Mitsubishi PLFY-P20VLMD-A, PLFY-P25VLMD-A, PLFY-P32VLMD-A, PLFY-P40VLMD-A, PLFY-P50VLMD-A Service Manual

...

2001

Air-Conditioners For Building Application

TECHNICAL & SERVICE MANUAL

Series PLFY Ceiling Cassettes

<Indoor unit>

Models PLFY-P20VLMD-A,PLFY-P63VLMD-A PLFY-P25VLMD-A,PLFY-P80VLMD-A PLFY-P32VLMD-A,PLFY-P100VLMD-A PLFY-P40VLMD-A,PLFY-P125VLMD-A PLFY-P50VLMD-A

CONTENTS

SAFETY PRECAUTIONS ·························1

1. FEATURES············································3

2. PART NAMES AND FUNCTIONS ········4

3. SPECIFICATION ···································6

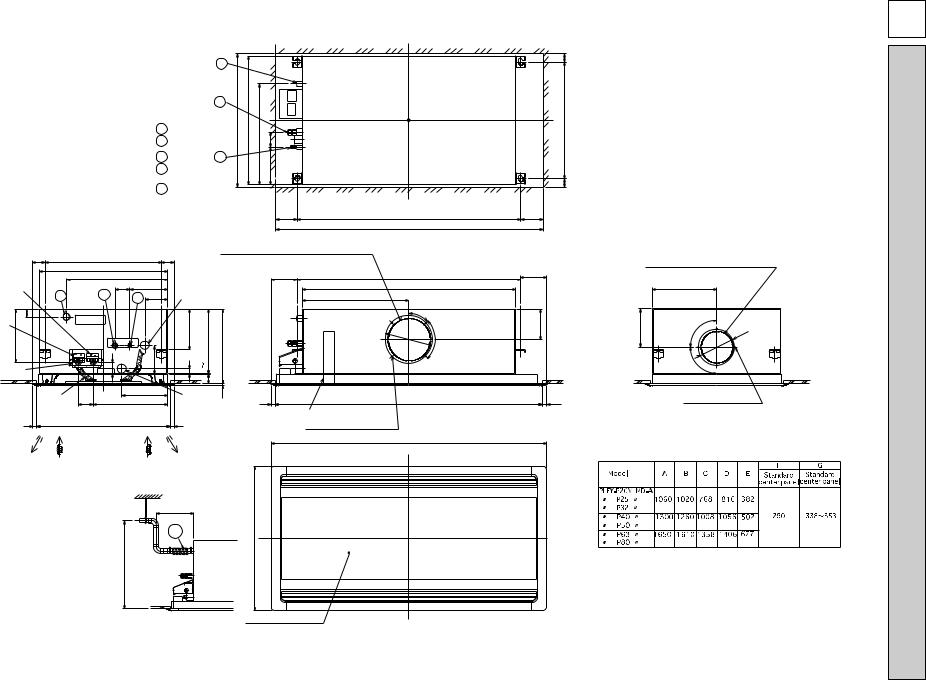

4. OUTLINES AND DIMENSIONS············8

5. WIRING DIAGRAM ·····························10

6. REFRIGERANT SYSTEM DIAGRAM····11

7. TROUBLE SHOOTING························12

8. DISASSEMBLY PROCEDURE ···········17

INDOOR UNIT

For use with the R407C & R22

SAFETY PRECAUTIONS

1.Before installation and electric work

sBefore installing the unit, make sure you read all the “Safety precautions”.

sThe “Safety precautions” provide very important points regarding safety. Make sure you follow them.

sThis equipment may not be applicable to EN61000-3- 2: 1995 and EN61000-3-3: 1995.

sThis equipment may cause the adverse effect on the same supply system.

sPlease report to or take consent by the supply authority before connection to the system.

Symbols used in the text

Warning:

Warning:

Describes precautions that should be observed to prevent danger of injury or death to the user.

Caution:

Caution:

Describes precautions that should be observed to prevent damage to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts. (This symbol is displayed on the main unit label.) <Color: Yellow>

: Indicates that caution should be taken with rotating parts. (This symbol is displayed on the main unit label.) <Color: Yellow>

: Beware of electric shock (This symbol is displayed on the main unit label.) <Color: Yellow>

: Beware of electric shock (This symbol is displayed on the main unit label.) <Color: Yellow>

Warning:

Warning:

Carefully read the labels affixed to the main unit.

Warning:

Warning:

•Ask the dealer or an authorized technician to install the air conditioner.

-Improper installation by the user may result in water leakage, electric shock, or fire.

•Install the air unit at a place that can withstand its weight.

-Inadequate strength may cause the unit to fall down, resulting in injuries.

•Use the specified cables for wiring. Make the connections securely so that the outside force of the cable is not applied to the terminals.

-Inadequate connection and fastening may generate heat and cause a fire.

•Prepare for typhoons and other strong winds and earthquakes and install the unit at the specified place.

-Improper installation may cause the unit to topple and result in injury.

•Always use an air cleaner, humidifier, electric heater, and other accessories specified by Mitsubishi Electric.

-Ask an authorized technician to install the accessories. Improper installation by the user may result in water leakage, electric shock, or fire.

•Never repair the unit. If the air conditioner must be repaired, consult the dealer.

-If the unit is repaired improperly, water leakage, electric shock, or fire may result.

•Do not touch the heat exchanger fins.

-Improper handling may result in injury.

•If refrigerant gas leaks during installation work, ventilate the room.

-If the refrigerant gas comes into contact with a flame, poisonous gases will be released.

•Install the air conditioner according to this Installation Manual.

-If the unit is installed improperly, water leakage, electric shock, or fire may result.

•Have all electric work done by a licensed electrician according to “Electric Facility Engineering Standard” and “Interior Wire Regulations”and the instructions given in this manual and always use a special circuit.

-If the power source capacity is inadequate or electric work is performed improperly, electric shock and fire may result.

•Securely install the cover of control box and the panel.

-If the cover and panel are not installed properly,dust or water may enter the outdoor unit and fire or electric shock may result.

•When installing and moving the air conditioner to another site, do not charge the it with a refrigerant different from the refrigerant (R407C or R22) specified on the unit.

-If a different refrigerant or air is mixed with the original refrigerant, the refrigerant cycle may malfunction and the unit may be damaged.

•If the air conditioner is installed in a small room, measures must be taken to prevent the refrigerant concentration from exceeding the safety limit even if the refrigerant should leak.

-Consult the dealer regarding the appropriate measures to prevent the safety limit from being exceeded. Should the refrigerant leak and cause the safety limit to be exceeded, hazards due to lack of oxygen in the room could result.

•When moving and reinstalling the air conditioner, consult the dealer or an authorized technician.

-If the air conditioner is installed improperly, water leakage, electric shock, or fire may result.

•After completing installation work, make sure that refrigerant gas is not leaking.

-If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or other heat source, it may generate noxious gases.

•Do not reconstruct or change the settings of the protection devices.

-If the pressure switch, thermal switch, or other protection device is shorted and operated forcibly, or parts other than those specified by Mitsubishi Electric are used, fire or explosion may result.

1

2.Precautions for devices that use R407C refrigerant

Caution:

Caution:

•Do not use the existing refrigerant piping.

-The old refrigerant and refrigerator oil in the existing piping contains a large amount of chlorine which may cause the refrigerator oil of the new unit to deteriorate.

•Use refrigerant piping made of C1220 (CU-DHP) phosphorus deoxidized copper as specified in the *JIS H3300 “Copper and copper alloy seamless pipes and tubes”. In addition, be sure that the inner and outer surfaces of the pipes are clean and free of hazardous sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or any other contaminant.

-Contaminants on the inside of the refrigerant piping may cause the refrigerant residual oil to deteriorate.

*JIS:Japanese Industrial Standard

•Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before brazing. (Store elbows and other joints in a plastic bag.)

-If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

•Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator oil to coat flares and flange connections.

-The refrigerator oil will degrade if it is mixed with a large amount of mineral oil.

•Use liquid refrigerant to fill the system.

-If gas refrigerant is used to seal the system, the composition of the refrigerant in the cylinder will change and performance may drop.

•Do not use a refrigerant other than R407C.

-If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may cause the refrigerator oil to deteriorate.

•Use a vacuum pump with a reverse flow check valve..

-The vacuum pump oil may flow back into the refrigerant cycle and cause the refrigerator oil to deteriorate.

•Do not use the following tools that are used with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow check valve, refrigerant charge base, vacuum gauge, refrigerant recovery equipment)

-If the conventional refrigerant and refrigerator oil are mixed in the R407C, the refrigerant may deteriorated.

-If water is mixed in the R407C, the refrigerator oil may deteriorate.

-Since R407C does not contain any chlorine, gas leak detectors for conventional refrigerants will not react to it.

•Do not use a charging cylinder.

-Using a charging cylinder may cause the refrigerant to deteriorate.

•Be especially careful when managing the tools.

-If dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deteriorate.

2

1

FEATURES

FEATURES

Series PLFY Ceiling Cassettes

Indoor unit

Cooling capacity/Heating capacity

Models

kW

PLFY-P20VLMD-A |

2.2/ |

2.5 |

PLFY-P25VLMD-A |

2.8/ |

3.2 |

PLFY-P32VLMD-A |

3.6/ |

4.0 |

PLFY-P40VLMD-A |

4.5/ |

5.0 |

PLFY-P50VLMD-A |

5.6/ |

6.3 |

PLFY-P63VLMD-A |

7.1/ |

8.0 |

PLFY-P80VLMD-A |

9.0/ 10.0 |

|

PLFY-P100VLMD-A |

11.2/ |

12.5 |

PLFY-P125VLMD-A |

14.0/ |

16.0 |

|

|

|

3

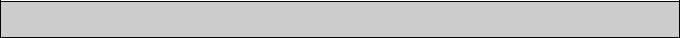

2

PART NAMES AND FUNCTIONS

PART NAMES AND FUNCTIONS

● Indoor (Main) Unit

Autovane

Disperses the airflow up and down and adjusts the angle of the airflow.

Long-life filter

Removes the sucked-in dust and dirt. Since the long-life filter is used as an air filter, it should be cleaned at the beginning of air-cooling and heating seasons. (During seasons with large amounts of dust and dirt, more frequent cleaning are recommended.)

Air inlet

Sucks the ambient air in.

● Remote controller [PAR-20MAA]

●Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

● Operation buttons

1

2

3

|

CENTRALLY CONTROLLED |

1Hr. |

|

|

|

|

ON OFF |

|

˚C |

|

CHECK |

CLOCK |

|

|

|

|

|

|

|

|

|

|

|

FILTER |

|

˚C |

|

|

CHECK MODE |

STAND BY |

ERROR CODE |

|

TEST RUN |

|

|

NOT AVAILABLE |

FUNCTION |

||

DEFROST |

|

|||

|

|

|||

|

TEMP. |

|

|

ON/OFF |

FILTER

CHECK TEST

PAR-20MAA |

TIMER SET |

B

A 0

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 5 6 8 7 9 |

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||

1 |

[Room temperature adjustment] Button |

7 |

[Up/down airflow direction] Button |

||||||||

2 |

[Timer/continuous] Button |

8 |

[Ventilation] Button |

||||||||

3 |

[Selecting operation] Button |

9 |

[Checking/built-in] Button |

||||||||

4 |

[Time selection] Button |

0 |

[Test run] Button |

||||||||

|

[Time-setting] Button |

A [Filter] Button |

|||||||||

5 |

[Louver] Button |

B [ON/OFF] Button |

|||||||||

6 |

[Fan speed adjustment] Button |

C Position of built-in room temperature |

|||||||||

•Never expose the remote controller to direct sunlight. Doing so can result in the erroneous measurement of room temperature.

•Never place any obstacle around the lower right-hand section of the remote controller. Doing so can result in the erroneous measurement of room temperature.

4

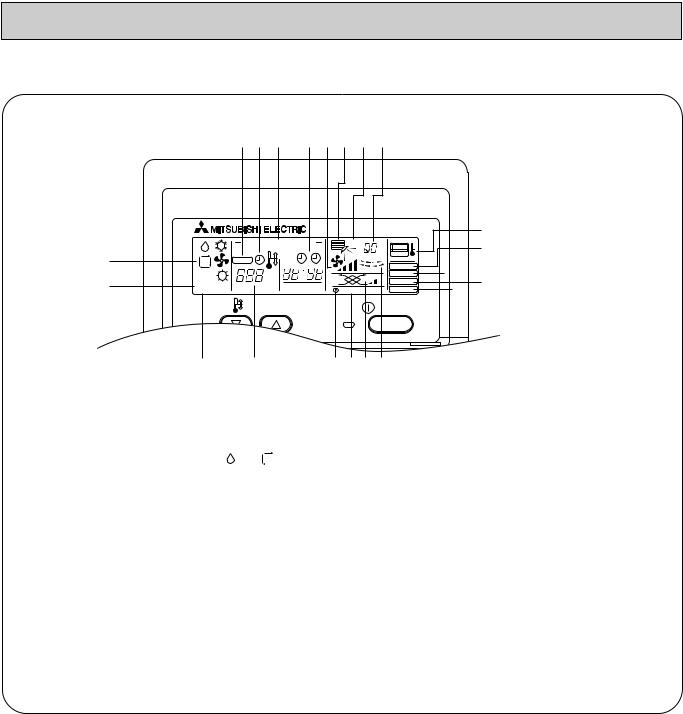

● Display

D C B A U T Q S

|

|

CENTRALLY CONTROLLED |

1Hr. |

|

E |

|

|

ON OFF |

˚C |

|

CHECK |

CLOCK |

|

|

|

|

|

|

|

|

|

|

|

FILTER |

|

|

˚C |

|

CHECK MODE |

F |

STAND BY |

ERROR CODE |

TEST RUN |

|

|

NOT AVAILABLE FUNCTION |

|||

DEFROST |

|

|||

|

|

TEMP. |

|

ON/OFF |

G H I KLJ

(A)Current time/Timer

(B)Centralized control

(C)Timer ON

(D)Abnormality occurs

(E)Operation mode: COOL, DRY,

COOL, DRY,

AUTO,

AUTO, FAN,

FAN, HEAT

HEAT

(F)Preparing for Heating mode

(G)Defrost mode

(H)Set temperature

(I)Power ON

(J)Louver

(K)Not available function

(L)Ventilation

(M)Function setting mode

(N)Test run mode

(O)Error check mode

(P)Filter sign

(Q)Set effective for 1 hr.

(R)Sensor position

(S)Room temperature

(T)Airflow

(U)Fan speed

R

P

O N

O N  M

M

5

3

SPECIFICATION

SPECIFICATION

3-1. Specification

Item |

Model |

|

PLFY-P20 |

PLFY-P25 |

PLFY-P32 |

PLFY-P40 |

PLFY-P50 |

|

|

|

|

VLMD-A |

VLMD-A |

VLMD-A |

VLMD-A |

VLMD-A |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

Power source |

Voltage |

|

~V |

|

|

220-240 |

|

|

Frequency |

|

Hz |

|

|

50 |

|

|

|

|

|

|

|

|

|

|||

Cooling capacity |

|

kW |

2.2 |

2.8 |

3.6 |

4.5 |

5.6 |

|

Heating capacity |

|

kW |

2.5 |

3.2 |

4.0 |

5.0 |

6.3 |

|

Power consumption |

Cooling |

|

kW |

0.09 |

0.10 |

0.16 |

||

Heating |

|

kW |

0.08 |

0.09 |

0.15 |

|||

|

|

|||||||

Current |

Cooling |

|

A |

0.43 |

0.48 |

0.77 |

||

Heating |

|

A |

0.38 |

0.43 |

0.71 |

|||

|

|

|||||||

External finish (Munsel No.) |

|

|

Unit: Galvanized steel plate Panel: 0.70Y8.59/0.97 |

|||||

|

Height |

|

mm |

|

|

338<8> |

|

|

Dimension |

Width |

|

mm |

|

768<1,060> |

|

1,008<1,300> |

|

|

Depth |

|

mm |

|

|

606<670> |

|

|

Net weight |

|

kg |

24<7> |

25<7> |

33.5<8> |

35<8> |

||

Heat exchanger |

|

|

Cross fin( Alminium plate fin and copper tube) |

|||||

|

Type |

|

|

|

Sirocco fanX1 |

Sirocco fanX2 |

||

Fan |

Airflow rate |

|

m3/min |

6.0-6.5-7.3-8.0 |

6.5-7.0-7.8-8.5 |

9.0-10.5-11.5-12.5 |

10.0-11.0-12.0-13.0 |

|

(Low-Middle2-Middle1-High) |

|

|||||||

|

External static pressure |

|

Pa |

|

|

0 |

|

|

Motor |

Type |

|

|

|

Single phase induction motor |

|

||

Output |

|

kW |

|

0.033 |

|

0.075 |

||

|

|

|

|

|||||

Air filter |

|

|

Synthetic fiber unwoven cloth filter( long life) |

|||||

Refrigerant |

Gas(Flare) |

|

mm |

|

ø12.7 |

|

ø15.88 |

|

pipe dimension |

Liquid(Flare) |

|

mm |

|

ø6.35 |

|

ø9.52 |

|

Drain pipe dimension |

|

|

|

|

VP-25 |

|

|

|

Noise level (Low-Middle2-Middle1-High) |

|

dB(A) |

28-30-33-35 |

29-31-34-36 |

29-32-34-36 |

32-34-36-38 |

||

Note:1

Note:1

Note:2

Note:2

Note:2

Note:2

Item |

|

Model |

|

PLFY-P63 |

PLFY-P80 PLFY-P100 PLFY-P125 |

|||

|

|

|

|

VLMD-A |

VLMD-A |

VLMD-A |

VLMD-A |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Power source |

|

Voltage |

|

~V |

|

220-240 |

|

|

|

Frequency |

|

Hz |

|

50 |

|

|

|

|

|

|

|

|

|

|||

Cooling capacity |

|

kW |

7.1 |

9.0 |

11.2 |

14.0 |

||

Heating capacity |

|

kW |

8.0 |

10.0 |

12.5 |

16.0 |

||

Power consumption |

|

Cooling |

|

kW |

0.22 |

0.23 |

0.25 |

0.28 |

|

Heating |

|

kW |

0.21 |

0.22 |

0.24 |

0.27 |

|

|

|

|

||||||

Current |

|

Cooling |

|

A |

1.05 |

1.10 |

1.20 |

1.35 |

|

Heating |

|

A |

1.00 |

1.05 |

1.15 |

1.33 |

|

|

|

|

||||||

External finish (Munsel No.) |

|

|

Unit: Galvanized steel plate |

Panel: 0.70Y8.59/0.97 |

||||

|

|

Height |

|

mm |

|

338<8> |

|

|

Dimension |

|

Width |

|

mm |

1,358<1,650> |

1,708<2,000> |

||

|

|

Depth |

|

mm |

|

606<670> |

|

|

Net weight |

|

kg |

39<10> |

41<10> |

56<11.5> |

|||

Heat exchanger |

|

|

Cross fin( Alminium plate fin and copper tube) |

|||||

|

|

Type |

|

|

Sirocco fanX2 |

Sirocco fanX4 |

||

Fan |

|

Airflow rate |

|

m3/min |

13.0-14.0-16.0-18.0 15.0-17.0-19.0-21.0 21.0-23.0-26.0-29.0 24.0-27.0-30.0-33.0 |

|||

(Low-Middle2-Middle1-High) |

|

|||||||

|

|

External static pressure |

|

Pa |

|

0 |

|

|

Motor |

|

Type |

|

|

Single phase induction motor |

|

||

|

Output |

|

kW |

0.078 |

0.078X2 |

|||

|

|

|

||||||

Air filter |

|

|

Synthetic fiber unwoven cloth filter( long life) |

|||||

Refrigerant |

|

Gas(Flare) |

|

mm |

ø15.88 |

ø19.05 |

|

|

pipe dimension |

|

Liquid(Flare) |

|

mm |

|

ø9.52 |

|

|

Drain pipe dimension |

|

|

|

VP-25 |

|

|||

Noise level (Low-Middle2-Middle1-High) |

|

dB(A) |

32-34-37-39 36-38-41-43 |

37-39-41-43 40-42-44-46 |

||||

Note: 1.Cooling / Heating capacity indicates the maximum value at operation under the following condition. |

||||||||

Cooling |

:Indoor 27¡CDB/19¡CWB |

Heating :Indoor 20¡C |

|

|

||||

|

|

:Outdoor 35¡CDB |

|

:Outdoor 7¡CDB/6¡CWB |

|

|||

2.The figure in < > indicates panel´s. |

|

|

|

|

|

|||

Note:1

Note:1

Note:2

Note:2

Note:2

Note:2

6

3-2. Electrical parts specifications

Model

Parts

name

Tranrsformer

Room temperature thermistor

Liquid pipe thermistor

Gas pipe thermistor

Fuse

(Indoor controller board)

Fan motor (with Inner-

thermostat)

Innerthermostat

(Fan motor)

Fan motor capacitor

Vane motor (with limit

switch)

Drain-up mechanism

Drain sensor

Linear expansion valve

Power supply terminal bed

Transmission

terminal bed

Symbol

T

TH21

TH22

TH23

FUSE

MF1,2

C1

MV

DP

DS

LEV

TB2

TB5

TB15

PLFY-P20 |

PLFY-P25 |

PLFY-P32 |

PLFY-P40 |

PLFY-P50 |

PLFY-P63 |

PLFY-P80 |

PLFY-P100 |

PLFY-P125 |

VLMD-A |

VLMD-A |

VLMD-A |

VLMD-A |

VLMD-A |

VLMD-A |

VLMD-A |

VLMD-A |

VLMD-A |

|

|

|

|

|

|

|

|

|

(Primary) 50/60Hz 220-240V (Secondry) (18.4V 1.7A)

Resistance 0˚C/15kW,10˚C/9.6kW˚C/6.3kW,25˚C/5.4kW,30˚C/4.3kW,40˚C/3.0kW

Resistance 0˚C/15kW,10˚C/9.6kW,20˚C/6.3kW,25˚C/5.4kW,30˚C/4.3kW,40˚C/3.0kW

Resistance 0˚C/15kW,10˚C/9.6kW,20˚C/6.3kW,25˚C/5.4kW,30˚C/4.3kW,40˚C/3.0kW

|

|

250V |

6.3A |

|

|

4-pole OUTPUT 33W |

|

4-pole Output 75W |

|

4-pole Output 78W |

|

|

|

||||

D094P35MW |

|

D104P85MW |

|

|

D104P95MW |

|

|

|

|

|

|

OFF 130˚C±5˚C

ON 90˚C±20˚C

2.5µFX440V |

5.0µF |

4.0µF |

6.0µF |

5.0µFX440V |

|

X440V |

X440V |

X440V |

|||

|

|

||||

|

|

|

|

|

MULB49Z 2.5/2W 4.99/5.99R.P.M

PJV-0720

INPUT 8/7.5W 24R/Hr

Heater resistance 82W/25˚C

Thermistor resistance 0˚C/15kW,10˚C/9.6kW,20˚C/6.3kW,25˚C/5.4kW,30˚C/4.3kW,40˚C/3.0kW

DC12V Stepping motor drive port |

DC12V Stepping motor drive |

dimension 3.2W (0~2000pulse) |

port dimension 5.2W(0~2000pulse) |

EDM-402MD |

EDM-804MD |

(L,N, ) 330V 30A |

|

(1,2),(M1,M2,S) 300V 10A |

|

7

Note:1.Use M10 screw for the lifing bolt (field supply).

|

|

|

<flare> |

1 |

|

Model |

Gas pipe |

:LP |

ø 12.7 |

||

·············· |

|||||

20·25·32·40 |

Liquid pipe :HP |

ø 6.35 |

·············· |

||

|

|

|

|

2 |

|

Model |

Gas pipe |

:LP |

ø15.88 |

··············1 |

|

50·63·80 |

Liquid pipe :HP |

ø 9.52 |

·············· |

||

|

|

|

|

2 |

|

Drain hose |

VP-25<flexible joint> (accessory) ········ 3 |

||||

3

1

630 |

606 |

|

|

476 |

70 |

2 |

|

178 |

|

|

102 |

D |

|

B |

Branch duct ø200 knock out hole (both side)

|

60 |

550(Lifting bolt pitch) |

|

60 |

|

|

|

|

|

606 |

|

|

|

|

|

|

|

|

476 |

|

|

|

|

Terminal bed(Power source) |

|

70 |

178 |

|

|

|

|

|

3 |

1 |

2 |

106 |

Water filling port |

||

Terminal bed(Transmission) |

38 |

|

|

|

|

|

|

|

|

|

|

192 |

|

|

|

235 |

|

|

|

|

F |

G |

|

Terminal box |

52 |

|

135 |

35 |

18 |

|

|

|

|

|

|

3 |

|

||

|

|

|

|

45 |

|

||

|

|

|

|

|

|

|

|

|

Air filter |

|

222 |

|

|

8 |

|

|

70 |

350 |

|

Drain hole |

|||

|

|

|

|||||

|

|

|

|

||||

122 |

D(Lifting bolt pitch) |

|

C |

|

E |

|

|

|

|

|

45˚ |

|

ø |

224 |

90˚ |

|

|

||

|

|

|

|

20 |

|

B (Ceiling opening) |

|

|

|

|

Control box |

20 |

630(Ceiling opening) |

20 |

4-ø2.9Mounting hole |

|

|

|

A

|

300mm or less |

|

|

3 |

670 |

600mmMAX |

|

Standard center panel

8

40 550 40

102

|

|

Fresh air intake ø150 knock out hole |

||

122 |

|

|

|

|

|

|

303 |

|

|

145 |

181 |

90˚ |

ø |

172 |

|

|

|

||

|

|

90˚ |

|

|

20 |

4-ø2.9Mounting hole |

A-P20·25·32·40·50·63·80VLMD-PLFY Unit Indoor

mm : Unit

DIMENSIONS AND OUTLINES 4

Loading...

Loading...