Mitsubishi PLFY-P20VCM-E2.TH, PLFY-P25VCM-E2.TH, PLFY-P32VCM-E2.TH, PLFY-P40VCM-E2.TH Service Manual

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

May 2009

No.OCH463

TECHNICAL & SERVICE MANUAL

R410A R407C

R22

R22

Indoor unit |

|

[Model names] [Service Ref.] |

|

PLFY-P20VCM-E2 |

PLFY-P20VCM-E2.TH |

|

|

PLFY-P25VCM-E2 |

PLFY-P25VCM-E2.TH |

|

|

PLFY-P32VCM-E2 |

PLFY-P32VCM-E2.TH |

|

|

PLFY-P40VCM-E2 |

PLFY-P40VCM-E2.TH |

|

|

Note :

•This manual describes only service data of the indoor units.

•RoHS compliant products have <G> mark on spec name plate.

|

CONTENTS |

|

|

|

|

.......................... |

|||

|

1. SAFETY PRECAUTION |

|

|

2 |

|

2. PART NAMES AND FUNCTIONS.......... 6 |

|||

|

................................... |

|||

|

3. SPECIFICATIONS |

|

|

9 |

|

................. |

11 |

||

|

4. 4-WAY AIR FLOW SYSTEM |

............ |

||

|

5. OUTLINES AND DIMENSIONS |

13 |

||

|

|

|

||

|

............................... |

14 |

||

|

6. WIRING DIAGRAM |

|

|

|

|

7. REFRIGERANT SYSTEM DIAGRAM |

...... |

15 |

|

|

|

|||

|

.......................... |

16 |

||

|

8. TROUBLESHOOTING |

|

|

|

|

9. DISASSEMBLY PROCEDURE............. |

23 |

||

Model name |

INDOOR UNIT |

|

|

|

indication |

PARTS CATALOG (OCB463) |

|

|

|

1

SAFETY PRECAUTION

SAFETY PRECAUTION

CAUTIONS RELATED TO NEW REFRIGERANT

Cautions for units utilizing refrigerant R407C

Do not use the existing refrigerant piping.

The old refrigerant and lubricant in the existing piping contains a large amount of chlorine which may cause the lubricant deterioration of the new unit.

Use liquid refrigerant to charge the system.

If gas refrigerant is used to seal the system, the composition of the refrigerant in the cylinder will change and performance may drop.

Use “low residual oil piping”

If there is a large amount of residual oil (hydraulic oil, etc.) inside the piping and joints, deterioration of the lubricant will result.

Store the piping to be used indoors during installation and both ends sealed until just before brazing.

(Store elbows and other joints in a plastic bag.)

If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

Use ESTR , ETHER or HAB as the lubricant to coat flares and flange connection parts.

If large amount of mineral oil enters, that can cause deterioration of refrigerant oil etc.

Do not use a refrigerant other than R407C.

If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may cause the lubricant deterioration.

Use a vacuum pump with a reverse flow check valve.

The vacuum pump oil may flow back into the refrigerant cycle and cause the lubricant deterioration.

Ventilate the room if refrigerant leaks during operation. If refrigerant comes into contact with a flame, poisonous gases will be released.

[1]Cautions for service

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of liquid refrigerant.

2

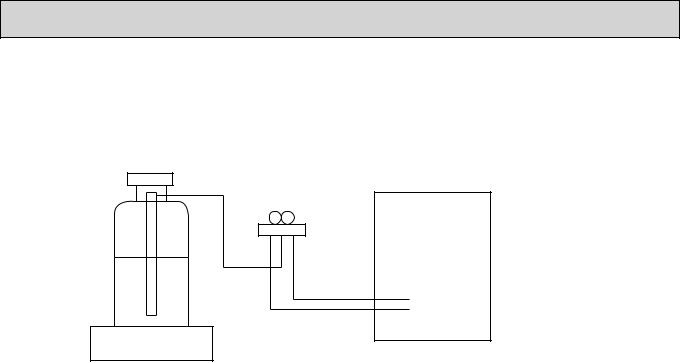

[2]Refrigerant recharging

(1)Refrigerant recharging process 1Direct charging from the cylinder

·R407C cylinder which is available on the market has a syphon pipe. ·Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

Unit

Gravimeter

(2) Recharge in refrigerant leakage case

·After recovering all the refrigerant in the unit, proceed to working. ·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of liquid refrigerant.

[3] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. |

Tool name |

Specifications |

|

|

|

1 |

Gauge manifold |

· Only for R407C |

|||

|

|

· Use the existing fitting SPECIFICATIONS. (UNF7/16) |

|||

|

|

· Use high-tension side pressure of 3.43MPa·G or over. |

|||

2 |

Charge hose |

· Only for R407C |

|||

|

|

· Use pressure performance of 5.10MPa·G or over. |

|||

3 |

Electronic scale |

|

|

|

|

|

|

|

|

||

4 |

Gas leak detector |

· Use the detector for R134a or R407C. |

|||

5 |

Adapter for reverse flow check |

· Attach on vacuum pump. |

|||

6 |

Refrigerant charge base |

|

|

|

|

|

|

|

|

||

7 |

Refrigerant cylinder |

· For R407C |

· Top of cylinder (Brown) |

||

|

|

· Cylinder with syphon |

|||

8 |

Refrigerant recovery equipment |

|

|

|

|

|

|

|

|

||

3

Cautions for units utilizing refrigerant R410A

Do not use the existing refrigerant piping.

The old refrigerant and lubricant in the existing piping contains a large amount of chlorine which may cause the lubricant deterioration of the new unit.

Use “low residual oil piping”

If there is a large amount of residual oil (hydraulic oil, etc.) inside the piping and joints, deterioration of the lubricant will result.

Store the piping to be used indoors during installation and both ends of the piping sealed until just before brazing. (Leave elbow joints, etc. in their packaging.)

If dirt, dust or moisture enters into refrigerant cycle, that can cause deterioration of refrigerant oil or malfunction of compressor.

Use ester oil, ether oil or alkylbenzene oil (small amount) as the refrigerant oil applied to flares and flange connections.

If large amount of mineral oil enters, that can cause deterioration of refrigerant oil etc.

Charge refrigerant from liquid phase of gas cylinder.

If the refrigerant is charged from gas phase, composition change may occur in refrigerant and the efficiency will be lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check valve.

Vacuum pump oil may flow back into refrigerant cycle and that can cause deterioration of refrigerant oil etc.

Use the following tools specifically designed for use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

|

Tools for R410A |

|

Gauge manifold |

|

Flare tool |

Charge hose |

|

Size adjustment gauge |

Gas leak detector |

|

Vacuum pump adaptor |

Torque wrench |

|

Electronic refrigerant |

|

|

charging scale |

Handle tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Ventilate the room if refrigerant leaks during operation. If refrigerant comes into contact with a flame, poisonous gases will be released.

4

[1]Cautions for service

(1)Perform service after recovering the refrigerant left in unit completely.

(2)Do not release refrigerant in the air.

(3)After completing service, charge the cycle with specified amount of refrigerant.

(4)When performing service, install a filter drier simultaneously. Be sure to use a filter drier for new refrigerant.

[2]Additional refrigerant charge

When charging directly from cylinder

·Check that cylinder for R410A on the market is syphon type.

·Charging should be performed with the cylinder of syphon standing vertically. (Refrigerant is charged from liquid phase.)

Unit

Gravimeter

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. |

Tool name |

Specifications |

||

1 |

Gauge manifold |

· Only for R410A |

||

|

|

· Use the existing fitting specifications. (UNF1/2) |

||

|

|

· Use high-tension side pressure of 5.3MPa·G or over. |

||

2 |

Charge hose |

· Only for R410A |

||

|

|

· Use pressure performance of 5.09MPa·G or over. |

||

3 |

Electronic scale |

|

|

|

|

|

|

||

4 |

Gas leak detector |

· Use the detector for R134a, R407C or R410A. |

||

5 |

Adapter for reverse flow check |

· Attach on vacuum pump. |

||

6 |

Refrigerant charge base |

|

|

|

|

|

|

||

7 |

Refrigerant cylinder |

· Only for R410A · Top of cylinder (Pink) |

||

|

|

· Cylinder with syphon |

||

8 |

Refrigerant recovery equipment |

|

|

|

|

|

|

||

5

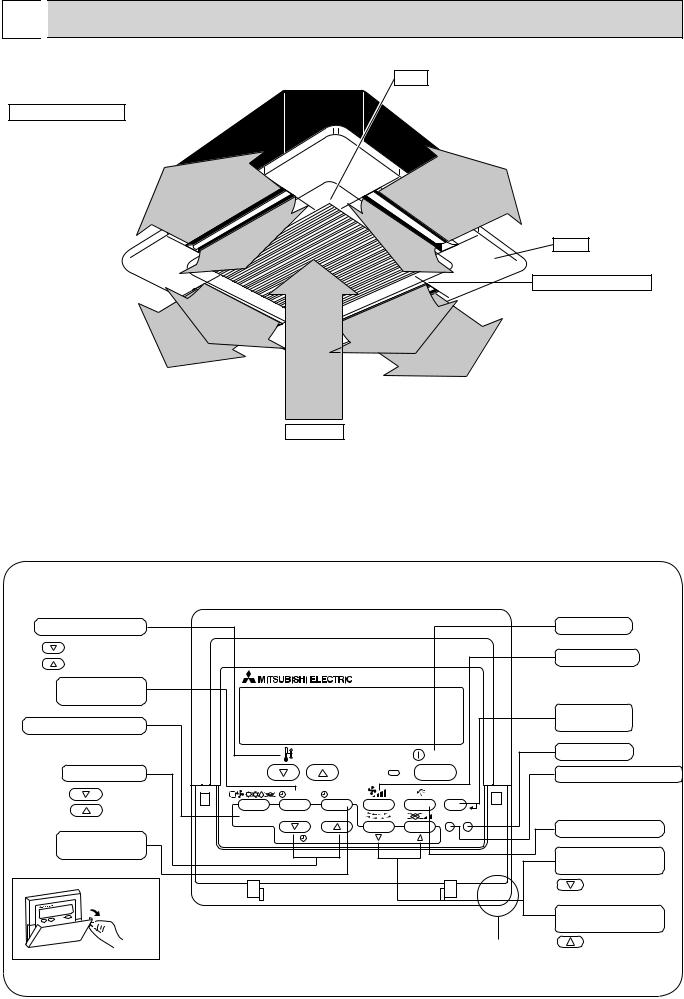

2

PART NAMES AND FUNCTIONS

PART NAMES AND FUNCTIONS

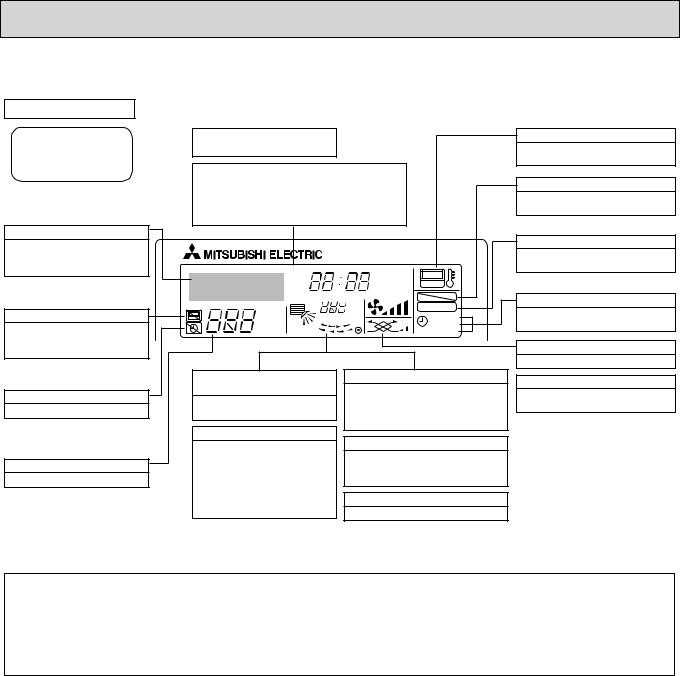

Indoor Unit

Indoor Unit

Horizontal Air Outlet

Sets horizontal airflow automatically during cooling or dehumidifying.

Filter

Remove dust and pollutants from inhaled air.

Grille

Auto Air Swing Vane

Disperses airflow up and down and adjusts the angle of airflow direction.

Air Intake

Inhales air from room.

Wired remote controller

Wired remote controller

Once the controllers are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

Temperature setting buttons |

|

|

|

Down |

|

|

|

Up |

|

|

|

Timer Menu button |

|

|

|

(Monitor/Set button) |

|

|

|

Mode button (Return button) |

|

|

|

|

|

TEMP. |

|

Set Time buttons |

|

|

|

Back |

|

MENU |

ON/OFF |

Ahead |

BACK |

MONITOR/SET |

DAY |

|

|||

Timer On/Off button |

PAR-21MAA |

CLOCK |

|

(Set Day button) |

|

|

|

Opening the |

|

|

|

lid |

|

|

|

|

ON/OFF |

|

|

FILTER |

|

|

CHECK |

TEST |

OPERATION |

CLEAR |

|

Built-in temperature sensor

ON/OFF button

Fan Speed button

Filter  button (<Enter> button)

button (<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

Operation button)

To return operation number

Ventilation button

( Operation button)

Operation button)

To go to next operation number

6

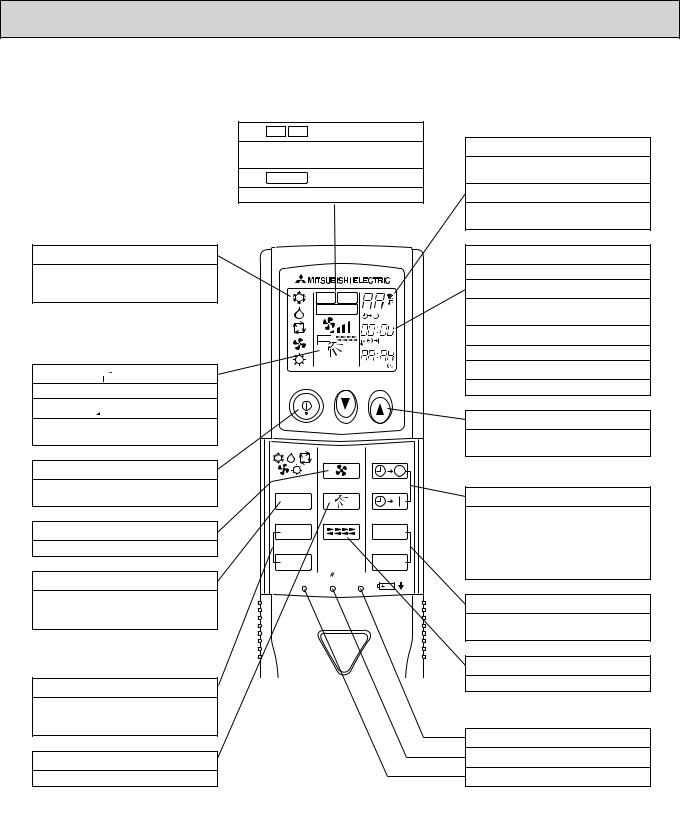

Wired remote controller

Wired remote controller

Display Section

For purposes of this explanation, |

Day-of-Week |

|

all parts of the display are shown |

Shows the current day of the week. |

|

as lit. During actual operation, only |

Time/Timer Display |

|

the relevant items will be lit. |

||

|

Shows the current time, unless the simple or Auto Off |

|

|

timer is set. |

|

|

If the simple or Auto Off timer is set, the time to be |

|

|

switched off is shown. |

|

Identifies the current operation

Shows the operating mode, etc. *Multilanguage display is available.

“Centrally Controlled” indicator

Indicates that operation from the remote controller has been prohibited by a master controller.

“Timer is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

TIME SUN MON TUE WED THU FRI SAT |

||

TIMER |

Hr |

ON |

AFTER |

AFTER |

OFF |

ERROR CODE |

|

FUNCTION |

°F°C |

|

FILTER |

°F°C |

|

|

|

WEEKLY |

|

ONLY1Hr. |

|

SIMPLE |

|

AUTO OFF |

|

Up/Down Air Direction indicator

Shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to low or downward during COOL or DRY mode. (Operation varies according to model.)

The indicator goes off in one hour, when the airflow direction also changes.

Room Temperature display

Shows the room temperature. The room temperature display range is 8~39 . The display blinks if the temperature is less than 8 or 39 or more.

Louver display

Indicates the action of the swing louver. Does not appear if the louver is not running.

(Power On indicator)

(Power On indicator)

Indicates that the power is on.

“Sensor” indication

Displayed when the remote controller sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

To be displayed on when it is time to clean the filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in Ventilation mode.

Note:

●“PLEASE WAIT” message

This message is displayed for approximately 3 minutes when power is supplied to the indoor unit or when the unit is recovering from a power failure.

●“NOT AVAILABLE” message

This message is displayed if an invalid button is pressed (to operate a function that the indoor unit does not have).

If a single remote controller is used to operate multiple indoor units simultaneously that are different types, this message will not be displayed as far as any of the indoor units is equipped with the function.

7

Wireless remote controller

Wireless remote controller

display

display

OPERATION MODE display

Operation mode display indicates which operation mode is in effect.

display

display

The vertical direction of air flow is indicated.

display

display

FAN SPEED display indicates which fan speed has been selected.

ON/OFF button

The unit is turned ON and OFF alternately each time the button is pressed.

FAN SPEED SELECT button

Used to change the fan speed.

MODE SELECT button

Used to switch the operation mode between cooling, drying, fan, heating and auto mode.

In case the outdoor unit is cool only type, the heating and auto mode are not available.

In case the outdoor unit is cool only type, the heating and auto mode are not available.

CHECK-TEST RUN button

Only press this button to perform an inspection check or test operation. Do not use it for normal operation.

VANE CONTROL button

Used to change the air flow

CHECK TESTRUN display

CHECK and TEST RUN display indicate that the unit is being checked or test-run.

MODELSELECT display

Blinks when model is selected.

CHECK TESTRUN

MODELSELECT

°C

°C

AMPM

AMPM

NOT AVAILABLE

ON/OFF  TEMP

TEMP

|

FAN |

AUTO STOP |

MODE |

VANE |

AUTO START |

CHECK |

LOUVER |

h |

TEST RUN |

|

min |

SET |

RESET CLOCK |

|

display

display

Lights up while the signal is transmitted to the indoor unit when the button is pressed.

display

display

SET TEMP. display indicates the set desired temperature.

CLOCK display

Displays the current time.

TIMER display

Displays when in timer operation or when setting timer.

“  ” “

” “ ” display

” display

Displays the order of timer operation.

“

” “

” “

” display

” display

Displays whether timer is on or off.

button

button

SET TEMPERATURE button sets any desired room temperature.

TIMER CONTROL buttons

AUTO STOP (OFF timer): when this switch is set, the air conditioner will be automatically stopped at the preset time.

AUTO START (ON timer): when this switch is set, the air conditioner will be automatically started at the preset time.

h and min buttons

Buttons used to set the “hour and minute” of the current time and timer settings.

LOUVER button

Changes left/right airflow direction.

(Not available for this model.)

CLOCK button

RESET button

SET button

8

3 |

|

|

SPECIFICATIONS |

|

|

|

|

|

||||

3-1. SPECIFICATIONS |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||

Model |

|

|

|

|

PLFY-P20VCM-E2 |

PLFY-P25VCM-E2 |

PLFY-P32VCM-E2 |

|

PLFY-P40VCM-E2 |

|

||

|

|

|

|

|

|

|

|

|

|

|

||

Power source |

|

|

|

|

|

Single phase 220-230-240V 50Hz |

|

|

||||

Cooling capacity |

1 |

|

kW |

2.2 |

2.8 |

3.6 |

|

4.5 |

|

|||

(Nominal) |

|

1 |

|

kcal / h |

1,900 |

2,400 |

3,100 |

|

3,900 |

|

||

|

|

|

|

1 |

|

Btu / h |

7,500 |

9,600 |

12,300 |

|

15,400 |

|

|

|

|

|

2 |

|

kcal / h |

2,000 |

2,500 |

3,150 |

|

4,000 |

|

|

|

|

|

Power input |

|

kW |

0.05 |

0.05 |

0.06 |

|

0.06 |

|

|

|

|

|

Current input |

|

A |

0.23 |

0.23 |

0.28 |

|

0.28 |

|

Heating capacity |

3 |

|

kW |

2.5 |

3.2 |

4.0 |

|

5.0 |

|

|||

(Nominal ) |

|

3 |

|

kcal / h |

2,200 |

2,800 |

3,400 |

|

4,300 |

|

||

|

|

|

|

3 |

|

Btu / h |

8,500 |

10,900 |

13,600 |

|

17,100 |

|

|

|

|

|

Power input |

|

kW |

0.05 |

0.05 |

0.06 |

|

0.06 |

|

|

|

|

|

Current input |

|

A |

0.23 |

0.23 |

0.28 |

|

0.28 |

|

External finish |

|

|

|

|

|

Unit: Galvanized sheets with grey heat insulation |

|

|

||||

External dimension H x W x D |

|

mm |

208 × 570 × 570 |

208 × 570 × 570 |

208 × 570 × 570 |

|

208 × 570 × 570 |

|

||||

|

|

|

|

|

|

in. |

8-1/4" × 22-1/2" × 22-1/2" |

8-1/4" × 22-1/2" × 22-1/2" |

8-1/4" × 22-1/2" × 22-1/2" |

|

8-1/4" × 22-1/2" × 22-1/2" |

|

Net weight |

|

|

|

kg (lb) |

15.5 (35) |

15.5 (35) |

17 (38) |

|

17 (38) |

|

||

Decoration panel |

Model |

|

SLP-2AAW or SLP-2ALW |

SLP-2AAW or SLP-2ALW |

SLP-2AAW or SLP-2ALW |

SLP-2AAW or SLP-2ALW |

|

|||||

|

|

|

|

External finish |

|

|

White Munsell(6.4Y 8.9/0.4) |

|

|

|||

|

|

|

|

Dimension |

|

mm |

20 × 650 × 650 |

20 × 650 × 650 |

20 × 650 × 650 |

|

20 × 650 × 650 |

|

|

|

|

|

H × W × D |

|

in. |

13/16" × 25-5/8" × 25-5/8" |

13/16" × 25-5/8" × 25-5/8" |

13/16" × 25-5/8" × 25-5/8" |

|

13/16" × 25-5/8" × 25-5/8" |

|

|

|

|

|

Net Weight |

|

kg (lb) |

3 (7) |

3 (7) |

3 (7) |

|

3 (7) |

|

|

|

|

|

Cord heater |

|

kW |

0.015 |

0.015 |

0.015 |

|

0.015 |

|

Heat exchanger |

|

|

|

|

Cross fin (Aluminum fin and copper tube) |

|

|

|||||

FAN |

|

Type × Quantity |

|

|

Turbo fan × 1 |

|

|

|||||

|

|

|

|

External static press. |

0Pa (0mmH2O) |

0Pa (0mmH2O) |

0Pa (0mmH2O) |

|

0Pa (0mmH2O) |

|

||

|

|

|

|

Motor type |

|

|

Single phase induction motor |

|

|

|||

|

|

|

|

Motor output |

|

kW |

0.011 |

0.015 |

0.02 |

|

0.02 |

|

|

|

|

|

Driving mechanism |

|

|

Direct-driven by motor |

|

|

|||

|

|

|

|

Airflow rate |

|

m3 / min |

8-9-10 |

8-9-10 |

8-9-11 |

|

8-9-11 |

|

|

|

|

|

(Low-Mid-High) |

|

L / s |

133-150-167 |

133-150-167 |

133-150-183 |

|

133-150-183 |

|

|

|

|

|

|

|

cfm |

283-318-353 |

283-318-353 |

283-318-388 |

|

283-318-388 |

|

Noise level (Low-Mid-High) |

|

dB <A> |

28-31-35 |

29-31-37 |

29-33-38 |

|

30-34-39 |

|

||||

(measured in anechoic room) |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|||||

Insulation material |

|

|

|

|

Polyethylene foam |

|

|

|||||

Air filter |

|

|

|

|

|

PP honeycomb fabric (long life type) |

|

|

||||

Protection device |

|

|

|

|

Fuse |

|

|

|||||

Refrigerant control device |

|

|

LEV |

|

|

|||||||

Connectable outdoor unit |

|

|

R410A, R407C, R22 CITY MULTI |

|

|

|||||||

Diameter of |

|

Liquid |

|

mm (in.) |

ø6.35 (ø1/4") Flare |

ø6.35 (ø1/4") Flare |

ø6.35 (ø1/4") Flare |

|

ø6.35 (ø1/4") Flare |

|

||

refrigerant pipe |

Gas |

|

mm (in.) |

ø12.7 (ø1/2") Flare |

ø12.7 (ø1/2") Flare |

ø12.7 (ø1/2") Flare |

|

ø12.7 (ø1/2") Flare |

|

|||

Field drain pipe size |

|

|

mm (in.) |

|

O.D. 32mm (1-1/4") (PVC pipe VP-25 connectable) |

|

|

|||||

Standard |

|

Document |

|

|

Installation manual, Instruction book |

|

|

|||||

attachment |

|

Accessory |

|

|

Drain hose I.D. 32mm (1-1/4"), Wireless junction cable |

|

|

|||||

Remark |

|

Optional parts |

|

|

Decoration panel : SLP-2AAW or SLP-2ALW |

|

|

|||||

|

|

|

|

|

|

|

|

*PLFY-P-VCM-E2 should use together with Decoration panel. |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Installation |

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other items shall be referred to |

||||

|

|

the Installation Manual. |

|

|

|

|

|

|

|

|

|

|

|

Note : |

1 Nominal cooling condition |

|

2 Nominal cooling condition |

3 Nominal heating condition |

|

Unit converter |

Indoor : |

27˚CDB/19˚CWB (81˚FDB/66˚FWB) |

27˚CDB/19.5˚CWB (81˚FDB/67˚FWB) |

20˚CDB (68˚FDB) |

kcal |

= kW × 860 |

|

Outdoor : |

35˚CDB (95˚FDB) |

|

35˚CDB (95˚FDB) |

7˚CDB/6˚CWB (45˚FDB/43˚FWB) |

||

|

Btu/h = kW × 3,412 |

|||||

Pipe length : |

7.5 m (24-9/16 ft) |

|

5 m (16-3/8 ft) |

7.5 m (24-9/16 ft) |

||

|

cfm |

= m3/min x 35.31 |

||||

Level difference : |

0 m (0 ft) |

|

0 m (0 ft) |

0 m (0 ft) |

||

* Nominal conditions 1, 3 are subject to JIS B8615-1. |

|

|

|

lb |

= kg / 0.4536 |

|

* Due to continuing improvement, above specification may be subject to change without notice. |

|

|

|

|||

9

Loading...

Loading...