Page 1

T30A / T60A Tape Library

-This User's Guide provides information to use the unit safely and correctly and to avoid a

personal injury and/or a damage to the customer's properties. Thoroughly read this manual to

fully understand handling of the unit.

-Keep this User's Guide with the unit to see whenever it is necessary.

-Make sure to provide this User's Guide along with the unit to a third party.

NF6303 / NF6306

User’s Guide

Rev.1

<T30A> <T60A>

856-129409-460-A

Page 2

Handling of laser product

When the Fibre Chanel drive is installed, class 1 laser product is used in this product.

1 Klassenlaserprodukt wird zu der Zeit des Einsatzes von einem Fibre Chanel-Antrieb mit diesem Produkt

benutzt.

Japanese acceptance statement

Chinese acceptance statement

Taiwan acceptance statement

WEEE

Disposing of your used NEC product

In the European Union

EU-wide legislation as implemented in each Member State requires that used

electrical and electronic products carrying the mark (left) must be disposed of

separately from normal household waste. This includes tape library or electrical

components, such as tape drive, AC power supply.

When you dispose of such products, please follow the guidance of your local

authority or ask the shop where you purchased the product, or if applicable,

follow applicable legislation or agreement you may have.The mark on electrical

and electronic products may only apply to the current Europian Union Menber

States.

Outside the European Union

If you wish to dispose of used electrical and electronic products outside the

European Union, please contact your local authority and ask for the correct

method of disposal.

-i-

Page 3

FCC acceptance statement

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

ICES acceptance statement

Industry Canada Class A Emission Compliance Statement/Avis de conformité à la réglementation

d`Industrie Canada:

CAN ICES-3(A) / NMB-3(A)

Other

Under the EN ISO 7779 standard, the maximum noise level is 70 decibels.

RoHS Compliance

This product complies with the EU's "Restriction of the use of certain hazardous substances in

electrical and electronic equipment" (RoHS).

Türkiye Cumhuriyeti:EEE Yönetmeliğine Uygundur

Complying with “CIRCULAR, No.30/2011/TT-BCT(Hanoi, August 10 2011), Temporary regulations

on content limit for certain hazardous substances in electrical products”

-ii-

Page 4

Safety Precautions

Indicates the presence of a hazard that may result in death or serious

personal injury if the instruction is ignored.

Indicates the presence of a hazard that may cause minor personal injury,

including burns, or property damage if the instruction is ignored.

SYMBOL

MEAN

This symbol indicates the presence of a hazard if the instruction is ignored. An image in

the symbol illustrates the hazard type. (Attention)

This symbol indicates prohibited actions. An image in the symbol illustrates a particular

prohibited action. (Prohibited Action)

This symbol indicates mandatory actions. An image in the symbol illustrates a mandatory

action to avoid a particular hazard. (Mandatory Action)

Before use, In order to use the product safely and correctly, be sure to read over this book, please handle it

properly.

This product has been designed with sufficient safety. In case of improper use of this product, the operator

may be injured and damage to property may result. After reading this manual, store it for future reference if

necessary.

Follow the instructions in this Guide for your safety to use the product.

The product contains components with possible danger, hazards that may cause by ignoring warnings, and

preventive actions against such hazards.

This product contains components with potential hazards, which are marked with a warning label placed on

or arount those components

In this Guide or warning labels, "WARNING" or "CAUTION" is used to indicate a degree of danger. These

terms are defined as follows:

Precautions and notices against hazards are presented with one of the following three symbols. The

individual symbols are defined as follows:

-iii-

Page 5

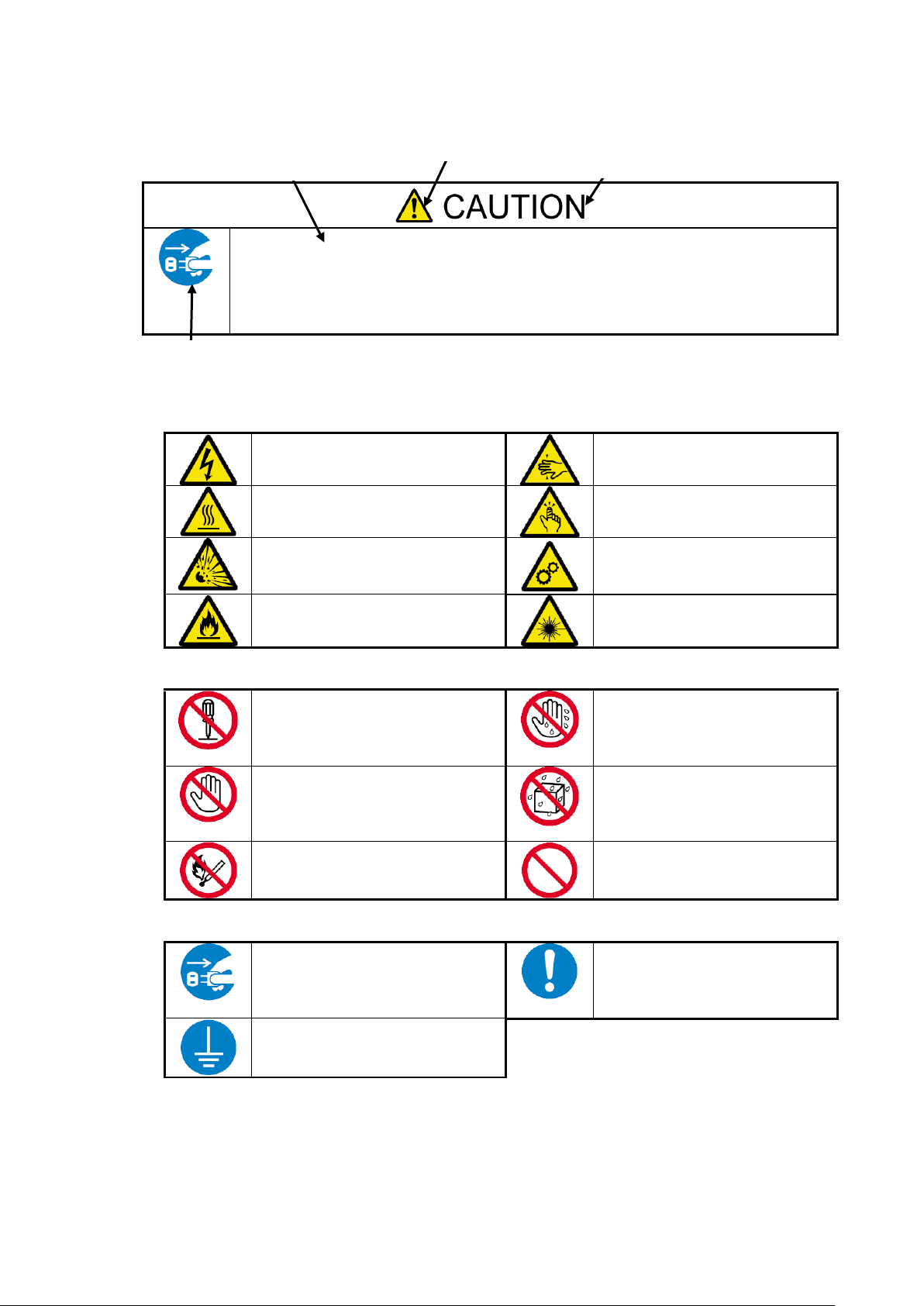

Disconnect the power cord(s) before installing or removing the product.

Make sure to power off the product and disconnect the power cord(s) from a power outlet

before installing/removing the server. All voltage is removed only when the power cords

are unplugged.

Indicates that improper use may

cause an electric shock.

Indicates that improper use may

cause fingers to be caught.

Indicates that improper use may

cause personal injury.

Indicates that improper use may

cause personal injury.

Indicates that improper use may

cause explosion or burst.

Indicates that improper use may

cause fingers or hands to be

caught.

Indicates that improper use may

cause fumes or fire.

Indicates that improper use may

cause eye damage.

Do not disassemble, repair, or

modify the server. Otherwise, an

electric shock or a fire may be

caused.

Do not touch the server

components with wet hand.

Otherwise, an electric shock may

be caused.

Do not touch any other component

than specified. Otherwise, an

electric shock or burn may be

caused.

Keep water or liquid away from

the server. Otherwise, an electric

shock or a fire may be caused.

Do not place the server near a fire.

Otherwise, a fire may be caused.

Indicates a general prohibited

action that cannot be specifically

identified.

Unplug the power cord of the

server. Otherwise, an electric shock

or a fire may be caused.

Indicates a mandatory action that

cannot be specifically identified.

Make sure to follow the

instruction.

Be sure to provide earthing.

Otherwise, an electric shock or a

fire may be caused.

Symbol indicating a prohibited

action (may not always be

indicated)

Description of a danger

Symbol to draw attention

Term indicating a degree of danger

(Example)

Attentions

Prohibited Actions

Mandatory Action

-iv-

Page 6

Do not use the product for services related to human lives or requiring high

reliability.

Your product is not intended to be used with or control facilities or devices concerning

human lives, including medical devices, nuclear facilities and devices, aeronautics and

space devices, transportation facilities and devices; and facilities and devices requiring

high reliability. NEC assumes no liability for any accident resulting in personal injury,

death, or property damage if the product has been used in the above conditions.

Do not use the product if any smoke, odor, or noise is present.

If smoke, odor, or noise is present, immediately turn off the product and disconnect the

power plug from the outlet, then contact your service representative. Using the product in

such conditions may cause a fire.

Keep needles or metal objects away from the product.

Keep needles or metal objects away from the product.

Do not insert needles or metal objects into ventilation holes or gaps in the product. Doing

so may cause an electric shock.

Do not use the product in any unapproved place.

Install the product on a standard EIA 19-inch rack assembly. Do not install the rack

containing the product in a place inappropriate to the rack installation environment. Failure

to follow these instructions may cause some bad influences to be imposed on the product

and other systems installed on the rack and also a fire or personal injury due to falling of

the rack may occur. For the detailed explanation on the place where the server should be

installed and the earthquake-resistant construction for the rack, refer to the manual attached

to the rack or contact you service representative.

Always install the product on a rack conforming to the relevant standard.

Install the product on a rack confirming to the EIA standard for the Server/Storage to be

used. Do not use the product installed on a rack that is not comply with EIA standard or

without mounting it on a proper rack. Failure to follow these instructions may cause the

server to operate incorrectly and/or personal injury or damages of surrounding devices to

occur. Contact your service representative for the racks available for the product.

Keep water or foreign matter away from the product.

Do not let any form of liquid (water etc.) or foreign matter (e.g., pins or paper clips) enter

the server. Failure to follow this warning may cause an electric shock, a fire, or a failure of

the server. When such things accidentally enter the server, immediately turn off the power

and disconnect the power plug from the outlet. Do not disassemble the product. Contact

your service representative.

General

-v-

Page 7

Do not overload the supply circuit by connecting this equipment with other

equipment so that the total exceeds the outlet rating.

To prevent fires, wiring and device damage, the total power drawn by the equipment in

the rack shall not exceed the rating of the branch circuit. Contact your electric constructor

or the local power company for the requirements on the wiring and installation of electric

facilities.

Do not carry or install the product only by a single person.

More than one person is required to carry or install the rack. Failure to follow this

instruction may cause the rack to fall to result in personal injury and/or breakages of

surrounding devices. In particular, a high rack (such as 44U rack) is unstable if it is not

fixed by stabilizers. More than one person is required to hold the rack to carry and install

the product.

Do not install the product so that the load may be concentrated on a specific

point.

Install stabilizers on the rack or connect more than one rack with each other to distribute

the load to avoid the weight is concentrated on one spot. Failure to follow this instruction

may cause the rack to fall to result in personal injury.

Do not install components on the product only by a single person.

More than one person is required to install parts including the doors and trays for the rack.

Failure to follow this instruction may cause some parts to fall to be broken and/or to result

in personal injury.

Anchor the equipment rack.

The equipment rack must be anchored (putting stabilizers or providing seismic protection)

to an unmovable support to prevent it from falling over when the product is removed from

the rack. The anchors must be able to withstand a force of up to 113kg (250lbs.) You must

also consider the weight of any other device installed in the rack.

Do not pull more than one device out of the rack at the same time.

Pulling out more than one device from the rack may cause the rack to be fallen. Only pull

out a single device from the rack at a time.

Rack

-vi-

Page 8

Elevated Operating Ambient.

If installed in a closed or multi-unit rack assembly, the operating ambient temperature of

the rack environment may be greater than room ambient. Therefore, consideration

should be given to installing the equipment in an environment compatible with the

maximum ambient temperature (Tma) specified by the manufacturer.

Reduced Air Flow.

Installation of the equipment in a rack should be such that the amount of air flow required

for safe operation of the equipment is not compromised.

Reliable Earthing.

Reliable earthing of rack-mounted equipment should be maintained. Particular attention

should be given to supply connections other than direct connections to the branch circuit

(e.g. use of power strips).

-vii-

Page 9

Do not hold the power plug with a wet hand.

Do not disconnect/connect the plug while your hands are wet. Failure to follow this

warning may cause an electric shock.

Do not connect the ground wire to a gas pipe.

Never connect the ground wire to a gas pipe. Failure to follow this warning may cause a

gas explosion.

If you disconnect the power, disconnect the two power lines.

The product might be powered from 2 AC power lines. If you disconnect the power from

the device, both 2 power sources must be disconnected. It may cause an electric shock if

the power is not disconnected properly.

Plug in to a proper power source.

Use a proper wall outlet. Use of an improper power source may cause a fire or a power

leak. Do not install the product where you need an extension cord. Use of a cord that does

not meet the power specifications of the product may heat up the cord and cause a fire.

Do not connect the power cord to an outlet that has an illegal number of

connections.

The electric current exceeding the rated flow overheats the outlet, which may cause a fire.

Insert the power plug into the outlet as far as it goes.

Heat generation resulting from a halfway inserted power plug (imperfect contact) may

cause a fire. Heat will also be generated if condensation is formed on dusty blades of the

halfway inserted plug, increasing the possibility of fire.

Do not use the attached power cord for any other devices or usage.

The power cord that comes with your product is designed aiming to connect with this

product and to use with the product, and its safety has been tested. Do not use the attached

power cord for any other purpose. Doing so may cause a fire or an electric shock.

Power Supply and Power Cord Use

-viii-

Page 10

Use the authorized power cord only.

Use only the power cord that comes with your product. Use of an unauthorized power

cord may cause a fire when the electric current exceeds the rated flow. Also, observe the

following to prevent an electric shock or a fire caused by a damaged cord.

・Do not stretch the cord harness.

・Do not pinch the power cord.

・Do not bend the power cord.

・Keep chemicals away from the power cord.

・Do not twist the power cord.

・Do not place any object on the power cord.

・Do not step on the power cord.

・Do not alter, modify, or repair the power cord.

・Do not bundle the power cords.

・Do not secure the power cord with staples or equivalents.

・Do not use any damaged power cord.

(Replace a damaged power cord with a new one of the same specifications. Ask your

service representative for replacement.)

-ix-

Page 11

Do not use or store this product in corrosive environment.

Avoid the usage or storage of this product in an environment which may be exposed to

corrosive gases, such as those including but not limited to: sulfur dioxide, hydrogen

sulfide, nitrogen dioxide, chlorine, ammonia and/or ozone. Avoid installing this product

in a dusty environment or one that may be exposed to corrosive materials such as sodium

chloride and/or sulfur. Avoid installing this product in an environment which may have

excessive metal flakes or conductive particles in the air. Such environments may cause

corrosion or short circuits within this product, resulting in not only damage to this

product, but may even lead to be a fire hazard. If there are any concerns regarding the

environment at the planned site of installation or storage, please contact your sales agent.

Do not install the product in any place other than specified.

Do not install the product in the following places or any place other than specified in this

Guide. Failure to follow this instruction may cause a fire.

・a dusty place

・a humid place such as near a boiler

・a place exposed to direct sunlight

・an unstable place

Do not install the parts other than specified.

Do not install third-party products or options on the device. Operation is no longer

successful, and may cause fire or malfunction.

Do not block the intake and exhaust holes.

Do not block air intake holes at the front or back of the product. Internal temperature rises

may cause malfunction and doing so may cause a fire.

Do not use any unauthorized interface cable.

Use only interface cables provided by NEC and locate a proper device and connector

before connecting a cable. Using an unauthorized cable or connecting the product to an

improper destination may result in a fire by short circuit. Also, observe the following

notes on using and connecting an interface cable.

・Do not step on the cable.

・Do not place any object on the cable.

・Do not use the device with loose cable connections.

・Do not use any damaged cable connector.

・Lock the cable certainly by the attachments such as screws.

Treat SAS cables with care and respect.

Rough treatment of SAS cables could cause deterioration of characteristics or mechanical

damage (line disconnection).

・Ensure a minimum bending radius of 150mm.

・Make sufficient allowance for the cable forming.

・Do not forcibly stretch a cable or otherwise stress it.

Installation, Relocation, Storage, and Connection

-x-

Page 12

Treat optical fiber cables with care and respect.

Rough treatment of optical fiber cables could cause deterioration of characteristics or

mechanical damage (line disconnection).

・Ensure a minimum bending radius of 38mm.

・Do not drop a cable on the floor or otherwise shock it.

・If not connecting a cable, place caps on it. When connecting a cable, do not discard the

caps but save them (as well as those for connectors on the unit).

As the optical power is attenuated by dust or dirt and it may cause data error, be sure to

clean the optical connector using the following procedure when optical fibre cable is

inserted to the product:

1. Spray air or another parts cleaning gas on the optical connector for several seconds.

2. Wipe the optical connector lightly several times with a non-fibrous cloth wetted with

isopropyl alcohol.

3. Spray parts cleaning gas on the optical connector for several seconds again.

Be careful when handling the laser products.

The product contains class-1 laser products based on JIS C6802, EN60825-1 (+A-11), and

21 CFR 1040.10 and 1040.11 issued by the U.S. Food and Drug Association (FDA).

Do not look straight at the optical fiber cable, optical fiber connector, or laser transceiver

module because there is a risk of eye damage, depending on the laser power level.

Note that JIS C6802, EN60825, and IEC60825 defines class-1 laser as the level of laser

which causes no injury if human is exposed to it.

Prevent damage from electrostatic discharge.

Components in the device is sensitive to static electricity. Even a slight discharge, could

damage the electrical components in the device. Even if a component receives damage, an

error may not occur immediately, but the state is aggravated and is causing a

"intermittent" problem gradually.

Before touching the product, touch an unpainted metal surface. It is effective to use

commercially available anti-static wrist strap with a clip terminal.

・If the frame of the device is metal, touch the frame.

・Otherwise, touch the wall part of the product or a screw of the door frame.

・Stay as still as possible when touching the components inside the product to avoid

produce static electricity.

Do not pinch your finger with rails or other components.

Be careful sufficiently not to pinch or cut your fingers with the rails etc. when you

mount/unmount the product on the rack.

Do not apply any load on the device pulled out from the rack.

Do not apply any load on the device pulled out from the rack. Doing so bends the frame of

the device. Consequently, the device cannot be pushed back into the rack. Placing an

object on the device may also cause personal injury if the device drops.

Relocation of the product.

Consult with your service representative for relocation of the product.

Disposal of the product.

The product contains liquid crystal display (LCD). Consult with your service

representative before disposing of the product. Dispose of the unit according to the

ordinance of the local government.

-xi-

Page 13

Do not disassemble, repair, or alter the product.

Never attempt to disassemble, repair, or alter the product on any occasion. Failure to

follow this instruction may cause an electric shock or fire as well as malfunctions of the

server.

Disconnect the power plug before cleaning the product.

Make sure to power off and disconnect the power plug from a power outlet before

cleaning product. Touching any internal components of the product with its power cord

connected to a power source may cause electric shock even if the product’s power is

offline. Disconnect the power plug from the outlet occasionally and clean the plug with a

dry cloth. Heat will be generated if condensation is formed on a dusty plug, which may

cause a fire.

Avoid installation in extreme temperature conditions.

Immediately after the device is powered off, its internal components are very hot. Please

work after confirming the product was cooled enough.

Make sure to complete installation.

Install power cords and interface cables surely.

Improper installation of the cords and cables may cause a contact failure, resulting in

smoking or fire.

Handling of damaged LCD (liquid crystal display)

The product uses the liquid crystal display that contains harmful liquid to the human body.

If you need to touch the damaged LCD, take extreme care not to touch the liquid inside

the display. If the liquid enters your mouth, immediately gargle and consult with your

doctor. If the liquid adheres your skin or eyes, rinse it for at least 15 minutes, and then

consult with your doctor.

Ask your service representative for repair of the LCD.

Cleaning and Working with Internal Devices

-xii-

Page 14

Do not use the product if any smoke, odor, or noise is present.

If smoke, odor, or noise is present, immediately turn off the product and disconnect the

power plug from the outlet, then contact your service representative. Using the product in

such conditions may cause a fire.

Do not put hand inside the device.

Do not put your hand inside the device. There is a possibility of injury by pinching your

hands with the internal components..

Stay away from the fan.

Keep your hand or hair away from the cooling fan on the rear of the product. Failure to

follow this warning may get your hand or hair caught in the fan, resulting in injury.

Avoid contact with the product during thunderstorms.

If it starts thundering before you disconnect the power plug, do not touch any part of the

product including the cables. Failure to follow this warning may cause an electric shock

by the thunderbolt.

Do not peep into device when magazine operations.

The part of the magazine has a mechanism to automatically open.

If you are peeping into the device during magazine operations, it may be injured part of

the magazine hit the face.

Do not put the finger in the opening of the magazine while operating the I/O

station.

The I/O station dashes out to a device front side after pressing the enter button. Please

there must not be danger from which the hand is placed between the moving part, and do

not affix the hand to the magazine, and do not put the finger in the opening of the

magazine until the I/O station dashes out. Please push the magazine a little when the

finger is placed in the opening of the magazine by any chance and pull out the finger

while returning it.

Keep any animal (Pet) away from the product.

Keep any animal (Pet) away from the product. Pet’s discharges or fur may enter the

device and cause a fire or electric shock.

To avoid incommoding reflections at visual display workplaces this device must

not be placed in the direct field of view.

This device is not intended for use in the direct field of view at visual display workplaces.

To avoid incommoding reflections at visual display workplaces this device must not be

placed in the direct field of view.

During Operation

-xiii-

Page 15

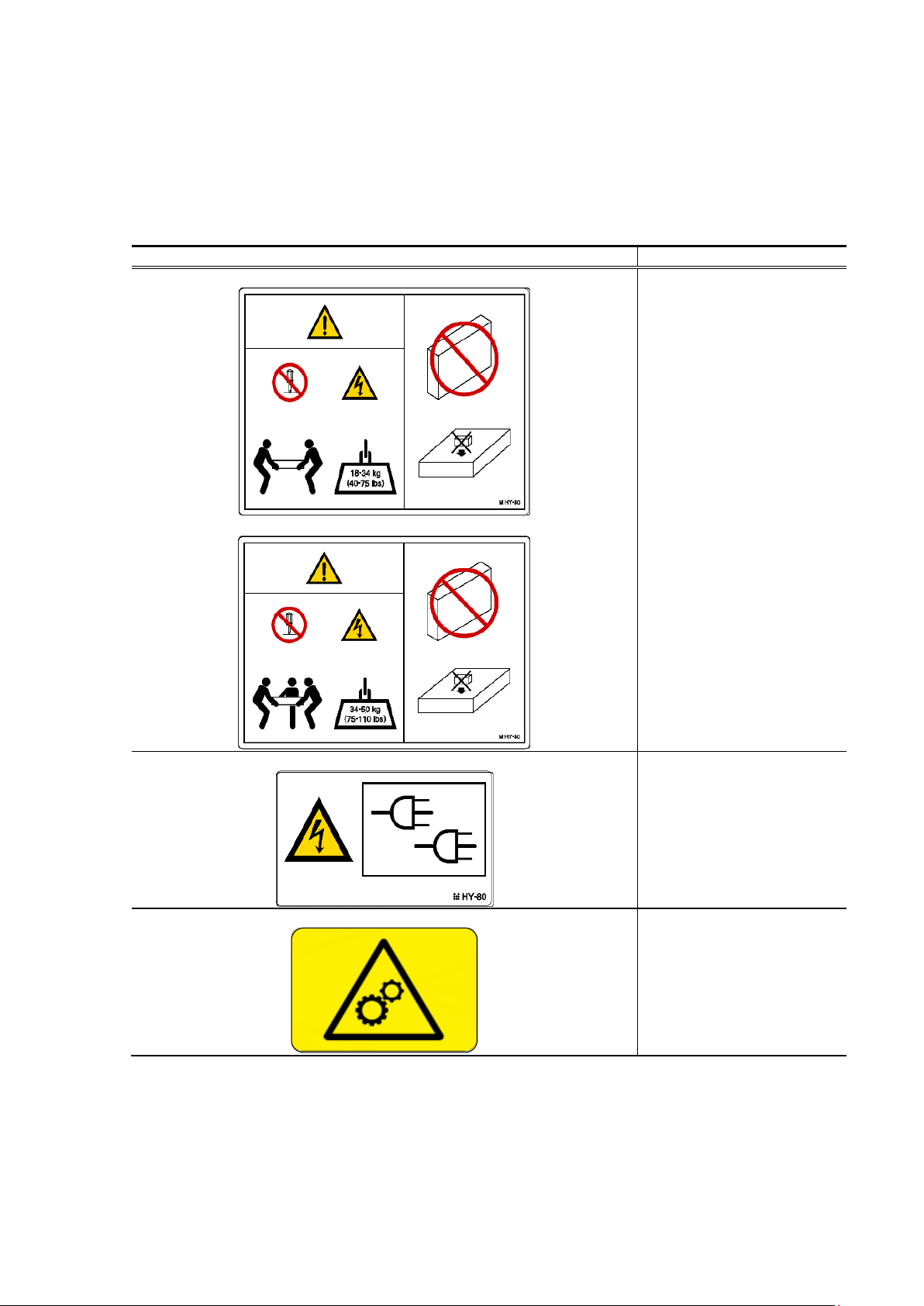

Warning Label

Meaning / Location

T30A

T60A

[Do not disassemble]

Only the maintenance

Personnelcan disassemble

the unit.

[Heavy load]

To avoid personal injury, at

least three persons must

carry the unit.

[Do not put the thing on]

Do not put the thing on the

device.

[Do not put on length.]

Do not put the device on

length.

Location: Top plate of the

unit

T60A

[Redundant power supply

use]

Location: back of device

T30A/T60A

[Attention that rolls hand and

finger]

Location:Drive

Warning Labels

The following warning labels have been attached to this unit. Customers and maintenance service personnel

are urged to keep these warnings in the forefront of their minds when operating this unit. (Do not remove or

soil these labels.)

If any of these labels are missing, removed, soiled, or otherwise unreadable, contact your local maintenance

service company.

-xiv-

Page 16

Kind of display

Kind

Content

It explains the content for which attention is especially necessary in

operating.

It explains information on the limitations in the operation.

It explains amplification of the text.

The mark of this manual

The following signs are used in this manual.

-xv-

Page 17

Contents

Handling of laser product .................................................................................................... i

Japanese acceptance statement ............................................................................................. i

Chinese acceptance statement .............................................................................................. i

Taiwan acceptance statement ............................................................................................... i

WEEE ................................................................................................................................ i

FCC acceptance statement .................................................................................................. ii

ICES acceptance statement ................................................................................................. ii

Other ................................................................................................................................ ii

RoHS Compliance ............................................................................................................. ii

Warning Labels ............................................................................................................... xiv

The mark of this manual ................................................................................................... xv

Contents ....................................................................................................................................... xvi

Figures ........................................................................................................................... xxi

Tables .......................................................................................................................... xxiii

Preface ....................................................................................................................................... xxiv

Remarks ....................................................................................................................... xxiv

Exemptions ................................................................................................................... xxv

Use Limitation ............................................................................................................... xxv

Chapter1 General Description ...................................................................................................... 1

1.1 Handling Precautions ................................................................................................................. 1

1.1.1 Notes on Use ....................................................................................................................... 1

1.2 Transfer of Library ..................................................................................................................... 1

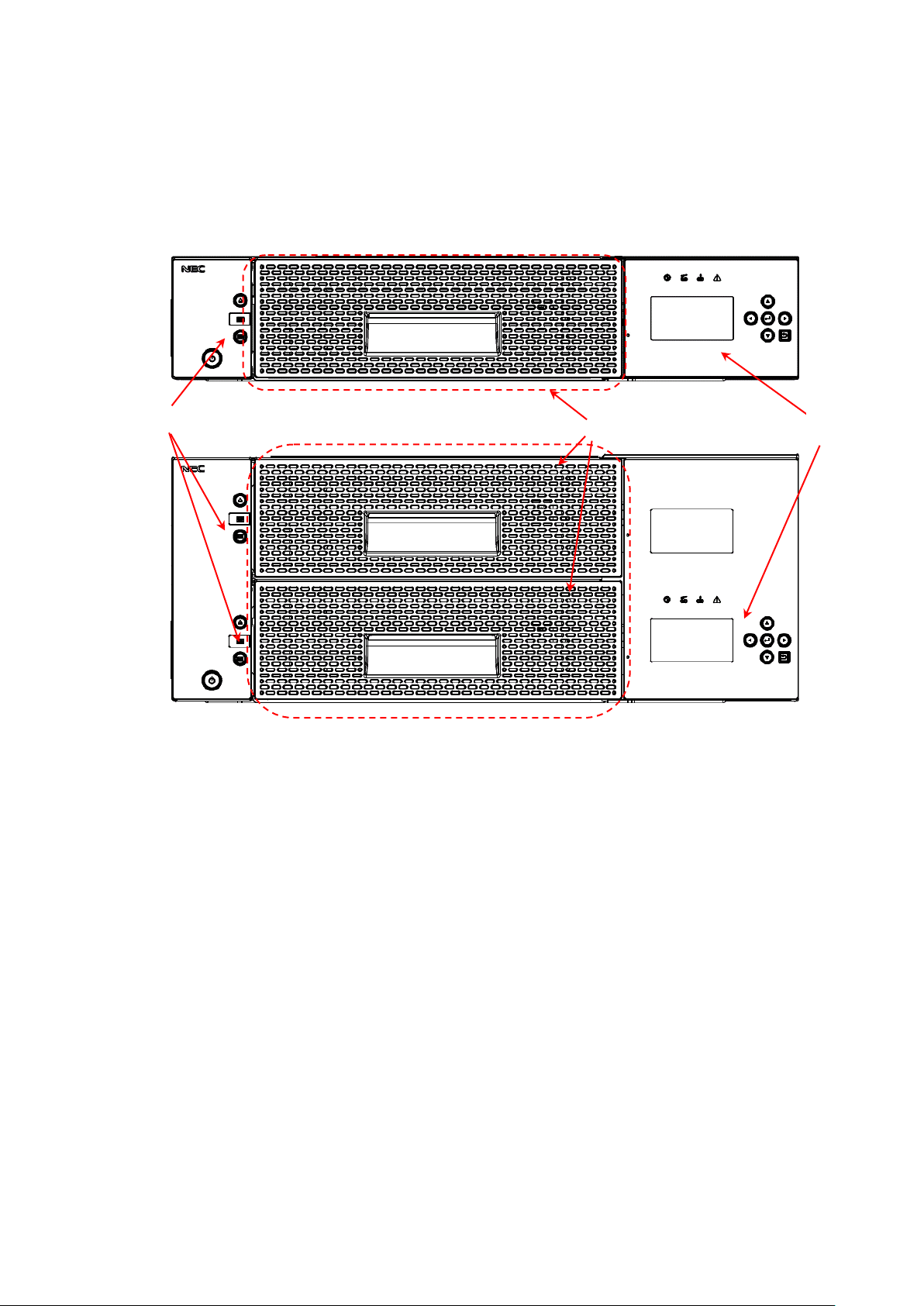

1.3 Names and Features of Components ............................................................................................ 2

1.3.1 Front View .......................................................................................................................... 2

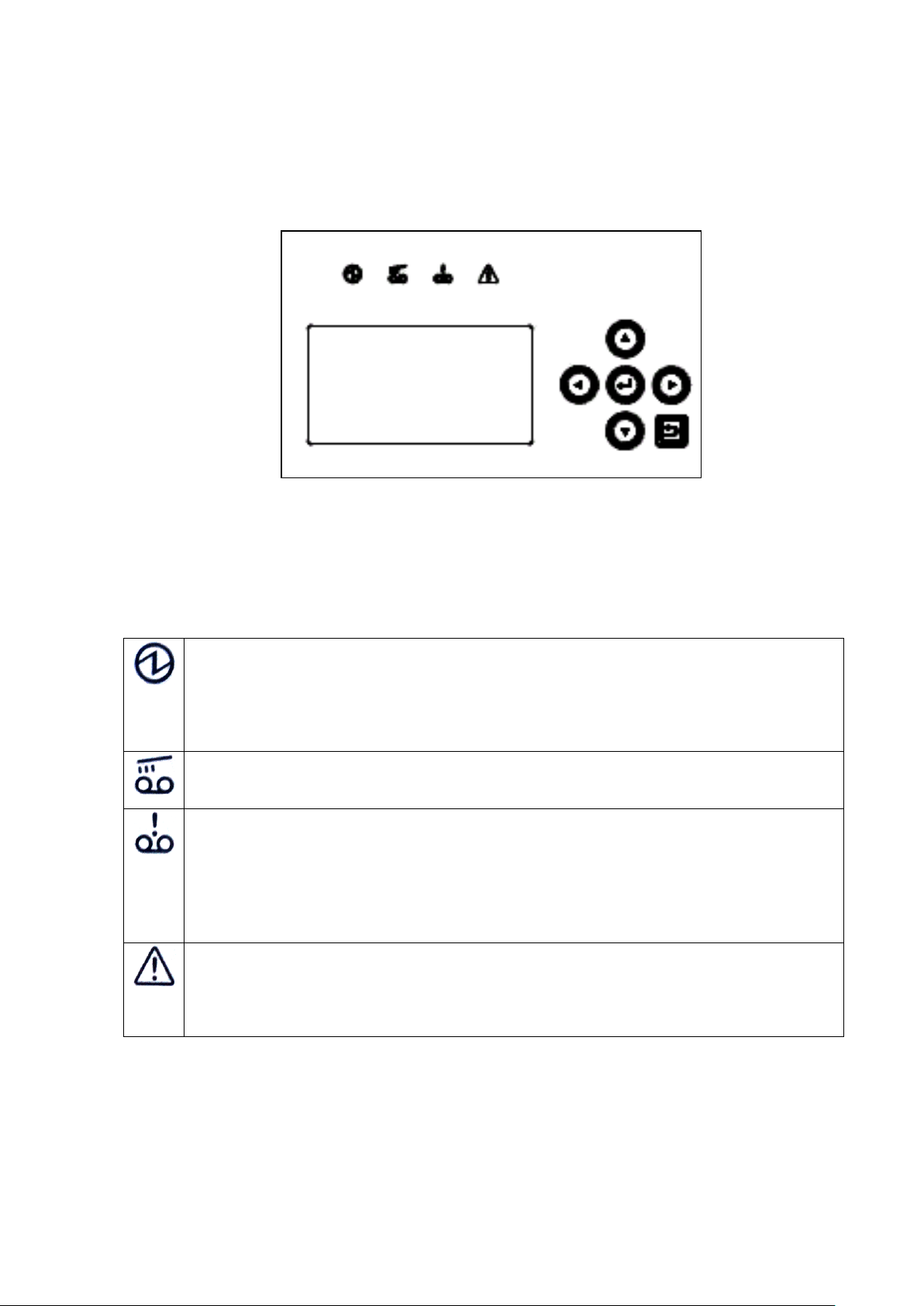

1.3.2 Operator panel ..................................................................................................................... 3

1.3.2.1 Status LED .................................................................................................................... 3

1.3.2.2 LCD .............................................................................................................................. 4

1.3.2.3 Button ........................................................................................................................... 4

1.3.3 Magazine operation panel ..................................................................................................... 5

1.3.3.1 Magazine Status LED ..................................................................................................... 5

1.3.3.2 Button ........................................................................................................................... 5

1.3.3.3 Ethernet connector for maintenance ................................................................................. 6

1.3.4 Magazine ............................................................................................................................ 7

1.3.4.1 Slot number ................................................................................................................... 7

1.3.4.2 Active Slot ..................................................................................................................... 8

1.3.4.3 I/O station ...................................................................................................................... 8

1.3.4.4 Escape slot ..................................................................................................................... 8

1.3.4.5 Cleaning Slot ................................................................................................................. 8

1.3.4.6 Inactive slot ................................................................................................................... 8

1.3.5 Rear View ........................................................................................................................... 9

1.3.6 Drive Sled Ingicator ........................................................................................................... 10

1.3.7 Power Module LED ............................................................................................................ 11

1.4 Encryption ............................................................................................................................... 12

1.5 Disposal of the Product and Comsumables ................................................................................. 13

1.6 Unpacking ............................................................................................................................... 14

1.6.1 Unpacking ........................................................................................................................ 14

1.7 Installing the Rack Mounting Kit .............................................................................................. 16

1.7.1 Components ...................................................................................................................... 16

1.7.2 Caution points for rack mounting ........................................................................................ 17

1.7.3 Rack mount rail attachment position ................................................................................... 19

1.7.4 Attachment of Rack mount rail L/R..................................................................................... 20

1.7.5 Attachment of Rack mount bracket L/R ............................................................................... 21

1.7.6 Installation of library ......................................................................................................... 22

1.7.7 Attachment of Rack ear ...................................................................................................... 24

-xvi-

Page 18

1.7.8 Attachment of label plate.................................................................................................... 25

1.8 Removal of shipment Stabilizer ................................................................................................. 26

Chapter2 Setup ......................................................................................................................... 27

2.1 Connection of a Interface Cable ................................................................................................ 27

2.1.1 Connection of SAS Cable ................................................................................................... 27

2.1.2 Connection of FC Cable ..................................................................................................... 28

2.2 Connection of AC Power Cable ................................................................................................ 29

2.3 Power-On and self test.............................................................................................................. 29

2.4 Setting Drive configuration ....................................................................................................... 29

2.5 Setting Library and Drive configuration ..................................................................................... 29

2.6 Diagnostic Test ........................................................................................................................ 30

2.7 Operation Checks after Installation ............................................................................................ 30

Chapter3 Power-On and Power-Off ............................................................................................ 31

3.1 Power-On and Power-On Sequence ........................................................................................... 31

3.2 Starting the System .................................................................................................................. 31

3.3 Shutting Down the System ........................................................................................................ 31

3.4 Power-Off and Power-Off Sequence .......................................................................................... 31

Chapter4 Operator Panel ........................................................................................................... 32

4.1 Panel Indications ...................................................................................................................... 32

4.1.1 Menu Screen ..................................................................................................................... 32

4.1.2 Status Display screen ......................................................................................................... 33

4.1.2.1 Library State ................................................................................................................ 33

4.1.2.2 Drive State ................................................................................................................... 37

4.1.3 Asynchronization message screen ....................................................................................... 39

4.2 Menu Tree ............................................................................................................................... 40

4.3 Login ...................................................................................................................................... 44

4.3.1 Service Login .................................................................................................................... 45

4.4 Top Menu ................................................................................................................................ 46

4.4.1 Commands ........................................................................................................................ 47

4.4.2 Configuration .................................................................................................................... 48

4.4.2.1 Library Settings ............................................................................................................ 49

4.4.2.2 Network Settings .......................................................................................................... 50

4.4.2.3 Drive Settings .............................................................................................................. 51

4.4.2.4 OP Panel Settings ......................................................................................................... 52

4.4.2.5 Date / Time .................................................................................................................. 52

4.4.2.6 Set Default ................................................................................................................... 52

4.4.3 Current Information ........................................................................................................... 53

4.4.3.1 Setting Information ....................................................................................................... 53

4.4.3.2 Slot Information ........................................................................................................... 53

4.4.4 Service .............................................................................................................................. 54

4.4.4.1 View Error Status ......................................................................................................... 54

4.4.4.2 Diagnostics .................................................................................................................. 54

4.4.4.3 Statistics ...................................................................................................................... 55

4.4.4.4 Telnet Service Port ....................................................................................................... 55

4.4.4.5 View Revision ............................................................................................................. 55

4.4.4.6 Drive Replacement ....................................................................................................... 55

4.4.4.7 Advanced Service ......................................................................................................... 56

4.4.4.8 Library Log ................................................................................................................. 56

4.4.5 Logout .............................................................................................................................. 56

4.5 Configuring the Library ............................................................................................................ 57

4.5.1 Viewing Configuration data of the library ............................................................................ 57

4.5.2 Change password ............................................................................................................... 57

4.5.3 Setting of Drive ................................................................................................................. 59

4.5.3.1 Setting of Serial Attached SCSI ..................................................................................... 59

4.5.3.2 Setting of Fibre Channel ............................................................................................... 60

4.5.3.3 Setting robot control path .............................................................................................. 61

4.5.3.4 Power Save Mode ........................................................................................................ 62

4.5.4 Switching between ONLINE and OFFLINE ........................................................................ 62

4.5.5 Setting of I/O Station ......................................................................................................... 63

-xvii-

Page 19

4.5.6 Setting of Active Slot ......................................................................................................... 63

4.6 Insertion and Removing Cartridge by Operator Panel ................................................................. 64

4.6.1 Magazine Operations ......................................................................................................... 64

4.6.1.1 Removing Magazine ..................................................................................................... 64

4.6.1.2 Insertion of cartridges into magazine .............................................................................. 66

4.6.1.3 Removal of cartridges from magazine ............................................................................ 66

4.6.1.4 Emergency removal of magazine ................................................................................... 67

4.6.2 I/O Station Operations ....................................................................................................... 68

4.7 Using the operation panel to move cartridges ............................................................................. 69

4.7.1 Load cartridge into drive .................................................................................................... 69

4.7.2 Removing from the drive.................................................................................................... 71

4.8 Cleaning .................................................................................................................................. 73

4.8.1 Cleaning by Operation panel .............................................................................................. 73

4.8.2 Auto Cleaning ................................................................................................................... 73

4.9 Rebooting the Library .............................................................................................................. 74

4.10 Rebooting Drive ..................................................................................................................... 75

Chapter5 Remote Manager Interface .......................................................................................... 76

5.1 Connection Configuration ......................................................................................................... 76

5.2 Connection Settings ................................................................................................................. 77

5.3 Startup of Remote Manager Interface ........................................................................................ 78

5.3.1 Connection of https ............................................................................................................ 79

5.4 Login Formats ......................................................................................................................... 80

5.5 Web Page Configuration ........................................................................................................... 81

5.6 Web Page Detail ...................................................................................................................... 82

5.6.1 Menu windows .................................................................................................................. 82

5.6.2 Login ................................................................................................................................ 83

5.6.3 Library information viewing menu(Monitor Sytem) ............................................................. 84

5.6.3.1 Library Basic Information(System Summary) ................................................................. 84

5.6.3.2 Library Detailed Information Window (Library Map) ..................................................... 86

5.6.4 Library management menu (Manage Library) ...................................................................... 93

5.6.4.1 Move Cartridge window (Move Cartridge) ..................................................................... 93

5.6.4.2 Unload Drive window (Unload Drive) ........................................................................... 95

5.6.4.3 Clean Drive window (Clean Drive) ................................................................................ 96

5.6.4.4 Library State (OFFLINE/ONLINE)switching window(Library State) ............................... 97

5.6.5 Library setting (Configure Library) ..................................................................................... 98

5.6.5.1 Account setting (User Access) ....................................................................................... 98

5.6.5.2 Physical View (Physical) ............................................................................................ 101

5.6.5.3 Library setup window (Logical)................................................................................... 102

5.6.5.4 Network setup window (Network) ............................................................................... 105

5.6.5.5 Date and Time setup window (Date and Time) ............................................................. 107

5.6.5.6 Event Notification setup window(SMTP) ..................................................................... 108

5.6.5.7 Event Notifications setup window (SNMP) .................................................................. 109

5.6.5.8 Encryption Basis ......................................................................................................... 112

5.6.5.9 Encryption Detail ........................................................................................................ 113

5.6.5.10 Licenses Registration ................................................................................................. 114

5.6.5.11 Saving the File Setting / Restore Screen (Save and Restore) .......................................... 115

5.6.6 Library maintenance (Service Library) ............................................................................... 117

5.6.6.1 View Library Logs ...................................................................................................... 117

5.6.6.2 Download Library /Drive logs (Download Logs) ........................................................... 118

5.6.6.3 Reset (Reset Library / Drive) ........................................................................................ 119

5.6.6.4 Firmware Refresh Screen (Firmware Update) ............................................................... 120

5.6.6.5 Statistical Information (Usage Statistics) ...................................................................... 121

5.6.6.6 Web Shell (web shell) ................................................................................................. 122

5.7 Event list ............................................................................................................................... 123

Chapter6 Encryption Key Management Function ...................................................................... 125

6.1 General Information ............................................................................................................... 125

6.1.1 Features of Encryption Key Management Option ............................................................... 125

6.1.2 Encryption Mechanism .................................................................................................... 125

6.1.3 Types of Keys ................................................................................................................. 125

-xviii-

Page 20

6.1.3.1 Master Key ................................................................................................................ 126

6.1.3.2 Encryption Key .......................................................................................................... 127

6.1.3.3 Backup of encryption key ........................................................................................... 127

6.2 Basic Operation of encryption key management function .......................................................... 128

6.2.1 Setup .............................................................................................................................. 128

6.2.1.1 Registering the activation key ...................................................................................... 129

6.2.1.2 Checking the license key registration status .................................................................. 129

6.2.1.3 Enabling the encryption key management function ....................................................... 130

6.2.1.4 Registering (importing) the master key......................................................................... 131

6.2.1.5 Exporting (backing up) the master key ......................................................................... 133

6.2.2 Operation ........................................................................................................................ 134

6.2.2.1 To Create encrypted medium ....................................................................................... 134

6.2.3 Checking tape media Information ..................................................................................... 135

6.2.3.1 Sharing tape medium among multiple libraries ............................................................. 135

6.2.4 Maintenance .................................................................................................................... 135

6.2.4.1 Backup of Encryption Key (Basic Operation) ............................................................... 135

6.2.4.2 Executing Set Default ................................................................................................. 136

6.2.4.3 Checking the encryption log ........................................................................................ 136

6.3 Advance Operation of encryption key management function ..................................................... 137

6.3.1 Enabling or Disableing Enctyption for Each tape medium................................................... 138

6.3.1.1 Setting tape medium encryption................................................................................... 139

6.3.1.2 Sharing tape medium among multiple libraries (advanced) ............................................ 140

6.3.2 Importing and Exporting the Encryption Key(For Each Tape Medium) ................................ 140

6.3.2.1 When to import the encryption key .............................................................................. 141

6.3.2.2 To import the encryption key ...................................................................................... 141

6.3.2.3 To export an encryption key ........................................................................................ 143

6.3.3 Disabling the Encryption Management Function for the Library .......................................... 144

6.3.4 Changing the Master Key ................................................................................................. 145

6.3.5 Backing Up and Restoring the KEY Database .................................................................... 145

6.3.5.1 Backing up the KEY database ..................................................................................... 146

6.3.5.2 Restoring the KEY database ........................................................................................ 146

6.3.6 Clearing encryption information ....................................................................................... 147

6.3.6.1 To clear encryption information................................................................................... 147

6.4 Points to Check When a Failure or Abnormality Occurs ............................................................ 148

6.5 FAQ about Encryption Key Management function ................................................................... 149

6.6 List of Encryption Event Log Messages ................................................................................... 150

Chapter7 Installation of Option ................................................................................................ 151

7.1 Install of drive ....................................................................................................................... 151

7.2 Install of power module .......................................................................................................... 151

7.3 Install of activation key .......................................................................................................... 152

Chapter8 Cartridges ................................................................................................................ 152

8.1.1 Data Cartridge ................................................................................................................. 153

8.1.2 WORM cartridge ............................................................................................................. 153

8.1.3 Cleaning cartridge ........................................................................................................... 153

8.1.4 Diagnosis cartridge .......................................................................................................... 153

8.2 Cartridge Label ...................................................................................................................... 154

8.2.1 Attaching a cartridge label ................................................................................................ 155

8.3 Write Protection ..................................................................................................................... 156

8.4 Notes on Handling ................................................................................................................. 157

8.4.1 Notes on Use ................................................................................................................... 157

8.4.2 General ........................................................................................................................... 157

8.4.3 Use protection standard .................................................................................................... 157

8.4.4 Service Life ..................................................................................................................... 158

8.4.5 Cartridge storage ............................................................................................................. 158

Chapter9 Maintenance............................................................................................................. 159

9.1 Drive Cleaning ...................................................................................................................... 159

9.1.1 Auto Cleaning ................................................................................................................. 159

9.2 Diagnosis test ........................................................................................................................ 160

9.3 Cleaning of device ................................................................................................................. 160

-xix-

Page 21

9.4 Cleaning of Magazine Filter .................................................................................................... 161

9.5 Cleaning of cartridge .............................................................................................................. 161

9.6 Updating the Firmware ........................................................................................................... 162

9.6.1 Confirming the Firmware Version ..................................................................................... 162

9.6.2 Updating the Library Firmware ......................................................................................... 163

9.6.3 Updating the Drive Firmware ........................................................................................... 164

9.7 Troubleshooting Procedures .................................................................................................... 165

9.8 Moving the Library ................................................................................................................ 166

Chapter10 Replacing Maintenance Parts ................................................................................... 167

10.1 Saving and Restoring Maintenance Information ...................................................................... 168

10.1.1 Saving Maintenance Information .................................................................................... 168

10.1.2 Restoring Maintenance Information ................................................................................ 169

10.2 Replacing the Device ............................................................................................................ 170

10.3 Replacing the Maintenance Chassis ....................................................................................... 170

10.4 Replacing the Contoller Board .............................................................................................. 171

10.5 Replacing the Drive Module ................................................................................................. 173

10.6 Replacing the Power Supply Module ..................................................................................... 174

10.7 Replacing the Operator Panel PKG ........................................................................................ 175

10.8 Replacing the Escape Slot ..................................................................................................... 177

10.9 Replacing the Front Magazine and Rear Magazine ................................................................. 177

10.10 Replacing the Air Filter ...................................................................................................... 178

10.11 Replacing the Drive fan ...................................................................................................... 181

10.12 Replacing the Internal FC cable ........................................................................................... 184

10.13 Replacing the Front bezel L................................................................................................. 185

10.14 Replacing the Front bezel R ................................................................................................ 186

Chapter11 Self-Diagnosis Function .......................................................................................... 187

11.1 Mechanism Test ................................................................................................................... 187

11.1.1 Demo (Slot-Drv-Slot) ..................................................................................................... 187

11.1.2 Demo (Slot-Slot) ........................................................................................................... 187

11.1.3 MSBF Test .................................................................................................................... 187

11.1.4 X-Move Test ................................................................................................................. 187

11.1.5 Y-Move Test ................................................................................................................. 187

11.1.6 Pick/Put Test ................................................................................................................. 187

11.1.7 Pick/Put/Move Test ........................................................................................................ 187

11.1.8 Vibration Test ............................................................................................................... 187

11.2 LCD/LED Test .................................................................................................................... 187

11.3 Phy Test .............................................................................................................................. 187

Chapter12 Action in breakdown and abnormal circumstances .................................................... 188

12.1 Trouble Shooting ................................................................................................................. 189

12.2 When you request maintenance ............................................................................................. 190

-xx-

Page 22

Figures

Figure 1-1 Front of the Library (Above: T30A/Below: T60A) ......................................................... 2

Figure 1-2 Operator panel ............................................................................................................. 3

Figure 1-3 Magazine operation panel(left:T30A,right:T60A) .......................................................... 5

Figure 1-4 Slot Number of Magazine(Above:T30A,Below:T60A) ................................................... 7

Figure 1-5 Components on the Rear of the Library(T30A) .............................................................. 9

Figure 1-6 Components on the Rear of the Library(T60A) .............................................................. 9

Figure 1-7 Components of Rack mount kit parts ........................................................................... 16

Figure 1-8 Illustration of Rack Bars ............................................................................................ 17

Figure 1-9 Rack Dimensions ....................................................................................................... 18

Figure 1-10 Rack mount rail attachment position.......................................................................... 19

Figure 1-11 attachment of rack mount rails .................................................................................. 20

Figure 1-12 attachment of rack mount bracket R(left:T30A , right :T60A) ...................................... 21

Figure 1-13 attachment of rack mount bracket L(left:T30A , right :T60A) ...................................... 21

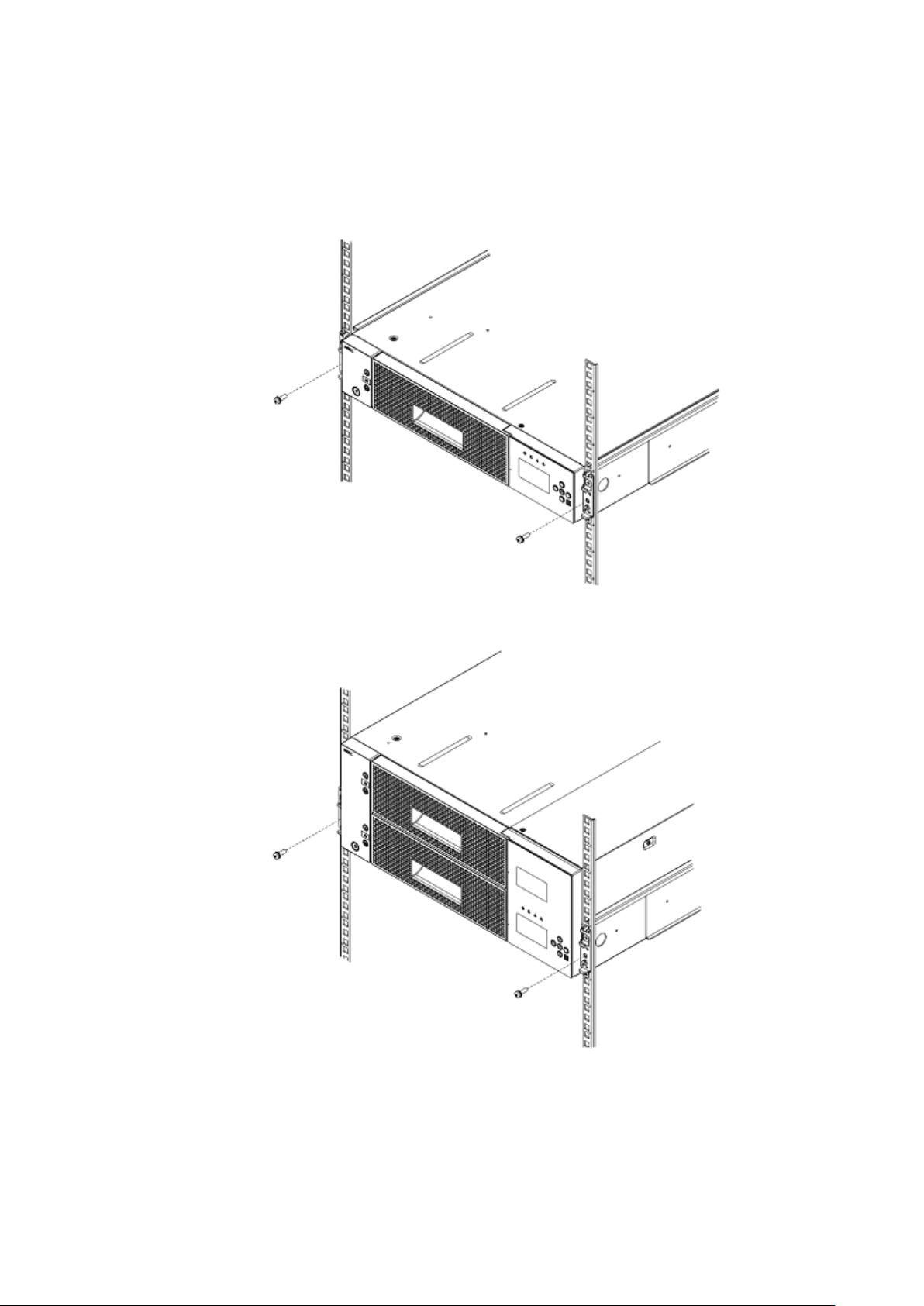

Figure 1-14 Mounting of library onto rack ................................................................................... 22

Figure 1-15 attachment of rack ears ............................................................................................. 23

Figure 1-16 Fastening of Library’s front side ............................................................................... 24

Figure 1-17 attachment of label plate ........................................................................................... 25

Figure 4-1 Menu Screen ............................................................................................................. 32

Figure 4-2 Component of Operator Panel ..................................................................................... 33

Figure 4-3 Accessor Icon ............................................................................................................ 34

Figure 4-4 Magazine Icon ........................................................................................................... 35

Figure 4-5 Magazine Icon(Magazine is Opened) .......................................................................... 35

Figure 4-6 Magazine Icon(I/O Station is set) ................................................................................ 35

Figure 4-7 Magazine Icon (I/O Station is opened) ........................................................................ 36

Figure 4-8 Magazine Icon(Slot Image) ........................................................................................ 36

Figure 4-9 Root screen of Top Menu ........................................................................................... 46

Figure 4-10 Move Cartidge ......................................................................................................... 69

Figure 4-11 Select source Screen................................................................................................. 69

Figure 4-12 Select Destination Screen ......................................................................................... 70

Figure 4-13 Select Execute ......................................................................................................... 70

Figure 4-14 Move Cartridge ....................................................................................................... 71

Figure 4-15 Select source screen ................................................................................................. 71

Figure 4-16 Select Destination screen .......................................................................................... 72

Figure 4-17 Select Execute ......................................................................................................... 72

Figure 4-18 Reboot Library ........................................................................................................ 74

Figure 5-1 Input URL................................................................................................................. 78

Figure 5-2 Login page(before entry) ............................................................................................ 83

Figure 5-3 Login page(after entry) .............................................................................................. 83

Figure 5-4 Library Basic Information Window ............................................................................. 84

Figure 5-5 Library map .............................................................................................................. 86

Figure 5-6 Detail(Magazine) ....................................................................................................... 87

Figure 5-7 Accessor Information ................................................................................................. 88

Figure 5-8 Library information ................................................................................................... 89

Figure 5-9 Network information.................................................................................................. 90

Figure 5-10 Notification information ........................................................................................... 91

Figure 5-11 Drive information .................................................................................................... 92

Figure 5-12 Move Cartridge ....................................................................................................... 93

Figure 5-13 Unload Drive ........................................................................................................... 95

Figure 5-14 Clean Drive ............................................................................................................. 96

Figure 5-15 Library state ............................................................................................................ 97

Figure 5-16 confirmation screen.................................................................................................. 97

Figure 5-17 UserAccess ............................................................................................................. 98

Figure 5-18 Add a User .............................................................................................................. 99

Figure 5-19 Remove a User confirmation screen ........................................................................ 100

Figure 5-20 Physical ................................................................................................................ 101

Figure 5-21 Logcal .................................................................................................................. 102

Figure 5-22 Network setup ....................................................................................................... 105

-xxi-

Page 23

Figure 5-23 Date and Time setup .............................................................................................. 107

Figure 5-24 SMTP setup ........................................................................................................... 108

Figure 5-25 SNMP setup .......................................................................................................... 109

Figure 5-26 SNMPv3 setup ....................................................................................................... 110

Figure 5-27 Trap list.................................................................................................................. 111

Figure 5-28 Encryption Basis setup ............................................................................................ 112

Figure 5-29 Encryption Detail setup ........................................................................................... 113

Figure 5-30 Licenses Registration .............................................................................................. 114

Figure 5-31 Save/Restore .......................................................................................................... 115

Figure 5-32 View Library logs ................................................................................................... 117

Figure 5-33 Download Logs ...................................................................................................... 118

Figure 5-34 Reset Library / Drive............................................................................................... 119

Figure 5-35 Firmware Update ................................................................................................... 120

Figure 5-36 Usage Statistics ..................................................................................................... 121

Figure 5-37 Web Shell .............................................................................................................. 122

Figure 6-1 activation key is not registered .................................................................................. 129

Figure 6-2 activation key is registered ....................................................................................... 129

Figure 6-3 Encryption Enable ................................................................................................... 130

Figure 6-4 Master key is registered ........................................................................................... 130

Figure 6-5 Manual Input of Master key...................................................................................... 131

Figure 6-6 File Input of Master key ........................................................................................... 132

Figure 6-7 Export of Master key ............................................................................................... 133

Figure 6-8 Encryption Detail .................................................................................................... 134

Figure 6-9 Encryption Detail .................................................................................................... 138

Figure 6-10 Encryption Setting ................................................................................................. 139

Figure 6-11 manual inputting of the encryption key .................................................................... 141

Figure 6-12 file inputting of the encryption key .......................................................................... 142

Figure 6-13 Export of the encryption key ................................................................................... 143

Figure 6-14 Disabling the Encryption Management Function ...................................................... 144

Figure 6-15 Changing Master Key ............................................................................................ 145

Figure 6-16 Backup or Restore of KEY Database ....................................................................... 145

Figure 6-17 Backup of KEY Database ....................................................................................... 146

Figure 6-18 Clear of Encryption information ............................................................................. 147

Figure 8-1 Names of Cartridge Parts ......................................................................................... 152

Figure 8-2 Data Cartridge Label ................................................................................................ 154

Figure 8-3 Attaching a cartridge label ........................................................................................ 155

Figure 8-4 Write Protection of cartridge ..................................................................................... 156

Figure 9-1 Confirming the Firmware Version ............................................................................. 162

Figure 9-2 Firmware Update Window (Library Firmware Update) ............................................... 163

Figure 9-3 Firmware Update Window (Drive Firmware Update) ................................................. 164

Figure 10-1 Save/Restore Window ............................................................................................ 168

Figure 10-2 Save/Restore Window ............................................................................................ 169

-xxii-

Page 24

Tables

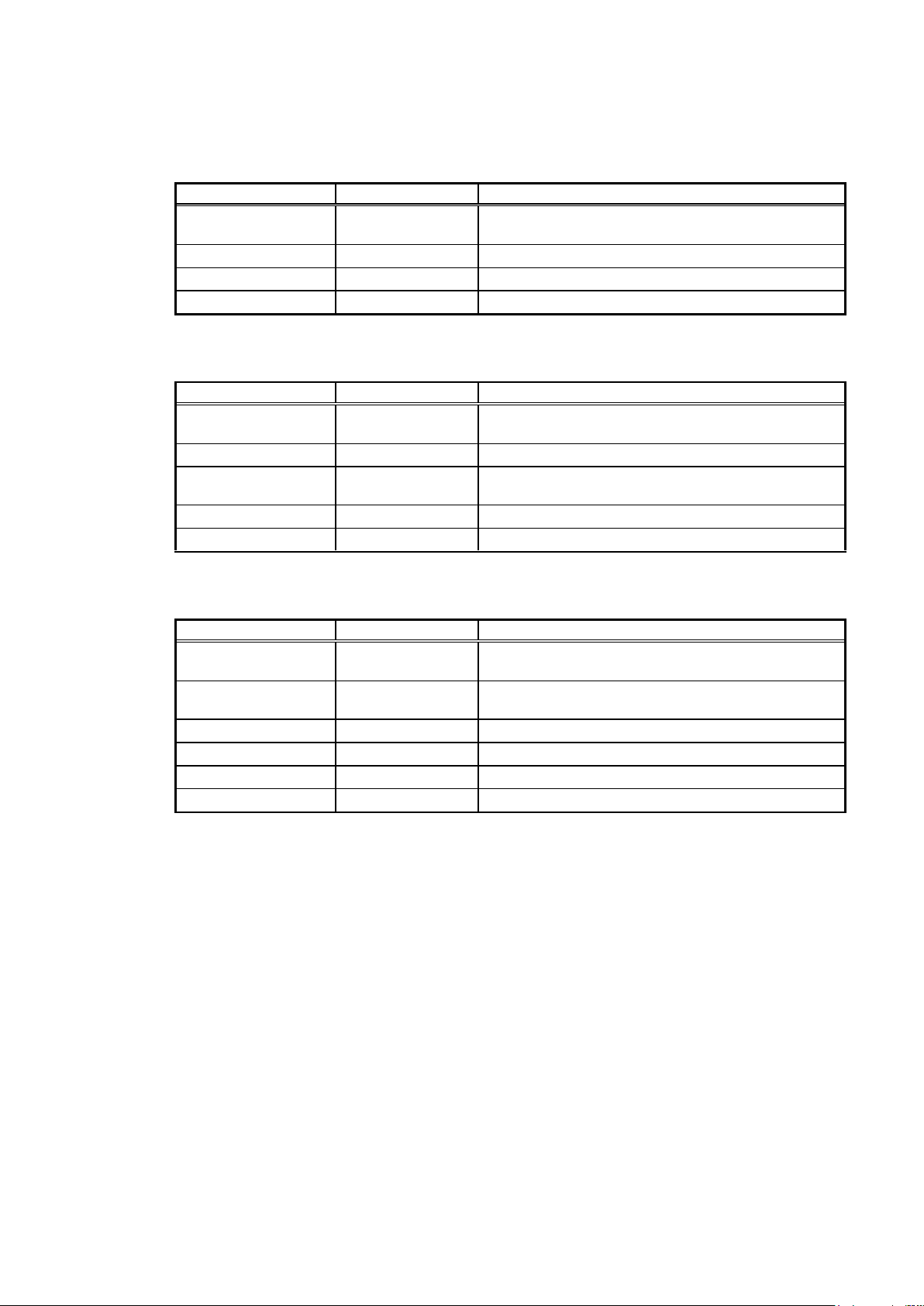

Table 1-1 Status LED on OperatorPanel......................................................................................... 3

Table 1-2 Button on OperatorPanel ............................................................................................... 4

Table 1-3 Status LED on Magazine Operation panel ....................................................................... 5

Table 1-4 Button on Magazine Operation panel .............................................................................. 5

Table 1-5 Drive Sled ingicator .................................................................................................... 10