Mitsubishi PEHD-P1.6EAH, PEHD-P2EAH, PEHD-P2.5EAH, PEHD-P3EAH, PEHD-P4EAH Service Manual

...

TECHNICAL & SERVICE MANUAL

<indoor unit> Service ref.

Models

PEHD-P1.6EAH

PEHD-P2EAH

PEHD-P2.5EAH

PEHD-P3EAH

PEHD-P4EAH

PEHD-P5EAH

PEHD-P6EAH

PEAD-P1.6EA

PEAD-P2EA

PEAD-P2.5EA

PEAD-P3EA

PEAD-P4EA

PEAD-P5EA

PEAD-P6EA

TM

1. COMBINATION OF INDOOR AND

OUTDOOR UNITS ····································· 1

2. SAFETY PRECAUTION ···························· 2

3. PART NAMES AND FUNCTIONS ············· 4

4. SPECIFICATION ······································· 7

5. DATA ························································ 15

6. REFRIGERANT SYSTEM DIAGRAM ······ 36

7. OUTLINES & DIMENSIONS ···················· 37

8. WIRING DIAGRAM ·································· 39

9. DISASSEMBLY INSTRUCTIONS ············ 40

10

. PARTS LIST ············································· 42

11

. OPTIONAL PARTS ·································· 49

CONTENTS

INDOOR UNIT

REMOTE CONTROLLER

This manual does not cover the

following outdoor units. When

servicing them, please refer to

the service manual No.OC180

REVISED EDITION-A and this

manual as a set.

PUH-P1.6VGA PU-P1.6VGA

PUH-P1.6YGA PUH-P2VGA

PU-P2VGA PUH-P2YGA

PUH-P2.5VGA

1 PU-P2.5VGA1

PUH-P2.5YGA1

PUH-P3VGA PU-P3VGA

PUH-P3YGA PU-P3YGA

PUH-P4YGA PU-P4YGA

PUH-P5YGA PU-P5YGA

PUH-P6YGA PU-P6YGA

ON/OFF

TEMP.

Series PEHD

/

PEAD

R407C

2004

SPLIT-TYPE, HEAT PUMP

AIR CONDITIONERS

1

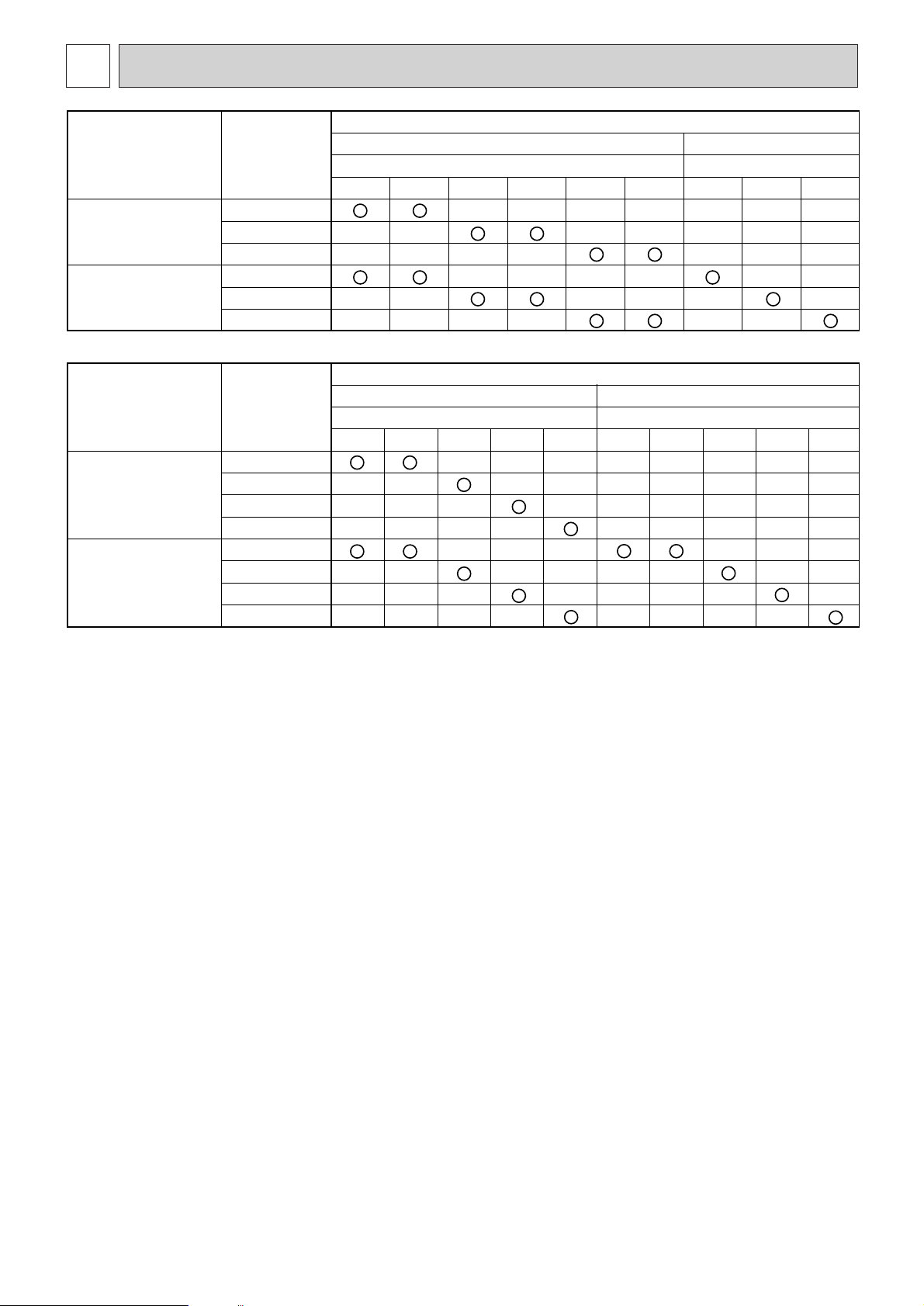

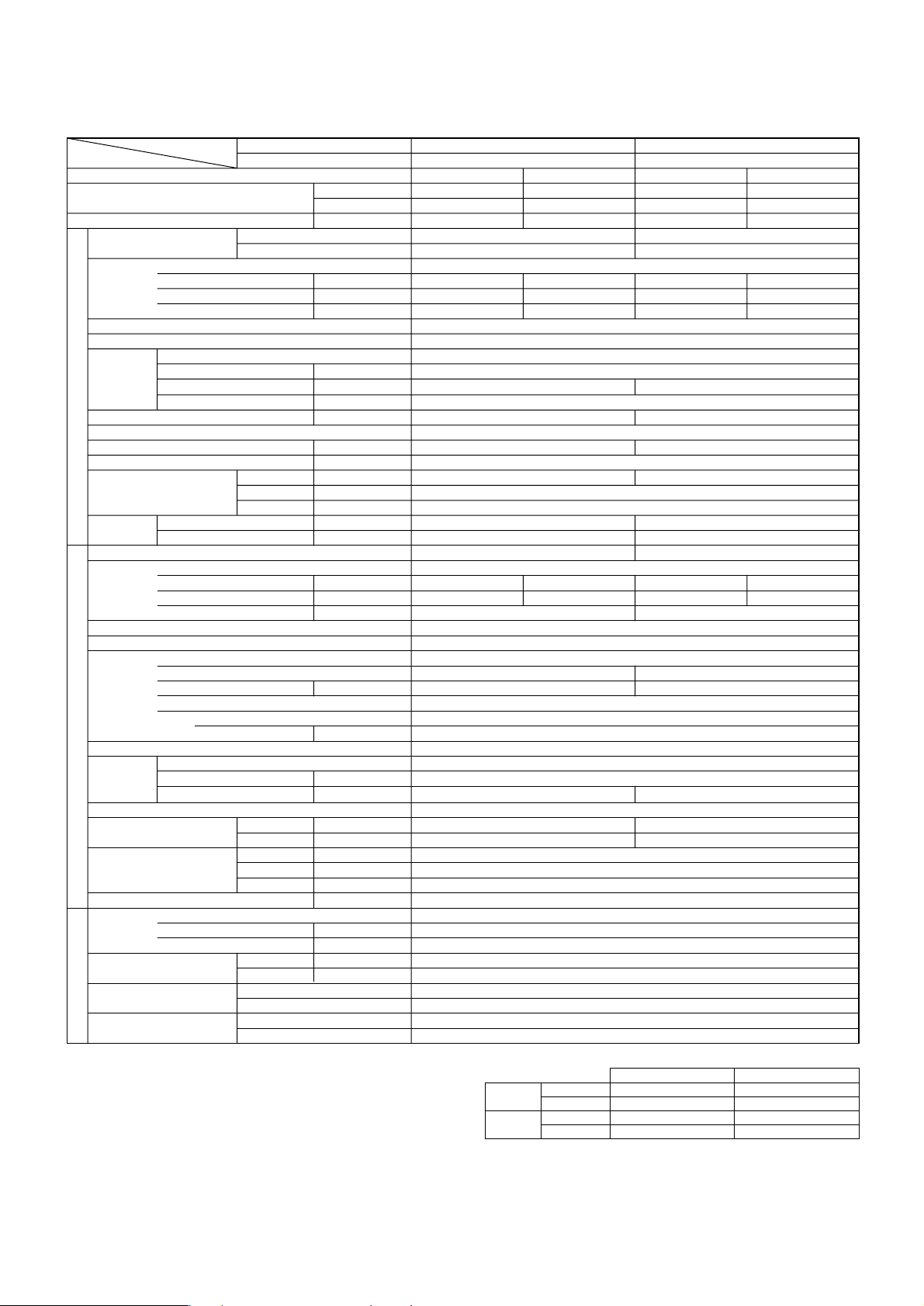

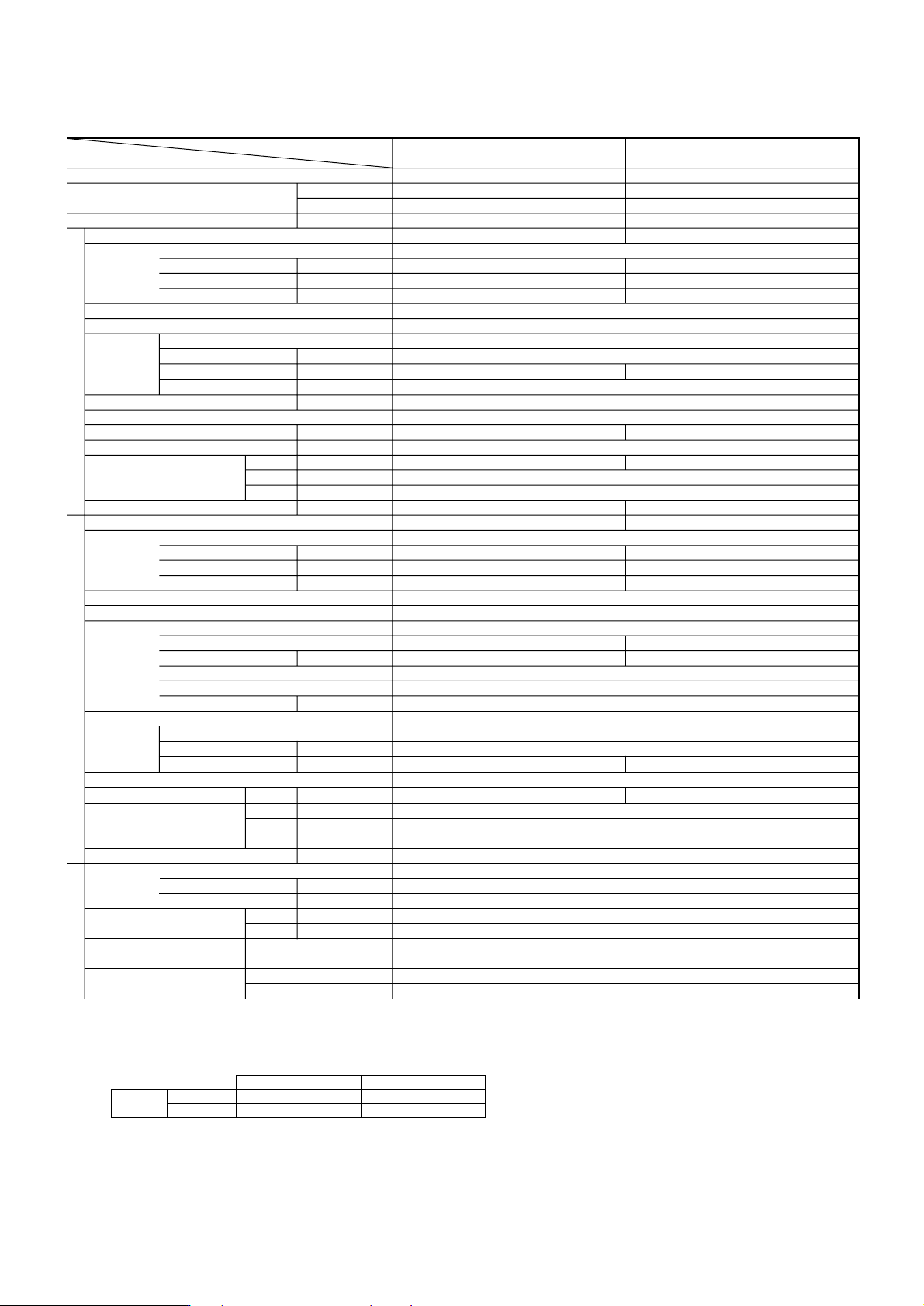

COMBINATION OF INDOOR AND OUTDOOR UNITS

1

Heat pump with

electric heater

Heat pump without

electric heater

or Cooling only

Heat pump with

electric heater

Heat pump without

electric heater

or Cooling only

Indoor unit

PEHD-P1.6EAH

PEHD-P2EAH

PEHD-P2.5EAH

PEAD-P1.6EA

PEAD-P2EA

PEAD-P2.5EA

Indoor unit

PEHD-P3EAH

PEHD-P4EAH

PEHD-P5EAH

PEHD-P6EAH

PEAD-P3EA

PEAD-P4EA

PEAD-P5EA

PEAD-P6EA

1.6VGA

—

—

—

—

3VGA

—

—

—

—

—

—

Heat pump type

PUH-P · VGA / YGA

1.6YGA

—

—

—

—

2VGA

—

—

—

—

Heat pump type

PUH-P · VGA / YGA

3YGA

—

—

—

—

—

—

4YGA

—

—

—

—

—

—

5YGA

—

—

—

—

—

—

Outdoor unit

2YGA

—

—

—

—

Outdoor unit

6YGA

—

—

—

—

—

—

2.5VGA

—

—

—

—

3VGA

2.5YGA1

1

—

—

—

—

—

—

—

Cooling only type

PU-P · VGA / YGA

1.6VGA

—

—

—

—

—

—

—

—

—

Cooling only type

PU-P · VGA / YGA

3YGA

—

—

—

—

—

—

—

4YGA

—

—

—

—

—

—

—

2VGA

—

—

—

—

—

5YGA

—

—

—

—

—

—

—

2.5VGA1

—

—

—

—

—

6YGA

—

—

—

—

—

—

—

2

Cautions for using with the outdoor unit which adopts R407C refrigerant.

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerant oil in the existing piping contains a large amount of chlorine which may cause the refrigerant oil of the new unit to deteriorate.

• Do not use copper pipes which are broken, deformed or discolour.

In addition, be sure that the inner surfaces of the pipes are clean, free of hazardous sulphur and oxides, or have no dust /

dirt, shaving particles, oils, moisture or any other contamination.

- If there is a large amount of residual oil (hydraulic oil, etc.) inside the piping and joints, deterioration of the refrigerant oil will

result.

•Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before

brazing. (Store elbows and other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

• Use ester oil, ether oil or alkyl benzene (small amount) as the refrigerant oil to coat flares and flange connections.

- The refrigerant oil will degrade if it is mixed with a large amount of mineral oil.

Use liquid refrigerant to fill the system.

- If gas refrigerant is used to fill the system, the composition of the refrigerant in the cylinder will change and performance may

drop.

• Do not use a refrigerant other than R407C.

- If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may cause the refrigerant oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and cause the refrigerant oil to deteriorate.

• Do not use the following tools that are used with conventional refrigerant.

(Gauge manifold , charge hose, gas leak detector, reverse flow check valve, refrigerant charge base, vacuum gauge, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerant oil are mixed in the R407C, the refrigerant may deteriorated.

- If water is mixed in the R407C, the refrigerant oil may deteriorate.

- Since R407C does not contain any chlorine, gas leak detectors for conventional refrigerant will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deteriorate.

• Do not use the drier which is sold in the field.

- The drier for R407C refrigerant is per-attached to outdoor unit refrigerant circuit.

- Some drier in the field are not in conformity with R407C refrigerant .

SAFETY PRECAUTION

2

3

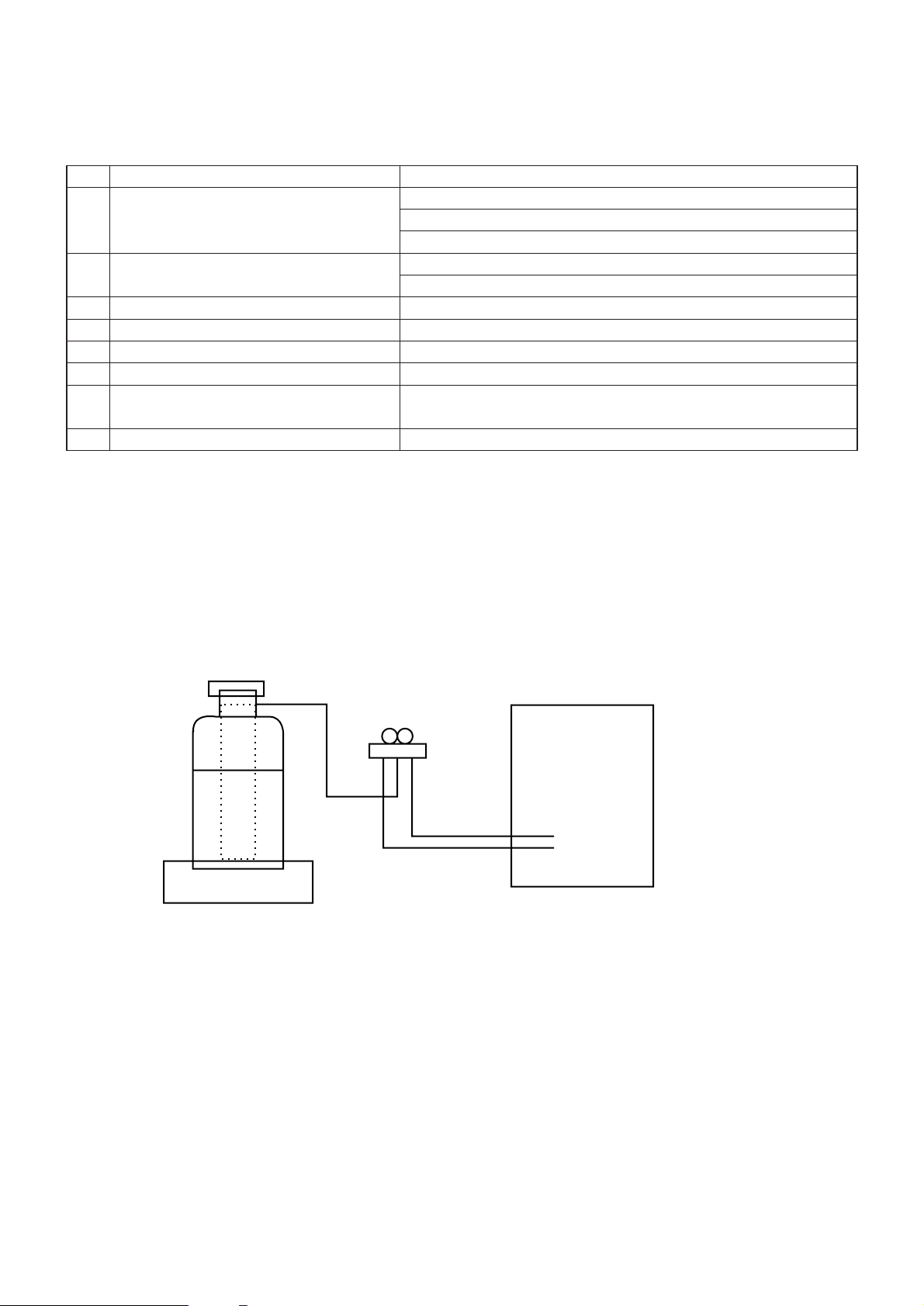

[3] Refrigerant recharging

(1) Refrigerant recharging process

1 Direct charging from the cylinder.

· R407C cylinder are available on the market with a syphon pipe.

· Leave the syphon pipe cylinder standing and recharge it. (By liquid refrigerant)

(2) Recharge in refrigerant leakage case

· After recovering all the refrigerant in the unit, repairs/servicing can proceed.

· Do not release the refrigerant in the air.

· After completing the repair service, recharge the circuit with the specified amount of liquid refrigerant.

Gravimeter

Unit

[1] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1

Gauge manifold · Only for R407C.

· Use the existing fitting SPECIFICATIONS. (UNF7/16)

· Use high-tension side pressure of 3.43MPa·G or over.

2

Charge hose · Only for R407C.

· Use pressure performance of 5.10MPa·G or over.

3

Electronic scale

4

Gas leak detector · Use the detector for R407C.

5

Adaptor for reverse flow check. · Attach on vacuum pump.

6

Refrigerant charge base.

7

Refrigerant cylinder. · For R407C · Top of cylinder (Brown)

· Cylinder with syphon

8

Refrigerant recovery equipment.

[2] Notice on repair service

· After recovering all the refrigerant in the unit, repairs/servicing can proceed.

· Do not release refrigerant in the air.

· After completing the repair service, recharge the circuit with the specified amount of liquid refrigerant.

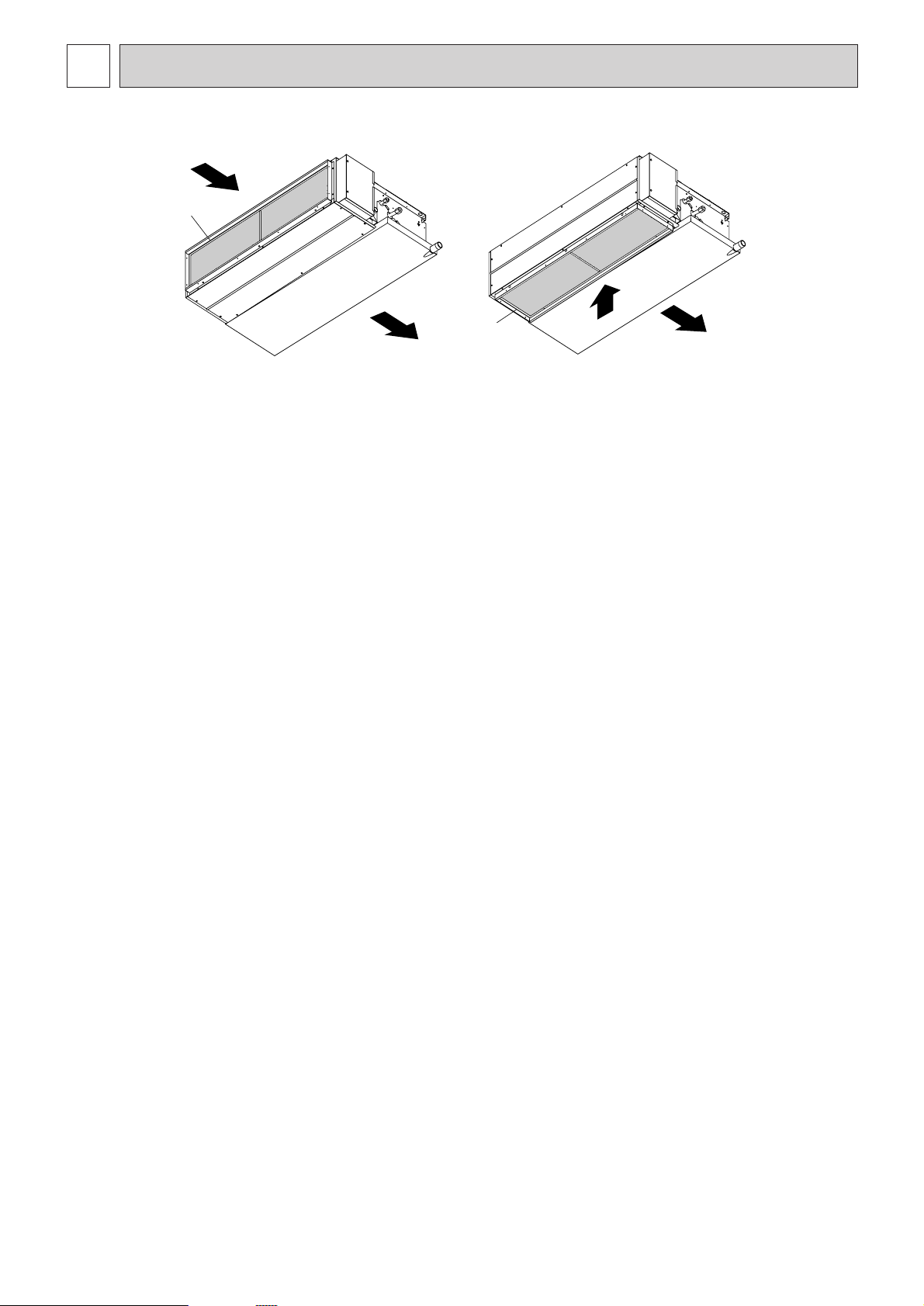

4

PART NAMES AND FUNCTIONS

3

● Indoor Unit

In case of rear inlet

Air intake (sucks

the air inside the

room into the

unit)

Air outlet

In case of bottom inlet

(Only 1.6~2.5HP)

A

A

5

● Remote controller

● Operation buttons

● Once the operation of the unit is set, subsequent operations can be

performed only by pressing the ON/OFF button repeatedly.

1 [Room temperature adjustment] Button

2 [Timer/continuous] Button

3 [Selecting operation] Button

4 [Time selection] Button

[Time-setting] Button

5 [Louver] Button (This button does not operate in this model)

6 [Fan speed adjustment] Button

7 [Up/down airflow direction] Button (This button does not operate in this model)

8 [Ventilation] Button

9 [Checking/built-in] Button

0 [Test run] Button

A [Filter] Button (This button does not operate in this model)

B [ON/OFF] Button

C Position of built-in room temperature

• Never expose the remote controller to direct sunlight. Doing so can result in the erroneous measurement of room temperature.

• Never place any obstacle around the lower right-hand section of the remote controller. Doing so can result in the erroneous

measurement of room temperature.

PAR-20MAA

ON/OFF

CENTRALLY CONTROLLED

ERROR CODE

CLOCK

ON OFF

˚C

CHECK

CHECK MODE

FILTER

TEST RUN

FUNCTION

˚C

1Hr.

NOT AVAILABLE

STAND BY

DEFROST

FILTER

CHECK TEST

TEMP.

TIMER SET

1

2

B

3

456 879

A

0

C

6

● Display

A Current time/Timer

B Centralized control

C Timer ON

D Abnormality occurs

E Operation mode: COOL, DRY, AUTO, FAN,

HEAT

F Preparing for Heating mode

G Defrost mode

H Set temperature

I Power ON

J Louver

K Not available function

L Ventilation

M Function setting mode

N Test run mode

O Error check mode

P Filter sign

Q Set effective for 1 hr.

R Sensor position

S Room temperature

T Airflow

U Fan speed

Caution

• Power ON display lights up when unit is in standby mode.

• When power is turned ON for the first time the (CENTRAL CTRL) display appears to go off momentarily but this is not

a malfunction.

• When the central control remote control unit, which is sold separately, is used the ON-OFF button, operation switch button and TEMP. adjustment button do not operate.

• “NOT AVAILABLE” is displayed when the Airflow direction button or Louver button are pressed.This indicates that this

room unit is not equipped with the fan direction adjustment function and the louver function.

• When power is turned ON for the first time, it is normal that “H0” is displayed on the room temperature indication (For

max. 2minutes). Please wait until this “H0” indication disappear then start the operation.

CENTRALLY CONTROLLED

˚C

CLOCK

ERROR CODE

E

F

STAND BY

DEFROST

CHECK

TEMP.

G

HIKLJ

ABCD

ON OFF

SQTU

1Hr.

˚C

CHECK MODE

NOT AVAILABLE

ON/OFF

FILTER

TEST RUN

FUNCTION

R

P

O

N

M

7

4

SPECIFICATION

1. Heat pump type Rating Conditions (ISO T1)

Item Without Electric heater PEAD-P1.6EA PEAD-P2EA

Function Cooling Heating Cooling Heating

Capacity ✻1

Total input ✻1kW1.75 1.80 (2.80) 2.44 2.22 (3.22)

Service Ref.

Power supply Single phase,50Hz,220-240V

External finish Galvanized sheets

Heat exchanger Plate fin coil

Fan

Booster heater ✻2kW <1.0> <1.0>

Operation control & Thermostat Built in remote controller

Noise level (Lo-Hi) dB 34-38 36-40

Unit drain pipe O.D mm (in.) 32 (1-1/4)

Dimensions

Weight

Service Ref. PUH-P1.6VGA/YGA PUH-P2VGA/YGA

Power supply Single phase,50Hz,220-240V / 3 phase,50Hz,380-415V (4 wires)

External finish Munsell 5Y 8/1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

Heat exchanger Plate fin coil

OUTDOOR UNITREFRIGERANT PIPING INDOOR UNIT

Fan

Defrost method Reverse cycle

Noise level

Dimensions

Weight kg (lbs) 55 (121) 71 (157)

Refrigerant R407C

Pipe size O.D

Connection method

Between the indoor &

outdoor unit

Notes 1. Rating Conditions (ISO T1)

Service Ref. With Electric heater PEHD-P1.6EAH PEHD-P2EAH

Btu/h 15,300 16,700 (20,100) 18,900 21,000 (24,400)

W 4,500 4,900 (5,900) 5,550 6,150 (7,150)

With Electric heater PEHD-P1.6EAH PEHD-P2EAH

Without Electric heater PEAD-P1.6EA PEAD-P2EA

Input ✻2kW 0.13 0.13 <1.13> 0.15 0.15 <1.15>

Running current ✻2A 0.55 0.55 <4.71> 0.63 0.63 <4.79>

Starting current ✻2A – – – –

Fan (drive) × No. Centrifugal (direct) × 2

Fan motor output kW 0.043 (at 70 Pa) 0.076 (at 70 Pa)

Airflow (Lo-Hi)

External static pressure Pa (mmAq) 30/70

W mm (in.) 935 (36-13/16)

D mm (in.) 700 (27-5/8)

H mm (in.) 295 (11-5/8)

With Electric heater kg (lbs) 35 (77) 35 (77)

Without Electric heater kg (lbs) 33 (73) 33 (73)

Input kW 1.62 1.67 2.44 2.22

Running current A 7.43/2.67 7.43/2.86 10.39/3.88 9.36/4.02

Starting current A 36/20 74/30

Model RE277VHSM/RE277YFKM NE38VMJM/NE38YEJM

Motor output kW 1.3 1.7

Starter type Line start

Protection devices

Crankcase heater W 30 38

Fan (drive) × No. Propeller (direct) × 1 Propeller (direct) × 1

Fan motor output kW 0.070 0.070

Airflow

Cooling dB 46 48

Heating dB 48 49

W mm (in.) 900 (35-7/16)

D mm (in.) 330+20 (13+3/4)

H mm (in.) 650 (25-5/8) 855 (33-5/8)

Charge kg (lbs) 2.6 (5.7) 3.1 (6.8)

Oil (Model) L 0.57 (Ester) MEL56 1.2 (Ester) MEL56

Liquid mm (in.) 9.52 (3/8)

Gas mm (in.) 15.88 (5/8)

Indoor side Flared

Outdoor side Flared

Height difference Max.40m

Piping length Max.40m

Cooling: Indoor: D.B.27°C (80°F), W.B.19°C (66°F)

Outdoor: D.B.35°C (95°F), W.B.24°C (75°F)

Heating: Indoor: D.B.20°C (68°F)

Outdoor: D.B.7°C (45°F), W.B.6°C (43°F)

Refrigerant piping length (one way): 5m (16ft)

3

m

/min (CFM)

m3/min (CFM)

11-14 <388-494> 13.5-17 <477-600>

VGA…Inner thermostat, HP switch, Discharge thermo.

YGA…Thermal relay, Discharge thermo, HP switch, Anti-phase protector.

45 (1,590) 55 (1,940)

2. Guaranteed operating range

Indoor Outdoor

Cooling

Heating

Upper limit D.B.35°C, W.B.22.5°CD.B.46°C

Lower limi D.B.19°C, W.B.15°CD.B.-5°C

Upper limit D.B.28°CD.B.24°C, W.B.18°C

Lower limi D.B.17°CD.B.-11°C, W.B .-12°C

3. Above data based on indicated voltage

Indoor Unit: Single phase 240V 50Hz

Outdoor Unit: Single phase 240V 50Hz / 3 phase 415V 50Hz

✻1 : ( ) Shows the total rating.

✻2 : < > Shows only the booster heater r ating.

8

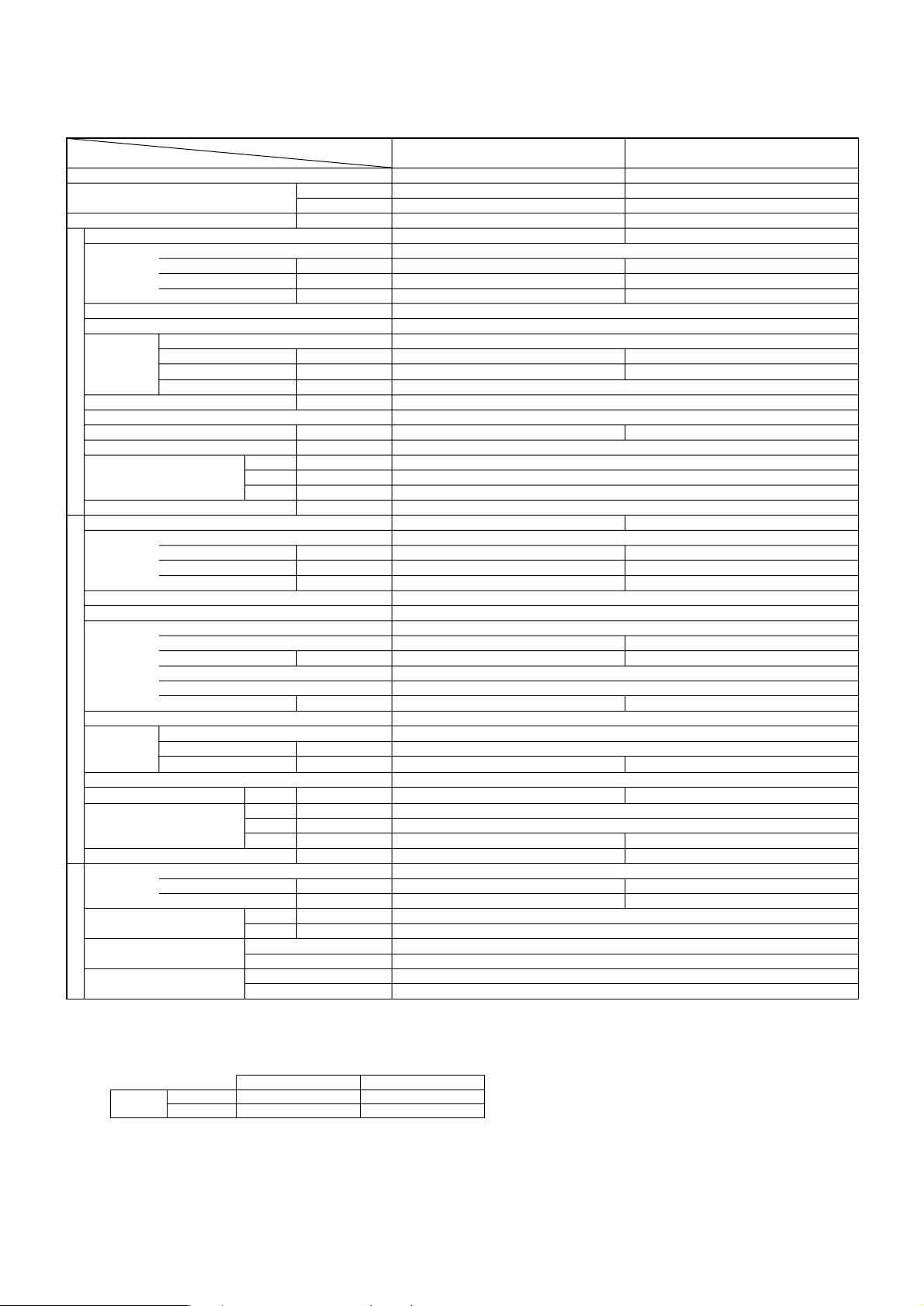

Rating Conditions (ISO T1)

Item Without Electric heater

Function

Capacity ✻1

Total input ✻1kW

Service Ref.

Power supply

External finish

Heat exchanger

Fan

Booster heater ✻2kW

Operation control & Thermostat

Noise level (Lo-Hi) dB

Unit drain pipe O.D mm (in.)

Dimensions

Weight

Service Ref.

Power supply

External finish

Refrigerant control

Compressor

Heat exchanger

OUTDOOR UNITREFRIGERANT PIPING INDOOR UNIT

Fan

Defrost method

Noise level

Dimensions

Weight kg (lbs)

Refrigerant

Pipe size O.D

Connection method

Between the indoor &

outdoor unit

Notes 1. Rating Conditions (ISO T1)

Service Ref. With Electric heater

Btu/h

W

With Electric heater

Without Electric heater

Input ✻2kW

Running current ✻2A

Starting current ✻2A

Fan (drive) × No.

Fan motor output kW

Airflow (Lo-Hi)

3

m

/min (CFM)

External static pressure Pa (mmAq)

W mm (in.)

D mm (in.)

H mm (in.)

With Electric heater kg (lbs)

Without Electric heater kg (lbs)

Input kW

Running current A

Starting current A

Model

Motor output kW

Starter type

Protection devices

Crankcase heater W

Fan (drive) × No.

Fan motor output kW

Airflow

m3/min (CFM)

Cooling dB

Heating dB

W mm (in.)

D mm (in.)

H mm (in.)

Charge kg (lbs)

Oil (Model) L

Liquid mm (in.)

Gas mm (in.)

Indoor side

Outdoor side

Height difference

Piping length

Cooling: Indoor: D.B.27°C (80°F), W.B.19°C (66°F)

Outdoor: D.B.35°C (95°F), W.B.24°C (75°F)

Heating: Indoor: D.B.20°C (68°F)

Outdoor: D.B.7°C (45°F), W.B.6°C (43°F)

Refrigerant piping length (one way): 5m (16ft)

Cooling Heating

22,800 24,500 (29,700)

6,700 7,200 (8,700)

2.68 2.45 (3.95)

0.17 0.17<1.67>

0.72 0.72<6.96>

––

Single phase,50Hz,220-240V / 3 phase,50Hz,380-415V (4 wires)

2.51 2.28

11.27/4.11 10.32/4.03

VGA…Inner thermostat, HP switch, Discharge thermo.

YGA…Thermal relay, Discharge thermo, HP switch, Anti-phase protector.

2. Guaranteed operating range

Cooling

Heating

PEHD-P2.5EAH

PEAD-P2.5EA

PEHD-P2.5EAH

PEAD-P2.5EA

Single phase,50Hz,220-240V

Galvanized sheets

Plate fin coil

Centrifugal (direct) × 2

0.116 (at 70 Pa)

17-21<600-741>

30/70

<1.5>

Built in remote controller

37-41

32 (1-1/4)

1,175 (46-1/8)

700 (27-5/8)

295 (11-5/8)

44 (97)

42 (92)

PUH-P2.5VGA/YGA

77/32

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

NE41VMJM/NE41YEJM

1.9

Line start

38

Plate fin coil

Propeller (direct) × 1

0.070

50 (1,770)

Reverse cycle

48

50

900 (35-7/16)

330+20 (13+3/4)

855 (33-5/8)

82 (181)

R407C

3.3 (7.3)

1.2 (Ester) MEL56

9.52 (3/8)

15.88 (5/8)

Flared

Flared

Max.50m

Max.50m

Indoor Outdoor

Upper limit D.B.35°C, W.B.22.5°CD.B.46°C

Lower limi D.B.19°C, W.B.15°CD.B.-5°C

Upper limit D.B.28°CD.B.24°C, W.B.18°C

Lower limi D.B.17°CD.B.-11°C, W.B .-12°C

3. Above data based on indicated voltage

Indoor Unit: Single phase 240V 50Hz

Outdoor Unit: Single phase 240V 50Hz / 3 phase 415V 50Hz

✻1 : ( ) Shows the total rating.

✻2 : < > Shows only the booster heater r ating.

9

Rating Conditions (ISO T1)

Item Without Electric heater

Service Ref. With Electric heater

Function

Capacity ✻1

Btu/h

W

Total input ✻1kW

Service Ref.

With Electric heater

Without Electric heater

Power supply

Input ✻2kW

Running current ✻2A

Starting current ✻2A

External finish

Heat exchanger

Fan

Fan (drive) × No.

Fan motor output kW

Airflow (Lo-Hi)

3

m

/min (CFM)

External static pressure Pa (mmAq)

Booster heater ✻2kW

Operation control & Thermostat

Noise level (Lo-Hi) dB

Unit drain pipe O.D mm (in.)

W mm (in.)

Dimensions

D mm (in.)

H mm (in.)

Weight

With Electric heater kg (lbs)

Without Electric heater kg (lbs)

Service Ref.

Power supply

Single phase,50Hz,220-240V / 3 phase,50Hz,380-415V (4 wires)

Input kW

Running current A

13.73/5.46 13.12/5.76 5.49 5.79

Starting current A

External finish

Refrigerant control

Compressor

Model

Motor output kW

Starter type

Protection devices

VGA…Inner thermostat, HP switch, Discharge thermo.

YGA…Thermal relay, Discharge thermo, HP switch, Anti-phase protector.

Crankcase heater W

Heat exchanger

OUTDOOR UNITREFRIGERANT PIPING INDOOR UNIT

Fan

Fan (drive) × No.

Fan motor output kW

Airflow

m3/min (CFM)

Defrost method

Noise level

Cooling dB

Heating dB

Dimensions

W mm (in.)

D mm (in.)

H mm (in.)

Weight kg (lbs)

Refrigerant

Charge kg (lbs)

Pipe size O.D

Oil (Model) L

Liquid mm (in.)

Gas mm (in.)

Connection method

Indoor side

Outdoor side

Between the indoor &

outdoor unit

Notes 1. Rating Conditions (ISO T1)

Cooling: Indoor: D.B.27°C (80°F), W.B.19°C (66°F)

Outdoor: D.B.35°C (95°F), W.B.24°C (75°F)

Heating: Indoor: D.B.20°C (68°F)

Outdoor: D.B.7°C (45°F), W.B.6°C (43°F)

Refrigerant piping length (one way): 5m (16ft)

Height difference

Piping length

PEHD-P3EAH PEHD-P4EAH

PEAD-P3EA PEAD-P4EA

Cooling Heating Cooling Heating

26,300 31,000 (38,200) 33,100 35,500 (43,700)

7,700 9,100 (11,200) 9,700 10,400 (12,800)

3.41 3.24 (5.34) 3.90 4.07 (6.47)

PEHD-P3EAH PEHD-P4EAH

PEAD-P3EA PEAD-P4EA

0.40 0.40 <2.50> 0.62 0.62 <3.02>

1.70 1.70 <10.41> 2.64 2.64 <12.58>

–– ––

0.15 0.27

20-25 <706-883> 27-34 <953-1,200>

<2.1> <2.4>

37-41 41-46

1,175 (46-1/8) 1,415 (55-11/16)

46 (101) 65 (143)

44 (97) 62 (136)

PUH-P3VGA/YGA PUH-P4YGA

3.01 2.84 3.28 3.45

93/41 45

NE52VNJM/NE52YDJM NE56YDJM

2.5 2.7

Propeller (direct)

0.070 0.070+0.070

50 (1,770) 85 (3,000)

49 51

51 53

855 (33-5/8) 1,260 (49-5/8)

82 (181) 96 (212)

3.7 (8.2) 4.0 (8.8)

15.88 (5/8) 19.05 (3/4)

2. Guaranteed operating range

Cooling

Heating

Single phase,50Hz,220-240V

Galvanized sheets

Plate fin coil

Centrifugal (direct)

× 2

70 (130)

Built in remote controller

32 (1-1/4)

740 (29-1/8)

325 (12-13/16)

3 phase,50Hz,380-415V (4 wires)

Munsell 5Y 8/1

Linear Expansion Valve

Hermetic

Line start

38

Plate fin coil

× 1 Propeller (direct) × 2

Reverse cycle

900 (35-7/16)

330+20 (13+3/4)

R407C

1.6 (Ester) MEL56

9.52 (3/8)

Flared

Flared

Max.50m

Max.50m

Upper limit D.B.35°C, W.B.22.5°CD.B.46°C

Lower limi D.B.19°C, W.B.15°CD.B.-5°C

Upper limit D.B.28°CD.B.24°C, W.B.18°C

Lower limi D.B.17°CD.B.-11°C, W.B .-12°C

Indoor Outdoor

3. Above data based on indicated voltage

Indoor Unit: Single phase 240V 50Hz

Outdoor Unit: Single phase 240V 50Hz / 3 phase 415V 50Hz

✻1 : ( ) Shows the total rating.

✻2 : < > Shows only the booster heater r ating.

10

Rating Conditions (ISO T1)

Item Without Electric heater PEAD-P5EA PEAD-P6EA

Function Cooling Heating Cooling Heating

Capacity ✻1

Total input ✻1kW4.93 4.81 (7.81) 5.90 5.96 (8.96)

Service Ref.

Power supply Single phase,50Hz,220-240V

External finish Galvanized sheets

Heat exchanger Plate fin coil

Fan

Booster heater ✻2kW <3.0> <3.0>

Operation control & Thermostat Built in remote controller

Noise level (Lo-Hi) dB 44-50 46-51

Unit drain pipe O.D mm (in.) 32 (1-1/4)

Dimensions

Weight

Service Ref. PUH-P5YGA PUH-P6YGA

Power supply 3 phase,50Hz,380-415V (4 wires)

External finish Munsell 5Y 8/1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

Heat exchanger Plate fin coil

Fan

OUTDOOR UNITREFRIGERANT PIPING INDOOR UNIT

Defrost method Reverse cycle

Noise level

Dimensions

Weight kg (lbs) 122 (269)

Refrigerant R407C

Pipe size O.D

Connection method

Between the indoor &

outdoor unit

Notes 1. Rating Conditions (ISO T1)

Service Ref. With Electric heater PEHD-P5EAH PEHD-P6EAH

Btu/h 42,000 47,400 (57,700) 48,100 57,000 (67,200)

W 12,300 13,900 (16,900) 14,100 16,700 (19,700)

With Electric heater PEHD-P5EAH PEHD-P6EAH

Without Electric heater PEAD-P5EA PEAD-P6EA

Input ✻2kW 0.64 0.64 <3.64> 0.66 0.66< 3.66>

Running current ✻2A 2.72 2.72 <15.17> 2.79 2.79 <15.24>

Starting current ✻2A – – ––

Fan (drive) × No. Centrifugal (direct) × 2

Fan motor output kW 0.40

Airflow (Lo-Hi)

External static pressure Pa (mmAq) 70 (130)

W mm (in.) 1,415 (55-11/16) 1,715 (67-1/2)

D mm (in.) 740 (29-1/8)

With Electric heater kg (lbs) 68 (150) 73 (161)

Without Electric heater kg (lbs) 65 (143) 70 (154)

Input kW 4.29 4.17 5.24 5.30

Running current A 8.39 8.74 10.17 10.28

Starting current A

Model HE86YAA HE101YAA

Motor output kW 4.3 5.1

Starter type Line start

Protection de

H mm (in.) 325 (12-13/16)

vices

Crankcase heater

Fan (drive) × No. Propeller (direct) × 2

Fan motor output kW 0.075+0.075

Airflow

Cooling dB 53 55

Heating dB 55 57

W mm (in.) 1,050 (41-5/16)

D mm (in.) 330+20 (13+3/4)

H mm (in.) 1,260 (49-5/8)

Charge kg (lbs) 5.8 (12.8)

Oil (Model) L 2.0 (Ester) MEL32

Cooling: Indoor: D.B.27°C (80°F), W.B.19°C (66°F)

Outdoor: D.B.35°C (95°F), W.B.24°C (75°F)

Heating: Indoor: D.B.20°C (68°F)

Outdoor: D.B.7°C (45°F), W.B.6°C (43°F)

Refrigerant piping length (one way): 5m (16ft)

Liquid mm (in.) 9.52 (3/8)

Gas mm (in.) 19.05 (3/4)

Indoor side Flared

Outdoor side Flared

Height difference Max.50m

Piping length Max.50m

3

m

/min (CFM)

W

m3/min (CFM)

33.5-42 <1,183-1,483> 36.5-46 <1,288-1,624>

79 84

Anti-phase protector, Internal thermostat, LP switch, HP switch, thermal relay, Discharge thermo

95 (3,360) 100 (3,530)

2. Guaranteed operating range

Cooling

Heating

Upper limit D.B.35°C, W.B.22.5°CD.B.46°C

Lower limi D.B.19°C, W.B.15°CD.B.-5°C

Upper limit D.B.28°CD.B.24°C, W.B.18°C

Lower limi D.B.17°CD.B.-11°C, W.B .-12°C

38

Indoor Outdoor

3. Above data based on indicated voltage

Indoor Unit: Single phase 240V 50Hz

Outdoor Unit: 3 phase 415V 50Hz

✻1 : ( ) Shows the total rating.

✻2 : < > Shows only the booster heater r ating.

11

2. Cooling only type Rating Conditions (ISO T1)

Item

Function Cooling Cooling

Capacity

Total input kW 1.75 2.44

Service Ref. PEAD-P1.6EA PEAD-P2EA

Power supply Single phase,50Hz,220-240V

External finish Galvanized sheets

Heat exchanger Plate fin coil

Fan

Booster heater kW –

Operation control & Thermostat Built in remote controller

Noise level (Lo-Hi) dB 34-38 36-40

Unit drain pipe O.D mm (in.) 32 (1-1/4)

Dimensions

Weight kg (lbs) 33 (73)

Service Ref. PU-P1.6VGA PU-P2VGA

Power supply Single phase,50Hz,220-240V

External finish Munsell 5Y 8/1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

Input kW 0.13 0.15

Running current A 0.55 0.63

Starting current A – –

Fan (drive) × No. Centrifugal (direct) × 2

Fan motor output kW 0.043 (at 70 Pa) 0.076 (at 70 Pa)

Airflow (Lo-Hi)

External static pressure Pa (mmAq) 30/70

W mm (in.) 935 (36-13/16)

D mm (in.) 700 (27-5/8)

H mm (in.) 295 (11-5/8)

Input kW 1.62 2.44

Running current A 7.43 10.39

Starting current A

Model RE277VHSM NE38VMJM

Motor output kW 1.3 1.7

Starter type Line start

Protection de

vices

Crankcase heater

Heat exchanger Plate fin coil

OUTDOOR UNITREFRIGERANT PIPING INDOOR UNIT

Fan

Defrost method –

Noise level

Dimensions

Weight kg (lbs) 55 (121) 71 (157)

Refrigerant R407C

Pipe size O.D

Connection method

Between the indoor &

outdoor unit

Notes 1. Rating Conditions (ISO T1)

2. Guaranteed operating range

Fan (drive) × No. Propeller (direct) × 1

Fan motor output kW 0.070

Airflow

Cooling dB 46 48

W mm (in.) 900 (35-7/16)

D mm (in.) 330+20 (13+3/4)

H mm (in.) 650 (25-5/8) 855 (33-5/8)

Charge kg (lbs) 2.6 (5.7) 3.1 (6.8)

Oil (Model) L 0.57 (Ester) MEL56 1.2 (Ester) MEL56

Cooling: Indoor: D.B.27°C (80°F), W.B. 19°C (66°F)

Outdoor: D.B.35°C (95°F), W.B. 24°C (75°F)

Refrigerant piping length (one way): 5m (16ft)

Cooling

Upper limit D.B.35°C, W.B.22.5°CD.B.46°C

Lower limi D.B.19°C, W.B.15°CD.B.-5°C

Liquid mm (in.) 9.52 (3/8)

Gas mm (in.) 15.88 (5/8)

Indoor side Flared

Outdoor side Flared

Height difference Max.40m

Piping length Max.40m

Service Ref.

Btu/h 15,300 18,900

W 4,500 5,550

3

m

/min (CFM)

W

m3/min (CFM)

Indoor Outdoor

PEAD-P1.6EA PEAD-P2EA

11-14 <388-494> 13.5-17 <477-600>

36 74

Inner thermostat, HP switch, Discharge thermo.

30 38

45 (1,590) 55 (1,940)

3. Above data based on indicated voltage

Indoor Unit: Single phase 240V 50Hz

Outdoor Unit: Single phase 240V 50Hz

12

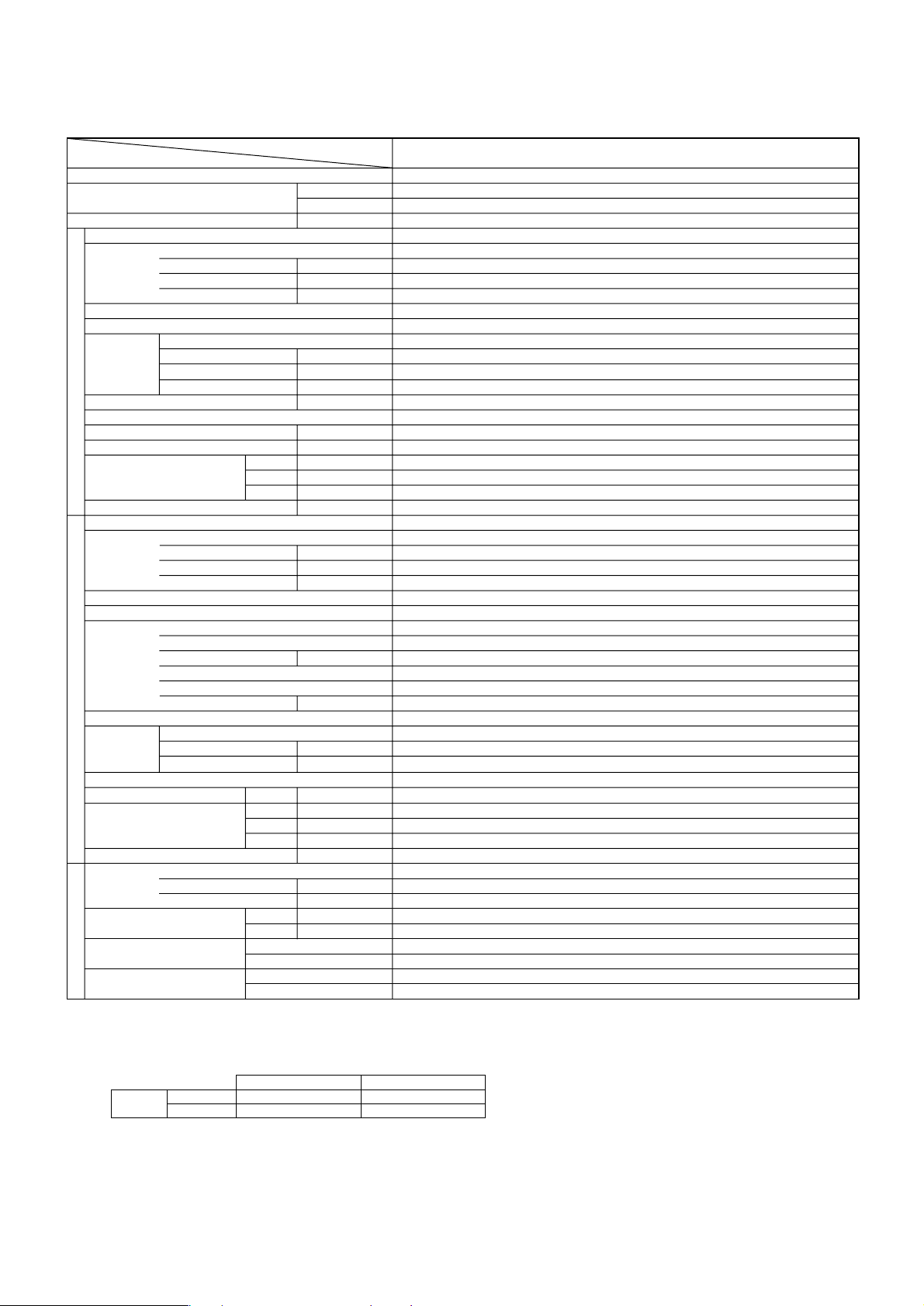

Rating Conditions (ISO T1)

Item

Function Cooling

Capacity

Total input kW 2.68

Service Ref. PEAD-P2.5EA

Power supply Single phase,50Hz,220-240V

External finish Galvanized sheets

Heat exchanger Plate fin coil

Fan

Booster heater kW –

Operation control & Thermostat Built in remote controller

Noise level (Lo-Hi) dB 37-41

Unit drain pipe O.D mm (in.) 32 (1-1/4)

Dimensions

Weight kg (lbs) 42 (92)

Service Ref. PU-P2.5VGA1

Power supply Single phase,50Hz,220-240V

External finish Munsell 5Y 8/1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

Input kW 0.17

Running current A 0.72

Starting current A –

Fan (drive) × No. Centrifugal (direct) × 2

Fan motor output kW 0.116 (at 70 Pa)

Airflow (Lo-Hi)

External static pressure Pa (mmAq) 30/70

W mm (in.) 1,175 (46-1/8)

D mm (in.) 700 (27-5/8)

H mm (in.) 295 (11-5/8)

Input kW 2.51

Running current A 11.27

Starting current A

Model NE41VMJM

Motor output kW 1.9

Starter type Line start

Protection de

vices

Crankcase heater

Heat exchanger Plate fin coil

OUTDOOR UNITREFRIGERANT PIPING INDOOR UNIT

Fan

Defrost method –

Noise level

Dimensions

Weight kg (lbs) 82 (181)

Refrigerant R407C

Pipe size O.D

Connection method

Between the indoor &

outdoor unit

Notes 1. Rating Conditions (ISO T1)

2. Guaranteed operating range

Fan (drive) × No. Propeller (direct) × 1

Fan motor output kW 0.070

Airflow

Cooling dB 48

W mm (in.) 900 (35-7/16)

D mm (in.) 330+20 (13+34)

H mm (in.) 855 (33-5/8)

Charge kg (lbs) 3.3 (7.3)

Oil (Model) L 1.2 (Ester) MEL56

Cooling: Indoor: D.B.27°C (80°F), W.B. 19°C (66°F)

Outdoor: D.B.35°C (95°F), W.B. 24°C (75°F)

Refrigerant piping length (one way) : 5m (16ft)

Cooling

Upper limit D.B.35°C, W.B.22.5°CD.B.46°C

Lower limi D.B.19°C, W.B.15°CD.B.-5°C

Liquid mm (in.) 9.52 (3/8)

Gas mm (in.) 15.88 (5/8)

Indoor side Flared

Outdoor side Flared

Height difference Max.50m

Piping length Max.50m

Service Ref.

Btu/h 22,800

W 6,700

3

m

/min (CFM)

W

m3/min (CFM)

Indoor Outdoor

Inner thermostat, HP switch, Discharge thermo.

PEAD-P2.5EA

17-21 <600-741>

77

38

50 (1,770)

3. Above data based on indicated voltage

Indoor Unit: Single phase 240V 50Hz

Outdoor Unit: Single phase 240V 50Hz

13

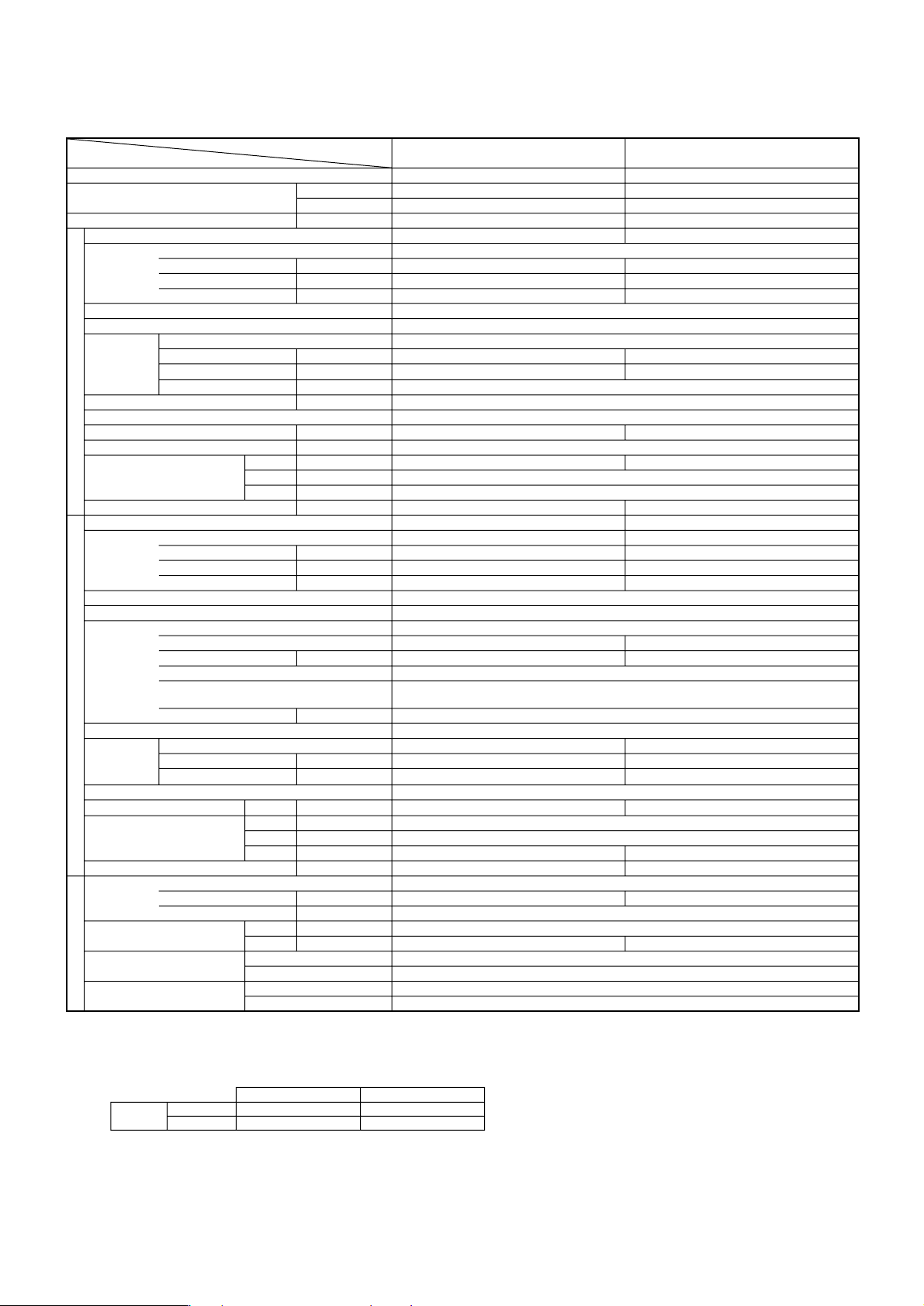

Rating Conditions (ISO T1)

Item

Function Cooling Cooling

Capacity

Total input kW 3.41 3.90

Service Ref. PEAD-P3EA PEAD-P4EA

Power supply Single phase,50Hz,220-240V

External finish Galvanized sheets

Heat exchanger Plate fin coil

Fan

Booster heater kW –

Operation control & Thermostat Built in remote controller

Noise level (Lo-Hi) dB 37-41 41-46

Unit drain pipe O.D mm (in.) 32 (1-1/4)

Dimensions

Weight kg (lbs) 44 (97) 62 (136)

Service Ref. PU-P3VGA/YGA PU-P4YGA

Power supply

External finish Munsell 5Y 8/1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

Input kW 0.40 0.62

Running current A 1.70 2.64

Starting current A – –

Fan (drive) × No. Centrifugal (direct) × 2

Fan motor output kW 0.15 0.27

Airflow (Lo-Hi)

External static pressure Pa (mmAq) 70 (130)

W mm (in.) 1,175 (46-1/8) 1,415 (55-11/16)

D mm (in.) 740 (29-1/8)

H mm (in.) 325 (12-13/16)

Input kW 3.01 3.28

Running current A 13.73/5.46 5.49

Starting current A 93/41 45

Model NE52VNJM/NE52YDJM NE56YDJM

Motor output kW 2.5 2.7

Starter type Line start

Protection devices

Heat exchanger Plate fin coil

OUTDOOR UNITREFRIGERANT PIPING INDOOR UNIT

Fan

Defrost method –

Noise level

Dimensions

Weight kg (lbs) 82 (181) 96 (212)

Refrigerant R407C

Pipe size O.D

Connection method

Between the indoor &

outdoor unit

Notes 1. Rating Conditions (ISO T1)

2. Guaranteed operating range

Crankcase heater W 38

Fan (drive) × No. Propeller (direct) × 1 Propeller (direct) × 2

Fan motor output kW 0.070 0.070+0.070

Airflow

Cooling dB 49 51

W mm (in.) 900 (35-7/16)

D mm (in.) 330+20 (13+3/4)

H mm (in.) 855 (33-5/8) 1,260 (49-5/8)

Charge kg (lbs) 3.7 (8.2) 4.0 (8.8)

Oil (Model) L 1.6 (Ester) MEL56

Cooling: Indoor: D.B.27°C (80°F), W.B. 19°C (66°F)

Outdoor: D.B.35°C (95°F), W.B. 24°C (75°F)

Refrigerant piping length (one way) : 5m (16ft)

Cooling

Upper limit D.B.35°C, W.B.22.5°CD.B.46°C

Lower limi D.B.19°C, W.B.15°CD.B.-5°C

Liquid mm (in.) 9.52 (3/8)

Gas mm (in.) 15.88 (5/8) 19.05 (3/4)

Indoor side Flared

Outdoor side Flared

Height difference Max.50m

Piping length Max.50m

Service Ref.

Btu/h 26,300 33,100

W 7,700 9,700

3

m

/min (CFM)

Single phase,50Hz,220-240V / 3 phase,50Hz,380-415V (4 wires)

VGA…Inner thermostat, HP switch, Discharge thermo.

YGA…Thermal relay, Discharge thermo, HP switch, Anti-phase protector.

m3/min (CFM)

Indoor Outdoor

PEAD-P3EA PEAD-P4EA

20-25 <706-883> 27-34 <953-1,200>

3 phase,50Hz,380-415V (4 wires)

50 (1,770) 85 (3,000)

3. Above data based on indicated voltage

Indoor Unit: Single phase 240V 50Hz

Outdoor Unit: Single phase 240V 50Hz/3 phase 415V 50Hz

14

Rating Conditions (ISO T1)

Item

Function Cooling Cooling

Capacity

Total input kW 4.93 5.90

Service Ref. PEAD-P5EA PEAD-P6EA

Power supply Single phase,50Hz,220-240V

External finish Galvanized sheets

Heat exchanger Plate fin coil

Fan

Booster heater kW –

Operation control & Thermostat

Noise level (Lo-Hi) dB 44-50 46-51

Unit drain pipe O.D mm (in.) 32 (1-1/4)

Dimensions

Weight kg (lbs) 65 (143) 70 (154)

Service Ref. PU-P5YGA PU-P6YGA

Power supply 3 phase,50Hz,380-415V (4 wires)

External finish Munsell 5Y 8/1

Refrigerant control Linear Expansion Valve

Compressor Hermetic

Input kW 0.64 0.66

Running current A 2.72 2.79

Starting current A – –

Fan (drive) × No. Centrifugal (direct) × 2

Fan motor output kW 0.40

Airflow (Lo-Hi)

External static pressure Pa (mmAq) 70 (130)

W mm (in.) 1,415 (55-11/16) 1,715 (67-1/2)

D mm (in.) 740 (29-1/8)

H mm (in.) 325 (12-13/16)

Input kW 4.29 5.24

Running current A 8.39 10.17

Starting current A

Model HE86YAA HE101YAA

Motor output kW 4.3 5.1

Starter type Line start

Protection de

vices

Crankcase heater

Heat exchanger Plate fin coil

OUTDOOR UNITREFRIGERANT PIPING INDOOR UNIT

Fan

Defrost method –

Noise level

Dimensions

Weight kg (lbs) 122 (269)

Refrigerant R407C

Pipe size O.D

Connection method

Between the indoor &

outdoor unit

Notes 1. Rating Conditions (ISO T1)

2. Guaranteed operating range

Fan (drive) × No. Propeller (direct) × 2

Fan motor output kW 0.075+0.075

Airflow

Cooling dB 53 55

W mm (in.) 1050 (41-5/16)

D mm (in.) 330+20 (13+3/4)

H mm (in.) 1,260 (49-5/8)

Charge kg (lbs) 5.8 (12.8)

Oil (Model) L 2.0 (Ester) MEL32

Cooling: Indoor: D.B.27°C (80°F), W.B. 19°C (66°F)

Outdoor: D.B.35°C (95°F), W.B. 24°C (75°F)

Refrigerant piping length (one way) : 5m (16ft)

Cooling

Upper limit D.B.35°C, W.B.22.5°CD.B.46°C

Lower limi D.B.19°C, W.B.15°CD.B.-5°C

Liquid mm (in.) 9.52 (3/8)

Gas mm (in.) 19.05 (3/4)

Indoor side Flared

Outdoor side Flared

Height difference Max.50m

Piping length Max.50m

Service Ref.

Btu/h 42,000 48,100

W 12,300 14,100

3

m

/min (CFM)

W

Anti-phase protector, Internal thermostat, LP switch, HP switch, thermal relay, Discharge thermo

m3/min (CFM)

Indoor Outdoor

PEAD-P5EA PEAD-P6EA

33.5-42 <1,183-1,483> 36.5-46 <1,288-1,624>

Built in remote controller

79 84

38

95 (3,360) 100 (3,530)

3. Above data based on indicated voltage

Indoor Unit: Single phase 240V 50Hz

Outdoor Unit: Single phase 240V 50Hz/3 phase 415V 50Hz

15

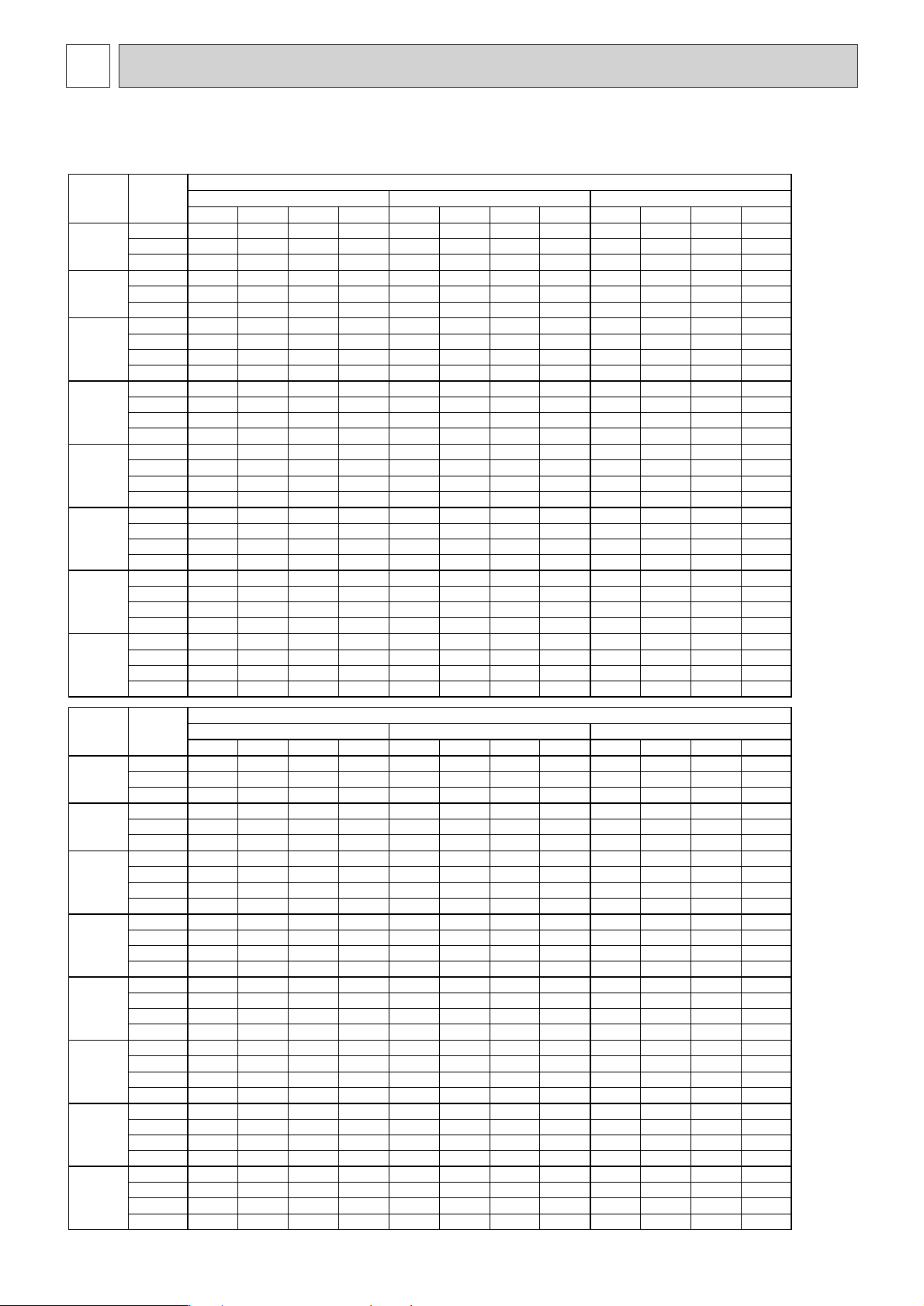

5

DATA

20 25 30

CA SHC(W) SHF P.C. CA SHC(W) SHF P.C. CA SHC(W) SHF P.C.

16 4455 2762 0.62 1.40 4320 2678 0.62 1.48 4185 2595 0.62 1.56

20 18 4770 2385 0.50 1.43 4635 2317 0.50 1.50 4478 2239 0.50 1.61

20 5130 1949 0.38 1.47 5018 1907 0.38 1.54 4883 1855 0.38 1.64

16 4455 3118 0.70 1.40 4320 3024 0.70 1.48 4185 2929 0.70 1.56

22 18 4770 2767 0.58 1.43 4635 2688 0.58 1.50 4478 2597 0.58 1.61

20 5130 2360 0.46 1.47 5018 2308 0.46 1.54 4883 2246 0.46 1.64

16 4455 3475 0.78 1.40 4320 3370 0.78 1.48 4185 3264 0.78 1.56

24

18 4770 3148 0.66 1.43 4635 3059 0.66 1.50 4478 2955 0.66 1.61

20 5130 2770 0.54 1.47 5018 2709 0.54 1.54 4883 2637 0.54 1.64

22 5468 2341 0.43 1.51 5355 2293 0.43 1.51 5220 2235 0.43 1.70

16 4455 3831 0.86 1.40 4320 3715 0.86 1.48 4185 3599 0.86 1.56

26

18 4770 3530 0.74 1.43 4635 3430 0.74 1.50 4478 3313 0.74 1.61

20 5130 3181 0.62 1.47 5018 3111 0.62 1.54 4883 3027 0.62 1.64

22 5468 2766 0.51 1.51 5355 2709 0.51 1.51 5220 2641 0.51 1.70

16 4455 4188 0.94 1.40 4320 4061 0.94 1.48 4185 3934 0.94 1.56

28

18 4770 3911 0.82 1.43 4635 3801 0.82 1.50 4478 3672 0.82 1.61

20 5130 3591 0.70 1.47 5018 3512 0.70 1.54 4883 3418 0.70 1.64

22 5468 3192 0.58 1.51 5355 3126 0.58 1.51 5220 3047 0.58 1.70

16 4455 4455 1.00 1.40 4320 4320 1.00 1.48 4185 4185 1.00 1.56

30

18 4770 4293 0.90 1.43 4635 4172 0.90 1.50 4478 4030 0.90 1.61

20 5130 4001 0.78 1.47 5018 3914 0.78 1.54 4883 3808 0.78 1.64

22 5468 3617 0.66 1.51 5355 3543 0.66 1.51 5220 3454 0.66 1.70

16 4455 4455 1.00 1.40 4320 4320 1.00 1.48 4185 4185 1.00 1.56

32

18 4770 4675 0.98 1.43 4635 4542 0.98 1.50 4478 4388 0.98 1.61

20 5130 4412 0.86 1.47 5018 4315 0.86 1.54 4883 4199 0.86 1.64

22 5468 4043 0.74 1.51 5355 3960 0.74 1.51 5220 3860 0.74 1.70

16 4455 4455 1.00 1.40 4320 4320 1.00 1.48 4185 4185 1.00 1.56

34

18 4770 4770 1.00 1.43 4635 4635 1.00 1.50 4478 4478 1.00 1.61

20 5130 4822 0.94 1.47 5018 4716 0.94 1.54 4883 4590 0.94 1.64

22 5468 4469 0.82 1.51 5355 4377 0.82 1.51 5220 4266 0.82 1.70

35 40 45

CA SHC(W) SHF P.C. CA SHC(W) SHF P.C. CA SHC(W) SHF P.C.

16 4005 2483 0.62 1.68 3825 2371 0.62 1.80 3645 2260 0.62 1.95

20 18 4320 2160 0.50 1.72 4185 2092 0.50 1.86 3915 1957 0.50 2.00

20 4680 1778 0.38 1.77 4500 1710 0.38 1.89 4230 1607 0.38 2.03

16 4005 2803 0.70 1.68 3825 2677 0.70 1.80 3645 2551 0.70 1.95

22 18 4320 2506 0.58 1.72 4185 2427 0.58 1.86 3915 2271 0.58 2.00

20 4680 2153 0.46 1.77 4500 2070 0.46 1.89 4230 1946 0.46 2.03

16 4005 3124 0.78 1.68 3825 2983 0.78 1.80 3645 2843 0.78 1.95

24

18 4320 2851 0.66 1.72 4185 2762 0.66 1.86 3915 2584 0.66 2.00

20 4680 2527 0.54 1.77 4500 2430 0.54 1.89 4230 2284 0.54 2.03

22 5040 2158 0.43 1.80 4860 2081 0.43 1.94 4590 1965 0.43 2.06

16 4005 3444 0.86 1.68 3825 3289 0.86 1.80 3645 3135 0.86 1.95

26

18 4320 3197 0.74 1.72 4185 3097 0.74 1.86 3915 2897 0.74 2.00

20 4680 2902 0.62 1.77 4500 2790 0.62 1.89 4230 2623 0.62 2.03

22 5040 2550 0.51 1.80 4860 2459 0.51 1.94 4590 2322 0.51 2.06

16 4005 3765 0.94 1.68 3825 3596 0.94 1.80 3645 3426 0.94 1.95

28

18 4320 3542 0.82 1.72 4185 3432 0.82 1.86 3915 3210 0.82 2.00

20 4680 3276 0.70 1.77 4500 3150 0.70 1.89 4230 2961 0.70 2.03

22 5040 2942 0.58 1.80 4860 2837 0.58 1.94 4590 2680 0.58 2.06

16 4005 4005 1.00 1.68 3825 3825 1.00 1.80 3645 3645 1.00 1.95

30

18 4320 3888 0.90 1.72 4185 3767 0.90 1.86 3915 3524 0.90 2.00

20 4680 3650 0.78 1.77 4500 3510 0.78 1.89 4230 3299 0.78 2.03

22 5040 3335 0.66 1.80 4860 3215 0.66 1.94 4590 3037 0.66 2.06

16 4005 4005 1.00 1.68 3825 3825 1.00 1.80 3645 3645 1.00 1.95

32

18 4320 4234 0.98 1.72 4185 4101 0.98 1.86 3915 3837 0.98 2.00

20 4680 4025 0.86 1.77 4500 3870 0.86 1.89 4230 3638 0.86 2.03

22 5040 3727 0.74 1.80 4860 3594 0.74 1.94 4590 3394 0.74 2.06

16 4005 4005 1.00 1.68 3825 3825 1.00 1.80 3645 3645 1.00 1.95

34

18 4320 4320 1.00 1.72 4185 4185 1.00 1.86 3915 3915 1.00 2.00

20 4680 4399 0.94 1.77 4500 4230 0.94 1.89 4230 3976 0.94 2.03

22 5040 4119 0.82 1.80 4860 3972 0.82 1.94 4590 3751 0.82 2.06

Indoor

Intake air

D.B. (°C)

Indoor

Intake air

W.B. ( °C)

Outdoor intake air D.B. (°C)

Indoor

Intake air

D.B. (°C)

Indoor

Intake air

W.B. ( °C)

Outdoor intake air D.B. (°C)

1) COOLING CAPACITY <1>

PEHD-P1.6EAH/PEAD-P1.6EA

Notes CA: Capacity (W) SHC (W): Sensible heat capacity

P.C.: Power consumption (kW) SHF: Sensible heat factor

1. PERFORMANCE DATA

Loading...

Loading...