Page 1

be certain.

m

SWIFT® 10 ATV Sensor

Product Information

Spinning Wheel Integrated Force Transducer

For Recreational and Small Vehicles

100-183-736 C

Page 2

Copyright information © 2008 MTS Systems Corporation. All rights reserved.

Trademark information MTS, SWIFT, TestStar, and TestWare are registered trademarks of MTS Systems

Corporation within the United States. These trademarks may be protected in

other countries.

Microsoft, Windows, Windows for Workgroups, Windows 95, and Windows NT

are registered trademarks of Microsoft Corporation. Apple and Macintosh are

registered trademarks of Apple Computer, Inc. UNIX is a registered trademark of

The Open Group. LabVIEW is a registered trademark of National Instruments

Corporation.

Publication information

MANUAL PART NUMBER PUBLICATION DATE

100-183-736 A February 2008

100-183-736 B April 2008

100-183-736 C November 2008

2

Page 3

Contents

Technical Support 7

How to Get Technical Support 7

Before You Contact MTS 7

If You Contact MTS by Phone 9

Problem Submittal Form in MTS Manuals 10

Preface 11

Before You Begin 11

Conventions 12

Documentation Conventions 12

Hardware Overview 15

Overview 16

Spinning Applications (Track or Road) 18

Non-spinning Applications (Laboratory) 19

Construction 20

Design Features 23

Coordinate System 24

Specifications 26

Calibration 30

Transducer Interface 32

TI Front Panel 35

TI Rear Panel 36

Interfacing with RPC 37

Software Utilities 39

Introduction 40

TI2STATUS - Transducer Interface Status 41

Description of TI2STATUS Indications 41

TI2XFER - Transducer Interface Transfer 43

TI2SHUNT - Transducer Interface Shunt 45

Setting Up Shunt Calibration Reference Values 48

Error Messages 49

SWIFT 10 ATV Sensors Contents

3

Page 4

Setting up the Transducer Interface 51

USB driver installation 52

Select a Zero Method 54

Calibration File Elements 55

Upload the Calibration File 56

Edit the Calibration File 57

Download the Calibration File 60

Installing the Transducer 61

Hazard Icon 62

Road and Track Vehicles 63

Attaching SWIFT Components to the Vehicle 67

Attaching Anti-rotate Assemblies 70

Installing the Transducer Interface Electronics 74

Setting up the SWIFT Sensor for Data Collection 77

Verifying the Quality of the Zero Procedure 80

Collecting Data 82

Road Simulator 85

Attaching SWIFT Components to the Fixturing 88

Zeroing the Transducer Interface 92

Analyzing SWIFT Data 97

The Data 98

Fx Data (Longitudinal Force) 99

Fz Data (Vertical Force) 101

Mx Data (Overturning Moment) 102

My Data (Brake Moment) 105

Acceleration and Braking Events Example 107

Slalom Curve Driving Example 109

Maintenance 111

Transducer 112

Transducer Interface 114

Cables 115

4

Contents

SWIFT 10 ATV Sensors

Page 5

Troubleshooting 117

Assembly Drawings 129

Cable Drawings 130

SWIFT 10 Mechanical Drawings 136

SWIFT 10 ATV Sensors Contents

5

Page 6

6

Contents

SWIFT 10 ATV Sensors

Page 7

Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

MTS web site

www.mts.com

E-mail techsupport@mts.com

Telephone MTS Call Center 800-328-2255

Fax 952-937-4515

Technical support

outside the U.S.

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes MTS software, look

for online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Technical Support link:

www.mts.com > Contact MTS > Service & Technical Support

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Please include “Technical Support” in the subject line.

For technical support outside the United States, contact your local sales and

service office. For a list of worldwide sales and service locations and contact

information, use the Global MTS link at the MTS web site:

www.mts.com > Global MTS > (choose your region in the right-hand

column) > (choose the location closest to you)

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

SWIFT 10 ATV Sensors Technical Support

The site number contains your company number and identifies your equipment

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

which system you are calling about. You can find your job number in the papers

sent to you when you ordered your system.

Example system number: US1.42460

7

Page 8

Know information from

prior technical

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions:

• How long and how often has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the model numbers of the suspect equipment?

• What model controller are you using (if applicable)?

• What test configuration are you using?

Know relevant

computer information

Know relevant

software information

If you are experiencing a computer problem, have the following information

available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive in which the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

For software application problems, have the following information available:

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

• It is also helpful if the names of other non-MTS applications that are

running on your computer, such as anti-virus software, screen savers,

keyboard enhancers, print spoolers, and so forth are known and available.

Technical Support

8

SWIFT 10 ATV Sensors

Page 9

If You Contact MTS by Phone

Your call will be registered by a Call Center agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, the agent will ask you for your site number, name, company, company

address, and the phone number where you can normally be reached.

If you are calling about an issue that has already been assigned a notification

number, please provide that number. You will be assigned a unique notification

number about any new issue.

Identify system type To assist the Call Center agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• Electromechanical materials test system

• Hydromechanical materials test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

troubleshoot

Write down relevant

information

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

Prepare yourself for troubleshooting while on the phone:

• Call from a telephone when you are close to the system so that you can try

implementing suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Prepare yourself in case we need to call you back:

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again and provide your original notification number.

SWIFT 10 ATV Sensors Technical Support

9

Page 10

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems you are experiencing

with your MTS software, hardware, manuals, or service which have not been

resolved to your satisfaction through the technical support process. This form

includes check boxes that allow you to indicate the urgency of your problem and

your expectation of an acceptable response time. We guarantee a timely

response—your feedback is important to us.

The Problem Submittal Form can be accessed:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form (electronic form to

be e-mailed to MTS)

Technical Support

10

SWIFT 10 ATV Sensors

Page 11

Preface

Before You Begin

Safety first! Before you attempt to use your MTS product or system, read and understand the

Safety manual and any other safety information provided with your system.

Improper installation, operation, or maintenance of MTS equipment in your test

facility can result in hazardous conditions that can cause severe personal injury or

death and damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very

important that you remain aware of hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional MTS manuals in paper or

electronic form.

If you have purchased a test system, it may include an MTS System

Documentation CD. This CD contains an electronic copy of the MTS manuals

that pertain to your test system, including hydraulic and mechanical component

manuals, assembly drawings and parts lists, and operation and preventive

maintenance manuals. Controller and application software manuals are typically

included on the software CD distribution disc(s).

SWIFT 10 ATV Sensors Preface

11

Page 12

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions As necessary, hazard notices may be embedded in this manual. These notices

contain safety information that is specific to the task to be performed. Hazard

notices immediately precede the step or procedure that may lead to an associated

hazard. Read all hazard notices carefully and follow the directions that are given.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury, equipment damage, or

endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be

aware that these illustrations are examples only and do not necessarily represent

your actual system configuration, test application, or software.

Electronic manual

conventions

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

12

Preface

SWIFT 10 ATV Sensors

Page 13

Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

SWIFT 10 ATV Sensors Preface

13

Page 14

Conventions

14

Preface

SWIFT 10 ATV Sensors

Page 15

Hardware Overview

Contents Overview 16

Spinning Applications (Track or Road) 18

Non-spinning Applications (Laboratory) 19

Construction 20

Design Features 23

Coordinate System 24

Specifications 26

Calibration 30

Transducer Interface 32

TI Front Panel 35

TI Rear Panel 36

Interfacing with RPC 37

SWIFT 10 ATV Sensors Hardware Overview

15

Page 16

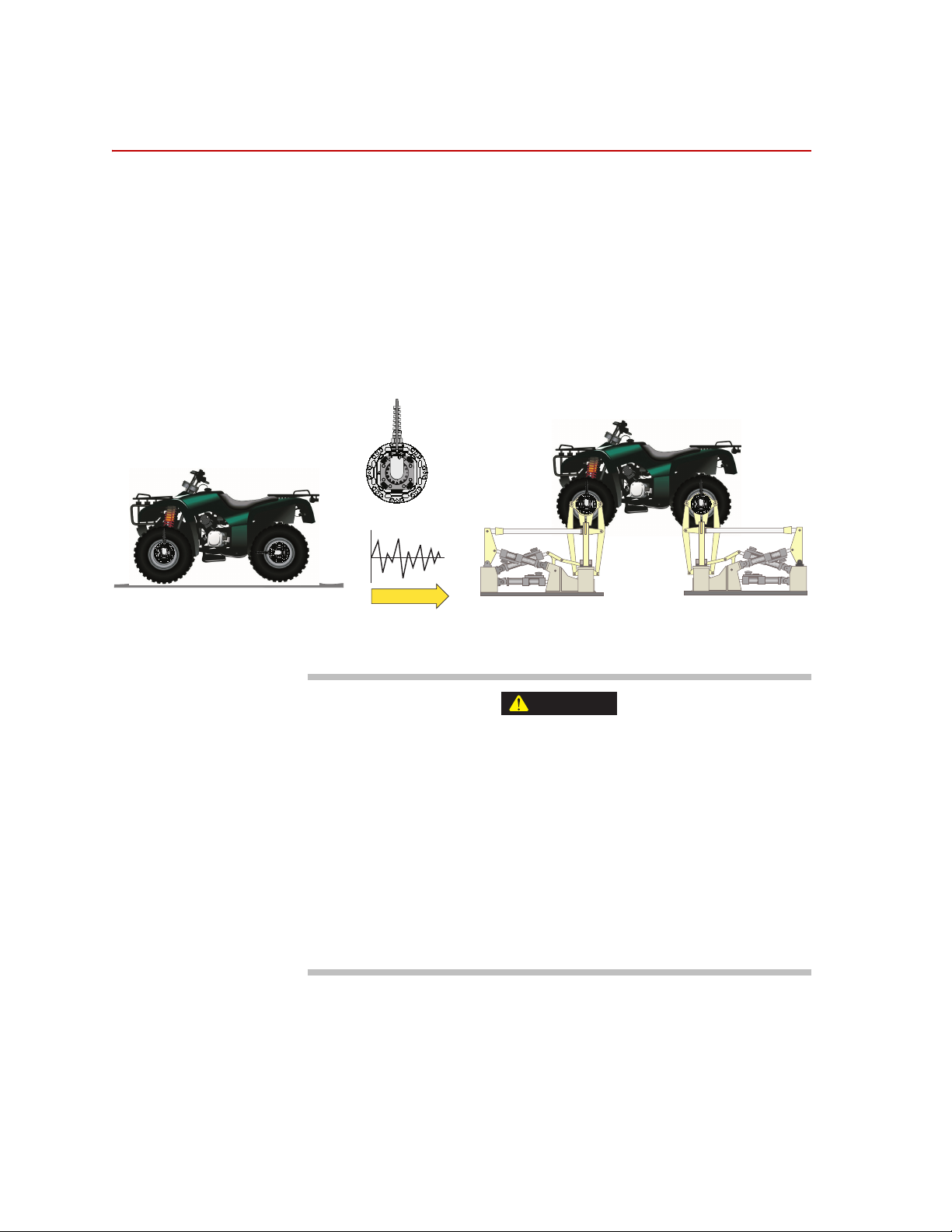

Overview

Data

S10-01

Track or Road

Laboratory Simulation

WARNING

Overview

The MTS Spinning Wheel Integrated Force Transducer (SWIFT®) sensor is a

light-weight, easy-to-use transducer that enables you to conduct faster, less

expensive data acquisition and road simulation testing.

The transducer is designed for use on the test track and public roads, as well as in

the test laboratory. It attaches to the test vehicle or an MTS Series 329 Road

Simulator using an adapter and a modified wheel rim.

You can achieve excellent data correlation using the same transducer and vehicle

on the test track or public road and on a road simulator. It is available in various

sizes and materials to fit various vehicle and loading requirements.

Hardware Overview

16

Driving a vehicle with SWIFT sensors mounted on it will change the

handling characteristics of the vehicle.

Driving a vehicle configured in this way on public roads can pose

unexpected dangers to pedestrians and other vehicle traffic.

Only authorized, licensed drivers, who are experienced driving a vehicle with

SWIFT sensors mounted on it, should be allowed to operate the vehicle on public

roads. Drive the vehicle with the SWIFT sensor attached on closed courses only

until you have proper experience.

When driving the vehicle on public roads, you must conform to all local laws and

regulations.

SWIFT 10 ATV Sensors

Page 17

Overview

CAUTION

Parts replacement,

disassembly, and care

The SWIFT sensor assembly, Transducer Interface box, and the accessory

components have no user serviceable parts. These components should not be

disassembled other than as outlined in “Troubleshooting” beginning on page 117.

Do not disassemble the SWIFT sensor, Transducer Interface (TI) electronics,

and accessory components.

The SWIFT sensor, TI electronics, and accessory components are not

intended to be disassembled, other than as outlined in “Troubleshooting”.

Disassembling or tampering with these components may result in damage to the

sensor, loss of watertight seal, and voiding of the warranty.

• The sensor assembly should be returned to MTS annually for recalibration

and inspection.

• Clean the sensor assembly after each use, as described in Maintenance

beginning on page 111, especially if it is exposed to corrosive or abrasive

material, such as salt or sand.

• Read and follow all warnings and cautions affixed to the transducer and in

this manual especially those warnings and cautions that deal with

installation, use, inspection and maintenance of the transducer.

The SWIFT sensor assembly should not:

• Be allowed to strike hard surfaces or objects while driving the vehicle.

• Be driven through grass or brush that is taller than the bottom edge of the

sensor.

• Be exposed to loads that exceed the full scale calibrated ranges. Refer to the

calibration sheets accompanying your transducers.

• Be used if the integrity of the sealed cover has been compromised or the

warning label has been removed.

• Be used if the sensor assembly shows indications of damage (such as dents

on the transducer or slip ring assembly, a bent anti-rotate assembly, etc.).

• Be used if any part of the assembly has been modified without explicit,

written authorization from MTS.

SWIFT 10 ATV Sensors Hardware Overview

17

Page 18

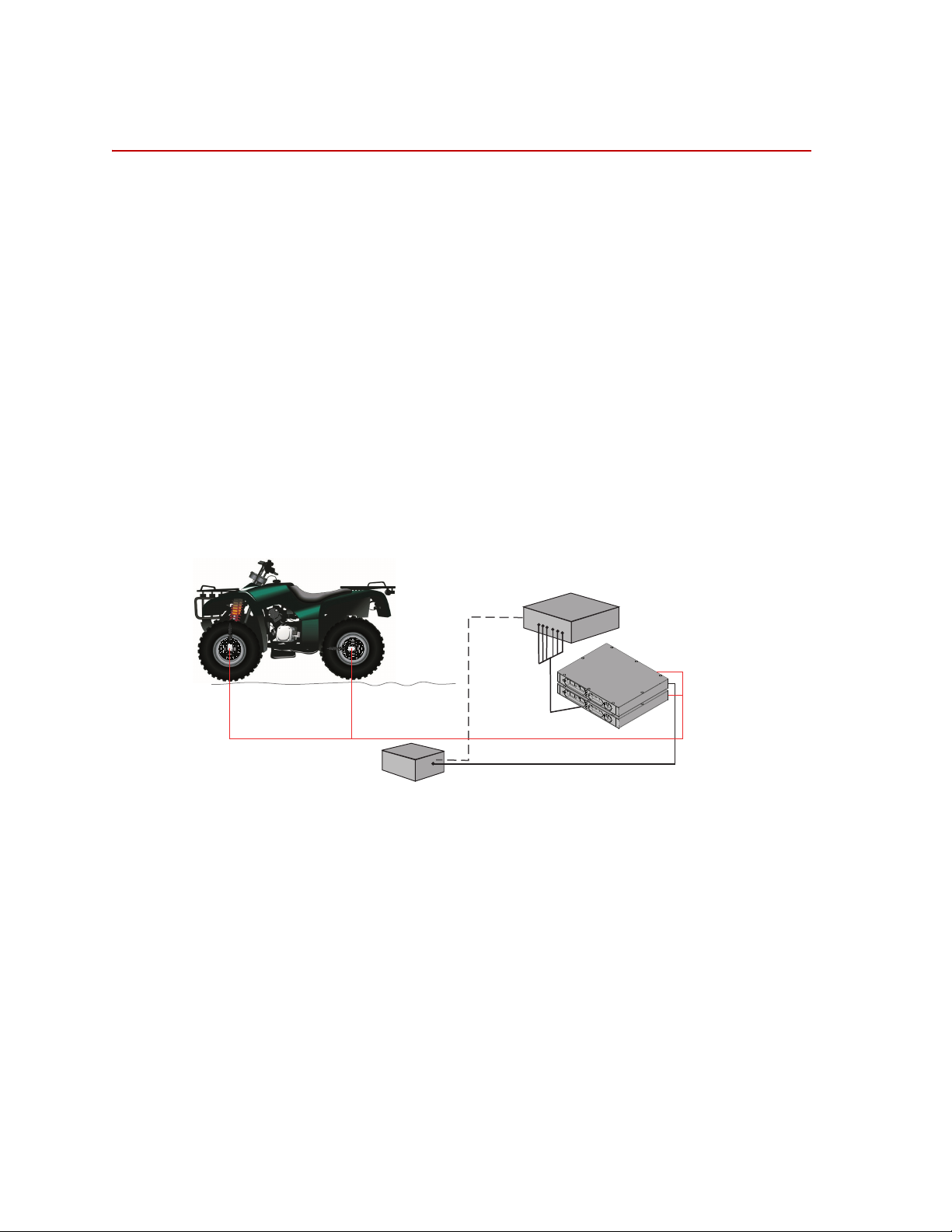

Spinning Applications (Track or Road)

Customer Supplied

Power Supply

Customer Supplied

Data Recorder

Transducer

Interface (TI)

Transducer Signals

Output

Signals

S10-02

Spinning Applications (Track or Road)

The SWIFT sensor can be used for road load data acquisition (RLDA)

applications:

• Durability

• Noise, Vibration and Harshness (NVH)

• Ride and Handling

• Tire Performance

The transducer is durable enough to withstand harsh road testing and data

acquisition environments. The transducer is splash resistant and suitable for use

in conditions where the test vehicle will encounter occasional standing or running

water, or will be exposed to precipitation. However, it should not be submerged.

In a typical spinning application, the transducer is mounted on a modified rim of

a tire on a test vehicle, as shown in the following figure. The Transducer

Interface (TI), power supply, and data recorder can be securely mounted on a

carriage rack. The TI box should be protected against environmental conditions

(water and mud splashes and dust), and it should not be allowed to be immersed.

18

Hardware Overview

Spinning Application (Track or Road)

SWIFT 10 ATV Sensors

Page 19

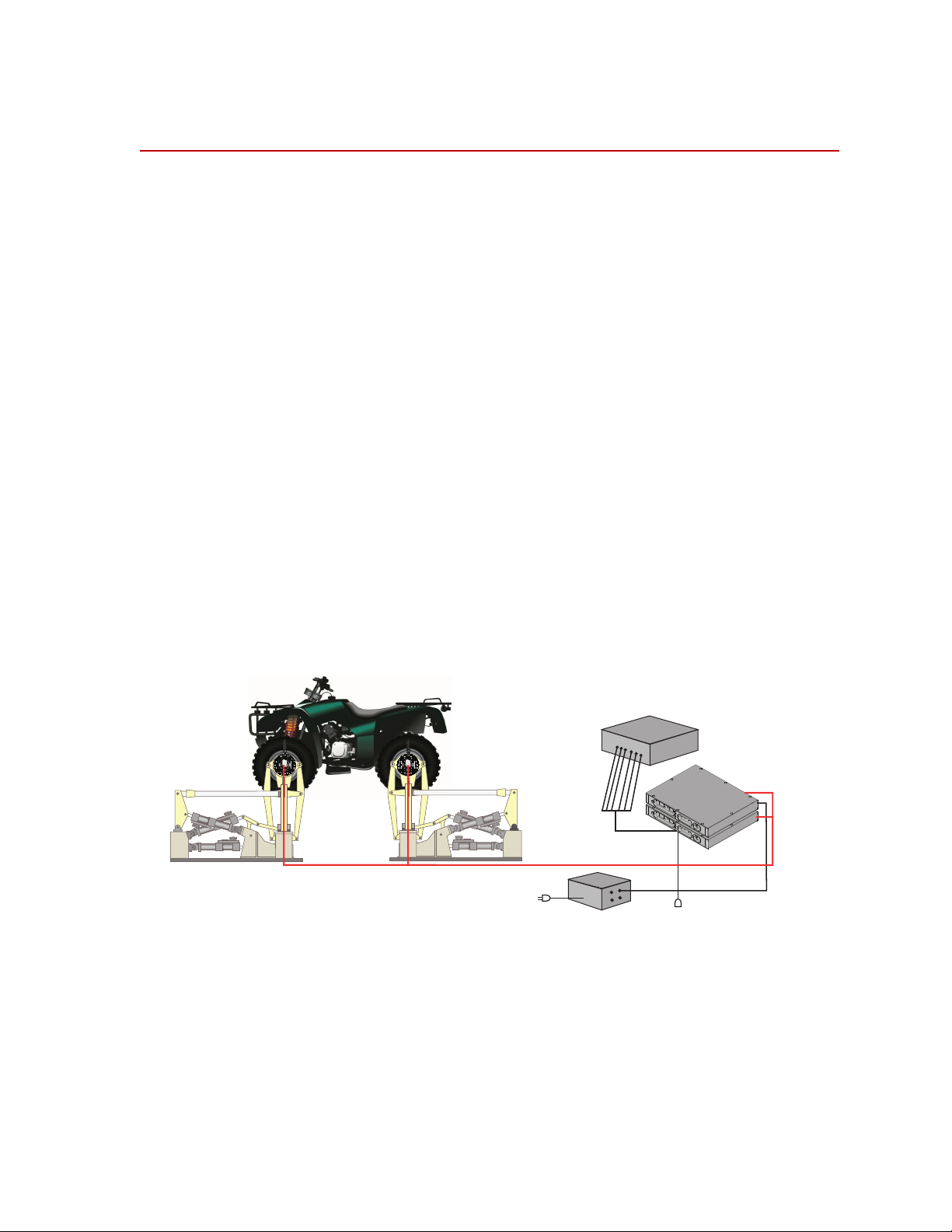

Non-spinning Applications (Laboratory)

Power Supply (with 4

connections)

Customer-Supplied

Test Control System

Transducer

Interface (TI)

Transducer Signals

Output

Signals

PC Communication

S10-03

Non-spinning Applications (Laboratory)

The SWIFT sensor can be fully integrated into the simulation process, since it is

an optimal feedback transducer for use with MTS Remote Parameter Control

®

) software. The transducer takes data at points where fixturing inputs are

(RPC

located rather than at traditional instrumentation points along the vehicle’s

suspension. Using the SWIFT sensor saves you instrumentation time, and fewer

iterations are required to achieve good simulation accuracy.

Measuring spindle loads allows engineers to generate generic road profiles.

Generic road profiles are portable across various vehicle models, do not require

new test track load measurements for each vehicle, and eliminate additional

RLDA tasks.

Several of the six loads measured by the transducer directly correlate to the MTS

Model 329 Road Simulator inputs.

The same transducers used to collect road data can be mounted directly in the

wheel adapters of the MTS Model 329 Road Simulator. For durability testing, the

SWIFT sensor can be used for iterations within the RPC process. The SWIFT

sensor should then be removed for the durability cycles, to preserve its fatigue

life. It can be replaced by an adapter plate, available from MTS, to duplicate the

mass and center of gravity of the actual SWIFT sensor. If a SWIFT sensor is to be

used during full durability tests, we suggest using the titanium model, which has

a higher fatigue rating.

®

In a typical non-spinning application, a SWIFT sensor is mounted on a road

simulation test fixture, as shown in the following figure.

Non-spinning Application (Laboratory Simulation)

SWIFT 10 ATV Sensors Hardware Overview

19

Page 20

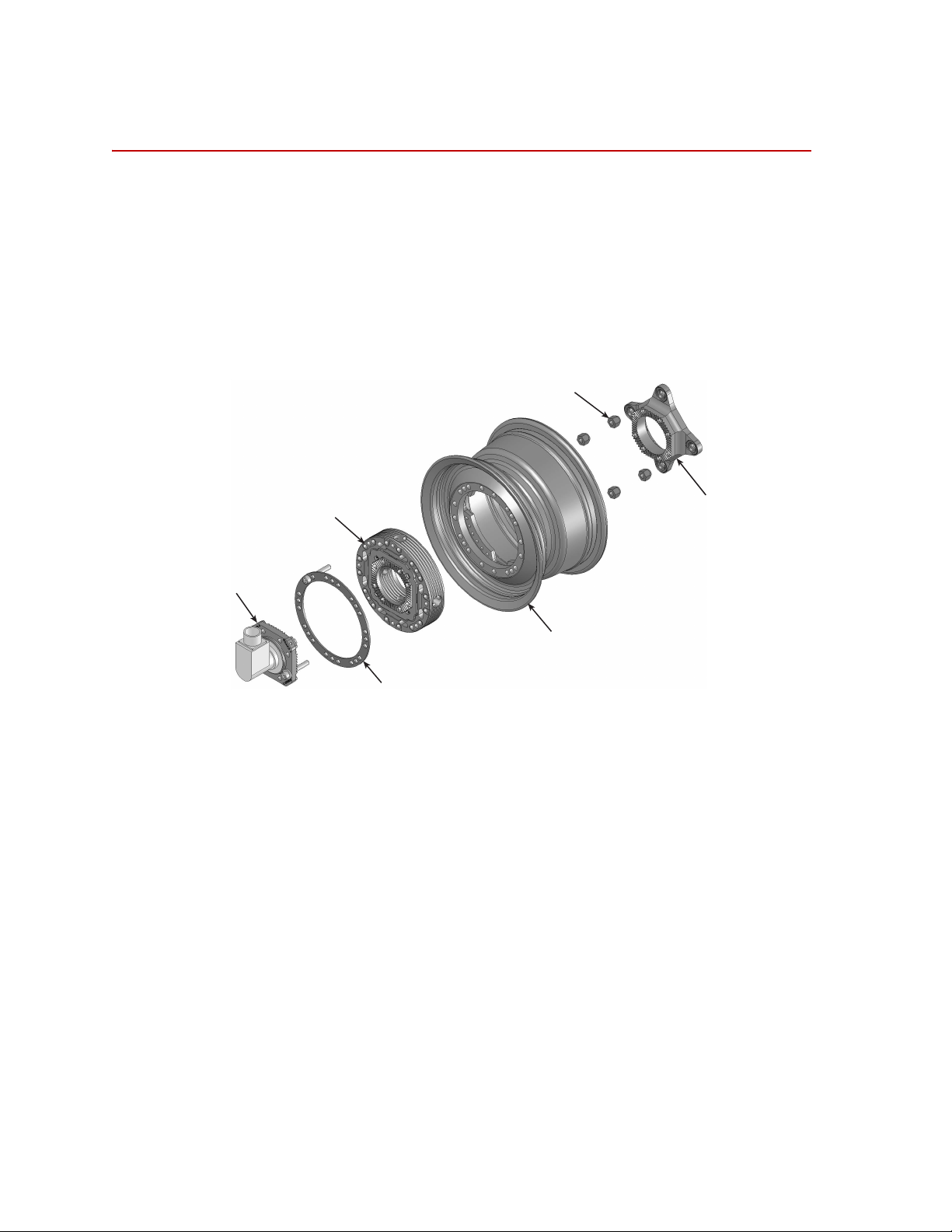

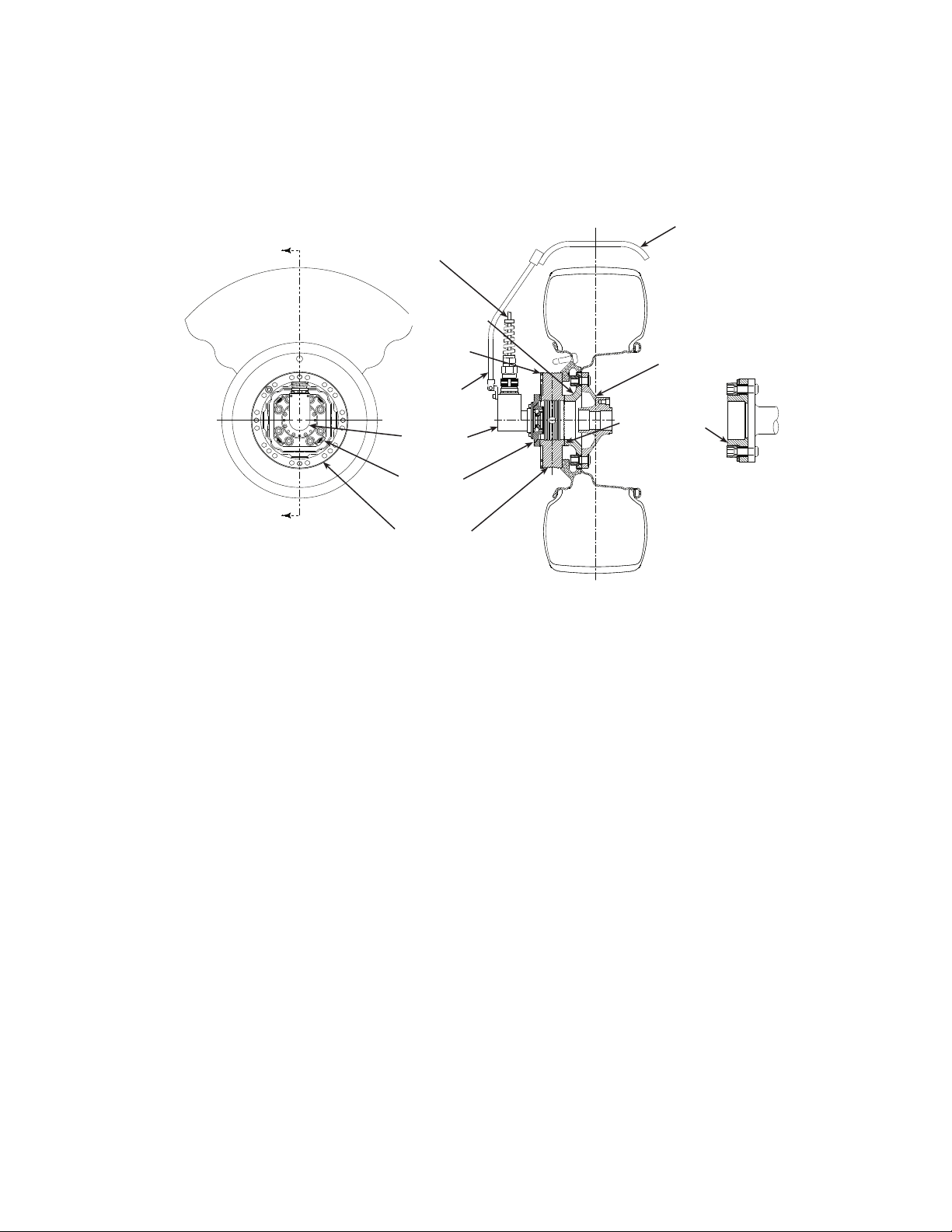

Construction

Slip Ring

Bracket

(with encoder)

Washer

Plate

Transducer

Modified Wheel Rim

Lug Nuts

Inner Hub

Adapter

S10-08

Construction

The SWIFT sensor has one-piece construction for outstanding fatigue life, low

hysteresis, and high stiffness. Its compact package has a minimal effect on inertia

calculations, and a minimal dynamic effect on the test vehicle.

The transducer can be used for developing conventional durability tests on the

MTS Model 329 Road Simulator. Normally, the transducer is replaced with an

equivalent wheel adapter after the simulation drive signals are developed and

prior to the start of the test.

The SWIFT sensor includes several mechanical and electrical components.

Hardware Overview

20

Transducer The transducer attaches directly to a modified wheel rim. On the test track

vehicle, the transducer spins with the wheel. On a road simulator, the transducer

attaches directly to an adapter plate on the 329 spindle housing. The slip ring can

be used to accommodate the range of motion of the rear swing arm.The

transducer is available in two materials.

The transducer’s unibody design means there are no multiple parts welded or

screwed together.

The transducer has four beams with strain gages that measure six orthogonal

outputs:

Fx—longitudinal force

Fy—lateral force

Fz—vertical force

Mx—overturning moment

My—acceleration and brake torque

Mz—steering moment

It has onboard conditioning and amplifiers to improve the signal-to-noise ratio.

SWIFT 10 ATV Sensors

Page 21

Construction

Anti-Rotate

Assembly

Slip Ring

and Encoder

Slip Ring

Bracket

Alternate

Spindle Hub

Interface

(for hub piloted

spindle)

Coupling Teeth

Interface

Transducer

Interface

Cable

Washer

Plate

Transducer

Vehicle

Spindle Hub

Inner

Hub Adapter

Anti-Rotate

Mounting Bracket

(customer supplied)

S10-04

Inner hub adapter The inner hub adapter attaches to the inner diameter of the transducer and the

spindle face of the vehicle. The inner hub adapter enables you to maintain the

original position of the tire on the vehicle (the tire will not protrude from the

vehicle) while the transducer is attached to the vehicle.

Components Set Up for Test Track

Slip-ring bracket The slip-ring bracket attaches the slip ring to the transducer. It has internal wiring

that provides excitation power to the strain gage bridges and brings signals out

from the transducer to the slip ring.

Encoder An encoder measures the angular position of the transducer. The SWIFT sensor

encoder is integrated into the slip ring assembly, and counts off “ticks” to

measure the angular position as the wheel rotates. It measures 2048 (512 pulse

quadrature) points per revolution (ppr) with a resolution of 0.18 degrees.

Slip ring The slip ring allows you to output the transducer bridge signals and angular

position to the TI. A transducer data cable attaches from the slip ring to the back

panel of the TI.

Anti-rotate device The anti-rotate device is attached to the slip ring and the vehicle’s suspension (or

other non-rotating point). It is able to move up and down with the vehicle. Its

primary function is to provide a fixed reference point for the angle sensor. Its

secondary function is to prevent the cable from rotating with the wheel and

becoming tangled or breaking.

The slip ring and anti-rotate device are used mainly for road data collection.

Although it can also be used for short periods of time on a road simulator. MTS

does not recommend this use. Due to the extreme fatigue loading characteristics

SWIFT 10 ATV Sensors Hardware Overview

of durability testing on road simulators, we suggest that you either remove the

slip ring assembly before installing the vehicle on a road simulator, or use it only

for iteration passes, then promptly remove it.

21

Page 22

Construction

The anti-rotate device should be configured such that no loading occurs to the

slip ring throughout all loading and suspension travel. This means that when you

attach the anti-rotate device to the vehicle, you must consider all possible motion

of the suspension. The anti-rotate device should not bump against the wheel well

at any time; any jarring of the anti-rotate arm will damage the slip ring. For

steering axles, the anti-rotate bracket must be mounted to part of the unsprung

suspension that steers with the tire, such as the brake caliper. For additional antirotate device mounting recommendations, refer to the Anti-Rotate Customer/

User Assembly drawing at the back of this manual.

Transducer Interface

(TI)

Additional

components

The TI provides power to the transducer and uses previously stored calibration

values to convert the raw transducer signals from the bridge outputs and the

encoder to three force outputs (Fx, Fy, Fz), three moment outputs (Mx, My, Mz)

and an angle output. The force and moment outputs have a value of 10 V full

scale, unless a different full-scale output is requested by a customer. The angle

output is a 0–5 V sawtooth output.

Additional components that are supplied with your SWIFT sensor include

transducer data cables, TI power cable, a SWIFT Transducer Interface Utilities

CD or disk, and the calibration file. MTS can also provide a 12 V DC power

converter for use in the test laboratory.

Hardware Overview

22

SWIFT 10 ATV Sensors

Page 23

Design Features

Flexure isolation The SWIFT sensor has a very stiff outer ring and flexured beam isolation which

Thermal stability The entire sensor is machined from a solid, specially forged billet of high

Construction

render it relatively insensitive to stiffness variations in matings with rims and

road simulator fixtures.

Flexure isolation minimizes thermal expansion stresses. With flexure isolation, if

the inner hub experiences thermal expansion the beams are allowed to expand

out, resulting in lower compressive stress on the beams.

strength titanium or aluminum. The absence of bolted joints permits an efficient

transfer of heat across the sensor structure, minimizing temperature differentials

in the gaged area.

The transducer is designed to accommodate the high temperature environments

that occur during severe driving and braking events. Individual temperature

compensation of each strain gage bridge minimize temperature induced

variations in accuracy. Since minimal electronics reside on the SWIFT sensor, it

can easily tolerate high temperatures. The temperature rating for the SWIFT

sensor is 125° C (257° F) at the spindle hub.

Temperature compensation is done on each bridge for better performance in

transient or non-uniform temperature occurrences.

Low hysteresis The SWIFT sensor has very low hysteresis, since the sensing structure is

constructed with no bolted joints. Micro slippage in bolted joints contributes

most of the hysteresis in highly stressed structures. Hysteresis errors due to

micro-slip at joints can contribute to unresolvable compounding errors in

coordinate transformation of the rotating sensor.

Low noise The SWIFT sensor uses a slip ring rather than telemetry for the transducer output

signals. On-board amplification of the transducer bridges minimizes any slip ring

noise contribution.

Low cross talk The advanced design of the SWIFT sensor means that it has very low cross talk.

The alignment of the sensing element is precision machined. This alignment is

critical to achieving minimum cross talk error between axes and minimum errors

in coordinate transformation (from a rotating to a non rotating coordinate

system). Any small amount of cross talk present is compensated by the TI.

Velocity information Angular output is available from the TI when it is used in the spinning mode with

the encoder. This angular output can be used to calculate wheel velocity. In nonspinning applications, accelerometers can be integrated into the transducer

connector housing.

MTS does not supply any conditioning electronics for accelerometers. Ask your

MTS consultant for more information about this option.

SWIFT 10 ATV Sensors Hardware Overview

23

Page 24

Coordinate System

Fx

Fy

Fz

Mz

Mx

My

Transducer

Interface

Output signals

±10 Volts

Angular

Position

Bridge

Outputs

S10-10

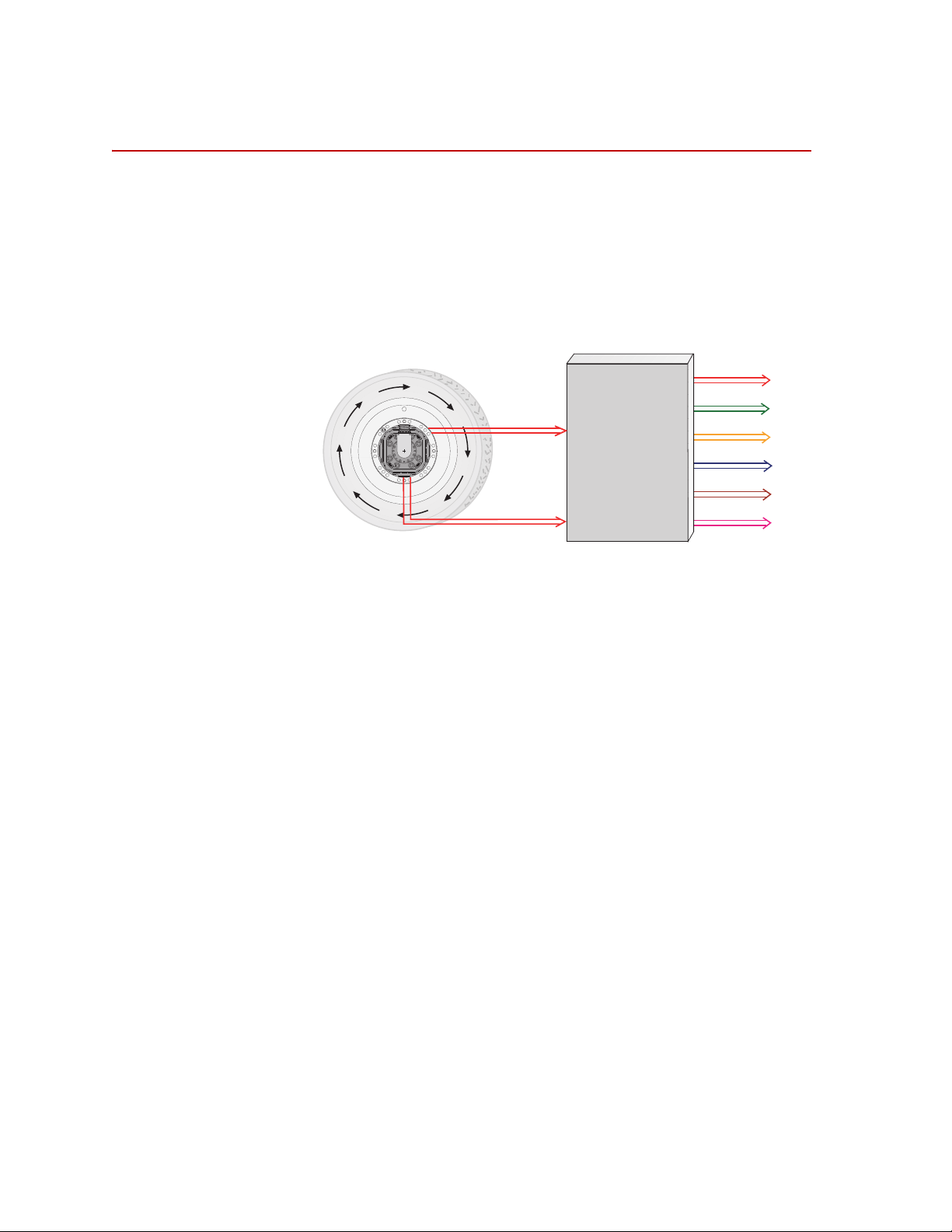

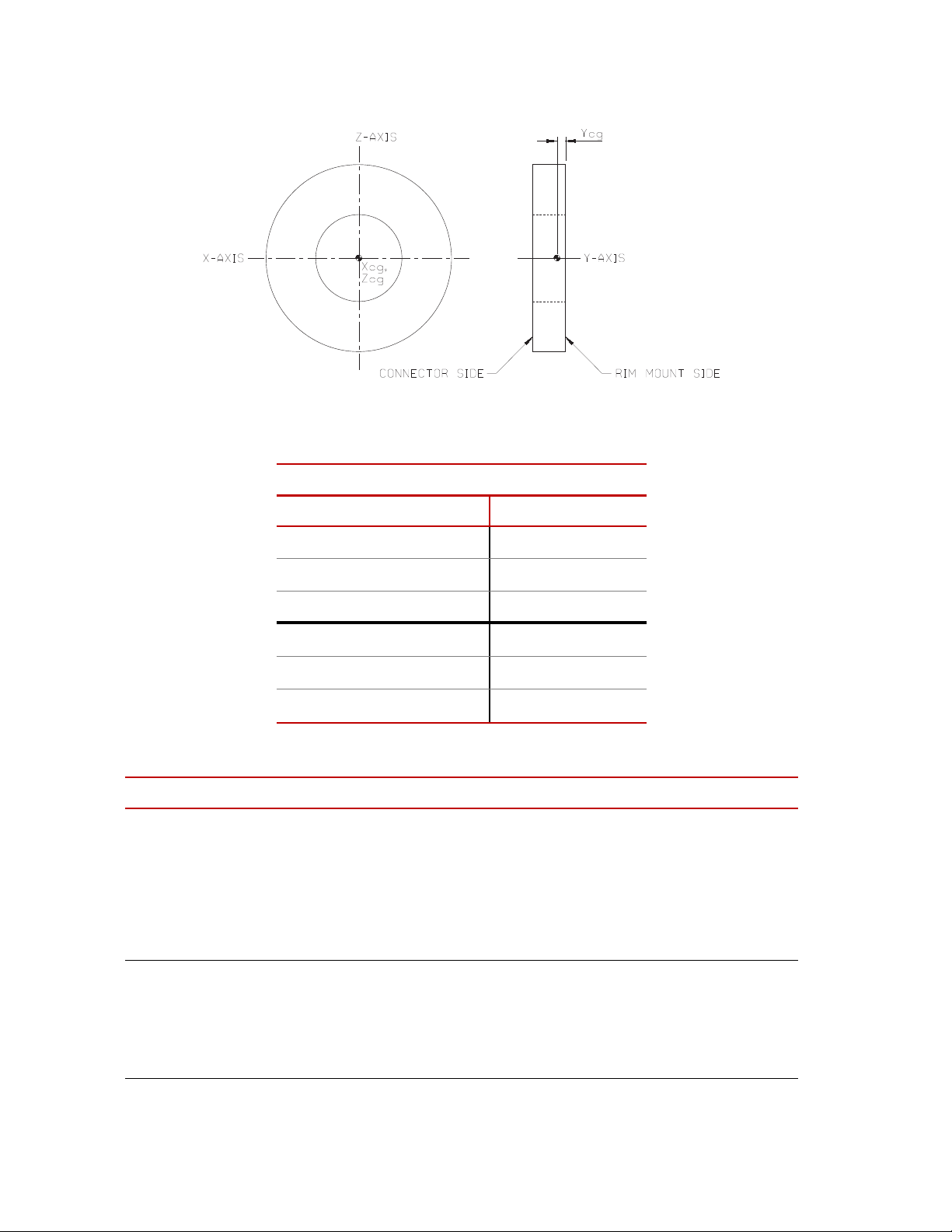

Coordinate System

In the transducer, independent strain gage bridges measure forces and moments

about three orthogonal axes. The signals are amplified to improve the signal-tonoise ratio. An encoder signal measures angular position, which is used to

convert raw force and moment data from the rotating transducer to a vehiclebased coordinate system. The force, moment, and encoder information are sent to

the transducer interface (TI).

The TI performs cross talk compensation and converts the rotating force and

moment data to a vehicle coordinate system. The result is six forces and moments

that are measured at the spindle: Fx, Fy, Fz, Mx, My, and Mz. A seventh

(angular) output is available for tire uniformity information, angular position, or

to determine wheel speed (depending on the data acquisition configuration).

Hardware Overview

24

SWIFT 10 ATV Sensors

Page 25

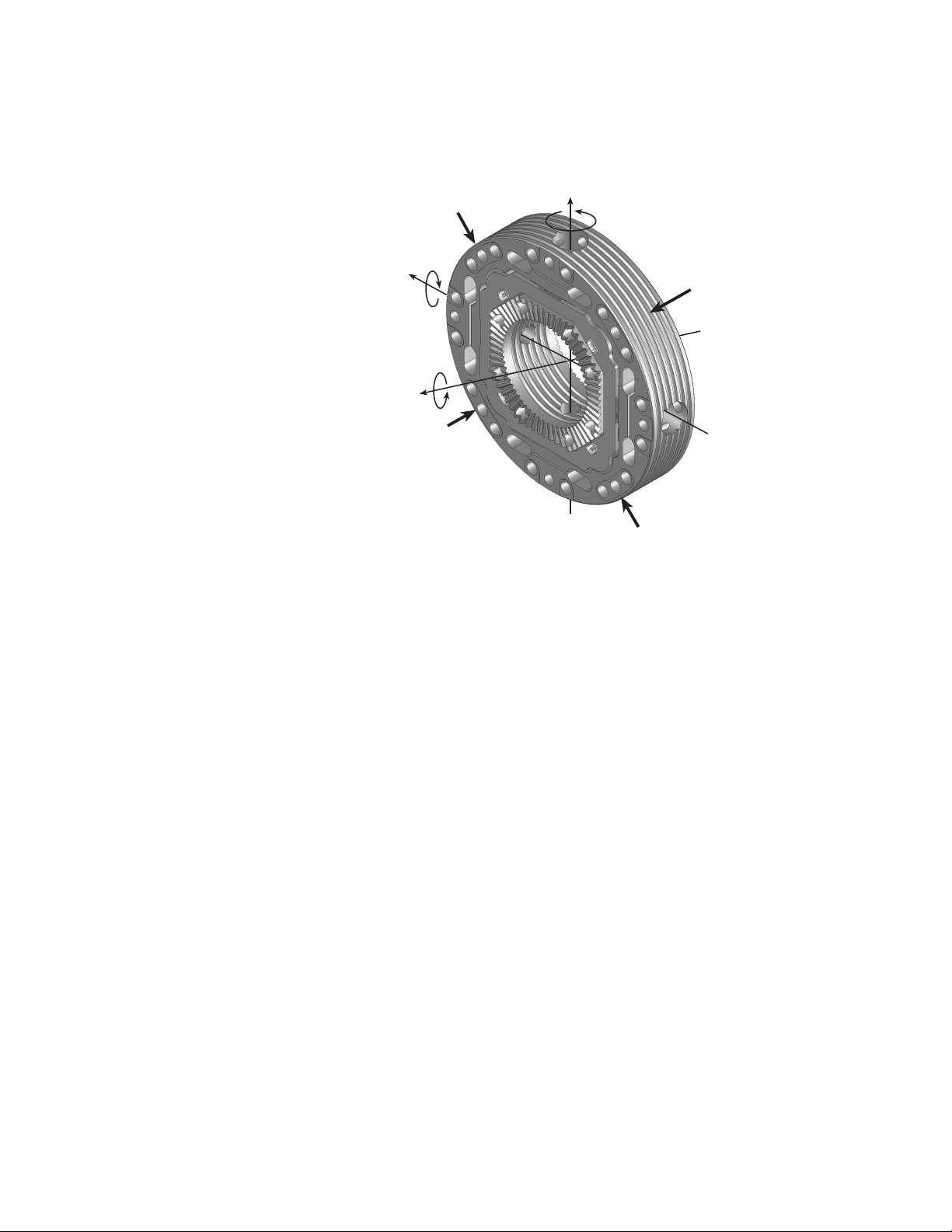

Coordinate System

+Fz

+Mz

+Fx

+Fy

S10-09

Forces Acting on Rim-side of Transducer

Hub Adapter

Mounting Side

Rim Flange

Mounting Side

+Mx

+My

The coordinate system shown below was originally loaded into the TI settings by

MTS. It uses the right-hand rule.

The SWIFT coordinate system is transducer-based, with the origin located at the

center of the transducer. Positive loads are defined as applied to the outer ring of

the transducer.

• Vertical force (Fz) is positive up.

• Lateral force (Fy) is positive out of the vehicle.

• Longitudinal force (Fx) follows the right-hand rule, consistent with Fz and

Fy described above.

You can change to the MTS Model 329 Road Simulator convention (lateral load

into the vehicle is always positive) or to any coordinate system by changing the

polarities in the calibration file. For instructions on how to change the coordinate

system polarities, see the chapter, “Setting up the Transducer Interface”.

SWIFT 10 ATV Sensors Hardware Overview

25

Page 26

Specifications

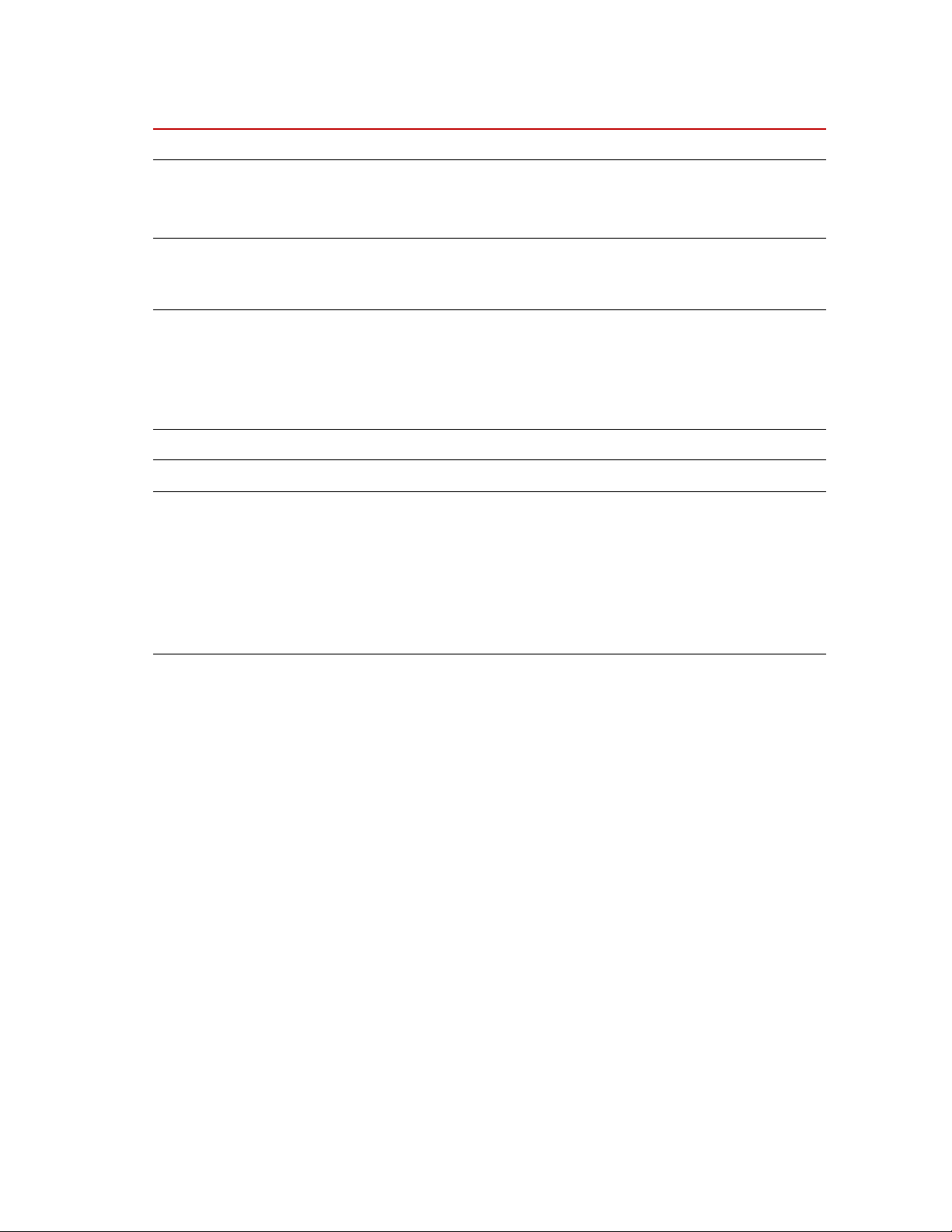

Specifications

SWIFT 10 ATV Transducer Performance (part 1 of 2)

P

ARAMETER SPECIFICATION

Use

SWIFT 10 ATV (aluminum) for:

SWIFT 10 ATV (titanium) for:

Maximum usable rpm

Maximum speed

Shock resistance, each axis

Fits rim size (usable range)

Number of Lug nuts accommodated

Hub bolt circle diameter accommodate

Wheel stud size accommodated

Input voltage required

Input power required per transducer

Output voltage ± full scale calibrated load

SAE J328

Rated load capacity

Bending moment

Full scale calibrated ranges

Resolution

Performance accuracy

Nonlinearity

Hysteresis

Modulation

Cross talk

Maximum operating temperature

Assembly Weight – single wheel

Transducer

Aluminum hub adapter/spacer

Slip ring assembly

Modified aluminum rim

Lug nuts

Outer steel washer plate

Attached fasteners

Total

#

‡

§

**

low weight, high sensitivity, lower measured forces

1.45 kN•m (12 869 lbf•in)

Consult the calibration range sheet that accompanies each

transducer

high fatigue life, longer durability, higher loads

2,200

250 kph (155 mph)

150 G

7-12 inch

*

4

All

All

9–30 V DC

7 Watts maximum (22 Watts typical)

†

±10 V

Aluminum

2.5 kN (550 lbf)

Titanium

4.2 kN (925 lbf)

4.76 kN•m (42117 lbf•in)

Infinite

1.0% full scale

0.50% full scale

≤5.0% reading

1.5% full scale

125°C (257°F

1.4 kg (3.0 lb)

0.5 kg (1.0 lb)

0.5 kg (1.1 lb)

2.4 kg (5.3 lb)

0.1 kg (0.2 lb)

0.2 kg (0.4 lb)

0.8 kg (1.8 lb)

5.8 kg (12.8 lb)

2.0 kg (4.5 lb)

0.5 kg (1.0 lb)

0.5 kg (1.1 lb)

2.4 kg (5.3 lb)

0.1 kg (0.2 lb)

0.2 kg (0.4 lb)

0.8 kg (1.8 lb)

6.5 kg (14.3 lb)

Hardware Overview

26

SWIFT 10 ATV Sensors

Page 27

Specifications

SWIFT 10 ATV Transducer Performance (part 2 of 2)

P

ARAMETER SPECIFICATION

Output connector type

Auto shunt calibration

* Contact MTS for other rim sizes. Larger diameter rims can be used, provided that overall clearance from

brake calipers and suspension components is maintained.

† Load impedance >1 k

‡ Half axle rated capacity per SAE J328.

§ Moment fatigue-rated for 100,000 cycles.

# Each SWIFT sensor is calibrated on an MTS calibration machine. MTS provides complete documentation

of calibration values for each SWIFT unit

** Measured at the spindle hub.

Ω; 0.01 µF (maximum) load capacitance.

D-shell or BNC via adapter

On vehicle or laboratory test rig.

SWIFT 10 ATV Sensors Hardware Overview

27

Page 28

Specifications

Transducer Center-of-Gravity

Transducer Center-of-Gravity and Inertia Specifications

M

ATERIAL

ALUMINUM TITANIUM

X

0.0 mm 0.000 in 0.0 mm 0.000 in

cg

Y

18.0 mm 0.710 in 18.0 mm 0.710 in

cg

Z

0.0 mm 0.000 in 0.0 mm 0.000 in

cg

I

xx

26 kg·cm29 lbm·in

I

yy

50 kg·cm217 lbm·in280 kg·cm227 lbm·in

I

zz

26 kg·cm29 lbm·in

2

42 kg·cm214 lbm·in

2

42 kg·cm214 lbm·in

Transducer Interface (part 1 of 2)

P

ARAMETER SPECIFICATION

Physical

Height

Width

Depth

Weight

Rack Mounting Kit

28 mm (1.100 in)

213 mm (8.375 in)

171 mm (6.750 in.)

0.907 kg (30 oz)

Optional

2

2

2

*

Environmental

Ambient temperature

Relative humidity

Protection

Hardware Overview

28

0° C (32° F) to 50° C (122° F)

0 to 90%, non-condensing

IP64 (complete dust protection, projected water

from all directions)

SWIFT 10 ATV Sensors

Page 29

Transducer Interface (part 2 of 2)

P

ARAMETER SPECIFICATION

Power Requirements

Input voltage

Fuses

10–28 V DC

Internal thermal, self-resetting

Specifications

Power Consumption

4 Watts maximum without transducer or encoder

6 Watts typical with transducer and encoder at 12

V DC

Angular velocity

Encoder limit

Processing limit

Encoder resolution

2,200 rpm maximum

10,000 rpm maximum

2048 counts per revolution

(512 pulses with quadrature)

Time delay (encoder tick to main output stable)

Transducer cable length

Analog outputs

Vol tag e

150 µs (typical)

100 ft maximum

±10 V range† (force and moment outputs)

0–5 V sawtooth (angle output)

Capacitive load

Current

Noise at output, with typical gains

0.01 µF maximum

2 mA maximum

7 mVpp, DC - 500 Hz (typical)

15 mVpp, DC - 500 Hz (maximum)

* Add 25.4 mm (1.0 in) for ground lugs.

† Standard from MTS. Other full scale voltages can be evaluated and may be provided at special

request.

SWIFT 10 ATV Sensors Hardware Overview

29

Page 30

Calibration

Calibration

Each transducer is calibrated by MTS before shipment. The transducer and TI

may be returned to MTS for repair and recalibration as required.

Calibration is performed at MTS on a special fixture that is capable of applying

multiple loads to the transducer. During calibration, raw signals are measured.

The calibration gains and cross talk compensation values are computed from this

raw data. These gains are recorded in a calibration file.

A unique calibration file is supplied for each transducer. The serial number of the

TI associated with the transducer is listed at the top of the calibration file. A label

with the serial number of the TI box (and the SWIFT sensor with which it was

originally calibrated) is attached to the back of each TI box.

The calibration file is loaded into the TI non-volatile memory by MTS before the

transducer is shipped. A copy of the file is also provided on a diskette.

MTS verifies the calibration by applying loads to the transducer, measuring the

main outputs and checking for accuracy. Final calibration reports are provided

with each transducer.

Shunt calibration At the end of the calibration process, a shunt calibration is performed. During a

shunt calibration, a resistance is introduced into the bridge circuit. The difference

between the shunted and unshunted voltage is the delta shunt reference value for

each bridge. That value is saved in the calibration file, which is downloaded from

a PC or laptop computer and stored in non-volatile memory in the TI.

At any time afterward, pressing the Shunt button on the front of the TI causes

each of the strain gage bridges to be shunted in sequence, and the measured shunt

voltage (delta shunt measured value ) is compared to the reference value.

An acceptable tolerance range is also loaded into the TI memory during system

calibration. One tolerance value is used for all bridges. This value is loaded as a

percentage of allowable deviation from the delta shunt values. For example, if the

FX1 bridge has a shunt delta reference value of –3.93, and the tolerance is set at 2

(percent), the acceptable range for the measured value would be –3.85 to –4.01.

Hardware Overview

30

SWIFT 10 ATV Sensors

Page 31

Calibration

When you press the Shunt button, the associated Shunt indicators toggle while

the shunt is in progress. As the TI automatically switches through the series of

bridges, it verifies that the outputs are within the accepted tolerance range. If all

bridge shunt values fall within the tolerance range, the Shunt indicators on the

front panel will go off (after several seconds). If any bridge fails the shunt test,

the red, fail indicator lights, indicating that the shunt calibration has failed. The

fail indicator remains lit until a shunt check passes or until you cycle power off

and on. Use the TI2STATUS utility to get more detailed information about the

shunt failure.

ShuntTolerance=2

FX1ShuntDeltaRef=-1.379

FX2ShuntDeltaRef=-1.386

FY1ShuntDeltaRef=-1.381

FY2ShuntDeltaRef=-1.378

FY3ShuntDeltaRef=-1.382

FY4ShuntDeltaRef=-1.381

FZ1ShuntDeltaRef=-1.380

FZ2ShuntDeltaRef=-1.380

FX1ShuntDeltaMeas=-1.378

FX2ShuntDeltaMeas=-1.386

FY1ShuntDeltaMeas=-1.380

FY2ShuntDeltaMeas=-1.379

FY3ShuntDeltaMeas=-1.382

FY4ShuntDeltaMeas=-1.382

FZ1ShuntDeltaMeas=-1.385

FZ2ShuntDeltaMeas=-1.382

Checking the

calibration

Example of Calibration File Shunt Data

The above example shows shunt data from the calibration file. This data may be

transferred, using the TI2XFER program, from the transducer interface memory

to a computer or from a computer to the transducer interface memory. Note that

items marked ShuntDeltaMeas are uploaded from memory, but not downloaded

from the computer.

For more information on TI2XFER, see the chapter, “Software Utilities”.

You can check the calibration of a transducer at any time by pressing the Shunt

switch (described earlier). Subsequent shunt commands compare the current

feedback values against those stored in the TI. You may set the tolerance values

for each TI by editing the calibration file. See the chapter, “Setting up the

Transducer Interface”, for instructions.

SWIFT 10 ATV Sensors Hardware Overview

31

Page 32

Transducer Interface

Fx

Fy

Fz

Mz

Mx

My

Transducer

Interface

Output signals

(±10 Volts)

Angular

Position

Bridge

Outputs

Transducer bridge output

signals and encoder

angular position signal are

sent through slip ring

Transducer Interface

converts signals to non-

spinning vehicle coordinates,

applies calibration gains and

cross talk compensation

Force, moment, and

angle analog signals

are output from

Transducer Interface

q

Angle signal

(05 Volts)

S10-05

Transducer Interface

The TI performs cross talk compensation, transforms the loads from a rotating to

a non-rotating coordinate system, and produces an analog output signal suitable

for any data recorder.

Cross talk

compensation

Cross talk occurs when a force is applied to one axis, but a non-real force is

measured on another axis. The SWIFT sensor design has very low inherent cross

talk. The TI compensates for cross talk by subtracting cross talk values measured

during calibration.

Signal conditioning The TI is specifically designed to be used for both spinning and non-spinning

applications. The TI performs signal conditioning and communications

functions. The output from the TI is a high-level signal suitable for input into a

multichannel data recorder or an MTS Automated Site Controller (ASC).

32

Hardware Overview

SWIFT 10 ATV Sensors

Page 33

Transducer Interface

Fx1

Fx2

Fy1

Fy2

Fy3

Fy4

Fz1

Fz2

Fx

Fy

Fz

Mx

My

Mz

Geometric

Matrix

Zero and

Scaling

q

Cross

Coupling

Matrix

Rotational

Transformation

q

Inputs Outputs

Transducer Interface Functions

S50-011

The TI transforms eight inputs (amplified bridge signals) into three forces and

three moments by the following process:

• Applying a zero offset and scaling the signals

• Using a geometric matrix to transform the signals into three forces and three

moments in the transducer reference frame

• Using a cross-coupling matrix calculation to scale and sum the individual

signals into each output

• In spinning applications, using a rotational transformation to put the forces

and moments into a stationary reference frame

The TI conditions the transducer signals, producing seven analog output signals

proportional to the following values:

• Longitudinal force (Fx)

• Lateral force (Fy)

• Vertical force (Fz)

• Overturning moment (Mx)

• Driving/Braking moment (My)

• Steering moment (Mz)

• Angle output (θ)

Analog signals The force and moment signals are output from the TI in the form of ±10 V

scale analog signals. These signals can be used by most data acquisition systems.

The angle output is an analog voltage that is proportional to angular position. At

0° the output is 0 V. At 360°, the output is 5 V.

1

full

1. Standard from MTS. Other full-scale output voltages can be evaluated and may be

provided at special request.

SWIFT 10 ATV Sensors Hardware Overview

33

Page 34

Transducer Interface

0 360°

5V

0° 360°

q

Angle

Output

1 rev = 360°

S20-10

The angle output for a tire rotating at constant velocity can be represented by the

following illustration:

Although you may not routinely use it, the angle output information is available

for tasks such as tire uniformity testing and troubleshooting. You may also

calculate angular velocity by measuring the frequency of the angle output signal.

If using the sawtooth angle output for analysis or computing velocity, care should

be taken when setting the data acquisition to avoid filter-induced ringing or

attenuation of the sawtooth output.

Communications The TI uses USB 2.0 for communication. The MTS supplied USB drivers must

be installed on each computer you connect to the TI.

Hardware Overview

34

SWIFT 10 ATV Sensors

Page 35

TI Front Panel

Power button and

Indicator and Fail

Indicator

Shunt button and Indicators

Zero button and Indicators

J5 USB Connector

J4 I/O Connector

Transducer Interface

Transducer Interface Front Panel

Power button and

Indicator

Shunt button and

indicators

Zero button and

indicators

The power button turns power on and off. Pressing and holding the button turns

on power and initializes the TI. During initialization, all indicators turn on

momentarily. When initialization is complete, all indicators will turn off with the

exception of the green Power indicator.

Pressing this button performs a shunt calibration (shunt cal) of the transducer.

You do not need to hold the button in continuously, only until the Shunt

indicators light up (indicating that the TI has started the shunt cal). The two

indicators will alternately toggle on and off as the TI sequences through the shunt

calibration of each bridge.

Before you perform a shunt cal, check that the appropriate shunt reference value

and error tolerance have been downloaded (these values are normally loaded

during system calibration, and are referred to as the shunt delta cal values).

A shunt calibration will determine the current delta values by measuring the

bridges unshunted and shunted values, and then compare these values to the

previously loaded calibration values.

If the measured values are outside of an acceptable tolerance the red status

indicator under the Power indicator with light.

Note The state of the shunt cal check is cleared at power-up, so the shunt cal

should be performed when the system installation is in question.

The zero button is used to zero the transducer inputs. When you press the button,

the TI executes the ZeroAlgorithm that you specify in the calibration file (see

following illustration).

J5 USB connector The USB connector is a standard USB 2.0 type B connector for output to a laptop

or PC with the correct drivers installed.

J4 I/O connector Not used at this time.

SWIFT 10 ATV Sensors Hardware Overview

35

Page 36

Transducer Interface

J3 Transducer Connector

J2 Output Connector

J1 Power Connector

TI Rear Panel

Transducer Interface Rear Panel

J1 Power connector Connect a power cable from the external power source.

J2 Output connector The J2 Output connector provides the conditioned sensor outputs that can be

connected to a data acquisition or test control system.

J3 Transducer

connector

Connect the data cable from the transducer slip ring to the Transducer Connector.

36

Hardware Overview

SWIFT 10 ATV Sensors

Page 37

Interfacing with RPC

The SWIFT sensor is directly compatible with the MTS Remote Parameter

Control (RPC) simulation software. The SWIFT system produces outputs that

directly correspond to the uncoupled spindle forces that the MTS Model 329

Road Simulator applies to the vehicle. Traditional instrumentation techniques

provide coupled suspension loads data. Using the SWIFT sensor, the RPC

simulation software needs to apply less correction to obtain the road simulator

drive signals. Fewer iterations are required to recreate the measured loads.

You must ensure that the full scale value for your data recorder and the MTS

electronics match. MTS electronics are typically set at ±10 V full scale, while

some data recorders are ±5 V full scale.

The SWIFT sensor is calibrated for ±10 V full scale. To recompute the TI gains

for ±5 V full scale, a verification pass must be run or the calibration will not be

traceable. Upon special request, MTS can evaluate and may provide calibration

for ±5 V or other full scale voltages.

Interfacing with RPC

SWIFT 10 ATV Sensors Hardware Overview

37

Page 38

Interfacing with RPC

Hardware Overview

38

SWIFT 10 ATV Sensors

Page 39

Software Utilities

Contents Introduction 40

TI2STATUS - Transducer Interface Status 41

TI2XFER - Transducer Interface Transfer 43

TI2SHUNT - Transducer Interface Shunt 45

Setting Up Shunt Calibration Reference Values 48

Error Messages 49

SWIFT 10 ATV Sensors Software Utilities

39

Page 40

Introduction

Introduction

The SWIFT utility programs in this distribution are for Win32 Operating

Systems (Windows 2000 and XP). They are designed to be run from the

Command Prompt or MSDOS Shell. However, it is possible to create a shortcut

to run the programs. If launched from a shortcut the application window may

close immediately when the application terminates making it impossible to see

any error messages. The Command Prompt application is usually found in

Start–>Programs–>Accessories but the actual location depends on the version

of your operating system.

To run a SWIFT utility program

• Copy it to your computer. For example, create the folder

the executables (*.exe) to that folder.

• Launch Command Prompt

• Change the working directory to where you copied the executables: cd bin.

This step can be eliminated if you set up the PATH environment variable to

include the directory where you copied the SWIFT utility executables.

• Type the name of a SWIFT utility program providing the necessary

command line arguments, for example:

from the TI box. Then select the desired function, for example:

to upload settings from the TI box. If no command line arguments are

provided the program will display a simple help message. This is helpful if

you forget the order of the command line arguments.

1

ti2xfer to transfer settings to or

C:\bin and drag

2

Choice 1

Software Utilities

40

1. You may want to change the layout properties for the Command Prompt

window to display a larger area or to increase the screen buffer size. Within

Command Prompt, select Properties and the Layout tab to modify the

screen buffer size or window size.

2. In Windows 2000 and Windows XP, the environment variables can be

changed at

Start–>Settings–>Control Panel–>System. Click on the Advanced tab,

and the Environment Variables button. The path is a system variable.

Adding

string will cause Command Prompt to search that directory for

applications.

;c:\bin, or whatever directory name you used, to the end of the

SWIFT 10 ATV Sensors

Page 41

TI2STATUS - Transducer Interface Status

TI2STATUS - Transducer Interface Status

This program gets status information from the SWIFT Transducer Interface (TI)

when the TI has encountered a problem and the red failed indicator is lit. You can

use this program to easily interpret the error. For certain errors this program may

provide additional information.

Syntax ti2status

The following is an example of the ti2status command report:

Example

C:\bin>ti2status

SWIFT Mini TI status (Version 1.3)

Fatal error: NONE

Boot Loader version: 1

FPGA version: 10

Firmware version: 24

Zero: Good

Fx1 Shunt: Good

Fx2 Shunt: Good

Fy1 Shunt: Good

Fy2 Shunt: Good

Fy3 Shunt: Good

Fy4 Shunt: Good

Fz1 Shunt: Good

Fz2 Shunt: Good

Calibration data is: Good

Unit serial number: 02036413

Description of TI2STATUS Indications

Fatal Error: Provides an indication that the CPU is unable to run. The message indicates the

possible reason (see, “Error Messages,” on page 49 for a list of the possible

errors).

Boot Loader version: The boot loader is a program that verifies that the main program is complete. The

version number is a reference for use by service personnel (see, “Error

Messages,” on page 49 for a list of the possible errors).

FPGA version: Identifies the version of the functions programmed in the field programmable

gate array. The version number is a reference for use by service personnel.

Firmware Version: Displays the version of the software installed in the TI. This software is stored in

flash memory and if needed can be upgraded in the field by an MTS service

engineer.

SWIFT 10 ATV Sensors Software Utilities

41

Page 42

TI2STATUS - Transducer Interface Status

Zero: Indicates whether the transducer zeroing was successful or not (see, “Error

Messages,” on page 49 for a list of the possible errors).

F## Shunt: Indicates the status of shunt test for each bridge (see, “Error Messages,” on page

49 for a list of the possible errors).

Calibration data is: Indicates the condition of the calibration data (see, “Error Messages,” on page 49

for a list of the possible errors).

Unit serial number: Displays the serial number of the TI box

Software Utilities

42

SWIFT 10 ATV Sensors

Page 43

TI2XFER - Transducer Interface Transfer

TI2XFER - Transducer Interface Transfer

This program is used to read the current settings in the TI and save them to the

computer (upload) or write the values from a calibration file on the computer to a

TI (download).

Syntax ti2xfer

Example The following is an example of the ti2xfer command:

C:\bin>ti2xfer

SWIFT Mini TI transfer (Version 1.0)

Upload and download settings

0...Exit

1...Upload settings from TI box

2...Download settings to TI box

Choice? 1

Filename? sample.cal

0...Exit

1...Upload settings from TI box

2...Download settings to TI box

Choice? 0

File Format The file used with commands contains a header and version number, and a list of

parameters. Transducer calibrations can be uploaded and saved individually. If a

test needs to be rerun at a later date but the original transducer is not available,

another transducer can be used by downloading its calibration information.

The header must be the first thing in the file, and it must be in the form:

[SWIFT]

Following the header is a list of parameter settings. The syntax is:

ParamName=ParamValue

The following rules apply:

Tabs and spaces are allowed.

The parameters can occur in any order

Names are case insensitive. If a parameter name is not recognized, an error

will be reported, and further processing will be stopped.

If an error causes the program to abort while downloading, any parameters

prior to the error will have been successfully downloaded because

parameters are downloaded as they are read.

SWIFT 10 ATV Sensors Software Utilities

43

Page 44

TI2XFER - Transducer Interface Transfer

CAUTION

CAUTION

Make important files (such as those containing calibration data) read-only

after uploading.

If not protected, important data may get overwritten.

Make important files read-only. Make backups of important data.

Check force and moment output signals after downloading new settings.

Downloading new settings may affect Transducer Interface outputs.

After downloading new settings, force and moment output signals should be

monitored to check basic system operation.

More about TI2XFER

files

The calibration files created by TI2XFER are plain text files that can be read by

Microsoft Notepad or WordPad (see the example calibration file on page 55). In

general, use a common extension such as “.cal” to help identify the files, but that

is not required. The settings files contain both configuration settings and

calibration settings. As a general rule parameters that begin with K are

calibration gains and should not be edited.

Whenever downloading settings, make sure the file is for the transducer

connected to the SWIFT Transducer Interface. Usually the filename for the

settings contains the serial number for the transducer. If settings for one

transducer are used with another they will not be accurate. Because the TI is

calibrated by itself, calibration settings for a given transducer can be used with

any TI, however, some calibration methodologies require the transducer, cable

and TI to be used as a calibration set (end-to-end calibration).

The serial number in the TI2XFER settings file is the serial number of the TI that

the settings were first uploaded from.

The bridge and angle zero values will change whenever a zero is activated by

pressing the TI front panel Zero button. Therefore, after a zero is performed the

zero values uploaded will not match those downloaded.

Software Utilities

44

SWIFT 10 ATV Sensors

Page 45

TI2SHUNT - Transducer Interface Shunt

TI2SHUNT - Transducer Interface Shunt

This program is a utility with various functions related to shunts. The SWIFT

system includes the ability to connect a shunt resistor across each of the resistive

bridges in the transducer. This shunt function can be used as a simple verification

that the SWIFT system is working normally. Shunt verification activates the

shunts and compares the results to those recorded during calibration. While this

does not guarantee the transducer is still in calibration, it provides some level of

confidence it is working normally. If the shunt results differ significantly from

those recorded during calibration the SWIFT system should be evaluated for

possible problems.

Syntax ti2shunt

Example

C:\bin>ti2shunt

SWIFT Mini TI Shunt (Version 1.0)

0...Exit

1...Read current shunt status

2...Set the TI shunt tolerance

3...Scan inputs with shunts

4...Command a shunt cal

5...Set references to last measured

Enter choice: 1

The Shunt Main Menu options are described in the following paragraphs.

Option 0 Use this option to exit the program.

Option 1 Use this option to read the last measured shunt values, the reference values, and

the shunt status.

Note The shunt status is not maintained over power cycles, so it is only valid if

the shunt is executed after power is applied. Refer to, “Error Messages,”

on page 49.

The following is typical of what is displayed when this selection is made:

Enter choice: 1

FX1 Ref: 0.854 Measured: 0.854 Status: Good

FX2 Ref: 0.855 Measured: 0.855 Status: Good

FY1 Ref: 0.857 Measured: 0.857 Status: Good

FY2 Ref: 0.858 Measured: 0.857 Status: Good

FY3 Ref: 0.856 Measured: 0.856 Status: Good

FY4 Ref: 0.857 Measured: 0.856 Status: Good

FZ1 Ref: 0.856 Measured: 0.856 Status: Good

FZ2 Ref: 0.856 Measured: 0.855 Status: Good

SWIFT 10 ATV Sensors Software Utilities

45

Page 46

TI2SHUNT - Transducer Interface Shunt

Option 2 Use this to set the shunt tolerance. When selected, the following is displayed:

Enter choice: 2

The current shunt tolerance is 2%

Enter new shunt tolerance in percent?

Option 3 Use this option to apply a shunt to each bridge individually, read the output of the

bridge, compare the result with the value stored in the Transducer Interface and

display the difference each bridge. See the table on the next page. The shaded

fields are the bridge being shunted. The actual sequence depends on the

transducer wiring. Note that this option does not update the shunt measured

values or error status.

Software Utilities

46

SWIFT 10 ATV Sensors

Page 47

Enter choice: 3

Unshunted:

Shunted1:

Differ1:

TI2SHUNT - Transducer Interface Shunt

FX1 FX2 FY1 FY2 FY3 FY4 FZ1 FZ2

0.00050 0.00042 0.00017 -0.00050 -0.00005 -0.00033 -0.00025 0.00000

0.85475 0.00008 -0.00017 -0.00050 0.00028 -0.00033 -0.00025 0.00000

0.85424 -0.00033 -0.00033 0.00000 0.00033 0.00000 0.00000 0.00000

Unshunted:

Shunted2: 0.00050 0.00042 0.85675 -0.00117 0.00028 -0.00000 0.00008 0.00000

Differ2: 0.00033 0.00033 0.85725 0.00100 -0.00033 0.00033 0.00000 0.00000

Unshunted:

Shunted3: 0.00050 0.00008 -0.00017 -0.00017 0.00062 -0.00000

Differ3: 0.00000 0.00000 -0.00033 0.00033 0.00067 0.00000

Unshunted:

Shunted4: 0.00050 0.00008 -0.00017

Differ4: 0.00033 0.00000 0.00033

Unshunted:

Shunted5: 0.00050 0.85557 -0.00017 -0.00050 -0.00005 -0.00033 0.00042 0.00000

Differ5: -0.00033 0.85582 0.00000 -0.00033 -0.00067 0.00000 0.00033 -0.00033

Unshunted:

Shunted6: -0.00017 0.00042 0.00017 -0.00017

Differ6: -0.00067 0.00033 0.00000 0.00033

Unshunted:

Shunted7: 0.00084 0.00008 0.00050 -0.00050 -0.00005 -0.00033 0.00008

Differ7: 0.00033 -0.00033 0.00067 0.00033 0.00000 0.00000 0.00000

0.00017 0.00008 -0.00050 -0.00117 0.00062 -0.00033 0.00008 0.00000

0.00050 0.00008 0.00017 -0.00050 -0.00005 -0.00000 0.00042 0.00000

0.85620 -0.00033

0.85579 -0.00033

0.00017 0.00008 -0.00050 -0.00084 -0.00005 -0.00000 0.00075 -0.00033

0.85747 -0.00005 -0.00033 0.00008 0.00000

0.85831 0.00000 -0.00033 -0.00067 0.00033

0.00084 -0.00025 -0.00017 -0.00017 0.00062 -0.00033 0.00008 0.00033

0.00050 0.00008 0.00017 -0.00050 -0.00038 -0.00000 0.00008 0.00033

0.85614 -0.00033 -0.00025 -0.00033

0.85653 -0.00033 -0.00033 -0.00067

0.00050 0.00042 -0.00017 -0.00084 -0.00005 -0.00033 0.00008 0.00000

0.85510

0.85510

Unshunted:

Shunted8: -0.00017 0.00008 0.00017 -0.00050 0.00028 0.85610 0.00008 0.00000

Differ8: -0.00033 0.00000 0.00000 0.00033 0.00033

0.00017 0.00008 0.00017 -0.00084 -0.00005 -0.00000 0.00008 0.00067

0.85610 0.00000 -0.00067

Option 4 Use this option to command a Shunt Cal in the Transducer Interface. This is the

same as pressing the Shunt button on the front panel of the TI. A period is

displayed on the screen for every change in the shunt state. This gives you a

quick view of the progress.

Option 5 A valid shunt calibration should be performed prior to executing this command.

This option allows an easy means of setting the Shunt Calibration Reference

values after calibration. After this option has executed, the file that was written

can then be downloaded (using TI2XFER option 2). Downloading the file will

set the Shunt Reference values to the last measured values, so that subsequent

Shunt Calibrations should pass when the SWIFT system is setup properly, and

fail when not setup properly.

Note This menu choice should only be used by qualified service personnel.

SWIFT 10 ATV Sensors Software Utilities

47

Page 48

TI2SHUNT - Transducer Interface Shunt

Setting Up Shunt Calibration Reference Values

The ti2shunt utility provides all of the necessary functions for setting up a

Transducer Interface with valid Shunt Cal Reference values.

Note This procedure should only be performed by qualified service personnel.

Before running the ti2shunt utility, connect the Transducer cable from the

SWIFT TI to the SWIFT Transducer Assembly. Power up the SWIFT TI and wait

for the red Fail indicator on the TI front panel to go out (this indicates that the TI

is ready).

Note that it is not necessary to perform a System (Transducer) Zero prior to the

Shunt Cal.

Procedure 1. Launch the ti2shunt utility.

2. Using Option 2, enter the desired shunt tolerance.

3. Using Option 4, command a shunt cal, and wait for it to complete. This

causes the TI to apply and measure each shunt delta. These measured values

will be written as the Cal Reference values. The Shunt indicator on the TI

front panel should not blink (blinking indicates that the shunt cal

verification failed).

4. Using Option 1, read the current shunt parameters. It is not necessary to

save these to a file. Review the measured values and verify that they are

correct.

5. Using Option 5, write the last shunt measurements to a parameter file. This

sets up a file that contains the eight Set Shunt Cal Reference commands,

with the last measured values as the values for the commands. This step

does not download the values, but forces the generation of a shunt cal

reference parameter file.

Write down the filename that is generated, as it will be required later.

6. Using TI2Xfer option 2 to download the shunt parameters from a file to the

TI. Enter the filename used in Option 5 (Step 5). The tishunt utility then

downloads the shunt cal reference values to the TI. These values are written

into non-volatile memory within the TI, and are automatically restored

whenever the TI is powered up.

7. Using Option 4, command another shunt cal, and wait for it to complete.

This provides a verification, showing that the values downloaded are valid.

The Shunt indicators on the TI Front Panel should toggle indicating the shunt

calibration is in process.

Software Utilities

48

SWIFT 10 ATV Sensors

Page 49

Error Messages

When a SWIFT utility encounters an error, the red failed indicator on the TI front

panel lights. Run the TI2STATUS program to identify the cause of the error.

Following is a list of possible error messages:

• Fatal Errors

Error Messages

NONE

Failed command port initialize

Failed I2C (integrated-integrated-circuit) initialize

Failed non-volatile memory initialize

Failed comput module initialize

Failed ADC (analog-to-digital converter) initialize

Failed DAC (digital-to-analog converter) initialize

Failed calibration multiplexer initialize

Failed while reading I2C

Failed timer initialize

Failed interrupt initialize

Failed encoder initialize

Failed zero module initialize

Failed shunt module initialize

Unrecognized failure code – This error could be due to hardware

failures or software bug.

• Boot Loader – The boot loader runs when you turn on power. This line

displays the version number if boot was successful.

Error, boot loader has not run – This occurs if the CPU is not

running.

Error, the boot loader has not finished – Something prevented the

CPU from completing booting the main program.

Error, the boot loader found a bad Flash CRC (cyclic redundancy

check) – This error is likely due to a corrupted Flash program.

Computed CRC =

Flash CRC =

Error, unrecognized boot loader error code of: – Possibly corrupted

memory or communications or the version of TI2STATUS is not

compatible with the firmware.

• Zero

Good – no problems detected

Bad Angle Offset – The change in angle was not 90°, ±2°.

Direction Change – The direction of 90° increments reversed.

SWIFT 10 ATV Sensors Software Utilities

49

Page 50

Error Messages

• Shunt

Good – no problems were detected.

Reference Bad – The shunt reference is out of range.

Shunted Bad – A shunt value does not match the shunt reference.

Unshunted Bad – While shunting one bridge another bridge output

unexpectedly changed.

• Calibration Data is:

Good – No problems were detected.

Bad – The unit has not been calibrated or the calibration memory is

corrupted.

Software Utilities

50

SWIFT 10 ATV Sensors

Page 51

Setting up the Transducer Interface

Overview Two different software configurations are used by the TI, depending on whether

you will be using the SWIFT sensor on the test track (typical for spinning

application) or in the laboratory (typical for non-spinning or fixed application).

Angular transformation is required on the test track only. If you are using the

same transducer and TI for data collection on the test track and simulation testing

in the laboratory, you must change the software configuration in the TI when you

change testing modes.

Contents USB driver installation 52

Select a Zero Method 54

Calibration File Elements 55

Upload the Calibration File 56

Edit the Calibration File 57

Download the Calibration File 60

SWIFT 10 ATV Sensors Setting up the Transducer Interface

51

Page 52

USB driver installation

USB driver installation

Two USB 2.0 drivers must be installed to recognize the Transducer Interface.

Perform the following procedure to install these drivers on a laptop or desktop

computer that does not already have these drivers installed.

Important Do not allow Windows to search for or choose the drivers for you.

Always direct Windows to the path containing the Mini TI USB

drivers.

1. Copy the Mini TI USB drivers from the Utilities CD provided to your hard

drive.

2. Push and hold the Power button on the Mini TI. Release the button when

the Power indicator lights.

All the indicators on the Mini TI will light briefly then go out leaving only

the Power indicator lit.

3. Connect the USB cable between the computer and the Mini TI.

The Found New Hardware Wizard will launch. On the screen that

displays, select the No, not this time radio button (see the next figure).

Setting up the Transducer Interface

52

SWIFT 10 ATV Sensors

Page 53

USB driver installation

4. On the next window, select the Install from a list or specific location

(Advanced) radio button.

5. If you copied the driver files from the CD to your hard drive, use the

browser to direct the wizard to the location where you copied the files as

shown in the next figure.

6. Click Next to install the loader for the MTS SWIFT TI Interface

7. When the installation is complete, click Finish on the window that displays.

8. Another Found New Hardware Wizard will display.

Repeat Steps 4 through 7 to install the MTS SWIFT TI Interface driver for

the TI Interface.

9. Restart your computer to activate the new settings.

SWIFT 10 ATV Sensors Setting up the Transducer Interface

53

Page 54

Select a Zero Method

Select a Zero Method

Before you install a transducer and zero it, you must configure the transducer

interface (TI) for the appropriate operating mode.

Equipment required You will need:

• A laptop computer (at test track) or desktop PC with Window 2000 or XP

operating system.

• A USB 2.0 communication cable with type A to type B connectors.

• SWIFT Transducer Interface Utilities diskette.

• Some experience with DOS commands and text editors.

Modes There are two separate modes for using the transducer interface. The mode you

choose depends on whether you will use the transducer in a spinning (test track)

application (AngleMode = 0) or non-spinning (road simulator) application

(AngleMode = 1).

If you are using the same transducer with a road simulator that you used

previously on the test track, or vice versa you must download the proper

calibration file and re-zero the transducer.

In either mode, the zero button on the front panel of the TI is used to zero the

angle and balance the bridges.

What you need to do To change the angle mode used by the TI you will need to:

1. Copy the original calibration file from the CD or diskette that came with the

transducer to the computer.

Note A separate calibration file was created at the factory for each transducer.

In the next steps, note the serial number of the transducer identified in

the calibration file and the serial number of the TI box that the file was

downloaded to. This information will be used later.

2. Edit the calibration file to select appropriate angle mode: 0 = spinning, 1 =

non-spinning (fixed).

3. Download the modified calibration file from the computer to the TI box.

4. Repeat the process for all of the transducers.

These steps are described in detail in the following sections.

Setting up the Transducer Interface

54

SWIFT 10 ATV Sensors

Page 55

Calibration File Elements

AngleMode=0

AngleOffset=2.10938

AngleFixed=0

EncoderSize=2048

FXPolarity=0

FYPolarity=0

FZPolarity=0

MXPolarity=1

MYPolarity=0

MZPolarity=1

ZFX1=-0.0249317

ZFX2=0.0181511

ZFY1=0.0692687

ZFY2=-0.275767

ZFY3=0.095961

ZFY4=-0.250816

ZFZ1=-0.042539

ZFZ2=0.00590447

FX1Channel=2

FX2Channel=6

FY1Channel=3

FY2Channel=5

FY3Channel=7

FY4Channel=1

FZ1Channel=4

FZ2Channel=0

InputRange=10.0

KFX1=0.497807

KFX2=0.497807

KFY1=0.478072

KFY2=0.478072

KFY3=0.478072

KFY4=0.478072

KFZ1=0.494473

KFZ2=0.494473

KMX=1.61575

KMYX=1.45028

KMYZ=1.45028

KMZ=1.56116

KFXFY=0.00366337

KFXFZ=-0.00238232

Polarity for each output

(0 = normal, 1 = inverted)

Angle Mode (0 = Spinning, 1 = Fixed)

Angle Offset

Fixed Angle

Bridge Zeroes

Do Not Modify

Calibration Gains

Do Not Modify

S10-33

Encoder Size

The following figure shows some elements of the calibration file:

Select a Zero Method

Typical Calibration File

Items you may edit • OutputPolarities—defines the polarities of the six outputs. Change these

• AngleMode—selects the mode used for determining the encoder sine and

only if your application requires different polarities from those identified on

the transducer label.

cosine.

• AngleFixed—used for non-spinning applications.

• AngleOffset— used for spinning applications. Normally you do not need to

change this value.

• EncoderSize–defines the size of the encoder.

SWIFT 10 ATV Sensors Setting up the Transducer Interface

55

Page 56

Upload the Calibration File

Upload the Calibration File

A unique calibration file was loaded into the TI memory by MTS before the