LCD Projector

MODEL VT440 VT540

VT440G VT540G

VT440J VT540J

(Japanese model) (Japanese model)

SERVICE MANUAL

Better Service

PART No.399911031

Better Reputation

Better Profit

SAFETY CAUTION:

Before servicing this chassis, it is important that the service

technician read and follow the “Safety Precautions” and “Product

Safety Notice” in this Service Manual.

WARNING:

SHOCK HAZARD - Use an isolation transformer when servicing.

CONTENTS

SAFETY PRECAUTIONS .................................................................................................................................. 2-1

USERS MANUAL............................................................................................................................................... 3-1

TROUBLE SHOOTING ...................................................................................................................................... 4-1

METHOD OF ADJUSTMENTS .......................................................................................................................... 5-1

CIRCUIT DESCRIPTION ................................................................................................................................... 6-1

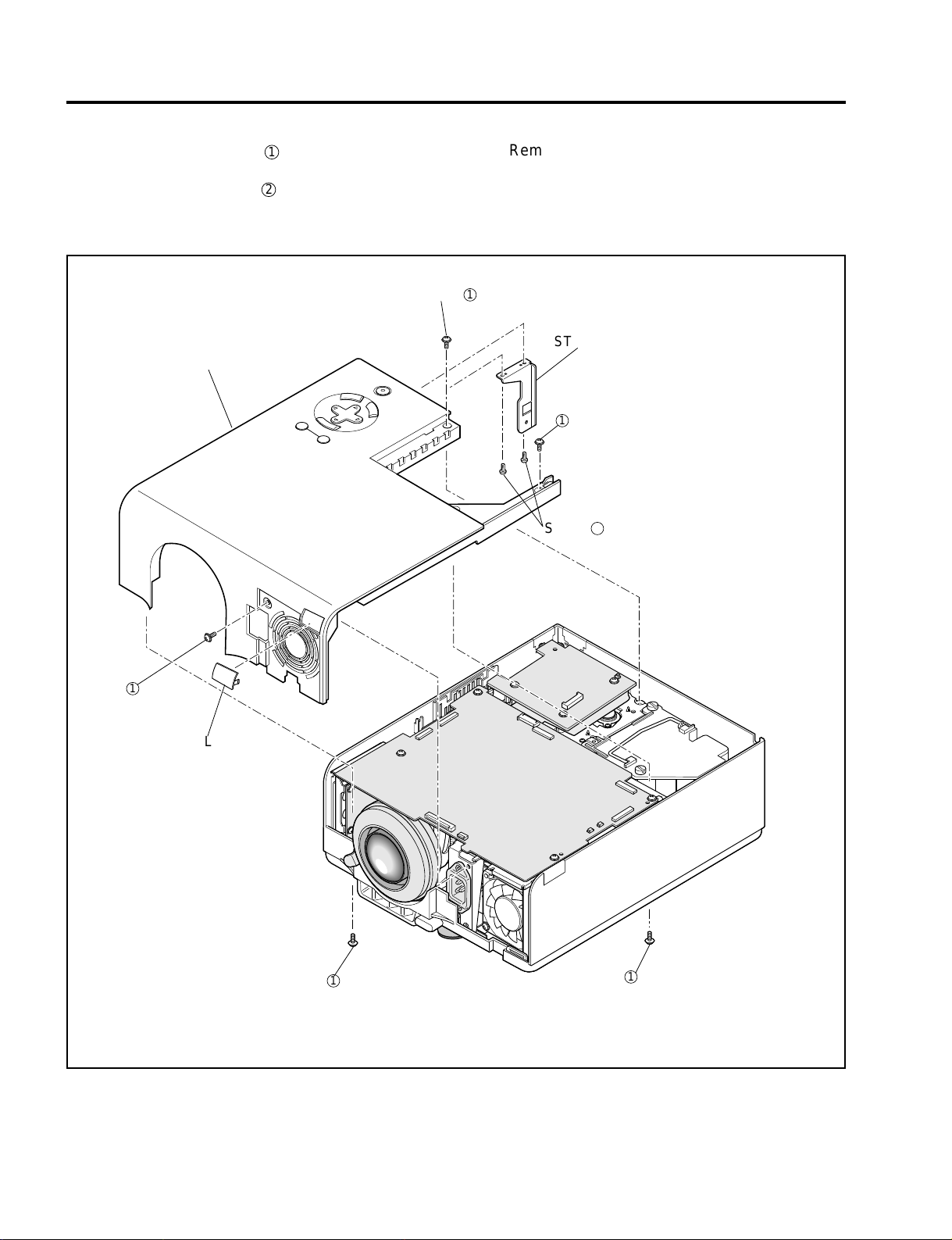

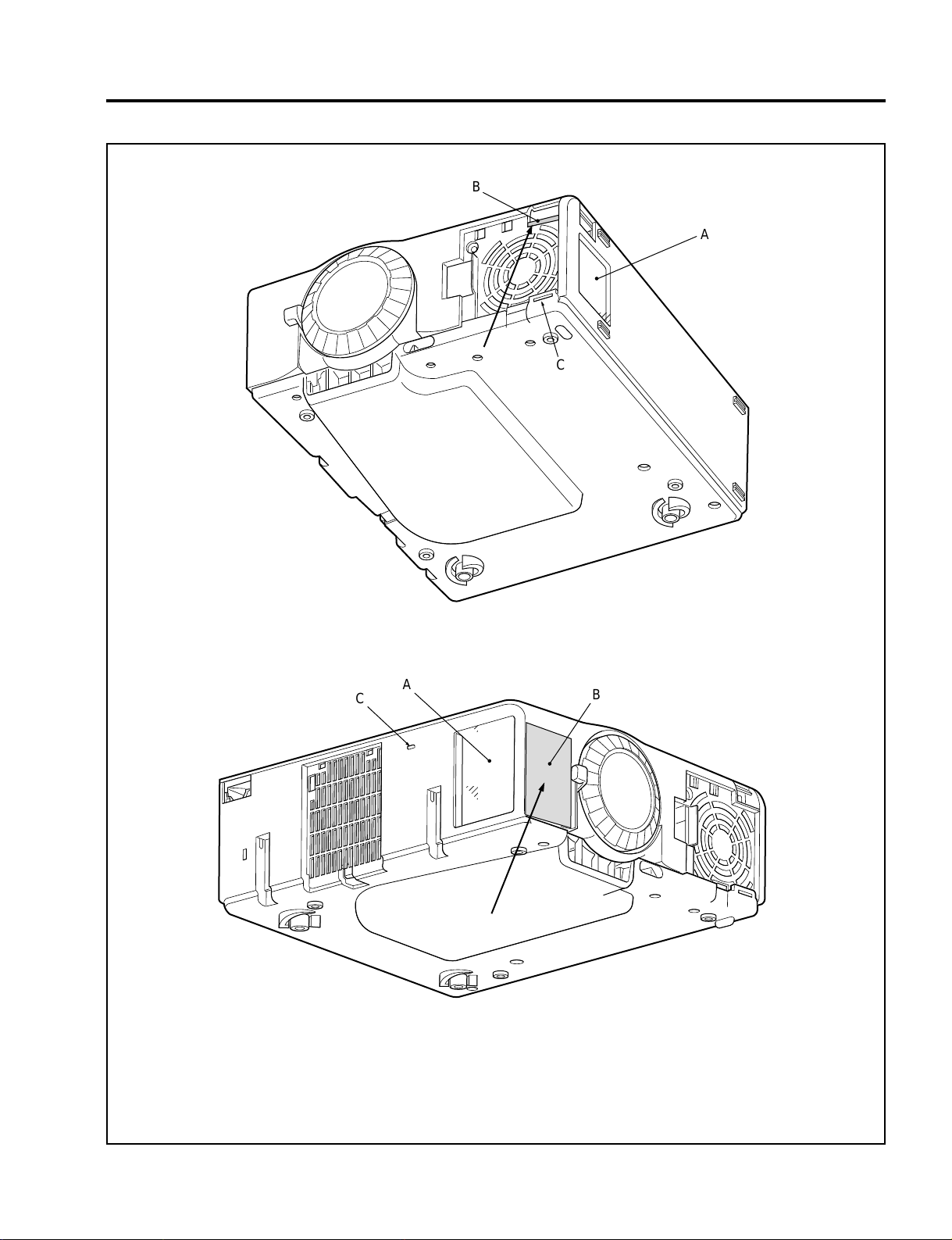

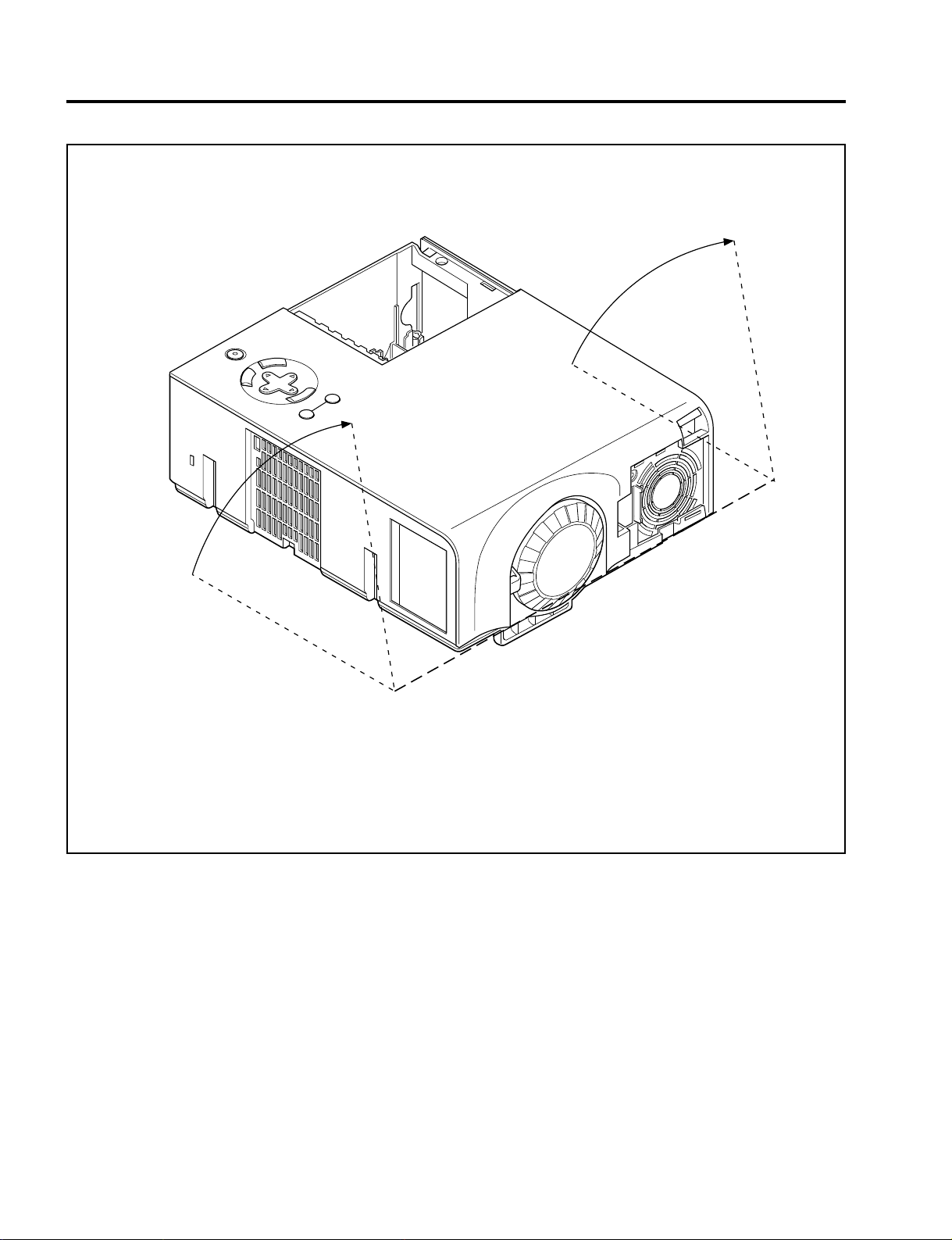

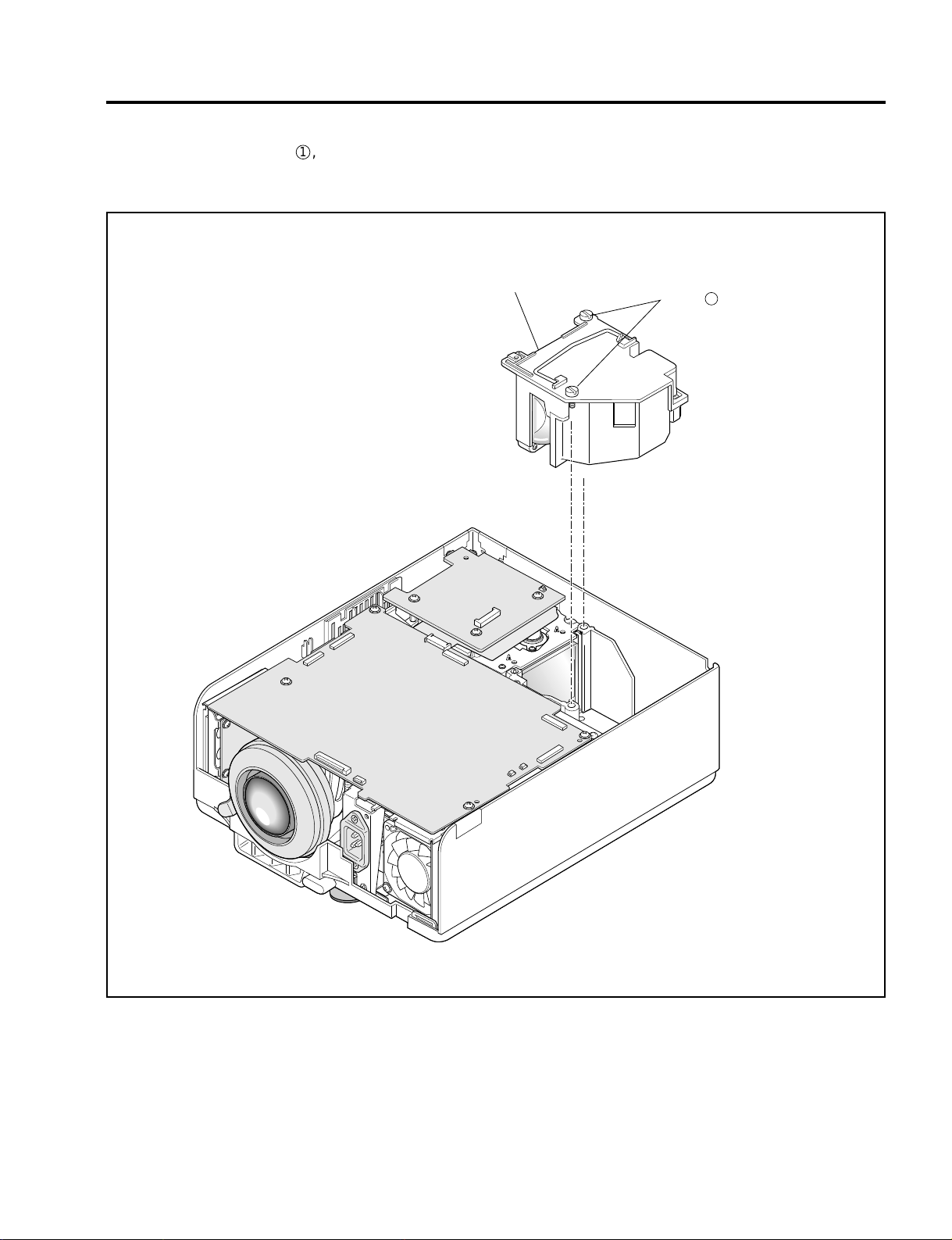

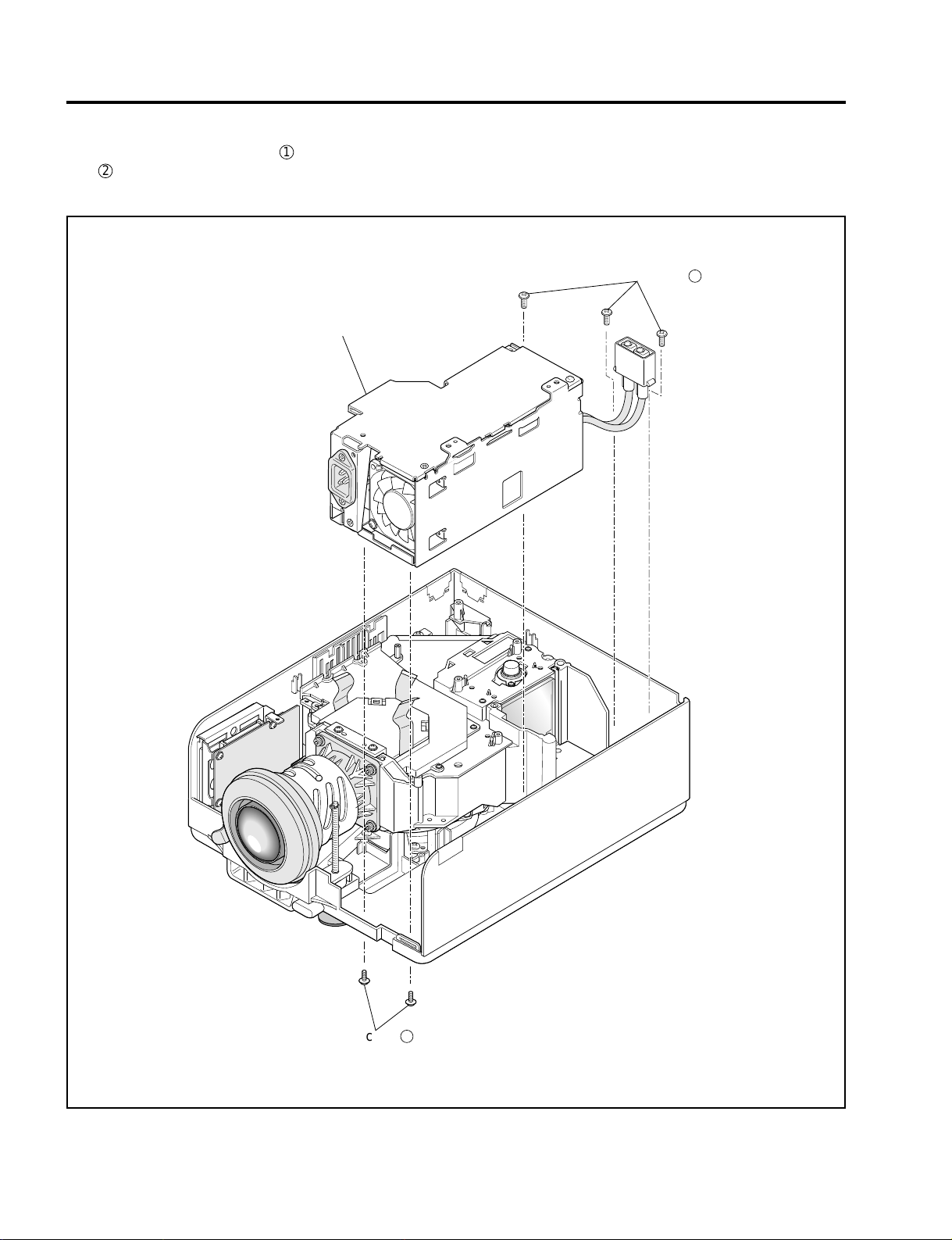

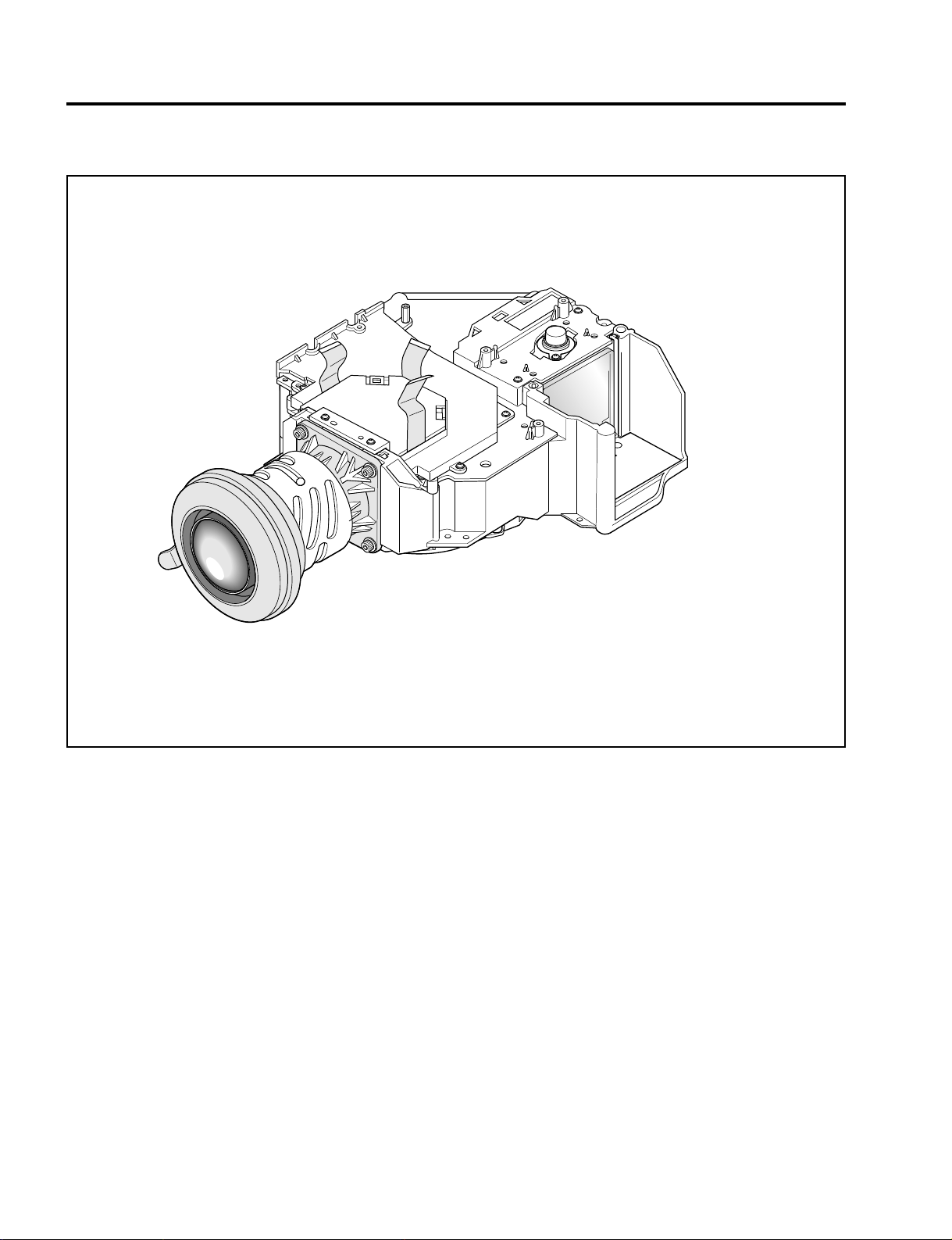

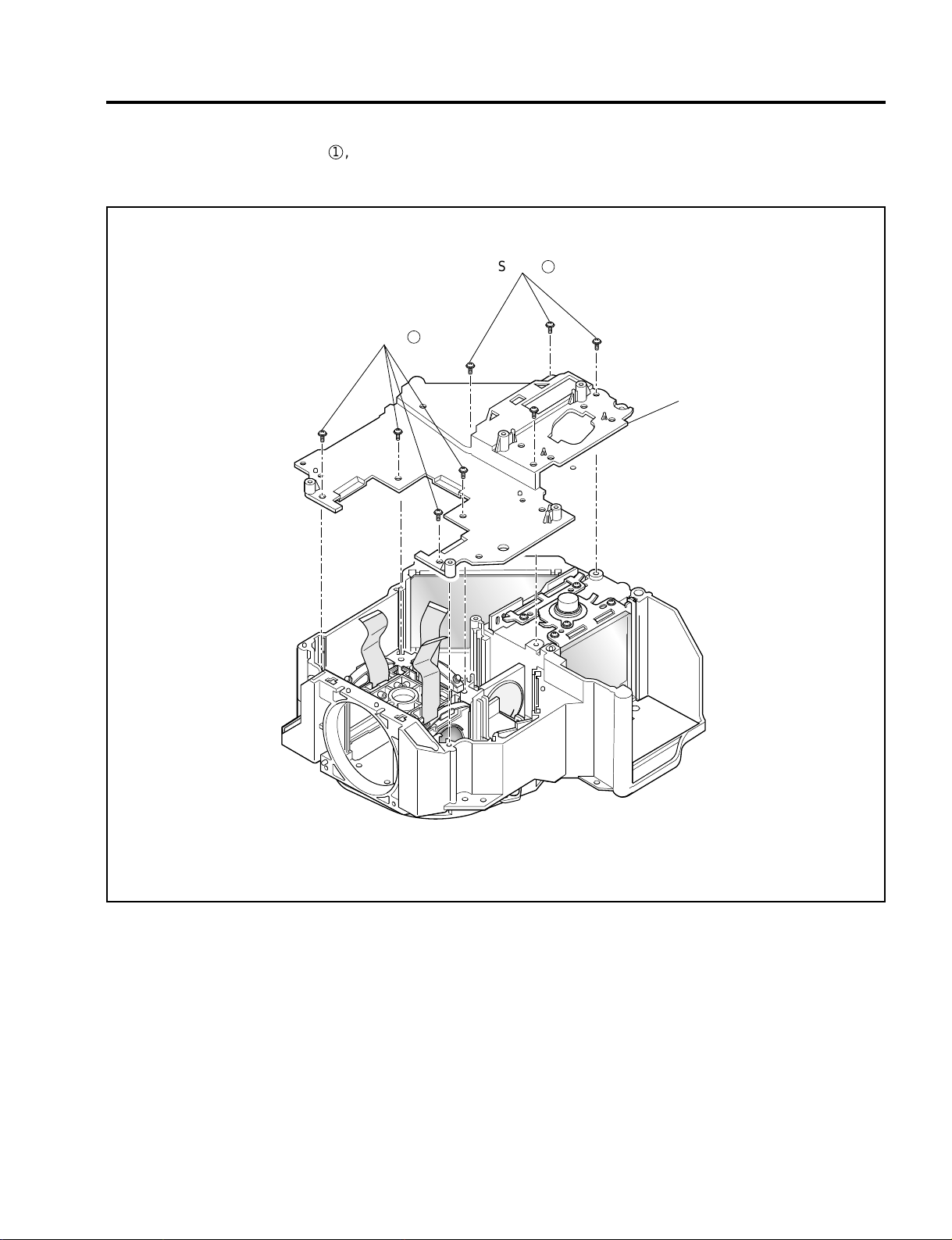

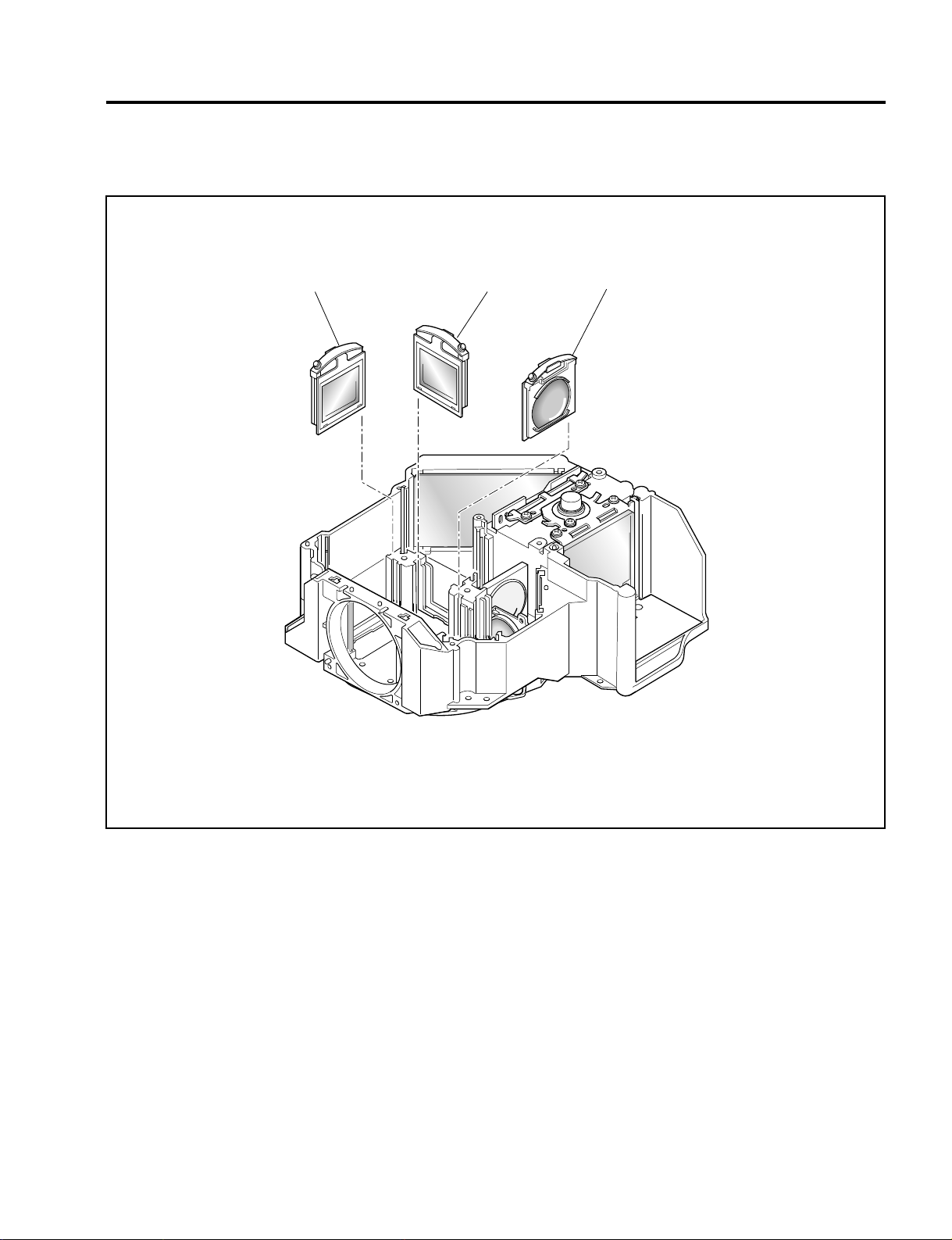

METHOD OF DISASSEMBLY ........................................................................................................................... 7-1

DISASSEMBLY.................................................................................................................................................. 8-1

PACKAGING...................................................................................................................................................... 9-1

REPLACEMENT PART LIST ........................................................................................................................... 10-1

CONNECTION DIAGRAMS............................................................................................................................. 11-1

BLOCK DIAGRAM ........................................................................................................................................... 12-1

SCHEMATIC DIAGRAMS................................................................................................................................ 13-1

1-1

SAFETY PRECAUTIONS

CAUTION

RISK OF ELECTRIC SHOCK

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE

COVER. NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

This symbol warns the user that uninsulated voltage within the unit may

have sufficient magnitude to cause electric shock. Therefore, it is dangerous

to make any kind of contact with any part inside of this unit.

This symbol alerts the user that important literature concerning the

operation and maintenance of this unit has been included.

Therefore, it should be read carefully in order to avoid any problems.

DO NOT OPEN

ATTENTION

RISQUE D'ELECTROCUTION

NE PAS OUVRIR

MISE EN GARDE: AFIN DE REDUIRE LES RISQUES D' ELECTROCUTION, NE PAS

DEPOSER LE COUVERCLE, IL N'Y A AUCUNE PIECE

UTILISABLE A L'INTERIEUR DE CET APPAREIL. NE CONFIER

LES TRAVAUX D'ENTRETIEN QU'A UN PERSONNEL QUALIFIE.

Ce symbole a pour but de prévenir I' utilisateur de la présence d'

une tension dangereuse, non isolée se trouvant à l' intérieur de l'

appareil. Elle est d' une intensité suffisante pour constituer un risque

d' électrocution. Eviter le contact avec les pièces à l' intérieur de

cet appareil.

Ce symbole a pour but de prévenir l' utilisateur de la présence d'

importantes instructions concernant l' entretien et le fonctionnement

de cet appareil. Par conséquent, elles doivent être lues

attentivement afin d' éviter des problèmes.

2-1

SAFTY PRECAUTIONS

During servicing carefully observe the following.

1. OBSERVE ALL PRECAUTIONS

Items and locations that require special care during servicing, such as the cabinet, chassis, and parts are labelled

with individual safety instructions. Carefully comply with

these instructions and all precautions in the instruction

manual.

2. BE CAREFUL OF ELECTRIC SHOCK

The chassis carries an AC voltage. If you touch the

chassis while it is still alive, you will get a severe shock.

If you think the chassis is alive, use an isolating

transformer or gloves, or pull out the plug before

replacing any parts.

3. USE SPECIFIED PARTS

The components have been chosen for minimum

flammability and for specific levels of resistance value

and withstand voltage. Replacement parts must match

these original specifications. Parts whose specifications

are particularly vital to safe use and maintenance of the

set are marked on the circuit diagrams and parts list.

Substitution of these parts can be dangerous for you

and the customer, so use only specified parts.

4. REMOUNT ALL PARTS AND RECONNECT ALL

WIRES AS ORIGINALLY INSTALLED

For safety, insulating tape and tubes are used

throughout, but some lift-off parts on the printed wiring

board require special attention.

All wires are positioned away from high-temperature and

high-voltage parts, and, if removed for servicing, they

must be retuned precisely to their original positions.

5. LAMP

Be very careful of the lamp because it generates high

heat while it is used at high voltage. When replacing

the bulb, make sure it is cool enough.

6. LENS

Do not look into the lens during projection. This important

to avoid damage to the eyes.

7. SERVICING

At the time of repair or inspection services, use an earth

band (wrist band), without fail.

8. RUN A COMPLETE SAFETY CHECK AT THE

COMPLETION OF SERVICING

After completion of servicing, confirm that all screws,

parts, and wiring, removed or disconnected for servicing,

have been returned to their original positions. Also

examine if the serviced sections and peripheral areas

have suffered from any deterioration as a result of

servicing. In addition, check insulation between external

metallic parts and blades of wall-outlet plugs. This

examination is indispensable in confirming complete

establishment of safety.

(Insulation check)

Pull out a plug from a wall outlet to disconnect the

connection cable. Then turn on the POWER switch.

Use a 500V megger (Note 2) and confirm that the

insulation resistance is 1MΩ or more between each

terminal of the plug and exposed external metal (Note

1). If the measured value is below the specified level,

then it is necessary to inspect and fix the set.

(Note 1)

Exposed external metal....RGB input terminals, control

terminals, etc.

(Note 2)

If a 500V megger is not available for an unavoidable

reason, then use a circuit tester or the like for inspection.

2-2

LCD Projector

MultiSync VT440/VT540

User’s Manual

IMPORTANT INFORMATION

Precautions

Please read this manual carefully before using your NEC

MultiSync VT440/VT540 Projector and keep the man ual

handy for future reference.

Your serial number is located under the name plate label

on the right side of your MultiSync VT440/VT540. Record

it here:

CAUTION

To turn off main power , be sure to remove the

plug from power outlet.

The power outlet socket should be installed

as near to the equipment as possible, and

should be easily accessible.

CAUTION

TO PREVENT SHOCK, DO NO T OPEN THE

CABINET.

NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED NEC

SERVICE PERSONNEL.

This symbol warns the user that uninsulated

voltage within the unit may be sufficient to

cause electrical shock. Therefore, it is dangerous to make any kind of contact with any

part inside of the unit.

This symbol alerts the user that important information concerning the operation and maintenance of this unit has been provided. The

information should be read carefully to avoid

problems.

W ARNING

TO PREVENT FIRE OR SHOCK, DO NOT EXPOSE THIS

UNIT TO RAIN OR MOISTURE.

DO NOT USE THIS UNIT’S GROUNDED PLUG WITH AN

EXTENSION CORD OR IN AN OUTLET UNLESS ALL

THREE PRONGS CAN BE FULLY INSERTED.

DO NOT OPEN THE CABINET. THERE ARE HIGH-VOLTAGE COMPONENTS INSIDE. ALL SERVICING MUST BE

DONE BY QUALIFIED NEC SERVICE PERSONNEL.

RF Interference

WARNING

The Federal Communications Commission does not

allow any modifications or changes to the unit EXCEPT

those specified by NEC Technologies in this manual.

Failure to comply with this government regulation could

void your right to operate this equipment.

This equipment has been tested and found to comply

with the limits for a Class B digital device , pursuant to

Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the

user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver .

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio / TV technician for help .

In UK, a BS approved power cable with moulded plug

has a Black (five Amps) fuse installed for use with this

equipment. If a po wer cable is not supplied with this equipment please contact your supplier.

DOC Compliance Notice

This Class B digital apparatus meets all requirements of

the Canadian Interference-Causing Equipment Regulations.

3. GSGV Acoustic Noise Information Ordinance:

The sound pressure level is less than 70 dB (A) according to ISO 3744 or ISO 7779.

• IBM is a registered trademark of International Business Machines

Corporation.

• Macintosh and PowerBook are registered trademarks of Apple

Computer, Inc.

• Other product and company names mentioned in this user's manual

may be the trademarks of their respective holders.

E–2

Important Safeguards

These safety instructions are to ensure the long life of

your projector and to prev ent fire and shock. Please read

them carefully and heed all warnings.

CAUTION

Do not unplug the power cable from the wall outlet under any

one of the following circumstances. Doing so can cause damage

to the projector:

Installation

1. For best results, use your projector in a darkened room.

2. Place the projector on a flat, level surface in a dry area away

from dust and moisture.

3. Do not place your projector in direct sunlight, near heaters

or heat radiating appliances.

4. Exposure to direct sunlight, smoke or steam can harm internal components.

5. Handle your projector carefully . Dropping or jarring can damage internal components.

6. Do not place heavy objects on top of the projector.

7. If you wish to have the projector installed on the ceiling:

a. Do not attempt to install the projector yourself.

b. The projector must be installed by qualified technicians

in order to ensure proper operation and reduce the risk

of bodily injury.

c. In addition, the ceiling must be strong enough to support

the projector and the installation must be in accordance

with any local building codes.

d. Please consult your dealer for more information.

Power Supply

1. The projector is designed to operate on a power supply of

100-120 or 200-240 V 50/60 Hz A C. Ensure that y our power

supply fits this requirement before attempting to use your

projector.

2. Handle the pow er cable carefully and a void e xcessive bending. A damaged cord can cause electric shock or fire.

3. If the projector is not to be used for an extended period of

time, disconnect the plug from the power outlet.

* While the Hour Glass icon appears.

* While the message "Please wait a little." appears. This mes-

sage will be displayed after the projector is turned off.

* Immediately after the power cable is plugged into the wall

outlet (the POWER indicator has not changed to a steady amber

glow).

* Immediately after the cooling fan stops working (The cooling

fan continues to work for 30 seconds after the projector is

turned off with the POWER button).

* While the POWER and the ST ATUS indicators are alternately

flashing.

Cleaning

1. Unplug the projector before cleaning.

2. Clean the cabinet periodically with a damp cloth. If heavily

soiled, use a mild detergent. Never use strong detergents

or solvents such as alcohol or thinner.

3. Use a blower or lens paper to clean the lens, and be careful

not to scratch or mar the lens.

E–3

Lamp Replacement

• T o replace the lamp , f ollow all instructions provided on page

E-33.

• Be sure to replace the lamp when the message "The lamp

has reached the end of its usable life. Please replace the

lamp."appears. If you continue to use the lamp after the lamp

has reached the end of its usable life, the lamp bulb may

shatter, and pieces of glass may be scattered in the lamp

case. Do not touch them as the pieces of glass may cause

injury. If this happens, contact your NEC dealer for lamp

replacement.

• Allow a minimum of 30 seconds to elapse after turning off

the projector. Then disconnect the power cable and allo w 60

minutes to cool the projector before replacing the lamp.

Fire and Shock Precautions

1. Ensure that there is sufficient ventilation and that vents are

unobstructed to prevent the build-up of heat inside y our projector. Allow at least 3 inches (10 cm) of space between

your projector and a wall.

2. Prevent foreign objects such as paper clips and bits of paper from falling into your projector. Do not attempt to retrieve any objects that might fall into your projector. Do not

insert any metal objects such as a wire or screwdriver into

your projector. If something should fall into your projector,

disconnect it immediately and have the object remov ed by a

qualified NEC service personnel.

3. Do not place any liquids on top of your projector.

• Do not look into the lens while the projector is on. Serious

damage to your eyes could result.

• Keep any items such as magnifying glass out of the light

path of the projector. The light being projected from the lens

is extensive, therefore any kind of abnormal objects that

can redirect light coming out of the lens, can cause unpredictable outcome such as fire or injury to the eyes.

• Do not cover the lens with the supplied lens cap or equivalent while the projector is on. Doing so can lead to melting of

the cap and possibly burning your hands due to the heat

emitted from the light output.

E–4

TABLE OF CONTENTS

1. INTRODUCTION

Introduction to the MultiSync VT440/VT540 Projector

Getting Started ............................................................ E-6

What’s in the Box ......................................................... E-7

Getting to Know Your MultiSync VT440/VT540 Projector

Front / Side Features ..............................................E-8

Rear / Side Features............................................... E-9

Top Features ......................................................... E-10

Terminal Panel Features ....................................... E-11

Remote Control Features...................................... E-12

.................E-6

..................E-8

2. INSTALLATION

Setting Up Your Projector........................................... E-14

Selecting a Location ..................................................E-14

Using a Tabletop or Cart ............................................E-14

Distance Chart...........................................................E-15

Ceiling Installation ..................................................... E-16

Reflecting the Image.................................................. E-16

Wiring Diagram..........................................................E-17

Connecting Y our PC ..............................................E-18

Connecting Your Macintosh Computer ..................E-19

Connecting an External Monitor............................ E-21

Connecting Your DVD Player................................. E-22

Connecting Your VCR or Laser Disc Player .......... E-23

3. OPERATION

General Controls ....................................................... E-24

Enlarging and Moving a Picture................................. E-24

Using the Menus........................................................ E-25

Menu Tree .................................................................. E-26

Menu Elements.......................................................... E-27

Menu Descriptions & Functions.................................E-28

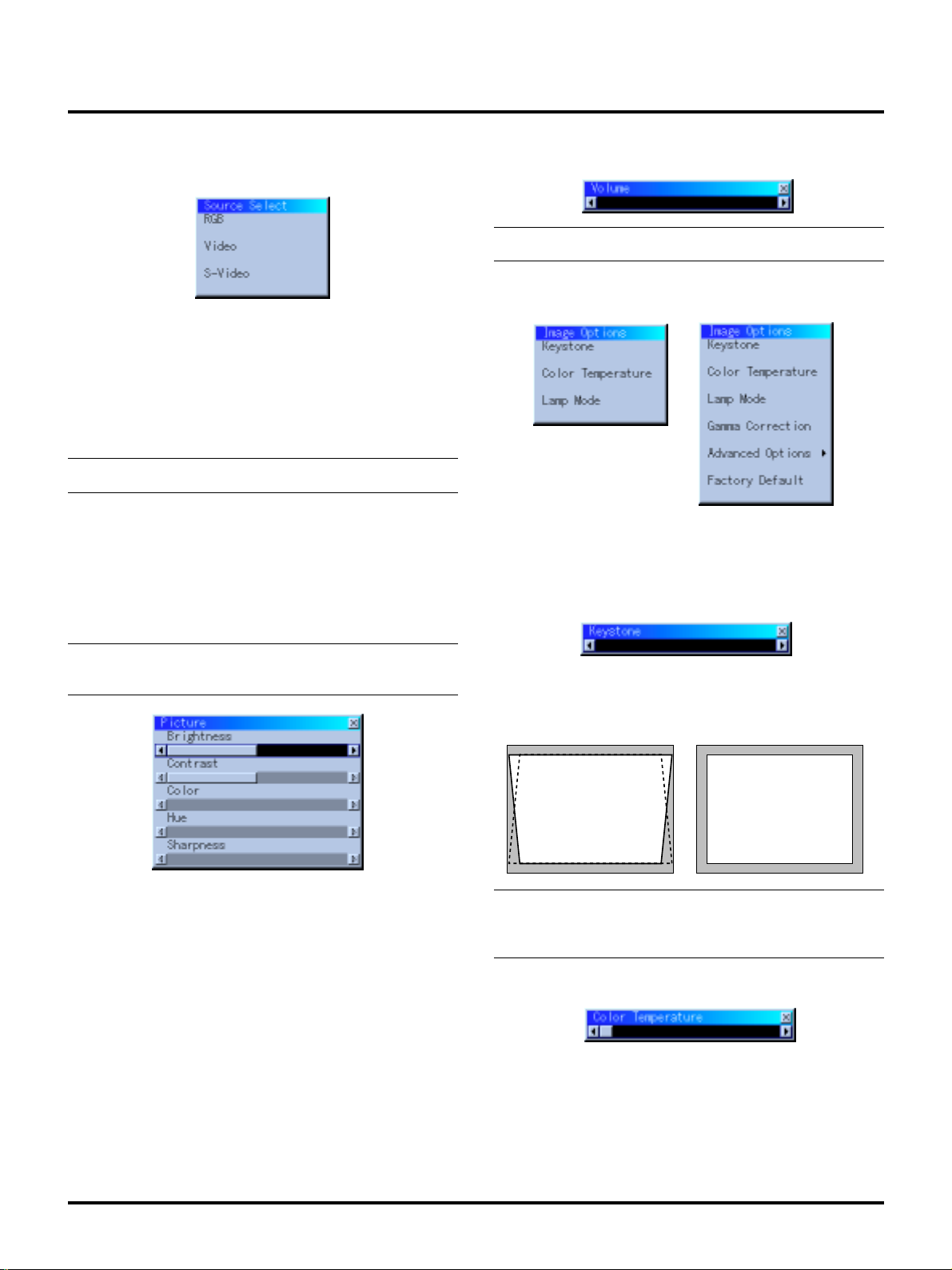

Source Select ............................................................E-28

RGB/Video/S-Video

Picture ....................................................................... E-28

Brightness/Contrast/Color/Hue/Sharpness

Volume.......................................................................E-28

Image Options ...........................................................E-28

Keystone ...............................................................E-28

Color Temperature ................................................ E-28

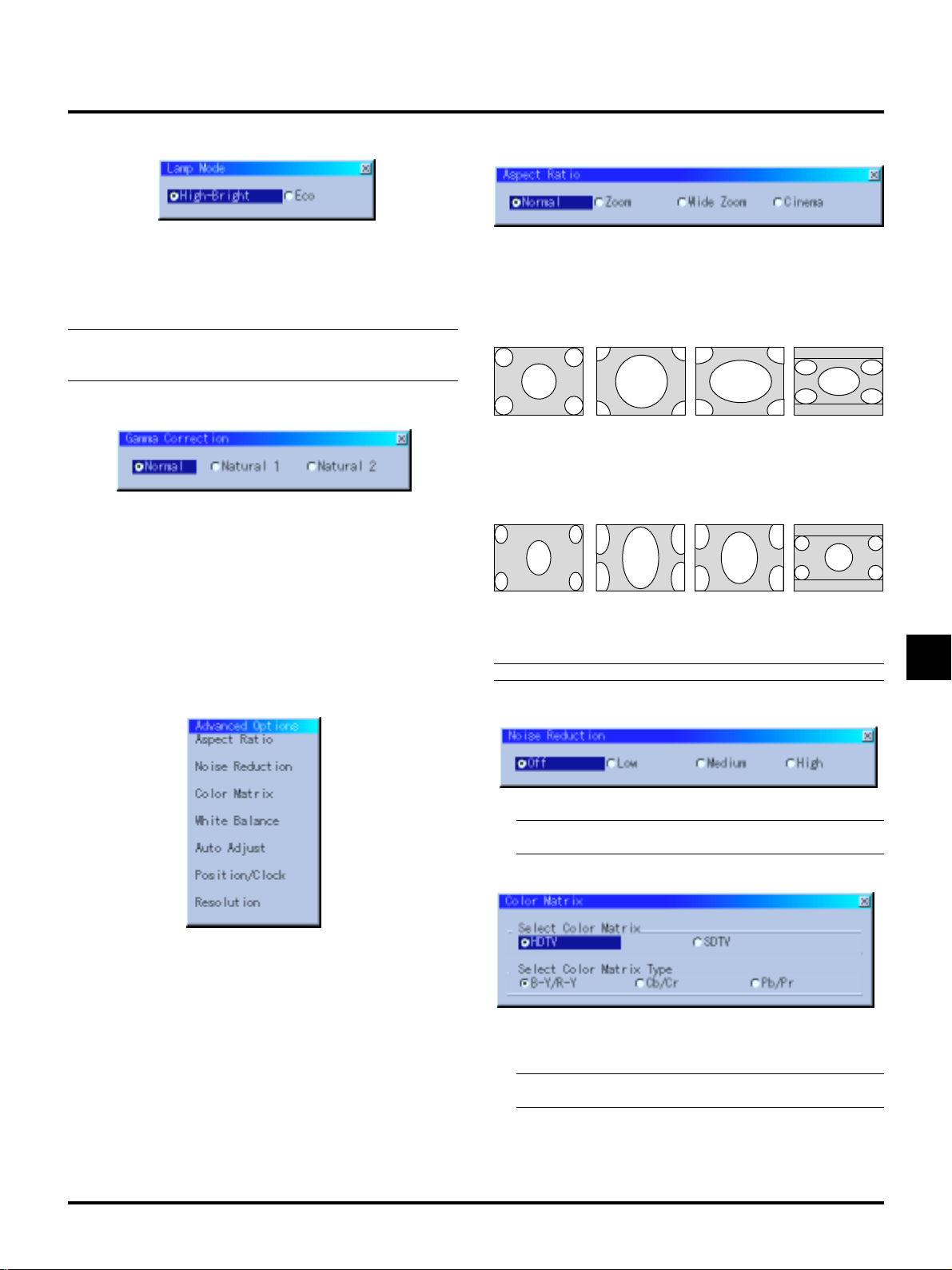

Lamp Mode ........................................................... E-29

Gamma Correction................................................ E-29

Aspect Ratio.......................................................... E-29

Noise Reduction.................................................... E-29

Color Matrix........................................................... E-29

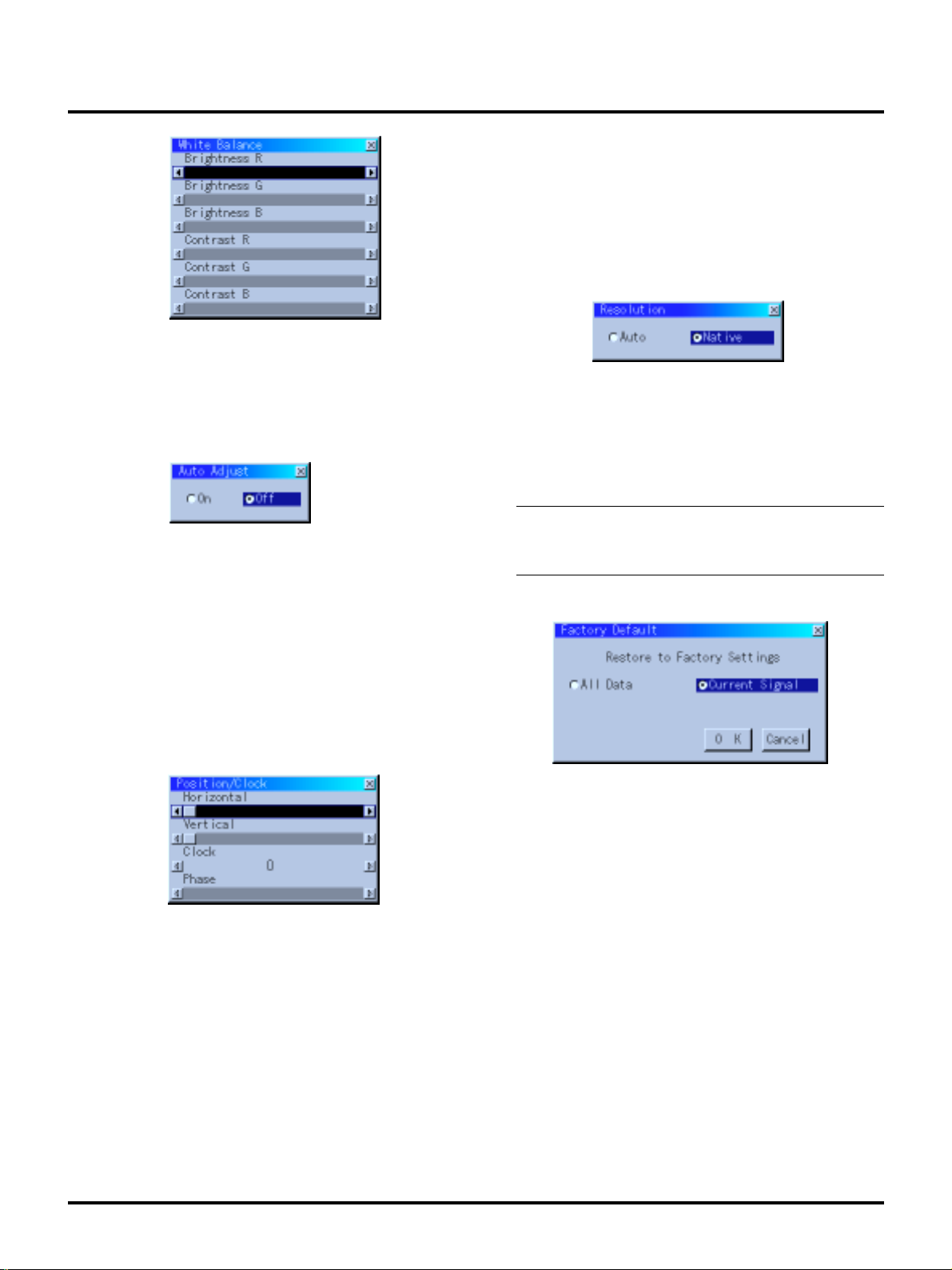

White Balance....................................................... E-30

Auto Adjust............................................................ E-30

Position/Clock ....................................................... E-30

Resolution .............................................................E-30

Factory Default...................................................... E-30

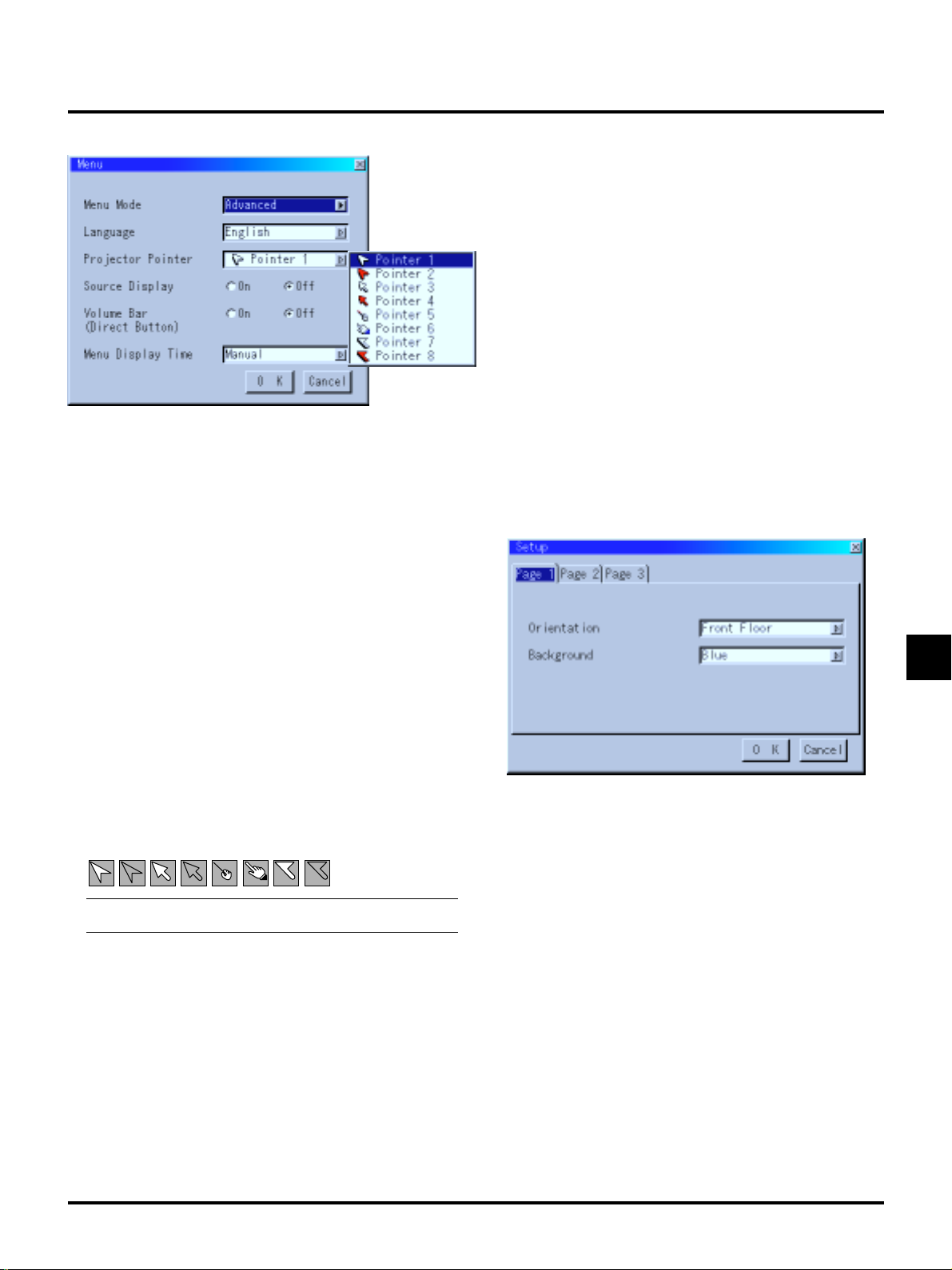

Menu.......................................................................... E-31

Menu Mode ........................................................... E-31

Basic/Advanced................................................E-31

Language ..............................................................E-31

Projector Pointer ................................................... E-31

Source Display...................................................... E-31

Volume Bar (Direct Button) ................................... E-31

Menu Display Time................................................ E-31

Setup .........................................................................E-31

Orientation ............................................................ E-31

Background........................................................... E-31

Signal Select .........................................................E-32

Auto Start ..............................................................E-32

Power Management.............................................. E-32

Power Off Confirmation......................................... E-32

Keystone Save ......................................................E-32

Clear Lamp Hour Meter ........................................ E-32

Help ...........................................................................E-32

Contents................................................................ E-32

Information ............................................................ E-32

4. MAINTENANCE

Replacing the Lamp................................................... E-33

Remote Control Battery Installation...........................E-34

Cleaning or Replacing the Filters .............................. E-34

5. TROUBLESHOO TING

Power / Status Light Messages ................................. E-35

Common Problems & Solutions................................. E-35

6. SPECIFICATIONS

Optical/Electrical/Mechanical..................................... E-36

Cabinet Dimensions .................................................. E-37

D-Sub Pin Assignments............................................. E-38

Timing Chart .............................................................. E-39

PC Control Codes...................................................... E-40

Cable Connection ...................................................... E-40

E–5

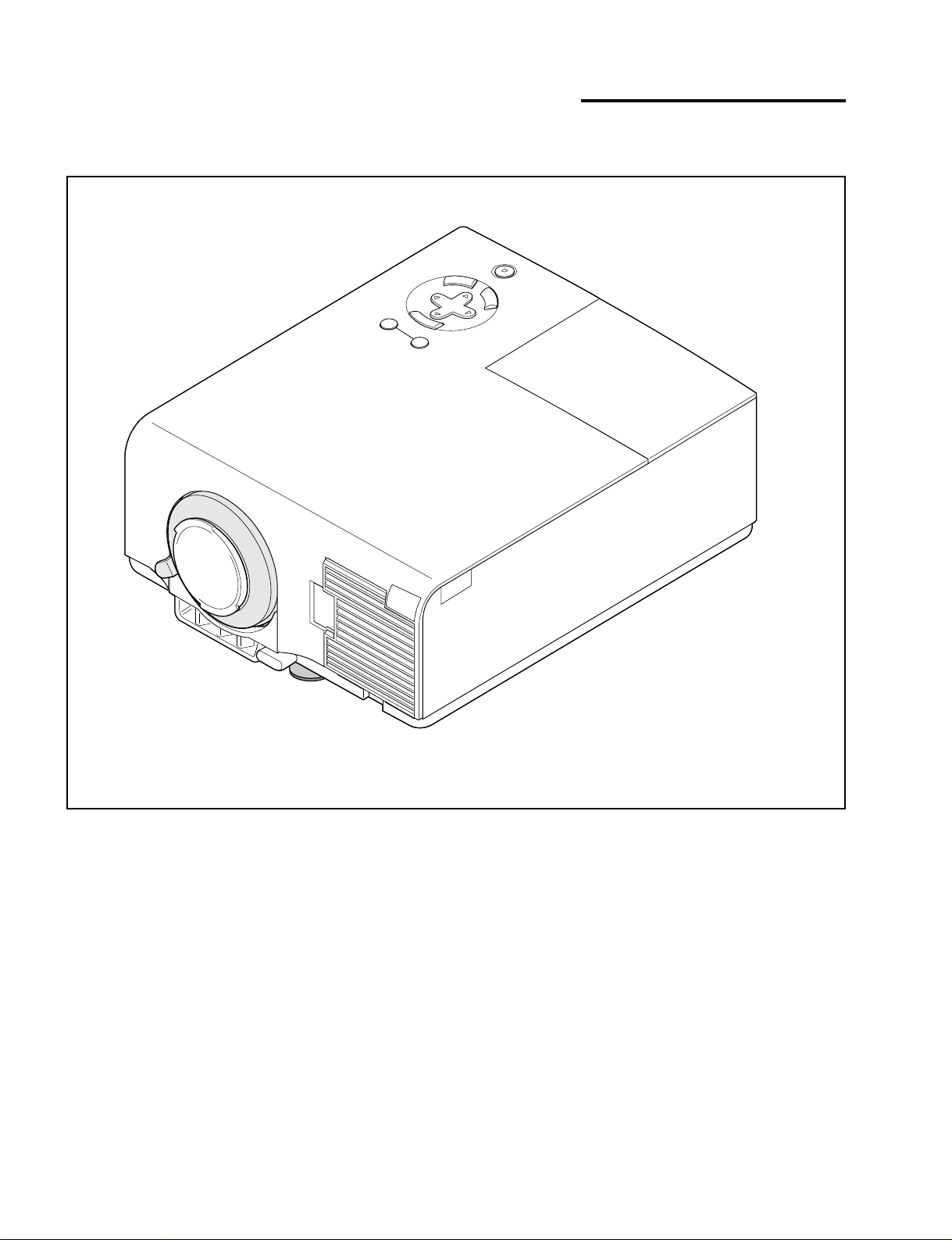

1. INTRODUCTION

Introduction to the MultiSync VT440/VT540 Projector

This section introduces you to your new MultiSync VT440 (SVGA)/

VT540 (XGA) Projector and describes the features and controls.

Congratulations on Your Purchase of The MultiSync VT440/

VT540 Projector

The MultiSync VT440/VT540 is one of the very best projector s available today. The MultiSync VT440/VT540 enables you to project precise images up to 300 inches across (measured diagonally) from your

PC or Macintosh computer (desktop or notebook), VCR, D VD player,

document camera, or even a laser disc player.

You can use the projector on a tabletop or cart, you can use the projector to project images from behind the screen, and the projector can

be permanently mounted on a ceiling*1. The remote control can be

used wirelessly.

• The supplied remote control can be used without a cable.

• You can control the projector with a PC using the PC Control

• The contemporary cabinet design is light, compact, easy to carry ,

• Eight pointers are available for your presentation.

*1 Do not attempt to mount the projector on a ceiling yourself.

*2 An XGA image (10242768) is con verted into an 8002600 crisp

*3 An SXGA image (128021024) is converted into a 10242768

Features you’ll enjoy:

• Simple set up and operation.

• Front ventilation directs hot air away from your audience.

• A high-performance 160 watt NSH (130 watt in Eco mode) lamp.

The lamp life can be extended up to 3000 hours by using the Eco

mode.

• The supplied wireless remote control that operates the projector

from any angle.

• Manual zoom control enables you to adjust the image between

25 (0.63 m) and 300 inches (7.6 m) (measured diagonally).

• Keystone correction allo ws you to correct trapezoidal distortion

so that the image is square.

• Y ou can choose between video modes depending on your source:

“normal” for a typical picture, “natural” for true color reproduction.

• An image can be projected from in front or behind a screen, and

the projector can even be installed on the ceiling.

• NEC Technologies’ exclusive Advanced AccuBlend intelligent

pixel blending technology - an extremely accurate image compression technology - offers a crisp image with SXGA (1280 x

1024) resolution*3.

• Supports most IBM VGA, SVGA, XGA*2 , SXGA(with Advanced AccuBlend)*3, Macintosh, component signal (YCbCr /

YPbPr) or any other RGB signals within a horizontal frequency

range of 15 to 100 kHz and a vertical frequency range of 50 to

117 Hz. This includes NTSC, PAL, PAL60, SECAM and

NTSC4.43 standard video signals.

NOTE: Composite video standards are as follows:

NTSC: U.S. TV standard for video in U.S. and Canada.

PAL: TV standard used in Western Europe.

PAL60: TV standard used for NTSC playback on PAL TVs.

SECAM: TV standard used in France and Eastern Europe.

NTSC4.43: TV standard used in Middle East countries.

Getting Started

The fastest way to get started is to take your time and do everything

right the first time. Take a few minutes now to review the user’s

manual. This may save you time later on. At the beginning of each

section of the manual you’ll find an overview. If the section doesn’t

apply, you can skip it.

port.

and complements any office, boardroom or auditorium.

The projector must be installed by qualified technicians in order

to ensure proper operation and reduce the risk of bodily injury.

In addition, the ceiling must be strong enough to support the projector and the installation must be in accordance with any local

building codes. Please consult your dealer for more information.

image with NEC technology’s Advanced AccuBlend on VT440.

crisp image with NEC technology’s Advanced AccuBlend on

VT540.

E–6

What's in the Box?

RGB

INPUT

OUTPUT

AUD

IN

OUT

PC-CONTROL S-VIDEO VID

Make sure your box contains everything listed. If any pieces are missing, contact your dealer.

Please save the original box and packing materials if you ever need to ship your MultiSync VT440/VT540 Projector.

POWER

STATUS

ON

N

E

T

E

/

R

OFF

C

A

N

C

E

L

RD-366E

MAGNIFY

HELP

SELECT

M

E

N

U

E

N

T

E

R

POINTER

POWER

MUTE

SOURCE AUTO ADJUST

Projector

SOURCE

N

U

E

M

SELECT

Vol.

C

A

N

C

PIC.

AUTO

ADJ.

Vol.

L

E

Card remote control

Lens cap

String and rivet

ON DIP

1

23456

Power cable

Quick

Connect

Signal cable

Pin adapter for Macintosh

Guide

User's

Manual

E–7

RGB

INPUT

OUTPUT

AUD

IN

OUT

PC-CONTROL S-VIDEO VID

Getting to Know Your MultiSync VT440/VT540 Projector

RGB

INPUT

OUTPUT

AUD

IN

INOUT

OUT

PC-CONTROL S-VIDEO VIDEO

Front/ Side Features

Remote Sensor

Slot for Kensington

MicroSaver

Security System

Air-Filter

(inlet)

Carrying Handle

Controls

Zoom Lever

POWER

ON

/

STAND BY

E

R

C

A

N

C

E

L

Terminal Panel

STATUS

N

T

E

SELECT

AC Input

Connect the supplied power

cable’s three-pin plug here.

Remote Sensor

SOURCE AUTO ADJUST

M

E

N

U

Air-Filter (inlet)

Lens Cap

Adjustable Tilt Foot Button

Adjustable Tilt Foot

Lens

Focus Ring

NOTE: Built-in Security Slot ( )

This security slot supports the MicroSaver® Security System.

MicroSaver® is a registered trademark of Kensington Microware

Inc.The logo is trademarked and owned by Kensington Microware

Inc.

Ventilation (outlet)

Carrying the Projector:

Raise the carrying handle up. Always carry your projector by the

carrying handle.

NOTE:When moving the pr ojector or when it is not in use , cover the

lens with the lens cap.

OFF

/

ON

L

E

C

N

A

C

R

E

T

SELECT

U

N

N

E

POWER

E

STATUS

M

SOURCE AUTO ADJUST

E–8

M

E

N

U

E

N

T

E

R

C

A

N

C

E

L

SELECT

POWER

STATUS

ON

/

STAND BY

SOURCE AUTO ADJUST

Rear/ Side Features

RGB

INPUT

OUTPUT

AUD

IN

OUT

PC-CONTROL S-VIDEO VID

B

UT

PUT

AUD

IN

OUT

L S-VIDEO VID

RD-366E

Remote Sensor

Remote Sensor

Built-in Monaural Speaker (1W)

Rear Foot

Lamp Cover

Card Remote Slot

Slot for Card Remote Control

The supplied card remote control can be stored in the cabinet.

To store the card remote control:

1. Insert the card remote control STRAIGHT into the slot.

2. Push the card remote control until it is into place.

AUTO

ADJ.

L

E

C

N

A

C

Vol.

SOURCE

To pull out the card remote control:

1. Push the bottom of the card remote control straight to eject the

card remote control.

2. Pull out the card remote control.

PIC.

U

SELECT

MUTE

N

Vol.

E

M

POWER

POINTER

R

E

T

N

E

HELP

RD-366E

MAGNIFY

Lamp Cover Screw

Rear Foot

Attaching the lens cap to the lens hood with the supplied string and rivet

1. Thread the string through the hole on the lens cap and then tie a

knot in the string.

Lens Cap

2. Tie a knot again

3. Use the rivet to attach the string to the bottom of the lens hood.

Rivet

String

NOTE: Do not push or pull the card remote control in a slanting

direction. Unless you push the card r emote control straight, you may

not eject the card remote contr ol. Should this happen, try pushing the

card remote control straight again.

E–9

Top Features

1

5

4

7

C

A

SELECT

N

C

STATUS

POWER

E

N

T

E

R

ON

/

STAND BY

6

8

9

1 Source Button

Use this button to select a video source such as a PC, VCR or D VD

player.

2 Auto Adjust Button

Use this button to adjust Position-H/V and Pixel Clock/Phase for

an optimal picture. Some signals may not be displayed correctly or

take time to switch between sources.

3 Menu Button

Displays the menu.

4 Select (▲▼§ ©) / Volume (+) (–) Buttons

▲▼: Use these buttons to select the menu of the item you wish

to adjust.

§ ©: Use these buttons to change the level of a selected menu

item.

A press of the © button executes the selection. When no menus

appear, these ▲▼ buttons work as a volume control.

When the pointer is displayed, these § © ▲▼ buttons move the

pointer.

SOURCE AUTO ADJUST

M

E

N

U

E

L

3

2

6 Cancel Button

Press this button to exit the menu. Press this button to return the

adjustments to the last condition while you are in the adjustment

or setting menu.

7 Status Indicator

When this is lit red (orange in Eco mode) continually, it’s warning

you that the projection lamp has exceeded 2000 hours (up to 3000

hours in Eco mode) of service. After this light appears, it is advisable to replace the projection lamp as soon as possible. (See page

E-33). In addition the message “The lamp has reached the end of

its usable life. Please replace the lamp.” appears continually until

the lamp is replaced.

If this light blinks red rapidly, it indicates that the lamp cover or

filter cover is not attached properly or the projector is overheated.

See the Power / Status Light Messages on page E-35 for more

details.

8 Power Indicator ( )

When this indicator is green, the projector is on; when the indicator is orange, it is in standby mode.

5 Enter Button

Executes your menu selection and activates items selected from

the menu.

9 Power Button (ON / STAND BY)

Use this button to turn the power on and off when the power is

supplied and the projector is in standby mode.

NOTE: To turn off the projector, press and hold this button for

minimum of two seconds.

E–10

Terminal Panel Features

RGB

AUDIO

INPUT

1

IN

OUT

OUTPUT

INOUT

2

PC-CONTROL S-VIDEO VIDEO

7

6

1. RGB Input Connector(Mini D-Sub 15 pin)

Connect your PC or other RGB equipment. Use the supplied signal cable to connect to a PC.

POWER

STATUS

ON

/

STAND BY

3

4

8

N

E

T

E

R

C

A

N

SELECT

C

E

L

E

N

U

SOURCE AUTO ADJUST

M

Slot for Kensington

MicroSaver Security System

5

5. Video Input (RCA)

Connect a VCR, DVD player, laser disc player, or document camera here to project video.

2. RGB Monitor Output Connector (Mini D-Sub 15 pin)

You can use this connector to loop your computer image to an

external monitor from the RGB input source.

3. Audio Input / Output Mini Jack

This is where you connect audio output from your computer. Or

connect additional external speakers here to listen to audio coming

from your Video or S- Video input.

4. Audio Input / Output Connector (RCA)

This is where you connect audio output from a VCR, D VD player ,

or laser disc player. Or connect additional e xternal speakers to listen to audio coming from your RGB source.

NOTE: Either connector 3 or 4 can be used for input or output, however they cannot both be used for input simultaneously. It can damage your equipment.

6. S-Video Input Port (Mini DIN 4 Pin)

Connect the S-Video input from an external source like a VCR.

7. PC Control Port (Mini DIN 8 Pin)

Use this port to connect your PC to control your projector. This

enables you to use your PC and serial communication protocol to

control the projector. If you are writing your o wn program, typical

PC control codes are on page E-40.

A cap is put on the port at the factory . Remove the cap when using

the port.

8. Built-in Security Slot (

)

This security slot supports the MicroSaver ® Security System.

MicroSaver ® is a registered trademark of K ensington Micro w are

Inc. The logo is trademarked and owned by K ensington Microware

Inc.

E–11

Remote Control Features

SELECT

POINTER

Vol.–

Vol.+

POWER

HELP

RD-366E

PIC.

MUTE

MAGNIFY

SOURCE

AUTO

ADJ.

M

E

N

U

E

N

T

E

R

C

A

N

C

E

L

1 Source Button

Press to select a video source.

2 Auto Adjust Button

Use this button to adjust Position-H/V and Pixel Clock/Phase for

an optimal picture. Some signals may not be displayed correctly,

or in some cases it may take some time for a source to switch between sources.

3 Menu Button

Displays the menu.

4 Select (▲▼

▲▼: Use these buttons to select the menu of the item you wish

§ ©: Use these buttons to change the level of a selected menu

A press of the © button executes the selection. When no menus

appear, these ▲▼ buttons work as a volume control.

When the pointer is displayed, these § © ▲▼ buttons move the

pointer.

5 Enter Button

Use this button to enter your menu selection.

6 Cancel Button

Press this button to exit “Menus”. Press this button to return the

adjustments to the last condition while you are in the adjustment

or setting menu.

7 Magnify Button

Use the (+) or (–) button to adjust the image size up to 400%.

When the Pointer is displayed, the magnified image is displayed at

the center of the Pointer. When the Pointer is not displayed, the

magnified image is displayed at the center of the screen.

When the image is magnified, the pointer is changed to the magnifying icon.

8 Pointer Button

Press this button to display one of the eight pointers; press again to

hide the pointer. You can move your pointer icon to the area you

want on the screen using the Select button.

9 Picture Mute Button

This button turns off the image and sound for a short period of

time. Press again to restore the image and sound.

10 Help Button

Provides information about operation and adjustment procedures

or the set information for the current menu or adjustment during

menu operation. This also displays information how to use the Help.

11 Power Button

If power is applied, you can use this button to turn your projector

on and off.

NOTE: To turn off the projector, press and hold the POWER button for a minimum of two seconds.

§ ©) / Volume (+) (–) Buttons

to adjust.

item.

Remote Control

1

12

2

3

4

5

6

8

9

7

11

10

NOTE: Remove the transparent insulation tape before use. See

page E-34 for battery installation.

H

N

A

P

A

J

S

T

L

M

O

n

V

CR2025

O

3

2

-

L

L

i

L

C

E

12 Infrared Transmitter

Direct the remote control toward the remote sensor on the projector cabinet.

Remote Control Precautions

• Handle the remote control carefully.

• If the remote control gets wet, wipe it dry immediately.

• Avoid excessive heat and humidity.

• Do not place the battery upside down.

NOTE: Before you use the card remote control for the first time, be

sure to remove the insulation tape from the card remote control.

* Keep the coin cell battery out of reach of children so as not to

allow them to swallow the cell battery.

CAUTION:

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Dispose of used batteries according to your local regulations.

E–12

Operating Range

7m

22 feet

30˚

7m7m

22 feet

30˚

E–13

2. INSTALLATION

RGB

INPUT

OUTPUT

AUD

IN

INOUT

OUT

PC-CONTROL S-VIDEO VIDEO

RGB

INPUT

OUTPUT

AUD

IN

OUT

PC-CONTROL S-VIDEO VID

E

LE

RGB

INPUT

OUTPUT

AUD

IN

OUT

PC-CONTROL S-VIDEO VID

ER

TA

This section describes how to set up your MultiSync VT440/VT540

projector and how to connect video and audio sources.

Setting up Your Projector

Y our MultiSync VT440/VT540 Projector is simple to set up and use.

But before you get started, you must first:

1. Determine the image size.

2. Set up a screen or select a non-glossy white wall onto which you

can project your image.

Carrying the Projector: Always carry your projector by the handle.

Ensure that the power cable and any other cables connecting to video

sources are disconnected before moving the projector.

When moving the projector or when it is not in use, cover the lens

with the lens cap.

Carrying handle

OFF

/

ON

L

E

C

N

A

C

R

E

T

SELECT

U

N

N

E

POWER

E

STATUS

M

SOURCE AUTO ADJUST

Selecting a Location

The further your projector is from the screen or wall, the larger the

image. The minimum size the image can be is approximately 25"

(0.64 m) measured diagonally when the projector is roughly 4 feet

(1.2 m) from the wall or screen. The largest the image can be is 300"

(7.6 m) when the projector is about 39.3 feet (12.0 m) from the wall

or screen.

Using a Tabletop or Cart

1. Place your projector on a flat level surface at the optimal distance

from the screen or wall so you realize the size image you want.

(Avoid having bright room lighting or sun light directly on the

screen or wall where you’ll be projecting the image.)

2. Connect the power cable, remove the lens cap and turn the projector on. (If no input signal is available, the projector will display a

background image.)

3. Ensure that the projector is square to the screen.

4. Move the projector left or right to center the image horizontally

on the screen.

5. To center the image vertically, lift the front edge of the projector

and press the One-Touch Tilt button on the front side of the projector to release the Front Adjustable foot.

Side view

Screen

(There is approximately 10 degrees of up and down adjustment

for the front of the projector.)

Adjusting the Tilt Foot

1) Press and hold the Tilt button on the front of the projector.

2) Lift the front edge of the projector to the height you want, and

release the button to lock the Adjustable Tilt Foot.

POWER

STATUS

ON

N

E

T

E

R

/

OFF

C

A

N

SELECT

C

E

L

SOURCE AUTO ADJUST

M

E

N

U

2

1

To fine-tune the image’s position vertically on the screen, rotate the

foot. Each of the rear feet height can be changed up to 0.6” (4mm).

CT

L

SOURCE AUTO ADJUST

M

E

N

U

Top view

Screen

S

POW

L

E

OFF

C

/

N

A

ON

C

U

N

E

M

SELECT

R

E

T

N

E

SOURCE AUTO ADJUST

POWER

STATUS

6. If the projected image does not appear square to the screen then

use keystone correction for proper adjustment.

7. Adjust the size of the image using the Zoom ring on the lens.

E–14

Distance Chart

C

A

E

α

D

Formulas(mm) Formulas(inch)

"H = Horizontal Screen Width "H = Horizontal Screen Width

A = C/cosα A = C/cosα

C (wide) = 36.8712 × (diagonal screen size/ 0.92205) – 43.5689 C (wide) = (36.8712 × (diagonal screen size/0.92205) – 43.5689) / 25.4

C (tele) = C(wide) × 1.2 C (tele) = C (wide) × 1.2

D = 1.45 × M – 62.9 D = 1.45 × M – 62.9 / 25.4

E = 62.9 + 5.5M E = (62.9 + 5.5M) / 25.4

M = 1.25H / 22.86 M = 1.25H / 0.9

Zoom Lens (Wide)

α degree 9.01 8.93 8.85 8.82 8.81 8.79 8.78 8.77 8.75 8.74 8.74 8.73 8.72 8.72

β (=sinα) 0.16 0.16 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15

γ (=cosα) 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99

Screen Size H-Width inch 24 32 48 56 64 72 80 96 120 144 160 192 216 240

4:3 Diagonal inch 30 40 60 70 80 90 100 120 150 180 200 240 270 300

A mm 1171 1575 2384 2789 3193 3598 4002 4811 6025 7238 8047 9666 10879 12093

C mm 1156 1556 2356 2756 3155 3555 3955 4755 5955 7154 7954 9554 10753 11953

D mm -15 2 34 50 66 82 98 130 179 227 259 324 372 420

E mm 246 307 430 491 552 613 674 796 980 1163 1285 1530 1713 1896

inch 46 62 94 110 126 142 158 189 237 285 317 381 428 476

inch 46 61 93 108 124 140 156 187 234 282 313 376 423 471

inch -1 0 1233457910131517

inch 10 12 17 19 22 24 27 31 39 46 51 60 67 75

Zoom Lens (Tele)

α degree 6.28 7.46 7.39 7.37 7.36 7.35 7.34 7.32 7.31 7.30 7.30 7.29 7.29 7.28

β (=sinα) 0.11 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13 0.13

γ (=cosα) 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99

Screen Size H-Width inch 20 32 48 56 64 72 80 96 120 144 160 192 216 240

4:3 Diagonal inch 25 40 60 70 80 90 100 120 150 180 200 240 270 300

A mm 1396 1883 2851 3334 3818 4302 4785 5753 7204 8655 9623 11558 13009 14460

C mm 1387 1867 2827 3307 3787 4266 4746 5706 7146 8585 9545 11464 12904 14344

D mm -23 2 34 50 66 82 98 130 179 227 259 324 372 420

E mm 216 307 430 491 552 613 674 796 980 1163 1285 1530 1713 1896

inch 55 74 112 131 150 169 188 226 284 341 379 455 512 569

inch 55 74 111 130 149 168 187 225 281 338 376 451 508 565

inch -1 0 1233457910131517

inch 8 12 17 19 22 24 27 31 39 46 51 60 67 75

Distance Chart

A: Distance between the

lens and the screen center

C: Horizontal throw dis-

tance between screen

surface and the lens

D: Vertical distance be-

tween projector base

and base of image

E: Vertical distance be-

tween projector base

and screen center

Screen (inch)

H

4:3 Diagonal

NOTE: Distances may vary +/–5%.

300

250

200

150

100

50

Screen Size (inch)

0

024681012

Throwing Distance (m)

wide

300

250

200

150

100

50

Screen Size (inch)

0

0 100 200 300 400

Throwing Distance (inch)

tele

Throwing Distance Screen Size (inch)

(inch) (m) Wide Tele

45 1.2 30 25

61 1.6 40 33

93 2.4 60 50

108 2.8 70 58

124 3.2 80 67

140 3.6 90 75

156 4.0 100 83

187 4.8 120 100

234 6.0 150 125

282 7.2 180 150

313 8.0 200 167

376 9.6 240 200

423 10.8 270 225

471 12.0 300 250

E–15

Ceiling Installation

Formulas(mm)

H” = Horizontal Screen Width (inch)

F

PC-CONTROLS-VIDEO VIDEO

INOUT

OUTPUT

OUT

IN

INPUT

RGB

B

α

AUDIO

A

C

A: Distance between the lens and the screen center

B: Vertical distance between the top of the supplied ceiling mount and the screen center

C: Horizontal throw distance between screen surface and the lens

F: Vertical distance between projector base and top of image

Zoom Lens (Wide)

α degree 9.01 8.93 8.85 8.82 8.81 8.79 8.78 8.77 8.75 8.74 8.74 8.73 8.72 8.72

β (=sinα) 0.16 0.16 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15

γ (=cosα) 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99

Screen Size H-Width inch 24 32 48 56 64 72 80 96 120 144 160 192 216 240

4:3 Diagonal inch 30 40 60 70 80 90 100 120 150 180 200 240 270 300

A mm 1171 1471 2242 2628 3013 3399 3785 4556 5713 6870 7641 9184 10341 11498

C mm 1156 1452 2214 2595 2976 3357 3738 4500 5644 6787 7549 9074 10217 11360

B mm 277 338 461 522 583 644 705 827 1011 1194 1316 1561 1744 1927

F mm -46 -29 3 19 35 51 67 100 148 196 229 293 341 390

inch 46 58 88 103 119 134 149 179 225 270 301 362 407 453

inch 46 57 87 102 117 132 147 177 222 267 297 357 402 447

inch 11 13 18 21 23 25 28 33 40 47 52 61 69 76

inch -2 -1 011234689121315

A = C/cosα

B = 94 + 5.5 × M

C (wide) = 36.8712 × (diagonal screen size/ 0.92205) – 43.5689

C (tele) = C(wide) × 1.2

F = 1.4516 × M – 94

M = 1.25H” / 22.86

Formulas(inch)

H” = Horizontal Screen Width

A = C/cosα

B = (94+5.5 × M) / 25.4

C

(wide) = (36.8712 × (diagonal screen size/0.92205) – 43.5689) / 25.4

C (tele) = C (wide) × 1.2

F = 1.4516 × M – 94/25.4

M = 1.25H / 0.9

Zoom Lens (Tele)

α degree 6.28 7.1 7.0 7.0 7.0 7.0 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9

β (=sinα) 0.11 0.12 0.12 0.12 0.12 0.12 0.12 0.12 0.12 0.12 0.12 0.12 0.12 0.12

γ (=cosα) 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99 0.99

Screen Size H-Width inch 20 32 48 56 64 72 80 96 120 144 160 192 216 240

4:3 Diagonal inch 25 40 60 70 80 90 100 120 150 180 200 240 270 300

A mm 1396 1902 2900 3399 3898 4397 4896 5893 7390 8887 9885 11881 13378 14875

C mm 1387 1887 2878 3373 3869 4364 4860 5851 7337 8823 9814 11796 13282 14768

B mm 247 338 461 522 583 644 705 827 1011 1194 1316 1561 1744 1927

F mm -54 -29 3 19 35 51 67 100 148 196 229 293 341 390

WARNING

• Installing your projector on the ceiling must be done by a qualified technician. Contact your NEC dealer for more information.

* Do not attempt to install the projector yourself.

• Only use your projector on a solid, lev el surface. If the projector falls to the ground, you can be injured and the projector

severely damaged.

• Do not use the projector where temperatures vary greatly . The

projector must be used at temperatures between 32˚F (0˚C)

and 95˚F (35˚C).

• Do not expose the projector to moisture, dust, or smoke. This

will harm the screen image.

• Ensure that you have adequate ventilation around your projector so heat can dissipate. Do not cover the vents on the side

or the front of the projector.

inch 55 75 114 134 153 173 193 232 291 350 389 468 527 586

inch 55 74 113 133 152 172 191 230 289 347 386 464 523 581

inch 10 13 18 21 23 25 28 33 40 47 52 61 69 76

inch -2 -1 011234689121315

If your projector is mounted on the ceiling and your image is upside

down, use the “Menu” and “Select” buttons on your projector cabinet or ▲▼ button on your remote control to correct the orientation.

(See page E-31.)

Reflecting the Image

Using a mirror to reflect your projector’s image enables you to enjoy

a much larger image. Contact your NEC dealer if you need a mirror.

If you’re using a mirror and your image is inverted, use the “Menu”

and “Select” buttons on your projector cabinet or ▲▼ buttons on

your remote control to correct the orientation. (See page E-31.)

E–16

Wiring Diagram

Macintosh or Compatibles

(Desktop type or notebook type)

Pin adapter for Macintosh (supplied)

Speaker System

Monitor

VCR, DVD Player or LaserDisc Player

RGB OUTPUT

PC CONTROL

To video, S-video, and audio

inputs on the projector.

S-VIDEO

AUDIORGB INPUT

IN

OUT

OUT

IN

VIDEO

IBM VGA or Compatibles

(Desktop type or notebook type)

Signal cable (supplied)

To mini D-Sub 15-pin connector on the

projector. It is recommended that you

use a commercially available distribution

amplifier if connecting a signal cable

longer than the supplied cable.

DVD Player (with component output)

Optional Component V cable

Document Camera

NOTE: When using with a notebook PC, be sure to connect between the projector and the notebook PC

before turning on the power to the notebook PC. In most cases signal cannot be output from RGB output

unless the notebook PC is turned on after connecting with the projector.

NOTE:

* If the screen goes blank while using your remote control, it may be the result of the computer’s screen-

saver or power management software.

* If you accidentally hit the POWER button on the remote control, wait 30 seconds and then press the

POWER button again to resume.

NOTE: If using video, S-video, or audio cables, the cables should be 3 m (9.8 feet) or shorter.

E–17

Connecting Your PC

IBM VGA or Compatibles

(Notebook type)

IBM VGA or Compatibles

(Desktop type)

Signal cable (supplied)

To mini D-Sub 15-pin connector on the projector. It is recommended that you use a commercially availab le distribution amplifier if connecting a signal cable longer than the supplied one.

RGB INPUT

RGB

INPUT

AUDIO

AUDIO

OUTPUT

PC-CONTROL S-VIDEO VIDEO

IN

OUT

INOUT

Audio cable

(not supplied)

Connecting your PC to your MultiSync VT440 (SVGA)/ VT540 (XGA) projector will enable you to project your computer’s screen image for

an impressive presentation.

To connect to a PC, simply:

1. Turn off the power to your projector and computer.

2. Use the supplied signal cable to connect your PC to the projector.

3. Turn on the projector and the computer.

4. If the projector goes blank after a period of inactivity, it may be caused by a screen saver installed on the computer you’ve connected to the

projector.

E–18

Connecting Your Macintosh Computer

Macintosh (Notebook type)

Audio cable

(not supplied)

Signal cable

(supplied)

RGB INPUT

RGB

INPUT

AUDIO

OUTPUT

PC-CONTROL S-VIDEO VIDEO

IN

OUT

AUDIO

INOUT

Macintosh (Desktop type)

For older Macintosh,

use the supplied pin

adapter to connect to

your Mac's video

port.

Pin adapter for Macintosh

(supplied)

NOTE: The new Macintosh computer

such as G3 will have the 15 pin HD connector. The VT440/VT540's "Plug and

Play" data will be downloaded to the

Macintosh. Therefore, the Mac adapter

will not be necessary.

To connect to a Macintosh, simply:

1. Turn off the power to your projector and your Macintosh com-

ON DIP

23456

1

puter.

2. Use the supplied signal cable to connect your Macintosh computer to the projector.

3. Turn on the projector and the Macintosh computer.

E–19

When using a Macintosh computer with the projector, set the DIP

switches of the supplied pin adapter according to your resolution.

After setting, restart your Macintosh computer.

See the following pages for setting of the DIP switches.

• When using with a Macintosh, SVGA(8002600 :VT440)/

XGA(10242768 : VT540) is recommended if your Macintosh

supports this mode.

• When using with a Macintosh PowerBook, output may not be

set to 8002600 unless “mirroring” is off on your PowerBook.

Refer to owner’s manual supplied with your Macintosh computer for mirroring.

NOTE: A Video Adapter cable manufactured by Apple Computer is

needed for a PowerBook which does not have a mini D-Sub 15-pin

connector.

Settings for Monitor Mode

Number of DIP switch

Resolution

13" multi-scan mode /16"-13" ON ON ON ON

17" multi-scan mode /19"-13" ON ON ON

21” multi-scan mode /21"-13" ON ON ON

13" fixed mode /640x480 ON ON

VGA/SVGA mode ON ON

16" fixed mode /832x624 ON ON

19" fixed mode /1024x768 ON ON

21" fixed mode /1152x870 ON ON ON ON

1 23 456

NOTE: For settings other than display modes supported by your

Macintosh and the projector, use of the DIP switch may bounce an

image slightly or may display nothing. If this happens, set the DIP

switch to the 13" fixed mode and then restart your Macintosh. After

that, restore to a displayable mode and then restart the Macintosh

again. Make sure that the projector and your Macintosh are connected with the pin adapter and the supplied signal cable (mini DSub 15-pin connector) and then restart your Macintosh.

Examples of DIP switch setting

17" multi-scan mode VGA/SVGA mode 19" fixed mode

ON

NOTE: Refer to your computer’s owner’s manual for more information about your computer’s video output requirements and an y special identification or configuring your projector’s image and monitor may require.

ON

654 321

321

ON

654321

654

E–20

Connecting an External Monitor

External monitor

RGB

INPUT

AUDIO

OUTPUT

PC-CONTROL S-VIDEO VIDEO

IN

RGB OUTPUT

AUDIO IN

OUT

INOUT

AUDIO OUT

You can connect a separate, external monitor to your VT440/VT540 to simultaneously vie w on a monitor the image you're projecting. To do so:

1. Turn off the power to your projector, monitor and computer.

2. Use a 15-pin cable to connect your monitor to the RGB Monitor Output (Mini D-Sub 15 pin) connector on your projector.

3. Turn on the projector, monitor and the computer.

E–21

Connecting Your DVD Player

DVD player

Y Cb Cr

R L

Red

White

RGB INPUT

RGB

Cr

Cb

Y

INPUT

AUDIO

OUTPUT

PC-CONTROL S-VIDEO VIDEO

IN

OUT

INOUT

Optional 15-pin-to-RCA23 cable

(Component V )

Audio Equipment

Audio cable

(not supplied)

R L

White

Red

You can connect your projector to a DVD player with component outputs or Video output. To do so, simply:

1. Turn off the power to your projector and DVD player.

2. If your DVD player has the component video (Y,Cb,Cr) output, use the optional 15-pin-to-RCA23 cable to connect your DVD player to the

RGB INPUT connector on the projector.

For a DVD player without component video (Y,Cb,Cr) outputs, use common RCA cables (not provided) to connect a composite VIDEO

output of the DVD player to the Video Input of the projector.

3. Turn on the projector and DVD player.

NOTE: Refer to your DVD player’s owner’s manual for more information about your DVD player’s video output requirements,

E–22

Connecting Your VCR or Laser Disc Player

VCR/ Laser disc player

L

R

White

Red

S-video cable

(not supplied)

RGB

INPUT

AUDIO

OUTPUT

S-VIDEO

PC-CONTROL S-VIDEO VIDEO

IN

OUT

INOUT

VIDEO

Audio equipment

Document camera

Audio cable

(not supplied)

L

R

VIDEO

White

Red

Video cable (not supplied)

Use common RCA cables (not provided) to connect your VCR, laser disc player or document camera to your projector.

To make these connections, simply:

1. Turn off the power to the projector and VCR, laser disc player or document camera.

2. Connect one end of your RCA cable to the video output connector on the back of your VCR or laser disc player, connect the other end to the

Video input on your projector. Use an audio cable (not supplied) to connect the audio from your VCR or laser disc player to your audio

equipment (if your VCR or laser disc player has this capability). Be careful to kee p your right and left channel connections correct for stereo

sound.

3. Turn on the projector and the VCR or laser disc player.

NOTE: Refer to your VCR or laser disc player owner’s manual for more information about your equipment’s video output requirements.

E–23

3.OPERATION

This section describes how to select a computer or video source, how

to adjust the picture, and how to customize the menu or projector

settings.

General Controls

Before you turn on your projector, ensure that the computer or video

source is turned on and that your lens cap is removed.

1. Turn on the Projector

Plug the supplied power cable in the wall outlet. The projector

will go into its standby mode and the power indicator will glow

orange.

Only after you press the “POWER” button on the projector cabinet or the remote control will the power indicator turn to green

and the projector become ready to use.

NOTE: To turn the projector on by plugging in the power cable,

use the menu and enable the “Auto Start” feature. (See page E-

32.)

NOTE: Re gardless of the lamp mode setting, the lamp always stays

in High-Bright mode for 3 minutes after the projector is turned

on. If you have selected the Eco mode, the STA TUS indicator blinks

green and the lamp will change to Eco mode in 3 minutes.

2. Select the Computer or Video Source

Press the Source button on the remote control or the projector

cabinet to select “Video” (VCR, document camera, or laser disc

player), S-Video” or “RGB” (computer or DVD with component

output) to display the image.

Or press the “Menu” button on the remote control or the cabinet

and use the menu to select your video source: “Video”, “S-V ideo”

or “RGB”.

3. Adjust the Image Size and the Focus

Use the Zoom lever to adjust the image size, then use the Focus

ring to obtain the best focus.

Use the “Magnify” button (+) or (-) on the remote control to make

the image larger up to 400%.

4. Turning off the Projector

First press the “POWER” button on the projector cabinet or the

remote control for a minimum of two seconds. The power indicator will glow orange. After the projector turns off, the cooling fans

keep operating for 30 seconds.

Do not disconnect the power cable during this time. Then, unplug

the power cable. The power indicator will go out.

Enlarging and Moving a Picture

You can enlarge the area you want up to 400 percent.

To do so:

1) Press the POINTER button on the card remote control to display the pointer.

POINTER

2) Move the pointer to the area you want to enlarge.

Vol.

SELECT

Vol.

3) Adjust the image size up to 400 percent.

MAGNIFY

MAGNIFY

IMPORTANT:

• The projector should be unplugged if it will not to be used for an

extended period.

• To turn off the image and sound briefly (five minutes or less),

use the “Picture Mute” button instead of turning the projector

off and on.

• The projector will display a black, blue image or logo if no input

signal is present.

• Do not turn the projector off and then immediately back on. The

projector needs to cool for 30 seconds before it can be restarted.

E–24

Using the Menus

NOTE: An interlaced motion video image may be blurred while

the menu is displayed.

1. Press the “Menu” button on the remote control or the projector

cabinet to display the Main Menu.

2. Press the ▲▼ buttons on the remote control or the projector cabinet to highlight the menu for the item you want to adjust or set.

3. Press the © button or the “Enter” button on the remote control or

the projector cabinet to select a submenu or item.

4. Adjust the level or turn the selected item on or off by using “Select” § or © buttons on the remote control or the projector cabinet. The on-screen slide bar will show you the amount of increase

or decrease.

5. The change is stored until you adjust it again.

ENTER: Stores the setting or adjustments.

CANCEL: Return to the previous screen without storing settings

or adjustments.

6. Repeat steps 2-5 to adjust an additional item, or press “Cancel”

on the remote control or the projector cabinet to quit the menu

display.

E–25

MENU Tree

Basic/ Advanced Menu

Sub Menu

(all)

(all)

(VCH)

(VCH)

(V)

Items

Hi-Bright/ Eco

(all)

(all)

(all)

(all)

Normal/ Natural1/ Natural2

Aspect Ratio

Noise Reduction

Color Matrix

White Balance

Auto Adjust

Position/ Clock

Resolution

All Data/ Current Signal

Menu Mode

English/ German/ French/ Italian/ Spanish/ Swedish/ Japanese

Pointer 1–8

Source Display

Volume Bar (Direct Button)

Menu Display Time

Signal Select

RGB

VIDEO/ S-VIDEO

Auto Start

Power Management

Power Off Confirmation

Keystone Save

Clear Lamp Hour Meter

(all)

Normal/ Zoom/ Wide Zoom/ Cinema

Off/ Low/ Medium/ High

HDTV/ SDTV/ B-Y/R-Y, Cb/Cr, Pb/Pr

Brightness R/G/B, Contrast R/G/B

On/ Off

Horizontal/ Vertical/ Clock/ Phase

Auto/ Native

Basic/ Advanced

On/ Off

On/ Off

Manual/ Auto 3sec/ Auto 10sec/ Auto 30sec

Auto/ RGB/ Component

Auto/ NTSC3.58/ NTSC4.43/ PAL/

PAL60/ SECAM

On/ Off

On/ Off

On/ Off

On/ Off

(VCH)

(VCH)

(CH)

(all)

(R)

(RH)/(R)

(R)

Source Name

Input T erminal

Horizontal Frequency

Vertical Frequency

Sync Polarity

Signal T ype

Video T ype

Sync T ype

Interlace

E–26

Orientation

Background

Resolution

Aspect Ratio

Gamma Correction

Noise Reduction

Color Matrix

Matrix T ype

Lamp Hour Meter

Projector Usage

Front/ Floor, Rear/Ceiling, Rear/Floor.

Front/Ceiling

Blue/ Black/ Logo

NOTE:

Adjustable sources

R=RGB V=Video/S-Video

C=Component H=HDTV

All=All sources

Menu Elements

Title bar

Highlight

Tab

OK Button

Cancel Button

Solid triangle

Check box

Radio button

Slide bar

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Menu windows or dialog boxes typically have the following elements:

Title bar: Indicates the menu title.

Highlight: Indicates the selected menu or item.

Solid triangle: Indicates further choices are available. A highlighted triangle indicates the item is active.

Tab: Indicates a group of features in a dialog box. Selecting on any tab brings its page to the front.

Radio button: Use this round button to select an option in a dialog box.

Check box: Place a checkmark in the square box to turn the option On.

Slide bar: Indicates settings or the direction of adjustment.

OK button: Press to confirm your setting. You will return to the previous menu.

Cancel button: Press to cancel your setting. You will return to the previous menu.

E–27

Menu Descriptions & Functions

Source Select

Enables you to select a video source such as a VCR, DVD player,

laser disc player, computer or document camera depending on what

is connected to your inputs. Press the “Select” button on the projector cabinet or ▲▼ buttons on your remote control to highlight the

menu for the item you want to adjust.

RGB

Selects the computer connected to your RGB or component signal.

NOTE: An optional component cable (Component V cable) is needed

for a component signal.

V olume

Adjusts the sound level of the projector.

NOTE:Y ou can display the volume bar without opening the menu.See

"Volume Bar (Direct Button)"on page E-31 for more details.

Image Options

Basic Mode

Advanced Mode

Video

Selects what is connected to your V ideo input-VCR, laser disc player ,

DVD player or document camera.

S-Video

Selects what is connected to your S-Video input-VCR, DVD player,

or laser disc player.

NOTE: A frame may freeze for a brief period of time when a video is

played back in fast-forward or fast-rewind with a Video or S-Video

source.

Picture

Provides access to controls for your image. Use the “Select” button

on the projector cabinet or the remote control to highlight the menu

for the item you want to adjust.

Brightness

Adjusts the brightness level or the back raster intensity.

Contrast

Adjusts the intensity of the image according to the incoming signal.

Color

Increases or decreases the color saturation level (not valid for RGB).

Hue

Varies the color level from +/- green to +/-blue. The red le v el is used

as reference. This adjustment is only valid for V ideo and Component

inputs (Not RGB).

Sharpness

Controls the detail of the image for V ideo (Not for RGB and Component).

Provides optional controls such as Keystone Correction, Color Temperature and Lamp Mode. When you select Adv anced Mode, the following options are availa ble: Gamma Correction, Aspect Ratio, Noise

Reduction, Color Matrix, White Balance, Auto Adjust, Position/Clock,

Resolution, and Factory Default.

Keystone

This feature corrects the keystone (trapezoidal) distortion to make

the top of the screen longer or shorter to be the same as the bottom.

Use the § or © buttons on the slide bar to correct the keystone

(trapezoidal) distortion.

Keystone distortion

NOTE: The maximum keystone angle that can be corrected is 15

degrees upward and downward with the projector placed horizontally. However, a picture will be blurred if you correct the keystone

angle beyond +12 degrees or more for SXGA signal on VT440.

Normal

Color T emperatur e

This feature adjusts the color temperature using the slide bar.

Move the slide bar to the right to increase the color temperature for a

bluish image; to the left to decrease it for a reddish image.

E–28

Lamp Mode

Aspect Ratio

This feature enables you to select two brightness mode of the lamp:

High-Bright and Eco modes. The lamp life can be extended up to

3000 hours by using the Eco mode.

High-Brigh Mode: This is the default setting.

Eco Mode: Select this mode to increase the lamp life.

NOTE: If you have selected the Eco mode, the lamp lights in HighBright mode for 3 minutes after the projector is turned on. After 3

minutes the lamp will change to Eco mode.

Gamma Correction (Advanced mode)

Use the § or © buttons to choose “Normal” when in a lighted

room and “Natural 1&2” when in a darkened room. “Natural 1”

for better flesh tone; “Natural 2” for true reproduction of middle

tones.

Each mode is recommended for :

Normal: the regular picture

Natural 1: true color reproduction of natural tones

Natural 2: dark portions of a picture

Advanced Options (Advanced mode)

Allows for adjustments of image position and stability.

Aspect Ratio allows you to select the best Aspect mode to display

your source image.

When 4:3 is selected from the source (i.e. DVD player), the following selections will display:

Normal Zoom Wide Zoom Cinema

A-Standard

4:3 Aspect

B-All 4 sides

stretched

C-Left & Right

stretched

D-Left and right

stretched

When Anamorphic or 16:9 is selected from the source (i.e. DVD

player), the following selections will display:

Normal Zoom Wide Zoom Cinema

A-16:9 image

displayed

in 4:3 mode

B- All 4 sides

stretched

C- Left & right

stretched

D- Left and right

stretched to

display the true

aspect

NOTE: Aspect Ratio is not available for “RGB”.

Noise Reduction:

When you select Advanced Options in Advanced mode, the following options are available: Aspect Ratio, Noise Reduction, Color Matrix, White Balance, Auto Adjust, Position/Clock, Resolution, and

Factory Default.

You can select three levels video noise reduction.

NOTE: The lower the Noise Reduction level, the better the image quality by way of higher video bandwidth.

Color Matrix

First select an appropriate color matrix to fit your component

signal for HDTV or SDTV. Then select an appropriate matrix

type from B-Y/R-Y, Cb/Cr or Pb/Pr.

NOTE: The Color Matrix feature is available for component

video signal only.

E–29

White Balance:

This allows you to adjust the white balance. Brightness for each

color (RGB)is used to adjust the black level of the screen;

Contrast for each color (RGB)to adjust the white level of the

screen.

First use the up or down buttons to select R, G, or B for the brightness and the contrast. Next use the

level.

Auto Adjust:

When “Auto Adjust” is set to “On”, the projector automatically

determines the best resolution for the current RGB input signal

to project an image using NEC’s Advanced AccuBlend Intelligent Pixel Blending Technology.

The image can be automatically adjusted for geometry and stability; “Horizontal Position”, “Vertical Position”, “Clock” and

“Phase”.

On: Automatically adjusts image “Horizontal Position”, “V er -

tical Position”, “Clock” and “Phase”.

Off: User can adjust the image display functions (“Horizontal

Position”, “Vertical Position”, “Clock” and “Phase”)

manually.

§ or © buttons to adjust the

Phase: Use this item to adjust the clock phase or to reduce video

noise, dot interference or cross talk. (This is evident when

part of your image appears to be shimmering.) Use the

§ and © buttons to adjust the image.

Use “Phase” only after the “Clock” is complete.

This adjustment is made automatically when the Auto

Adjust is turned on.

Resolution (when Auto Adjust is off):

This allows you to activa te or deactivate the Advanced AccuBlend

feature.

Auto: Turns on the Advanced AccuBlend feature. The projec-

tor automatically reduces or enlarges the current image

to fit the full screen.

Native: Turns off the Advanced AccuBlend feature. The projec-

tor displays the current image in its true resolution.

NOTE: While you are displaying an image with higher resolution than the projector's native resolution, even when you are in

the Native mode, the image is displayed full screen using the

Advanced AccuBlend feature.

Factory Default (Advanced mode)

Position/ Clock (when Auto Adjust is off)

This allows you to manually adjust the image horizontally and

vertically, and adjust Clock and Phase.

Horizontal/Vertical Position:

Adjusts the image location horizontally and vertically

using the § and © buttons.

This adjustment is made automatically when the Auto

Adjust is turned on.

Clock: Use this item with the “Auto Adjust off” to fine tune the

computer image or to remove any vertical banding that

might appear. This function adjusts the clock frequencies that eliminate the horizontal banding in the image.

Press the § and © buttons until the banding disappears.

This adjustment may be necessary when you connect your

computer for the first time. This adjustment is made automatically when the Auto Adjust is turned on.

Changes all adjustments and setting to the factory preset for each

source individually except Lamp Usage Hours. (To reset the lamp

usage time, see “Clear Lamp Hour Meter” on page E-32.)

All Data: Reset all the adjustments and settings for all

the signals to the factory preset.

Current Signal: Resets the adjustments for the current signal to

the factory preset levels.

The items that can be reset are: Picture, Color T emper ature, Gamma

Correction, Aspect Ratio, Noise Reduction, Color Matrix, White

Balance, Position/Clock and Resolution.

E–30

Menu

Menu Display Time (Advanced mode):

This option allows you to select how long the projector waits

after the last touch of a button to turn off the menu.

The preset choices are "Manual", "Auto 3 sec", "Auto 10 sec",

and "Auto 30 sec". The "Auto 30 sec" is the factory preset.

Manual............The menu can be turned off manually.

Auto 3 sec .......The menu will automatically be turned off in 3

seconds if no buttons are pressed within 3 seconds.

Auto 10 sec.....The menu will automatically be turned off in 10

seconds if no buttons are pressed within 10 seconds.

Auto 30 sec.....The menu will automatically be turned off in 30

seconds if no buttons are pressed within 30 seconds.

Allows you to set preferences for the on-screen menu.

Menu Mode:

This feature allows you to select two menu modes: one has basic

functionality and the other more advanced functionality.

Basic Mode........... This is the normal mode.

Advanced Mode ... This mode is used for advanced users. In this

mode you can change the following settings:

Gamma Correction, Aspect Ratio, Noise Reduction, Color Matrix, White Balance, Auto

Adjust, Position/Clock, Resolution, Factory

Default, Menu Display Time, Signal Select,

Auto Start, Power Management, Power Off

Confirmation and Keystone Save and Clear

Lamp Hour Meter.

Language:

You can choose one of seven languages for on-screen instructions. The options are: English, German, French, Italian, Spanish, Swedish and Japanese.

Projector Pointer:

This enables you to select from eight different Pointer icons for

the “Pointer” button on your remote control.

After moving your Pointer icon to the area you want on the screen,

press the Magnify button on the remote control to enlarge the

selected area on the screen. See page E-24 for more details.

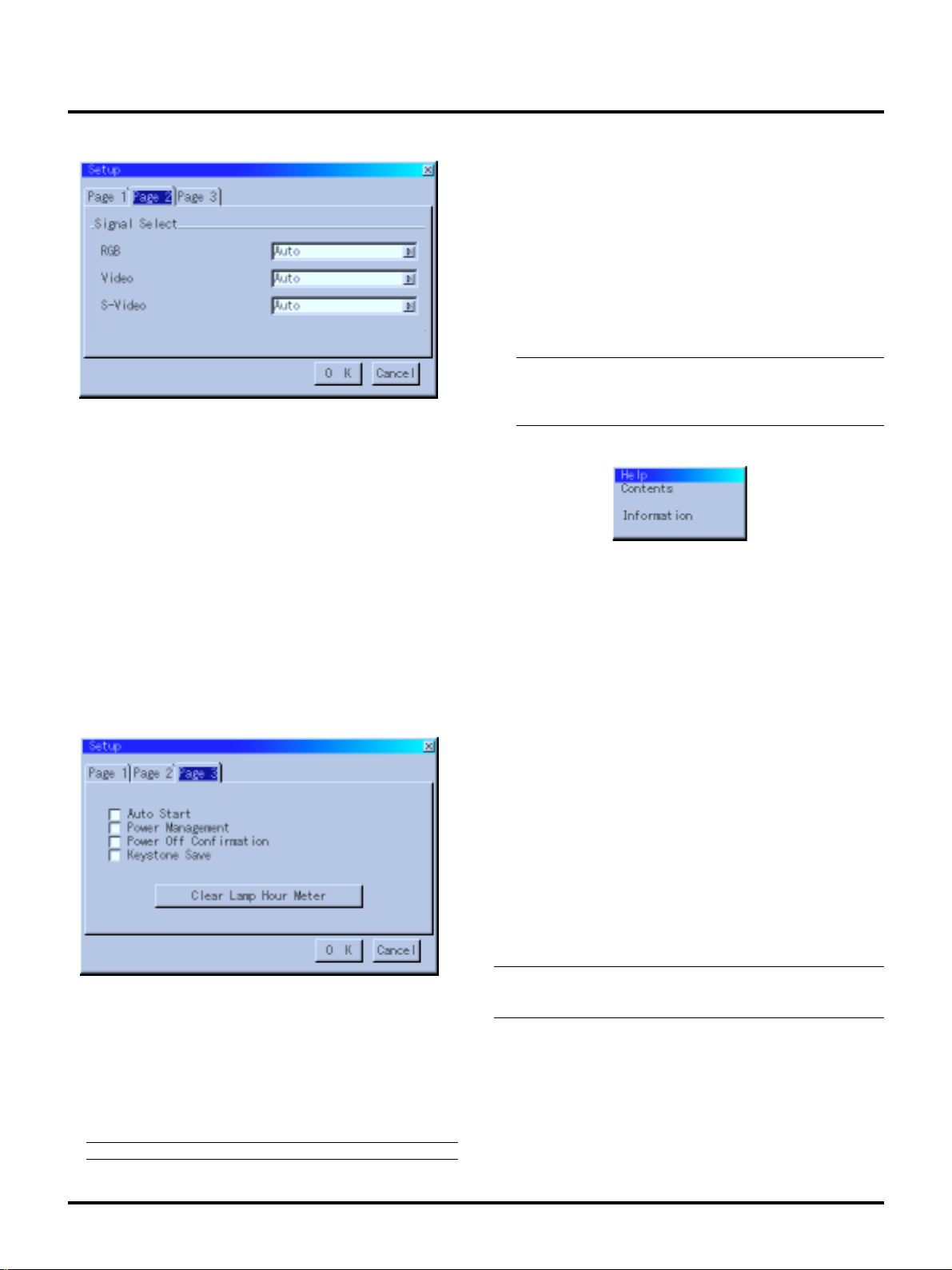

NOTE: There may be cases where the P ointer function is not a vailable (ex. a non-interlace signal at 15kHz such as video game.)