MANUAL No.4769AԘ

SERIES No.176

TM-500 Series

TOOLMAKER’S

MICROSCOPE

User’s Manual

Read this User's Manual thoroughly

before operating the instrument. After reading,

retain it close at hand for future reference.

㩷

㩷

PREFACE

r

r

㩷

Thank you for purchasing the Mitutoyo TM-500 series Measuring Microscope.

䃂This User's Manual explains the hardware operations of the Mitutoyo TM-500 series and the

precautions to be observed during operation. To obtain the best possible performance and

longest service life from your TM-500 series Measuring Micro-scope, please read this user's

manual thoroughly. Be sure to read PRECAUTIONS before using this Measuring

Microscope.

䃂After reading this user's manual retain it for future reference.

CONVENTIONS USED IN THIS MANUAL

The following visual cues are used throughout this manual to identify different types of information:

Indicates that the operator should exercise care to avoid danger of fire, explosion, o

personal injury.

DANGER

Indicates that operating the instrument in this manner may damage it or may cause it

to malfunction.

CAUTION㩷

㩷㩷㩷

㩷

Draws attention to important information, recommended operation techniques, o

helpful tips.

Gives reference location for further information on topic.

Highlights installation, measurement, or other procedures.

PREFACE /CONVENTIONS USED IN THIS MANUAL i

PRECAUTIONS

(1) Relocation

䃂The Measuring Microscope is a precision instrument. Handle it with care when

transporting/relocating. Do not touch the movable members, which must be secured, during

transportation.

䃂

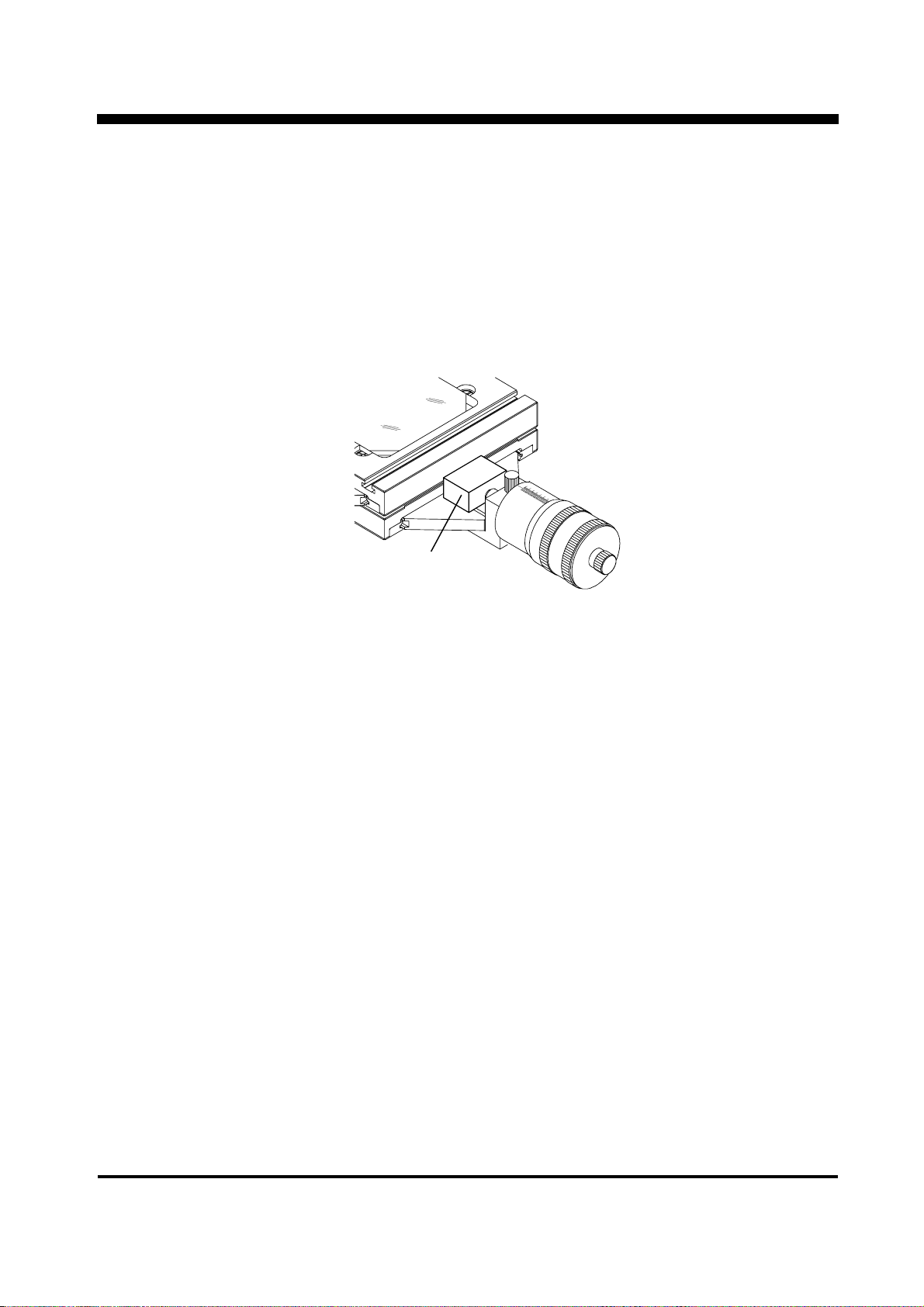

Place a cushioning pad between the Micrometer Head and the XY stage, as shown below, to

prevent the Micrometer Head spindle from hitting the table.

Cushioning pad

(2) Installation

Install the TM-500 in a site with:

䃂 as little dirt, dust, and humidity as possible. Put the supplied dust cover on it if it is not

going to be used for an extended period of time.

䃂

no vibrations.

䃂

no sudden temperature changes, which may result if the site is subjected to direct sunlight.

(3) Explosive Hazard

䃂Do not operate the Measuring Microscope in the presence of explosive gas.

(4) Power Supply

䃂Depending on the installation site, voltage fluctuation may cause a change in light intensity

or flickering of the illumination bulb. Although this does not affect measurement, use a

voltage stabilizer if a stable light intensity is required.

䃂Use an AC power supply which is isolated from high-voltage, large-current machinery.

High-voltage, large-current machinery often emits a substantial amount of electric noise due

to surge currents, which can adversely affect this measuring system if it draws power from

an AC outlet often provided on such equipment. Therefore, the Measuring Microscope

should draw power from a separate outlet. The power cable of the Measuring Microscope

should run as far apart as possible from such noise sources.

ii

PRECAUTIONS

䃂Only use the power cord that is supplied with the instrument. For a replacement power cord,

contact Mitutoyo.

䃂Only use the supplied replacement fuse or a fuse with identical specifications (type, nominal

voltage and current).

(5) Ground Positively

䃂Ground the Measuring Microscope positively, especially if it must be installed near

equipment emitting substantial amounts of electric noise. To do this connect the grounding

wire from the Measuring Microscope to the body of a piece of equipment, which also must

be grounded. The grounding wire should be as short as possible and should not be wound

into a loop or coil.

(6) Do Not Disassemble

㩷䃂There are high-voltages inside the Measuring Microscope. Do not attempt to disassemble it

unless otherwise specified.

WARRANTY

In the event that the Mitutoyo Measuring Microscope TM-500 series should prove

defective in workmanship or material, within one year from date of purchase for use, it

will be repaired or replaced, at our option, free of charge upon its prepaid return to us.

PRECAUTIONS/WARRANTY iii

CONTENTS

㩷

γ

γ

δ

ε

1.

PREFACE...........................................................................................................................

CONVENTIONS USED IN THIS MANUAL...................................................................

PRECAUTIONS.................................................................................................................

WARRANTY .....................................................................................................................

1. Outline..............................................................................................................................7

1.1 Description..............................................................................................................7

2 Name of Each Part .................................................................................................8

2. Installation and Setup .....................................................................................................11

2.1 Package Contents.................................................................................................. 11

2.2 Installation Site .....................................................................................................11

2.3 Setting-up..............................................................................................................12

2.4 Checking and Adjustment.....................................................................................13

2.4.1 Checking the reticle position against the XY stage movement direction ..13

2.4.2 Checking the centering of the reticle .........................................................13

2.4.3 Adjusting the reticle ...................................................................................14

3. Measurement ..................................................................................................................17

3.1 Preparations for Measurement .............................................................................. 17

3.1.1 Precautions for measurement .....................................................................17

3.1.2 Replacing the lenses................................................................................... 18

3.1.3 Fixing the workpiece..................................................................................18

3.1.4 Illumination modes.....................................................................................19

3.1.5 Replacing reticles.......................................................................................20

3.1.6 Adjusting the diopter..................................................................................20

3.1.7 Bringing the measuring surface into focus.................................................21

3.1.8 Positioning the workpiece ..........................................................................21

iv

CONTENTS

3.2 Measurement.........................................................................................................22

8.

3.2.1 Dimensional measurement .........................................................................22

3.2.2 Angle measurement.................................................................................... 23

3.2.3 Template matching inspection ...................................................................24

3.2.4 Step measurement ......................................................................................24

4. Maintenance ...................................................................................................................25

4.1 Cleaning and Lubrication......................................................................................25

4.2 Inspection..............................................................................................................25

4.3 Replacing Consumable Parts ................................................................................27

4.4 Consumable Parts..................................................................................................29

5. Troubleshooting..............................................................................................................31

6. Specifications .................................................................................................................35

7. Optional Accessories...................................................................................................... 37

Reference Diagrams...................................................................................................... 39

SERVICE NETWORK....................................................................................................... 41

CONTENTS

v

vi

CONTENTS

㪈

Outline㩷

This chapter outlines the Mitutoyo Toolmaker’s Microscope TM-500 series and

gives the name of each part.

1.1 Description

The Mitutoyo Toolmaker’s Microscope TM-500 series (TM- 505 and TM-510) are easy-to-use,

compact-size Toolmaker’s Microscopes that feature a vertical supporting column. Designed with

measurement of workpiece contours and inspection of surface features in mind, the TM-500 series

supports a wide range of applications from shop-floor inspection, measurement of tools and

machined parts, to precision measurement of test tools in a measuring room.

z A long vertical working distance (67mm) and erecting image have improved operability.

z The XY stage is mounted on a compact body to support wide travel ranges (50mm㬍50mm

for TM-505, 100mm㬍50mm for TM-510) for effective measurement.

z Fine/coarse focusing can be performed with a single focusing knob.

z The angle dial built into the eyepiece portion of the optical tube allows easy angle

measurement.

1.

Outline 7

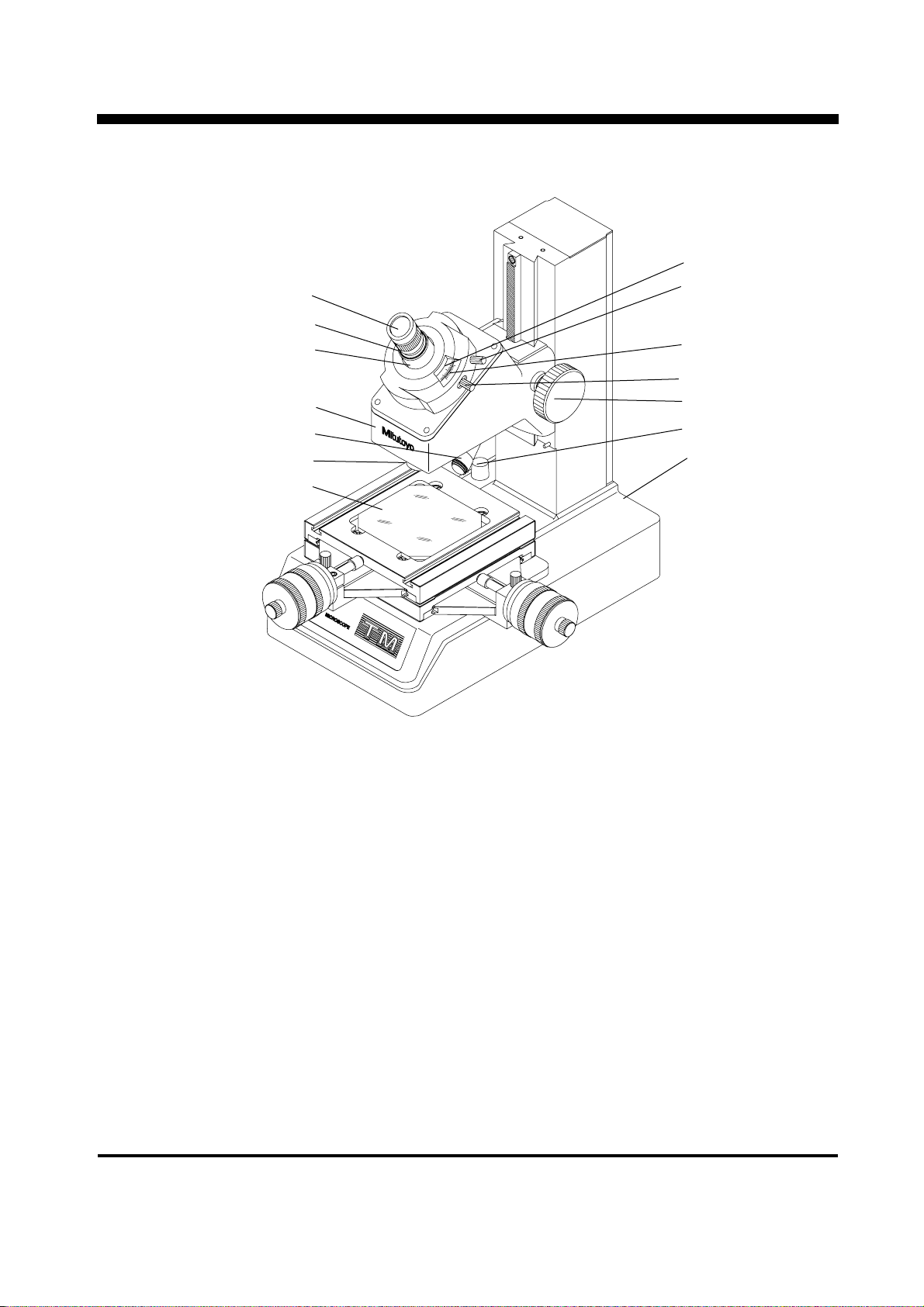

1.2 Name of Each Part

8

1. Eyepiece

1

9

2

3

10

11

4

5

6

12

13

14

7

8

2. Diopter adjustment ring

3. Eyepiece mount

4. Optical tube

5. Surface illuminator

6. Objective

7. XY stage

8. Angle dial

9. Angle dial clamp screw

10.Vernier

11.Vernier clamp screw

12.Focusing knob

13.Control panel

14.Power panel

1.Outline

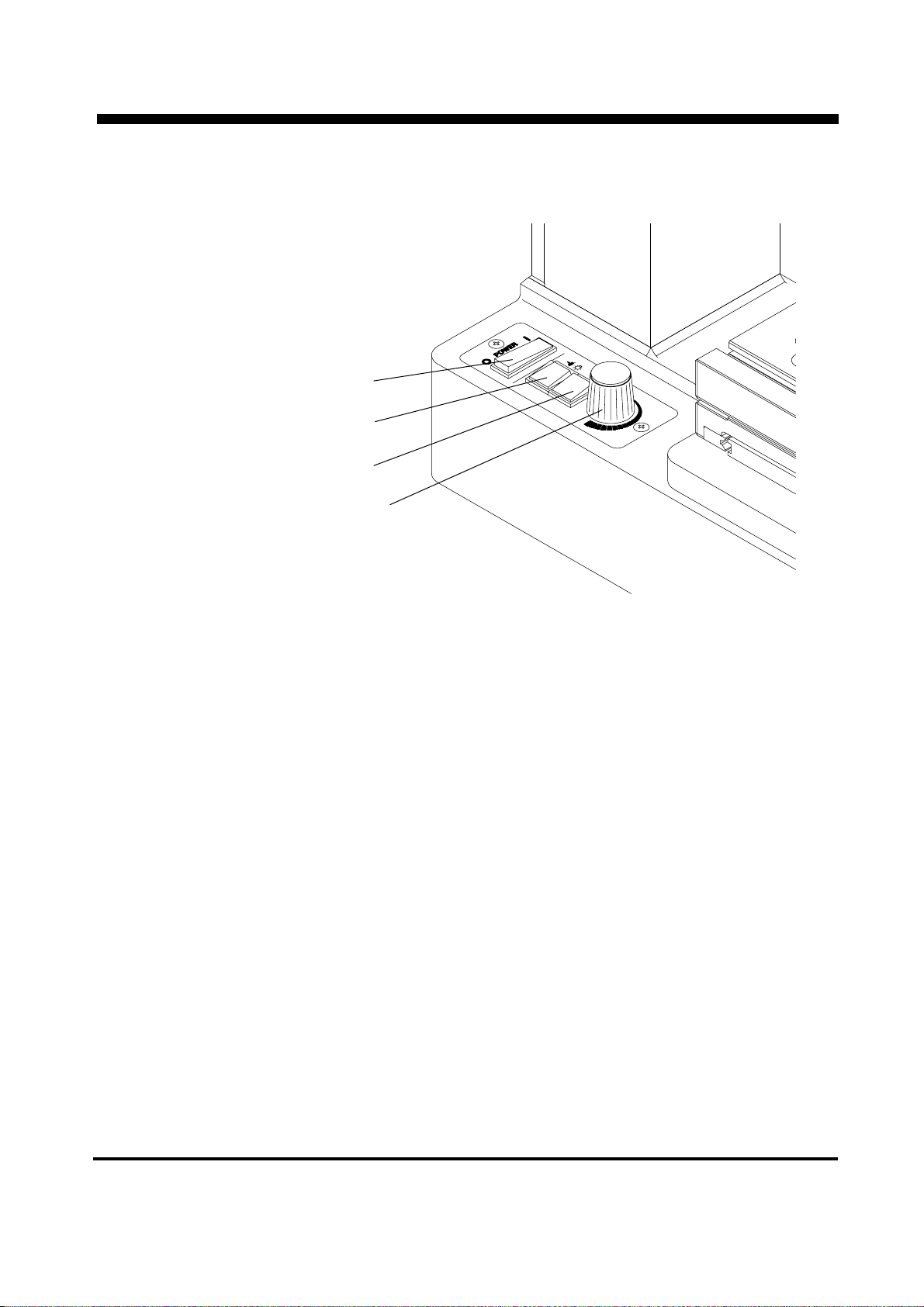

13. Control panel

Power switch

Contour illumination switch

Surface illumination switch

Light control knob

1. Outline

9

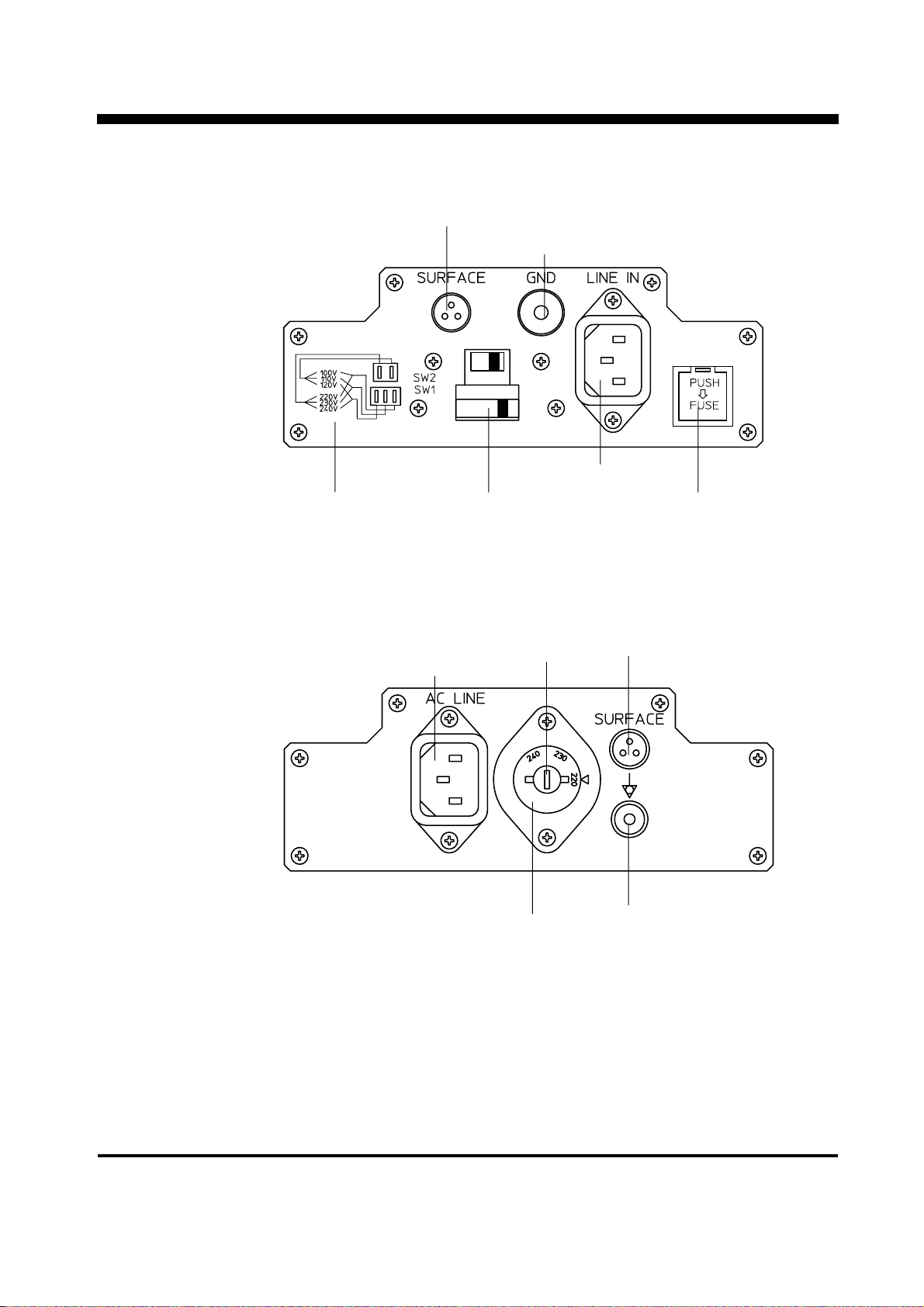

14. Power panel (for standard model)

Surface illuminator

cable connector

The voltage setting

method display

Power panel (for CE correspondences)

GND terminal

Voltage selector

AC inlet

Fuse holder

Surface illuminator

AC inlet

Fuse holder

cable connector

Voltage selector GND terminal

10

1.Outline

Installation and Setup㩷

This chapter lists the contents of the TM-500 series package and describes the

setup and adjustment procedures.

㪉

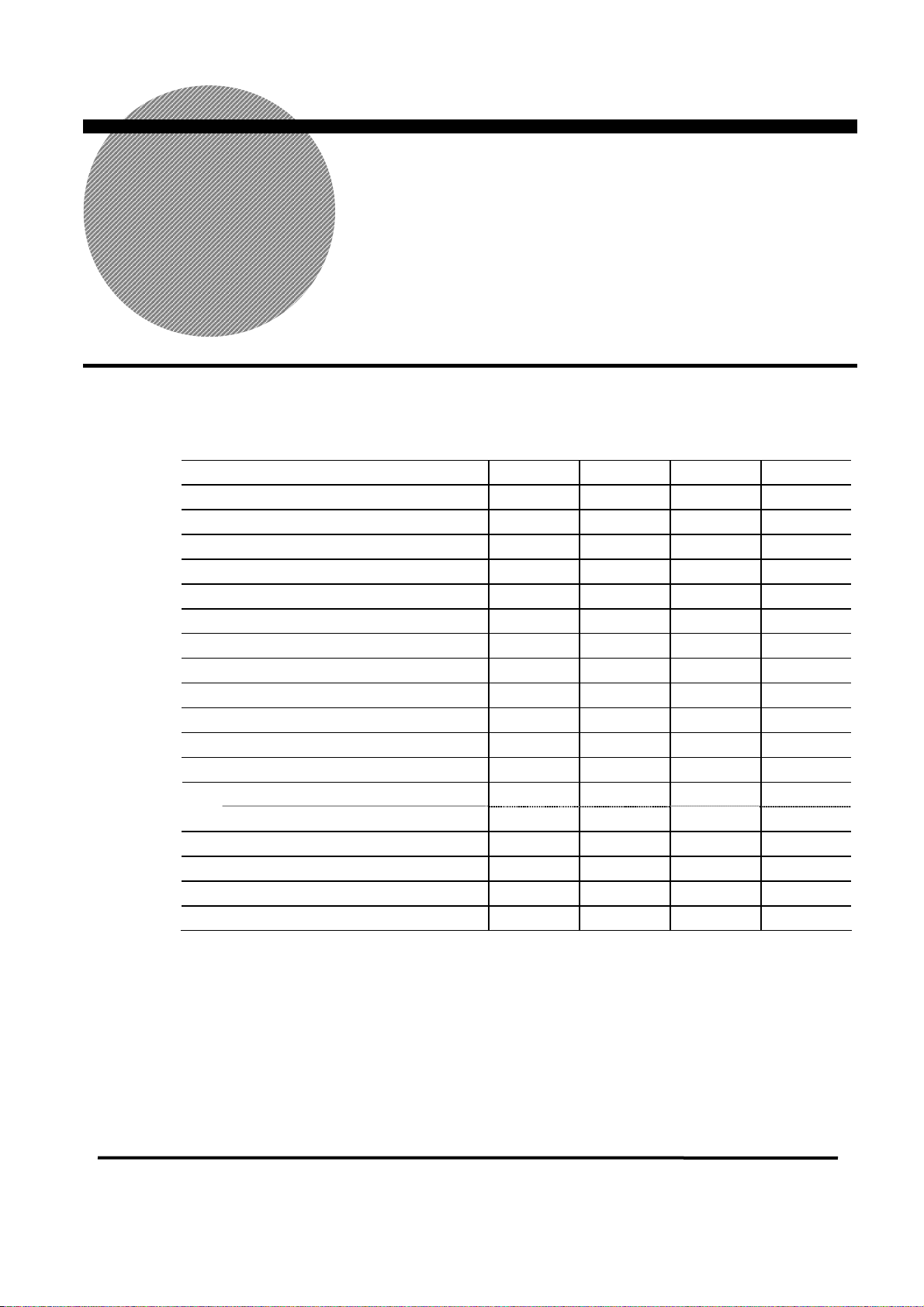

2.1 Package Contents

Standard accessories

Name TM-505 TM-505R TM-510 TM-510R

1.

Objective㧔2㧕 176-138

2.

Eyepiece㧔15㧕 176-116

3. Lens cap 511187 1 1 1 1

4. Cross-hair line reticle 176-126 1 1 1 1

5. Surface illuminator 1 1 1 1

6. Micrometer Head

7. Mounting screw 380597

8. Reticle setting screw 200624 1 1 1 1

9. Bulb setter 511188 1 1 1 1

10. Allen key nominal 3 538616 1 1 1 1

11. Vinyl cover 512555 1 1 1 1

12.

Spare bulb 㧔24V㧕 383038

Spare fuse㧔1A㧕not CE 350279

13.

Spare fuse㧔1A㧕for CE 384204

14. Power cord 1 1 1 1

15. Grounding wire 1 1 1 1

16. User’s Manual 1 1 1 1

17. Warranty 1 1 1 1

*㧦Keep the mounting screws in the TM-510/510R package. They are provided to install the optional

mounting jigs on the XY stage.

1111

1111

㧙

㧙㧙

1111

1111

1111

2

㧙

2* 2*

2

2.2 Installation Site

Install the Measuring Microscope in a place which is free from vibration and dust. Exposing the

instrument to vibrations over long periods of time can deteriorate its measuring accuracy. Dust

adversely affects the optical parts, the XY stage, and moving parts.

2. Installation and setup 11

2.3 Setting-up

1.

Install the Micrometer Head on the XY stage.

Loosen the hex-socket head screw on the bracket. Fully insert the stem of the Micrometer Head . Then,

tighten the hex-socket head screw with the stem in place.

The clamp screw is provided to secure the spindle of the Micrometer Head. If using a Micrometer Head

with a fitting hole in the stem, insert the stem so the hole is aligned with the clamp screw. If this puts the

scale on the Micrometer head in a poor position for viewing the zero graduation, adjust the scale position

by turning the Micrometer Head sleeve. If using a Micrometer Head with no hole to clamp the spindle,

lightly tighten the clamp screw.

XY stage

Clamp screw

Bracket

Hex-socket head screw

2. Connect the surface illuminator cable to the connector on the power panel, which is at the back of the

Measuring Microscope. Insert the cable firmly into the connector and secure it with the nut.

3. Set the voltage selector plug to the supply voltage as follows.

When the voltage selector on the back panel is as in the

upper left figure, the combination of two slide switches on

the upper and lower sides performs a voltage setup. Set up

the voltage according to the voltage setting method display.

Voltage setting

Voltage selector

method display.

When the voltage selector on the back panel is as in the

lower left figure, remove the fuse holder by turning it

counterclockwise using a screw driver.

Turn the voltage selector with a coin, etc., and align the

rated voltage display with the position of the arrow. Replace

the fuse holder as before.

Fuse holderVoltage selector

12

2. Installation and setup

2.4 Checking and Adjustment

2.4.1 Checking the reticle position against the XY stage

movement direction

1䋮 Place a small workpiece on the stage glass and bring it into focus.

2䋮 Turn the Micrometer Heads to align an edge of the workpiece with the center of the cross-hair.

3䋮 While turning the Micrometer Head to move the workpiece left and right, turn the angle dial so

that the horizontal cross-hair is oriented to coincide with the direction of the stage movement.

Small workpiece

㪋㪅 Loosen the vernier clamp screw. Align the “0” graduation on the angle dial with that of the

vernier scale. Ensure the margin is sufficient for adjusting the vernier scale position. If space for

adjusting the vernier scale position is limited, re-adjust the vernier scale position by referring to

"2.4.3 (1) Adjusting the reticle to the XY stage movement direction".

㩷

㩷

2.4.2 Checking the centering of the reticle㩷

To perform dimensional measurement by turning the angle dial or after replacing the reticle, align the

cross-hair with the center of rotation of the angle dial, as follows.

1䋮 Place a small workpiece on the stage glass and bring it into focus.

2䋮 Turn the Micrometer Heads to align an edge of the workpiece with the center of the cross-hair.

3䋮 Turn the angle dial 180q. Make sure the edge of the workpiece remains within 3μm of the center of the

cross-hair. If it is not within 3μm, adjust the center of the reticle by referring to "2.4.3 (2) Centering

the reticle".

㩷

2. Installation and setup

13

2.4.3 Adjusting the reticle

㩷

㩷

㩷

㩷

(1) Adjusting the reticle with the XY stage moving direction

㩷

Angle dial cover

Screws (4 pcs.) Eyepiece mount

Fixing screws (4 pcs.) Adjustment screws (4 pcs.)

㩷㩷㩷㩷㩷 㩷

Angle dial

Vernier scale

Angle dial clamp

knob

Vernier scale

clamp knob

㩷

㪈䋮 Remove the clamp knobs from the angle dial and vernier scale.㩷

㪉䋮 Remove the four screws from the angle dial cover and remove the cover.㩷

3㧚 Screw-in the clamp knobs on the angle dial and vernier scale.

4㧚 Approximately center the vernier scale in the adjustable range. Then secure it with the clamp

knob.

5㧚 Align the “0” graduation of the angle dial with that on the vernier scale. Then, secure the angle

dial with the clamp knob.

6㧚 Loosen the adjustment screws and fixing screws (4 pcs. each) so that the eyepiece mount can be

moved manually.

㪎䋮 While looking into the eyepiece, adjust the position of the eyepiece mount so that the horizontal

cross-hair is oriented to coincide with the direction of the stage movement.

8㧚 Temporarily secure the eyepiece mount by lightly tightening the fixing screws.

㪐䋮 Centering the reticle as described in "(2) Centering the reticle" below. Firmly secure the

eyepiece mount by fully tightening the fixing screws.

㪈㪇䋮Remove the clamp knobs from the angle dial and vernier scale.㩷

㪈㪈䋮Replace the angle dial cover and secure it to the optical tube with the four screws.

㪈㪉䋮Screw-in the clamp knobs on the angle dial and vernier scale.

㩷

㩷

14

2. Installation and setup

(2) Centering the reticle

1䋮 Place a small workpiece on the stage glass. Turn the Micrometer Heads to align an edge of the

workpiece with the center of the cross-hair.

2䋮 Rotate the angle scale disc 180q and read the displacement between the edge of the workpiece

and the center of the cross-hair.

3䋮 Remove the four screws from the angle dial cover and dismount it. Slightly loosen the four fixing

screws.

4䋮 Adjust the eyepiece mount position with the four adjustment screws to minimize the

displacement between the edge of the workpiece and the center of the cross-hair. Centering is

easily performed by moving the eyepiece mount by half the displacement in both the X and Y

directions.

Two pairs of adjustment screws are located at the opposite sides (for adjusting the X and Y

displacements). Adjust the screws in pairs. Loosen one on one side, and then tighten its counterpart

on the other side to adjust the displacement.

5䋮 Turn the Micrometer Heads to align an edge of the workpiece with the center of the cross-hair.

Rotate the angle dial 180q and check the displacement.

6䋮 Repeat steps 1, 2, 4, 5 until the displacement is within 3μm.

7䋮 Confirm that the four adjustment screws are fully tightened.

8䋮 Tighten the four fixing screws and replace the angle dial cover.

1㧚 2㧚 4㧚

Small workpiece

2. Installation and setup

15

16

2. Installation and setup

㪊

Measurement㩷

This chapter describes the preparations for measurement and the

measuring procedures.

3.1 Preparations for Measurement

3.1.1Precautions for measurement

z Installation site

When selecting an installation site, take vibration, dust and humidity into due consideration.

Vibration can affect measuring accuracy. Dust and humidity can impair optical parts, such as the

objective and prism, and the XY stage and moving parts.

z Precaution for operation

If focusing, making measurements, or mounting work pieces, take surrounding conditions into

account. Be careful not to bump the objective, stage glass, etc.

z Objective and Eyepiece

The supplied objective and eyepiece were finely adjusted before shipment.

To maintain performance and accuracy, handle them with care and do not disassemble. Do not

allow the surface of the lens to be scratched or to be exposed to machine oil. If the lens is soiled,

clean it as described in “4.1 Dusting and Applying Oil”.

z Stage glass

Since workpieces are mounted on it, the stage glass is likely to be scratched or even severely

damaged. Dust the workpiece before placing it on the stage glass. Exercise care so as not to

bump the stage glass with the workpiece. Do not slide the workpiece on the stage.

3. Measurement 17

3.1.2 Replacing the lenses

An objective (2x) and an eyepiece (15x) are provided with a total magnification of 30x.

1䋮 The following objectives and eyepieces are available as optional accessories.

z Eyepiece (10x, 20x)

z 5x Objective (working distance: 33mm), 10x Objective (working distance: 14mm)

2. To mount the eyepiece, insert it into the eyepiece mount. The objective can be screwed into the

optical tube.

Before dismounting the objective, remove the fixture clamping down the surface illuminator from

the objective. The fixture is attached to the objective. The O-ring is between the fixture and the

㩷

objective. Pull down the fixture by gently swinging it back and forth.

3.1.3 Fixing the workpiece

Once the workpiece is mounted, secure it to the stage glass. Use the fixing jigs secured to the

T-groove on the XY stage if required.

The workpiece must be positioned so that the measuring surface faces the objective.

The following optional fixing jigs are available.

1. Swivel center support (No.176-105 for TM-505/505R, 172-197 for TM-510/510R)

Used to secure cylindrical workpieces (with center hole) and screws.

2. V-block (No.172-378)

Used to mount cylindrical workpieces (without center hole).

3. Holder with clamp (No.176-107)

Used to mount thin flat workpieces.

4.

Chart clip (for XY stage) No.990561 (for TM-505/505R)

Used to mount thin flat workpieces (securing to the T-grooves on the XY stage).

Swivel center support

No.176-105

No.172-197

䇯

18

3. Measurement

Chart clip䋨for XY stage䋩

No.990561

V-block

No.172-378

Holder with clamp

No.176-107

3.1.4 Illumination modes

The TM-500 series supports the following illumination modes. Select appropriate illumination mode

according to your application.

(1) Contour illumination

The contour illumination generates the contour image of a workpiece, and is suited for measurement

and inspection of workpiece contours. The illuminator is equipped with a green filter.

(2) Surface illumination

Surface illumination shows the surface of a workpiece, and is used in observation and inspection of

workpiece surfaces. Adjust the angle and orientation of this illuminator so the workpiece surface can

be observed under optimum conditions.

(3) Simultaneous use of contour and surface illuminations

Both the contour and surface of a workpiece can be observed simultaneously.

Power switch

Contour illumination switch

Surface illumination switch

Light control knob

3. Measurement

19

3.1.5 Replacing reticles

To replace reticles, use the supplied reticle setting screw, as described below.

1.

Pull up and remove the eyepiece.

2. Screw the reticle setting screw into the reticle. Pull out the reticle setting screw along with the

reticle.

3.

Screw the reticle setting screw into the reticle to be mounted. Insert the reticle into the eyepiece

mount.

The reticle is provided with a positioning pin. Fit the pin in the groove on the eyepiece mount and

insert the eyepiece as far as possible.

4.

Remove the reticle setting screw and insert the eyepiece.

Reticle setting screw

Reticle

Reticle setting screw

Reticle

Positioning pin

Positioning pin

3.1.6 Adjusting the diopter

While looking into the eyepiece, turn the diopter adjustment ring until the reticle can be seen

sharply.

Diopter adjustment ring

20

Focusing knob

3. Measurement

3.1.7 Bringing the measuring surface into focus

Bring the measuring surface into focus by moving the optical tube up and down with the focusing

knob. Look into the eyepiece to make sure the cross-hairs are kept in ocular focus during this

focusing operation.

If moving the optical tube, be careful, especially if the workpiece is stepped or is secured with

CAUTION

fixing jigs, not to bump the workpiece.

3.1.8 Positioning the workpiece

Align the measuring direction of the workpiece with the traversing direction of the stage.

䋨䋱䋩

Follow the procedure in "2.4.3 (1) Adjusting the reticle with the XY stage moving

direction".

䋨䋱䋩

Move the workpiece or the fixing jigs to align the measuring direction of the workpiece with the

cross-hair reticle.

After making the above adjustment, confirm that the workpiece is parallel with the traveling direction

by moving the XY stage.

3. Measurement

21

3.2 Measurement

3.2.1 Dimensional measurement

Align a measuring point on the workpiece with one of the cross-hairs and take the reading from the

Micrometer Head. Then, move the XY stage by turning the Micrometer Head and align another

measuring point with the same cross-hair and take the reading at this point. The difference between

the two readings represents the dimension between the two measuring points.

A Digimatic Head and Digital Counter can be used, in place of the Micrometer Head, for digital

display of the displacement. They also eliminate reading errors. Since the zero-set button zeroes the

counter at any position, the displacement can be read directly.

22

3. Measurement

3.2.2 Angle measurement

Angles are measured with the angle dial, using either of the following two procedures.

(1) (2)

(1) Align an edge of the workpiece with the cross-hair reticle and align the end edge with the center

of the cross-hair. Turn the angle dial to align the cross-hair with the other edge of the workpiece.

Take readings from the angle dial.

(2)

Align two edges of the workpiece with the same cross-hair, one after another, by turning the

CAUTION

angle dial and moving the XY stage. Take readings from the angle dial.

1䋮In both procedures, measuring points on the workpiece are aligned with a cross-hair, one after

another. The angle is determined from the difference in readings.

2䋮The resolution of the angle dial is 1q with the main scale and 6' with the vernier scale.

㩷

㩷㩷㩷㩷㩷<Reading the angle dial>

Main scale䋺34¡

34¡42㶅

Vernier scale䋺42㶅

3䋮The zero position of the angle dial can be adjusted by turning the vernier scale. This allows the

angle measurement origin to be set to 0.

After turning the vernier scale, check the reticle position. Refer to "2.4.3 (1) Adjusting the reticle

against the XY stage moving direction" if necessary.

3. Measurement

23

㩷

CAUTION

3.2.3 Template matching inspection

This Measuring Microscope allows inspection of screw threads and involute gear teeth using the

optional template reticles.

To perform template matching inspection, set the appropriate optional template reticle according to

the procedure in "3.1.5 Replacing the reticle".

For information about the various template reticles, see "7. Optional Accessories".

3.2.4 Step measurement

Stepped dimensions can be measured using the optional height measurement attachment and a dial

indicator.

This measurement is performed by bringing the measuring faces in focus. A high-precision

measurement cannot be made if using a lens with a large depth of focus. To obtain high-accuracy

measurements, use a high-magnification lens with a shallow depth of focus, as shown below.

䃂30x lens with a depth of focus of approximate 0.12mm

䃂150x lens with a depth of focus of approximate 0.02mm

Attach the height measurement attachment to the top face of the column as shown in the figure below.

Use a gauge block that is appropriate for the optical tube position.

Dial indicator

Mounting screw

Height measurement attachment

Gauge block

Column

24

3. Measurement

㪋

Maintenance

This chapter describes the daily and periodical inspection and maintenance

required to maintain the performance of this microscope.

4.1 Cleaning and Lubrication

(1) Main unit

Periodically apply a thin layer of grease over the slide guide surfaces and rack of the optical tube using

a brush.

(2) XY stage

Apply a thin layer of spindle oil to guide rails. After dusting the stage glass wipe it gently with a soft

cloth.

(3) Eyepiece and objective

Since the optical glass used for lenses is soft and subject to scratches, always use an air-blower or a

feather to dust the lens surface. To remove contaminants such as oil and fingerprints, gently wipe them

in a circular motion with gauze dampened in high-grade alcohol.

4.2 Inspection

To maintain this microscope in prime condition, periodically inspect the parts specified below. If the

microscope is not operating perfectly, inspect it in detail according to the procedure in “5.

Troubleshooting”.

(1)Connecting parts

Turn off the power switch and pull out the power cord from the AC outlet to prevent electric

shocks.

DANGER

z Check the power cord, input connector (AC inlet), voltage selector, GND terminal, surface

illuminator connector, and other joints for looseness and poor connections.

(2)Power and illumination switch and light control knob

z Check the power switch

z Check that the contour and surface illuminators light by turning on the illumination switch.

z Check that the light intensity of each illuminator changes by turning on the light control knob.

4. Maintenance 25

(3)Focusing knob

z Check this knob for any abnormal tightness, play, unevenness, and sound.

(4)XY stage

z Check the stage glass for scratches and contaminants.

z Move the XY stage over the measuring range by hand to check for any abnormal tightness, play,

unevenness, and sound. (Perform the same cheek on the stage by turning the micrometer heads.)

(5)Angle dial

z Loosen the angle dial clamp knob and turn the dial to check for any abnormal tightness, play,

unevenness, and sound.

(6)Field of view

z Look into the eyepiece under contour illumination and check the entire filed of view for

vignetting and uneven illumination.

(7)XY stage feeding accuracy

z This inspection will be affected by the measuring environment, alignment error, and other

adverse conditions. Keeping these factors in mind, check the feeding accuracy by measuring a

workpiece or a standard scale with an appropriate dimension of 5mm.

1. Position a workpiece, for which accurate dimensions are known, on the stage glass and

bring it into focus.

2. Align a measuring point on the workpiece with one of the cross-hairs, according to the

moving direction of the workpiece.

3. Obtain the dimension from the readings on the Micrometer Head. Refer to “3.2.1

Dimensional measurement”.

4. Measure the X- and Y-axis dimensions of the workpiece.

If the difference between the measured and nominal dimensions is less than 5Ǵm (for any 5mm

travel range), the XY stage feeding accuracy is adequate.

(8)Resolution

z Position a workpiece on the XY stage and bring it into focus. Check if any region of the image in

the field of view has poor resolution.

26

4. Maintenance

4.3 Replacing Consumable Parts

(1) Replacing the fuse

When a fuse holder is as in the upper left figure

1. Turn off the contour and surface illumination switches and the

power switch, and the pull out the power cord.

2. Insert a screwdriver in the rectangular hole of the fuse holder

and raise the screwdriver grip, then a latch will separate and the

fuse holder will come out from the front.

3. Replace the fuse, and replace the fuse holder.

When a fuse holder is as in the lower left figure

1. Turn off the contour and surface illuminator switches and the

power switch and pull out the power cord.

2. Insert a screwdriver in the rectangular hole on the fuse holder

and turn it counterclockwise, then a latch will separate and a

fuse holder will come out from the front.

3. Replace the fuse, and replace the fuse holder.

(2)Replacing the stage glass

1. While pushing the stage glass in the direction of the leaf spring, raise the glass at the front edge,

CAUTION

and then remove it.

2. Attach the leaf spring in place and mount new stage glass.

Leaf spring

Stage glass

Since the stage glass is pushed forward with the leaf spring, when you remove the stage glass, be

careful not to lose the leaf spring.

㩷

4. Maintenance

27

CAUTION㩷

(3)Replacing the contour illumination bulb

The bulb remains hot after it has been turned off. Do not replace the bulb until it had cooled down.

㩷

1. Turn off the contour illumination switch and power switch.

2. Remove the stage glass. (See (2) above.)

3. Turn the green filter counterclockwise to remove it.

4. Remove the bulb by turning it counterclockwise with the supplied bulb setter.

5. Mount a new bulb using the bulb setter.

6. Turn on the power switch and contour illumination switch. Check that the bulb lights.

7. Replace the green filter and the stage glass, in this order.

28

4. Maintenance

CAUTION㩷

(4)Replacing the surface illumination bulb

The bulb remains hot after it has been turned off. Do not replace the bulb until it has cooled down.

㩷

1. Turn off the surface illumination switch and power switch.

2. Turn the white filter counterclockwise to remove it.

3. Remove the bulb by turning it counterclockwise with the supplied bulb setter. Mount a new bulb

using the bulb setter.

4. Switch the illuminator select switch knob to the surface illumination.

5. Check that the bulb lights.

6. Turn on the power switch and surface illumination switch. Check that the bulb lights.

7. Replace the white filter.

4.3 Consumable Parts

Order No. Name

380405 Stage glass 96x96 (for TM-505/505R)

380495 Stage glass 154x96 (for TM-510/510R)

512555 Vinyl cover

383038 Illumination bulb (24V)

350279 Fuse (1A) for other than CE

384204 Fuse (1A) for CE

380240 Leaf spring

4. Maintenance

29

30

4. Maintenance

Troubleshooting

If a problem occurs, diagnose and remedy the problem with the aid of the

following procedures.

㪌

(1)The contour illumination bulb will not light.

Check1䋺

Check2䋺

Check3䋺

Check4䋺

Check5䋺

Check6䋺

Check7䋺

Is the power switch turned on?

YES No Turn on the power switch.

Is the contour illumination switch turned on?

YES No Turn on the contour illumination switch.

Is the light control knob properly set?

Turn the knob clockwise to increase the light intensity (if

YES No

Is the power cord connected correctly?

YES No Connect the power cord correctly.

Is the voltage selector set to the correct voltage?

YES No Set the voltage selector to the correct voltage.

Is the bulb normal (conductive)?

YES No Replace the bulb.

Is the fuse normal (conductive)?

YES No Replace the fuse.

turned fully counterclockwise).

Check8䋺

Check9䋺

Is the voltage from the AC outlet normal (supplied)?

YES No Supply power to the outlet.

Is the voltage at the AC inlet on the main unit normal (input)?

YES No Replace the power cord.

Contact Mitutoyo.

5. Troubleshooting 31

㩿㪉㪀The surface illumination bulb will not light.

Check1䋺

Check2䋺

Check3䋺

Check4䋺

Check5䋺

Check6䋺

Check7䋺

Is the power switch turned on?

YES No Turn on the power switch.

Is the surface illumination switch turned on?

YES No Turn on the surface illumination switch.

Is the light control knob properly set?

Turn the knob clockwise to increase the light intensity (if

YES No

Is the power cord connected correctly?

YES No Connect the power cord correctly.

Is the voltage selector set to the correct voltage?

YES No Set the voltage selector to the correct voltage.

Is the bulb normal (conductive)?

YES No Replace the bulb.

Is the fuse normal (conductive)?

YES No Replace the fuse.

turned fully counterclockwise).

Check8䋺

Check9䋺

Is the voltage from the AC outlet normal (supplied)?

YES No Supply power to the outlet.

Is the voltage at the AC inlet on the main unit normal (input)?

YES No Replace the power cord.

Contact Mitutoyo.

(3)The light intensity of contour illumination cannot be adjusted

(if the contour illumination switch is turn on ).

Check䋺

Is the contour illumination bulb lit?

Refer to "(1) The contour illumination bulb will not light".

YES No

Contact Mitutoyo.

32

5. Troubleshooting

(4)The light intensity of surface illumination cannot be adjusted

(if the surface illumination switch is turn on ).

Check䋺

Is the surface illumination bulb lit?

Refer to "(2) The surface illumination bulb will not light".

YES No

Contact Mitutoyo.

(5)The optical tube will not move up and down properly.

If there is any abnormal tightness, play, unevenness, or sound when the optical tube is moved, contact

Mitutoyo. Should this be the case, do not continue to move the optical tube or disassemble it.

(6)The angle dial will not rotate properly.

If there is any abnormal tightness, play, unevenness, or sound when the optical tube is moved, contact

Mitutoyo. Should this be the case, do not continue to move the optical tube or disassemble it.

(7)The XY stage will not properly be fed.

If there is any abnormal tightness, play, unevenness, or sound when the XY stage is fed, contact Mitutoyo.

Should this be the case, do not continue to feed the XY stage or disassemble it. If the feeding accuracy has

deteriorated, determine whether the stage or the Micrometer Head is the problem and contact Mitutoyo.

(8)There is a shadow in the field of view.

Check for:

z Obstruction between the contour illumination bulb and the objective .

z Contaminated reticle.

z Contaminated objective or eyepiece.

If the problem cannot be rectified, contact Mitutoyo.

(9)The resolution in a region of the field of view is poor.

Check for:

z Poor focusing (because of a stepped workpiece).

z Oil soiling the workpiece.

z Improperly mounted objective or eyepiece.

z Contaminated or damaged (such as scratch) objective or eyepiece.

z Contaminated or damaged (such as scratch) reticle.

If the problem cannot be rectified, contact Mitutoyo.

5. Troubleshooting

33

34

5. Troubleshooting

Specifications

㪍

(1)Optical tube

z Optical axis:30qfrom vertical

z Cross-hair reticule supplied

z Adjustable diopter

z Angle dial: Graduation 1q

Angleofrotation360q

Anglereading6’(vernier)

Vernier zero position adjustable

(2)Eyepiece

z Magnification :15

z Field number :13

(3)Objective

z Magnification :2

z Working distance :67mm (2.63”)

(4)XY stage

Order No. TM-505/TM-505R TM-510/TM-510R

Dimensions

Stage glass size

Feeding range

㧔if used with gauge block㧕

Maximum height 115mm 107mm

workpiece 5Kg 5Kg

152152mm 240152mm

9696mm 15496mm

5050mm 10050mm

(5)Transmitted illuminator

z Light source :24V, 2W (special bulb)

z Continuously adjustable light intensity

z Green filter supplied

6. Specifications 35

(6)Surface illuminator

z Light source : 24V㧘2W (special bulb)

z Continuously adjustable light intensity

(7)Mass

TM-505 TM-505R TM-510 TM-510R

13.5Kg 14.0Kg 14.5Kg 15.0Kg

(8)Main unit dimensions

36

6. Specifications

k

Optional Accessories

㪎

OrderNo. Name

176-105 Swivel-center support㧔for TM-505/TM-505R㧕

172-197 Swivel-center support 㧔for TM-510/TM-510R㧕

176-106 Rotary table㧔for TM-505/TM-505R㧕

172-196 Rotary table 㧔for TM-510/TM-510R㧕

176-107 Holder with clamp

172-378 V-block with clamp

176-203 Twin-bulb surface illumination unit

176-204 Height measurement attachment

176-115 Eyepiece 10

176-117 Eyepiece 20

176-137 Objective 10

176-139 Objective 5

176-109 Reticle (Template) Metric screw p=0.25㨪1.0

176-110 Reticle (Template) Metric screw p=1.25㨪2.0

176-111 Reticle (Template) Concentric circles Ǿ0.05㨪4.00mm

176-112

176-113 Reticle (Template) 55qangle line

176-114 Reticle (Template) 60qangle line

176-120 Reticle (Template) Whiworth screw thread (inch) 60㨪26TPI

176-121 Reticle (Template) Whiworth screw thread (inch) 24㨪18TPI

176-122 Reticle (Template) Whiworth screw thread (inch) 16㨪11TPI

176-123 Reticle (Template) Unified screw thread 80㨪28TPI

176-124 Reticle (Template) Unified screw thread 24㨪14TPI

176-125 Reticle (Template) Unified screw thread 13㨪10TPI

Reticle (Template) Involute gear tooth m0.1㨪1.0, pressure angle 20q

reference rac

7. Optional Accessories 37

k

176-127 Reticle (Template) Unified screw thread NF80㨪28TPI

176-128 Reticle (Template) Unified screw thread NF24㨪14TPI

176-129 Reticle (Template) Unified screw thread NF13㨪10TPI

176-130

176-135 Reticle (Template) Concentric circles Ǿ.01” pitch, maximum diameter Ǿ.2”

176-140 Reticle (Template) ISO metric screw thread p=0.075㨪0.7

176-141 Reticle (Template) ISO metric screw thread p=0.75㨪2.0

176-142 Reticle (Template) ISO unified screw thread 80㨪28TPI

176-143 Reticle (Template) ISO unified screw thread 24㨪14TPI

176-144 Reticle (Template) ISO unified screw thread 13㨪10TPI

990561 Chart clip (for XY stage)

Reticle (Template) Involute gear tooth m0.1㨪1.0 pressure 14” 30’ ,

reference rac

176-366

176-344

264-140ٌ

164-161

164-162

937387 ً

965013 ً

264-002 ً MUX-10F

12AAD194 ً

: The order number differs depending on the shipping destination.

ٌ: When using QM-Data200 it also requires MDH-50M (2 units), connecting cables (2 pcs of either

length), MUX-10F and connecting cable C.

Fiber-optic circular illumination unit

Twin fiber optics illumination unit, twin fiber-optic illum inat o r

data processing unit QM-Data200

2D

Digimatic micrometer head MHD-50M

ً

Digimatic micrometer head MHD-2M

Connecting cable (1m): connect between MHD-50M and MUX-10F

Connecting cable (2m): connect between MHD-50M and MUX-10F

Connecting cable C: connect between MUX-10F and QM-Data200

38

7. Optional Accessories

Top view of XY stage

TM-505/505R

㪏

Reference Diagrams

Detail drawing of T-groove

8. Reference Diagrams 39

TM-510/510R

Detail drawing of T-groove

40

8. Reference Diagrams

Loading...

Loading...