Page 1

NAD

SERVICE MANUAL

C 525BEE

C 525BEE

COMPACT

DISC PLAYER

COMPACT

DISC PLAYER

Page 2

- 3 -

CAUTION

The lightning flash with arrowhead, within an equilateral tri-

angle i s intended t o alert the us er of the pr esence of

uninsulated "dangerous voltage" within the product's

enclosure; that may be of sufficient magnitude to consti-

tute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intend-

ed to alert the user of the presence of important operating

and maintenance (servicing) instructions in the literature

accompanying the appliance.

CA

TUION

H

G

K

JD

H

S

G

K

JH

G

S

JK

ADV

ARSEL

HG

KJ

D

H

SG

K

JH

G

S

K

BV

N

C

LK

NB

C

V

LK

N

LK

N

VL

K

NC

V

N

C

LV

K JK

ADV

ARSEL

H

G

K

LF

H

;L;H

JM

N

M

D

H

FK

LJH

JL

D

K

L

JLK

D

JL

K

F

H

JH

S

G

M

M

K

JH

G

S

JK

V

ARING

H

GKJD

HSG

KJHG

KLG

DJH

KLH

KFG;LKNG

;LKJGF;LKJG

F;LKJFL;

S

JK

V

ARO!

HG

KJD

HSGK

JH

JBJKB

KJBJKG

S

K

BVNCLKN

BCVLKNLKN

VLKNC

VNC

L

VK JK

VORSICT!

HG

KLFH

;L;H

HBHH

JD

JHFKLJH

JLDKLJLKD

JLKFHJHSG

KJHG

SJK

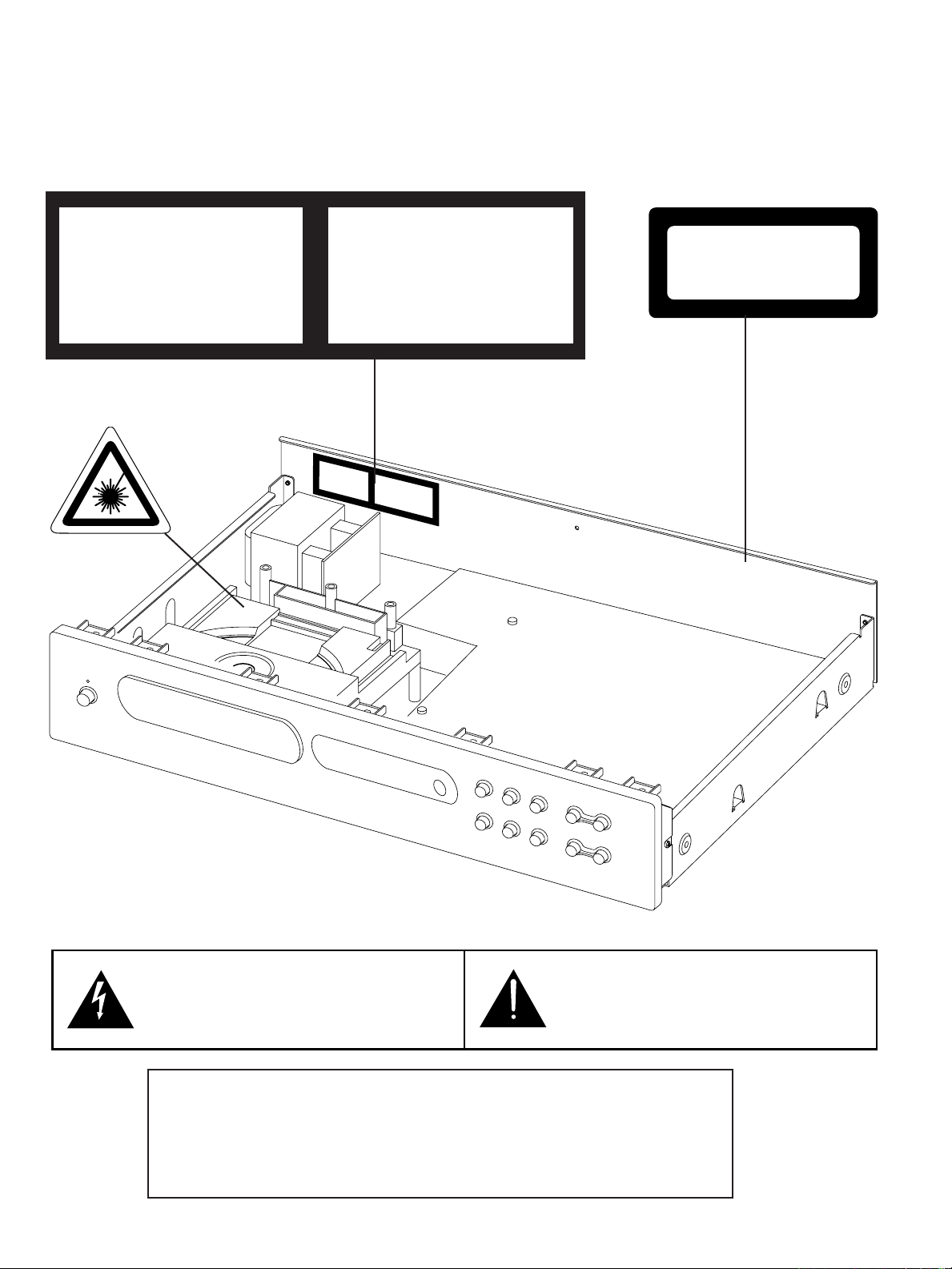

CLASS 1

LASER PRODUCT

SAFETY INFORMATION

CAUTION

- INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL

- USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG

SIKKERHEDSLÅS BRYTES. UNNGÅ EKSPONERING FOR STRÅLEN.

ADVARSEL

- USYNLIG LASERSTRÅLING VED ÅBNING, NÅR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION. UNDGÅ

UDSÆTTELSE FOR STRÅLING.

- OSYNLING LASERSTRÅLNING NÄR DENNA DEL ÄR

VARING

ÖPPNAD OCH SPÄRRAR ÄR URKOPPLADE. STRÅLEN ÄR FARLIG.

- AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET

VARO!

ALTTIINA NÄKTMÄTÖNTÄ LASERSÄTEILYLLE. ÄLÄ KAISO

SÄTEESEEN.

VORSICT!

- UNSICHTBARE LASERSTRAHLUNG TRITT AUS, WENN

DECKEL GEÖFFNET UND WENN SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT IST. NICHT DEM STRAHL AUSSETZEN.

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES.

OPERATION IS SUBJECT TO THE FOLLOWING TWO CONDITIONS:(1) THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE, AND

(2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED,

INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED

OPERATION.

- 2 -

Page 3

SERVICE SAFETY PRECAUTIONS

1. Replacing the fuses

CAUTION: FOR CONTINUED PROTECTION AGAINST THE RISK OF FIRE REPLACE ONLY WITH SAME TYPE

OF FUSE.

Reference No Part Number Description

M502-M504 *CA 5120-0020+0 FU T1A 250V UL/CSA 5x20MM

M502-M504 *EU 5120-0018+0 FU T1A 250V SEMKO/UDE 5x20MM

M505 *CA 5120-0052+0 FUSE T1.6A 250V 5x20MM UL/CSA

M505 *EU 5120-0050+0 FUSE T1.6A 250V 5x20MM SEMKO/VDE

NOTE:

<*CA > : CANADIAN MODEL ONLY.

<*EU > : EUROPEAN MODEL ONLY.

2. Safety check out

(Only U.S.A. model)

Before returning the product to the customer, make leakage current or resistance measurements to determine that

exposed parts are acceptably insulated from the supply circuit.

Parts marked with the symbol are critical with regard to the risk of fire and electric shock.

Replace only with parts recommended by the manufacturer.

CONTENTS

DESCRIPTION PAGE

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

REAR PANEL / FRONT PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

DISASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

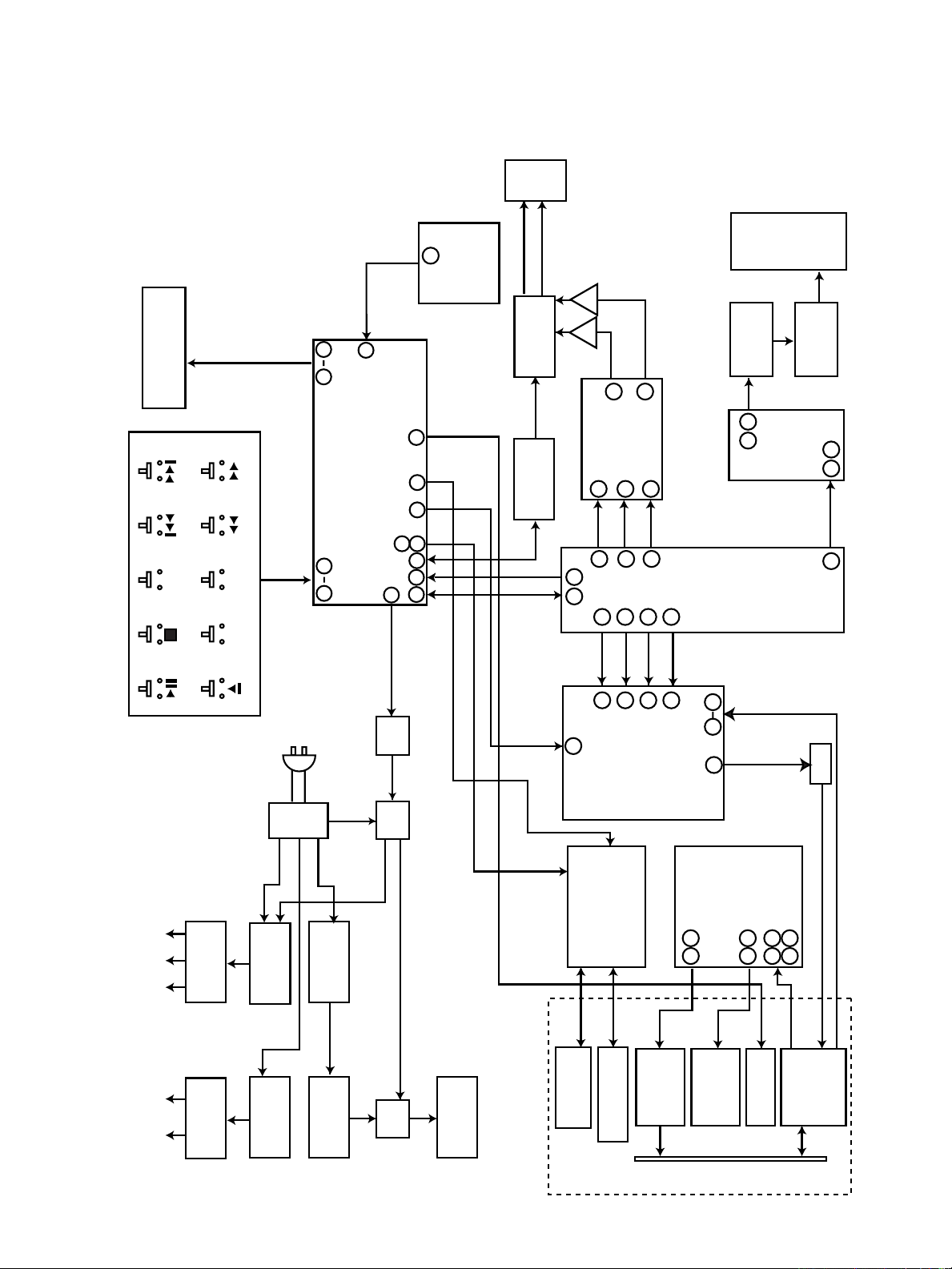

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

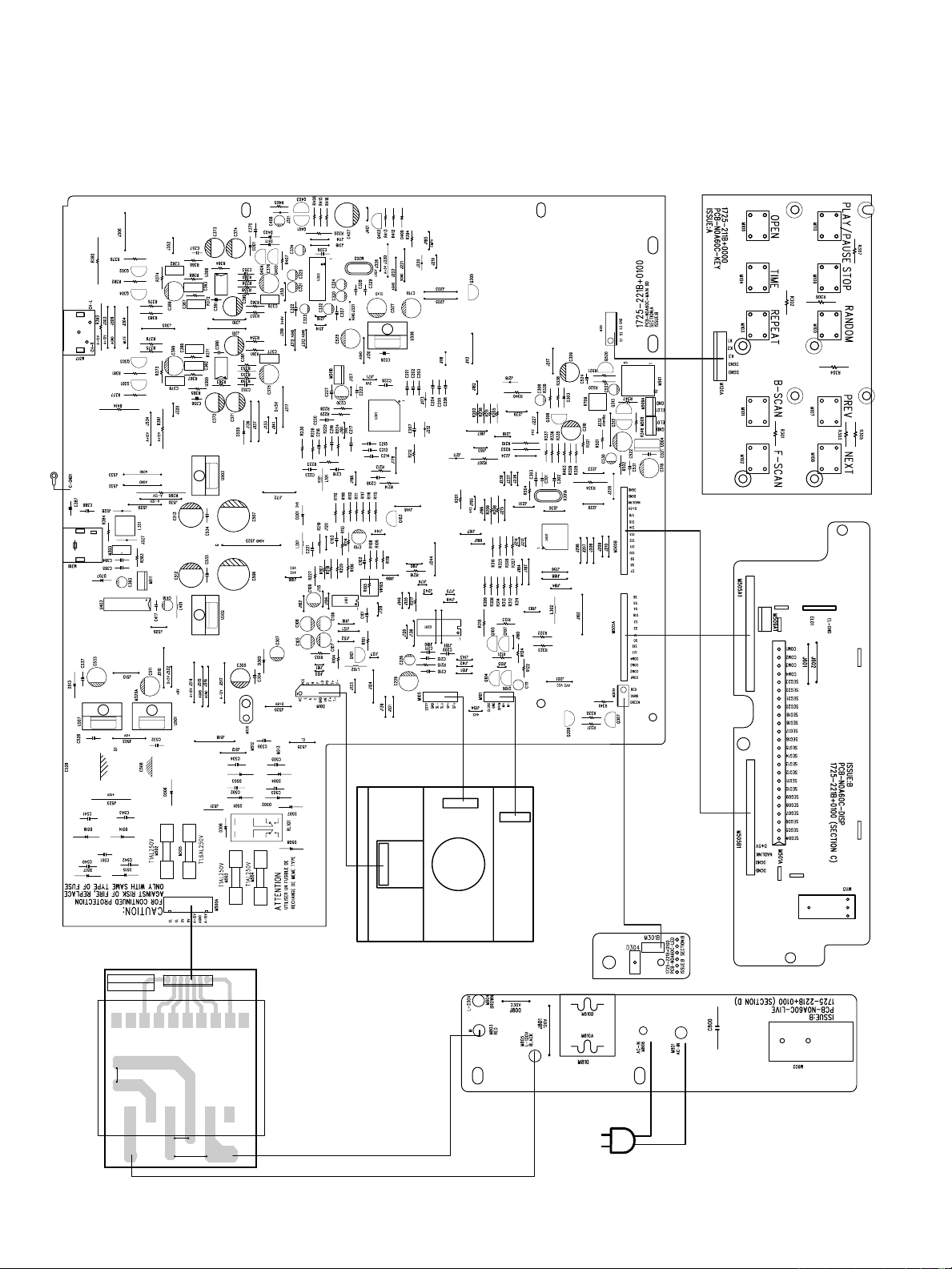

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

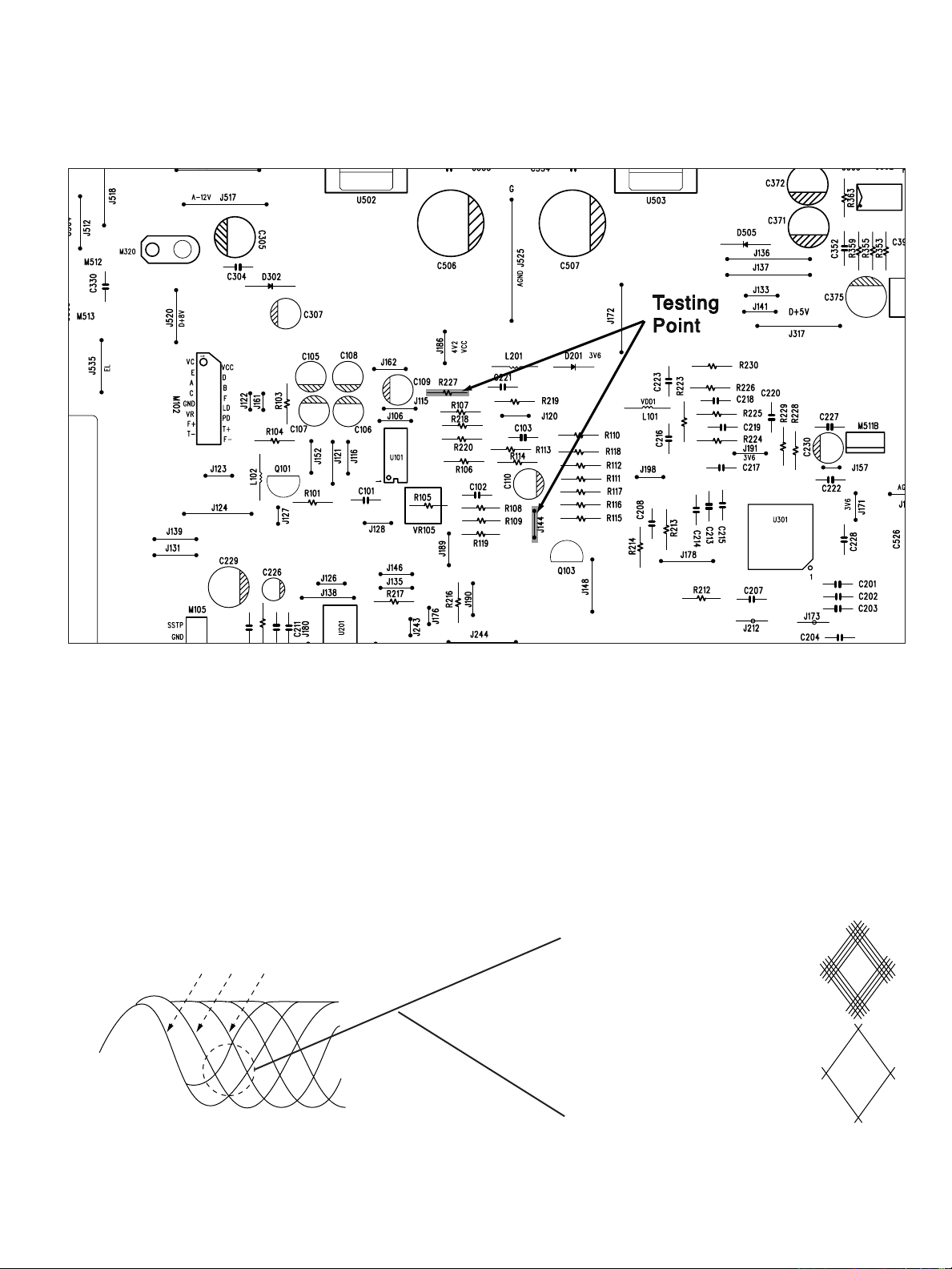

RF PATTERN TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

IMPORTANT NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

PCB LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-18

IC BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-22

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ELECTRICAL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-33

MECHANISM EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

MECHANISM EXPLODED VIEW PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

EXPLODED VIEW PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37-38

PACKING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

- 3 -

Page 4

- 5 -

SPECIFICATIONS

Disc Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . One Disc, 120 or 80 mm

Decoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BURR-BROWN Delta Sigma 20bit

Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Times oversample

Analog Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 pole active

Frequency Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +/- 0.5 dB, 5Hz - 20kHz

De-Emphasis Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +/- 0.3 dB

THD (at 0 dB, 1kHz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.003%

Intermodulation Distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . . < - 100 dB

(19 + 20 kHz)

Dynamic Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 dB

Linearity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +/- 0.5 dB, 0 dB to -80 dB

Signal / Noise Ratio (A-Weight) . . . . . . . . . . . . . . . . . . . . . . . ≥106 dB, De-Emphasis on

≥106 dB, De-Emphasis off

Channel Separation 1kHz . . . . . . . . . . . . . . . . . . . . . . . . . . . >90 dB

10 kHz . . . . . . . . . . . . . . . . . . . . . . . . . >80 dB

Wow and Flutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Unmeasurable (Quartz Crystal Accuracy)

Output Impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 Ω

Output Level at 0 dB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 V rms

Digital Error Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IRC with double error correction in C1 and C2

Digital Code Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sony / Philips Serial data format

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12W

CONTROLS

Play / Pause, Stop, Random, Skip (< >), Scan (< >), Open, Time, Repeat.

PHYSICAL SPECIFICATIONS

Dimensions 435 x 80 x 285 mm

(Width x Height x Depth)

Net weight 4 kg (8.8 lbs)

Shipping weight 5.1 kg (11.22 lbs)

- 4 -

Page 5

© 2006 NAD C525BEE

© 2006 NAD C525BEE

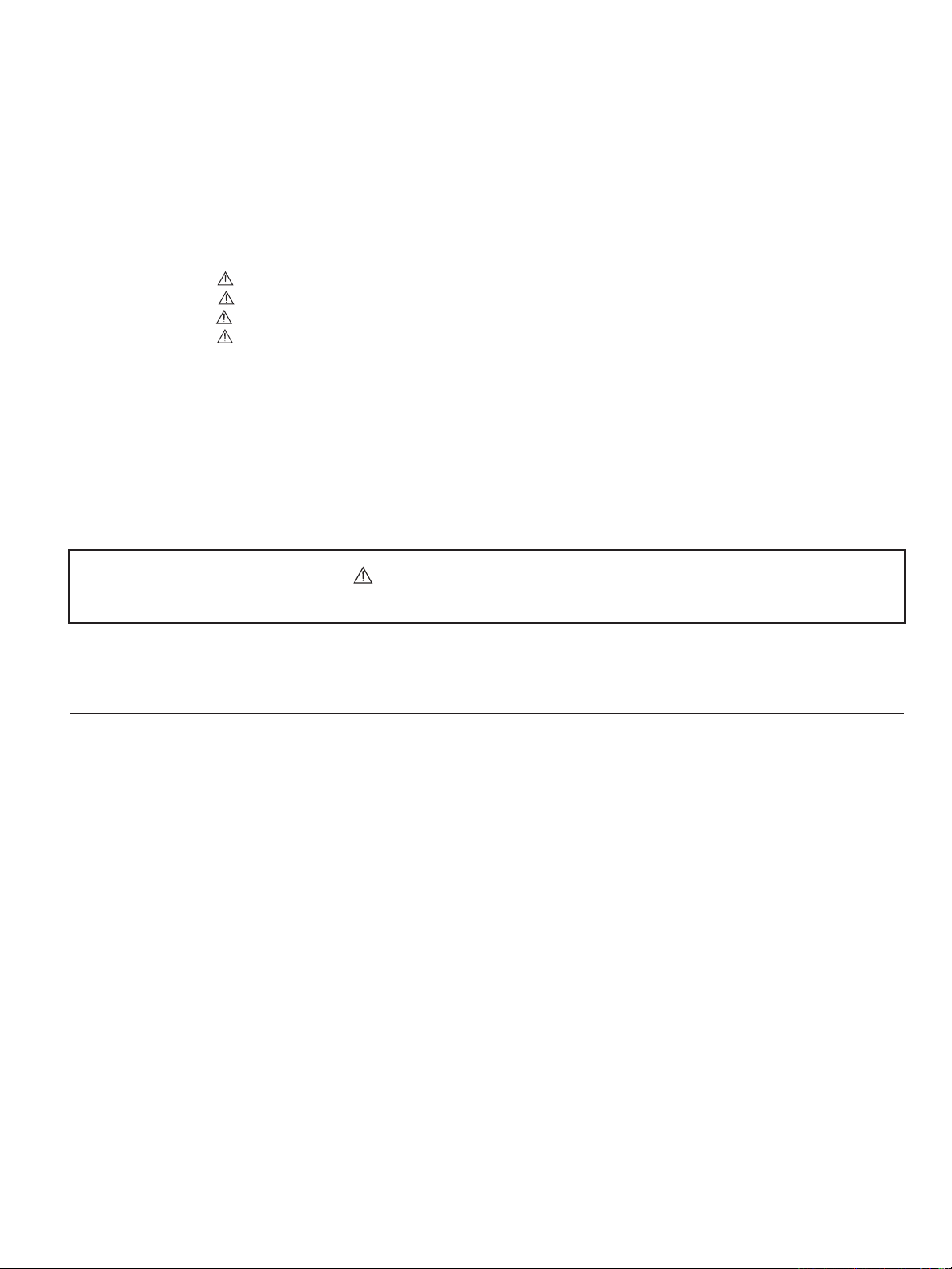

REAR PANEL / FRONT PANEL

REAR PANEL

1. LINE OUT

2. DIGITAL OUT

FRONT PANEL

1. POWER ON / OFF

2. DISC DRAWER

3. DISPLAY

4. OPEN

5. PLAY / PAUSE

6. TIME

3. AC LINE CORD

7. STOP

8. REPEAT

9. RANDOM

10. SCAN Back ( ) / Forward ( )

11. SKIP Back ( ) / Forward ( )

12. STANDBY LED

- 5 -

Page 6

- 7 -

7

6

6

5

4

3

1

2

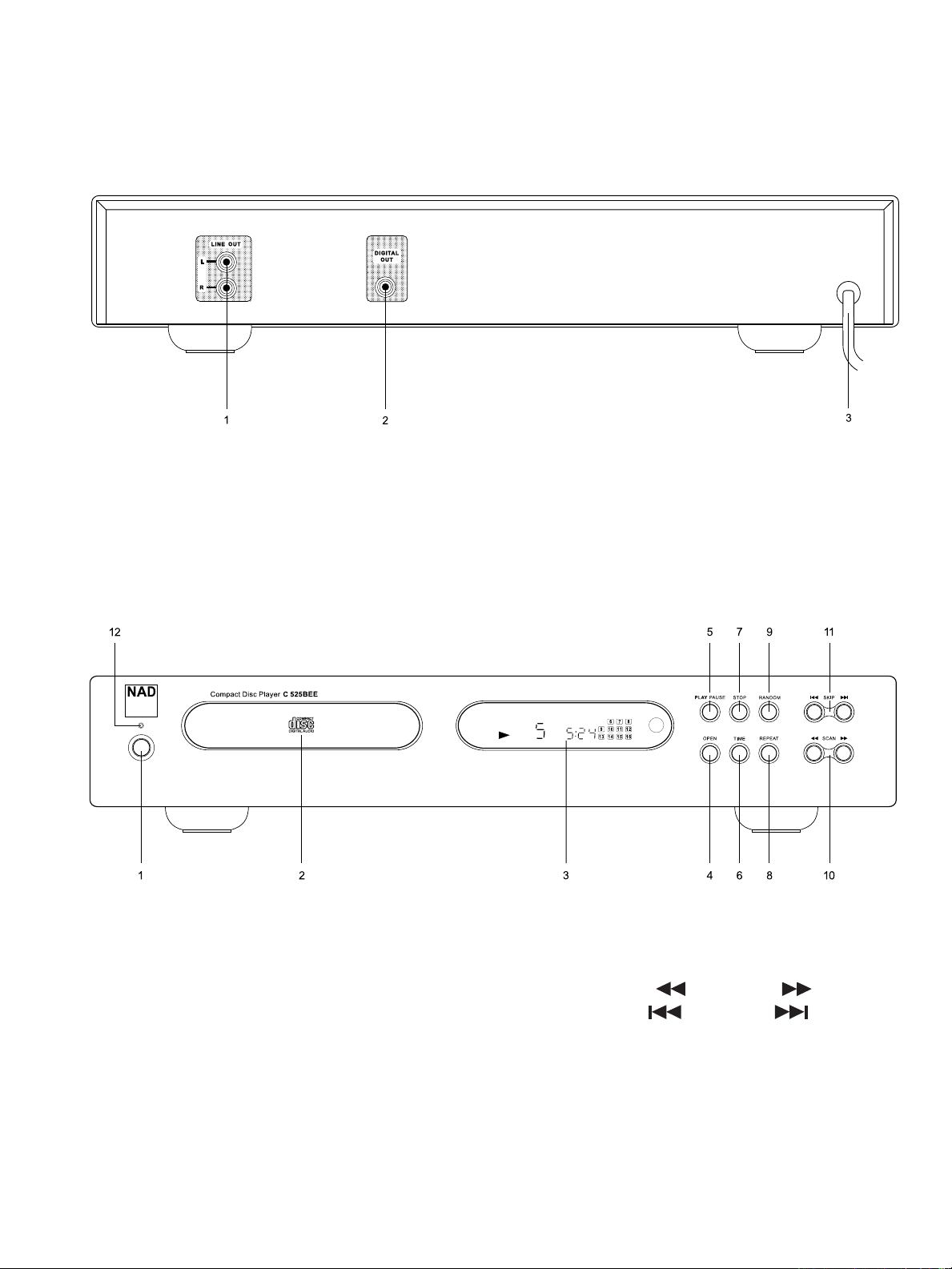

DISASSEMBLY INSTRUCTIONS

1. Remove machine screws M 4.0 x 6.0 ( 1 to 4 ) from the side panels.

Remove tapping screw 3.0 x 8.5 ( 5 )from the back panel.

Refer to Figure No.1.

Figure No.1

2. Pull both sides of the TOP COVER slightly outwards 6 and tilt approx. 35˚ and then remove

in the direction as indicated by the arrow 7 . Refer to Figure No.2.

Figure No.2.

- 6 -

Page 7

BLOCK DIAGRAM

U401 M38223E4HP4

SYSTEM CONTROL CP

U

& LCD DISPLAY DRIVE

R

Q401- Q405

MUTE CIRCUIT

Q301-Q304

MUTE

M317

RCA

JACK

U302

PMC1710

M318

RCA JACK

DIGITAL

OUTPUT

M501*

LCD DISPLAY

8

7

27

22

2

1

3

51

78

35

1

2

16

13

3

61

62

63

51

43

39

40

46

45

38

24

12

9

2

4

3

6

60

L

R

L

R

CD AUDIO

O/P

12

15

28

16

18

6

1

U301

CXD3017Q

DIGITAL

SIGNAL

PROCESSOR

26

1

27

2

12

16

13

17

U101 CXA2581

ANALOG SIGNAL

PROCESSOR/SERVO

RFAC

RFDC

FE

SE

Q104~Q107

MOTOR DRIVER

U201 BA6392

FOCUS &

TRACKING

MOTOR

DRIVER

LOADING

MOTOR

LOADING MOTOR

LIMIT SWITCH

SPINDLE

MOTOR

SLED

MOTOR

PU-IN

LIMIT SWITCH

PICK

UP

DISC

M113

REMOTE

SENSOR

CD MECHANISM UNIT

POWER

TRANSFORMER

AC POWER I / P

KEYBOARD

M110

M109

REPEAT

M105

M108

M107

RANDOM

M102

M106

M104

M103

TIME

M101

Q101

DAC

U306

U305

11

U501,U507

DIGITAL

POWER

U502-3,U506

ANALOGUE

POWER

+8V

+5V

+12V

5V

-12V

D514-D517

RECTIFIER

DIODES

D501-D504

RECTIFIER

DIODES

D506

RECTIFIER

DIODES

U504

POWER FOR

EL LIGHT

M502

EL LIGHT

Q307,

Q309

Q312,

Q313

RL101

RELAY

U403

74HC00

NAND GATE

M303

EMC FILTER

L301

DIGITAL COIL

M500

1

- 7 -

Page 8

- 9 -

WIRING DIAGRAM

115V:J401,J404

230V:J403

L401

J403

J406

J407

J402

J404

J401

1723- 006A+0000

8V0V0V

8V

15V

0V

15V

ISSUE B

M120C

M505B

M301

LIVE

NEUTRAL

M500A

M102

(16PIN)

M105

(6PIN)

M505A

CD MECHANISM

TRANSFORMER BOARD

DISPLAY BOARD

LED BOARD

KEY BOARD

LIVE BOARD

M101

(5PIN)

TO

CHASSIS

M805

BROWN

M803

BROWN

- 8 -

Page 9

RF PATTERN TESTING

3T

4T

5T – 11T

NAD - C 525BEE PCB TESTING POINTS DIAGRAM

TESTING PROCEDURE

(1) Load the test disc (Sony Test CD YEDS-7) and set the unit into PLAY mode.

(2) Connect the scope to R227 (Pin 15 of U101) and DGND (J144).

Scope setting: Coupling : AC.

Vertical sensitivity : 0.2 V/ div.

Horizontal time base : 0.5 µS/div.

(3) Observe the waveform is 2.0V p-p +/-5% and the eye pattern is at its best shape (see FIG. 1).

FIG. 1 (a) FIG. 1 (b) Poor eye pattern

FIG. 1 (C) Good eye pattern

- 9 -

Page 10

- 11 -

IMPORTANT NOTES

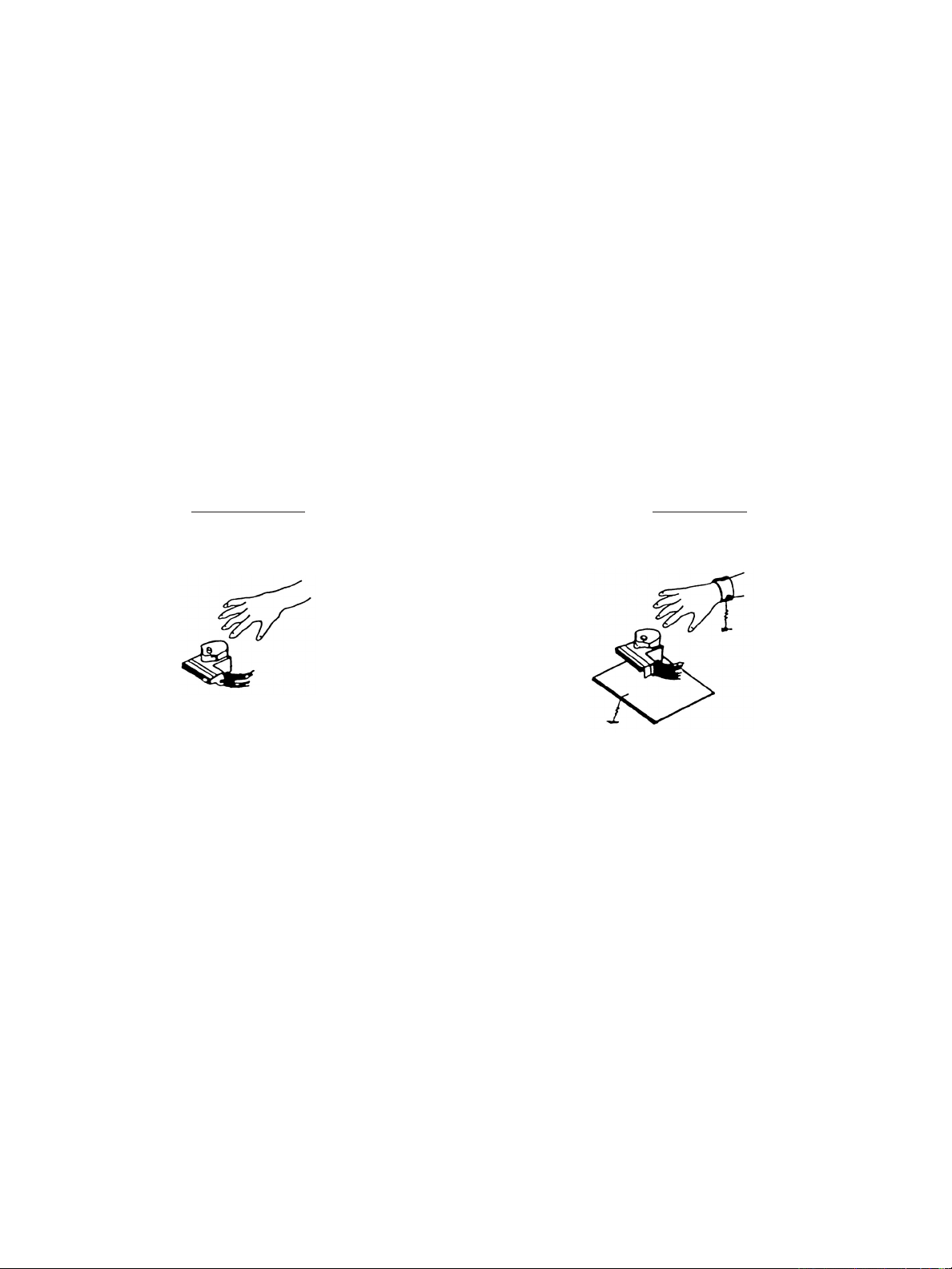

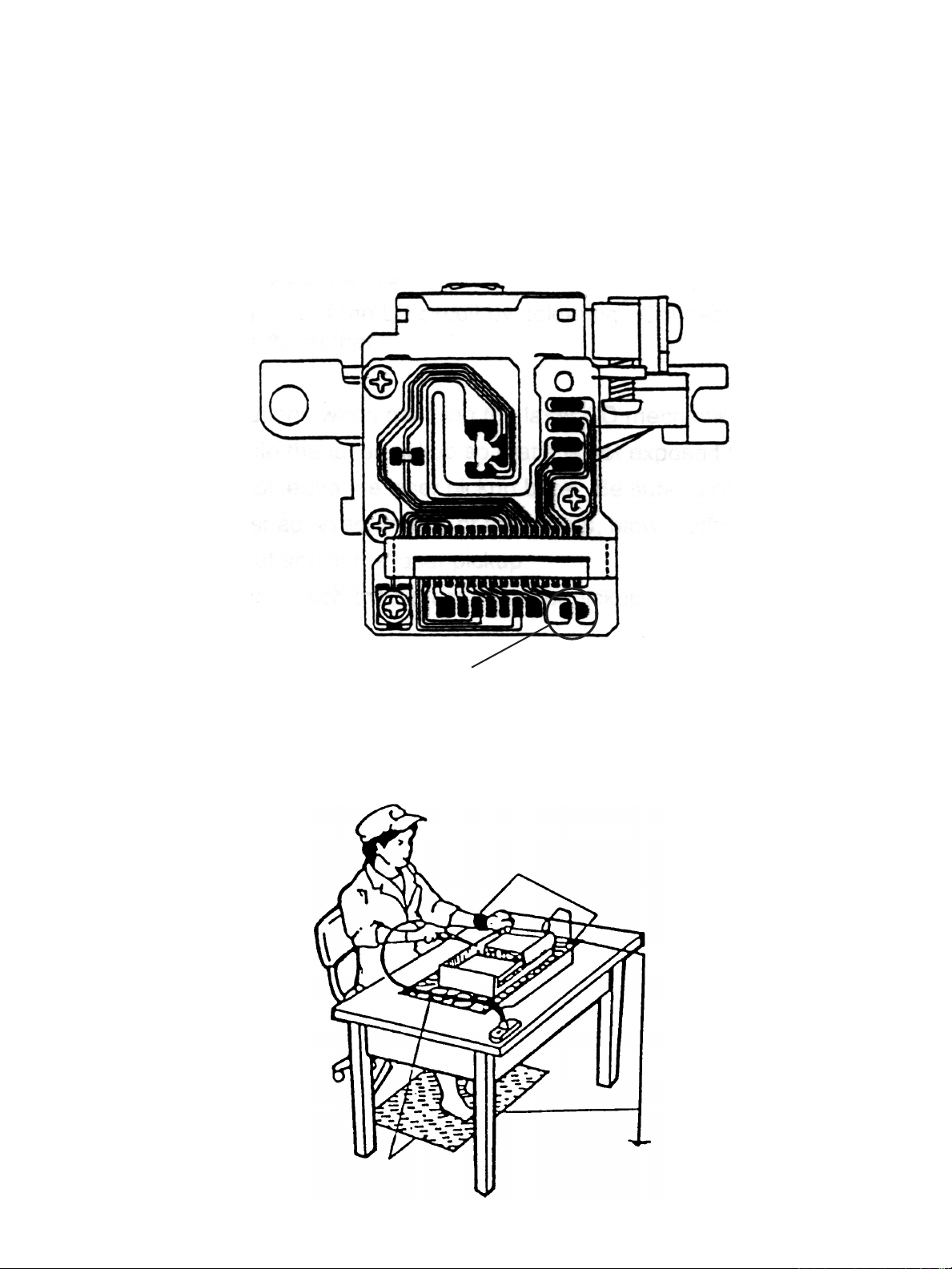

INSTRUCTION FOR HANDLING OPTICAL SYSTEM BLOCK PICK-UP

Electrostatic breakdown of the laser diode in the optical system block may occur due to a potential difference caused

by electrostatic charge accumulated on clothing, human body, etc. A ground must be provided as follows to prevent

any electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a ground band (1M ohm) that is properly to remove any static electricity that may be charged on the

body.

2. Ground for Work Bench

Be sure to place a conductive sheet (1M ohm) or copper plate with proper grounding on the work bench or other surface on which the pick-up is to be placed.

3. Because the static electricity charge on the clothing does not discharge through the body grounding band, do not

let clothing to get in contact with the pick-up unit.

INCORRECT CORRECT

1.Grounding band

1M ohm

1M ohm

2.Conductive Sheet

or Copper Plate

NOTE: Laser diodes are so susceptible to damage from

static electricity that even if a static discharge does not

ruin the diode, it can shorten its life or cause it to work

improperly.

PRECAUTIONS FOR CHECKING BEAM EMISSION

The laser beam of this unit is focused on the reflecting surface of the objective lens in the optical system block.

Therefore, keep your eyes at least 12 inches (30 cm) away from the objective lens when the laser diode is ON.

(Operation Check Method for Laser Diode and Focus Search Function.)

When the POWER switch is turned ON after the chucking plate is removed, observe the objective lens and confirm

that the following operations are performed properly.

(The optical system should be at the lead-in area position when it is checked at this time.)

(1) The laser should be at the innermost position after the chucking plate is removed.

(2) The diffused light of the laser beam can be seen when the POWER switch is turned ON.

(3) Vertical (up and down) movement of the objective lens (2 or 3 times) will take place.

- 10 -

Page 11

PRECAUTIONS WHEN CHANGING LASER PICK-UP

When removing the pick-up assembly, short circuit the PCB tracks on the optical block as show in the drawing in

order to protect the pick-up before removal.

NOTE: Replacement pick-up assemblies are supplied with the PCB pattern already protected.

DO NOT REMOVE THE SHORT CIRCUITS UNTIL YOU HAVE FINISHED FITTING THE PICK-UP.

Protective soldering place

for laser diode

Caution:

Laser diodes are extremely susceptible to damage from static electricity. Even if a static discharge does not ruin

the diode, it can shorten its life or cause it to work improperly. When replacing the pick-up, use a conductive mat, a

grounded soldering iron, and so on, to protect the laser diode from static damage.

Ground Conductive

Wrist Band for Body

Soldering

Iron with

Ground

wire

Ground Line

Less than

10 ohm

Conductive Gum Mat

- 11 -

Page 12

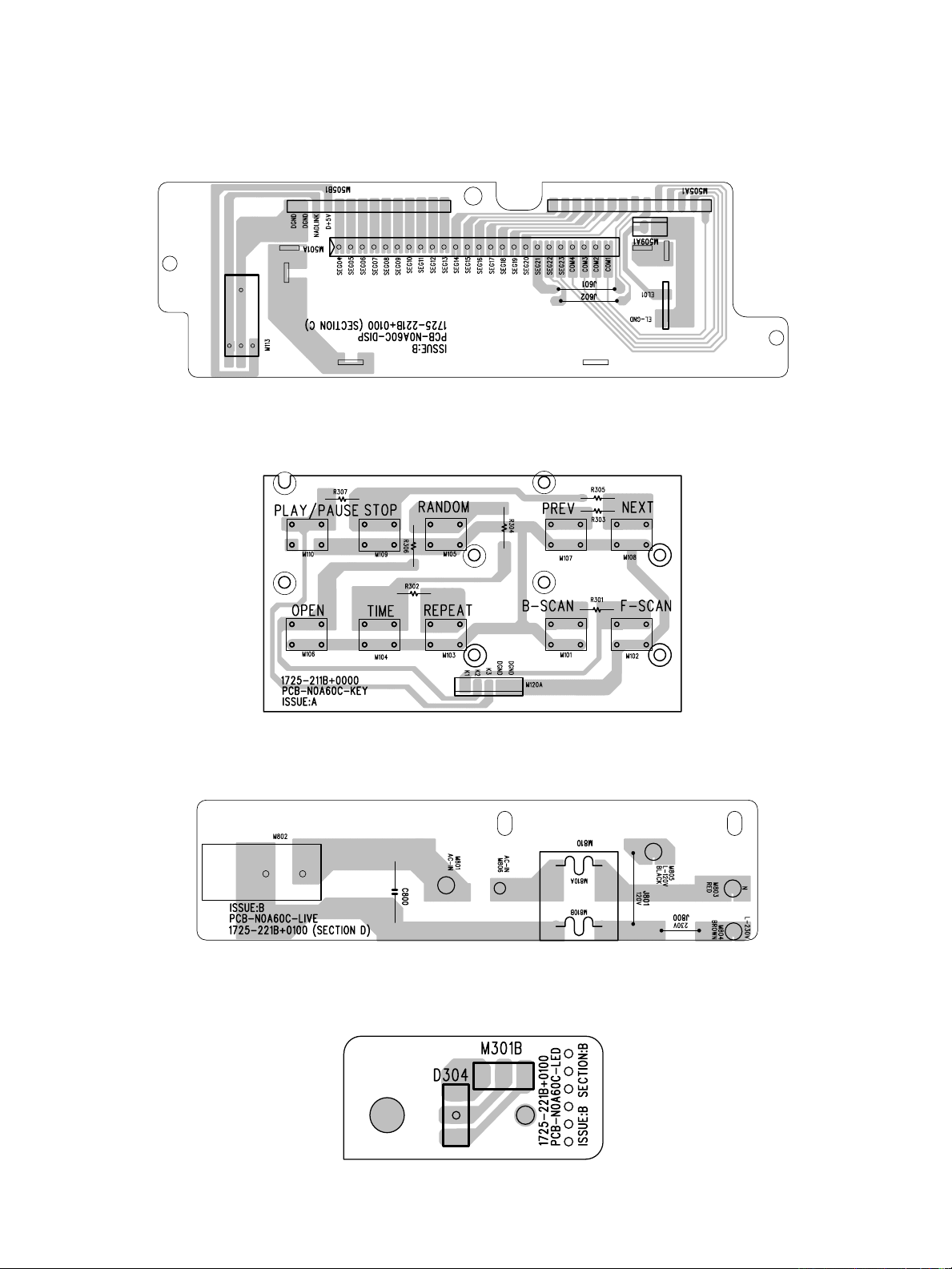

PCB LAYOUT

DISPLAY BOARD

KEY BOARD

LIVE BOARD

LED BOARD

- 12 -

Page 13

MAIN BOARD

- 13 -

Page 14

- 15 -

SCHEMATIC DIAGRAM

SL+

1

SL-

2

RCIN1

3

SRDR

4

SFDR

5

VREFI

6

VREFO

7

GND

8

FRDR

9

FFDR

10

RCIN2

11

FCS+

12

FCS-

13

GND1

14

MUTE

15

TRK+

16

TRK-

17

RCIN3

18

TFDR

19

TRDR

20

VCC

21

VCC1

22

VBIN

23

SPDR

24

VBIN1

25

SP-

26

SP+

27

GND2

28

GND

29

GND

30

U201

BA6392

SQSO

1

SQCK

2

XRST

3

SYSM

4

DATA

5

XLAT

6

CLOK

7

SENS

8

SCLK

9

VDD

10

ATSK

11

SPOA

12

SPOB

13

XLON

14

WFCK

15

XUGF

16

XPCK

17

GFS

18

C2PO

19

SCOR

20

COUT

21

MIRR

22

DFCT

23

FOK

24

LOCK

25

MDP

26

SSTP

27

SFDR

28

SRDR

29

TFDR

30

TRDR

31

FFDR

32

FRDR

33

VSS

34

TEST

35

TES1

36

XTST

37

VC

38

FE

39

SE

40

TE

41

CE

42

RFDC

43

ADIO

44

AVSS0

45

IGEN

46

AVDD0

47

ASYO

48

ASYI

49

BIAS

50

RFAC

51

AVSS3

52

CLTV

53

FILO

54

FILI

55

PCO

56

AVDD3

57

VSS

58

VDD

59

DOUT

60

LRCK

61

PCMID

62

BCK

63

EMPH

64

XVDD

65

XTAI

66

XTAO

67

XVSS

68

AVDD1

69

AOUT1

70

AIN1

71

LOUT1

72

AVSS1

73

AVSS2

74

LOUT2

75

AIN2

76

AOUT2

77

AVDD2

78

RMUT

79

LMUT

80

U301

CXD3017Q

R2014K7

R2021K

R2031K

R2041K

R2051K

R2061K

R2071K

R2081K

R2091K

R2101K

R2111K

R212 100K

R213 10K

R214 8K2

R215

4R7

R216 0R

R217

1K

R21847K

R21915K

R220100K

R222 0R

R22333K

R224

10K

R225100K

R226

1M

R227

0R

R228

3K3

R229

3K3

R230

10K

C207 0.1u

C208

0.1u

C209

1500p

C210

0.1u

C211

27p

C212

27p

C214470p

C215470p

C2130.1u

XLAT

DATA

SYSM

XRST

SQCK

SQSO

/SQSO

/SQCK

/XRST

/SYSM

/DATA

/XLAT

/CLOK

/SENS

/SCLK

/GFS

/SCOR

/SQSO

/SQCK

/XRST

/SYSM

/DATA

/XLAT

/CLOK

/SENS

/SCLK

/GFS

/SCOR

V3V6

C201

220p

C202

220p

C203

0.01u

C204

220p

C205

220p

C206

330p

CLOK

SENS

SCLK

GFS

SCOR

CLOK

SENS

SCLK

GFS

SCOR

V3V6

VC

SFDR

SFDR

SRDR

SRDR

TFDR

TFDR

TRDR

TRDR

FFDR

FFDR

FRDR

FRDR

SPDR

SPDR

VC

VC

C229

470U/16V

TE

SE

FE

FE

SE

TE

C217

0.1u

C216

0.01u

C219

0.47u

V3V6

C218100p

V3V6

C221

3900P

RFDC

RFAC

C220

0.47u

C223

1500p

V3V6

C222

0.1u

TP214

AGN

D

EMPH

BCK

PCMD

LRCK

XLAT

DATA

SYSM

XRST

SQCK

SQSO

RFDC

RFAC

1

2

3

4

5

6

M105

CON6

FCS-

FCS+

TRK-

TRK+

C226

0.33u/50V

D201

1N4001

L201

27uH

VCC

C230

100uF/16V

FCSFCS+

TRKTRK+

EMPH

BCK

PCM

D

LRC

K

C227

0.1u

C228

0.1u

CN202

DEBUG

CLKO

DIG-OUT

XRST

D+8V

DISPLAY

NOTE: 1. RESISTORS, ARE CARBON FILM 5% 1/8W UNLESS

OTHERWISE SPECIFIED.

2. CERAMIC CAPACITORS, ARE 50V 10%. UNLESS

OTHERWISE SPECIFIED.

- 14 -

Page 15

MCU

P67/AN7

1

P66/AN6

2

P65/AN5

3

P64/AN4

4

P63/AN3

5

P62/AN2

6

P61/AN1

7

P60/AN0

8

P57/ADT

9

P56/TOUT

10

P55/CNTR1

11

P54/CNTR0

12

P53/RTP1

13

P52/RTP0

14

P51/INT3

15

P50/INT2

16

P47/SRDDY

17

P46/SCLK

18

P45/TXD

19

P44/RXD

20

P43/I1

21

P42/INT0

22

P41

23

P40

24

/RESET

25

P71/XCIN

26

P70/XOUT

27

XIN

28

XOUT

29

VSS

30

P27

31

P26

32

P25

33

P24

34

P23

35

P22

36

P21

37

P20

38

P17/S31

39

P16/30

40

P15/29

41

P14/S28

42

P13/S27

43

P12/S26

44

P11/S25

45

P10/S24

46

P07/S23

47

P06/S22

48

P05/S21

49

P04/S20

50

P03/S19

51

P02/S18

52

P01/S17

53

P00/S16

54

P37/S15

55

P36/S14

56

P35/S13

57

P34/S12

58

S11

59

S10

60

S9

61

S8

62

S7

63

S6

64

S5

65

S4

66

S3

67

S2

68

S1

69

S0

70

VCC

71

VREF

72

AVSS

73

COM3

74

COM2

75

COM1

76

COM0

77

VL3

78

VL2

79

VL1

80

U401

M38223E

COM0

COM1

COM2

COM3

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

M505AB

LCD

L302

10uH

VCC

R314

22K

R313

22K

R312

22K

R311

1K

VCC

R308

3K

R309

3K

X301A

8.00M

UNLD

LOAD

XRST

XLAT

CLOK

DATA

SCOR

SYSM

RW/ROM/LDOFF

RW/ROM/LDOFF

SCLK

SQCK

1/2X

DISCO

DI/SW

R327 4K7

R326 4K7

R325 4K7

R323 4K7

R322 4K7

R321 4K7

SQSO

SENS

C301

33p

C302

33p

C303

0.01u

1

2

3

Q308

8050

R329 4K7

R328 4K7

D303

IN4148

R338

10K

R339

100K

C308

10u/6.3V

VCC

C307

47uF/10V

VCC

DAT

GND

2

VCC

3

M113

IR

R340

10R

C309

47uF/10V

VCC

1

2

3

4

KEY302

OPEN/CLOSE

1

2

3

4

KEY307

PREV

1

2

3

4

KEY305

NEXT

1

2

3

4

KEY309

F.SCAN

1

2

3

4

KEY308

REPEAT

1

2

3

4

KEY306

TIME

1

2

3

4

KEY304

RANDOM

1

2

3

4

KEY303

STOP

1

2

3

4

KEY301

PLAY

R303 6K2

R302 6K2

R305 2K

R304 2K

R307 1K

R306 1K

VCC

GFS

SYSM

SENS

SCOR

DATA

CLOK

XLAT

GFS

XRST

LOAD

UNLD

SCLK

SQCK

1/2X

DISCO

DI/SW

R3361K

R3351K

R334

560R

VCC

1

2

3

M301B

LED1

GREEN

Trig IN

Tr ig SW

ST AND BY LED

Rel ay

D+5V

R310

3K

1

2

3

4

KEY310

B.SCAN

R301 1K

SCLK

SQCK

1/2X

CD/CDR

1

2

3

M301A

LED1

RED

GR EEN

RE D

GND

R341

560R

VCC

R330

10K

R331

1K

1

2

3

Q309

8050

STANDBY CNL

RL101

D306

IN4148

1

2

3

Q307

8050

D403

3V3

D409

1N4148

R403

10K

R412 4K7

R413

47K

1

2

3

Q402

2SD1012F

1

2

3

Q403

2SA1015

1

2

3

Q401

2SA1015

R415

7K5

R405

22K

R406

7K5

A+12V

R416

47K

MUT E

C407

2200u/16V

D411

1N4148

C408

22u/16V

A+12V

D302

5393

C305

220uF/16V

C304

0.1u

4. 2V

D+5V

D+10V

C310

1000uF/10V

- 15 -

NOTE: 1. RESISTORS, ARE CARBON FILM 5% 1/8W UNLESS

OTHERWISE SPECIFIED.

2. CERAMIC CAPACITORS, ARE 50V 10%. UNLESS

OTHERWISE SPECIFIED.

Page 16

- 17 -

VC

1

VCC

2

E

3

D

4

A

5

B

6

C

7

F

8

GND

9

LD

10

VR

11

PD

12

FCS +

13

TRK+

14

TRK-

15

FCS -

16

M102

16PIN

LD

1

PD

2

EQ_IN

3

AC_SUM

4

GND

5

A

6

B

7

C

8

D

9

E

10

F

11

SW

12

DVCC

13

DVC

14

RFAC

15

FE

16

FEI

17

TE

18

TE_BAL

19

CE

20

CEI

21

VCC

22

RFG

23

BST

24

VFC

25

RFC

26

VC

27

RFDC O

28

RFDC I

29

DC_OF ST

30

U101

CXA2581

1

2

3

Q101

8550

R101

10

R102

0

R103 15K

R104 15K

R105

3K

R106

150K

R107

100K

R108

68K

R109 15K

R110 3K

R111 4K7

R112 5K1

R1135K1

R114

5K1

R115

1K8

R116 12K

R117 12K

R118

10K

R119 15K

C101

0.1u

C102

0.1u

C103

0.1u

C105

100u/16V

C106

100u/16V

C107

100u/16V

C108

100u/16V

C109

100u/16V

VDD1

VC

VDD1

C110

100u/10V

VDD1

FE

TE

SE

SE

TE

FE

RFAC

RW/ROM/LDOFF

RFDC

FCS -

TRK-

TRK+

FCS +

FCS -

FCS +

TRK+

TRK-

V3V6

RFDC

RFAC

RW/ROM/LDOFF

1

2

3

Q103

8050

1/2X

1/2X

1

2

3

4

5

M101

5PIN

1

2

3

Q104

8550

1

2

3

Q105

8550

1

2

3

Q106

8050

1

2

3

Q107

8050

R121

1K

R122

1K

R123

1K

R124

1K

VCC

LOAD

UNLD

TRAY-

TRAY+

DI/SW

DISCO

DISCO

DI/SW

LOAD

UNLD

DI/SW

DISCO

L102

10uH

L101

10uH

R315

4R7

C111

2.2uF/6.3V

J127

RF AMP

OTHERWISE SPECIFIED.

OTHERWISE SPECIFIED.

NOTE: 1. RESISTORS, ARE CARBON FILM 5% 1/8W UNLESS

2. CERAMIC CAPACITORS, ARE 50V 10%. UNLESS

- 16 -

Page 17

LRSY

ROMXA

CK2

CLKO

A

16.9344MHz

C328

20p

C329

20p

DGND

DGND

C320

10u/6.3V

AGND

C332

10u/6.3V

C376

22u/25V

C378

224K

R356

6K

8

R360 6K8

C353

330p

R364

1K

5

R368

2K

2

R372

2K

2

C357

2700p(M)

C363

4700p(M

)

C367

680p(P)

C369

22u/25V

C382

224K(M)

R376

150R

R374

100K

R380

150R

1

2

M317A

L

Q302

2SD655F

Q304

2SD655F

C321

10u/6.3V

R320

470R

EMPH

C323

10u/6.3V

C322

104K

A+5V

D+5V

2

3

1

U306A

5532

6

5

7

U306B

5532

8

4

U305C

5532

DGND

R378

4K7

R382

4K7

R414

100K

A-12V

C375

22u/25V

C377

224K

R355

6K

8

R359 6K8

C352

330p

R363

1K

5

R367

2K

2

R371

2K

2

C356

2700p

C362

4700p

C366

680p

C368

22u/25V

C379

224K(M)

R375

150R

R373

100K

R379

150R

3

2

M317B

R

Q301

2SD655F

Q303

2SD655F

2

3

1

U305A

5532

6

5

7

U305B

OPA260

4

8

4

U306C

5532

R377

4K7

R381

4K7

MUTE

C536

103K

CHASIS

1

2

M318

DIGITAL OU

T

R384

75R

C387

103K

1

2

3

4

L301

CHASIS

R383

150R

C385

2200p

Vin

GND

Vout

1

2

3

M303

DST310

C386

104K

J528

C383

22u/10V

C384

1000p

1

2

3

U403A

74HC00

4

5

6

U403B

74HC00

DIG_OUT

DGND

12

13

11

U403D

74HC00

9

10

8

U403C

74HC00

14

7

U403E

74HC00

C380

104K

C381

104K

C371

470u/16V

C372

470u/16V

R391

220R 1/2

W

R390

220R 1/2W

C374

470u/16V

C373

470u/16V

R393

220R 1/2W

R392

220R 1/2W

A+12V

A-12V

C417

104K

C418

10u/25V

D+5V

C370 103K

C333

104K

AGND

A+5V

A+5V

C325

10u/6.3V

C326

104K

D+5V

DGND

DGND

LRCIN

DIN

BCKIN

CLKO

XTI

XTO

DGND

VDD

VCC2R

AGND2R

EXT1R

EXT2R

VOUTR

AGND1

VCC1

VOUTL

EXT2L

EXT1L

AGND2L

VCC2L

VDD

DGND

CKSL

MODE

MUTE

MD/DM1

MC/DM2

ML/DSD

1

2

3

4

5

6

7

8

9

10

11

12

13

1415

16

17181920212223

24

252627

28

U302

PCM1710U

R385

10R

AGND

AGND

AGND

AGND

C324

10u/6.3V

C327

104K

A+12V

A-12V

AGNDAGND

M302

1

2

3

Q305

DTC114

R394

10K

XRST

R358

1K

2

R353

1K

2

R357

270R

R354

270R

R362

68K

R361

68K

AGND

DA

OTHERWISE SPECIFIED.

NOTE: 1. RESISTORS, ARE CARBON FILM 5% 1/8W UNLESS

2. CERAMIC CAPACITORS, ARE 50V 10%. UNLESS

OTHERWISE SPECIFIED.

- 17 -

Page 18

- 19 -

10

1

2

3

4

5

6

7

8

9

M500

1

2

3

4

M810

TLN120A150W3R0

AC1

AC CORD EST

FERRITE

�

RING * ONLY IN C VERSION

M802

POWER_SW

C800

4700p

J800

230V

J801

120V

D514

IN4001

D516

IN4001

C543

104K

C541

104K

C501

104K

D515

1N4001

D517

1N4001

C542

104K

C540

104K

Vin

GND

Vout

1

2

3

U507

7808

DGND

C529

4700u/16V

C528

104K

DGND

C532

104K

C508

1000u/10V

C533

470u/10V

Vin

GND

Vout

1

2

3

U501

7805

C511

220u/10V

C710

100u/6.3V

D+5V

D+8V

M512 T1A 250V

M502

T1.6A 250 V

Vin

GND

Vout

1

2

3

U504

7809

C518

100u/25V

C521

104K

EL_GND

D506

1N4001

R709

470R

Q520

8050

R520

51K

C523

2u2/16V

C524

0.022u

R521

150R

C522

100u/16V

ELD1

C502 104K

C503 104K

D501 1N4001

D502 1N4001

C506

2200u/25V

Vin

GND

Vout

1

2

3

U502

7812

C504 104K

D504 1N4001

D503 1N4001

C505 104K

C507

2200u/25V

C526

104K

C512

1000u/16V

C513

1000u/16V

C525

1000u/10V

C535

104K

C534

104K

D505

3V3 1.3W

Vin

GND

Vout

1

2

3

U503

7912

M503 T1A 250V

AGND

M504

T1A 250V

AGND

A+12V

A-12V

Vin

GND

Vout

1

2

3

U506

7805

C527

470u/10V

A+5V

AGND

AGND

6

9

4

2

M501

D+10V

DGN D

RL101A

Relay

2

4

Q312

8550

+9V-IN

R346

10K

R347

1K

+9V-OUT

Q313

8550

R502

18K

+9V-OUT

+9V-IN

C537

104K

R501

27K

C531

104K

C530

10u/25V

D507

IN4001

D508

1N4001

A1

A2

1 3

A2

A1

D513 1N5393

POWER

OTHERWISE SPECIFIED.

OTHERWISE SPECIFIED.

PARTS.

NOTE: 1. RESISTORS, ARE CARBON FILM 5% 1/8W UNLESS

2. CERAMIC CAPACITORS, ARE 50V 10%. UNLESS

3. COMPONENTS MARKED “ ” ARE SAFETY CRITICAL

- 18 -

Page 19

AC

SUM

AC

VCA

EQ_ON/OFF

VC

DVcc

RW/ROM

RW/ROM

RW/ROM

RW/ROM

RW/ROM

RW/ROM

RW/ROM

VC

VC

VC

DV

C

DV

C

VOFST

VOFST

B

C

A

D

VOFST

EQ

APC

23

RFG

24

BST

26

RFC

25

VFC

14

DVC

27

VC

5

GND

22

Vcc

1

LD

2

PD

12

SW

11

E

10

F

9

D

8

C

7

B

6

A

15

RFAC

30

DC_OFST

29

RFDCI

28

RFDCO

17

FEI

16

FE

19

TE_BAL

18

TE

21

CEI

20

CE

13

DVcc

3

EQ_IN

4

AC_SUM

-

+

-

+

VC

VC

DVC

DVcc

-

+

-

+

-

+

-

+

DVcc

-

+

-

+

DVcc

-

+

gm

gm

VC

VC

VOFST

DVC

DV

C

-

+

+

VC

Vcc

APC-OFF (Hi-Z)

RW/ROM

(H/L)

Vcc

+

IC BLOCK DIAGRAM

1CH1OUTF

28 GND

2

F

INTER

FACE

REV

FW

D

R

CH1OUTR

27 CH4OUTF

3RCIN1

26 CH4OUTR

4CH1RIN

25 VBIN

190K

100K

25K

25K

DRIVE

MUTE

5CH1FIN

24 VSIN

6VREFIN

23 VBIN

7VREFOUT

22 VCC

8GND

21 VCC

9CH2FIN

20 CH3FIN

10CH2RIN

19 CH3RIN

11RCIN2

18 RCIN3

12CH2OUTR

17 CH3OUTR

13CH2OUTF

16 CH3OUTF

14GND

15 MUTE

+

-

+

-

THERMAL

SHUTDOWN

CIRCUIT

F

INTER

FACE

REV

FW

D

R

F

INTER

FACE

REV

FW

D

R

LEVEL

SHIFT

MAIN BOARD

U101: CXA2581N

MAIN BOARD

U201: BA6392FP

- 19 -

Page 20

- 21 -

MAIN BOARD

Clock

Generator

EFM

demodurator

Error

Corrector

16K

RAM

Digital

OUT

D/A

Interface

Serial-In

Interface

Over sampling

Digital Filter

PWM

PWM

Timing

Logic

3rd-Order

Noise Shaper

Sub Code

Processor

Servo

Auto

Sequencer

SERVO

Interface

Servo Block

DA

C Block

Signal Processor Block

MIRR

DFCT

FOK

FOCUS SERVO

TRACKING

SERVO

SLED SERVO

SERVO DSP

FOCUS PWM

GENERATO

R

TRACKING PWM

GENERATO

R

SLED PWM

GENERATO

R

PWM GENERATOR

OPAmp

Analog SW

A/D

Converter

Asymmtery

Corrector

Digital

PLL

Digital

CLV

CPU

Interface

XTSL

XUGF

GFS

EMPH

WFCK

C2PO

LRCK

PCMD

BCK

SYSM

TES1

TEST

XRST

RMUT

LMUT

XTAI

XTAO

AOUT1

AIN1

LOUT1

AOUT2

AIN2

LOUT2

SCLK

COUT

SSTP

ATSK

MIRR

DFCT

FOK

FFDR

FRDR

TFDR

TRDR

SFDR

SRDR

ADIO

IGEN

VC

FE

SE

TE

CE

RFDC

SQCK

SQSO

SCOR

XLON

SPOB

SPOA

CLOK

XLAT

DATA

SENS

LOCK

MDP

CLTV

PCO

FILI

FILO

XPCK

BIAS

ASYO

ASYI

RFAC

DOUT

+

-

+

-

+

-

+

-

51

49

48

50

17

54

55

56

53

26

25

8

5

6

7

12

13

14

20

1

2

43

42

41

40

39

38

46

29

28

31

30

33

32

24

23

22

11

27

21

9

60

75

76

77

72

71

70

67

66

80

79

3

35

36

4

63

62

61

19

15

64

18

16

37

44

U301: CXD3017Q

- 20 -

Page 21

Input

Interface

Timing

Control

Digital

Filter

Mode

Control

Noise

Shaper

5-Level DAC

Left

Low Pass Filter

Left

CMOS Amp

Left

5-Level DAC

Right

Low Pass Filter

Right

CMOS Amp

Right

1

2

3

4

6

8

10

12

5

7

9

11

13

14

LRCIN

DIN

BCKIN

CLKO

XTI

XTO

DGND

VDD

VCC2R

AGND2R

EXT1R

EXT2R

VOUTR

AGND1

28

27

26

25

23

21

19

17

24

22

20

18

16

15

ML/DSD

MC/DM2

MC/DM1

MUTE

MODE

CKSL

DGND

VDD

VCC2L

AGND2L

EXT1L

EXT2L

VOUTL

VCC1

MAIN BOARD

28

Clock

input

X

IN

X

CIN

Sub-

clock

input

X

COUT

Sub-

clock

output

ø

29

Clock

input

X

OUT

Clock generating

circuit

Data bus

CPU

ROM

RAM

LCD displa

y

RAM

(16 bytes)

LCD

drive control

circuit

A

25

Reset input

RESET

71

(5V)

Vcc

(0V)

Vss

30

78

V

L3

77

COM

0

76

COM

1

75

COM

2

74

COM

3

70

SEG

0

69

SEG

1

68

SEG

2

67

SEG

3

66

SEG

4

65

SEG

5

64

SEG

6

63

SEG

7

62

SEG

8

61

SEG

9

60

SEG

10

59

SEG

11

79

V

L2

80

V

L1

54

53

52

51

50

49

48

47

I/O port P0

P0(8)

46

45

44

43

42

41

40

39

I/O port P1

P1(8)

38

37

36

35

34

33

32

31

I/O port P2Input port P3

P2(8)

Key-on wake up

Real time port function

ø

INT

0

, INT

1

INT

2

, INT

3

ADT

RTP0, RTP

1

CNTR0, CNTR

1

T

OUT

X

COUT

X

CIN

58

57

56

55

P3(4)

SI/O(8)

24

23

22

21

20

19

18

17

I/O port P4

P4(8)

16

15

14

13

12

11

10

9

I/O port P5

P5(8)

A-D converter(8)

8

7

6

5

4

3

2

1

I/O port P6

I/O port P7

V

REF

AV

SS

(0V)

P6(8)

27

26

P7(2)

73

72

Time X(16)

Time Y(16)

Time 1(8)

Time 2(8)

Time 3(8)

X

Y

S

PC

L

PC

H

PS

U302: PCM1710U

MAIN BOARD

U401: M38223E4HP4

- 21 -

Page 22

- 23 -

A1

B1

Y1

A2

B2

Y2

GND

VCC

B4

A4

Y4

B3

A3

Y3

1

2

3

4

5

6

7

14

13

12

11

10

9

8

V

0

GND

V

1

AMPLIFIER 1

OUTPUT

INVERTING

INPUT

NON-INVERTING

INPUT

V –

AMPLIFIER

2

V +

OUTPUT

INVERTING

INPUT

NON-INVERTING

INPUT

1

2

3

4

8

7

6

5

+ – – +

MAIN BOARD

OUT

IN

GND

U305, U306: NE5532

MAIN BOARD

U403: TC74HC00AP

MAIN BOARD

U501, U502, U504,

U506, U507: 78XX

MAIN BOARD

U503: UPC79M12HF

- 22 -

Page 23

TROUBLESHOOTING GUIDE

SET POWER SWITCH TO ON.

IS POWER TURNED ON ?

CHECK FUSES

M507, M512-M514 OPEN ?

M507,M512-M514 DEFECTIVE

CRYSTAL X301 DEFECTIVE.

MICROPROCESSOR IC U401 DEFECTIVE.

MOTOR DRIVE TRANSISTOR Q104,

Q105, Q106, Q107 DEFECTIVE.

CAN TRAY BE OPENED ?

CAN TRAY BE CLOSED ?

DOES INITIAL READING OCCUR ?

CAN DISC BE PLAYED ?

CHECK TRACKING SERVO CIRCUIT CORRECT ?

SERVO IC U101 OR U202 DEFECTIVE.

CHECK DISC OR MECHANISM AND CONNECTOR

CHECK OUTPUT PULSE AT PIN 61,62,63 OF U201

CHECK OUTPUT SIGNAL AT PIN 13,16 OF U302

AUDIO OUTPUT IS CORRECT ?

IS POWER SUPPLY NORMALLY ?

CHECK POWER SUPPLY PATTERNS.

OK

CHECK POWER SUPPLY

CIRCUIT NORMAL ?

IC U302 DEFECTIVE.

CHECK OUTPUT SIGNAL AT PIN 1,7 OF U305, U306

IC U305 OR U306 DEFECTIVE.

CHECK MUTE CIRCUIT Q301, Q302, Q303, Q304

LINE OUT PLUG OR PATTERNS DEFECTIVE.

MUTE CIRCUIT DEFECTIVE.

IC U201 DEFECTIVE.

M101 SWITCH, DEFECTIVE

OR PATTERN AND CONNECTOR OPEN.

IS OSCILLATOR CIRCUIT

OSCILLATING ?

POWER SUPPLY PATTERNS OPEN

OR U501-U507 DEFECTIVE.

IS THERE OPEN/ CLOSE KEY SIGNAL

INPUT ? U401 PIN 66, 65

IS LOADING MOTOR DRIVE CIRCUIT

OPERATION NORMAL ?

CHECK OPEN/ CLOSE SIGNAL AT U401

PIN 65 PIN 66

TRAY OPEN H L

TRAY CLOSE L H

LOADING MOTOR AND LEAD WIRE DEFECTIVE

OR LOADING PART OF MECHANISM DEFECTIVE.

CHECK LASER LIGHT ?

DOES LENS MOVE UP AND DOWN ?

RF SIGNAL OUTPUT ?

U101 DEFECTIVE.

FEED MOTOR OR WIRING DEFECTIVE.

CHECK FOCUS SIGNAL OUTPUT ?

U101 DEFECTIVE.

CHECK CONNECTION OR PICKUP.

CHECK LASER CIRCUIT CORRECT ?

CONNECTION OR PICKUP DEFECTIVE.

YES

YES

YES

YES

YES

YES

YES

YESNO

NO

NO

NO

YES

YES

YES YES YES

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO NO NO

NO

NONO

NO

NO

NO NO

NO

NO

NO

CHECK CLOCK PULSE AT PIN4 OF U302

M302 OR U302 DEFECTIVE.

YES

NO

NO

NO

NO

NO

- 23 -

Page 24

- 25 -

ELECTRICAL PARTS LIST

Location Part Number Description

LIVE ASSY

PC BOARD

*EU TITANIUM/GREY PCB-C521B27+LIVE PCB ASSY LIVE C521BEEC

*CA TITANIUM/GREY PCB-C521BD7+LIVE PCB ASSY LIVE C521BEE

CAPACITORS

C800

SWITCH

M802 5200-3151+0-01 POWER SWITCH

PC BOARD

8910-0049+0 CAP400V 4700P

1725-221B+0100 PCB MAIN N0A60C C521 BEE

MISCELLANEOUS

M801, M803 4132-1071+0 TERMINAL PIN

M804 *EU TITANIUM/GREY 4132-1071+0 TERMINAL PIN

M805 *CA TITANIUM/GREY 4132-1071+0 TERMINAL PIN

M806 4132-1071+0 TERMINAL PIN

M810 EU TITANIUM/GREY 1806-2170+0 EMI FILTER TLN12UA

POWER ASSY

PC BOARD

*EU TITANIUM/GREY PCB-C521B27+PWR PCB ASSY POWER C521BEEC

*CA TITANIUM/GREY PCB-C521BD7+PWR PCB ASSY POWER C521BEE

TRANSFORMER

M500

PC BOARD

1806-2194+0 EI-57 TRANSFORMER 740

1723-006A+0000 PCB-TRANSFORMER A0140C

WIRE

M500A 7012-7310+0 WIRE-CONN 7P P2.5 #26

- 24 -

Page 25

Location Part Number Description

MISCELLANEOUS

J406, J407 4132-1071+0 TERMINAL PIN

DISPLAY ASSY

PC BOARD

PCB-C521BD7+DISP PCB ASSY DISPLAY C521BEE

WIRE

M509A 7010-1300+1 CN ASSY SHIELD 2P P2.5

PC BOARD

1725-221B+0100 PCB MAIN N0A60C C521 BEE

WIRE

M505A, M505B 7009-9630+1 CONN WIRE ASSY 14P 100MM

MISCELLANEOUS

0011 4134-3011+0 LCD/EL HOLDER

0015 3716-3505+0 PC SHEET FILTER 75X20

0016 3716-3502+0 POLYESTER SHEET LEE

0017 4134-3041+0 LCD CORNER BRACKET

M113 4816-043T+3 IR SENSOR KSM-603TM2

M501 2460-1340+2 LCD DISPLAY NEGATIVE

M502 2450-1146+0 EL BACKLIGHT

KEY ASSY

PC BOARD

PCB-C521BD7+KEY PCB ASSY KEY C521BEE

RESISTOR

R301 4711-102A+2 RMF 1/8W 1K 1% AT

R302, R303 4711-622A+2 RMF 1/8W 6.2K 1% AT

R304, R305 4711-202A+2 RMF 1/8W 2K 1% AT

R306, R307 4711-102A+2 RMF 1/8W 1K 1% AT

SWITCH

M101, M102, M103, M104, M105, M106, M107, M108,

M109, M110

5200-3538+0 SWITCH, TACT SKHHBY 7MM

- 25 -

Page 26

- 27 -

Location Part Number Description

WIRE

M120C 7012-6347+0 CONNECTOR WIRE ASSY

PC BOARD

1725-211B+0000 PCB KEY N0A60C

LED ASSY

PC BOARD

PCB-C521BD7+LED PCB ASSY LED C521BEE

LED

D304 3700-3517+RG LED RED/GREEN (L-469HGW)

PC BOARD

1725-221B+0100 PCB MAIN N0A60C C521 BEE

WIRE

M301B 7012-7300+0 WIRE-CONN 3P P2.5 #26

MAIN ASSY

PC BOARD

PCBC521BD7+MAIN

CAPACITORS

C101, C102, C103 150F-104K+2-FC CC 50V 0.1UF 10% AT

C105, C106, C107, C108, C109, C110 157D-107M+5-IUI CE 16V 100UF 20% RL 5X11

C111 157F-225M+5-IUNK CE 50V 2.2UF 20% RL 5X11

C201, C202 150F-221K+2-FC CC 50V 220pF 10% AT 3.5x

C203 150F-103K+2-FC CC 50V 0.01uF 10% AT 3.5

C204, C205 150F-221K+2-FC CC 50V 220pF 10% AT 3.5x

C206 150F-331K+5-GE CC 50V 330pF 10% RL 4x3

C207, C208 150F-104K+2-FC CC 50V 0.1UF 10% AT

PCB ASSY MAIN C521BEE

C209 153F-152J+5-JM CM 50V 1500PF 5% RL

C210 150F-104K+2-FC CC 50V 0.1UF 10% AT

C211, C212 15CH-270J+5-GG CTC 0/60 27pF 5% RL 4x4

C213 150F-104K+2-FC CC 50V 0.1UF 10% AT

C214, C215 150F-471K+2-FC CC 50V 470pF 10% AT 3.5x

- 26 -

Page 27

Location Part Number Description

C216 150F-103K+2-FC CC 50V 0.01uF 10% AT 3.5

C217 150F-104K+2-FC CC 50V 0.1UF 10% AT

C218 150F-101K+2-FC CC 50V 100pF 10% AT 3.5x

C219, C220 150F-474M+5-II CC 50V 0.47UF 20% RL 5X5

C221 150F-392K+2-GD CC 50V 0.0039UF 10% AT

C222 150F-104K+2-FC CC 50V 0.1UF 10% AT

C223 153F-152J+5-JM CM 50V 1500PF 5% RL

C226 157F-334K+5-IU CE 50V 0.33uF 10% RL

C227, C228 150F-104K+2-FC CC 50V 0.1UF 10% AT

C229 157D-477M+K-OVI CE 16V 470UF 20% RLT

C230 157D-107M+5-IUI CE 16V 100UF 20% RL 5X11

C301, C302 15CH-330J+5-IG CTC 0/60 33pF 5% RL 5x4

C303 150F-103K+2-FC CC 50V 0.01uF 10% AT 3.5

C304 150F-104K+2-FC CC 50V 0.1UF 10% AT

C305 157D-227M+5-OMK CE 16V 220uF 20% RL 8x7

C307 157C-476M+5-IU CE 10V 47uF 20% RL 5x11

C308 157B-106M+5-EI CE 6.3V 10uF 20% RL 3x5

C309 157C-476M+5-IU CE 10V 47uF 20% RL 5x11

C310 157C-108M+5-S5 CE 10V 1000uF 20% RL

C320, C321 157B-106M+5-EI CE 6.3V 10uF 20% RL 3x5

C322 150F-104K+5-II CC 50V 0.1uF 10% RL 5x5

C323, C324, C325 157B-106M+5-EI CE 6.3V 10uF 20% RL 3x5

C326, C327 150F-104K+5-II CC 50V 0.1uF 10% RL 5x5

C328, C329 15CH-200J+5-GG CTC 0/60 20pF 5% RL 4x4

C330 153F-103J+5-IM CM 50V 0.01u 5% RL 5X7

C332, C334 157B-106M+5-EI CE 6.3V 10uF 20% RL 3x5

C352, C353 150F-331K+5-GE CC 50V 330pF 10% RL 4x3

C356, C357 153F-272J+5-JM CM 50V 2700PF 5% RL

C362, C363 153F-472J+5-KM CM 50V 4700pF 5% RL 6x7

C366, C367 158F-681J+5-KW CP 50V 680pF 5% RL 6x12

C368, C369 157E-226K+5-IU CE 25V 22uF 10% RL 5x11

C370 153F-103J+5-IM CM 50V 0.01u 5% RL 5X7

C371, C372, C373, C374 157D-477M+K-OVI CE 16V 470UF 20% RLT

C375, C376 157E-226K+5-IU CE 25V 22uF 10% RL 5x11

C377, C378, C379 153F-224J+5-MIB CM 50V 0.22uF 5% RL 7x5

C380, C381 150F-104K+5-II CC 50V 0.1uF 10% RL 5x5

C382 153F-224J+5-MIB CM 50V 0.22uF 5% RL 7x5

C383 157C-226M+5-IU CE 10V 22uF 20% RL 5x11

C384 150F-102K+2-FC CC 50V 1000pF 10% AT 3.5

C385 150F-222K+2-GD CC 50V 0.0022UF 10% AT

- 27 -

Page 28

- 29 -

Location Part Number Description

C386 150F-104K+2-FC CC 50V 0.1UF 10% AT

C387 150F-103K+2-FC CC 50V 0.01uF 10% AT 3.5

C390, C391 157D-477M+K-OVI CE 16V 470UF 20% RLT

C407 157D-228M+5-X=I CE 16V 2200UF 20% RL

C417 150F-104K+5-II CC 50V 0.1uF 10% RL 5x5

C418 157E-106M+5-IU CE 25V 10uF 20% RL 5x11

C501, C502, C503, C504, C505 150F-104K+5-II CC 50V 0.1uF 10% RL 5x5

C506, C507 157E-228M+5-X9 CE 25V 2200uF 20% RL

C508 157C-108M+5-S5 CE 10V 1000uF 20% RL

C511 157C-227M+5-KW CE 10V 220uF 20% RL 6x12

C512, C513 157D-108M+5-S5I CE 16V 1000uF 20% RL

C518 157E-107M+5-KW CE 25V 100uF 20% RL 6x12

C521 150F-104K+2-FC CC 50V 0.1UF 10% AT

C522 157D-107M+5-IUI CE 16V 100UF 20% RL 5X11

C523 157F-225M+5-IU CE 50V 2.2uF 20% RL 5x11

C524 153F-223K+5-LQ CM 50V 0.022uF 10% RL 6.

C525 157C-108M+5-S5 CE 10V 1000uF 20% RL

C526 150F-104K+5-II CC 50V 0.1uF 10% RL 5x5

C527 157C-477M+5-OW CE 10V 470uF 20% RL 8x12

C528 150F-104K+5-II CC 50V 0.1uF 10% RL 5x5

C529 157D-338M+5-W@ CE 16V 3300uF 20% RL

C530 157E-106M+5-IU CE 25V 10uF 20% RL 5x11

C531, C532 150F-104K+5-II CC 50V 0.1uF 10% RL 5x5

C533 157D-477M+K-OVI CE 16V 470UF 20% RLT

C534, C535, C537, C540, C541, C542, C543 150F-104K+5-II CC 50V 0.1uF 10% RL 5x5

C710 157B-107M+5-KM CE 6.3V 100uF 20% RL 6x7

DIODES

D201 4804-0010+2 DIODE W1N4001-A(WA) AT

D301, D303, D306, D409, D411 4804-1480+2 DIODE 1N4148T AT

D302 4805-3930+2 DIODE 1N5393-B 200V 1.5A

D403 4837-3V36+2 DZ 1/2W +-5% 3.3V TEMIC

D501, D502, D503, D504, D506, D507, D508 4804-0010+2 DIODE W1N4001-A(WA) AT

D513 4805-3930+2 DIODE 1N5393-B 200V 1.5A

D514, D515, D516, D517 4804-0010+2 DIODE W1N4001-A(WA) AT

WAFERS/SOCKETS

M102 2101-3102+0 CONNECTOR FFC 16PIN P1.0

M120 2102-051S+004 5P ST.WAFER

M301A 2102-031S+004 3 PIN ST. WAFER

- 28 -

Page 29

Location Part Number Description

M500A 2102-071S+004 WF T8 DE 7PIN COULOMB

M505A, M505B 2102-141S+004 14P ST. WAFER P=2.5

M509 2102-021S+004 2P ST.WAFER

M509A 2102-022S+008 WAFER 2PIN PITCH=2.54MM

JACKS/SOCKETS

M317 2113-1300+0 2P RCA JACK W/R AU

M318 2113-1170+0 1P RCA JACK YL AU

COILS

L201 1801-270K+M COIL 27 UH,10%,AL,BL7

L301 1802-0450+0 DIGITAL COIL

CRYSTAL

M302 2300-0110+0 CRYSTAL 16.9344 MHZ

RELAY

RL101 4500-0200+1 RELAY 2P2T BT-12S 12VDC

TRANSISTOR

Q101 4860-0060+5 TR SS8550 C/D RL

Q103 4860-0050+K TR SS8050 C/D RLT

Q104, Q105 4860-0060+5 TR SS8550 C/D RL

Q106, Q107 4860-0050+K TR SS8050 C/D RLT

Q301, Q302, Q303, Q304 4860-1780+K TR 2SD655F HFE600-1200

Q305 485C-114E+5 TR DTC114ES

Q307, Q308, Q309 4860-0050+K TR SS8050 C/D RLT

Q312, Q313 4860-0060+5 TR SS8550 C/D RL

Q401 4860-0660+5 TR 2SA1015-GRF(T5L,T) RL

Q402 4851-012F+5 TR 2SD1012F-SPA HFE

Q403 4860-0660+5 TR 2SA1015-GRF(T5L,T) RL

Q404 485A-114E+5 TR DTA114ES ROHM

Q405 485C-114E+5 TR DTC114ES

Q520 4860-0050+K TR SS8050 C/D RLT

RESISTOR

R101 4711-100A+2 RMF 1/8W 10R 1% AT

R103, R104 4701-153J+2 RCF 1/8W 15K 5% AT

R105 4701-302J+2 RCF 1/8W 3K 5% AT

R106 4701-154J+2 RCF 1/8W 150K 5% AT

- 29 -

Page 30

- 31 -

Location Part Number Description

R107 4701-104J+2 RCF 1/8W 100K 5% AT

R108 4701-683J+2 RCF 1/8W 68K 5% AT

R109 4711-153A+2 RMF 1/8W 15K 1% AT

R110 4701-302J+2 RCF 1/8W 3K 5% AT

R111 4701-472J+2 RCF 1/8W 4.7K 5% AT

R112, R113, R114 4701-512J+2 RCF 1/8W 5.1K 5% AT

R115 4701-182J+2 RCF 1/8W 1.8K 5% AT

R116, R117 4701-123J+2 RCF 1/8W 12K 5% AT

R118 4701-103J+2 RCF 1/8W 10K 5% AT

R119 4711-153A+2 RMF 1/8W 15K 1% AT

R121, R122, R123, R124 4701-102J+2 RCF 1/8W 1K 5% AT

R201 4701-472J+2 RCF 1/8W 4.7K 5% AT

R202, R203, R204, R205, R206, R207, R208, R209,

R210, R211

R212 4701-104J+2 RCF 1/8W 100K 5% AT

R213 4701-103J+2 RCF 1/8W 10K 5% AT

R214 4701-822J+2 RCF 1/8W 8.2K 5% AT

R215 4701-4R7J+2 RCF 1/8W 4.7R 5% AT

R217 4701-102J+2 RCF 1/8W 1K 5% AT

R218 4701-473J+2 RCF 1/8W 47K 5% AT

R219 4701-153J+2 RCF 1/8W 15K 5% AT

R220 4701-104J+2 RCF 1/8W 100K 5% AT

R223 4701-333J+2 RCF 1/8W 33K 5% AT

R224 4701-103J+2 RCF 1/8W 10K 5% AT

R225 4701-104J+2 RCF 1/8W 100K 5% AT

R226 4701-105J+2 RCF 1/8W 1M 5% AT

R228, R229 4701-332J+2 RCF 1/8W 3.3K 5% AT

R230 4701-103J+2 RCF 1/8W 10K 5% AT

R308, R309, R310 4701-302J+2 RCF 1/8W 3K 5% AT

R311 4701-102J+2 RCF 1/8W 1K 5% AT

4701-102J+2 RCF 1/8W 1K 5% AT

R312, R313, R314 4701-223J+2 RCF 1/8W 22K 5% AT

R315 4701-4R7J+2 RCF 1/8W 4.7R 5% AT

R320 4701-471J+2 RCF 1/8W 470R 5% AT

R321, R322, R323, R325, R326, R327, R328, R329 4701-472J+2 RCF 1/8W 4.7K 5% AT

R330 4701-103J+2 RCF 1/8W 10K 5% AT

R331 4701-102J+2 RCF 1/8W 1K 5% AT

R334 4701-561J+2 RCF 1/8W 560R 5% AT

R335 4701-102J+2 RCF 1/8W 1K 5% AT

R338 4701-103J+2 RCF 1/8W 10K 5% AT

R339 4701-104J+2 RCF 1/8W 100K 5% AT

- 30 -

Page 31

Location Part Number Description

R340 4701-100J+2 RCF 1/8W 10R 5% AT

R341 4701-561J+2 RCF 1/8W 560R 5% AT

R346 4701-103J+2 RCF 1/8W 10K 5% AT

R347 4701-102J+2 RCF 1/8W 1K 5% AT

R353 4711-122A+2 RMF 1/8W 1.2K 1% AT

R354 4701-271J+2 RCF 1/8W 270R 5% AT

R355, R356 4711-682A+2 RMF 1/8W 6.8K 1% AT

R357 4701-271J+2 RCF 1/8W 270R 5% AT

R358 4711-122A+2 RMF 1/8W 1.2K 1% AT

R359, R360 4701-682J+2 RCF 1/8W 6.8K 5% AT

R361, R362 4711-683A+2 RMF 1/8W 68K 1% AT

R363, R364 4701-152J+2 RCF 1/8W 1.5K 5% AT

R367, R368, R371, R372 4701-222J+2 RCF 1/8W 2.2K 5% AT

R373, R374 4701-104J+2 RCF 1/8W 100K 5% AT

R375, R376 4701-151J+2 RCF 1/8W 150R 5% AT

R377, R378 4701-472J+2 RCF 1/8W 4.7K 5% AT

R379, R380 4701-151J+2 RCF 1/8W 150R 5% AT

R381, R382 4701-472J+2 RCF 1/8W 4.7K 5% AT

R383 4701-151J+2 RCF 1/8W 150R 5% AT

R384 4701-750J+2 RCF 1/8W 75R 5% AT

R390, R391, R392, R393 4717-221J+C RMF 1/2W 220R 5% ATS

R394, R403 4701-103J+2 RCF 1/8W 10K 5% AT

R405 4701-223J+2 RCF 1/8W 22K 5% AT

R406 4701-752J+2 RCF 1/8W 7.5K 5% AT

R407 4701-102J+2 RCF 1/8W 1K 5% AT

R412 4701-472J+2 RCF 1/8W 4.7K 5% AT

R413 4701-473J+2 RCF 1/8W 47K 5% AT

R414 4701-104J+2 RCF 1/8W 100K 5% AT

R415 4701-752J+2 RCF 1/8W 7.5K 5% AT

R416 4701-473J+2 RCF 1/8W 47K 5% AT

R501 4711-273A+2 RMF 1/8W 27K 1% AT

R502 4701-183J+2 RCF 1/8W 18K 5% AT

R520 4701-513J+2 RCF 1/8W 51K 5% AT

R521 4701-151J+2 RCF 1/8W 150R 5% AT

IC

U101 3131-8030+0 IC CXA2581N ASP FOR CD S

U201 3131-8040+0 IC BA6392FP-E2 4-CHANNEL

U301 3131-8000+0 IC CXD3017Q DSP FOR CD

U302 3130-5660+0 IC PCM1710U/1K D/A

- 31 -

Page 32

- 33 -

Location Part Number Description

U305, U306 3130-9340+0 IC OPA2604 OPAMP DIP8

U403 3130-4160+0 IC TC74HC00AP(F/M)

U501 3130-2020+3 IC MC7805CTG REG 5V 1.5A

U502 3130-2520+2 IC NJM7812FA-#ZZZB

U503 3130-3800+0 IC NJM7912FA-#ZZZB

U504 3130-9030+0 IC REGULATOR NJM78L09L2A

U506 3130-2020+3 IC MC7805CTG REG 5V 1.5A

U507 3130-2790+1 IC NJM7808FA-#ZZZB

SEMI FIXED

R709 4756-4716+3-06 SVR 470 H3 7X7.6 RH0615C

TRANSFORMER

M501

HEATSINKS

U501 5400-9130+0 HEAT SINK FOR 7805 2438-

1806-2320+0 TRANSFORMER STEP-UP 5V

U502 5400-0831+0 HEATSINK

U503, U506, U507 5400-9130+0 HEAT SINK FOR 7805 2438-

WIRE

M101 7012-6536+0 CONN WIRE ASSY 5PIN P2.0

M105 7012-6538+0 CONN WIRE ASSY 6PIN P2.0

M102C 7012-6232+1 CABLE FFC 16P P1.0

PC BOARD

1725-221B+0100 PCB MAIN N0A60C C521 BEE

IC

U401 3131-8020+0 IC MCU OTP ROM M38227ECH

MISCELLANEOUS

2601-2608+0601 FIBRE WASHER M2.6 0.8T

2954-2608+3000 SCREW B-TITE BIND M2.6X8

2954-3008+0000 SCREW B-TITE BIND M3X8

3000-9812+0 BLANK LABEL (5X10)

3005-0360+2 RIBBON 60MMX600M TEC

C-GND1 4132-1061+0 SOLDER TAG

- 32 -

Page 33

Location Part Number Description

D505 4840-1140+0 DZ 1.3W 3.3V 5% AT

L101, L102, L302 1801-100K+M-2 COIL 10UH 10% BL7.0 AT

M303 2704-0060+0 EMC FILTER

M320 4132-1061+0 SOLDER TAG

M502, M503, M504, M505 4131-9131+0 FUSE HOLDER 6.5MM PITCH

X301 2703-0280+0 CR 8MHZ CSTLA8M00T55-B0

NOTE: - The components identified by

Replace only with part number specified.

- <*CA > : Canadian model only.

- <*EU > : European model only.

- Capacitors : CP-Polystyrene, CM-Mylar, CE-Electrolytic, CC-Ceramic, CTC-NPO.

- Resistors : RMF-Metal Film, RCF-Carbon Film, RWR-Wirewound Metal Oxide.

mark are critical for risk of fire and electrical shock.

- 33 -

Page 34

- 35 -

MECHANISM EXPLODED VIEW

27

11

3

15

28

29

22

10

1

9

24

(x2)

21

(x4)

(x2)

(x4)

23

30

31

(x2)

8

26

26

5

12

17

16

6

25

(x2)

(x2)

14

32

20

13

25

19

18

(x2)

2

7

4

WSL-2130CCM

- 34 -

Page 35

MECHANISM EXPLODED VIEW PARTS LIST

Item Part No. Description Qty

1 4102-9000+0 Outside Main Chassis 1

2 4102-9001+0 Tray 1

3 4102-9002+0 Subchassis 1

4 4102-9003+0 Chucking Plate 1

5 4102-9004+0 Drive Gear 1

6 4102-9005+0 Control Cam 1

7 4102-9006+0 Chucking Pulley 1

8 4102-9007+0 Gear Cover 1

9 4102-9008+0 Tray Gear 1

10 4102-9009+0 Intermediate Gear 1

11 4102-9010+0 Loading Pulley 1

12 4102-9011+0 Motor Pulley 1

13 4102-9012+0 SW Pin 1

14 4102-9013+0 Chucking Yoke 1

15 4102-9014+0 Optical Pickup Unit 1

16 4102-9015+0 Loading PWB 1

17 4102-9016+0 Motor JQ32-55K415, 4.5V, 10G-CM 1

18 4102-9017+0 Leaf Switch 1

19 4102-9018+0 Connector pin (5P) 1

20 4102-9019+0 Magnet 1

21 4102-9020+0 Insulator 4

22 4102-9021+0 Coil Spring (Front) 2

23 4102-9022+0 Coil Spring (Rear) 2

24 4102-9023+0 Screw-Motor M2.6x2.5 2

25 4102-9024+0 Screw M2.6x7 2

26 4102-9025+0 Screw Washer Based M2.6x16 4

27 4102-9026+0 Rubber Belt 1

28 4102-9027+0 Center Ring 1

29 4102-9028+0 Turn Table 1

30 4102-9029+0 Gear (A) 1

31 4102-9030+0 Motor Gear 1

32 4102-9031+0 Damper 1

- 35 -

Page 36

- 37 -

EXPLODED VIEW

0006

0205

0001

0204

0008

0010

0216

0019

0228

0227

0013

0210

U506

0226

U503

0225

M317

U501

U507

0003

0014

0101

M501

0219

0012

0219

0005

0201

0202

0219

0219

0213

0206

0211

0018

0208

0207

0225

0304

0002

0218

0209

0020

0223

0224

0226

0007

- 36 -

Page 37

EXPLODED VIEW PARTS LIST

Item Part No. Description

0001 *EU GREY / *CA GREY 1466-510A+2 FASCIA BLACK NACDC525B

0001 *EU TITANIUM / *CA TITANIUM 1466-510B+2 FASCIA SILVER NACDC525B

0002 1402-3783+2 STRAP (C542)

0003 *EU TITANIUM/GREY 1402-352I+1 CHASSIS-REAR C NACDC525B

0003 *CA TITANIUM/GREY 1402-352J+1 CHASSIS-REAR AH

0005 *EU TITANIUM / *CA TITANIUM 1402-3532+0 TOP COVER SILVER (C542)

0006 *EU GREY / *CA GREY 2442-1002+0 POWER BUTTON BLACK

0006 *EU TITANIUM / *CA TITANIUM 2442-1003+0 POWER BUTTON SILVER

0007 *EU GREY / *CA GREY 4154-4192+1 CD DOOR BLACK (C521BEE)

0007 *EU TITANIUM / *CA TITANIUM 4154-4194+1 CD DOOR SILVER (C521BEE)

0008 *EU GREY / *CA GREY 3716-4313+0 WINDOW LENS (C520) W/SS

0010 *EU TITANIUM / *CA TITANIUM 2444-1203+0 BUTTON TRIO BLACK

0010 *EU GREY / *CA GREY 2444-1204+0 BUTTON TR10 TITANIUM

0012 *EU TITANIUM / *CA TITANIUM 4111-1051+1 CD DECK WSL-2130CCM

0013 4157-0501+1 RUBBER FOOT

0014 4151-9461+0 STRAIN RELIEF BUSHING

0018 4152-4641+1 CUSHION FOOT W/RUBBER WA

0019 2444-1903+0 DUO BUTTON BLACK

0019 2444-1904+0 DUO BUTTON TITANIUM

0020 4132-6191+0 BRACKET,MTG,X’FORMER

0023 4154-1931+1 DUSTPROOF CUSHION

0024 3714-5706+0 LED LENS (412) CLEAR SAN

0052 4152-4841+1 BLACK CUSHION (EL/LCD)

0101 *EU GREY / *CA GREY 1402-3533+0 COVER-TOP BLACK (C542)

0101 *CA TITANIUM/GREY 7009-3100+2 AC CORD 18AWGX2

0101 *EU TITANIUM/GREY 7009-3110+0 AC CORD (SEMKO)

0160 2600-4008+0973 FLAT WASHER 4*9.7*0.8

0201 *EU TITANIUM / *CA TITANIUM 2900-4006+2010 SCM PW M4X6 RECESS WHITE

0201 *EU GREY / *CA GREY 2900-4006+3010 M4X0.5PX6MM W/FLAT

0202 *EU GREY / *CA GREY 2954-3008+3000 SCREW B-TITE BIND HEAD

0202 *EU TITANIUM / *CA TITANIUM 2954-3010+4000 ST SCREW 3X10 BH

0204 2954-3008+3000 SCREW B-TITE BIND HEAD

0205 2954-3008+0000 SCREW B-TITE BIND M3X8

0206, 0207 2954-3008+3000 SCREW B-TITE BIND HEAD

0208 2842-3367+0 METAL WASHER

0209 2900-4010+3030 PH W/WASHER M4X10 BL ZN

0210 2954-3008+0000 SCREW B-TITE BIND M3X8

0211 2904-3006+0000 SCREW M3X6

0213 2954-3008+3000 SCREW B-TITE BIND HEAD

0216 2954-3008+0000 SCREW B-TITE BIND M3X8

- 37 -

Page 38

- 39 -

Item Part No. Description

0217 2842-3367+0 METAL WASHER

0218 2954-3006+0000 3X6MM B-TITE (YEL.ZN)

0219 2904-3006+3000 SCREW M3X6 BINDING (BLK)

0223 2600-4008+0973 FLAT WASHER 4*9.7*0.8

0224 2640-4030+0703 M4 NUT (BLK)

0225 2954-3008+0000 SCREW B-TITE BIND M3X8

0226 2954-2006+0000 TAPPING SCREW 2X6

0227 2954-2608+0000 SCREW B-TITE BIND M2.6X8

0228 2600-4008+0973 FLAT WASHER 4*9.7*0.8

0230 2954-3008+0000 SCREW B-TITE BIND M3X8

0301 4153-3331+0 EVA GASKET 5*500

0309 3100-5101+0 PC SHEET 50X7X0.25

0310 1635-0110+0 TAPE HIGH TEMP W=12

0311 4152-0241+0 PAD CORK 15X12X3MM GRAY

0312 4154-1401+0 PC SHEET 14X350X0.5 THK

0315 3100-5101+0 PC SHEET 50X7X0.25

0316 4154-1371+0 PC SHEET 14X260X0.5 THK

0317 4157-0751+0 TRANSFORMER RUBBER PAD

0500 *CA TITANIUM/GREY 3000-4290+0 LABEL, BLANK 45X10

0500 *CA TITANIUM/GREY 3005-0360+2 RIBBON 60MMX600M TEC

0501 3009-1689+0 CD LASER LABEL YELLOW

0502 3000-4205+0 LABEL, CD WARNING

M502, M503, M504 *EU TITANIUM/GREY 5120-0018+0 FUSE T1A 250V 5X20

M502, M503, M504 *CA TITANIUM/GREY 5120-0020+0 FU T1A 250V UL/CSA 5X20

M505 *EU TITANIUM/GREY 5120-0050+0 FUSE T1.6A/250V 5X20

M505 *CA TITANIUM/GREY 5120-0052+0 FUSE T1.6A 250V 5X20

NOTE: - The components identified by

Replace only with part number specified.

- <*CA > : Canadian model only.

- <*EU > : European model only.

mark are critical for risk of fire and electrical shock.

- 38 -

Page 39

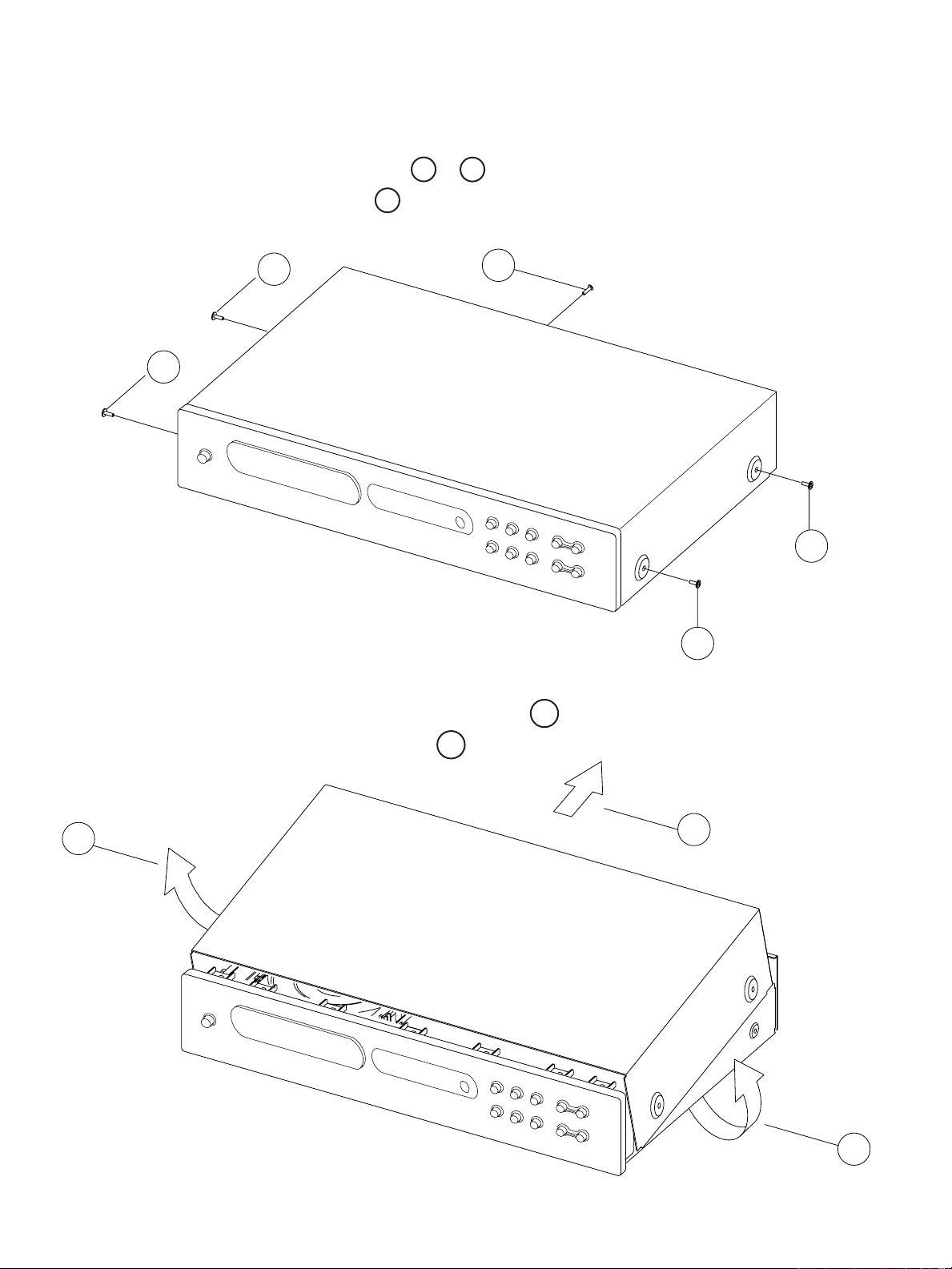

PACKING DIAGRAM

1

2

9

10

4

8

3

5

7

11

2

6

ITEM PART NO. DESCRIPTION Q’TY

1. 1435-8302+0-2 CARTON BOX C525BEE 1

2. 1490-3783+2 POLYFORM ENDCAP 2

3. 1497-1062-0 POLYBAG MANUAL 1

4. 1497-1302+0 POLYBAG 1

5. 1497-1332+1 POLYBAG 1

6. 1497-1432+0 EPE BAG (412) 1

7. 4301-7231+0 INSTRUCTION MANUAL 1

8. 2103-7302+1 RCA PLUG (MALE) 1

9. 4060-0530+0 GREENCELL 3A SIZE GP24G2 2

10. 8912-0038+0 REMOTE CONTROL C521BEE 1

11. 1450-2520+0 WHITE PAPER 1

Proprietary information for servicing purposes only. The information herein may not be used commercially without the prior written agreement of NAD Electronics International, Toronto, Canada.

- 39 -

Page 40

SERVICE MANUAL

© NAD 2006

NAD ELECTRONICS INTERNATIONAL

TORONTO

COMPACT

DISC PLAYER

C 525BEE

Loading...

Loading...