Page 1

Interface (Cased)

PAC-IF013B-E PAC-SIF013B-E

INSTALLATION MANUAL

For safe and correct use, read this manual thoroughly before installing the interface unit.

OPERATION MANUAL

For safe and correct use, please read this operation manual thoroughly before operating the interface unit.

INSTALLATIONSHANDBUCH

Aus Sicherheitsgründen und zur richtigen Verwendung vor der Installation der Schnittstelleneinheit das vorliegende Handbuch gründlich durchlesen.

BEDIENUNGSHANDBUCH

Aus Sicherheitsgründen und zur richtigen Verwendung vor dem Betrieb der Schnittstelleneinheit das vorliegende Bedienungshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Avant d’installer l’unité d’interface, lire attentivement ce manuel pour une utilisation sûre et correcte.

MANUEL D’UTILISATION

Avant d’installer l’unité d’interface, lire attentivement ce guide d’utilisation pour une utilisation sûre et correcte.

INSTALLATIEHANDLEIDING

Lees deze handleiding voor een veilig en juist gebruik goed door voordat u met het installeren van het interface-apparaat begint.

BEDIENINGSHANDLEIDING

Lees deze bedieningshandleiding voor een veilig en juist gebruik goed door voordat u het interface-apparaat bedient.

MANUAL DE INSTALACIÓN

Para un uso correcto y seguro, lea detalladamente este manual antes de instalar la unidad de interfaz.

MANUAL DE INSTRUCCIONES

Para un uso correcto y seguro, lea detalladamente este manual de instrucciones antes de instalar la unidad de interfaz.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente il presente manuale prima di installare l’unità interfaccia.

ISTRUZIONI DI FUNZIONAMENTO

Per un uso sicuro e corretto, leggere attentamente le istruzioni di funzionamento prima di utilizzare l’unità interfaccia.

FOR INSTALLER

FOR USER

FÜR INSTALLATEURE

FÜR BENUTZER

POUR L’INSTALLATEUR

POUR L’UTILISATEUR

vOOR DE INSTALLATEUR

vOOR DE GEBRUIKER

PARA EL INSTALADOR

PARA EL USUARIO

PER L’INSTALLATORE

PER L’UTENTE

English (EN)

Deutsch (DE)

Français (FR)

Nederlands (NL)

Español (ES)

Italiano (IT)

Για την ασφαλή και σωστή χρήση, διαβάστε προσεκτικά αυτό το εγχειρίδιο προτού εγκαταστήσετε τη μονάδα διασύνδεσης.

ΕΓΧΕΙΡΙΔΙΟ ΟΔΗΓΙΩΝ ΧΡΗΣΕΩΣ

Για την ασφαλή και σωστή χρήση, διαβάστε προσεκτικά αυτό το εγχειρίδιο λειτουργίας πριν από τον χειρισμό της μονάδας διασύνδεσης.

MANUAL DE INSTALAÇÃO

Para uma utilização segura e correcta, leia atentamente este manual antes de instalar a unidade de interface.

MANUAL DE OPERAÇÃO

Para uma utilização segura e correcta, leia atentamente este manual de operação antes de instalar a unidade de interface.

INSTALLATIONSMANUAL

For sikker og korrekt brug skal denne manual læses grundigt igennem, inden interfaceenheden installeres.

BRUGSvEjLEDNING

For sikker og korrekt brug skal denne brugsanvisning læses grundigt igennem, inden interfaceenheden betjenes.

INSTALLATIONSMANUAL

Läs igenom denna manual noggrant innan du installerar gränssnittsenheten för en säker och korrekt användning.

ANväNDARMANUAL

För en säker och korrekt användning, vänligen läs igenom denna driftmanual noggrant innan du använder gränssnittsenheten.

Güvenli ve doğru kullanım için arayüz ünitesini monte etmeye başlamadan önce bu kılavuzu dikkatlice okuyun.

Işletme Elkitabı

Güvenli ve doğru kullanım için arayüz ünitesini kullanmaya başlamadan önce lütfen bu kılavuzu dikkatlice okuyun.

Чтобы обеспечить безопасную и правильную эксплуатацию устройства, перед установкой интерфейсного блока внимательно прочтите данное руководство.

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ

Чтобы обеспечить безопасную и правильную эксплуатацию устройства, перед эксплуатацией интерфейсного блока внимательно прочтите данное руководство по эксплуатации.

ΓΙΑ ΤΟΝ ΧΡΗΣΤΗ

PARA O INSTALADOR

PARA O UTILIZADOR

TIL INSTALLATØREN

TIL BRUGER

FÖR INSTALLATÖREN

FÖR ANväNDAREN

KULLANICI İÇİN

ДЛЯ ПОЛЬЗОВАТЕЛЯ

Eλληνικά (GR)

Português

(PT)

Dansk (DA)

Svenska (SV)

Türkçe (TR)

(RU) (RU)

Page 2

Contents

1. Safety precautions .....................................................................................2

2. Installing the interface unit .........................................................................3

3. System ......................................................................................................4

4. Electrical work ...........................................................................................7

1. Safety precautions

Before installing the interface unit, make sure you read all the “Safety

precautions”.

Please report to your supply authority or obtain their consent before

connecting this equipment to the power supply system.

Warning:

Precautions that must be observed to prevent injuries or death.

Caution:

Precautions that must be observed to prevent damages to the unit.

Warning:

• The unit must not be installed by the user. Ask an installer or an authorised

technician to install the unit. If the unit is installed improperly, electric

shock, or re may be caused.

• For installation work, follow the instructions in the Installation Manual and

use tools and pipe components specically made for use with refrigerant

specied in the outdoor unit installation manual.

• The unit must be installed according to the instructions in order to minimize the risk of damages by earthquakes, typhoons, or strong winds.

Improperly installed unit may fall down and cause damage or injury.

The unit must be securely installed on a structure that can sustain its weight.

•

If the unit is mounted on an unstable structure, it may fall down and cause

damage or injury.

• All electric work must be performed by a qualied technician according to

local regulations and the instructions given in this manual. The unit must

be powered by dedicated power lines and the correct voltage and circuit

breakers must be used. Power lines with insufcient capacity or incorrect

electrical work may result in electric shock or re.

5. Remote controller operation ....................................................................15

6. Service and Maintenance ........................................................................20

7. Requirement on local design ...................................................................21

After installation, perform the test run to ensure normal operation. Then explain

your customer the “Safety Precautions,” use, and maintenance of the unit based on

the information in the Operation Manual provided by local application manufacturer.

Both the Installation Manual and the Operation Manual must be given to the user.

These manuals must always be kept by the actual users.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels attached to the unit.

• Only the specified cables can be used for wiring. Connections must be

made securely without tension on the terminals. If cables are connected or

installed improperly, It may result in overheating or re.

• Terminal block cover panel of the unit must be rmly xed. If the cover

panel is mounted improperly, dust and moisture may enter the unit, and it

may cause electric shock or re.

• Make sure to use accessories authorised by Mitsubishi Electric and ask

an installer or an authorised technician to install them. If accessories are

improperly installed, it may cause electric shock, or re.

• Do not remodel the unit. Consult an installer for repairs. If alterations or

repairs are not performed correctly, it may cause electric shock or re.

• The user should never attempt to repair the unit or transfer it to another

location. If the unit is installed improperly, it may cause electric shock or

re. If the interface unit needs to be repaired or moved, ask an installer or

an authorised technician.

• When installing sensors and parts, do not expose the terminals.

1.1. Before installation (Environment)

Caution:

• Do not install the interface unit in outdoor location as it is designed for

indoor installation only. Otherwise electric shock or breakdown may be

caused by water drop, wind or dust.

Do not use the unit in an unusual environment. If the interface unit is installed

•

or exposed to steam, volatile oil (including machine oil), or sulfuric gas, or

exposed to briny air, the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced,

ow, or accumulate. If combustible gas accumulates around the unit, it may

cause re or explosion.

1.2. Before installation or relocation

Caution:

• Be very careful when moving the units. Do not hold the packaging bands.

Wear protective gloves to unpack and to move it, in order to avoid your

hands being injured by parts.

1.3. Before electric work

Caution:

• Be sure to install a circuit breaker. If it is not installed, there may be a risk

of electric shock.

• For the power lines, use standard cables of sufcient capacity. Otherwise,

it may cause a short circuit, overheating, or re.

• When installing the power lines, do not apply tension to the cables. The

cables may be cut or overheated resulting in a re.

1.4. Before starting the test run

Caution:

• Turn on the main power switch of the outdoor unit more than 12 hours

before starting operation. Starting operation immediately after turning on

the power switch can severely damage the internal parts. Keep the main

power switch turned on during the operation period.

• When installing the unit in a hospital or in a building where communica-

tions equipment are installed, you may need to take measure to noise and

electronic interference. Inverters, home appliances, high-frequency medical

equipment, and radio communications equipment can cause the interface

unit to malfunction or to breakdown. At the same time, the noise and electric interference from the interface unit may disturb the proper operation of

medical equipment, and communications equipment.

• Be sure to safely dispose of the packaging materials. Packaging materials,

such as nails and other metal or wooden parts may cause injury.

• Do not wash the interface unit. You may receive an electric shock.

• Make sure to ground the unit. Do not connect the ground wire to gas or

water pipes, lightning rods, or telephone grounding lines. If the unit is not

properly grounded, there may be a risk of electric shock.

• Make sure to use circuit breakers (ground fault interrupter, isolating switch

(+B fuse), and molded case circuit breaker) with the specied capacity. If

the circuit breaker capacity is larger than the specified capacity, breakdown or re may result.

• Before starting operation, check that all protective parts are correctly in-

stalled. Make sure not to get injured by touching high voltage parts.

• Do not touch any switch with wet hands. There may be a risk of electric

shock.

• After stopping operation, wait at least 5 minutes before turning off the

main power. Otherwise, it may cause breakdown.

2

Page 3

2. Installing the interface unit

EN

1 2

3 4

<Fig. 2.1.1>

B

<Fig. 2.3.1>

30 mm or more

Cover

Base

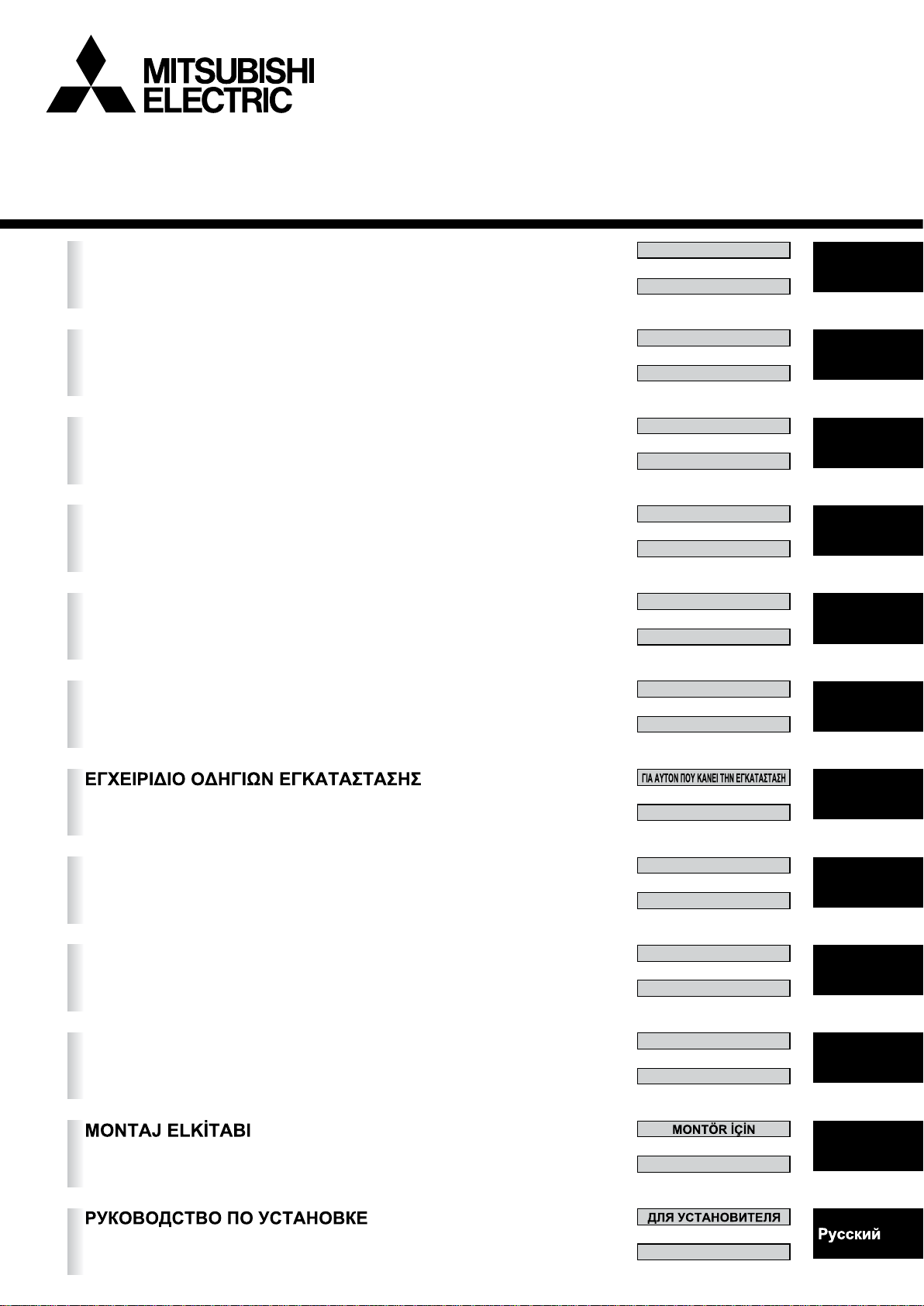

2.1. Check the parts (Fig. 2.1.1)

The interface unit should be supplied with the following parts.

Part Name PAC-IF013B-E PAC-SIF013B-E

Interface unit 1 1

1

Thermistor 4 4

2

Remote controller cable (5m) 1 ─

3

Remote controller 1 ─

4

2.2. Choosing the interface unit installation location

• Do not install the interface unit in outdoor location as it is designed for indoor

installation only. (The interface board and casing are not waterproof.)

• Avoid locations where the unit is exposed to direct sunlight or other sources of

heat.

• Select a location where easy wiring access to the power source is available.

• Avoid locations where combustible gases may leak, be produced, ow, or accu-

mulate.

• Select a level location that can bear the weight and vibration of the unit.

• Avoid locations where the unit is exposed to oil, steam, or sulfuric gas.

• Do not install in location that is hot or humid for long period of time.

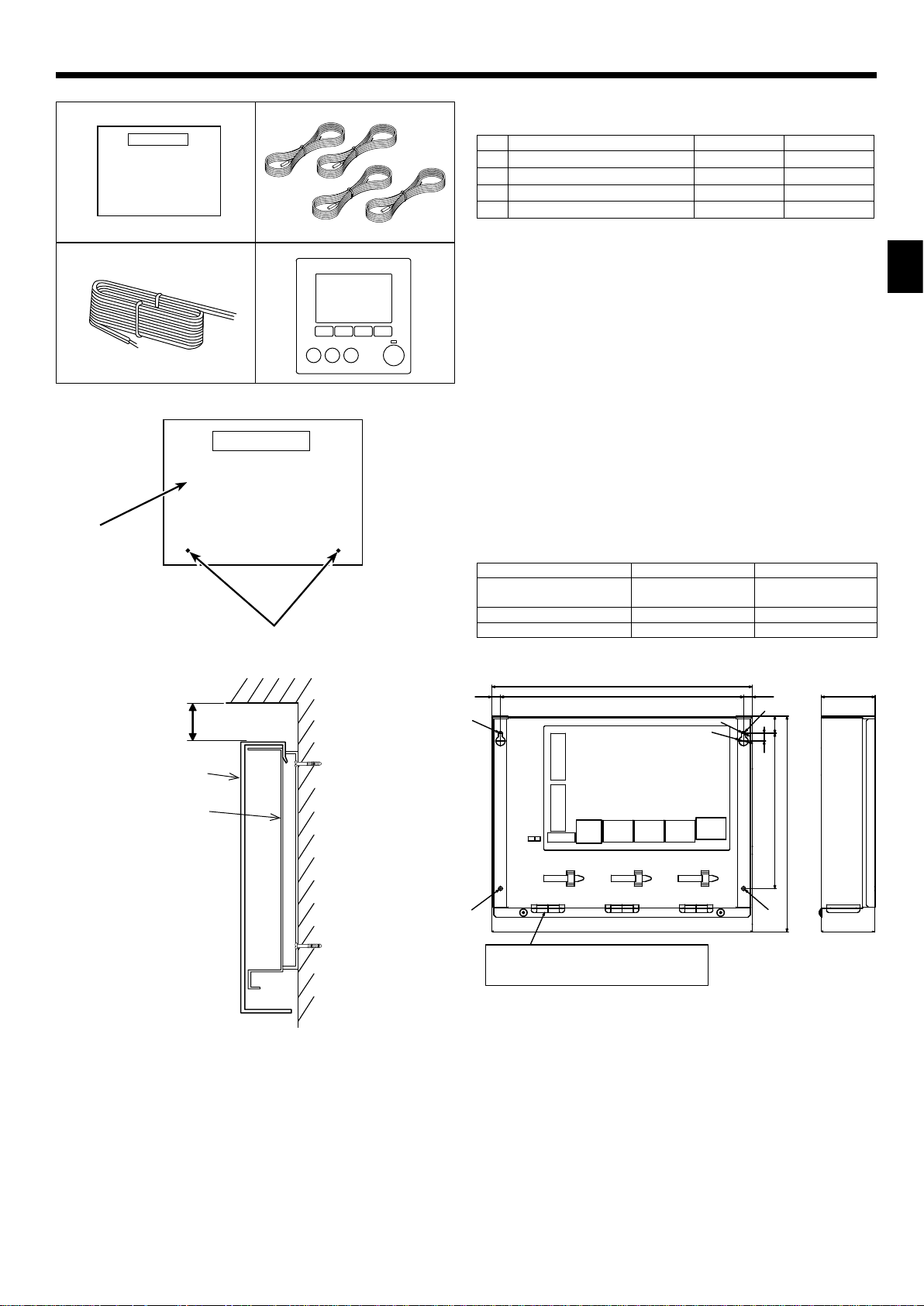

2.3. Installing the interface unit (Fig. 2.3.1, 2.3.2, 2.3.3)

1. Remove 2 screws A from interface unit and remove the cover by sliding it upward

(See Fig. 2.3.1).

2. Install the 4 screws (locally supplied) in 4 holes (C hole).

* To prevent the unit from falling off the wall, select the appropriate screws (lo-

cally supplied) and secure the base horizontally to the appropriate wall location.

(See Fig. 2.3.2)

A Screw B Cover C Hole for installation

PAC-IF013B-E PAC-SIF013B-E

Weight

Allowable ambient temperature 0 to 35°C 0 to 35°C

A

Wall

Allowable ambient humidity 80% RH or less 80% RH or less

C

TB61

TB62

2.5 kg + ACCESSORIES

0.8 kg

336

31311.5

2.5 kg + ACCESSORIES

0.4 kg

(11.5)

C

[

5

[

12

22200

10

Unit: mm

69

278

<Fig. 2.3.2>

Service space

TB63

C

3-ELECTRIC WIRE INLET

When install on a wall: Lower side

<Fig. 2.3.3>

TB6

TB141TB142TB143

C

3

Page 4

3. System

3 1

2

Step mode (Input) Target temperature Number of outdoor unit Intelligent multiple outdoor unit control System

Manual

─

Auto

*1. It is recommended to select Intelligent multiple outdoor unit control.

Design local AHU controller to make sure the following points.

• Minimum capacity request should be 20% or more of total capacity.

• Operate all outdoor units when outdoor temperature is below -15 °C.

Supply air temp. control 1-5 Not available See (1-2) below.

Return air temp. control 1-5 Not available See (1-3) below.

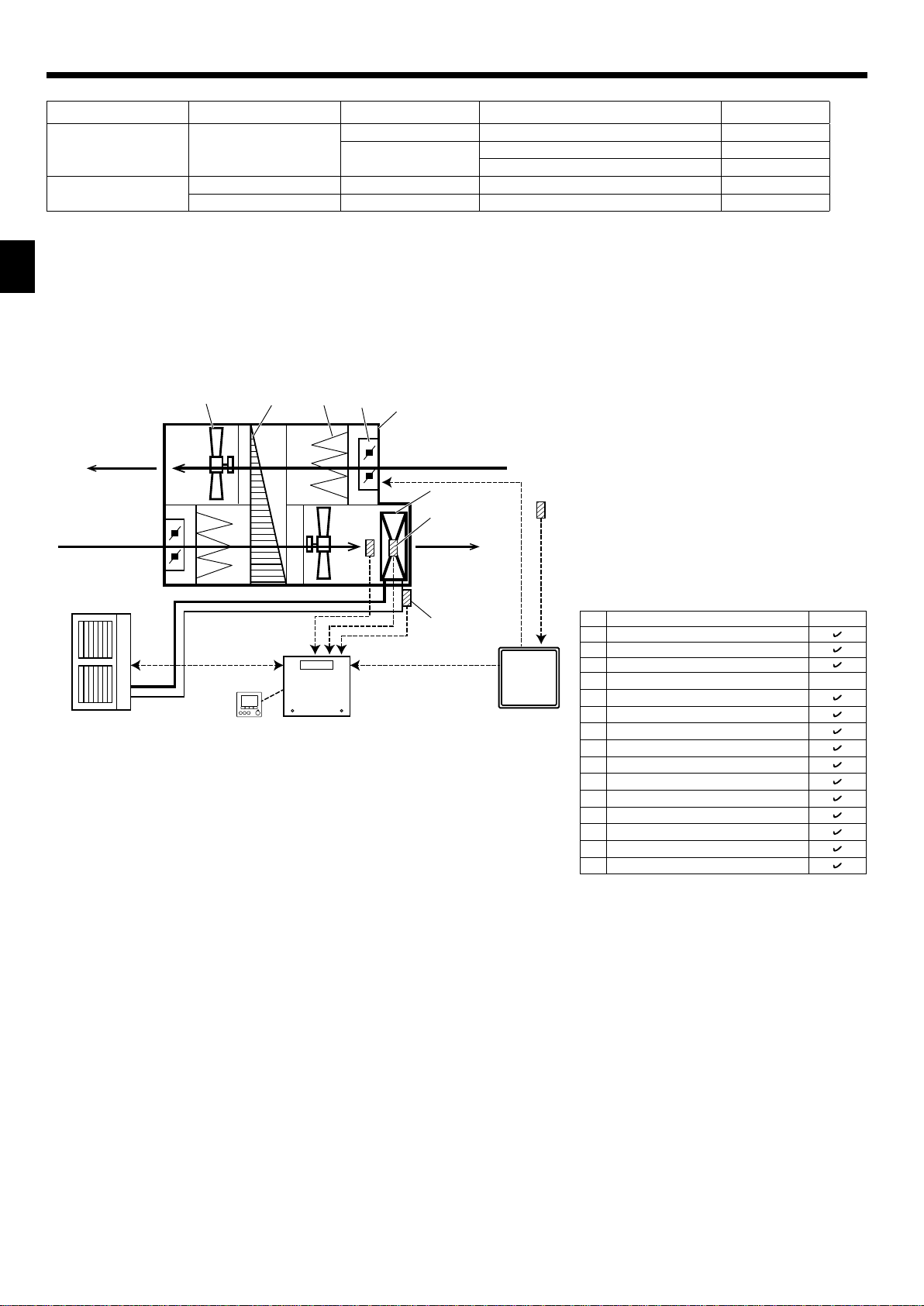

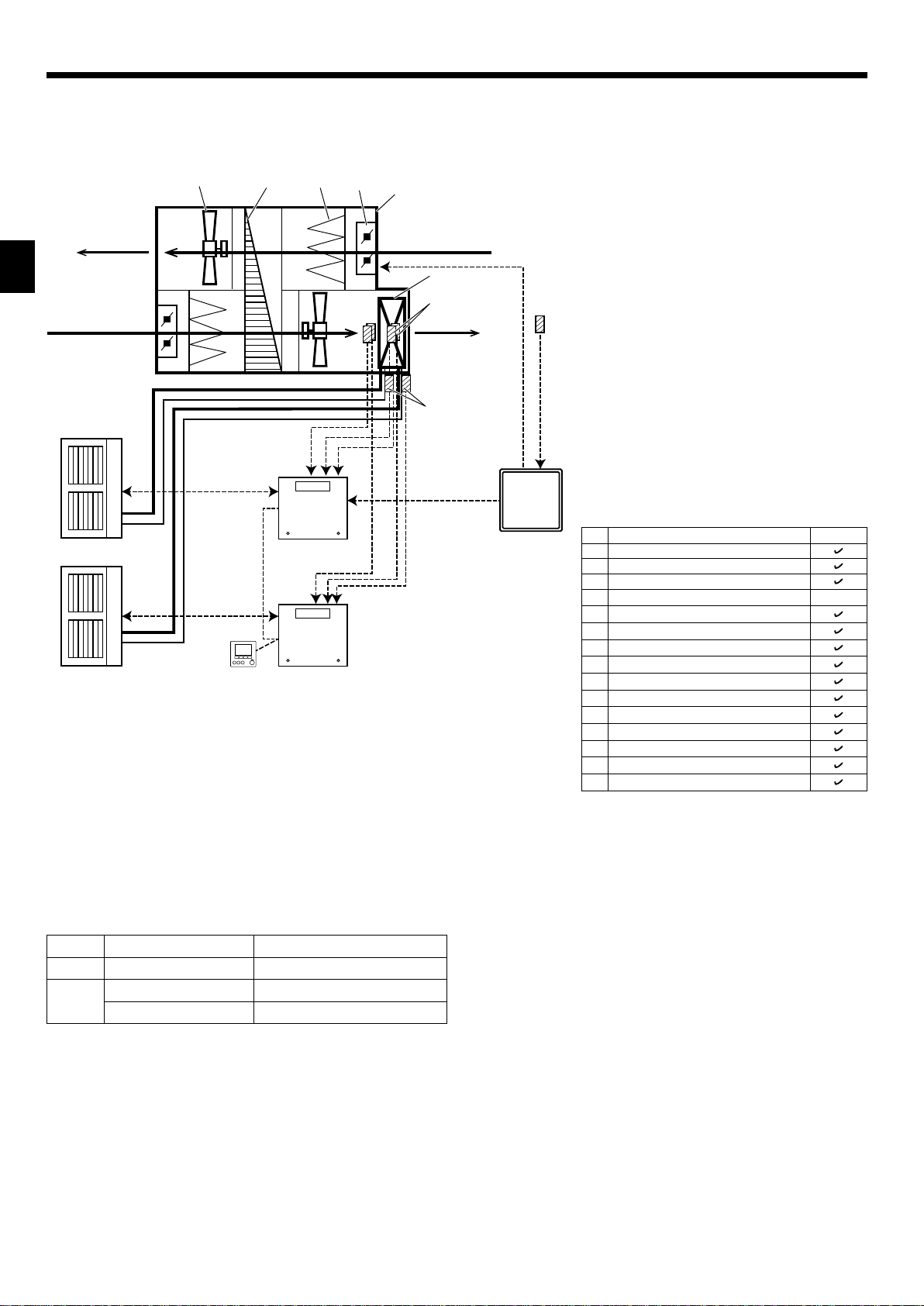

3.1. System conguration (Single outdoor unit)

1 Not available See (1-1) below.

2-6

Apply See (2-1) below.

Not apply See (1-1) below.

*1

(1-1) Manual step mode

15

Exhaust Air

(E.A.)

Outdoor Air

(O.A.)

*1

14

13

<Fig. 3.1.1>

12

*1. Manual step mode:

• Variable capacity request signals for heat pump need to be

8

Return Air

(R.A.)

10

11

6

7

Supply Air

(S.A.)

5

9

calculated by AHU local controller.

• AHU local controller can send “Capacity steps” by non-

voltage contact signals or analog signals to the interface

unit.

• Operation mode can be set by remote controller, external

input or DIP switch.

Note

• Do NOT select STEP 0 for 3 minutes after compressor is

ON. (Keep compressor ON for 3 minutes at least.)

• When changing STEP, make it less than 5 steps in a single

request, and keep at least 5 minutes interval between the

changes.

• Keep operation range shown at the following section 3.3.

• Do NOT send STEP 0 during defrost operation.

• Do NOT change operation mode frequently.

No. Part name

1 Interface unit

2 Remote controller

3 Outdoor unit

4 Target air temp. thermistor (TH1)

5 Ref. liquid temp. thermistor (TH2)

6 2-Phase temp. thermistor (TH5)

7

HEX inlet (Coil on) temp. thermistor (TH11)

8 Air-Handling Unit (AHU) (Local supply)

9 AHU local controller (Local supply)

10 Heat exchanger of AHU (Local supply)

11

Target air temp. thermistor (Local supply)

12 Louver (Local supply)

13 Air lter (Local supply)

14 Heat recovery (Local supply)

15 Fan (Local supply)

*2. Set the DIP SW 2-8 to ON.

*3. If outdoor unit is SHW series, It’s not needed to install

this thermistor, and set the DIP SW 1-5 to ON.

System (1-1)

*2

─

*3

4

Page 5

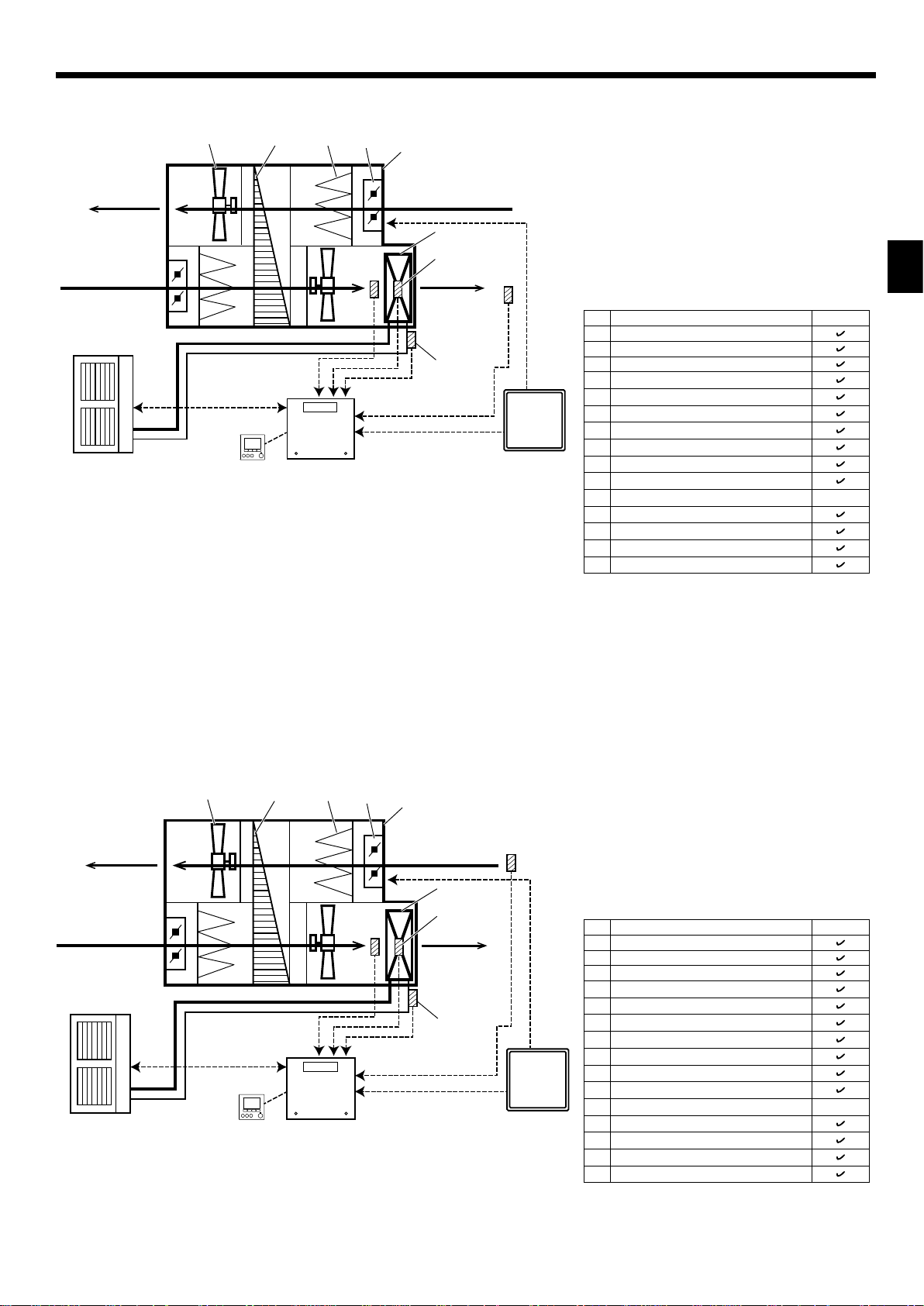

3. System

3 12

EN

(1-2) Auto step mode *4 & Supply air temp. control

15

14

13

12

Exhaust Air

(E.A.)

7

Outdoor Air

(O.A.)

<Fig. 3.1.2>

8

Return Air

(R.A.)

10

6

Supply Air

(S.A.)

5

*4. Auto step mode:

• In this mode, the capacity step of the outdoor unit is controlled automatically to let the target temperature reach the

set temperature.

Note

• Auto change over function between cooling and heating

mode is NOT available in this system.

• Keep operation range shown at the following section 3.3.

• Standard setting of DIP SW3-4 and SW3-5 is 3°C

(SW3-4 : ON , SW3-5 : OFF).

4

9

(Refer to “4.1.7 Switch setting”.)

No. Part name

1 Interface unit

2 Remote controller

3 Outdoor unit

4 Target air temp. thermistor (TH1)

5 Ref. liquid temp. thermistor (TH2)

6 2-Phase temp. thermistor (TH5)

7

HEX inlet (Coil on) temp. thermistor (TH11)

8 Air-Handling Unit (AHU) (Local supply)

9 AHU local controller (Local supply)

10 Heat exchanger of AHU (Local supply)

11

Target air temp. thermistor (Local supply)

12 Louver (Local supply)

13 Air lter (Local supply)

14 Heat recovery (Local supply)

15 Fan (Local supply)

*5. If outdoor unit is SHW series, It’s not needed to install

this thermistor, and set the DIP SW 1-5 to ON.

System (1-2)

*5

─

(1-3) Auto step mode *6 & Return/ Room air temp. control

Exhaust Air

(E.A.)

15

14

13

12

8

Return Air

(R.A.)

7

Outdoor Air

(O.A.)

Supply Air

3 12

<Fig. 3.1.3>

*7

10

6

(S.A.)

5

*6. Auto step mode:

• In this mode, the capacity step of the outdoor unit is controlled automatically to let the target temperature reach the

set temperature.

*7. Return/Room air temp. control:

• Set the DIP SW 1-7 to ON.

4

9

Note

• Auto change over function between cooling and heating

mode is available ONLY when this system is selected and

the input selection of capacity setting (DIP SW1 and SW6)

is ″No input (Auto step mode)″.

• Keep operation range shown at the following section 3.3.

No. Part name

1 Interface unit

2 Remote controller

3 Outdoor unit

4 Target air temp. thermistor (TH1)

5 Ref. liquid temp. thermistor (TH2)

6 2-Phase temp. thermistor (TH5)

7

HEX inlet (Coil on) temp. thermistor (TH11)

8 Air-Handling Unit (AHU) (Local supply)

9 AHU local controller (Local supply)

10 Heat exchanger of AHU (Local supply)

11

Target air temp. thermistor (Local supply)

12 Louver (Local supply)

13 Air lter (Local supply)

14 Heat recovery (Local supply)

15 Fan (Local supply)

*8. If outdoor unit is SHW series, It’s not needed to install this

thermistor, and set the DIP SW 1-5 to ON.

System (1-3)

*8

─

5

Page 6

3. System

2

3.2. System conguration

(Intelligent multiple outdoor unit control *1)

(2-1) Manual step mode (example)

Exhaust Air

(E.A.)

Outdoor Air

(O.A.)

3(Ref. adress: 0)

3(Ref. adress: 1)

15

14

<Fig. 3.2.1>

13

1(Main)

1(Sub)

12

*1. Interface system receives step request signal corre-

spond to total capacity of outdoor units, and calculates

necessary capacity for each outdoor unit automatically.

8

Return Air

(R.A.)

10

7

6

11

Supply Air

(S.A.)

5

9

Note

• This intelligent multiple outdoor unit control function is

available only when Manual step mode is selected.

• Up to 6 outdoor units can be connected.

• 2 different type of outdoor units (capacity and/or series) can

be mixed,but connecting the same capacity outdoor units is

highly recommended.

• Ref. address setting on each outdoor unit is needed.

• Interface unit which connects to the Ref. address 0 outdoor

unit, becomes main interface unit.

• Connect AHU local controller (Part No. 9) to the main interface unit.

• Connect ONE remote controller (Part No. 2) to the interface

unit.

• Connect between the interface units with a remote controller (daisy chain). MAX. : 500m

• When using this function, set the DIP SW 1-8 of all interface unit to ON.

• Do NOT select STEP 0 for 3 minutes after compressor is

ON. (Keep compressor ON for 3 minutes at least.)

• When changing STEP, make it less than 5 steps in a single

operation, and keep at least 5 minutes interval between the

changes.

• Keep operation range shown at the following section 3.3.

• Do NOT send STEP 0 during defrost operation.

• Do NOT change operation mode frequently.

No. Part name

1 Interface unit

2 Remote controller

3 Outdoor unit

4 Target air temp. thermistor (TH1)

5 Ref. liquid temp. thermistor (TH2)

6 2-Phase temp. thermistor (TH5)

7

HEX inlet (Coil on) temp. thermistor (TH11)

8 Air-Handling Unit (AHU) (Local supply)

9 AHU local controller (Local supply)

10 Heat exchanger of AHU (Local supply)

11

Target air temp. thermistor (Local supply)

12 Louver (Local supply)

13 Air lter (Local supply)

14 Heat recovery (Local supply)

15 Fan (Local supply)

*2. Set the DIP SW 2-8 to ON.

*3. If outdoor unit is SHW series, It’s not needed to install

this thermistor, and set the DIP SW 1-5 to ON.

System (2-1)

*2

─

*3

3.3. Indoor operation range

Mode Number of outdoor unit HEX inlet air temp. operation range

Cooling 1 or more

Heating

1

2 or more

15 - 32 °C

0 - 28 °C

5 - 28 °C

6

Page 7

4. Electrical work

EN

4.1. Electrical connection

All electrical work should be carried out by a suitably qualied technician. Failure to

comply with this could lead to electrocution, re, and death. All wiring should be ac-

cording to national wiring regulations.

Connections should be made to the terminals indicated in the following gures.

Use ring terminals and insulate the wires.

Tighten the screw from the bottom terminals rst.

Notes:

1. Do not run the low voltage cables through a slot that the high voltage cables

go through.

2. Do not bundle power cables together with other cables.

3. Bundle cables as Fig. 4.1.1 by using clamps.

INPUT

Remote controller

thermistor

OUTPUT Power cables

<Fig. 4.1.1>

4.1.1. Interface unit power supplied from outdoor unit

The following connection patterns are available.

The outdoor unit power supply patterns vary on models.

D

B C

A

L

N

S1

S2

S3

F

TB6

S1

S2

S3

E

Note:

In accordance with IEE regulations the circuit breaker/isolating switch located on the outdoor unit should be installed with lockable devices (health and safety).

Interface unit - Outdoor unit *3 3 × 1.5 (polar)

× size

(mm²)

Interface unit - Outdoor unit earth *3 1 × Min. 1.5

Wiring

Wire No.

Interface unit - Outdoor unit S1-S2 *4 230 V AC

rating

Interface unit - Outdoor unit S2-S3 *4 24 V DC

Circuit

Notes: 1. Wiring size must comply with the applicable local and national code.

2. Interface unit/outdoor unit connecting cords shall not be lighter than polychloroprene sheathed exible cord. (Design 60245 IEC 57)

Interface unit power supply cords shall not be lighter than polychloroprene sheathed exible cord. (Design 60227 IEC 53)

3. Install an earth longer than other cables.

A Outdoor unit power supply

B Earth leakage breaker *1, *2

C Wiring circuit breaker or isolating switch

D Outdoor unit

E Interface unit/outdoor unit connecting cables

F Interface unit

*1 If the installed earth leakage circuit breaker does not have a function to protect over-current,

install a breaker with that function along the same power line.

*2. A breaker with at least 3.0 mm contact separation in each pole shall be provided. Use earth

leakage breaker (NV).

The breaker shall be provided to ensure disconnection of all active phase conductors of the

supply.

*3. Max. 45 m

If 2.5 mm² used, Max. 50 m

If 2.5 mm² used and S3 separated, Max. 80 m

*4.The values given in the left table are not always measured against the ground value.

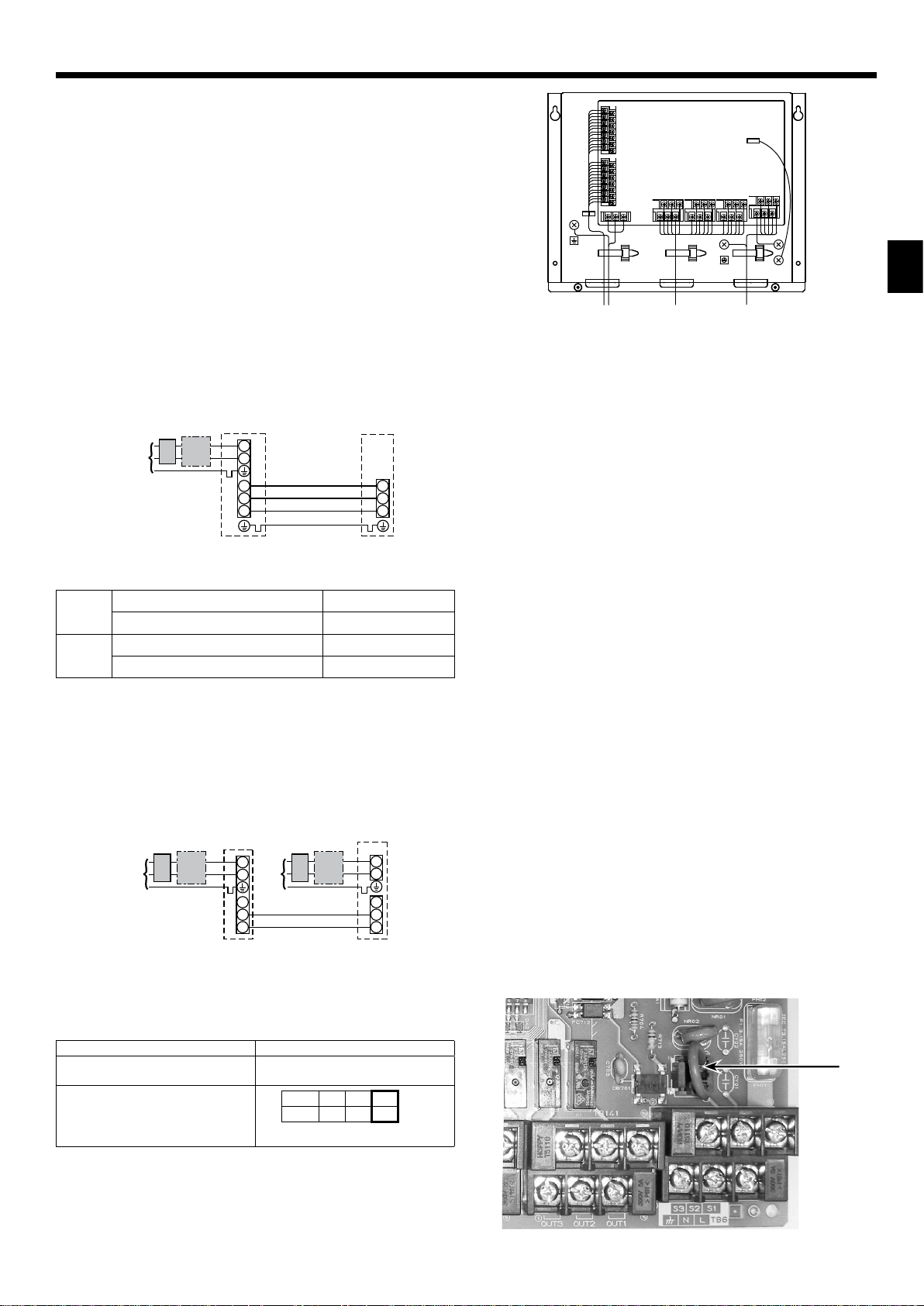

4.1.2. Separate interface unit/outdoor unit power supplies

The following connection patterns are available.

The outdoor unit power supply patterns vary on models.

D

A

CB

L

N

S1

S2

S3

B

G

E

F

TB6

C

L

N

S1

S2

S3

Note:

In accordance with IEE regulations the circuit breaker/isolating switch located on the outdoor unit should be installed with lockable devices (health and safety).

If the interface and outdoor units have separate power supplies, refer to the table

below.

Separate power supply specications

Interface unit controller connector

(CNS2) connection change

Outdoor unit DIP switch settings (when

using separate interface unit/outdoor

unit power supplies only)

Disconnected

ON 3

OFF 1 2

(SW8)

Set the SW8-3 to ON.

A Outdoor unit power supply

B Earth leakage breaker *1, *2

C Wiring circuit breaker or isolating switch

D Outdoor unit

E Interface unit/outdoor unit connecting cables

F Interface unit

G Interface unit power supply

*1 If the installed earth leakage circuit breaker does not have a function to protect over-current,

install a breaker with that function along the same power line.

CNS2

<Photo 4.1.2>

7

Page 8

4. Electrical work

Interface unit power supply ~/N 230 V 50 Hz

Interface unit input capacity *2

Main switch (Breaker)

Interface unit power supply 2 × Min. 1.5

Interface unit power supply earth 1 × Min. 1.5

size

Interface unit-Outdoor unit *3 2 × Min. 0.3

(mm²)

Wiring

Wire No. ×

Interface unit-Outdoor unit earth —

Interface unit L-N *4 230 V AC

Interface unit-Outdoor unit S1-S2 *4 —

rating

Circuit

Interface unit-Outdoor unit S2-S3 *4 24 V DC

Notes: 1. Wiring size must comply with the applicable local and national code.

2. Interface unit/outdoor unit connecting cords shall not be lighter than polychloroprene sheathed exible cord. (Design 60245 IEC 57)

Interface unit power supply cords shall not be lighter than polychloroprene sheathed exible cord. (Design 60227 IEC 53)

3. Install an earth longer than other cables.

4.1.3. Connecting thermistor cable

Connect the thermistor 2 for the interface controller.

1. Target temp. thermistor (TH1)

Connect the thermistor for the target temp. to 1 and 2 on the terminal block (TB61)

on the interface controller.

2. HEX inlet temp. thermistor (TH11)

Connect the thermistor for the HEX inlet temp. to 3 and 4 on the terminal block

(TB61) on the interface controller.

3. Ref. liquid temp. thermistor (TH2)

Connect the thermistor for the ref. liquid temp. to 5 and 6 on the terminal block

(TB61) on the interface controller.

4. 2-phase temp. thermistor (TH5)

Connect the thermistor for the 2-phase temp. to 7 and 8 on the terminal block

(TB61) on the interface controller.

When the thermistor cables are too long, cut it to the appropriate length.

Do not bind it in the interface unit.

The 4 thermistors have the same specication except the color of cables, thus we do not specify which thermistor should be

installed to which position.

Notes: When multiple outdoor units are connected, conect thermistors to each interface unit respectively.

Caution:

Do not route the thermistor cables together with power cables.

The sensor part of the thermistor should be installed where user can not access. (It should be separated by the supplementary insulation from areas the user can access.)

4.1.4. Connecting external input

Demand control is available by external input.

Select input type by setting the switch of the interface controller, and it is possible to set capacity request when manual step mode (“Analog input” , “Remote switch” or “Modbus”) is selected.

Switch1, Switch 6 : Input selection of inverter capacity setting

REMOTE SWITCH Type A (4bit-8 setting) OFF OFF OFF OFF OFF

REMOTE SWITCHType B (1bit-1 setting) ON OFF OFF OFF OFF

Analog (4-20mA) ON ON OFF ON ON

Analog (1-5V) ON ON OFF OFF ON

Analog (0-10V) OFF OFF ON OFF OFF

Analog (0-10kΩ) ON OFF ON OFF OFF

No input (Auto step mode) OFF ON ON OFF OFF Only Auto step mode

Modbus ON ON ON OFF OFF OFF/Step1/Step2/…/Step11

• Capacity setting

Variable

resistor

(0-10kΩ)

OPEN(12kΩ-) – – – OFF – – – – – – Stop

10kΩ – – – Auto OFF OFF OFF ON Auto Auto

7.5kΩ 19-20mA 4.75-5V 9.75-10V Step11 max. ON ON ON OFF Step11 max. –

– – – 9.02V Step10 – – – – – –

5.6kΩ 17mA 4.25V 8.20V Step9 OFF ON ON OFF Step9 –

4.3kΩ 15mA 3.75V 7.38V Step8 ON OFF ON OFF Step8 –

– – – 6.56V Step7 – – – – – –

3.3kΩ 13mA 3.25V 5.75V Step6 OFF OFF ON OFF Step6 Step11 max.

– – – 4.93V Step5 – – – – – –

2kΩ 11mA 2.75V 4.11V Step4 ON ON OFF OFF Step4 –

1kΩ 9mA 2.25V 3.29V Step3 OFF ON OFF OFF Step3 Step6

– – – 2.47V Step2 – – – – – –

510Ω 7mA 1.75V 1.66V Step1 min. ON OFF OFF OFF Step1 min. Step1 min.

0-100Ω 4-5mA 0-1.25V 0-0.63V OFF OFF OFF OFF OFF OFF OFF Stop

Input SW 1-1 SW 1-2 SW 1-3 SW 6-1 SW 6-2 Step for capacity setting

Analog input

4-20mA 1-5V 0-10V Analog input

Step for

capacity setting

TB 62

10-11

(COM-IN5)

16 A

*2. A breaker with at least 3.0 mm contact separation in each pole

shall be provided. Use earth leakage breaker (NV).

The breaker shall be provided to ensure disconnection of all active

phase conductors of the supply.

*3. Max. 120 m

*4. The values given in the left table are not always measured against

the ground value.

TB61

TH1

TH11

TH2

TH5

See the "Capacity setting" table below.

Remote switch Step for capacity setting

TB 62

10-12

(COM-IN6)

TB 62

10-13

(COM-IN7)

TB 62

10-14

(COM-IN8)

Remote SW

(Type A)

<Photo 4.1.3>

Remote SW

(Type B)

Remark

Auto step mode

Hz xed mode

At site

OFF – AUTO

{

8

I/F

10

11

12

13

14

TB62

At site

Step1

Step6

Step11

AUTO

I/F

10

11

12

13

14

TB62

Page 9

4. Electrical work

EN

• 4-20mA / 1-5V / 0-10V / 0-10kΩ

1 Use 4-20mA / 1-5V / 0-10V

Connect the transmission cables to No. 11 and 12 on the terminal block (TB61).

No. 11 on the terminal block(TB62) : Plus side

No. 12 on the terminal block(TB62) : Minus side (Reference side)

2 Use variable resistor (0-10kΩ)

Connect the transmission cables to No. 9 and 10 on the terminal block (TB61).

Note:

The values of the "capacity setting" table on the previous page show the center

of the input value.

Cable length: Maximum 10m

• Remote switch Type A (4 bit - 8 setting)/Type B (1 bit - 1 setting)

Demand control is available by connecting remote switches with terminal No.10 - 14.

Make sure to use the non-voltage switch (for the remote switch)

Remote switch cable length : Maximum 10m

Remote switch : Minimum applicable load 12V DC, 1mA

Note:

When using intelligent multiple outdoor unit control function, input the capacity request

signal to the main interface which connects to the ref. address 0 outdoor unit.

•

External function setting

This function is setting operation mode or stopping compressor, by the external signal.

TB62 Item OFF ON Remark

1-2 (IN1) Forced Comp. OFF *1 Normal Forced Comp. OFF

3-4 (IN2)Item Fixed operation mode Cooling Heating

*1 The operation continues during defrosting operation.

The “Forced Comp. OFF” signal should not be turned ON frequently. It should only

be used if an abnormality occurs.

Cable length : Maximum 10m

Remote switch : Minimum applicable load 12V DC, 1mA

Note:

When using IN1 with intelligent multiple outdoor unit control function, input

IN1 to the interface unit respectively. Input IN2 to the main interface which connects to the ref. address 0 outdoor unit.

Caution:

The external input signals are separated by basic insulation from power supply for the unit.

The external input signals should be separated by supplementary insulation

from where user may touch in case that it is installed where user may touch.

Connect the terminals by using the ring terminals and also insulate the cables of adjoining terminals when wiring to terminal block.

Available when SW2-1 and SW2-2 are ON

TB61

TB62

<Photo 4.1.4>

0-10 kΩ

4-20mA/1-5V/0-10V

Wired remote controller

(For maintenance)

IN1

IN2

At site

(

(

(

I/F

9

10

11

12

13

14

TB61

1

2

3

4

TB62

+

4.1.5. Connecting External Output

Name Terminal block Item OFF ON

OUT1 TB141 5-6 Operation Output OFF ON

OUT2 TB141 3-4 Error Output Normal Error

OUT3 TB141 1-2 Comp. ON Output

OUT4 TB142 5-6 Defrost Output OFF ON(Defrosting)

OUT5 TB142 3-4 Mode(Cool) Output OFF ON(Cooling)

OUT6 TB142 1-2 Mode(Heat) Output OFF ON(Heating)

OUT7 TB143 5-6 Self protection Output OFF ON

OUT8 TB143 3-4 Pre-Defrost Output

*1 The output may not be available depending on connected outdoor unit models.

Cable length : Maximum 50m

Output specication : Non-voltage switch 1A, 240V AC/30V DC or less

*Connect the surge absorber according to the load at site.

Note:

•

External output signals are separated by basic insulation from other circuit

of interface.

• When

intelligent

OUT4, OUT7 and OUT8 will work individually on each interface.

Caution: When 2 or more external outputs are used, the power supply on

10 mA, 5 V DC or more

multiple outdoor unit control function is selected, OUT2, OUT3,

the output side should be the same.

OFF(Comp. OFF)

*1

OFF ON

ON(Comp. ON)

TB143

TB143

TB142

TB141

<Photo 4.1.5>

X8 X7 X6 X5 X4 X3 X2 X1

1

2 3 4 5 6

OUT8 OUT7

TB142

1

2 3 4 5 6

OUT6

OUT5 OUT4

TB141

1

2 3 4 5 6

OUT3

OUT2 OUT1

9

Page 10

4. Electrical work

4.1.6. Wiring specication External output / External input

Locally supplied parts

Item Name Model and specications

External output function External output signal wire Use sheathed vinyl coated cord or cable.

Display lamp, etc. Non-voltage Contact 220-240V AC (30V DC), 1A or less

External input function External input signal wire Use sheathed vinyl coated cord or cable.

Switch Non-voltage "a" contact

4.1.7. Switch setting

It is possible to set the following function by setting the switch of the interface controller.

• SW2-1/2-2 : Fixed operation mode

SW2-1 SW2-2 Details

OFF OFF Not FIX (Depending on Remote controller setting)

ON OFF [Cooling] FIX

OFF ON [Heating] FIX

ON ON External input (Depending on TB62 3-4)

• SW2-3/2-4/2-5 : Fixed set temperature [For Auto step mode only]

SW2-3 SW2-4 SW2-5 Details

OFF OFF OFF Not xed (Remote controller setting)

ON OFF OFF Cooling 19°C/Heating 17°C FIX

OFF ON OFF 20°C FIX

ON ON OFF 22°C FIX

OFF OFF ON 24°C FIX

ON OFF ON 26°C FIX

OFF ON ON 28°C FIX

ON ON ON Cooling 30°C/Heating 28°C FIX

Set switches in case of auto step mode.

Wire type : CV, CVS or equivalent.

Wire size : Stranded wire 0.5mm

Solid wire: {

0.65mm to {1.2mm

10 mA, 5 V DC or more

Wire type : CV, CVS or equivalent.

Wire size : Stranded wire 0.5mm

Solid wire : {

0.65mm to {1.2mm

2

to 1.25mm

2

to 1.25mm

2

2

• SW3-4/3-5 : Thermo OFF point by HEX inlet air temp.

(difference between target temp. and HEX inlet temp.)

[For Auto step mode and supply air temp. control]

Compressor is forced to stop when HEX inlet temp. is close to target temp. to reduce frequent ON/OFF cycling under low heating/cooling load condition.

SW3-4 SW3-5 Differential

OFF OFF 1°C

OFF ON 2°C

ON OFF 3°C

*1

ON ON 4°C

*1. Standard setting : 3°C

• Other DIP switch setting

DIP switch Function OFF ON

SW1-4 HEX inlet temp. thermistor (TH11)

SW1-5 2-phase temp. thermistor (TH5) WITH WITHOUT

SW1-6 Time stamp function on SD card data

*2

WITH WITHOUT

Not available

Available

*1

SW1-7 Position of target temp. thermistor (TH1) Supply Air temp. control Return Air temp. control

SW1-8 Intelligent multiple outdoor units control Inactive Active

SW2-6 LEV self control

SW2-7 Ref. liquid temp. thermistor (TH2)

*2

*2

OFF ON

WITH WITHOUT

SW2-8 Target temp. thermistor (TH1) WITH WITHOUT

*1. This function is valid only with remote controller.

*2. This SW must be set to “OFF”.

4.1.8. Before test run

After completing installation and the wiring and piping of the local application and outdoor units, check for refrigerant leakage, looseness in the power supply or control

wiring, wrong polarity, and no disconnection of one phase in the supply.

Use a 500-volt megohmmeter to check that the resistance between the power supply terminals and ground is at least 1.0MΩ.

Warning:

Do not use the system if the insulation resistance is less than 1.0MΩ.

Caution:

Do not carry out this test on the control wiring (low voltage circuit) terminals.

10

Page 11

4. Electrical work

EN

4.2 Using SD memory card

The interface unit is equipped with an SD memory card interface.

Using an SD memory card can store operating logs.

<Handling precautions>

(1) Use an SD memory card that complies with the SD standards. Check that the SD

memory card has a logo on it of those shown to the right.

(2) SD memory cards to the SD standards include SD, SDHC, miniSD, micro SD,

and microSDHC memory cards. The capacities are available up to 32 GB.

Choose that with a maximum allowable temperature of 55ºC.

(3) When the SD memory card is a miniSD, miniSDHC, microSD, or micro SDHC

memory card, use an SD memory card converter adapter.

(4) Before writing to the SD memory card, release the write-protect switch.

(a) For insertion, push on the SD memory card until it clicks into place.

(b) For ejection, push on the SD memory card until it clicks.

Note: To avoid cutting ngers, do not touch sharp edges of the SD

memory card connector (CN108) on the interface controller.

(a)

(b)

Logos

(5) Before inserting or ejecting an SD memory card, make sure to power off the

system. If an SD memory card is inserted or ejected with the system powered on,

the stored data could be corrupted or the SD memory card be damaged.

*An SD memory card is live for a short duration after the system is powered off.

Before insertion or ejection wait until the LED lamps on the interface control

board are all off.

(6) The read and write operations have been veried using the following SD memory

cards, however, these operations are not always guaranteed as the specications of these SD memory cards could change.

Manufacturer Model Tested in

Verbatim #44015 0912-61 Mar. 2012

SanDisk SDSDB-002G-B35 Oct. 2011

Panasonic RP-SDP04GE1K Oct. 2011

Arvato 2GB PS8032 TSB 24nm MLC Jun. 2012

Arvato 2GB PS8035 TSB A19nm MLC Jul. 2014

Lexar LSD 8GB ABEUCL6 Rev A Jul. 2014

Before using a new SD memory card, always check that the SD memory card

can be safely read and written to by the interface board.

<How to check read and write operations>

a) Check for correct wiring of power supply to the system. For more details,

refer to section 4.1.

(Do not power on the system at this point.)

b) Insert an SD memory card.

c) Power on the system.

d) The LED6 lamp lights if the read and write operations are successfully

completed. If the LED6 lamp continues blinking or does not light, the SD

memory card cannot be read or written to by the interface controller.

(7) Make sure to follow the instruction and the requirement of the SD memory

card’s manufacturer.

(8) Format the SD memory card if determined unreadable in step (6). This could

make it readable.

Capacities

2 GB to 32 GB *1

SD speed classes

All

• The SD Logo is a trademark of SD-3C, LLC.

The miniSD logo is a trademark of SD-3C, LLC.

The microSD logo is a trademark of SD-3C, LLC.

*1 A 2-GB SD memory card stores up to 30 days of operation logs.

(9) Interface board supports FAT le system but not NTFS le system.

(10) Mitsubishi Electric is not liable for any damages, in whole or in part, including

failure of writing to an SD memory card, and corruption and loss of the saved

data, or the like. Back up saved data as necessary.

(11) Do not touch any electronic parts on the interface controller when inserting or

ejecting an SD memory card, or else the control board could fail.

11

Page 12

4. Electrical work

4.3. Connecting the remote controller

4.3.1. Connect the remote controller cable to Interface unit

Connect the remote controller cable to 13 and 14 on the terminal block (TB61) on

the interface controller. <Fig. 4.3.1>

Wiring wire No. × size (mm²): 2 × 0.3 (non polar)

The 5 m wire is attached as an accessory. Max. 500 m

Wiring size must comply with the applicable local and national codes.

Circuit rating: 12V DC

Circuit rating is NOT always against the ground.

No.13,14

(TB61)

Remote controller prole

Installation pitch

Wall

Bushing

<Fig. 4.3.1>

30

83.5

<Fig. 4.3.2>

30

46

120

Conduit tube

Locknut

Switch box

Required clearances

surrounding the remote

30

controller

Unit: mm

Notes:

Wiring for remote controller cable shall be (5 cm or more) apart from power

source wiring so that it is not inuenced by electric noise from power source

wiring. (Do not insert the remote controller cable and power source wiring in

the same conduit.) (Refer to Fig. 4.1.1)

When wiring to TB61, use the ring type terminals and insulate them from the

cables of adjoining terminals.

4.3.2. Installing the remote controller

1. The remote controller can be installed either in the switch box or directly on the

wall. Perform the installation properly according to the method.

(1) Secure clearances shown in <Fig. 4.3.2> regardless of whether installing the

remote controller either directly on the wall or in the switch box.

(2) Prepare the following items in the eld.

Double switch box

Thin metal conduit

Locknut and bushing

Cable cover

Wall plug

2. Drill an installation hole in the wall.

■ Installation using a switch box

Drill a hole in the wall for the switch box, and install the switch box in the hole.

•

• Fit the conduit tube into the switch box.

■ Direct wall installation

• Drill a cable access hole and thread the remote controller cable through it.

Caution:

To prevent entry of dew, water, and insects, seal the gap between the cable

and the hole through which the cable is threaded with putty. Otherwise, electric shock, re, or failure may result.

Seal the gap with putty.

Remote controller cable

<Fig. 4.3.3>

Front cover and top case Bottom case

<Fig. 4.3.4>

Thread the sheath part

of the cable to the front.

Sheath

10mm

6mm

Front

Thread the cable.

Back

2-core wire must not

be seen on the back.

3. Have the remote controller ready.

Remove the bottom case from the remote controller.

4. Connect the remote controller cable to the terminal block on the bottom case.

Modify the remote controller cable as shown in <Fig. 4.3.5>, and thread the cable from behind the bottom case.

Completely thread the cable to the front so that the unsheathed part of the cable

cannot be seen behind the bottom case.

Connect the remote controller cable to the terminal block on the bottom case.

■ Direct wall installation

• Seal the gap between the cable and the hole through which the cable is

threaded.

Caution

To prevent electric shock or failure, keep the sheath ends or any other

foreign objects out of the terminal block.

Do not use ring terminals to connect the wires to the terminal block on the

bottom case. The terminals will come in contact with the control board and

the front cover and top case, which will result in failure.

Connect the cable.

(non-polarized)

Connect the cable so that the

cable sheath is not pinched.

Route the cable from behind

the remote controller.

Remote controller cable

Seal the gap with putty.

12

<Fig. 4.3.5>

Page 13

4. Electrical work

EN

Double switch box

Roundhead cross

slot screws

Wood screw

Seal the cable access

hole with putty.

See Step 2.

Remote controller cable

See Step 4.

Remote controller cable

See Step 4.

Thread the cable through the groove.

<Fig. 4.3.6>

<Fig. 4.3.7>

5. Install the bottom case.

■ Installation using a switch box

• When installing the bottom case in the switch box, secure at least two cor-

ners of the switch box with screws.

■ Direct wall installation

• Thread the cable through the slot provided.

• When mounting the bottom case on the wall, secure at least two corners of

the remote controller with screws.

• To prevent the bottom case from lifting, use top-left bottom-right corners of

the remote controller (viewed from the front) to secure the bottom case to the

wall with wall plugs or the like.

Caution:

To avoid causing deformation or cracks to the remote controller, do not

overtighten the screws and make an additional installation hole(s).

6. Cut out the cable access hole.

■ Direct wall installation

• Cut out the knockout hole (indicated with grey in <Fig. 4.3.7>) in the front

cover by knife or nipper.

• Thread the remote controller cable from the slot behind the bottom case

through this access hole.

Securely connect

the connectors.

Hold the wires in place

with clamps.

<Fig. 4.3.8>

<Fig. 4.3.9>

Clamps

7. Plug the lead wire cable into the top case.

Plug the lead wire cable coming from the bottom case into the top case.

Caution:

To avoid failures, do not remove the controller board protective sheet and the

controller board from the top case.

After the cable is plugged into the top case, do not hang the top case as

shown in <Fig. 4.3.8>. Otherwise, the remote controller cable could sever,

which could cause malfunction to the remote controller.

8. Fit the lead wires into the clamps.

Caution:

Hold the wires in place with clamps to prevent excessive strain from being

applied on the terminal block and causing cable breakage.

13

Page 14

4. Electrical work

Seal the gap between the cable

and the access hole with putty.

Thread the remote controller cable through the cable

access hole at the top of the remote controller.

<Fig. 4.3.10>

<Fig. 4.3.11>

Check that the cover is

securely installed and not

lifted.

Use a cable cover.

9. Fit the top case and the front cover onto the bottom case.

The top case assembly (tted with the front cover at factory shipment) has two

tabs on top. Hook the tabs onto the bottom case and snap the top case onto the

bottom case into place. Check that the cover is securely installed.

Caution:

When the top case is correctly attached to the bottom case a click is heard. If

the front cover is not clicked into place it may fall off.

■ Direct wall installation (when routing the remote controller cable along the wall

surface)

• Thread the remote controller cable through the cable access hole at the top

of the remote controller.

• Seal the gap between the cable and the access hole with putty.

• Use a cable cover.

<Fig. 4.3.12>

Disassembling the top case and the front cover

●

(1) Remove the front cover.

Insert a at head screwdriver into either of two open slots at the bottom of the

remote controller and move the screwdriver handle downward as shown. The

engagement of the tabs will be released. Then pull the front cover toward the

front to remove the front cover.

(2) Remove the top case.

Insert a at head screwdriver into either of two open slots at the bottom of the

remote controller. The subsequent procedure is the same as that of the front

cover.

Caution:

Use a 5 mm- at head screwdriver. Do not turn the screwdriver forcibly while

placing the blade in the slots. Doing so could break the covers.

14

Page 15

EN

5. Remote controller operation

Disposal of the Unit

Note: This symbol mark is for EU countries only.

This symbol mark is according to the directive 2012/19/EU

Article 14 Information for users and Annex IX, and/or to the

directive 2006/66/EC Article 20 Information for end-users and

Annex II.

Your Mitsubishi Electric heating system products have been manufactured with high quality materials and components which can

<Figure 5.1>

be recycled and/or reused. The symbol in Figure 5.1 means that

electrical and electronic equipment, batteries and accumulators

at the end of their life, should be disposed of separately from your

household waste.

If a chemical symbol is printed beneath the symbol (Figure 5.1),

this chemical symbol means that the battery or accumulator contains a heavy metal at a certain concentration. This is indicated as

follows;

Hg: mercury (0.0005%), Cd: (cadmium (0.002%), Pb: lead (0.004%)

In the European Union there are separate collection systems for used electrical

and electronic products, batteries and accumulators.

Please dispose of this equipment, batteries and accumulators correctly at your local community waste collection/recycling centre.

Contact your local Mitsubishi Electric dealer for country-specic details on

disposal.

Please, help us to conserve the environment we live in.

5.1. Safety precautions

► Before installing the unit, make sure you read all the “Safety Precau-

tions”.

► The “Safety Precautions” provide very important points regarding

safety. Make sure you follow them.

► Please report to or take consent by the supply authority before connec-

tion to the system.

Warning:

• The unit must not be installed by the user. Ask the dealer or an author-

ized company to install the unit. If the unit is installed improperly, electric

shock or re may result.

• Do not stand on, or place any items on the unit.

• Do not splash water over the unit and do not touch the unit with wet hands.

An electric shock may result.

• Do not spray combustible gas close to the unit. Fire may result.

• Do not place a gas heater or any other open-ame appliance where it will

be exposed to the air discharged from the unit. Incomplete combustion

may result.

• Do not remove the front panel or the fan guard from the outdoor unit when

it is running.

• When you notice exceptionally abnormal noise or vibration, stop operation, turn off the power switch, and contact your dealer.

Caution:

• Do not use any sharp object to push the buttons, as this may damage the

remote controller.

• Never block or cover the interface unit’s intakes or outlets.

FOR USER

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates a part which must be grounded.

• Never insert ngers, sticks etc. into the intakes or outlets.

• If you detect odd smells, stop using the unit, turn off the power switch and

consult your dealer. Otherwise, a breakdown, electric shock or re may

result.

• If the supply cable is damaged, it must be replaced by the manufacturer,

its service agent or similarly qualied persons in order to avoid a hazard.

• This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction con-

cerning use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the ap-

pliance.

• If the refrigeration gas blows out or leaks, stop the operation of the air

conditioner, thoroughly ventilate the room, and contact your dealer.

• Do not install in location that is hot or humid for long periods of time.

Disposing of the unit

When you need to dispose of the unit, consult your dealer.

15

Page 16

5. Remote controller operation

Fan

5.2. Names and functions of controller components

Display

Full mode

6

7

8

1

9

Basic mode

1

* All icons are displayed for explanation.

The main display can be displayed in two different modes: "Full" and "Basic."

The factory setting is "Full."

1Operation mode

Interface unit operation mode appears here.

43210

Fri

3

2Preset temperature

Preset temperature appears here.

3Clock

Room

Cool

Set temp.

Mode Temp.

5

5

2

4

2

Fri

3

Current time appears here.

4Fan speed

This function is not available.

5Button function guide

Functions of the corresponding buttons

appear here.

6

Appears when the ON/OFF operation is

centrally controlled.

7

Appears when the operation mode is

centrally controlled.

8

Cool

Mode Te mp.

Set temp.

5

4

Appears when the preset temperature is

centrally controlled.

9Room temperature

Current room temperature appears here.

0

Appears when the buttons are locked.

1

Appears when the On/Off timer function is

enabled.

2

Appears when the Weekly timer is enabled.

3

Appears while power is ON.

4

Appears when the built-in thermistor on the

remote controller is activated to monitor the

room temperature (9).

appears when the thermistor on the

interface unit is activated to monitor the

room temperature.

5

Appears when the preset temperature range

is restricted.

Controller interface

Function buttons

7 8 9 0

• When the backlight is off, pressing any button turns the backlight on and

does not perform its function. (except for the ON/OFF button)

• Most settings (except ON/OFF, mode, fan speed, temperature) can be

made from the Menu screen.

1 ON/OFF button

Press to turn ON/OFF the interface unit.

2 SELECT button

Press to save the setting.

3 RETURN button

5

Press to return to the previous screen.

4 MENU button

Press to bring up the Main menu.

6

1234

5 Backlit LCD

Operation settings will appear.

When the backlight is off, pressing any

button turns the backlight on and it

will stay lit for a certain period of time

depending on the screen.

6 ON/OFF lamp

This lamp lights up in green while the unit

is in operation. It blinks while the remote

controller is starting up or when there is

an error.

The functions of the function buttons

change depending on the screen. Refer

to the button function guide that appears

at the bottom of the LCD for the functions

they serve on a given screen.

When the system is centrally controlled,

the button function guide that

corresponds to the locked button will not

appear.

Main display Main menu

Cool

Mode Te mp.

7 8 9 0 7 8 9 0

Room

Set temp.

Fri

Function guide

Main

Main menu

Vane·Louver·Vent. (Lossnay)

High power

Timer

Weekly timer

OU silent mode

Main display:

Cursor Page

7 Function button F1

Main display: Press to change the operation

mode.

Main menu: Press to move the cursor down.

8 Function button F2

Main

display

Main menu: Press to move the cursor up.

: Press to decrease temperature.

9 Function button F3

Main

display

Main menu: Press to go to the previous page.

: Press to increase temperature.

0 Function button F4

Main

display

Main menu: Press to go to the next page.

: Not available.

16

Page 17

5. Remote controller operation

EN

5.3. Initial settings

From the Main display, press “MENU” button, select “Initial setting”, and make the remote controller settings on the screen that appears.

· Main/Sub

· Clock

· Main display

· Contrast

· Display details

-Clock

-Temperature

-Room temp.

-Auto mode (Auto cooling/heating operation)

· Auto mode (Auto cooling/heating operation)

· Administrator password

· Language selection

(1) Main/Sub setting

When connecting two remote controllers, one of them needs to be designated as a

sub controller.

(2) Clock setting

Clock setting is necessary for time display, SD card data logging, weekly timer, timer

setting and error history.

Make sure to perform clock setting when the unit is used for the first time or has not

used for a long time.

(3) Main display setting

Use the F3 or F4 button to select the display mode “Full” or “Basic.” (The factory

setting is “Full.”)

(4) Remote controller display details setting

Make the settings for the remote-controller-related items as necessary.

Press the SELECT button to save the changes.

[1] Clock display

[2] Temperature unit setting

[3] Room temperature display

[4] Auto mode (Auto cooling/heating operation) display setting

(The factory setting is “Yes”.)

· Yes: “AUTO COOL” or “AUTO HEAT” is displayed during Auto mode (Auto cooling/

heating operation).

· No: Only “AUTO” is displayed during Auto mode (Auto cooling/heating operation).

(5) Auto mode (Auto cooling/heating operation) setting

· Yes: The Auto mode (Auto cooling/heating operation) can be selected in the

operation mode setting.

· No: The Auto mode (Auto cooling/heating operation) cannot be selected in the

operation mode setting.

(The factory setting is “Yes”.)

(6) Administrator password setting

• The initial administrator password is “0000.” Change the default password as

necessary to prevent unauthorized access. Have the password available for those

who need it.

• If you forget your administrator password, you can initialize the password to the

default password “0000” by pressing and holding the F1 and F2 buttons

simultaneously for three seconds on the administrator password setting screen.

• The administrator password is required to make the settings for the following items.

· Timer setting

· Weekly timer setting

· Restriction setting

Clock

Temperature

Room temp.

Auto mode

Select:

Cursor

Display details

No 24h

°C / °F / 1°C

Yes / No

Yes / No

Change

17

Page 18

5. Remote controller operation

5.4. Basic operations

Operation mode icons

Cool Fan Auto

Auto cool Auto heat

Turning ON and selecting operation mode

Press button 1 ( ON/OFF ).

1

Press button 7 ( F1 ) to go through the operation

2

modes.

Cool Fan Heat

Auto

(Auto cooling/heating operation)

*1

F1

Preset temperature setting

Press button 8 ( F2 ) to decrease the preset temperature.

Press button 9 ( F3 ) to increase the preset temperature.

* Pressing once changes the value by 1ºC (1ºF).

Operation mode Preset temperature range

Cool (Supply air temp. control) 12 – 30 ºC (54 – 87 ºF)

Cool (Return air temp. control) 19 – 30 ºC (67 – 87 ºF)

Heat 17 – 28 ºC (63 – 83 ºF)

Auto cooling/heating operation

19 – 28 ºC (67 – 83 ºF)

Fan Not settable

Automatic cooling/heating operation

Heat

The ON/OFF lamp and the LCD will light up.

*1 Operation mode is available ONLY when input selection of capacity

setting (DIP SW1 and SW6) is “No input (Auto step mode)” and

Return air temp. control is selected (DIP SW 1-7 is ON).

* The temperature range restriction setting will be applied preferentially, if any. If

the setting value is outside of the range, a message "Temp. range locked" will

appear.

Press button 1 ( ON/OFF ).

1

Press button 7 ( F1 ) to display the operation mode

2

"Auto".

* The current operation mode ("Auto cool" or "Auto heat") will be displayed after the mode is determined.

If "Display/non-display of COOL/HEAT during AUTO mode" has been set to "Non-display" while making the initial settings, only "Auto" will be displayed.

F1

When the room temperature is higher than the preset temperature, cooling

operation starts.

When the room temperature is lower than the preset temperature, heating

operation starts.

5.5. Troubleshooting

When an error occurs, the following screen will appear.

Check the error status, stop the operation, and consult your dealer.

Error information

Error code

Error unit IU

Ref. address Unt#

Model name

Serial No.

Reset error: Reset button

ResetPage

F1 F2 F3 F4

blinks

Error code, error unit, refrigerant address, unit model name, and serial number will

appear.

The model name and serial number will appear only if the information have been

registered.

Press button 7 ( F1 ) or 8 ( F2 ) to go to the next page.

18

Error information

Contact information

Dealer

Tel

Reset error: Reset button

Contact information (dealer's phone number) will appear if the information have

been registered.

ResetPage

Page 19

5. Remote controller operation

EN

5.6. Timer and Weekly timer

The settings for Timer and Weekly timer operation can be made from the remote

controller.

Press button 4 ( MENU ) to go to the Main menu, and move the cursor to the

desired setting with button 7 ( F1 ) or 8 ( F2 ).

Timer

On/Off timer

•

Operation On/Off times can be set in 5-minute increments.

Auto-Off timer

•

Auto-Off time can be set to a value from 30 to 240 in 10-minute increments.

Weekly timer

Operation On/Off times for a week can be set.

Up to eight operation patterns can be set for each day.

5.7. Service

Maintenance password setting

The initial administrator password is "9999". Change the default password

•

as necessary to prevent unauthorized access. Have the password

available for those who need it.

If you forget your administrator password, you can initialize the password

•

to default password "9999" by pressing and holding the F1 and F2 buttons

simultaneously for three seconds on the maintenance password setting

screen.

Main

Main menu

Vane·Louver·Vent. (Lossnay)

High power

Timer

Weekly timer

OU silent mode

Main display:

Cursor Page

F1 F2 F3 F4

5.8. Others

The following functions are NOT available.

(1) In main menu (Press button 4 (MENU), main menu appears.)

• “Vane Louver Vent (Lossnay)”

• “High power”

• “OU silent mode”

• In “Energy saving” menu, “schedule” function is NOT available.

• “Filter information”

• “Maintenance”

• In “Service” menu, “Drain pump test run”, “Check” functions are NOT

available, except for “Request code” in “Check” function.

19

Page 20

6. Service and Maintenance

Error Codes

Code Error Action

Target air temperature thermistor (TH1) failure

P1

Ref. liquid temperature thermistor (TH2) failure

P2

P6

P9

E0 - E5

E6 - E7

Fb Interface controller board failure

PL

PU

"EE" or "System error 1"

System error 2

System error 3

System error 4

"System error 5" or

"System error 6"

System error 11

"6831" or

"Please wait" remains

displayed on the remote

controller for more than 6

minutes.

Freezing/ overheating protection

2-Phase temperature thermistor (TH5) failure

Communication failure between remote controller

and interface controller board

Communication failure between interface

unit and outdoor unit

Abnormal refrigerant circuit

HEX inlet temperature thermistor (TH11) failure

DIP SW setting error

(Intelligent multiple outdoor unit controll)

Controller board is incompatible with this model.

Incompatible controller board is mixed when multiple

interface units are connected.

DIP SW 1-8 of some interface units are ON

and those of the other interface units are OFF.

2 or more Interface units are connected with one

remote controller and manual step mode is

selected, but DIP SW1-8 are OFF.

7 or more interface units are connected.

(Up to 6 interface units can be connected.)

Remote controller is incompatible with this model.

Check connection of thermistor.

・

Check resistance value of thermistor.

・

0ºC 15.0 kΩ

10ºC 9.6 kΩ

20ºC 6.3 kΩ

30ºC 4.3 kΩ

Check connection of thermistor.

・

Check resistance value of thermistor.

・

For characteristics, refer to (P1) above.

Check local system if air ow is reduced.

・

Check outdoor fan motor.

・

Check connection of thermistor.

・

Check resistance value of thermistor.

・

For characteristics, refer to (P1) above.

Check connection cable for damage or loose connections.

・

Check system conguration of remote controller.

・

(Refer to "3. System")

Check that outdoor unit has not been turned off.

・

Check connection cable for damage or loose connections.

・

Refer to outdoor unit service manual.

・

Replace interface controller board.

・

Replace the 4-way valve.

・

Check refrigerant pipes for disconnection or leakage.

・

Refer to outdoor unit service manual.

・

Check connection of thermistor.

・

Check resistance value of thermistor.

・

For characteristics, refer to (P1) above.

Set DIP SW 1-8 to "OFF", if system is single outdoor unit

・

control.

Connect between interface units and set Ref. address

・

of each outdoor unit. (See "3. System".)

Install interface controller board that is compatible with

・

PAC-IF013B-E or PAC-SIF013B-E.

Check all interface controller boards are compatible with PAC-

・

IF013B-E or PAC-SIF013B-E.

Set DIP SW 1-8 of all interface units to ON, or SW1-8 of all

・

interface units to OFF.

Set SW1-8 of all interface units to ON if system is intelligent

・

multiple outdoor unit controll.

Disconnect between interface units and connect remote

・

controllers separately to each interface unit, if manual

step mode is selected and intelligent multiple outdoor unit

control is not selected.

Connect 6 or less interface units in one system.

・

Remote controller included in the package of PAC-IF013B-E

・

is exclusive for PAC-IF013B-E or PAC-SIF013B-E. Use the

remote controller that has a drawing number "BH00J360" on the

bottom.

20

Page 21

7. Requirement on local design

EN

• This interface is to connect Mr. Slim inverter outdoor unit of MITSUBISHI ELECTRIC to local applications. Please check the following when designing the local system.

• MITSUBISHI ELECTRIC does not take any responsibility on the local system design. Therefore, MITSUBISHI ELECTRIC does NOT take any responsibility on the failure

(including outdoor unit) caused by local AHU and system design.

• Conformity of regulations and laws must be conrmed on the system on your side.

7.1. Air ow volume

Standard air ow volume

Model capacity of outdoor unit ZRP 35 50 60 71 100 125 140 200 250

Maximum air volume [m³/min] 12.3 18 21 24 33.6 42 48 67.2 81

Minimum air volume [m³/min] 6.2 8.6 10.5 12.2 16.3 21.5 23.0 32.6 37.8

Make sure to keep the air ow volume within the limits of maximum and minimum below.

(1) Maximum air volume

Step mode

Manual 2-6 The same 500% of selected outdoor unit's maximum standard air volume

Auto 2-5 – 500% of the smallest capacity outdoor unit's maximum standard air volume

*1. 600% of selected outdoor unit's maximum standard air volume is available ONLY when 6 same capacity outdoor units are connected.

Number of

outdoor unit

1 –

1 – 200% of selected outdoor unit's maximum standard air volume

P – – – – – – – 200 250

SHW – – – 80 112 140 – 230 –

[m³/h] 738 1080 1260 1440 2016 2520 2880 4032 4860

[m³/h] 372 516 630 732 978 1290 1380 1956 2268

Capacities of the

connected outdoor units

Different

If smaller capacity outdoor unit's rated heating capacity is under 20% of total

heating capacity, 500% of bigger capacity outdoor unit's maximum standard air

volume is allowable.

If smaller capacity outdoor unit's rated heating capacity is 20% or more of total

heating capacity, 500% of smaller capacity outdoor unit's maximum standard air

volume is allowable.

200% of selected outdoor unit's maximum standard air volume

Maximum air volume

*1

Note:

• When multiple outdoor units are connected, basically select one interlaced heat exchanger which has multiple refrigerant circuit or multiple heat exchanger placed

in parallel to the air ow. If multiple heat exchangers placed in series with the air ow have to be used, maximum 2 heat exchanger in series are acceptable.

(2) Minimum air volume

Total amount of selected outdoor unit's minimum standard air volume is allowable.

7.2. Indoor heat exchanger

(1) Indoor heat exchanger volume

Make sure to keep the HEX capacity within the following range.

If the piping length is 30m or shorter, HEX capacity can be increased as follows.

Model capacity of outdoor unit ZRP 35 50 60 71 100 125 140 200 250

Max. volume [cm

Min. volume [cm

Note: Calculate them by linear interpolation in case of other piping lengths not shown on this table.

3

]

Pipe length 30m - 1050 1500 1800 2130 3000 3750 4200 6000 7500

3

] 350 500 600 710 1000 1250 1400 2000 2500

(2) Diameter of header

With a bigger size header , the refrigerant ow velocity decreases and this disturbs the sufcient circulation of refrigerant oil. As a result, the refrigerant oil does not

ow properly and could cause a serious damege of compressor.

Use the pipe whose outside diameter is less than the value shown in the table below.

Model capacity of outdoor unit ZRP 35 50 60 71 100 125 140 200 250

Max. diameter of header [mm]

(3) Withstanding pressure

Design pressure of outdoor unit is 4.15 MPa. Following must be satised for burst pressure of connecting application.

Burst pressure : More than 12.45 MPa (3 times more than design pressure)

(4) Contamination maintenance

1. Wash the inside of heat exchanger to keep it clean. Be sure to rinse not to leave ux. Do not use chlorine detergent when washing.

2. Be sure that the amount of contamination per unit cubic content of heat transfer pipe is less than the following amount.

Example) In case of ø9.52mm

Residual water : 0.6 mg/m, Residual oil : 0.5 mg/m, Solid foreign object : 1.8 mg/m

P – – – – – – – 200 250

SHW – – – 80 112 140 – 230 –

20m 1350 1800 2700 3030 3900 4650 5100 7800 9300

10m 1650 2100 3600 3930 4800 5550 6000 9600 11100

P – – – – – – – 200 250

SHW – – – 80 112 140 – 230 –

{

19

{

28

21

Page 22

7. Requirement on local design

7.3. Thermistor position

< Target temp. thermistor (Locally supplied) >

Put thermistor where average supply or return air temperature for heat exchanger can be detected.

Put thermistor where it does NOT pick up the temperature of heat exchanger.

< Liquid refrigerant pipe thermistor (TH2) >

Put thermistor where liquid refrigerant pipe temperature can be detected.

Protect the thermistor with heat insulating materials not to be affected by the ambient temperature, etc.

In case that the refrigerant is distributed by distributor, put thermistor before the distributor.

< 2-Phase temp. thermistor (TH5) >

Put thermistor where 2-Phase temperature can be detected on the indoor HEX pipe.

It should be located in the middle of inlet and outlet ports.

If there are some paths, locate it on the top of them.

Protect the thermistor with heat insulating materials not to be affected

by the ambient temperature, etc.

< Target temp. thermistor (TH1) >

Put thermistor where average supply or return air temperature for heat exchanger can be detected.

Put thermistor where it does NOT pick up the temperature of heat exchanger.

< HEX inlet temp. thermistor (TH11) >

Put thermistor where average air temperature of heat exchanger inlet can be detected.

Put thermistor where it does NOT pick up the temperature of heat exchanger.

7.4. Restriction on input signals to the interface unit

Follow the "Note" in section 3.1 and 3.2.

Distributor

TH2

TH5

TH5

7.5. Indoor operation range

Follow the operation range shown in section 3.3.

22

Page 23

EC DECLARATION OF CONFORMITY

EG-KONFORMITÄTSERKLÄRUNG

DÉCLARATION DE CONFORMITÉ CE

MITSUBISHI ELECTRIC CORPORATION, SHIZUOKA WORKS

18-1, OSHIKA 3-CHOME, SURUGA-KU, SHIZUOKA-CITY 422-8528, JAPAN

hereby declares under its sole responsibility that the heating system components described below for use in residential, commercial and light-industrial environments: