MSD 8394 Installation

MSD Pro-Billet Digital E-Curve Distributor

PN 8394 - U.S. Patent 6820602

ONLINE PRODUCT REGISTRATION: Register your MSD product online and you’ll be entered in our monthly 8.5mm Super Conductor Spark Plug Wire give-away! Registering your product will help if there is ever a warranty issue with your product and helps the MSD R&D team create new products that you ask for! Go to www.msdperformance.com/registration.

Important: Read these instructions before attempting the installation.

|

Parts Included: |

1 - 3-Pin Harness |

|

|

|

|

|||

|

1 |

- Digital E-Curve Distributor |

|

|

|

1 - Gasket |

|

||

|

1 |

- Rotor, PN 8467 |

|

|

|

1 - Tube of Gear Lubricant |

|

||

|

1 |

- Distributor Cap, PN 8433 |

|

|

|

2 - O-Rings |

|

||

|

1 |

- Wire Retainer |

|

|

|

1 - Timing Tape Set, PN 8985 |

|

||

|

2 |

- 1.5" Self Tapping Screws |

|

|

|

|

|

||

|

|

|

|

|

WARNING: Before installing the MSD Digital E-Curve Distributor, disconnect the battery cables. When disconnecting the battery cables, always remove the Negative (-) cable first and install it last.

Note: The terminals of this Digital E-Curve Distributor require spark plug style terminals. You may need to change the terminals and boots of your wires. MSD offers two kits, PN 8849 or PN 8848 that are supplied with nine boots and terminals.

Note: If the gear is ever replaced, MSD Gear (PN 8531) |

|

Rev |

|

|

|

|

is required for replacement due to the .500" |

|

Limiter |

|

|

|

|

|

|

|

|

|

||

diameter shaft. |

|

|

|

|

|

|

DIGITAL E-CURVE FUNCTIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

RPM LIMIT |

|

Timing |

|

|

|

|

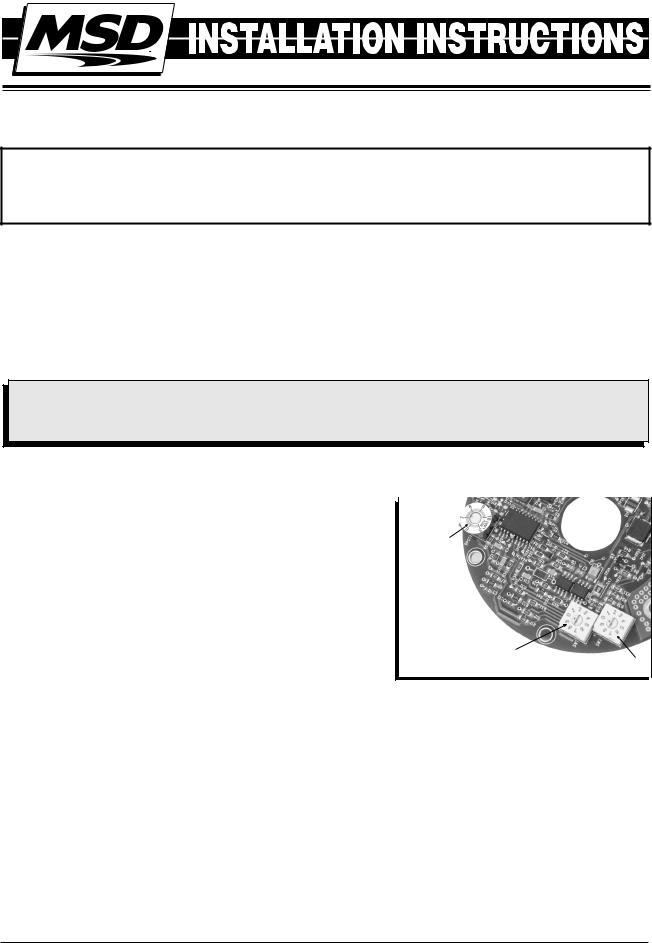

This distributor is equipped with an adjustable rev limiter. It |

|

|

|

|

||

|

Switch 1 |

|

|

|

||

is adjustable from 5,000 - 10,000 rpm by a rotary dial under |

|

Timing Switch 2 |

|

|||

|

|

|

||||

the cap and rotor (Figure 1). The rpm will not exceed your |

|

|

|

|||

|

Figure 1 Rotary Dial Adjustments. |

|

||||

selected amount to protect the engine from overrev damage. |

|

|

||||

|

|

|

|

|

||

TIMING FUNCTIONS

Electronic Advance Curve Operation: The Electronic Advance Curve is managed by a microprocessor built into the ignition module. You can program an electronic timing advance curve by adjusting two rotary switches under the distributor cap (Figure 1). A magnetic pickup is used as a trigger device that tells the ignition module when to fire the coil. The pickup is triggered by a reluctor mounted to the distributor shaft. This means that you have to set the distributor at the highest, or Total, amount of advance that you want to achieve (including vacuum advance) and compensate with one of the selectable ignition curves (shown on page 4). Following are important definitions that will be used to set up your timing.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

2 |

INSTALLATION INSTRUCTIONS |

|

|

Electronic Centrifugal Advance: Since this distributor is all electronic, there really is no mechanical or centrifugal advance. On a standard distributor, this advance would be called centrifugal so it will be referred to as the electronic centrifugal advance. The chart on page 4 shows all of the different combinations you can achieve by simply turning the two rotary dials located under the distributor cap.

Total Timing: This is the total amount of timing that the engine will achieve. This is the amount that all of the electronic curve and settings will be based from. This setting also includes any amount of vacuum advance that you plan to use.

Vacuum Advance: The vacuum advance will advance the timing under part throttle conditions when the engine is not under a heavy load. This advance is added on to the electronic timing curve as well. The advance will begin as low as 4-in. of vacuum and will max out at 10-in. of vacuum. There is a separate chart in Figure 3 that illustrates the vacuum curve selection.

Locked-Out Timing: If you do not want to have a timing advance, set the rotary dials in the LockedOut position. This means the timing will not move from the setting you position the distributor in. You may however, take advantage of a start retard (see below).

Start Retard: When you select Locked-Out timing, the engine may be hard to crank. A start retard amount can be selected to aid in cranking. This amount can range from 5°, 10°, 15° and 20°. When the engine is cranking, the timing will be retarded. Once the engine reaches 600 rpm, the timing will return to the locked-out setting.

Note: The total amount of any timing change that can be achieved is 34° (25° for the electronic advance with vacuum an additional 9°). This includes the electronic advance as well as the vacuum advance.

Note: It is recommended to have a dial-back timing light, timing tape or a fully degreed balancer to set the timing correctly.

CHOOSING AN ADVANCE CURVE

The function of the advance curve is to match the ignition timing to the burning rate of the fuel with the speed (rpm) of the engine. The piston is traveling much faster through the combustion stroke at 5,000 rpm compared to 1,000 rpm. Any factor that changes the burning rate of the fuel or the engine speed can cause a need for an ignition timing change. Figure 2 shows some of the factors that will affect engine timing.

|

|

|

|

|

|

|

|

|

FACTOR |

Advance Timing |

Retard Timing |

|

|

|

|

|

For |

For |

|

|

|

|

Cylinder Pressure |

Low |

High |

|

|

|

|

|

|

|

|

|

|

|

Vacuum |

High |

Low |

|

|

|

|

Energy of Ignition |

Low |

High |

|

|

|

|

|

|

|

|

|

|

|

Fuel Octane |

High |

Low |

|

|

|

|

Mixture (Air/Fuel) |

Rich |

Lean |

|

|

|

|

Temperature |

Cool |

Hot |

|

|

|

|

Combustion Chamber Shape |

Open |

Compact |

|

|

|

|

|

|

|

|

|

|

|

Spark Plug Location |

Offset |

Center |

|

|

|

|

Combustion Turbulence |

Low |

High |

|

|

|

|

Load |

Light |

Heavy |

|

|

|

|

|

|

|

|

|

|

|

Figure 2 |

Ignition Timing Factors. |

|

|

|

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

INSTALLATION INSTRUCTIONS |

3 |

|

|

As you can see from the chart, most factors will change throughout the range of the engine operation. The Digital E-Curve allows you to make timing changes based on these factors.

Example: An engine has 11:1 compression, a high energy ignition and turns 5,500 rpm. With the specifications given, you will have to retard the timing for the high compression and high energy ignition. By comparing the engine’s specifications against the chart, a usable timing guideline can be found. Engines with a combination of items from both columns will require a timing that is set in the mid range.

Obviously a full technical explanation of correct ignition timing would be very complicated. The best way to arrive at a suitable ignition curve for your engine is to use the Ignition Timing Factors Chart as a guide and compare it to the Advance Graphs in Figure 3 until a suitable curve is found. When selecting your advance curve, use detonation (engine ping) as an indicator of too much advance, and a decrease in power as an indicator of too little advance. Also consider how the engine cranks and starts. Too much advance can cause an engine to crank slow or even kick back. Here are a couple of suggestions.

•Use as much initial advance as possible without encountering excessive starter load.

•Start the electrical advance just above the idle rpm.

•Select an advance curve that produces good acceleration without detonation.

SETTING UP THE DISTRIBUTOR

Rotate the engine to TDC then to 12° - 15° BTDC. With the rotary switches set to "1" and "7" (These settings will be used to start the engine and adjusted later.) install the distributor with th rotor pointing to the number 1 spark plug wire and start the engine.

With the engine running and a timing light connected, adjust the timing to the desired Total Timing. (Example 32° without vacuum advance) Once you've set the total timing, turn the engine off and remove the distributor cap. Set the rotary dials to achieve the desired timing curve (Figure 3 and 4).

For example with total timing set at 32° and the rotary dials set to "2" and "9". The engine will idle at 12°, timing will start to advance at 1,100 rpm and will be fully advanced by 3,500 rpm, plus a 15° vacuum advance at 10 in-Hg (inches of vacuum).

If your balancer does not have any timing marks, MSD offers timing tape kit PN 8985.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Loading...

Loading...