Page 1

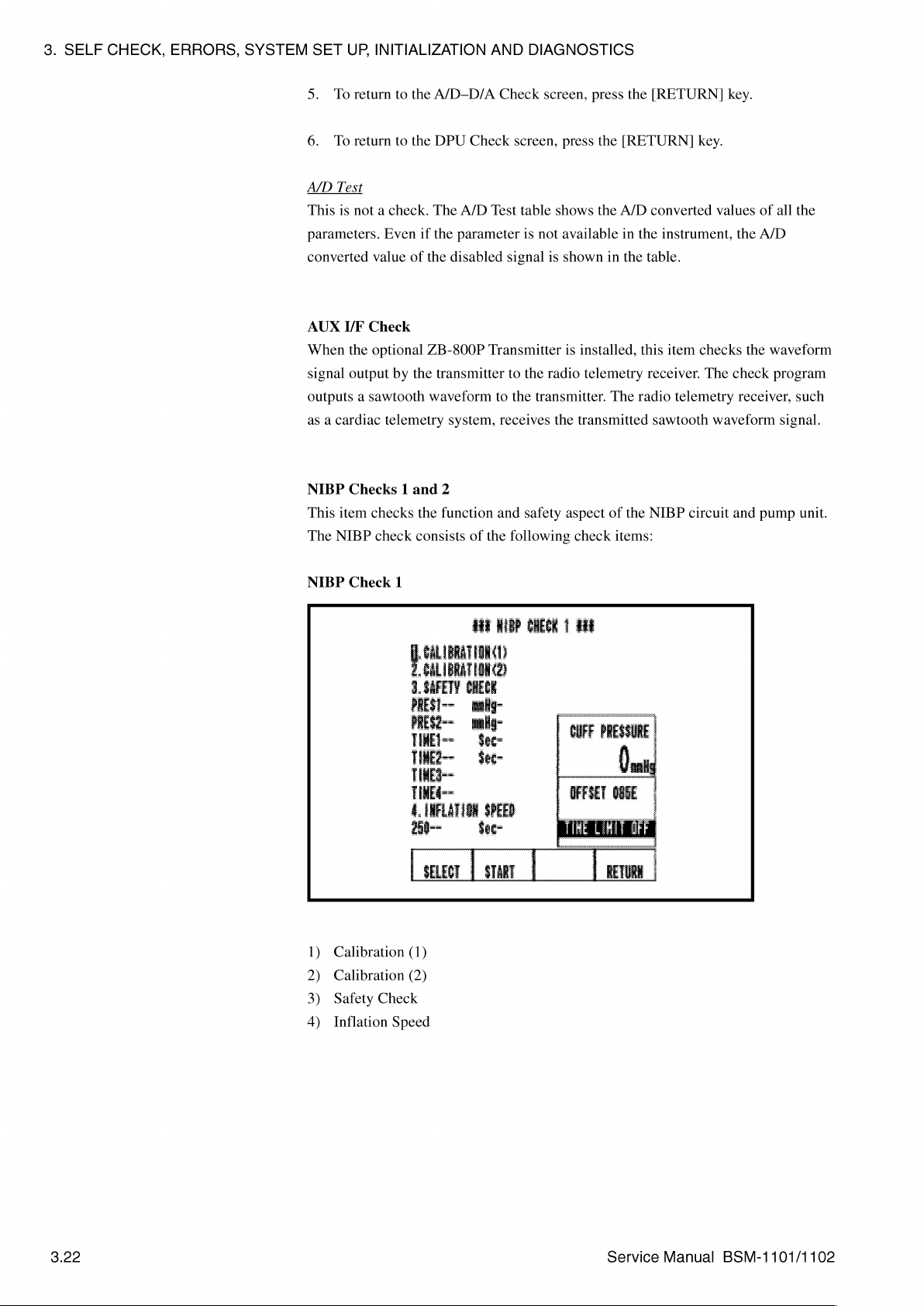

Life

Scope

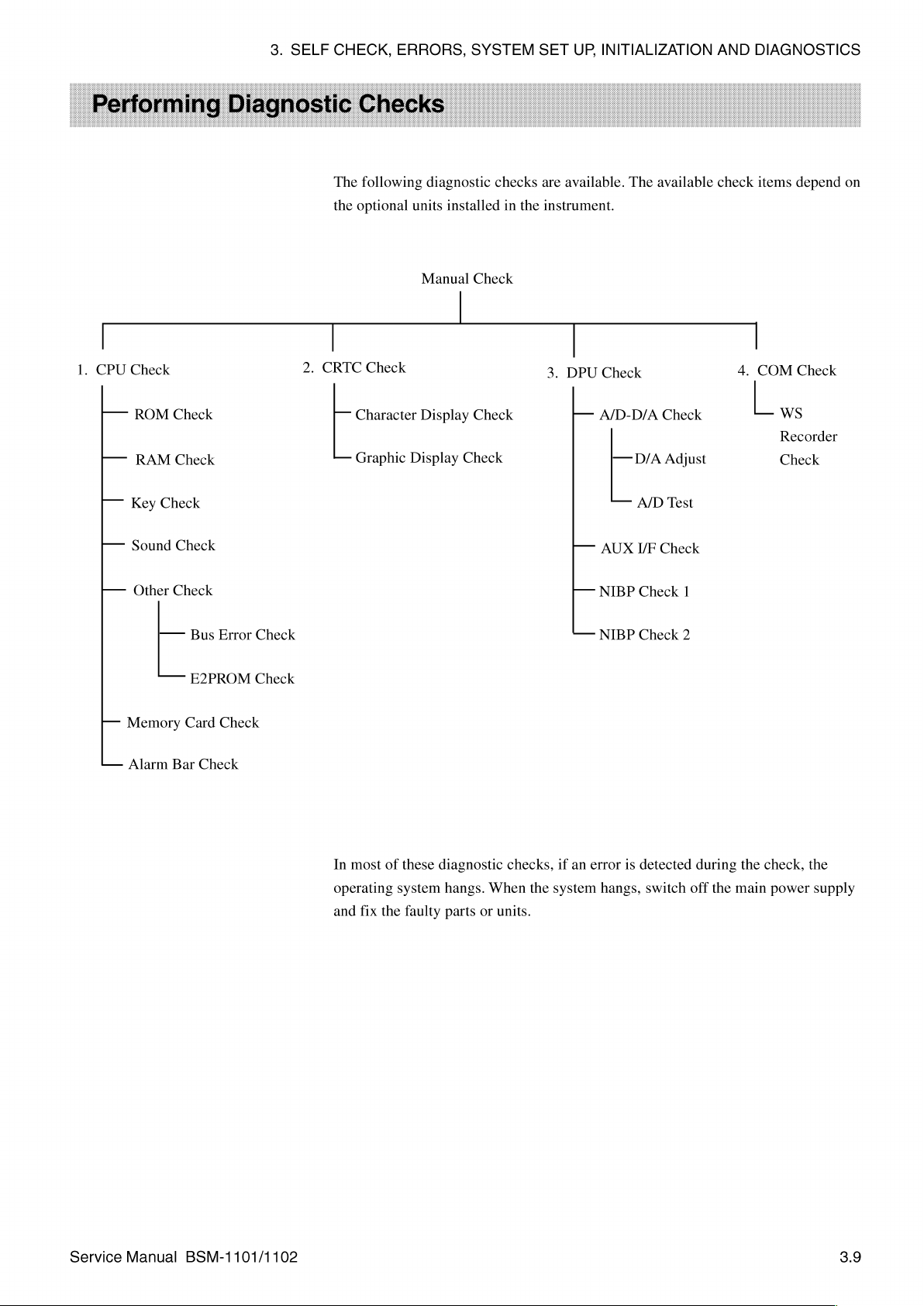

EC

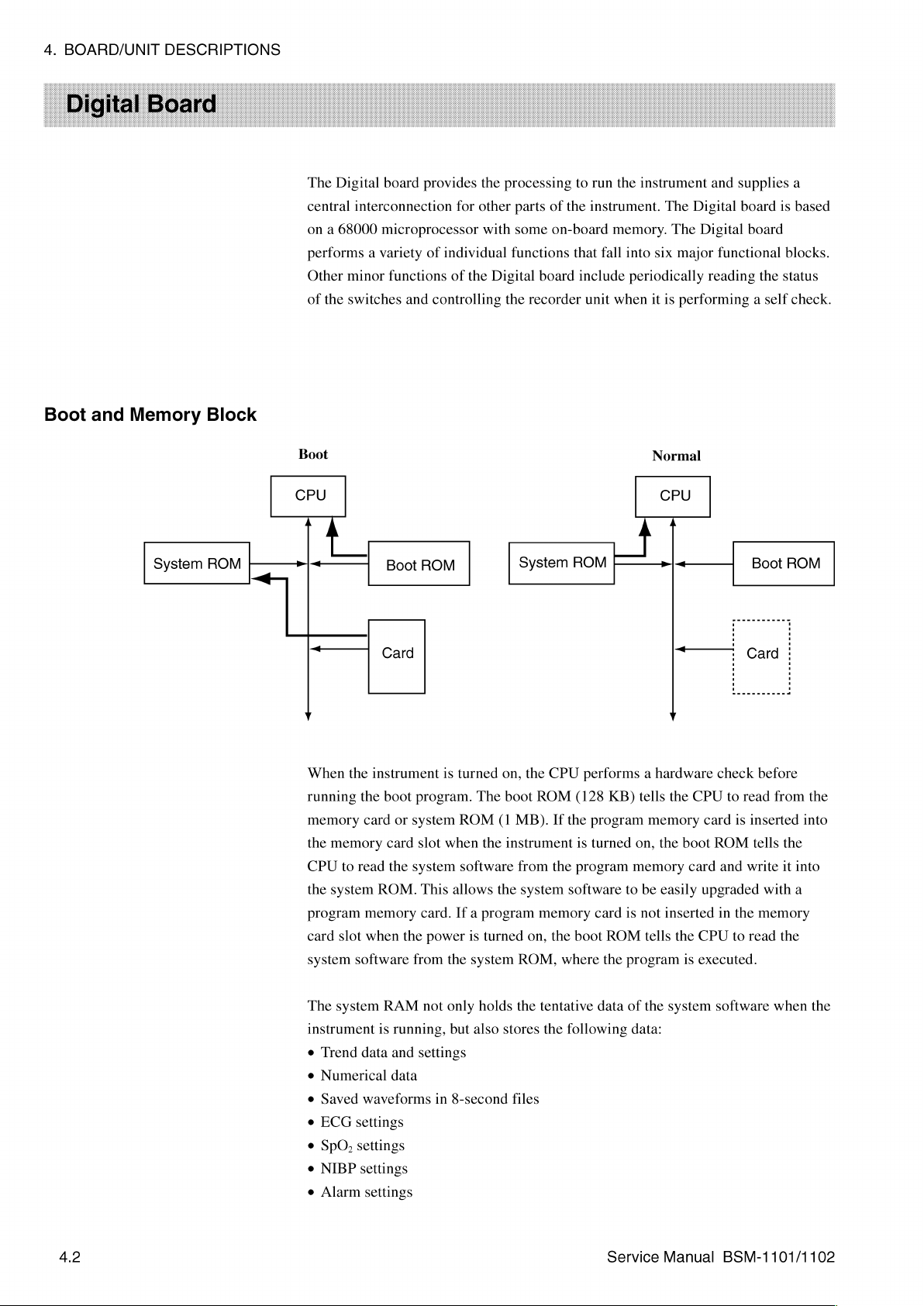

BEDSIDE

BSM-1101/1102

MONITOR

0634-001334B

Page 2

Page 3

Page 4

Page 5

Page 6

0Ο,

Problems

Diagnostic

BoardÜnitDescriptions..........................................

Disassembly

Maintenance

Replaceable

QI-101P

Network

General

Parts

Troubleshooting

Manual

Functional

Removing

Maintenance

Check

Power

on

Мапиа|

Functional

Digital

Analog

General

Ветоута

Disassembling

AssemblingAA-101P................................

Measuring

External

safetyCheck......................................

Check

СПеск

Circuit

Circuit

and

of

Parts

Card

i

Description

Check

Block

the

Network

...........................................

Measuring

External

safetyCheck......................................

Check

of

.Ne

Self

Check

.............

Block

Diagram

1…… せ …

せ せ

eo

ASSEMDIY

Information

АА-101Р

and

Check

Measuring

................

Нот

AA-101P

Test

Equipment

i

List

ii

eee

.4

Diagram

and

Check

Communication

.............

Card

Test

Equipment

i

2000000000000

"ie

.........

В$М-1101/1102

eo

2000000000000

Parameters

e

from

the

e

нии

"VV.

Bedside

нии

000

nn

............

on

PK PK

Monitor

nK O KKK

PKR KRK

o

KKK

KKK PKR ARR

KK

PRK

PK

KKK KKK

ーーーーーー………・

PK

KR

PPK

KR P KKK

eee

eee

eee

nn n n n nn

K K K

KK KKK KKK

AKE

KKK

PREPARE

eee

нинининненнне:

KRK

KKK PKR

aneen

eee

ee

CONTENTS

KAKAO K nné

es

eee

ELEG

KKK

Kn

rn

aneen

P

KKK KRK

PARK

KRK

KK

LEE

EEEE

rn

aneen

nn

ner

εν

ner

A.3

A.4

A.4

А.4

A.8

A.8

A.9

A.9

A.10

A.10

A.10

A.11

A.12

A.12

A.12

A.12

A.12

A.13

A.14

A.15

A.15

A.15

A.15

A.16

A.22

A.23

A.23

A.23

A.23

A.24

A.24

Service

Manual

BSM-1101/1102

C.5

Page 7

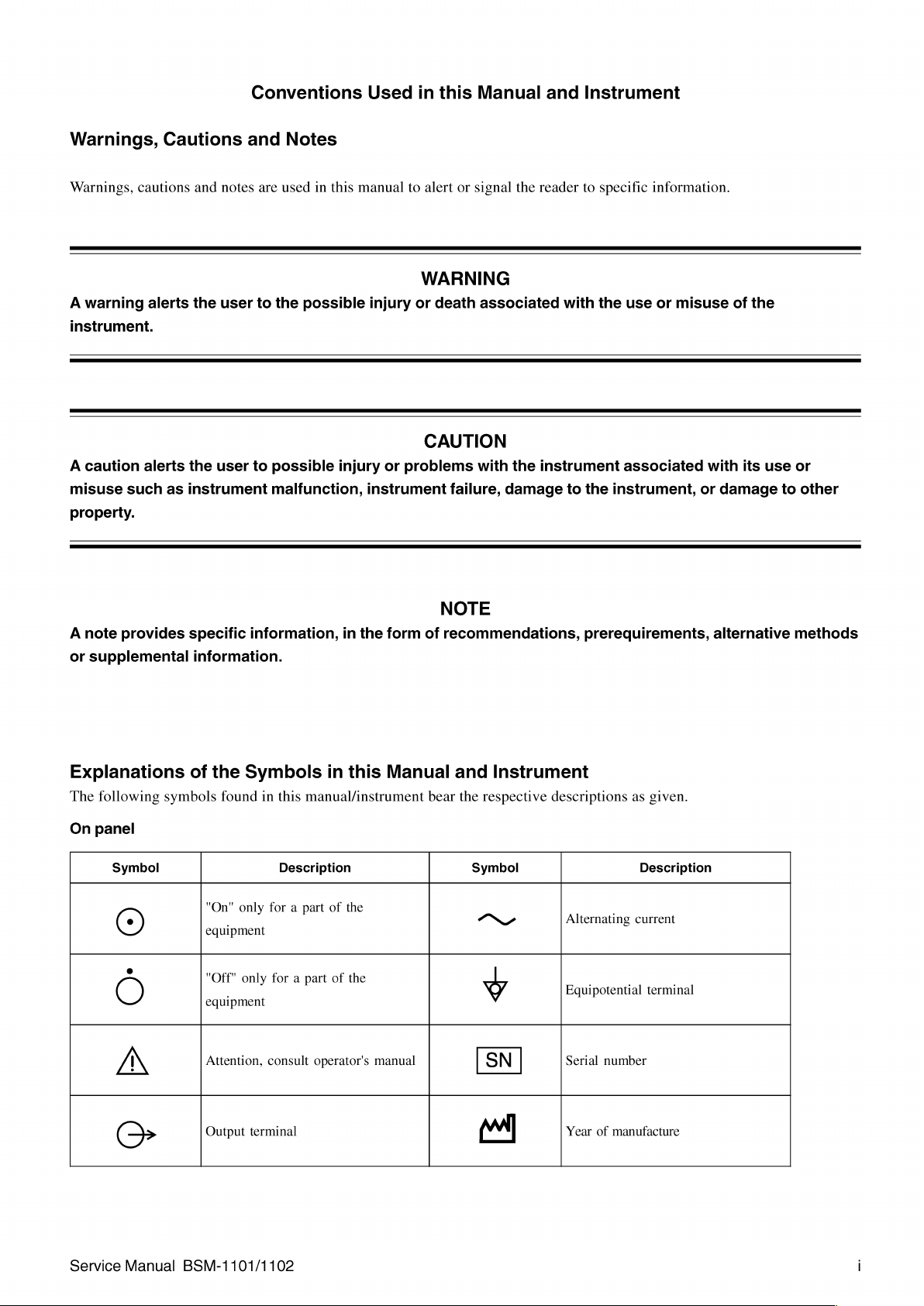

Conventions

Used

in

this

Manual

and

Instrument

Warnings,

Warnings,

A

warning

instrument.

A

caution

misuse

property.

cautions

alerts

alerts

such

Cautions

and

notes

the

user

the

user

as

instrument

and

Notes

are

used

to

the

to

possible

malfunction,

in

this

possible

injury

manual

to

injury

or

problems

instrument

alert

or

WARNING

or

death

CAUTION

failure,

signal

the

associated

with

the

damage

reader

to

specific

with

the

instrument

to

the

information.

use

or

misuse

associated

instrument,

with

or

of

the

its

damage

use

to

or

other

A

note

provides

or

supplemental

Explanations

The

following

On

panel

Symbol

(9)

symbols

specific

information.

of

information,

the

Symbols

found

"On"

only

|

equipment

"Off"

only

|

equipment

in

in

in

this

manual/instrument

Description

for a part

for a part

of

of

the

this

the

the

form

of

Manual

bear

NOTE

recommendations,

and

Instrument

the

respective

Symbol

ONY

prerequirements,

descriptions

Alternating

Equipotential

|

| | |

as

given.

Description

current

terminal

alternative

methods

/N

Service

Manual

Attention,

Output

terminal

BSM-1101/1102

consult

operator's

manual

Serial

number

Year

of

manufacture

Page 8

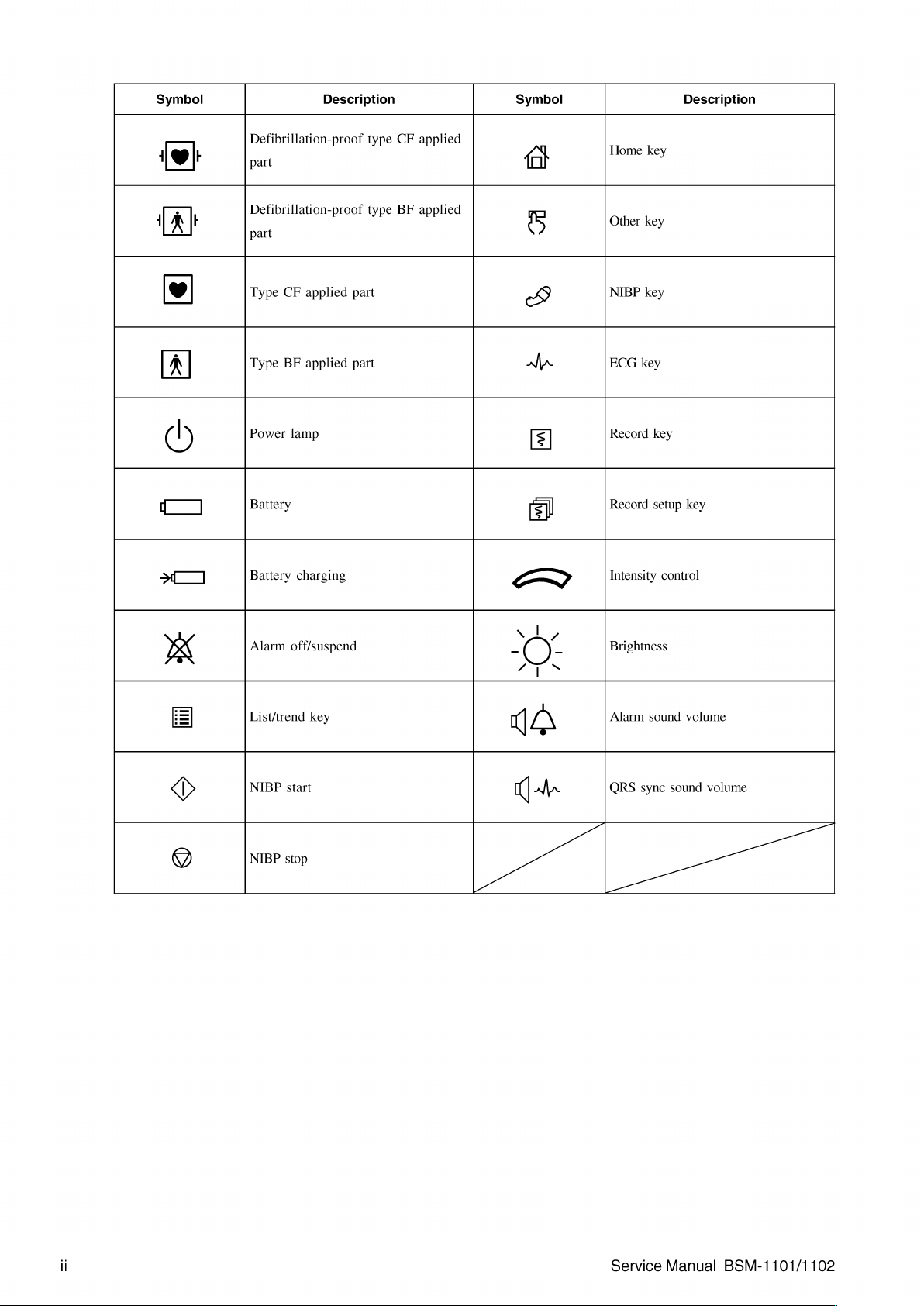

Symbol

Description

Symbol

Description

1 y |

| À E

®

A

(Г

Ч

|

>]

Defibrillation-proof

part

Defibrillation-proof

part

Type

CF

Type

BF

Power

lamp

Battery

Battery

applied

applied

charging

part

part

type

type

CF

BF

applied

applied

<

(at

5

©

a

>

Home

key

Other

key

NIBP

key

ECG

key

Record

key

Record

setup

Intensity

control

key

Alarm

off/suspend

B

|

im

©

|

9

List/trend

NIBP

start

NIBP

stop

key

"O:

Brightness

Alarm

sound

QRS

sync

volume

sound

volume

Service

Manual

BSM-1101/1102

Page 9

On

screen

Symbol

Dx

€

Alarm

Alarm

minutes

Alarm

QRS

Description

recording

suspend

recording

syne

mark

off

with

remaining

Symbol

[|<

4

G

Out

of

paper

Paper

magazine

Manual

Periodic

Description

open

recording

recording

PR

Ki

CA

Other

Symbol

ES

CE

0086

Pulse

sync

Network

mark

communicatin

5

(O

Description

Recycle

The

CE

mark

is a protected

conformity

Community.

comply

Medical

93/42/EEC.

mark

with

Device

of

the

The

products

the

requirements

Directive

European

herewith

of

the

Calibration

Service

Manual

BSM-1101/1102

Page 10

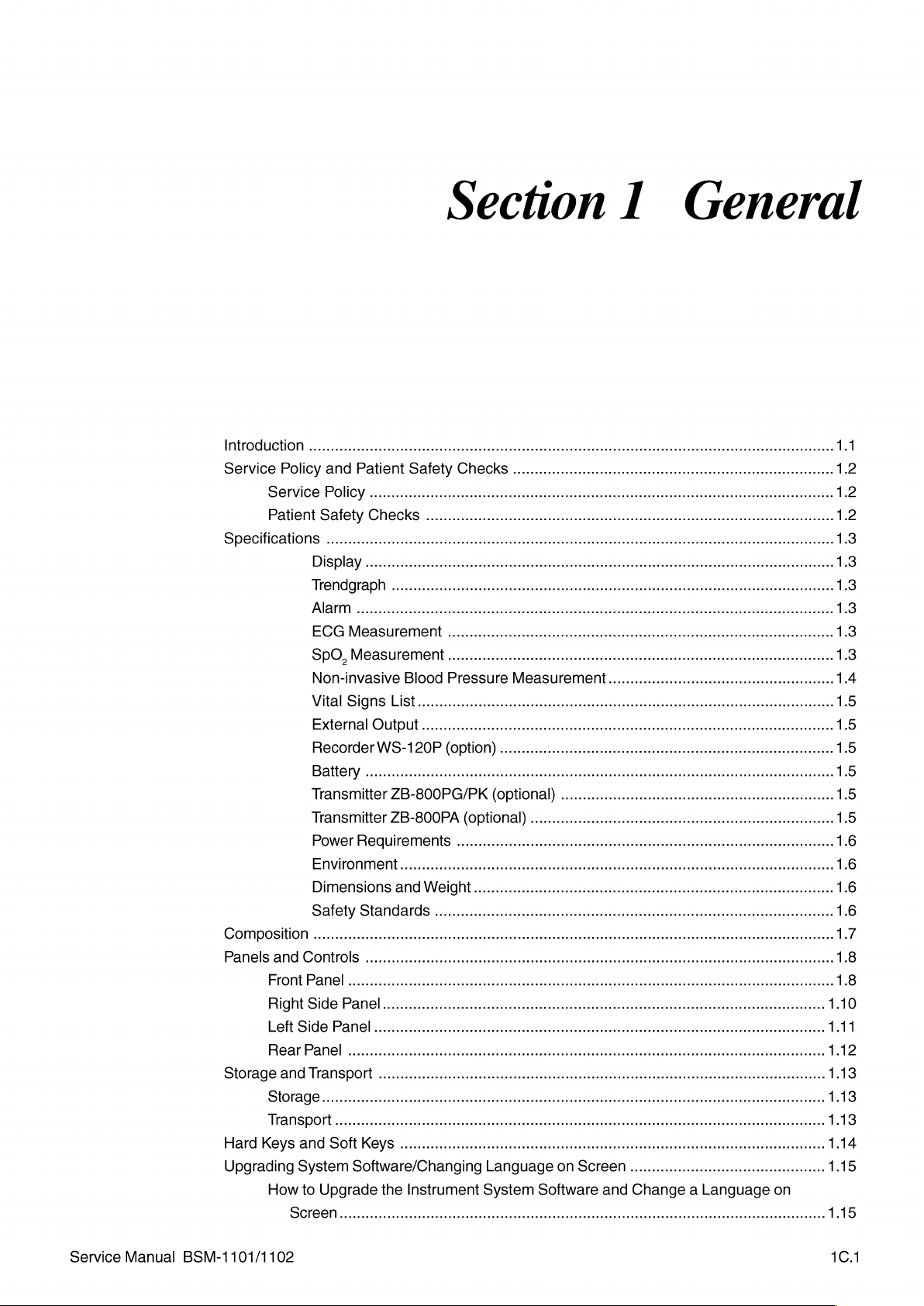

Section

1

General

Introductiom

Service

Specifications

Composition

Panels

Storage

Hard

Keys

Upgrading

.4

Policy

and

Patient

Service

PatientSafetyChecks

and

Front

Right

leftSidePanel......................................

Rear

Storage...................

TTANSPOTNt

How

Policy

.4

DISPÍQY

TrendgrapP

Аагт

...........

ECGMeasuremeni..............................

SpO,

Measurement

Non-invasiveBloodPressureMeasurement.............».»..»...............

VitalSignsList...................................

External

Recorder

Battery … せ

Transmitter

Transmitter

PowerReguiremenis

ENVIFONMENT............

DimensionsandWelight.....................................

Safety

Controls

Pane|

Side

Panel

and

TranSpott

and

System

to

능 아 6611

StandardS

ини

.4

Panhel................

eee

i

..........

Soft

Keys

Software/Changing

Upgrade

./

이이

Safety

.4

cooooccooccococnononcnncncnncconcncnncnonnnn

eee

Output

WS-120P

ee

ZB-800PG/PK

ZB-800PA

.4

.......................

i

Checks

............................................

(Option)

.................

...............

(optional)

(optional)

.........................................

e

i

Language

the

Instrument

이니 이 이 이 미

이 다 파 파 파 피 파 파 마 파 파 파 파 마 파 마 파 다 마 파 마 파 파 파 파 마 파 마 파 파 파 파 마 마 다 파 파 마 파 마 파 다 다 디 이니

System

nan

nn

narra

nr

rn

ини

pp

0000000000000

on

Software

nn n KK

Screen

and

eee

rn

rn

nr

rnrrr

rn

nrrnnnrrnrrrnnrrnnrrrnnrrnnannnnes

K

KK

KK

KKK O KKK

KKK

e

e

eee

nn

P

KKK P KKK P KKK

eee

KRKA

KK

KK P KK KR P KKK

„ee

Change a Language

ne

nen

KKK

KKK

ss

eee

kk

n K n

seen K Kan

KK

KR

KAKAO

on

1.1

nen

1.2

1.2

enao

1.2

1.3

1.3

KKK

tn

1.3

1.3

1.3

Rent

ne

1.3

1.4

1.5

1.5

nn n 1.5

1.5

1.5

ーー

1.5

1.6

ーー

1.6

n

1.6

1.6

KK

1.7

1.8

1.8

KARR

RKK

1.10

1.11

1.12

1.13

1.13

1.13

KKK K nn n 1.14

1.15

1.15

Service

Manual

BSM-1101/1102

1C.1

Page 11

This

service

provides

and

the

repair

the

“instrument”

All

replaceable

clearly

listed

and

repair.

manual

is

intended

information

BSM-1101

in

this

service

parts

or

subassemblies

and

illustrated

for

required

or

BSM-1102

manual).

with

use

by

to

understand,

Bedside

of

exploded

qualified

troubleshoot,

Monitor

this

instrument

parts

views

service

(referred

and

to

aid

1.

personnel

service,

to

its

optional

you

in

parts

GENERAL

only.

It

maintain,

as

the

units

location

are

Section

6,

qualified

describes

Although

service

manual

personnel

before

“Maintenance,”

service

personnel

the

maintenance

the

operator’s

attempting

to

thoroughly

describes

only.

that

can

manual

to

troubleshoot,

the

The

maintenance

be

is

written

read

both

maintenance

performed

primarily

the

service

service,

that

section

by

the user.

for

manual

or

maintain

should

in

the

the

user,

and

the

be

performed

operator’s

it

is

important

the

operator’s

instrument.

by

manual

for

Service

Manual

BSM-1101/1102

1.1

Page 12

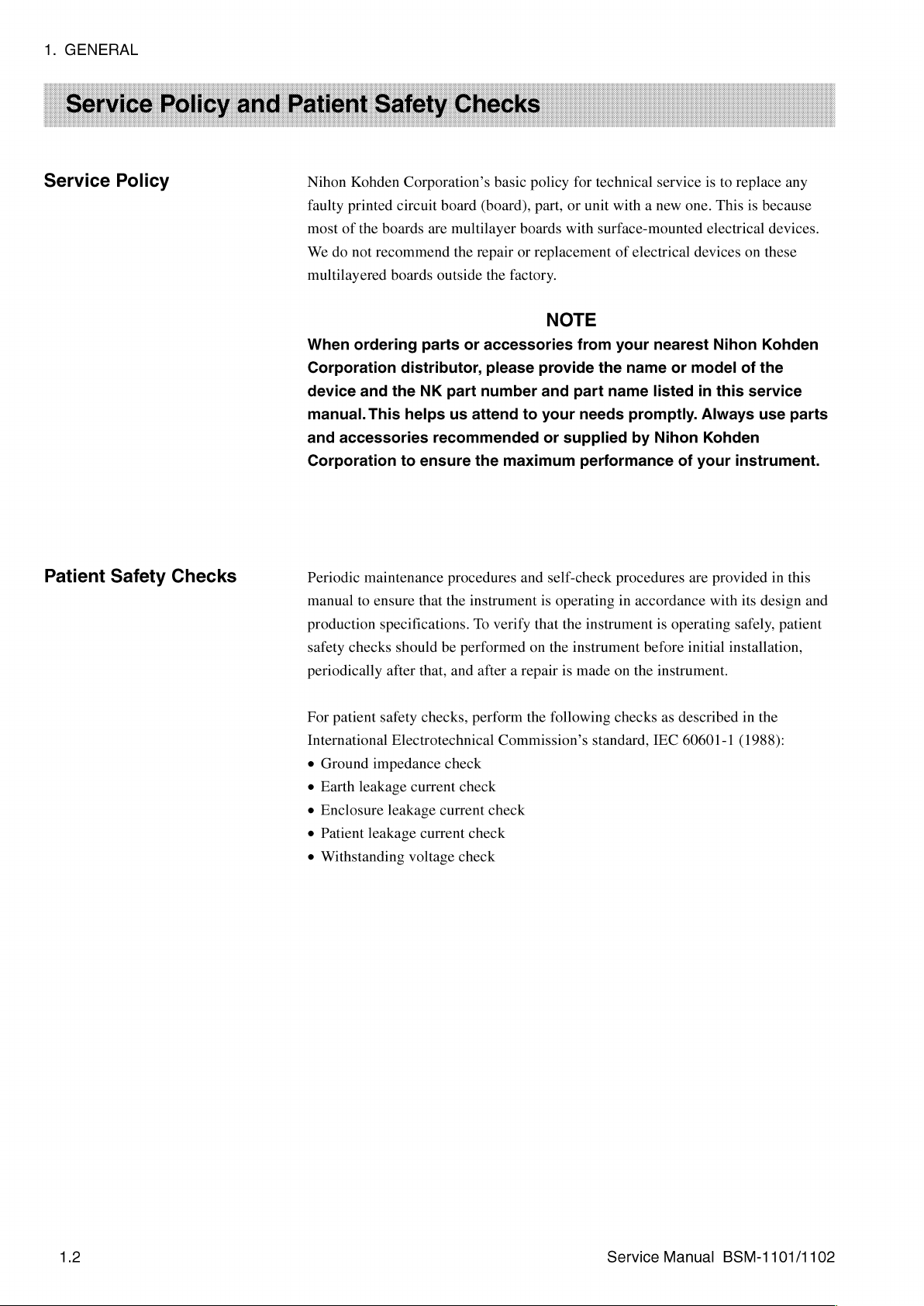

1.

GENERAL

Service

Policy

Nihon

Kohden

faulty

printed

most

of

the

boards

We

do

not

recommend

multilayered

When

device

and

ordering

Corporation

and

manual.

Corporation

This

accessories

Corporation’s

circuit

board

are

multilayer

the

boards

outside

parts

or

distributor,

the

NK

part

helps

us

recommended

to

ensure

basic

policy

(board),

boards

repair

or

the

factory.

accessories

please

number

attend

the

to

maximum

for

technical

part,

or

unit

with

surface-mounted

replacement

NOTE

from

provide

and

your

or

the

part

needs

supplied

performance

service

with a new

of

electrical

your

nearest

name

name

listed

promptly.

by

Nihon

or

of

one.

model

devices

in

your

is

to

replace

This

is

electrical

on

Nihon

of

this

service

Always

Kohden

instrument.

any

because

devices.

these

Kohden

the

use

parts

Patient

Safety

Checks

Periodic

manual

production

safety

periodically

For

International

e

e

e

e

e

maintenance

to

ensure

specifications.

checks

after

patient

Ground

Earth

Enclosure

Patient

Withstanding

safety

Electrotechnical

impedance

leakage

leakage

leakage

that the

should

that,

checks,

current

current

voltage

procedures

instrument

To

verify

be

performed

and

after a repair

perform

check

check

current

check

check

check

and

self-check

is

operating

that

the

on

the

instrument

is

made

the

following

Commission’s

procedures

in

accordance

instrument

before

on

the

checks

standard,

are

provided

with

is

operating

initial

instrument.

as

described

IEC

60601-1

in

this

its

design

and

safely,

patient

installation,

in

the

(1988):

1.2

Service

Manual

BSM-1101/1102

Page 13

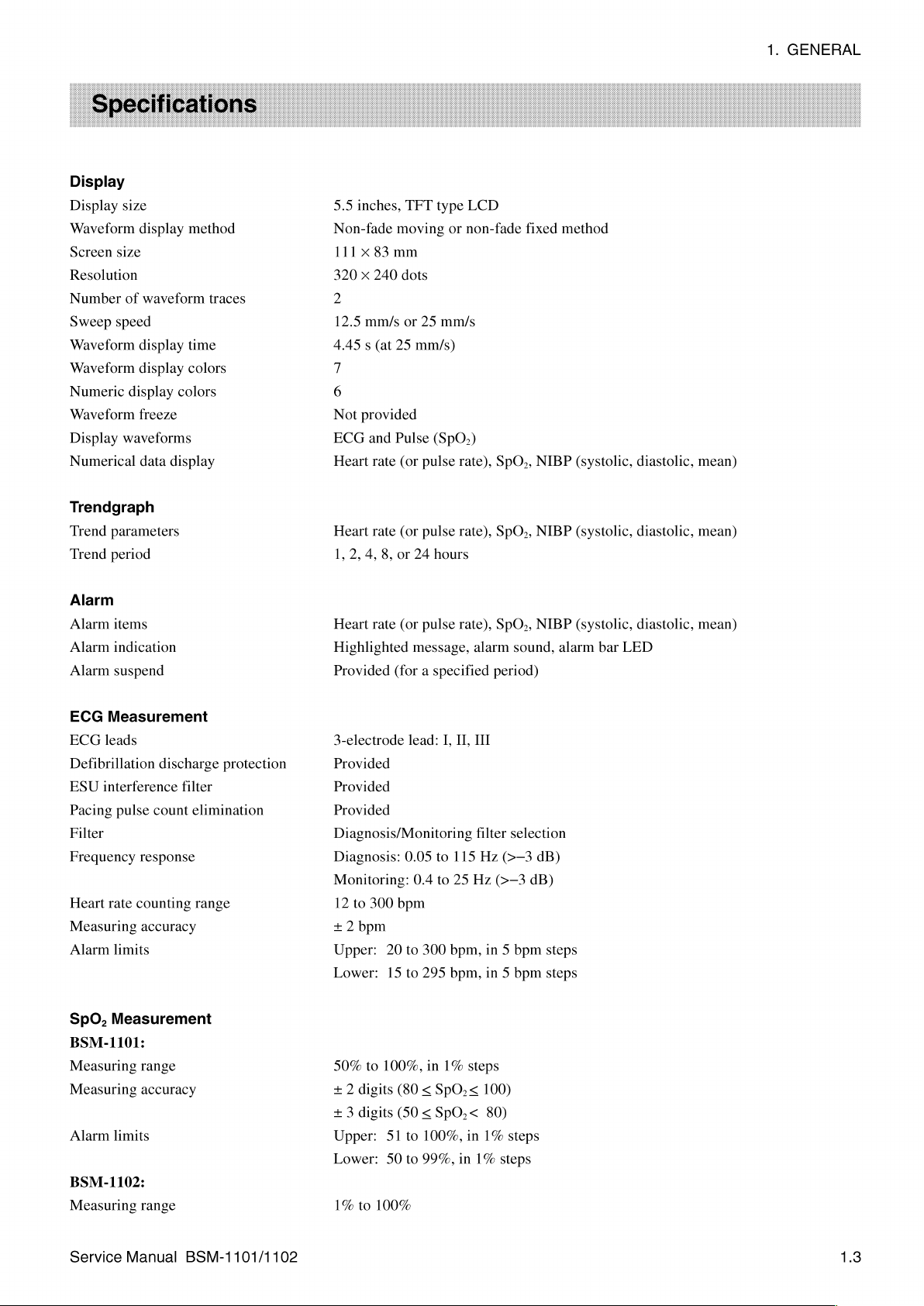

Display

Display

size

Waveform

Screen

size

Resolution

Number

Sweep

of

speed

Waveform

Waveform

Numeric

display

Waveform

Display

waveforms

Numerical

display

waveform

display

display

colors

freeze

data

display

method

traces

time

colors

5.5

inches,

Non-fade

111 x 83

320 x 240

2

12.5

mm/s

4.45 s (at

7

6

Not

provided

ECG

and

Heart

rate

TFT

moving

mm

dots

or

25

25

mm/s)

Pulse

(or

pulse

type

LCD

or

non-fade

mm/s

(SpO,)

rate),

fixed

SpO,,

NIBP

method

(systolic,

diastolic,

mean)

1.

GENERAL

Trendgraph

Trend

parameters

Trend

period

Alarm

Alarm

items

Alarm

indication

Alarm

suspend

ECG

Measurement

ECG

leads

Defibrillation

ESU

interference

Pacing

pulse

discharge

count

Filter

Frequency

Heart

Measuring

Alarm

rate

limits

response

counting

accuracy

protection

filter

elimination

range

Heart

rate

(or

pulse

rate),

1,

2,

4,

8,

or

24

hours

Heart

rate

(or

pulse

rate),

Highlighted message,

Provided

3-electrode

(for a specified

lead:

I,

II,

Provided

Provided

Provided

Diagnosis/Monitoring

Diagnosis:

Monitoring:

12

to

300

0.05

bpm

0.4

to

to

115

25

+ 2 bpm

Upper:

Lower:

20

15

to

to

300

295

bpm,

bpm,

SpO.,

SpO.,

alarm

period)

III

filter

Hz

(>—3

Hz

(>—3

in 5 bpm

in 5 bpm

NIBP

NIBP

sound,

alarm

selection

dB)

dB)

steps

steps

(systolic,

(systolic,

bar

LED

diastolic,

diastolic,

mean)

mean)

SpO,

Measurement

BSM-1101:

Measuring

Measuring

Alarm

limits

BSM-1102:

Measuring

Service

range

accuracy

range

Manual

BSM-1101/1102

50%

to

100%,

+ 2 digits

+ 3 digits

Upper:

Lower:

1%

to

51

50

100%

in

1%

(80 < SpO;<

(50 < SpO,<

to

100%,

to

99%,

in

steps

100)

80)

in

1%

1%

steps

steps

1.3

Page 14

1.

GENERAL

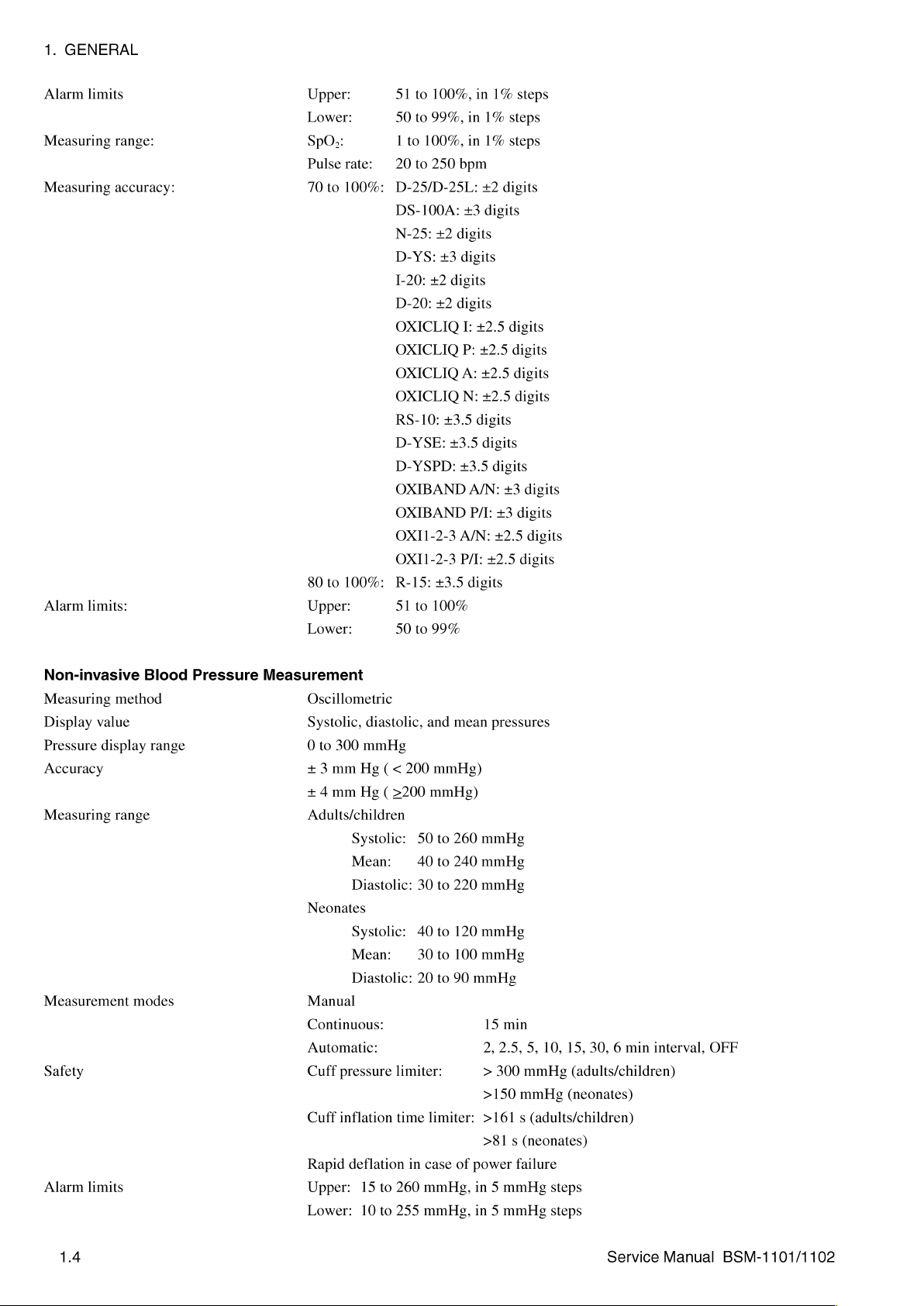

Alarm

limits

Measuring

Measuring

Alarm

limits:

range:

accuracy:

Upper:

Lower:

SDO>:

Pulse

70

to

80

to

Upper:

Lower:

rate:

100%:

100%:

51

to

100%,

50

to

99%,

1

to

100%,

20

to

250

bpm

D-25/D-25L:

DS-100A:

N-25:

D-YS:

1-20:

D-20:

OXICLIQ

OXICLIQ

OXICLIQ

OXICLIQ

RS-10:

D-YSE:

D-YSPD:

+2

+3

+2

+2

+3.5

+3

digits

digits

digits

digits

I:

P:

A:

N:

+3.5

+3.5

OXIBAND

OXIBAND

OXI1-2-3

OXI1-2-3

R-15:

51

50

to

to

A/N:

P/I:

+3.5

100%

99%

in

1%

in

1%

in

1%

+2

digits

digits

+2.5

+2.5

+2.5

+2.5

digits

digits

digits

A/N:

P/I:

+3

+2.5

£2.5

digits

steps

steps

steps

digits

digits

digits

digits

+3

digits

digits

digits

digits

Non-invasive

Measuring

Display

Pressure

value

display

Accuracy

Measuring

Measurement

Safety

Alarm

limits

Blood

method

range

range

modes

Pressure

Measurement

Oscillometric

Systolic,

0

to

+3

+ 4 mm

Adults/children

Neonates

Manual

Continuous:

Automatic:

Cuff

Cuff

Rapid

Upper:

Lower:

diastolic,

300

mmHg

mm

Hg ( <

Hg ( >200

Systolic:

Mean:

Diastolic:

Systolic:

Mean:

Diastolic:

pressure

inflation

deflation

15

to

10

to

and

200

mmHg)

mmHg)

50

to

40

to

30

to

40

to

30

to

20

to

limiter:

time

limiter:

in

case

260

mmHg,

255

mmHg,

mean

pressures

260

mmHg

240

mmHg

220

mmHg

120

mmHg

100

mmHg

90

mmHg

15

min

2,

2.5,

5,

10,

15,

>

300

>150

mmHg

mmHg

(adults/children)

(neonates)

>161 s (adults/children)

>81 s (neonates)

of

power

failure

in 5 mmHg

in 5 mmHg

steps

steps

30, 6 min

interval,

OFF

1.4

Service

Manual

BSM-1101/1102

Page 15

Vital

Signs

Parameters

Total

number

measurement

List

of

times

in

list

Heart

NIBP

120

120

rate,

(systolic,

for

periodic

for

NIBP

pulse

list

rate

diastolic,

vital

signs

mean)

list

and

SpO,

1.

GENERAL

External

ZB-800PA

ZB-800PG

ZB-800PK

Recorder

Paper

speed

Recording

Number

of

Annotation

Effective

printing

Battery

Type

of

battery:

Operation

Charging

Battery

mode:

life:

Output

interface

interface

interface

WS-120P

mode

channels

printing

width

time:

(option)

12.5

mm/s,

25

mm/s

Waveform

2

max

Date

sensitivity,

48

mm

NKB-101,

and

time,

recording,

reason

recording

NiCd,

Approx. 2 hours

the

POWER

Standard

Approx.

SAVE

and

trickle

200

charge/discharge

trend

for

speed

1.7

AH

(no

recording,

MODE

charging

recording,

recording,

no

set

to

on)

mode,

cycles

list

recording

parameter

alarm

occurrence,

with

automatic

fully

data,

ECG

no

NIBP

charged

new

selection

lead,

filter

measurement

battery

on/off,

and

Transmitter

Transmission

Transmission

Modulation

Bandwidth

Frequency

method

deviation

ZB-800PG/PK

frequency

power

(optional)

CH1001

CH2001

CH3001

CH4001

CH5001

CH6001

CH8001

CH8011

CH8021

CH8025

CH8037

CH8047

CH8070

CHA000

0.4mW

FSK

8.5

+1.75

to

1080:

to

2120:

to

3040:

to

4080:

to

5080:

to

6080:

to

8009:

to

8020:

to

8024:

to

8032:

to

8046:

to

8069:

to

8136:

to

COFF:

(Frequency-Shift-Keying)

kHz

max.

kHz

420.0500

424.4875

429.2500

440.5625

444.5125

448.6750

450.930

439.700

457.525

467.750

448.000

458.5125

433.100

420.000

to

421.0375

to

425.9750

to

429.7375

to

441.5500

to

445.5000

to

449.6625

to

451.090

to

439.925

to

457.600

to

467.925

to

448.275

to

458.7875

to

434.750

to

472.79375

MHz,

MHz,

MHz,

MHz,

MHz,

MHz,

MHz,

MHz,

MHz,

MHz,

MHz,

MHz,

MHz,

MHz,

20

25

25

25

25

25

12.5

12.5

12.5

12.5

12.5

12.5

kHz

kHz

kHz

kHz

kHz

12.5

kHz

6.25

kHz

kHz

kHz

kHz

kHz

kHz

steps

steps

steps

steps

steps

kHz

steps

kHz

steps

steps

steps

steps

steps

steps

steps

steps

Transmitter

Transmission

Transmission

Modulation

Service

method

Manual

ZB-800PA

frequency

power

BSM-1101/1102

(optional)

CH7001

0.4

FSK

to

7997:

mW

(Frequency-Shift-Keying)

457.5125

to

469.9625

MHz,

12.5

kHz

steps

Page 16

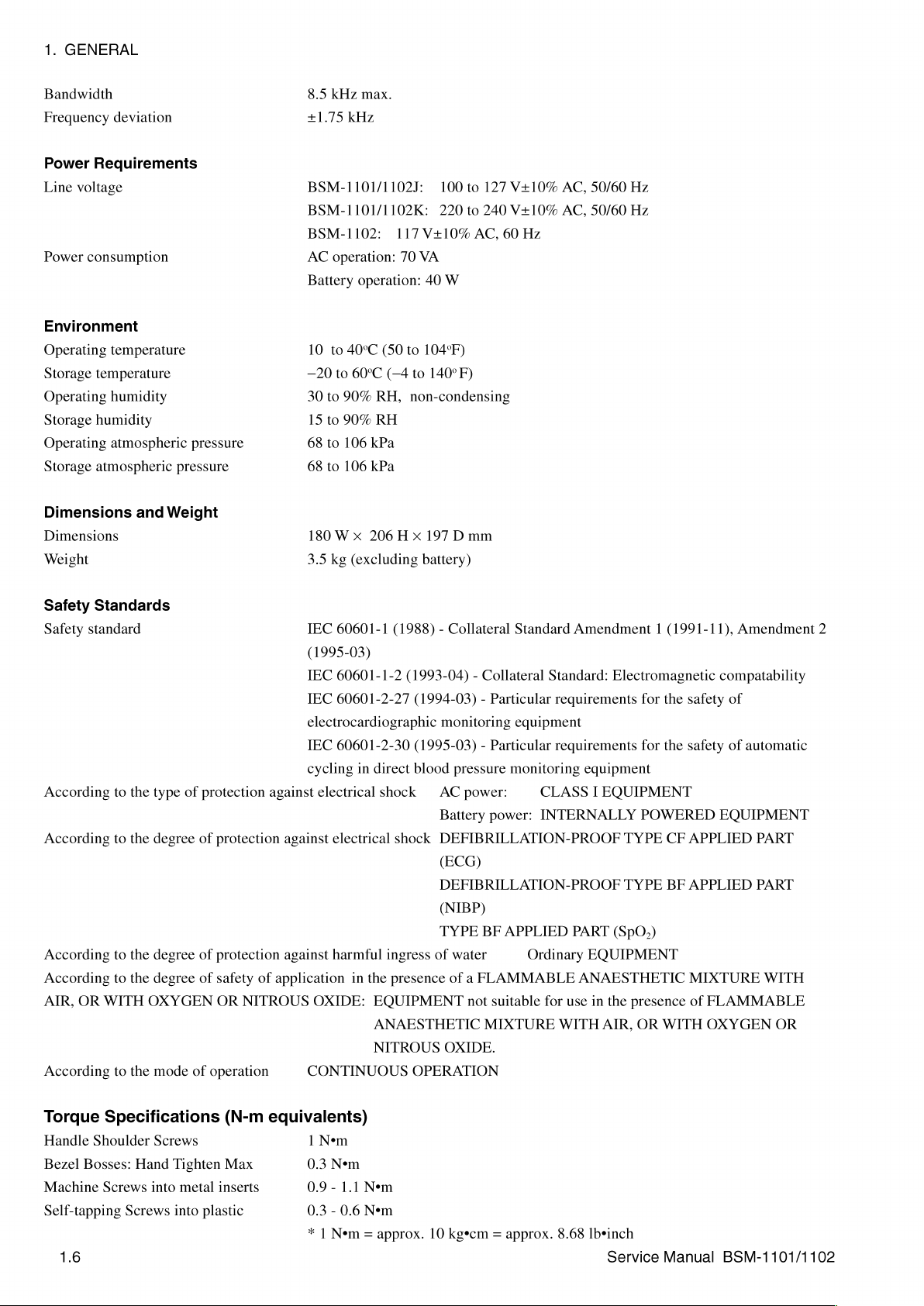

1.

GENERAL

Bandwidth

Frequency

Power

Line

Power

Requirements

voltage

consumption

Environment

Operating

Storage

Operating

Storage

Operating

Storage

temperature

temperature

humidity

humidity

atmospheric

atmospheric

Dimensions

Dimensions

Weight

deviation

and

Weight

pressure

pressure

8.5

kHz

max.

+1.75

kHz

BSM-1101/1102J:

BSM-1101/1102K:

BSM-1102:

AC

operation:

Battery

10

to

40°C

—20

to

30

to

90%

15

to

90%

68

to

106

68

to

106

180 W x

3.5

kg

117

70

operation:

(50

60°C

(—4

RH,

RH

kPa

kPa

206 H x

(excluding

100

to

220

to

240

V+10%

AC,

VA

40

W

to

104°F)

to

140°

F)

non-condensing

197

Dmm

battery)

127

V+10%

V+10%

60

Hz

AC,

AC,

50/60

50/60

Hz

Hz

Safety

Safety

Standards

standard

According

According

According

According

AIR,

OR

According

to

to

to

to

WITH

to

the

the

the

the

the

type

degree

degree

degree

OXYGEN

mode

of

protection

of

protection

of

protection

of

safety

OR

of

operation

against

of

application

NITROUS

IEC

60601-1

(1988) - Collateral

(1995-03)

IEC

60601-1-2

IEC

60601-2-27

electrocardiographic

IEC

60601-2-30

cycling

against

against

in

direct

electrical

electrical

harmful

in

the

OXIDE:

EQUIPMENT

shock | AC

ingress

presence

ANAESTHETIC

NITROUS

CONTINUOUS

Standard

(1993-04) - Collateral

(1994-03) - Particular

monitoring

equipment

(1995-03) - Particular

blood

pressure

monitoring

power:

Battery

shock

DEFIBRILLATION-PROOF

power:

(ECG)

DEFIBRILLATION-PROOF

(NIBP)

TYPE

BF

APPLIED

of

water

of a FLAMMABLE

not

suitable

MIXTURE

OXIDE.

OPERATION

Amendment 1 (1991-11),

Standard:

Electromagnetic

requirements

requirements

equipment

CLASS I EQUIPMENT

INTERNALLY

TYPE

TYPE

PART

(SpO;)

Ordinary

EQUIPMENT

ANAESTHETIC

for

use

in

the

presence

WITH

AIR,

OR

for

the

for

the

POWERED

CF

BF

WITH

Amendment

compatability

safety

of

safety

of

EQUIPMENT

APPLIED

APPLIED

MIXTURE

of

FLAMMABLE

OXYGEN

2

automatic

PART

PART

WITH

OR

Torque

Handle

Bezel

Machine

Specifications

Shoulder

Bosses:

Screws

Self-tapping

1.6

Screws

Hand

into

Screws

Tighten

metal

into

plastic

(N-m

Max

inserts

equivalents)

1

Nem

0.3

Nem

0.9-

1.1

0.3 - 0.6

* | Nem

Nem

Nem

—approx.

10

kgecm — approx.

8.68

İbeinch

service

Manual

BSM-1101/1102

Page 17

1.

GENERAL

BSM-1101

BSM-1102

Front

|

—

Enclosure

Rear

Internal

Enclosure

Support

LI

Assembly,

UR-3496

UR-3500

Assembly

Assembly,

UR-3492

UR-34921

Encoder

Power

with

Pump

Analog

Analog

UR-3495

Board

Switch

Power

Valve

Board

Board

MP-205

|

UR-3493

UR-3494

Digital

Board

PCMCIA

ZB800

Interface

Assembly

Assembly

SpO,

SpO,

Assembly

Board

Assembly

Board

Assembly

Board

Board

Assembly

Board

for

BSM-1101

for

BSM-1102

Assembly

Assembly

Assembly

for

BSM-1101

for

BSM-1102

WS-120P

Recorder

RG-920P

UR-3501

UR-3497

UR-3514

Assembly

UR-3491

—

UR-3502

Drive

Unit

Recorder

Hall

Option

Recorder

Recorder

Interface

Effect

Interface

Power

Digital

Board

Board

Assembly

Board

Assembly

Board

Assembly

Board

Assembly

Assembly

Service

Manual

BSM-1101/1102

1.7

Page 18

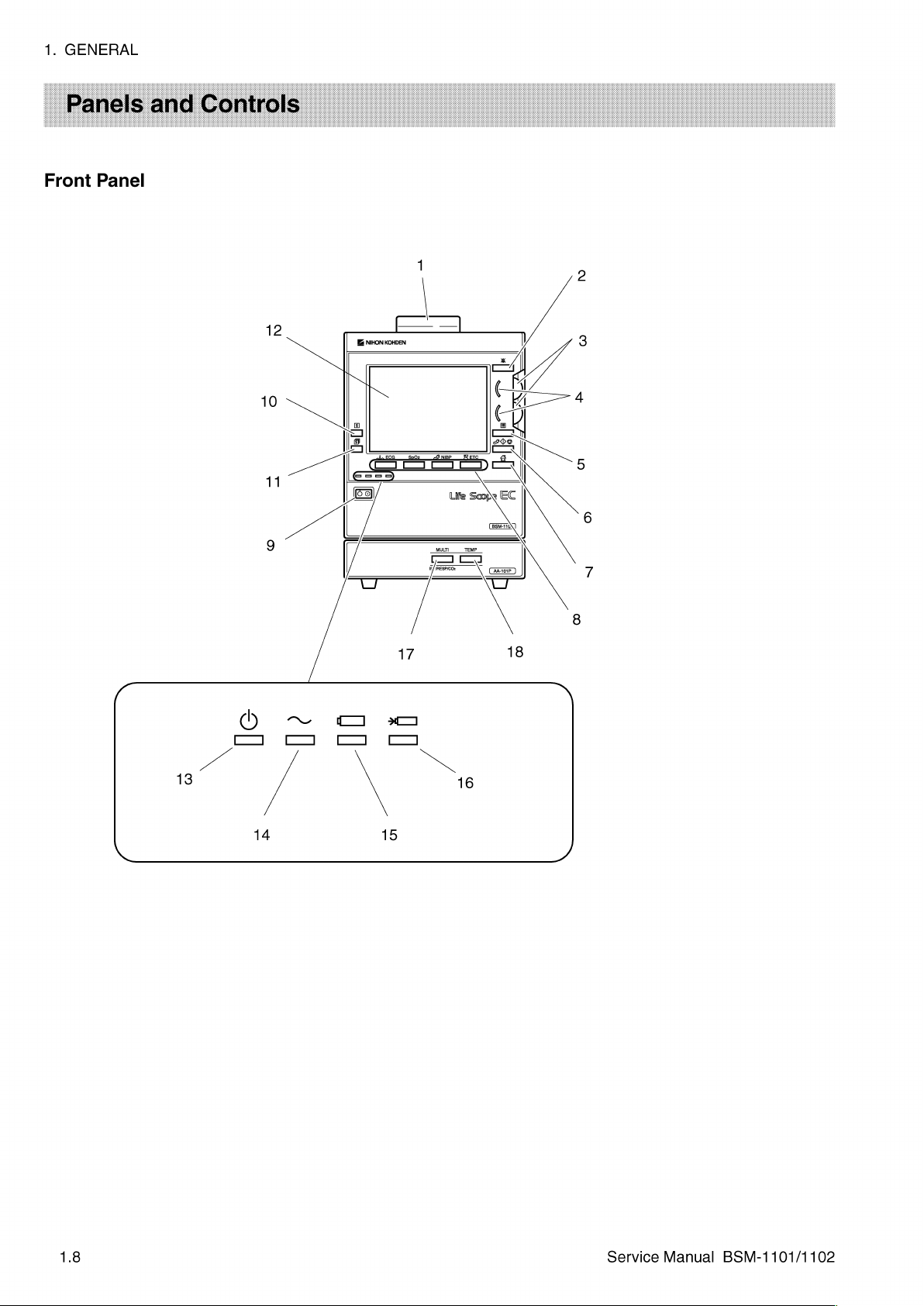

1.

GENERAL

Front

Panel

1.8

Service

Manual

BSM-1101/1102

Page 19

1.

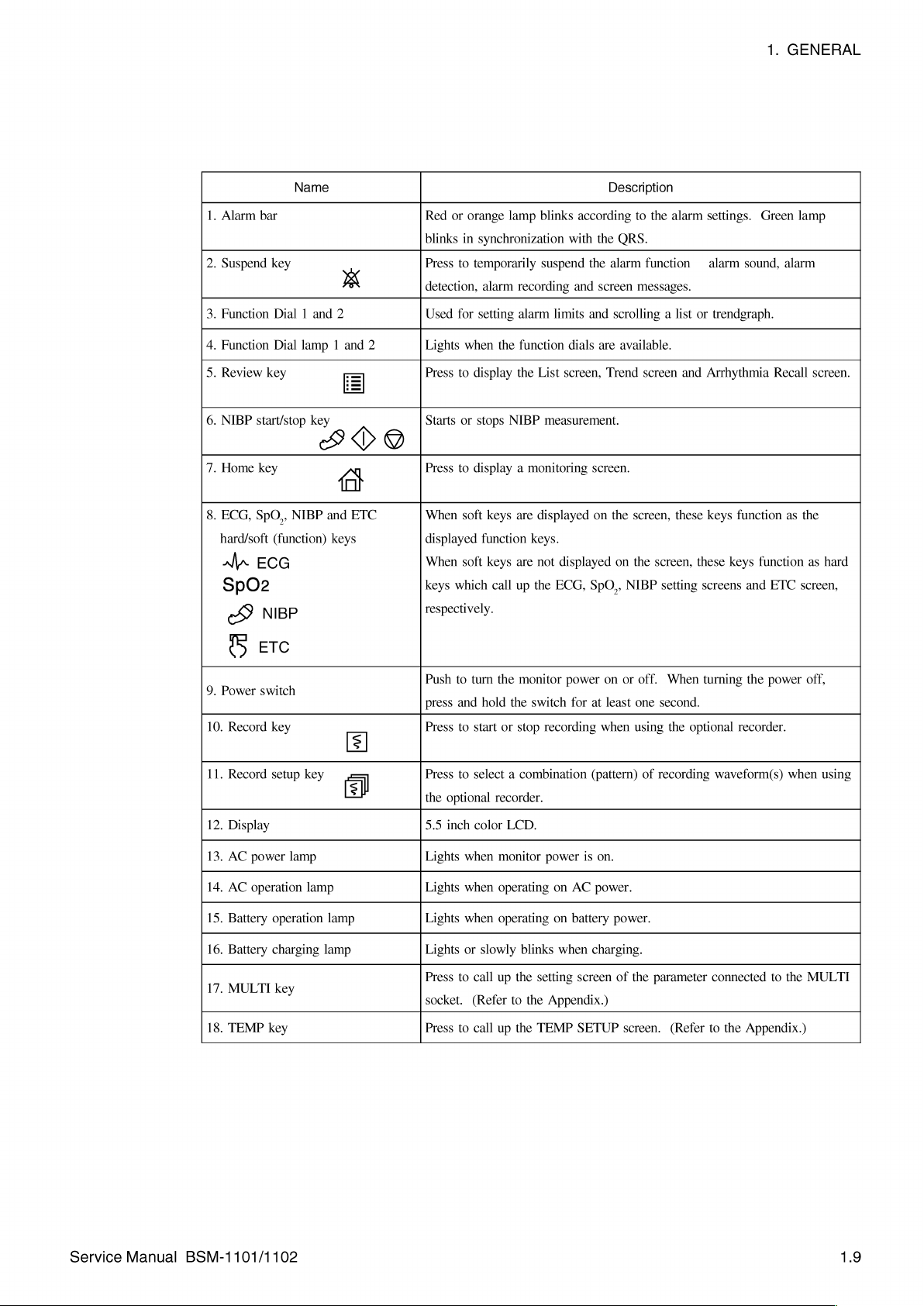

Alarm

2.

Suspend

3.

Function

4.

Function

5.

Review

6.

NIBP

7.

Home

8.

ECG,

hard/soft

^\^

SpO2

e

Name

bar

key

Dial 1 and

Dial

lamp 1 and

key

start/stop

key

SpO,,

key

NIBP

(function)

ECG

NIBP

2

A

and

keys

党

ETC

1.

GENERAL

Description

Red

or

orange

lamp

blinks

according

blinks

in

synchronization

Press

to

temporarily

detection,

Used

2

Lights

Press

Starts

Press

When

displayed

When

keys

respectively.

alarm

recording

for

setting

alarm

when

the

function

to

display

the

or

stops

NIBP

to

display a monitoring

soft

keys

are

function

soft

keys

are

which

call

up

with

suspend

and

limits

dials

List

screen,

measurement.

displayed

keys.

not

displayed

the

ECG,

to

the

QRS.

the

alarm

function

screen

messages.

and

scrolling a list

are

available.

Trend

screen

screen.

on

the

screen,

on

the

SpO,,

NIBP

the

alarm

these

screen,

setting

settings.

alarm

or

trendgraph.

and

Arrhythmia

keys

these

screens and

Green

sound,

function

keys

function

alarm

Recall

as

ETC

lamp

screen.

the

as

hard

screen,

(5

Power

Record

ETC

switch

key

9.

10.

S

11.

Record

setup

key

12.

Display

13.

AC

power

14.

AC

15.

Battery

16.

Battery

7

.

MULTI

18.

TEMP

lamp

operation

operation

charging

τικ

ke

?

key

lamp

lamp

lamp

Push

to

turn

the

monitor

press

and

hold

the

Press

to

start

or

stop

Press

to

select a combination

the

optional

5.5

inch

Lights

Lights

Lights

Lights

Press

socket.

Press

color

when

when

when

or

to

call

(Refer

to

call

recorder.

LCD.

monitor

operating

operating

slowly

up

to

up

the

the

switch

recording

power

blinks

setting

the

Appendix.)

TEMP

power

for

on

AC

on

battery

when

on

at

least

when

(pattern)

is

on.

power.

charging.

screen

SETUP

or

power.

of

screen.

off.

one

second.

using

of

recording

the

parameter

When

the

optional

(Refer

turning

the

recorder.

waveform(s)

connected

to

the

Appendix.)

power

when

to

the

off,

using

MULTI

Service

Manual

BSM-1101/1102

1.9

Page 20

1.

GENERAL

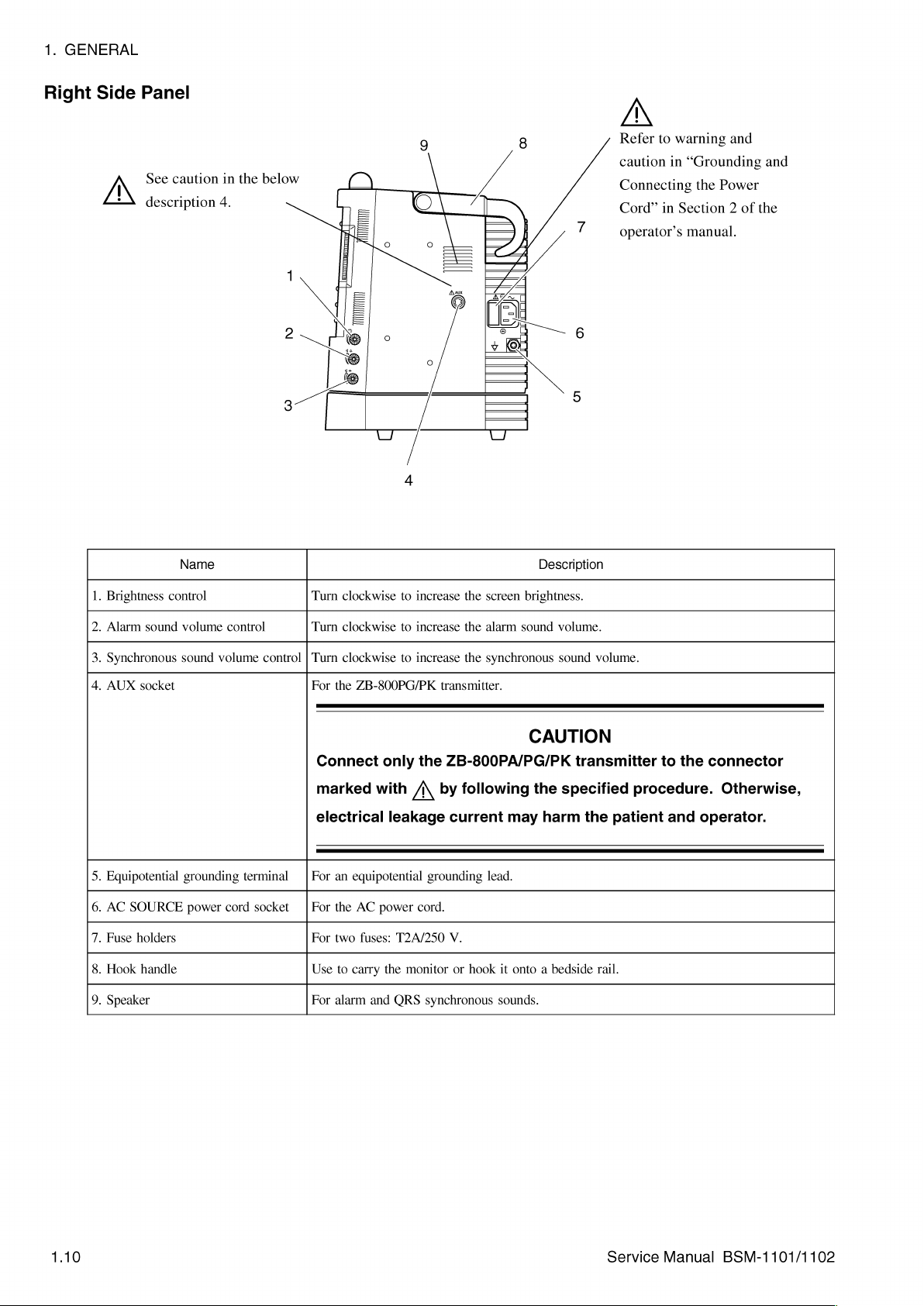

Right

Side

Panel

See

caution

description

in

4.

the

below

4

A

Refer

to

warning

caution

Connecting

Cord”

operator’s

in

in

Section

and

“Grounding

the

Power

2

of

manual.

and

the

control

sound

socket

holders

handle

Name

volume

sound

grounding

power

1.

Brightness

2.

Alarm

3.

Synchronous

4.

AUX

5.

Equipotential

6.

AC

SOURCE

7.

Fuse

8.

Hook

9.

Speaker

control

volume

terminal © |

cord

Turn

Turn

control | Turn

For

Connect

marked

electrical

For

socket | For

For

Use

For

clockwise

clockwise

clockwise

the

ZB-800PG/PK

only

with

leakage

an

equipotential

the

AC

power

two

fuses:

to

carry

the

alarm

and

to

increase

to

increase

to

increase

the

/\

grounding

cord.

T2A/250

monitor

ORS

synchronous

the

screen

brightness.

the

alarm

sound

the

synchronous

transmitter.

ZB-800PA/PG/PK

by

following

current

V.

or

lead.

hook

sounds.

may

it

onto a bedside

Description

volume.

sound

CAUTION

transmitter

the

specified

harm

volume.

the

rail.

to

the

connector

procedure. Otherwise,

patient

and

operator.

1.10

Service

Manual

BSM-1101/1102

Page 21

Left

Side

Panel

A

Refer

to

warning

“General

Section | of

manual.

Safety

1.

and

Information”

the

operator’s

GENERAL

caution

in

in

Refer

to

warning

"General

Section | of

Safety

and

Information”

the

operator’s

caution

manual.

in

in

1.

Paper

2.

Recorder

3.

Cuff

4,

SpO,

5.

ECG

6.

Temp

7.

MULTI

magazine

(option)

socket

socket

socket

socket

socket

Name

release

lever

Push

to

open

2-channel

Connects

Connects

Connects

Connects

Connects

pressure,

the

paper

thermal

to

to

to

to

to

respiration

array

the

NIBP

the

SpO,

the

ECG

the

temperature

the

parameter

or

Description

magazine.

recorder.

air

hoses.

connection

connection

probe

to

be

CO,.

(Refer

cord.

cord

for

cable.

measured

to

the

measuring

(Refer

to

from

invasive

Appendix.)

ECG.

the

Appendix.)

blood

Service

Manual

BSM-1101/1102

Page 22

1.

GENERAL

Rear

Panel

NIHON

πο

KOHDEN

ση

See

Caution

below

2

3

о

4

in

the

description

1.

==

card

Name

slot

For a OI-101P

network

card.

1.

PC

Description

2.

PC

card

3.

PC

card

4.

Battery

lamp

eject

pack

button

holder

e

Use

only

e

Do

not

is

lit.

Lights

while

Press

to

eject

Remove

the

press

This

data

the

cover

the

may

is

PC

and

Nihon

the

damage

read

card.

insert

PC

from

Kohden

card

or

written

the

battery

CAUTION

card.

eject

the

PC

to

the

pack.

button

card

and

PC

card.

while

monitor.

the

PC

card

lamp

Service

Manual

BSM-1101/1102

Page 23

1.

GENERAL

Storage

Follow

Before

1.

Disconnect

2.

Remove

3.

Cover

4.

If

5.

Make

duration

Storage

Storage

these

procedures

storing

the

the

the

instrument

possible,

sure

the

of

temperature

humidity

instrument

the

power

battery

store

the

storage

the

storage:

when

storing

for a long

cord

from

from

the

instrument.

with a dust

instrument

place

meets

—20

to

15

to

the

cover.

in

60°C

90%

or

transporting

time,

perform

instrument.

its

original

the

following

(-4

to

130°F)

RH,

non-condensing

the

instrument.

the

following

shipping

storage

steps:

container.

conditions

for

the

Transport

To

transport

1.

Disconnect

2.

Remove

3.

Cover

4.

If

the

the

the

instrument

possible,

instrument,

the

power

cord

battery

from

with a dust

transport

the

perform

the

from

the

the

instrument.

cover.

instrument

following

steps:

instrument.

in

its

original

shipping

container.

Service

Manual

BSM-1101/1102

1.13

Page 24

1.

GENERAL

The

four

soft

keys,

When

the

ECG,

SpO,,

screens,

When

any

display

key

functions.

screen,

LEAD

In

this

NAME]

keys

on

depending

normal

NIBP,

respectively.

screen

appears

the

NAME

manual,

key).

ECG

at

For

setting

(ECG

soft

the

front

panel

on

the

monitoring

and

ETC

other

than

the

bottom

example,

screen

waveform

keys

are

below

screen

display.

screen

hard

keys,

the

normal

of

the

screen

when

the

displays

lead

indicated

the

screen

is

displayed,

and

call

monitoring

and

ECG

key

and

the

selector

by

brackets

up

the

is

ECG

soft

function

the

four

the

ECG,

screen

four

keys

pressed

key

key).

(for

example,

as

either

hard

keys

function

SpO,,

NIBP,

appears, a soft

correspond

at

the

normal

function

changes

the

[LEAD

keys

or

as

the

and

ETC

key

to

the

soft

monitoring

to

Service

Manual

BSM-1101/1102

Page 25

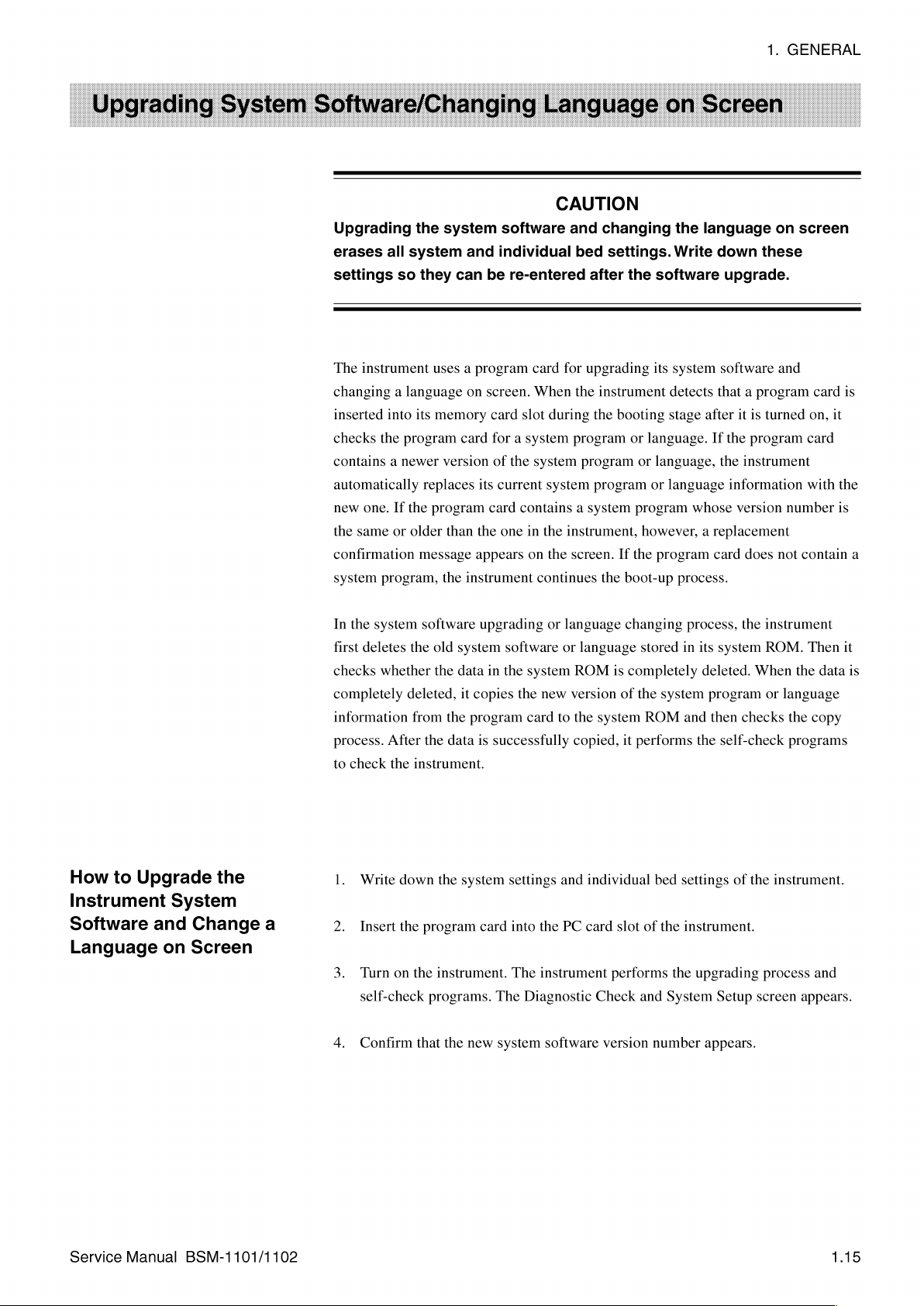

Upgrading

erases

settings

The

instrument

changing a language

inserted

checks

contains a newer

automatically

new

one.

the

same

confirmation

system

the

all

system

so

they

into

its

the

program

replaces

If

the

or

older

message

program,

system

can

uses a program

memory

version

program

than

the

software

and

individual

be

re-entered

on

screen.

card

card

for a system

of

the

its

current

card

contains a system

the

one

appears

instrument

CAUTION

card

for

When

slot

during

system

system

in

the

on

the

continues

and

changing

bed

settings.

after

the

upgrading

the

instrument

the

booting

program

program

program

instrument,

screen.

If

the

boot-up

the

language

Write

down

software

its

system

detects

stage

or

language.

or

language,

or

language

program

however, a replacement

the

program

process.

upgrade.

software

that a program

after

it

If

the

the

instrument

information

whose

version

card

does

1s

program

1.

GENERAL

on

these

and

turned

number

not

screen

card

on,

it

card

with

the

is

contain

1s

a

How

to

Upgrade

Instrument

Software

and

Language

System

Change

on

Screen

the

a

In

the

system

first

deletes

checks

whether

completely

information

process.

to

1.

2.

3.

4.

After

check

the

Write

down

Insert

the

Turn

on

self-check

Confirm

software

the

old

system

the

data

deleted,

from

the

it

the

the

data

instrument.

the

system

program

instrument.

programs.

that

the

upgrading

software

in

the

copies

the

program

is

successfully

settings

card

into

The

The

new

system

or

language

or

language

system

card

Diagnostic

ROM

new

version

to

the

copied,

and

individual

the

PC

card

instrument

software

changing

is

completely

of

system

it

slot

performs

Check

version

stored

in

the

system

ROM

and

performs

bed

settings

of

the

instrument.

the

and

System

number

process,

its

system

deleted.

program

then

the

self-check

of

upgrading

Setup

appears.

the

instrument

ROM.

When

or

checks

the

instrument.

process

screen

Then

the

data

language

the

copy

programs

and

appears.

it

is

Service

Manual

BSM-1101/1102

Page 26

Section

2

Troubleshooting

General

How

Power-Related

DisplayProblems..........................................

SsoundProblems................................

Key

Recording

ECG

spO,Problems..............................................

Non-Invasive

Signal

Information

to

TroubleSNOOt

Operation

Problems

Problems

Noise

.4

..................

Problems

Problems

..............

.4

Blood

Pressure

Problems

.4

eee

e

sise

Problems

2.1

ii

neee

eeeaeeeeeeneeeneeneenenenenenanın

eee

rara

ii

PKR K RKK

i

2.2

2.3

2.4

2.5

2.6

2.7

2.9

2.10

2.11

2.14

Service

Manual

BSM-1101/1102

2C.1

Page 27

Use

this

section

troubleshooting

e

Power-related

e

Display

e

Sound

e

Key

operation

e

Recording

e

ECG

e

SpO,

e

NIBP

to

locate,

tables

identify,

in

this

and

section

solve

are

an

divided

2.

TROUBLESHOOTING

instrument

problem.

into 8 general

The

problem

areas:

Service

Manual

BSM-1101/1102

2.1

Page 28

2.

TROUBLESHOOTING

1.

Determine

2.

Inthe

3.

Do

the

4.

Ifthe

criteria.

5.

If

none

Corporation

Before

contacting

technical

Sheet

of

on

Sheet

this

the

Nihon

best

(the

manual),

problem.

to

Kohden

support.

which

“Problem”

action

recommended

problem

of

the

actions

dealer.

support,

original

Nihon

Kohden

Corporation

troubleshooting

column,

is

not

find

solved,

solve

Nihon

please

is

and

Send

Kohden

complete a copy

provided

if

possible,

the

completed

Corporation

the

in

the

do

the

problem,

at

or

your

table

to

item

that

“Action”

the

action

NOTE

Corporation

the

end

provide

copy

or

distributor

use.

matches

column.

for

the

next

contact

of

of

Section

your

the

additional

of

the

your

distributor.

the

problem.

possible

nearest

or

your

Maintenance

6,

detailed

Maintenance

provide

cause

or

Nihon

Kohden

distributor

for

Check

“Maintenance,”

information

Check

This

helps

you

with

the

2.2

Service

Manual

BSM-1101/1102

Page 29

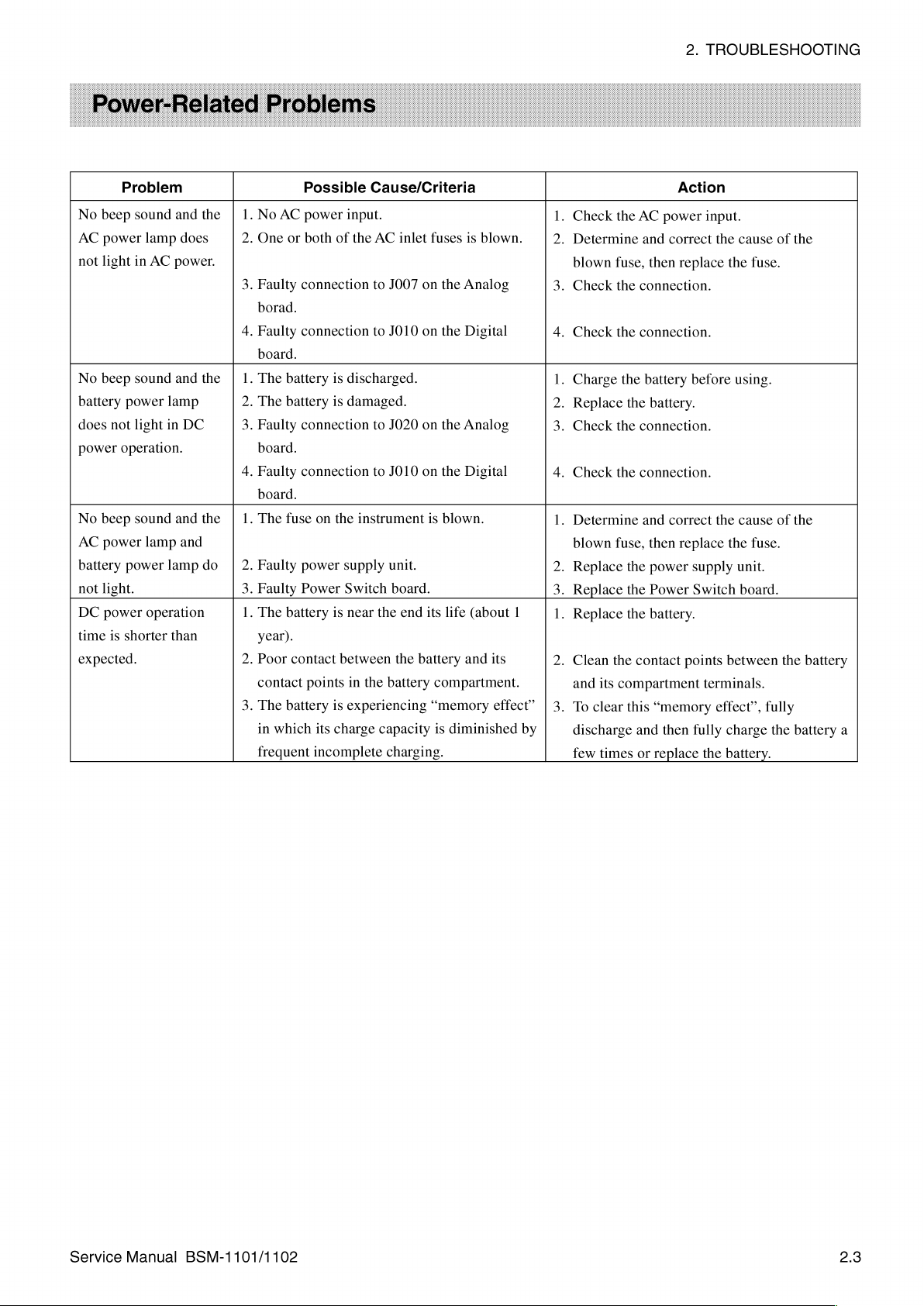

Problem

No

beep

sound

AC

power

not

light

in

No

beep

sound

battery

does

power

No

AC

battery

not

DC

time

expected.

power

not

light

operation.

beep

sound

power

power

light.

power

is

shorter

and

the

lamp

does

AC

power.

and

the

lamp

in

DC

and

the

lamp

and

lamp

do

operation

than

Possible

1.

No

AC

power

input.

.

One

or

both

of

the

.

Faulty

connection

borad.

.

Faulty

connection

board.

1.

The

battery

is

discharged.

2.

The

battery

is

damaged.

3.

Faulty

connection

board.

.

Faulty

connection

board.

.

The

fuse

on

the

instrument

2.

Faulty

power

supply

3.

Faulty

Power

Switch

.

The

battery

is

near

year).

.

Poor

contact

contact

.

The

battery

in

which

frequent

between

points

in

is

experiencing

its

charge

incomplete

the

Cause/Criteria

AC

inlet

fuses

to

J007

on

the

to

JO10

on

the

to

J020

on

the

to

JO10

on

the

is

blown.

unit.

board.

the

end

its

life

the

battery

battery

capacity

charging.

compartment.

“memory

is

diminished

is

blown.

Analog

Digital

Analog

Digital

(about

and

its

effect”

1.

Check

the

.

Determine

blown

fuse,

.

Check

the

.

Check

the

1.

Charge

2.

Replace

3.

Check

the

.

Check

the

.

Determine

blown

fuse,

2.

Replace

3.

Replace

1

.

Replace

.

Clean

the

and

its

compartment

.

To

clear

by

discharge

few

times

AC

power

and

then

connection.

connection.

the

battery

the

battery.

connection.

connection.

and

then

the

power

the

Power

the

battery.

contact

this

“memory

and

then

or

replace

2.

TROUBLESHOOTING

Action

input.

correct

correct

the

replace

before

the

replace

supply

Switch

points

terminals.

effect”,

fully

the

cause

the

using.

cause

the

unit.

board.

between

charge

battery.

of

fuse.

of

fuse.

fully

the

the

the

the

battery

battery

a

Service

Manual

BSM-1101/1102

2.3

Page 30

2.

TROUBLESHOOTING

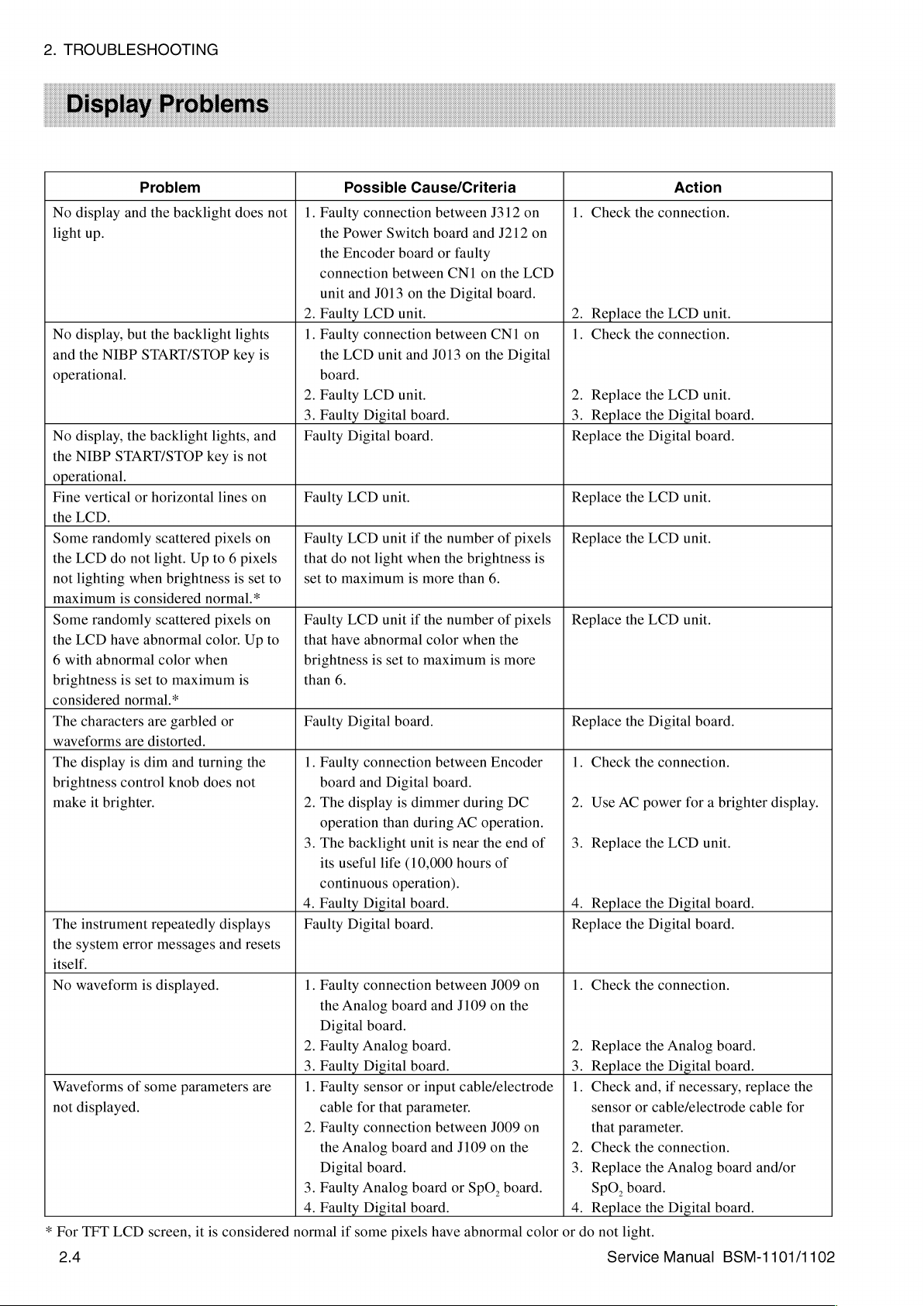

No

display

light

up.

No

display,

and

the

operational.

No

display,

the

NIBP

operational.

Fine

vertical

the

LCD.

Some

randomly

the

LCD

not

lighting

maximum

Some

randomly

the

LCD

6

with

brightness

considered

The

characters

waveforms

The

display

brightness

make

it

The

instrument

the

system

itself.

No

waveform

Waveforms

not

displayed.

*

For

TFT

2.4

Problem

and

but

NIBP

START/STOP

the

START/STOP

or

do

not

when

is

considered

have

abnormal

abnormal

is

set

normal.*

are

is

dim

control

brighter.

error

is

of

some

LCD

the

backlight

the

backlight

backlight

horizontal

scattered

light.

scattered

color

to

are

distorted.

repeatedly

messages

displayed.

screen,

lights,

key

Up

to 6 pixels

brightness

normal.*

color.

when

maximum

garbled

and

turning

knob

does

parameters

it

is

does

not

lights

key

is

and

is

not

lines

on

pixels

on

is

set

to

pixels

on

Up

to

is

or

the

not

displays

and

resets

are

considered

Possible

1.

Faulty

the

Power

the

Encoder

connection

unit

and

2.

Faulty

1.

Faulty

the

LCD

board.

2.

Faulty

3.

Faulty

Faulty

Digital

Faulty

LCD

Faulty

LCD

that

do

not

set

to

maximum

Faulty

LCD

that

have

brightness

than

6.

Faulty

Digital

1.

Faulty

board

and

2.

The

display

operation

3.

The

backlight

its

useful

continuous

4.

Faulty

Faulty

Digital

1.

Faulty

the

Analog

Digital

2.

Faulty

Analog

3.

Faulty

1.

Faulty

cable

for

2.

Faulty

the

Analog

Digital

3.

Faulty

Analog

4.

Faulty

normal

if

some

Cause/Criteria

connection

Switch

board

between

J013

on

the

LCD

unit.

connection

unit

and

LCD

unit.

Digital

board.

board.

unit.

unit

if

the

light

when

is

more

unit

if

the

abnormal

is

connection

life

Digital

connection

board.

Digital

sensor

that

connection

board.

Digital

color

set

to

maximum

board.

Digital

is

dimmer

than

during

unit

(10,000

operation).

board.

board.

board

board.

board.

or

input

parameter.

board

board

board.

pixels

between

board

or

between

J013

between

board.

is

between

and

between

and

have

J312

and

J212

faulty

CNT

on

the

Digital

number

the

number

board.

CN1

on

the

of

brightness

than

6.

of

when

the

is

Encoder

during

AC

operation.

near

the

hours

of

J009

J109

on

cable/electrode

J009

J109

on

or

SpO,

abnormal

on

on

LCD

on

Digital

pixels

15

pixels

more

DC

end

of

on

the

on

the

board.

color

Action

1.

Check

the

connection.

2.

Replace

1.

Check

2.

Replace

3.

Replace

Replace

Replace

Replace

Replace

Replace

1.

Check

2.

Use

3.

Replace

4.

Replace

Replace

1.

Check

2.

Replace

3.

Replace

1.

Check

sensor

that

2.

Check

3.

Replace

SpO,

4.

Replace

or

do

the

the

the

the

the

the

the

AC

power

the

the

and,

or

parameter.

the

board.

not

light.

Service

the

LCD

unit.

connection.

the

LCD

unit.

the

Digital

Digital

LCD

LCD

LCD

Digital

connection.

the

LCD

the

Digital

Digital

connection.

the

Analog

the

Digital

if

cable/electrode

connection.

the

Analog

the

Digital

Manual

board.

board.

unit.

unit.

unit.

board.

for a brighter

unit.

board.

board.

board.

board.

necessary,

board

board.

BSM-1101/1102

display.

replace

cable

for

and/or

the

Page 31

Problem

No

sound.

No

sound,

except

hissing

The

The

volume

synchronous

volume

operational.

sound.

sound

alarm

control

control

is

sound

for

muffled.

and/or

sound

are

not

1.

Faulty

Digital

2.

Faulty

3.

Faulty

Faulty

a

board

1.

The

instrument

2.

The

way.

1.

Faulty

2.

Faulty

Possible

connection

board

speaker.

Digital

connection

and

J114

on

speaker

volume

on

is

control

Digital

Encoder

Cause/Criteria

between

and

J114

on

board.

between

the

speaker.

the

right

blocked.

is

not

board.

board.

JO14

the

J014

side

turned

on

the

speaker.

on

the

Digital

of

the

up

all

the

1.

Check

2.

Replace

3.

Replace

Check

1.

Remove

2.

Adjust

1.

Replace

2.

Replace

the

the

the

the

connection.

the

the

the

the

2.

Action

connection.

speaker.

Digital

volume.

Digital

Encoder

object

board.

blocking

board.

TROUBLESHOOTING

the

speaker.

board.

Service

Manual

BSM-1101/1102

2.5

Page 32

2.

TROUBLESHOOTING

No

keys,

switch,

Some

(excluding

panel

Power

Function

Problem

except

are

operational.

keys

are

keys

and

Power

switch

dials

the

Power

not

operational

on

the

switch).

is

not

operational.

are

not

1.

2.

3.

1.

connector | 2.

1.

2.

operational. | 1.

2.

3.

Possible

Faulty

panel

and

Faulty

Faulty

Faulty

Faulty

Faulty

Faulty

Faulty

panel

and

Faulty

Faulty

Cause/Criteria

connection

JO17

on

Digital

membrane

membrane

Digital

Power

Digital

connection

Encoder

Digital

JO18

board.

board.

Switch

board.

on

board.

board.

between

the

Digital

switch

switch

board.

between

the

Digital

the

key

board.

assembly.

assembly.

the

key

board.

1.

2.

3.

1.

2.

1.

2.

1.

2.

3.

Check

Replace

Replace

Replace

Replace

Replace

Replace

Check

Replace

Replace

the

connection.

the

Digital

the

membrane

the

membrane

the

Digital

the

Power

the

Digital

the

connection.

the

Encoder

the

Digital

Action

board.

board.

Switch

board.

board.

board.

assembly.

switch

assembly.

board.

2.6

Service

Manual

BSM-1101/1102

Page 33

Missing

Fixed

lines

Paper

causing

Abnormally

sound

No

Problem

dots

lengthwise

along

the

does

not

skewing.

loud

of

recorder

recording

in

the

recording.

straight

recording.

feed

properly, | 1.

rotating

unit

on

the

paper.

1.

2.

Faulty

2.

3.

4.

5.

Faulty

motor.

1.

2.

3.

4.

5.

Possible

Dirty

thermal

Faulty

thermal

thermal

Dirty

gear.

Faulty

gear.

Dirty

platen

Damaged

If

the

recorder

constant

between:

e

e

e

e

The

paper

Faulty

Faulty

board,

Interface

Faulty

Digital

Faulty

e

e

e

e

speed,

the

recorder

Recorder

J515

on

J415

on

J315

on

J215

on

J115

on

and

JO15

platen

heat-sensitive

is

facing

thermal

recorder

Recorder

board

+24 V output

board.

connection

the

recorder

Recorder

J515

on

J415

on

J315

on

J215

on

J115

on

and

JO15

Cause/Criteria

head.

head.

head.

roller.

platen

roller.

unit

there

unit

Power

the

Recorder

the

Recorder

the

Recorder

the

Recorder

the

Recorder

on

the

roller

or

the

head.

unit,

Digital

or

unit

Power

the

Recorder

the

Recorder

the

Recorder

the

Recorder

the

Recorder

on

the

motor

rotates

is a faulty

and

J615

board

Power

Digital

Digital

Interface

Interface

Digital

side

wrong

Digital

between:

Digital

gear.

of

Recorder

board,

from

and

J615

board

Power

Digital

Digital

Interface

Interface

board

the

way.

board.

JO15

board

on

board

recording

Power

Recorder

on

on

board

at

a

connection

the

and

board

board

and

board

board

the

the

and

board

board

and

board

board

2.

TROUBLESHOOTING

Action

1.

Clean

the

thermal

2.

Replace

Replace

1.

Clean

2.

Replace

3.

Clean

4.

Replace

5.

Check

Replace

unit.

1.

Make

detection

the

2.

Replace

3.

Replace

board.

4.

Check

necessary,

5.

Check

the

the

thermal

the

the

the

the

the

the

platen

sure

paper.

the

the

the

the

gear.

platen

connections.

mark

+24 V output

replace

connections.

thermal

head.

gear.

roller.

platen

roller

the

side

faces

thermal

recorder

head.

head.

roller.

or

with

the

up

when

head.

unit

and,

the

Digital

the

recorder

black

or

faulty

inserting

if

board.

Service

Manual

BSM-1101/1102

2.7

Page 34

2.

TROUBLESHOOTING

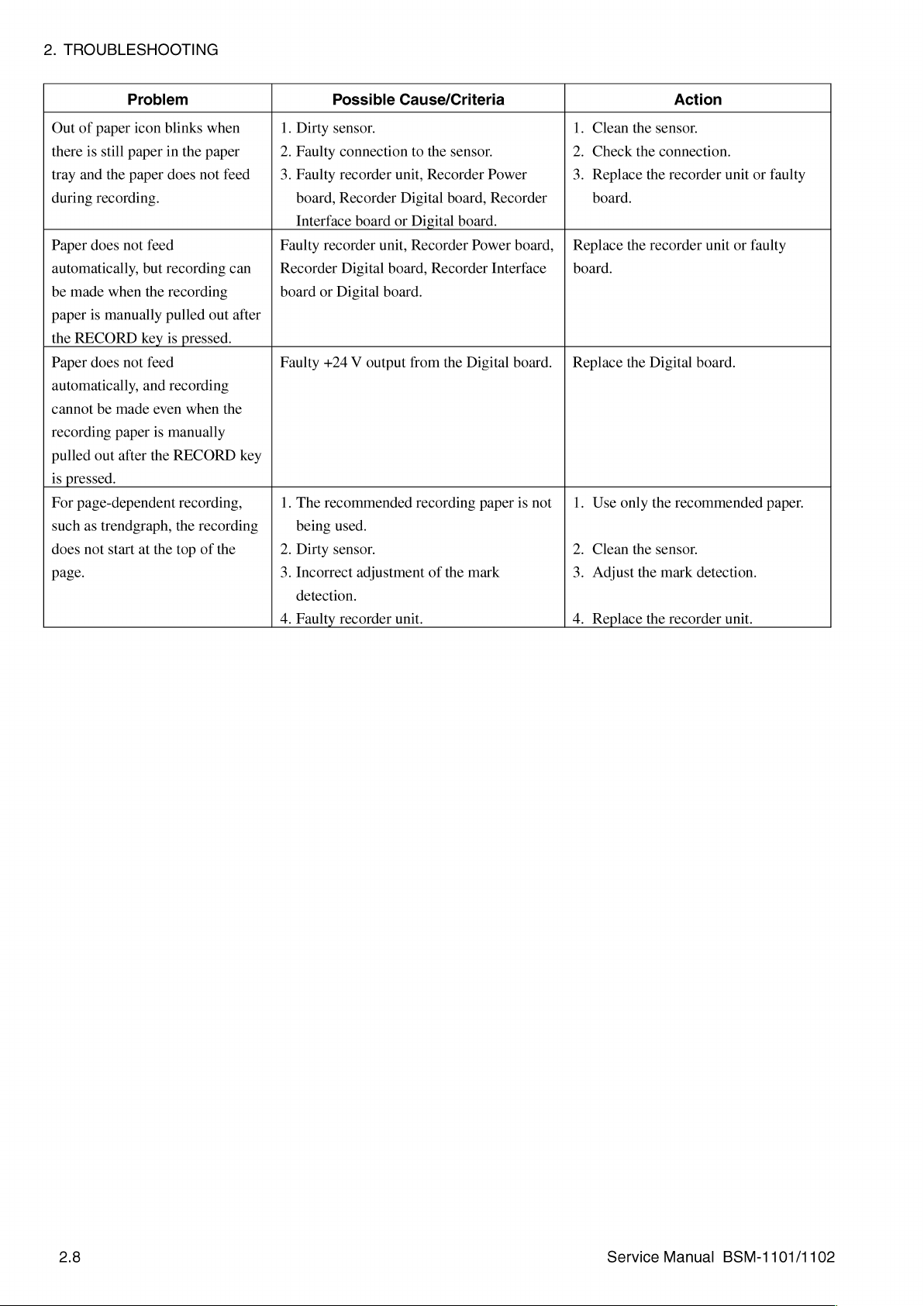

Out

of

there

tray

and

during

Paper

automatically,

be

made

paper

the

RECORD

Paper

automatically,

cannot

recording

pulled

1s

pressed.

For

page-dependent

such

does

page.

Problem

paper

icon

is

still

paper

the

paper

recording.

does

not

when

is

manually

does

not

be

made

paper

out

after

as

trendgraph,

not

start

blinks

in

does

feed

but

recording

the

pulled

key

is

feed

and

even

is

manually

the

at

the

when

the

paper

not

feed

recording

out

pressed.

recording

when

the

RECORD

recording,

the

recording

top

of

the

1.

Dirty

2.

Faulty

3.

Faulty

board,

Interface

Faulty

can

after

Recorder

board

Faulty

key

1.

The

being

2.

Dirty

3.

Incorrect

detection.

4.

Faulty

Possible

sensor.

connection

recorder

Recorder

board

recorder

or

+24 V output

recommended

Digital

Digital

used.

sensor.

adjustment

recorder

unit,

board,

board.

Cause/Criteria

to

the

sensor.

unit,

Recorder

Digital

board,

or

Digital

Recorder

from

unit.

board.

Power

Recorder

the

Digital

recording

of

the

mark

paper

Power

Recorder

board,

Interface

board.

is

not

Action

1.

Clean

the

sensor.

2.

Check

the

connection.

3.

Replace

board.

Replace

board.

Replace

1.

Use

2.

Clean

3.

Adjust

4.

Replace

the

the

only

the

the

the

recorder

recorder

Digital

the

recommended

sensor.

mark

the

recorder

unit

or

unit

or

faulty

board.

detection.

unit.

faulty

paper.

2.8

Service

Manual

BSM-1101/1102

Page 35

ECG

its

AC

interference

waveform.

CHECK

message

recommendations

Operator’s

not

PACING

appears

recommendations

Operator’s

not

Problem

baseline

normal

position.

noise-like

LEADS

appears

correct

message

and

correct

is

out

on

the

and

Manual

the

problem.

the

Manual

the

problem.

in

do

in

do

of

the

the

the

1.

If

the

input,

2.

If

the

ECG

1.

Poor

position.

2.

Faulty

3.

Electrical

electric

4.

If

the

is

set

faulty.

5.

If

the

disconnected,

If

the

leads

1.

Faulty

2.

Faulty

panel.

3.

Faulty

board

4.

Faulty

5.

Faulty

1.

Spike

waveform.

2.

If

the

signal

input,

Possible

baseline

the

Analog

baseline

lead

is

changed,

electrode

electrode

interference

blanket,

trouble

to

trouble

message

are

message

persists

monitoring

persists

the

does

short-circuited:

electrode

ECG

input

connection

and

J109

Analog

Digital

or

narrow

from

the

the

Analog

is

not

board

does

not

to

skin

leads

near

mode,

Analog

not

leads

connector

between

on

the

board.

board.

QRS

still

appears

AX-800P

board

normal

Cause/Criteria

the

contact

or

emitting

the

when

after the

disappear

or

Digital

complex

even

1s

faulty.

change

even

Analog

or

bad

electrode

source,

instrument.

the

ECG

the

Analog

electrode

board

is

when

electrode

on

the

J009

on

board.

on

when a normal

Vital

Sign

is

faulty.

when

ECG

when

board

is

electrode

cable.

such

setup

board

leads

faulty.

the

cable.

connector

the

Analog

the

ECG

Simulator

is

not

.

Replace

the

faulty.

as

an

setting . Replace

is

are

electrode

ECG

is

.

Replace

.

Refer

correct

.

Replace

electrode

.

If

possible,

instrument

.

Replace

.

Check

electrode

.

Replace

.

Check

4.

Replace

.

Replace

.

Turn

.

Replace

2.

the

the

to

the

this

the

cable.

the

the

and,

leads

the

the

connection.

the

the

pacing

the

TROUBLESHOOTING

Action

Analog

Analog

Operator’s

problem.

electrode

place

away

Analog

Analog

if

ECG

Analog

Digital

mode

Analog

board.

board.

leads

the

patient

from

such

board.

board.

necessary,

or

electrode

input

board.

board.

off.

board.

Manual

replace

connector.

to

or

and

the

source.

the

cable.

Service

Manual

BSM-1101/1102

2.9

Page 36

2.

TROUBLESHOOTING

Problem

PROBE

message

continuously

displayed.

PROBE

message

continuously

displayed,

when

SDO2

are

PULSE

SEARCH

message

continuously

displayed.

INSERT

CONNECTOR

message

continuously

displayed.

SpO2

MODULE

ERROR

message

appears.

1102

other

probes

used.

only)

OFF

is

OFF

is

even

is

is

(BSM-

1.

The

SpO2

probe

2.

The

external

1.

Faulty

2.

Faulty

3.

Faulty

J109

on

4.

Faulty

board.

5.

Faulty

6.

Faulty

7.

Faulty

1.

The

patient’s

probe.

2.

If

the

used,

1.

If

this

turned

If

this

message

connector

connector

2.

Faulty

3.

Faulty

4.

Faulty

J109

on

5.

Faulty

board.

6.

Faulty

7.

Faulty

8.

Faulty

SpO2

hardware

light

SpO2

probe.

SpO2

input

connection

the

Digital

connection

SpO2

board.

Analog

Digital

pulse

same

message

the

SpO2

message

on,

the

is

from

the

on

the

SpO2

probe.

SpO2

input

connection

the

Digital

connection

SpO2

board.

Analog

Digital

malfunction.

Possible

is

is

board.

board.

board

appears

SpO2

continuously

probe

connector

board.

board.

Cause/Criteria

not

correctly

too

bright.

connector

between

board.

between

is

too

weak

appears

is

faulty.

immediately

board

is

inserted

panel,

connector

between

board.

between

attached

on

the

J009

on

the

SpO2

to

when

is

faulty.

displayed

then

on

the

JOO9

on

the

SpO2

to

connector

the

Analog

board

be

picked

other

SpO2

after

even

into

the

there

connector

the

Analog

board

the

and

up

the

when

SpO2

is

a:

and

patient.

panel.

board

the

Analog | 4.

by

the

probes

power

is

the

input

panel.

board

the

Analog | 5.

1.

2.

1.

2.

and

SpO2 | 1.

are

SpO2

and

3.