DATA SHEET

5 4

1 2 3

1.

2.

3.

4.

5.

Marking: DB

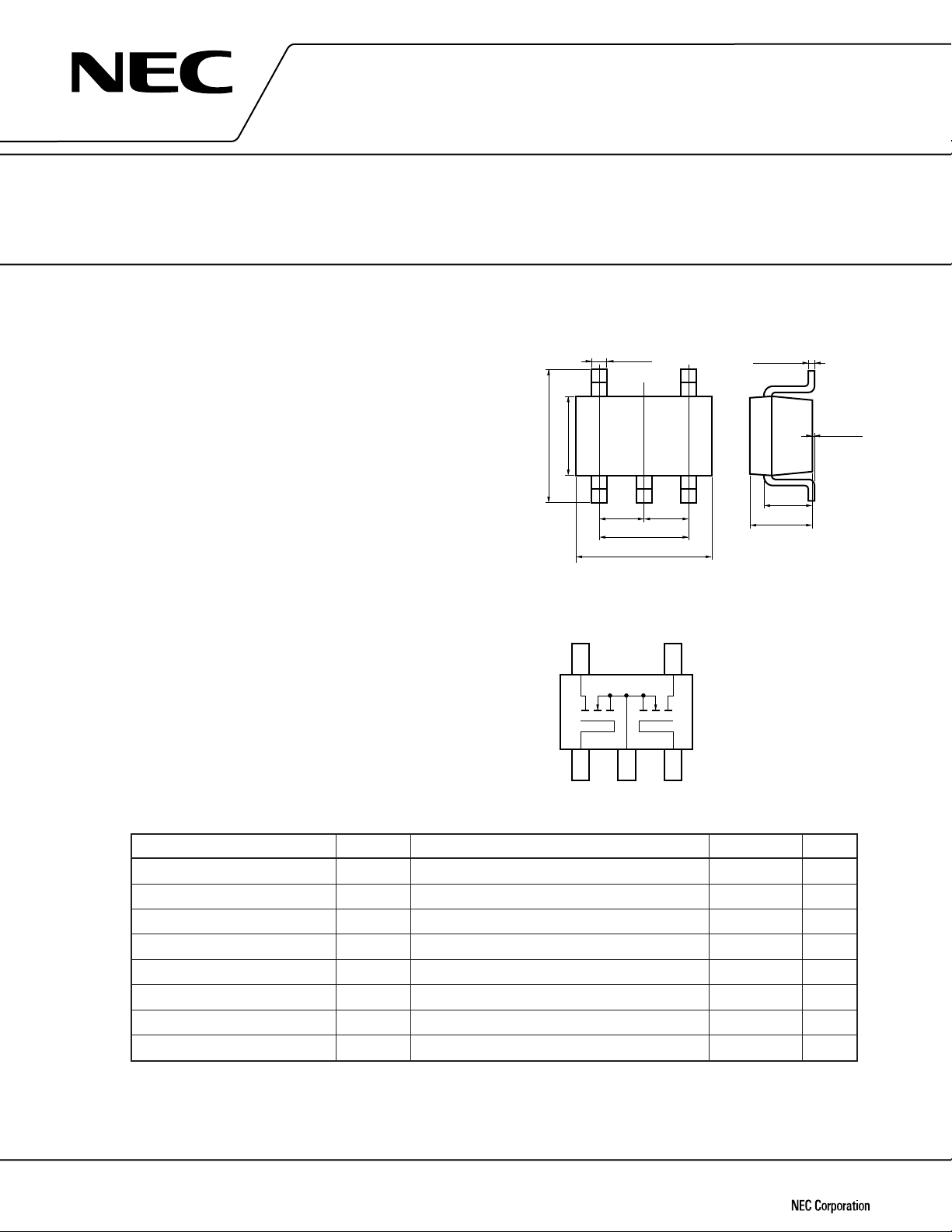

PIN CONNECTION

(G1)

(common)

(G2)

(D2)

(D1)

Gate 1

Source

Gate 2

Drain 2

Drain 1

MOS FIELD EFFECT TRANSISTOR

µ

N-CHANNEL MOS FET (5-PIN 2 CIRCUITS)

FOR SWITCHING

PA572T

The µPA572T is a super-mini-mold device provided with

two MOS FET circuits. It achieves high-density mounting

and saves mounting costs.

FEATURES

• Two source common MOS FET circuits in package the

same size as SC-70

• Directly driven by 3 V power supply

• Automatic mounting supported

PACKAGE DIMENSIONS (in millimeters)

2.1 ±0.1

1.25 ±0.1

+0.1

0.2

–0

0.65 0.65

1.3

2.0 ±0.2

0.15

0.9 ±0.1

+0.1

–0.05

0.7

0 to 0.1

EQUIVALENT CIRCUIT

Document No. G11244EJ1V0DS00 (1st edition)

Date Published June 1996 P

Printed in Japan

ABSOLUTE MAXIMUM RATINGS (TA = 25 ˚C)

PARAMETER SYMBOL TEST CONDITIONS RATINGS UNIT

Drain to Source Voltage VDSS V GS = 0 30 V

Gate to Source Voltage VGSS VDS = 0 ±7V

Drain Current (DC) ID(DC) ±100 mA

Drain Current (pulse) ID(pulse) PW ≤ 10 ms, Duty Cycle ≤ 50 % ±200 mA

Total Power Dissipation PT 200 (Total) mW

Channel Temperature Tch 150 ˚C

Operating Temperature Topt –55 to +80 ˚C

Storage Temperature Tstg –55 to +150 ˚C

©

1996

µ

PA572T

ELECTRICAL CHARACTERISTICS (TA = 25 ˚C)

PARAMETER SYMBOL TEST CONDITIONS MIN. TYP. MAX. UNIT

Drain Cut-off Current IDSS VDS = 30 V, VGS = 0 1.0

Gate Leakage Current IGSS VGS = ±5 V, VDS = 0 ±3.0

Gate Cut-off Voltage VGS(off) VDS = 3 V, ID = 10 µA 0.8 1.0 1.5 V

Forward Transfer Admittance |yfs|VDS = 3 V, ID = 10 mA 20 50 mS

Drain to Source On-State Resistance

Drain to Source On-State Resistance

RDS(on)1 VGS = 2.5 V, ID = 1 mA 7 13 Ω

RDS(on)2 VGS = 4.0 V, ID = 10 mA 5 8 Ω

Input Capacitance Ciss VDS = 5.0 V, VGS = 0, f = 1 MHz 16 pF

Output Capacitance Coss 14 pF

Reverse Transfer Capacitance Crss 2pF

Turn-On Delay Time td(on) VDD = 5 V, ID = 10 mA, VGS(on) = 5 V, 15 ns

Rise Time tr

RG = 10 Ω, RL = 500 Ω

20 ns

Turn-Off Delay Time td(off) 100 ns

Fall Time tf 100 ns

µ

A

µ

A

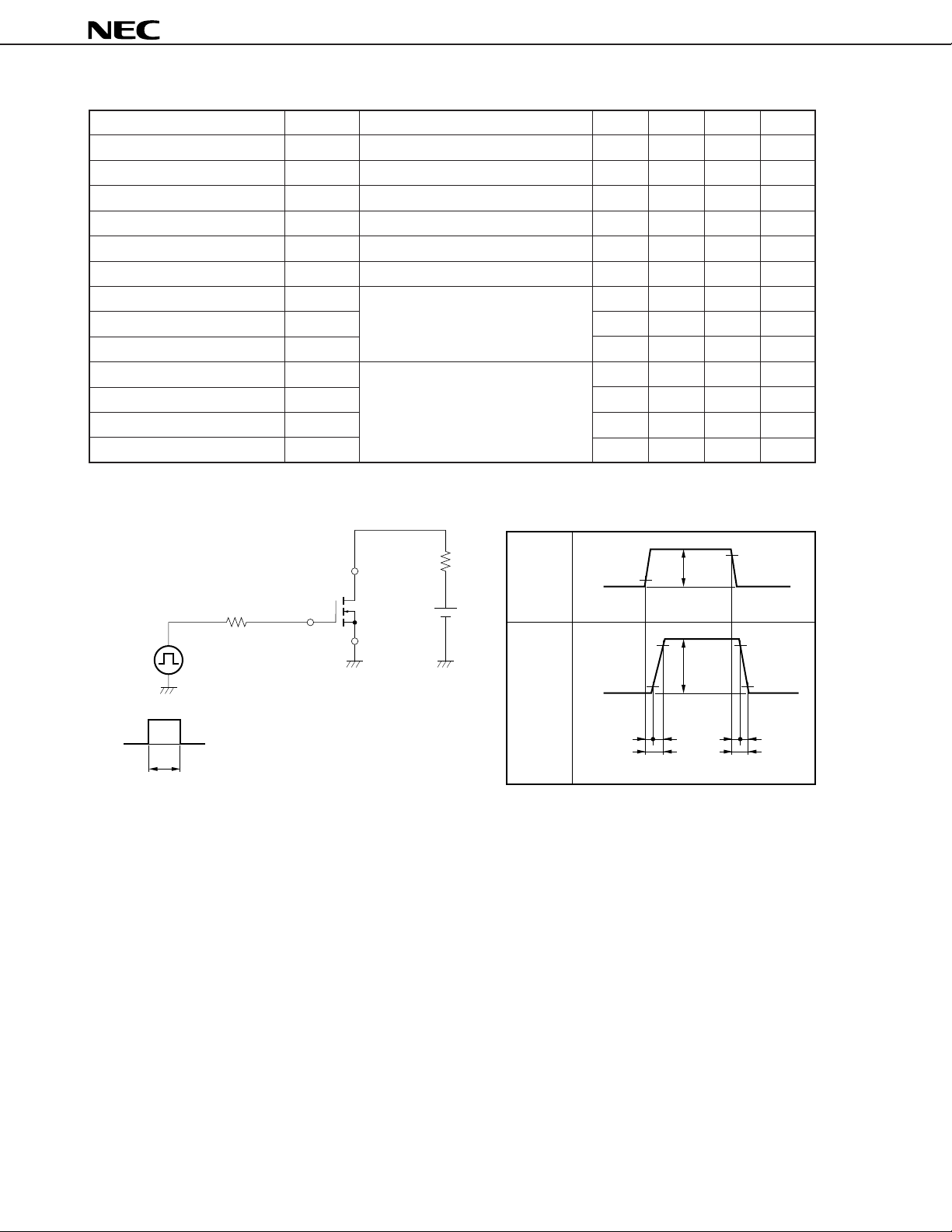

SWITCHING TIME MEASUREMENT CIRCUIT AND CONDITIONS (RESISTANCE LOADED)

V

PG.

GS

V

0

τ

τ = 1 s

µ

Duty Cycle ≤ 1 %

GS

R

DUT

L

V

G

R

Gate

voltage

waveform

DD

Drain

current

10 %

0

I

D

10 % 10 %

0

90 %

V

I

D

waveform

t

d(on)

t

r

t

t

on

GS(on)

d(off)

t

off

90 %

90 %

t

r

2

TYPICAL CHARACTERISTICS (TA = 25 ˚C)

µ

PA572T

DERATING FACTOR OF FORWARD BIAS

SAFE OPERATING AREA

100

80

60

40

dT - Derating Factor - %

20

0

20 40 60 80 100 120 140 160 30 60 90 120 150 180

T

C

- Case Temperature - ˚C

TRANSFER CHARACTERISTICS

500

VDS = 3 V

Pulsed

100

measurement

10

1

TOTAL POWER DISSIPATION vs.

AMBIENT TEMPERATURE

250

200

150

Total

100

50

- Total Power Dissipation - mW

T

P

0

A

- Ambient Temperature - ˚C

T

GATE TO SOURCE CUTOFF VOLTAGE

vs. CHANNEL TEMPERATURE

2.0

1.6

1.2

Total power

dissipation

V

DS

= 30 V

I

D

= 10 A

µ

TA = 150 ˚C

0.1

- Drain Current - mA

D

I

0.01

0.001

0.1

GS

V

1.00.5 1.5 2.0 2.5 3.0 3.5

- Gate to Source Voltage - V

75 ˚C

25 ˚C

–25 ˚C

FORWARD TRANSFER ADMITTANCE

vs. DRAIN CURRENT

400

VDS = 3 V

Pulsed

200

measurement

100

–25 ˚C

50

20

10

5

| - Forward Transfer Admittance - mS

2

fs

|y

1

0.5

1 2 5 10 20 50 100 200

D

- Drain Current - mA

I

TA = 25 ˚C

75 ˚C

150 ˚C

0.8

- Gate Cut-off Voltage - V

0.4

GS(off)

V

0

–50

0 50 100 150

ch

- Channel Temperature - ˚C

T

DRAIN TO SOURCE ON-STATE RESISTANCE

vs. GATE TO SOURCE VOLTAGE

12

10

8

6

10 mA

4

- Drain to Source On-State Resistance - Ω

DS(on)

R

2

0

21 345678

GS

- Gate to Source Voltage - V

V

Pulsed

measurement

ID = 100 mA

3

µ

PA572T

DRAIN TO SOURCE ON-STATE RESISTANCE

vs. DRAIN CURRENT

24

20

16

- Drain to Source On-State Resistance - Ω

DS(on)

R

12

8

4

0

12 51020 60

0.5

TA = 150 ˚C

75 ˚C

25 ˚C –25 ˚C

D

- Drain Current - mA

I

CAPACITANCE vs.

DRAIN TO SOURCE VOLTAGE

50

30

10

- Capacitance - pF

3

rss

, C

oss

, C

1

iss

C

VDS = 5 V

f = 1 MHz

0.3

0.3

1 3 10 30 50

DS

- Drain to Source Voltage - V

V

VGS = 2.5 V

Pulsed

measurement

C

C

C

DRAIN TO SOURCE ON-STATE RESISTANCE

vs. DRAIN CURRENT

V

GS

30

= 4 V

Pulsed

measurement

20

75 ˚C

10

–25 ˚C

25 ˚C

TA = 150 ˚C

- Drain to Source On-State Resistance - Ω

DS(on)

R

0

0.5

1 3 10 30 100 200

I

D

- Drain Current - mA

SWITCHING CHARACTERISTICS

300

t

d(on)

VDD = 5 V

V

GS

= 5 V

R

in

= 10 Ω

200

t

d(off)

t

iss

oss

rss

100

50

- Switching Time - ns

f

, t

d(off)

20

, t

r

, t

d(on)

10

t

10 20 50 100 300

6

f

t

r

D

- Drain Current - mA

I

SOURCE TO DRAIN DIODE

FORWARD VOLTAGE

200

100

GS

= 0 V

V

Pulsed

measurement

30

10

3

1

- Source to Drain Current - mA

SD

0.3

I

0.1

0.3

0.4 0.70.5 0.6 0.8 0.9 1.0 1.1

SD

- Source to Drain Voltage - V

V

4

DRAIN CURRENT vs.

DRAIN TO SOURCE VOLTAGE

100

4.0 V

80

60

40

- Drain Current - mA

D

I

20

0

12345

DS

V

3.5 V

3.0 V

2.5 V

VGS = 2.0 V

- Drain to Source Voltage - V

µ

PA572T

REFERENCE

Document Name Document No.

NEC semiconductor device reliability/quality control system TEI-1202

Quality grade on NEC semiconductor devices IEI-1209

Semiconductor device mounting technology manual C10535E

Guide to quality assurance for semiconductor devices MEI-1202

Semiconductor selection guide X10679E

5

µ

PA572T

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this

document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customer must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

“Standard“, “Special“, and “Specific“. The Specific quality grade applies only to devices developed based on

a customer designated “quality assurance program“ for a specific application. The recommended applications

of a device depend on its quality grade, as indicated below. Customers must check the quality grade of each

device before using it in a particular application.

Standard:Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special:Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific:Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices in “Standard“ unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact NEC Sales Representative in advance.

Anti-radioactive design is not implemented in this product.

M4 94.11

Loading...

Loading...