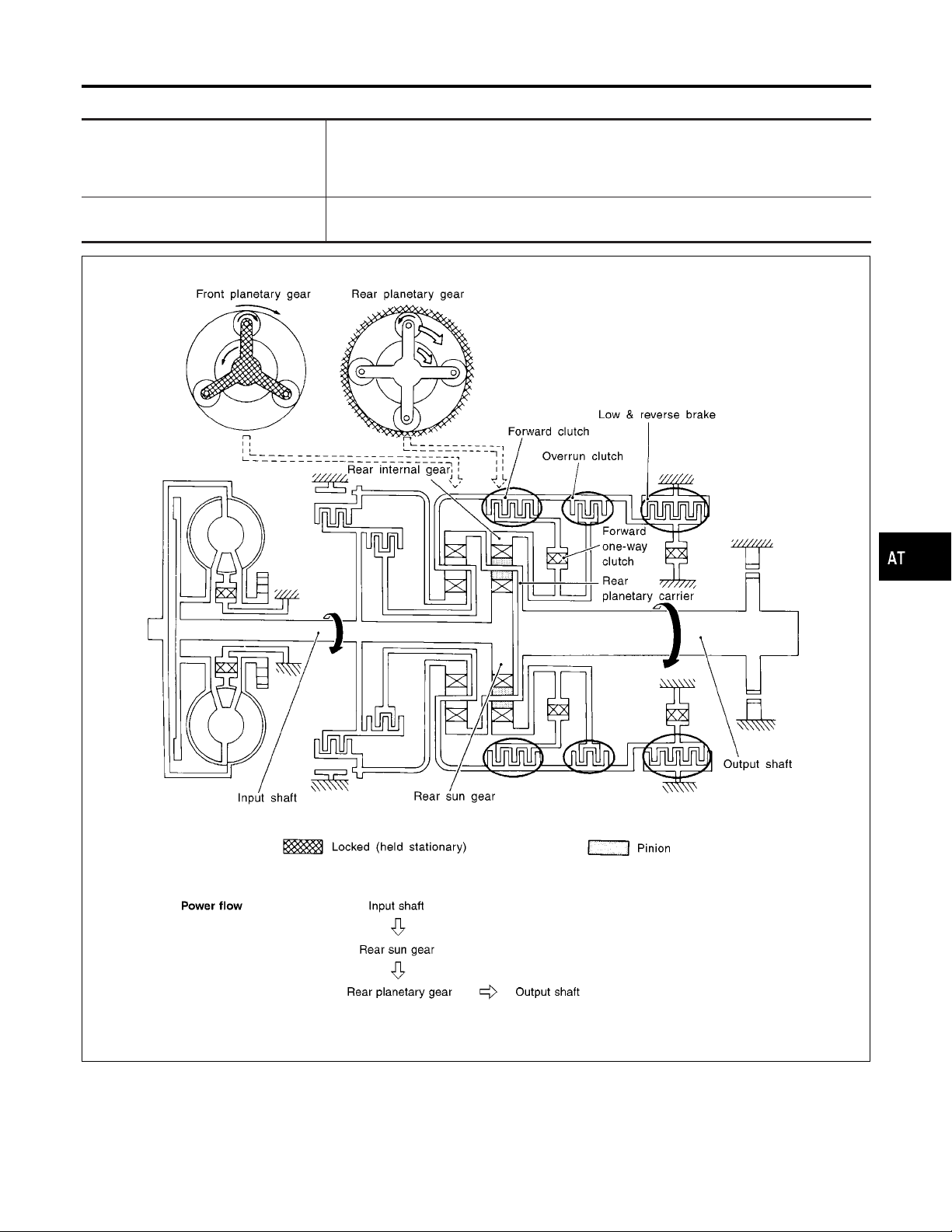

P and N Positions

I P position

Similar to the N position, no control members operate. The parking pawl interconnected with the select

lever engages with the parking gear to mechanically hold the output shaft so that the power train is locked.

I N position

No control members operate. Power from the input shaft is not transmitted to the output shaft since the

clutch does not operate.

=NGAT0012S04

NGAT0012S0401

AT-18

SAT039J

OVERALL SYSTEM

Shift Mechanism (Cont’d)

11Position

Forward clutch

Forward one-way clutch

Overrun clutch

Low and reverse brake

Engine brake Overrun clutch always engages, therefore engine brake can be obtained when decelerat-

As overrun clutch engages, rear internal gear is locked by the operation of low and

reverse brake.

This is different from that of D

ing.

and 21.

1

=NGAT0012S0406

GI

MA

EM

LC

EC

FE

CL

MT

SAT100J

TF

PD

AX

SU

BR

ST

RS

BT

HA

AT-19

SC

EL

IDX

Shift Mechanism (Cont’d)

OVERALL SYSTEM

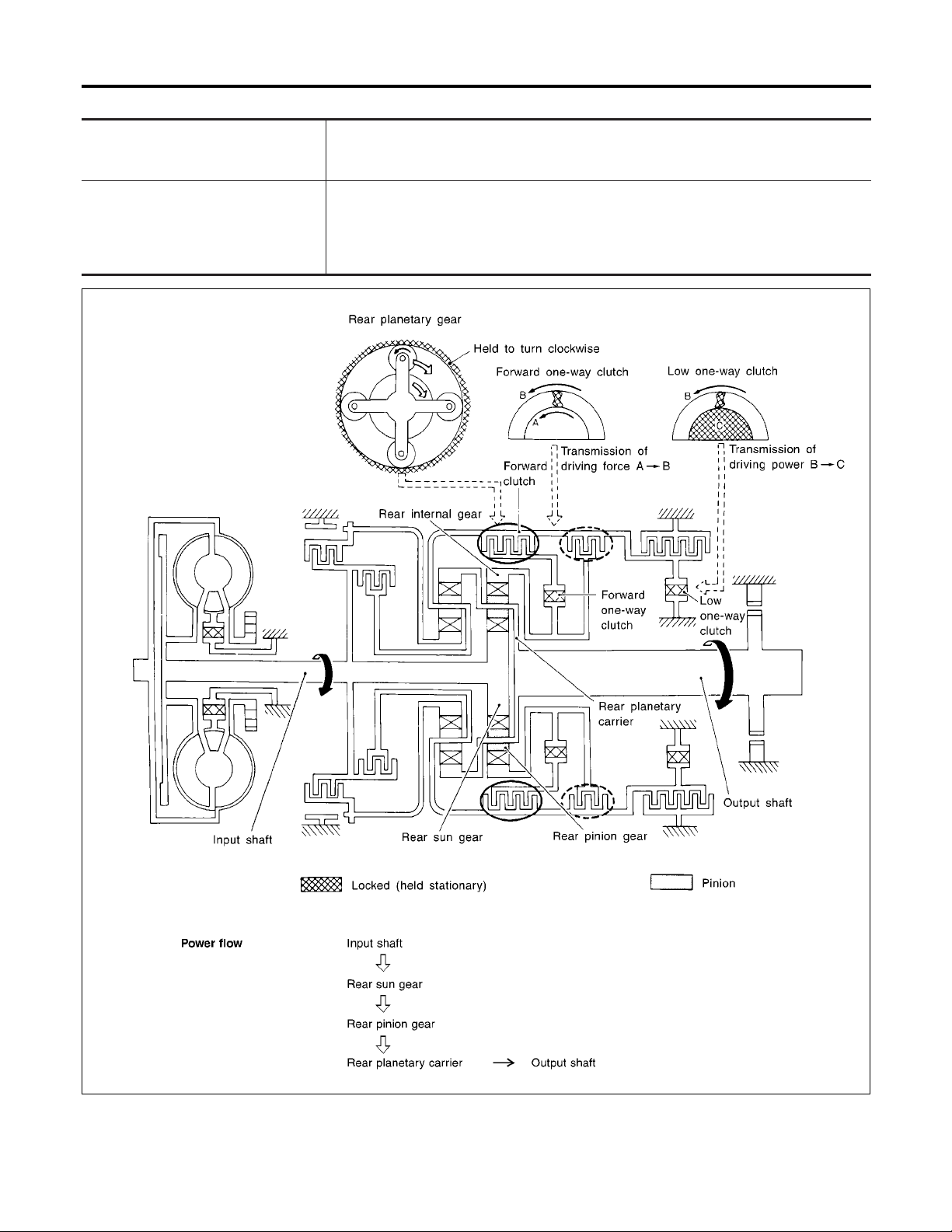

D1and 21Positions

Forward one-way clutch

Forward clutch

Low one-way clutch

Overrun clutch

engagement conditions

(Engine brake)

=NGAT0012S0402

Rear internal gear is locked to rotate counterclockwise because of the functioning of

these three clutches. (Start-up at D

D

: Overdrive control switch in OFF

1

)

1

Throttle opening less than 3/16

: Throttle opening less than 3/16

2

1

At D

and 21positions, engine brake is not activated due to free turning of low one-way

1

clutch.

AT-20

SAT096J

OVERALL SYSTEM

Shift Mechanism (Cont’d)

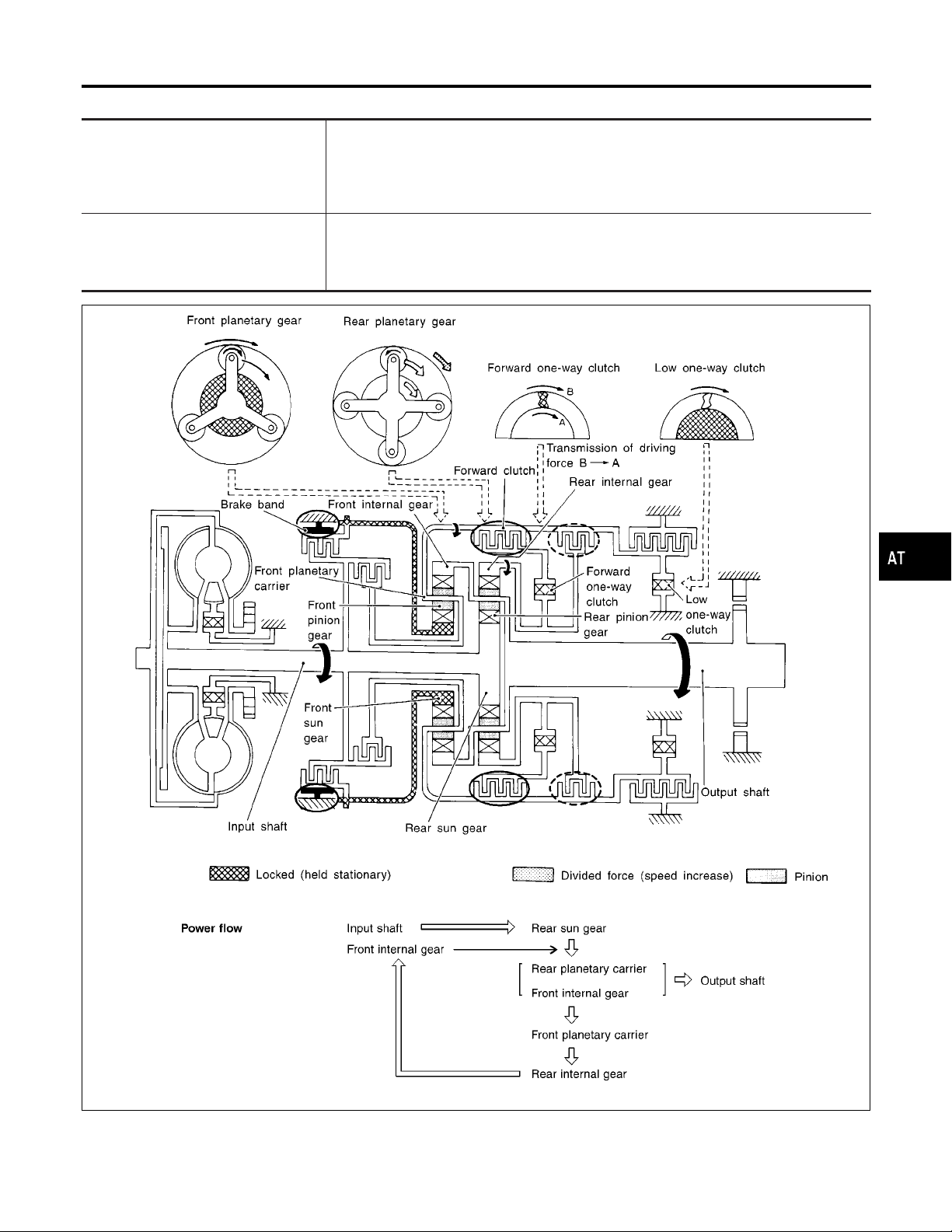

D2,22and 12Positions

Forward clutch

Forward one-way clutch

Brake band

Overrun clutch

engagement conditions

=NGAT0012S0403

Rear sun gear drives rear planetary carrier and combined front internal gear. Front internal gear now rotates around front sun gear accompanying front planetary carrier.

As front planetary carrier transfers the power to rear internal gear through forward clutch

and forward one-way clutch, this rotation of rear internal gear increases the speed of rear

planetary carrier compared with that of the 1st speed.

D

: Overdrive control switch in OFF

2

Throttle opening less than 3/16

2

: Throttle opening less than 3/16

2

1

: Always engaged

2

GI

MA

EM

LC

EC

FE

CL

MT

TF

PD

AX

SU

BR

ST

RS

BT

HA

AT-21

SC

SAT097J

EL

IDX

Shift Mechanism (Cont’d)

OVERALL SYSTEM

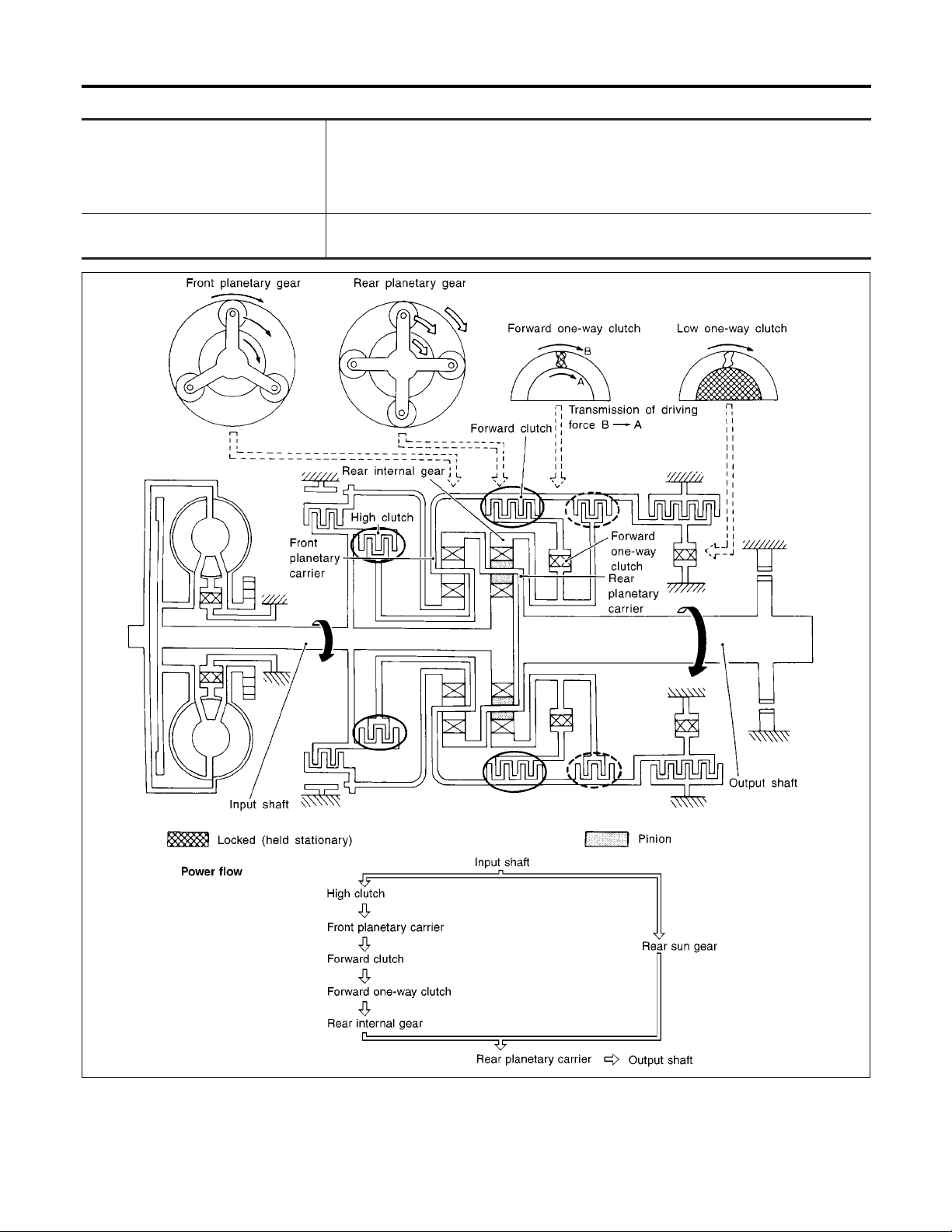

D3Position

High clutch

Forward clutch

Forward one-way clutch

Overrun clutch

engagement conditions

=NGAT0012S0404

Input power is transmitted to front planetary carrier through high clutch. And front planetary carrier is connected to rear internal gear by operation of forward clutch and forward

one-way clutch.

This rear internal gear rotation and another input (the rear sun gear) accompany rear

planetary carrier to turn at the same speed.

D

: Overdrive control switch in OFF

3

Throttle opening less than 3/16

AT-22

SAT098J

OVERALL SYSTEM

Shift Mechanism (Cont’d)

D4(O/D) Position

High clutch

Brake band

Forward clutch

(Does not affect power transmission)

Engine brake At D

=NGAT0012S0405

Input power is transmitted to front carrier through high clutch.

This front planetary carrier turns around the sun gear which is fixed by brake band and

makes front internal gear (output) turn faster.

position, there is no one-way clutch in the power transmission line and engine

4

brake can be obtained when decelerating.

GI

MA

EM

LC

EC

FE

CL

MT

SAT099J

TF

PD

AX

SU

BR

ST

RS

BT

HA

AT-23

SC

EL

IDX

Shift Mechanism (Cont’d)

OVERALL SYSTEM

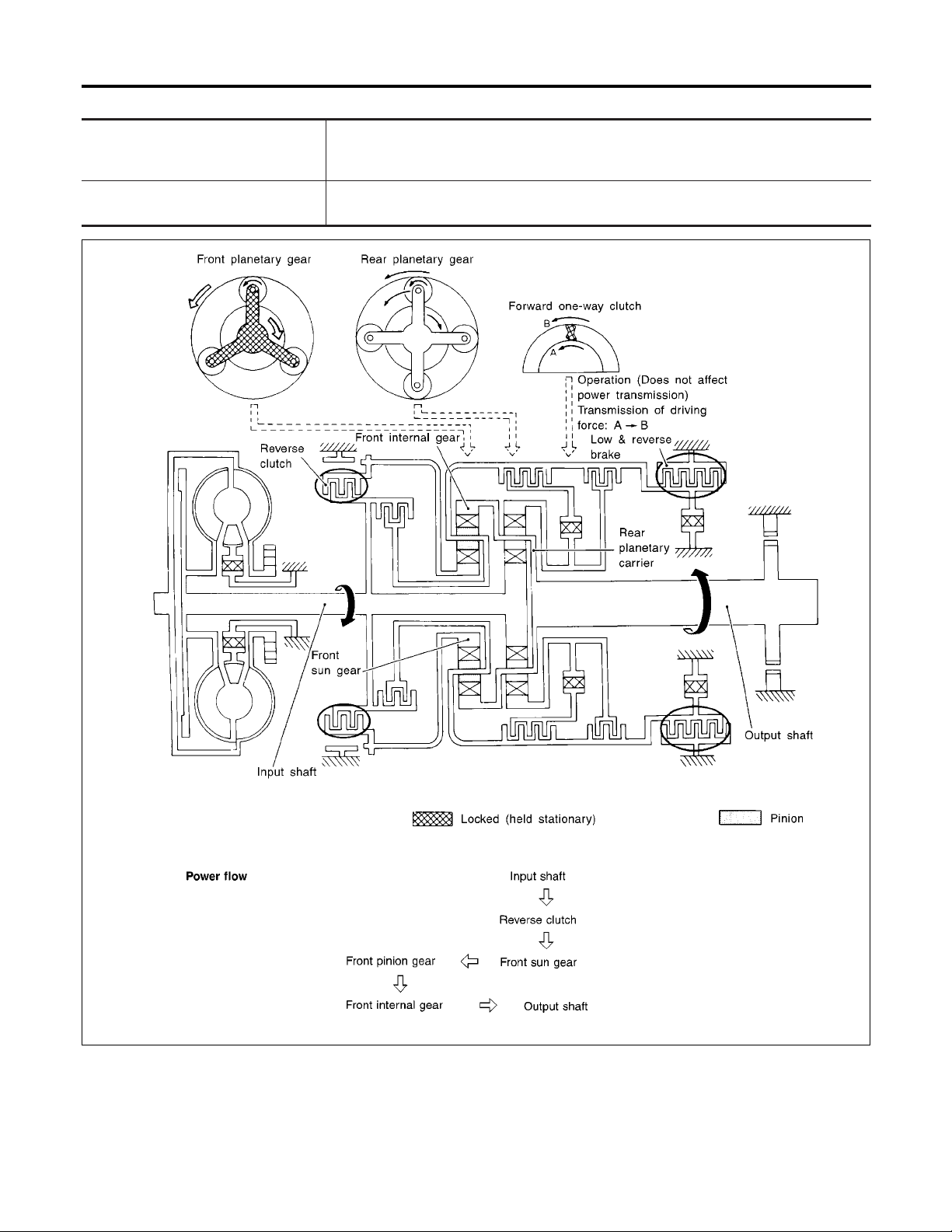

R Position

Reverse clutch

Low and reverse brake

Engine brake As there is no one-way clutch in the power transmission line, engine brake can be

Front planetary carrier is stationary because of the operation of low and reverse brake.

Input power is transmitted to front sun gear through reverse clutch, which drives front

internal gear in the opposite direction.

obtained when decelerating.

=NGAT0012S0407

AT-24

SAT101J

OVERALL SYSTEM

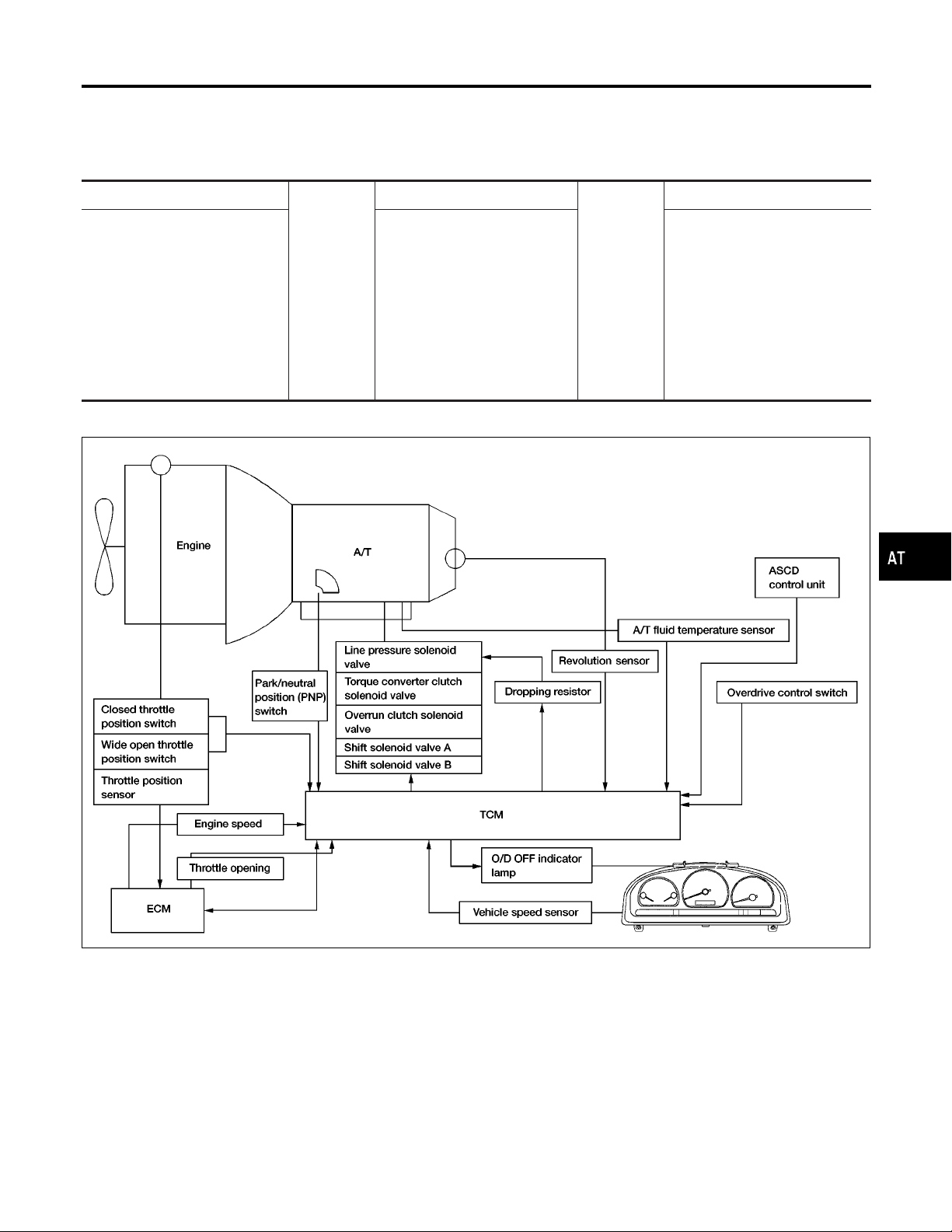

Control System

Control System

OUTLINE

=NGAT0013

NGAT0013S01

The automatic transmission senses vehicle operating conditions through various sensors. It always controls

the optimum shift position and reduces shifting and lock-up shocks.

SENSORS

PNP switch

Throttle position sensor

Closed throttle position switch

Wide open throttle position

switch

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed sensor

Overdrive control switch

ASCD control unit

CONTROL SYSTEM

Shift control

Line pressure control

Lock-up control

E

Overrun clutch control

Timing control

Fail-safe control

Self-diagnosis

CONSULT communication line

Duet-EU control

TCM

ACTUATORS

Shift solenoid valve A

Shift solenoid valve B

E

Overrun clutch solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

O/D OFF indicator lamp

NGAT0013S02

GI

MA

EM

LC

EC

FE

CL

MT

AAT471A

TF

PD

AX

SU

BR

ST

RS

BT

HA

AT-25

SC

EL

IDX

Control System (Cont’d)

OVERALL SYSTEM

TCM FUNCTION

The function of the TCM is to:

I Receive input signals sent from various switches and sensors.

I Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

I Send required output signals to the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCM

Sensors and solenoid valves Function

PNP switch Detects select lever position and sends a signal to TCM.

Throttle position sensor Detects throttle valve position and sends a signal to TCM.

Closed throttle position switch Detects throttle valve’s fully-closed position and sends a signal to TCM.

Detects a throttle valve position of greater than 1/2 of full throttle and sends

a signal to TCM.

Used as an auxiliary vehicle speed sensor. Sends a signal when revolution

sensor (installed on transmission) malfunctions.

Sends a signal, which prohibits a shift to “D

TCM.

” (overdrive) position, to the

4

Input

Wide open throttle position switch

Engine speed signal From ECM.

A/T fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

Revolution sensor Detects output shaft rpm and sends a signal to TCM.

Vehicle speed sensor

Overdrive control switch

=NGAT0013S03

NGAT0013S04

Output

ASCD control unit

Shift solenoid valve A/B

Line pressure solenoid valve

Torque converter clutch solenoid

valve

Overrun clutch solenoid valve

O/D OFF indicator lamp Shows TCM faults, when A/T control components malfunction.

Sends the cruise signal and “D

control unit to TCM.

Selects shifting point suited to driving conditions in relation to a signal sent

from TCM.

Regulates (or decreases) line pressure suited to driving conditions in relation

to a signal sent from TCM.

Regulates (or decreases) lock-up pressure suited to driving conditions in

relation to a signal sent from TCM.

Controls an “engine brake” effect suited to driving conditions in relation to a

signal sent from TCM.

” (overdrive) cancellation signal from ASCD

4

Control Mechanism

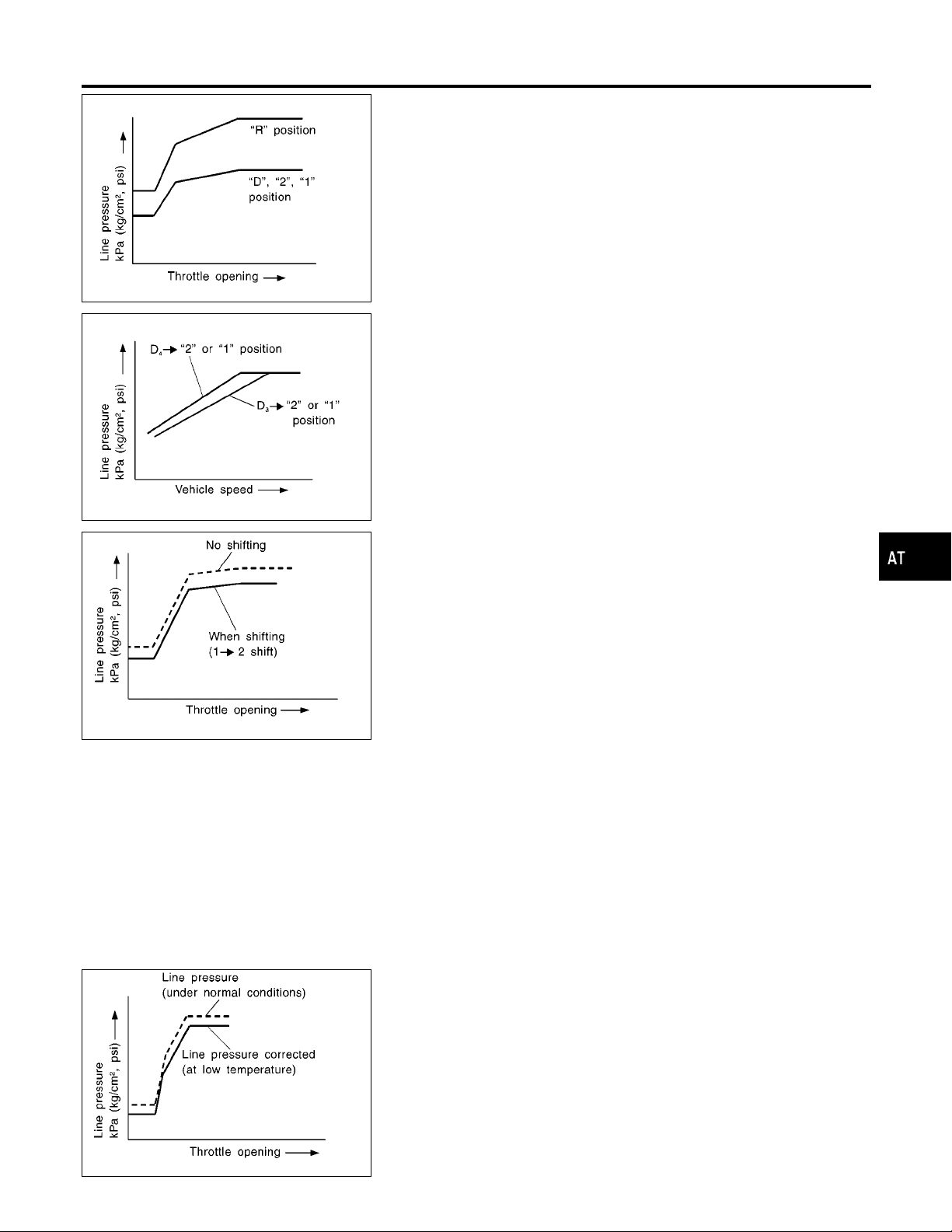

LINE PRESSURE CONTROL

TCM has the various line pressure control characteristics to meet

the driving conditions.

An ON-OFF duty signal is sent to the line pressure solenoid valve

based on TCM characteristics.

Hydraulic pressure on the clutch and brake is electronically controlled through the line pressure solenoid valve to accommodate

engine torque. This results in smooth shift operation.

NGAT0180

NGAT0180S01

AT-26

OVERALL SYSTEM

Control Mechanism (Cont’d)

SAT003J

SAT004J

Normal Control

The line pressure to throttle opening characteristics is set for suitable clutch operation.

Back-up Control (Engine brake)

If the selector lever is shifted to “2” position while driving in D4(OD)

, great driving force is applied to the clutch inside the trans-

or D

3

mission. Clutch operating pressure (line pressure) must be

increased to deal with this driving force.

During Shift Change

The line pressure is temporarily reduced corresponding to a

change in engine torque when shifting gears (that is, when the shift

solenoid valve is switched for clutch operation) to reduce shifting

shock.

NGAT0180S0101

NGAT0180S0102

NGAT0180S0103

GI

MA

EM

LC

EC

FE

CL

MT

TF

SAT005J

At Low Fluid Temperature

I Fluid viscosity and frictional characteristics of the clutch facing

change with fluid temperature. Clutch engaging or band-contacting pressure is compensated for, according to fluid

temperature, to stabilize shifting quality.

I The line pressure is reduced below 60°C (140°F) to prevent

shifting shock due to low viscosity of automatic transmission

fluid when temperature is low.

NGAT0180S0104

PD

AX

SU

BR

ST

RS

BT

HA

SC

SAT006J

EL

IDX

AT-27

Control Mechanism (Cont’d)

SAT007J

OVERALL SYSTEM

I Line pressure is increased to a maximum irrespective of the

throttle opening when fluid temperature drops to −10°C (14°F).

This pressure rise is adopted to prevent a delay in clutch and

brake operation due to extreme drop of fluid viscosity at low

temperature.

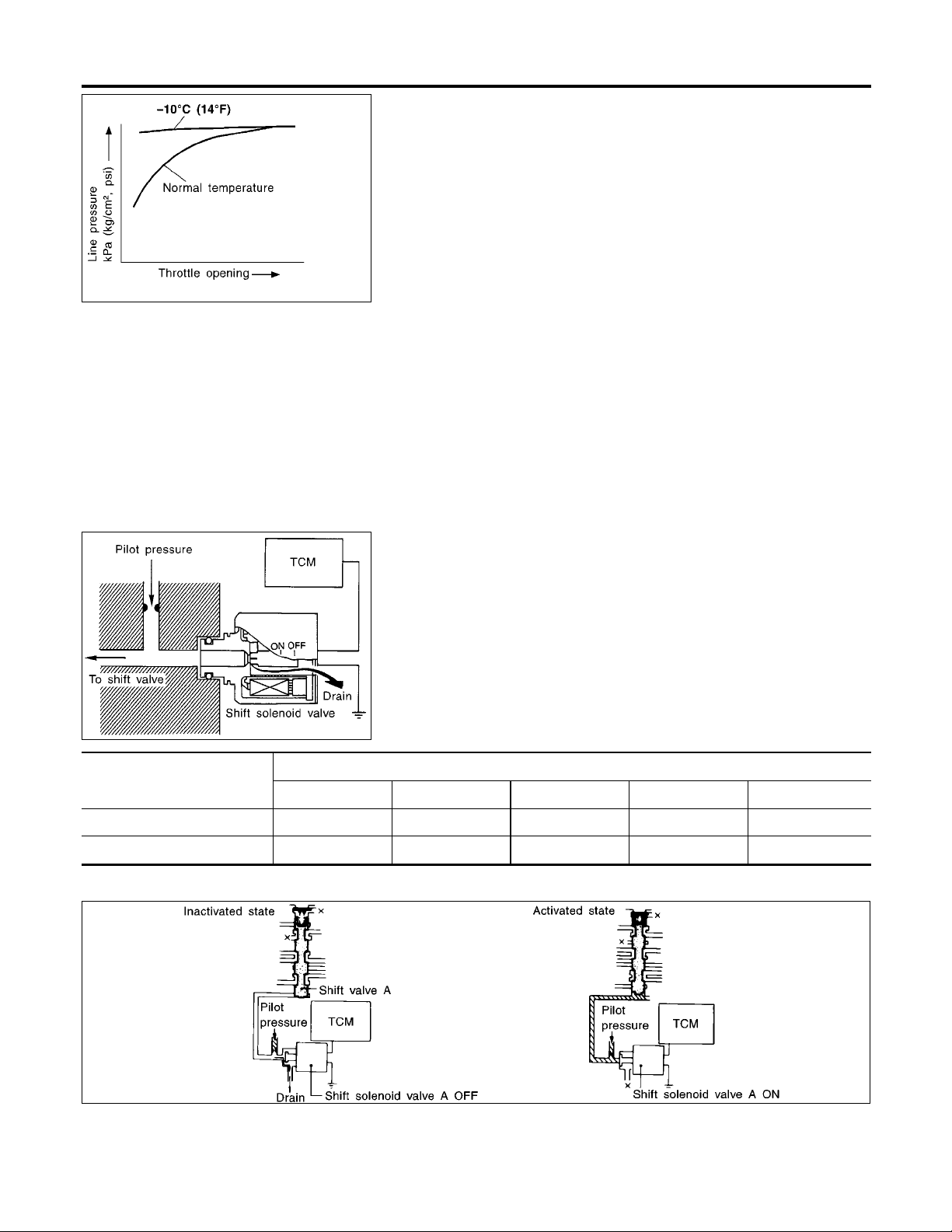

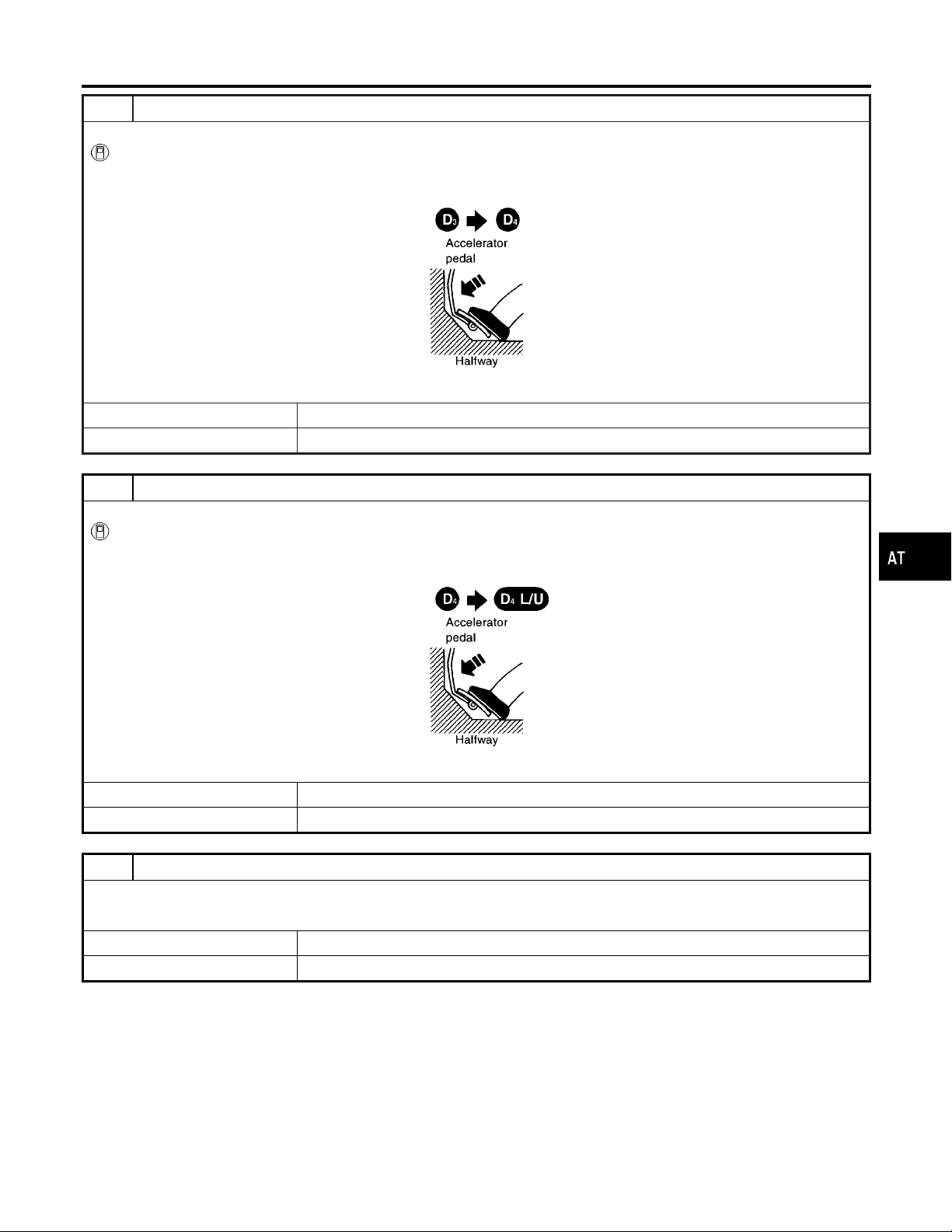

SHIFT CONTROL

The shift is regulated entirely by electronic control to accommodate

vehicle speed and varying engine operations. This is accomplished

by electrical signals transmitted by the revolution sensor and

throttle position sensor. This results in improved acceleration performance and fuel economy.

NGAT0180S02

Shift solenoid valve

A ON (Closed) OFF (Open) OFF (Open) ON (Closed) ON (Closed)

B ON (Closed) ON (Closed) OFF (Open) OFF (Open) ON (Closed)

SAT008J

D

1,21,11

Control of Shift Solenoid Valves A and B

NGAT0180S0201

The TCM activates shift solenoid valves A and B according to signals from the throttle position sensor and revolution sensor to

select the optimum gear position on the basis of the shift schedule

memorized in the TCM.

The shift solenoid valve performs simple ON-OFF operation. When

set to ON, the drain circuit closes and pilot pressure is applied to

the shift valve.

[Relation between shift solenoid valvesA and B and gear positions]

Gear position

D2,22,1

2

Control of Shift Valves A and B

D

3

D4(OD) N-P

NGAT0180S0202

AT-28

SAT047J

OVERALL SYSTEM

Control Mechanism (Cont’d)

Pilot pressure generated by the operation of shift solenoid valves

A and B is applied to the end face of shift valves A and B.

The drawing above shows the operation of shift valve B. When the

shift solenoid valve is “ON”, pilot pressure applied to the end face

of the shift valve overcomes spring force, moving the valve upward.

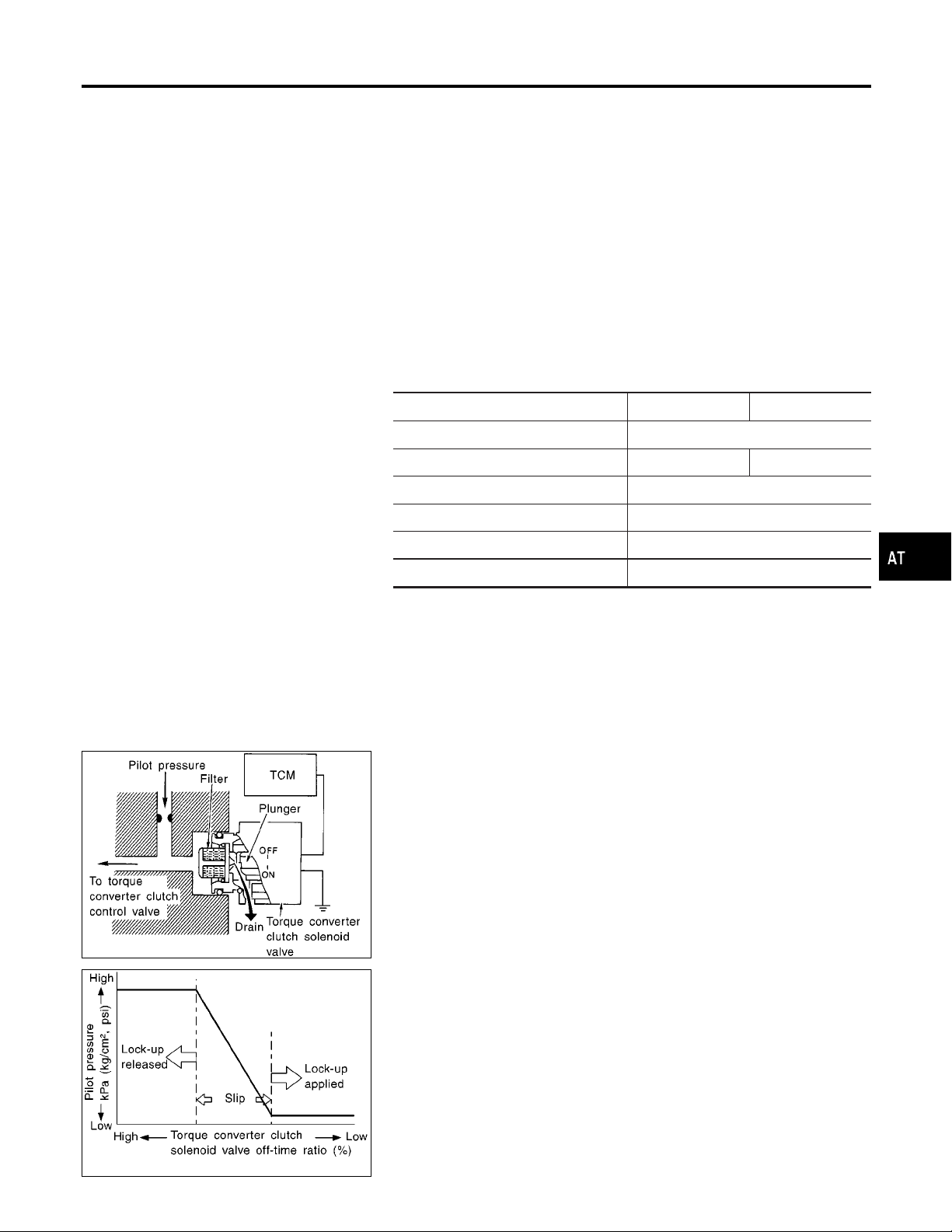

LOCK-UP CONTROL

The torque converter clutch piston in the torque converter is locked

to eliminate torque converter slip to increase power transmission

efficiency. The solenoid valve is controlled by an ON-OFF duty

signal sent from the TCM. The signal is converted to oil pressure

signal which controls the torque converter clutch piston.

Conditions for Lock-up Operation

When vehicle is driven in 4th gear position, vehicle speed and

throttle opening are detected. If the detected values fall within the

lock-up zone memorized in the TCM, lock-up is performed.

Overdrive control switch ON OFF

Selector lever “D” position

Gear position D

Vehicle speed sensor More than set value

Throttle position sensor Less than set opening

4

NGAT0180S03

NGAT0180S0301

D

3

GI

MA

EM

LC

EC

FE

CL

MT

SAT010J

Closed throttle position switch OFF

A/T fluid temperature sensor More than 40°C (104°F)

Torque Converter Clutch Solenoid Valve Control

The torque converter clutch solenoid valve is controlled by the

TCM. The plunger closes the drain circuit during the OFF period,

and opens the circuit during the ON period. If the percentage of

OFF-time increases in one cycle, the pilot pressure drain time is

reduced and pilot pressure remains high.

The torque converter clutch piston is designed to slip to adjust the

ratio of ON-OFF, thereby reducing lock-up shock.

OFF-time INCREASING

"

Amount of drain DECREASING

"

Pilot pressure HIGH

"

Lock-up RELEASING

NGAT0180S0302

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

SAT011J

EL

IDX

AT-29

Control Mechanism (Cont’d)

OVERALL SYSTEM

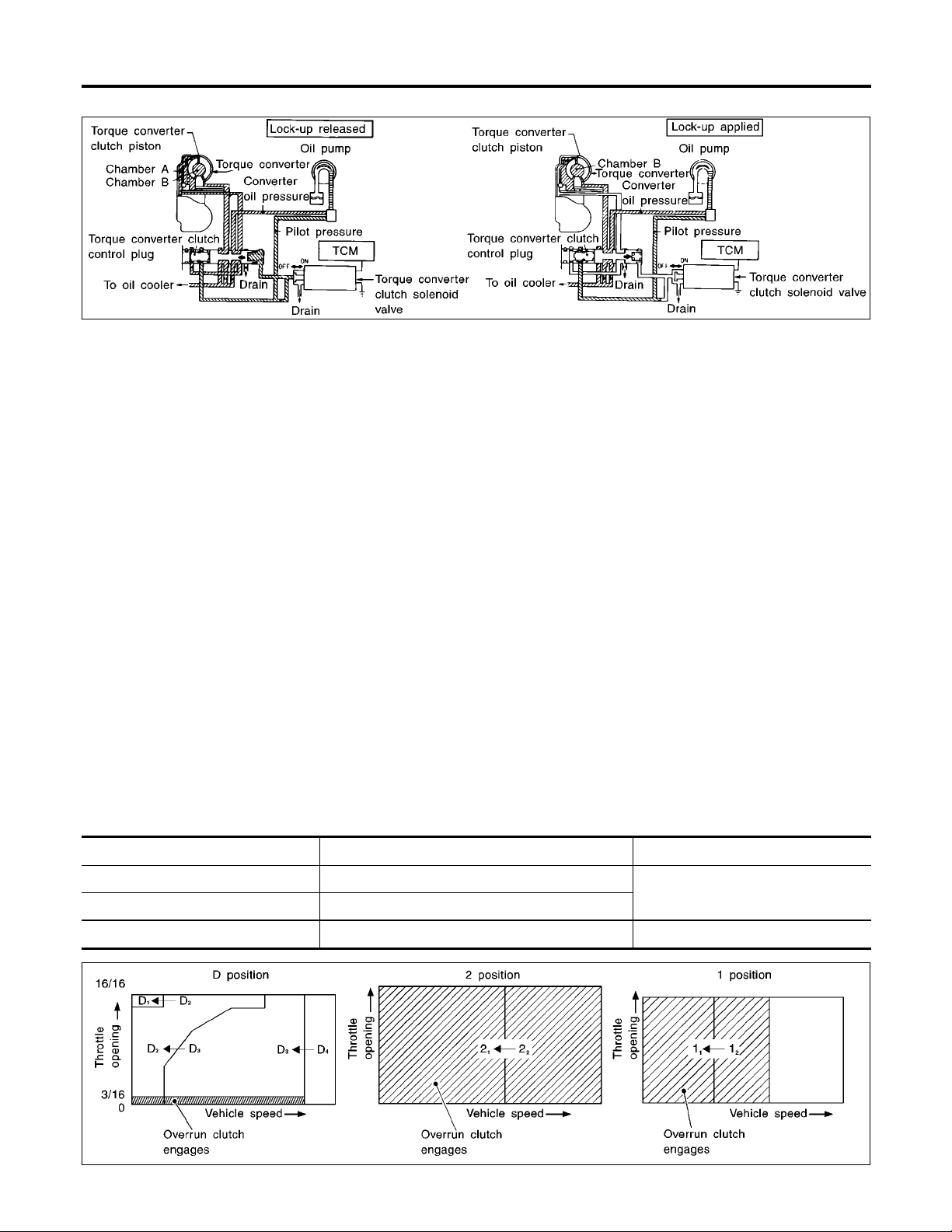

Torque Converter Clutch Control Valve Operation

NGAT0180S0303

SAT048J

Lock-up Released

The OFF-duration of the torque converter clutch solenoid valve is

long, and pilot pressure is high. The pilot pressure pushes the end

face of the torque converter clutch control valve in combination with

spring force to move the valve to the left. As a result, converter

pressure is applied to chamber A (torque converter clutch piston

release side). Accordingly, the torque converter clutch piston

remains unlocked.

Lock-up Applied

When the OFF-duration of the torque converter clutch solenoid

valve is short, pilot pressure drains and becomes low. Accordingly,

the control valve moves to the right by the pilot pressure of the

other circuit and converter pressure. As a result, converter pressure is applied to chamber B, keeping the torque converter clutch

piston applied.

Also smooth lock-up is provided by transient application and

release of the lock-up.

OVERRUN CLUTCH CONTROL (ENGINE BRAKE

CONTROL)

Forward one-way clutch is used to reduce shifting shocks in downshifting operations. This clutch transmits engine torque to the

wheels. However, drive force from the wheels is not transmitted to

the engine because the one-way clutch rotatesidle. This means the

engine brake is not effective.

The overrun clutch operates when the engine brake is needed.

Overrun Clutch Operating Conditions

D position D

2 position 2

1 position 1

Gear position Throttle opening

1,D2,D3

gear position

gear position

1,22

gear position At any position

1,12

Less than 3/16

NGAT0180S04

NGAT0180S0401

AT-30

SAT014J

OVERALL SYSTEM

Control Mechanism (Cont’d)

SAT015J

Overrun Clutch Solenoid Valve Control

NGAT0180S0402

The overrun clutch solenoid valve is operated by an ON-OFF signal transmitted by the TCM to provide overrun clutch control

(engine brake control).

When this solenoid valve is ON, the pilot pressure drain port

closes. When it is OFF, the drain port opens.

During the solenoid valve ON pilot pressure is applied to the end

face of the overrun clutch control valve.

Overrun Clutch Control Valve Operation

NGAT0180S0403

When the solenoid valve is ON, pilot pressure A is applied to the

overrun clutch control valve. This pushes up the overrun clutch

control valve. The line pressure is then shut off so that the clutch

does not engage.

When the solenoid valve is OFF, pilot pressure A is not generated.

At this point, the overrun clutch control valve moves downward by

spring force. As a result, overrun clutch operation pressure is provided by the overrun clutch reducing valve. This causes the overrun clutch to engage.

In the 1 position, the overrun clutch control valve remains pushed

down so that the overrun clutch is engaged at all times.

GI

MA

EM

LC

EC

FE

CL

MT

SAT049J

Control Valve

FUNCTION OF CONTROL VALVE

Valve name Function

I Pressure regulator valve

I Pressure regulator plug

I Pressure regulator sleeve plug

Pressure modifier valve Used as a signal supplementary valve to the pressure regulator valve. Regulates

Modifier accumulator piston Smooths hydraulic pressure regulated by the pressure modifier valve to prevent pul-

Pilot valve Regulates line pressure to maintain a constant pilot pressure level which controls

Accumulator control valve

Accumulator control sleeve

Manual valve Directs line pressure to oil circuits corresponding to select positions.

Regulate oil discharged from the oil pump to provide optimum line pressure for all

driving conditions.

pressure-modifier pressure (signal pressure) which controls optimum line pressure for

all driving conditions.

sations.

lock-up mechanism, overrun clutch, 3-2 timing required for shifting.

Regulate accumulator backpressure to pressure suited to driving conditions.

Hydraulic pressure drains when the shift lever is in Neutral.

NGAT0181S01

NGAT0181

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

AT-31

IDX

OVERALL SYSTEM

Control Valve (Cont’d)

Valve name Function

Shift valve A Simultaneously switches three oil circuits using output pressure of shift solenoid valve

A to meet driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and up-shifting (1st , 2nd , 3rd , 4th gears/4th

, 3rd , 2nd , 1st gears) in combination with shift valve B.

Shift valve B Simultaneously switches three oil circuits using output pressure of shift solenoid valve

B in relation to driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and up-shifting (1st , 2nd , 3rd , 4th gears/4th

, 3rd , 2nd , 1st gears) in combination with shift valve A.

Shuttle shift valve S Switches hydraulic circuits to provide 3-2 timing control and overrun clutch control in

relation to the throttle opening.

Inactivates the overrun clutch to prevent interlocking in 4th gear when the throttle is

wide open.

Overrun clutch control valve Switches hydraulic circuits to prevent engagement of the overrun clutch simulta-

neously with application of the brake band in 4th gear. (Interlocking occurs if the

overrun clutch engages during D

4-2 relay valve Memorizes that the transmission is in 4th gear. Prevents the transmission from down-

shifting from 4th gear to 3rd and then to 2nd in combination with 4-2 sequence valve

and shift valves A and B when downshifting from 4th to 2nd gear.

4-2 sequence valve Prevents band servo pressure from draining before high clutch operating pressure

and band servo releasing pressure drain (from the same circuit) during downshifting

from 4th to 2nd gear.

gear operation.)

4

Servo charger valve An accumulator and a one-way orifice are used in the 2nd gear band servo oil circuit

to dampen shifting shock when shifting from 1st to 2nd gear.

To maintain adequate flowrate when downshifting from 4th or 3rd gear to 2nd gear,

the servo charger valve directs 2nd gear band servo hydraulic pressure to the circuit

without going through the one-way orifice when downshifting from 3rd or a higher

gear.

3-2 timing valve Prevents a late operation of the brake band when shifting selector lever from D to 1

or 2 position while driving in D

1 reducing valve Reduces low & reverse brake pressure to dampen engine-brake shock when down-

shifting from the 1 position 2nd gear to 1st gear.

Overrun clutch reducing valve Reduces oil pressure directed to the overrun clutch and prevents engine-brake shock.

In 1 and 2 positions, line pressure acts on the overrun clutch reducing valve to

increase the pressure-regulating point, with resultant engine brake capability.

Torque converter relief valve Prevents an excessive rise in torque converter pressure.

Torque converter clutch control valve,

torque converter clutch control plug and

torque converter clutch control sleeve

Shuttle shift valve D Switches hydraulic circuits so that output pressure of the torque converter clutch sole-

Activate or inactivate the lock-up function.

Also provide smooth lock-up through transient application and release of the lock-up

system.

noid valve acts on the lock-up valve in the D position of 2nd, 3rd and 4th gears. (In

the D position 1st gear, lock-up is inhibited.)

I Lock-up control is not affected in D position 2nd, 3rd or 4th gears, unless output

pressure of the torque converter clutch solenoid valve is generated by a signal

from the control unit.

.

3

AT-32

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Introduction

Introduction

The A/T system has two self-diagnostic systems.

The first is the emission-related on board diagnostic system (OBD-II) performed by the TCM in combination

with the ECM. The malfunction is indicated by the MIL (malfunction indicator lamp) and is stored as a DTC in

the ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the O/D OFF indicator lamp. The malfunction is

stored in the TCM memory. The detected items are overlapped with OBD-II self-diagnostic items. For detail,

refer to AT-46.

OBD-II Function for A/T System

The ECM provides emission-related on board diagnostic (OBD-II) functions for the A/T system. One function

is to receive a signal from the TCM used with OBD-related parts of the A/T system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-related part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indicator lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation to A/T system parts.

One or Two Trip Detection Logic of OBD-II

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored

in the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — First Trip

If the same malfunction as that experienced during the first test drive is sensed during the second test drive,

the MIL will illuminate. — Second Trip

A/T-related parts for which the MIL illuminates during the first or second test drive are listed below.

MIL

Items

One trip detection Two trip detection

NGAT0014

NGAT0182

NGAT0015

NGAT0015S01

NGAT0015S02

GI

MA

EM

LC

EC

FE

CL

MT

TF

PD

Shift solenoid valve A — DTC: P0750 (1108) X

Shift solenoid valve B — DTC: P0755 (1201) X

Throttle position sensor or switch — DTC: P1705 (1206) X

Except above X

The “trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC)

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

1. (

2. (

I 1st trip DTC No. is the same as DTC No.

I Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction.

No Tools) The number of blinks of the malfunction indicator lamp in the Diagnostic Test Mode II

(Self-Diagnostic Results) Examples: 1101, 1102, 1103, 1104, etc. For details, refer to “Malfunction Indicator Lamp (MIL)”, “ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION”,

These DTCs are controlled by NISSAN.

with CONSULT-II or GST) CONSULT-II or GST (Generic Scan Tool) Examples: P0705, P0710,

P0720, P0725, etc.

These DTCs are prescribed by SAE J2012.

(CONSULT-II also displays the malfunctioning component or system.)

However, in case of the Mode II and GST they do not indicate whether the malfunction is still

occurring or occurred in the past and returned to normal.

CONSULT-II can identify them as shown below. Therefore, using CONSULT-II (if available) is recommended.

EC-69

.

NGAT0016

NGAT0016S01

AT-33

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

OBD-II Diagnostic Trouble Code (DTC) (Cont’d)

A sample of CONSULT-II display for DTC is shown at left. DTC or 1st trip DTC of a malfunction is displayed

in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with CONSULT-II. Time data indicates how many times

the vehicle was driven after the last detection of a DTC.

SAT580J

If the DTC is being detected currently, the time data will be “0”.

SAT581J

If a 1st trip DTC is stored in the ECM, the time data will be “[245]”.

SAT582J

Freeze Frame Data and 1st Trip Freeze Frame Data

NGAT0016S0101

The ECM has a memory function, which stores the driving condition such as fuel system status, calculated

load value, engine coolant temperature, short term fuel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II

or GST. The 1st trip freeze frame data can only be displayed on the CONSULT-II screen, not on the GST. For

detail, refer to “CONSULT-II”, “ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION”,

EC-78

.

Only one set of freeze frame data (either 1st trip freeze frame data of freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the following priorities to update the data.

AT-34

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Priority Items

OBD-II Diagnostic Trouble Code (DTC) (Cont’d)

1 Freeze frame data Misfire — DTC: P0300 - P0306 (0701, 0603 - 0608)

Fuel Injection System Function — DTC: P0171 (0115), P0172 (0114), P0174 (0209), P0175

(0210)

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Both 1st trip freeze frame data and freeze frame data (along with the DTCs) are cleared when the ECM

memory is erased.

HOW TO ERASE DTC

The diagnostic trouble code can be erased by CONSULT-II, GST or ECM DIAGNOSTIC TEST MODE as

described following.

I If the battery terminal is disconnected, the diagnostic trouble code will be lost within 24 hours.

I When you erase the DTC, using CONSULT-II or GST is easier and quicker than switching the mode

selector on the ECM.

The following emission-related diagnostic information is cleared from the ECM memory when erasing DTC

related to OBD-II. For details, refer to “Emission-related Diagnostic Information”, “ON BOARD DIAGNOSTIC

SYSTEM DESCRIPTION”,

I Diagnostic trouble codes (DTC)

I 1st trip diagnostic trouble codes (1st trip DTC)

I Freeze frame data

I 1st trip freeze frame data

I System readiness test (SRT) codes

I Test values

EC-57

.

HOW TO ERASE DTC (WITH CONSULT-II)

I If a DTC is displayed for both ECM and TCM, it needs to be erased for both ECM and TCM.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 5

seconds and then turn it ON (engine stopped) again.

2. Turn CONSULT-II ON and touch “A/T”.

3. Touch “SELF-DIAG RESULTS”.

4. Touch “ERASE”. (The DTC in the TCM will be erased.) Then touch “BACK” twice.

5. Touch “ENGINE”.

6. Touch “SELF-DIAG RESULTS”.

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

NGAT0016S02

NGAT0016S03

GI

MA

EM

LC

EC

FE

CL

MT

TF

PD

AX

SU

BR

AT-35

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

OBD-II Diagnostic Trouble Code (DTC) (Cont’d)

SAT583J

HOW TO ERASE DTC (WITH GST)

NGAT0016S04

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 5

seconds and then turn it ON (engine stopped) again.

2. Perform “OBD-II SELF-DIAGNOSTIC PROCEDURE (No Tools)”. Refer to AT-46. (The engine warm-up

step can be skipped when performing the diagnosis only to erase the DTC.)

3. Select Mode 4 with Generic Scan Tool (GST). For details, refer to “Generic ScanTool (GST)”, “ON BOARD

DIAGNOSTIC SYSTEM DESCRIPTION”,

HOW TO ERASE DTC (NO TOOLS)

EC-89

.

NGAT0016S05

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 5

seconds and then turn it ON (engine stopped) again.

2. Perform “TCM SELF-DIAGNOSTIC PROCEDURE (No Tools)”. Refer toAT-47. (The engine warm-up step

can be skipped when performing the diagnosis only to erase the DTC.)

3. Change the diagnostic test mode from Mode II to Mode I by turning the mode selector on the ECM.

Refer to “HOW TO SWITCH DIAGNOSTIC TEST MODES”, “Malfunction Indicator Lamp (MIL)”, “ON

BOARD DIAGNOSTIC SYSTEM DESCRIPTION”,

EC-71

.

AT-36

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Malfunction Indicator Lamp (MIL)

SAT964I

Malfunction Indicator Lamp (MIL)

1. The malfunction indicator lamp will light up when the ignition

switch is turned ON without the engine running. This is for

checking the lamp.

I If the malfunction indicator lamp does not light up, refer to

“System Description”, “WARNING LAMPS”,

(Or see MIL & Data link connector in EC section.)

2. When the engine is started, the malfunction indicator lamp

should go off.

If the lamp remains on, the on board diagnostic system has

detected an emission-related (OBD-II) malfunction. For detail,

refer to “ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION”.

EL-73

CONSULT-II

After performing “SELF-DIAGNOSTIC PROCEDURE (WITH CONSULT-II)” (AT-38), place check marks for results on the “Diagnostic Worksheet”, AT-55. Reference pages are provided following the

items.

NOTICE:

1) The CONSULT-II electrically displays shift timing and lock-up

timing (that is, operation timing of each solenoid).

Check for time difference between actual shift timing and the

CONSULT-II display. If the difference is noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical parts using applicable diagnostic procedures.

2) Shift schedule (which implies gear position) displayed on

CONSULT-II and that indicated in Service Manual may differ

slightly. This occurs because of the following reasons:

I Actual shift schedule has more or less tolerance or allowance,

I Shift schedule indicated in Service Manual refers to the point

where shifts start, and

I Gear position displayed on CONSULT-II indicates the point

where shifts are completed.

3) Shift solenoid valve “A” or “B” is displayed on CONSULT-II at

the start of shifting. Gear position is displayed upon completion

of shifting (which is computed by TCM).

4) Additional CONSULT-II information can be found in the Operation Manual supplied with the CONSULT-II unit.

NGAT0183

.

NGAT0184

GI

MA

EM

LC

EC

FE

CL

MT

TF

PD

AX

SU

BR

ST

RS

BT

HA

AT-37

SC

EL

IDX

CONSULT-II (Cont’d)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

SAT580J

SAT584J

SELF-DIAGNOSTIC PROCEDURE (WITH CONSULT-II)

NGAT0184S01

1. Turn on CONSULT-II and touch “ENGINE” for OBD-II detected

items or touch “A/T” for TCM self-diagnosis.

If A/T is not displayed, check TCM power supply and ground

circuit. Refer to AT-92. If result is NG, refer to “POWER SUPPLY ROUTING”,

EL-9

.

2. Touch “SELF-DIAG RESULTS”.

Display shows malfunction experienced since the last erasing

operation.

CONSULT-II performs REAL-TIME SELF-DIAGNOSIS.

Also, any malfunction detected while in this mode will be displayed at real time.

SELF-DIAGNOSTIC RESULT TEST MODE

NGAT0184S02

Detected items

(Screen terms for CONSULT-II, “SELFDIAG RESULTS” test mode)

“A/T” “ENGINE”

PNP switch circuit I TCM does not receive the correct

—

Revolution sensor I TCM does not receive the proper

VHCL SPEED

SEN·A/T

Vehicle speed sensor (Meter) I TCM does not receive the proper

VHCL SPEED

SEN·MTR

A/T 1st gear function I A/T cannot be shifted to the 1st

—

A/T 2nd gear function I A/T cannot be shifted to the 2nd

—

PNP SW/CIRC

VEH SPD SEN/CIR

AT

—

A/T 1ST GR

FNCTN

A/T 2ND GR

FNCTN

Malfunction is detected when ...

voltage signal (based on the gear

position) from the switch.

voltage signal from the sensor.

voltage signal from the sensor.

gear position even if electrical circuit is good.

gear position even if electrical circuit is good.

TCM self-diagnosis OBD-II (DTC)

Available by

O/D OFF

indicator lamp or

“A/T” on CONSULT-II

— P0705

X P0720

X—

— P0731*1

— P0732*1

Available by

malfunction

indicator lamp*2,

“ENGINE” on CON-

SULT-II or GST

A/T 3rd gear function I A/T cannot be shifted to the 3rd

gear position even if electrical circuit is good.

—

A/T 3RD GR

FNCTN

AT-38

— P0733*1

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont’d)

Detected items

(Screen terms for CONSULT-II, “SELFDIAG RESULTS” test mode)

“A/T” “ENGINE”

A/T 4th gear function I A/T cannot be shifted to the 4th

—

A/T TCC S/V function (lock-up) I A/T cannot perform lock-up even

—

Shift solenoid valve A I TCM detects an improper voltage

SHIFT

SOLENOID/V A

Shift solenoid valve B I TCM detects an improper voltage

SHIFT

SOLENOID/V B

Overrun clutch solenoid valve I TCM detects an improper voltage

OVERRUN

CLUTCH S/V

T/C clutch solenoid valve I TCM detects an improper voltage

T/C CLUTCH

SOL/V

A/T 4TH GR

FNCTN

A/T TCC S/V

FNCTN

SFT SOL A/CIRC

SFT SOL B/CIRC

O/R CLUCH SOL/

CIRC

TCC SOLENOID/

CIRC

Malfunction is detected when ...

gear position even if electrical circuit is good.

if electrical circuit is good.

drop when it tries to operate the

solenoid valve.

drop when it tries to operate the

solenoid valve.

drop when it tries to operate the

solenoid valve.

drop when it tries to operate the

solenoid valve.

TCM self-diagnosis OBD-II (DTC)

Available by

O/D OFF

indicator lamp or

“A/T” on CONSULT-II

— P0734*1

— P0744*1

X P0750

X P0755

X P1760

X P0740

Available by

malfunction

indicator lamp*2,

“ENGINE” on CON-

SULT-II or GST

GI

MA

EM

LC

EC

FE

CL

MT

TF

PD

Line pressure solenoid valve I TCM detects an improper voltage

LINE PRESSURE

S/V

Throttle position sensor

Throttle position switch

THROTTLE POSI

SEN

Engine speed signal I TCM does not receive the proper

ENGINE SPEED SIG

A/T fluid temperature sensor I TCM receives an excessively low

BATT/FLUID TEMP

SEN

TCM (RAM) I TCM memory (RAM) is malfuncCONTROL UNIT

(RAM)

TCM (ROM) I TCM memory (ROM) is malfuncCONTROL UNIT

(ROM)

L/PRESS SOL/

CIRC

TP SEN/CIRC A/T

ATF TEMP SEN/

CIRC

—

—

drop when it tries to operate the

solenoid valve.

I TCM receives an excessively low

or high voltage from the sensor.

voltage signal from the ECM.

or high voltage from the sensor.

tioning.

tioning.

X P0745

AX

SU

X P1705

BR

X P0725

X P0710

ST

RS

BT

——

HA

——

SC

EL

AT-39

IDX

CONSULT-II (Cont’d)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Detected items

(Screen terms for CONSULT-II, “SELFDIAG RESULTS” test mode)

“A/T” “ENGINE”

TCM EEPROM I TCM memory (EEPROM) is malCONTROL UNIT

(EEPROM

Initial start I This is not a malfunction message

INITIAL START

No failure

(NO SELF DIAGNOSTIC FAILURE INDICATED FURTHER TESTING MAY BE

REQUIRED**)

X: Applicable