Mitsubishi PLH-1.6KKHB.UK, PLH-2.5KKHB.UK, PLH-2KKHB.UK Service Manual

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1997 |

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

SPLIT-TYPE, HEAT PUMP, AIR CONDITIONERS |

||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. OC147 |

|||||||||

TECHNICAL & SERVICE MANUAL

Series PLH Ceiling Cassettes

Indoor unit [Model names]

PLH-1.6KKHB

PLH-2KKHB

PLH-2.5KKHB

[Service Ref.]

PLH-1.6KKHB·UK PLH-2KKHB·UK PLH-2.5KKHB·UK

This manual does not cover the following outdoor units. When servicing them, please refer to the service manual No.OC150 and this manual in a set.

[Service Ref.] PUH-1.6VKA3·UK PUH-2VKA2·UK PUH-2.5VKA2·UK

INDOOR UNIT

FILTER

CHECK MODE

CHECK MODE

TEST RUN

CONTENTS |

|

|

1. |

FEATURES.......................................... |

2 |

2. PART NAMES AND FUNCTIONS ...... |

3 |

|

3. |

SPECIFICATIONS............................... |

6 |

4. |

DATA ................................................... |

9 |

5. OUTLINES AND DIMENSIONS........ |

13 |

|

6. WIRING DIAGRAM ........................... |

15 |

|

7. |

REFRIGERANT SYSTEM DIAGRAM ..... |

16 |

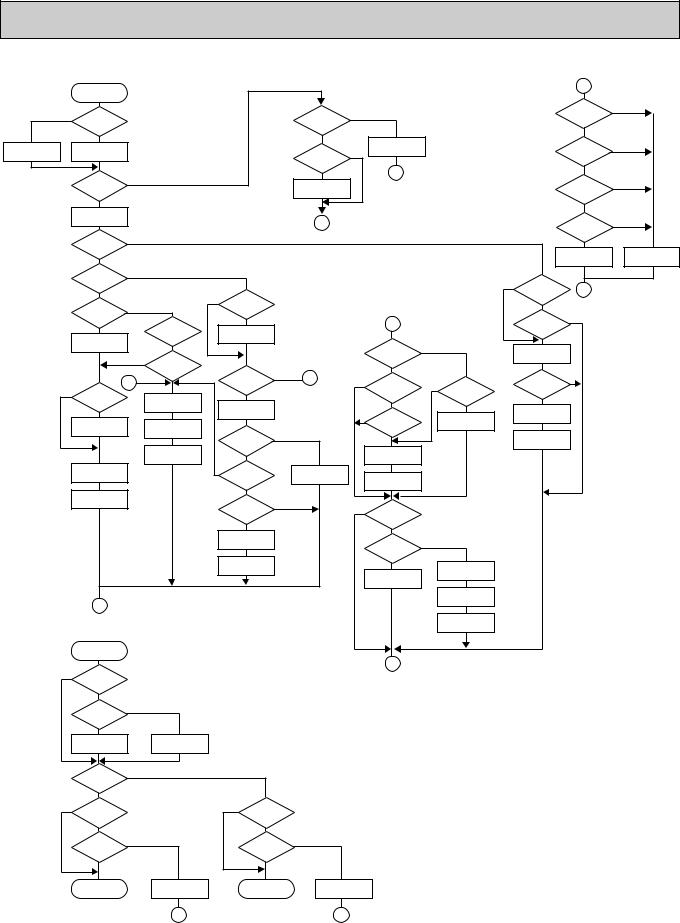

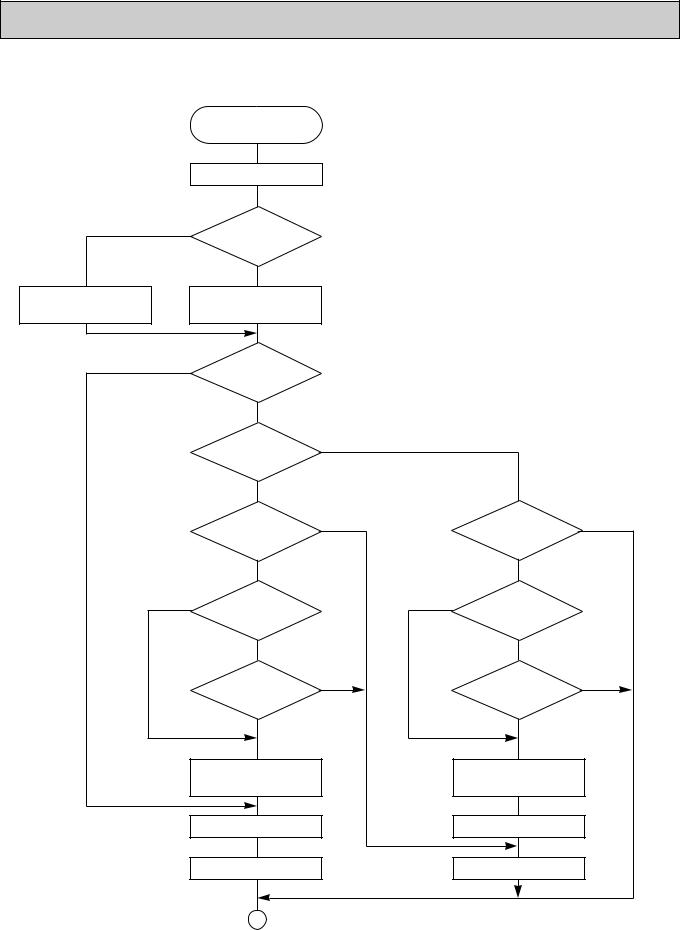

8. OPERATION FLOW-CHART ............ |

17 |

|

9. MICROPROCESSOR CONTROL..... |

21 |

|

10. TROUBLESHOOTING ...................... |

43 |

|

11. 4-WAY AIR FLOW SYSTEM ............. |

51 |

|

12. SYSTEM CONTROL ......................... |

52 |

|

13. DISASSEMBLY PROCEDURE ......... |

57 |

|

14. |

PARTS LIST...................................... |

60 |

15. |

OPTIONAL PARTS ........................... |

64 |

REMOTE CONTROLLER

The Slim Line.

From Mitsubishi Electric.

1

FEATURES

FEATURES

Series PLH Ceiling Cassettes

FILTER

CHECK MODE

TEST RUN

|

Indoor unit |

Remote controller |

|

|

|

||

|

|

|

|

Service Ref. |

Cooling capacity/Heating capacity |

||

|

|

||

W |

Btu/h |

||

|

|||

|

|

|

|

PLH-1.6KKHB.UK |

4,400/4,650[6,050] |

15,000/15,900[20,600] |

|

|

|

|

|

PLH-2KKHB.UK |

5,400/5,800[7,200] |

18,400/19,800[24,600] |

|

|

|

|

|

PLH-2.5KKHB.UK |

6,300/[7,200/9,300] |

21,500/24,600[31,700] |

|

|

|

|

|

1.PURSUING CONPACTNESS

(1)Panel size and body volume reduced to 64% of previous models

The width and depth of the panel have been reduced by 19cm respectively, resulting in a compact model which fits smaller environments (like shops) perfectly.

(2)Multi-application panels flexibly adapt to installation conditions.

Space panel and Wide panel may be installed on ceilings with shallow depth using the exiting opening .

2."SMUDGE-FREE", PRECISELY TARGETED AIRFLOW SYSTEM

The new control system regulates airflow to prevent smudging. A projection inside the air passage distributes air evenly over the top and bottom of the vane. Two projections on the air outlet work to prevent cooled air from rising to the celling, and also to stop outside air being dragged into the cooled air stream.

3.AIRFLOW ADJUSTABLE TO ANY INDOOR ENVIRONMENT

Airflow can be adjusted according to celling height and the number of air outlets. "Wide Zoming Flow" creates anoptimum airflow for any indoor environment.

4.A FURTHER REFINEMENT OF COMFORT WITH NOISE SUPPRESION

The celling 4-way airflow cassette has a special "silent-design". The "2-Tap"system allows a choice between silent and standard modes according to the height of the cellig. For ordinary residenced which have a low celling, selection of the silent mode will result in remarkable noise reductions.

5.ECONOMICAL AND EASY MAINTENANCE

(1)Push-open grill

Filter clogging is widely recognized as a cause of reduced perfomance, but up until now it has been troublesome to clean filters. With the "push-open grill" the fillter can be smoothly opened out at the push of a button, enabling speedy cleaning.

(2)An unprecedented level of vane-cleaning

The unique airflow system prevents the intake of indoor air. Dewing therefore does not occur, and the vane is flockless. The resulting level of dirt on the vane due to tobacco smoke, dust, etc. is very light,and can be wiped off easily with a neutral detergent

(3)Long-life fillter

This new celling 4-way airflow cassette employs a long life fillter which requires no maintenance for up to 2,500 hours of operation in general office environments. It adds uo to an ideal blend of comfort and low maintenance.

2

6.COMPACT DIMENSIONS MEAN EASY INSTALLATION

(1)Carefree suspension work with lightweight unit

The new unit weighs in at 20kg (9kg lighter than the previous model) and is easy to handle and install. What's more, suspension work is facillitated by compact dimensions ensuring a snug fit.

(2)Smooth installation with "one-direction"bolts

Suspension bolts can be fixes consistently from one direction easing suspension work.

(3)Trouble-free fitting work with slender refrigerant piping

Refrigerant piping has been reduced in size, and pipe-curving work at the installation site can now be completed quickly and economically. In addition, refrigerant and drain piping are set at different corners, which means that flare connections and drain piping heat insulation work can be smoothly and reliably implemented.

(4)Easy-access terminal and control panels for efficient wiring

When performing wiring work, progress can be checked on the power source terminal and control panels simply by removing the electrical parts cover. Adress setting can also be done easily from beneath at a convenient angle.

(5)"One-push"to provisionally position front panel

Panel weight has been redused from 7kg to 3.7kg. The previous 3-step process for provisionally positioning the panel has been streamlined, and now a simple "one-push" action at the diagonal corners fixed it into place, resulting in major time-saving.

2

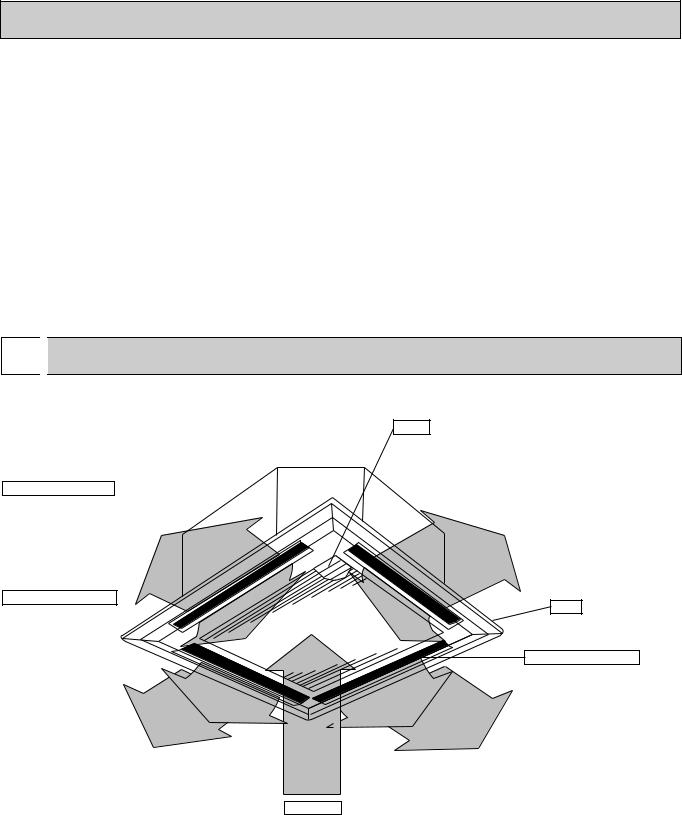

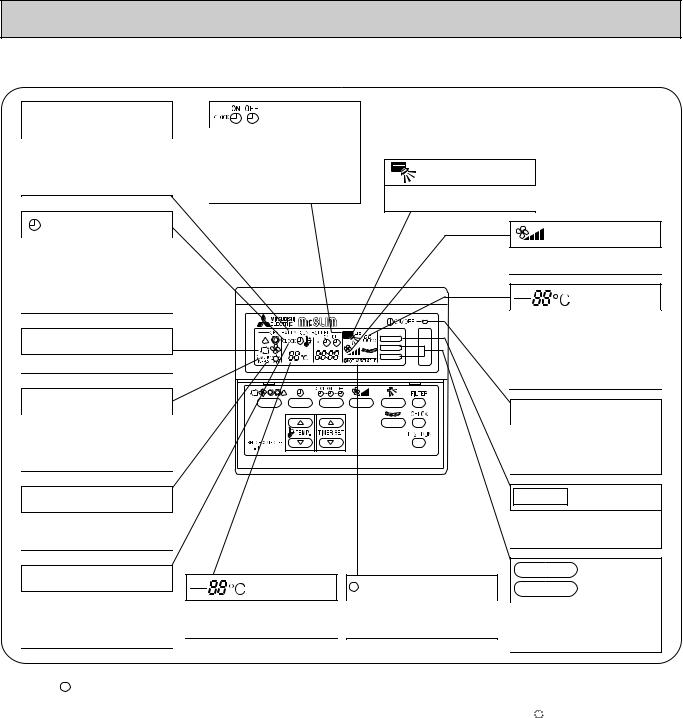

PART NAMES AND FUNCTIONS

PART NAMES AND FUNCTIONS

● Indoor (Main) Unit

PLH-1.6KKHB·UK

PLH-2KKHB·UK

PLH-2.5KKHB·UK

Horizontal Air Outlet

Sets airflow horizontal automatically during cooling or dehumidifying.

Downward Air Outlet Sets airflow downward automatically during heating.

Filters

Remove dust and pollutants from inhaled air

Grill

Auto Air Swing Vane Disperses airflow up and down and adjusts the angle of airflow direction.

Air Intake

Inhales air from room.

3

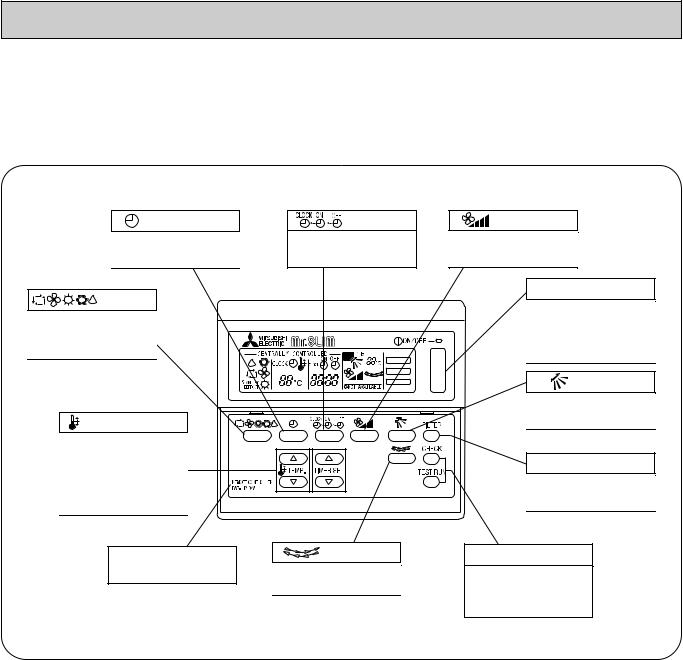

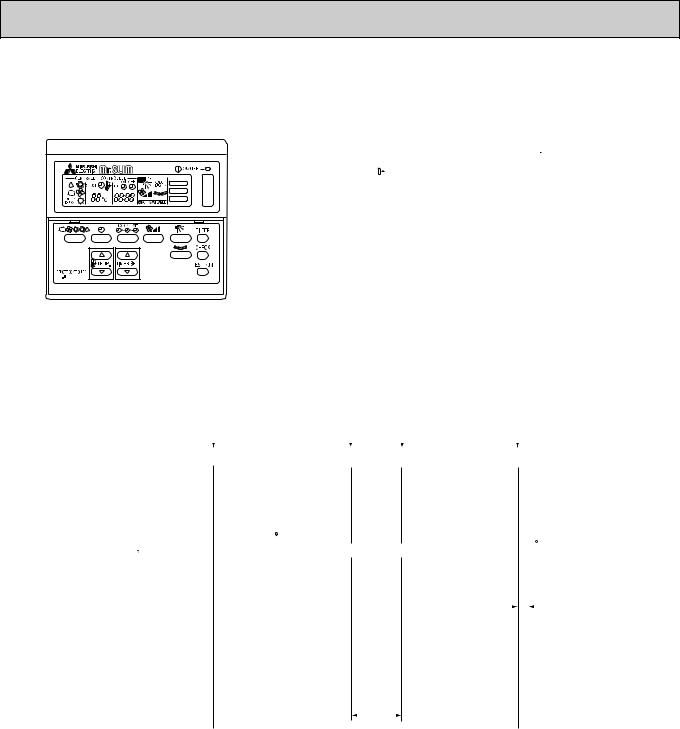

● Remote controller

Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

● Operation buttons

|

button |

button |

|

This switches between |

This sets or switches the |

||

continuous operation and the |

current time. start time and |

||

timer operation. |

stop time. |

||

button |

|

||

Press this button to switch |

|

||

the cooler electronic dry |

|

||

(dehumidify) automatic and |

|

||

heater modes. |

|

|

|

|

|

FILTER |

|

|

|

CHECK MODE |

|

|

|

TEST RUN |

|

TEMP button |

|

||

This sets the room |

|

||

temparature The temparature |

|

||

setting can be performed in |

|

||

1°C units |

|

|

|

Setting range |

4 |

||

Cooler |

19°C to 30°C |

||

|

|||

Heater |

17°C to 28°C |

|

|

This model name of the |

button |

||

remote controller is indicated. |

This switches the horizontal |

||

|

|

||

|

|

fan motion ON and OFF. |

|

|

|

(This button dose not operate in |

|

|

|

this model) |

|

button

This sets the ventilation fan speed.

ON/OFF button

This switches between the operation and stop modes each time it is pressed. The lamp on this butoon lights during operation.

button

This adjusts the vertical angle of the ventilation.

FILTER button

This resets the filter service indication display.

CHECK-TEST RUN button

Only press this button to perform an inspection check or test operation. Do not use it for normal operation.

4

● Display

CENTRALLY CONTROLLED display

This indicates when the unit is controlled by optional features such as central control type remote controller.

display

The current time , start time and stop time can be displayed in tensecond intervals by pressing the time switch button. The start time or stop time is always displayed during the timer operation.

In this display example on the bottom left, a condition where all display lamps light is shown for explanation purposes although this differs from actual operation.

display

This displays the air direction.

display

This indicates when the continous operation and time operation modes are set.

It also display the time for the timer operation at the same time as when it is set.

OPERATION MODE display

This indicates the operation mode.

STANDBY display

This indicates when the standby mode is set from the time the sleep

operation starts until the heating air

240KA is discharged.

240KA is discharged.

DEFROST display

This indicates when the defrost operation is performed.

CHECK display

display

This indicates when a malfunction has occurred in the unit which should

This displays the selected setting

be checked.

temperature.

|

display |

|

The selected fan speed is displayed. |

|

display |

|

The temperature of the suction air is |

|

displayed during operation. The |

FILTER |

display range is 8° to 39°C. The |

CHECK MODE |

display flashes 8°C when the actual |

TEST RUN |

temperature is less than 8° and |

|

|

|

flashes 39°C when the actual |

|

temperature is greater than 39°C. |

|

Operation lamp |

|

This lamp lights during operation, |

|

goes off when the unit stops and |

|

flashes when amalfunction occurs. |

display

display

This lamp lights when electricity is supplied to the unit.

FILTER Display

This lamp lights when the filter need to be cleaned.

CHECK MODE

display

TEST RUN

This display lights in the check mode or when a test operation is performed.

Caution

●Only the  display lights when the unit is stopped and power supplied to the unit.

display lights when the unit is stopped and power supplied to the unit.

●When power is turned ON for the first time the (CENTRAL CTRL) display appears to go off momentarily but this is not a malfunction.

●When the central control remote control unit, which is sold separately, is used the ON-OFF button,

button and

button and  TEMP button do not operate.

TEMP button do not operate.

●“NOT AVAILABLE” is displayed when the k button are pressed.This indicates that this room unit is not equipped with the fan direction adjustment function and the louver function.

5

3 |

|

SPECIFICATIONS |

|

||

|

|

|

|

|

Service Ref. |

|

|

|

|

|

|

Item |

|

|

|

|

|

Function |

|

|

|

||

Capacity |

|

|

Btu/h |

||

|

|

W |

|||

|

|

|

|

|

|

Total input |

|

|

kW |

||

|

Service Ref. |

|

|

|

|

|

Power supply(phase, cycle,voltage) |

|

|||

|

|

Input |

|

|

kW |

|

|

Running current |

|

|

A |

|

|

Starting current |

|

|

A |

|

External finish |

|

|

|

|

UNIT |

Heat exchanger |

|

|

kW |

|

|

Fan motor output |

|

|

||

|

|

Fan(drive) x No. |

|

|

|

INDOOR |

Booster heater |

|

|

kW |

|

|

|

Airflow(Low-High) |

|

|

K/min(CFM) |

|

|

External static pressure |

|

mmAq,Pa |

|

|

Operation control & Thermostat |

|

|

|

|

|

|

|

|

||

|

Noise level(Low-High) |

|

|

dB(A) |

|

|

Cond. drain conn. O.D. |

|

|

mm,(in.) |

|

|

|

|

W |

|

mm,(in.) |

|

Dimensions |

D |

|

mm,(in.) |

|

|

|

|

H |

|

mm,(in.) |

|

Weight |

|

|

kg,(lbs) |

|

|

Service Ref. |

|

|

|

|

|

Power supply (phase, cycle, voltage) |

|

|||

|

|

Input |

|

|

kW |

|

|

Running current |

|

|

A |

|

|

Starting current |

|

|

A |

|

External finish |

|

|

|

|

|

Refrigerant control |

|

|

|

|

|

Compressor |

|

|

|

|

UNIT |

|

Model |

|

|

|

|

Motor output |

|

|

kW |

|

OUTDOOR |

|

Fan(drive) x No. |

|

|

|

|

|

Starter type |

|

|

|

|

|

Protection devices |

|

|

|

|

Heat exchanger |

|

|

|

|

|

|

Fan motor output |

|

|

kW |

|

|

|

|

||

|

|

Airflow |

|

|

K/min(CFM) |

|

Defrost method |

|

|

|

|

|

Noise level |

|

|

dB(A) |

|

|

|

|

W |

|

mm,(in.) |

|

Dimensions |

D |

|

mm,(in.) |

|

|

|

|

H |

|

mm,(in.) |

|

Weight |

|

|

kg,(lbs) |

|

PIPING |

Refrigerant |

|

|

|

|

|

Charge |

|

|

kg,(lbs) |

|

|

|

|

|

||

REEFRIGERANT |

Pipe size O.D. |

Liquid |

|

mm,(in.) |

|

Gas |

|

mm,(in.) |

|||

|

|

||||

|

|

|

|

||

|

Connection method |

Indoor side |

|

||

|

Outdoor side |

||||

|

|

|

|||

|

Between the indoor & outdoor unit |

Height difference |

|||

|

|

|

Piping length |

||

|

PLH-1.6KKHB.UK |

|

Cooling |

|

Heating |

|

||

15,000 |

|

15,900[20,600] |

4,400 |

|

4,650[6,050] |

1.59 |

|

1.51[2.91] |

|

PLH-1.6KKHB.UK |

|

|

Single. 50Hz. 220-240V |

|

0.15 |

|

0.10[1.50] |

0.64 |

|

0.45[6.28] |

0.70 |

|

0.50[6.63] |

Galvanized sheets with gray heat insulation

Plate fin coil

Turbo fan (direct) x 1

0.030

13-16(460-565)

0(direct blow)

[1.4]

Remote controller & built-in

32-37

32(1-1/4)

UNIT : 660(26) |

PANEL : 760(30) |

UNIT : 660(26) |

PANEL : 760(30) |

UNIT : 253(10) |

PANEL : 30(1-1/8) |

UNIT : 20(44) |

PANEL :3.7(8) |

|

PUH-1.6VKA3.UK |

|

|

Single. 50Hz. 220-240V |

|

1.44 |

|

1.41 |

6.74 |

|

6.60 |

33

Munsell 5Y 7/1

Capillary tube

Hermetic

RH247VFC

1.2

Line start

Inner thermostat, High pressure switch

Plate fin coil

Propeller (direct) x1

0.065

45(1,590)

Reverse cycle

49

870(34-1/4)

295+24 (11-5/8 add 1)

650(25-5/8)

53(117)

R-22

2.2(4.8)

9.52 (3/8)

15.88(5/8)

Flared

Flared

Max. 40m

Max. 40m

6

Service Ref.

Item

Function

Capacity |

|

Btu/h |

||

|

W |

|||

|

|

|

||

Total input |

|

kW |

||

|

Service Ref. |

|

|

|

|

Power supply(phase, cycle,voltage) |

|

||

|

Input |

|

kW |

|

|

Running current |

|

A |

|

|

Starting current |

|

A |

|

|

External finish |

|

|

|

UNIT |

Heat exchanger |

|

kW |

|

Fan motor output |

|

|||

|

Fan(drive) x No. |

|

|

|

INDOOR |

Booster heater |

|

kW |

|

|

Airflow(Low-High) |

|

K/min(CFM) |

|

|

External static pressure |

mmAq,Pa |

||

|

Operation control & Thermostat |

|

|

|

|

|

|

||

|

Noise level(Low-High) |

|

dB(A) |

|

|

Cond. drain conn. O.D. |

|

mm,(in.) |

|

|

|

W |

mm,(in.) |

|

|

Dimensions |

D |

mm,(in.) |

|

|

|

H |

mm,(in.) |

|

|

Weight |

|

kg,(lbs) |

|

|

Service Ref. |

|

|

|

|

Power supply (phase, cycle, voltage) |

|

||

|

Input |

|

kW |

|

|

Running current |

|

A |

|

|

Starting current |

|

A |

|

|

External finish |

|

|

|

|

Refrigerant control |

|

|

|

|

Compressor |

|

|

|

UNIT |

Model |

|

|

|

Motor output |

|

kW |

||

OUTDOOR |

Fan(drive) x No. |

|

|

|

|

Starter type |

|

|

|

|

Protection devices |

|

|

|

|

Heat exchanger |

|

|

|

|

Fan motor output |

|

kW |

|

|

|

|||

|

Airflow |

|

K/min(CFM) |

|

|

Defrost method |

|

|

|

|

Noise level |

|

dB(A) |

|

|

|

W |

mm,(in.) |

|

|

Dimensions |

D |

mm,(in.) |

|

|

|

H |

mm,(in.) |

|

|

Weight |

|

kg,(lbs) |

|

PIPING |

Refrigerant |

|

|

|

Charge |

|

kg,(lbs) |

||

|

|

|||

REEFRIGERANT |

Pipe size O.D. |

Liquid |

mm,(in.) |

|

Gas |

mm,(in.) |

|||

|

||||

|

|

|||

|

Connection method |

Indoor side |

|

|

|

Outdoor side |

|||

|

|

|||

|

Between the indoor & outdoor unit |

Height difference |

||

|

|

Piping length |

||

|

PLH-2KKHB.UK |

|

Cooling |

|

Heating |

|

||

18,400 |

|

19,800[24,600] |

5,400 |

|

5,800[7,200] |

2.34 |

|

2.32[3.72] |

|

PLH-2KKHB.UK |

|

|

Single. 50Hz. 220-240V |

|

0.14 |

|

0.10[1.50] |

0.65 |

|

0.45[6.28] |

0.72 |

|

0.50[6.63] |

Galvanized sheets with gray heat insulation

Plate fin coil

Turbo fan (direct) x 1

0.030

13-16(460-565)

0(direct blow)

[1.4]

Remote controller & built-in

32-37

32(1-1/4)

UNIT : 660(26) |

PANEL : 760(30) |

UNIT : 660(26) |

PANEL : 760(30) |

UNIT : 253(10) |

PANEL : 30(1-1/8) |

UNIT : 20(44) |

PANEL :3.7(8) |

|

PUH-2VKA2.UK |

|

|

Single. 50Hz. 220-240V |

|

2.20 |

|

2.22 |

9.86 |

|

9.95 |

45

Munsell 5Y 7/1

Capillary tube

Hermetic

NH38VMD

1.7

Line start

Inner thermostat, HP switch

Plate fin coil

Propeller (direct) x1

0.065

45(1590)

Reverse cycle

49

870(34-1/4)

295+24 (11-5/8 add 1)

650(25-5/8)

64(141)

R-22

2.2(4.8)

9.52 (3/8)

15.88(5/8)

Flared

Flared

Max. 40m

Max. 40m

7

Service Ref.

Item

Function

Capacity |

|

Btu/h |

||

|

W |

|||

|

|

|

||

Total input |

|

kW |

||

|

Service Ref. |

|

|

|

|

Power supply(phase, cycle,voltage) |

|

||

|

Input |

|

kW |

|

|

Running current |

|

A |

|

|

Starting current |

|

A |

|

|

External finish |

|

|

|

UNIT |

Heat exchanger |

|

kW |

|

Fan motor output |

|

|||

|

Fan(drive) x No. |

|

|

|

INDOOR |

Booster heater |

|

kW |

|

|

Airflow(Low-High) |

|

K/min(CFM) |

|

|

External static pressure |

mmAq,Pa |

||

|

Operation control & Thermostat |

|

|

|

|

|

|

||

|

Noise level(Low-High) |

|

dB(A) |

|

|

Cond. drain conn. O.D. |

|

mm,(in.) |

|

|

|

W |

mm,(in.) |

|

|

Dimensions |

D |

mm,(in.) |

|

|

|

H |

mm,(in.) |

|

|

Weight |

|

kg,(lbs) |

|

|

Service Ref. |

|

|

|

|

Power supply (phase, cycle, voltage) |

|

||

|

Input |

|

kW |

|

|

Running current |

|

A |

|

|

Starting current |

|

A |

|

|

External finish |

|

|

|

|

Refrigerant control |

|

|

|

|

Compressor |

|

|

|

UNIT |

Model |

|

|

|

Motor output |

|

kW |

||

OUTDOOR |

Fan(drive) x No. |

|

|

|

|

Starter type |

|

|

|

|

Protection devices |

|

|

|

|

Heat exchanger |

|

|

|

|

Fan motor output |

|

kW |

|

|

|

|||

|

Airflow |

|

K/min(CFM) |

|

|

Defrost method |

|

|

|

|

Noise level |

|

dB(A) |

|

|

|

W |

mm,(in.) |

|

|

Dimensions |

D |

mm,(in.) |

|

|

|

H |

mm,(in.) |

|

|

Weight |

|

kg,(lbs) |

|

PIPING |

Refrigerant |

|

|

|

Charge |

|

kg,(lbs) |

||

|

|

|||

REEFRIGERANT |

Pipe size O.D. |

Liquid |

mm,(in.) |

|

Gas |

mm,(in.) |

|||

|

||||

|

|

|||

|

Connection method |

Indoor side |

|

|

|

Outdoor side |

|||

|

|

|||

|

Between the indoor & outdoor unit |

Height difference |

||

|

|

Piping length |

||

|

PLH-2.5KKHB.UK |

|

Cooling |

|

Heating |

|

||

21,500 |

|

24,600[31,700] |

6,300 |

|

7,200[9,300] |

2.60 |

|

2.33[4.43] |

|

PLH-2.5KKHB.UK |

|

|

Single. 50Hz. 220-240V |

|

0.14 |

|

0.10[2.20] |

0.61 |

|

0.45[9.20] |

0.67 |

|

0.50[9.55] |

Galvanized sheets with gray heat insulation

Plate fin coil

Turbo fan (direct) x 1

0.030

14-17(495-600)

0(direct blow)

[2.1]

Remote controller & built-in

35-39.5

32(1-1/4)

UNIT : 660(26) |

PANEL : 760(30) |

UNIT : 660(26) |

PANEL : 760(30) |

UNIT : 253(10) |

PANEL : 30(1-1/8) |

UNIT : 21(46) |

PANEL :3.7(8) |

|

PUH-2.5VKA2.UK |

|

|

Single. 50Hz. 220-240V |

|

2.46 |

|

2.23 |

10.68 |

|

9.78 |

52

Munsell 5Y 7/1

Capillary tube

Hermetic

NH41VMD

2.0

Line start

Inner thermostat, HP switch

Plate fin coil

Propeller (direct) x1

0.085

50(1764)

Reverse cycle

52

870(34-1/4)

295+24 (11-5/8 add 1)

850(34-1/4)

68(150)

R-22

2.8(6.2)

9.52 (3/8)

15.88(5/8)

Flared

Flared

Max. 50m

Max. 50m

8

4 |

|

|

DATA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1. PERFORMANCE DATA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

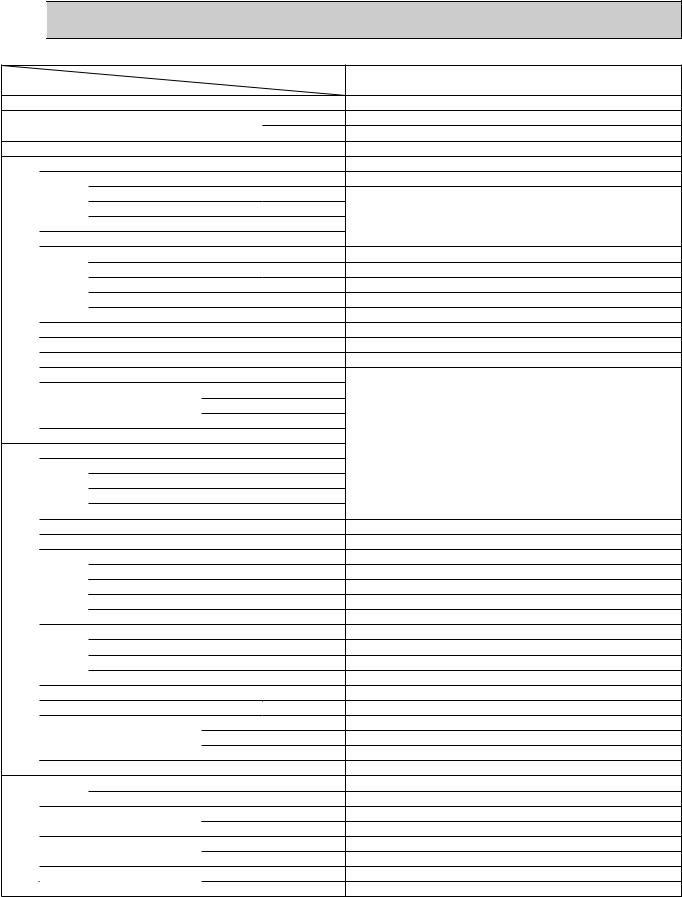

1) COOLING CAPACITY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Indoor |

|

|

|

|

|

|

|

|

|

|

|

Outdoor intake air DB C |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Service Ref. |

|

|

intake |

20 |

|

|

|

25 |

|

30 |

|

|

|

|

|

35 |

40 |

|

|

|

|

|

45 |

|

|||||||||||||

|

|

|

air |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WB C |

|

CA |

|

P.C. |

|

CA |

|

P.C. |

|

CA |

|

P.C. |

|

CA |

|

P.C. |

|

CA |

|

P.C. |

|

CA |

|

P.C. |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

4,439 |

|

1.27 |

|

4,317 |

|

|

1.33 |

4,159 |

|

1.43 |

|

3,990 |

|

1.53 |

3,812 |

|

1.64 |

|

3,624 |

|

1.74 |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PLH-1.6KKHB.UK |

|

18 |

4,726 |

|

1.30 |

|

4,602 |

|

|

1.36 |

4,434 |

|

1.46 |

|

4,258 |

|

1.57 |

4,074 |

|

1.68 |

|

3,882 |

|

1.79 |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

20 |

5,017 |

|

1.32 |

|

4,899 |

|

|

1.38 |

4,724 |

|

1.50 |

|

4,542 |

|

1.61 |

4,352 |

|

1.72 |

|

4,154 |

|

1.84 |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

5,310 |

|

1.35 |

|

5,209 |

|

|

1.41 |

5,028 |

|

1.53 |

|

4,840 |

|

1.65 |

4,645 |

|

1.77 |

|

4,442 |

|

1.90 |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

5,448 |

|

1.88 |

|

5,299 |

|

|

1.96 |

5,104 |

|

2.11 |

|

4,897 |

|

2.26 |

4,678 |

|

2.41 |

|

4,447 |

|

2.56 |

|

|||||||||

|

PLH-2KKHB.UK |

|

18 |

5,800 |

|

1.91 |

|

5,648 |

|

|

2.00 |

5,442 |

|

2.15 |

|

5,226 |

|

2.31 |

5,000 |

|

2.47 |

|

4,764 |

|

2.63 |

|

||||||||||||

|

|

20 |

6,157 |

|

1.95 |

|

6,012 |

|

|

2.04 |

5,798 |

|

2.20 |

|

5,574 |

|

2.37 |

5,341 |

|

2.54 |

|

5,099 |

|

2.71 |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

6,517 |

|

1.99 |

|

6,392 |

|

|

2.08 |

6,171 |

|

2.25 |

|

5,940 |

|

2.42 |

5,700 |

|

2.61 |

|

5,451 |

|

2.80 |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

6,356 |

|

2.08 |

|

6,182 |

|

|

2.17 |

5,955 |

|

2.34 |

|

5,713 |

|

2.51 |

5,472 |

|

2.68 |

|

5,207 |

|

2.85 |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PLH-2.5KKHB.UK |

|

18 |

6,767 |

|

2.13 |

|

6,589 |

|

|

2.22 |

6,349 |

|

2.39 |

|

6,097 |

|

2.57 |

5,841 |

|

2.74 |

|

5,571 |

|

2.92 |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

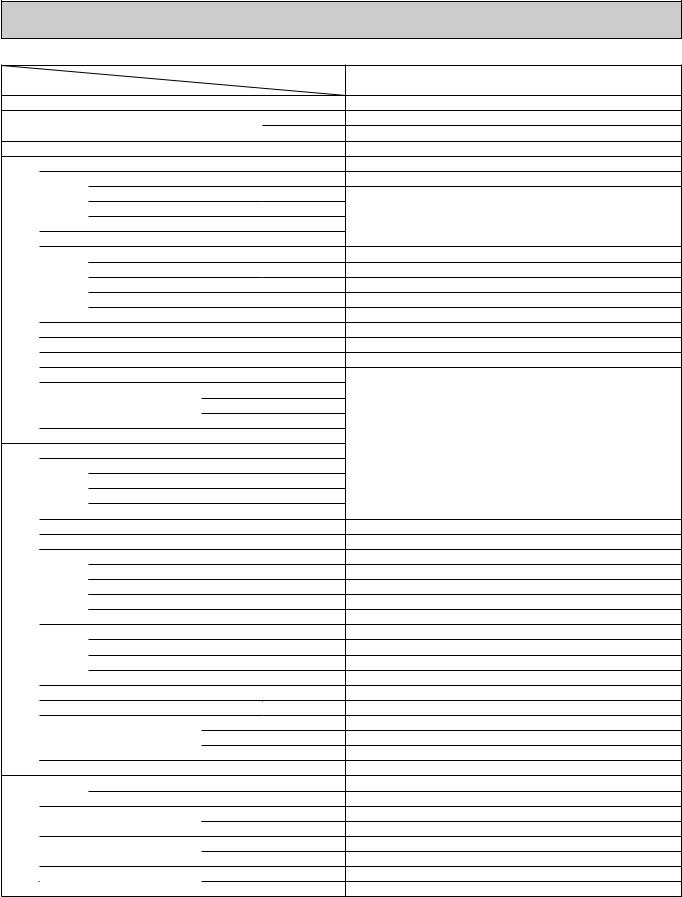

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

20 |

7,183 |

|

2.17 |

|

7,014 |

|

|

2.26 |

6,764 |

|

2.45 |

|

6,503 |

|

2.63 |

6,232 |

|

2.82 |

|

5,954 |

|

3.01 |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

7,603 |

|

2.21 |

|

7,458 |

|

|

2.31 |

7,199 |

|

2.50 |

|

6,930 |

|

2.69 |

6,645 |

|

2.90 |

|

6,359 |

|

3.11 |

|

|||||||||

Note CA:Capacity (W) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

P.C.:Power consumption (kW) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Cooling capacity correction factors |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

Service Ref. |

|

|

|

|

|

|

|

|

|

|

|

Refrigerant piping length(one way) |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

5m |

|

10m |

|

|

15m |

|

|

20m |

|

25m |

|

|

30m |

|

|

35m |

|

40m |

|

|

45m |

|

|

50m |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

PLH-1.6KKHB.UK |

|

1.00 |

|

0.993 |

|

|

0.984 |

|

|

0.978 |

|

0.969 |

|

|

0.961 |

|

0.956 |

|

0.948 |

|

|

— |

|

|

— |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

PLH-2KKHB.UK |

|

1.00 |

|

0.992 |

|

|

0.983 |

|

|

0.978 |

|

0.966 |

|

|

0.959 |

|

0.950 |

|

0.945 |

|

|

— |

|

|

— |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

PLH-2.5KKHB.UK |

|

1.00 |

|

0.989 |

|

|

0.980 |

|

|

0.970 |

|

0.960 |

|

|

0.950 |

|

0.940 |

|

0.930 |

|

0.920 |

|

0.910 |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooling performance curve(50Hz)

TOTAL INPUT (RATIO) CAPACITY (RATIO)

1.4 |

|

|

|

|

|

1.0 |

|

|

|

|

22 |

|

|

|

|

|

20 |

0.8 |

|

|

|

|

18 |

|

|

|

|

16 |

|

0.6 |

|

|

|

|

|

1.4 |

|

|

|

|

|

1.2 |

|

|

|

|

22 |

|

|

|

|

20 |

|

|

|

|

|

|

18 |

1.0 |

|

|

|

|

16 |

|

|

|

|

|

|

0.8 |

|

|

|

|

|

0.6 |

|

|

|

|

|

0.4 |

|

|

|

|

|

-5 |

5 |

15 |

25 |

35 |

46 |

1.2 |

|

OUTDOOR DB(°C) |

INDOOR WB(°C) |

||

INDOOR WB(°C)

9

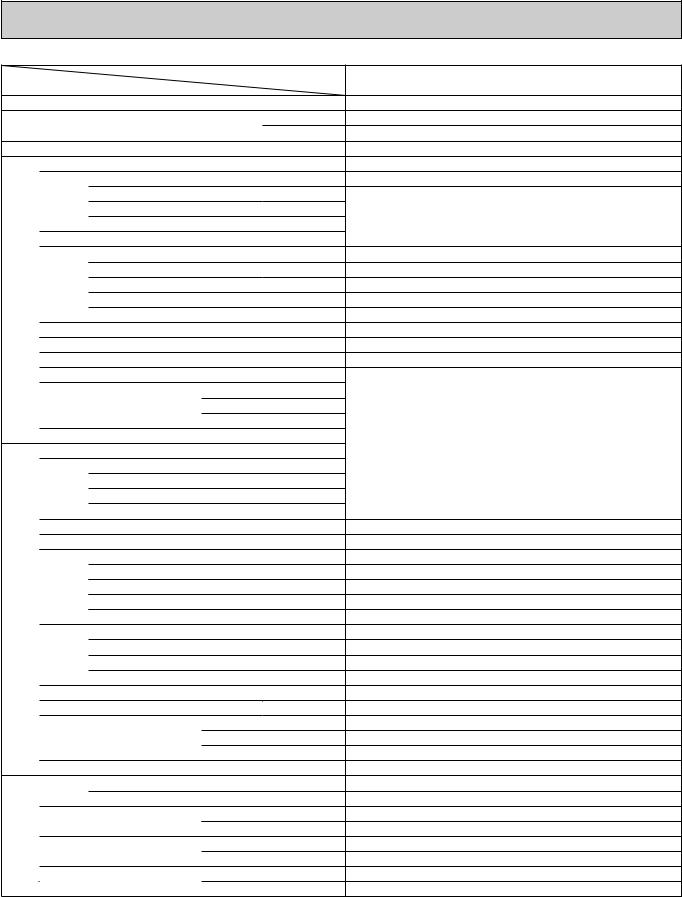

2) HEATING CAPACITY

|

|

Indoor |

|

|

|

|

|

|

|

|

|

|

|

Outdoor intake air WB C |

|

|

|

|

|

|

|

|

|

|

||||||||

Service Ref. |

|

|

intake |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-10 |

|

|

|

-5 |

|

0 |

|

|

|

|

5 |

10 |

|

|

|

|

|

15 |

|||||||||||||

|

|

air |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DB C |

|

CA |

|

P.C. |

|

CA |

|

P.C. |

|

CA |

|

P.C. |

|

CA |

|

P.C. |

|

CA |

|

P.C. |

|

CA |

|

P.C. |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

3,184 |

|

1.03 |

|

3,650 |

|

|

1.14 |

4,160 |

|

1.25 |

|

4,714 |

|

1.38 |

5,312 |

|

1.51 |

|

5,952 |

|

1.64 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PLH-1.6KKHB.UK |

|

20 |

3,049 |

|

1.11 |

|

3,506 |

|

|

1.23 |

4,003 |

|

1.35 |

|

4,538 |

|

1.48 |

5,112 |

|

1.62 |

|

5,724 |

|

1.77 |

||||||||

|

|

25 |

2,930 |

|

1.18 |

|

3,364 |

|

|

1.31 |

3,844 |

|

1.44 |

|

4,370 |

|

1.59 |

4,942 |

|

1.74 |

|

5,560 |

|

1.90 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

3,972 |

|

1.58 |

|

4,552 |

|

|

1.75 |

5,188 |

|

1.93 |

|

5,880 |

|

2.11 |

6,625 |

|

2.31 |

|

7,424 |

|

2.52 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PLH-2KKHB.UK |

|

20 |

3,803 |

|

1.71 |

|

4,373 |

|

|

1.89 |

4,993 |

|

2.08 |

|

5,661 |

|

2.28 |

6,376 |

|

2.49 |

|

7,139 |

|

2.71 |

||||||||

|

|

25 |

3,655 |

|

1.81 |

|

4,196 |

|

|

2.01 |

4,795 |

|

2.22 |

|

5,451 |

|

2.44 |

6,165 |

|

2.67 |

|

6,935 |

|

2.91 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

4,931 |

|

1.59 |

|

5,651 |

|

|

1.76 |

6,441 |

|

1.93 |

|

7,299 |

|

2.12 |

8,225 |

|

2.32 |

|

9,216 |

|

2.53 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PLH-2.5KKHB.UK |

|

20 |

4,721 |

|

1.71 |

|

5,429 |

|

|

1.89 |

6,198 |

|

2.09 |

|

7,027 |

|

2.29 |

7,916 |

|

2.50 |

|

8,863 |

|

2.73 |

||||||||

|

|

25 |

4,537 |

|

1.82 |

|

5,209 |

|

|

2.02 |

5,952 |

|

2.23 |

|

6,767 |

|

2.45 |

7,653 |

|

2.68 |

|

8,609 |

|

2.92 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note CA:Capacity (W) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

P.C.:Power consumption (kW) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Heating capacity correction factors |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Service Ref. |

|

|

|

|

|

|

|

|

|

|

|

Refrigerant piping length(one way) |

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

5m |

|

10m |

|

|

15m |

|

|

20m |

|

25m |

|

|

30m |

|

35m |

|

40m |

|

|

45m |

|

|

50m |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

PLH-1.6KKHB.UK |

|

1.00 |

|

1.00 |

|

|

1.00 |

|

|

1.00 |

|

1.00 |

|

|

1.00 |

0.998 |

|

0.995 |

|

|

— |

|

|

— |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

PLH-2KKHB.UK |

|

1.00 |

|

1.00 |

|

|

1.00 |

|

|

1.00 |

|

1.00 |

|

|

1.00 |

0.998 |

|

0.995 |

|

|

— |

|

|

— |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

PLH-2.5KKHB.UK |

|

1.00 |

|

1.00 |

|

|

1.00 |

|

|

1.00 |

|

1.00 |

|

|

1.00 |

0.998 |

|

0.995 |

|

0.993 |

|

0.990 |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heating performance curve(50Hz)

CAPACITY (RATIO)

TOTAL INPUT (RATIO)

1.4 |

|

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

1.2 |

|

|

|

|

|

|

|

|

|

25INDOOR DB ( C) |

|

|

|

|

|

|

|

|

|

||

1.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.4 |

|

|

|

|

|

|

|

|

|

25INDOOR DB ( C) |

|

|

|

|

|

|

|

|

|

||

1.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

15 |

1.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

5 10 15 |

|

|||||

-12-10 -5 |

|

|||||||||

OUTDOOR WB( C)

10

2. ELECTRICAL DATA

Indoor unit 220V 50Hz 1phase

Outdoor unit 220V 50Hz 1phase

Service Ref. |

Indoor unit |

PLH-1.6KKHB.UK |

PLH-2KKHB.UK |

PLH-2.5KKHB.UK |

|||||

|

|

|

|

|

|

|

|||

Outdoor unit |

PUH-1.6VKA3.UK |

PUH-2VKA2.UK |

PUH-2.5VKA2.UK |

||||||

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

Mode |

|

|

Cool |

Heat |

Cool |

Heat |

Cool |

Heat |

|

|

|

|

|

|

|

|

|

||

Capacity (W) |

4,300 |

4,550[5,720] |

5,300 |

5,700[6,870] |

6,200 |

6,900[8,660] |

|||

|

|

|

|

|

|

|

|

||

Total Input (kW) |

1.48 |

1.40[2.57] |

2.24 |

2.22[3.39] |

2.53 |

2.25[4.01] |

|||

|

|

|

|

|

|

|

|

|

|

unit |

Input (kW) |

0.12 |

0.08[1.25] |

0.12 |

0.08[1.25] |

0.12 |

0.09[1.85] |

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

Indoor |

Current (A) |

0.60 |

0.41[5.75] |

0.61 |

0.42[5.76] |

0.57 |

0.42[8.44] |

||

|

|

|

|

|

|

|

|

||

Starting current (A) |

0.66 |

0.45[6.14] |

0.67 |

0.46[6.14] |

0.63 |

0.46[8.79] |

|||

|

|

|

|

|

|

|

|

|

|

unit |

Input (kW) |

1.36 |

1.32 |

2.12 |

2.14 |

2.41 |

2.16 |

||

|

|||||||||

Outdoor |

|

|

|

|

|

|

|

|

|

Starting current (A) |

30 |

30 |

43 |

43 |

52 |

52 |

|||

|

Current (A) |

6.79 |

6.59 |

9.83 |

9.93 |

11.18 |

10.02 |

||

|

|

|

|

|

|

|

|

|

|

Indoor unit 230V 50Hz 1phase

Outdoor unit 230V 50Hz 1phase

Service Ref. |

Indoor unit |

PLH-1.6KKHB.UK |

PLH-2KKHB.UK |

PLH-2.5KKHB.UK |

|||||

|

|

|

|

|

|

|

|||

Outdoor unit |

PUH-1.6VKA3.UK |

PUH-2VKA2.UK |

PUH-2.5VKA2.UK |

||||||

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

Mode |

|

|

Cool |

Heat |

Cool |

Heat |

Cool |

Heat |

|

|

|

|

|

|

|

|

|

||

Capacity (W) |

4,350 |

4,600[5,890] |

5,350 |

5,750[7,040] |

6,250 |

7,050[8,980] |

|||

|

|

|

|

|

|

|

|

||

Total Input (kW) |

1.54 |

1.45[2.74] |

2.29 |

2.27[3.56] |

2.57 |

2.29[4.22] |

|||

|

|

|

|

|

|

|

|

|

|

unit |

Input (kW) |

0.14 |

0.09[1.38] |

0.13 |

0.09[1.38] |

0.13 |

0.09[2.02] |

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

Indoor |

Current (A) |

0.62 |

0.43[6.02] |

0.63 |

0.44[6.03] |

0.59 |

0.43[8.82] |

||

|

|

|

|

|

|

|

|

||

Starting current (A) |

0.68 |

0.47[6.39] |

0.69 |

0.48[6.39] |

0.65 |

0.47[9.19] |

|||

|

|

|

|

|

|

|

|

|

|

unit |

Input (kW) |

1.40 |

1.36 |

2.16 |

2.18 |

2.44 |

2.20 |

||

|

|||||||||

Outdoor |

|

|

|

|

|

|

|

|

|

Starting current (A) |

32 |

32 |

44 |

44 |

52 |

52 |

|||

|

Current (A) |

6.76 |

6.57 |

9.78 |

9.87 |

10.94 |

9.86 |

||

|

|

|

|

|

|

|

|

|

|

Indoor unit 240V 50Hz 1phase

Outdoor unit 240V 50Hz 1phase

Service Ref. |

Indoor unit |

PLH-1.6KKHB.UK |

PLH-2KKHB.UK |

PLH-2.5KKHB.UK |

|||||

|

|

|

|

|

|

|

|||

Outdoor unit |

PUH-1.6VKA3.UK |

PUH-2VKA2.UK |

PUH-2.5VKA2.UK |

||||||

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

Mode |

|

|

Cool |

Heat |

Cool |

Heat |

Cool |

Heat |

|

|

|

|

|

|

|

|

|

||

Capacity (W) |

4,400 |

4,650[6,050] |

5,400 |

5,800[7,200] |

6,300 |

7,200[9,300] |

|||

|

|

|

|

|

|

|

|

||

Total Input (kW) |

1.59 |

1.51[2.91] |

2.34 |

2.32[3.72] |

2.60 |

2.33[4.43] |

|||

|

|

|

|

|

|

|

|

|

|

unit |

Input (kW) |

0.15 |

0.10[1.50] |

0.14 |

0.10[1.50] |

0.14 |

0.10[2.20] |

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

Indoor |

Current (A) |

0.64 |

0.45[6.28] |

0.65 |

0.45[6.28] |

0.61 |

0.45[9.20] |

||

|

|

|

|

|

|

|

|

||

Starting current (A) |

0.70 |

0.50[6.63] |

0.72 |

0.50[6.63] |

0.67 |

0.50[9.55] |

|||

|

|

|

|

|

|

|

|

|

|

unit |

Input (kW) |

1.44 |

1.41 |

2.20 |

2.22 |

2.46 |

2.23 |

||

|

|||||||||

Outdoor |

|

|

|

|

|

|

|

|

|

Starting current (A) |

33 |

33 |

45 |

45 |

52 |

52 |

|||

|

Current (A) |

6.74 |

6.60 |

9.86 |

9.95 |

10.68 |

9.78 |

||

|

|

|

|

|

|

|

|

|

|

11

3. STANDARD OPERATION DATA

|

Service Ref. |

|

PLH-1.6KKHB.UK |

PLH-2KKHB.UK |

PLH-2.5KKHB.UK |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

Mode |

|

Cooling |

|

Heating |

Cooling |

|

Heating |

Cooling |

|

Heating |

|

|

|

|

|

|

|

|

|

|

|

|

|

Total |

Capacity |

W |

4,400 |

|

4,650 |

5,400 |

|

5,800 |

6,300 |

|

7,200 |

|

|

|

|

|

|

|

|

|

|

|

|

Input |

kW |

1.59 |

|

1.51 |

2.34 |

|

2.32 |

2.60 |

|

2.33 |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|||

|

Indoor unit Service Ref. |

PLH-1.6KKHB.UK |

PLH-2KKHB.UK |

PLH-2.5KKHB.UK |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Phase,Hz |

|

|

1,50 |

|

1,50 |

|

1,50 |

|||

circuit |

|

|

|

|

|

|

|

|

|

|

|

Volts |

V |

|

240 |

|

240 |

|

240 |

||||

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Electrical |

Amperes |

A |

0.64 |

|

0.45 |

0.65 |

|

0.45 |

0.61 |

|

0.45 |

|

|

|

|

|

|

|

|

|

|

|

|

Phase,Hz |

|

|

1,50 |

|

1,50 |

|

1,50 |

||||

|

Outdoor unit Service Ref. |

PUH-1.6VKA3.UK |

PUH-2VKA2.UK |

PUH-2.5VKA2.UK |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Volts |

V |

|

240 |

|

240 |

|

240 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Amperes |

A |

6.74 |

|

6.60 |

9.86 |

|

9.95 |

10.68 |

|

9.78 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Discharge pressure |

MPa·G |

1.80 |

|

1.70 |

1.90 |

|

1.94 |

1.95 |

|

1.71 |

|

(O/F·G) |

(18.3) |

|

(17.3) |

(19.3) |

|

(19.7) |

(19.8) |

|

(17.4) |

|

circuit |

|

|

|

|

|||||||

Suction pressure |

MPa·G |

0.54 |

|

0.40 |

0.46 |

|

0.34 |

0.50 |

|

0.36 |

|

|

(O/F·G) |

(5.51) |

|

(4.08) |

(4.69) |

|

(3.47) |

(5.1) |

|

(3.67) |

|

|

|

|

|

|

|||||||

Refrigerant |

Discharge temperature |

C |

78.7 |

|

77.2 |

84.0 |

|

86.4 |

82.8 |

|

76.0 |

|

|

|

|

|

|

|

|

|

|

|

|

Condensing temperature |

C |

48.5 |

|

— |

50.7 |

|

— |

51.8 |

|

— |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Suction temperature |

C |

8.5 |

|

0.7 |

4.8 |

|

–1.8 |

6.7 |

|

–1.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Ref. pipe length |

m |

5 |

|

5 |

5 |

|

5 |

5 |

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

side |

Intake air temperature |

DB C |

27 |

|

20 |

27 |

|

20 |

27 |

|

20 |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

Indoor |

|

WB C |

19 |

|

15 |

19 |

|

15 |

19 |

|

15 |

|

|

|

|

|

|

|

|

|

|

|

|

Discharge air temperature |

DB C |

16.1 |

|

35.2 |

15.0 |

|

39.4 |

13.8 |

|

41.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor side |

|

WB C |

24 |

|

6 |

24 |

|

6 |

24 |

|

6 |

|

Intake air temperature |

DB C |

35 |

|

7 |

35 |

|

7 |

35 |

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SHF |

|

0.83 |

|

— |

0.76 |

|

— |

0.75 |

|

— |

|

|

|

|

|

|

|

|

|

|

|

|

|

BF |

|

0.21 |

|

— |

0.21 |

|

— |

0.14 |

|

— |

|

|

|

|

|

|

|

|

|

|

|

|

The unit of pressure has been changed to Mpa on the international system of unit (SI unit system.) The converted score against the traditional unit system can be gotten according to the formula below.

1 (Mpa·G)=10.2(O/F·G)

4. OUTLET AIR SPEED AND COVERAGE RANGE

|

Service Ref. |

|

PLH-1.6KKHB.UK |

PLH-2KKHB.UK |

PLH-2.5KKHB.UK |

|

|

|

|

|

|

|

|

Standard |

Air flow |

m3/min |

16.0 |

16.0 |

17.0 |

|

Air speed |

m/sec. |

5.6 |

5.6 |

5.9 |

||

|

||||||

|

|

|

|

|

|

|

|

Coverage range |

m |

6.0 |

6.0 |

6.4 |

|

|

|

|

|

|

|

|

ceiling |

Air flow |

m3/min |

17.0 |

17.0 |

18.0 |

|

Air speed |

m/sec. |

5.9 |

5.9 |

6.3 |

||

|

||||||

High |

|

|

|

|

|

|

Coverage range |

m |

6.4 |

6.4 |

6.8 |

||

|

||||||

|

|

|

|

|

|

|

|

Total width of dischsrge outlets |

mm |

0 |

0 |

0 |

|

|

|

|

|

|

|

wThe air coverage range is the value up to the position where the air speed is 0.25m/sec. When air is blown out horizontally from the unit at the Hi notch position.

The coverage range should be used only as a general guideline since it varies according to the size of the room and the furniture inside the room.

12

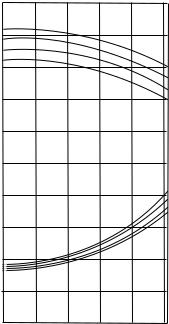

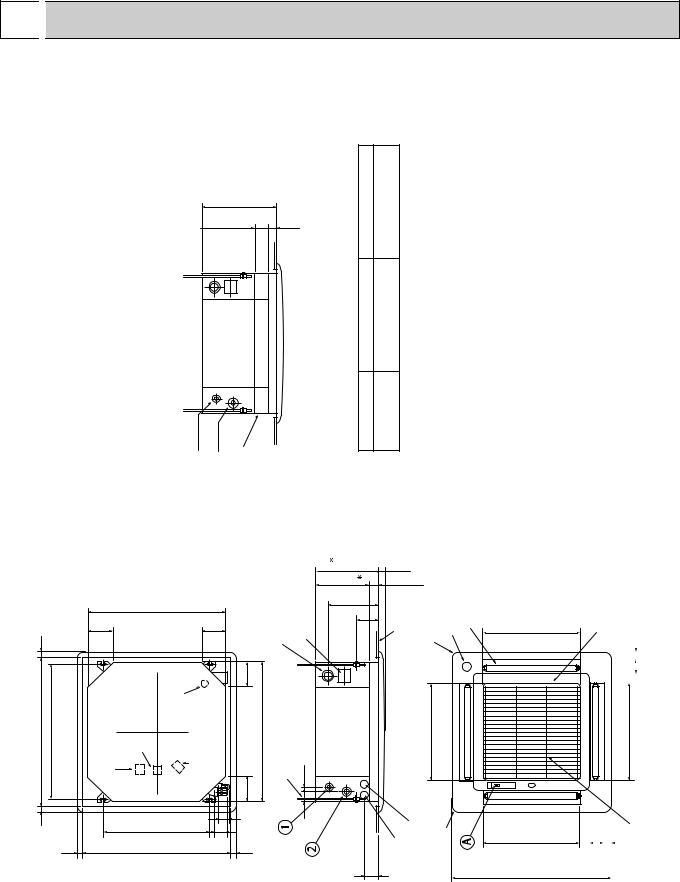

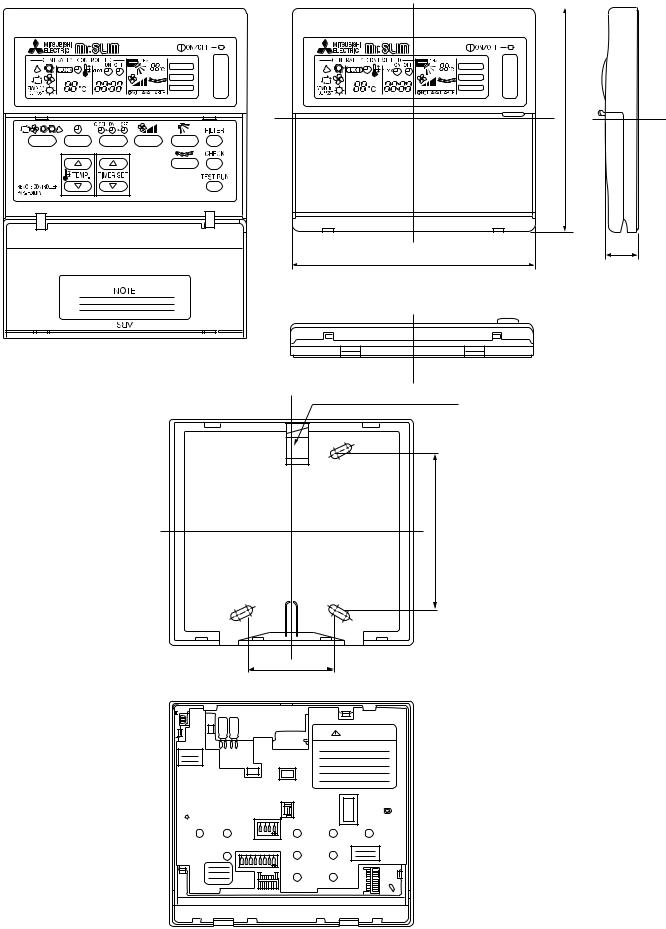

5

OUTLINES AND DIMENSIONS

OUTLINES AND DIMENSIONS

1.INDOOR UNIT PLH-1.6KKHB.UK PLH-2KKHB.UK PLH-2.5KKHB.UK

partselectricalForNOTE1.box may be removed during servicing. When |

linepowertheconnectingand the control wire, provide enough length to |

wires.electricthe theinstallingWhenNOTE2.optional high-efficiency filter, the dimension |

andtransomthebetweenceiling shall be more than 440mm. Also,when |

casement,optionaltheinstallingthe dimension between the transom |

morebeshallceilingandthan 440m. (The optional highefficiency filter |

installed.)bealsocan |

|

|

pipeLiquid |

|

pipeGas |

hilterefficiency |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

435 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

135 |

|

|

45 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Optional high- |

|

|

|

|

|

|

|

|

|

|

|

|

660 |

|

|

|

|

|

|

Drainhole 25-VPconnection |

Feedinghole |

(Drainpump) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25~35 690~710 25~35 |

|

|

|

117 |

|

|

|

117 |

|

|

|

|

|

||

|

Ceiling hole |

640 |

Suspension bolt pitch |

|

Terminal block for control |

Terminal block for remote controller |

Drain hole |

Terminal block for |

power supply |

|

117 117 |

660 |

Suspension bolt M10 or |

W3/8 |

41 25 |

||

|

|

|

|

|

|

|

Suspensionboltpitch |

|

53 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

507 |

|

|

|

54 |

|

|

|

|

|